Method for overprinting color identification and make-up applied to gravure printing

A technology of chasing color and gravure printing, which is applied in the field of overprinting color chasing recognition and imposition, which can solve the problems of registration failure, increase product cost, and no pattern, etc., and achieve the effects of reducing production cost, saving consumption, and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

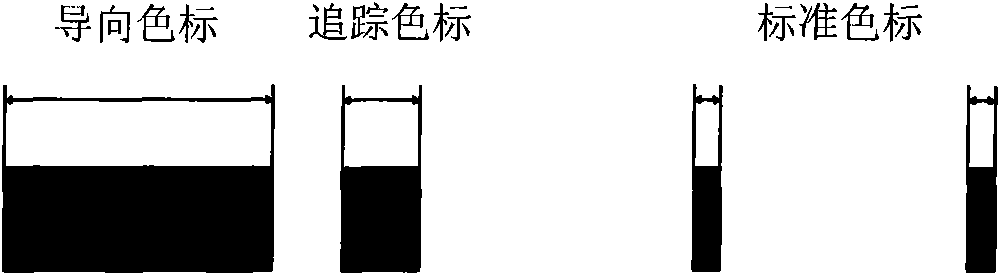

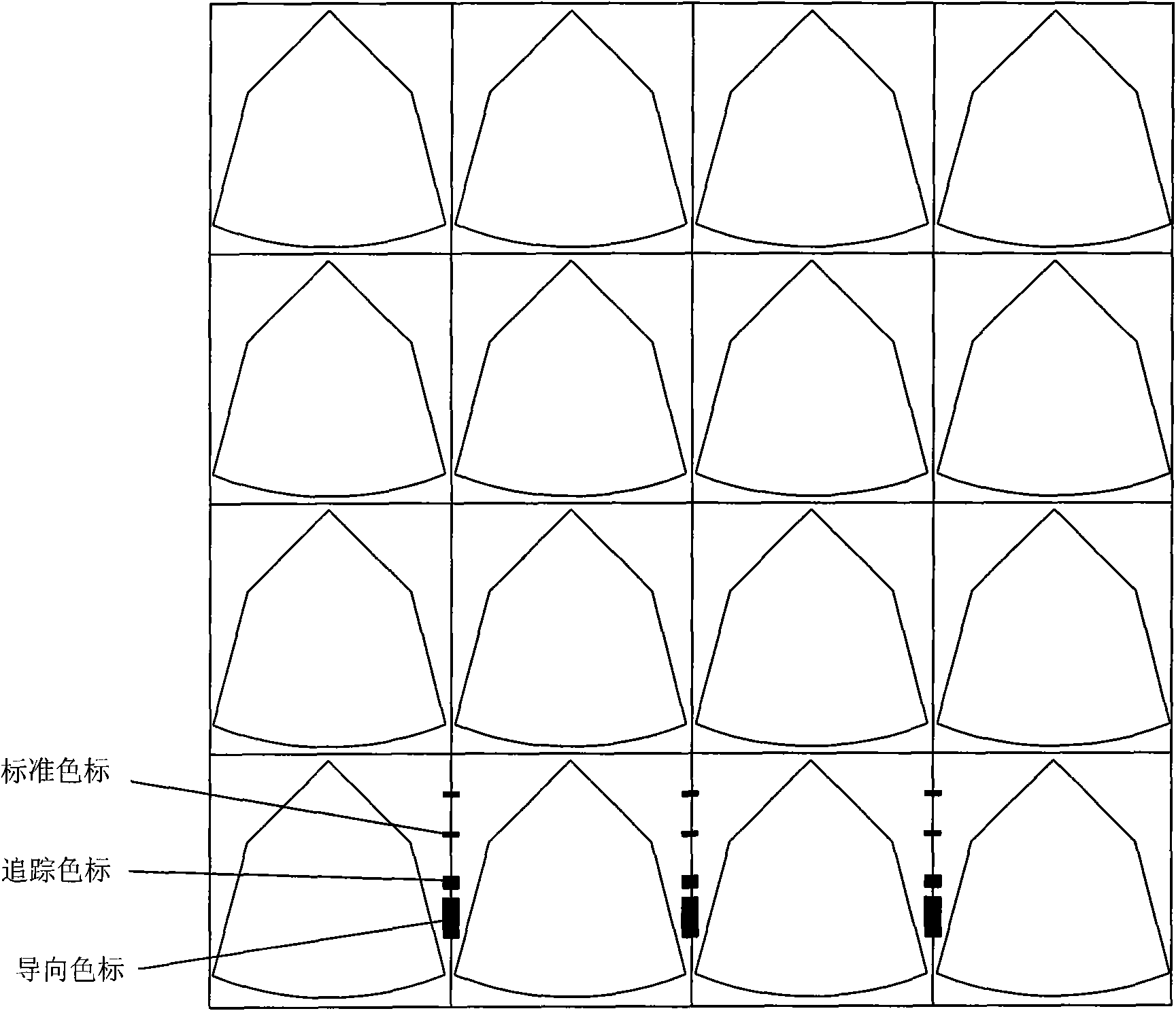

[0040] refer to image 3 If the blank position of the product is enough to place an independent color mark, the same direction is used for imposition, and the combination is made according to the shape of the pattern to ensure that there is enough space between the layouts of the same radial direction to accommodate the color mark; set the standard color in the blank space Standard color mark, tracking color mark and guide color mark, among them, the standard color mark, tracking color mark and guide color mark have the same width, all set according to the corresponding standard, in order to meet the standard suitable for photoelectric eye recognition, secondly, the standard color mark is in accordance with the original standard After setting, set the tracking color mark about 20mm in front of the standard color mark, which is used for the activation of the photoelectric eye. It is desirable to have a length that is easy for human eyes to observe, such as 30mm, and it can be m...

