Patents

Literature

497 results about "Overprinting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Overprinting refers to the process of printing one colour on top of another in reprographics. This is closely linked to the reprographic technique of 'trapping'. Another use of overprinting is to create a rich black (often regarded as a colour that is "blacker than black") by printing black over another dark colour.

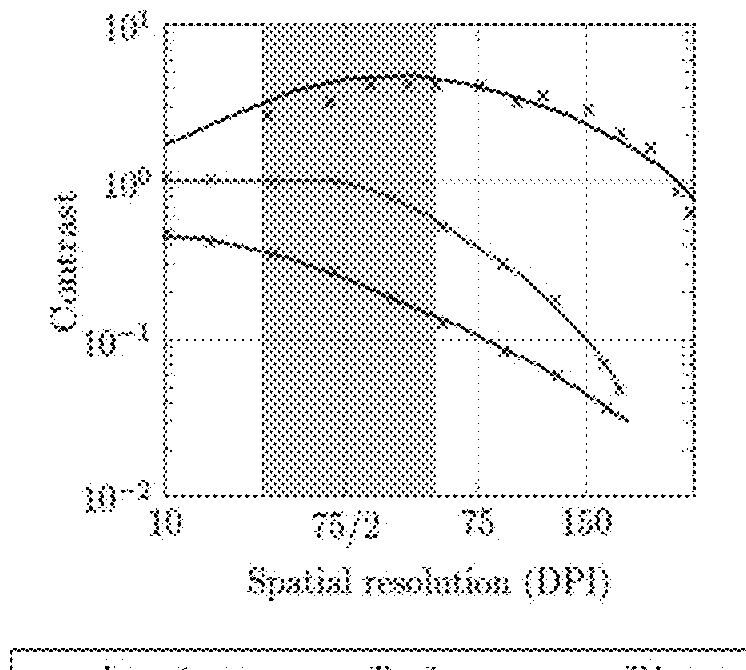

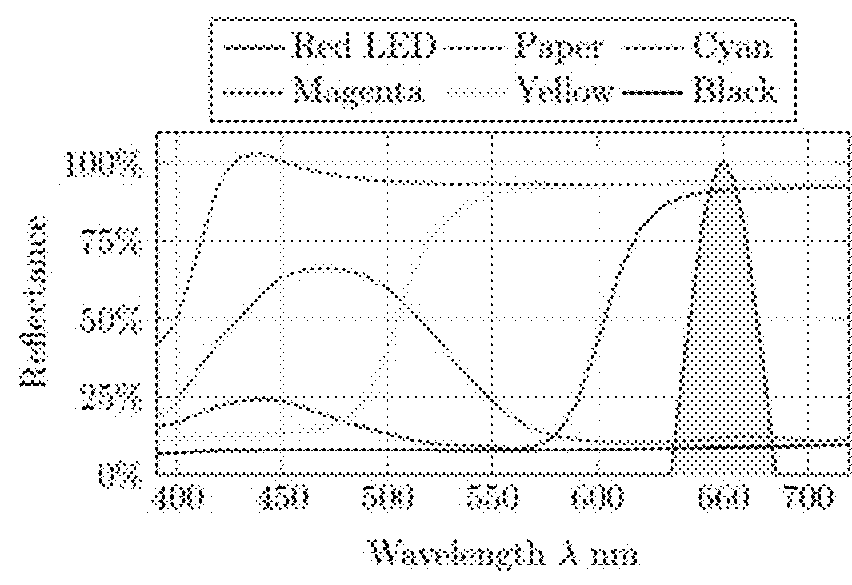

Data hiding for spot colors in product packaging

ActiveUS20150156369A1Image analysisCharacter and pattern recognitionPattern recognitionPatent document

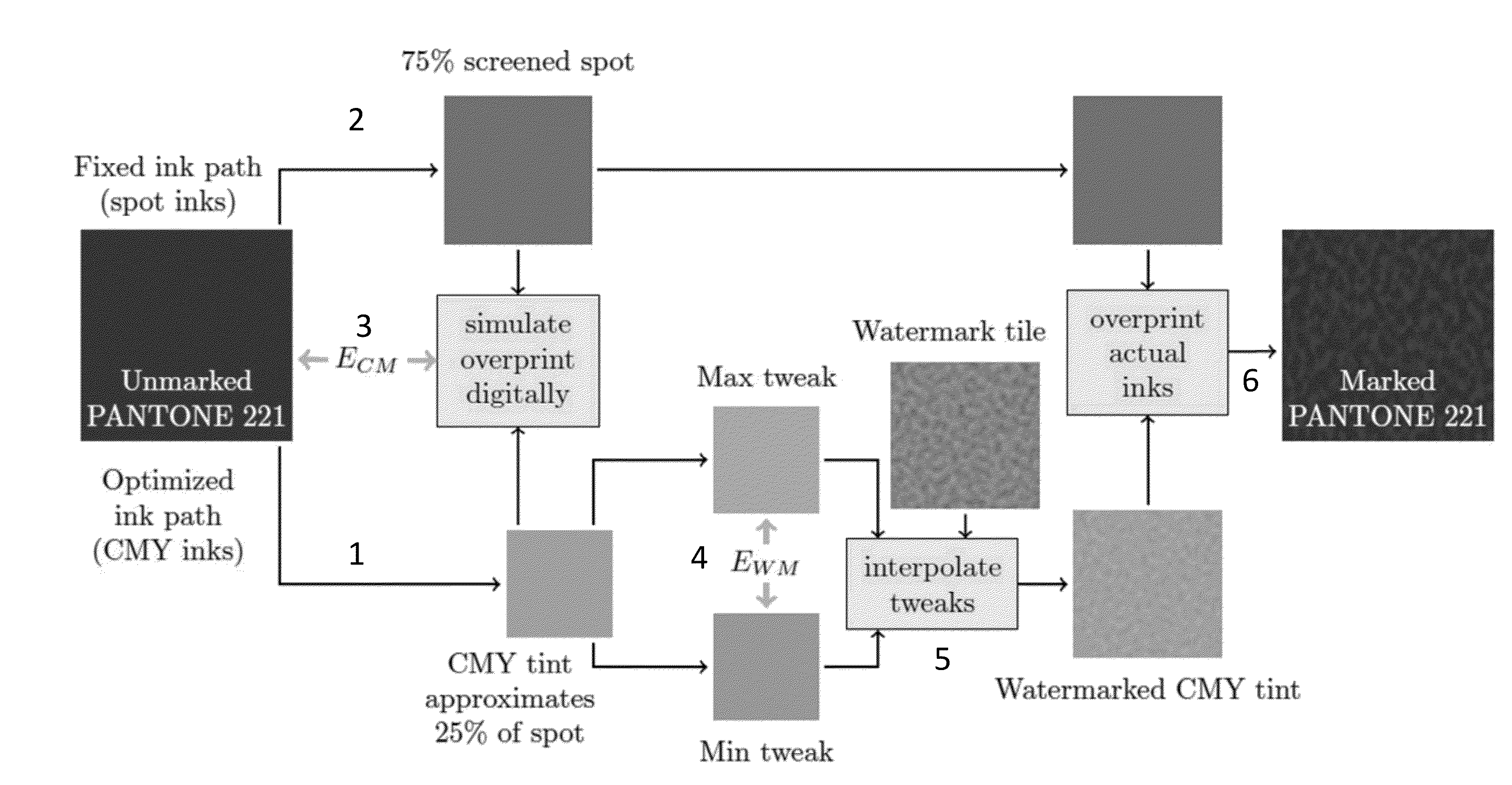

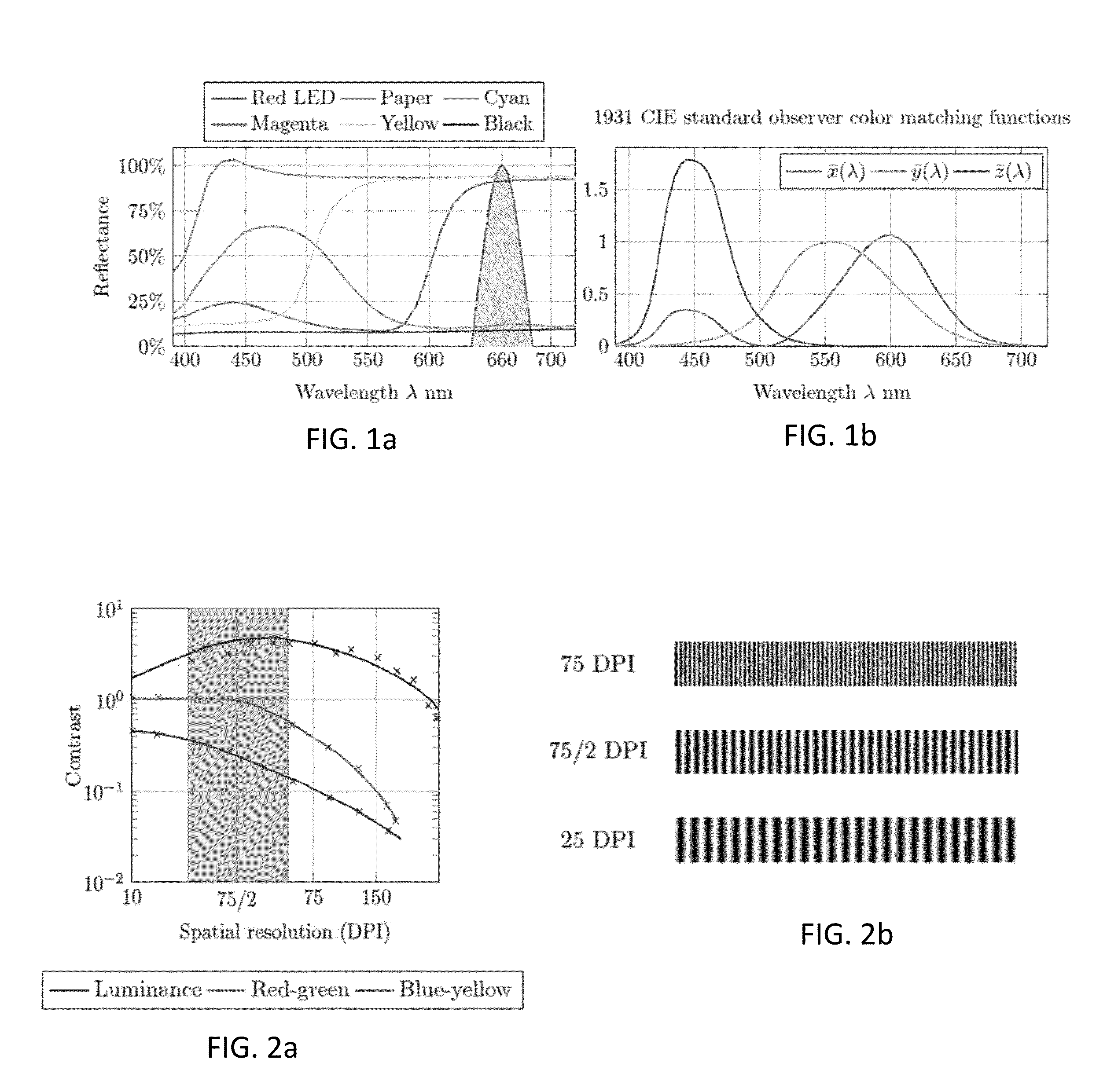

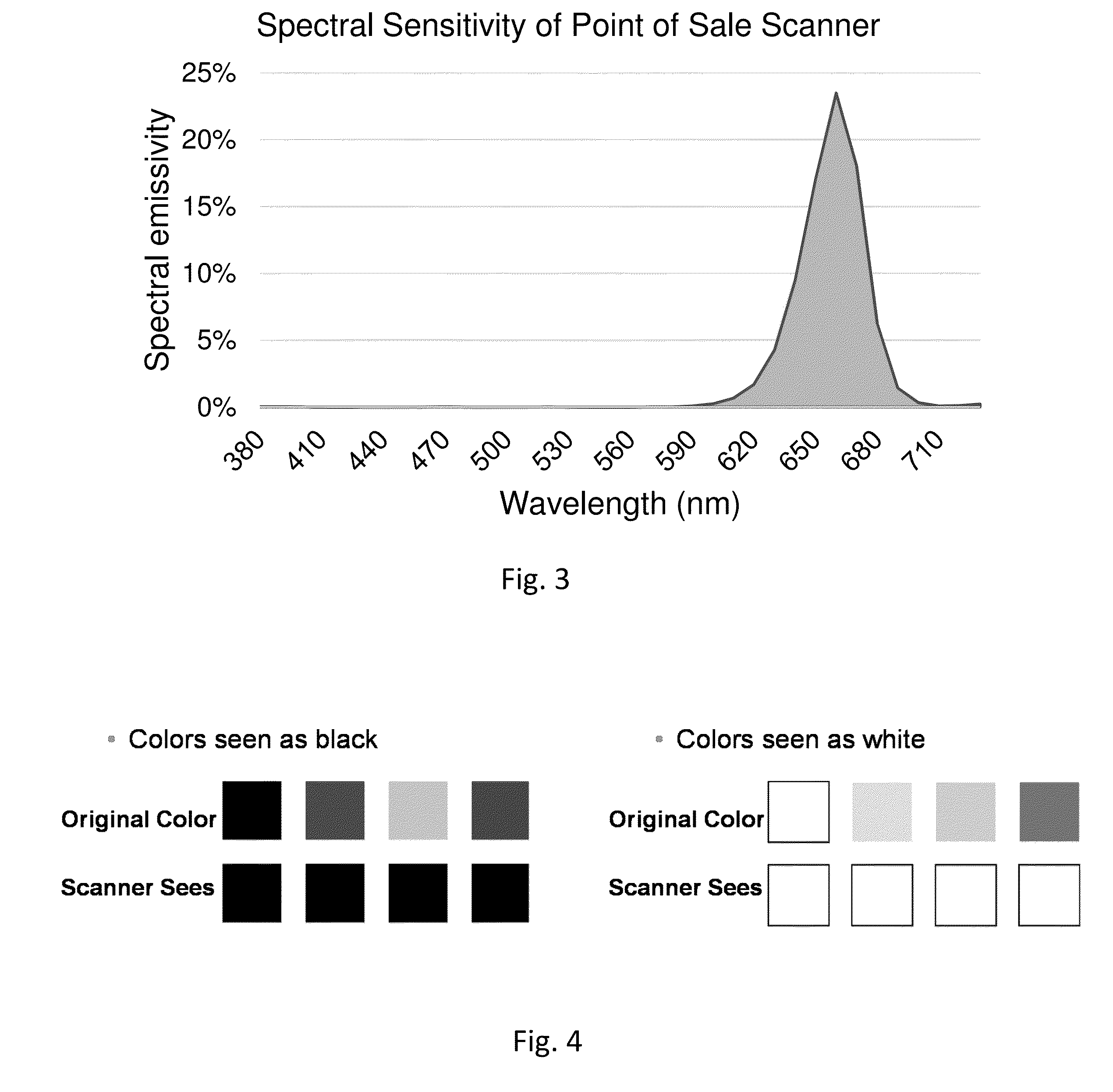

The present disclosure relates generally to data hiding for product packaging and other printed objects. One embodiment embeds an information signal in a spot color for product packaging. The spot color is screened, and overprinted with process color tint. The tint is modulated prior to overprinting with optimized signal tweaks. The optimization can include consideration of a detector spectral dependency (e.g., red and / or green illumination). Other embodiments and combinations are described in the subject patent document.

Owner:DIGIMARC CORP

Data hiding for spot colors in product packaging

ActiveUS9380186B2Image analysisCharacter and pattern recognitionComputer graphics (images)Engineering

The present disclosure relates generally to data hiding for product packaging and other printed objects. One embodiment embeds an information signal in a spot color for product packaging. The spot color is screened, and overprinted with process color tint. The tint is modulated prior to overprinting with optimized signal tweaks. The optimization can include consideration of a detector spectral dependency (e.g., red and / or green illumination). Other embodiments and combinations are described in the subject patent document.

Owner:DIGIMARC CORP

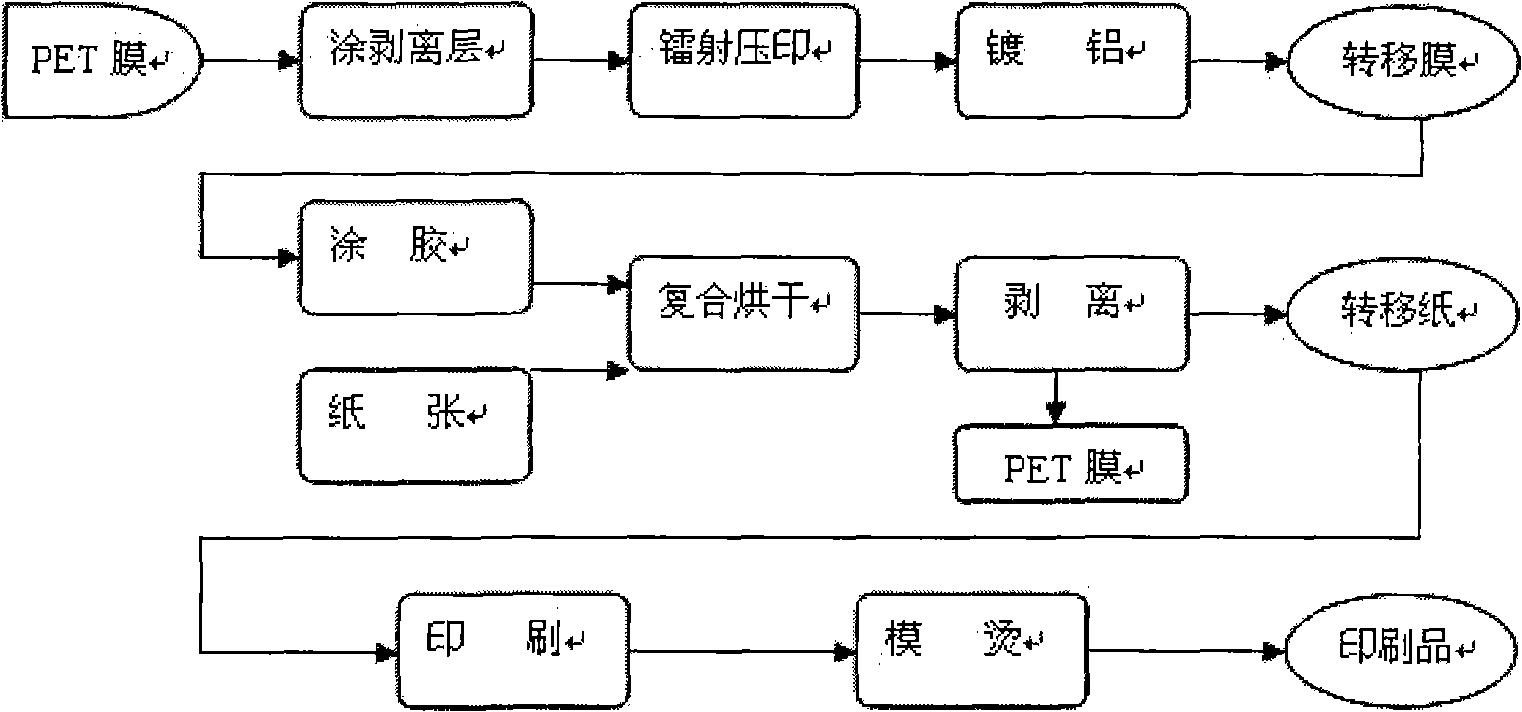

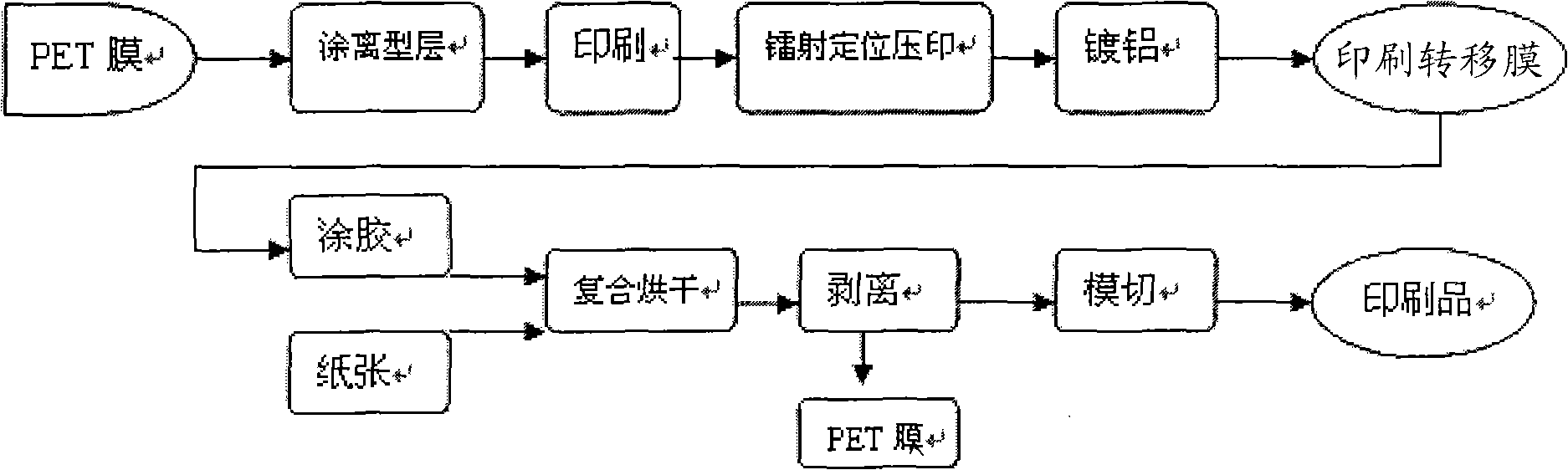

More environment-friendly print transferring method and product thereof

InactiveCN101524930AImprove printing qualityImprove printing efficiencyVacuum evaporation coatingSputtering coatingPulp and paper industryLaser

The invention discloses a more environment-friendly print transferring method and a product thereof. The method comprises steps of coating, picture and text printing, laser stamping, aluminium plating, glue coating, compositing and peeling. Instead of printing on rough paper or manufacturing a laser transfer paper first before carrying out picture and text printing in the traditional technique, printing is carried out on surface of more smooth PET light membrane. Therefore, the product has higher printing quality and printing efficiency, more beautiful appearance, more precise overprint and lower cost.

