High-precision overlay gold stamping paper and manufacturing method thereof

A technology of stacking hot stamping and tipping paper, applied in printing devices, chemical instruments and methods, printing, etc., can solve the problems of losing metallic luster, damaging the anodized aluminum layer, and poor hot stamping, and achieves outstanding anti-counterfeiting performance and improved Accurate, three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

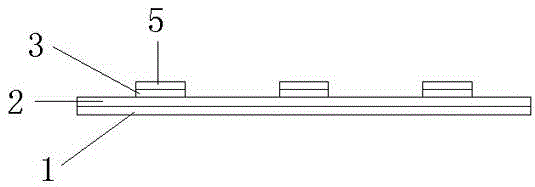

[0029] A high-precision overlay hot stamping tipping paper, from bottom to top, includes a tipping paper base paper layer 1, a printing layer 2, an ordinary golden anodized aluminum hot stamping layer 3, and an ordinary hot stamping layer on the ordinary golden anodized aluminum hot stamping layer 3. Red anodized aluminum hot stamping layer 5; the front side of the tipping paper base paper layer 1 is provided with a printing layer 2. The ordinary gold anodized aluminum hot stamping layer 3 is a pattern pressed on the printed layer 2 with a certain pressure and temperature; pattern spacing A certain distance is distributed on the lower part of the tipping paper, each pattern is 5 mm long and 6 mm wide; the ordinary red anodized aluminum hot stamping layer 5 is laminated on the ordinary golden anodized aluminum hot stamping layer 3.

Embodiment 2

[0031] A high-precision overlay hot stamping tipping paper, from bottom to top, includes a tipping paper base paper layer 1, a printing layer 2, a common anodized aluminum hot stamping layer, and a laser anodized aluminum hot stamping stacked on the ordinary anodized aluminum hot stamping layer The front side of the base paper layer 1 of the tipping paper is provided with a printing layer 2. The ordinary anodized aluminum hot stamping layer is used to press the text on the printing layer 2 with a certain pressure and temperature; the text is distributed on the tipping paper at a certain distance In the lower part, the text of each unit is 10 mm long and 8 mm wide; the laser anodized aluminum hot stamping layer is the same text as the ordinary anodized aluminum hot stamping layer but with different colors.

[0032] The production method includes the following steps:

[0033] A. Print on the base paper of the tipping paper according to the printing requirements of the tipping paper,...

Embodiment 3

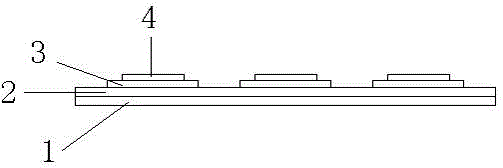

[0041] A high-precision overlay hot stamping tipping paper, from bottom to top, includes a tipping paper base paper layer 1, a printing layer 2, an ordinary purple line anodized aluminum hot stamping layer 3, and a hot stamping layer on the ordinary purple line anodized aluminum hot stamping layer Laser anodized aluminum hot stamping layer 4; the front side of the tipping paper base paper layer 1 is provided with a printing layer 2. The ordinary purple line anodized aluminum hot stamping layer 3 is a pattern pressed on the printed layer 2 with a certain pressure and temperature; Distributed at a certain distance on the lower part of the tipping paper, each pattern is 10 mm long and 5 mm wide; the hollow laser anodized aluminum hot stamping layer is overlapped by a circular pressing method, so that the first hot stamping layer passes through the hollow laser anodized aluminum hot stamping layer The cutout is exposed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com