Patents

Literature

58 results about "Out of plane displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

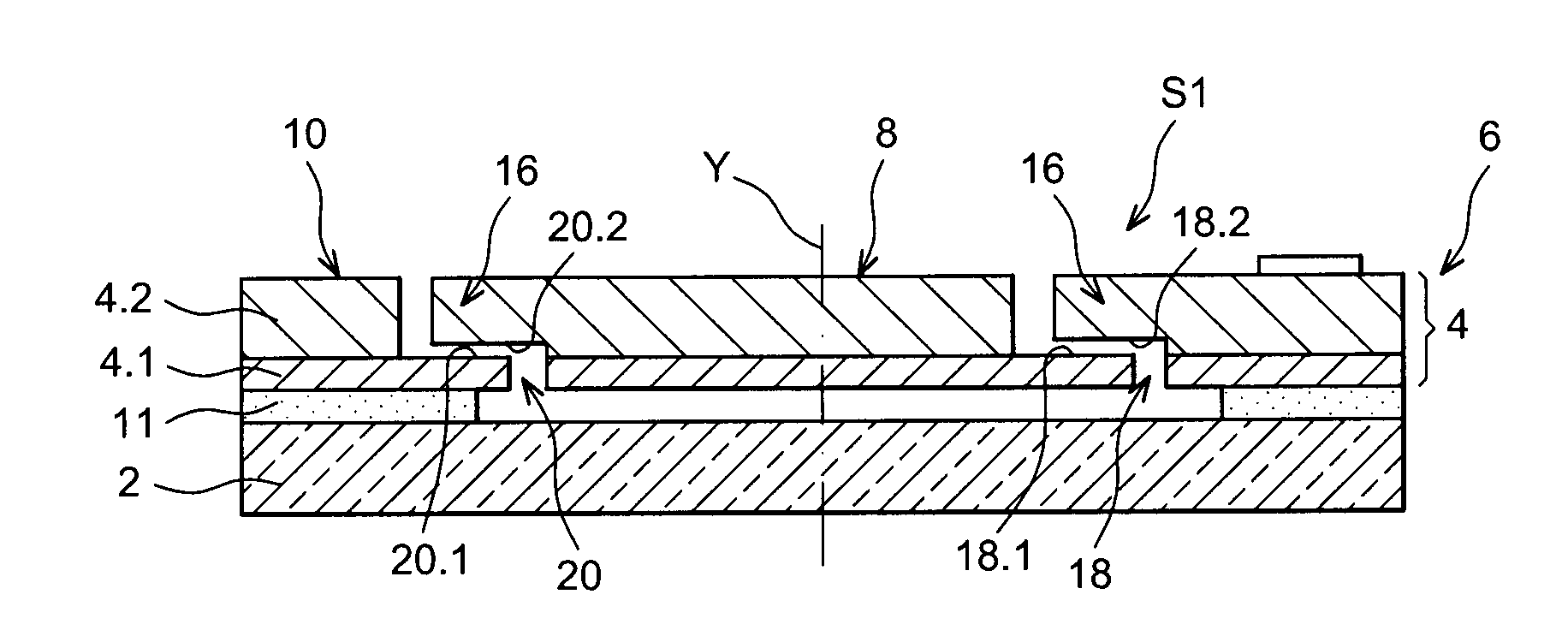

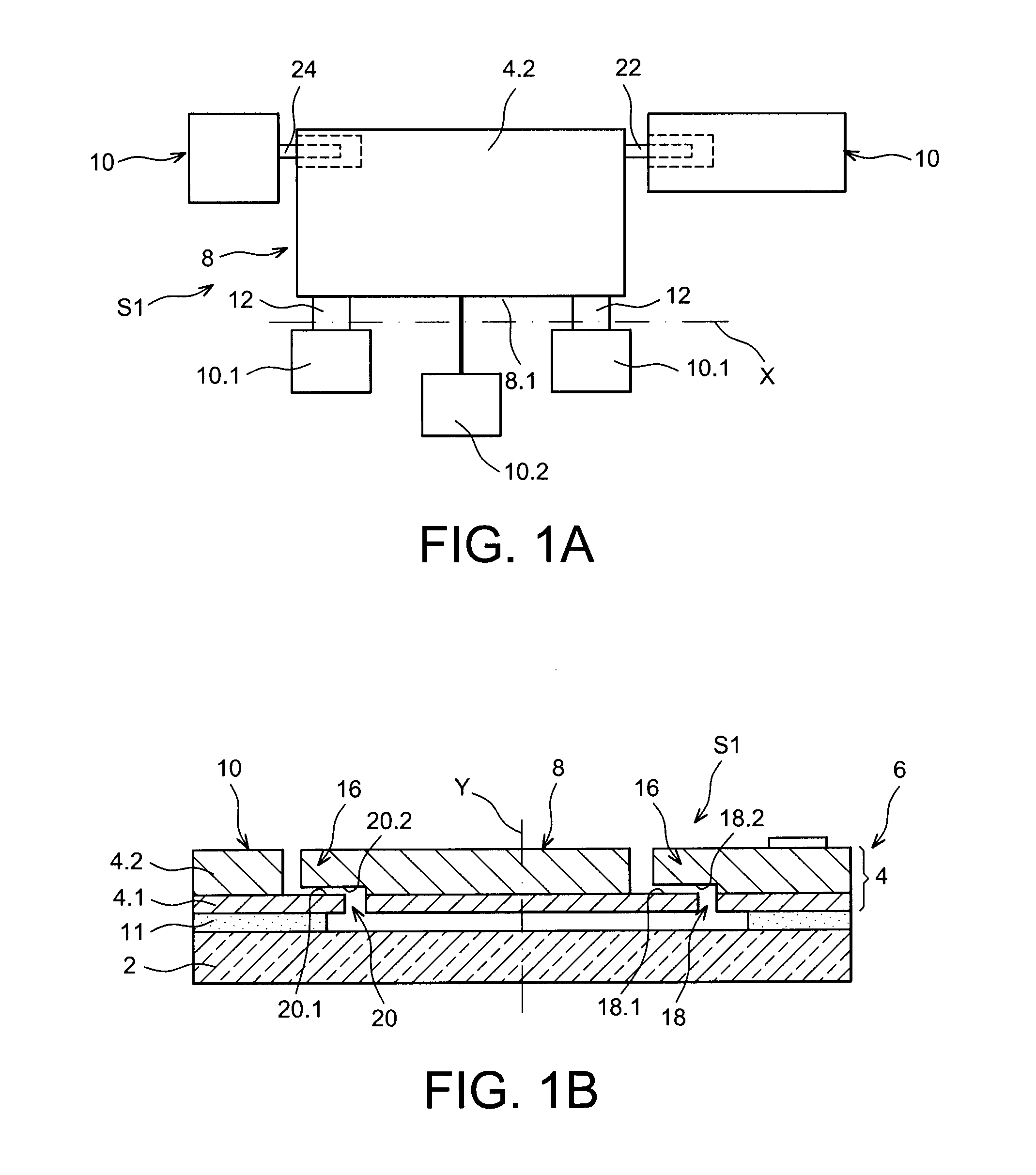

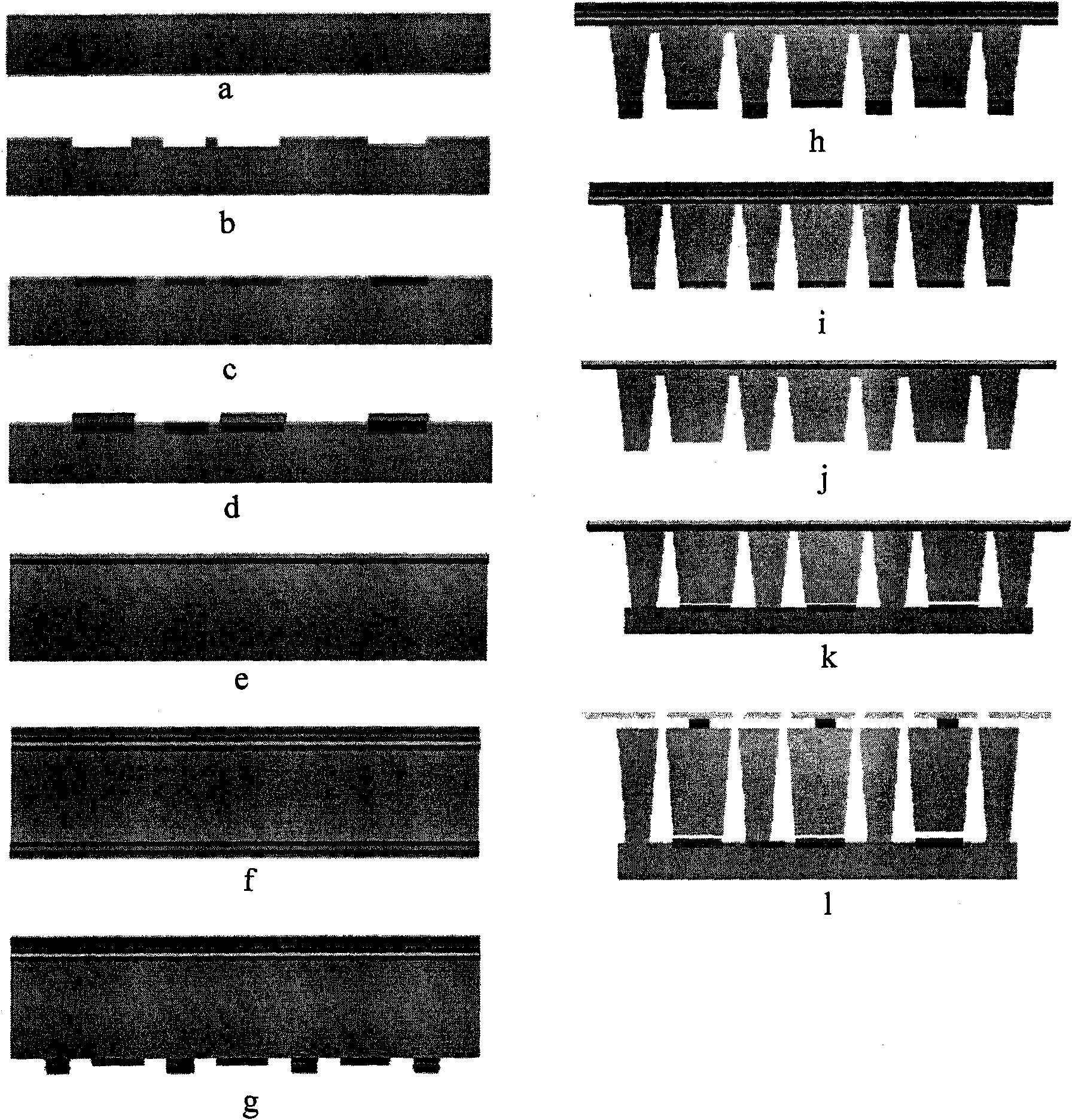

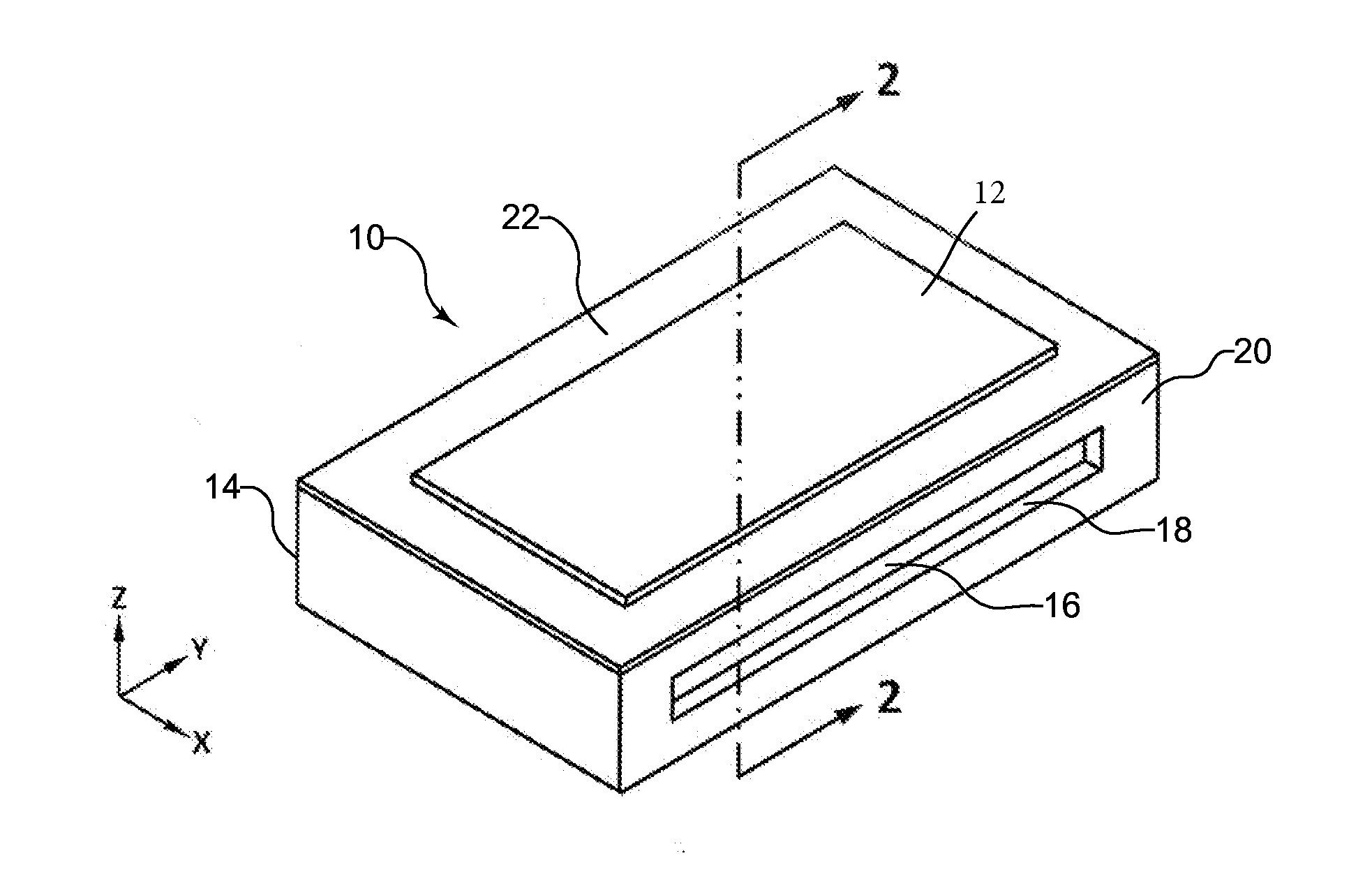

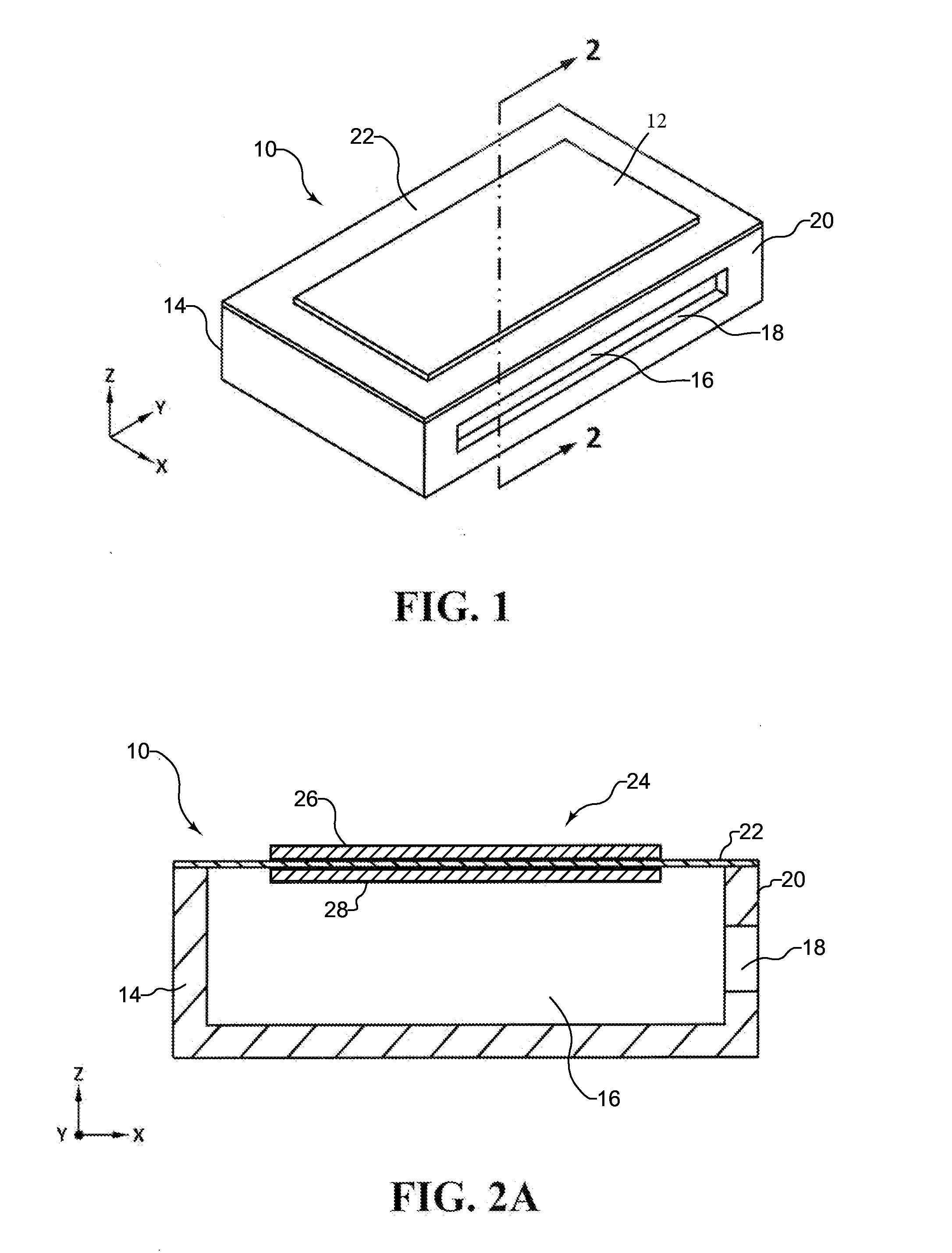

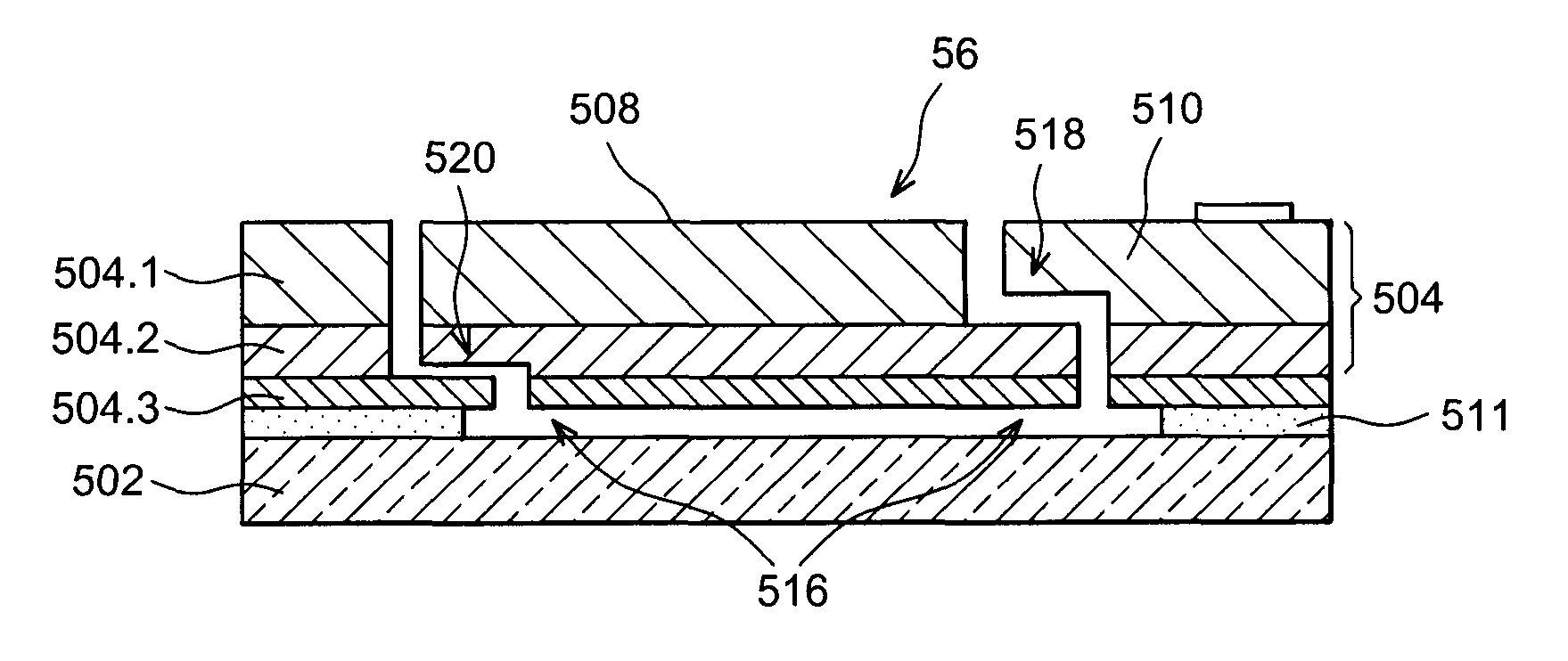

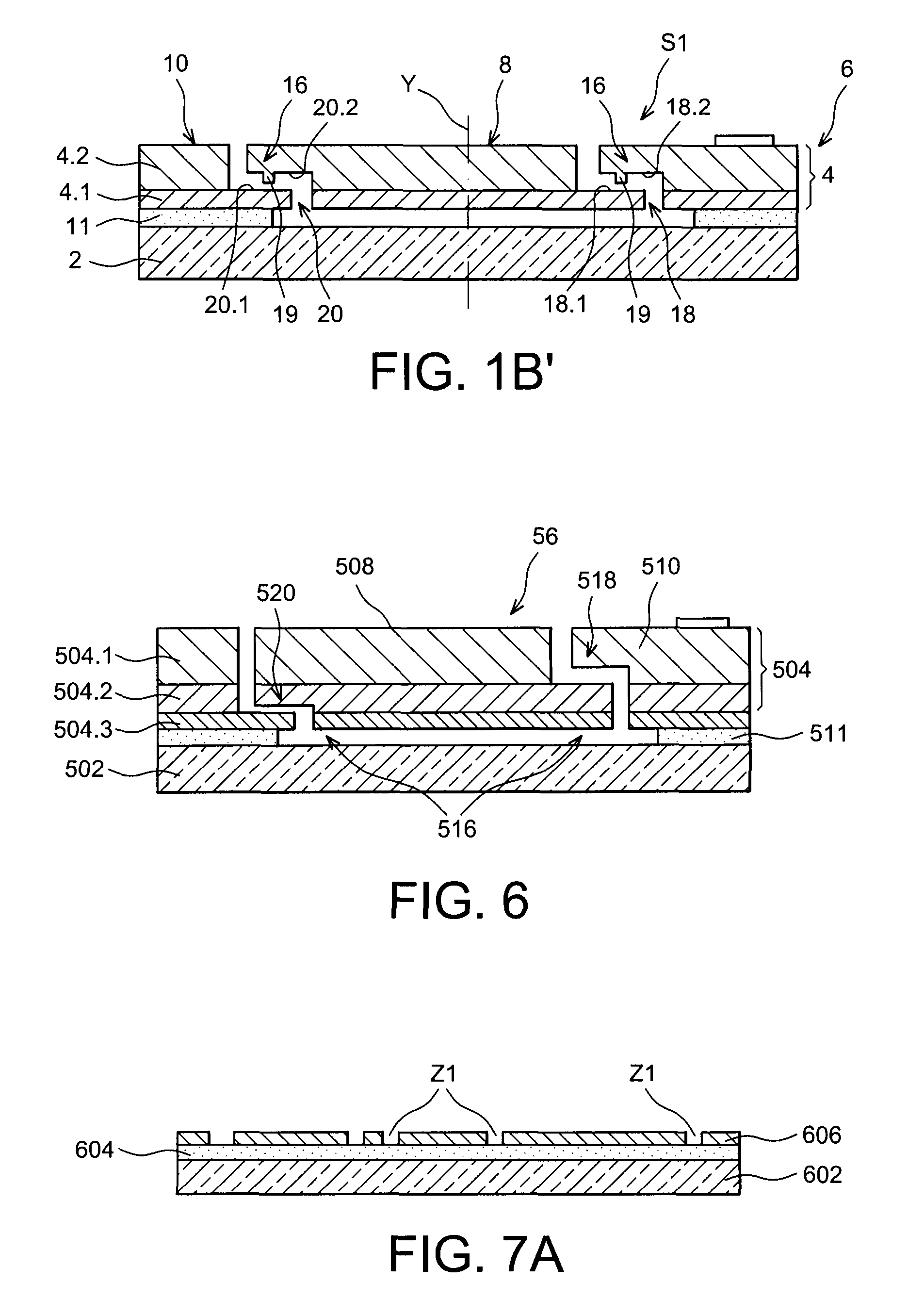

Micromechanical structure comprising a mobile part having stops for out-of-plane displacements of the structure and its production process

ActiveUS20110147860A1Simple processReduce riskMicrophonesElectrical transducersOut of plane displacementOut of plane

Process for producing a micromechanical structure comprising a substrate and a stack of at least two layers arranged on the substrate, a mobile part formed in the stack and a fixed part relative to the substrate formed in the stack, and an opposite surface formed between the fixed part and the mobile part, forming for example stop means to limit displacement of the mobile part in a direction substantially perpendicular to the stack, which process using at least one sacrificial layer between the substrate and the stack made of material suitable to be etched selectively relative to the materials of the stack.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

