A secondary overprinting process for front electrodes

A technology of secondary overprinting and front electrode, which is applied in printing, circuit, printing device, etc. It can solve the problems of large silver paste loss, strict requirements on the overprinting accuracy of the two printing patterns, uneven thickness, etc., and achieve the effect of uniform printing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

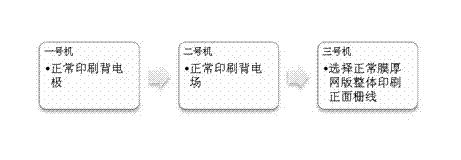

[0025] like figure 2 Shown: A secondary overprinting process for front electrodes, including the following steps:

[0026] 1) Use the No. 1 screen printing machine to print the back electrode;

[0027] 2) Use the No. 2 screen printing machine to print the back electric field;

[0028] 3) After the printing of the back electrode and the back electric field is completed, use the No. 3 screen printing machine to print the auxiliary grid line;

[0029] 4) Use No. 4 screen printing machine to print the main grid lines after the auxiliary grid lines are printed.

[0030] The auxiliary gate line adopts a high film thickness of 28 um, and the main gate line adopts a low film thickness of 10 um.

[0031] The secondary overprinting screen is designed such that the auxiliary grid lines are completely connected, and there is no disconnection in the middle to reserve the position of the main grid lines. Therefore, silver pastes with different silver contents are selected for the print...

Embodiment 2

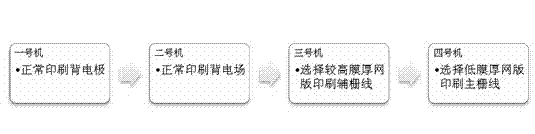

[0033] like image 3 Shown: A secondary overprinting process for front electrodes, including the following steps:

[0034] 1) Use the No. 1 screen printing machine to print the back electrode;

[0035] 2) Use the No. 2 screen printing machine to print the back electric field;

[0036] 3) After the printing of the back electrode and the back electric field is completed, the No. 3 screen printing machine is used to print the busbar;

[0037] 4) After the main grid lines are printed, use No. 4 screen printing machine to print the auxiliary grid lines.

[0038] The auxiliary gate line adopts a high film thickness of 25 um, and the main gate line adopts a low film thickness of 5 um. The secondary overprinting screen is designed to reserve the position of the main grid line by disconnecting the auxiliary grid lines in the middle, and adding mark points on the screen pattern to facilitate alignment during the secondary overprinting. Therefore, silver pastes with different silver ...

Embodiment 3

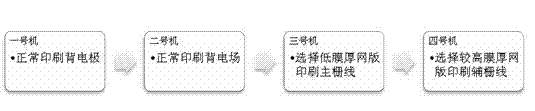

[0040] A secondary overprinting process for front electrodes, comprising the following steps:

[0041] 1) Use the No. 1 screen printing machine to print the back electrode;

[0042] 2) Use the No. 2 screen printing machine to print the back electric field;

[0043] 3) After the printing of the back electrode and the back electric field is completed, the No. 3 screen printing machine is used to print the busbar;

[0044] 4) After the main grid line is printed, replace the screen pattern of No. 3 screen printing machine to print the auxiliary grid line.

[0045] The auxiliary gate line adopts a high film thickness of 25 um, and the main gate line adopts a low film thickness of 8 um. The secondary overprinting screen is designed to reserve the position of the main grid line by disconnecting the auxiliary grid lines in the middle, and adding mark points on the screen pattern to facilitate alignment during the secondary overprinting. Therefore, silver pastes with different silve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com