Patents

Literature

45 results about "Structural transition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Structural transition joints (STJ) are bimetal strips that make it possible to weld different metals together. These strips are mainly used when two metals cannot actually be connected to each other. If a conventional welding process is not possible, a mechanical joining technique should normally be used.

Method of preparing positive active material for rechargeable lithium battery, positive active material for rechargeable lithium battery prepared by same, and rechargeable lithium battery including positive active material

InactiveUS20090253042A1Improve mobilityHigh characteristicsNon-aqueous electrolyte accumulator electrodesLi-accumulatorsSource materialConductive materials

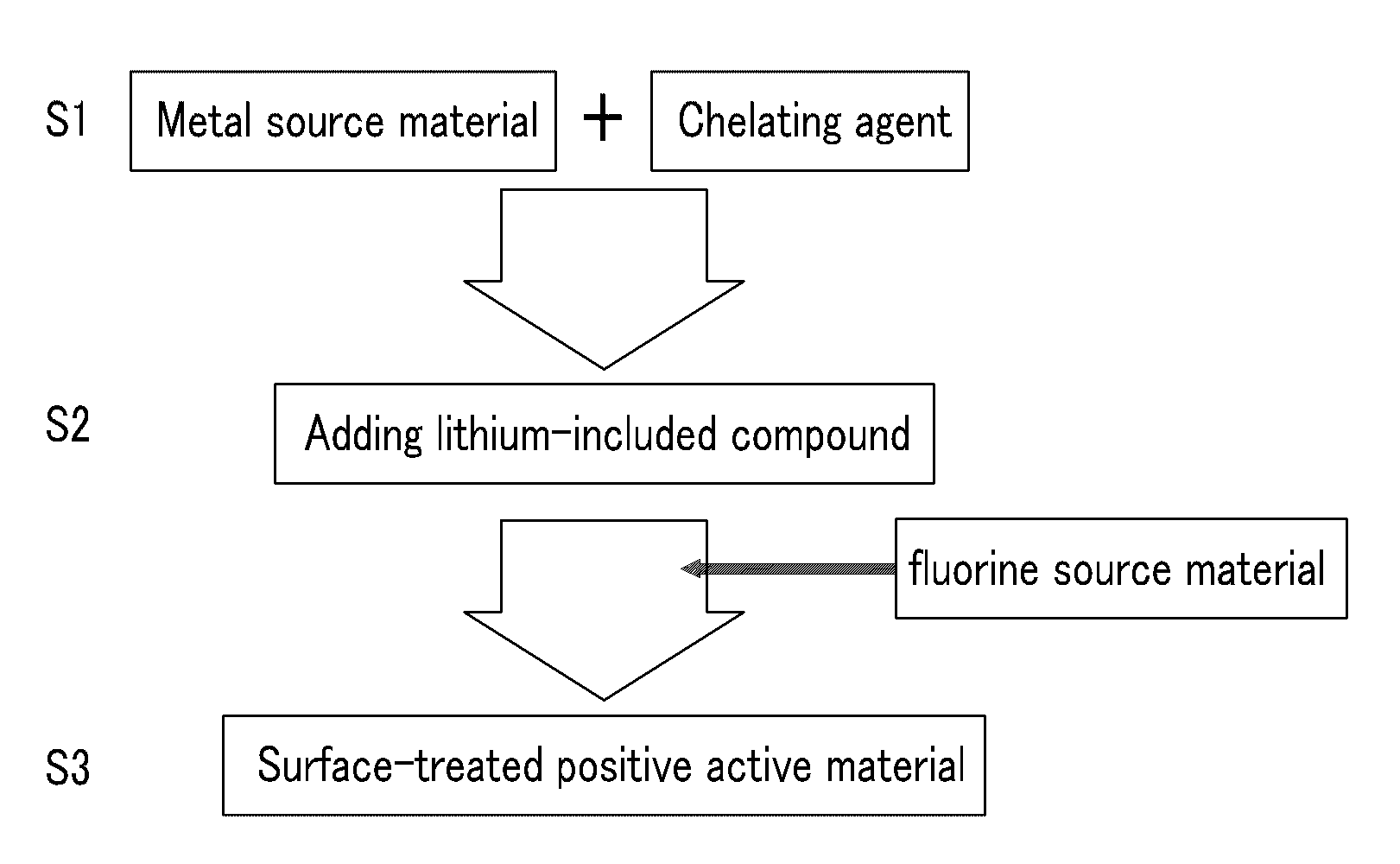

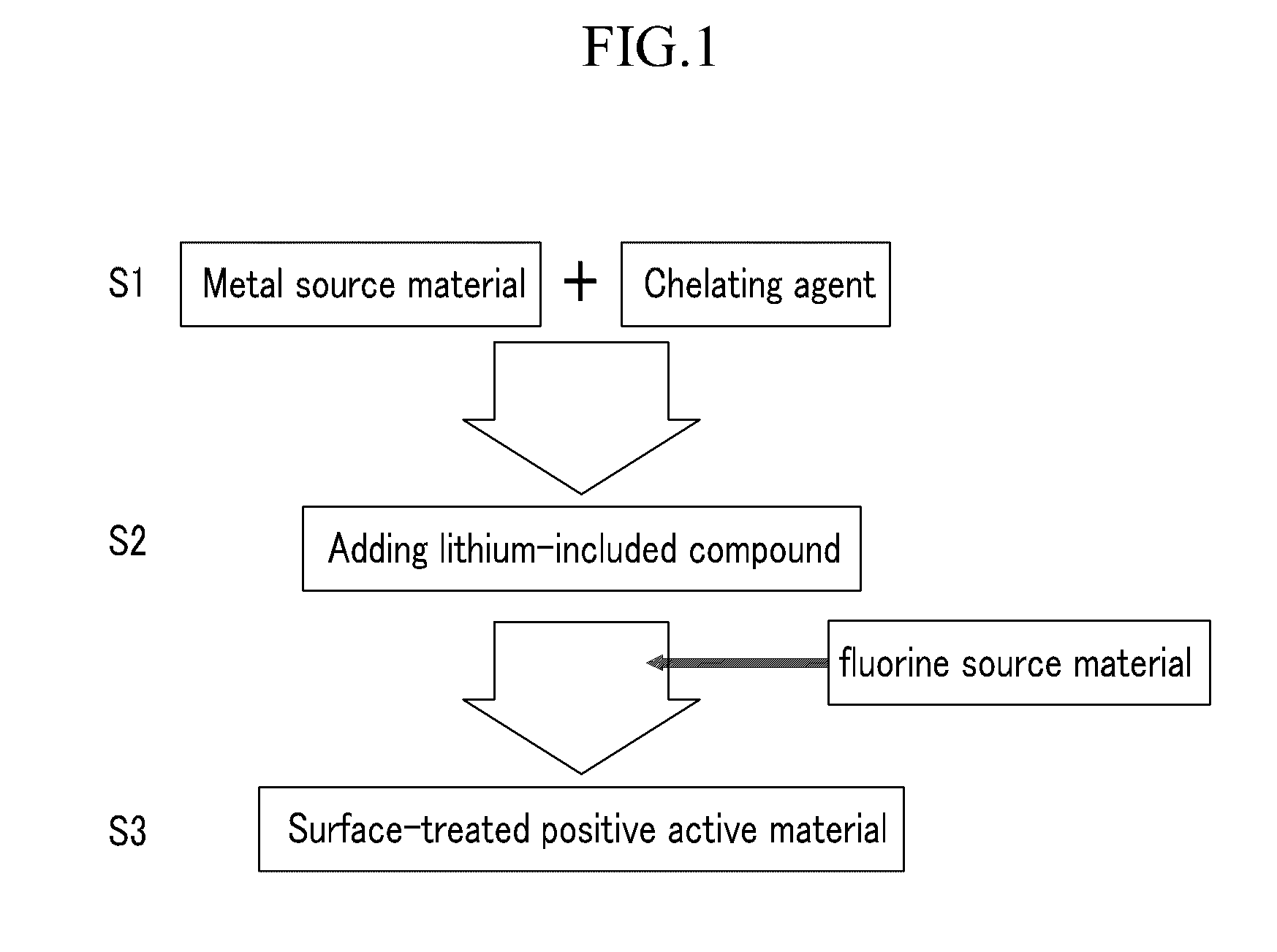

The present invention relates to a method of preparing a positive active material for a rechargeable lithium battery, a positive active material prepared according to the method, and a rechargeable lithium battery including the same. This manufacturing method includes preparing a complex salt solution by mixing a solution including a metal source material and a chelating agent, disposing the complex salt on the surface of a lithium-included compound by adding a lithium-included compound to the complex salt solution, adding a solution including a fluorine source material to the solution including a lithium-included compound with the complex salt on the surface, and heat-treating the mixture. The present invention provides a simple method of economically preparing a positive active material in which structural transition on the surface is prevented and securing a uniform coating layer. In addition, the positive active material can have improved charge and discharge characteristics, cycle life characteristic, and rate characteristic. It also has improved ion conductivity, and accordingly can improve mobility of lithium ions in an electrolyte and thereby improve discharge potential of a battery. Furthermore, the positive active material can decrease the amount of a conductive material and increase density of a substrate.

Owner:ENERCERAMIC

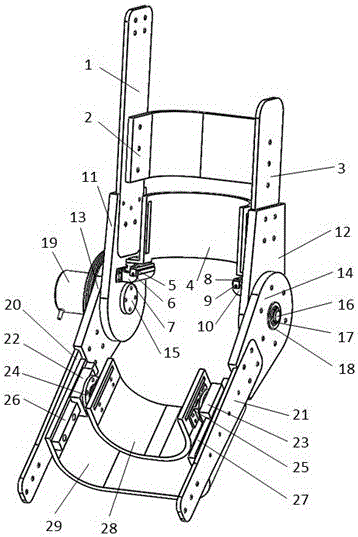

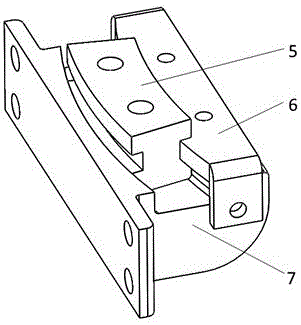

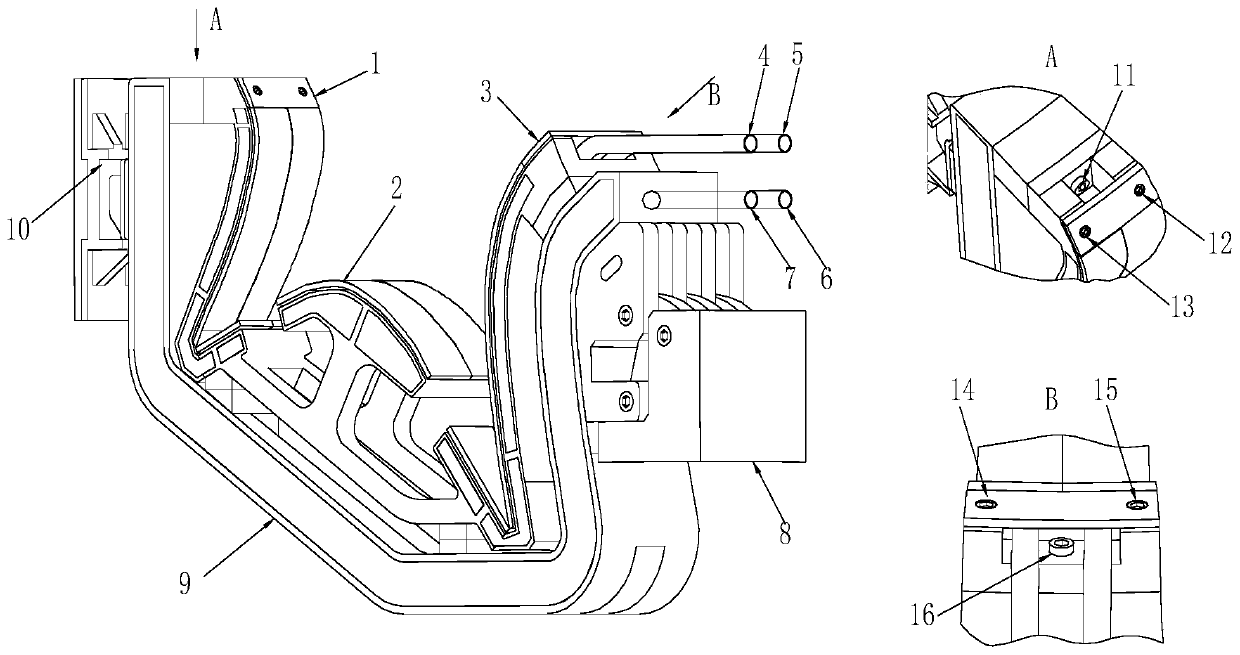

Portable type flexible-elbow-joint exoskeleton robot

ActiveCN106393073AHigh control precisionLow output impedanceProgramme-controlled manipulatorGymnastic exercisingExoskeleton robotDegrees of freedom

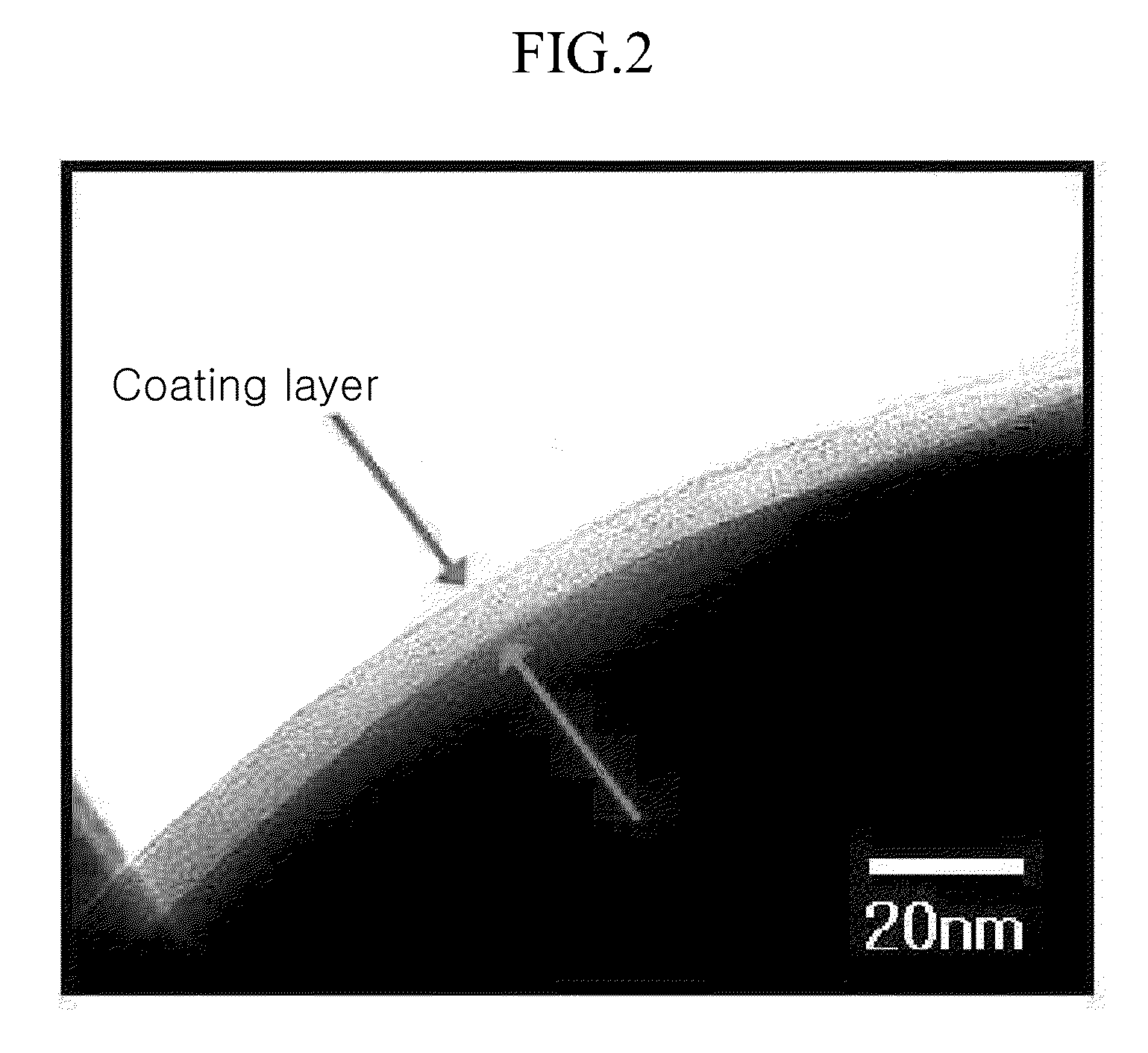

The invention discloses a portable type flexible-elbow-joint exoskeleton robot which mainly comprises an elbow joint exoskeleton mechanism, a drive mechanism and a control device. According to the portable type flexible-elbow-joint exoskeleton robot disclosed by the invention, exoskeletons and the drive mechanism are separately arranged, so that transmission is realized through structural transition of a steel wire rope and a wheel disc. With the aspect of a drive mode, a rope drive structure is in series connected with an elastic driver in a matched mode, so that the portable type flexible-elbow-joint exoskeleton robot has the advantages of high control precision, low output impedance, strong impact resistance, good wearing portability and the like. Two passive degrees of freedom are designed into exoskeletons, and movement characteristics of human elbow joints is simulated, so that self-adaptive regulation on the exoskeletons and the human elbow joints is realized, and therefore, the human elbow joints are protected from being harmed during movement. The portable type flexible-elbow-joint exoskeleton robot is simple and compact in structure and realizes scientific rehabilitation training on elbow joints of a patient. Meanwhile, the portable type flexible-elbow-joint exoskeleton robot further has a power assisting function, and is suitable for being applied and popularized in transportation, climbing and the like.

Owner:WUHAN UNIV

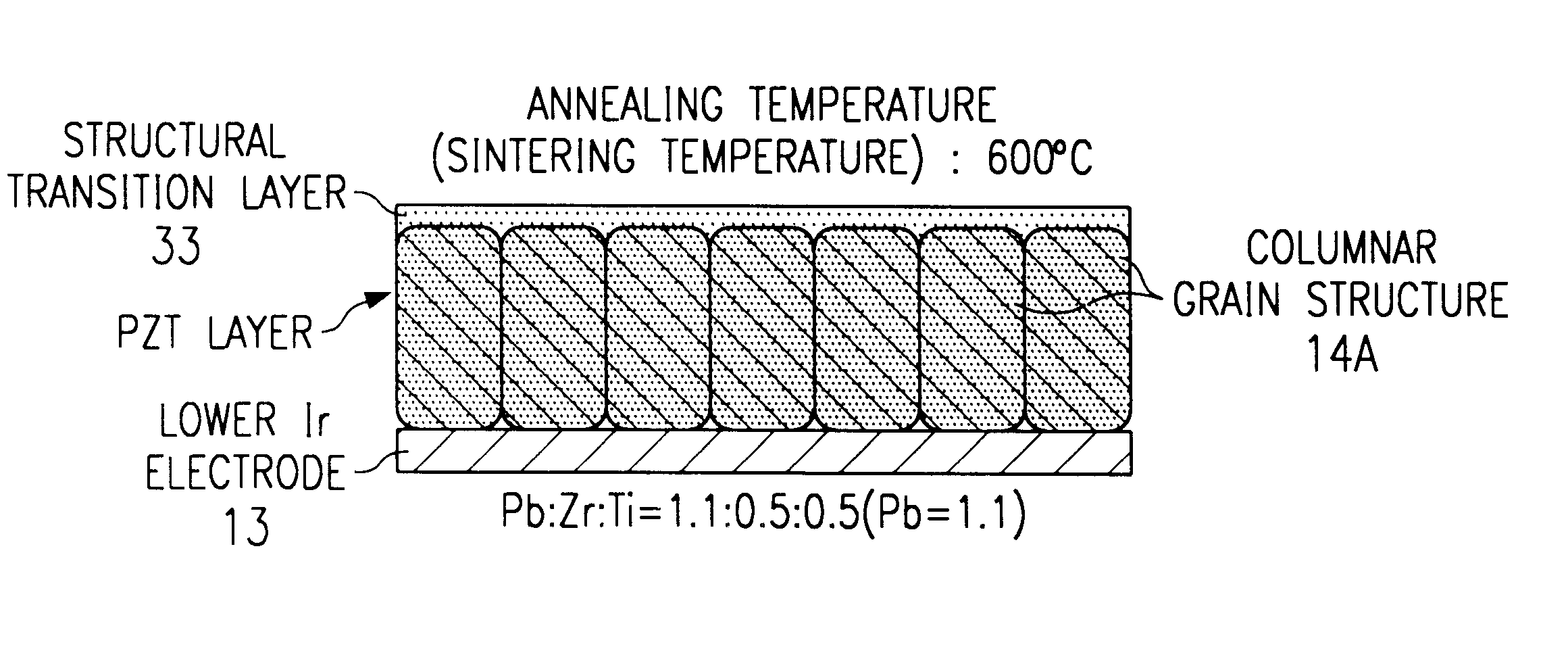

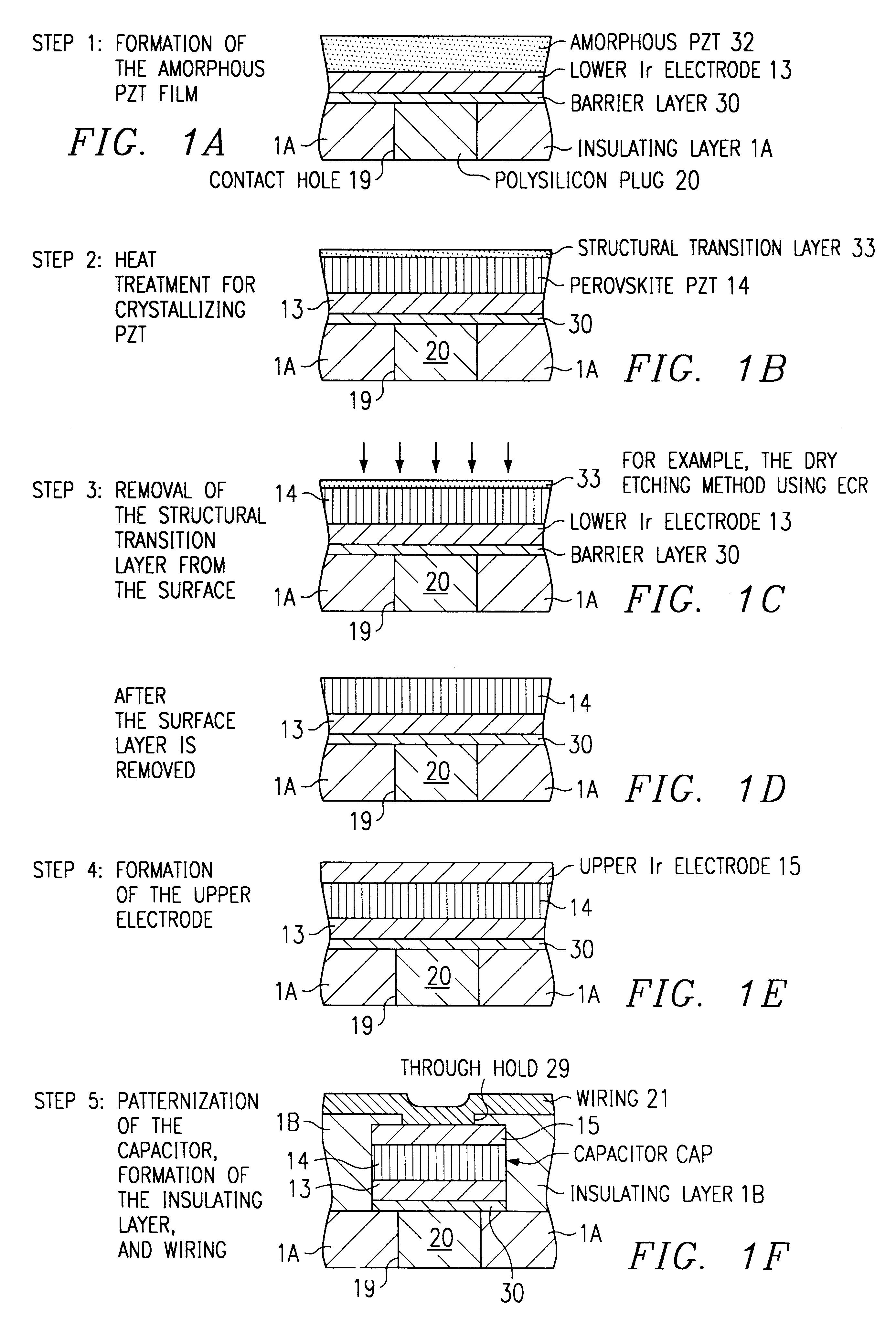

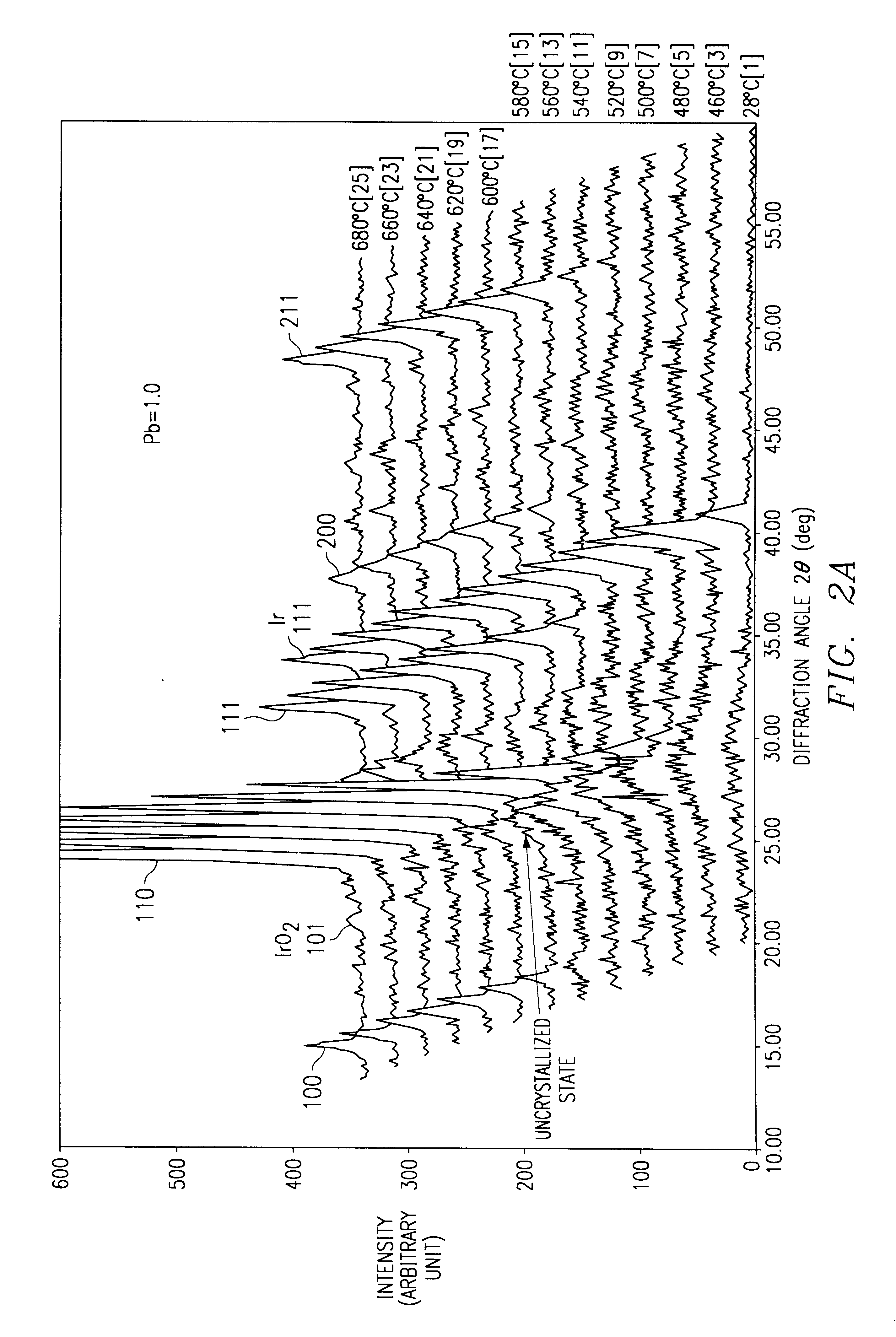

Method for manufacturing a ferroelectric capacitor having improved polarization characteristics and a method for manufacturing a ferroelectric memory device incorporating such capacitor

InactiveUS6472229B1Good polarization inversion characteristicAvoid changeTransistorSolid-state devicesIridiumLead zirconate titanate

The purpose of this invention is to provide a method for manufacturing capacitors free of polarization fatigue even when the treatment is performed at a low temperature.Amorphous layer 32 made of lead zirconate titanate and containing excess lead is formed on lower electrode 13 made of iridium. The amorphous layer is crystallized by a heat treatment to form PZT film 14. Structural transition layer 33 containing excess Pb formed on the surface of PZT film 14 during the aforementioned crystallization is removed by means of dry etching. In this way, a PZT capacitor is obtained.

