Composite conductive rear panel of solar cell assembly and preparation and usage methods thereof

A technology of solar cells and conductive backplanes, applied in chemical instruments and methods, electrical components, circuits, etc., can solve the problems of complex back-contact cell assembly process, increase equipment cost, and restrict industrialization, etc., to reduce punching alignment Process and alignment dispensing steps, increase production capacity, and simplify the effect of packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

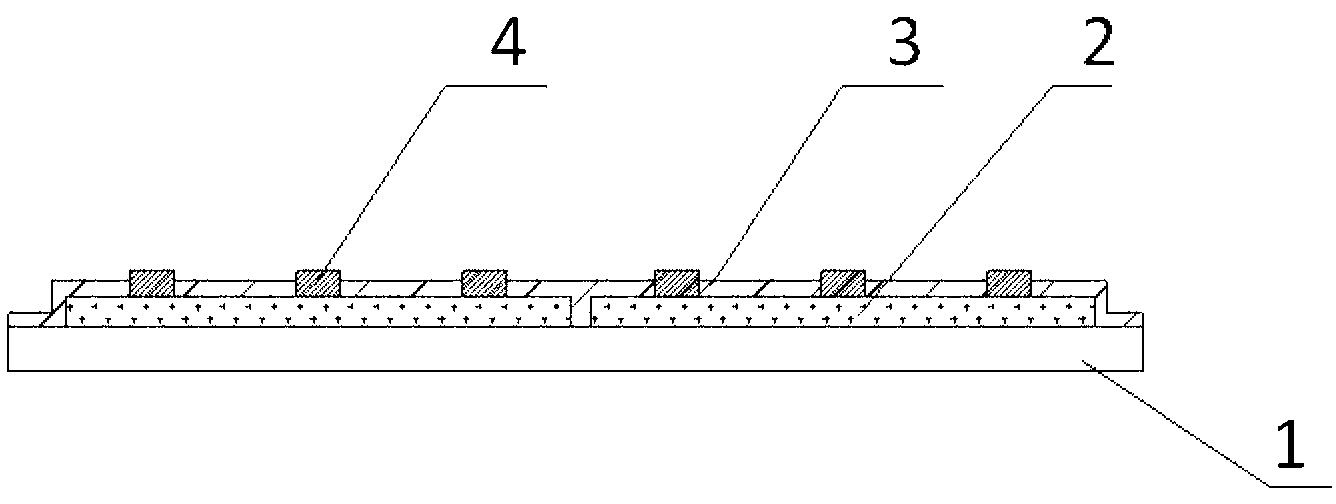

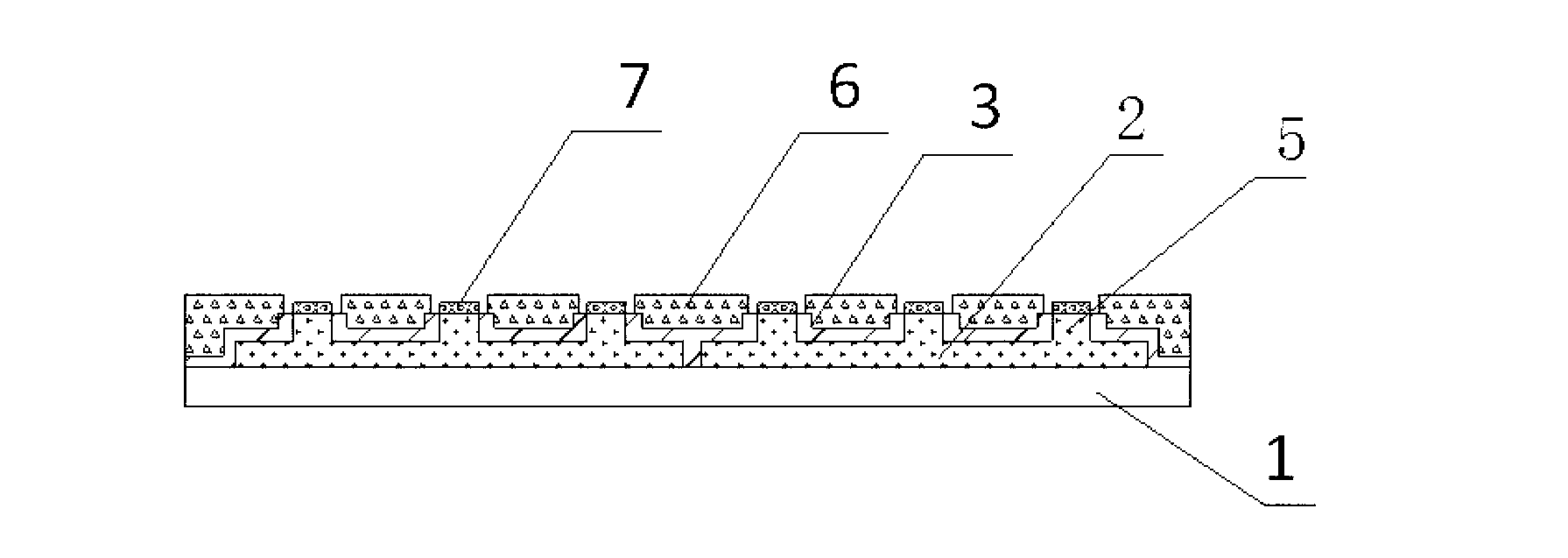

[0017] Such as figure 2 As shown, a composite conductive backsheet for a solar cell module includes an outer polymer layer 1, a conductive metal foil 2, a dielectric layer 3 and an interlayer film 6 sequentially composited, and the conductive metal foil 2 is electrically connected to the battery electrode The corresponding protruding structure 5 is set on the position, the electrode opening exposing the protruding structure 5 is opened on the dielectric layer 3 and the interlayer film 6, and the composite conductive resin for electrically connecting with the battery electrode is arranged on the protruding structure 5 Layer 7.

[0018] The outer polymer layer 1 needs to have dielectric properties, barrier properties, and environmental durability, and materials with a TPT structure and a composite backsheet structure such as an outer layer of PVF and an inner layer of PET can be used.

[0019] The conductive metal foil 2 of the present invention can use a metal such as copper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com