Owner:FUJIAN TAIXING SPECIAL PAPER CO LTD

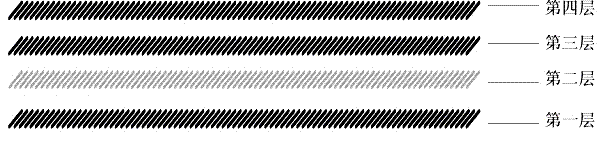

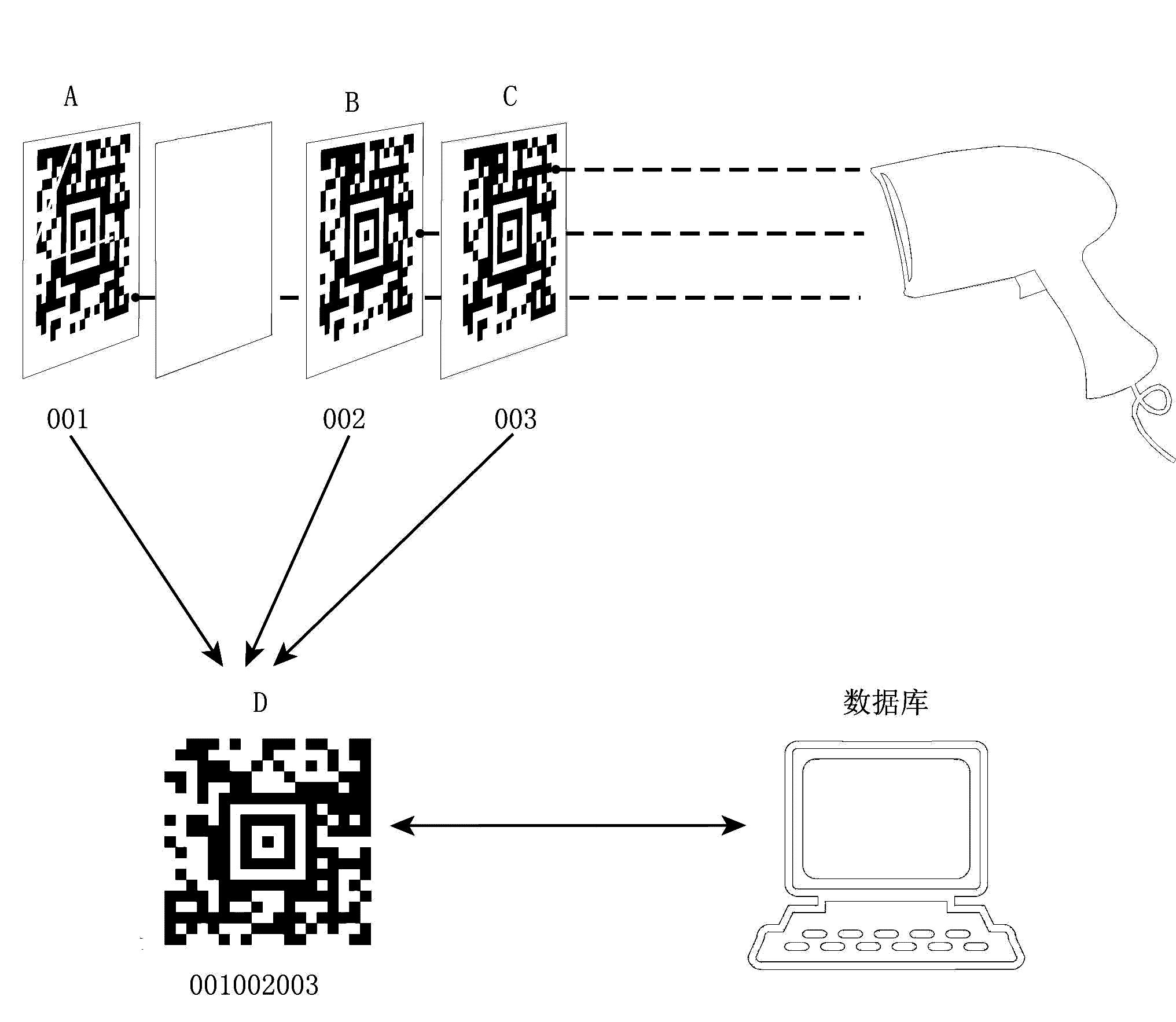

Anti-counterfeiting printing method by using invisible two-dimensional codes

InactiveCN101819647AEliminate the risk of imitationImprove use valuePattern printingRecord carriers used with machinesUltraviolet absorptionAbsorbent material

The invention relates to an anti-counterfeiting printing method by using invisible two-dimensional codes. The anti-counterfeiting printing method is characterized in that at least four printing layers for printing are adopted, and comprises the following steps of: firstly, providing a digital serial number and splitting the serial number into three fields of which information is assigned to three groups of two-dimensional codes; secondly, printing one group of two-dimensional codes on a first layer by using aqueous ink black materials; thirdly, overprinting a grey isolating layer on the first two-dimensional code layer by using infrared non-absorbent materials to form a second layer; fourthly, overprinting a second group of two-dimensional codes on the second layer of the grey isolating layer by using the infrared non-absorbent materials to form a third layer; and finally, overprinting a third group of two-dimensional codes on the third two-dimensional code layer by using ultraviolet absorption materials to form a fourth layer. The method has the advantages of eliminating the possibility of imitation by scanning the two-dimensional codes and achieving relatively higher use value because the overprinting is performed in the same area in an offset printing and digital jet printing way and the upper printing layer covers the lower layer naturally.

Owner:HONGBO CO LTD

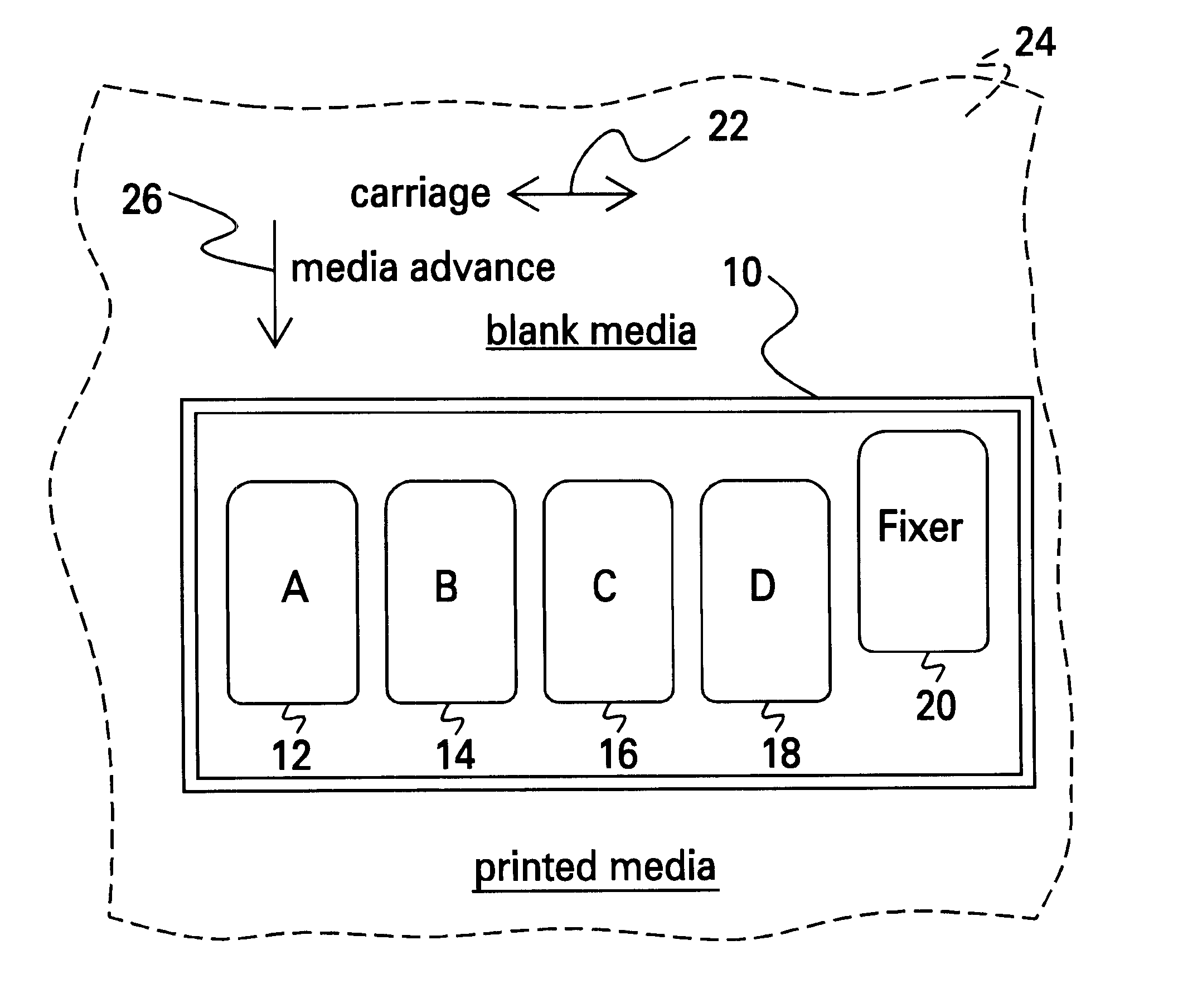

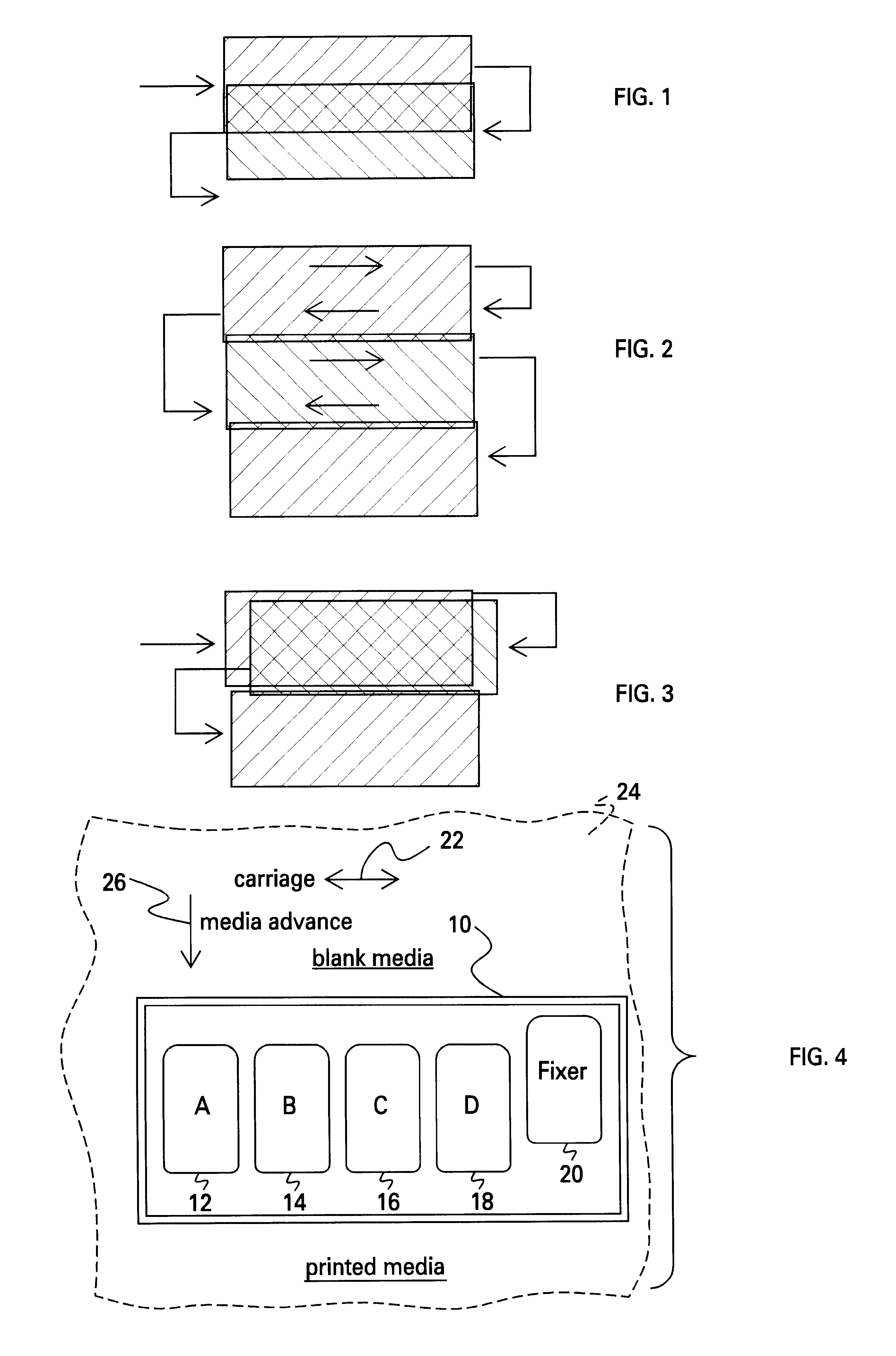

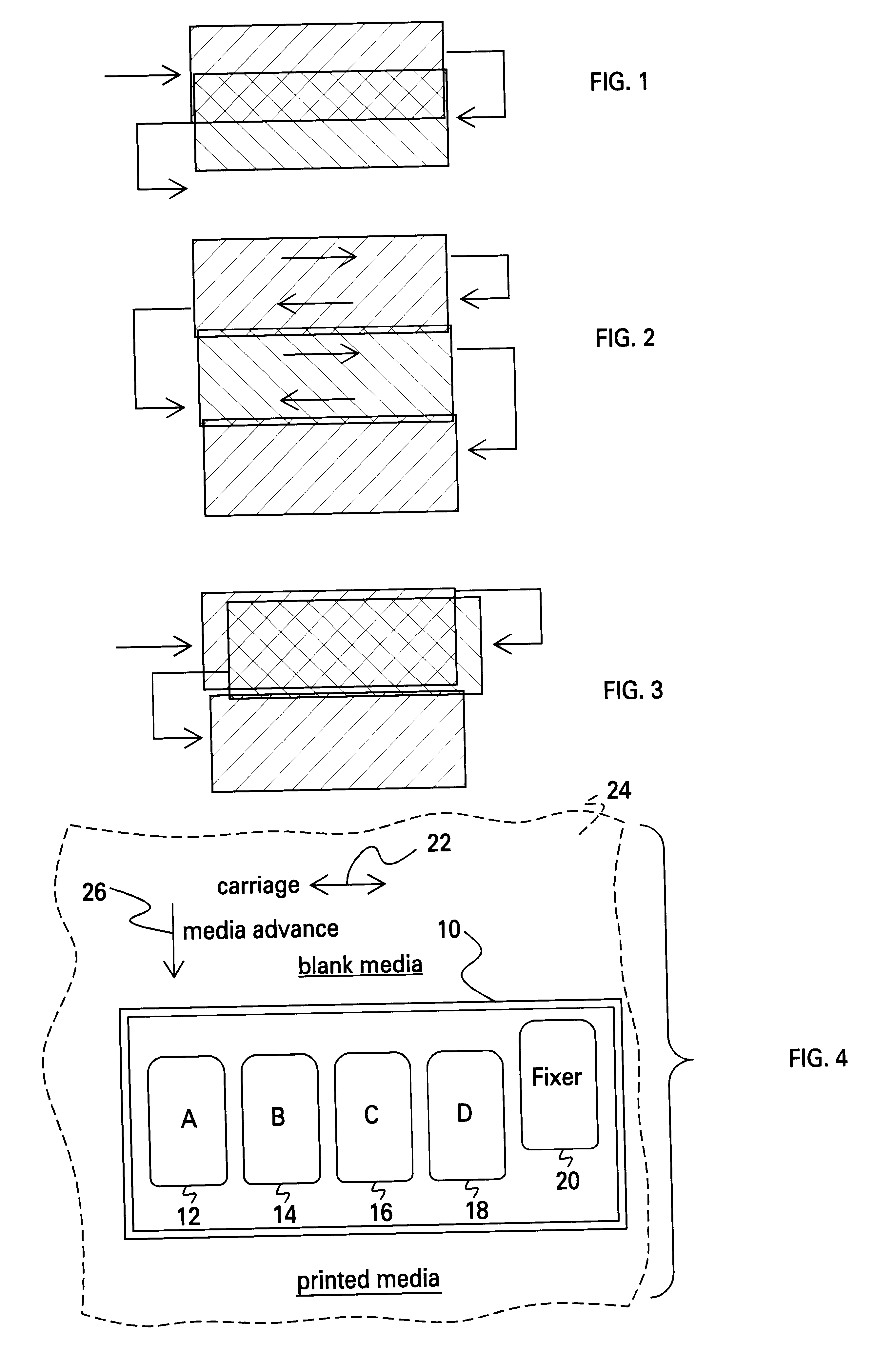

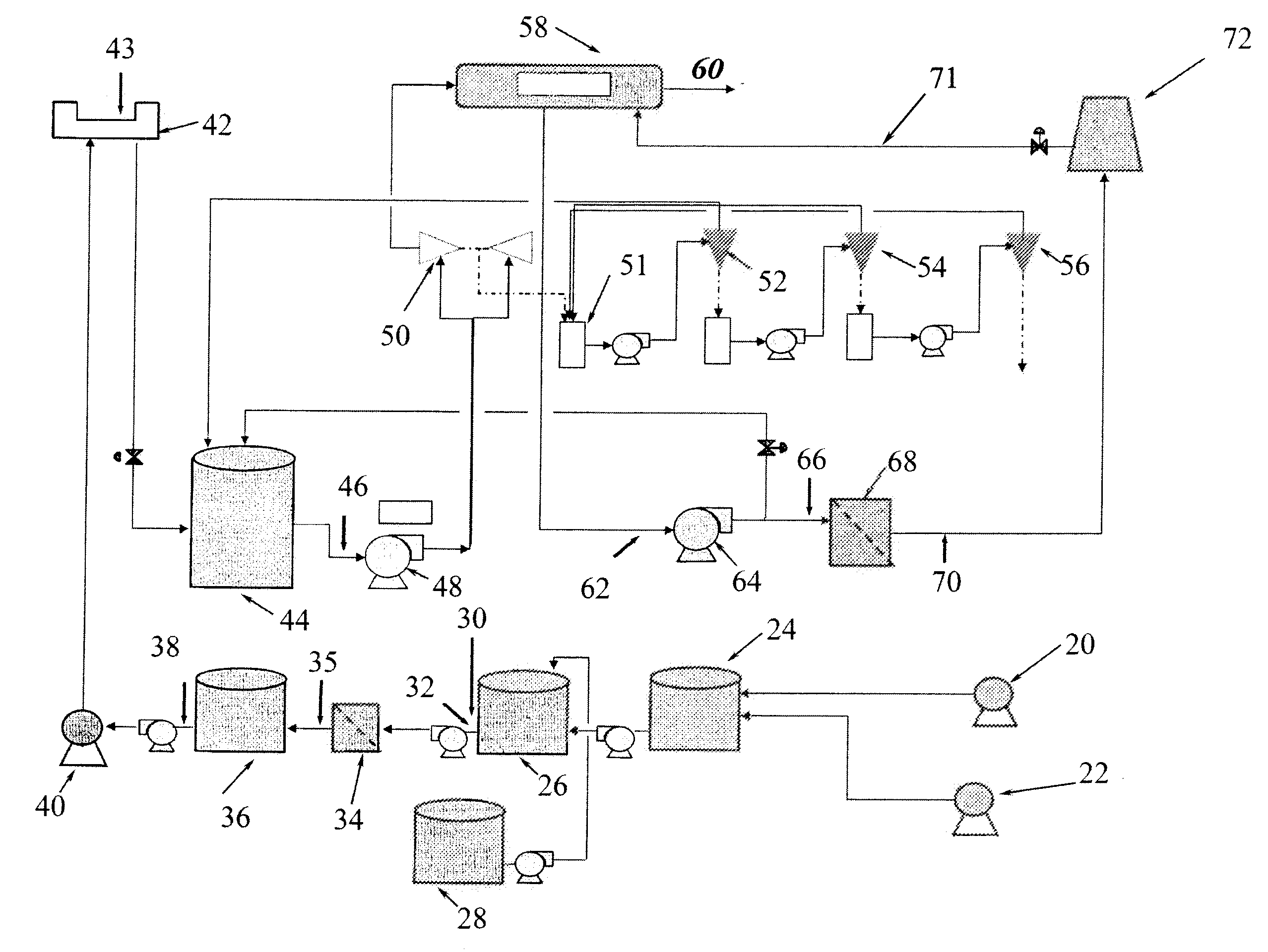

Application of clear overcoat fluid

InactiveUS6412935B1Larger dot gainMeasurement apparatus componentsDuplicating/marking methodsPorous mediumEngineering

A method of applying a fixer fluid overcoat to a porous or semi-porous medium printed in an ink jet printer is provided. The method includes: (a) providing at least one ink including a colorant and contained in at least one ink-printing pen maintained within the ink jet printer; (b) providing the fixer fluid in a fixer fluid pen maintained within the ink jet printer; (c) printing the ink(s) on the print medium; and (d) overprinting the ink(s) with the fixer fluid by advancing the print medium a few dot rows per print swath and either (i) applying the fixer fluid to the ink(s) on an Nth pass where the fixer fluid pen trails the ink-printing pen(s), or (ii) printing an additional swath without an advance of the print medium with the fixer fluid where the fixer fluid pen leads the ink-printing pen(s).

