Emulsified bitumen for vertical connected plate type unballasted track cement emulsified bitumen mortar

A technology of slab ballastless track and cement emulsified asphalt, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of cement compatibility not meeting requirements, mortar stability and fluidity difficult to meet, and achieve good mixing Synergistic effect, good emulsifying effect, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

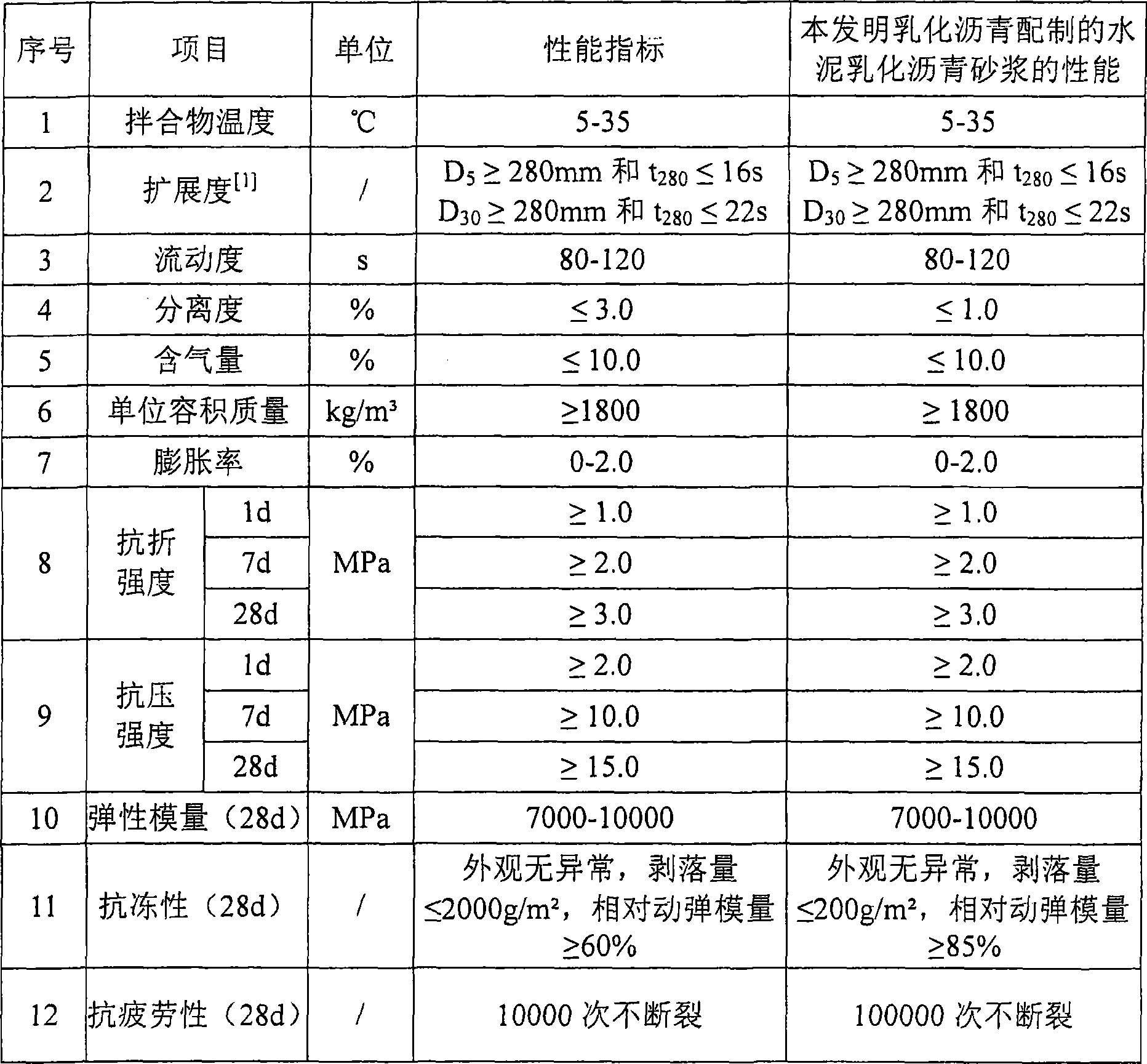

[0036] The asphalt adopted in the emulsified asphalt provided by the present embodiment is No. 90 heavy traffic road petroleum asphalt (penetration is 88, the unit is 1 / 10mm, and the wax content is 1.7); anionic emulsifier is alkyl ether carboxylic acid Salts (the alkyl chain length is 16 carbon atoms); the auxiliary agent is caustic soda; the stabilizer is cellulose ether (molecular weight is about 50000), and its composition is shown in Table 3.

[0037] The preparation method of the emulsified asphalt provided by the present embodiment may further comprise the steps:

[0038] Dehydrate the asphalt at 100°C first, then heat it to about 130°C;

[0039] Dissolve emulsifiers, stabilizers and additives in water at 60°C according to the ratio to form a mixed aqueous solution;

[0040] Mix the heated asphalt with the above-mentioned mixed aqueous solution according to the proportion in Table 3, and emulsify through a colloid mill to obtain an asphalt emulsion;

[0041] The aspha...

Embodiment 2

[0043] The asphalt adopted in the emulsified asphalt provided by the present embodiment is No. 70 heavy traffic road petroleum asphalt (penetration is 64, the unit is 1 / 10mm, and the wax content is 2.0); anionic emulsifier is alkylbenzenesulfonic acid Salts (the alkyl chain length is 12 carbon atoms); the nonionic surfactant is lauryl sorbitan and polyoxyethylene ethers (PEO=15); the auxiliary agent is caustic soda, and the stabilizer is cellulose ether and polyether ( Molecular weight is about 80000), and its composition is as shown in table 3.

[0044] The preparation method of the emulsified asphalt provided by the present embodiment may further comprise the steps:

[0045] The bitumen is first dehydrated at 100°C, and then gently heated to about 130°C;

[0046] Dissolve emulsifiers, stabilizers and additives in water at 60°C according to the ratio to form a mixed aqueous solution;

[0047] Mix the heated asphalt with the above-mentioned mixed aqueous solution according t...

Embodiment 3

[0050] The asphalt adopted in the emulsified asphalt provided by the present embodiment is PG70-22 modified asphalt (wax content is 1.6); anionic emulsifier is alkyl sulfonate (alkyl chain length is 18 carbon atoms); The amphoteric emulsifier is an alkyl tertiary amine salt (the alkyl chain length is 8 carbon atoms); the auxiliary agent is caustic soda; the stabilizer is polyether (molecular weight is about 50,000), and its composition is shown in Table 3.

[0051] The preparation method of the emulsified asphalt provided by the present embodiment may further comprise the steps:

[0052] The asphalt is first dehydrated at 100°C, and then gently heated to about 165°C;

[0053] Dissolve emulsifiers, stabilizers and additives in water at 60°C according to the ratio to form a mixed aqueous solution;

[0054] Mix the heated asphalt with the above-mentioned mixed aqueous solution according to the proportion in Table 3, and emulsify through a colloid mill together to obtain an aspha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com