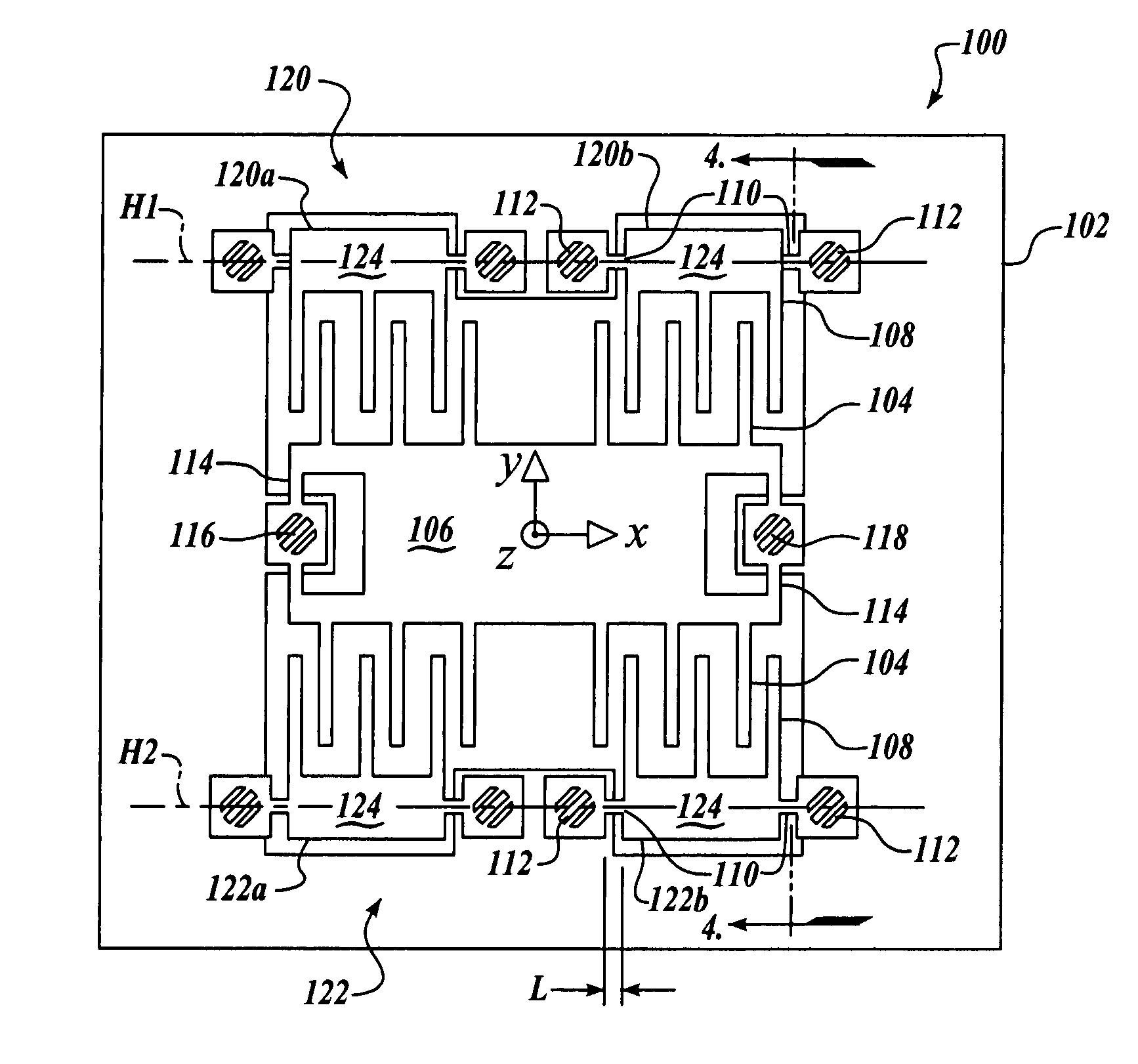

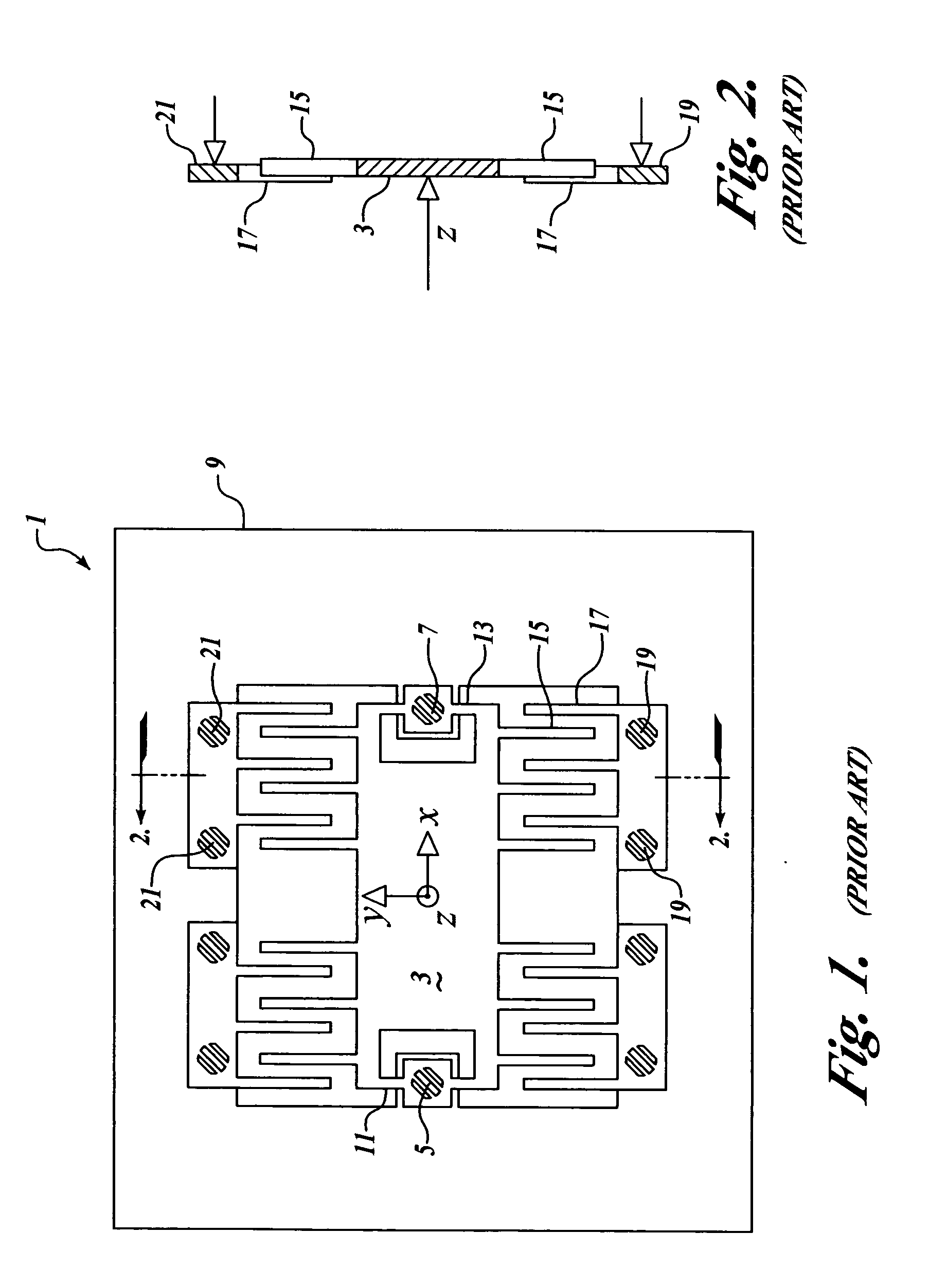

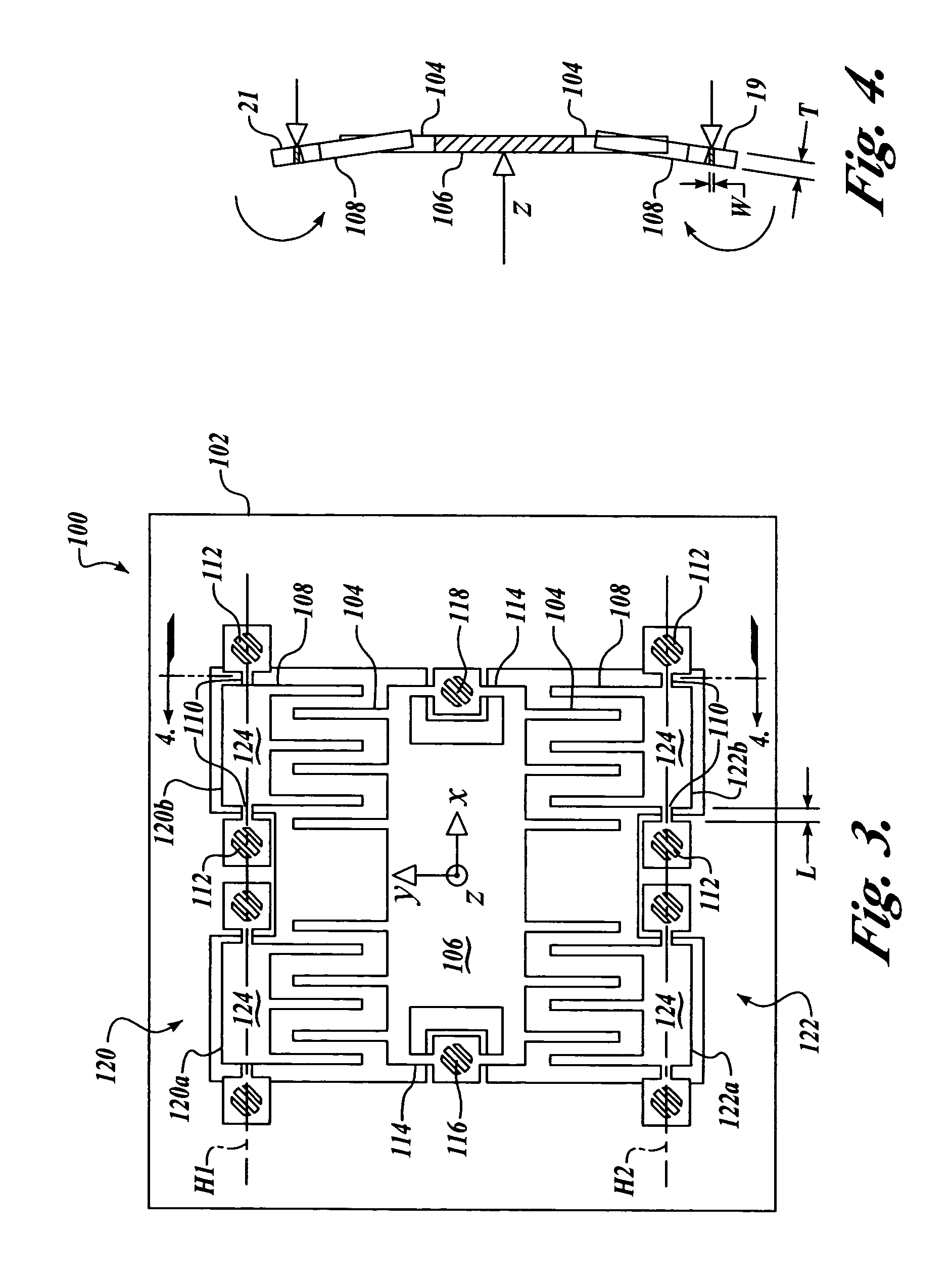

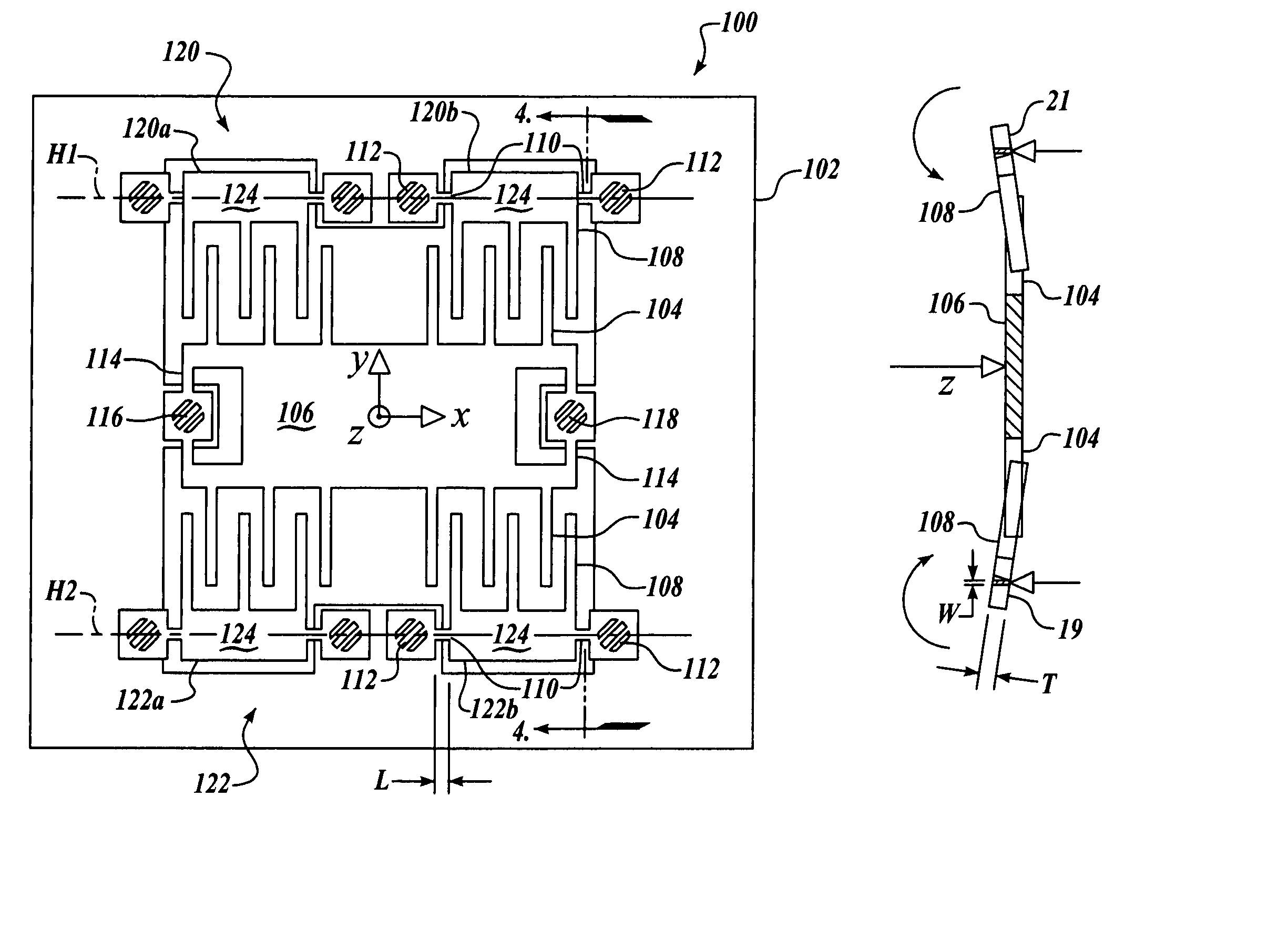

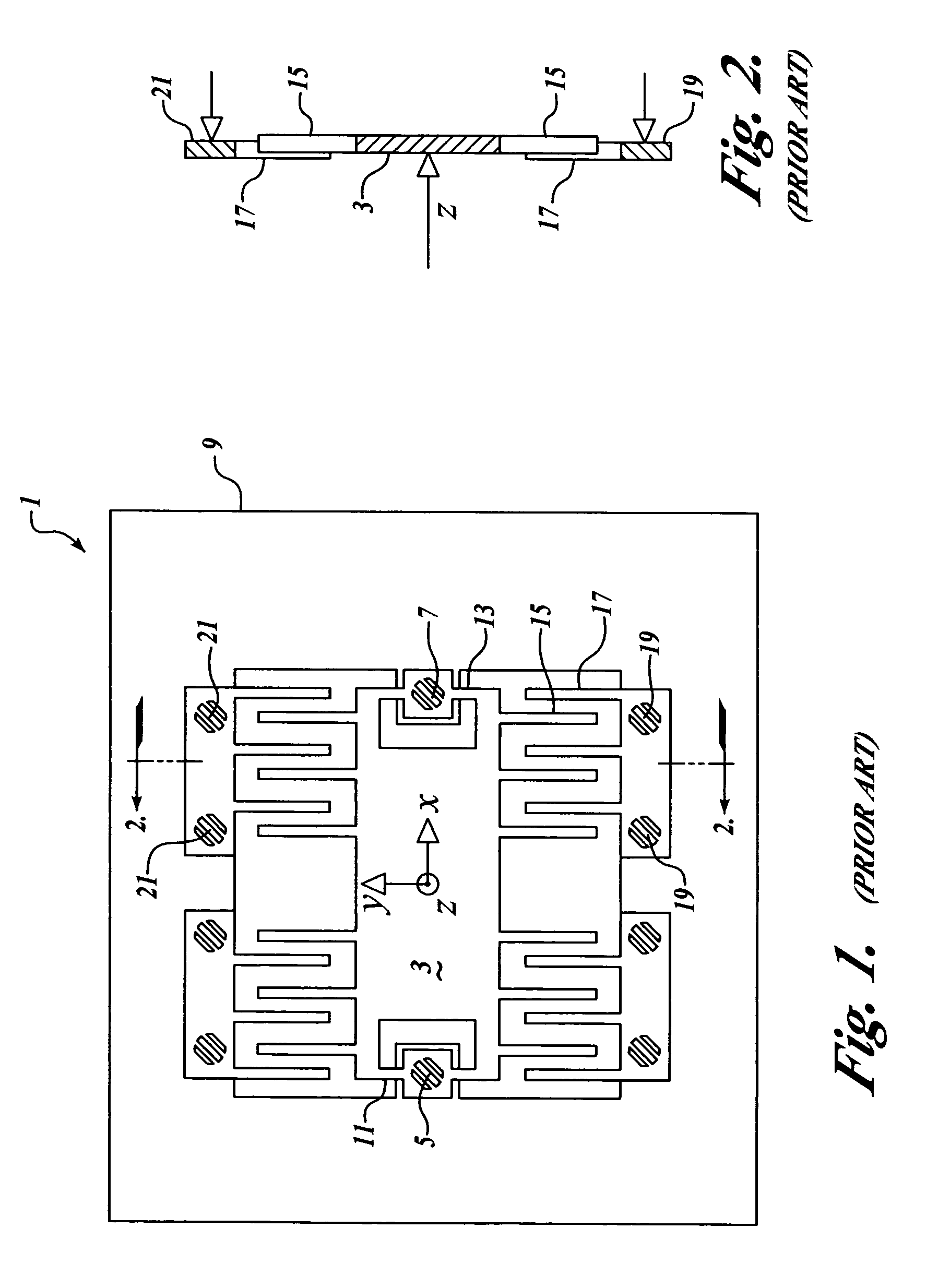

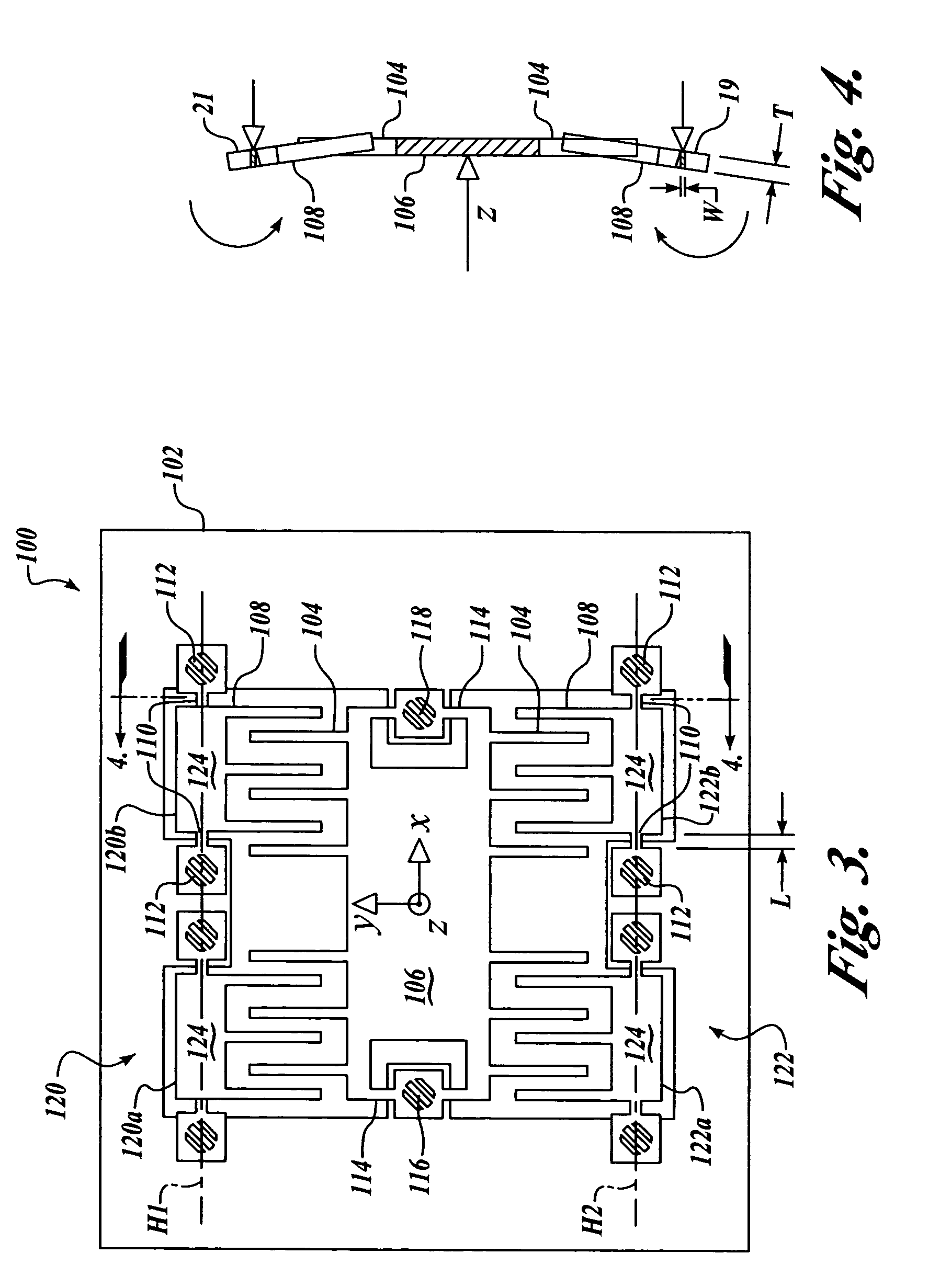

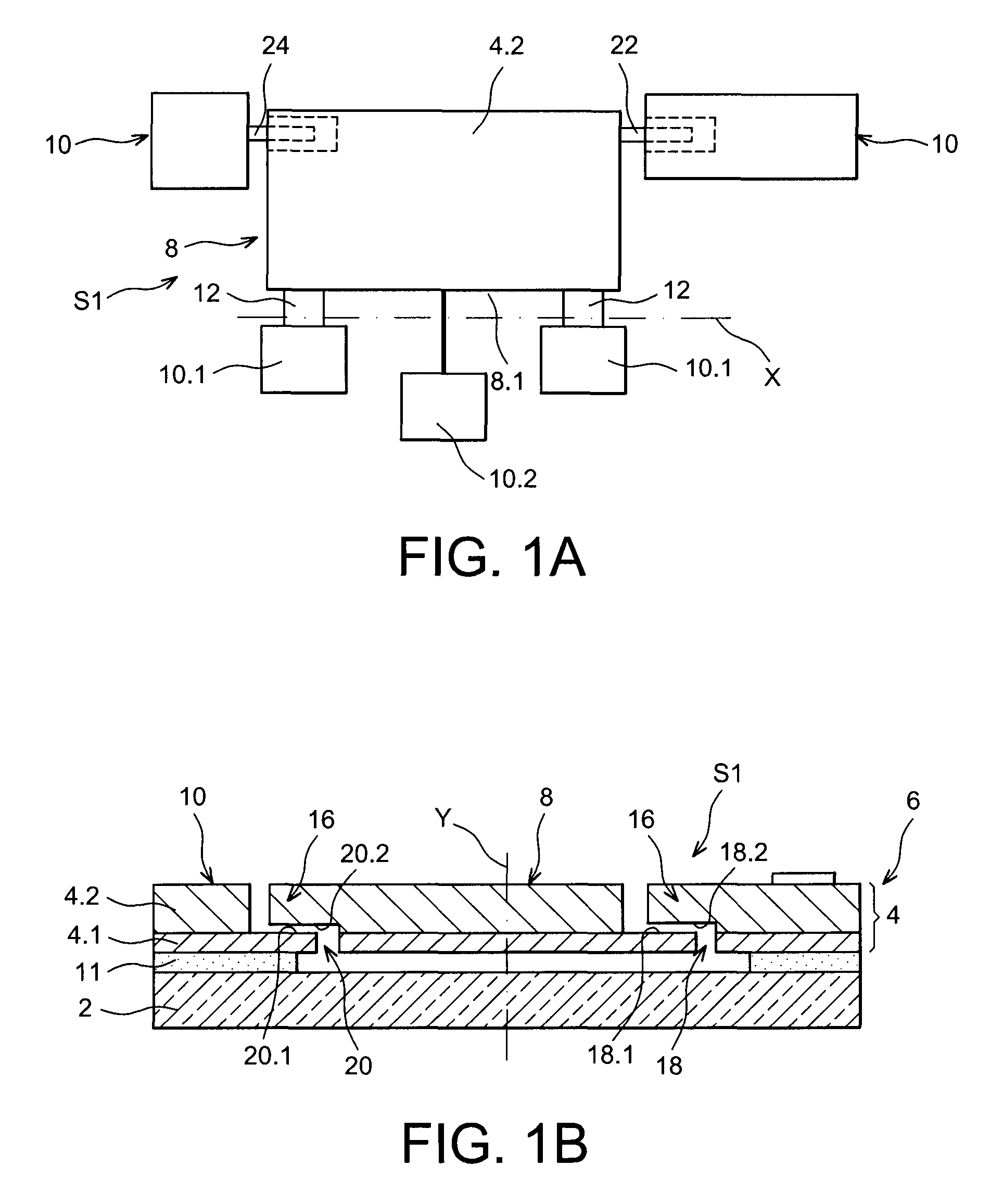

Out-of-plane compensation suspension for an accelerometer

InactiveUS20050092107A1Reduces and eliminates out-of-plane separationAcceleration measurement using interia forcesForce measurementAxis of symmetryClassical mechanics

A high aspect ratio microelectromechanical system device for measuring an applied force and having a suspension structure for compensating out-of-plane displacements of the device proof mass, wherein the device includes a frame; a proof mass coupled to the frame for in-plane motion along an axis of symmetry, the proof mass having first and second sets of spaced apart capacitor plates projected therefrom on each side of the axis of symmetry and oriented substantially crosswise to the axis of symmetry; and third and fourth sets of spaced apart capacitor plates oriented substantially crosswise to the axis of symmetry of the proof mass and intermeshed respectively with the first and second sets of capacitor plates, the third and fourth sets of capacitor plates being suspended for motion relative to the frame about respective first and second axes of motion oriented substantially parallel with the axis of symmetry of the proof mass.

Owner:HONEYWELL INT INC

Out-of-plane compensation suspension for an accelerometer

InactiveUS6910379B2Acceleration measurement using interia forcesForce measurementAxis of symmetryClassical mechanics

A high aspect ratio microelectromechanical system device for measuring an applied force and having a suspension structure for compensating out-of-plane displacements of the device proof mass, wherein the device includes a frame; a proof mass coupled to the frame for in-plane motion along an axis of symmetry, the proof mass having first and second sets of spaced apart capacitor plates projected therefrom on each side of the axis of symmetry and oriented substantially crosswise to the axis of symmetry; and third and fourth sets of spaced apart capacitor plates oriented substantially crosswise to the axis of symmetry of the proof mass and intermeshed respectively with the first and second sets of capacitor plates, the third and fourth sets of capacitor plates being suspended for motion relative to the frame about respective first and second axes of motion oriented substantially parallel with the axis of symmetry of the proof mass.

Owner:HONEYWELL INT INC

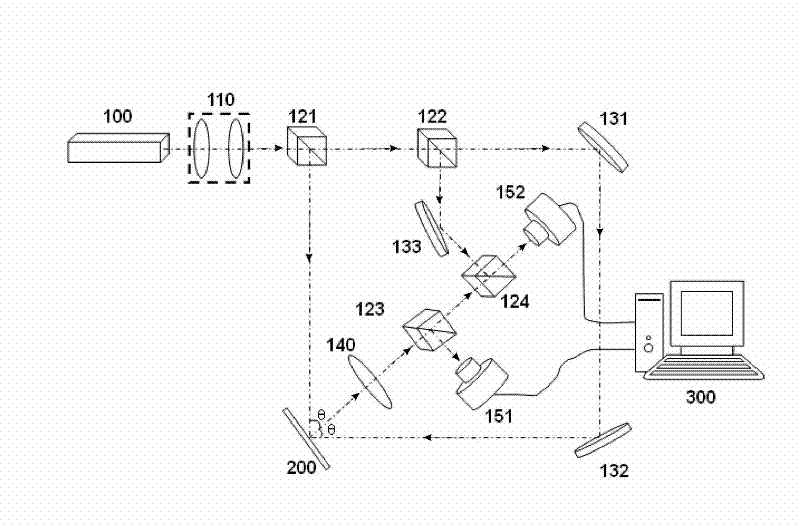

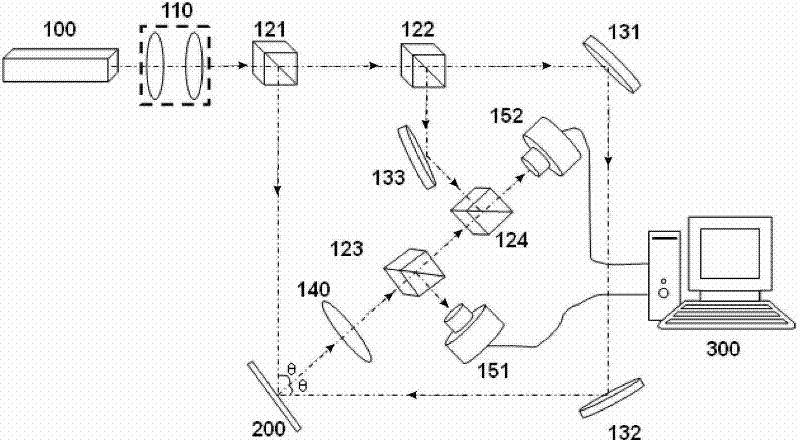

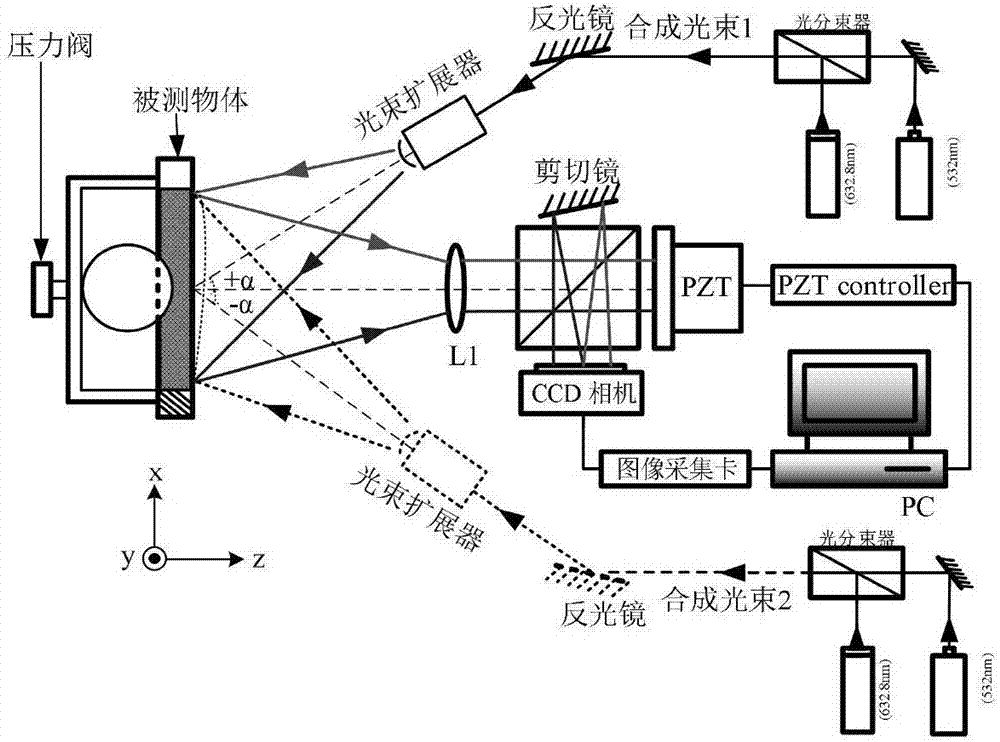

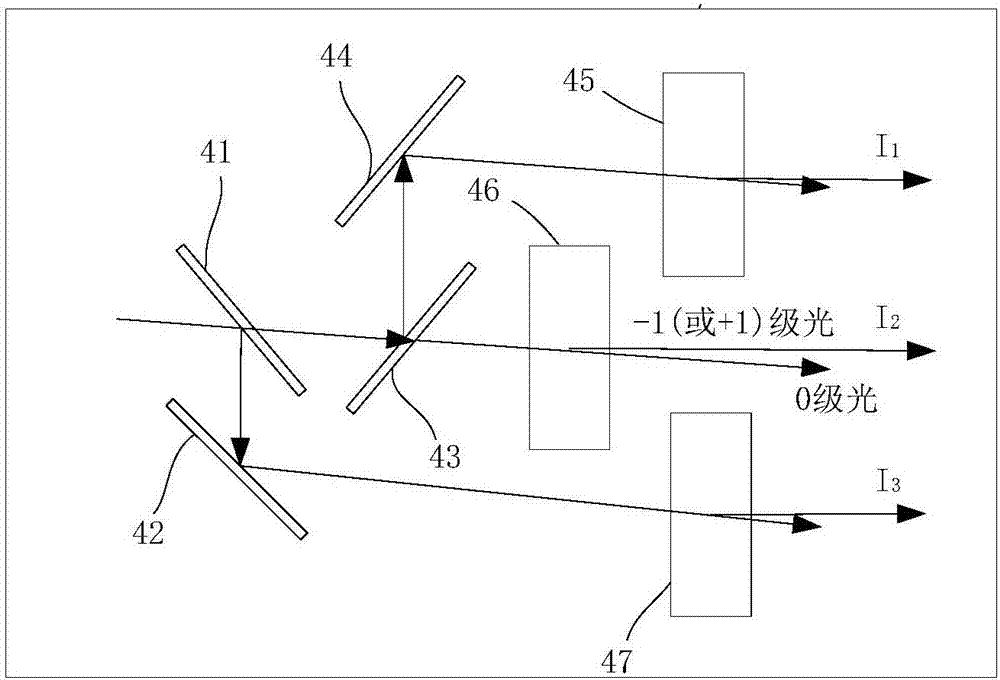

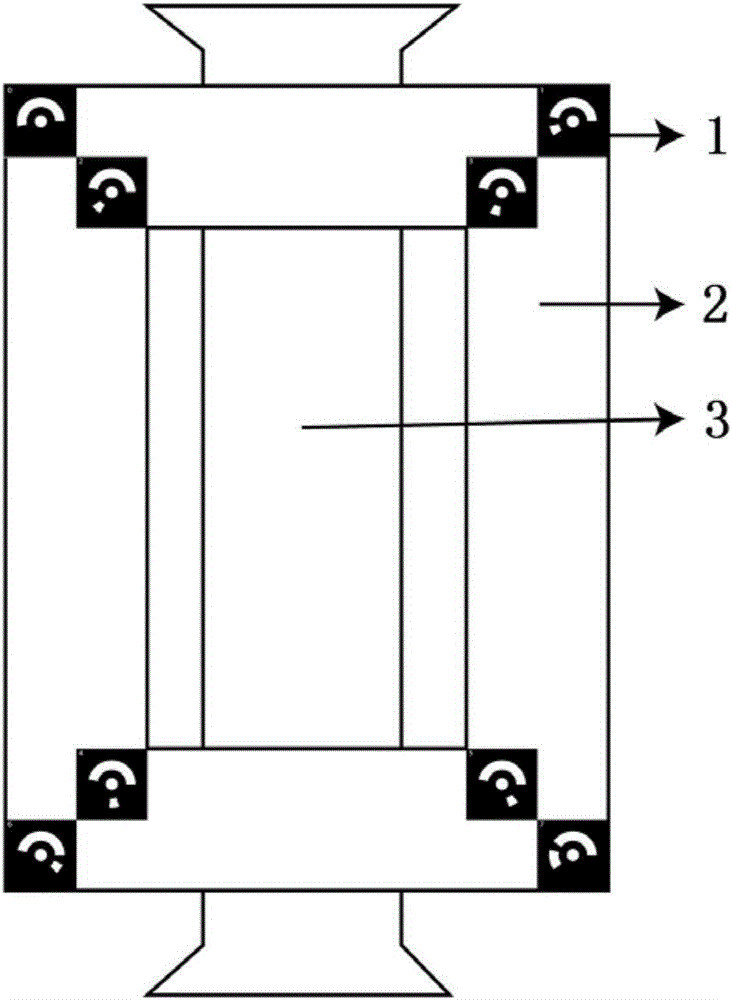

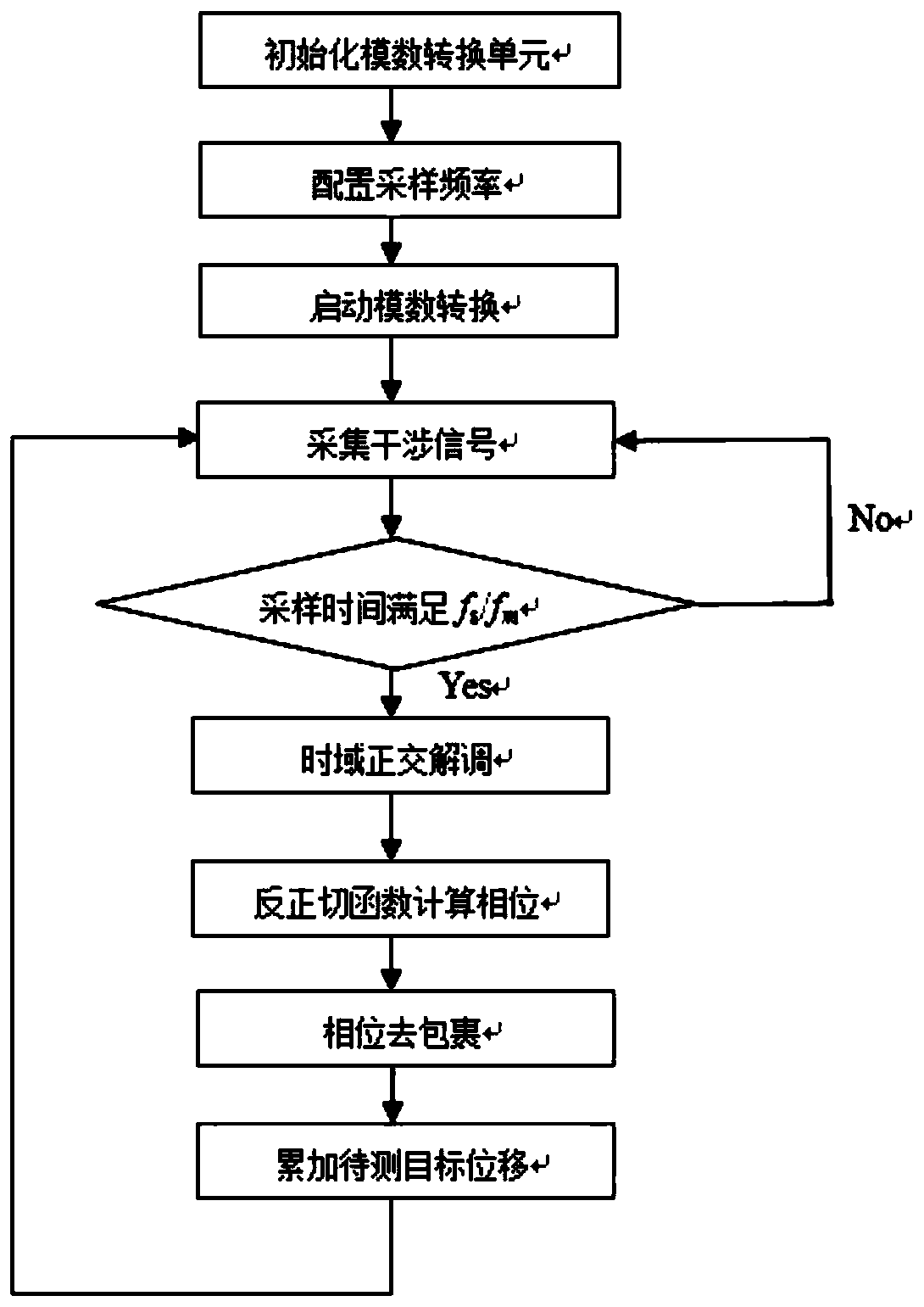

Laser speckle measuring device and method for measuring in-plane displacement and out-of-plane displacement simultaneously

The invention relates to a laser speckle measuring device and a method for measuring in-plane displacement and out-of-plane displacement simultaneously; in the invention, a method that a laser speckle interferometry measuring light path of the in-plane displacement and a laser speckle interferometry measuring light path of the out-of-plane displacement are combined is utilized to realize the measurement of distribution information of the in-plane displacement and the out-of-plane displacement of an object to be measured simultaneously through once light path arrangement. The device and the method in the invention have the characteristics of simplicity in operation, rapidness and accuracy, and can be widely applied to reliable real-time and high-precision measurement for tiny displacement in the field such as opto-electrical nondestructive testing and the like.

