Secondary pre-alignment device and pre-alignment method

A technology for pre-aligning and mounting plates, which is applied in the direction of exposure devices, optics, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

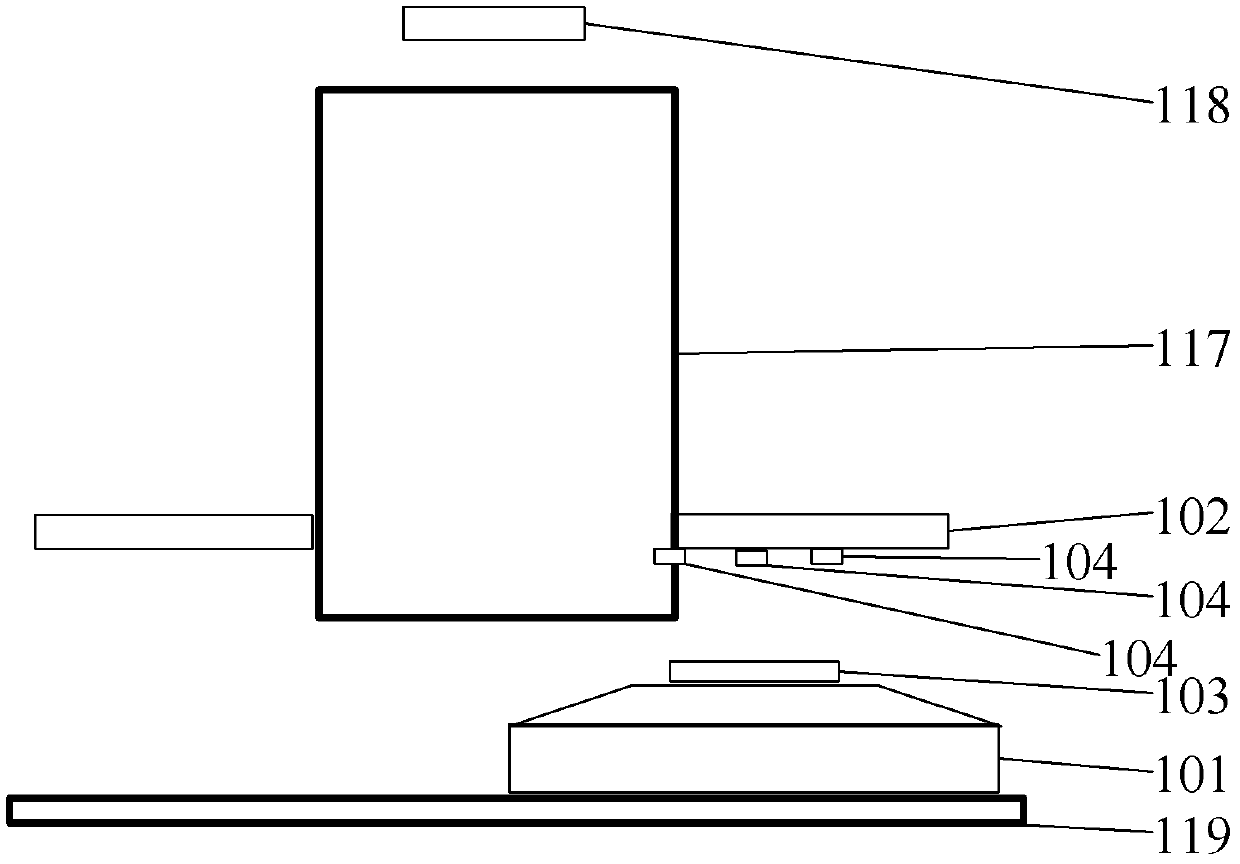

[0046] see Figure 1-Figure 7 , this secondary pre-alignment device is set between the moving table 101 and the main substrate 102, and is used to perform secondary pre-alignment on the wafer 103 placed on the moving table 101, and the wafer 103 is placed on the moving On stage 101. A projection objective lens 117 is disposed on the main substrate 102 , and a mask table 118 is disposed above the projection objective lens 117 . The exercise table 101 is arranged on a marble slab 119 .

