Digital printing overprinting method of jacquard fabric

A digital printing and fabric technology, applied in printing, printing devices, etc., can solve the problems of fabrics that cannot be combined with jacquard and digital printing, patterns that do not have layers and three-dimensional effects, and undisclosed jacquard and digital printing, etc., to achieve the best results Excellent, precise overprint positioning, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

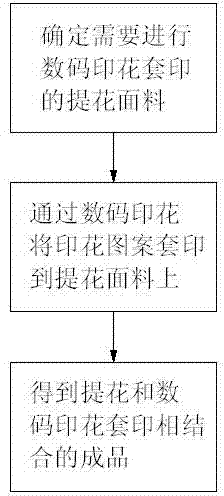

[0047] see figure 1 , the digital printing and overprinting method of the jacquard fabric in this embodiment includes the following steps.

[0048] 1) Determine the jacquard fabric that needs to be overprinted by digital printing.

[0049] The jacquard fabric in this embodiment is ready-made, that is, the jacquard fabric that has been made. The jacquard pattern on the jacquard fabric has a three-dimensional effect, but the color is relatively single.

[0050] 2) The printing pattern is overprinted on the jacquard fabric through digital printing, and the printing pattern corresponds to the jacquard pattern on the jacquard fabric, so that the digital printing pattern on the jacquard fabric and the jacquard pattern match and coincide, thereby forming a jacquard pattern on the jacquard fabric. Synthetic pattern combining jacquard pattern and digital printing pattern.

Embodiment 2

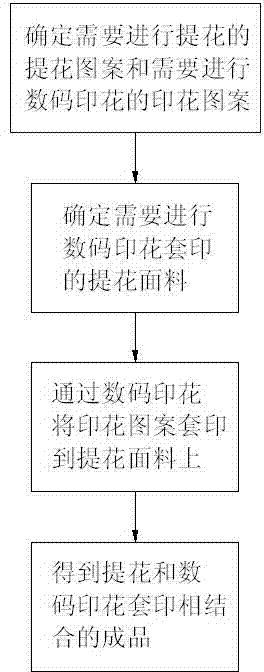

[0052] see figure 2 , the digital printing and overprinting method of the jacquard fabric in this embodiment includes the following steps.

[0053] 1) Determine the jacquard pattern that needs to be jacquard and the printing pattern that needs to be digitally printed, that is, determine the jacquard pattern and the printing pattern according to the actual needs in advance, and then you can know the situation of the synthetic pattern, and then make it through the jacquard operation A jacquard fabric with a jacquard pattern, the jacquard operation is the same or similar to the prior art.

[0054] 2) Determine the jacquard fabric that needs to be overprinted by digital printing.

[0055] The jacquard fabric in this embodiment is the jacquard fabric manufactured in step 1), and the jacquard pattern on the jacquard fabric is designed in advance according to actual needs.

[0056] 3) Overprint the printing pattern on the jacquard fabric through digital printing, so that the digit...

Embodiment 3

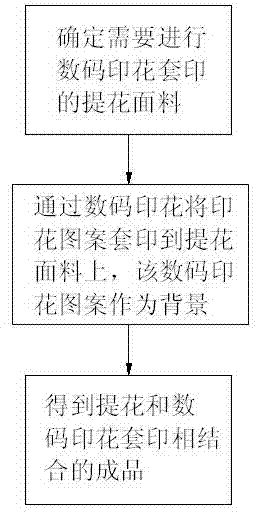

[0058] see image 3 , the digital printing and overprinting method of the jacquard fabric in this embodiment includes the following steps.

[0059] 1) Determine the jacquard fabric that needs to be overprinted by digital printing.

[0060] The jacquard fabric in this embodiment is ready-made, that is, the jacquard fabric that has been made. The jacquard pattern on the jacquard fabric has a three-dimensional effect, but the color is relatively single.

[0061] 2) The printing pattern is overprinted on the jacquard fabric through digital printing, and the digital printing pattern is used as the background, so that the pattern relationship between the digital printing pattern on the jacquard fabric and the jacquard pattern matches each other. The pattern corresponds, so that the digital printing pattern on the jacquard fabric matches and coincides with the jacquard pattern, thereby forming a composite pattern combining the jacquard pattern and the digital printing pattern on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com