Owner:HEWLETT PACKARD DEV CO LP

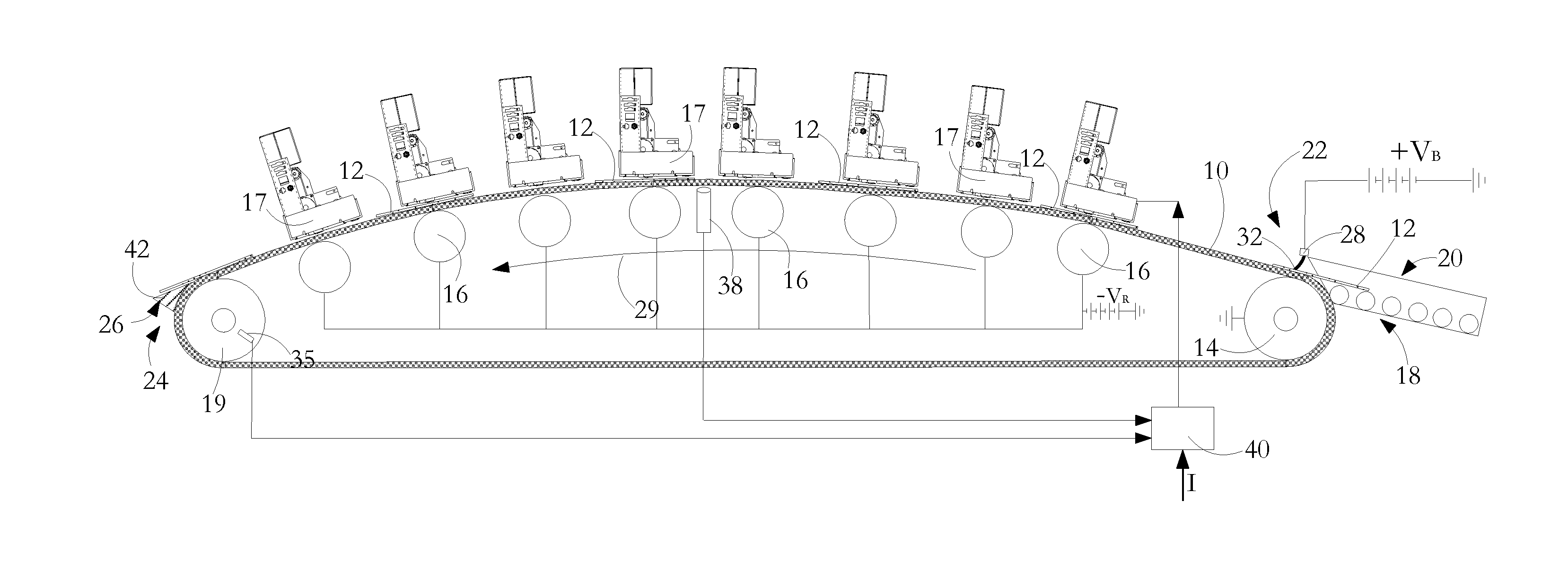

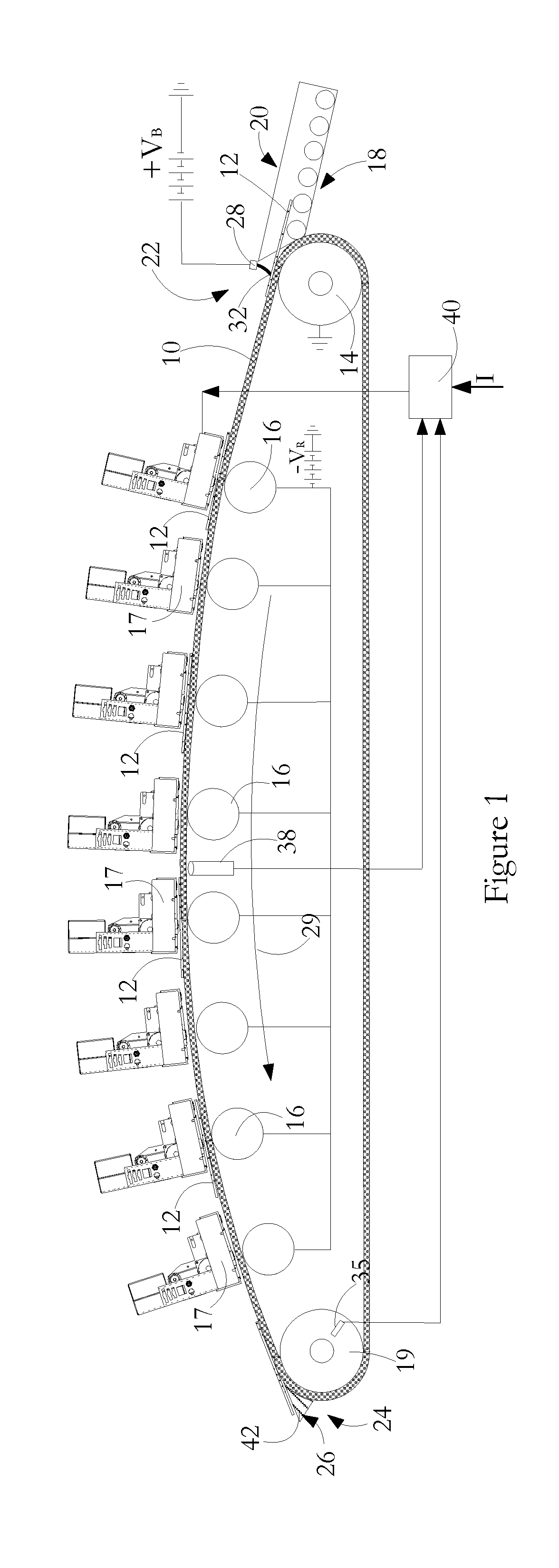

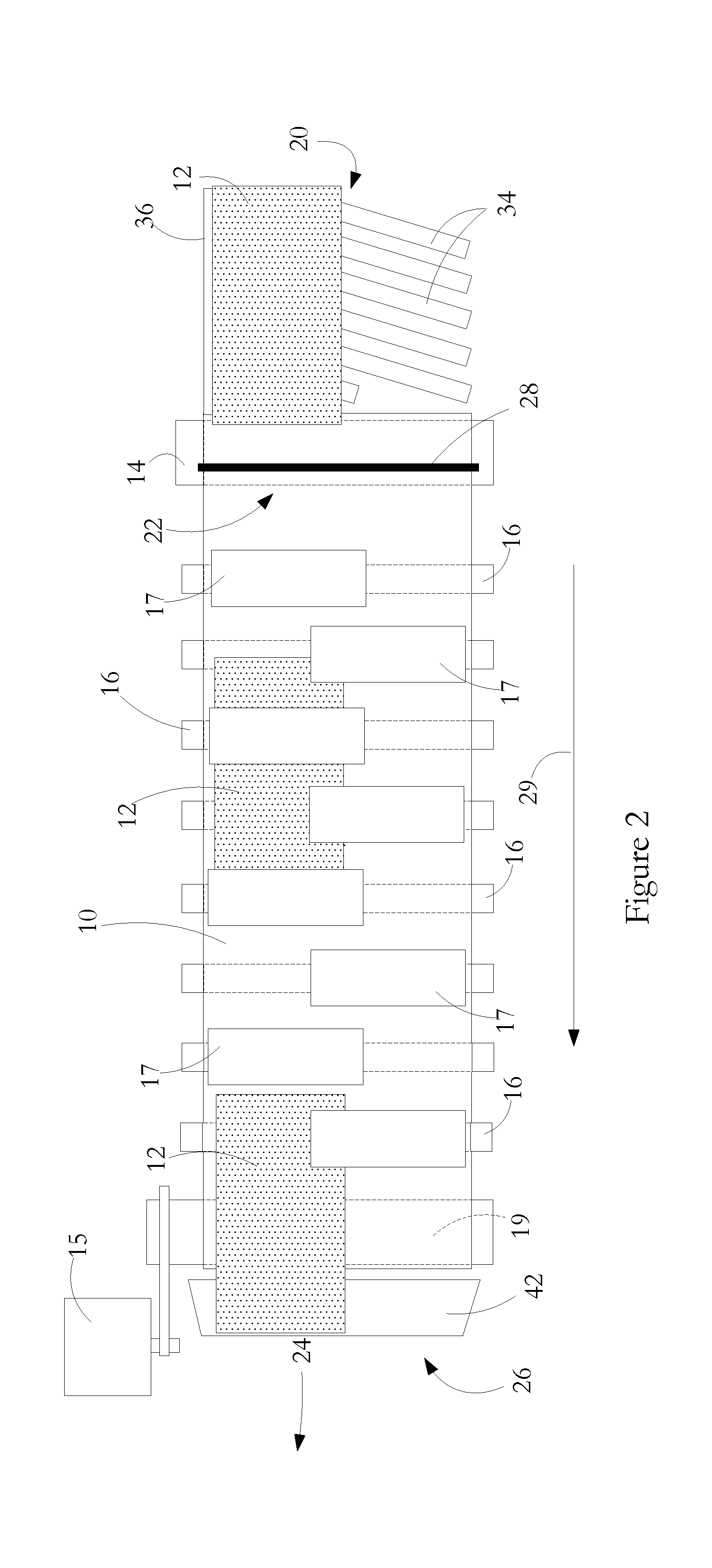

Multiple print head printing apparatus and method of operation

ActiveUS20130201237A1Precise positioningSmall toleranceTypewritersOther printing apparatusEngineeringMotor coordination

A printing apparatus has a series of inkjet print heads spaced from one another in a transport direction. A continuous belt driven around a roller system is used to feed sheet media successively to the print heads so that a partial image printed by one print head is overprinted at a subsequent print head with registration of the partial images. A sheet medium is caused to become electrostatically tacked to the belt by passing the sheet past a charging device. Movement of the belt is tracked by a tracking sub-system and operation of the print heads is coordinated with the tracked belt movement to achieve precise registration of the partial images.

Owner:DELPHAX TECH

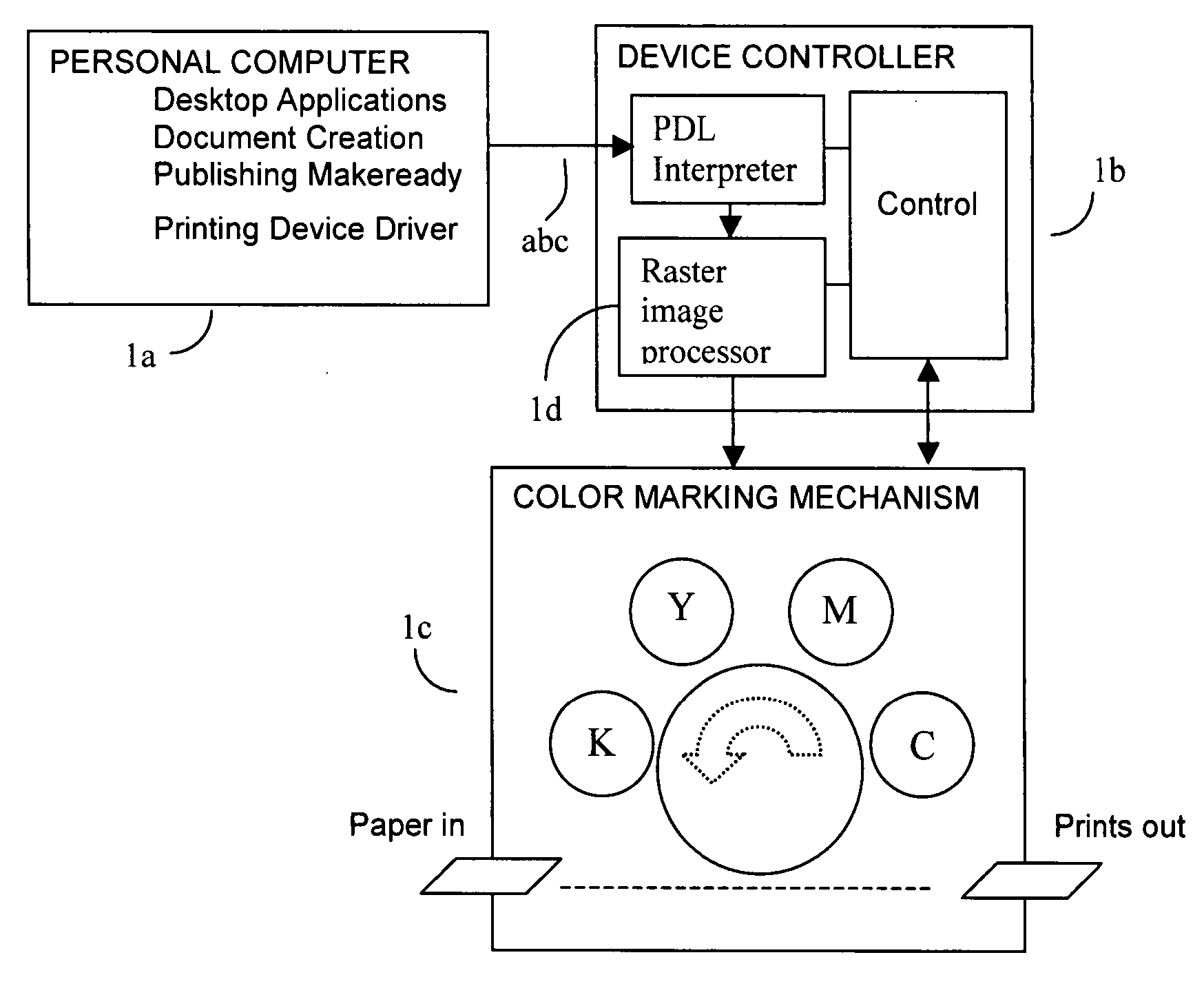

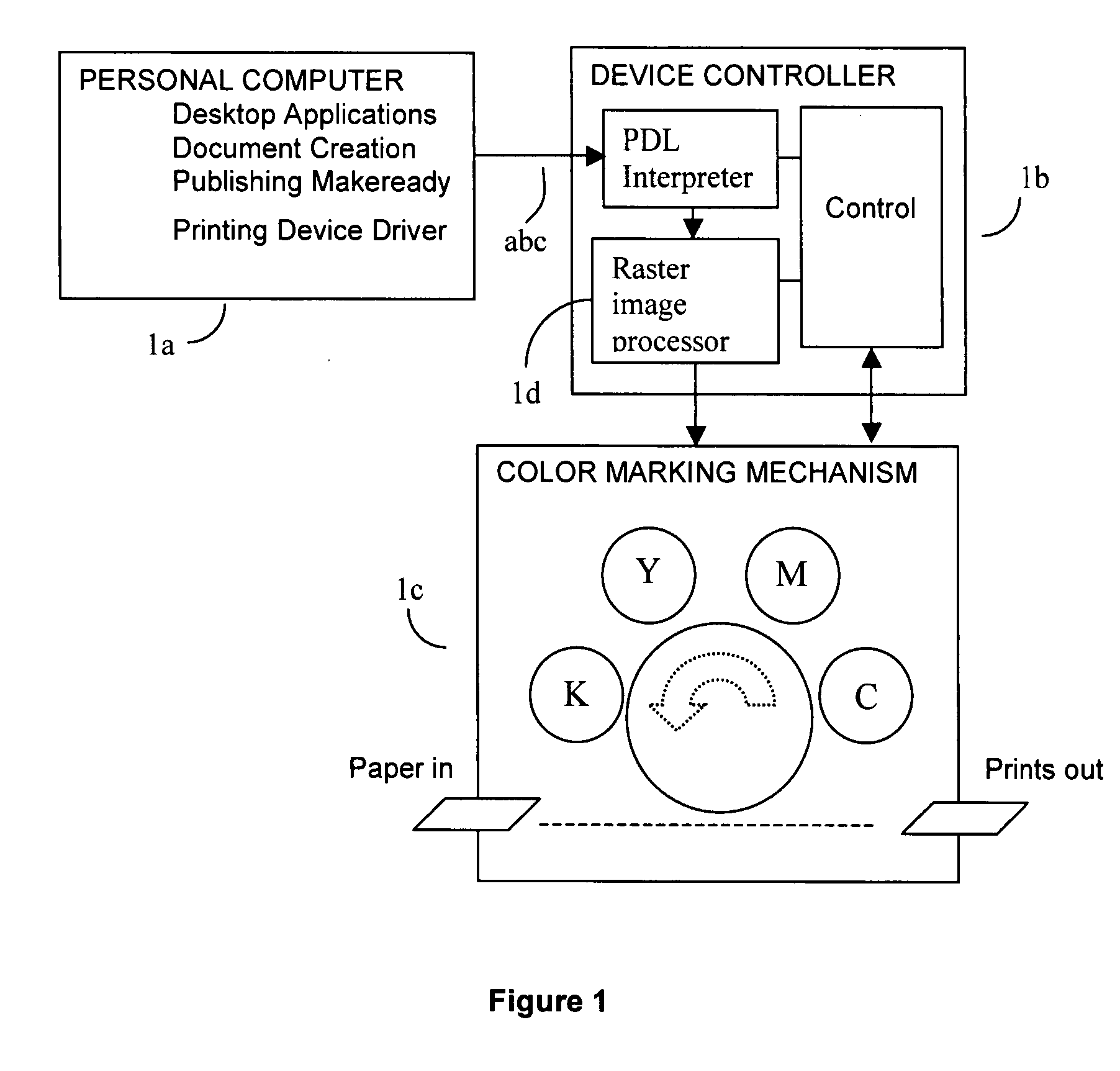

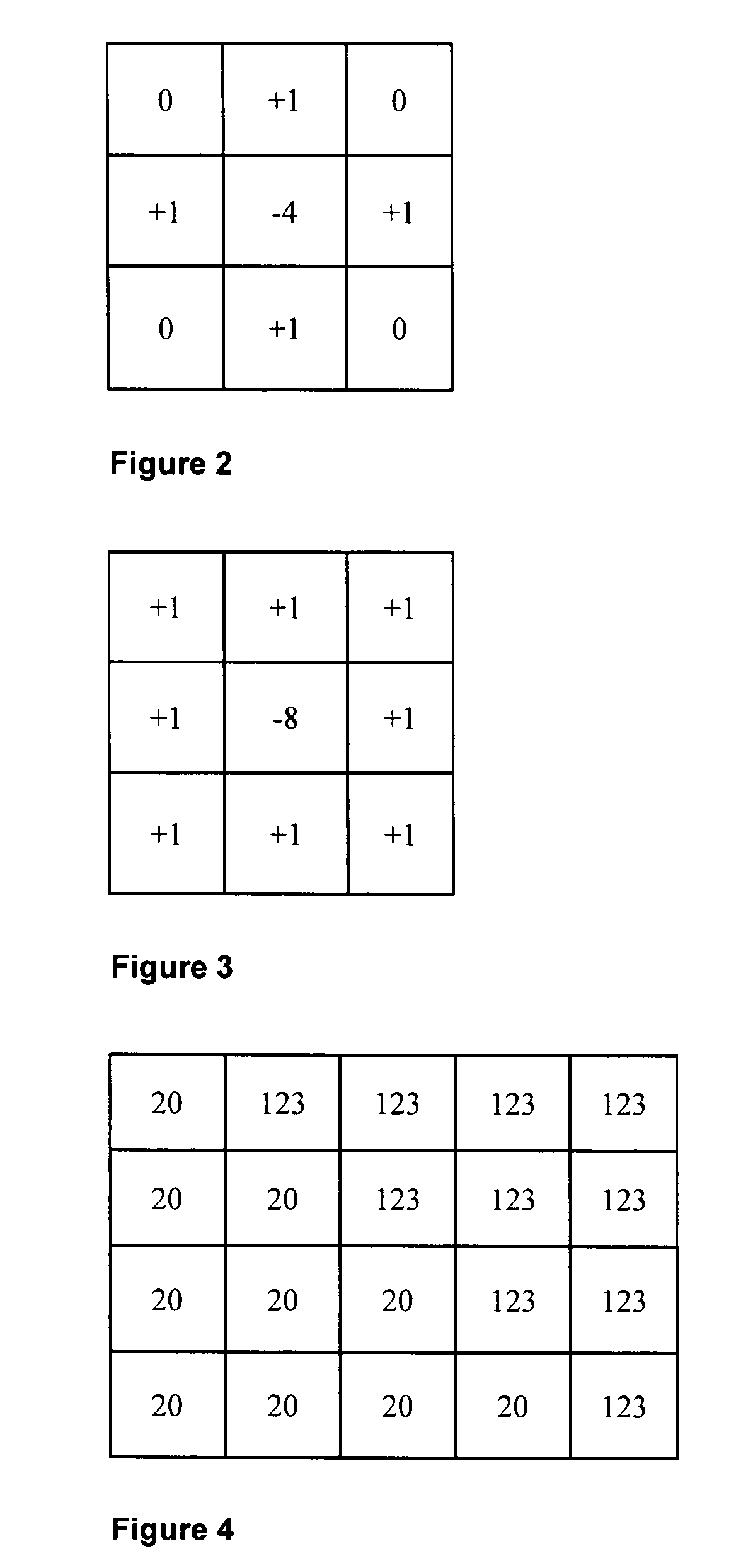

Trapping method for digital color printing

InactiveUS20080007752A1Reduce visibilityConceal errorDigitally marking record carriersDigital computer detailsColor printingMultiple component

A system and method for trapping in electrophotographic color printing and related technologies for printing or display in which the final image is an overlay of multiple components subject to alignment errors. Trapping is based on the cyan (C), magenta (M), and black (K) planes. There are four steps as follows: detect object edges on each of the four color planes; detect coincident and opposing edge transitions on each pair of planes (CM, CK, and KM); determine which plane to trap, i.e., to extend object across edge; and generate trap on that plane using a simple trap generation rule and a single trap generation rule.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Ink jettable overprint compositions

ActiveUS20050249895A1Quality improvementIncreased durabilityDigitally marking record carriersImpression capsOligomerPhotoinitiator

Ink jettable, radiation curable overprint compositions containing at least one radiation curable oligomer / monomer, at least one photoinitiator, and at least one surfactant are disclosed. The overprint compositions are particularly well-suited for protecting ink-based and toner-based images on substrates subjected to abrasives, heat, and / or sunlight since the compositions protect such images from smearing, cracking, and fading.

Owner:XEROX CORP

Enhancement of ink jet image waterfastness with overprinting

InactiveUS6503978B1Increased durabilityWet waterfastnessDuplicating/marking methodsInksOrganic acidEngineering

In a four pen ink jet printer comprising cyan, yellow, magenta, and black inks, a clear liquid is applied to printed ink on a print medium via a fifth pen, thereby fixing. the colorants, which in turn improves the durability of the printed ink. The clear fixer fluid comprises at least one organic acid and, optionally, a salt of at least one polymeric acid.