Owner:TEXAS INSTR INC

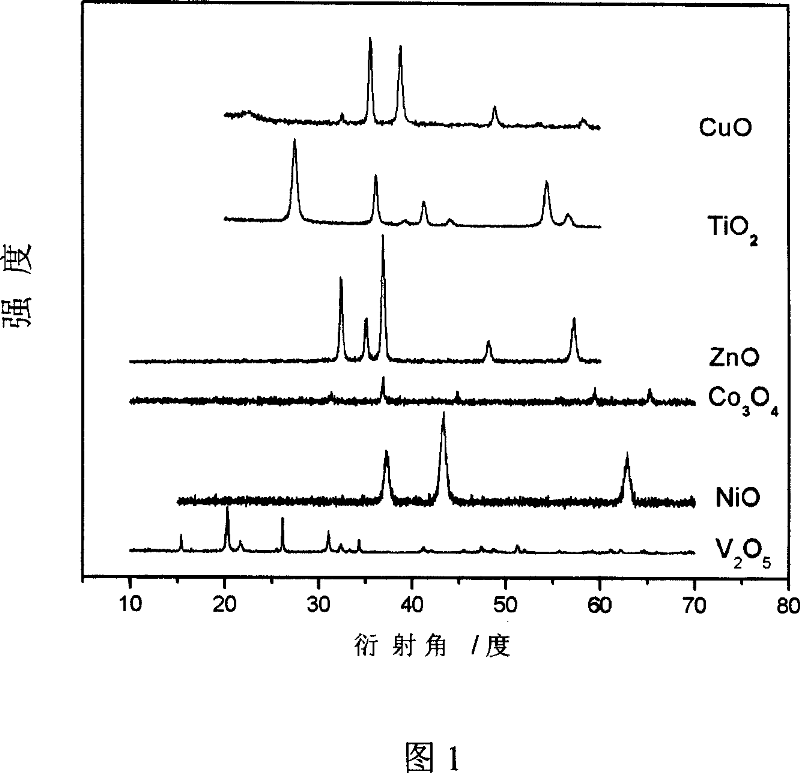

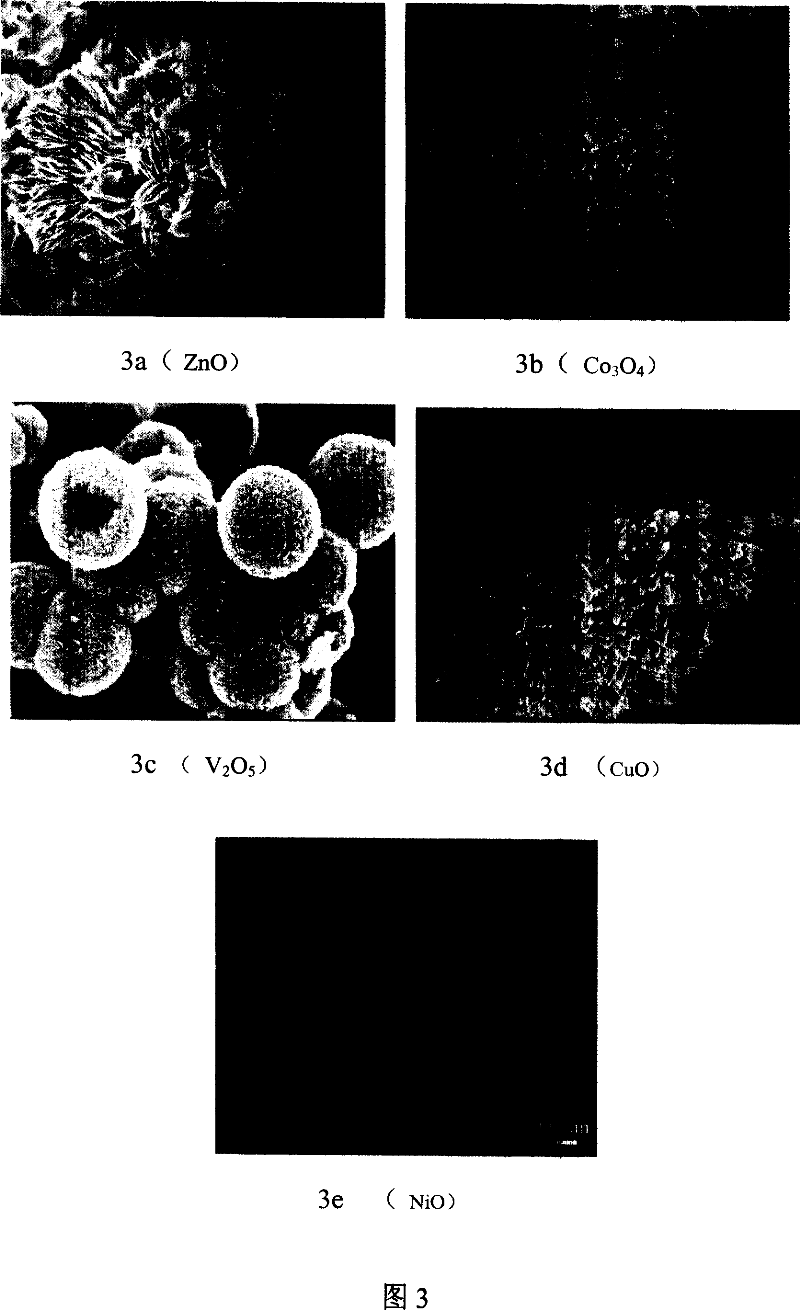

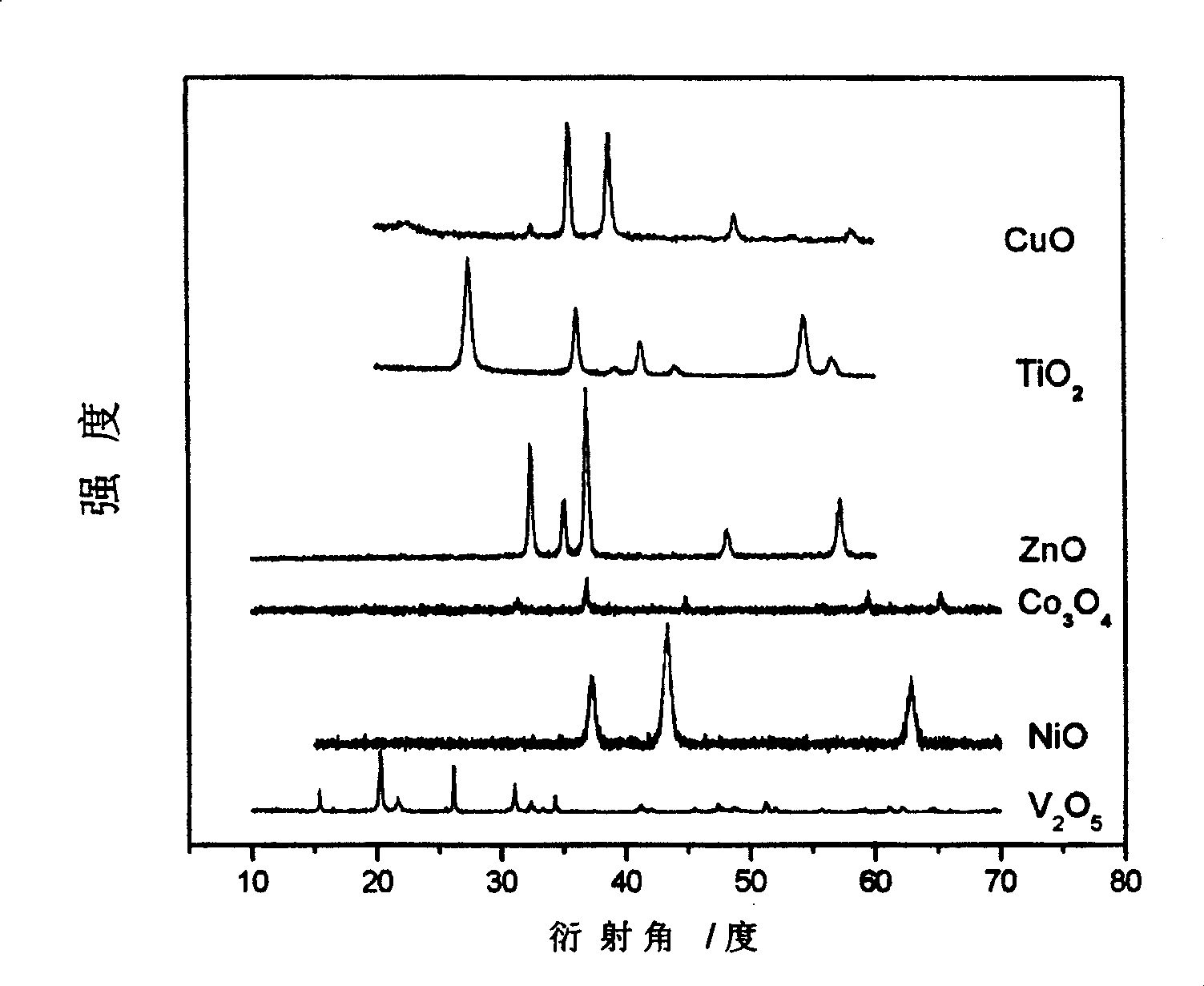

Preparation of graduated nano-structural transition metal oxide by two-phase solvent soft interface process

InactiveCN101037228AImprove versatilityImprove photocatalytic activityZinc oxides/hydroxidesCopper oxides/halidesWater insolubleSolvent

The present invention provides a preparation method of gradate nanostructure transition metal oxide by a two phase solvent soft interface method which comprises the steps of that: metal salt or metal oxide is added into water, and the pH value of the solution is adjusted by acid or base, then the corresponding reactant precursor is obtained; another water insoluble organic solvent is added into the solution, and the whole mixture is subjected to solvothermal treatment, and then the solid product is obtained by pumping filter, finally, the corresponding gradate nanostructure transition metal oxide is obtained after scrubbing and drying. The transition metal oxide of the present invention has excellent gradate structure, for example, titanium dioxide has a main structure of micron order spheroidal particle which is formed by the ordered array of a plurality of nanorods. The titanium dioxide of the present invention has a high visible light photocatalysis activity, a simple synthetic route, an easy technology, available raw material, low cost and high yield, and is adapted to mass production.

Owner:HUAZHONG NORMAL UNIV

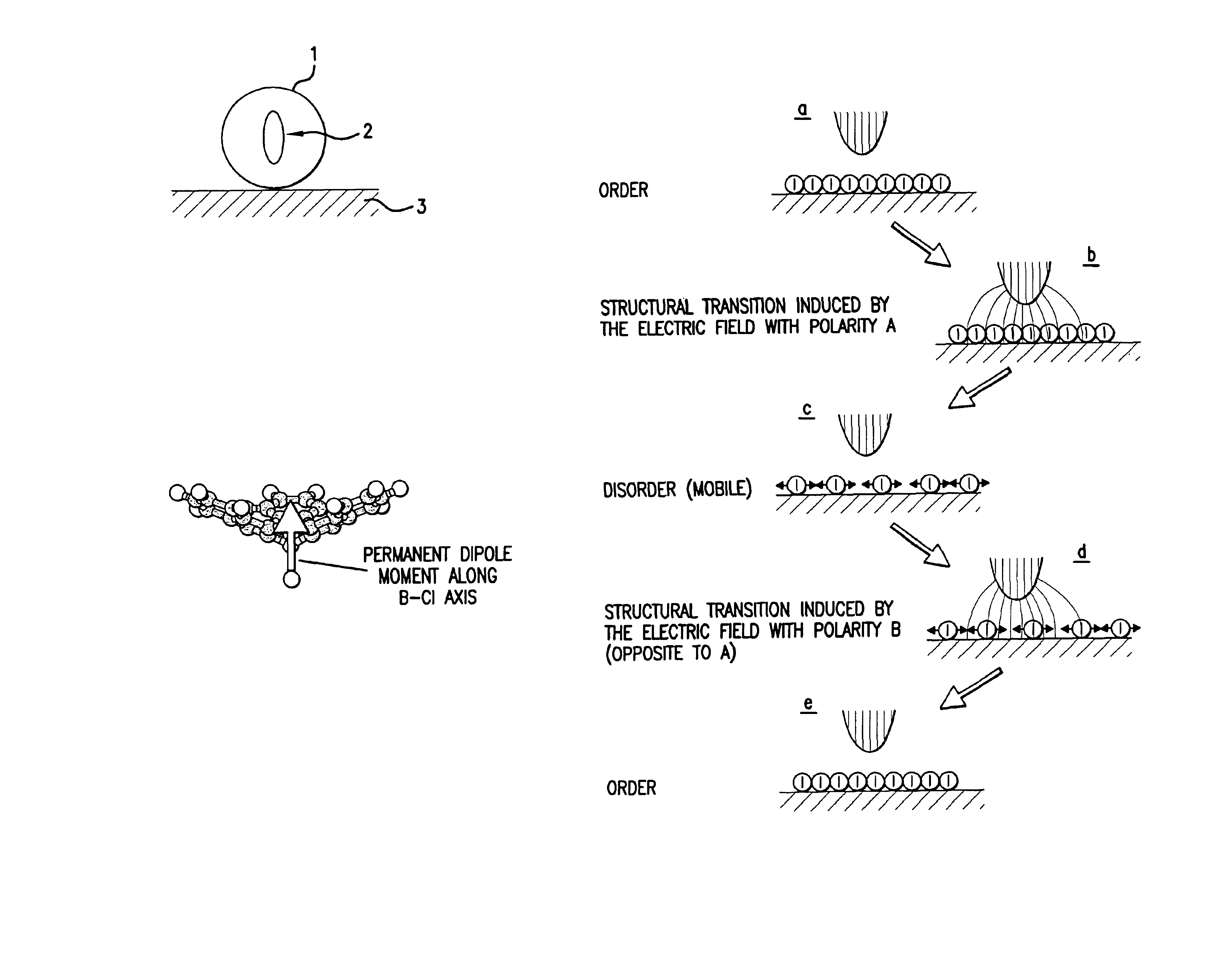

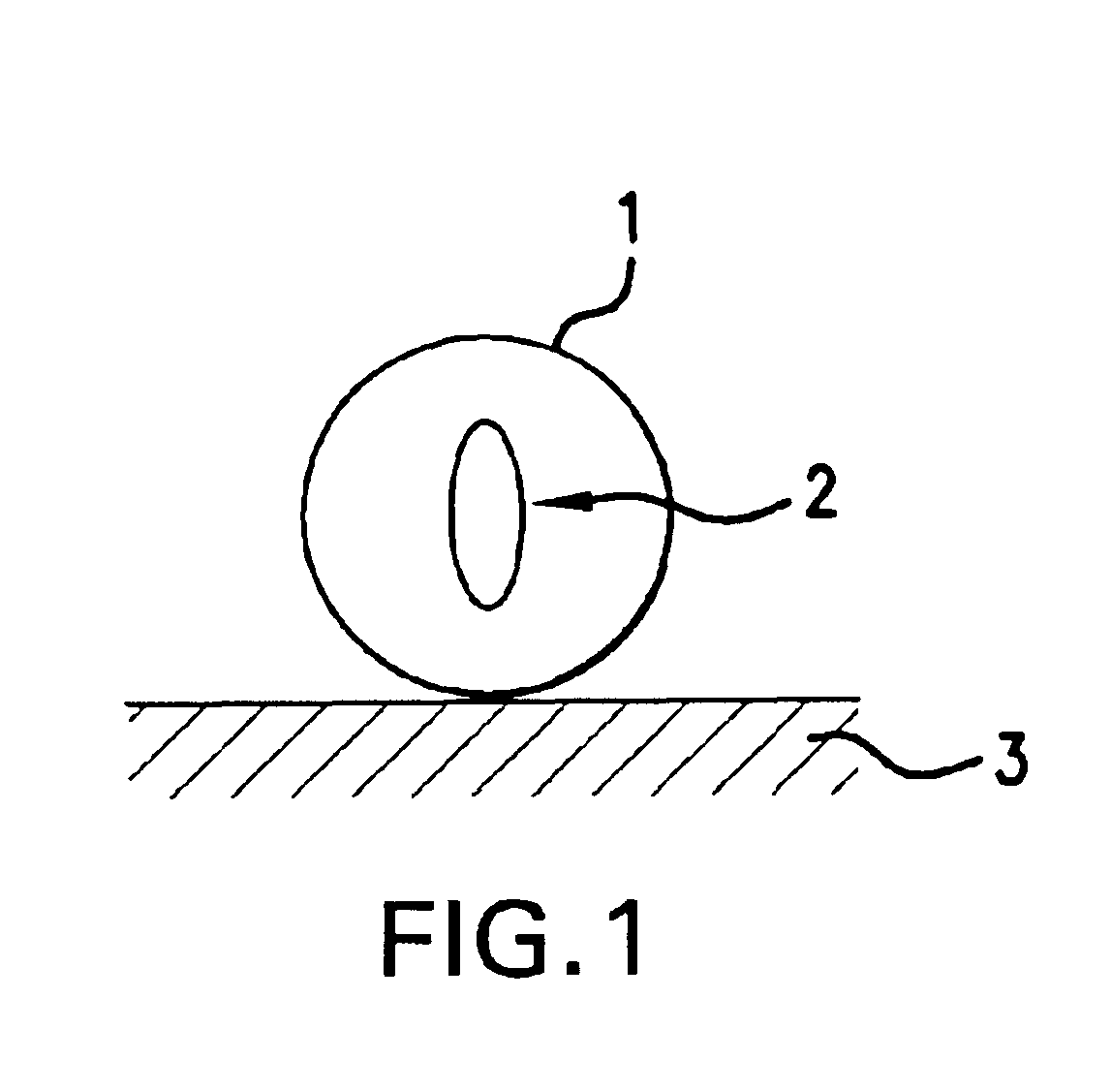

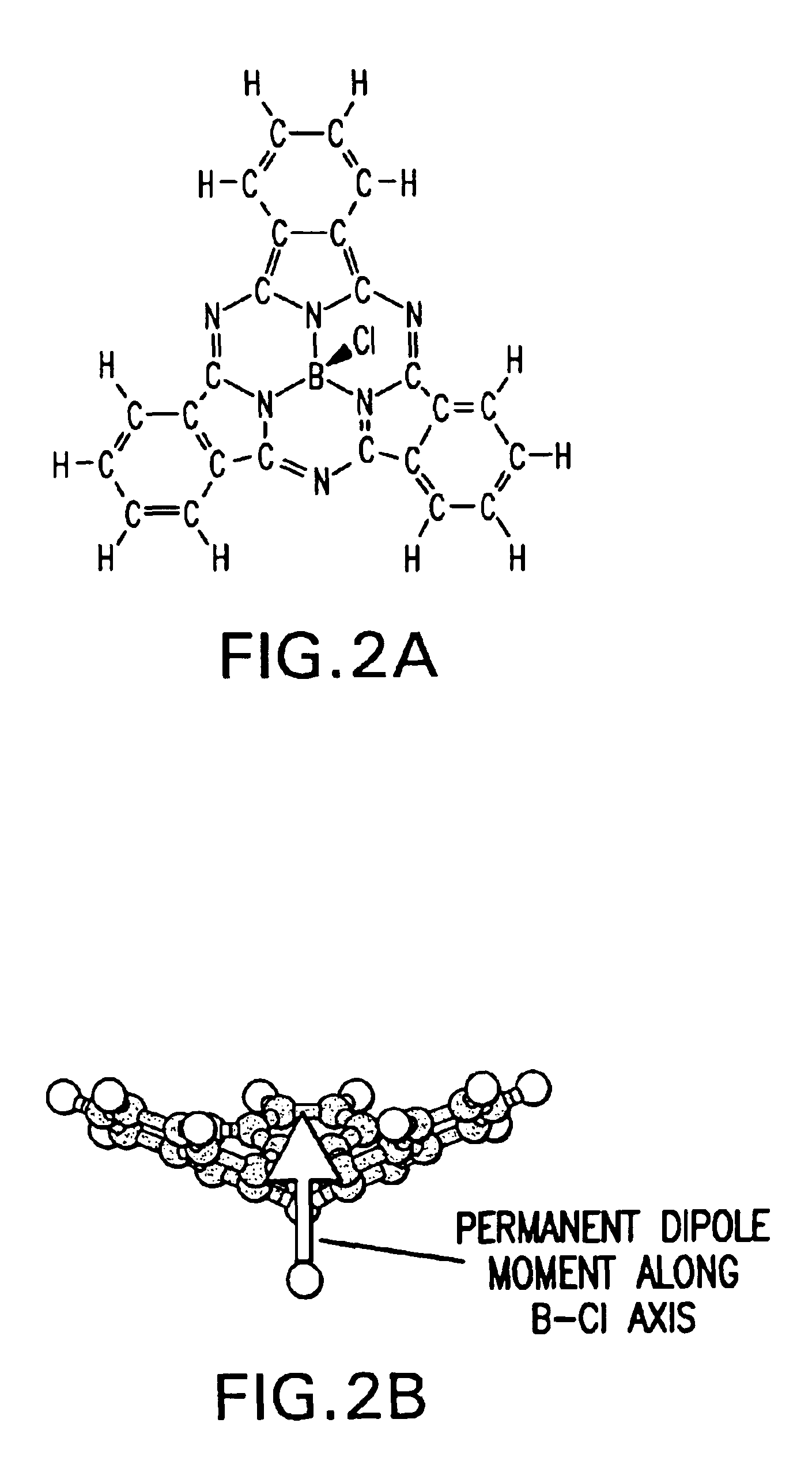

Two-dimensional structural transition controlled by an electric field, memory storage device thereof, and method of making a memory storage device

InactiveUS6947311B2Wide applicabilityPhotosensitive materialsNanoinformaticsOptical propertyStructural transition

This invention relates to the controlled two-dimensional structural transition of a dipole monolayer at a metal, semi-conducting or insulating interface. The dipole monolayer consists of objects / molecules with a permanent electric dipole moment. A transition between the structures of the molecular layer can be performed locally and reversibly by applying an electrical field and the structures / patterns can be reversibly switched many times between two different structures / states. Both of the two structures, the ordered and the disordered structures, are intrinsically stable without the presence of the switching electrical field. This controlled switch of the local layer structure can be used to change layer properties (i.e., mechanical, electrical, optical properties). The controlled reversible modifications of the dipole monolayer structures are usable as bit assignments in data storage applications for example.