Owner:HENAN UNIV OF SCI & TECH

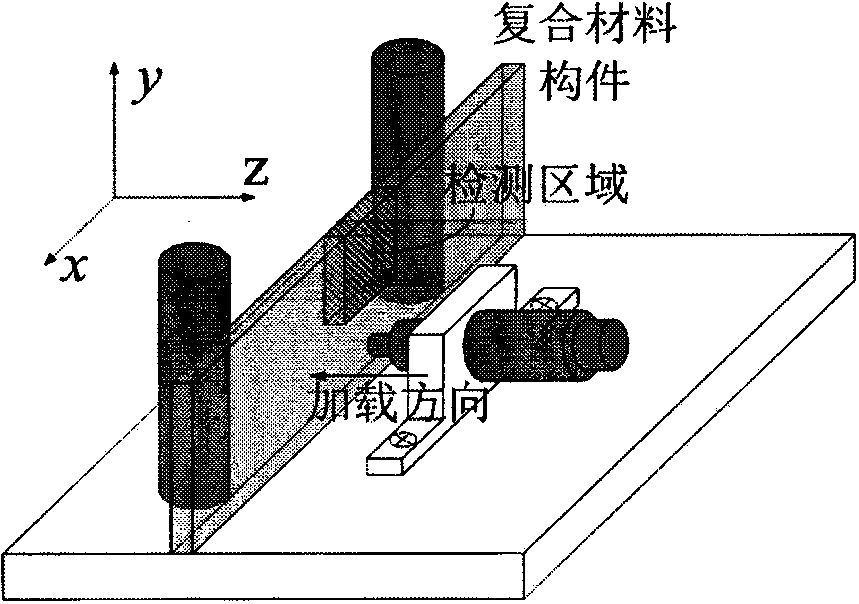

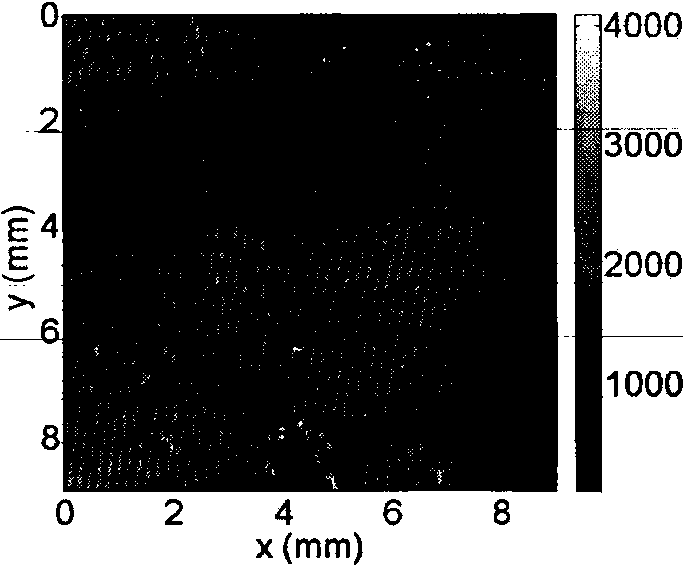

Device and method of perspective measurement of distribution of out-of-plane displacement field in resin matrix composite

The invention discloses a device and a method of perspective measurement of distribution of an out-of-plane displacement field in a resin matrix composite. The device is an optical system designed with Michelson multi-surface interference, and a double-surface optical wedge is introduced into a reference arm end, so that an interference image between the optical wedge and a reflected signal in the measured resin matrix composite is formed. The optical wedge has two effects, and is firstly used for monitoring a laser wave number k and is secondly used for providing an interferential reference plane. Through temperature scan, the wave number of output laser of a semiconductor laser controller is scanned, and meanwhile, multiple frames of interference images are shot by a CCD (Charged Coupled Device) camera. Fourier transform is respectively carried out on interference image sequences before and after loading, the distribution of the out-of-plane displacement field in the measured resin matrix composite component can be demodulated through a phase difference corresponding to an interference peak value. The device and the method have the advantages that the perspective measurement can be realized, and the measuring precision of the out-of-plane displacement field is high, so that a novel technology platform for the mechanical property measurement and the nondestructive testing in the resin matrix composite is provided.

Owner:GUANGDONG UNIV OF TECH

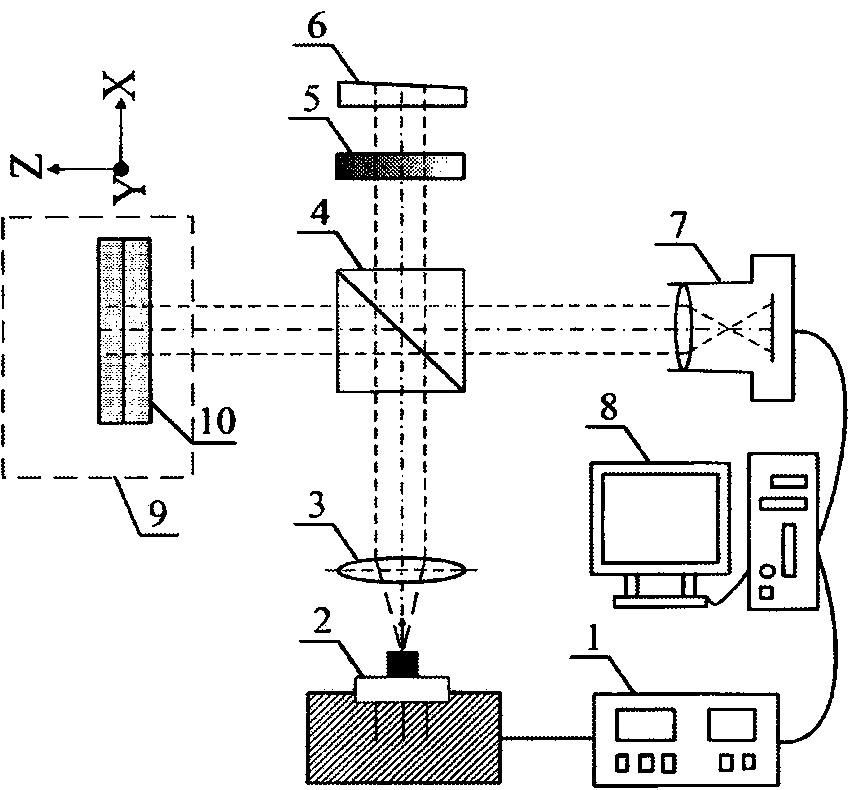

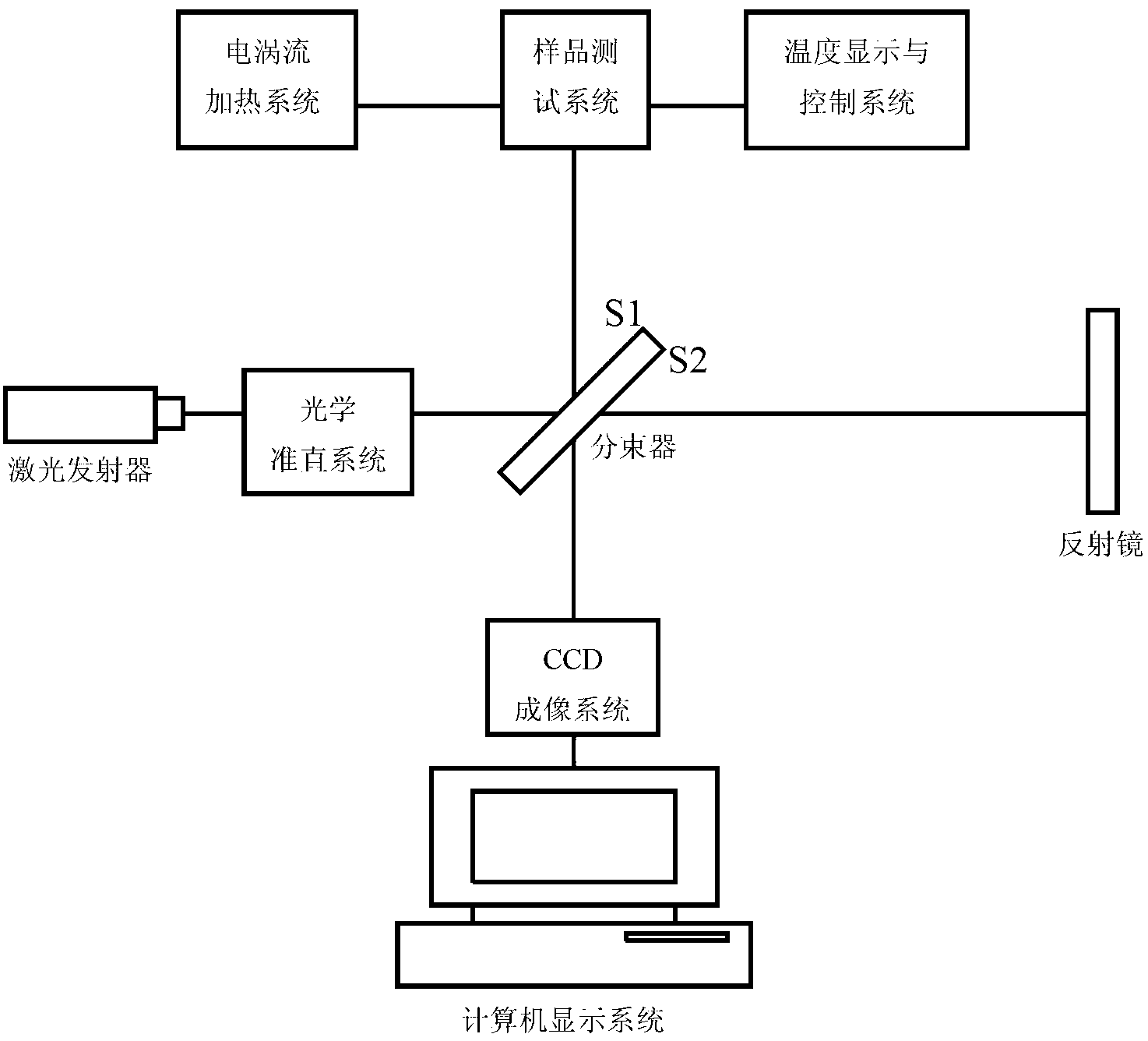

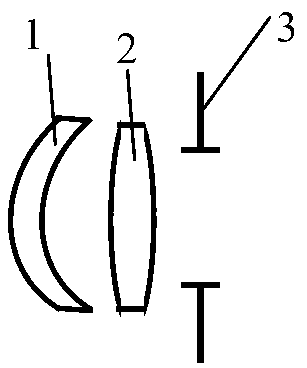

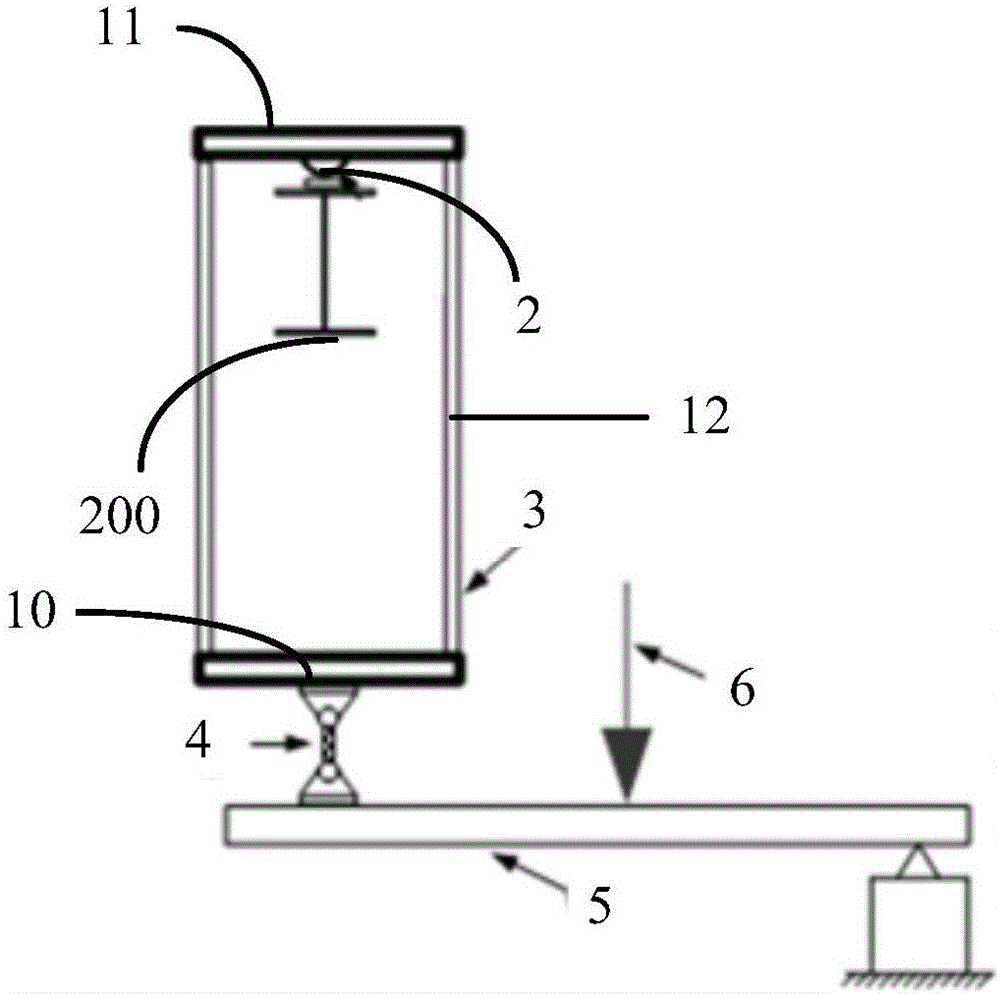

Multifunctional intelligent type laser speckle interference measuring device and method

ActiveCN103063145AWith collimation effectHigh precisionUsing optical meansImaging qualityOut of plane displacement

The invention discloses a multifunctional intelligent type laser speckle interference measuring device and a measuring method. Measurement of out-of-plane displacement of materials such as magnetic conduction and electric conduction materials under different temperature and pressure is achieved through combination of an optical alignment system, a beam splitter, a reflecting mirror, a material testing system, a charge coupled device (CCD) imaging system, temperature sensing technology and single chip technology. The optical alignment system has functions of alignment and spherical aberration elimination, and can ensure high-quality interference imaging. Out-of-plane displacement measuring tests of cylindrical samples, cube-shaped samples, cuboid samples and the like with different materials, shapes and sizes can be achieved by a material frame, and thus application range is wide. Strength of pressing can be judged by quantizing a rotation angle. Temperature of a tested object is improved by an electrical eddy current heating system so as to enable test researches to be free from influence of objective temperature environment. Accuracy of temperature measurement is improved by a temperature sensor and a single chip so that a temperature control system is intelligent. The measuring device has the advantages of being compact in structure, convenient to use, flexible, high in imaging quality, intelligent and the like, and is suitable for being widely used in the fields of machinery, construction, water conservancy, electrical equipment, aerospace, weapon industry, biomedicine and the like.

Owner:SHENYANG NORMAL UNIV

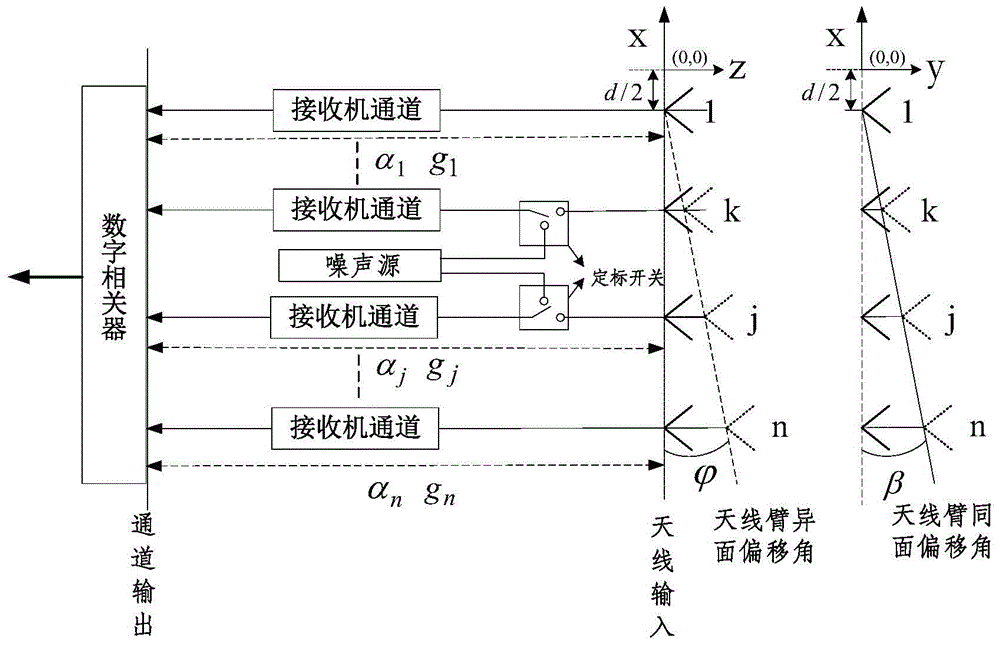

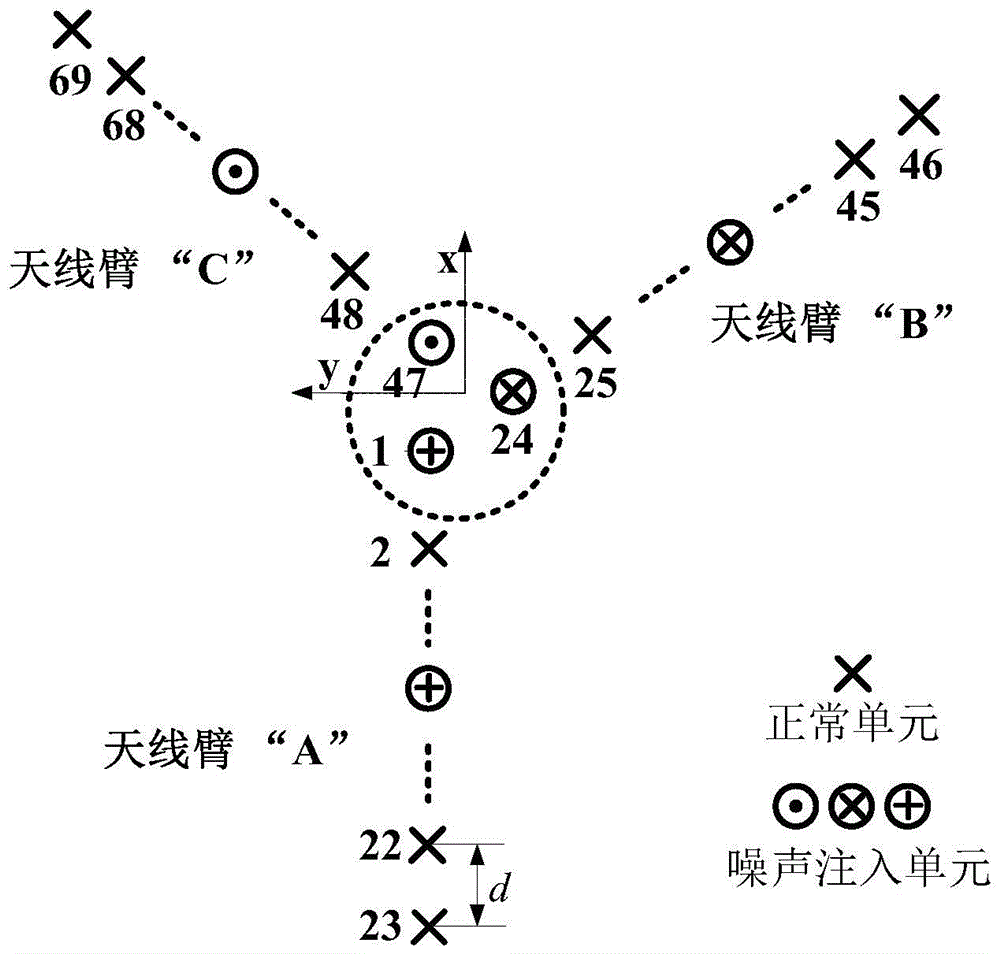

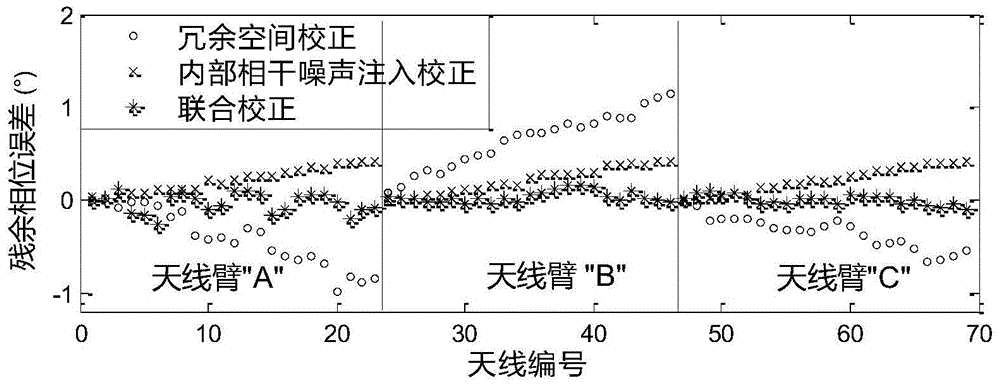

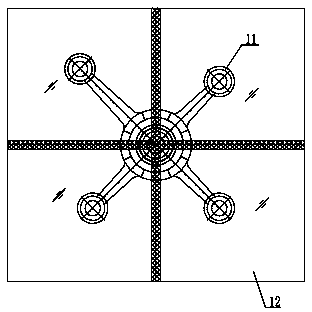

Synthetic aperture microwave radiometer combined correction method

ActiveCN105738851AReduce volumeReduce weightElectrical measurementsBrightness temperatureClassical mechanics

The invention provides a synthetic aperture microwave radiometer combined correction method comprising the steps that (1) the shortest baseline is selected to act as a redundant baseline, and all the related calibration equations are constructed; (2) a few receiver units are selected to act as internal coherent noise injection units, the amplitude and phase error are acquired through a noise injection correction method, and the calibration equations related to the noise injection units are constructed; (3) all the calibration equations of (1) and (2) form simultaneous equations so that a combined calibration equation group based on redundant space and internal coherent noise injection is formed; (4) the constructed combined calibration equation group is solved so that the amplitude and phase error of all the receivers and the out-of-plane displacement angle of an antenna arm are acquired; and (5) the measured visibility function is corrected according to the amplitude and phase error and the out-of-plane displacement angle of the antenna arm which are acquired in the step (4), and the corrected brightness temperature image is acquired by adopting a brightness temperature inversion method.

Owner:HUAZHONG UNIV OF SCI & TECH +1

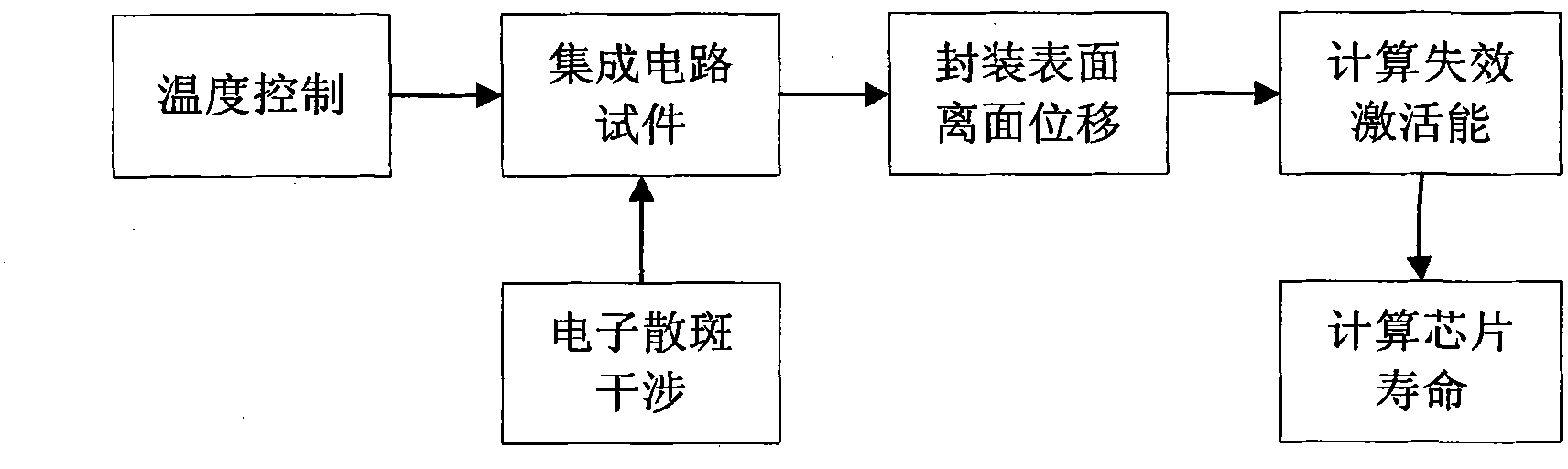

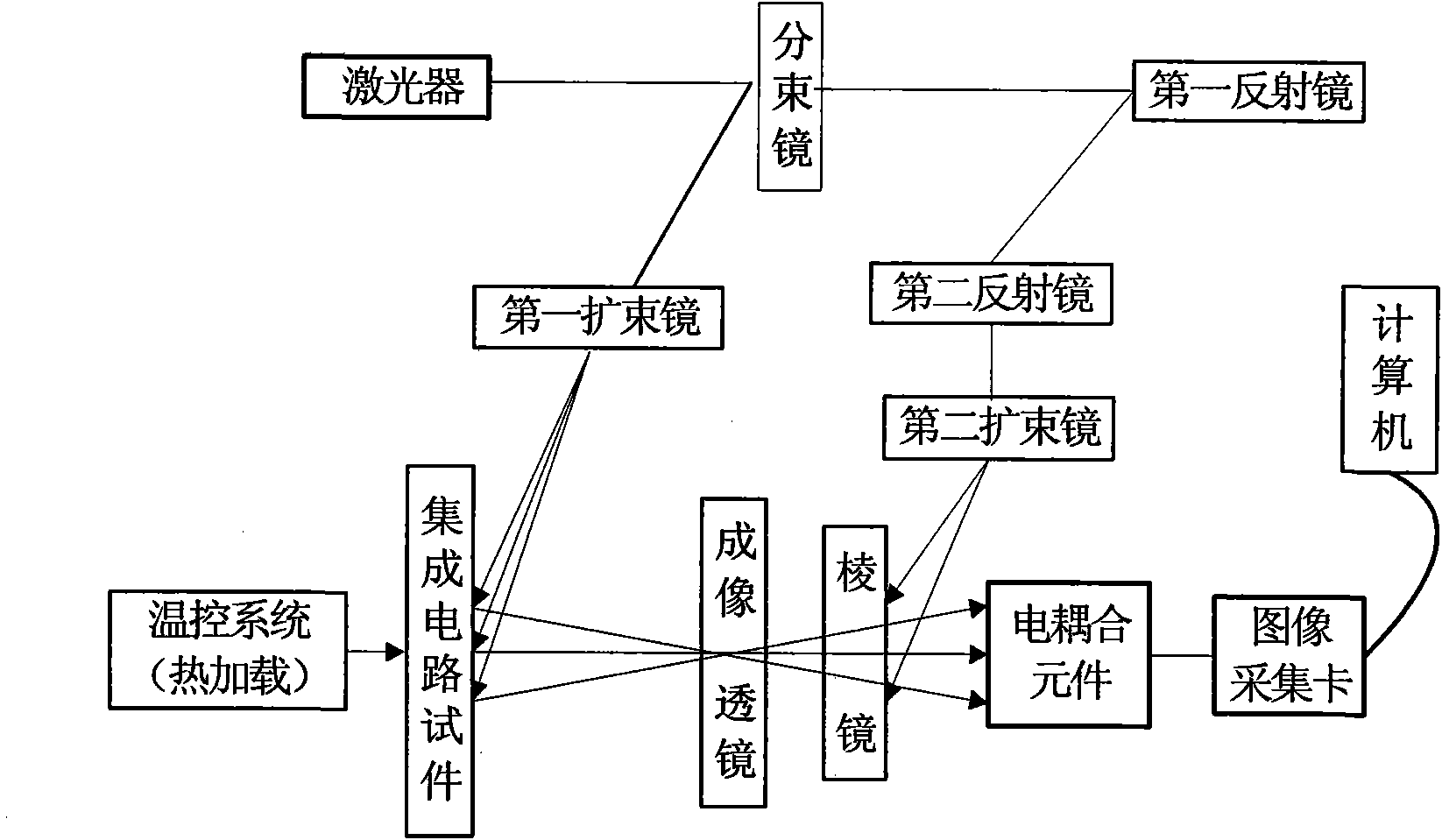

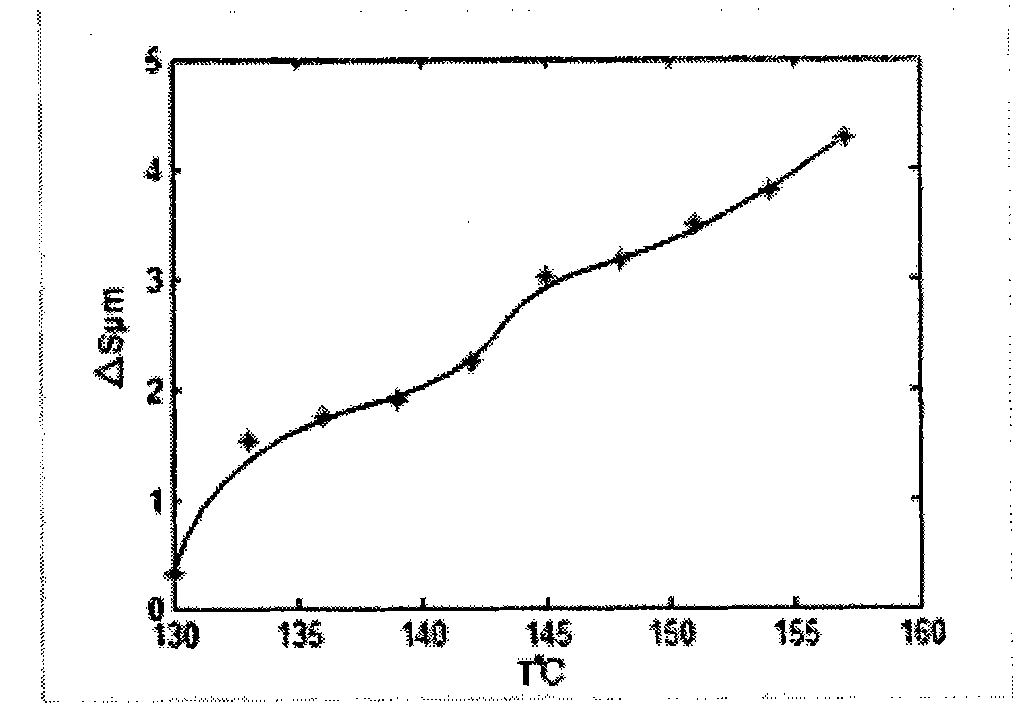

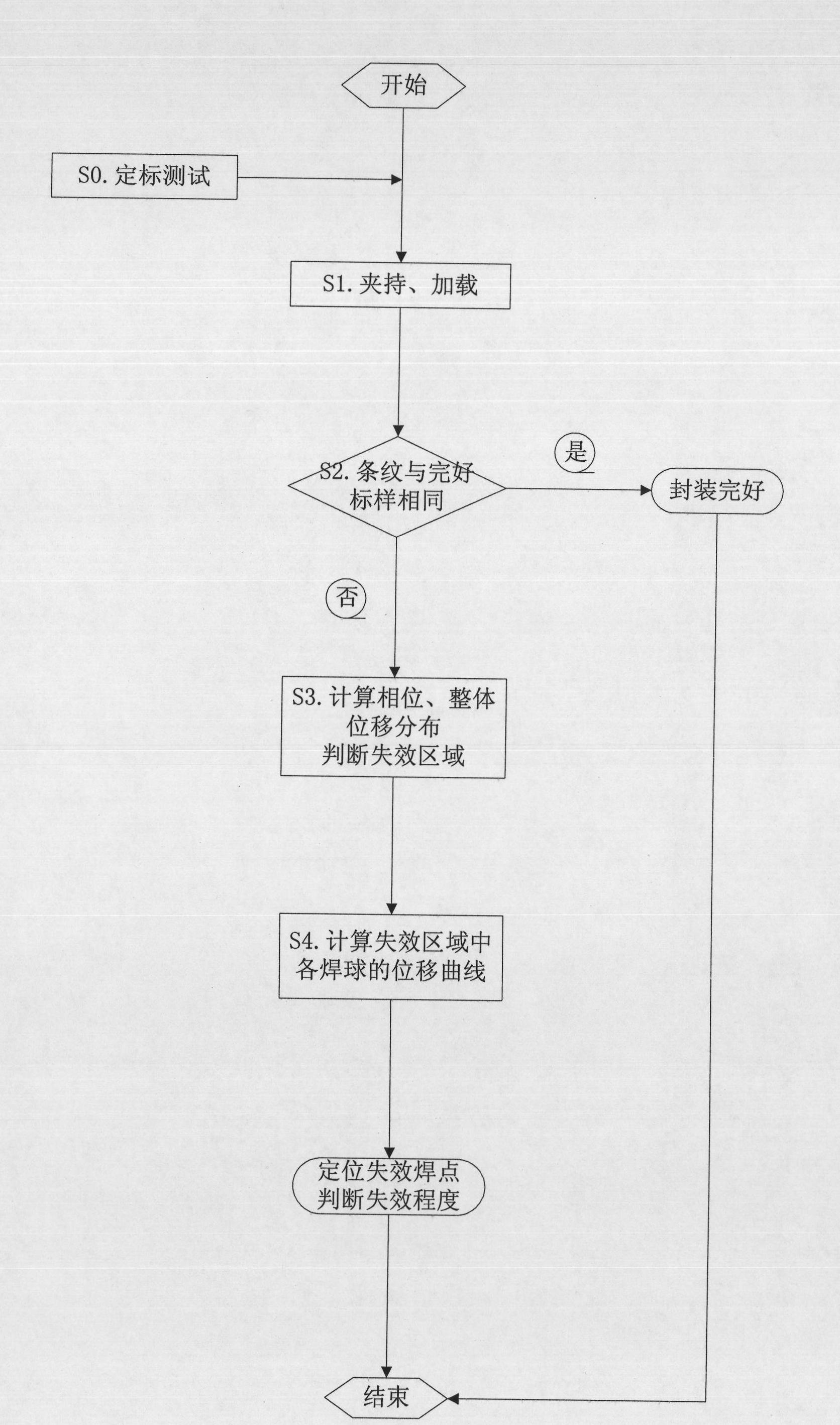

Method for forecasting working life of integrated circuit based on electronic speckle technique

InactiveCN101915893ASolve the misjudgment problem caused by reliability life predictionAvoid errorsContactless circuit testingTemperature stressActivation energy

The invention discloses a method for forecasting the working life of an integrated circuit based on an electronic speckle technique, and the method comprises the following steps: applying temperature stress to an integrated circuit test piece by establishing a measuring system based on the electronic speckle technique, measuring change rules of out-of-plane displacement of the integrated circuit test piece encapsulation along with temperature, finding a temperature point where a failure mechanism of the integrated circuit test piece changes, and then determining a temperature range consistent with the failure mechanism; then exacting failure activation energy according to the change rules of the out-of-plane displacement of the integrated circuit test piece in the temperature range consistent with the failure mechanism; and finally, establishing a life forecasting model in combination with an Arrhenius model and an accumulative failure model and obtaining the working life of the integrated circuit test piece in different temperature environments.