Embodiment 2

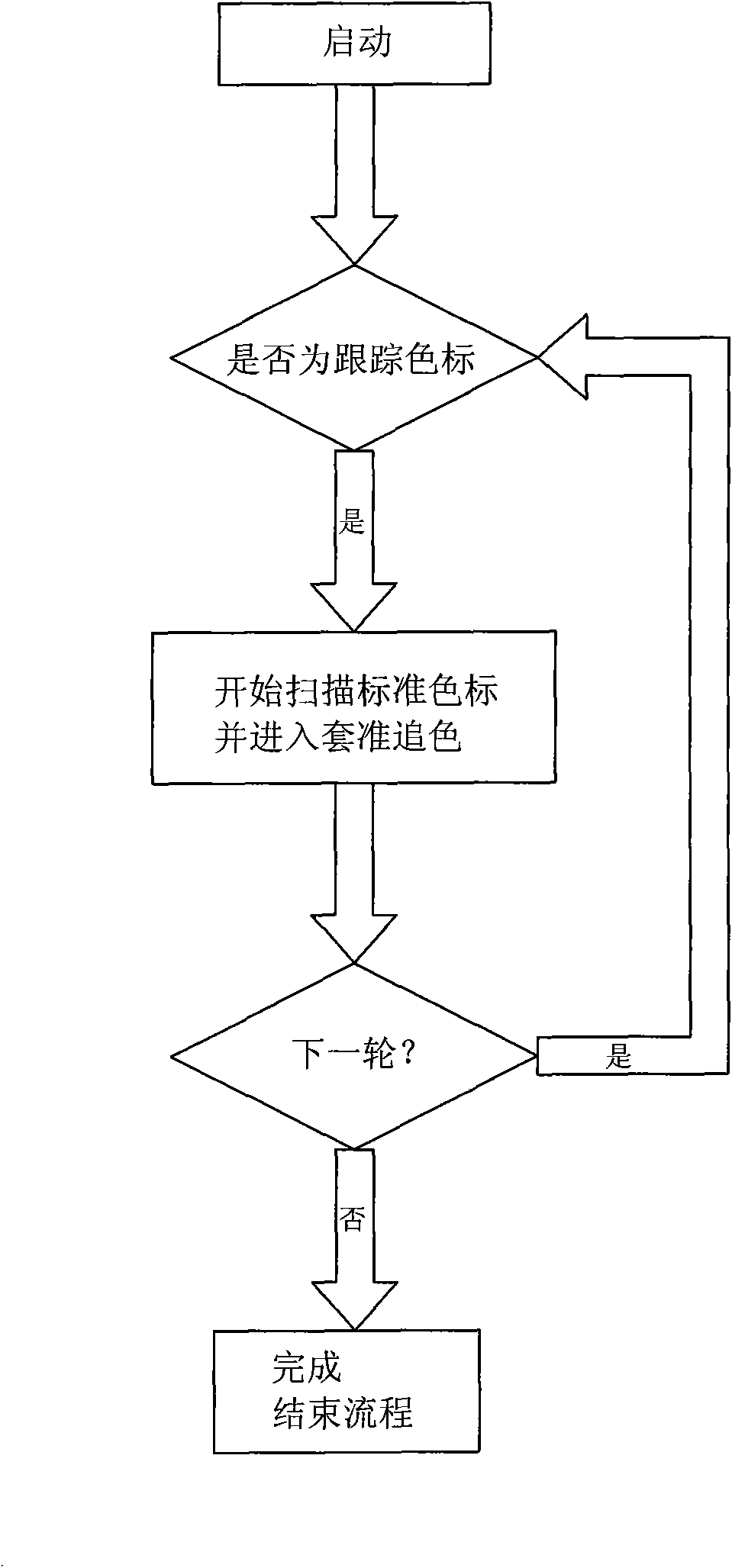

[0042] refer to Figure 4 , if the color mark is not enough between the layout and the layout when using a single direction imposition, use the opposite direction imposition of the opposite direction between the pattern and the pattern. For example, the waist-shaped product shown in the figure has a concave arc at the bottom, so the two arcs are aligned head-to-head, and a blank area for the color code can be formed, so that the corresponding color code can be set. Moreover, if the blank area If the position is not enough to set the guide color mark, the guide color mark can be omitted. In this way, when registering the process steps of color tracking, the operator needs to adjust the color mark to the corresponding position of the photoelectric eye. Generally, the front of the tracking color mark can be adjusted to the corresponding position of the photoelectric eye. After starting the registration system, the photoelectric The eye can immediately scan to the tracking color ...

Embodiment 3

[0044] For products with different patterns, imposition can be carried out according to the actual situation to meet the requirements of color code setting, for example Figure 5 As shown, a triangular-like product can be transposed and face-to-face imposition in a rectangle, so that there is enough space between each rectangle to set the color mark.

[0045] In addition, according to products with different patterns, it is also possible to flexibly carry out imposition in different ways to meet the needs.

[0046] Please refer to Image 6 , is the contrast between the original imposition and color code setting method and the imposition and color code setting method of the present invention: in the original imposition method, a blank of about 20mm width must be left at the appropriate position of the raw material, which is generally arranged in the middle of the material , to set the color code, after the production is completed, this part of the blank tape will be discarded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com