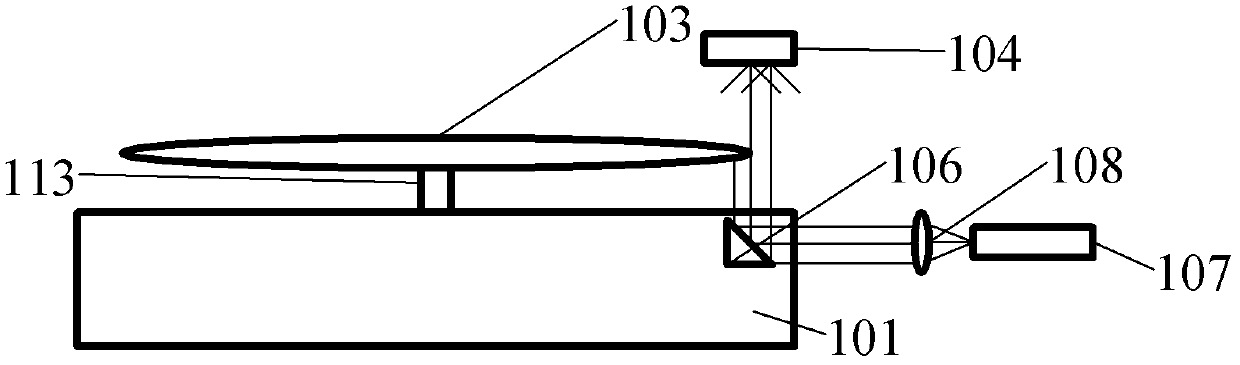

[0047] The secondary pre-alignment device includes three area array CCD104 (including CCD1, CCD2 and CCD3), three groups of optical path systems (including the first group of optical path systems, the second group of optical path systems and the third group of optical path systems) and an image processing device 105. The full name of the area array CCD104 refers to Charge-coupled device, which refers to a charge-coupled device. The three sets of optical path systems respectively project thre...

Embodiment 2

[0077] The difference between this embodiment and embodiment 1 is:

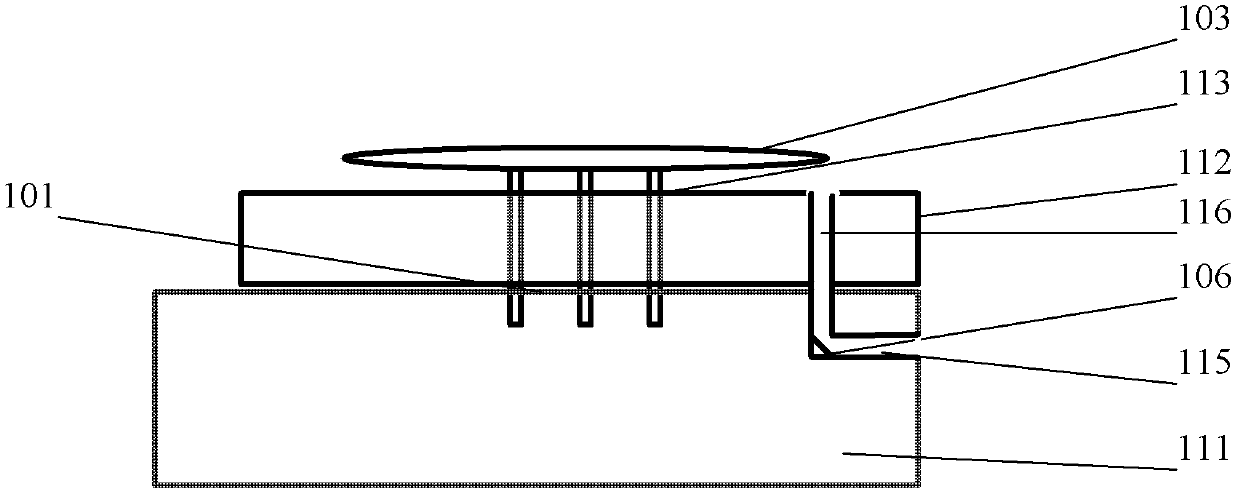

[0078] see Figure 8-Figure 9 , Figure 8 and Figure 9 Among them, 218-mask stage, 217-projection objective lens, 220-second 45-degree triangular mirror, 202-main substrate, 204-array CCD, 203-wafer, 201-moving stage, 219-marble plate, 224 -Area array mounting plate. The difference between this embodiment and Embodiment 1 is that each group of optical path systems includes a first 45-degree triangular reflector 206 and a second 45-degree triangular reflector 220 that receive light beams from the light source, and the first 45-degree triangular reflector 206 Corresponding to the second 45-degree triangular mirror 220, it is arranged on the upper and lower sides of an edge of the wafer 203. The edge image of circle 3 is projected to the corresponding area array CCD204. The first 45-degree triangular reflector 206 is distributed in the interior of the moving table 201 in a triangular shape, and the second ...

Embodiment 3

[0080] see Figure 10 , Figure 10 Among them, 301-motion table, 306-first 45-degree triangular mirror, 307-light source, 308-light path collimation mechanism, 309-light source installation bracket, 314-mechanical transmission hand, 317-projection objective lens, 319-marble plate. The difference between this embodiment and Embodiment 1 is that the three groups of optical path systems are the first group of optical path systems, the second group of optical path systems and the third group of optical path systems, and the three groups of optical path systems share a light source 307 and an optical path collimation mechanism 308, and the first group of optical path systems also includes a triangular reflector 321 of 2 / 3 light transmittance, the second group of optical path systems also includes a triangular reflector 322 of 1 / 2 light transmittance, and the third group of optical path systems also includes a third 45 degree triangular reflector 323. The light source 307 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com