Owner:UNIVERSITY OF BASEL

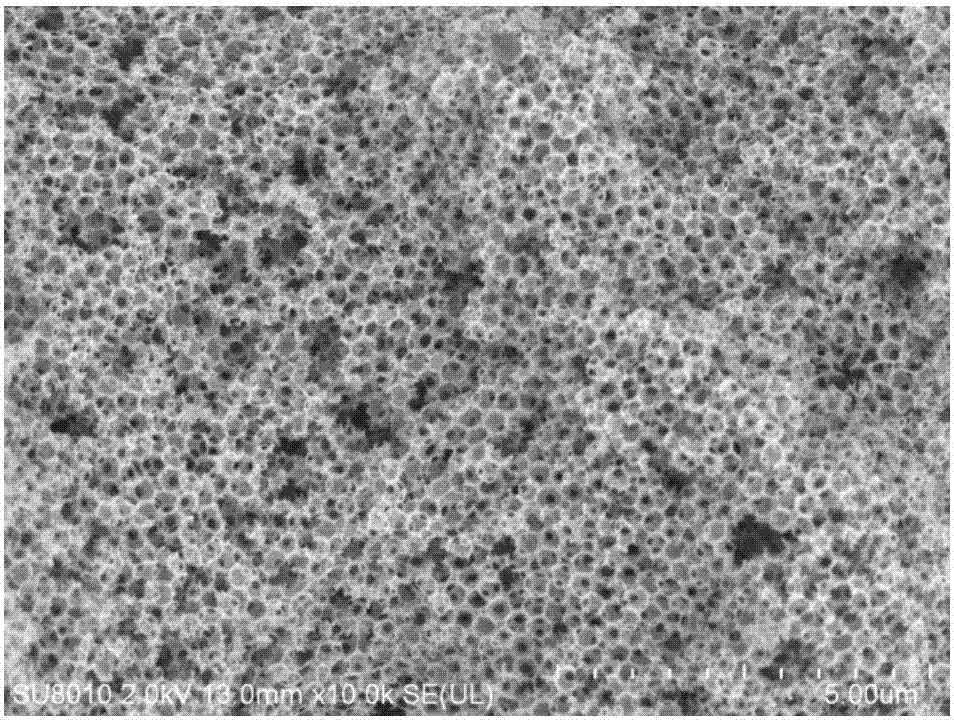

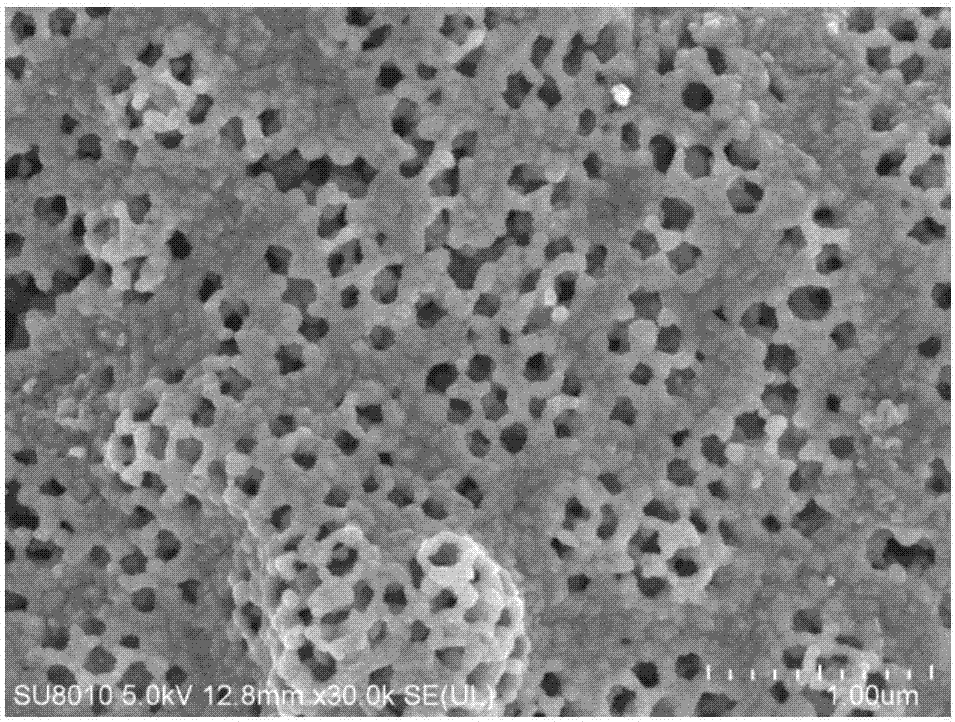

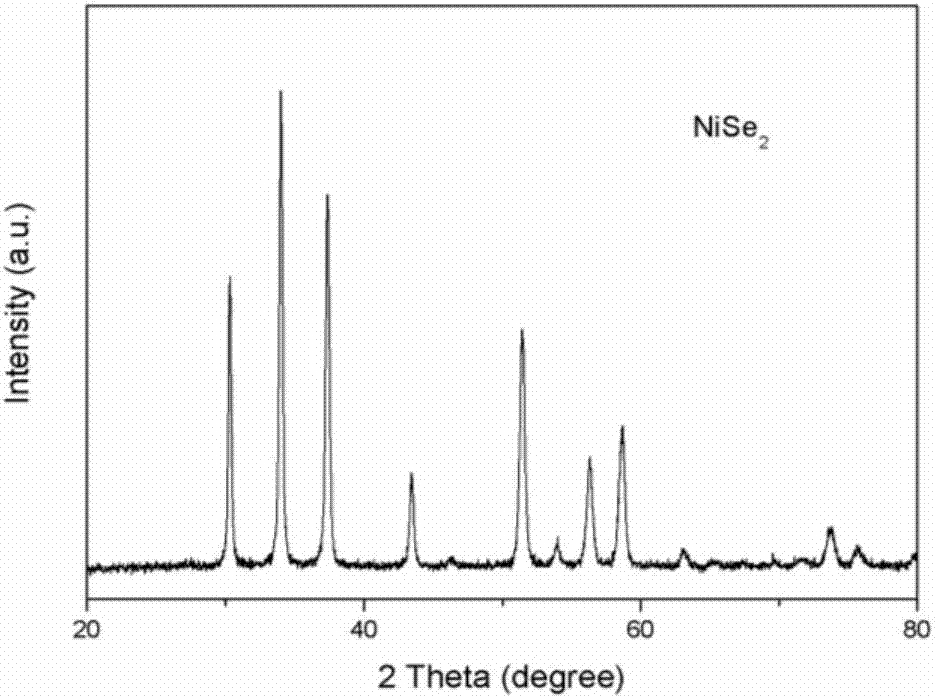

Transition metal based catalyst electrode of honeycomb macroporous structure as well as preparation method and application thereof

ActiveCN107008461AHigh catalytic efficiencyAvoid reunionPhysical/chemical process catalystsElectrolysis componentsMicrospherePolystyrene

The invention relates to a transition metal based catalyst electrode of a honeycomb macroporous structure as well as a preparation method and application thereof. The preparation method disclosed by the invention comprises the following steps: S1, synthesizing a polystyrene sub-microsphere aqueous solution; S2, preparing a transition metal salt solution, mixing the transition metal salt solution and the polystyrene sub-microsphere aqueous solution to obtain a mixed solution, spraying the mixed solution onto a conductive substrate for forming a film, and calcining at a high temperature so as to obtain an oxide film with a honeycomb macroporous structure; and S3, performing sulfidizing or selenizing or phosphating treatment on the oxide film at the high temperature in an inert atmosphere, thereby obtaining the transition metal based catalyst electrode of the honeycomb macroporous structure. The preparation method disclosed by the invention has the advantages that the operation is simple, the macroporous structure of the catalyst is easily maintained, the reproducibility is high, and a large-area electrode is conveniently prepared. Moreover, the catalyst electrode prepared by the invention has high specific surface area and capable of exposing more active sites and can be applied to dye-sensitized solar cells, electrochemical decomposition of water and the like.

Owner:SUN YAT SEN UNIV

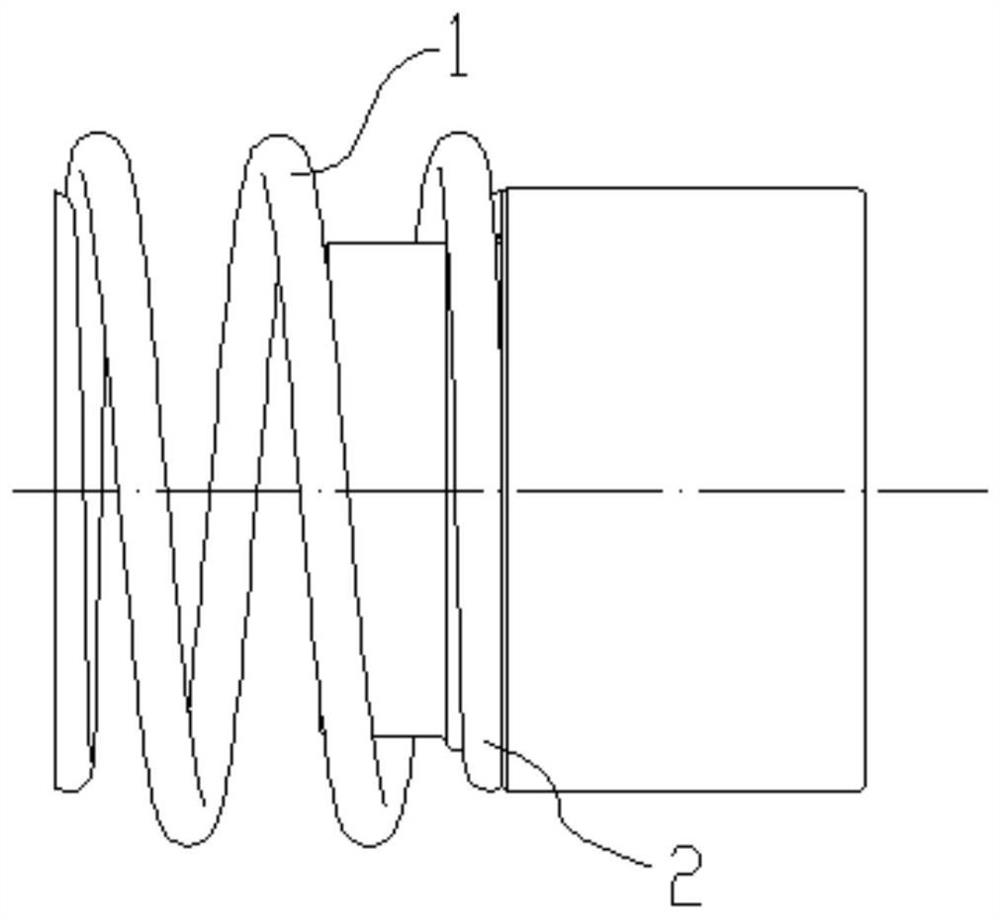

Combined extrusion method using transition cellpacking to realize helical slow-wave structure

InactiveCN1571096AAvoid difficultiesTransit-tube circuit elementsCold cathode manufactureWave structureManufacturing technology

The invention relates to a travelling wave tube manufacturing technique, especially a novel technique of manufacturing spiral slow-wave structure (SWS). It has the following steps: 1. fixing spiral line together with medium rod by mould; 2. axially sending them in a transition tube casing; 3. squeezing the transition tube casing together with them by the technical method of elastic or plastic deformation cold extrusion so as to obtain a transition module of the SWS; 4. firstly heating the tube casing to 800-1000 deg.C, axially sending the transition module at room temperature in the tube casing at high temperature, and locating; 5. cooling the whole workpiece obtained in the step 4 to room temperature, enclasping the transition module with the tube casing by the shrinkage of the tube casing, thus obtaining the SWS product. It is especially applied to composite tube casing with a more complex structure.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

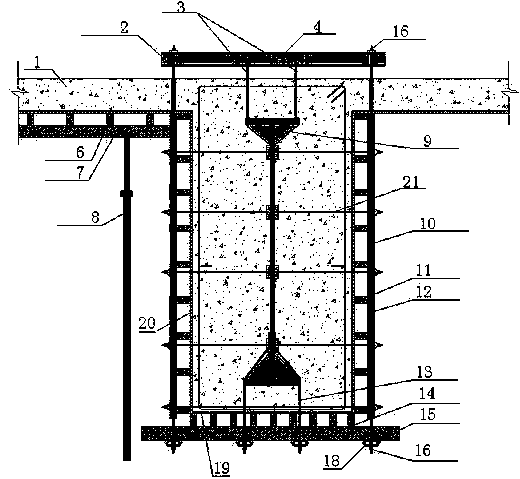

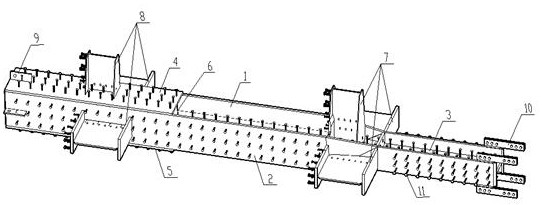

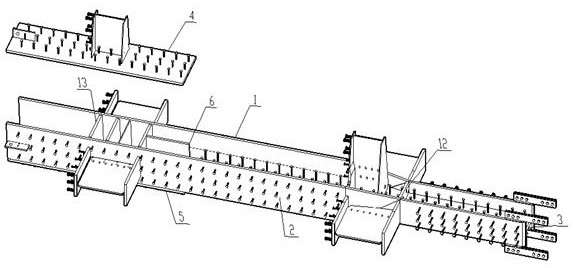

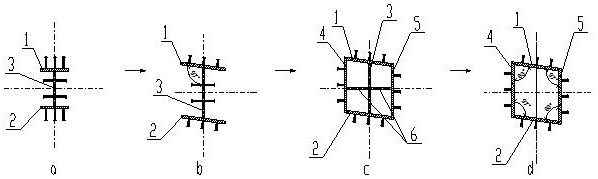

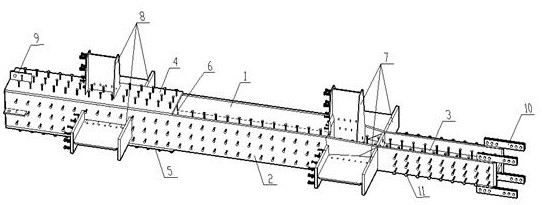

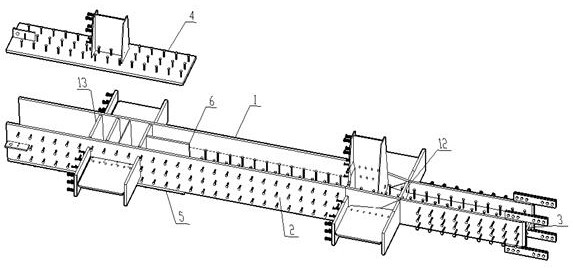

Erecting method for concrete pouring formwork with structural transition layer comprising H-type steel crossbeam

The invention relates to an erecting method for a concrete pouring formwork with a structural transition layer comprising an H-type steel crossbeam. The method includes erecting an adjustable scaffolding; mounting two steel pipes; mounting a main horizontal keel and an auxiliary horizontal keel; paving a bottom concrete pouring formwork; hanging the H-type steel crossbeam to a designed position; allowing a hanging rib to penetrate the bottom concrete pouring formwork to fasten with the two steel pipes; binding a reinforcement cage; mounting side main keels, side auxiliary keels and side concrete pouring formworks on two sides of the H-type steel crossbeam; mounting horizontal oppositely-pulling bolts; transversely mounting a U-steel above the H-type steel crossbeam and the floor top plate; mounting side hanging ribs, which are firmly connected to the U-steel and the H-type steel crossbeam, on two sides of the U-steel; separating the scaffolding from the formwork; pouring concrete; dismantling the formwork through a temporary scaffolding when the dismantling condition is met; dismantling the temporary scaffolding. The erecting method has the advantages that a simple and feasible scheme is provided for structural transition layer crossbeam construction on the premise of guaranteeing the anti-bending, anti-shearing and anti-disturbance performances.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

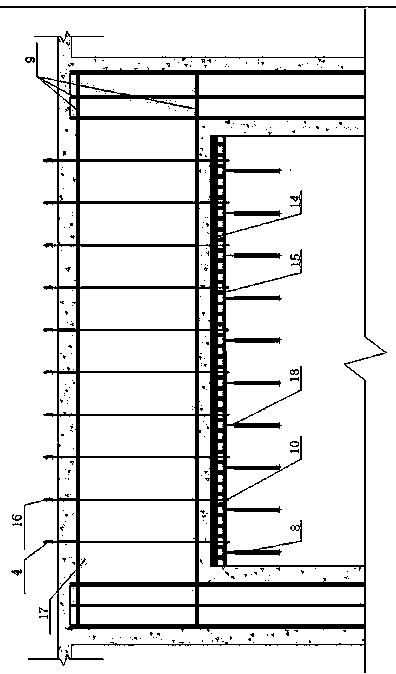

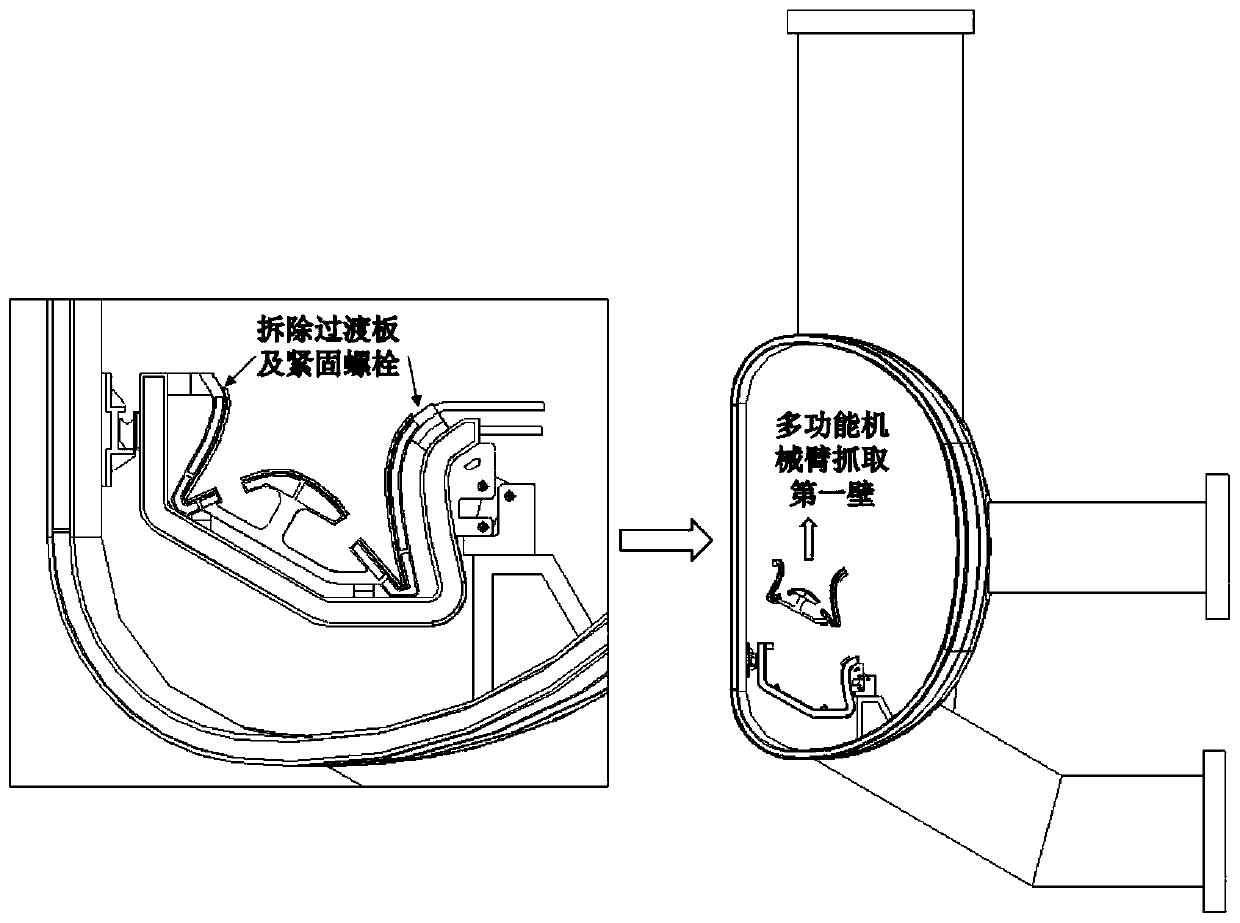

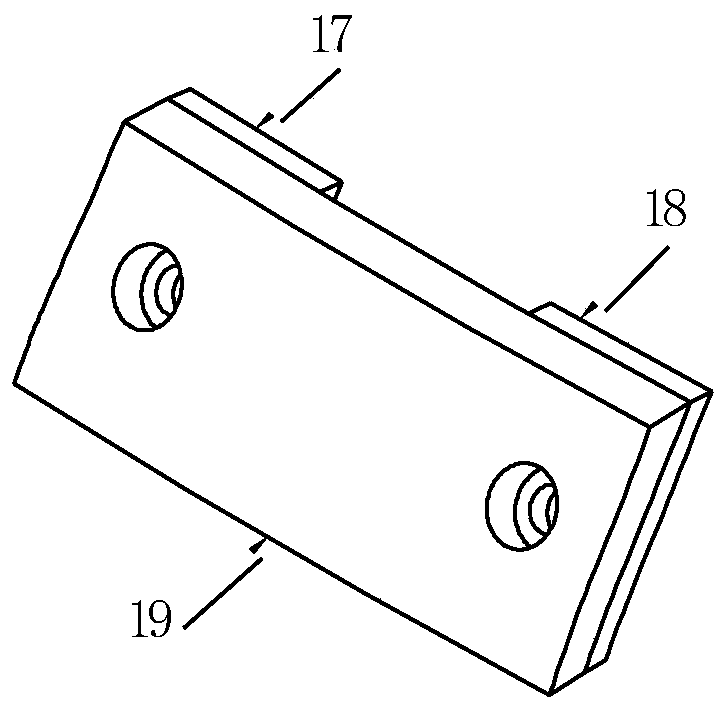

Transition plate structure suitable for independent teleoperation of first wall of divertor

ActiveCN110895974AMeet the six-point positioning principleReduce wasteNuclear energy generationThermonuclear fusion reactorClassical mechanicsStructural engineering

The invention discloses a transition plate structure suitable for independent teleoperation of a first wall of a divertor. The transition plate structure is formed by welding a protective armor and asupport plate; tungsten is used as a protective armor material; chromium zirconium copper is used as a support plate material; the transition plate structure is connected with a first wall support structure through two connecting bolts; a water inlet / outlet pipe of the first wall structure and divertor first wall structure connecting bolts are located on the back surface of the transition plate; amultifunctional mechanical arm can enter a vacuum chamber from an upper window and a middle window; and the transition plate is detached, and a first wall structure is independently removed or installed. According to the invention, the first wall structure of the divertor can be automatically and quickly assembled or disassembled with high precision in a nuclear-related environment; the installation precision of the first wall structure of the divertor is improved, and installation steps are simplified; the first wall structure only needs to be independently maintained through the middle window or the upper window, so material waste is reduced; and the structure has the advantages of money saving, time saving, high efficiency and high precision.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

