Printing, positioning and knurling production and manufacturing process and equipment of soft material

A soft material, manufacturing process technology, applied in printing process, printing, printing machine and other directions, can solve problems such as uneven wind speed, large system wind resistance, inability to match, etc., to improve production efficiency, product appearance, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment first describes the processing equipment.

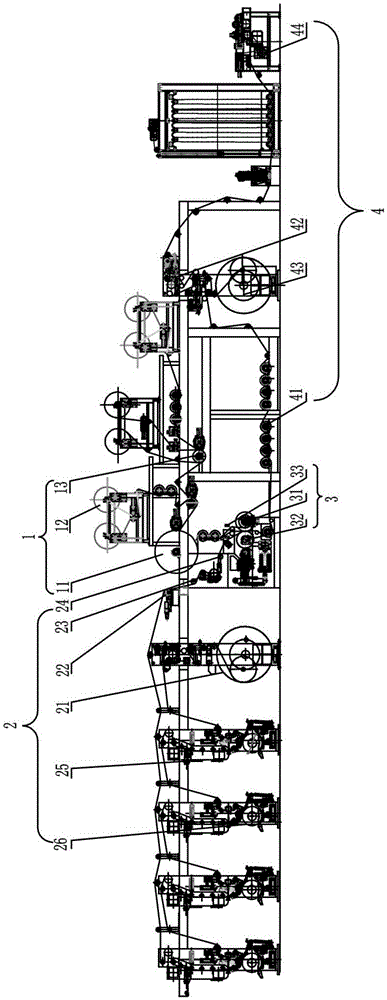

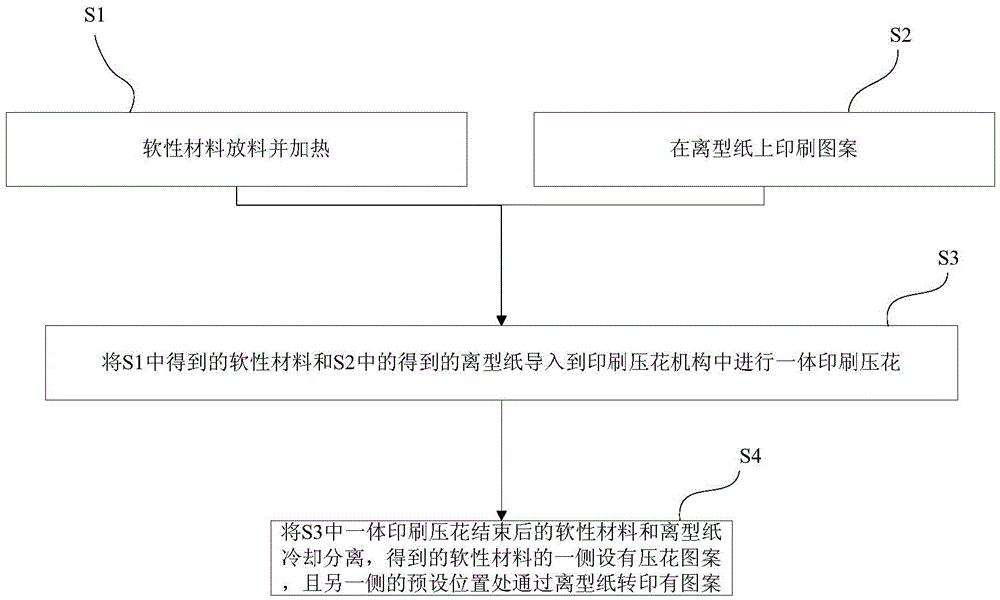

[0041] like figure 1As shown, the processing equipment in this embodiment is soft material printing positioning embossing manufacturing equipment, specifically, it includes a soft material discharging heating mechanism 1, a release paper printing mechanism 2, a printing embossing mechanism 3 and a separating and collecting mechanism. The roll mechanism 4, the outlet of the soft material discharging heating mechanism 1 and the outlet of the release paper printing mechanism 2 are respectively connected to the entrance of the printing embossing mechanism 3, and the outlet of the printing embossing mechanism 3 is connected to the separation and collection The roll mechanism 4 is connected; the printing and embossing mechanism 3 includes a decal roller 31 and a support roller 32, and the decal roller 31 and the support roller 32 are arranged side by side and between the decal roller 31 and the support roller 32 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com