Multilayer three-dimensional topping luminous character and production technique thereof

A technology of luminous characters and color registration, which is applied to illuminated signs, instruments, display devices, etc., can solve the problems of monochromatic, non-layered advertising characters, etc., and achieve the effect of low production cost, low cost and high speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The production process of flat monochrome resin luminous characters: 1. Use a cutting plotter to write the same product typeface on paper, positive typeface and reverse typeface. 2. Use glass as the work surface, and paste the reverse type on the back of the glass surface Then evenly beat on the glass with a film-removing cream (or film-removing liquid), and finally use a double-sided adhesive strip to surround the typeface on the top of the glass to form the original shape of the font. 3. To make side strips, use double-sided adhesive strips to surround a shape with a required size on the other glass, pour the adjusted liquid side material into the surrounded shape to make it level and solidify. After curing, use a blade to press Cut out multiple strips according to the required size, and then put the cut strips into the encircled shape and font to enclose the side shape of the word. 4. Finally, put the adjusted liquid fabric Pour it into the glass surface of the well-...

Embodiment 2

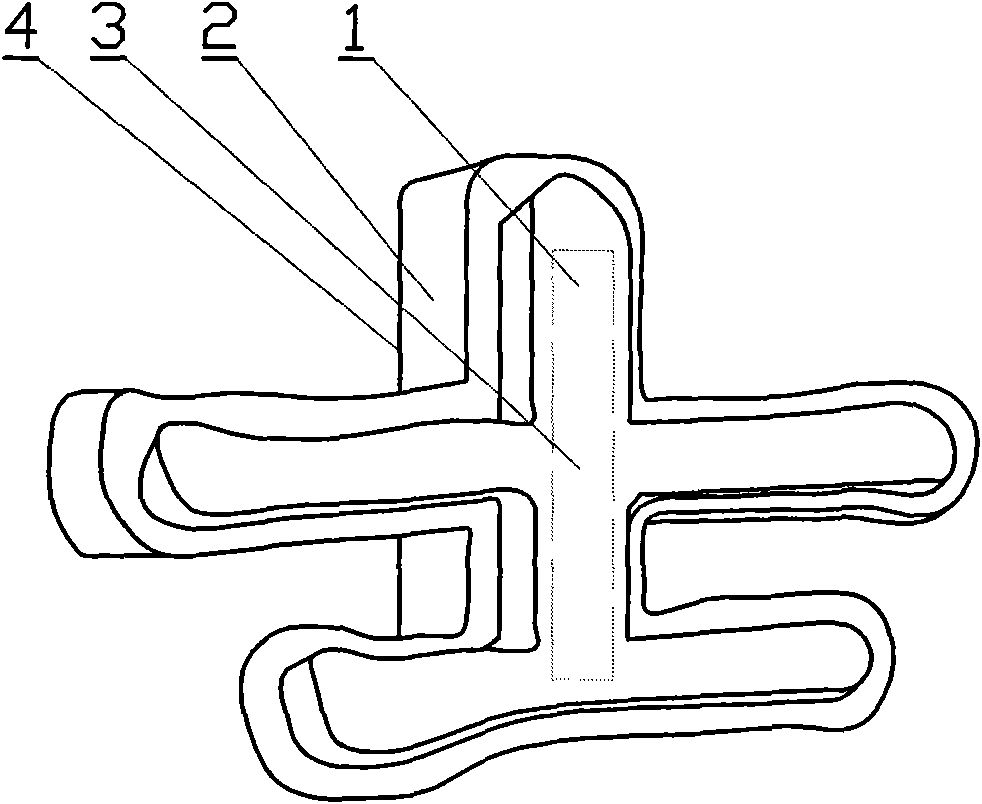

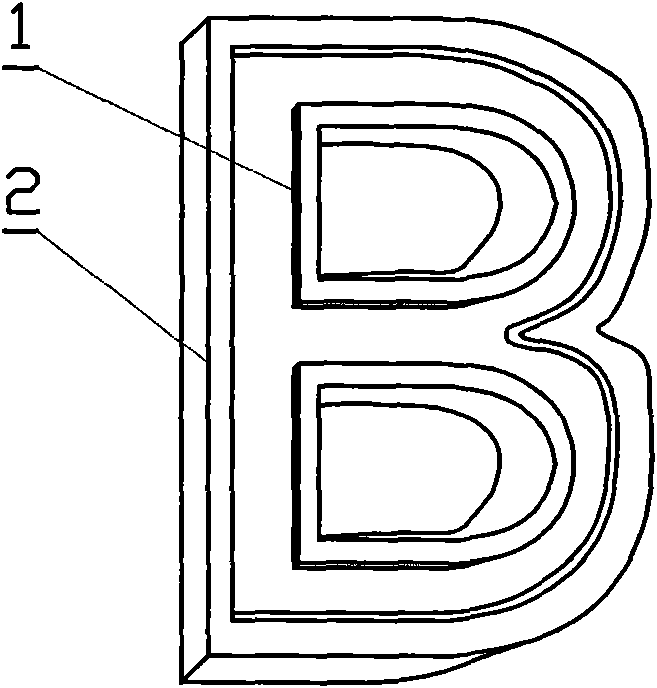

[0034] The front is made of multi-layer convex three-dimensional coloring surface. Use a plotter to write the double-contour reverse type on paper, use glass as the work surface, paste the double-contour reverse type under the glass table, and apply a release paste (or release paste) on the glass. Membrane liquid), use the prepared side strips to surround and solidify the side of the font (word shape side), and then use double-sided adhesive strips to surround the inner side of the (word core side) on the top of the glass, on the (word side side) ) into the liquid fabric, and after solidification, it will be separated from the glass by releasing the film. The second step is to use double-sided adhesive strips to surround the finished literal side, and then press the literal side to the glass surface. , so that the other side of the double-sided adhesive strip is firmly bonded to the glass surface, pour the adjusted liquid fabric on the glass (inside the core surface), and add t...

Embodiment 3

[0036] The multi-layer concave three-dimensional coloring surface on the front is the opposite of the convex three-dimensional coloring. First, the core surface is made, and the smooth side tape can be used as the edge around the word core, and the smooth side tape is fixed on the glass surface with hot melt. The adjusted liquid fabric is poured into the surface of the word core, leveled and solidified, and after it is cured, it is released from the glass and separated from the glass. A double-sided adhesive strip is placed around the edge of the prepared word core to make a mold, and the word core faces The edge of the quasi-inverted type mold is superimposed and pressed on the glass surface, and then the outer edge (shaped edge) is surrounded by the prepared edge strips, and the adjusted fabric is poured on the surface (edge surface) to level and solidify. After it is solidified, it is separated from the glass by stripping the film, and finally the lamp is installed as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com