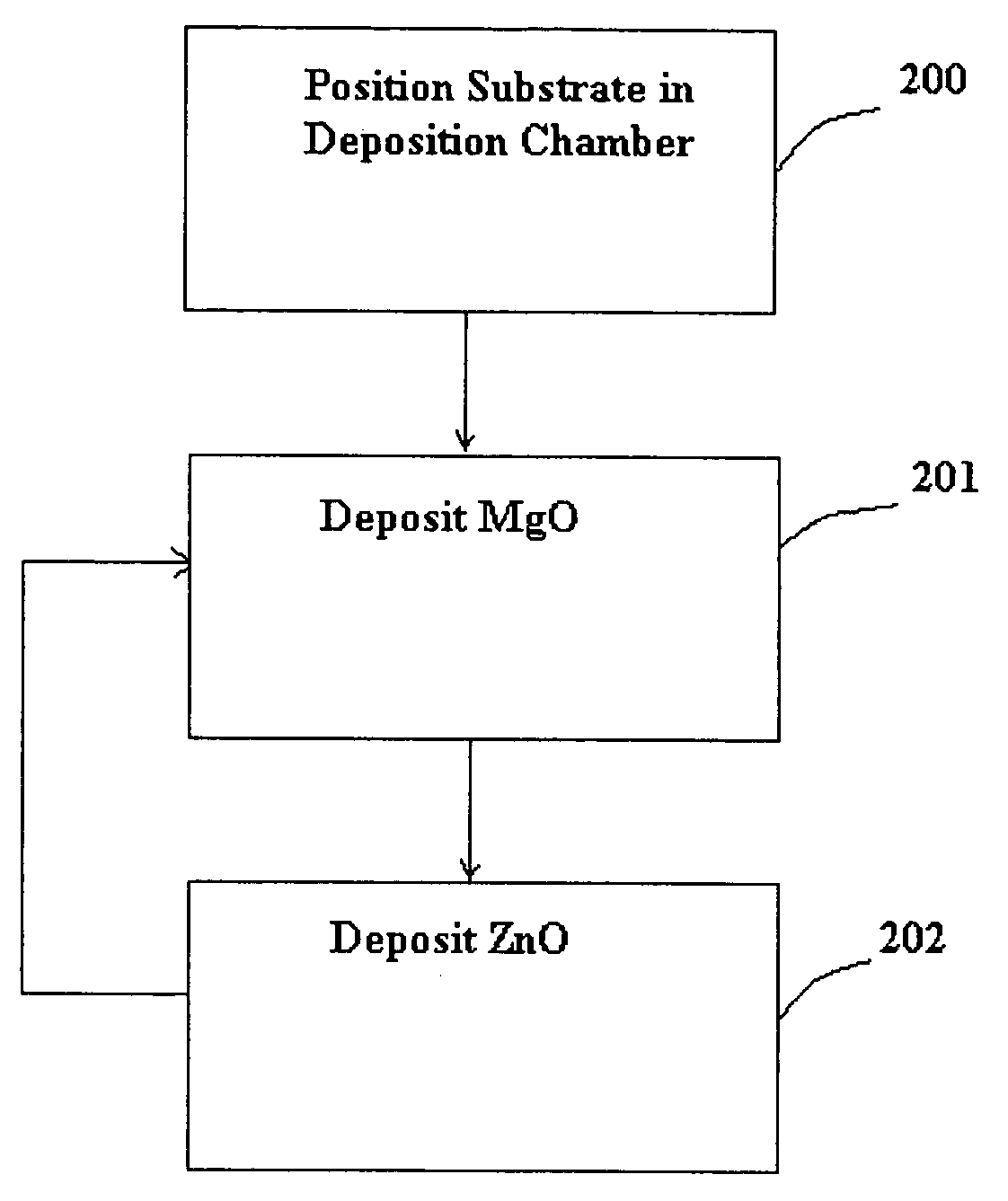

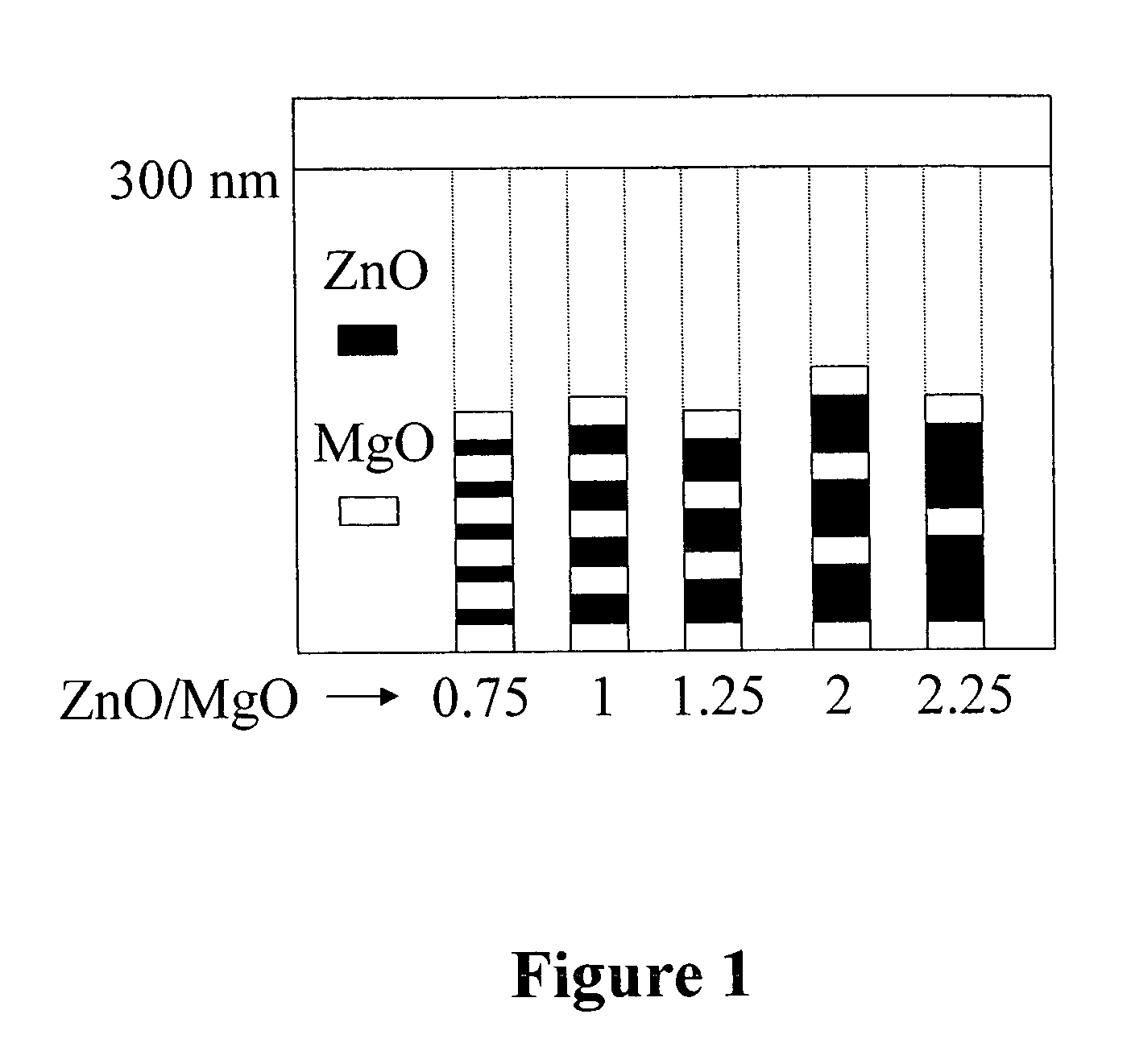

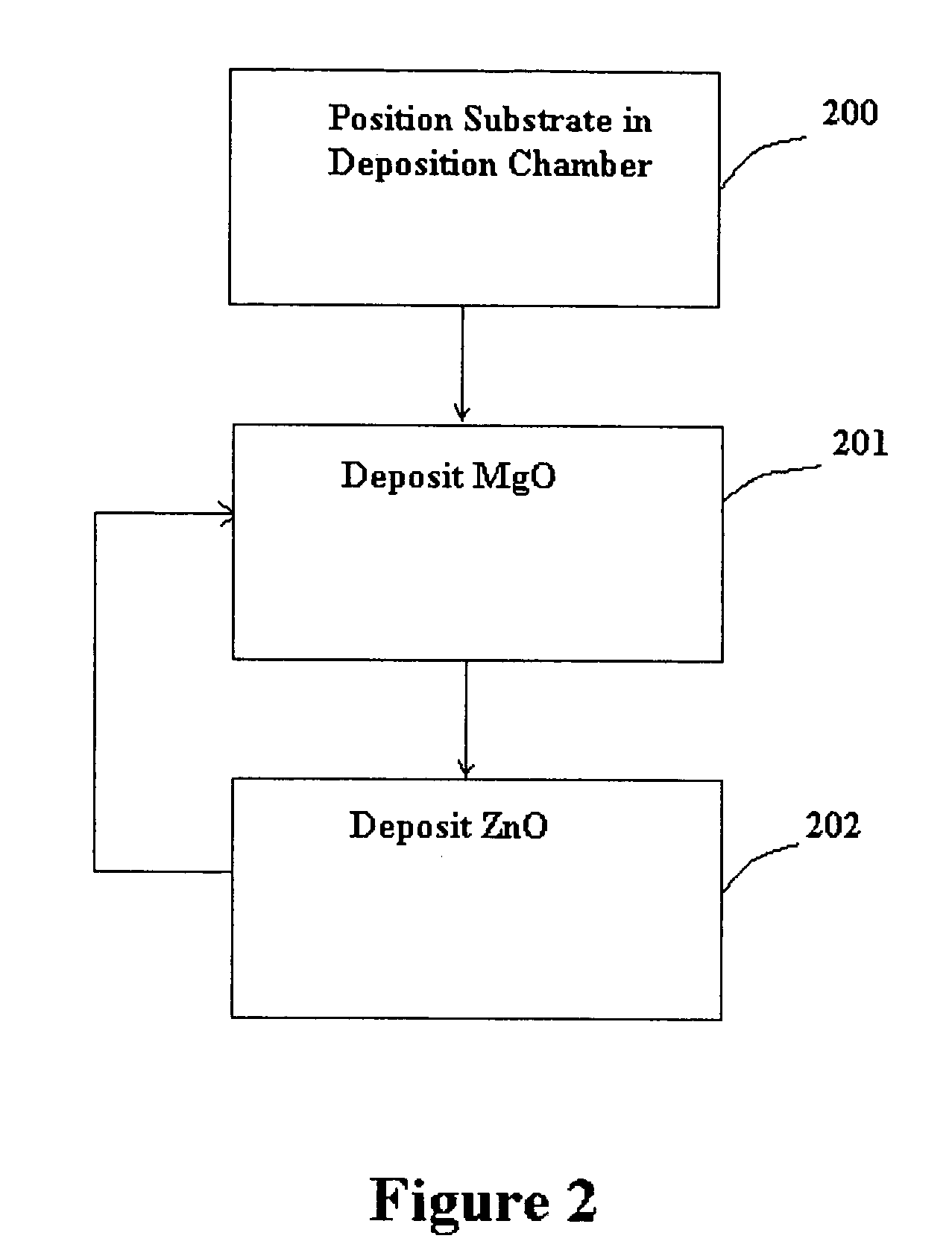

Fabrication of stable, wide-bandgap thin films of Mg, Zn and O

ActiveUS7081371B1Polycrystalline material growthSemiconductor/solid-state device manufacturingOptical propertyCrystal structure

A stable, wide-bandgap (approximately 6 eV) ZnO / MgO multilayer thin film is fabricated using pulsed-laser deposition on c-plane Al2O3 substrates. Layers of ZnO alternate with layers of MgO. The thickness of MgO is a constant of approximately 1 nm; the thicknesses of ZnO layers vary from approximately 0.75 to 2.5 nm. Abrupt structural transitions from hexagonal to cubic phase follow a decrease in the thickness of ZnO sublayers within this range. The band gap of the thin films is also influenced by the crystalline structure of multilayer stacks. Thin films with hexagonal and cubic structure have band-gap values of 3.5 and 6 eV, respectively. In the hexagonal phase, Mg content of the films is approximately 40%; in the cubic phase Mg content is approximately 60%. The thin films are stable and their structural and optical properties are unaffected by annealing at 750° C.

Owner:UNIVERSITY OF PUERTO RICO

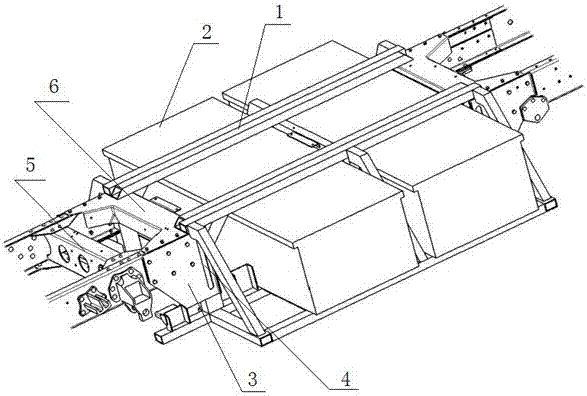

Transition beam of truss type structure

InactiveCN107010115AEven by forceReduce distortionElectric propulsion mountingUnderstructuresPower batteryVehicle frame

The invention discloses a transition beam with a truss structure. A power battery is arranged in the transition beam. The truss structure is set as a trapezoidal structure. The truss structure is divided into corresponding grids according to the shape, size and quantity of the batteries, and the batteries are placed in the grid horizontally. The truss structure The lap joint between the transition beam and the frame is connected, and a transverse reinforcement plate and a longitudinal reinforcement plate are respectively arranged at the transverse and longitudinal stress places for strengthening and fixing. The truss structure transition beam of the present invention is formed by cutting, drilling and welding rectangular steel, and the overall strength is relatively high; The stability of the car; the production process is completed by welding, the operation is simple, and there is no need to reopen the mold, and the cost is low; the truss-type structure transition beam also provides enough space for the arrangement of waterways, airways, and high and low voltage wiring harnesses.

Owner:天津恒天新能源汽车研究院有限公司

Manufacturing method for composite steel column of transition section of tower crown of super high-rise building

ActiveCN111644727AImprove bearing capacityReduce dockingStrutsArc welding apparatusSteel columnsTower

The invention discloses a manufacturing method for a composite steel column of a transition section of a tower crown of a super high-rise building. The composite steel column comprises a steel columnwhich is vertically arranged, upper brackets and lower brackets, wherein the upper brackets and the lower brackets are arranged on the steel column at intervals, and the steel column is sequentially composed of an orthogonal H-shaped steel column section, a connecting H-shaped steel column section, an oblique-crossing H-shaped steel column section and a rhombic steel column section from bottom totop; center lines of webs of the orthogonal H-shaped steel column section, the connecting H-shaped steel column section and the oblique-crossing H-shaped steel column section are located in the same straight line; the lower brackets are arranged on the connecting H-shaped steel column section; and a left flange plate and a right flange plate are correspondingly arranged between an upper flange plate and a lower flange plate of the upper end of the oblique-crossing H-shaped steel column section, the two sides of the left flange plate and the right flange plate are correspondingly and fixedly connected with the edge of the lower flange plate and the edge of the corresponding upper flange plate, so as to close the left and right sides of the upper flange plate and the lower flange plate, andan inclination angle of the rhombic steel column section corresponds to that of the tower crown. According to the manufactured composite steel column, the transition from the main structure of a towerbuilding to the tower crown structure can be effectively achieved.

Owner:中冶建工集团重庆建筑工业有限公司

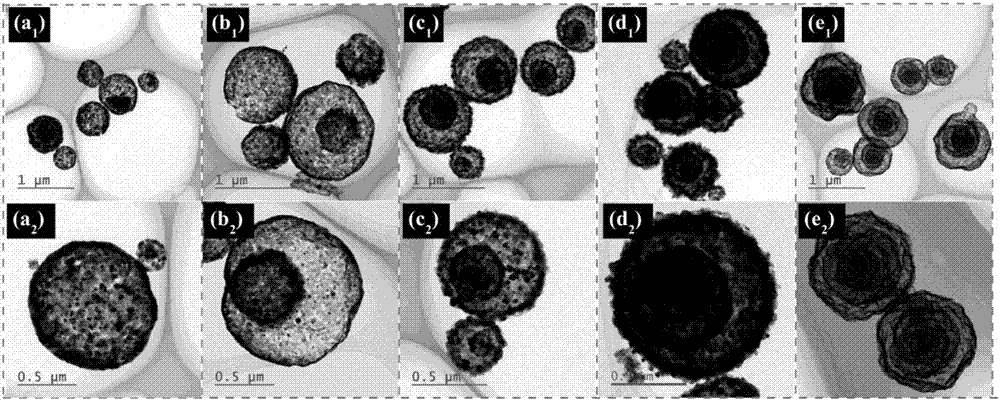

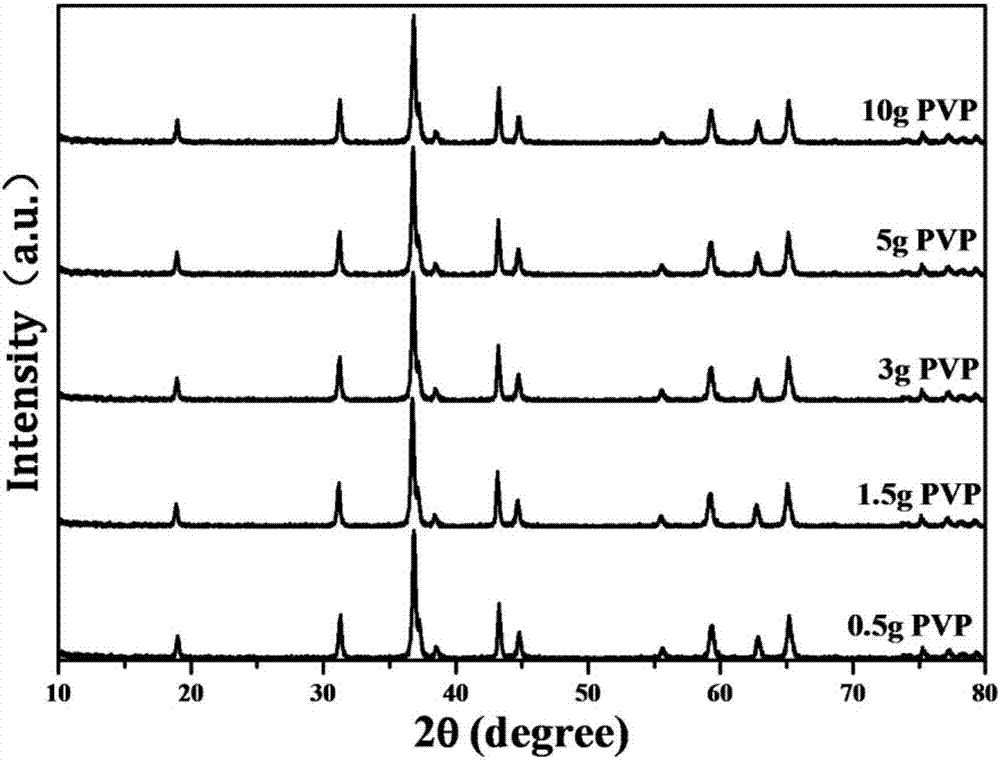

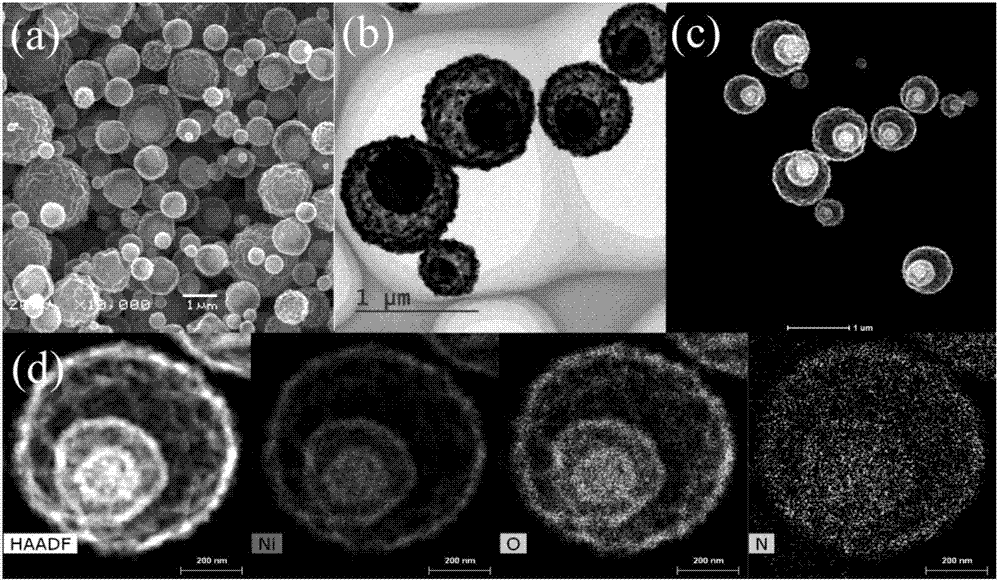

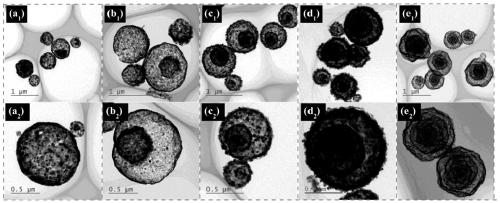

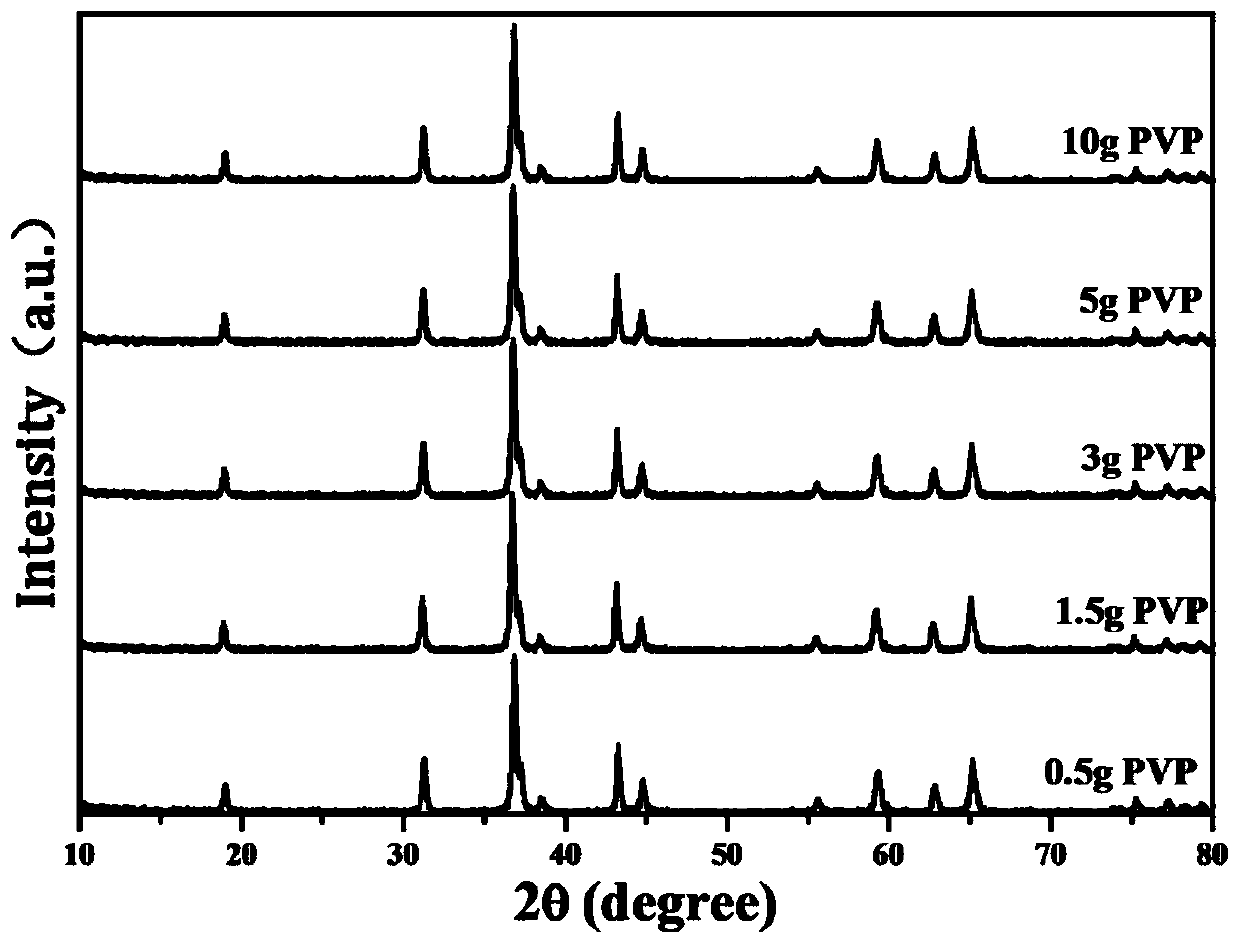

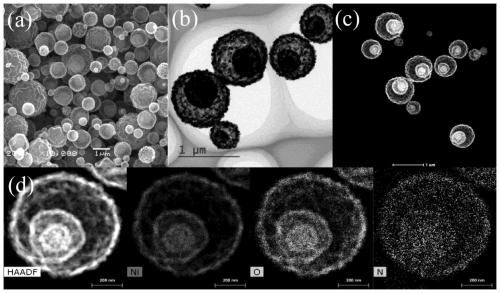

Method for preparing multilayer core-shell structure transition metal oxide at one step

ActiveCN107098405AUniform compositionShape is easy to controlNickel oxides/hydroxidesCobalt oxides/hydroxidesVertical tubeStructural transition

The invention relates to a method for preparing multilayer core-shell structure transition metal oxide at one step. The method comprises the following steps: dissolving a transition metal salt with a solvent, and then adding an organic additive to obtain a precursor solution; atomizing the precursor solution with an atomizer, and feeding the precursor solution into a vertical tube furnace with carrier gas for pyrolysis to obtain the multilayer core-shell structure transition metal oxide material. By adopting the method, the synthesized transition metal oxide is uniform in components, and is controllable in appearance and shell quantity; a high-purity and high-crystallinity multilayer core-shell structure transition metal oxide can be prepared without any separate subsequent burning process. Compared with the conventional method, the method has the advantages of easiness in operation, short flow, high efficiency, high suitability and the like.

