A method for automatic detection of registration deviation of color printed matter

A registration deviation and automatic detection technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve problems such as low speed and low precision, improve detection accuracy, reduce analysis difficulty, and improve detection speed and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

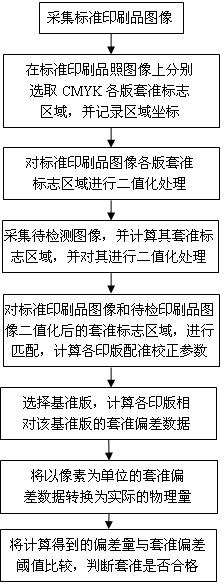

[0045] A method for automatic detection of registration deviation of color printed matter, which is specifically implemented through the following steps:

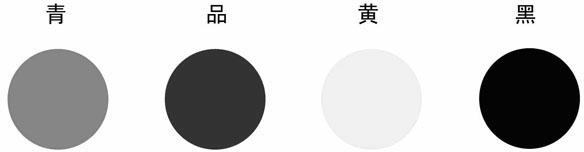

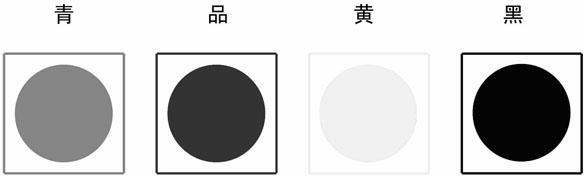

[0046] Step 1, place the designed registration mark image on a certain edge position of the printed image to be printed, and print it together, and use it as the design original to print the standard printed matter and the printed matter to be tested; figure 2 As shown, the registration mark is composed of four solid circles of cyan (C), magenta (M), yellow (Y) and black (K) arranged at a certain distance, and are respectively composed of cyan, magenta, and yellow , and black are printed on four printing plates, and the color values of the four solid circles are: cyan is (C100M0Y0K0), product is (C0M100Y0K0), yellow is (C0M0Y100K0), black is (C0M0Y0K100);

[0047] Step 2: Use a color line-scan camera to capture the printed standard printed matter image, and use the human-computer interaction method to drag multiple recta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com