Alcoholic group liquid ink capable of realizing high-speed printing and preparation method thereof

A high-speed printing, alcohol-based technology, used in inks, household appliances, applications, etc., can solve problems such as increased mechanical volume and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

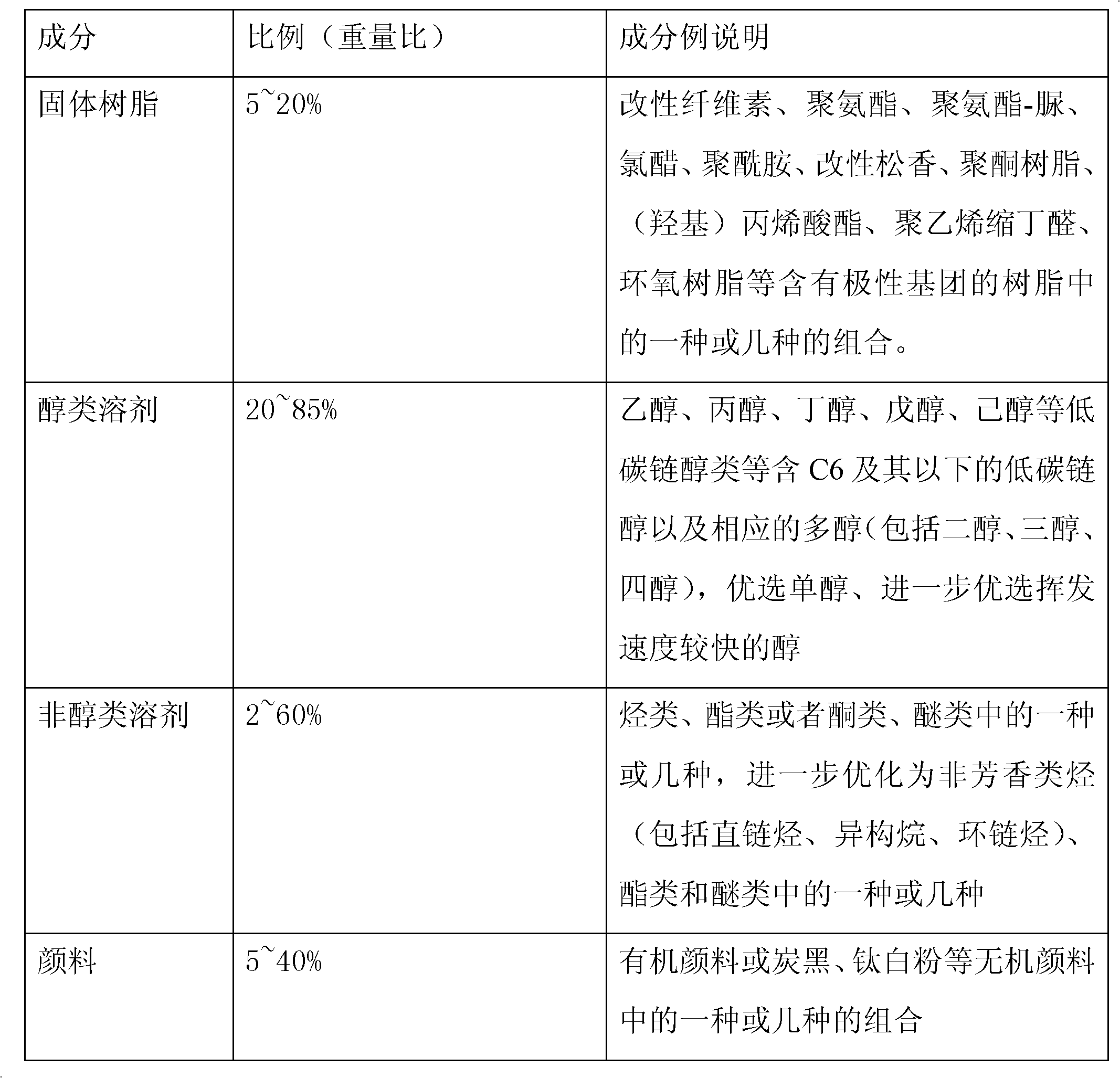

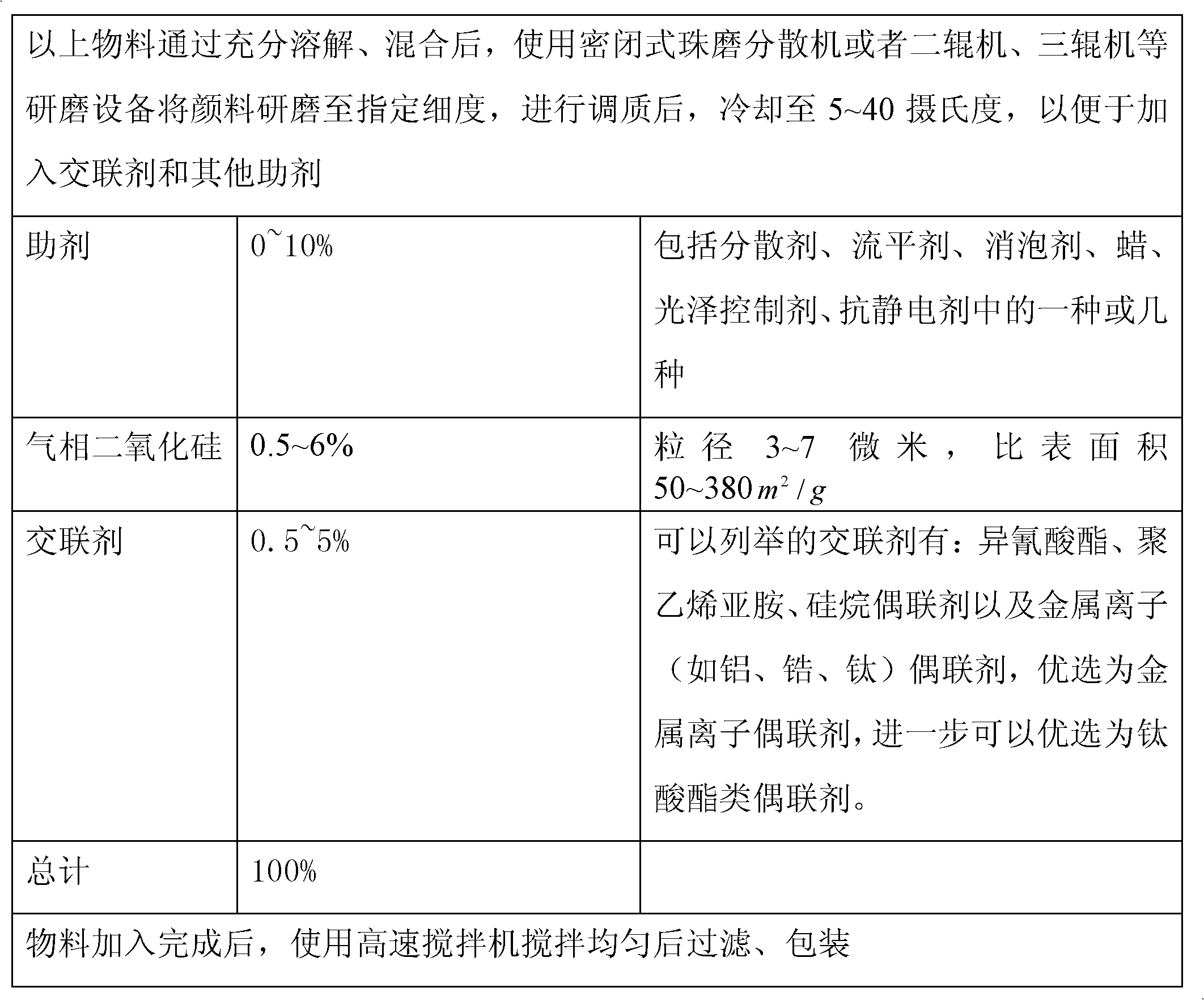

Method used

Image

Examples

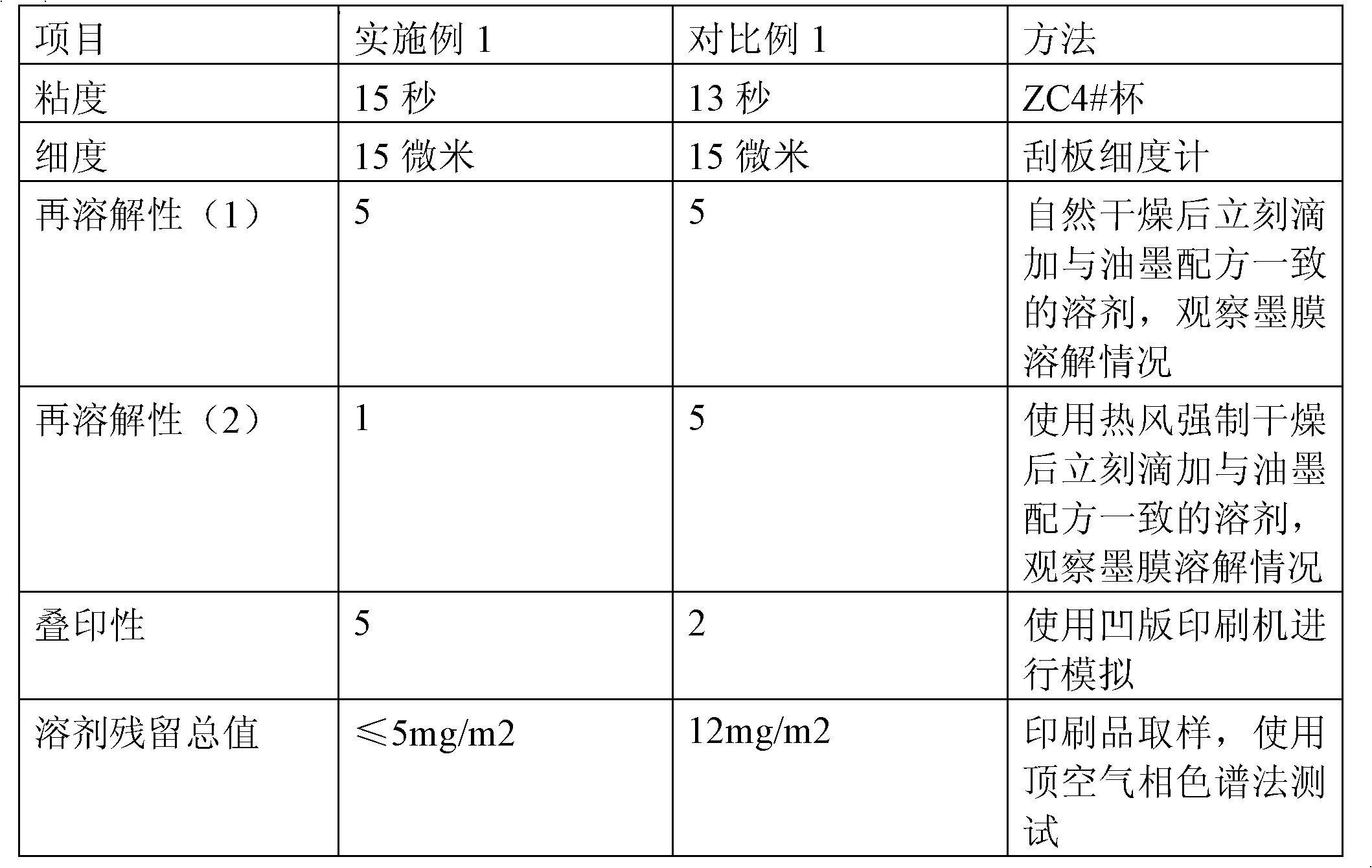

Embodiment 1

[0027] Example 1: Weigh 9 parts of nitrocellulose with a specification of 1 / 8 second (all refer to weight ratio in the following formulations), 11 parts of ethanol, and 10 parts of ethyl acetate, mix well and use a high-speed mixer to stir for more than 60 minutes until the resin is completely Dissolve to obtain 30 parts of nitrocellulose resin solution