Owner:GUILIN UNIV OF ELECTRONIC TECH

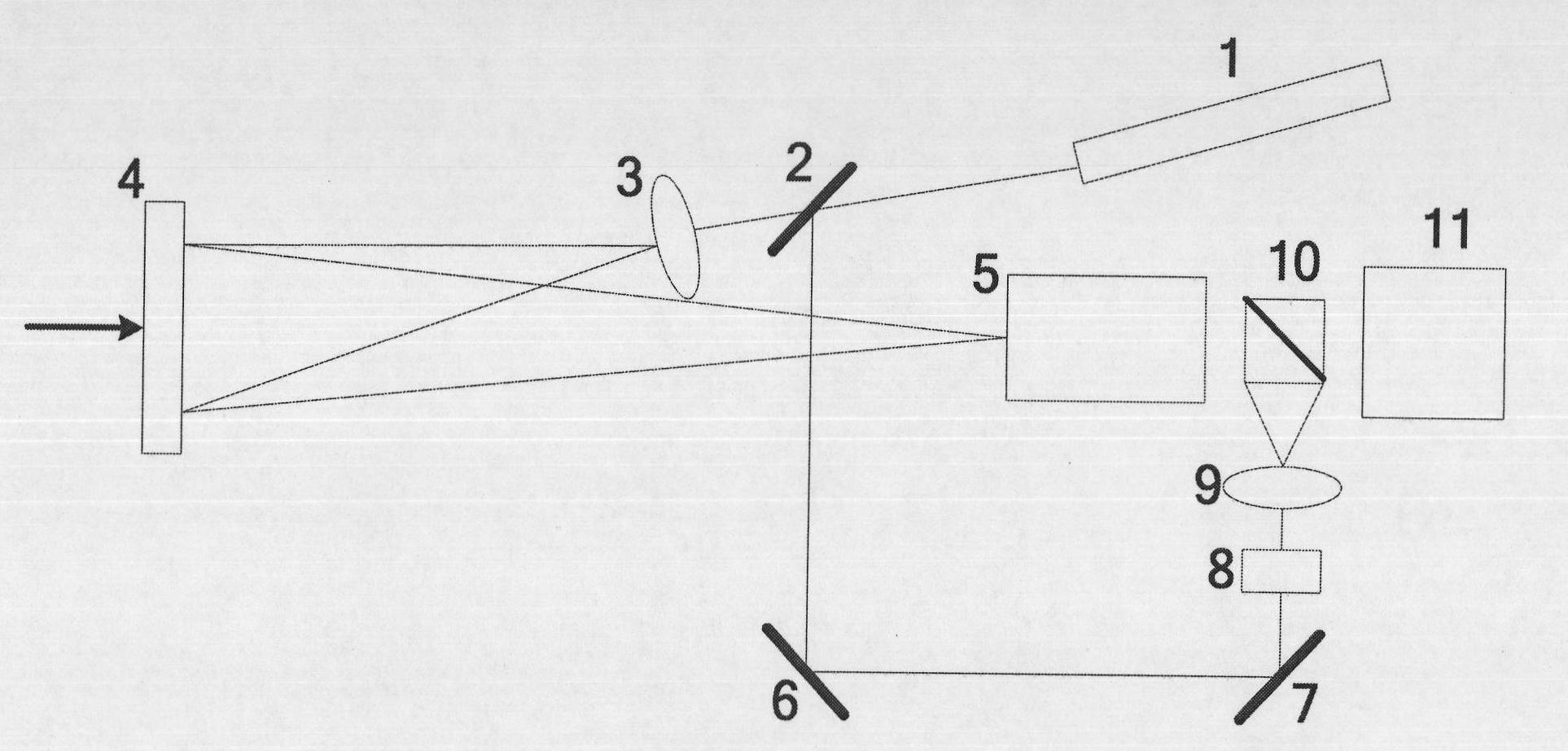

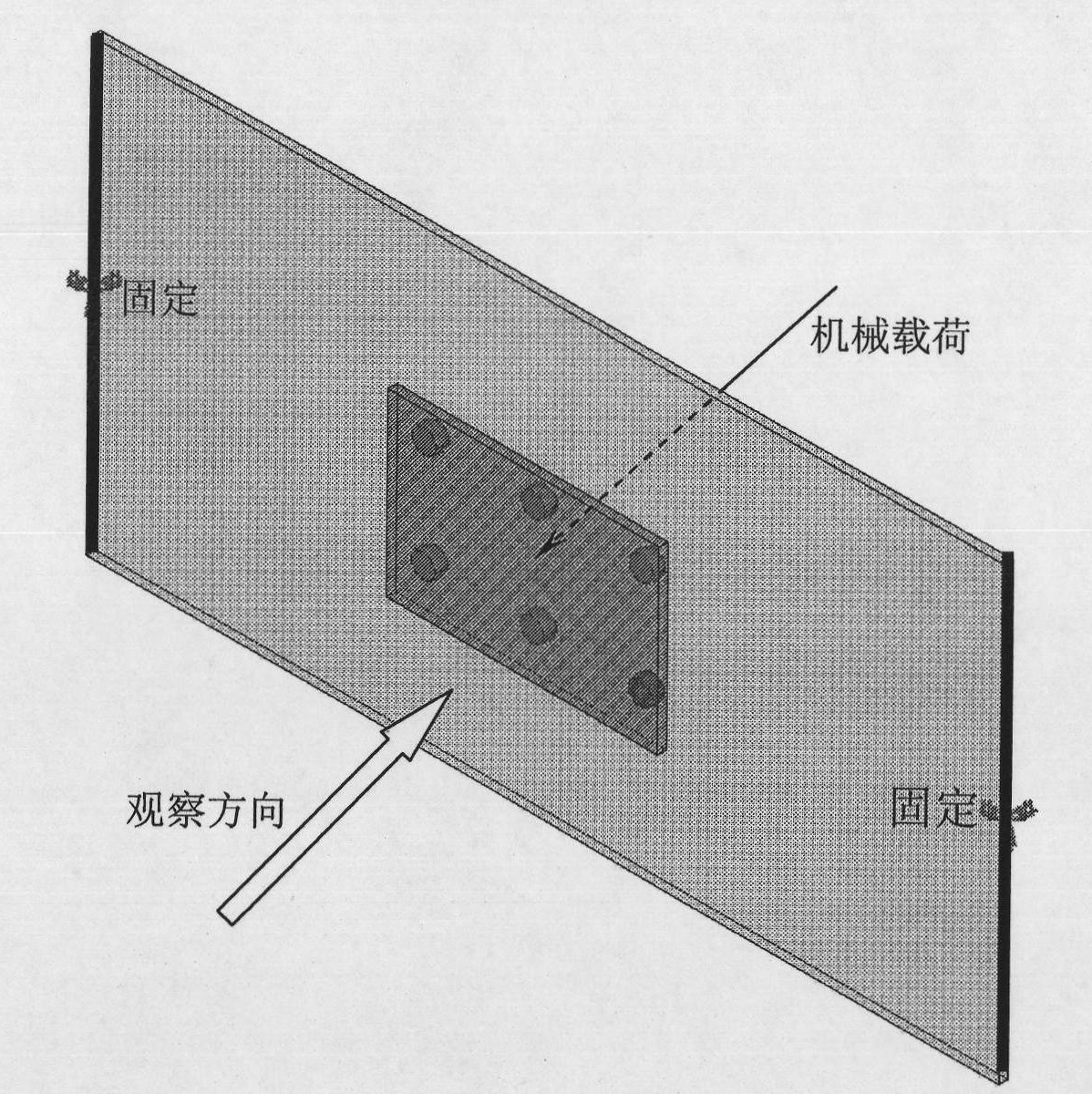

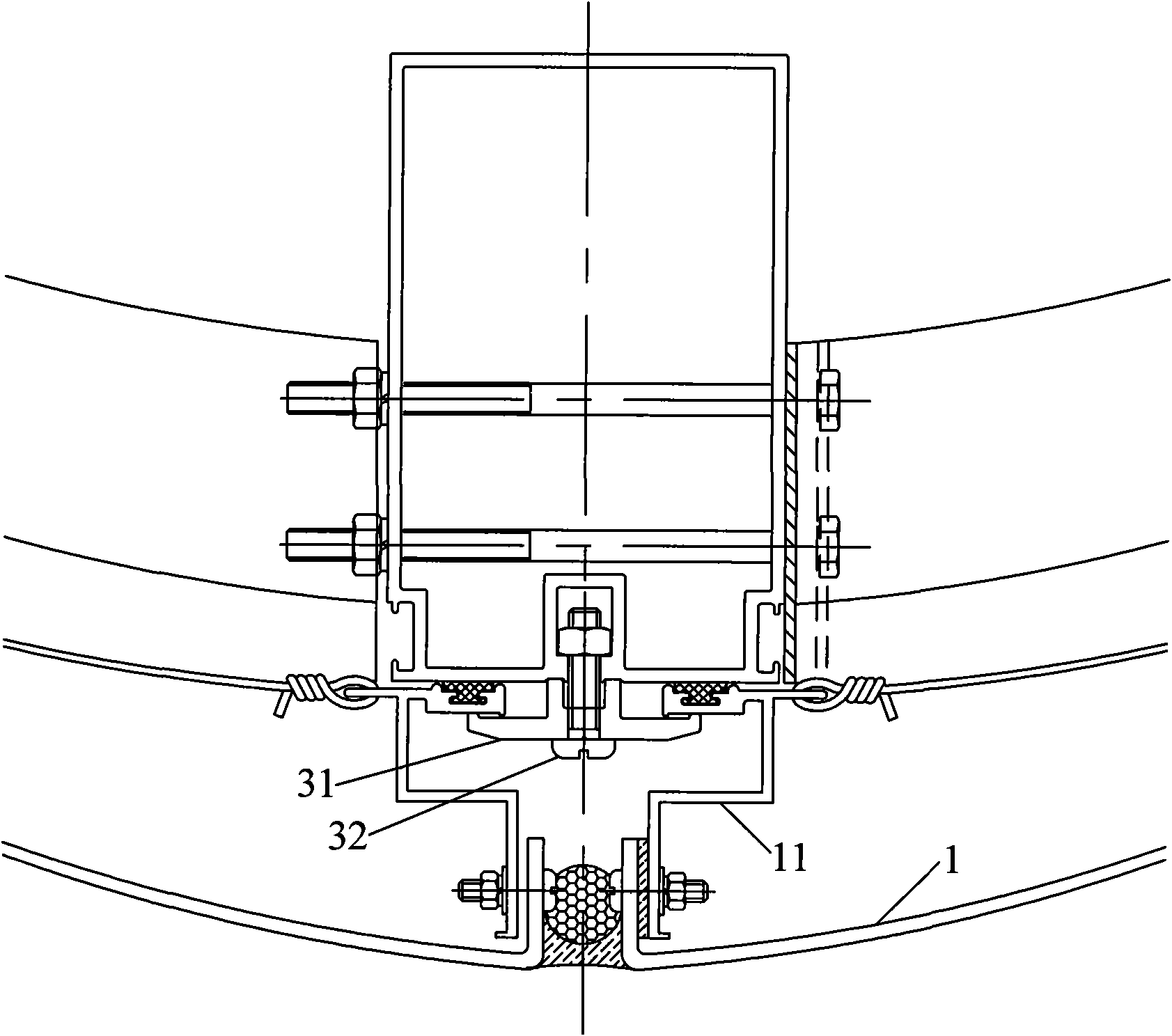

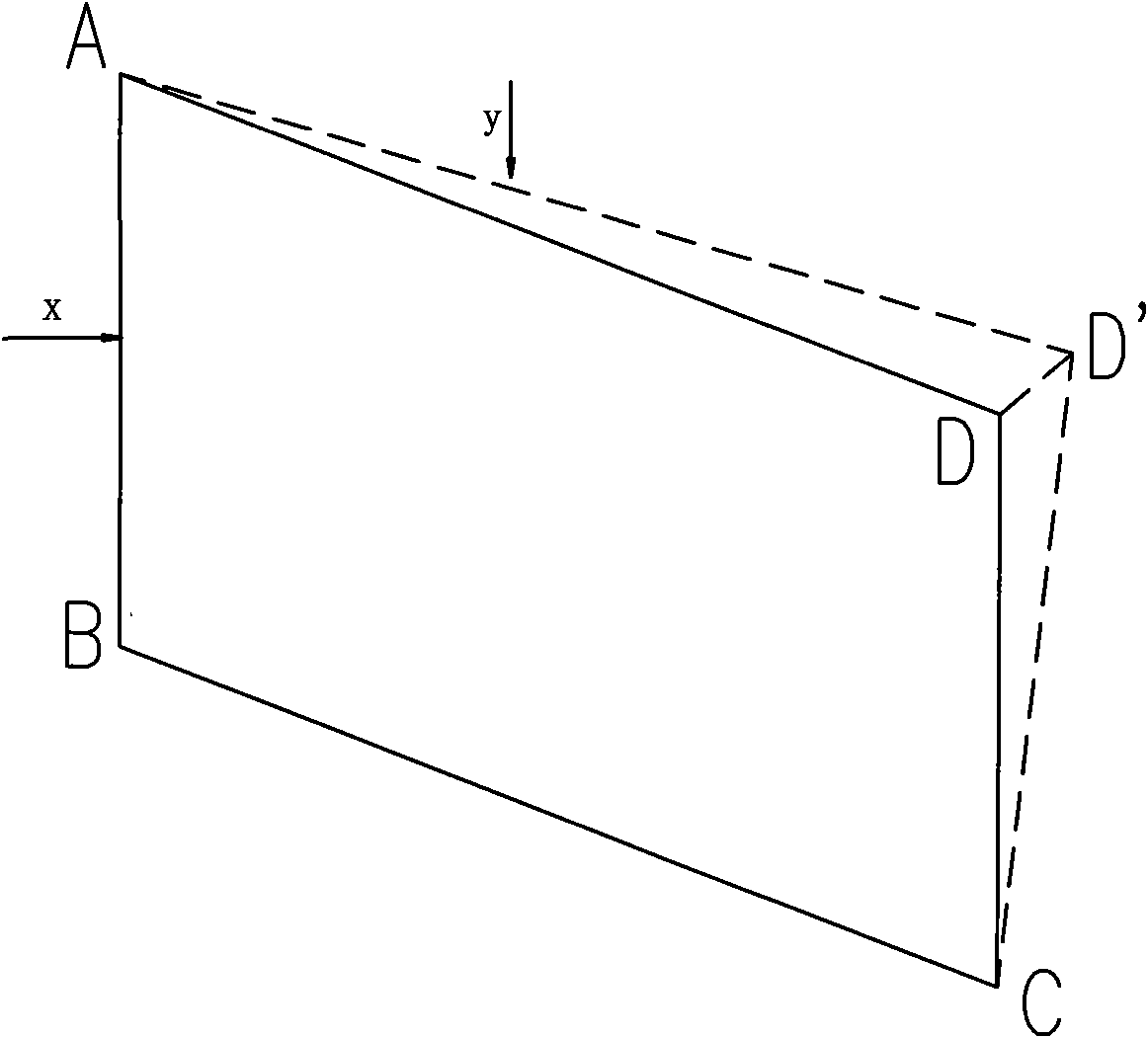

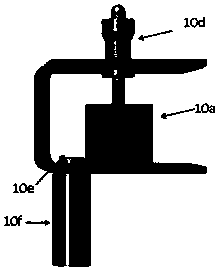

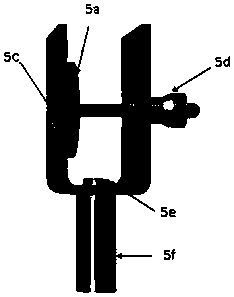

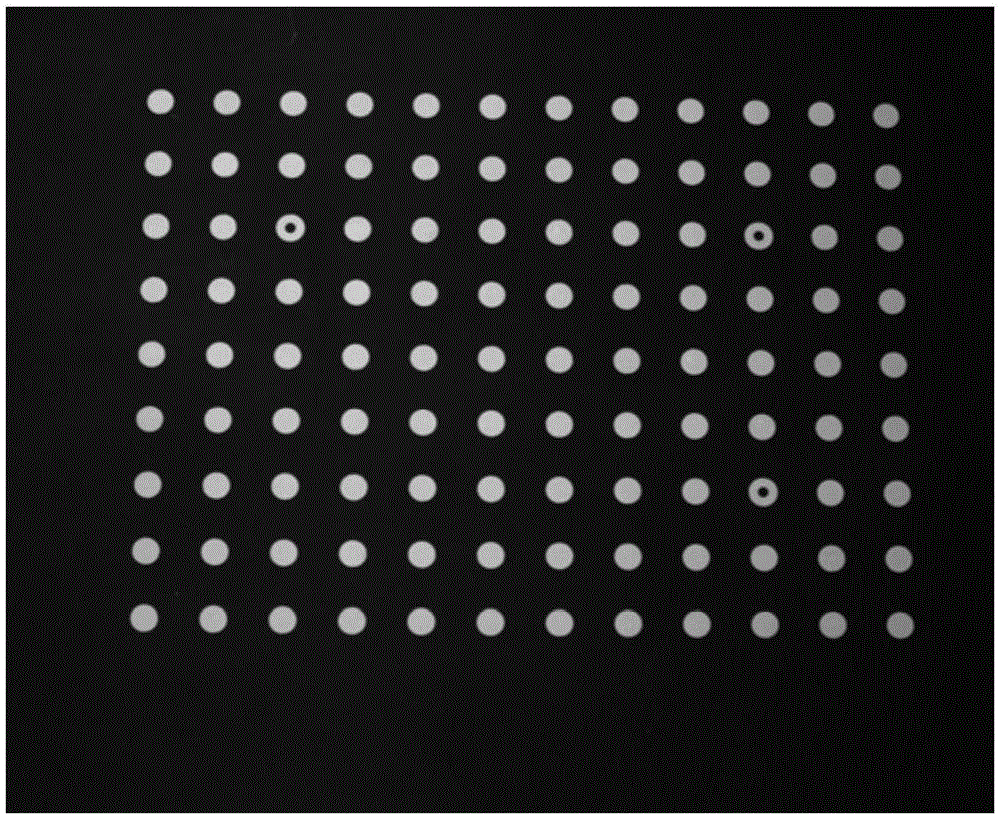

Electronic speckle pattern interference detection system and lossless detection method for failures of solder balls

InactiveCN102141524ADetermine the extent of damageSo as not to damageOptically investigating flaws/contaminationOut of plane displacementBall grid array

The invention belongs to the field of electronic packaging and relates to an electronic speckle pattern interference detection system and method for failures of solder balls in board assembly ball grid array packaging devices. The system provided by the invention comprises a detection sample fixing and loading part, an electronic speckle pattern interference out-of-plane displacement testing light path part and a computer data analyzing and processing part, wherein the electronic speckle pattern interference out-of-plane displacement testing light path part is used for forming the interference fringes of the detection sample after deforming under a mechanical load, namely out-of-plane micro-displacement information; the computer data analyzing and processing part is used for collecting the fringes, carrying out phase unpacking and displacement computation and positioning failure regions; and the out-of-plane displacement fringes of a standard sample and the sample are compared to determine whether the sample is subjected to the failure of the solder balls or not. The system provided by the invention has the advantages of simple composition components, no damage on the devices in a measuring course, simple and convenient detection method, good process integrity and real-time measurement realization on a production line, thereby greatly enhancing the detection efficiency of the failure of the solder balls in the board assembly ball grid array packaging devices.

Owner:FUDAN UNIV

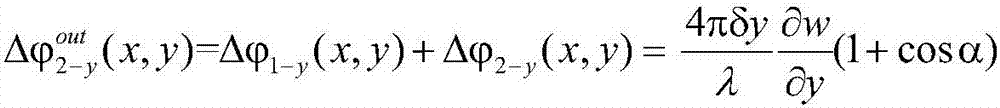

Elastic forming method for panel of curtain wall and curved-surface building curtain wall

ActiveCN101560802ASmooth and beautiful appearanceSolve the appearanceWallsArchitectural engineeringOut of plane displacement

The invention discloses an elastic forming method for a panel of a curtain wall and a curved-surface building curtain wall constructed by the same. The curved-surface building curtain wall at least comprises two parts in four parts, namely a panel, a framework, nipping points and a support; the panel is provided with the nipping points by utilizing the elasticity of a material through the elastic forming method; and the support of the nipping points applies the out-of-plane displacement on the panel, so that the panel generates elastic deformation to form and maintain the curved surface of a building. The invention can be also applied in the fields such as building roofing or ceiling and the like. The prior construction methods for the curved-surface building curtain wall are mainly a casting forming method, a plastic forming method and a plane fitting method; the plastic forming method is to preprocess the curved surface on the panel by casting and plastic methods and arrange the panel onto the framework and the support, but has high cost; and the plane fitting method has low cost but has not ideal construction effect. Adjacent plates of the curved-surface building curtain wall have natural transition, the whole appearance of the building is more smooth and beautiful, and the building has better appearance and the cost is lower than the curved-surface building curtain wall constructed by the casting forming method, the plastic forming method and the plane fitting method. The elastic forming method achieves perfect integration of the building appearance and construction cost.

Owner:SHANGHAI JANGHO CURTAIN WALL SYST ENG +2

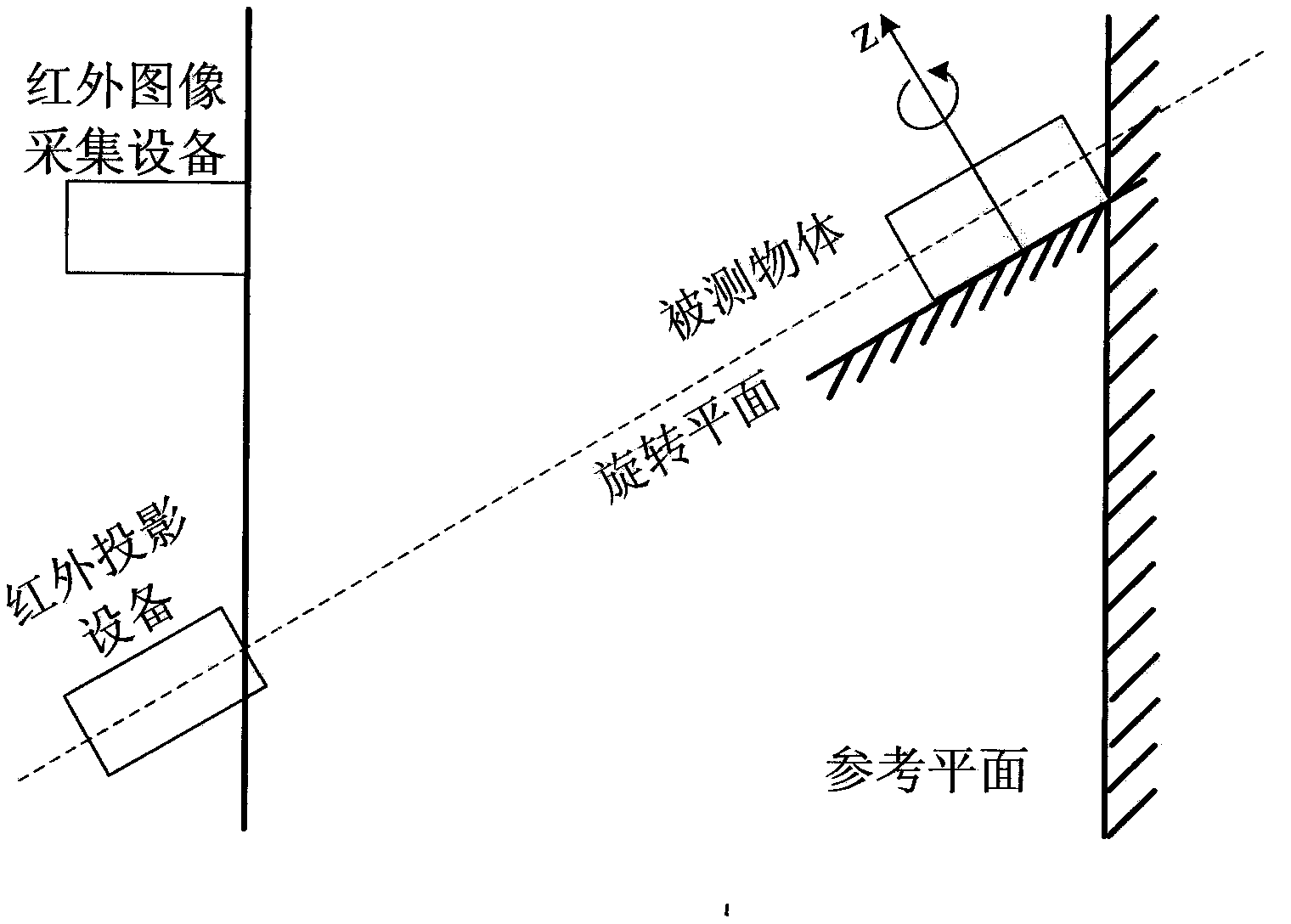

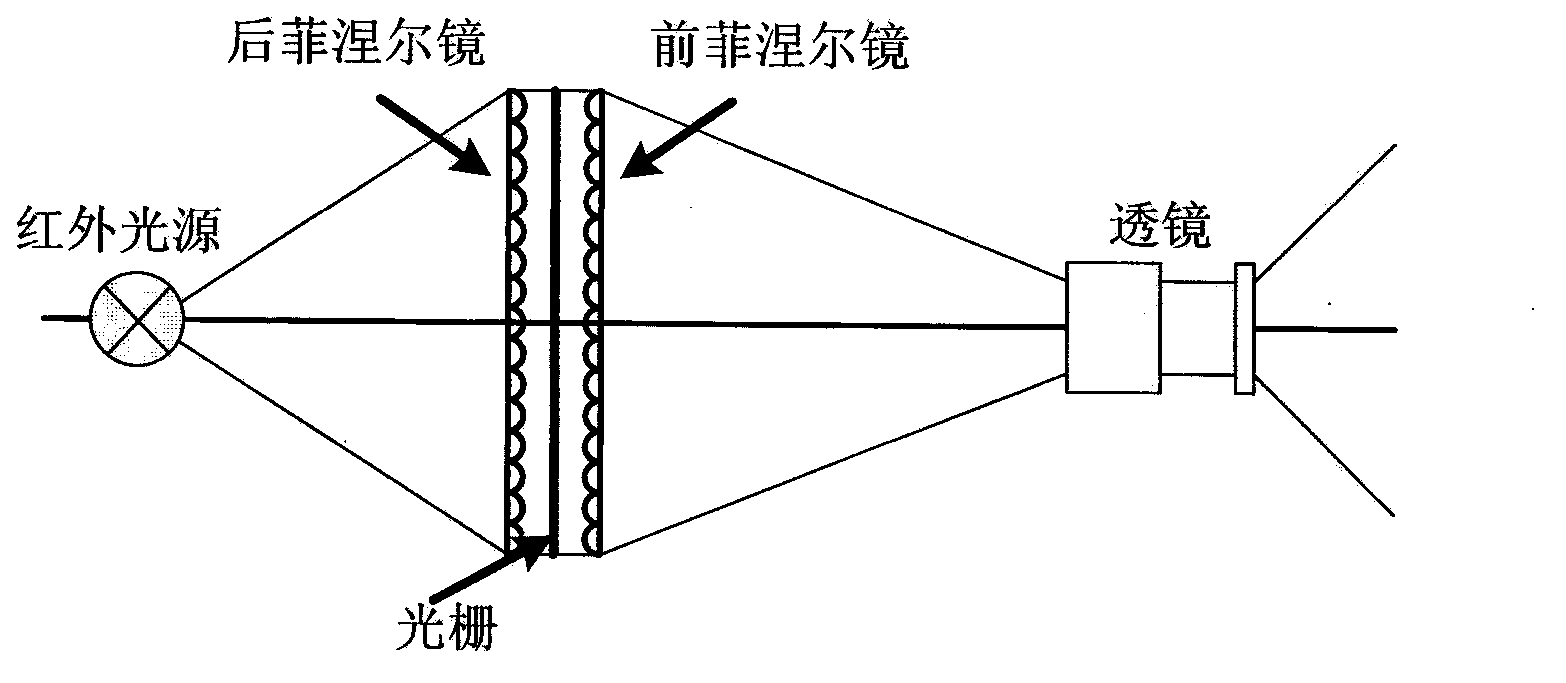

Wide view field type infrared light three-dimensional morphology measurement method and device thereof

The invention relates to a large-scale infrared light three-dimensional morphology measurement method. The method comprises the following steps: 1) a 0.5 line / mm type grating is projected onto an object to be measured by an infrared projector; 2) projected images are acquired from three angles, calibrated images of projection apparatuses projected onto a reference plane at different view angles are recorded successively, and then measured images of each projection apparatus projected onto the surface of the object to be measured at the measurement time are recorded successively; 3) the partitioning algorithm is used in the calibrated images and the measured images to partition projection lines, and the centerline recognition algorithm is used to determine the centerline position of the projection lines; 4) the triangulation theory is used to obtain height difference data of corresponding points between the calibrated images and the measured images, that is the out-of-plane displacement curve of each projection line; 5) the rotation translation matrix between two adjacent shooting angles is calculated through the curve Euclidean distance and quaternion; 6) and the height difference data of each projection apparatus is merged into the final three-dimensional morphology data to obtain the three-dimensional morphology measurement result; in the projected image acquisition process, the projected images are acquired from three angles; wherein the constraint condition is that part of information between two adjacent acquisition angles is coincident for calculating the rotation translation matrix in the step 5).

Owner:PEKING UNIV

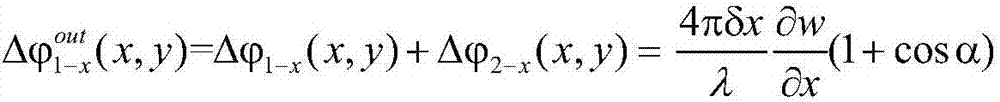

Three-dimensional deformation measuring method based on synthesis wavelength double-light-source shearing speckle interferometry

InactiveCN108007375ASimple optical path designHigh precisionUsing optical meansElectricityPhase shifted

The invention provides a three-dimensional deformation measuring method based on synthesis wavelength double-light-source shearing speckle interferometry, and belongs to the technical field of opticalimaging. The method includes: red laser and green laser respectively pass through a light beam splitter and are irradiated to a measured object through a reflecting mirror and a light beam expander,reflection occurs on the surface of the measured object, the reflected light passes through a convex lens and performs light interference through a shearing mirror, and an interference image is acquired in a CCD camera; a PZT phase shift amount is controlled through a piezoelectric ceramic controller, and the red laser and the green laser are respectively and simultaneously recorded through the CCD camera through an R channel and a G channel of a color camera; the pressure in a vacuum box is adjusted through a pressure adjusting valve, and a pressure value is displayed through a pressure meter; Fourier transform is performed on the interference image, and the relation between the synthesis wavelength phase fringe number and the single wavelength fringe number is calculated; and an in-planedisplacement derivative matrix and an out-of-plane displacement derivative matrix are calculated, and a three-dimensional deformation matrix of the object is obtained according to optical geometric characteristics of a measuring system to realize three-dimensional deformation measurement of the object.

Owner:QIQIHAR UNIVERSITY

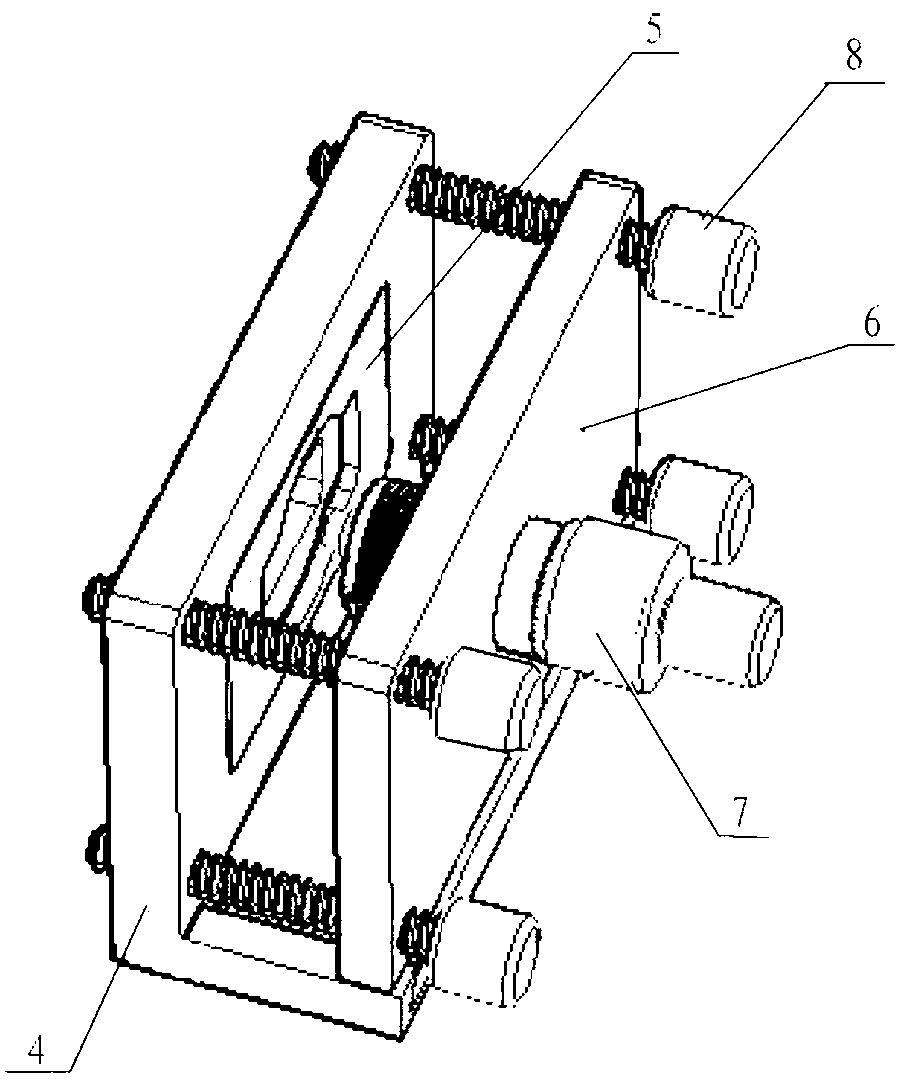

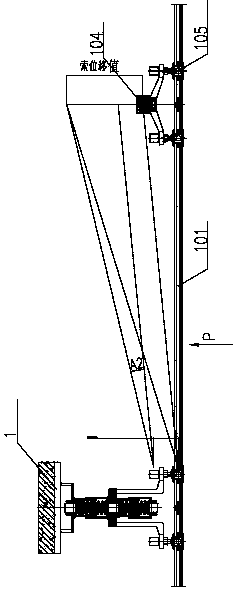

Single-cable structural point supporting type glass curtain wall out-of-plane deformation limiting device

InactiveCN103938778AImprove securityShort processing cycleWallsOut of planeOut of plane displacement

The invention provides a single-cable structural point supporting type glass curtain wall out-of-plane deformation limiting device which is a safety protection device applicable to a unidirectional single-cable structural point supporting type glass curtain wall project. The single-cable structural point supporting type glass curtain wall out-of-plane deformation limiting device structurally comprises a pre-tightening nut, a locking nut, a spring protecting seat with scales, a spring guide rod, a compression spring and a movable steel claw. The spring protecting seat with scales is welded on a body steel structure or connected with the body steel structure. The movable steel claw is connected with the compression spring, the locking nut and the spring protecting seat through the spring guide rod and limit a glass out-of-plane displacement value through the compression spring. By reading the scale on the spring protecting seat, a working state of the limiting device can be read and monitored at any time, and a pressure value and a deformation value of the compression spring can be intuitively read.