Owner:HEWLETT PACKARD DEV CO LP

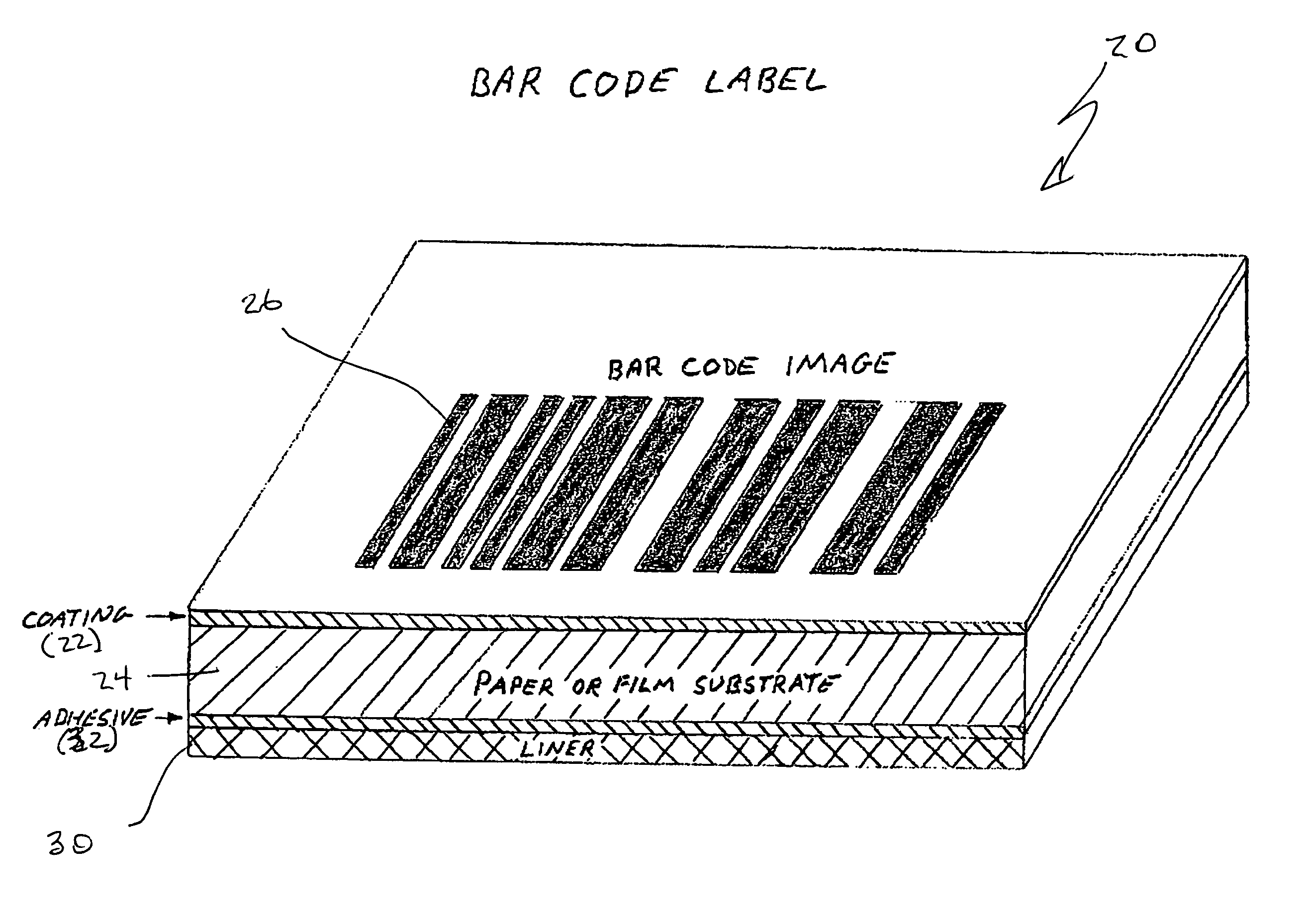

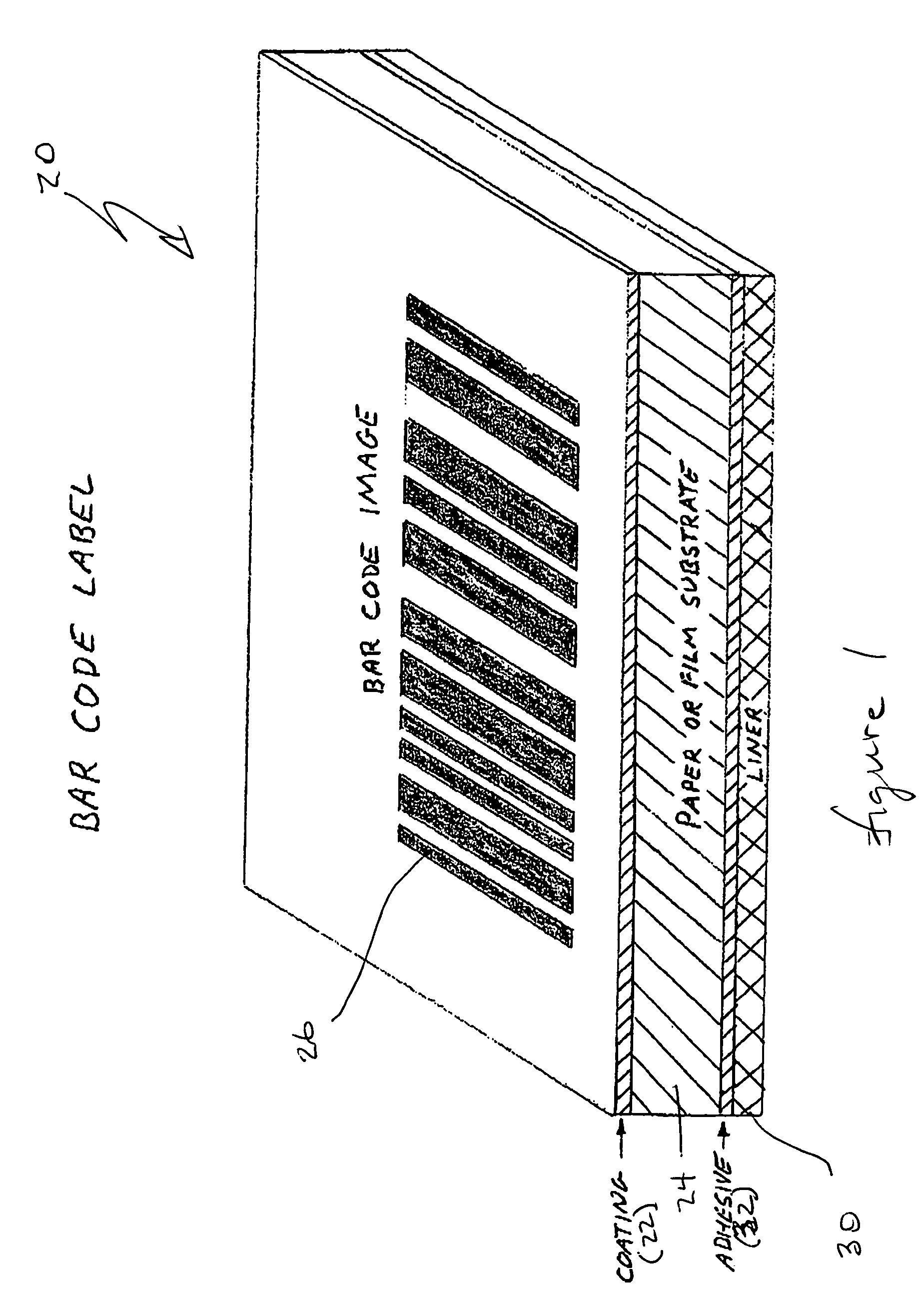

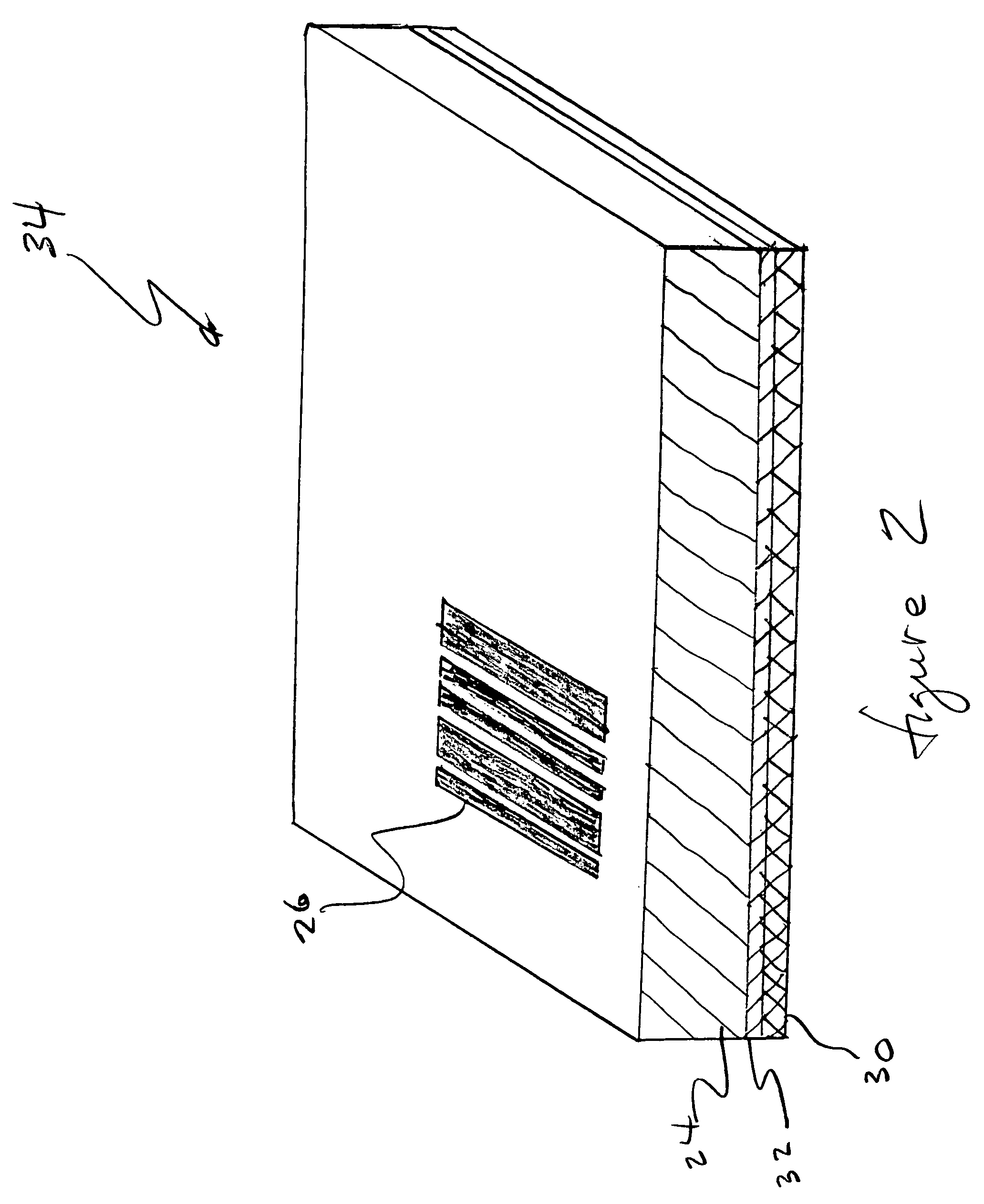

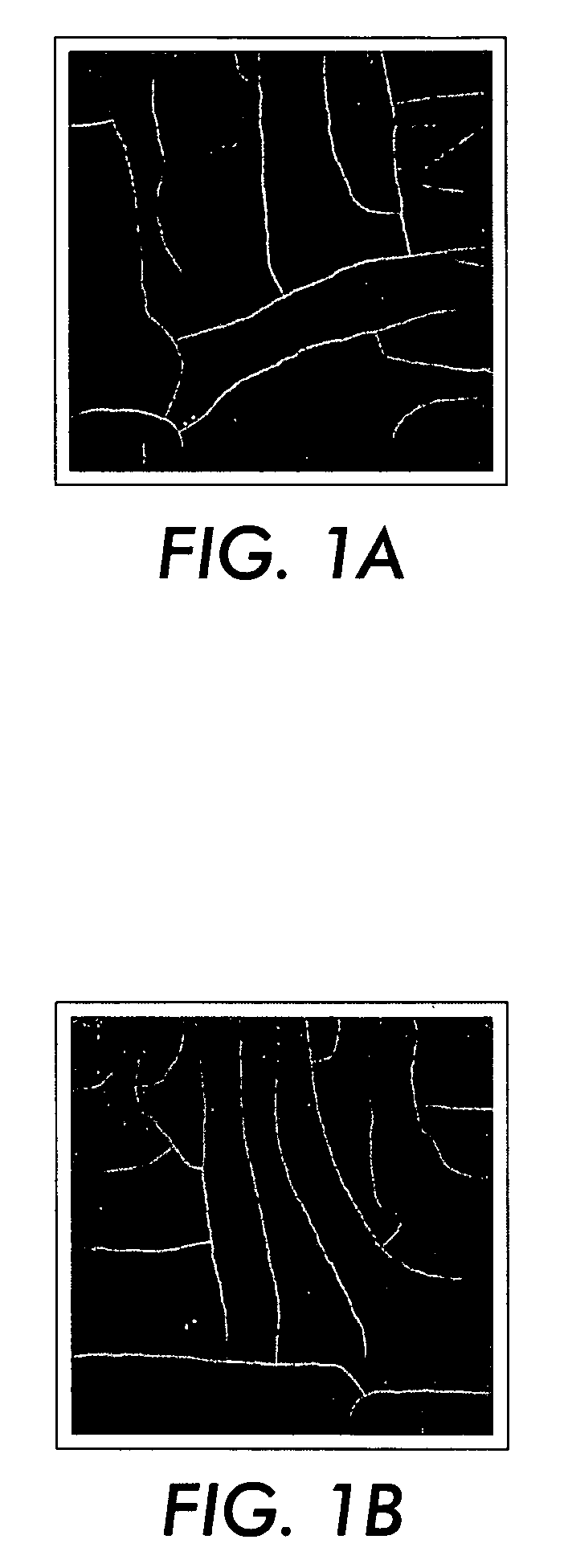

Method for making and a business form having printed bar codes on a coated substrate

ActiveUS7883018B2Improve scannabilityImproves its scannabilityRecord carriers used with machinesDigital marking by printing code marksFluorescenceBarcode

A business form such as a wristband or label includes an imaging area of face stock overprinted with a fluorescent ink for receiving a printed bar code to enhance the scannability of the bar code. The ink may be applied by overprinting to a thickness of between about 0.2 to about 0.5 mils, and even more preferably to a thickness of about 0.2 mils. The overprint ink is also print receptive allowing a bar code to be printed onto it with no deleterious effects. The imaging area of the wristband form may be overlaminated and the bar code scannability will still be enhanced. An alternative embodiment comprises a face stock manufactured to have a finished surface exhibiting a fluorescent effect similar to that achieved by overprinting through mixing in appropriate components as the face stock is made.

Owner:ZEBRA TECH CORP

Prevention or reduction of thermal cracking on toner-based prints

InactiveUS20050250038A1Permit overwritingProvide image permanenceOptical articlesElectrographic process apparatusPolymer scienceOligomer

Overprint compositions for toner-based prints containing at least one radiation oligomer / monomer, at least one photoinitiator, and at least one surfactant are disclosed. The overprint compositions provide a number of advantages to toner-based prints, such as, for example, those subjected to abrasives, heat, and / or sunlight since the compositions protect such images from cracking, fading, and smearing. In addition, the overprint compositions provide resistance to thermal cracking, which is assessed by image analysis of the thermal crack area after exposure of the print to thermal shock.

Owner:XEROX CORP

Valuable document and security mark using a marking substance

InactiveCN1564998ANon-fibrous pulp additionOther printing matterDocument preparationComputer science

The invention relates to a document of value, a security element and a security marking that have a marking substance absorbing in the infrared spectral region between 1000 and 2500 nanometers which does not significantly absorb either in the visible spectral region or at 800 nanometers. Said marking substance is therefore not accessible with the widespread, simple IR readers working at about 800 nanometers. Preferably, an additional print is added that absorbs in the visible and also at about 800 nanometers but not in the range from 1000 to 2500 nanometers. According to the inventive checking method, the marked place is irradiated with infrared light from the range from 1000 to 2500 nanometers and the absorption determined.

Owner:GIESECKE & DEVRIENT GMBH

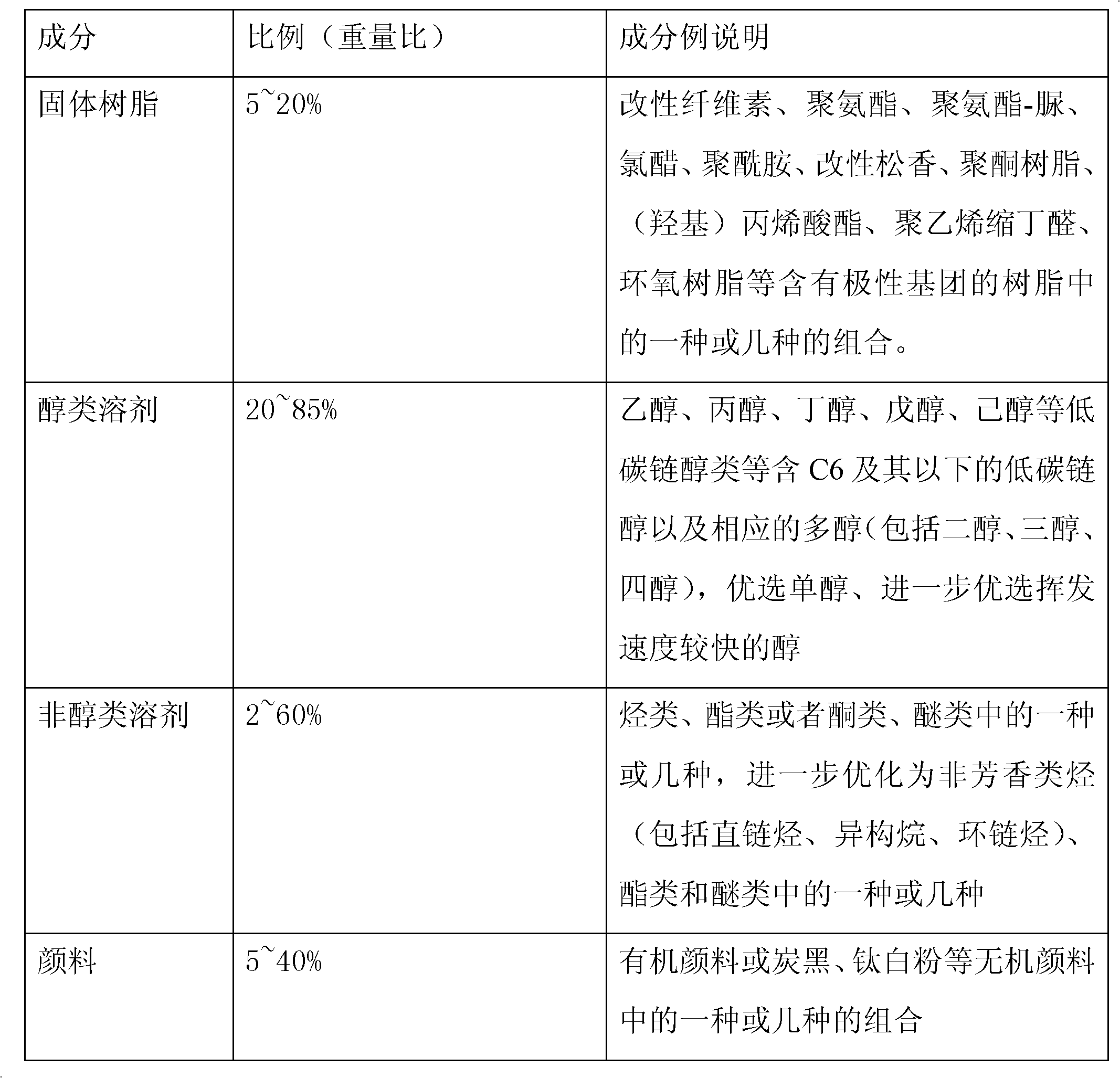

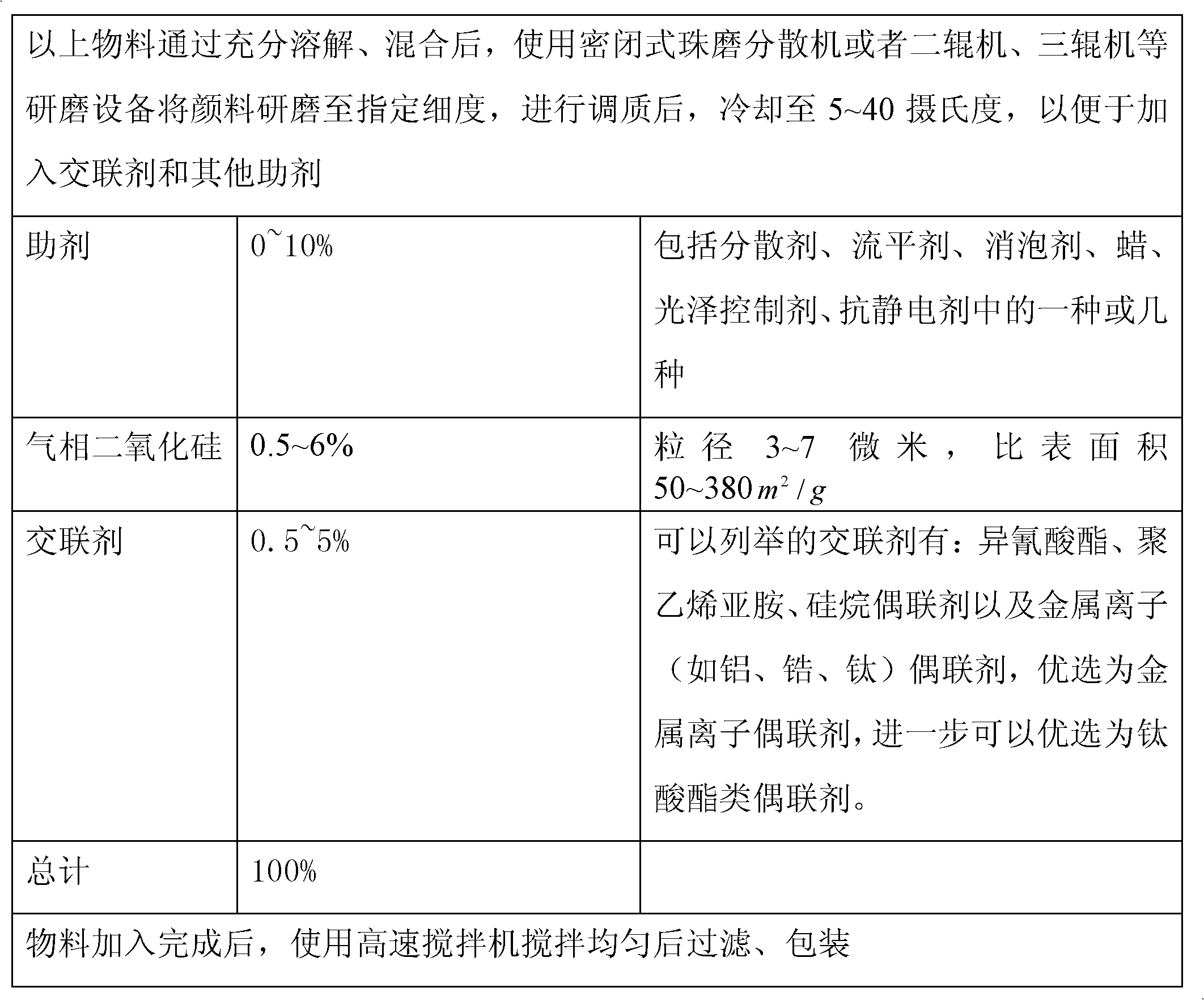

Alcoholic group liquid ink capable of realizing high-speed printing and preparation method thereof

The invention discloses an alcoholic group liquid ink capable of realizing high-speed printing, which comprises the components by weight percent: 5-20% of solid resin, 20-85% of alcohols solvent, 2-60% of non-alcohols solvent, 5-40% of pigment, 0-10% of accessory ingredient, 0.5-5% of cross-linking agent and 0.5-6% of gas-phase silicon dioxide. The cross-linking agent is added into a former-colorink during overprinting, so that the cross-linking reaction is performed during drying, the molecular weight of carrier (comprising dispersing agent) resin in the ink is fast increased, the carrier (comprising dispersing agent) resin can not be dissolved or can be hardly dissolved in the dissolvent in the ink, and a later-color ink can not be fast dissolved in the former-color ink during contacting in an overlapping way, therefore, the overprinting working procedure can be smoothly completed.