A; weigh 8 parts of alcohol-soluble polyamide resin and 12 parts of isopropanol, mix evenly and use a high-speed mixer to stir for more than 120 minutes until the resin is completely dissolved to obtain 20 parts of polyamide resin solution B;

[0028] Weigh 30 parts of the dissolved nitrocellulose resin solution A and 20 parts of the polyamide resin solution B, then weigh 15 parts of ethanol, 5 parts of butyl acetate, 10 parts of phthalocyanine blue pigment, 0.5 parts of polyethylene micropowder wax, dispersant 1 part; after mixing evenly, use a closed bead mill dispersant to grind until the maximum particle size of the pigment ...

Embodiment 2

[0041] Take by weighing 4 parts of hydroxyl acrylic resin (all refer to weight ratio in the following formula), 6 parts of ethanol, after mixing evenly, use high-speed mixer to stir for more than 60 minutes until the resin is completely dissolved, add polyurethane resin liquid (30% solid part, solvent is 50 % isopropanol, 20% n-propyl acetate 35%) 30 parts, titanium dioxide 30 parts, polyethylene micropowder wax 0.5 parts, n-propanol 10 parts, after mixing evenly, use a closed bead mill dispersant to grind to the largest pigment Particle size ≤ 15 microns, stop grinding, cool the ink temperature to room temperature, weigh 11 parts of n-propanol, 5.5 parts of propylene glycol methyl ether acetate, 2 parts of fumed silica, isopropoxyethoxy diacetylacetonate titanate 1 portion, fully stirred evenly, after the inspection is completed, filter and pack.

[0042] The drying speed of the solvent used in the above-mentioned formula, with butyl acetate as the reference solvent (assuming...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com