Owner:BEIJING DEHONG CURTAIN WALL ENG TECH

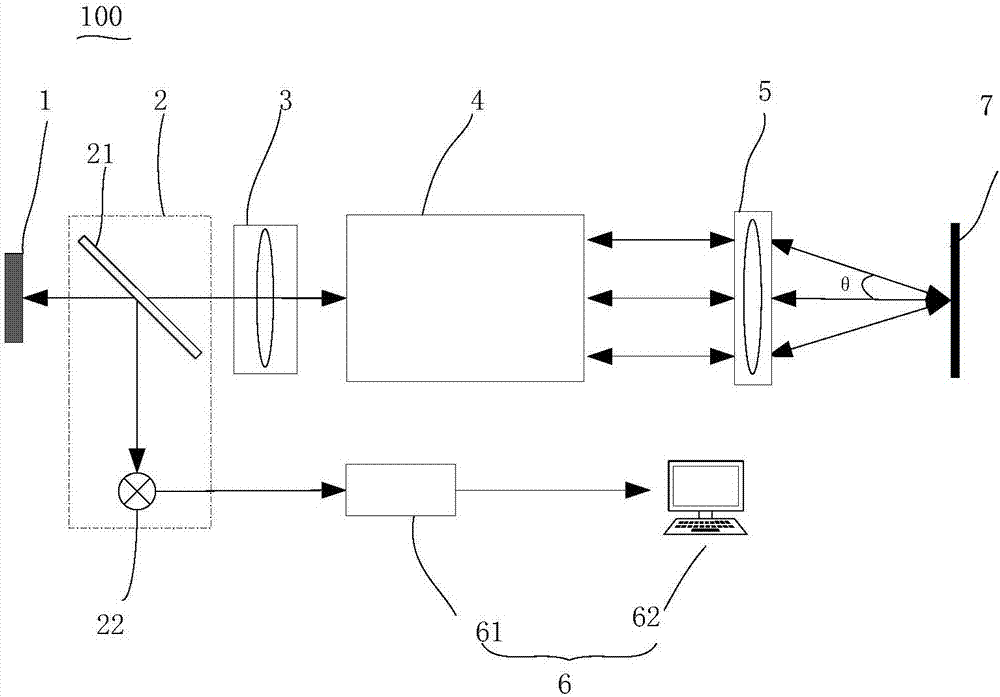

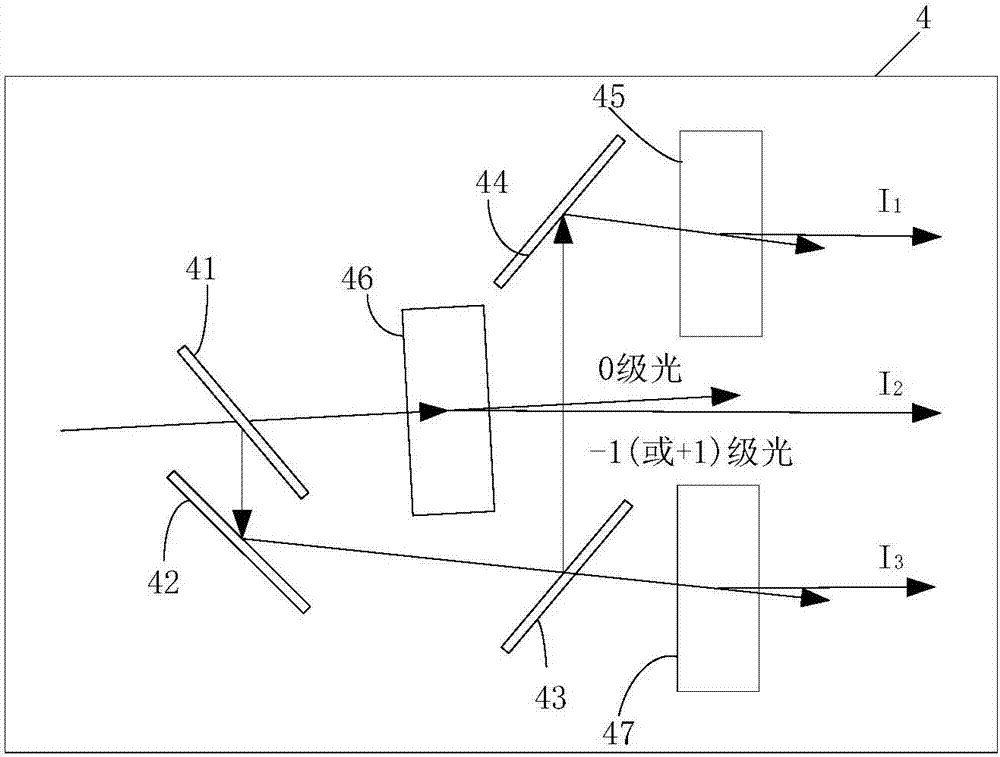

Two-dimensional displacement measurement device and method

The present invention relates to a two-dimensional displacement measurement device. The device comprises a laser configured to output polarization laser; a light splitting frequency shift module configured to perform light splitting of the polarization laser and realize differential frequency shift to form at least three beams of light, wherein the frequencies of the three beams of light are different; a gathering module configured to gather the at least three beams of light, allow the at least three beams of light to enter a target to be measured and receive laser returned back through scattering by the target to be measured to allow the returned laser to enter a laser to modulate the light intensity of the laser outputted by the laser; a signal detection module arranged on the optical path of the polarization laser being emergent from the laser and configured to perform detection of the light intensity of the laser outputted by the laser and convert the light intensity of the laser as electric signals; and a signal processing module connected with the signal detection module and configured to process and calculate the electric signals outputted by the signal output module and obtain out-of-plane displacement and in-plane displacement. The present invention further provides a displacement measurement method. The two-dimensional displacement measurement device and method are high in measurement precision.

Owner:TSINGHUA UNIV

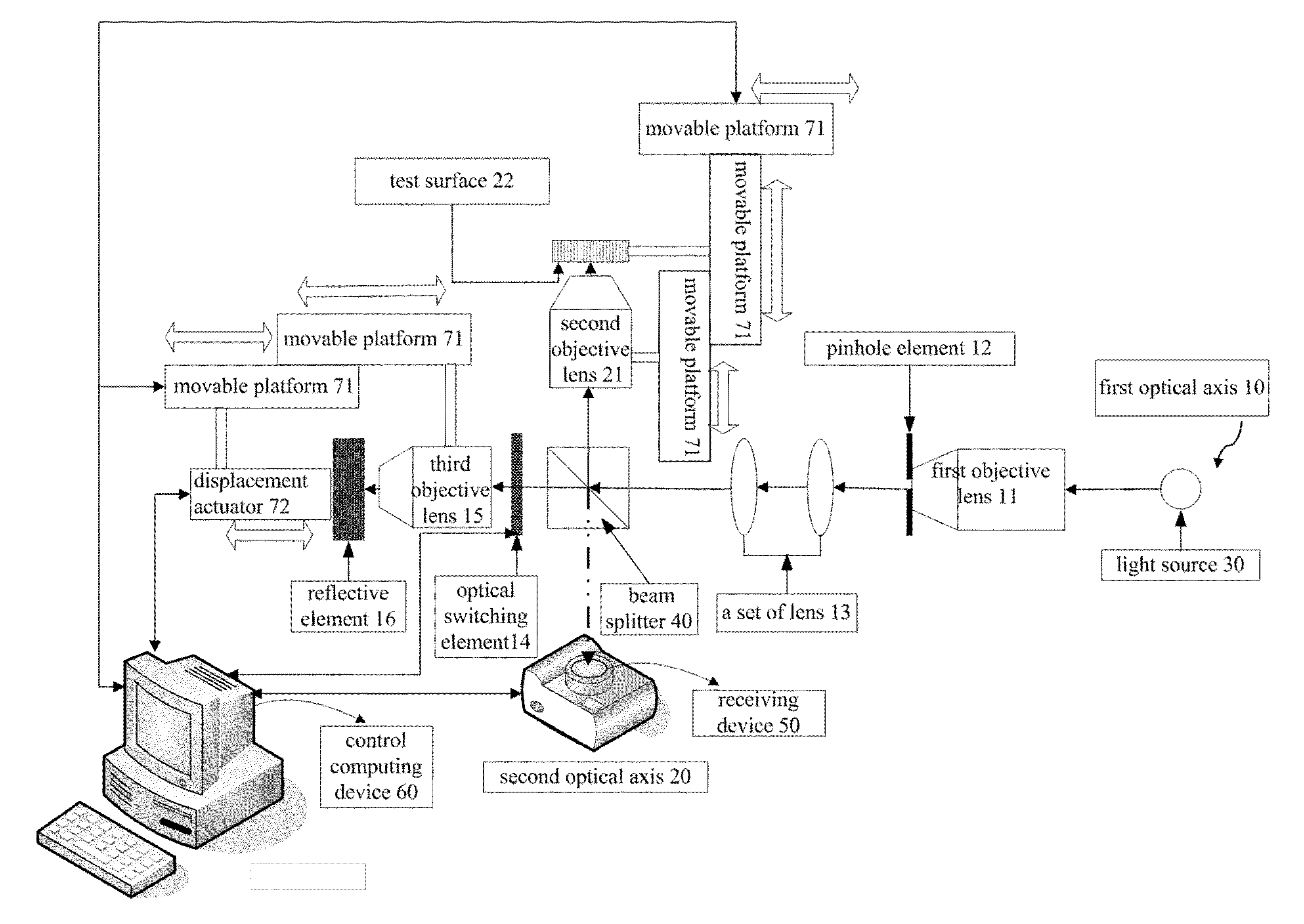

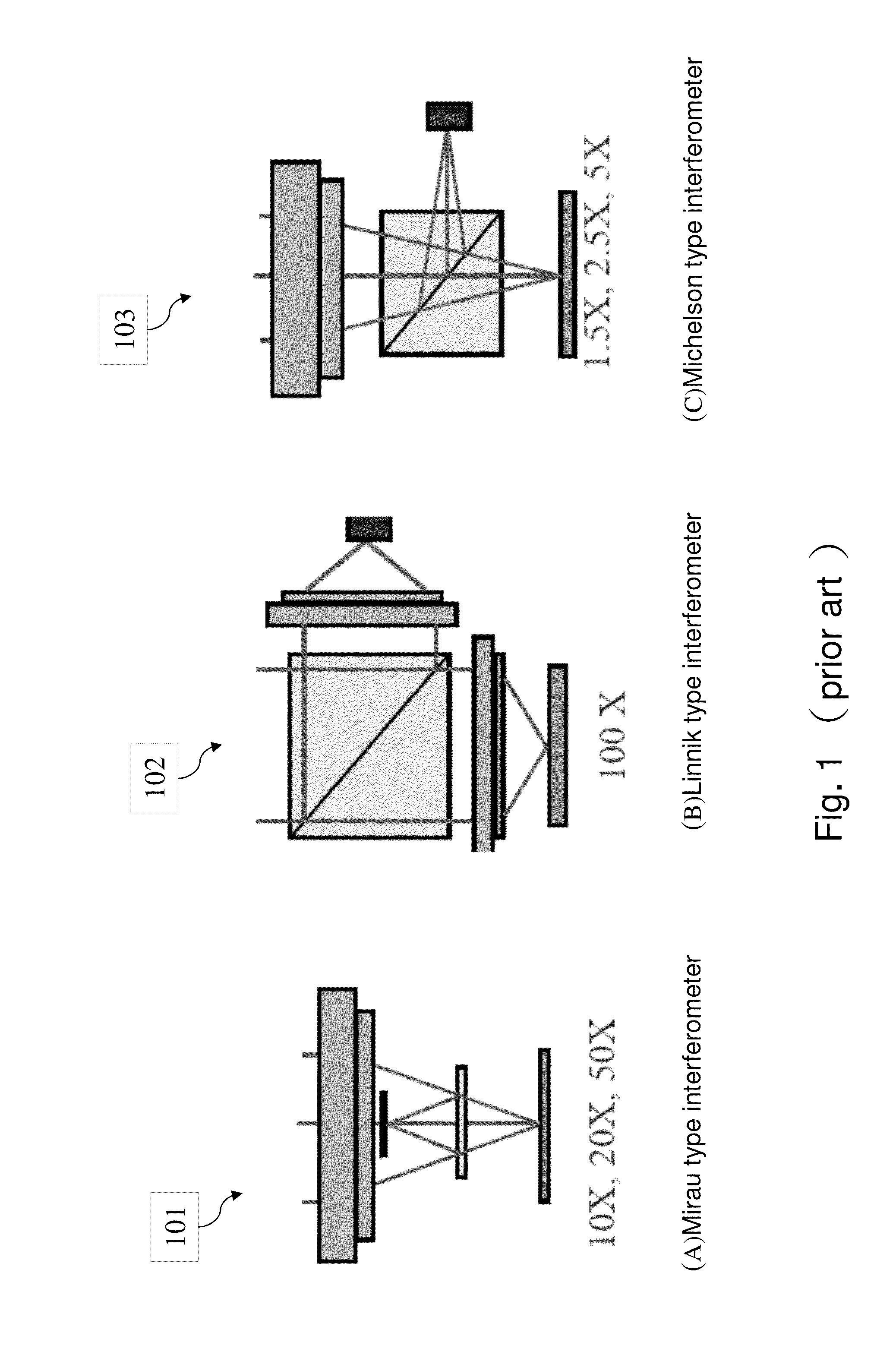

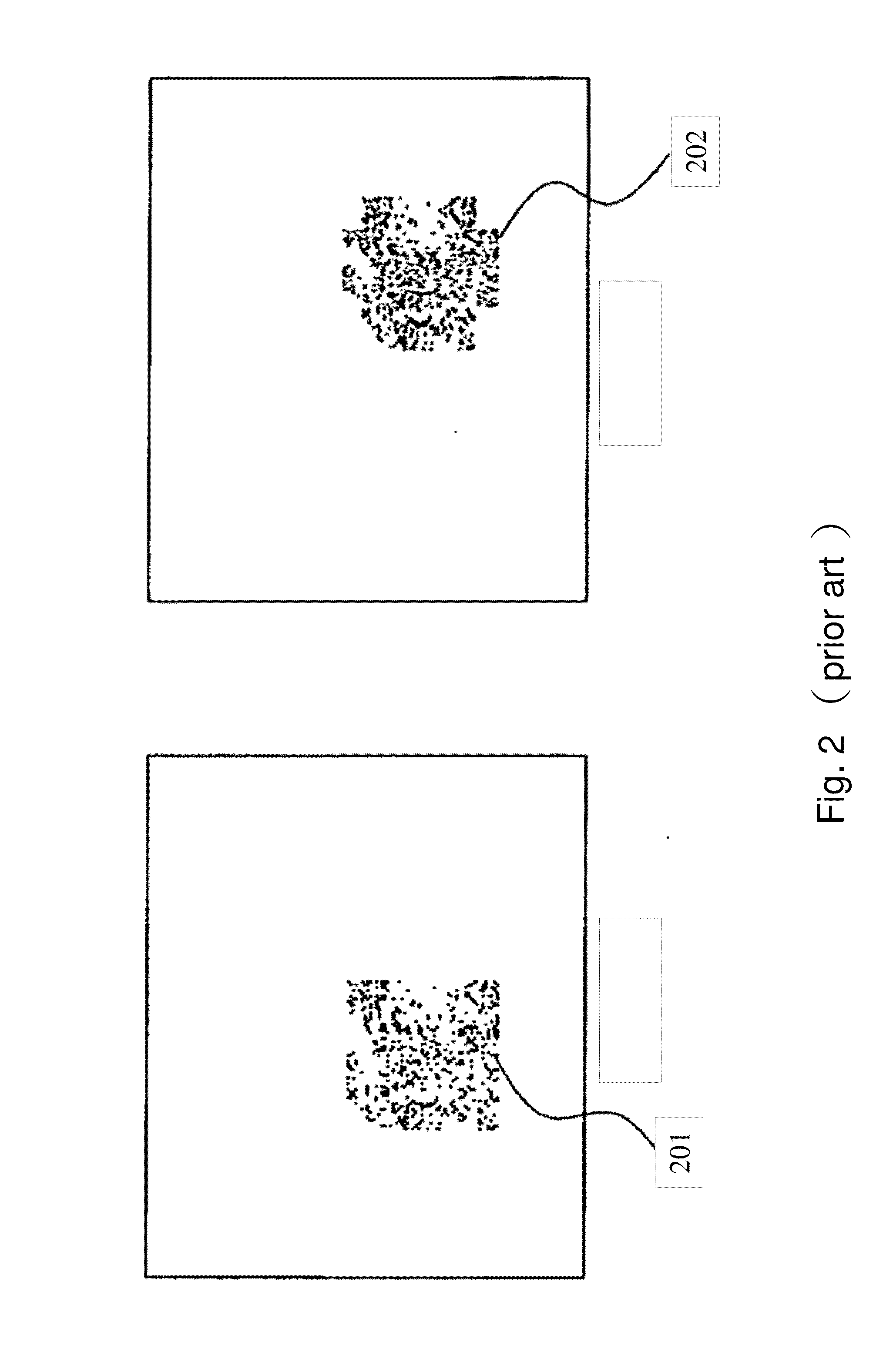

System of computing surface reconstruction, in-plane and out-of-plane displacements and strain distribution

InactiveUS20140111810A1Expand the measurement rangeReduce complexityUsing optical meansIn planeOut of plane displacement

A system of computing surface reconstruction, in-plane and out-of-plane displacements and strain distribution utilizes the optical switching element to switch the reference beam to analyze the images of the test object before and after deformation, to measure the topography, in-plane and out-of-plane displacements and surface two-dimensional strain distribution on the test surface of the test object, and thus to increase the measurement range on the test surface of the test object with the use of image registration. Thereby, the complexity and error of scanning the test object can be reduced. Such a system need not to move the image capturing device or test object to generate relative displacement for reaching the measurement effect of the test surface of the test object in three-dimensional coordinates.