Owner:CENT SOUTH UNIV

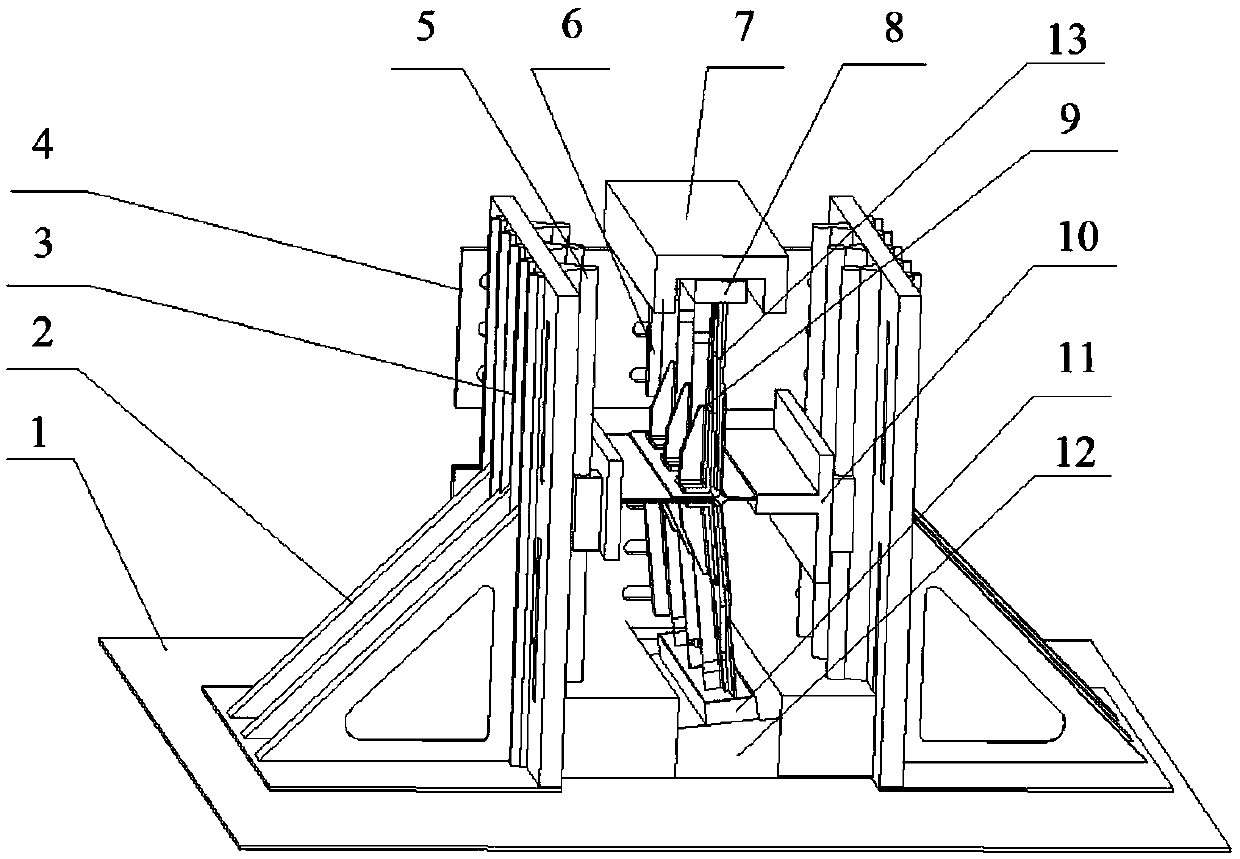

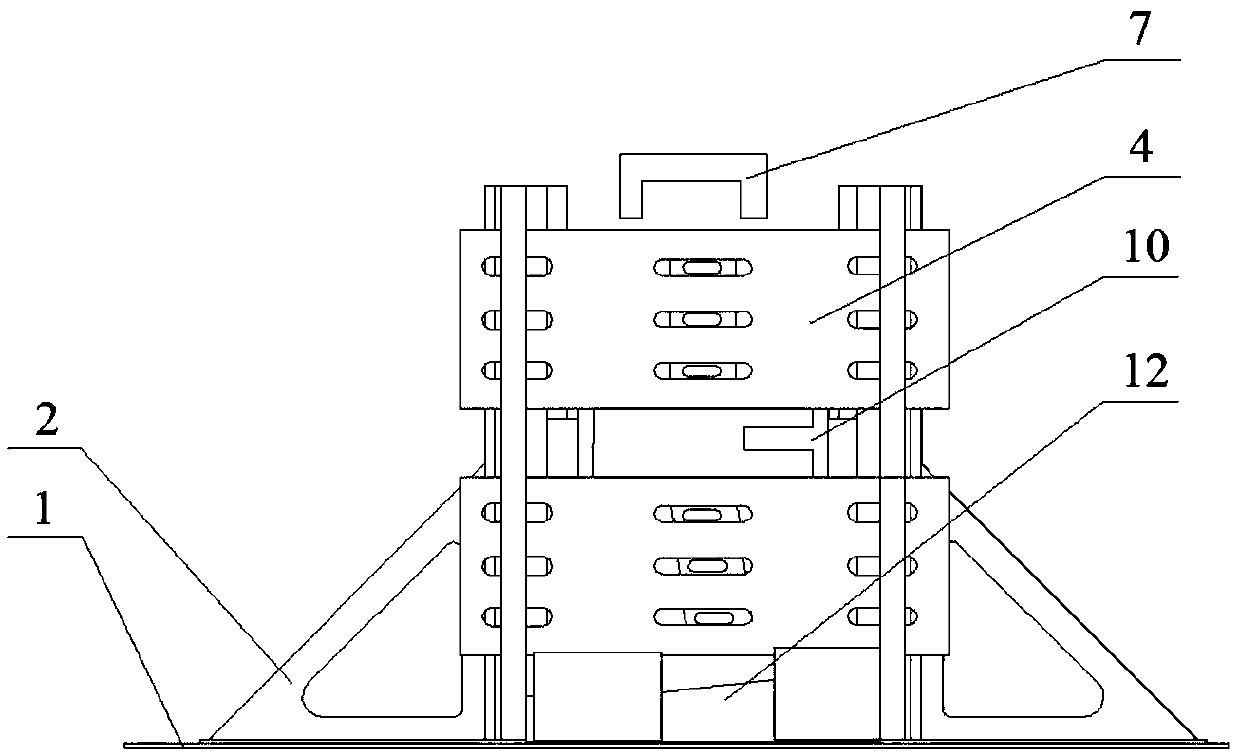

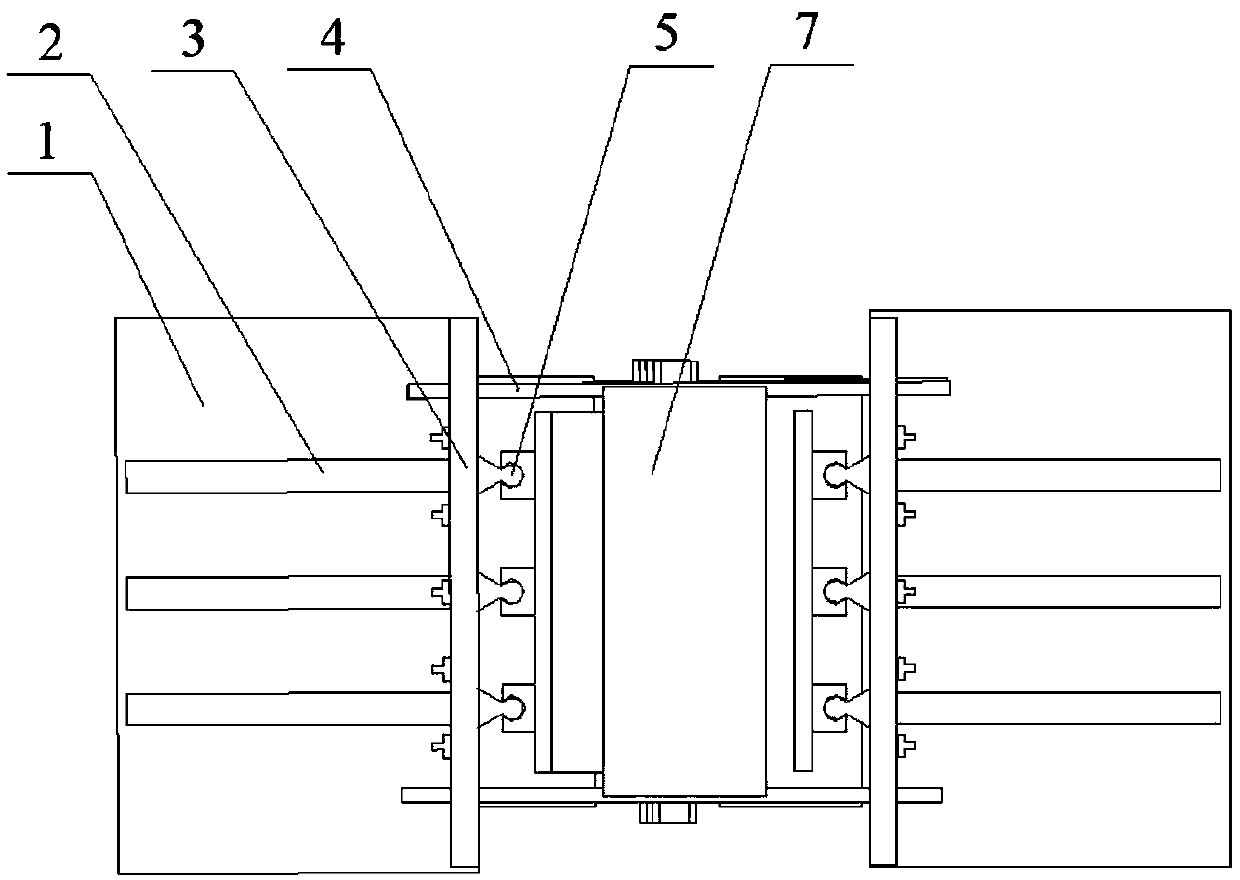

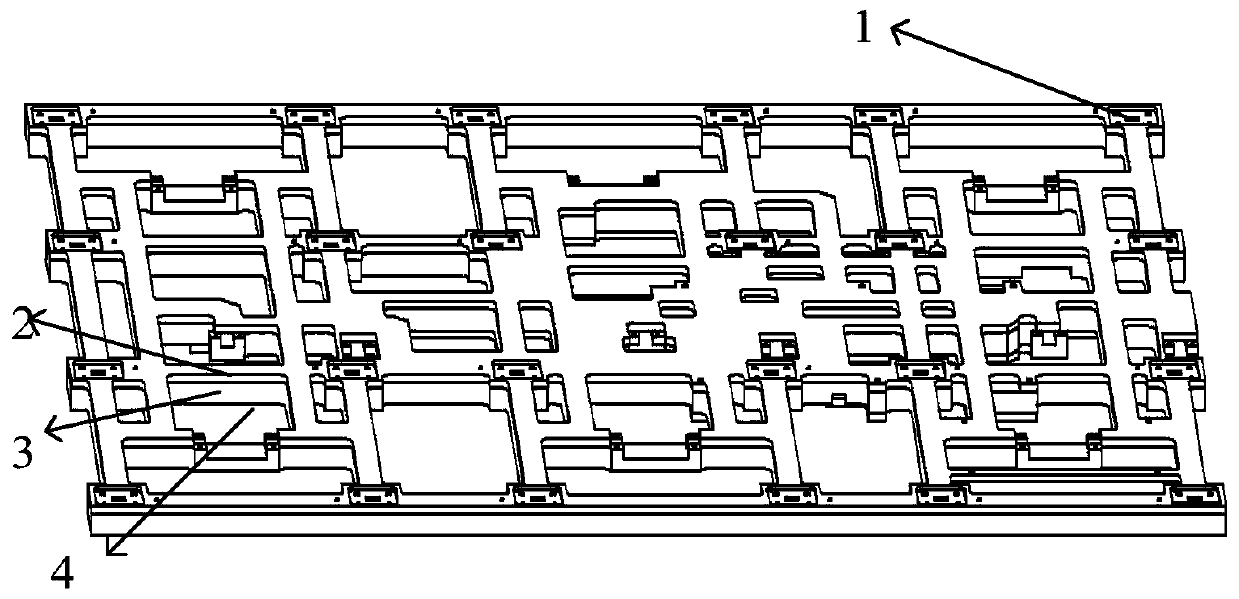

Vertical compression test device suitable for bending large panels

ActiveCN109612836ALimited out-of-plane displacementControl stressMaterial strength using tensile/compressive forcesEngineeringOut of plane displacement

The invention discloses a vertical compression test device suitable for bending large panels, belonging to the field of structural test mechanics. Fixed baffle plates are arranged on a base; sliding rails are welded to the inner sides of the fixed baffle plates; sliding bearings are installed on the sliding rails on two sides; a test piece is vertically arranged above the base and located betweenthe fixed baffle plates; the test piece, namely the panel is clamped by the sliding bearings; a loading chuck is arrange above the test piece; and the front and rear sides of the test piece are provided with detachable protective baffle plates. The vertical compression test device adopts a sliding bearing supporting mode, the friction force is reduced and the stress at the structural transition isbalanced, the out-of-plane displacement of the test piece is limited, so that that the out-of-plane load at the joint is prevent from causing material failure ahead of time, the compression load testof the bent large panel can be realized simply and efficiently, the structure is simple and reliable, the precision is high, the maintenance is simple and convenient, the compression test of the bentlarge panel can be realized on an ordinary press, and the vertical compression test device is suitable for use in various environments.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

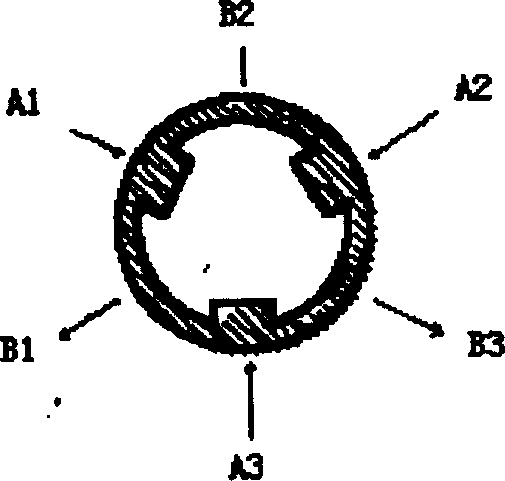

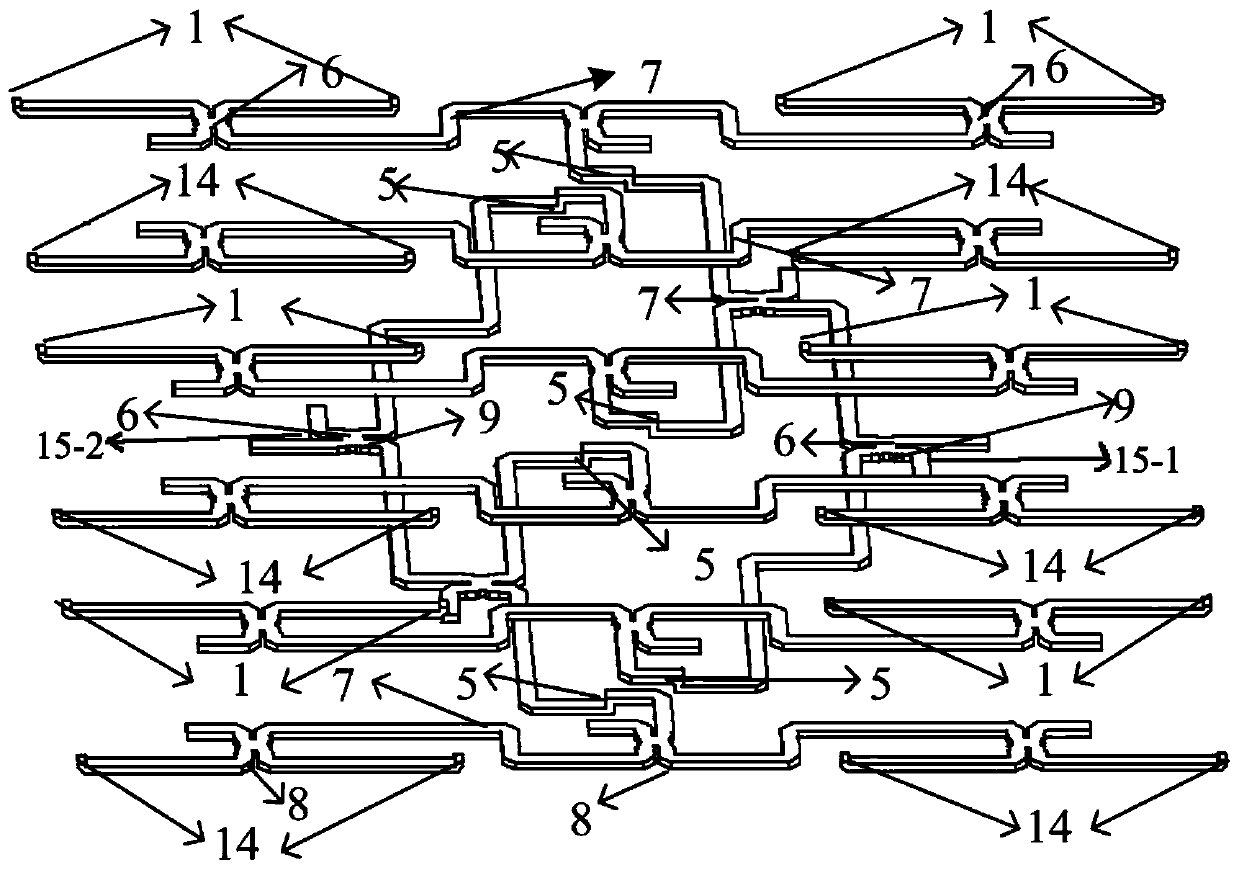

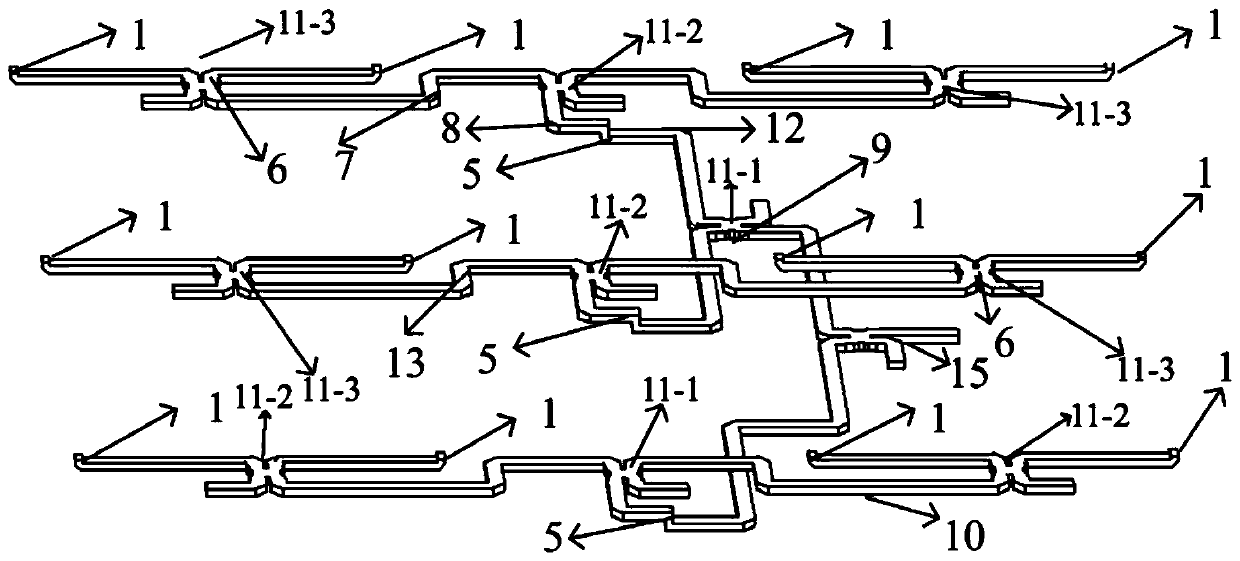

Miniaturized waveguide power division network

ActiveCN110459851AMiniaturizationRequires minimizationCoupling devicesPhased array feedMiniaturization

The invention discloses a miniaturized waveguide power division network, which is composed of at least two one-into-many waveguide power dividers adopting a double-layer waveguide structure. Each one-into-many waveguide power divider includes a first layer of waveguide structure, a second layer of waveguide structure and at least one first-type transition mechanism, and the first-type transition mechanism is provided with a first height transition part and a second height transition part which are in transition connection with the first layer of waveguide structure and the second layer of waveguide structure respectively so that the first layer of waveguide structure and the second layer of waveguide structure are in planes at different heights. The advantages are as follows: because the waveguide power dividers adopting a double-layer waveguide structure are placed alternately, the space is fully utilized, and the volume of the device is reduced; and for a large phased array feed network, a miniaturized waveguide power division network is realized and the demand of the modern phased array technology for a miniaturized feed network is satisfied under the premise of ensuring excellent isolation of the output port and easy integration of the output port with the circuit.

Owner:SHANGHAI RADIO EQUIP RES INST

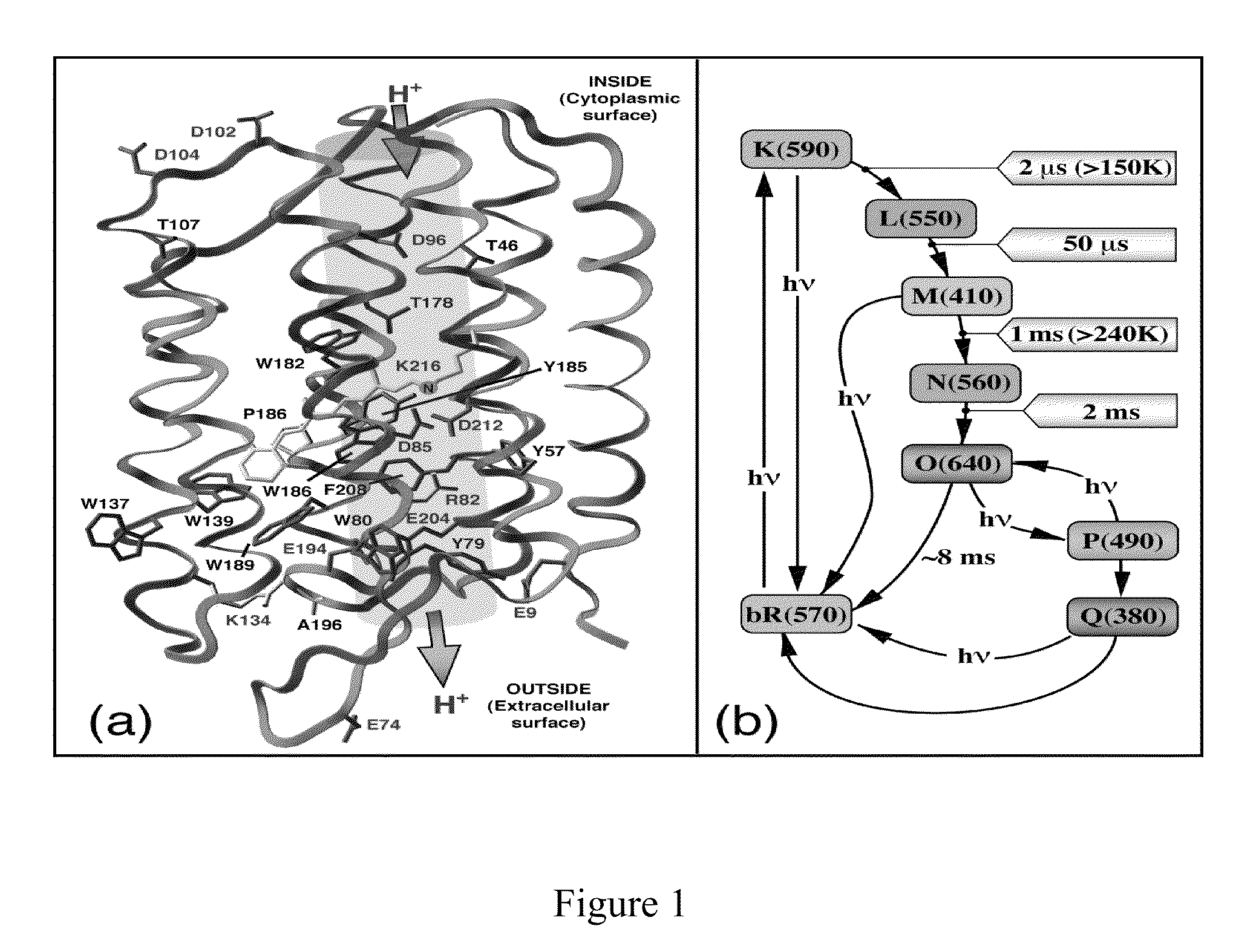

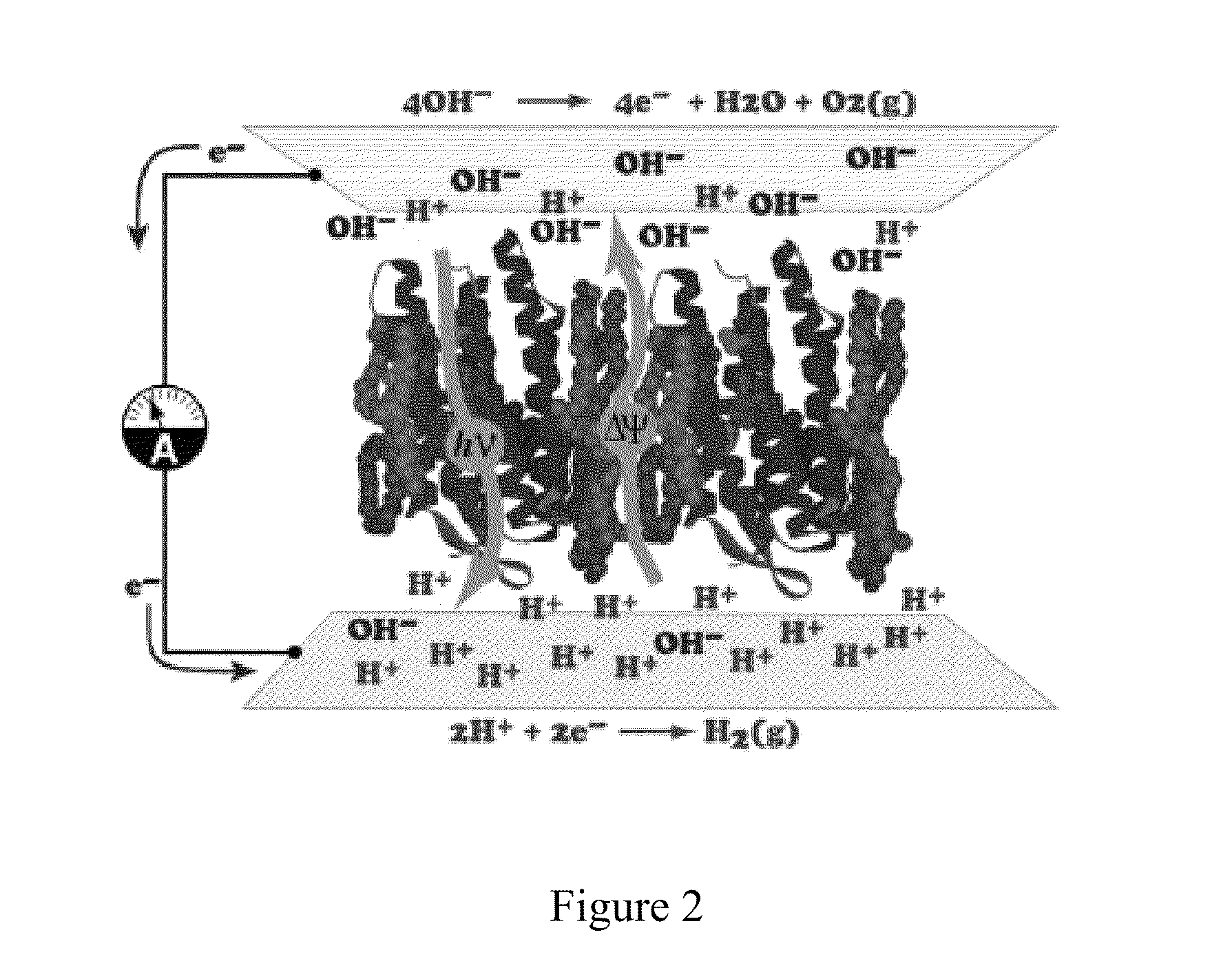

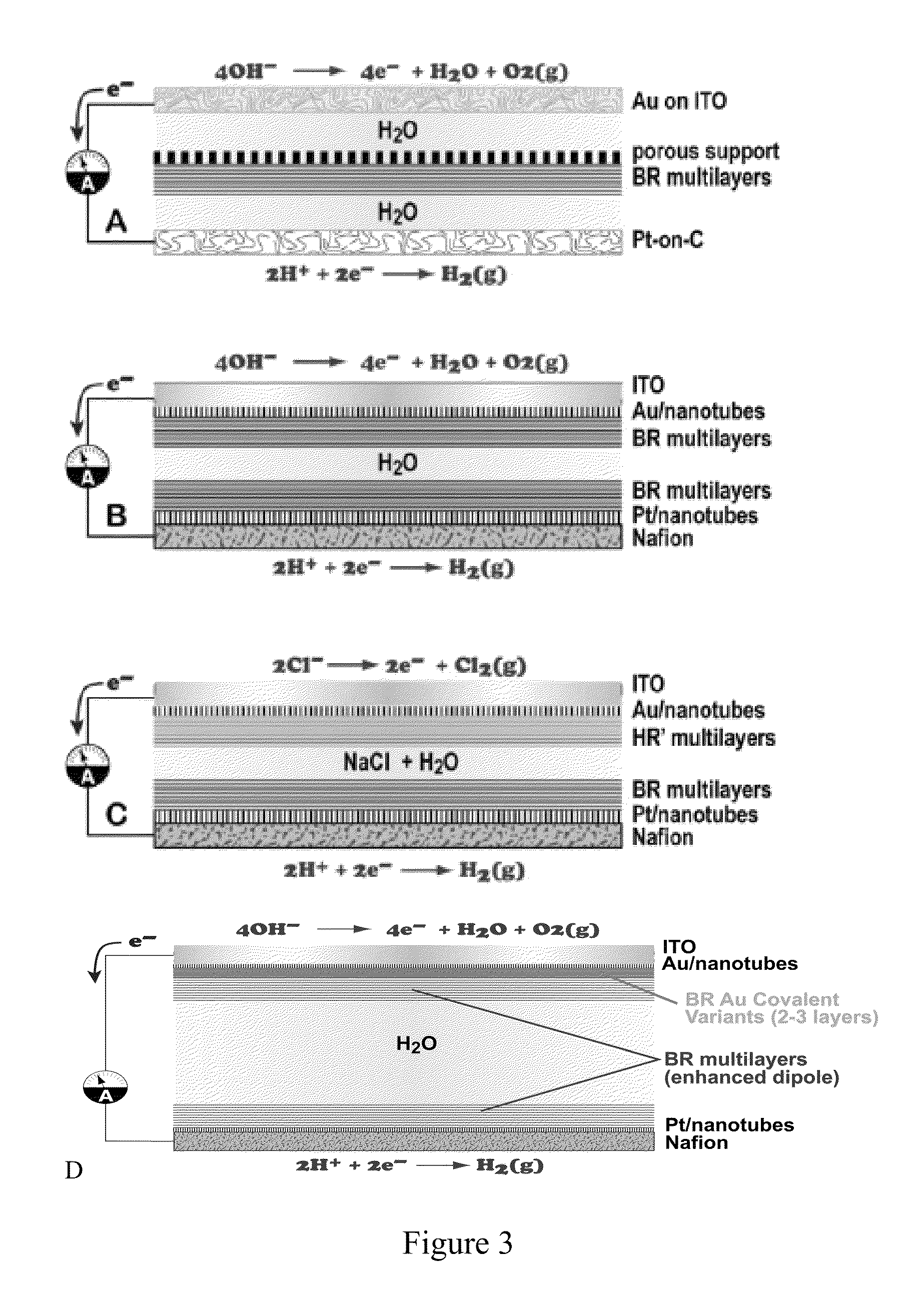

Protein-based photovoltaics and methods of use

ActiveUS9023989B2Easy to attachEnhanced dipoleFinal product manufactureNanoinformaticsHalobacterium salinarumBiology