Owner:杭华油墨股份有限公司

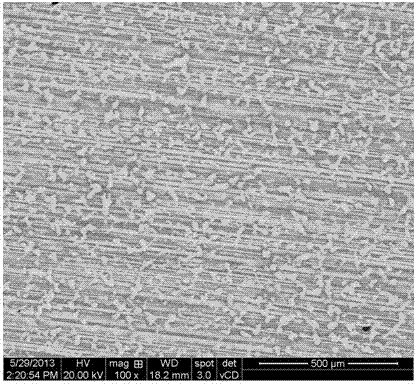

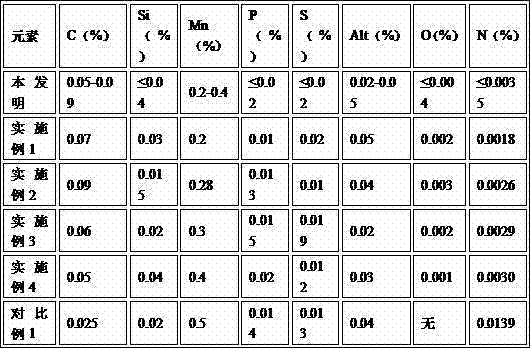

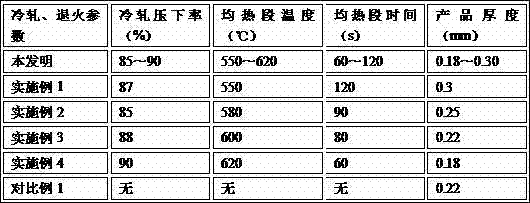

Cold rolled tin-plated steel plate for multiple printing and painting and manufacturing method thereof

The invention relates to a cold rolled tin-plated steel plate for multiple printing and painting and a manufacturing method thereof, and aims to solve the technical problems that in the prior art, the coating on the conventional cold rolled tin-plated steel plates for multiple printing and painting can be easily peeled off, the adhesive force between the coating and the steel plate is weak, and the color developing effect is bad after printing. The manufacturing method comprises the following steps: washing a hot-rolled hard tin-plated steel plate with a thickness of 1.8 to 2.3 mm by acid, performing continuous cold rolling, carrying out continuous annealing, flattening, electroplating tin on the steel plate, passivating the steel plate, and finally rolling the steel plate to obtain a finished product; wherein the cold rolling reduction ratio is 85 to 90%, the annealing temperature is 550 to 620 DEG C, the temperature is maintained for 60 to 120 seconds, the steel plate is flattened by two machines, the work roller of the first machine is an electro-discharge texturing roller with a Ra of 1.2 to 1.6 um, the rolling force is 500 to 700 t; the work roller of the second machine is a grinding roller with a Ra of 0.3 to 0.5 um, the rolling force is 250 to 350 t; the flattening elongation rate is 1 to 2%, and the passivation is carried out through an electrochemical method and a chemical method. The provided steel plate is mainly used to produce food / beverage cans, which have requirements on multi-color printing.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Aqueous flexible plate printing ink and preparation thereof

InactiveCN101328329AReduce pollutionFine inkInksOther printing apparatusSolubilityAtmospheric contamination

A water-basedsoft printing ink comprises the following compositions: 30 to 35 percent of pigment, 25 to 32 percent of acrylic resin, 0.2 to 0.5 percent of antifoaming agent, 2 to 5 percent of ethylene glycol monomethyl ether, 1.0 to 2.5 percent of wax slurry, 0.9 to 1.5 percent of leveling agent, and 23 to 30 percent of water. A preparation method comprises the three working procedures of colored slurry grinding, aquosity treatment and printing ink preparation in turn. The water-basedsoft printing ink has novel compositions, scientific blending, simple preparation, lower cost, fine ink quality, mellow brightness, high color saturation, brilliant color, high drying speed, grid point superimposition and overprinting, good water solubility, easy cleaning, corrosiveness free on printing rollers, low viscosity, high color content, good penetrability and printing adaptability, suitability for multicolor machine high-speed printing, high abrasion resistance, difficult decolorization, wide color range, closeness to a normal color sample, and consistency to the requirements on top-grade printing; and the printing ink also meets EU ROHS standards, and facilitates safe production and environmental protection with low air pollution and without any noxious solvent residual.

Owner:广东佳景科技股份有限公司

Dual Mode Ink Jet Paper

InactiveUS20090017235A1Excellent jet ink bleedExcellent cockle resistance propertyNatural cellulose pulp/paperSpecial paperDual modeEngineering

In web / ink-jet operations in which ink jet data is over-printed on forms prepared by offset litho, undesirable interactions between the surface size and litho-fountain are controlled by use of a PCC basesheet having a size press coating of starch and alum, the alum amount being at least 0.75% by weight.

Owner:GPCP IP HLDG LLC

Overprint compositions for xerographic prinits

InactiveUS20050250039A1Reduce document offsetReduce and prevent thermal crackingOptical articlesElectrographic process apparatusOligomerMedicine

Radiation curable overprint compositions containing a radiation curable oligomer / monomer, at least one photoinitiator, and at least one surfactant are disclosed. The overprint compositions are particularly well-suited for reducing or preventing document offset and for protecting xerographic images on substrates subjected to abrasives, heat, and / or sunlight since the compositions protect such images from cracking, fading, and smearing.

Owner:XEROX CORP

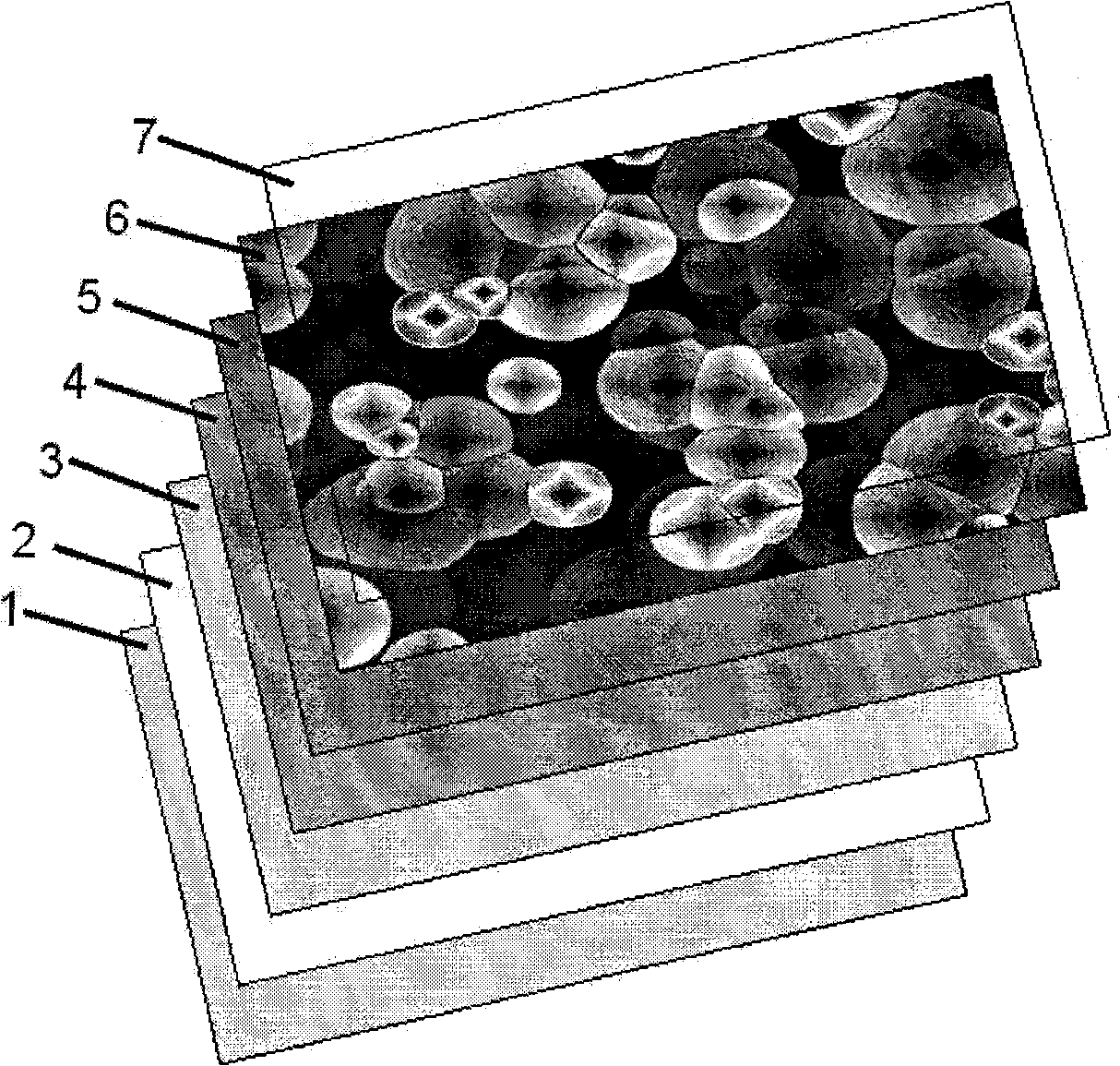

High-precision overlay gold stamping paper and manufacturing method thereof

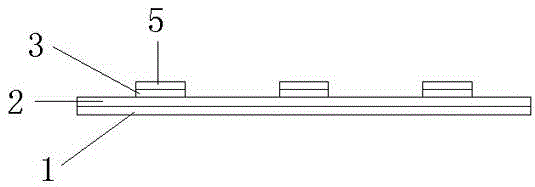

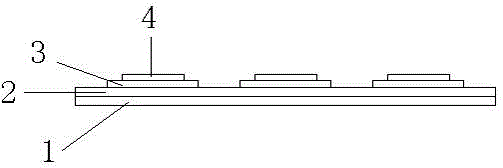

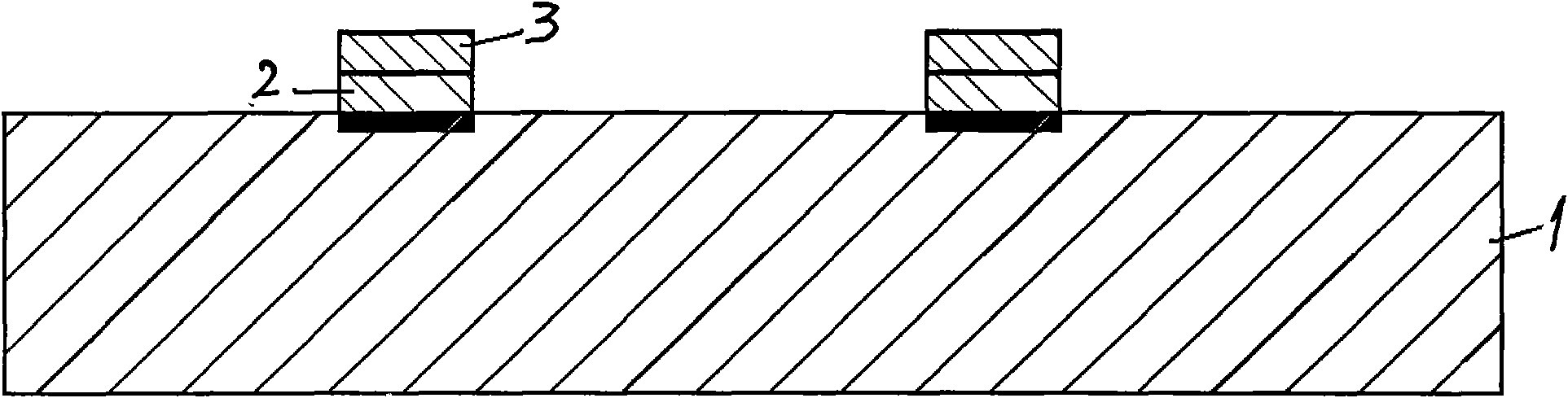

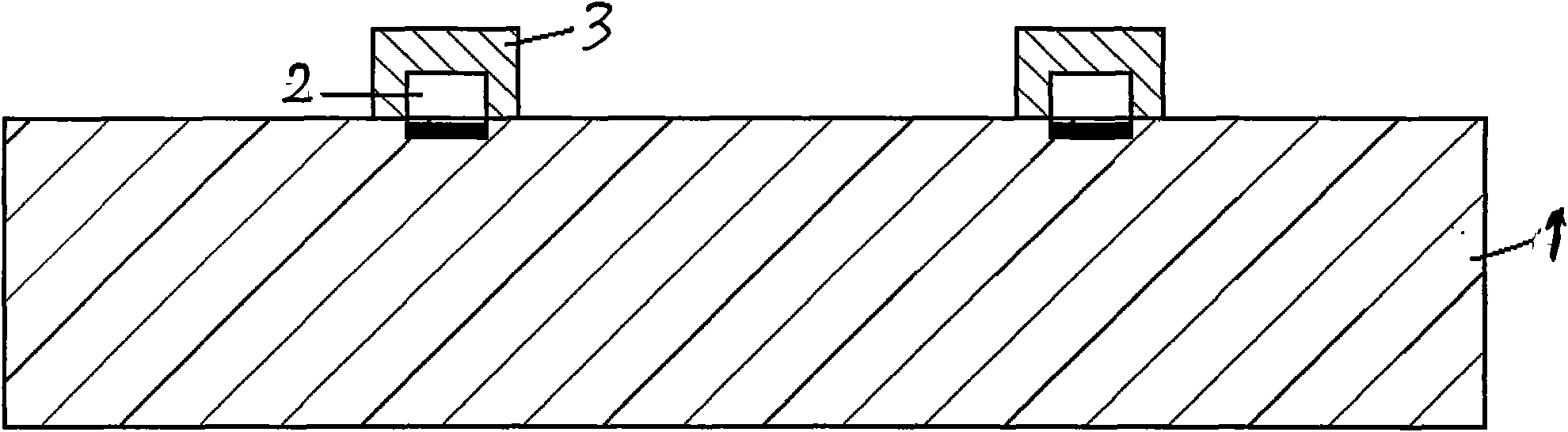

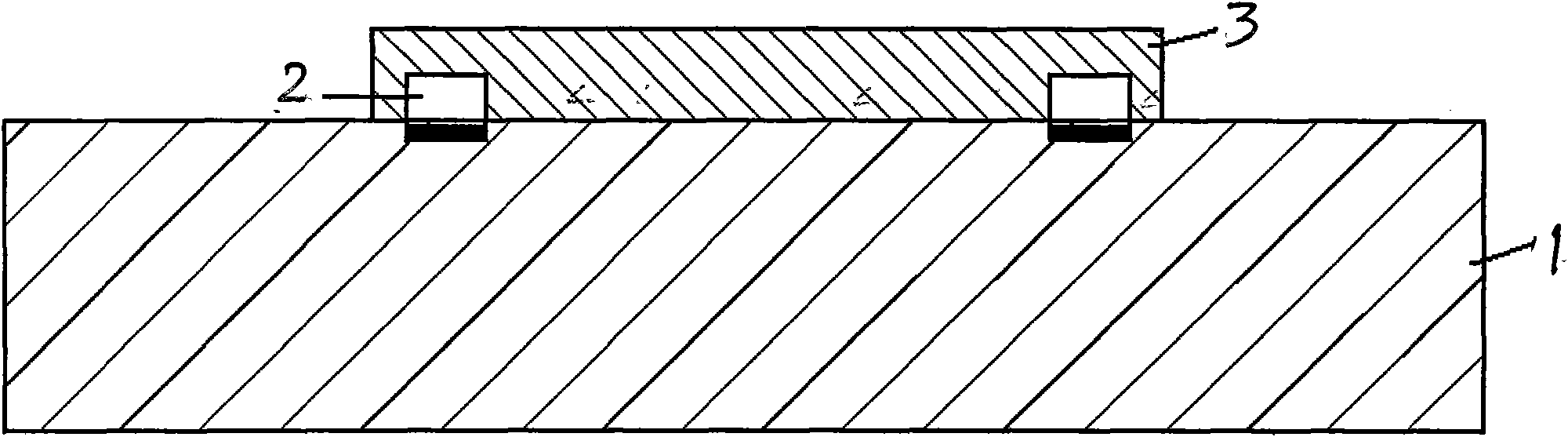

ActiveCN104924790AHigh precisionThere is no phenomenon of inaccurate ironingPaper/cardboard layered productsOther printing apparatusHot stampingProcess engineering

The invention provides a piece of high-precision overlay gold stamping paper and a manufacturing method thereof. When printing and overprinting are conducted through two existing types of alumite, the printing and stamping accuracy is not high, the printing deflection is large, and waste is prone to happening. The high-precision overlay gold stamping paper sequentially comprises a tipping base paper layer (1), a printing layer (2), a first gold stamping layer (3) and an overlay stamping layer from bottom to top. The manufacturing method includes the following steps of firstly, printing a piece of tipping paper; secondly, designing a pattern; thirdly, manufacturing an overlay gold stamping plate; fourthly, preparing hot stamping; fifthly, conducting the first time of hot stamping; fifthly, conducting overlay stamping; sixthly, conducting checking and unwinding. In the post-printing gold stamping and overlay stamping process, no inaccurate printing phenomena exist, the transverse and longitudinal overlay stamping accuracy is 0.01 mm, the printing accuracy is greatly improved, and the gold stamping plate does not need to be aligned multiple times. Due to the fact that positioned overlay stamping is conducted at a specific position of a tipping paper ink layer, products are more personalized, and meanwhile the anti-counterfeit function is achieved.

Owner:YUNNAN YUXI TIPPING PAPER FACTORY

Method for preparing crystalline silicon solar battery electrode by utilizing overprinting way

InactiveCN101656276AMeet contactImprove electrical conductanceFinal product manufactureSemiconductor devicesGraphicsAdditive ingredient

The invention discloses a method for preparing a crystalline silicon solar battery electrode by utilizing an overprinting way. The processing steps are as follows: A, preparing silicon slice for manufacturing electrodes, carrying out first electrode printing according to printing graphic aiming at contact design, and then drying and sintering; B, carrying out second electrode printing according tothe printing image of the first electrode printing or the printing image designed aiming at battery conductive resistance, overprinting on the first print graphic, and then drying and sintering. In the method of the invention, as subsequent overprinting can adopt sizing agents with different material ingredients, electrical conduction is improved, the method after whole sintering not only meets metal contact but also obtains good electrical conduction, thereby being capable of effectively improving filling factor and finally impacting on battery performance. Subsequent overprinting is attached on the surface of the first printing electrode to form a conductive structure. Overprinting process can effectively avoid frequent disconnection and incomplete printing occasions in existing printing.

Owner:CHINA SUNERGY CO LTD

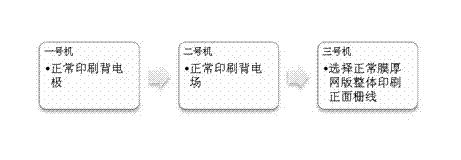

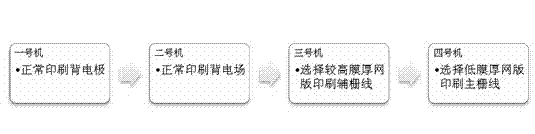

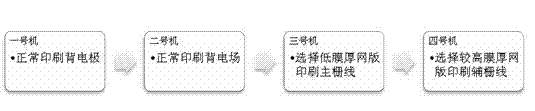

A secondary overprinting process for front electrodes

InactiveCN102270696AImprove the situation of virtual printingUniform printing pressureFinal product manufactureOther printing apparatusEngineeringSolar cell

The invention discloses a secondary overprinting process of the front electrode, which comprises the following steps: using No. 1 screen printing machine to print the back electrode; using No. 2 screen printing machine to print the back electric field; after the back electrode and the back electric field are printed, the battery The pattern printing of the grid lines on the front side of the chip is completed through the secondary overprinting of the main grid lines and the auxiliary grid lines, that is, the main grid lines and the auxiliary grid lines are printed separately. The present invention adopts the secondary overprinting technology for the grid lines on the front of the cell, without affecting the aspect ratio of the auxiliary grid lines, reduces the height of the main grid lines, improves the printing quality, and reduces the consumption of silver paste, so as to reduce the production cost of the battery sheet. cost and improve conversion efficiency.