Owner:NAT APPLIED RES LAB

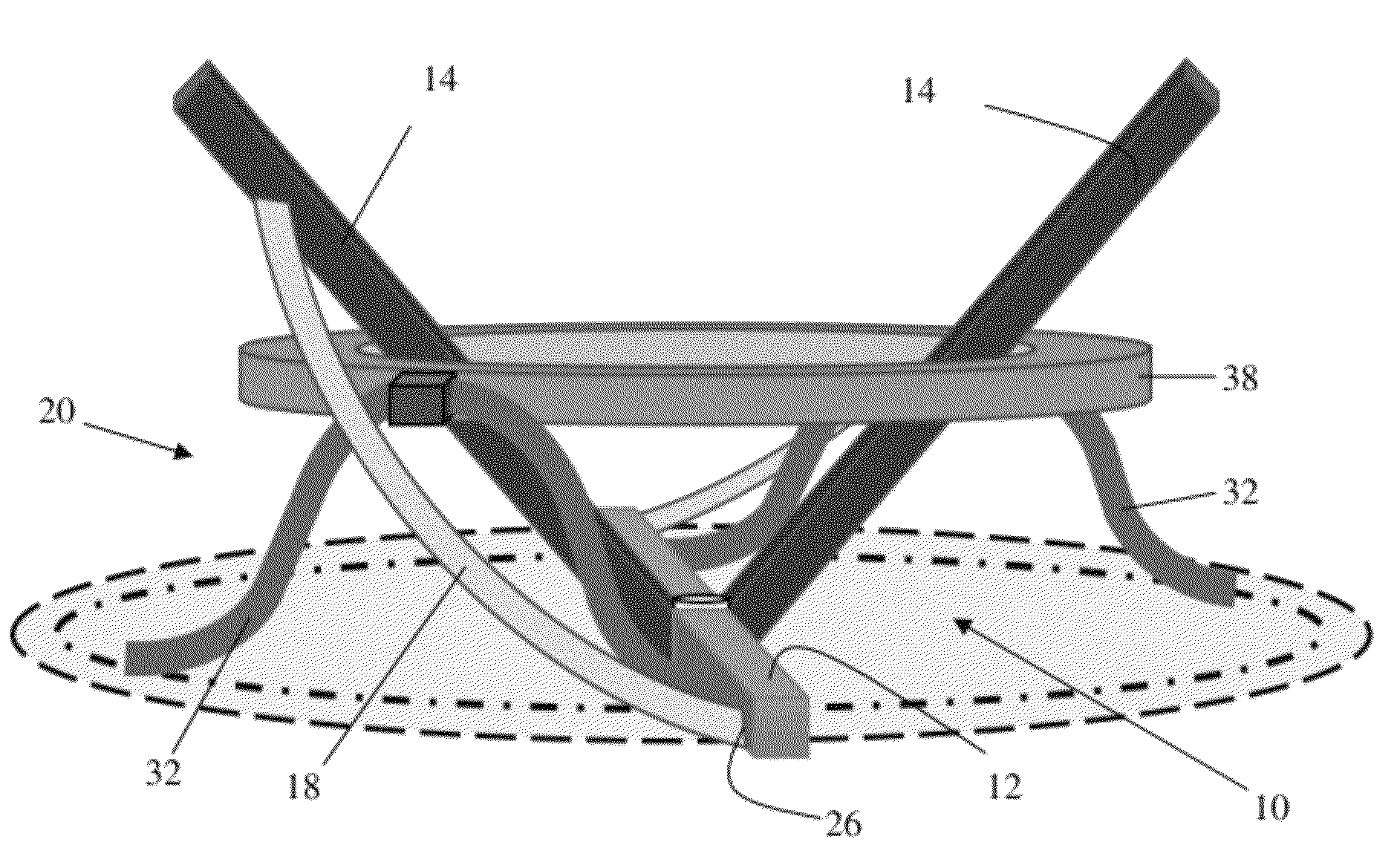

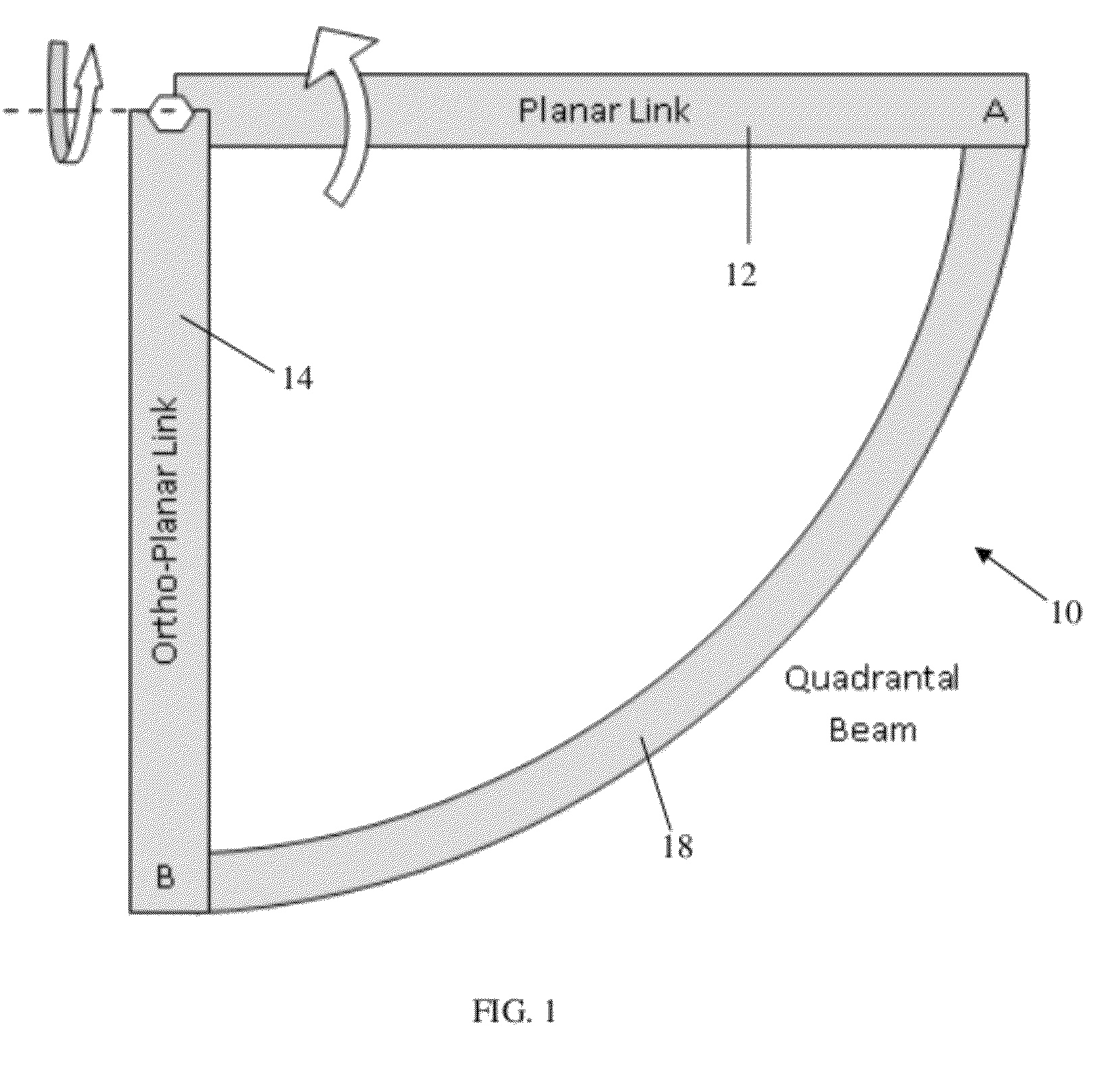

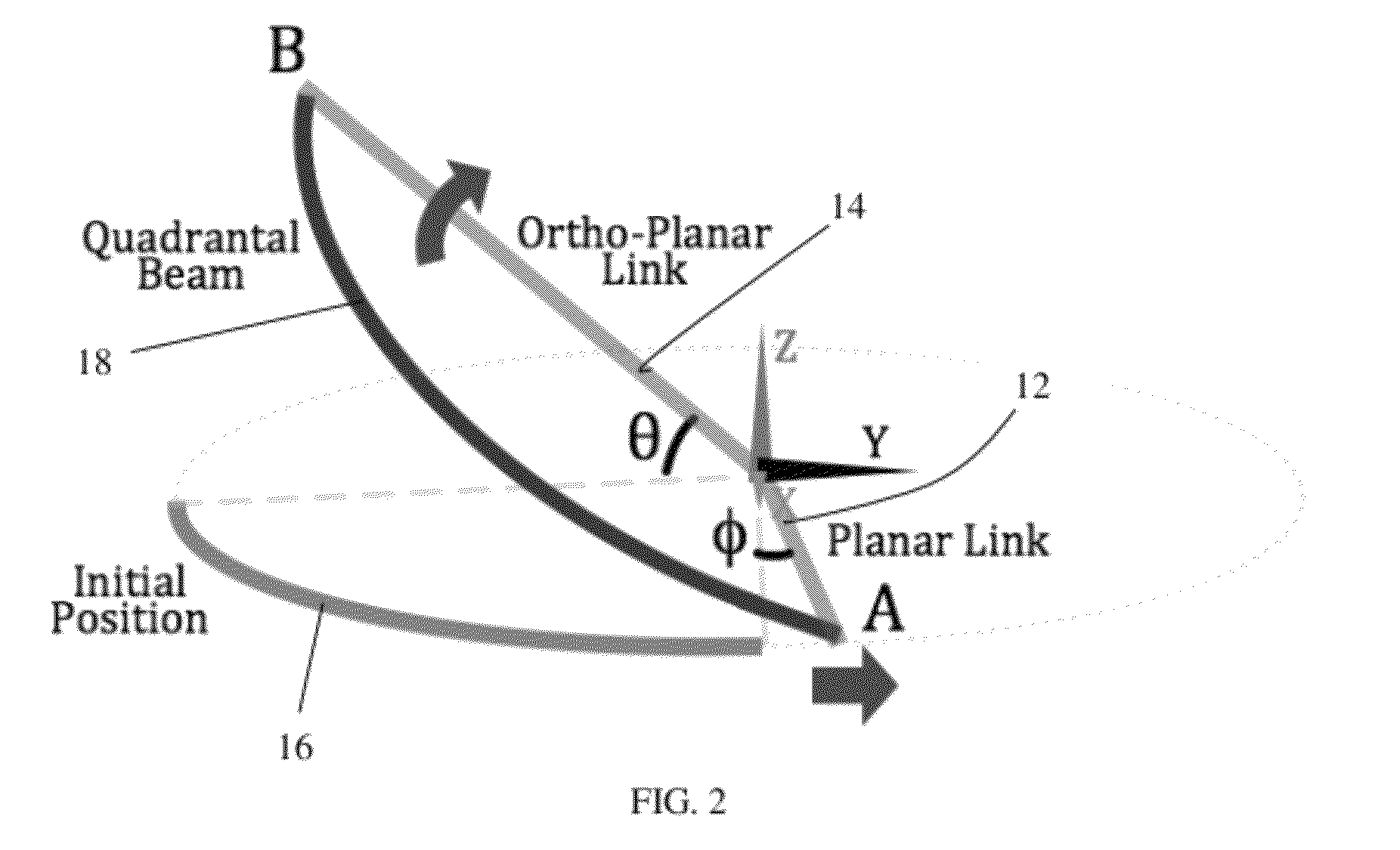

Bistable aerial platform

Owner:UNIV OF SOUTH FLORIDA

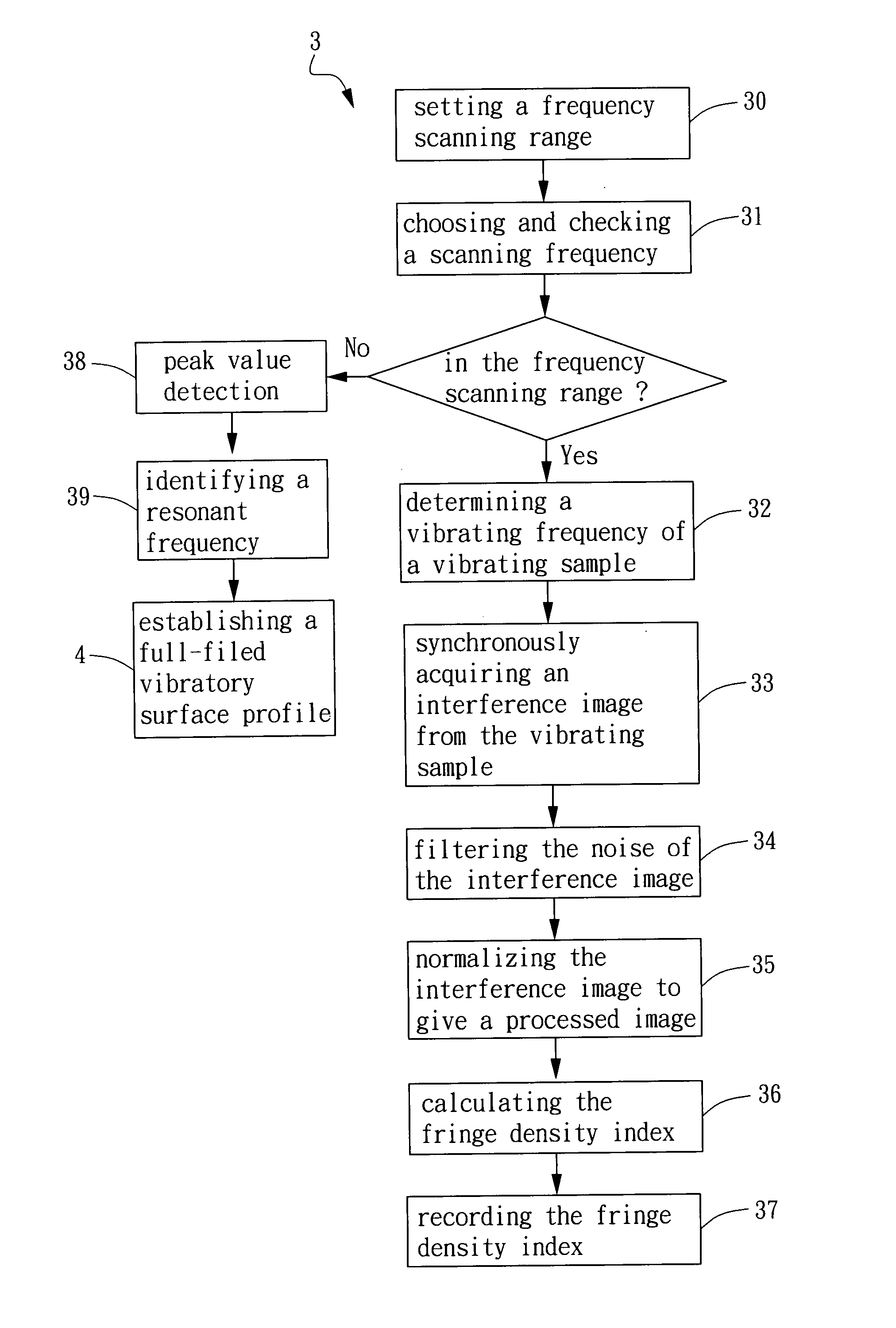

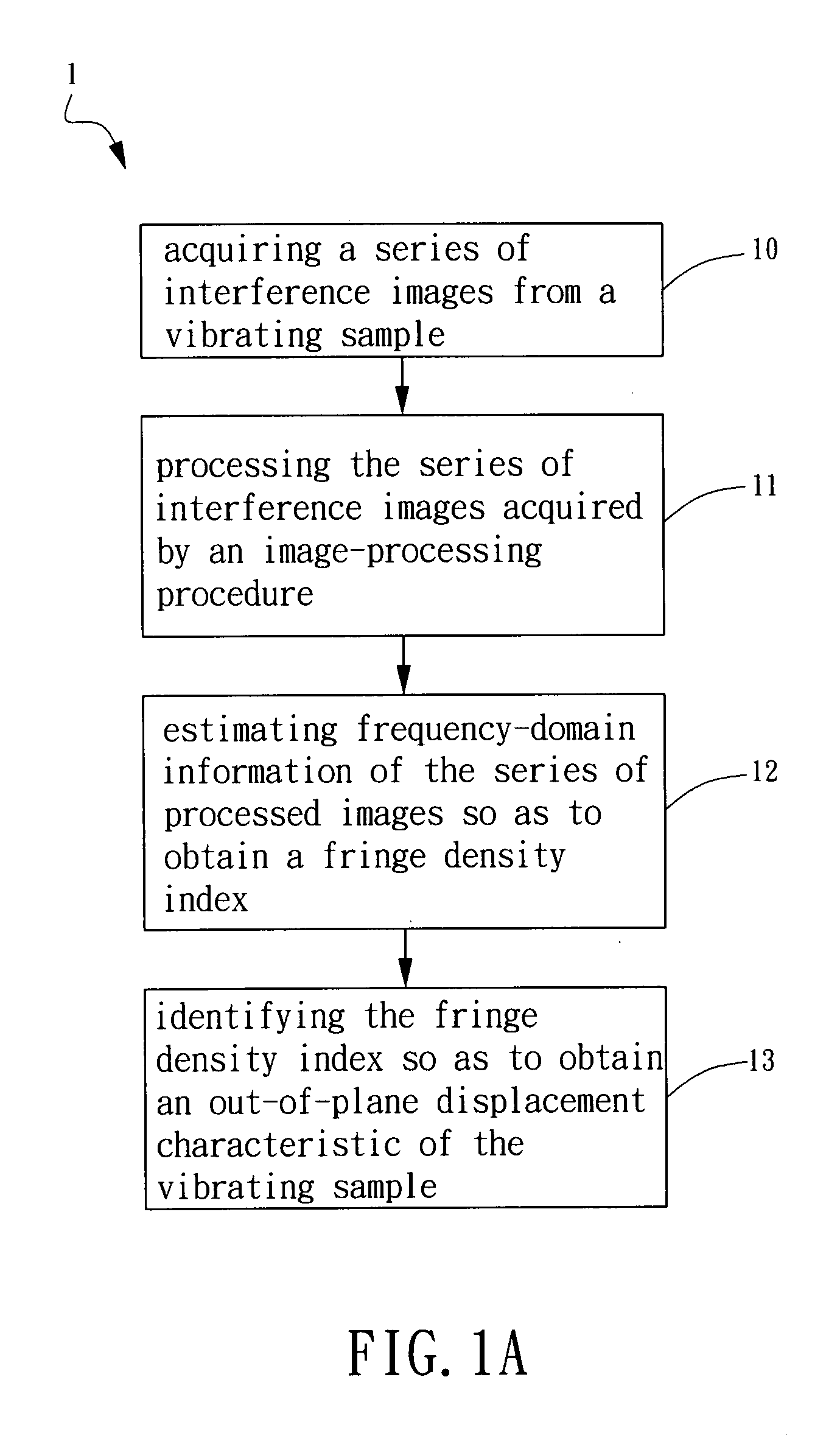

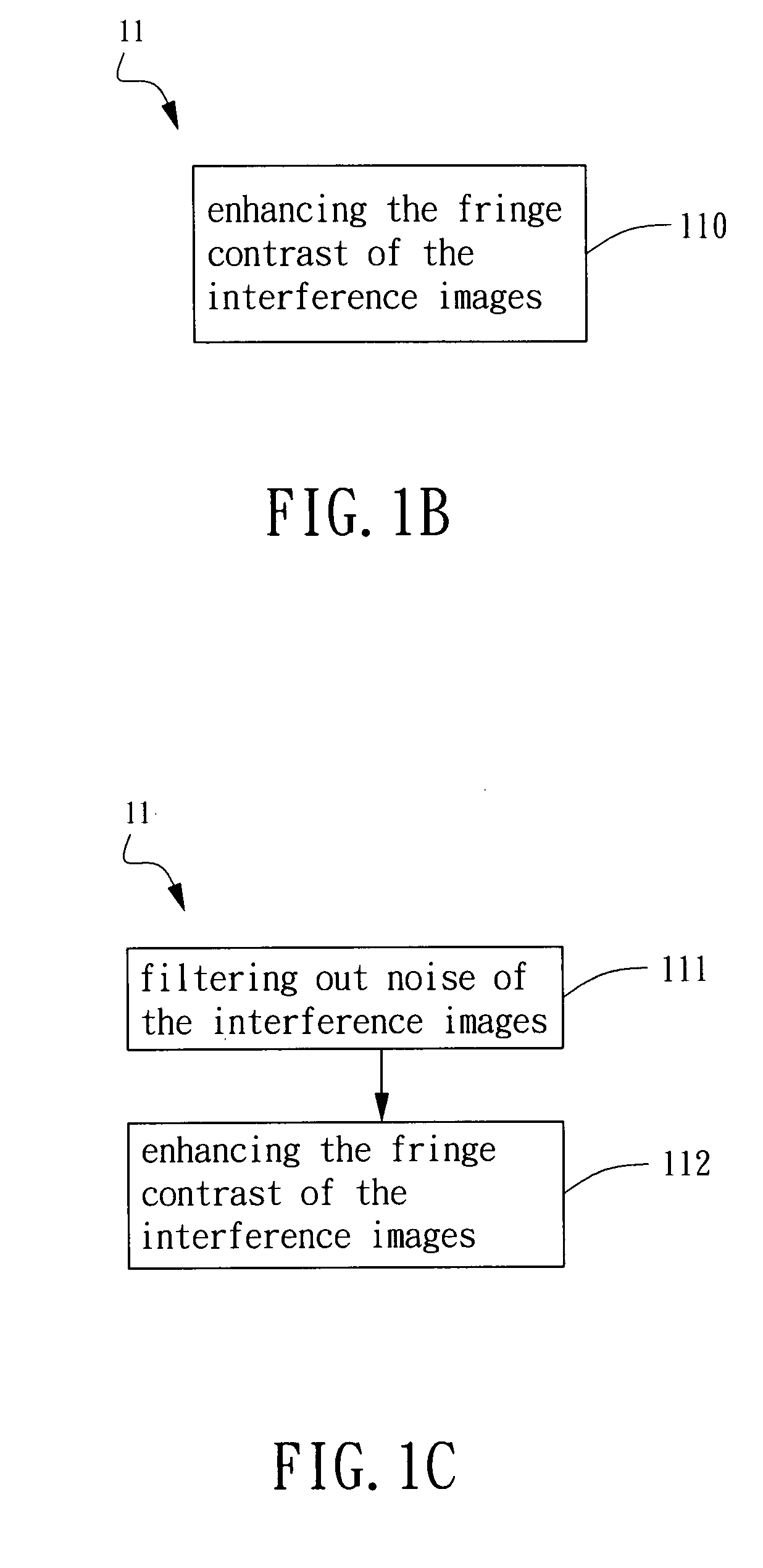

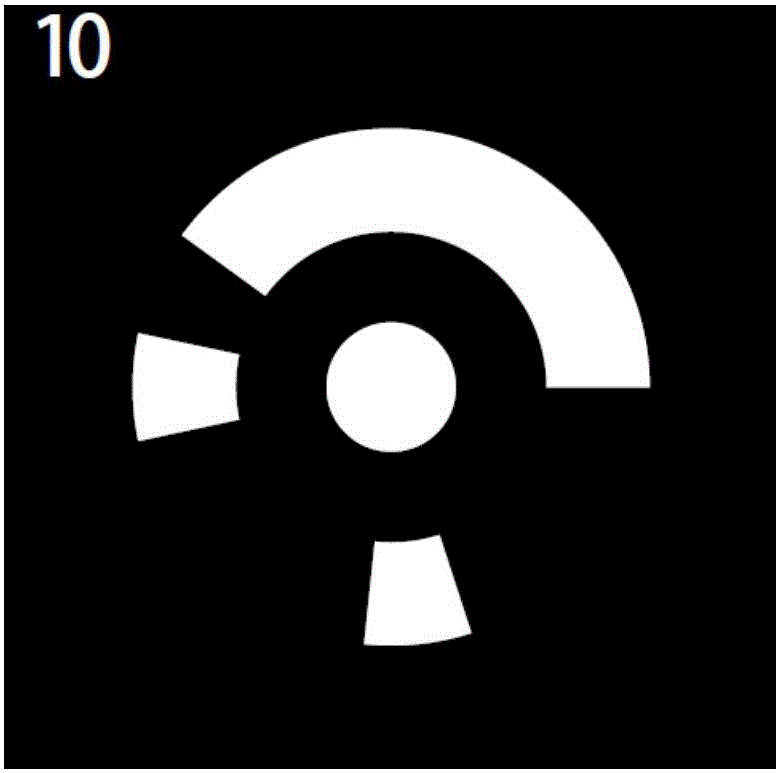

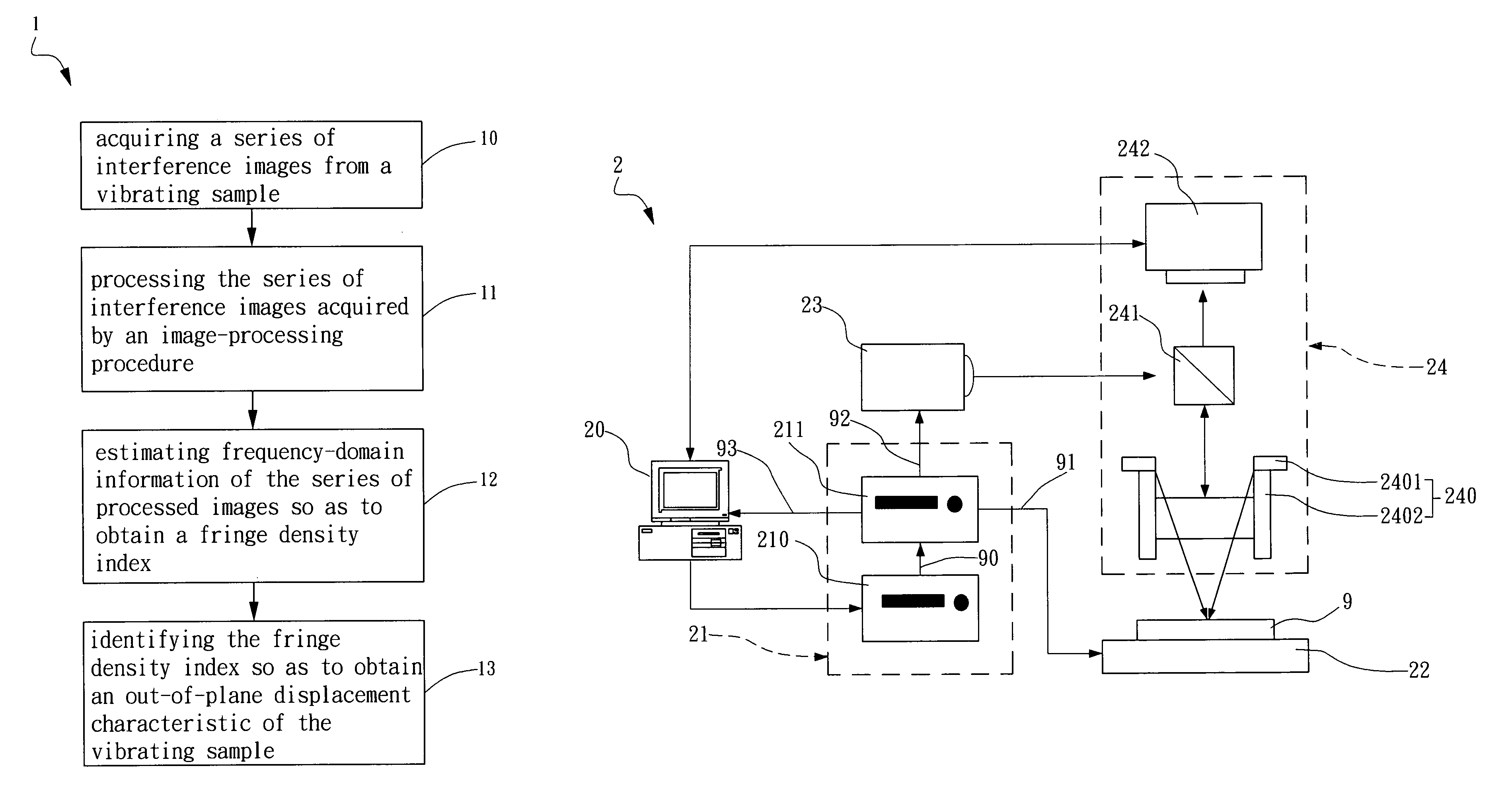

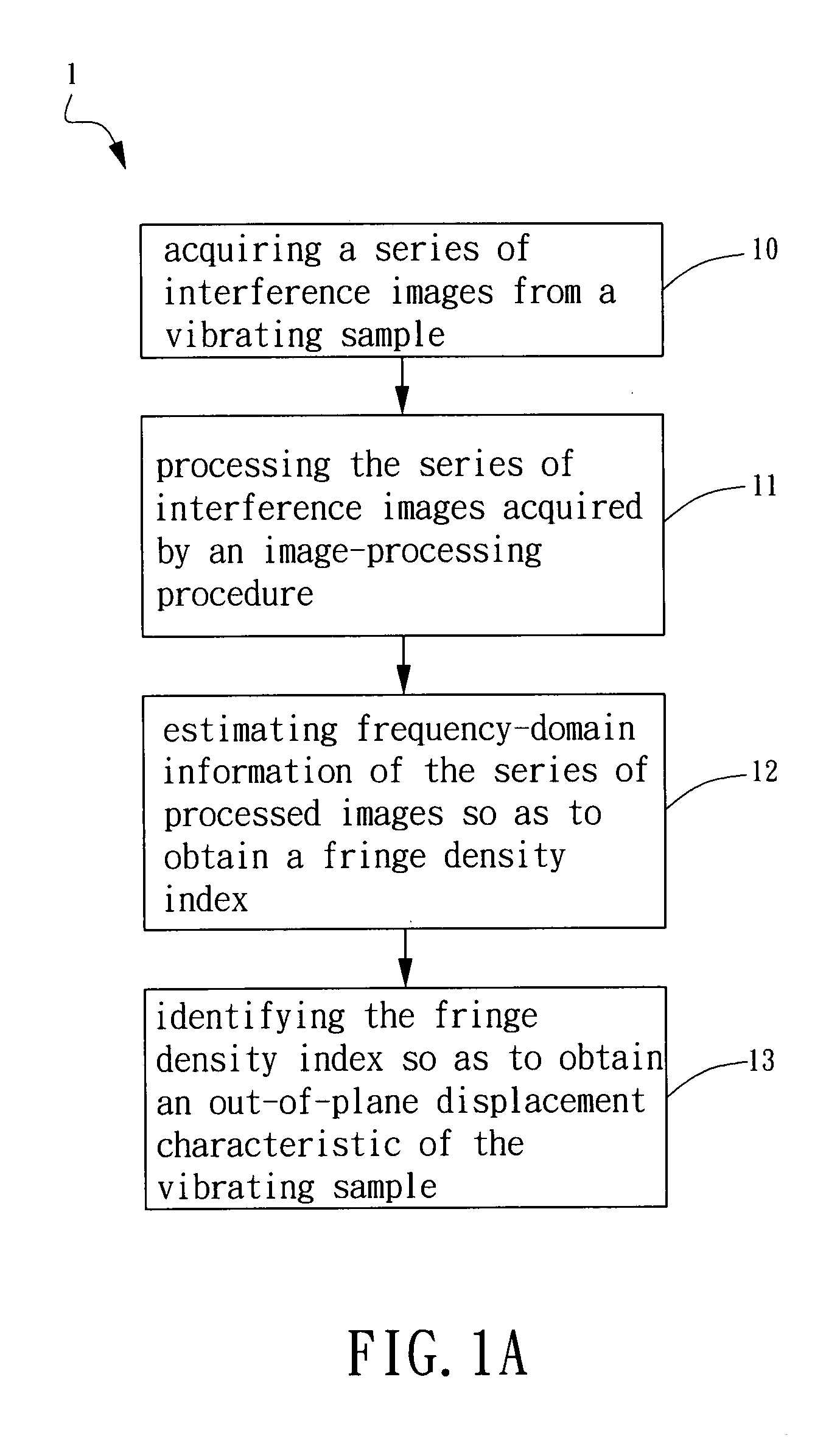

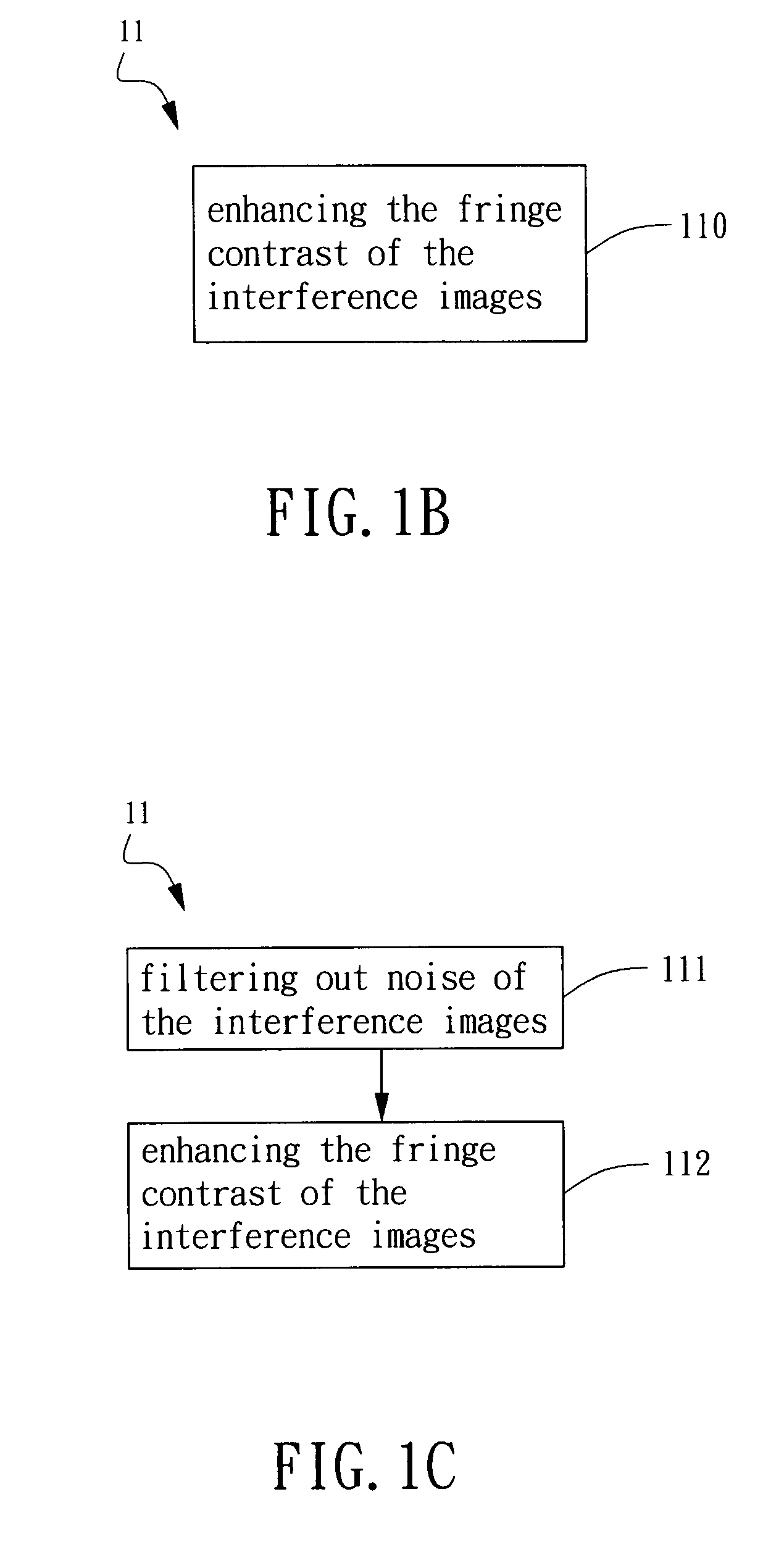

Method and apparatus for resonant frequency identification through out-of-plane displacement detection

A method for out-of-plane displacement detection is disclosed. The out-of-plane displacement is detected by analyzing all the fringe density indexes calculated using the frequency-domain information extracted from a series of interference images of the sample vibrating at different frequencies. The present invention further discloses a method and an apparatus for resonant frequency identification by detecting the peak value of all the fringe indexes calculated at different scanning frequencies. With the identified resonant frequency, the full-field vibratory surface profile of the sample in various resonance modes can be reconstructed.

Owner:IND TECH RES INST +1

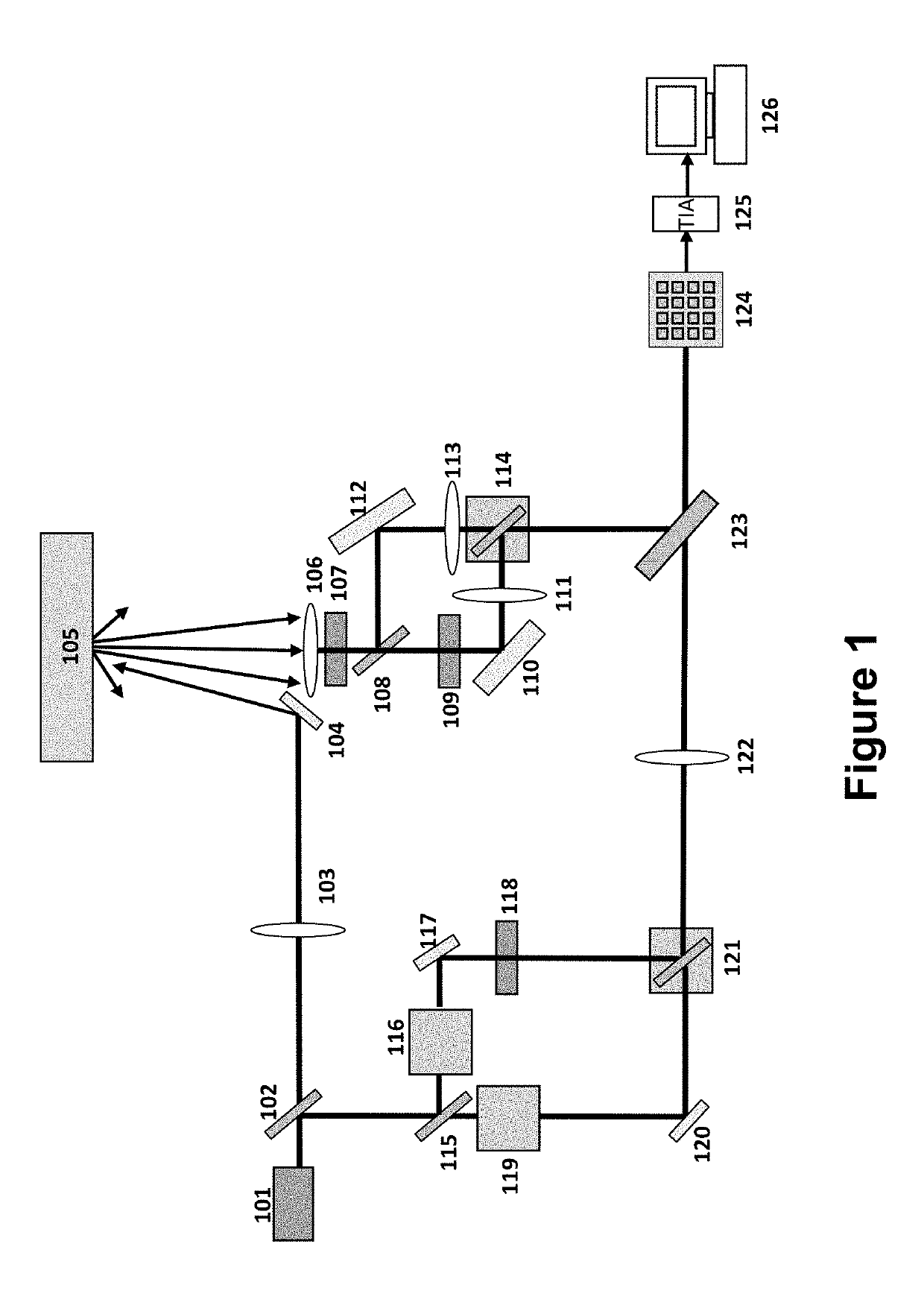

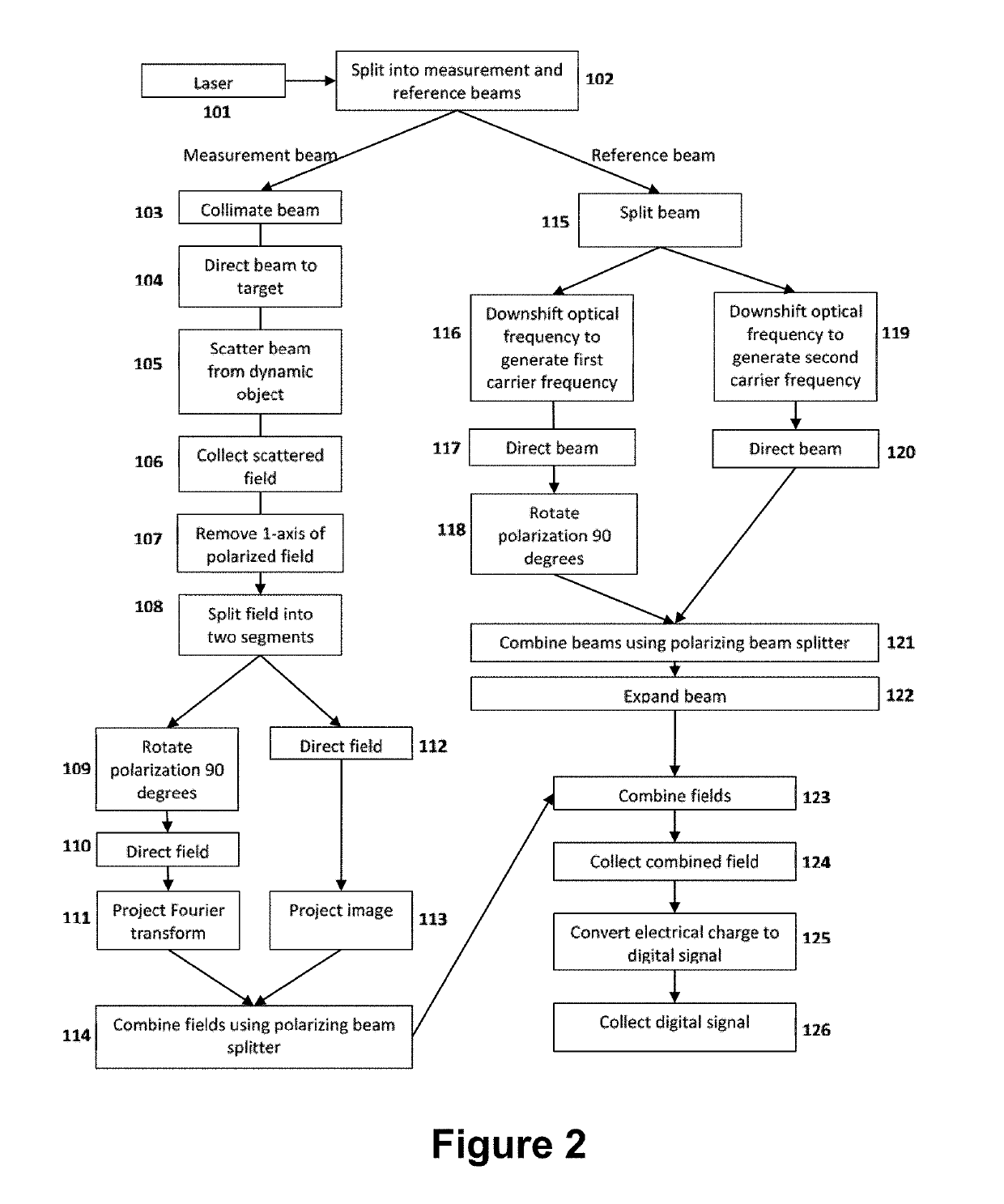

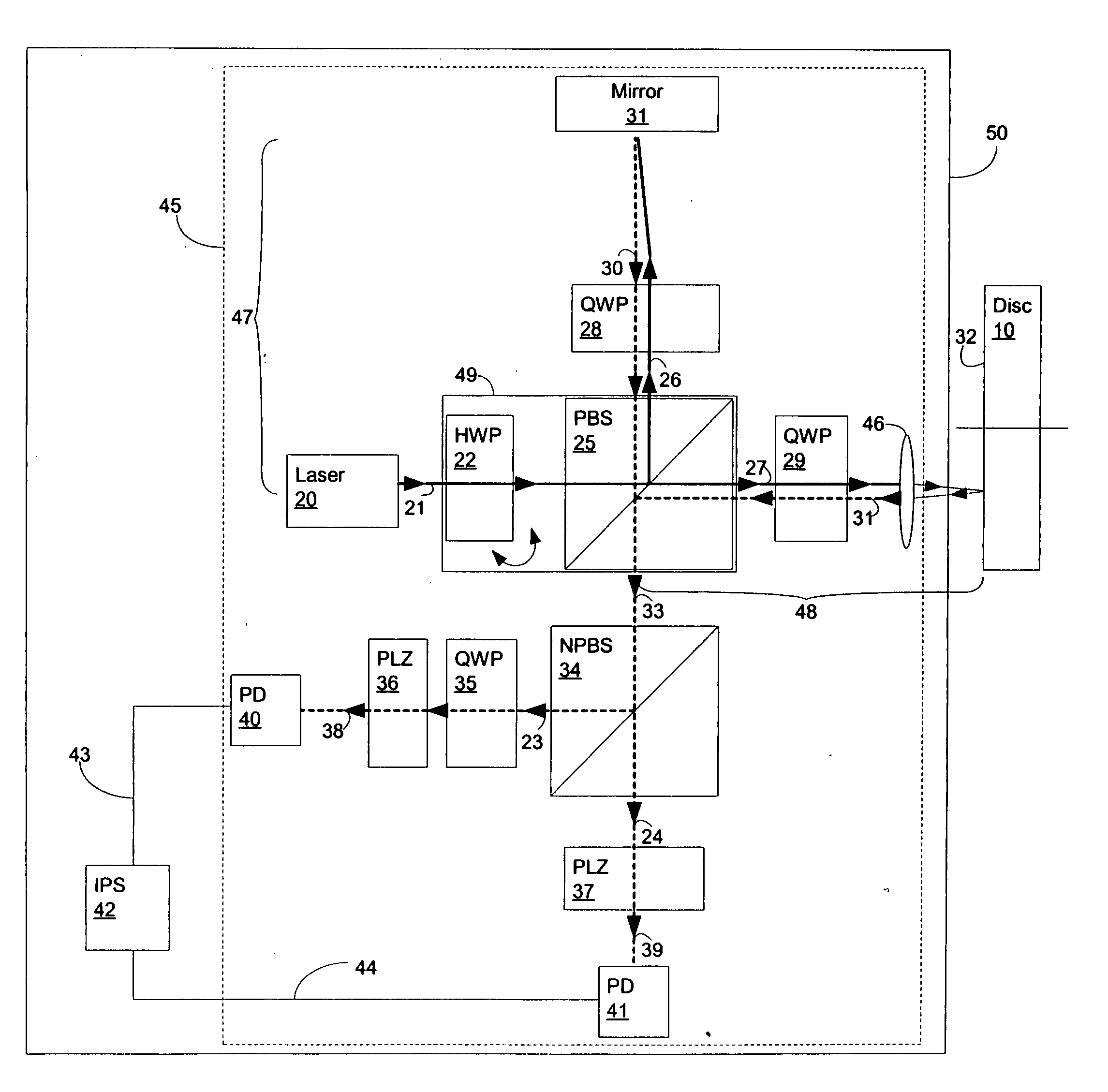

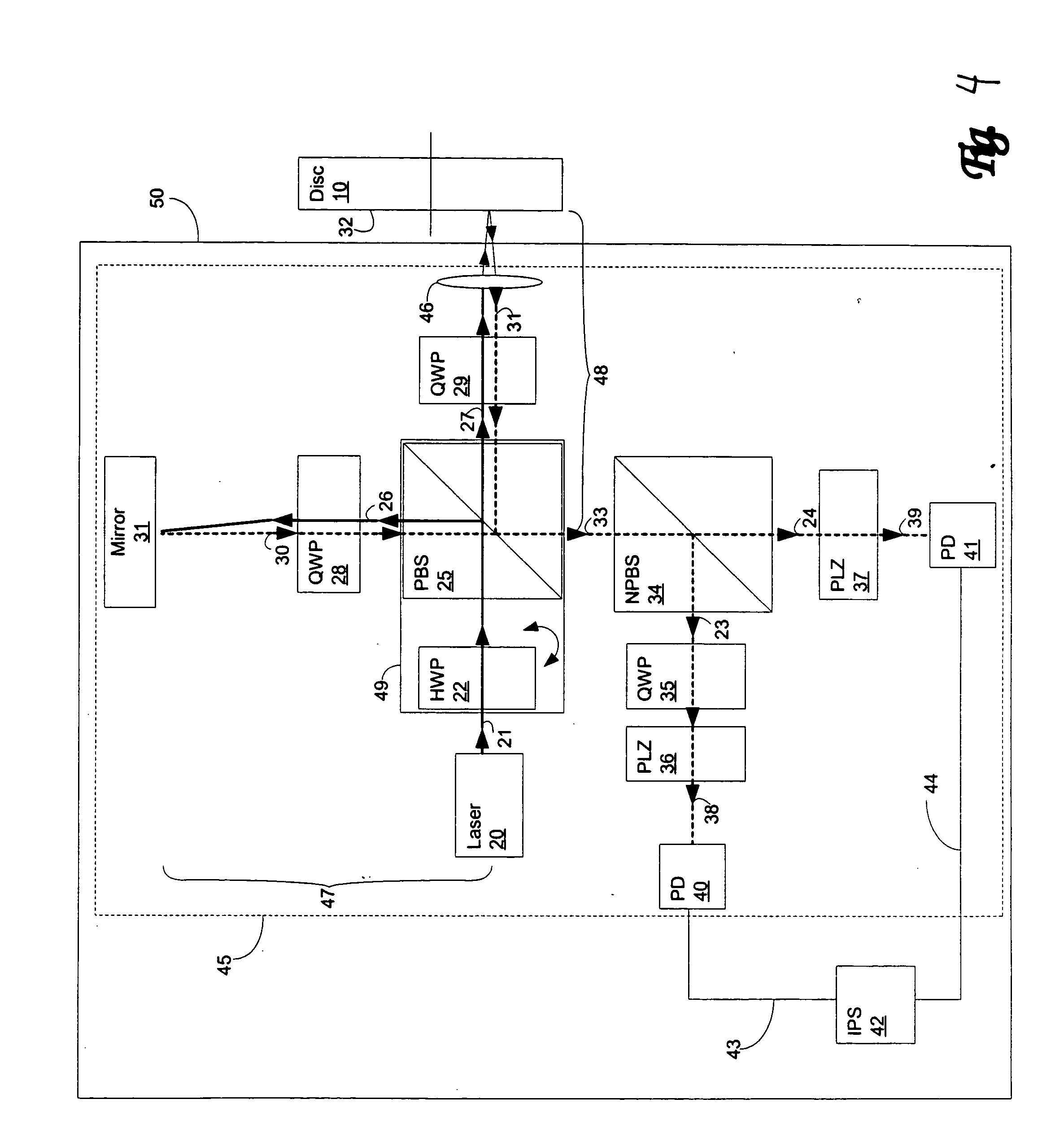

Apparatus for a dynamic multi-axis heterodyne interferometric vibrometer

InactiveUS10386171B1Subsonic/sonic/ultrasonic wave measurementInterferometersIn planeHeterodyne interferometer

