Patents

Literature

52results about How to "Transfer completely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

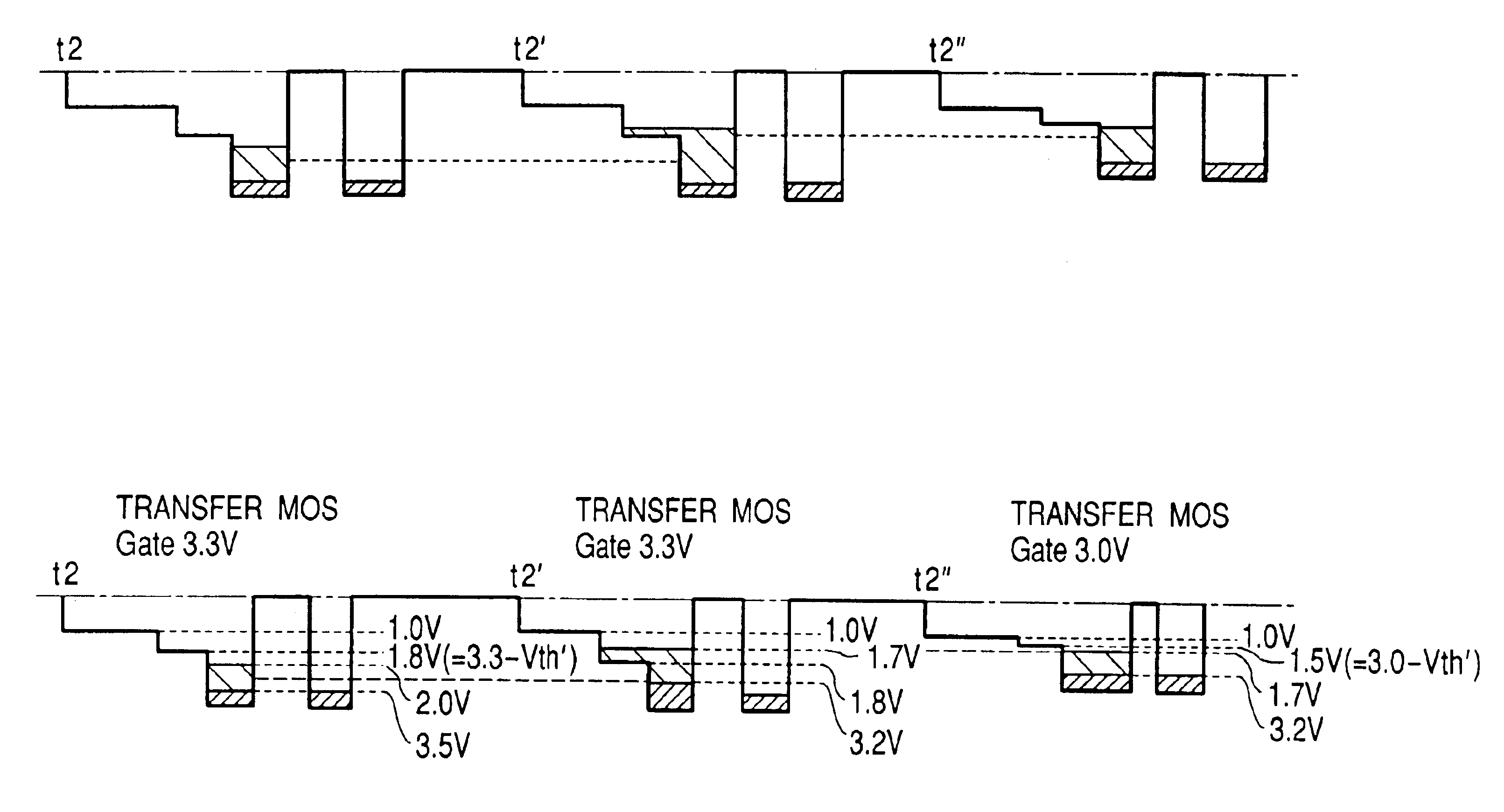

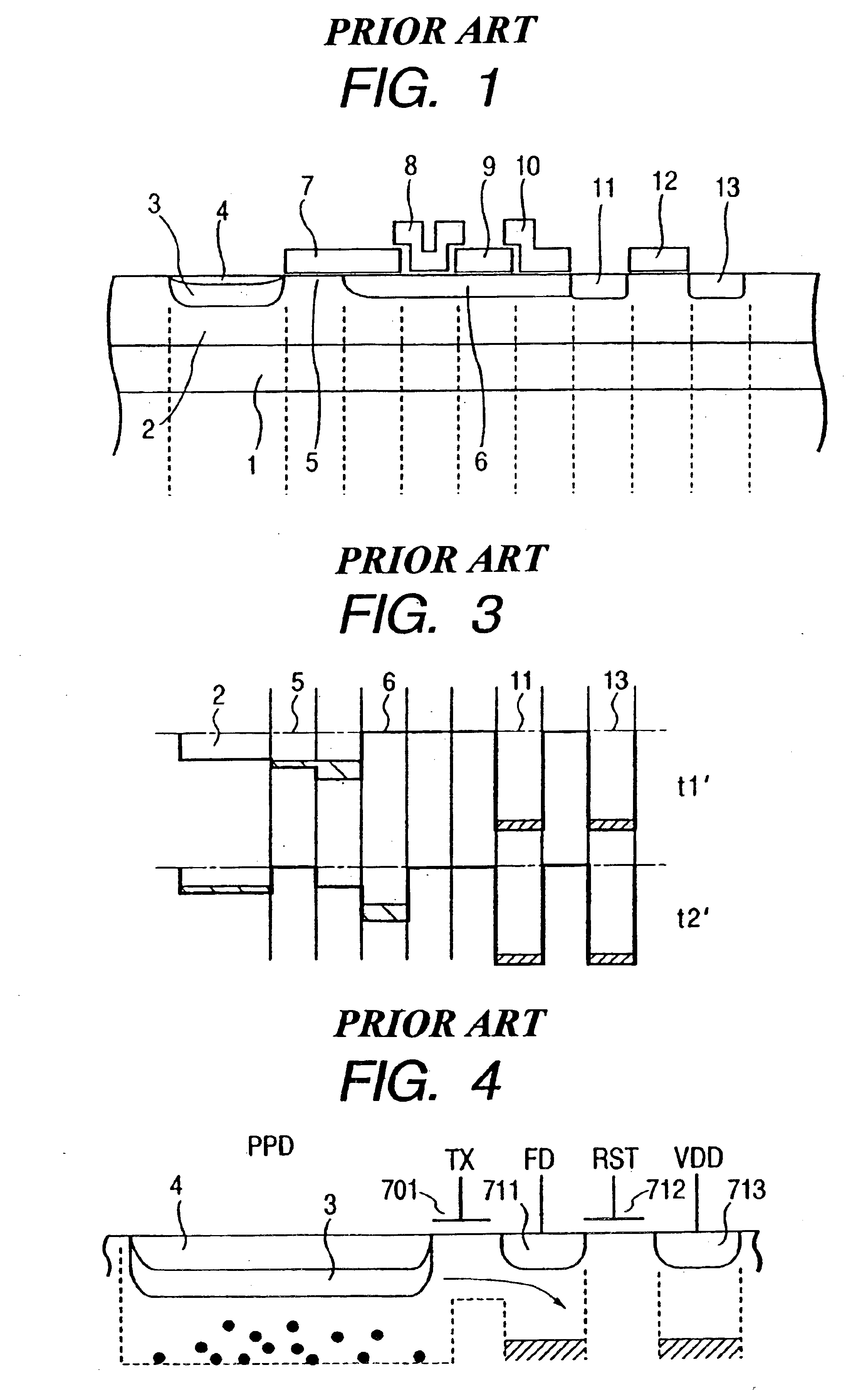