Owner:HEFEI HAREON SOLAR TECH

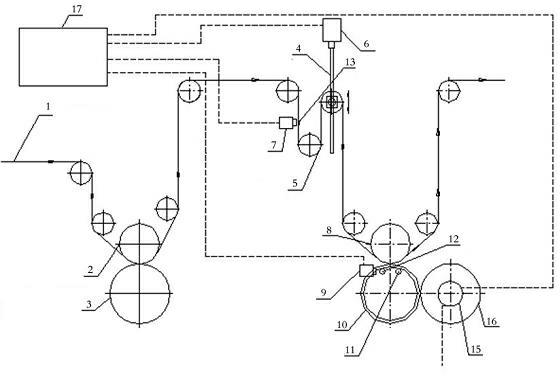

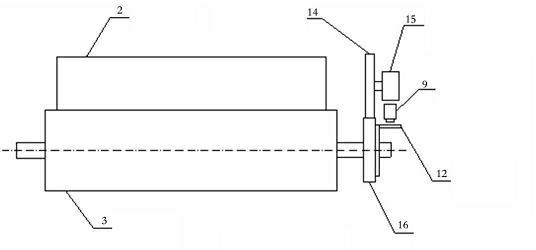

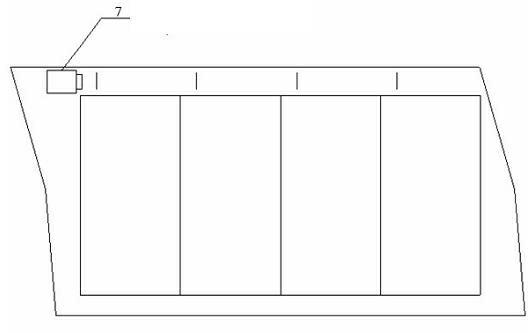

Reel material printer pre-positioning automatic overprinting system and automatic overprinting method

InactiveCN102423965ASimplify InterferenceSimple and reliable control systemPrinting press partsStroboscopeControl system

The invention relates to a reel material printer pre-positioning automatic overprinting system of various color overprinting in printing machinery and an automatic overprinting method. The system comprises an overprint color mark line of a first color a photoelectric sensor, a plate cylinder, two position signal rods and a photoelectric sensor, a rotary encoder synchronized with the gear of the plate cylinder, an overprint motor, an overprint screw rod, a control system and other mechanisms, the error of overprinting of a subsequent printing color and the first color is regulated to be zero by means of observation of vision (or stroboscope, still picture system and the like), and the condition is confirmed that: the photoelectric sensor measures that the position of a signal of the overprint color mark line of the first color and the plate cylinder virtual reference register central position are positions with zero overprint error. In each subsequent time of printing, the system is controlled to instruct the overprint motor to drive an overprint screw shaft and an overprint regulating shaft to perform error regulation according changes of the position of the signal of the overprint color mark line of the first color and the plate cylinder virtual register central position of the nth color detected by the photoelectric sensor.

Owner:任继平 +2

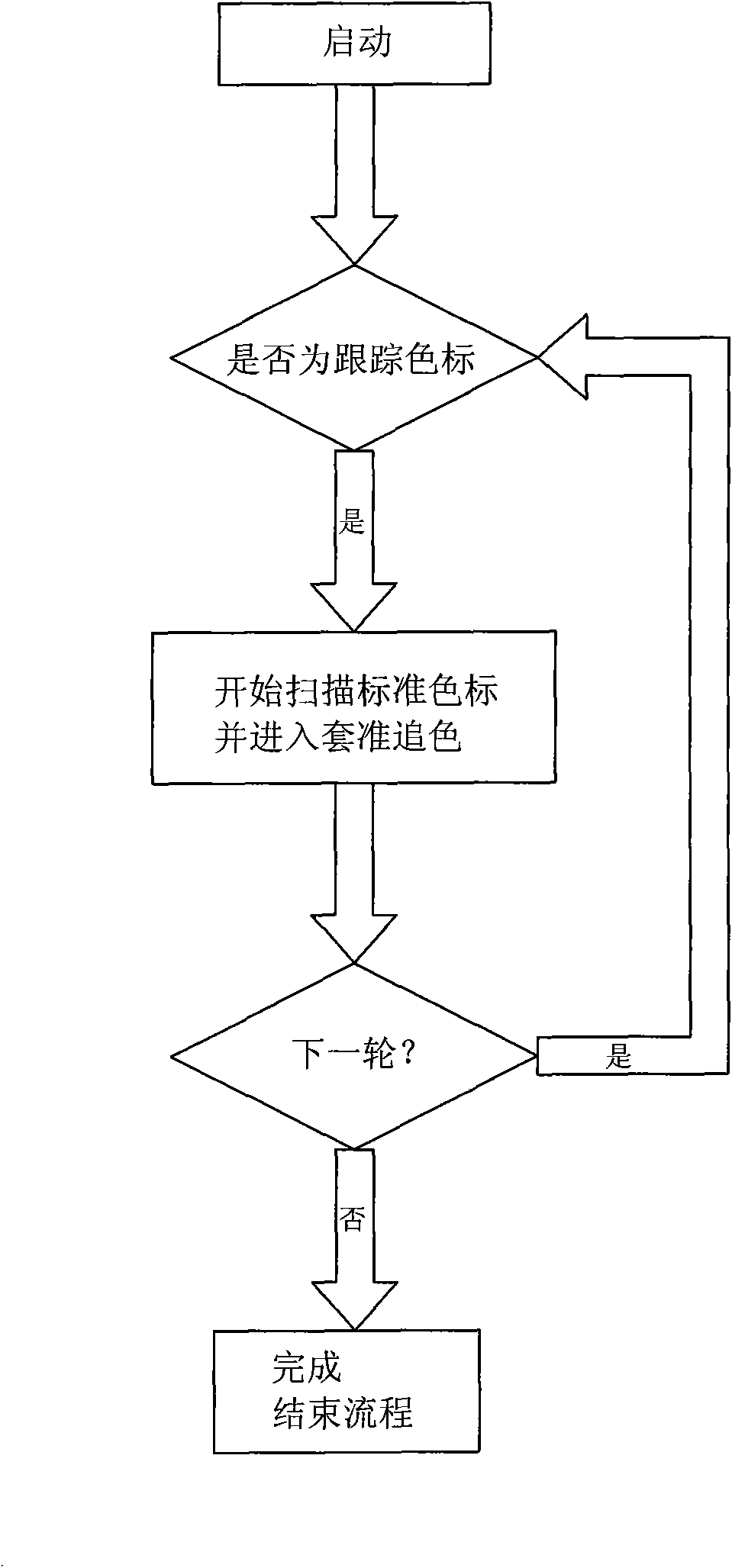

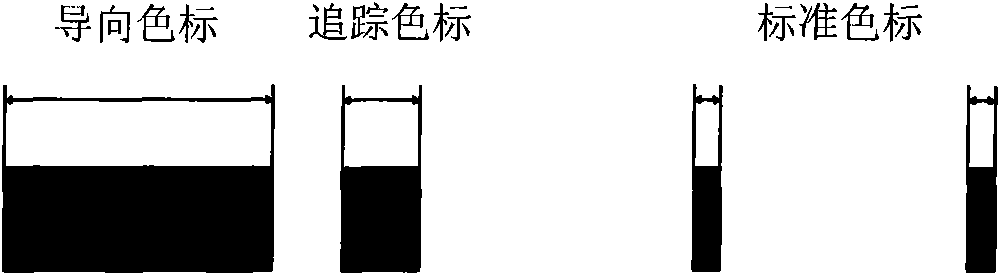

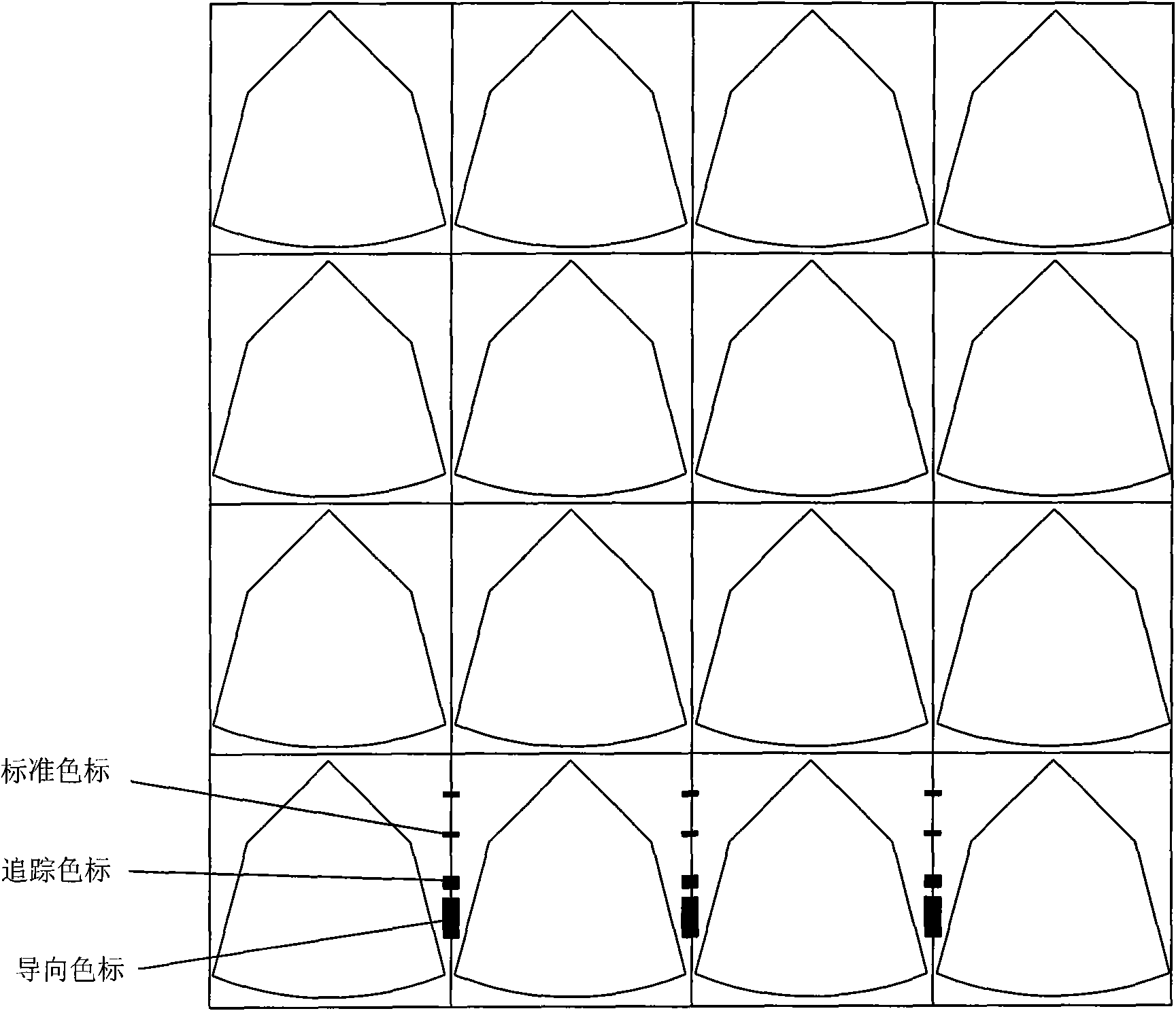

Method for overprinting color identification and make-up applied to gravure printing

InactiveCN101596805AReduce consumptionTo achieve the purpose of printing tracking registrationRotary pressesColor ScalePunching

The invention discloses a method for overprinting colour identification and make-up applied to gravure printing, comprising the following steps: make-up, colour code set, and registration colour; when gravure printing products are in punching, blank waste material with a certain area is left between patterns, in the invention colour code is set on the blank material to blank material to register colour, thereby achieving the purpose of printing and tracing registration, saving the around 20mm of waste material band which must be left in current gravure printing process, and ensuring no influence on the efficiency of the follow-up production, thus greatly saving the consumption of raw material and lowering production cost, therefore, the invention has broad practicability.

Owner:广东万昌印刷包装股份有限公司 +2

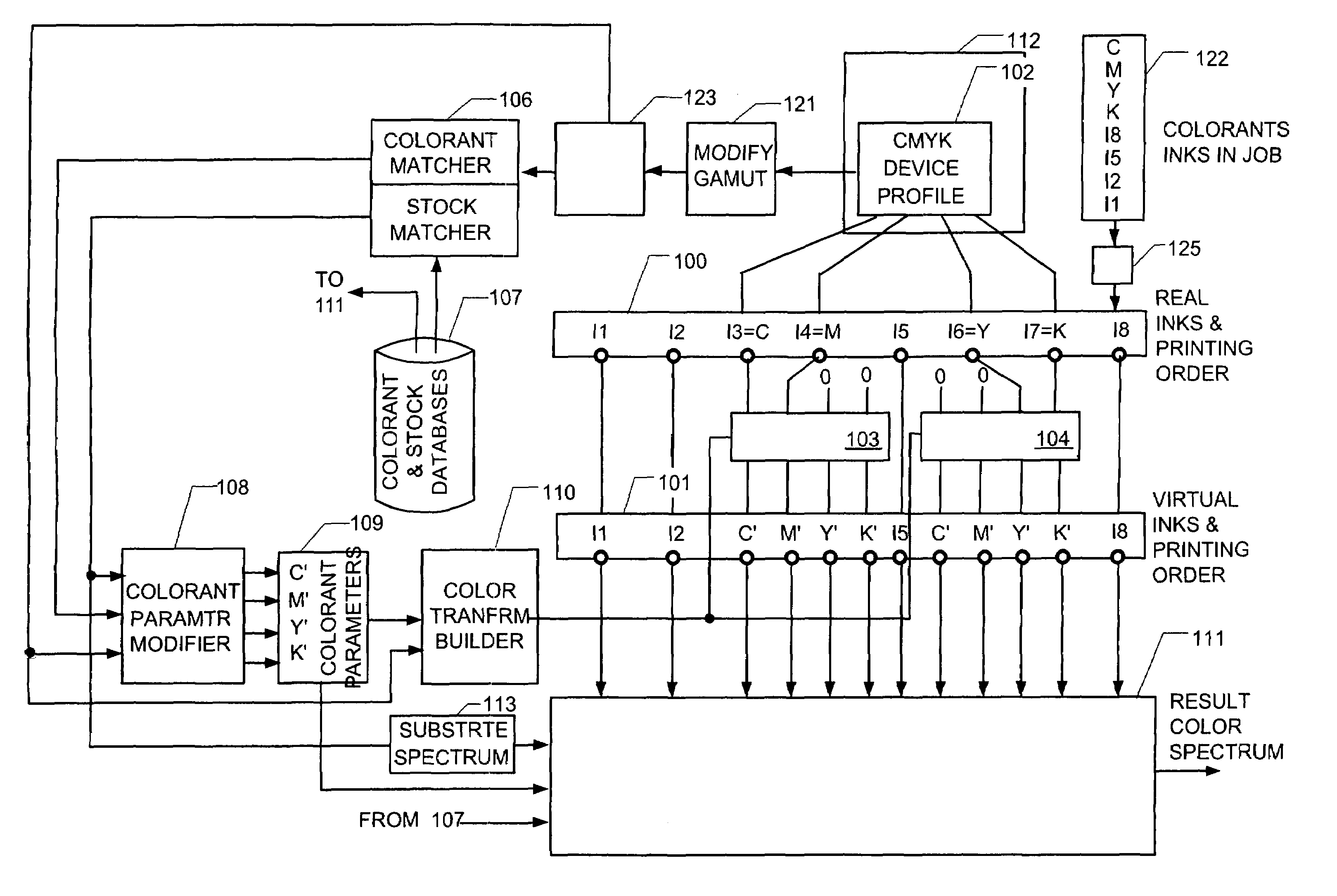

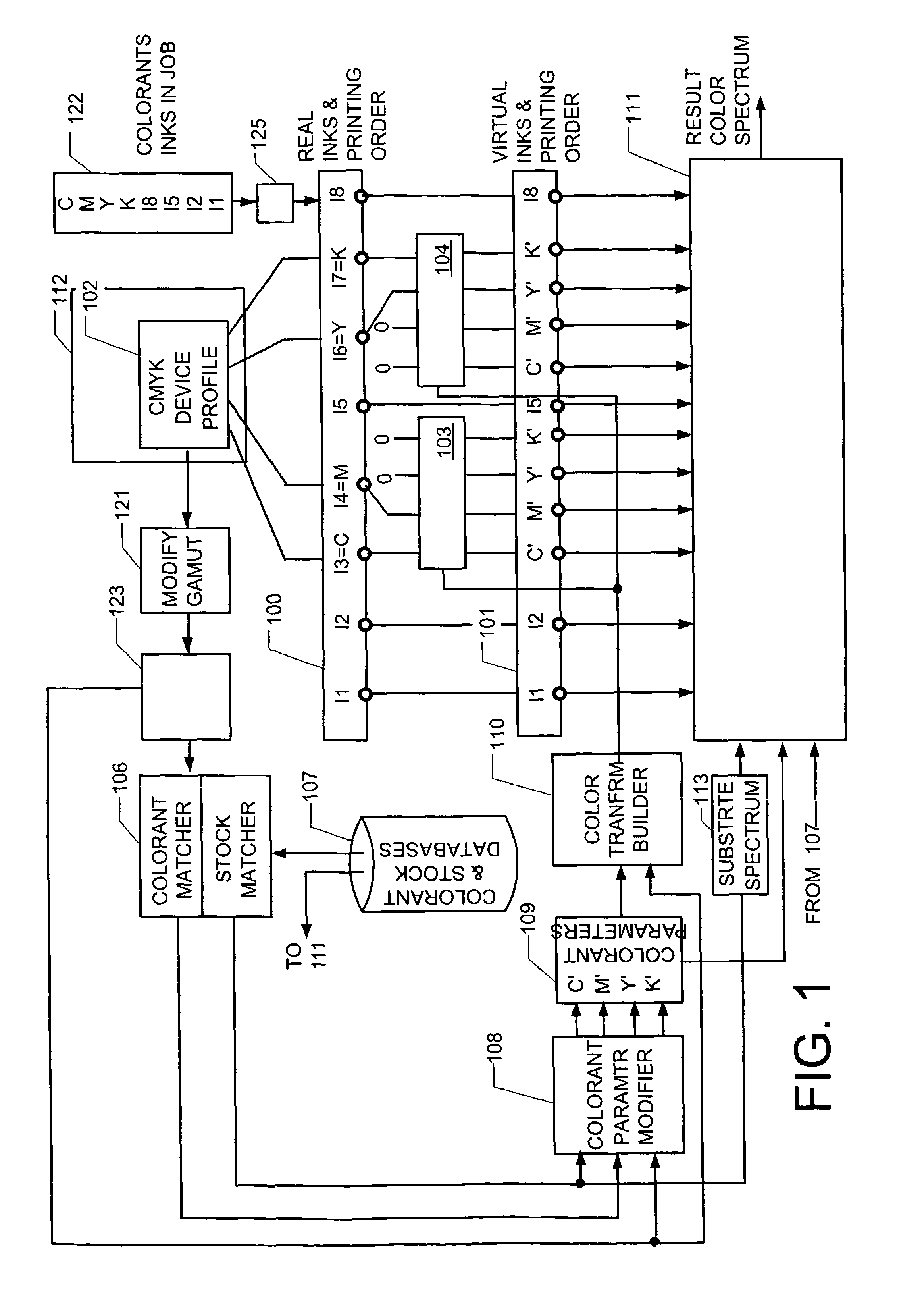

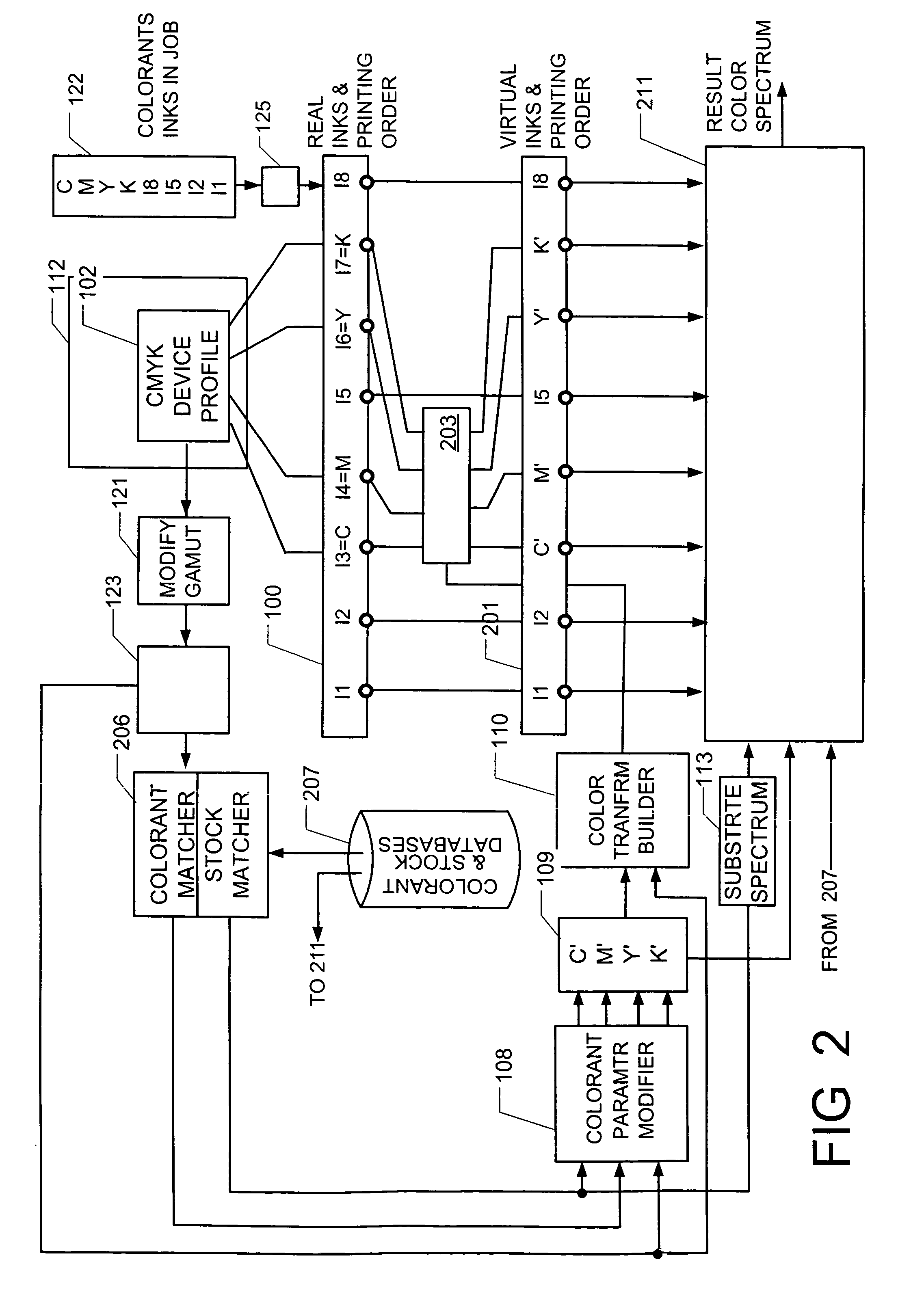

Method and device for determining the color appearance of color overprints

InactiveUS7199903B2Digitally marking record carriersDigital computer detailsSubstrate typePattern recognition

A method and apparatus to predict the color of an overprint of a set of colorants at a set of respective coverage percentages on a substrate of a substrate type using a printing technique. The colorants include some for which a device profile is provided. The method includes determining the colorant parameters of the device profile colorants; determining the spectrum of the substrate, providing spectral colorant parameters for the non-device profile colorants, and determining the color of the overprint. One version including modifying the data of the device profile such that the colorant parameters determined in the step of determining colorant parameters determines the colorant parameters of modified colorants that match the color of the device profile colorants and that cover at least the gamut of the device profile colorants. In one version, the step of determining the determining the color of the overprint includes determining the coverage percentages of the modified colorants corresponding to the colorants of each subset, and using the coverage percentages of the modified colorants to determine the color of the overprint.

