Novel disc type oxygen sensor and preparation method and detection method thereof

An oxygen sensor and sensor technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of unfavorable superimposition, small cavity thickness, and rising scrap rate, and achieve the effect of improving stability and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

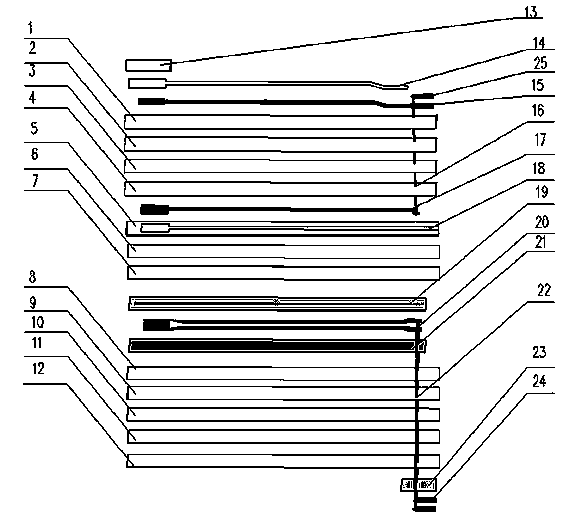

[0079] like figure 1 As shown, a new type of chip oxygen sensor, the sensor is composed of an upper protective layer, a signal layer, an air reference channel layer and a heating layer stacked from top to bottom and then sintered.

[0080] The signal layer includes a first layer of cast substrate 1, a second layer of cast substrate 2, a third layer of cast substrate 3 and a fourth layer of cast substrate 4 stacked sequentially from top to bottom. A signal external electrode 15 and a signal internal electrode 17 are arranged on the upper surface of the layered casting substrate 1 and the lower surface of the fourth layer casting substrate 4 respectively; a lead wire A is passed between the signal external electrode 15 and the signal internal electrode 17 After connection, one end of the lead wire A is connected to the signal inner electrode 17, and the other end runs through the fourth layer of cast substrate 4, the third layer of cast substrate 3, the second layer of cast subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com