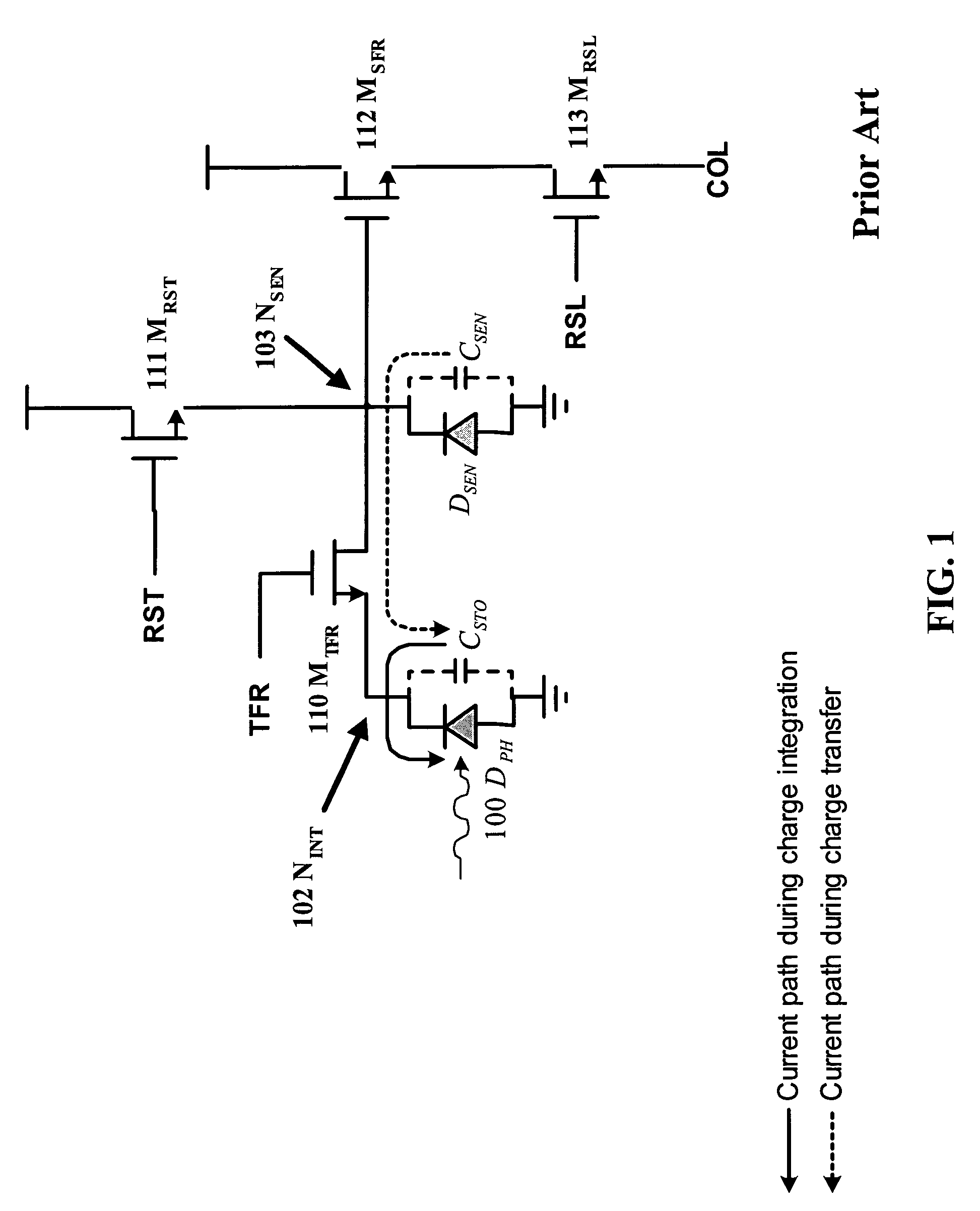