Owner:AGFA NV

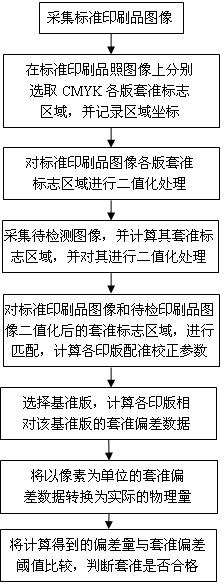

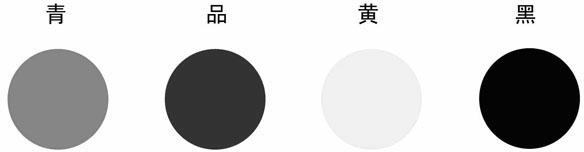

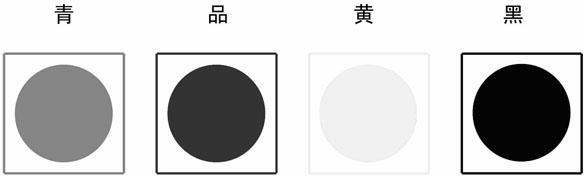

A method for automatic detection of registration deviation of color printed matter

ActiveCN102275382AAccurate detectionImprove detection accuracyPrinting press partsTemplate matchingComputer graphics (images)

The invention discloses a method for automatically detecting the registering deviations of color printed matters. The method comprises the following steps: firstly, designing a set of registration marks capable of meeting the needs of automatic registration; then, respectively acquiring an image of a standard printed matter and an image of a printed matter to be detected by using a color linear array camera, selecting the registration mark area of each forme one by one on the image of the standard printed matter in an man-machine interaction mode, carrying out preprocessing on the registration mark area of each forme on the image of the standard printed matter and corresponding areas on the image to be detected, and through carrying out small neighborhood template match-searching, obtaining registering calibration parameters between the image of the standard printed matter and the image of the printed matter to be detected; and finally, selecting some forme as a reference forme, calculating the differences between the calibration parameter of the reference forme and the registering calibration parameters of other formes, and converting the differences into actual physical quantities, namely, the registering calibration data of other formes obtained through detection. The method disclosed by the invention is suitable to be applied to the detection on registering deviations in the process of carrying out multi-color overprint; and by using the method disclosed by the invention, the axial and circumferential registering deviations of each forme can be obtained quickly.

Owner:烟台市裕同印刷包装有限公司

Transferring method of holographic anti-counterfeiting patterns suitable for gravure positioning overprinting

ActiveCN104149506AIncrease productivityAchieve productionPattern printingOther printing apparatusLacquerBiochemical engineering

The invention discloses a transferring method of holographic anti-counterfeiting patterns suitable for gravure positioning overprinting. The transferring method comprises the following steps that a laser plate provided with positioning patterns is manufactured, and a holographic positioning mark is manufactured near each positioning pattern; a base film is coated with a transferring acrylic acid lacquer coating layer with a mould pressing property; the locating patterns and the holographic positioning marks on the laser plate are embossed on the acrylic acid lacquer coating layer on the base film; the face, provided with the positioning patterns, on a positioning holographic film is aluminized in a vacuum mode; paper and the positioning holographic transfer film are composited; the positioning holographic paper is dried through a drying oven to be formed; the base film in the formed positioning holographic paper is peeled off and finally the coating carrying the positioning holographic patterns is kept on the paper. The transferring method of the holographic anti-counterfeiting patterns can effectively control the relative positions of all the positioning patterns of the transfer film and the size deviation between the holographic positioning marks on the transfer film and printing positioning marks on the paper.

Owner:SHANGHAI ZIJIANG METALLIZATION ENVIRONMENTAL PROTECTION MATERIAL

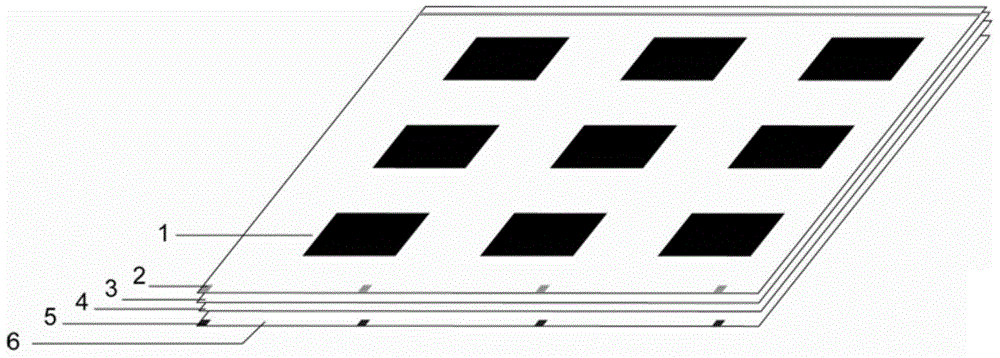

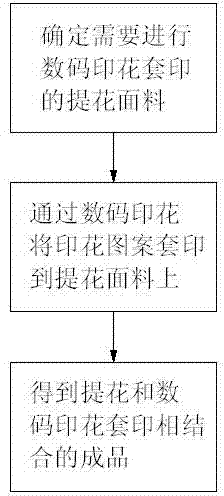

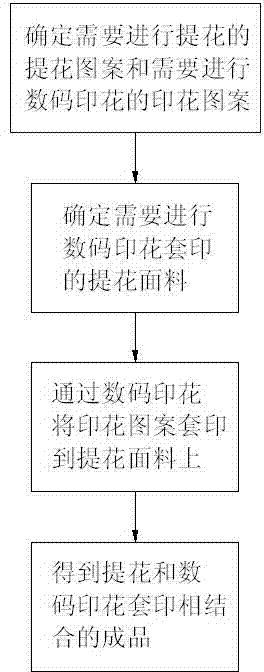

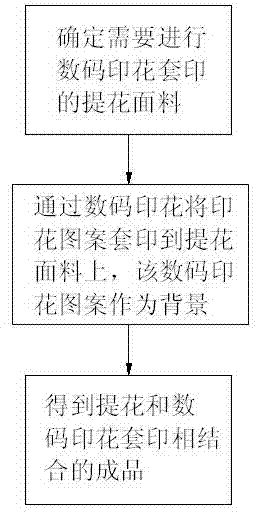

Digital printing overprinting method of jacquard fabric

ActiveCN102756581AThree-dimensionalImprove qualityTypewritersOther printing apparatusEngineeringDigital printing

The invention relates to a digital printing overprinting method of jacquard fabric. At present, a manufacturing method for organically combining the jacquard weaving and the digital printing of the fabric does not exist. The digital printing and overprinting method is characterized by comprising the steps of 1) determining the jacquard fabric needing to be subjected to digital printing overprinting; 2) overprinting printing patterns on the jacquard fabric by digital printing so as to match the digital printing patterns on the jacquard fabric with jacquard patterns and form combined patterns combining the jacquard patterns and the digital printing patterns on the jacquard fabric. According to the digital printing overprinting method, the process design is scientific, the operation is simple and convenient, the complicated positioning is not needed, the jacquard of the fabric and the digital printing can be combined organically, a product with the jacquard patterns and digital printing patterns can be produced, has a strong three-dimensional effect, is layered, colorful and strong in expression.

Owner:HANGZHOU HONGHUA DIGITAL TECH

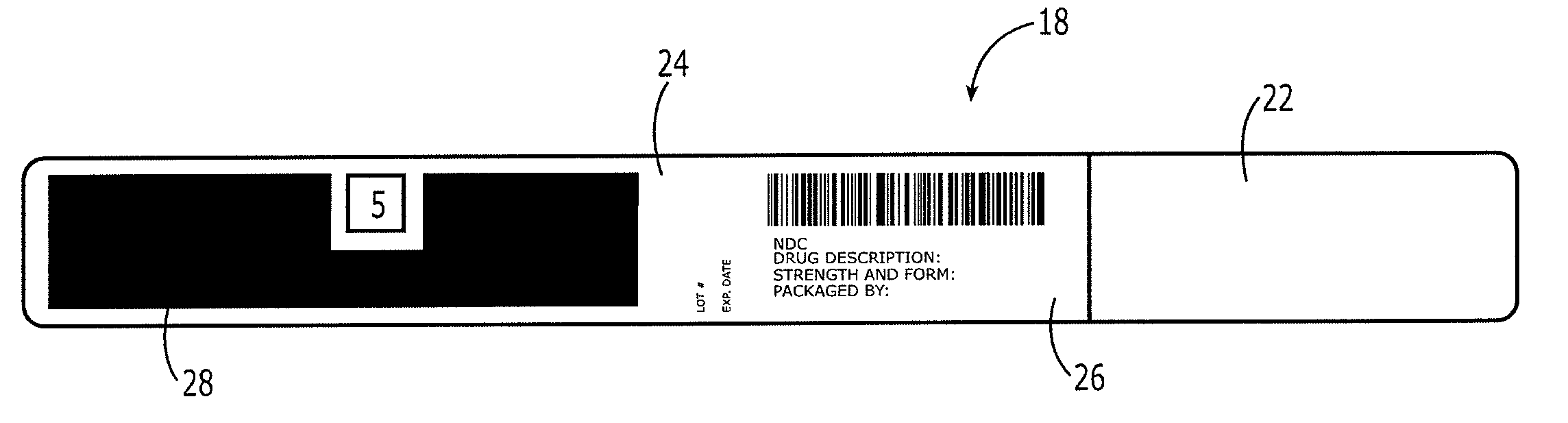

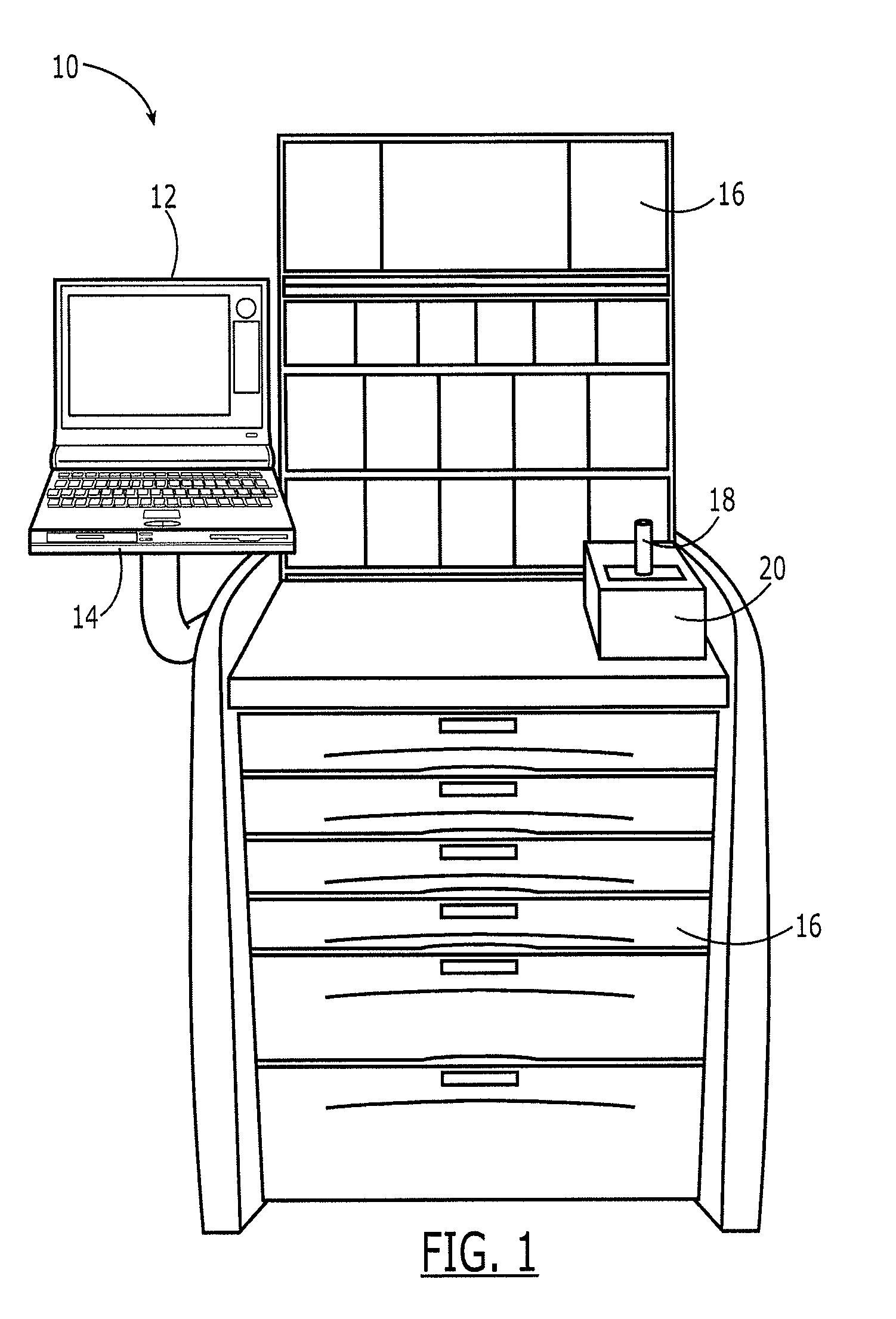

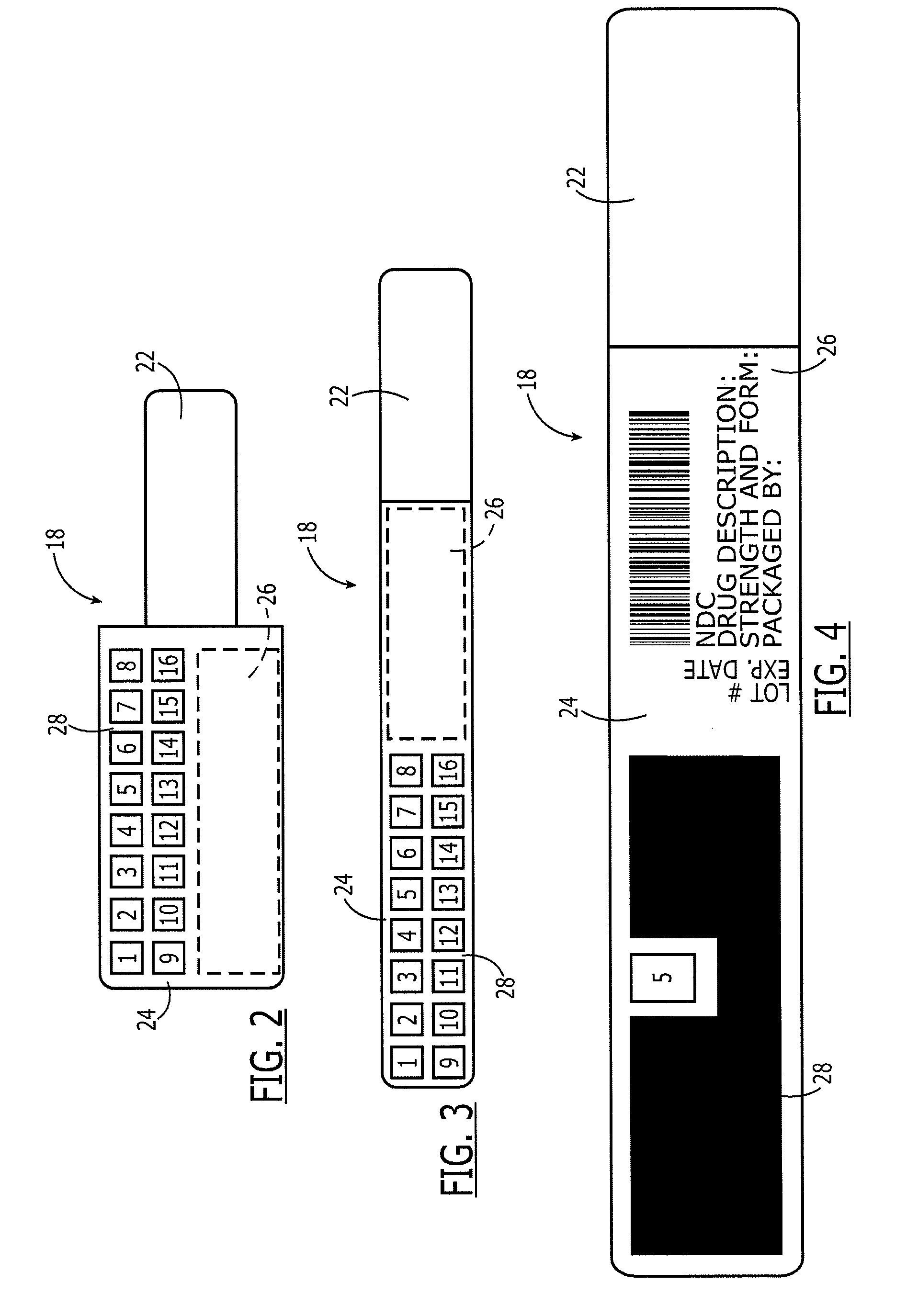

Visibly-Coded Medication Label And Associated Method, Apparatus And Computer Program Product For Providing Same

ActiveUS20100241446A1Cost effectiveStampsData processing applicationsComputer scienceComputer program

A visibly-coded medication label and an associated method, apparatus and computer program product for providing a visibly-coded medication label are provided. A label having an attachment portion and an informational portion may be provided. The informational portion includes a plurality of regions having different visible indicia, such as different colors. Information may be imprinted upon the informational portion that is related to the medication with which the label is to be associated. At least one region that has visible indicia representative of the associated medication may be identified. At least one of the regions other than the region that has been identified to have visible indicia representative of the associated medication may then be overprinted and at least partially obscured. However, the region that has been identified to have visible indicia representative of the associated medication remains visible following the overprinting.