Protein-based photovoltaic cells and the manufacture and use of protein-based photovoltaic cells are described. In one embodiment, bacteriorhodopsin from Halobacterium salinarum, which undergoes structural transitions when irradiated with a given wavelength of light, is used as the protein in the protein-based photovoltaic cells. In another embodiment, mutant bacteriorhodopsin from H. salinarum is used. Exposure of the protein to sunlight causes proton transfer across a membrane resulting in the generation of an electrical charge. The protein can be oriented and / or layered on a substrate and modified by mutation to enhance transmembrane proton transfer, covalent binding to a substrate and layering. The protein-based photovoltaic cells sequentially or simultaneously generate hydrogen gas from water or salt, which also can be harnessed to produce electricity.

Owner:UNIV OF CONNECTICUT

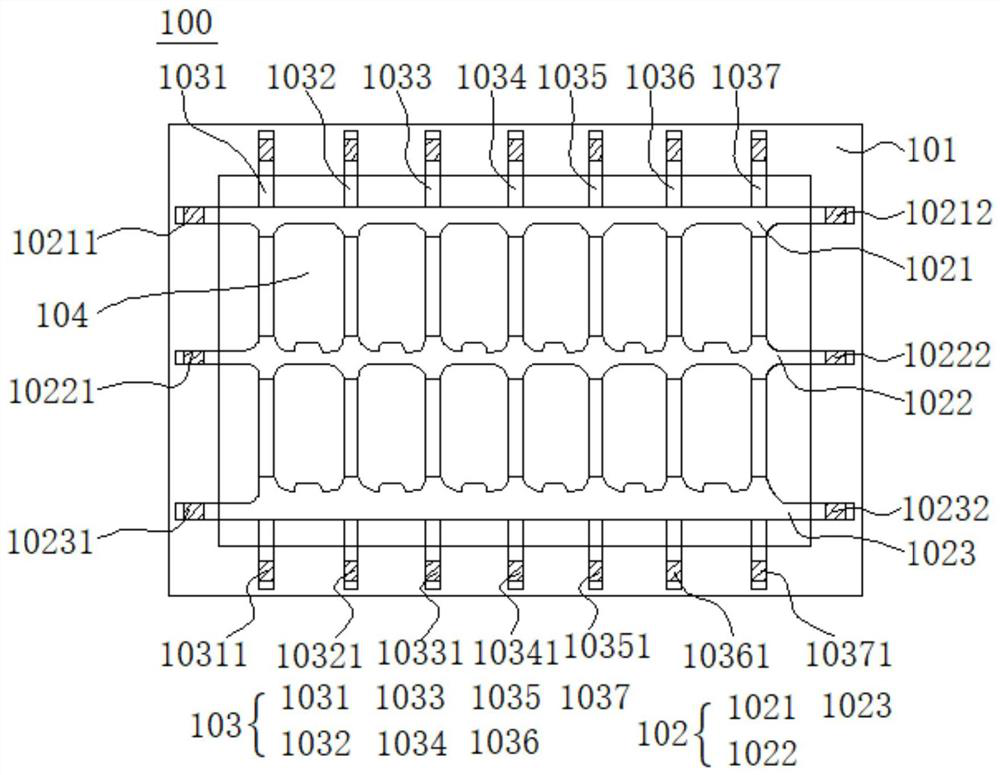

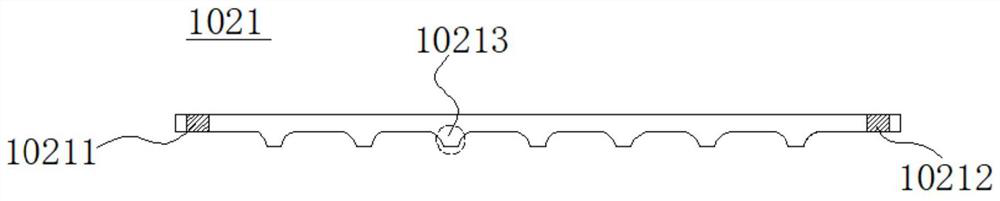

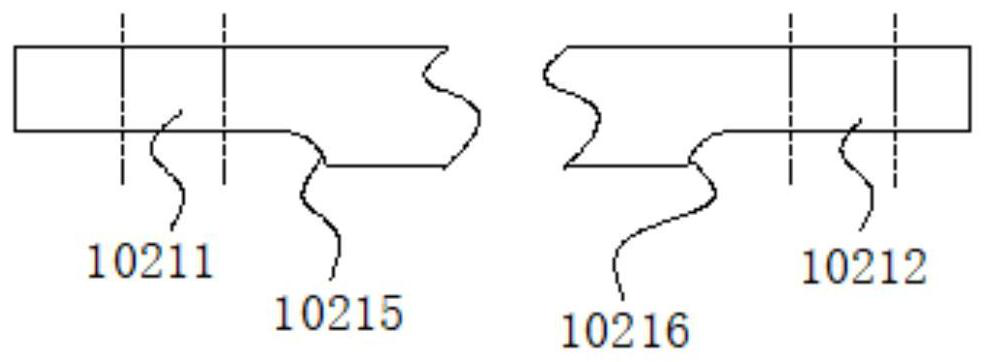

Metal mask

PendingCN111748766AImprove accuracyImprove stabilityVacuum evaporation coatingSolid-state devicesStructural engineeringStructural transition

The invention provides a metal mask. A special-shaped shielding strip of the metal mask comprises a main body, a special-shaped protruding block which is arranged on one side of the main body and a straight edge which is arranged on the other side of the main body and opposite to the special-shaped protruding block; and the straight edge is provided with a protrusion which has a reverse stretchingeffect with the special-shaped protruding block relative to the main body, welding areas are arranged at the two ends of the main body respectively, and smooth structure transition is adopted betweenthe special-shaped protruding block and the welding areas. According to the metal mask, when the metal mask is subjected to tension welding, due to the fact that the special-shaped protruding block and the smooth transition structure are adopted on the main body, the sudden change amount generated by welding is effectively reduced, the stability of the metal mask in the Y direction is improved, the situation that the tension precision is poor due to the fact that the Y-direction structure of a special-shaped supporting strip is asymmetric is avoided, and therefore, high-precision tension of the metal mask is realized, and the accuracy of film coating is ensured.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

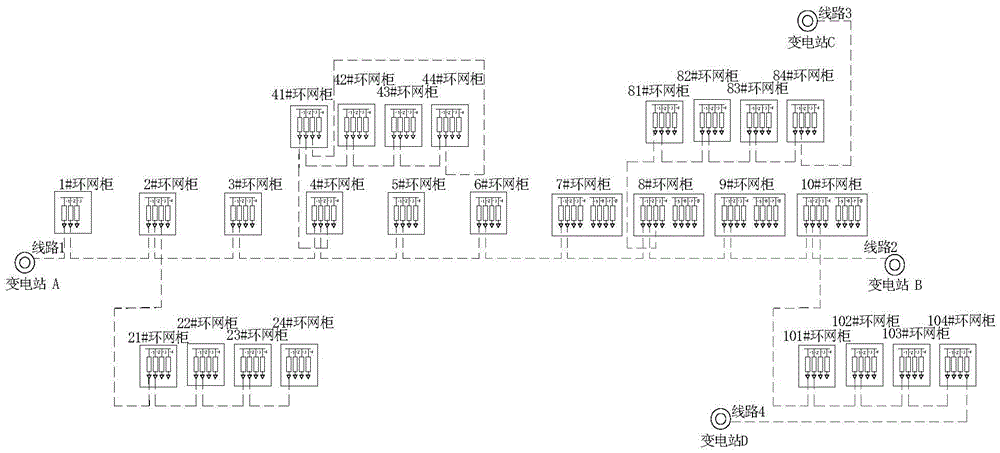

Method for improvement on electric network and service expansion by using single-ring network structure

InactiveCN105529702AIncrease the proportion of standardized structuresEasy to implementAc network circuit arrangementsPower gridRing network

The invention relates to a method for improvement on electric network and service expansion by using a single-ring network structure. The method comprises the following steps of (1) determining a wiring mode to a single-ring network node mode, namely a path of circuit journey ring network is led from each of two substations, the ring network circuits are lay in parallel and has no branches, the ring network circuits are connected by copper cables, and the copper cables are connected by a ring network cabinet; and (2) determining a contact point, wherein the contact point is an opened ring point and is arranged at the middle position of a single ring network, and the average allocation of circuit loads of the single ring network is facilitated. By the improvement on the single ring network mode, engineering construction is facilitated, the standard structural proportion of the circuit can be rapidly increased, a newly-formed power grid structure of a matched engineering can be constrained, and meanwhile, the ring network structure transiting to the whole line in future is also facilitated.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

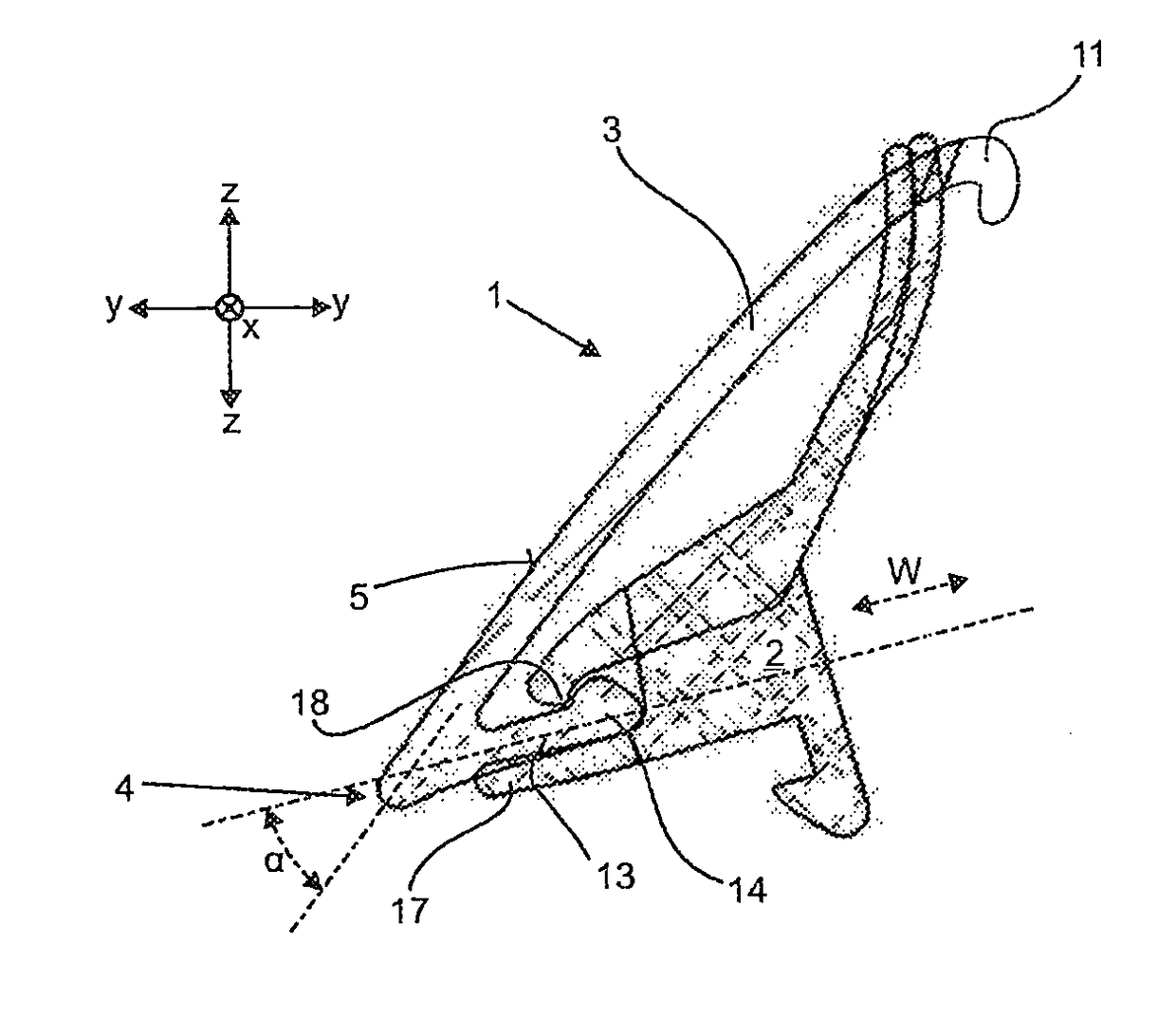

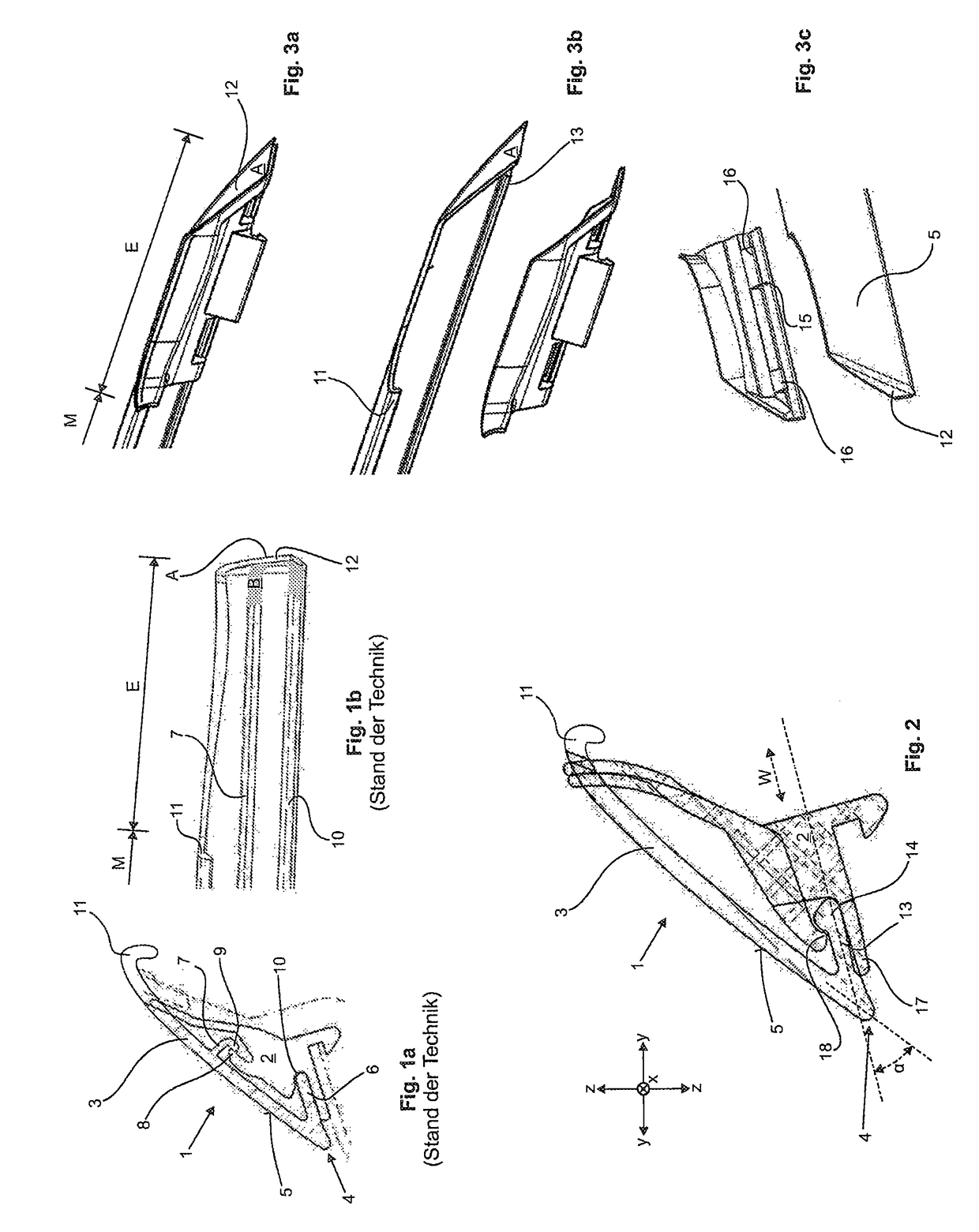

Bridging component and edge trim strip as well as system made from them

InactiveUS20170136965A1Stable appearanceSuperstructure subunitsVehicle sealing arrangementsStructural transitionMechanical engineering

In a system made from an edge trim strip and a bridging component for the bridging, especially in optical manner, of a structural transition between the edge trim strip and the bridging component, a simple and secure connection of the edge trim strip and the bridging component should be made possible with the simplest possible fabrication and design of the edge trim strip. The securing of the bridging component to the edge trim strip is accomplished solely by a fastening leg provided on the edge strip and forming an undercut, and the fastening leg is the sole leg of the cross section profile of the edge trim strip serving to secure the bridging component. The bridging component has a locking means in the form of a locking groove, which is able to engage at top and bottom with the fastening leg provided with the undercut in a locking manner.

Owner:DURA AUTOMOTIVE HLDG U K LTD

Manufacturing process of screw rod of ceramic-phase nanocrystalline composite coating injection molding machine

InactiveCN103215545AImprove adhesionHigh hardnessVacuum evaporation coatingSputtering coatingDiamond-like carbonSingle substance

The invention discloses a manufacturing process of a screw rod of a ceramic-phase nanocrystalline composite coating injection molding machine. The manufacturing process comprises the following steps of: cleaning the screw rod; using the cleaned screw rod as a base material, and depositing a 500nm-thick ceramic-phase nanocrystalline structure transition layer of a single substance or a nitride or a carbide or a nitrogen carbide of Ti, Si, W, Al, Cr and Zr on the base material; depositing at least two alternately deposited 5-8-micron-thick ceramic-phase nanocrystalline structure composite layers of the nitride or the carbide or an oxide or the nitrogen carbide of the Ti, Si, W, Al, Cr and Zr on the transmission layer as main functional layers; and depositing 2-3-micron-thick AlCrN doped DLC (Diamond-Like Carbon) film layer on the main functional layers as a self-lubricating layer. The manufacturing process of the screw rod of the ceramic-phase nanocrystalline composite coating injection molding machine can be used for enabling the screw rod to have better abrasive resistance, corrosion resistance and lubrication exclusion, so that the equipment failure rate of the injection molding machine is lowered, the equipment operation stability is improved and the service life of the screw rod is prolonged in multiples.

Owner:李固加

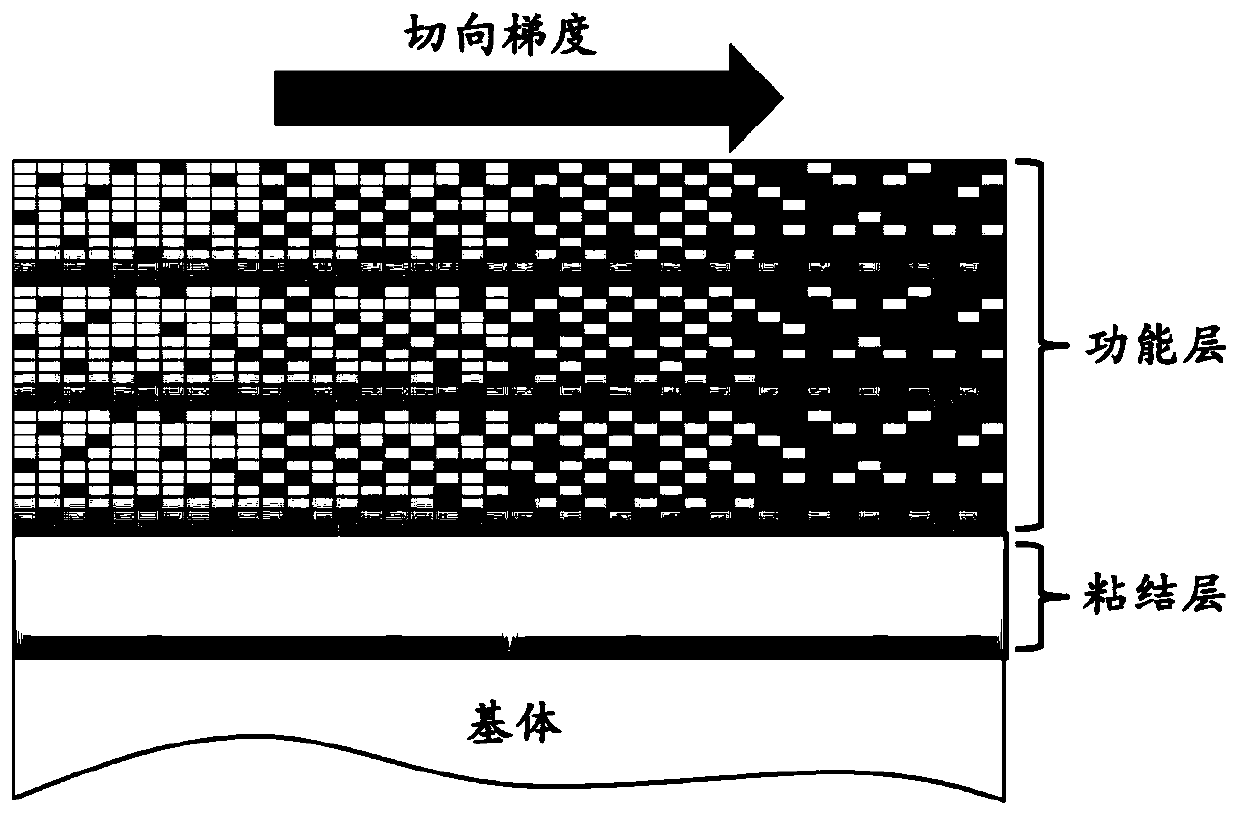

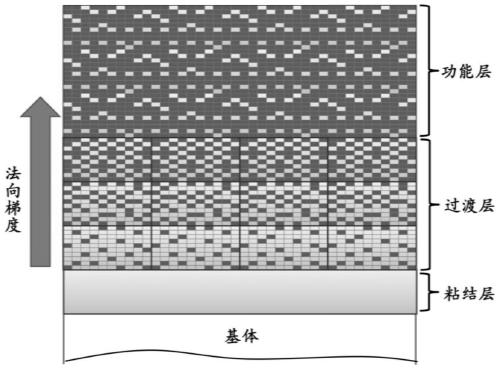

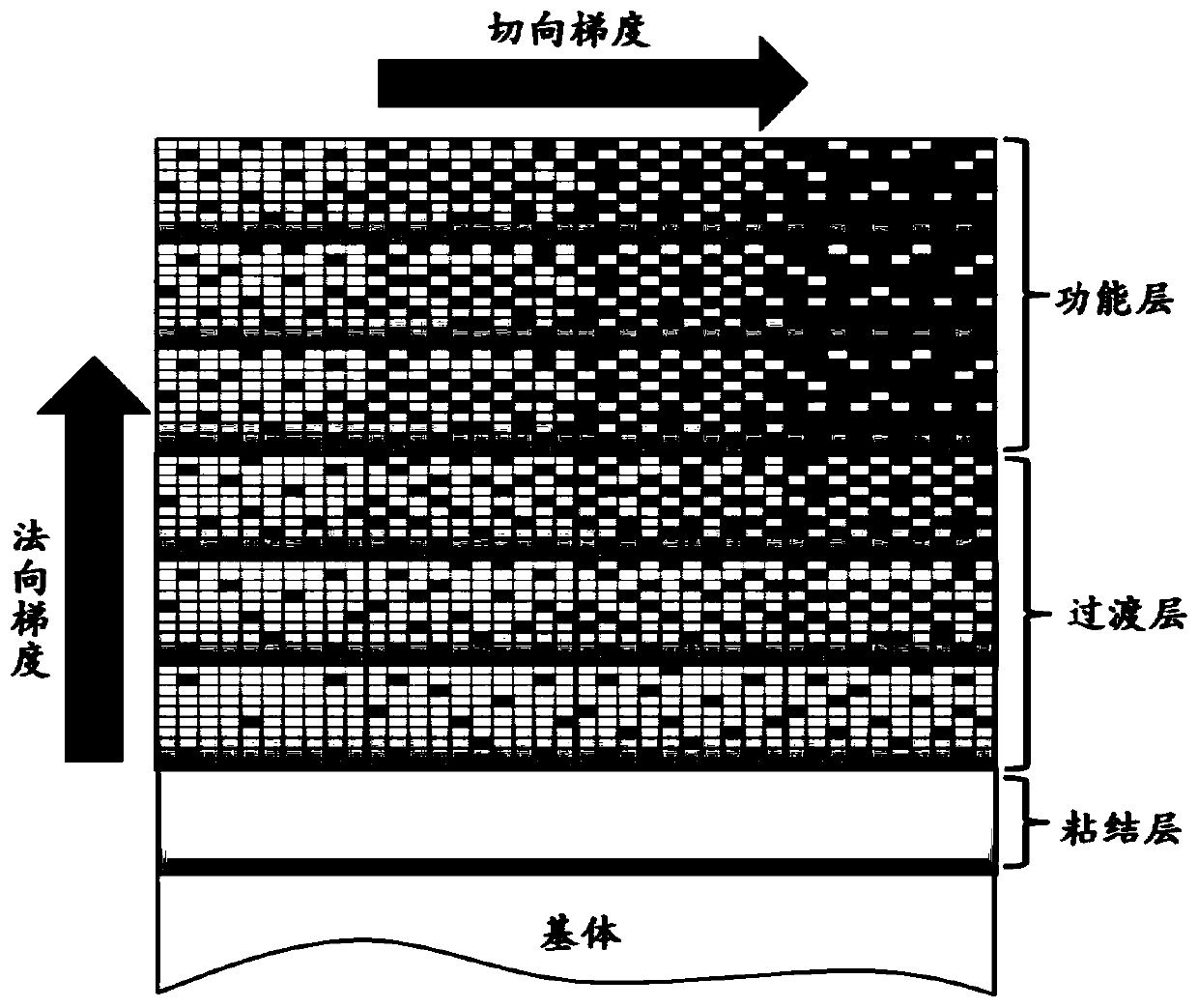

Two-dimension gradient structure transition layer

ActiveCN109825796AGood tangential consistencyImprove service performanceMolten spray coatingThermodynamicsStructural transition