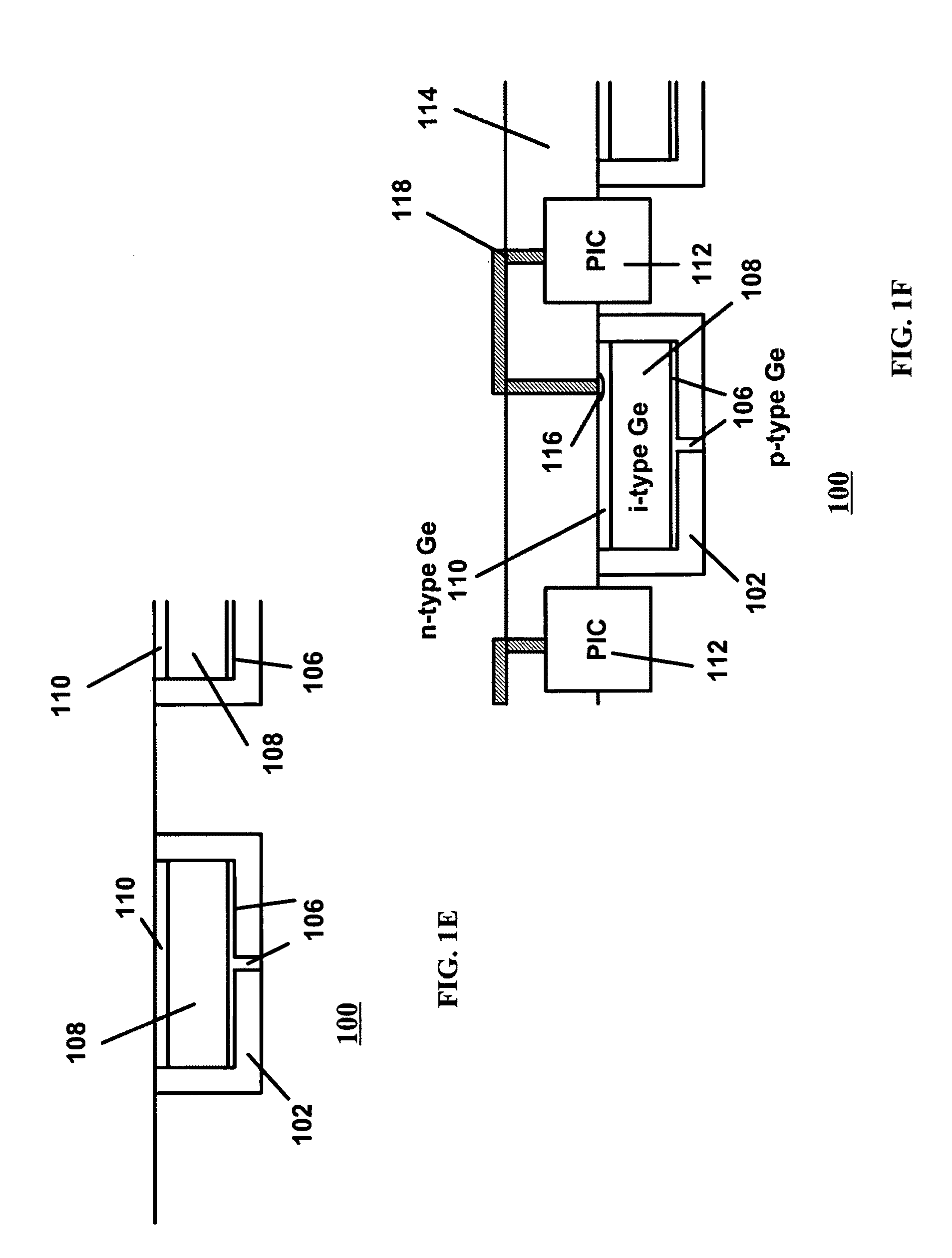

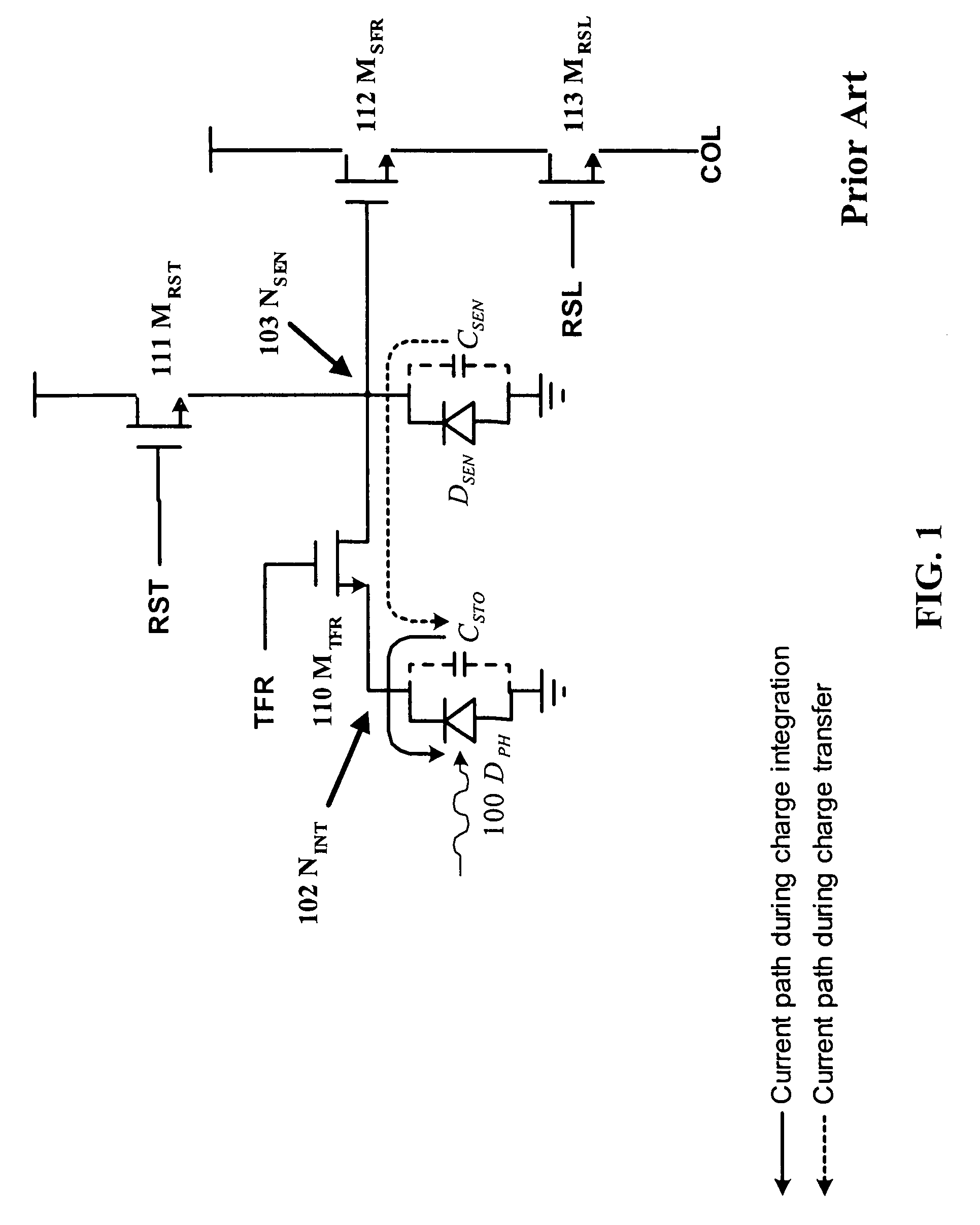

