Air gap-adjustable magnetic gear with side positive rotating magnetic adjusting device

A magnetic gear, a technology on the application side, applied in the field of air gap adjustable magnetic gear, can solve problems such as damage, structural deformation of the magnetic adjustment device, poor heat resistance, etc., to improve movement accuracy, improve structural strength, and improve transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

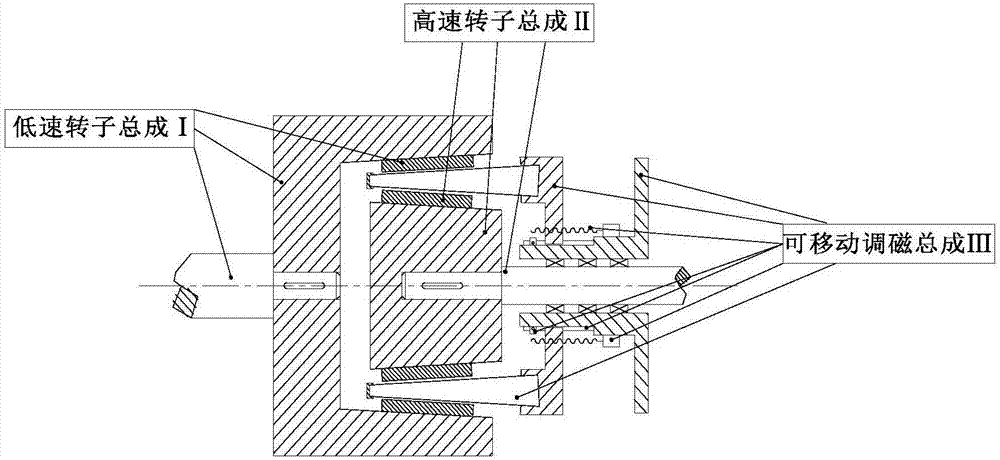

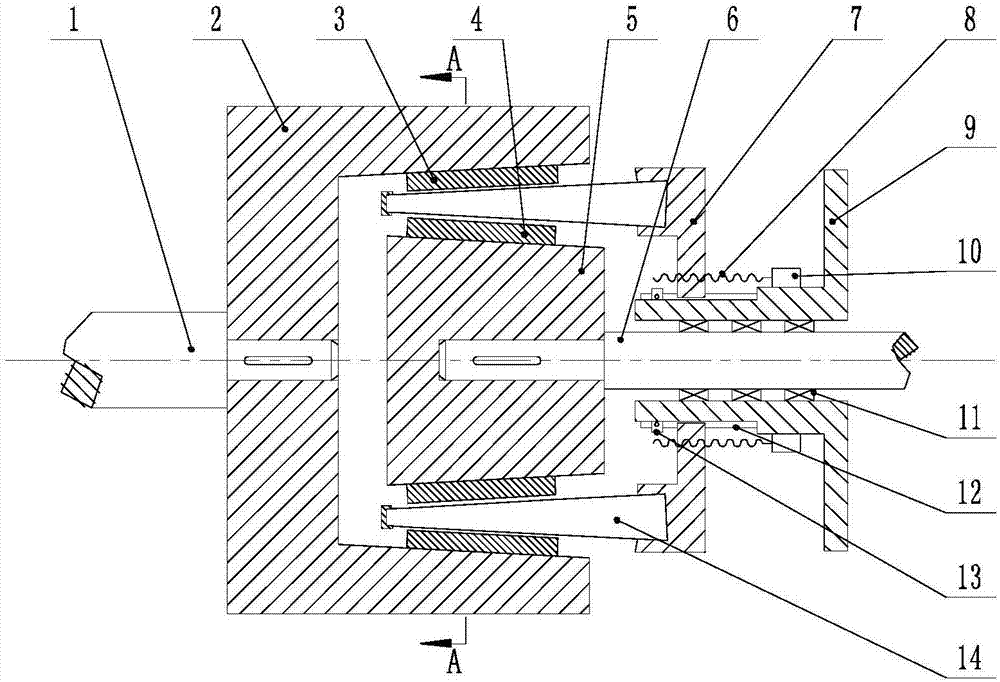

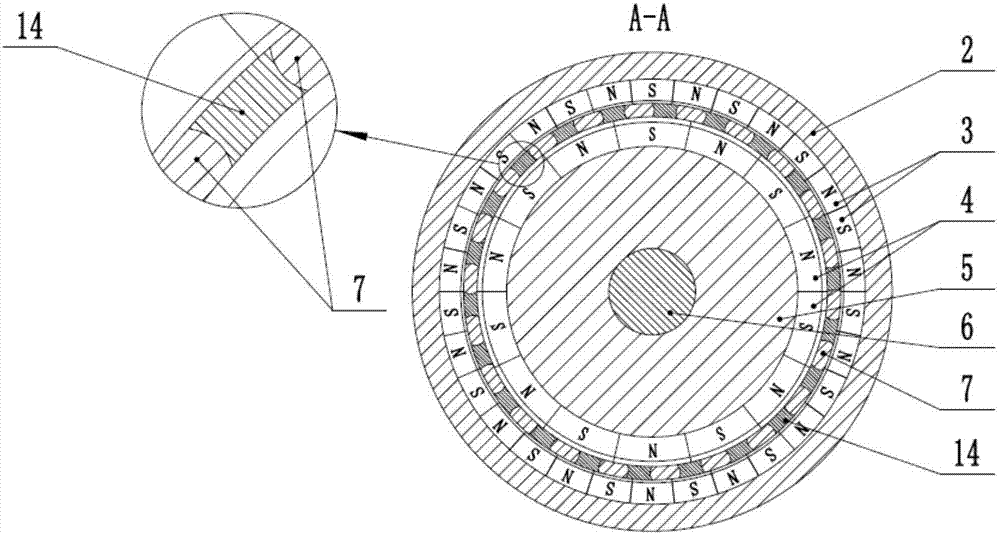

[0031] Such as figure 1 As shown, an air-gap adjustable magnetic gear using a side sinusoidal magnetic modulation device includes a low-speed rotor assembly I, a high-speed rotor assembly II, and a movable magnetic modulation assembly III; figure 2 , image 3 and Figure 4As shown, the low-speed rotor assembly I includes a low-speed shaft 1, an outer rotor base 2 and an outer rotor permanent magnet 3, wherein the right side of the low-speed shaft 1 is connected to the outer rotor base 2 through a common flat key, and the inner side of the outer rotor base 2 is The surface is inclined with respect to the outer surface on the right side of the outer rotor base 2, the inclination angle is β, and the value range of β is 5°-15°. The permanent magnets of the rotor 3 are closely arranged alternately by N poles and S poles, and the number of magnetic pole pairs is P 1 The high-speed rotor assembly II includes an inner rotor permanent magnet 4, an inner rotor base body 5 and a high...

Embodiment 2

[0036] The structure of this embodiment is basically the same as that of Embodiment 1, and the working principle is the same as that of Embodiment 1, such as Figure 10 , Figure 11 and Figure 12 As shown, the difference between the two is that in the present embodiment, the card slot 16 provided on the support frame 7 runs through the support frame, and the card notch 20 is formed on the support frame 7, and two sides of each card notch 20 are provided with A threaded hole, the magnetic adjustment device 14 formed by superimposing the positively rotating magnetic pole piece 17 on the side is installed into the card slot 16 through the card notch 20, and each card notch 20 is connected with a fastening block 19 through a bolt 18, and the fastening block The left side of 19 is in close contact with the magnetic adjustment device 14, clamping the magnetic adjustment device 14, thereby the magnetic adjustment device 14 can be sealed, and has both the magnetic adjustment and spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com