A multi-axis heterodyne interferometer is disclosed for observations of five degrees of dynamic freedom using a single illumination source. The sensor utilizes polarization and frequency multiplexing to simultaneously observe and separate the image and Fourier planes following scattering of coherent illumination from a dynamic surface. Multiple carrier frequencies and polarizations separate two segments of a Mach-Zehnder interferometer. Segments of this interferometer have unique optical configurations to generate the image and Fourier planes simultaneously on a focal plane array. The measured irradiance contains information pertaining to an object's in-plane translation, out-of-plane rotation, and out-of-plane displacement.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

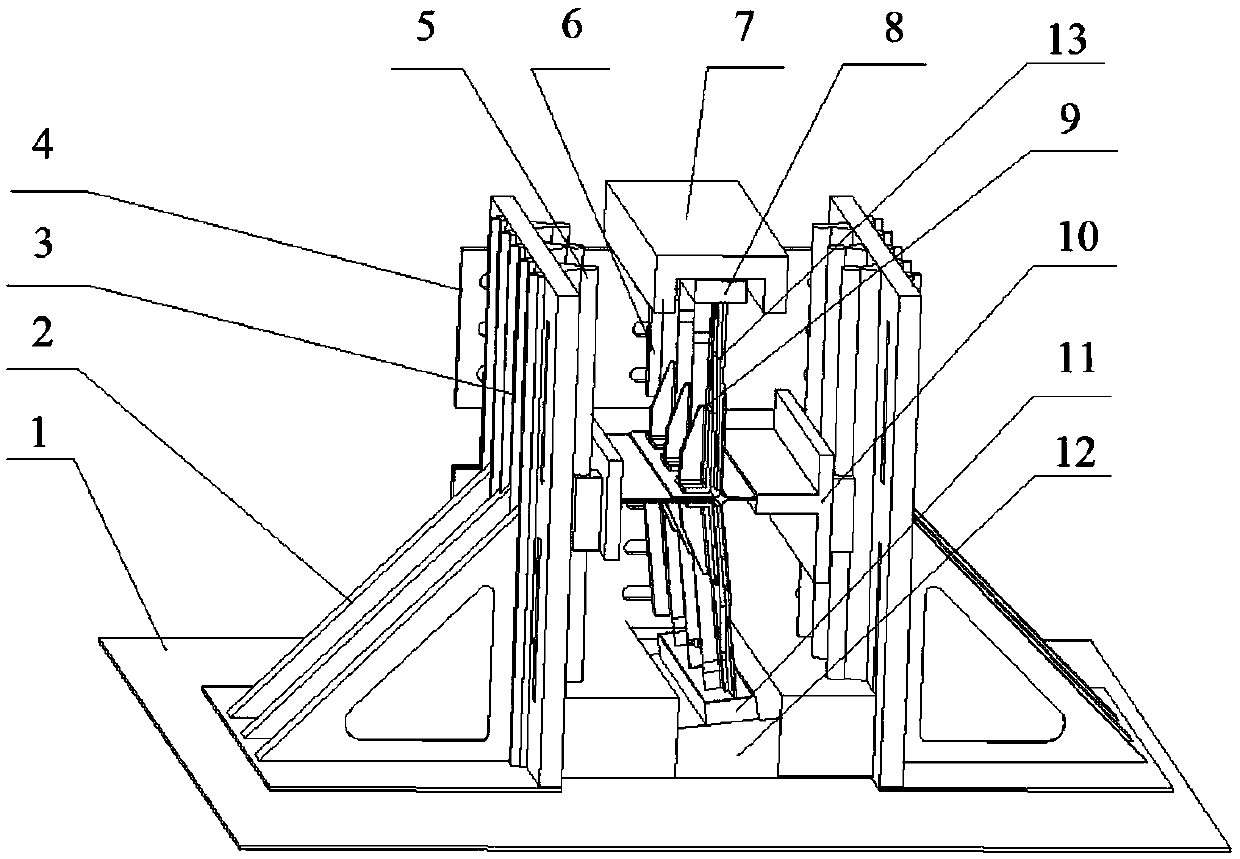

Process for manufacturing three-layer continuous surface type MEMS deformable mirror based on bonding process

InactiveCN101604069ASolve the disadvantages of difficult processingEliminates the effects of static pull-inOptical elementsBonding processOut of plane displacement

The invention discloses a process for manufacturing a three-layer continuous surface type MEMS deformable mirror based on a bonding process, which mainly comprises the following steps: performing dry-etching of a releasing hole on the upper surface of an SOI wafer, partially releasing a middle oxidation layer of the SOI wafer, performing wet-etching on the lower surface of the SOI wafer, depositing a metal on another substrate (silicon wafer or glass) as an electrode structure, and finally bonding the substrate and the SOI wafer. The process is characterized in that a bulk silicon micromachining process and a surface micromachining process are combined, and an upper two-layer structure obtained by adopting the bulk silicon process and a lower electrode structural layer obtained by adopting surface micromachining are bonded to form a three-layer micromechanical structure. The process for manufacturing the three-layer continuous surface type MEMS deformable mirror based on the bonding process has a relatively easy manufacturing process, overcomes the defect that the prior continuous surface micromechanical deformable mirror is difficult to process through three-layer surface micromachining, can eliminate the defect of short circuit due to electrostatic draw-in by adding a silicon nitride insulating layer, and can be widely applicable in the fields of optical communication and adaptive optics; and the machined deformable mirror can obtain large out-of-plane displacement.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

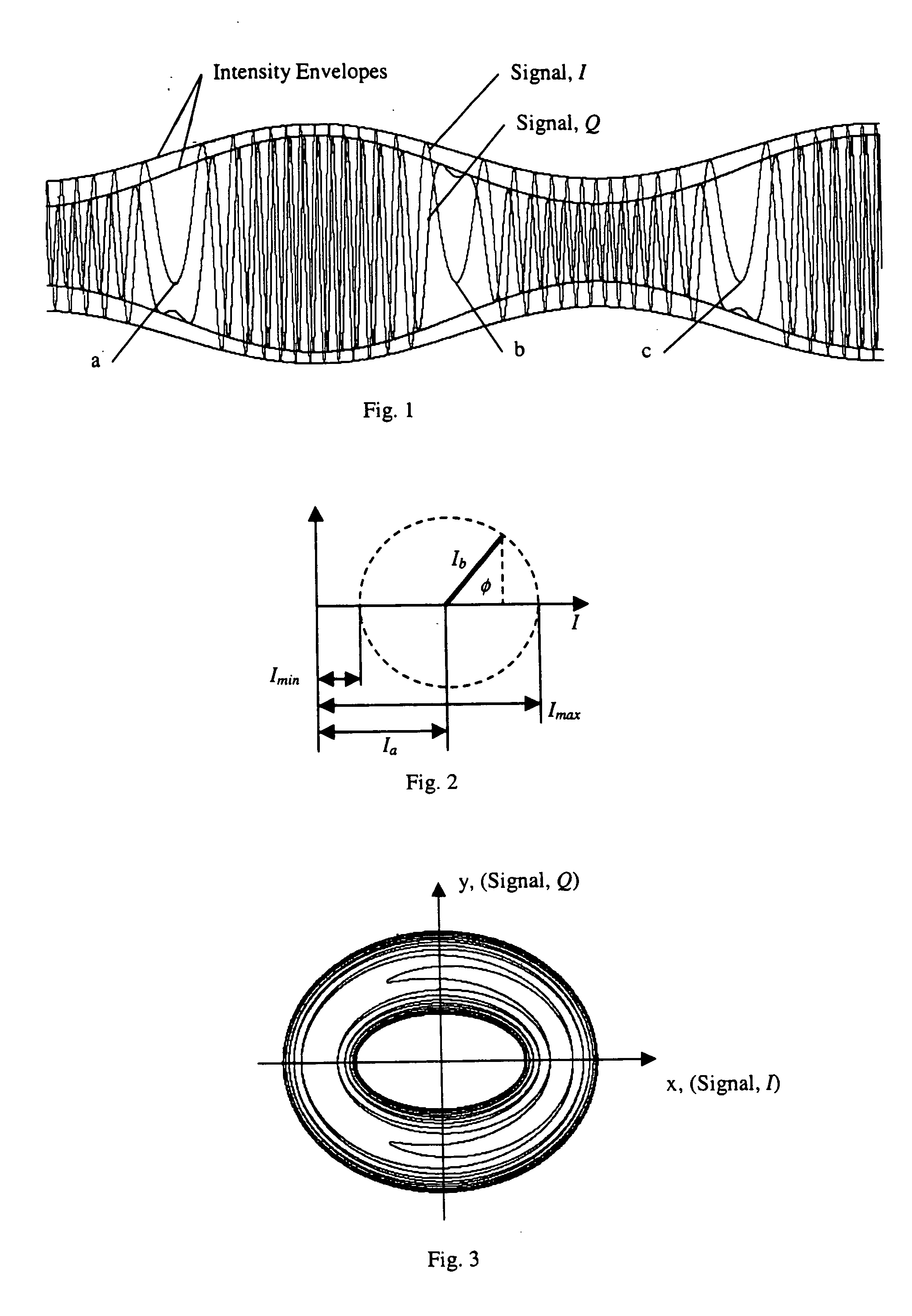

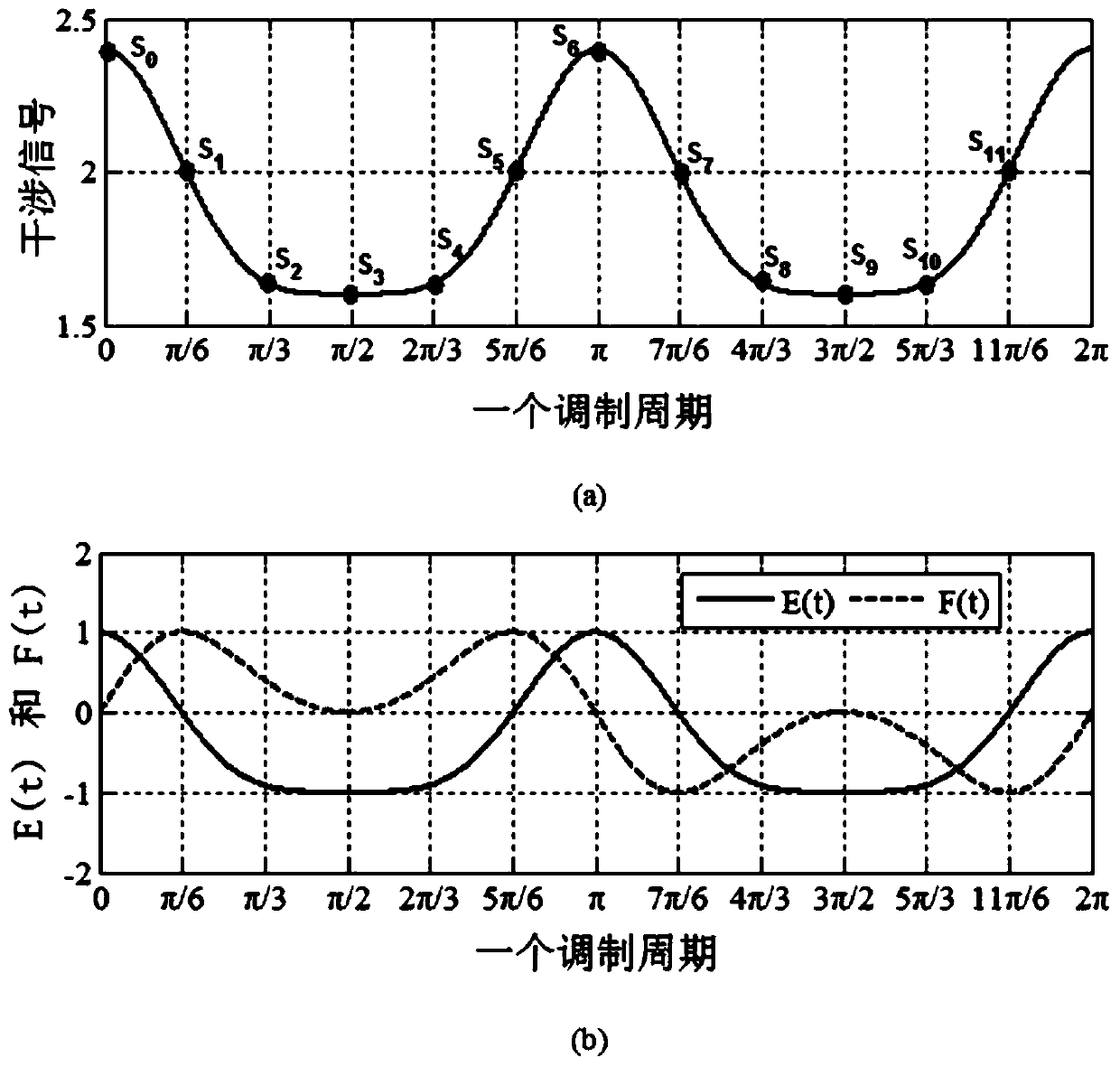

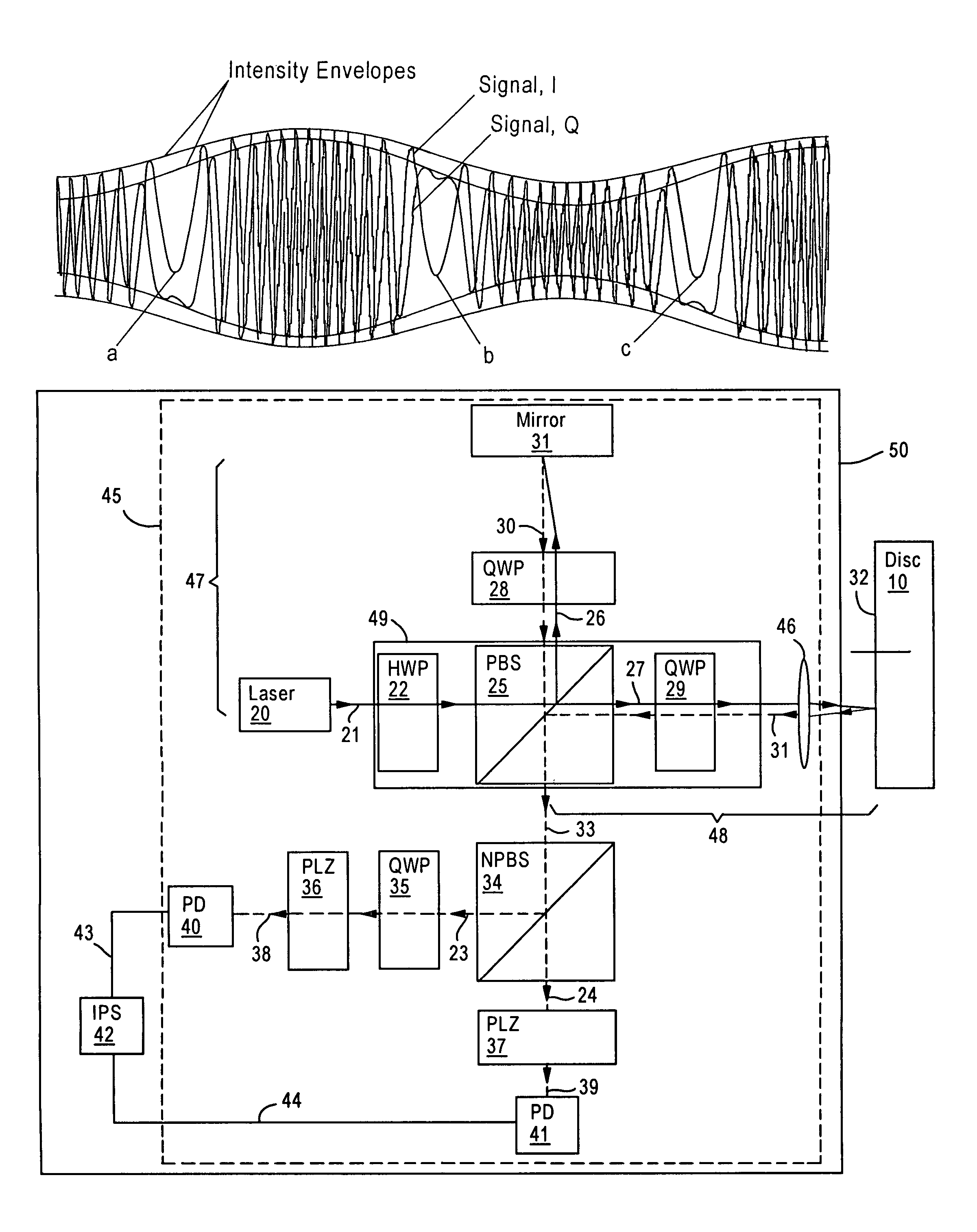

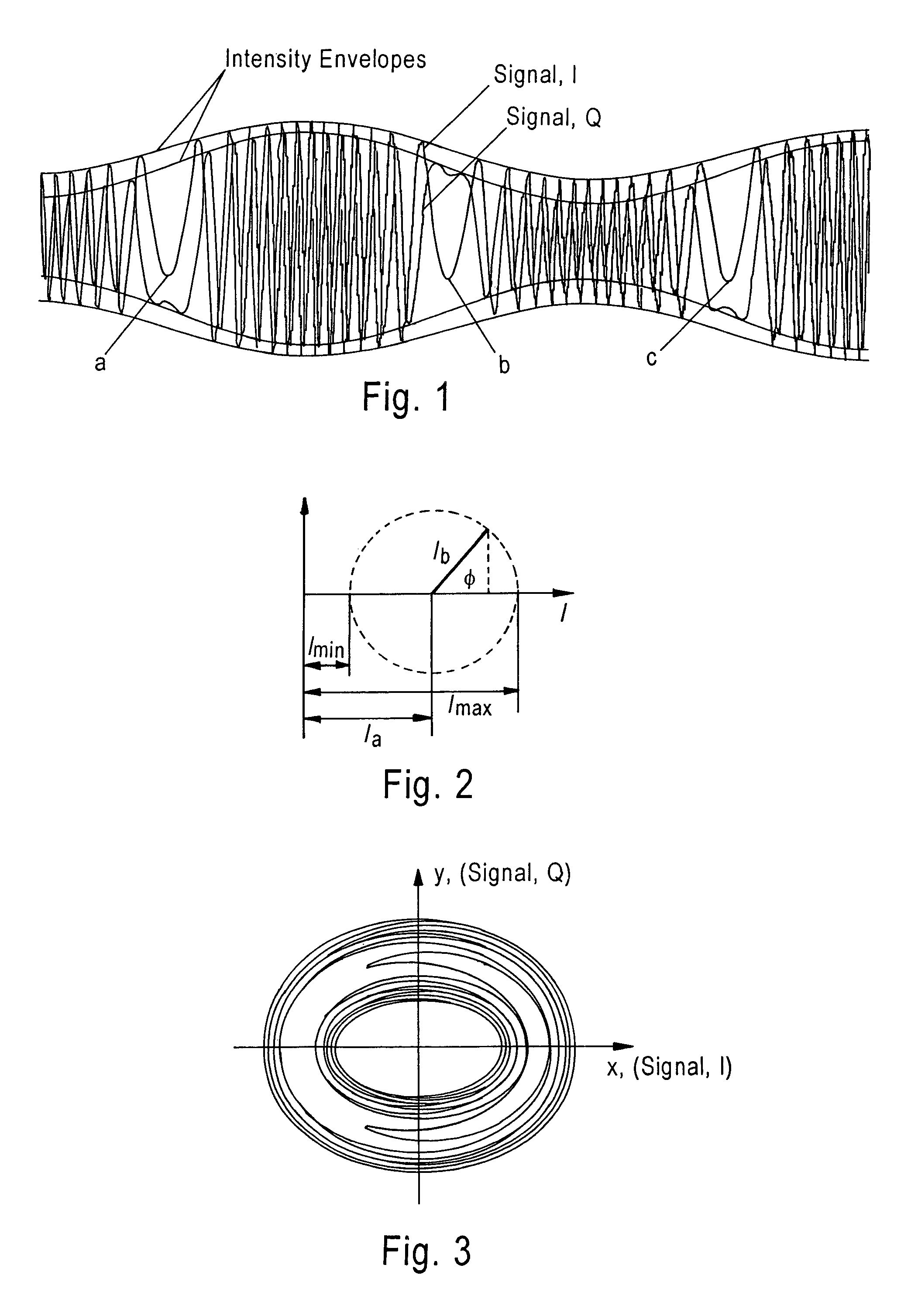

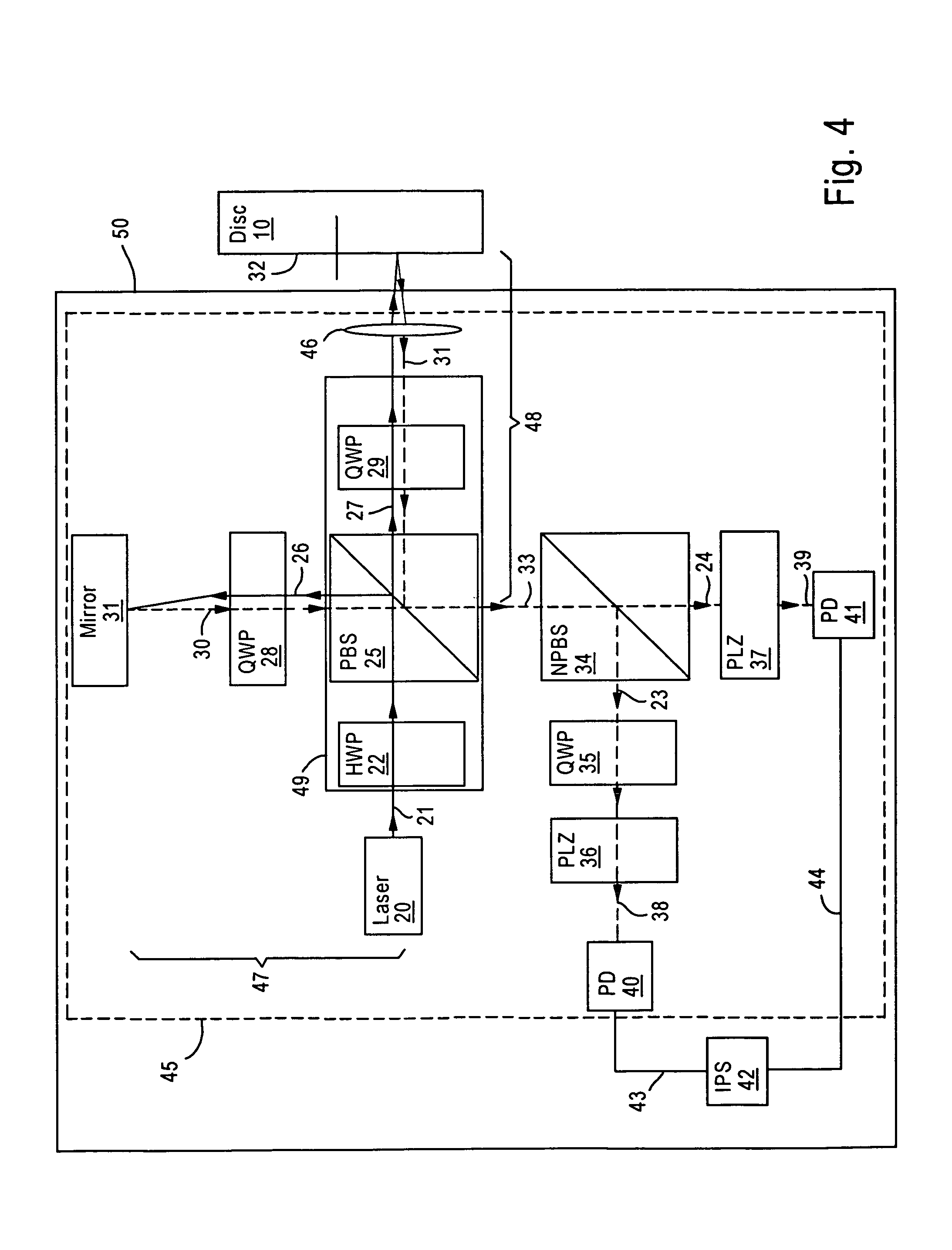

Quadrature phase shift interferometer (QPSI) decoder and method of decoding

InactiveUS20050259769A1Accurate intensity envelopeEnsure correct executionError preventionInterferometersPhase shiftedWave form

An arrangement and method for reliably finding the wave form extrema of interference signals produced by a quadrature phase shift interferometer (QPSI) takes advantage of the quadrature property of I and Q signals. The zero-crossing points in the I and Q signals are determined. Peak detection is performed for peaks and valleys in the Q signal in close proximity to the zero-crossing points in the I signal, and for peaks and valleys in the I signal in close proximity to the zero-crossing points in the Q signal. These represent the maximum and minimum points of the I and Q signals. From these points, intensity envelopes are created and QPSI phase wrapping is performed to determine the phase angle and ultimately, out-of-plane displacement may be determined.

Owner:SEAGATE TECH LLC

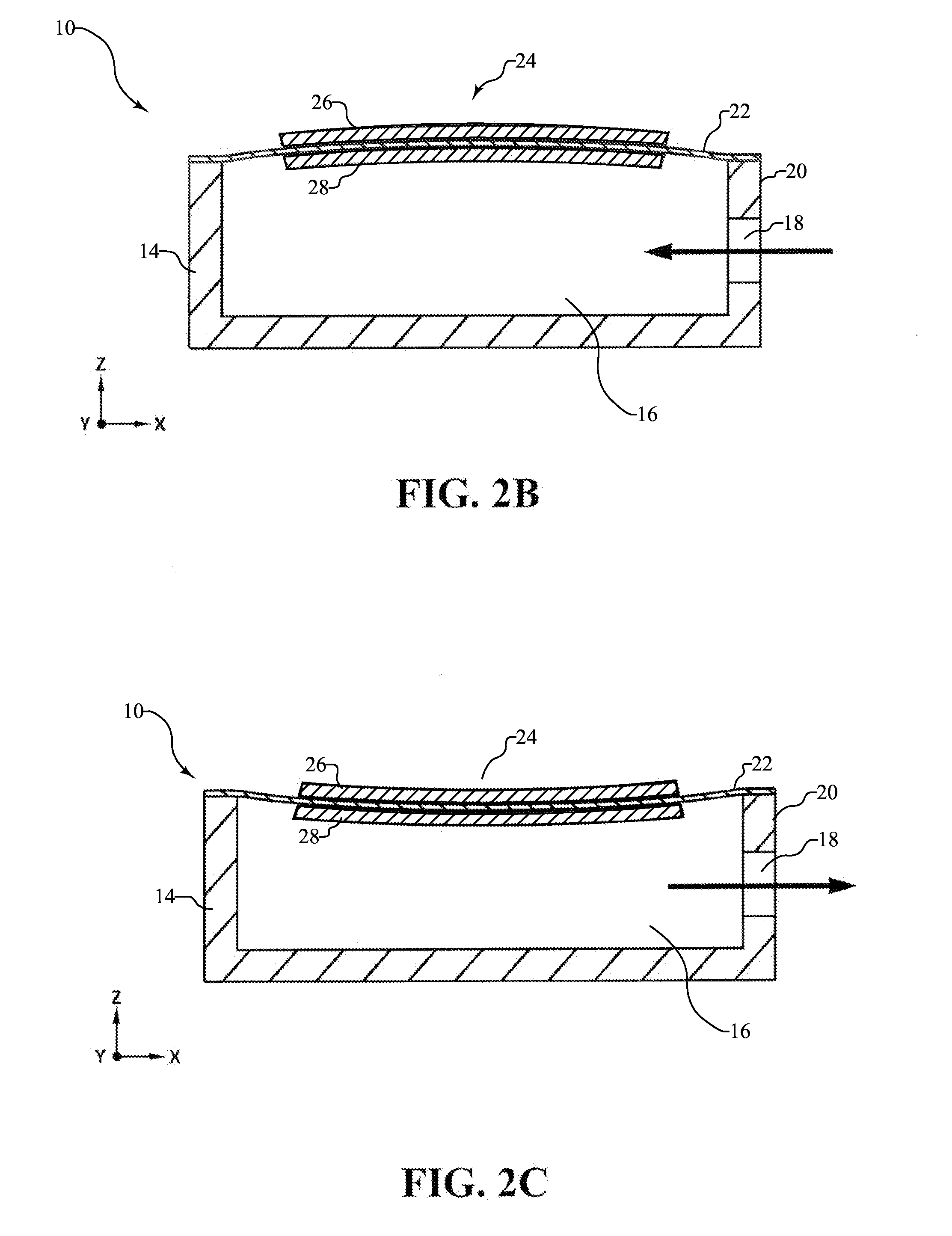

Orthotropic Bimorph for Improved Performance Synthetic Jet

ActiveUS20160013395A1Magnetostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesIn planeCoupling

Piezoelectric actuators for synthetic jets and other devices are disclosed having orthotropic piezoelectric bimorphs with increased out-of-plane displacements for greater responsiveness to applied electric fields. In some embodiments, the piezoelectric actuators may include interdigitated electrodes applied to a surface of a piezoelectric plate to produce greater in-plane strains in the plate and greater out-of-plane displacements of a flexible diaphragm of the synthetic jet. In other embodiments, the actuator includes an orthotropic piezoceramic plate having a greater d coupling coefficient in one in-plane direction and in the other in-plane direction to cause desired diaphragm out-of-plane displacements when an electric field is applied by electrodes.

Owner:THE BOEING CO

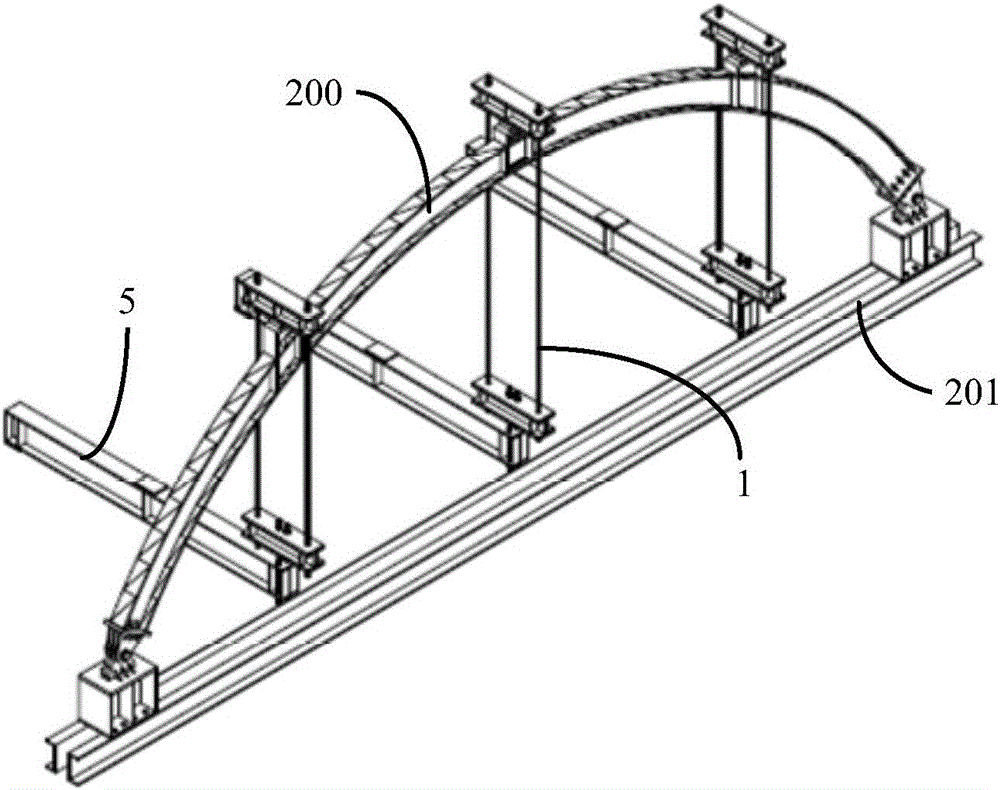

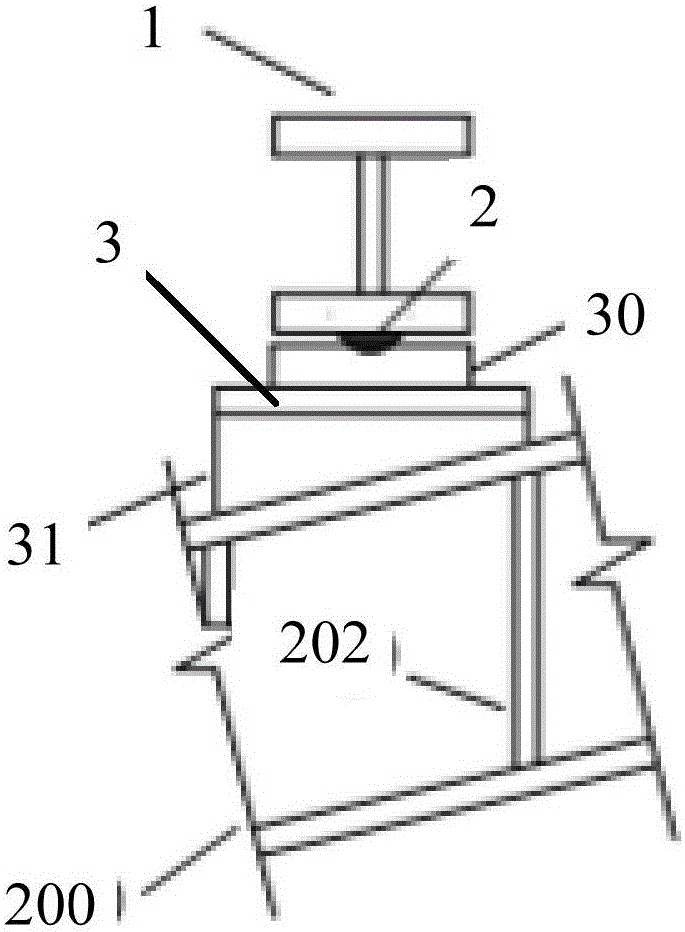

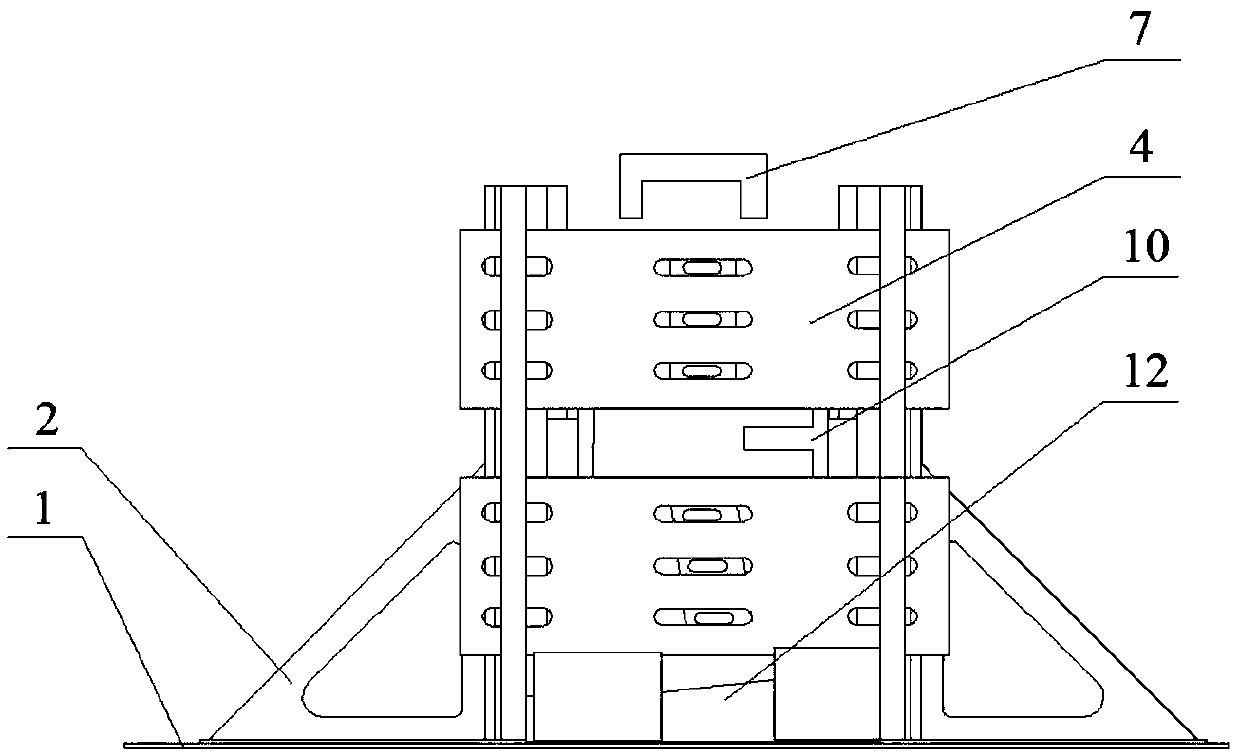

Device for out-of-plane stability bearing capacity test of arched steel structure

ActiveCN105716894AReflect out-of-plane instability characteristicsTest accurateStructural/machines measurementIn planeInstability

The invention provides a device for out-of-plane stability bearing capacity testing of an arched steel structure. The device comprises a loading frame, a loading hemisphere, a U-shaped bidirectional hinge, a reinforcing beam, a ground beam and a jack. One end of the loading hemisphere is connected to the arched steel structure, the other end of the loading hemisphere is connected to the loading frame, one end of the U-shaped bidirectional hinge is connected with the lower end of the loading frame, the other end of the U-shaped bidirectional hinge is connected with one end of the reinforcing beam, the jack acts on the middle position of the reinforcing beam, and the other end of the reinforcing beam opposite to the U-shaped bidirectional hinge forms a hinged support together with the ground. The two ends of the arched steel structure are connected with the ground beam. The device not only has accuracy and reliability in testing, but also enables the tested arched steel structure to be freely subject to out-of-plane displacement, torsional deformation, in-plane displacement and in-plane rotation, and the out-of-plane instability characteristics of the arched steel structure are reflected genuinely.

