Mold supporting structure for variable cross-section cast-in-place box girder at section combining horizontal and longitudinal curves, and construction method of the mold supporting structure

A technology of variable cross-section and box girder, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems of short construction period, reduce the amount of foundation treatment engineering, and less investment in support materials, so as to achieve the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In this embodiment, the production process requirements of scaffolding and composite wood boards, the construction technical requirements of prestressed anchor cable tensioning, the construction process requirements of concrete pouring, etc. will not be repeated, and the focus will be on the variable cross-section cast-in-place of the flat and longitudinal curve combination section involved in the present invention. The implementation mode of the refined composite formwork structure construction of the box girder.

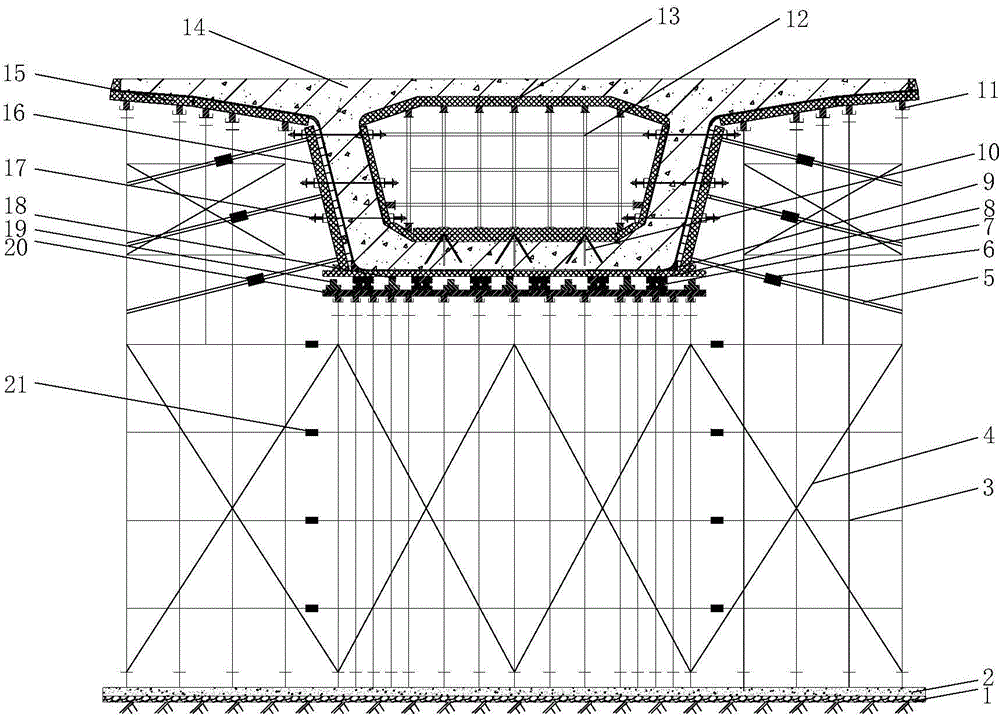

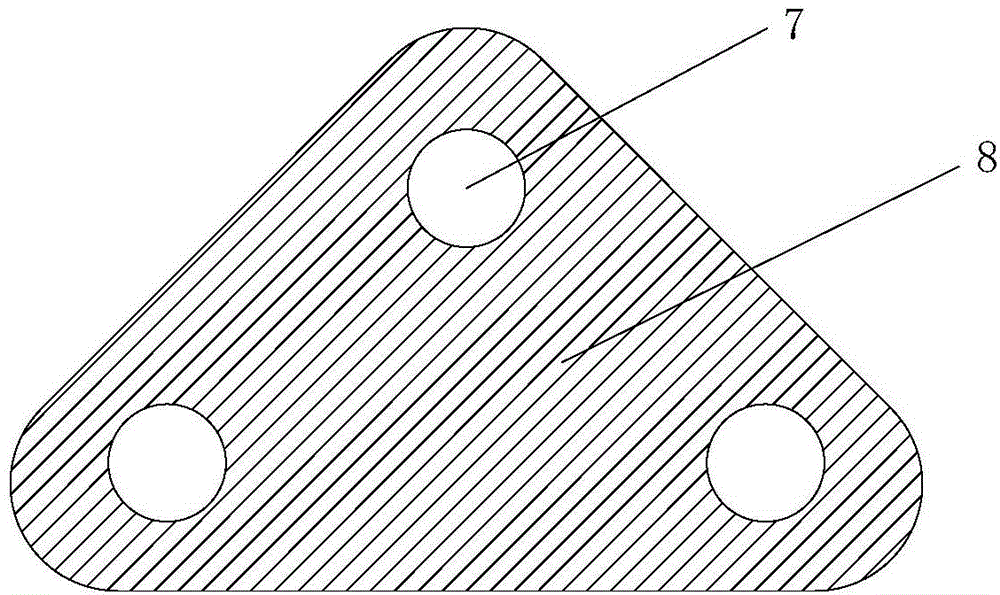

[0037] figure 1 It is a schematic diagram of the refined composite formwork structure of the variable cross-section cast-in-place box girder of the horizontal and vertical curve combination section of the present invention, figure 2 It is a sectional view of the structure of the adjustable support in the present invention. refer to figure 1 The refined composite formwork structure of the variable cross-section cast-in-place box girder with horizontal and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com