The invention relates to a two-dimension gradient structure transition layer. A two-dimension gradient transition layer is introduced between a base body and a tangential gradual changing coating, andthe composite ratio of the transition layer is in two-dimension gradient changes in the normal direction and the tangential direction. Through the composite ratio normal-direction gradient changes ofthe transition layer, heat stress between the coating and the base body can be relieved, and through the composite ratio tangential-direction gradient changes of the transition layer, the differenceof the heat stress in the tangential direction is overcome.

Owner:SHANDONG UNIV

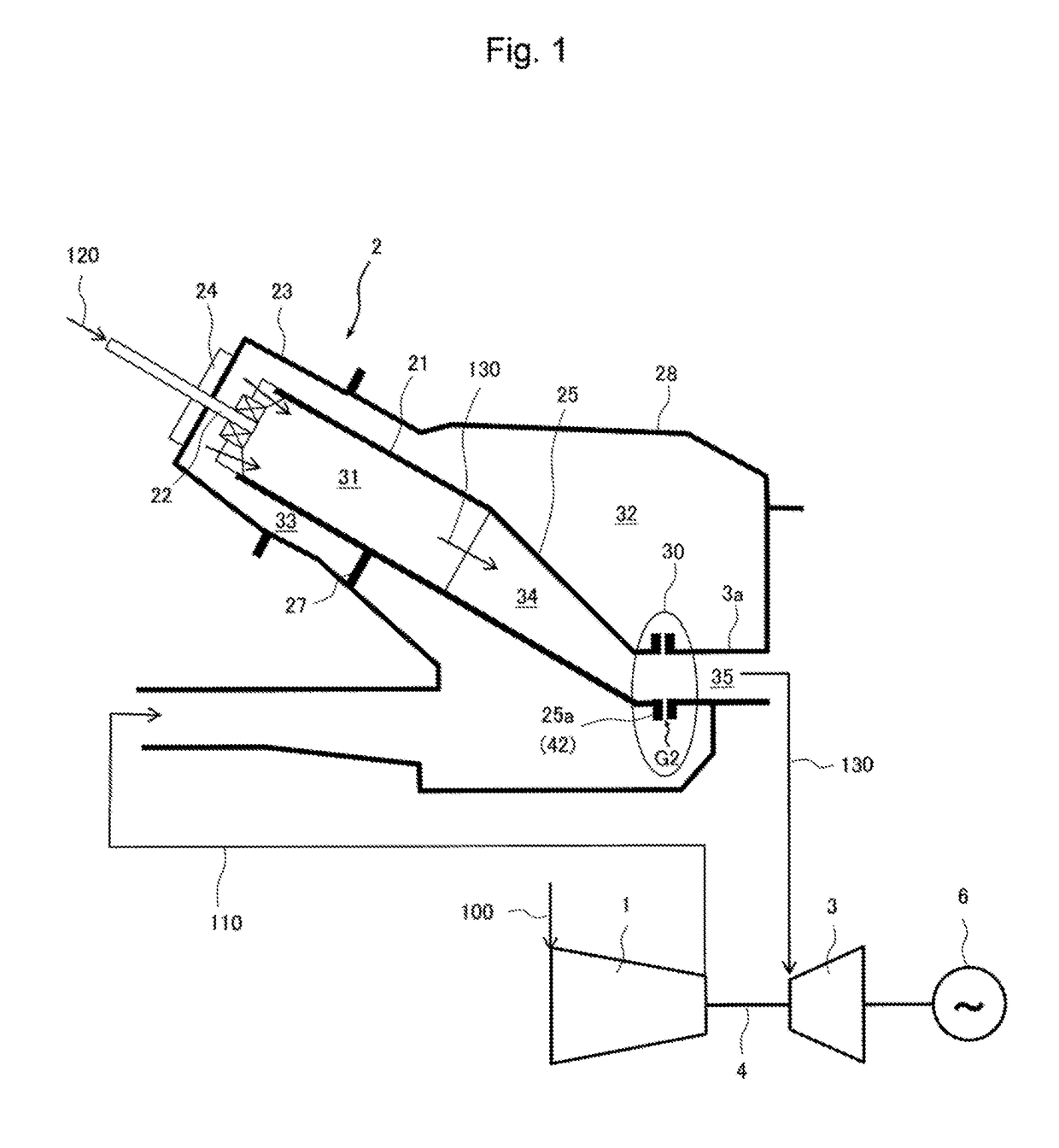

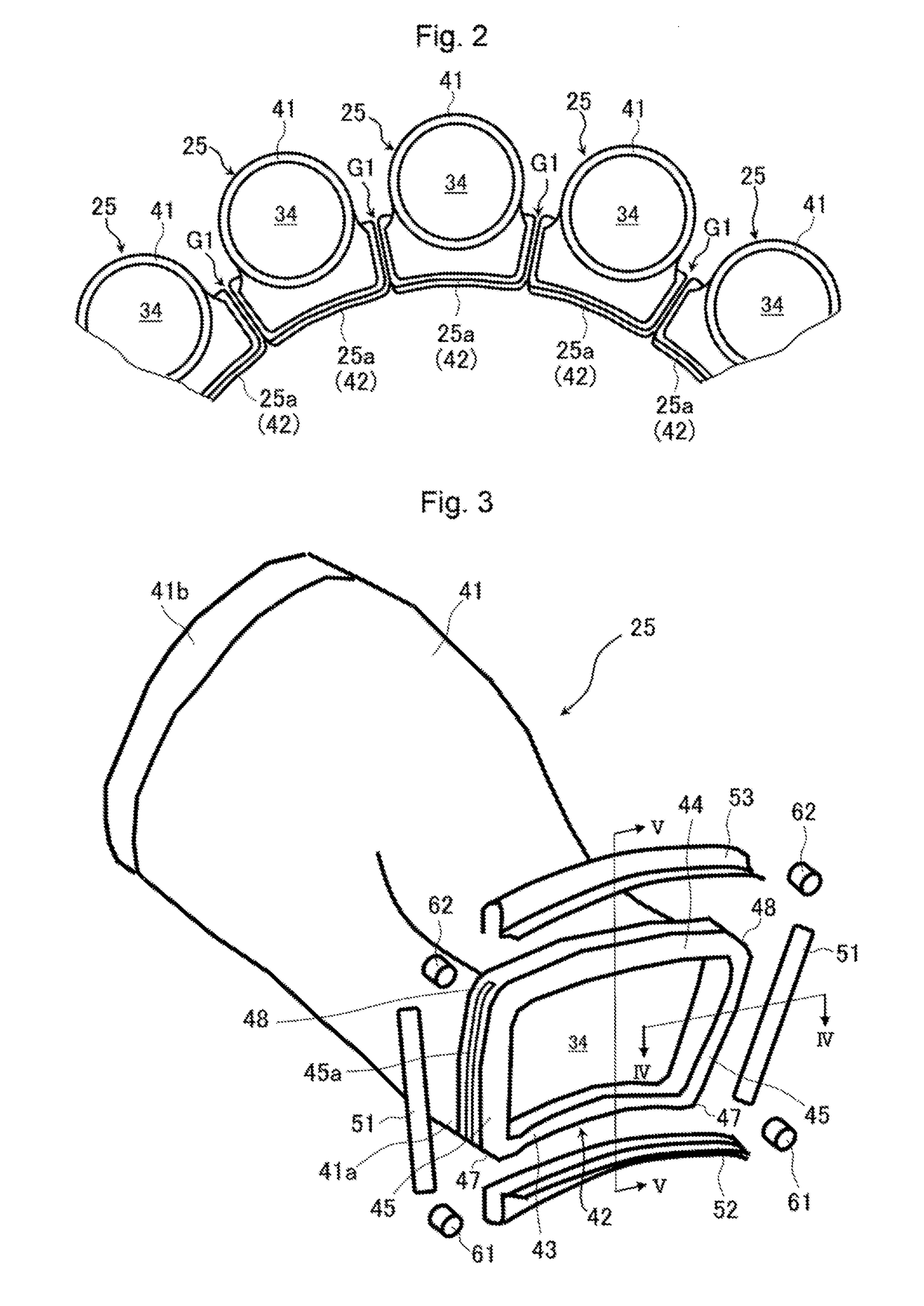

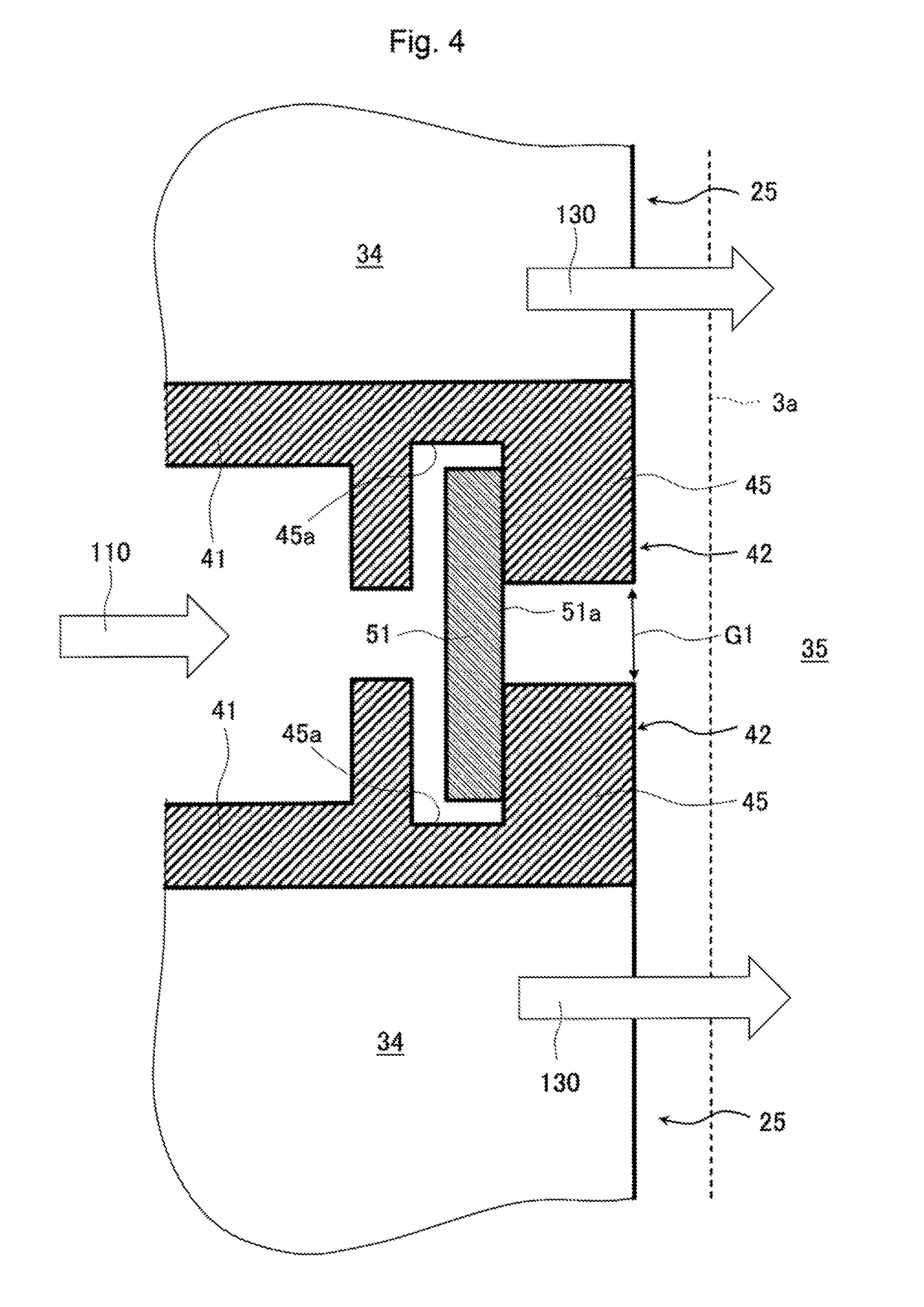

Gas Turbine

InactiveUS20190063240A1Keep tightPrevent leakageLeakage preventionGas turbine plantsEngineeringStructural transition

A gas turbine has a sealing structure at a connection portion between the transition pieces and a turbine inlet portion. A frame of the transition piece has an inner frame portion extending in the circumferential direction, an outer frame portion situated radially outside the inner frame portion, and a pair of side frame portions provided between both side end portions of the inner frame portion and the outer frame portion. The sealing structure includes an inner circumferential seal member and an outer circumferential seal member for sealing a gap between the inner frame portion and the outer frame portion and the turbine inlet portion, a side seal member for sealing a gap between the adjacent side frame portions, a first obstacle arranged in a gap between first corner portions adjacent to each other, and a second obstacle arranged in a gap between second corner portions adjacent to each other. The first obstacle and the second obstacle are in contact with the side seal member at the side of the turbine inlet portion.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

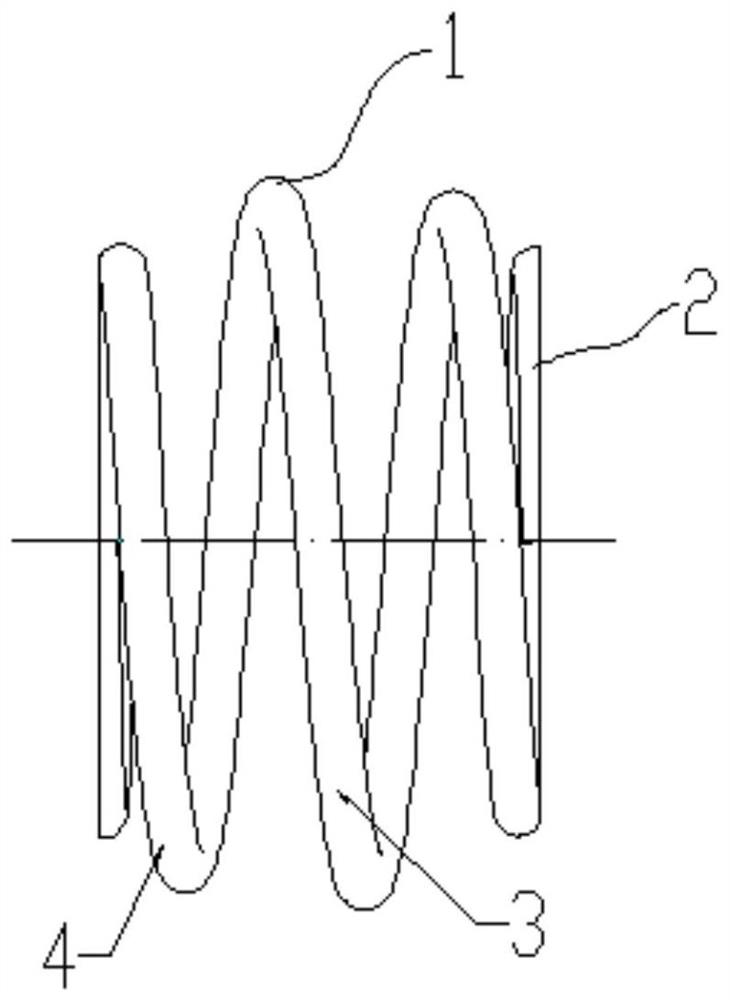

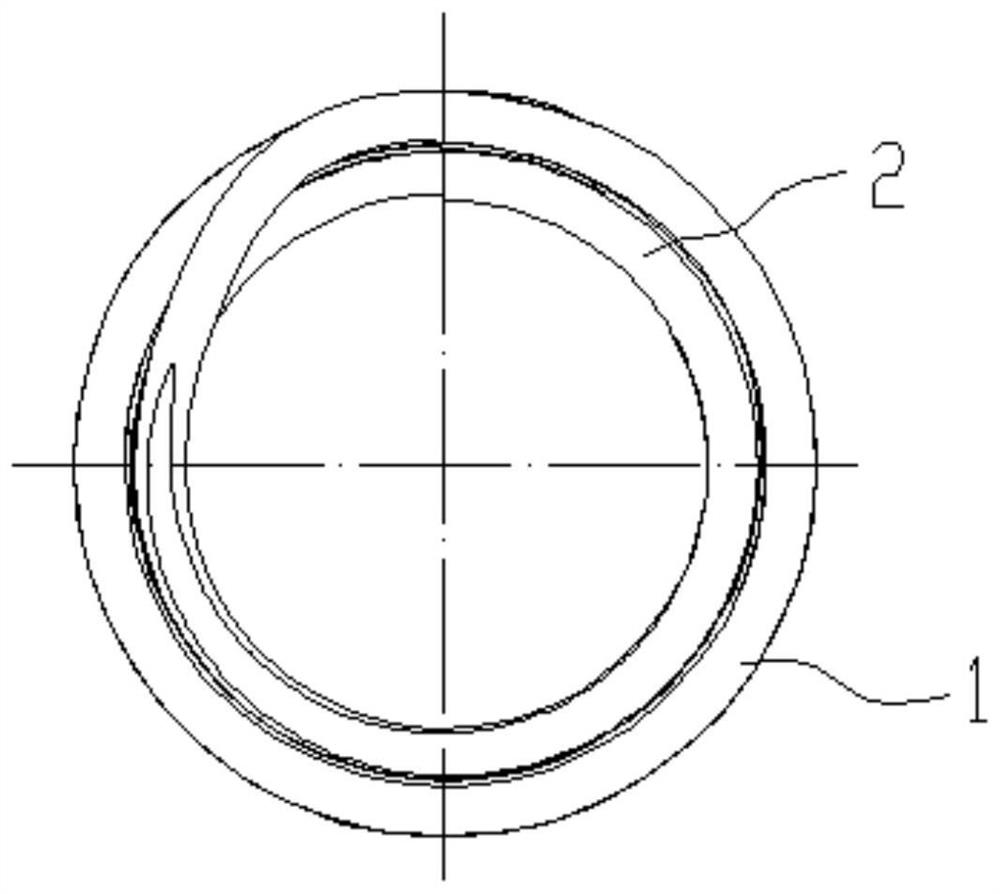

Anti-abrasion and anti-breakage long-service-life drain valve spring

PendingCN113483044ASimple structureNo contactPositive displacement pump componentsWound springsSpring steelStructural transition

The invention provides an anti-abrasion and anti-breakage long-service-life drain valve spring. The anti-abrasion and anti-breakage long-service-life drain valve spring comprises a main body structure and supporting rings at the two ends of the main body structure. The main body structure comprises a working ring and transition rings at the two ends of the working ring, the inner diameter of the working ring is larger than the outer diameter of the transition rings, and after the spring is pressed, even if the supporting ring retracts into the main body structure, the transition rings do not make contact with the main body structure. By means of the anti-abrasion and anti-breakage long-service-life drain valve spring, the structure of the working ring of the spring is improved, the outer diameter of the transition rings is smaller than the inner diameter of the working ring, it is guaranteed that when the spring is compressed to the limiting position, steel wires do not interfere with one another, the steel wires do not make contact with one another when the whole spring works, and the fatigue life is greatly prolonged; and materials are selected from conventional spring steel materials, so that the cost is also greatly reduced.