Owner:OMNICELL

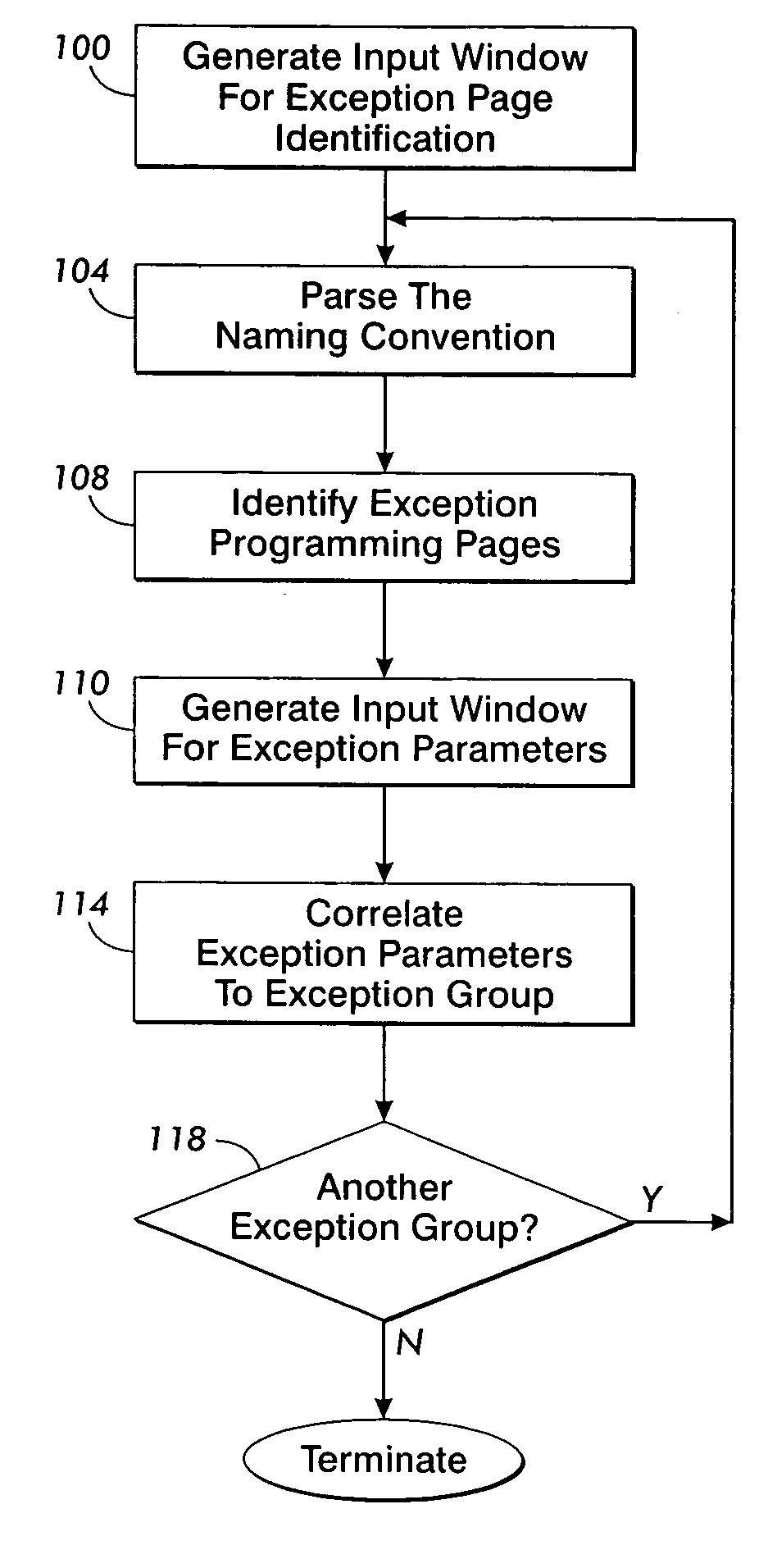

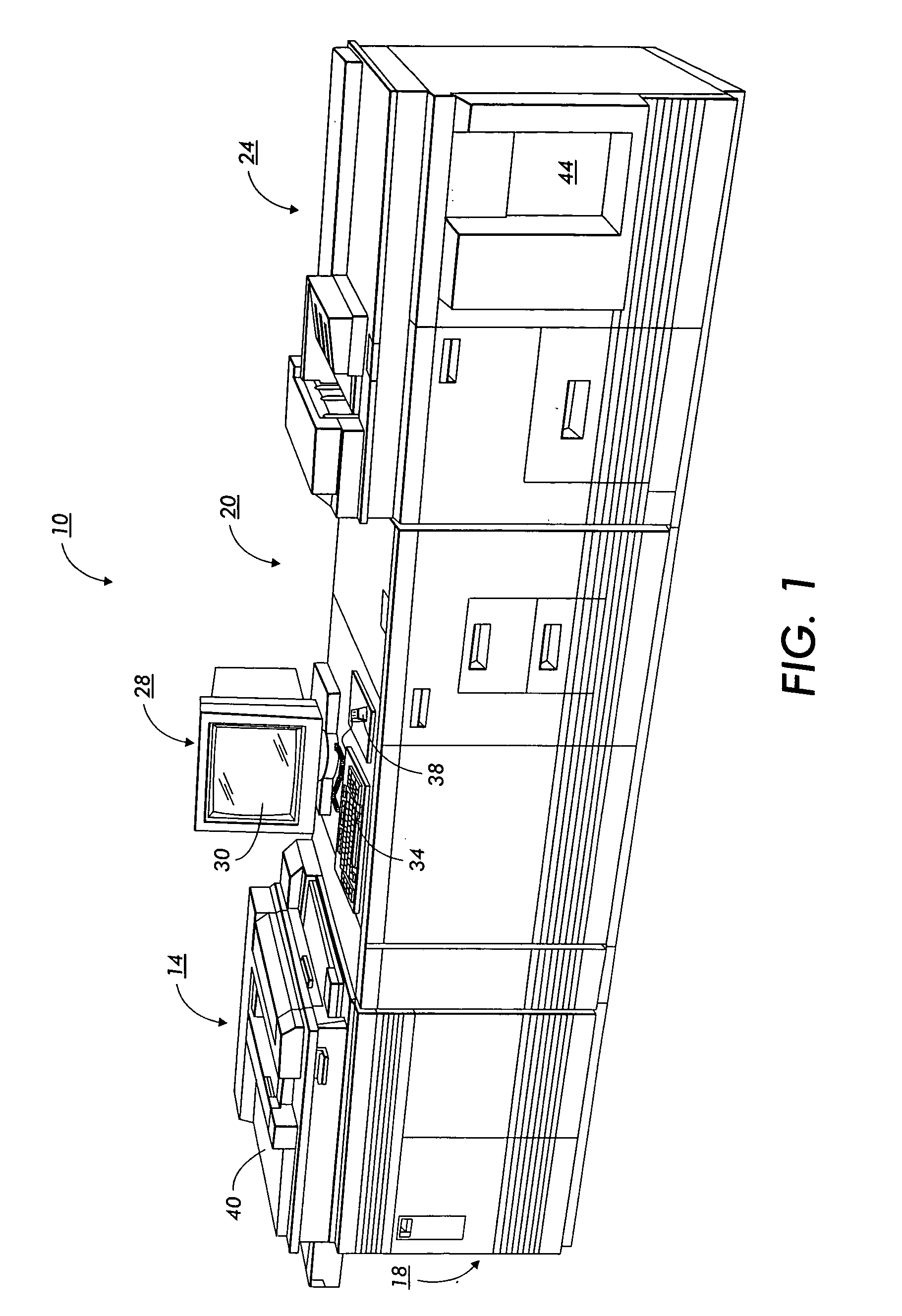

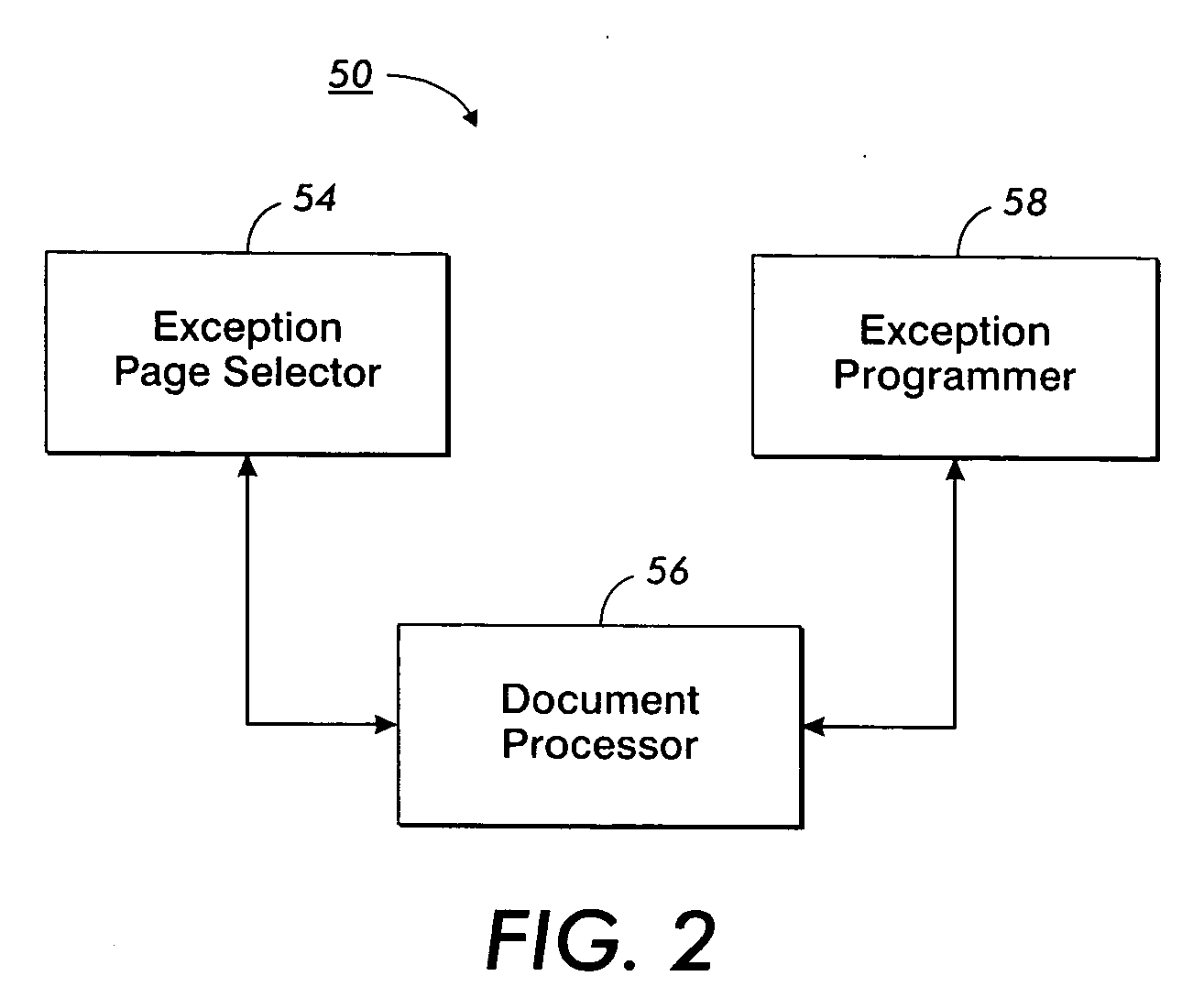

Method and system for multi-page exception programming in a document management system

InactiveUS20050152000A1Digitally marking record carriersDigital computer detailsAnti-aliasingConfigfs

A system supports page exception programming in a document reproduction system without requiring cursor control to identify each page subject to exception processing. The exception page selector receives input that uses a naming convention to identify pages within a document for exception programming. The naming convention may include an odd / even designation, an imposition template identifier and / or page numerals. An exception programmer enables an operator to correlate different device color profiles for pages identified by the exception page selector. Exception parameters that may also be correlated to pages identified by the exception page selector include anti-aliasing, trapping, black overprinting parameters, and other known printing parameters.

Owner:XEROX CORP

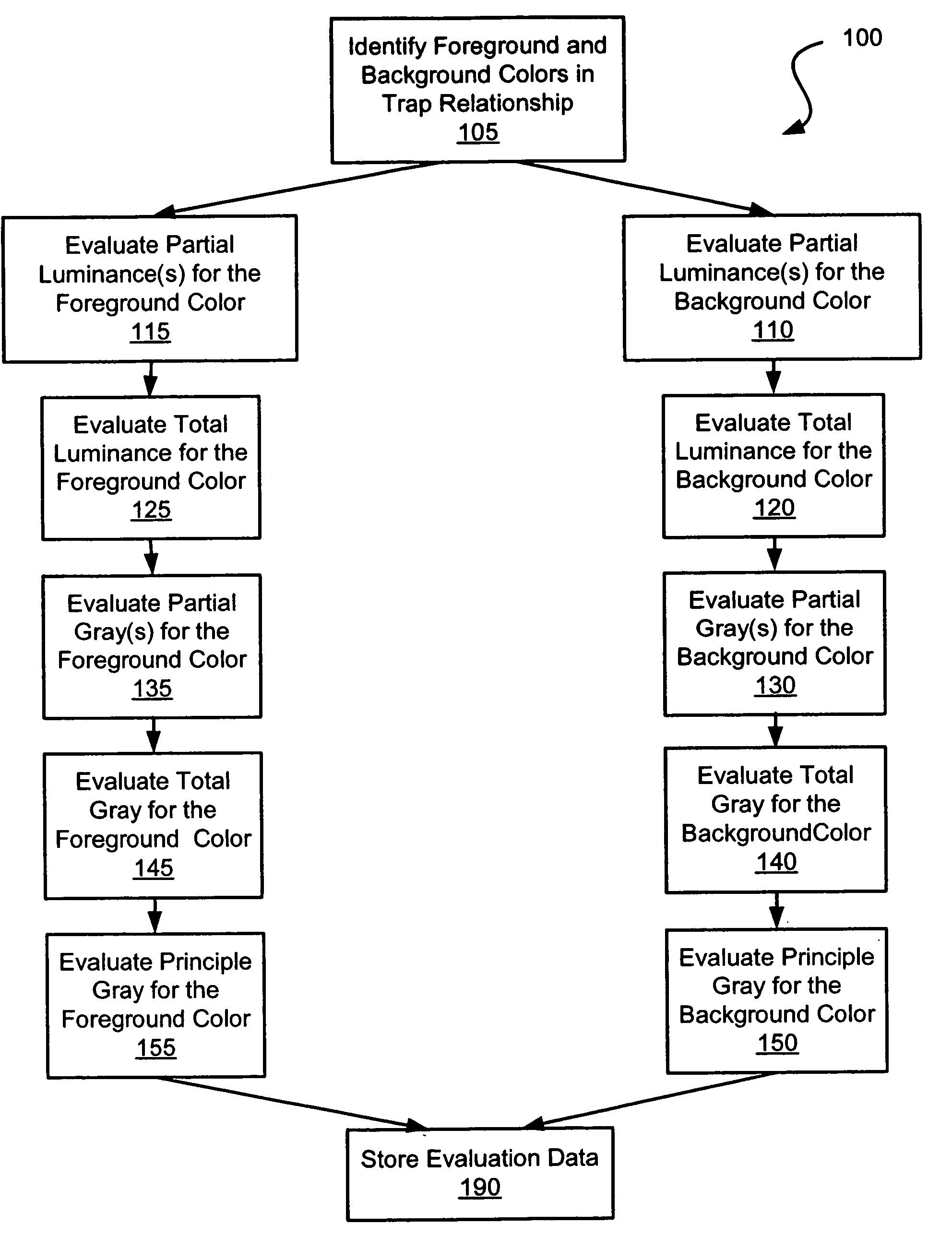

Systems and methods for trapping in a publishing environment

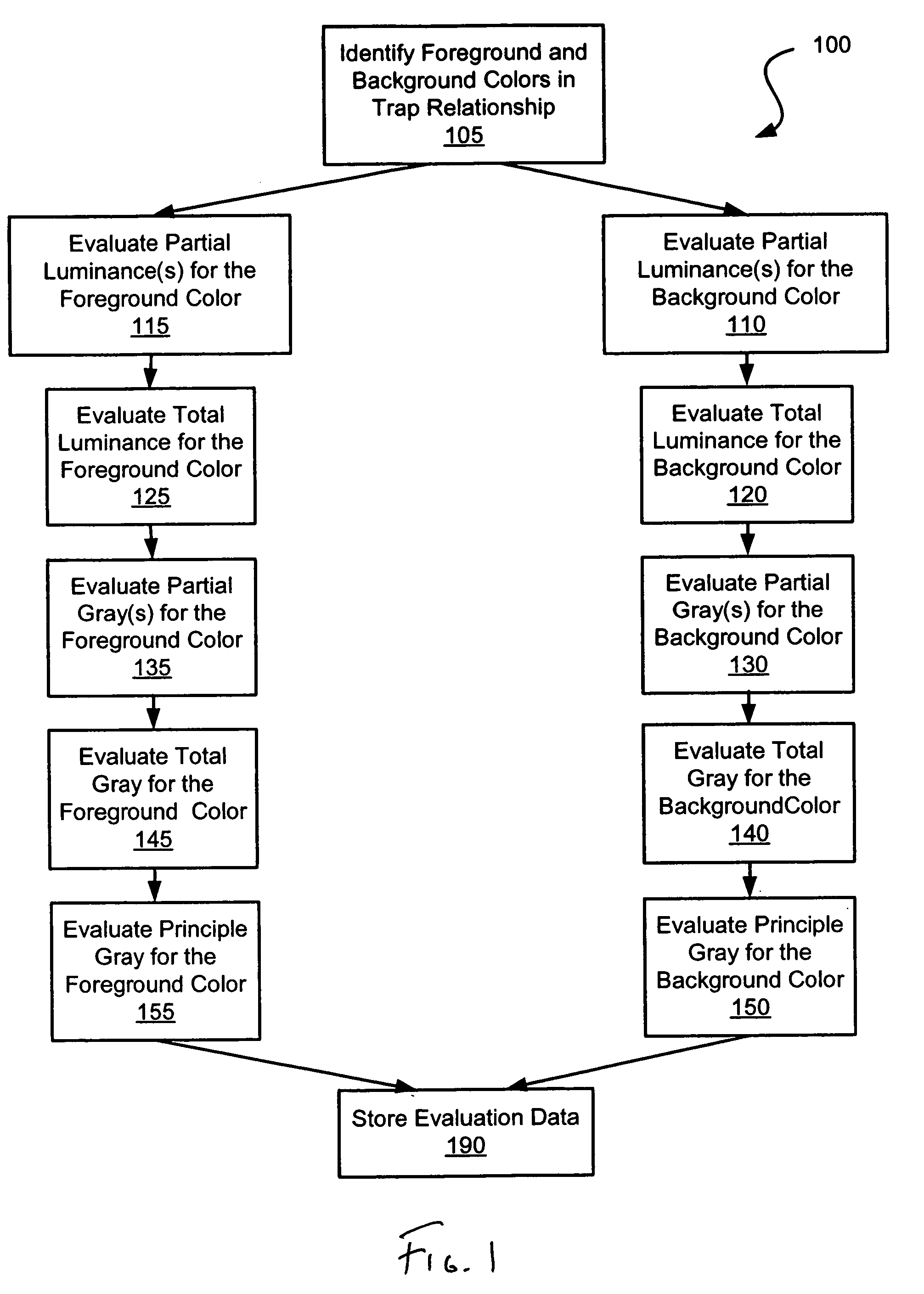

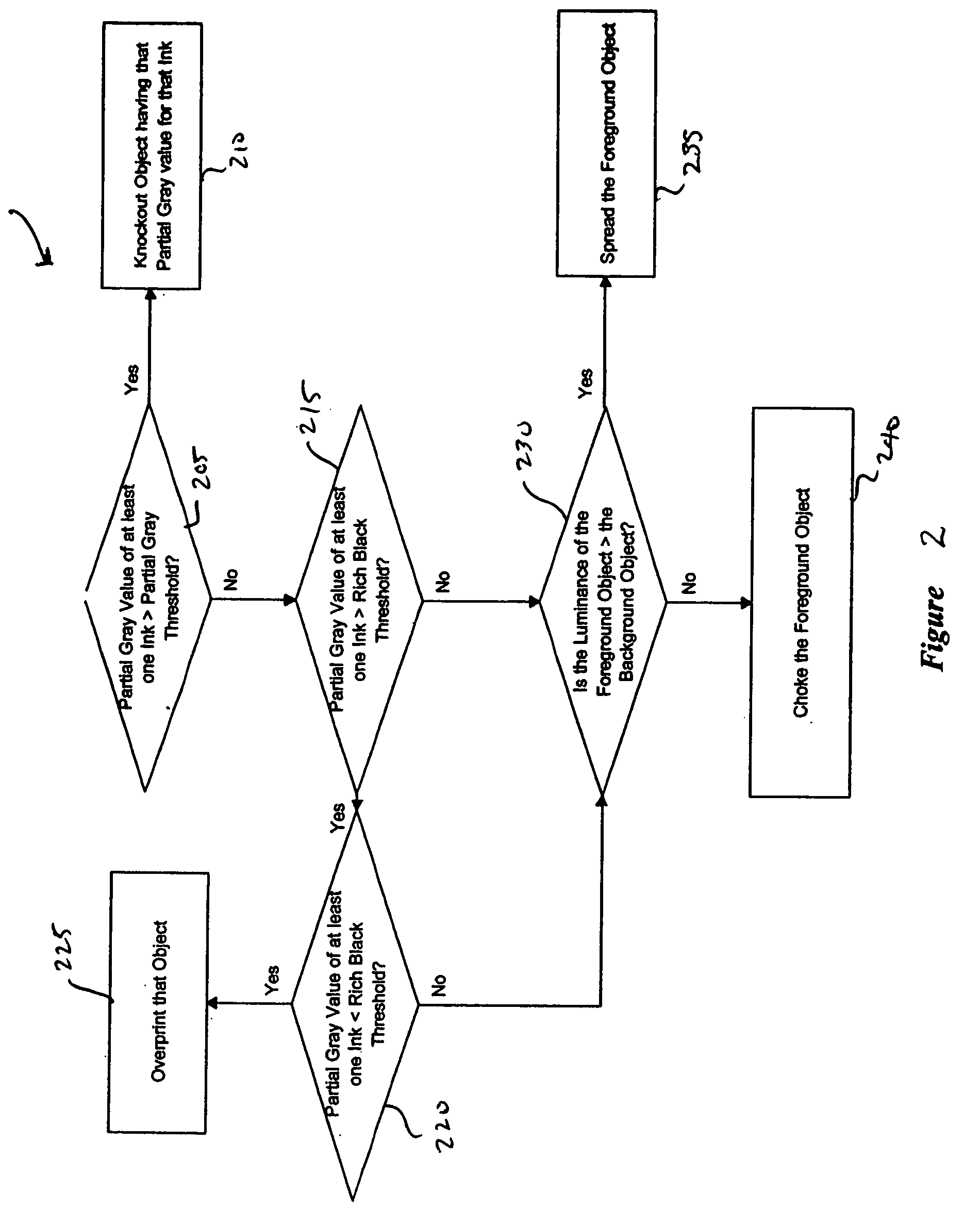

Various systems and methods for trapping in a publishing environment are disclosed. For example, a method for trapping in a printing process is disclosed and includes identifying two objects associated with the trap. One of the objects is a foreground object, and the other is a background object. A trap zone is created around at least one of the foreground and background objects, and a trap direction is determined based at least in part on an ink characteristic of an ink associated with a color of the background and / or foreground. The trap direction may include a choke, an overprinting, a spread, and / or a knockout.

Owner:QUARK INC

UV (Ultraviolet) impressing gloss oil and preparation method thereof

ActiveCN103756552AHigh solid contentImprove adhesionPolyurea/polyurethane coatingsEvaporationUltraviolet

The invention provides UV (Ultraviolet) impressing gloss oil. The UV impressing gloss oil contains components according to the following weight ratios: 10-30 parts of polyacrylic acid resin, 20-40 parts of polyurethane resin, 40-60 parts of diluent monomer, 2-10 parts of photoinitiator, and 1-5 parts of auxiliary. The invention also provides a preparation method of the UV impressing gloss oil. The UV impressing gloss oil provided by the invention adopts the matching of the polyacrylic acid resin and the polyurethane resin, can meet the requirements on both adhesive force and curing speed, has excellent adhesive force to a plastic film, such as a PET (Polyethylene Terephthalate) film, and can be rapidly cured; moreover, in the process of rapid curing, the coating volume shrinkage of the UV impressing gloss oil provided by the invention is little, and the deformation of a base material of the plastic film can be reduced so as to be beneficial to the precise overprinting of impressing images and texts and printing images and texts; the UV impressing gloss oil provided by the invention is high in solid content, the impressing of images and texts with deeper grains is easy to realize, and a large amount of evaporation of a solvent does not exist in use, so that the UV impressing gloss oil has good environmental protection performance.

Owner:汕头市龙湖昌丰化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com