Erecting method for concrete pouring formwork with structural transition layer comprising H-type steel crossbeam

A technology of H-shaped steel and concrete, which is applied in the direction of construction, building structure, and construction material processing, etc., and can solve the problems of inability to turn around materials and materials, occupying labor, and insufficient construction space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further illustrated below by specific examples.

[0028] Take the construction of a transfer beam with a length of 1200×2500mm and a span of 8400mm as an example.

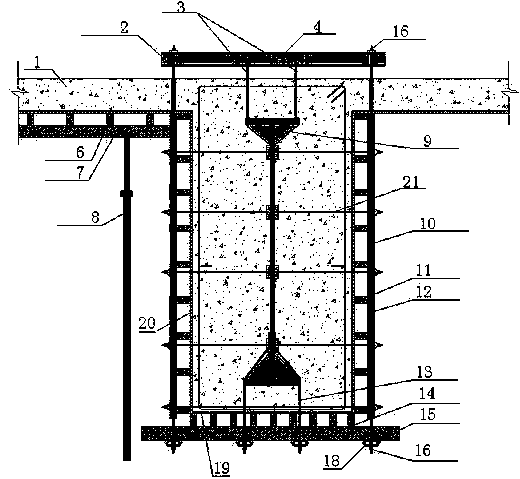

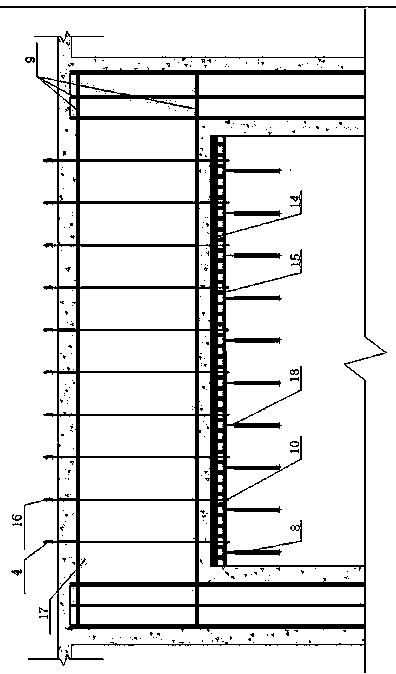

[0029] like figure 1 , figure 2 Shown:

[0030] In the first step, the adjustable scaffolding 8 is set up under the H-shaped steel beam 17 with a vertical pole spacing of 700mm, a horizontal vertical pole spacing of 512mm, 416mm, and 512mm, and a step distance of 1500mm;

[0031] In the second step, on the top of the adjustable scaffold 8, double steel pipes 18 with a diameter of 48mm and a wall thickness of 3.5mm are installed along the longitudinal direction of the H-shaped steel beam 17 as horizontal load-bearing members, a total of 4;

[0032] The third step is to install H-shaped steel beams 17 horizontal main keels 15 and horizontal secondary keels 14 on the double steel pipes 18 as required. The horizontal main keel 15 is made of 50×100mm wooden squares with a spacing of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com