Owner:绍兴美力精密弹簧有限公司

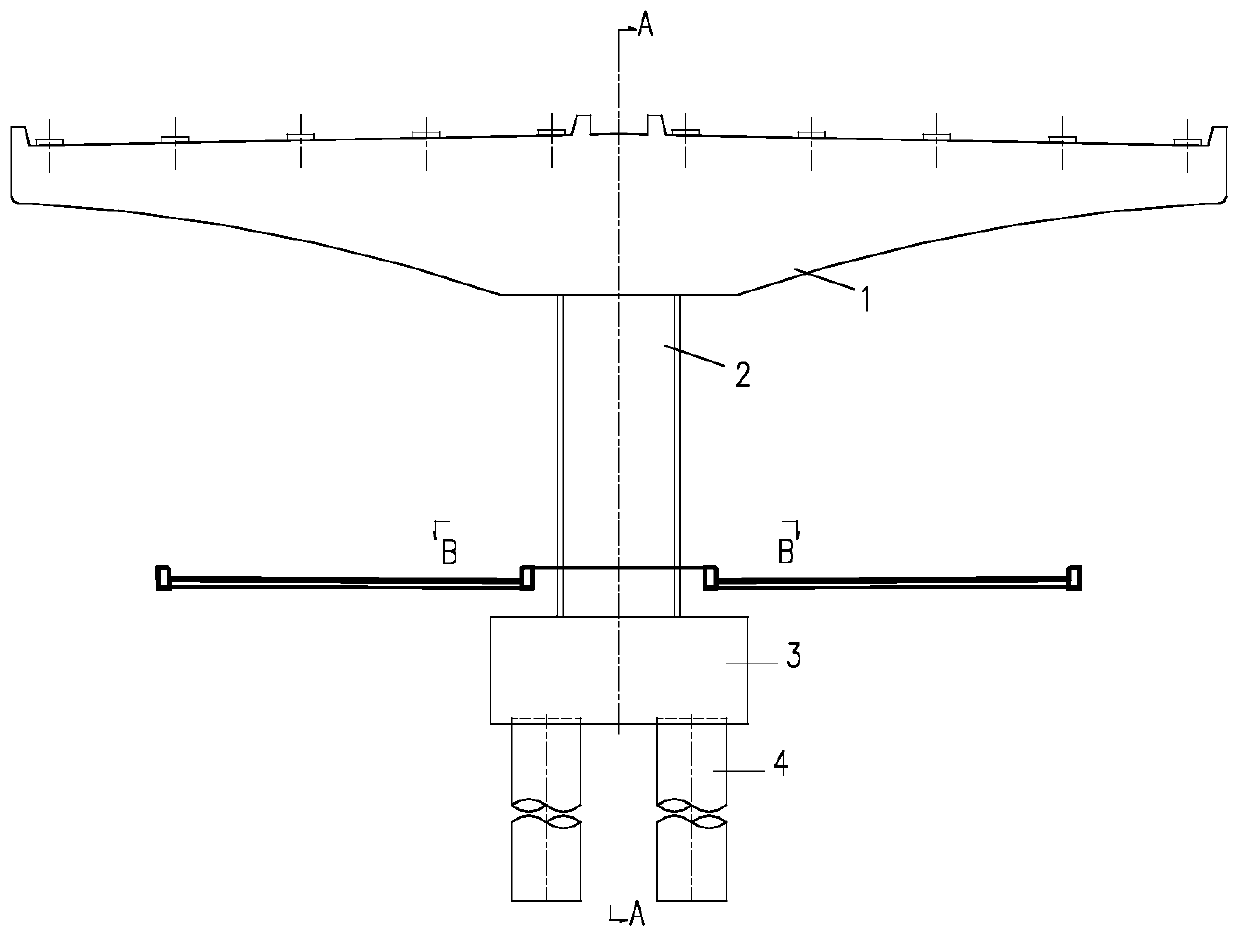

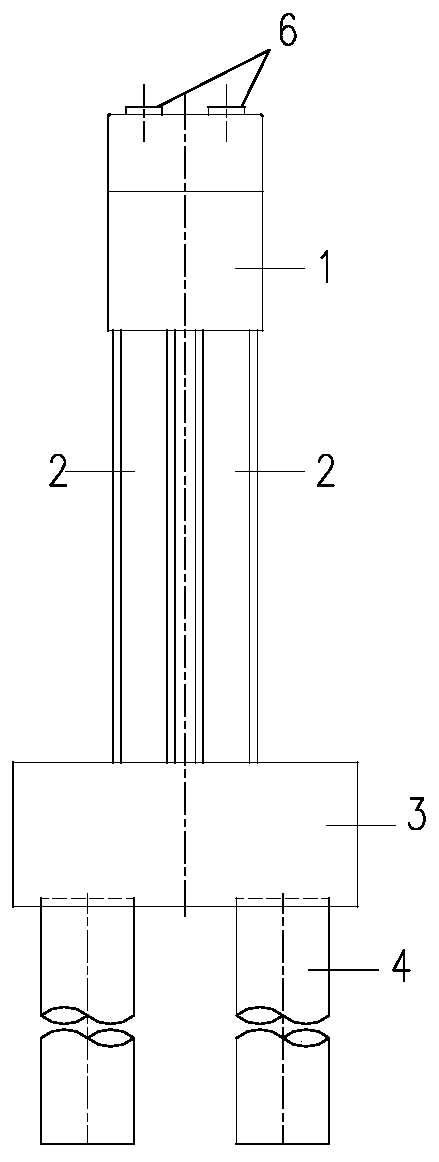

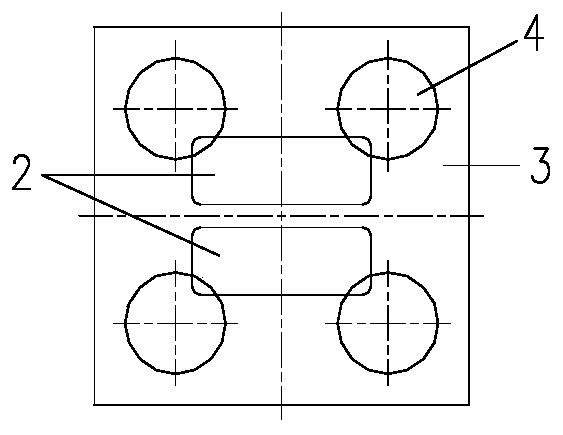

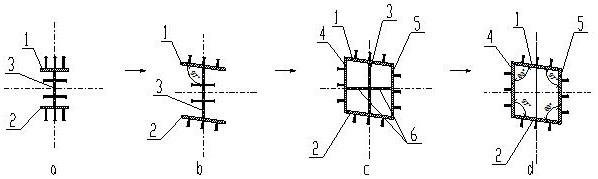

Double-limb pier bent cap

PendingCN111560843AReduce horizontal forceLow costBridge structural detailsFoundation engineeringRebarStructural safety

The invention relates to a double-limb pier bent cap which comprises a bent cap body. Two longitudinally separated stand columns are arranged at the bottom of the bent cap and arranged on a bearing platform, and a foundation is arranged below the bearing platform. The bent cap can be of a common reinforced concrete structure or a prestressed concrete structure. The stand columns have reinforced concrete solid structures, the side length of the cross section of each stand column in the transverse direction of the bridge is larger than that of the cross section in the longitudinal direction of the bridge, the stand columns are divided into two independent stand columns in the longitudinal direction of the bridge to form double-limb piers, and the centers of the two stand columns correspond to the upper structure supports in position. The double-limb piers and a group of pile foundations composed of cast-in-situ bored piles are in structural transition through the bearing platform, and the two ends of the double-limb piers should be fixedly connected with the bent cap and the bearing platform respectively. The anti-bending rigidity of the structure in the bridge direction can be greatly reduced, the structural anti-seismic property objective is achieved, the construction cost is saved, the under-bridge driving view is enlarged, and the structure is safe, reliable, economical and attractive.

Owner:JSTI GRP CO LTD

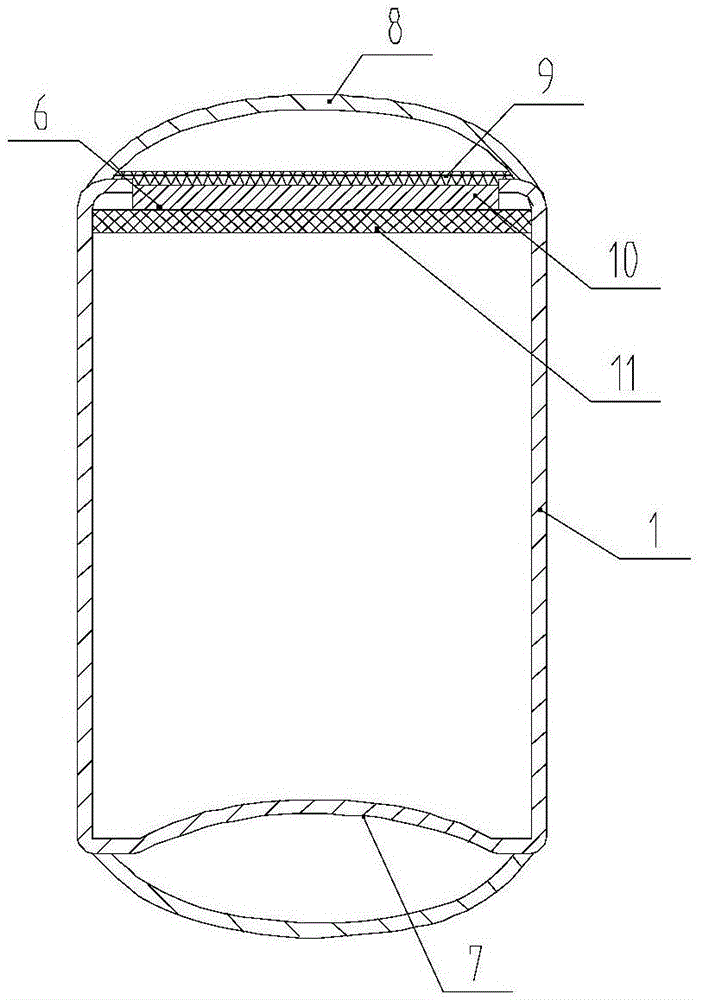

High-performance capacitor

InactiveCN105469994AReduce burstOffset bloatLiquid electrolytic capacitorsCapacitor housing/encapsulationCapacitanceEngineering

The invention provides a high-performance capacitor. The high-performance capacitor comprises a shell and an electrolyte sealed in the shell, wherein a positive electrode pin and a negative electrode pin are arranged on the shell; a cross-shaped concave is formed in one side of the positive electrode pin of the shell; a horizontal-line-shaped groove is formed in one side of the negative electrode pin; a cover body is arranged at the upper end of the shell while an anti-explosive concave part is formed in the lower end of the shell; anti-explosive bands are arranged at the upper and lower ends of the shell; the exterior of the shell is coated with an anti-explosive net; and the anti-explosive net is normally made from nylon. The high-performance capacitor is durable; the anti-explosive concave part is formed in the lower end of the shell, and the cover body is arranged at the upper end of the shell, so that the anti-explosive performance of the capacitor shell is improved; the electric energy in the capacitor can be locked without causing loss of power easily; the bottom surface of the anti-explosive concave part adopts an inwardly-concave spherical surface, so that the anti-explosive concave part is smooth in structural transition; when the anti-explosive concave part is deformed, the load-carrying capability is high; and the capacitor is safe and reliable without exploding when the stretch limit of the capacitor is not achieved.

Owner:天津市科达斯特光电科技有限公司

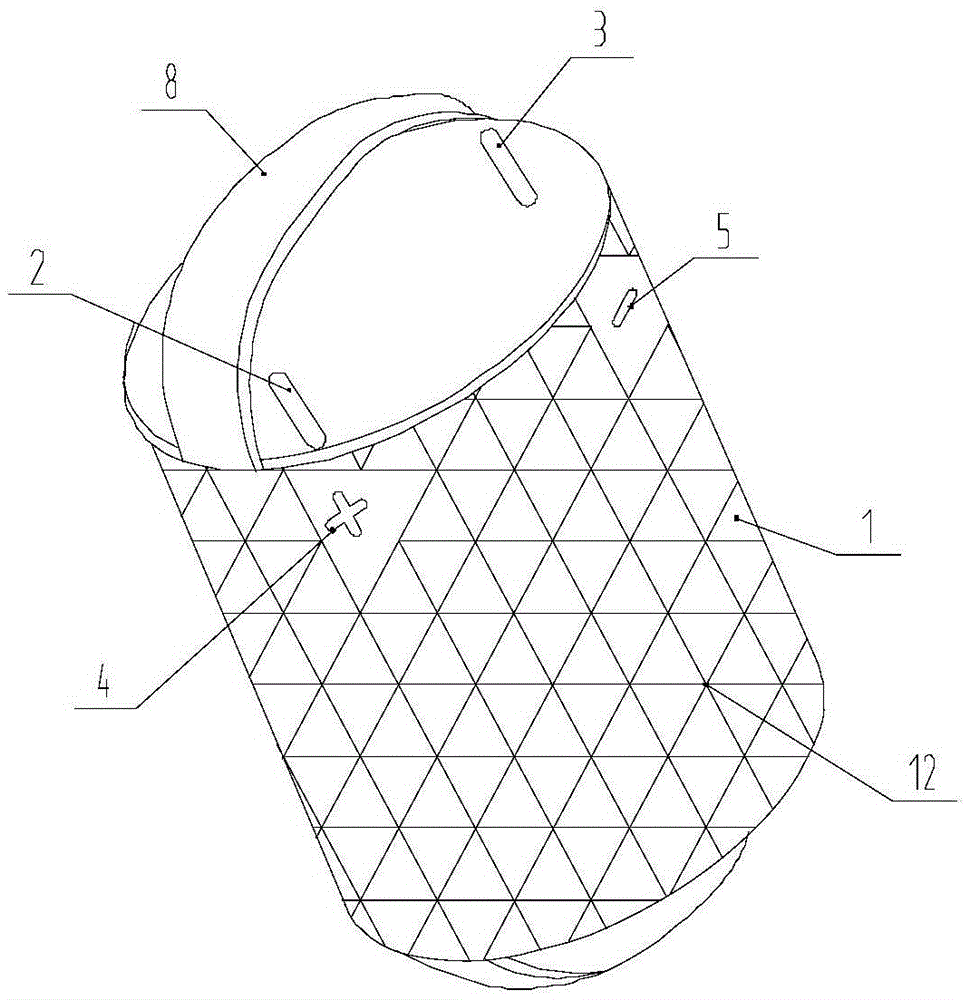

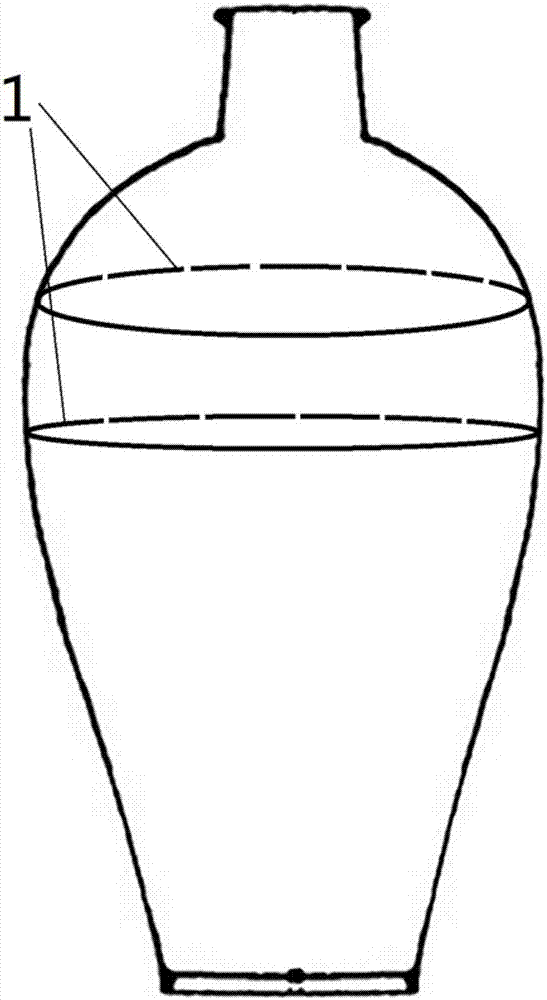

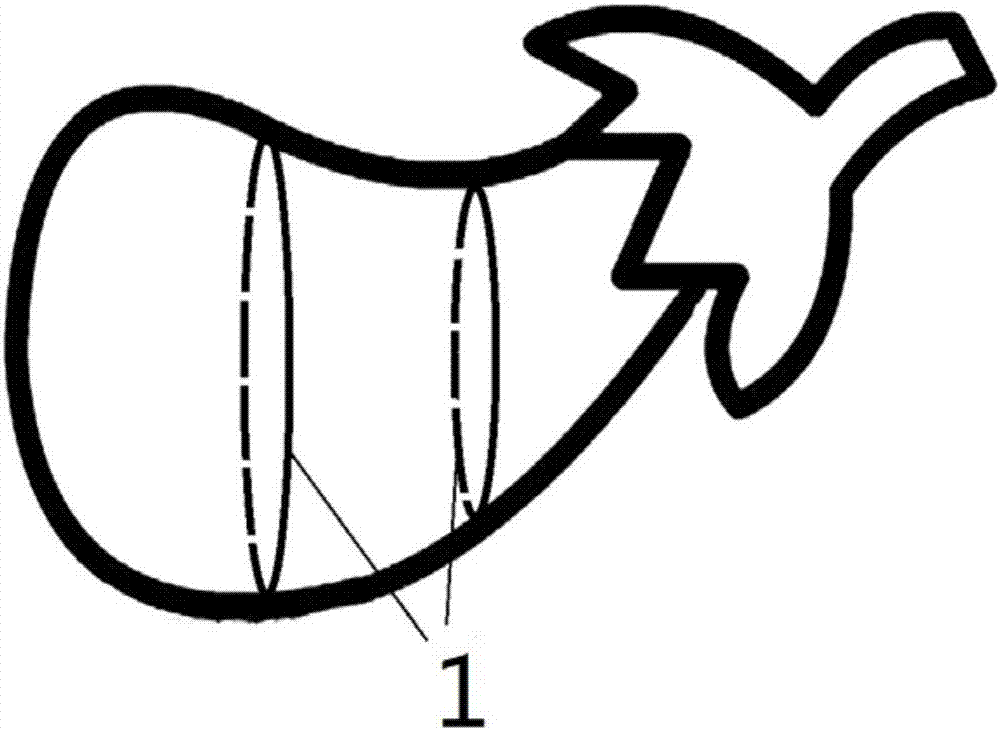

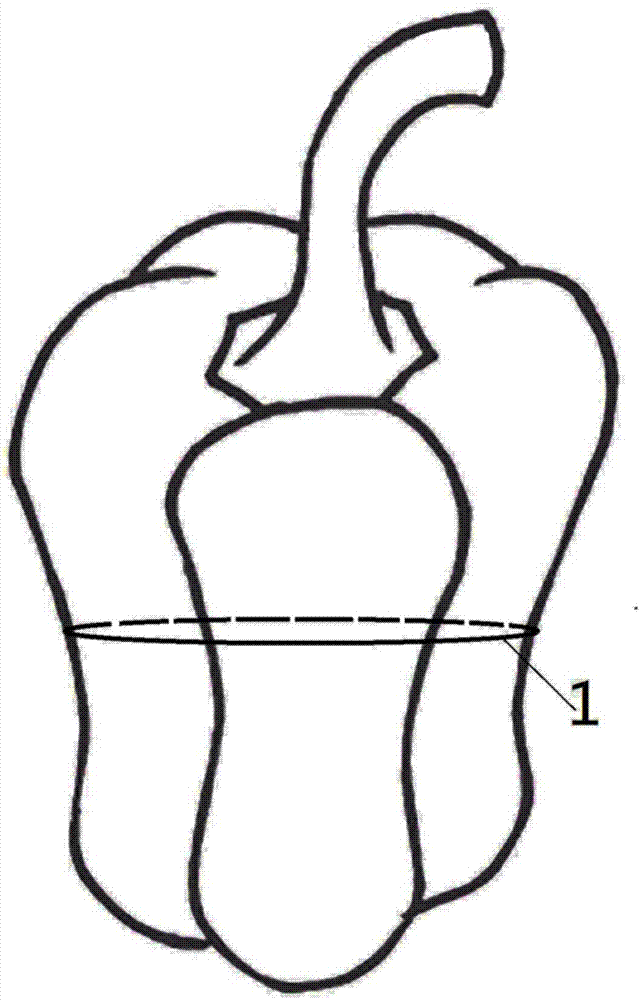

Ordinary still life transparent model

PendingCN107221224AShorten research timeImprove training effectTeaching apparatusEngineeringStructural transition

The invention discloses an ordinary still life transparent model. The surface of a structural transition place is provided with auxiliary structure lines, and the whole is transparent. Particularly, ordinary still life transparent models are divided to a jar-kind ordinary still life transparent model, a fruit-kind ordinary still life transparent model and a vegetable-kind ordinary still life transparent model. According to the ordinary still life transparent model of the invention, through the design of the auxiliary structure lines and the design of the transparent state, a sketch beginner can effectively master the inner structure, the outer structure, the space and the perspective law of an ordinary still life during a learning process.

Owner:宣俊杰 +1

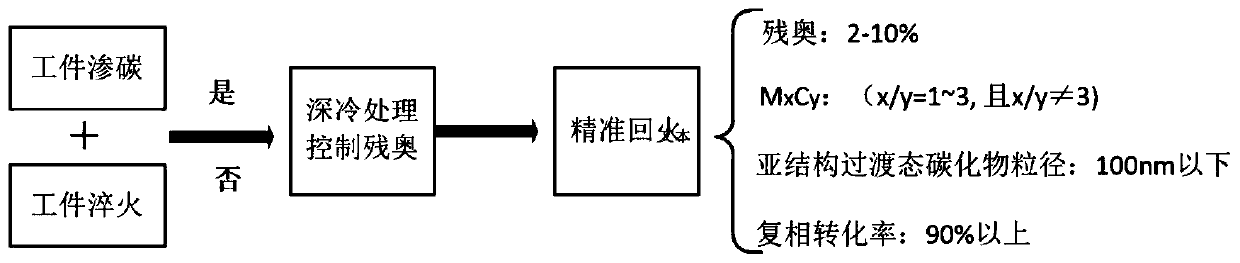

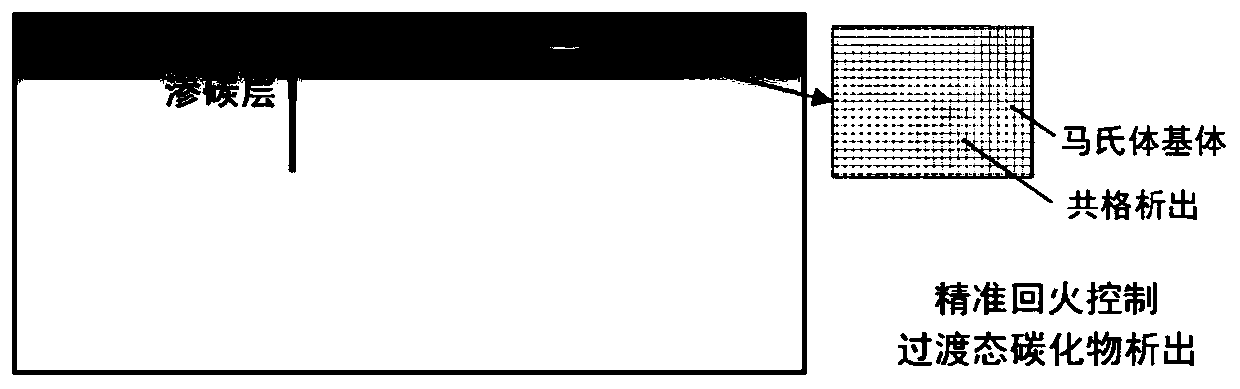

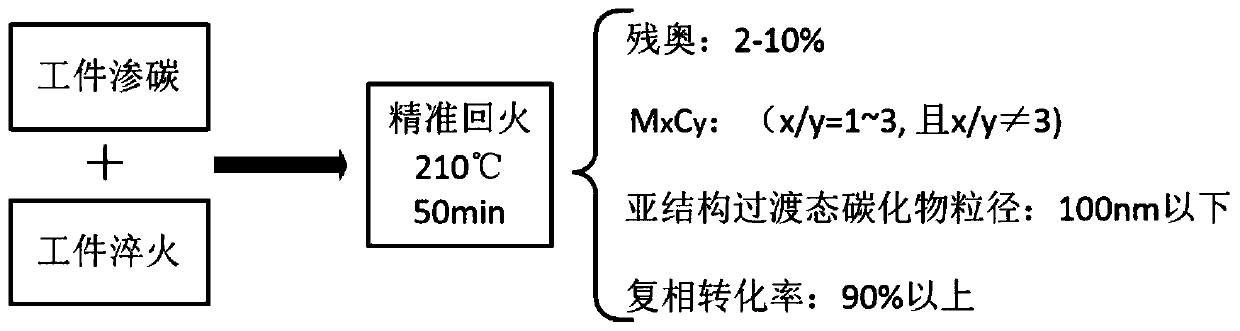

Tempering heat treatment method of carburized part and carburized part

ActiveCN111500830AWithout sacrificing plasticityImprove contact fatigue service performanceSolid state diffusion coatingFurnace typesTemperingMetallic materials

The invention discloses a tempering heat treatment method of a carburized part and the carburized part, and belongs to the technical field of heat treatment of metal materials. The method solves the problems that matching of high plasticity is poor, resistance performance to contact fatigue is poor and service reliability is poor due to the fact the content of high-carbon martensite of which carbides are not precipitated is too high in the structure after a carburized layer is tempered in the prior art. The heat treatment method comprises the steps that tempering heat treatment is carried outon the part after carburizing and quenching, and the tempering heat treatment is terminated before Fe3C precipitation-type tempered martensite is formed so as to obtain a carburized layer with volumefraction of the tempered martensite being 90% or above and volume fraction of the Fe3C precipitation-type tempered martensite and bainite being 1% or below, wherein the microstructure of the carburized layer is characterized by carbon atom clustering and substructure transition state carbide precipitation. According to the carburized part prepared by the tempering heat treatment method, the wear resistance is obviously improved, and the contact fatigue service performance is good.

Owner:CHINA UNIV OF MINING & TECH +1

Preparation of graduated nano-structural transition metal oxide by two-phase solvent soft interface process

InactiveCN100460334CImprove versatilityImprove photocatalytic activityZinc oxides/hydroxidesCopper oxides/halidesWater insolubleSolvent

The present invention provides a preparation method of gradate nanostructure transition metal oxide by a two phase solvent soft interface method which comprises the steps of that: metal salt or metal oxide is added into water, and the pH value of the solution is adjusted by acid or base, then the corresponding reactant precursor is obtained; another water insoluble organic solvent is added into the solution, and the whole mixture is subjected to solvothermal treatment, and then the solid product is obtained by pumping filter, finally, the corresponding gradate nanostructure transition metal oxide is obtained after scrubbing and drying. The transition metal oxide of the present invention has excellent gradate structure, for example, titanium dioxide has a main structure of micron order spheroidal particle which is formed by the ordered array of a plurality of nanorods. The titanium dioxide of the present invention has a high visible light photocatalysis activity, a simple synthetic route, an easy technology, available raw material, low cost and high yield, and is adapted to mass production.

Owner:HUAZHONG NORMAL UNIV

A method for preparing multilayer core-shell structure transition metal oxides in one step

ActiveCN107098405BUniform compositionShape is easy to controlNickel oxides/hydroxidesCobalt oxides/hydroxidesVertical tubeStructural transition

The invention relates to a method for preparing multilayer core-shell structure transition metal oxide at one step. The method comprises the following steps: dissolving a transition metal salt with a solvent, and then adding an organic additive to obtain a precursor solution; atomizing the precursor solution with an atomizer, and feeding the precursor solution into a vertical tube furnace with carrier gas for pyrolysis to obtain the multilayer core-shell structure transition metal oxide material. By adopting the method, the synthesized transition metal oxide is uniform in components, and is controllable in appearance and shell quantity; a high-purity and high-crystallinity multilayer core-shell structure transition metal oxide can be prepared without any separate subsequent burning process. Compared with the conventional method, the method has the advantages of easiness in operation, short flow, high efficiency, high suitability and the like.

Owner:CENT SOUTH UNIV

A method for manufacturing a composite steel column in the crown transition section of a super high-rise building

ActiveCN111644727BImprove bearing capacityReduce dockingStrutsArc welding apparatusEngineeringSteel columns

The invention discloses a method for manufacturing a combined steel column in the crown transition section of a super high-rise building. The combined steel column includes a vertically arranged steel column, upper corbels and lower corbels arranged on the steel column at intervals, and the steel column From bottom to top, it consists of orthogonal H-shaped steel column section, connecting H-shaped steel column section, oblique H-shaped steel column section and diamond-shaped steel column section; orthogonal H-shaped steel column section, connecting H-shaped steel column section and oblique H-shaped steel column section The center line of the web plate of the section is located on the same straight line; the lower corbel is set on the connecting H-shaped steel column section; the left and right flange plates are respectively arranged between the upper and lower flange plates at the upper end of the oblique H-shaped steel column section. Both sides of the flange plate and the right flange plate are fixedly connected with the edge of the lower flange plate and the corresponding edge of the upper flange plate to respectively close the left and right sides of the upper and lower flange plates, and the inclination angle of the diamond-shaped steel column section corresponds to the inclination angle of the tower crown. The fabricated composite steel column can effectively realize the transition from the main structure of the tower to the crown structure.

Owner:中冶建工集团重庆建筑工业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com