Owner:CHINA CONSTR STEEL STRUCTURE CORP LTD +1

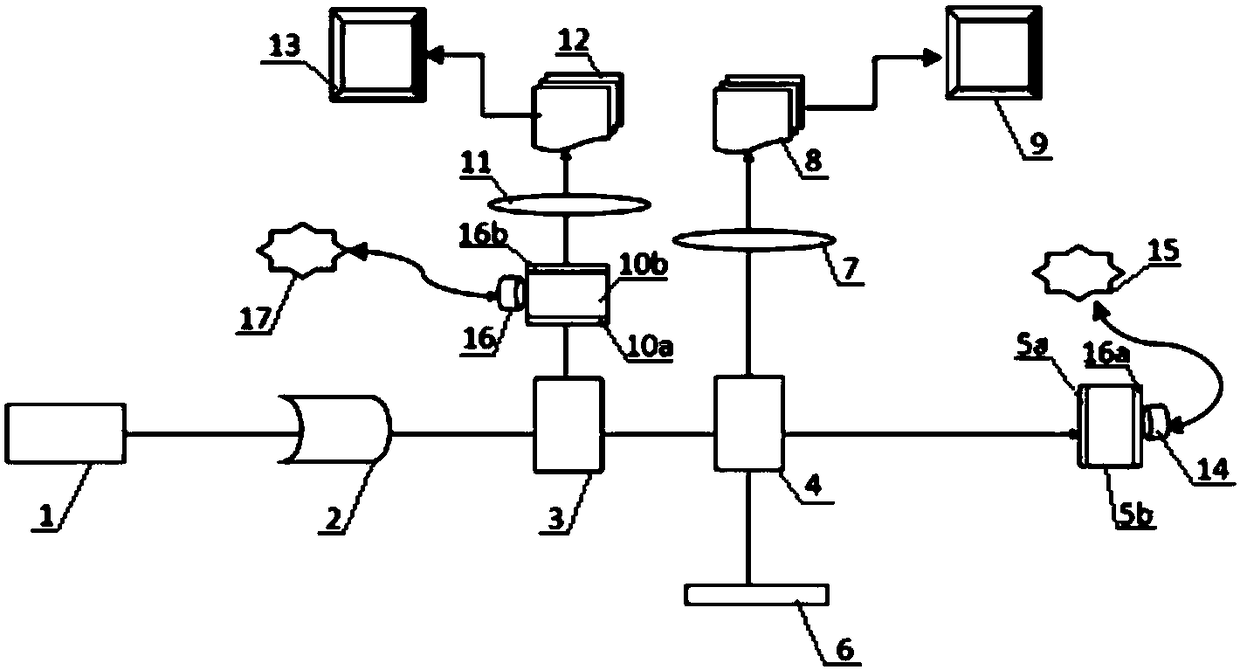

Laser speckle device for measuring out-of-plane and in-plane displacement of objects and measurement method

The invention discloses a laser speckle device for measuring the out-of-plane and in-plane displacement of objects and a measurement method. According to the device of the invention, a laser is adopted as a light source; a collimation beam splitter, beam splitters, focusing mirrors, a total-reflection mirror and other optical devices are adopted to form an in-plane displacement and out-of-plane displacement integrated measurement optical system; by means of temperature control devices, display devices and heating sheets, the environment temperature of a measured object can be automatically changed, at the same time, the in-plane displacement and out-of-plane displacement of the same object or different objects can be tested; and a novel in-plane displacement sample holder and an out-of-plane displacement sample holder are adopted, so that the range of test samples can be further extended. The laser speckle device and measurement method of the invention have the advantages of high intelligent degree, high precision, real-time monitoring, wide application range, high flexibility, great convenience and high comprehensiveness, and are suitable for being widely applied to many fields such as industry, agriculture, forestry and biomedicine.

Owner:SHENYANG NORMAL UNIV

2 dimensional digital image related compensation method based on transformation of coordinates and 2 dimensional optical digital image related extensometer

The invention discloses a 2 dimensional digital image related compensation method based on transformation of coordinates and a 2 dimensional optical digital image related extensometer, and relates to the field of non-contact type optical measuring. According to the invention, in order to address the in-plane deformation of a panel test specimen in 2 dimensional digital image related measuring, due to the error caused by out-of-plane displacement, the method and related compensation method and the related extensometer can be applied to accurate measuring of the in-plane deformation of the panel test specimen. According to the invention, the method is based on the transformation of coordinates of a compensation plate, and the acquisition of a single frame image can real-time acquire the out-of-plate displacement and rotation information of the compensation plate, thus removing the effects on the result of measuring by the out-of-plate displacement and rotation information. The method overcomes the problems of excessively large errors or smaller requirement angle of traditional measuring methods, and can be applied to real-time measuring of in-plane deformation of a 2 dimensional panel test specimen.

Owner:UNIV OF SCI & TECH OF CHINA

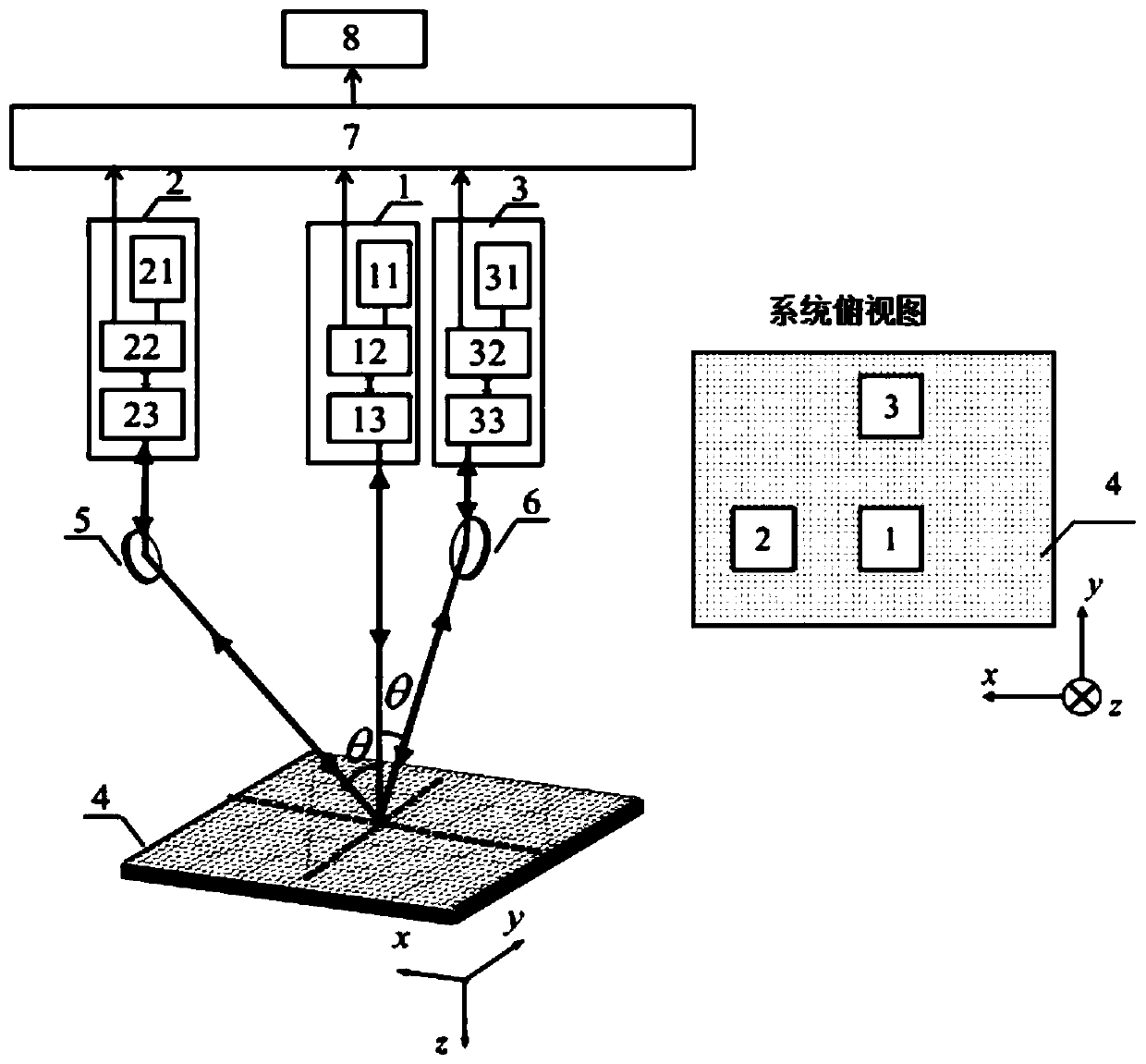

Three-dimensional displacement measurement system and method based on laser self-mixing grating interference

The invention discloses a three-dimensional displacement measurement system and method based on laser self-mixing grating interference, and the system comprises a semiconductor laser sensor head, a plane reflector, a reflective two-dimensional plane grating, a data acquisition card and a computer, wherein the laser emitted from the semiconductor laser sensor head is incident on the reflective two-dimensional grating, the corresponding diffracted light is fed back to the semiconductor laser sensor head along the original optical path to generate self-mixing interference, the self-mixing interference signal is converted into an electrical signal by the photodetector built in the semiconductor laser and is output to the data acquisition card to obtain three-dimensional displacement of the target to be measured after computer processing. The invention solves the problem that the range of a traditional grating interferometer is limited when performing out-of-plane displacement measurement,is more compact than the traditional grating interferometer, maintains the advantages of self-collimation of the laser self-mixing interferometer, and can realize three-dimensional real-time displacement measurement system and method with a simple structure, wide rang and high resolution.

Owner:NANJING NORMAL UNIVERSITY

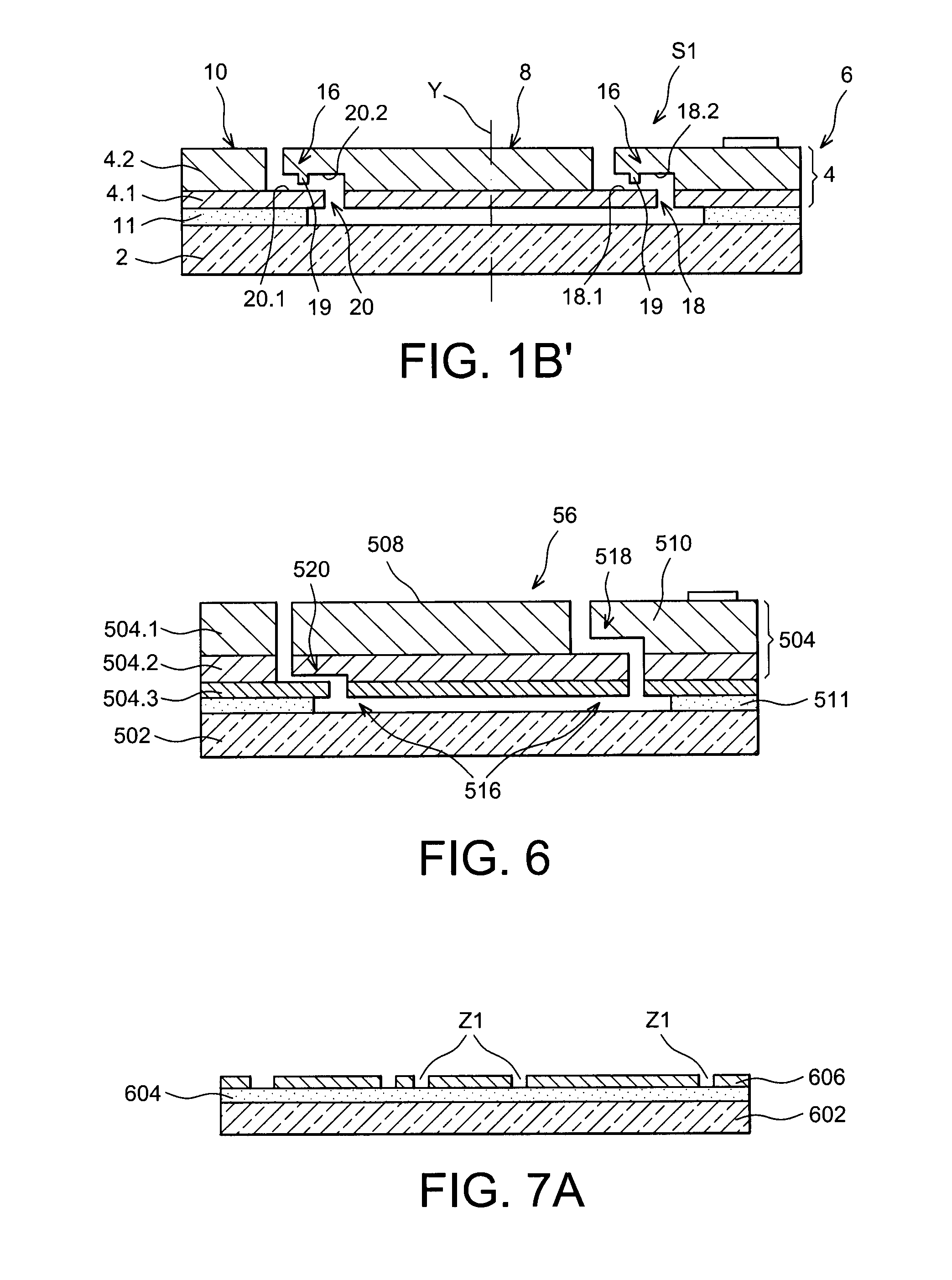

Micromechanical structure comprising a mobile part having stops for out-of plane displacements of the structure and its production process

ActiveUS9061895B2Simple processReduce riskMicrophonesElectrical transducersStops deviceOut of plane displacement

A process for producing a micromechanical structure including a substrate and a stack of at least two layers arranged on the substrate is provided. A mobile part is formed in the stack and a fixed part relative to the substrate is formed in the stack, and an opposite surface is formed between the fixed part and the mobile part, to present a stop device to limit displacement of the mobile part in a direction substantially perpendicular to the stack. The process uses at least one sacrificial layer between the substrate and the stack made of material suitable to be etched selectively relative to the materials of the stack.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

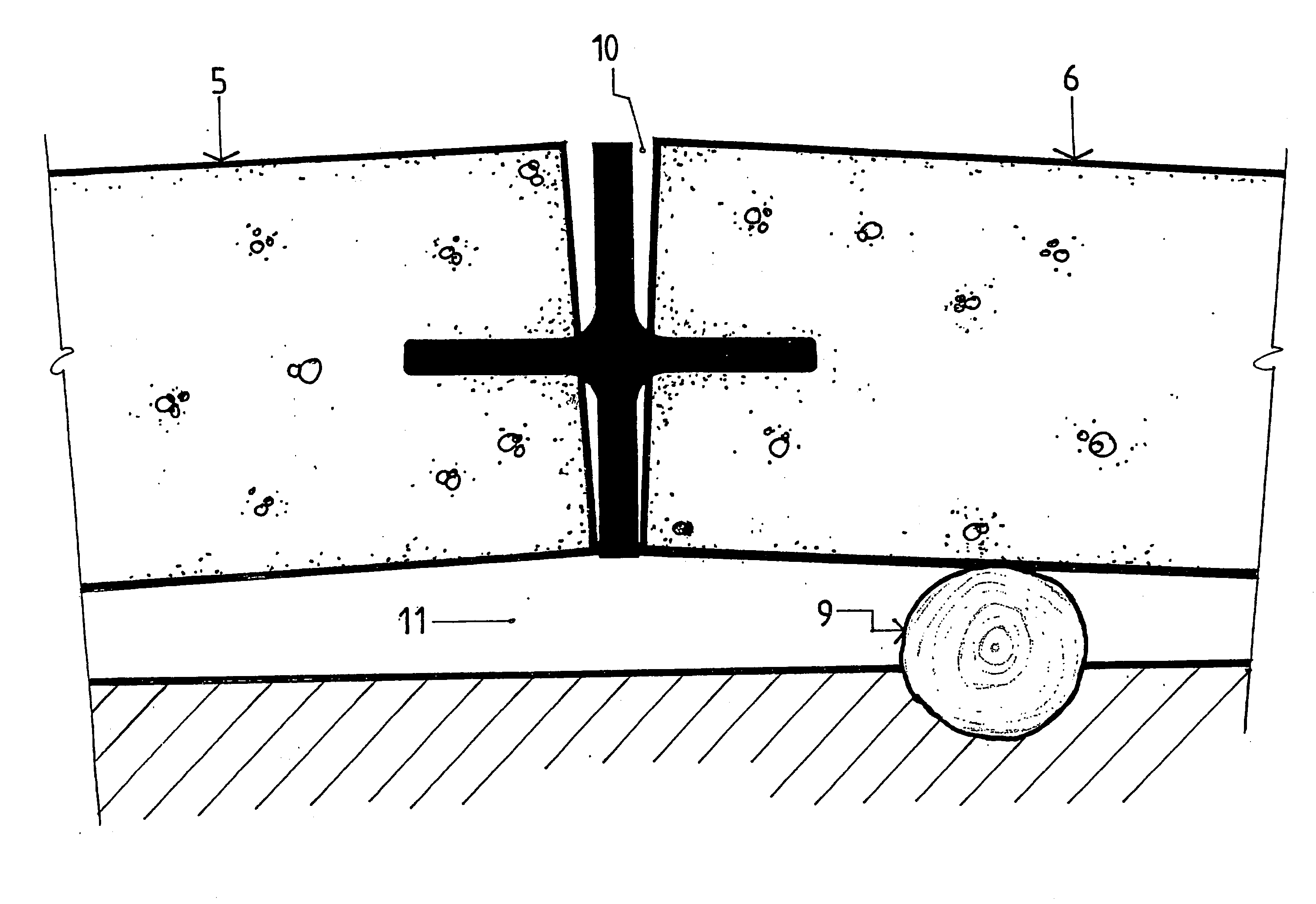

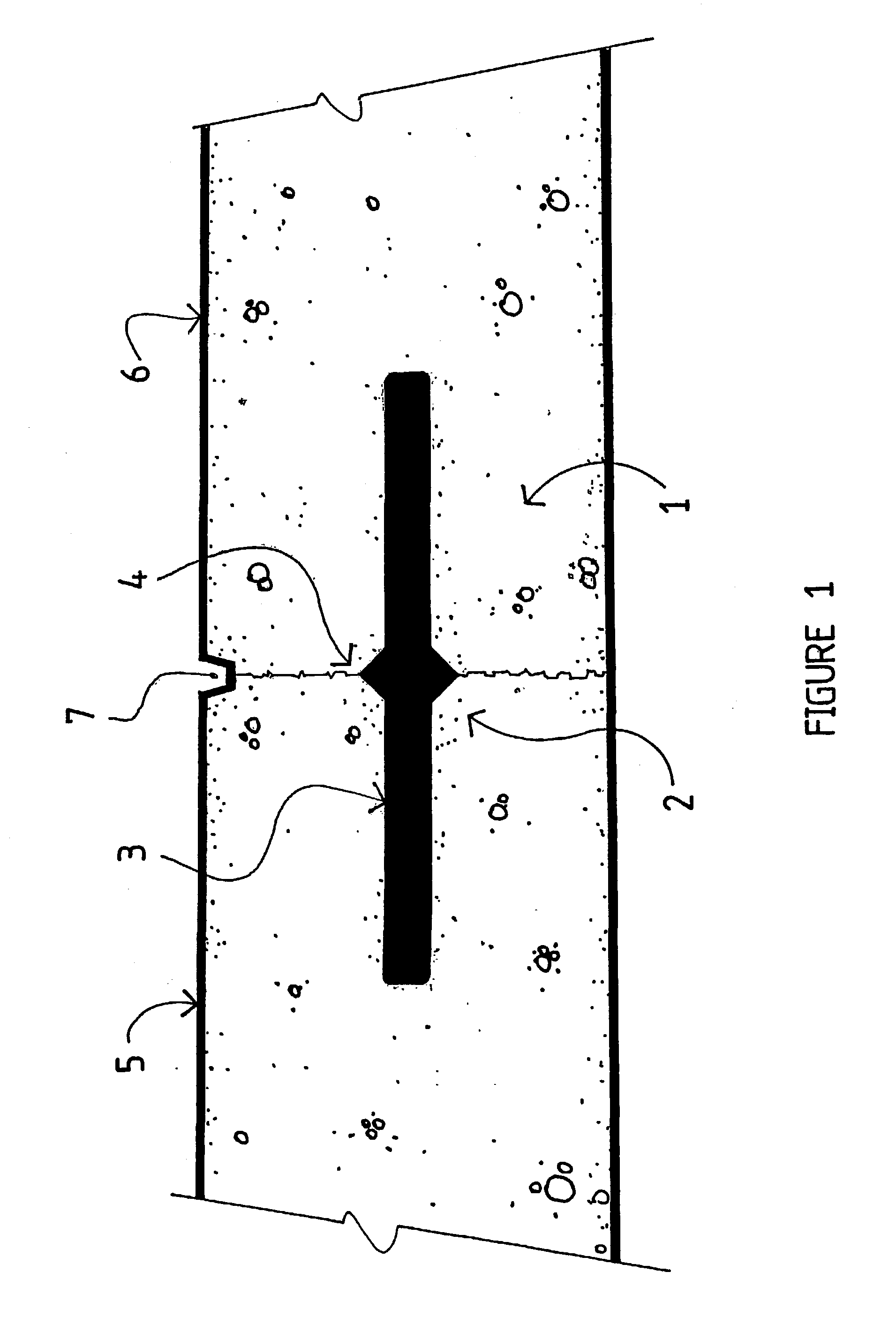

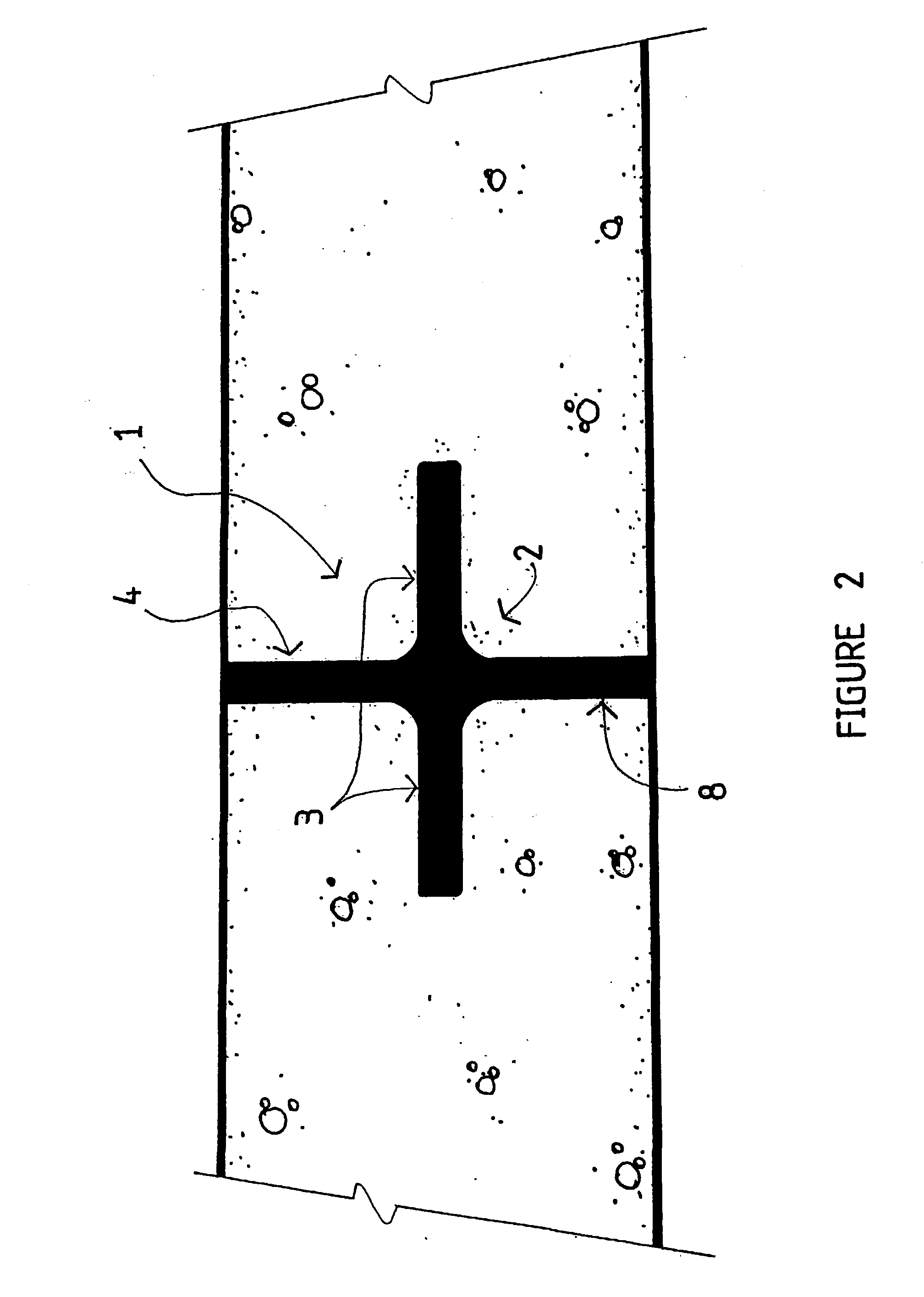

Articulated concrete joint member

InactiveUS20030190190A1Crack controlControl crackingPaving detailsJoint componentOut of plane displacement

An articulated concrete joint member (1) including a resilient core (2), the core (2) having connections means (3) attached thereto, the connection means (3) adapted to link two co-planar concrete slabs (5, 6) along an adjacent peripheral edge of each slab, wherein on application of an out-of-plane displacement to one of the co-planar concrete slabs (5, 6) the displacement is transmitted to the other slab through pivoting about the articulated joint member (1). In one embodiment, the articulated concrete joint member (1), which further includes crack propagation means (4), is fully immersed in the concrete slab so that the slab is subjected to extraneous loads, the slab cracks along predetermined lines of weakness (7).

Owner:GALLAGHER STEPHEN JAMES

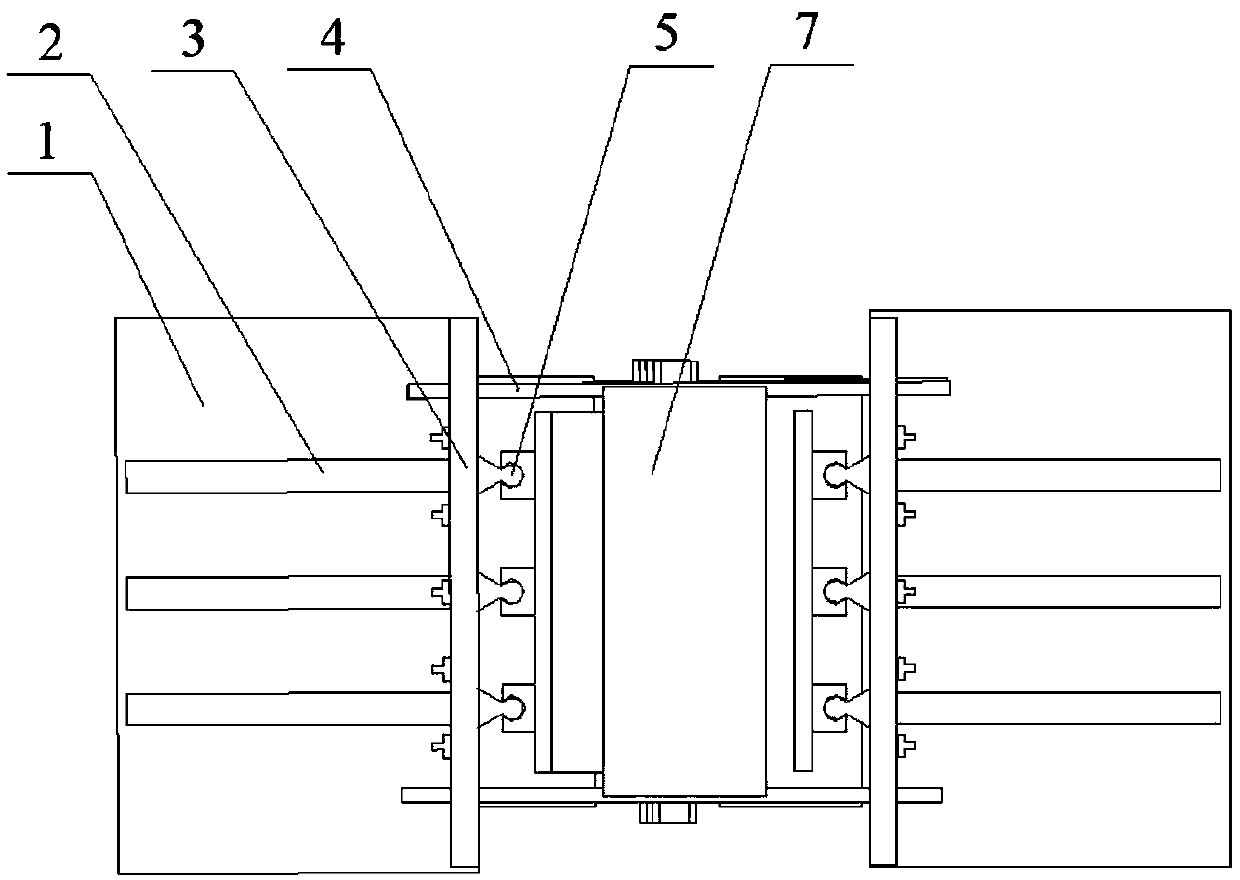

Vertical compression test device suitable for bending large panels

ActiveCN109612836ALimited out-of-plane displacementControl stressMaterial strength using tensile/compressive forcesEngineeringOut of plane displacement

The invention discloses a vertical compression test device suitable for bending large panels, belonging to the field of structural test mechanics. Fixed baffle plates are arranged on a base; sliding rails are welded to the inner sides of the fixed baffle plates; sliding bearings are installed on the sliding rails on two sides; a test piece is vertically arranged above the base and located betweenthe fixed baffle plates; the test piece, namely the panel is clamped by the sliding bearings; a loading chuck is arrange above the test piece; and the front and rear sides of the test piece are provided with detachable protective baffle plates. The vertical compression test device adopts a sliding bearing supporting mode, the friction force is reduced and the stress at the structural transition isbalanced, the out-of-plane displacement of the test piece is limited, so that that the out-of-plane load at the joint is prevent from causing material failure ahead of time, the compression load testof the bent large panel can be realized simply and efficiently, the structure is simple and reliable, the precision is high, the maintenance is simple and convenient, the compression test of the bentlarge panel can be realized on an ordinary press, and the vertical compression test device is suitable for use in various environments.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Method and apparatus for resonant frequency identification through out-of-plane displacement detection

A method for out-of-plane displacement detection is disclosed. The out-of-plane displacement is detected by analyzing all the fringe density indexes calculated using the frequency-domain information extracted from a series of interference images of the sample vibrating at different frequencies. The present invention further discloses a method and an apparatus for resonant frequency identification by detecting the peak value of all the fringe indexes calculated at different scanning frequencies. With the identified resonant frequency, the full-field vibratory surface profile of the sample in various resonance modes can be reconstructed.

Owner:IND TECH RES INST +1

Quadrature phase shift interferometer (QPSI) decoder and method of decoding

InactiveUS7092100B2Ensure correct executionIntensity PreciseError preventionInterferometersPhase shiftedWave form

An arrangement and method for reliably finding the wave form extrema of interference signals produced by a quadrature phase shift interferometer (QPSI) takes advantage of the quadrature property of I and Q signals. The zero-crossing points in the I and Q signals are determined. Peak detection is performed for peaks and valleys in the Q signal in close proximity to the zero-crossing points in the I signal, and for peaks and valleys in the I signal in close proximity to the zero-crossing points in the Q signal. These represent the maximum and minimum points of the I and Q signals. From these points, intensity envelopes are created and QPSI phase wrapping is performed to determine the phase angle and ultimately, out-of-plane displacement may be determined.

Owner:SEAGATE TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com