Three-dimensional deformation measuring method based on synthesis wavelength double-light-source shearing speckle interferometry

A technology of three-dimensional deformation and synthesis of wavelengths, which is applied in the field of optical imaging, can solve the problems of poor anti-interference and low precision, and achieve the effects of high precision, large measurement range and reduced spectrum aliasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

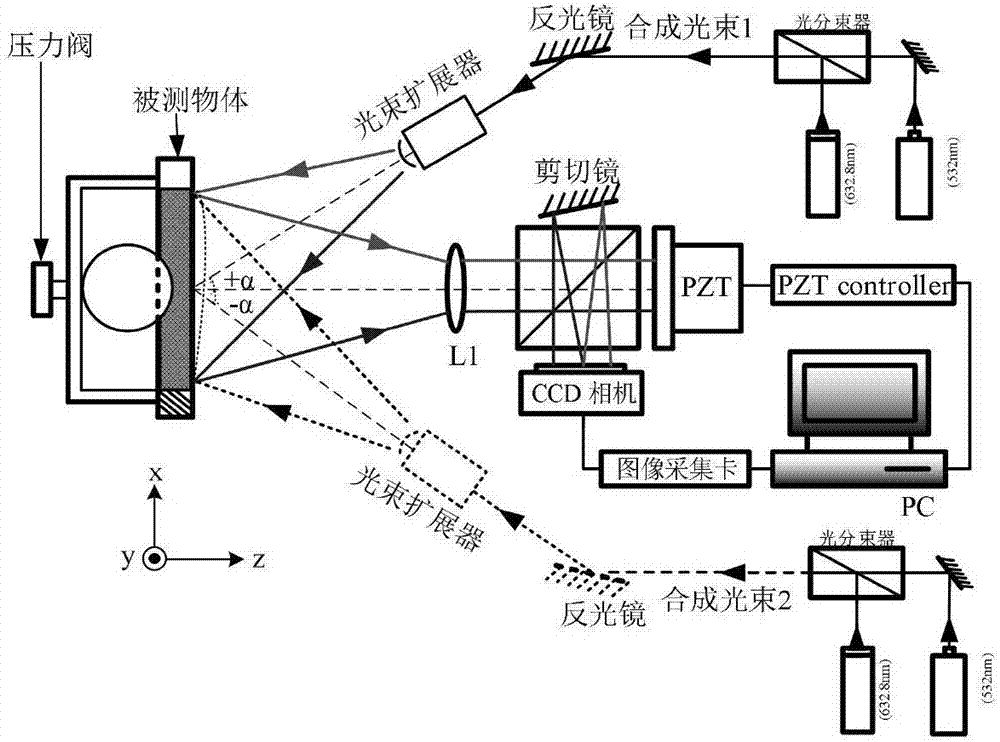

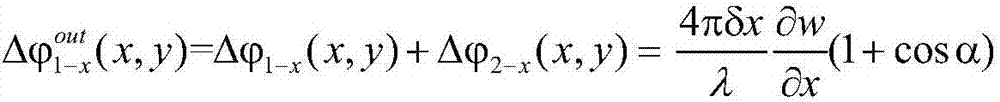

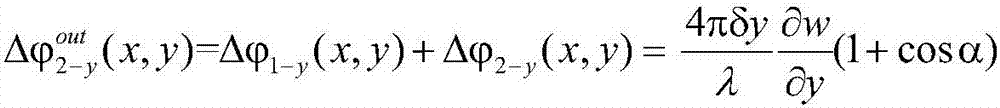

[0046] Specific implementation mode one: as figure 1 As shown, what is described in this embodiment is a three-dimensional deformation measurement method based on synthetic wavelength dual-light source shearing speckle interference, and the steps of the method are as follows:

[0047] Step 1: Two beams of red laser and green laser with different wavelengths pass through the optical beam splitter, and are irradiated by the reflector and beam expander and placed on the measured object in the vacuum box, reflected on the surface of the measured object, and the reflected light passes through The convex lens L1 performs light interference through the shearing mirror in the shearing interference device, and collects the interference image in the CCD camera;

[0048] Step 2: Control the PZT phase shift through the PZT controller (piezoelectric ceramic controller). The red laser passes through the R channel of the color camera, and the green laser passes through the G channel of the c...

Embodiment 1

[0085] Assume that in the selected measurement system, the diode-pumped laser emits green light with a wavelength of λ g =532nm, the helium-neon laser emits red light with a wavelength of λ r =632.8nm, due to the good coherence of the laser, after the two laser beams are coherent, the energy of the center spot of the beam is enhanced, and a high-power coherent beam can be obtained, which makes the wavelength longer and the measurement range larger, which helps to reduce the degree of spectrum aliasing , whose synthetic equivalent wavelength is λ s :

[0086]

[0087] The synthetic wavelength can be obtained by calculation, that is, λ s = 3.3398 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com