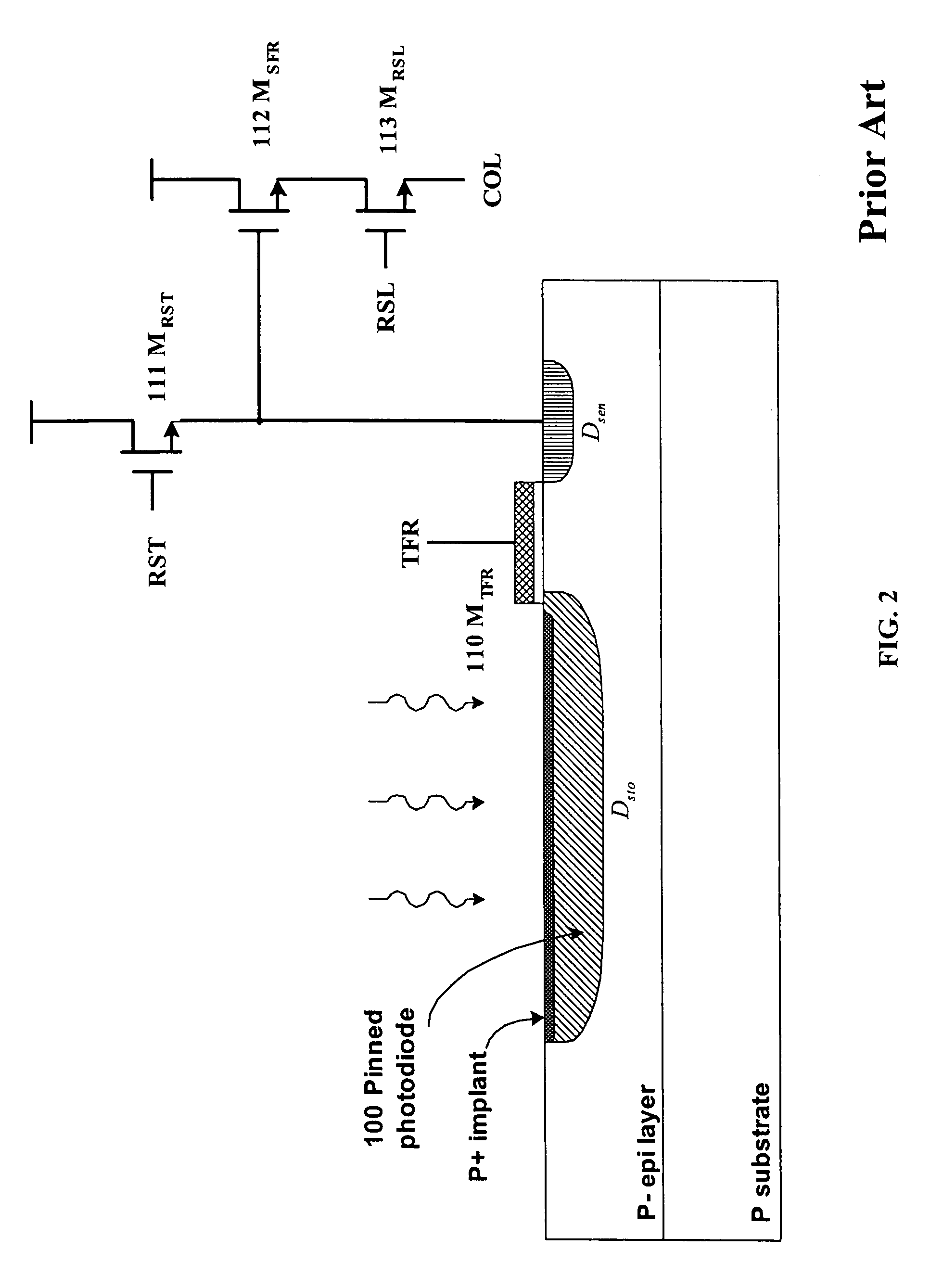

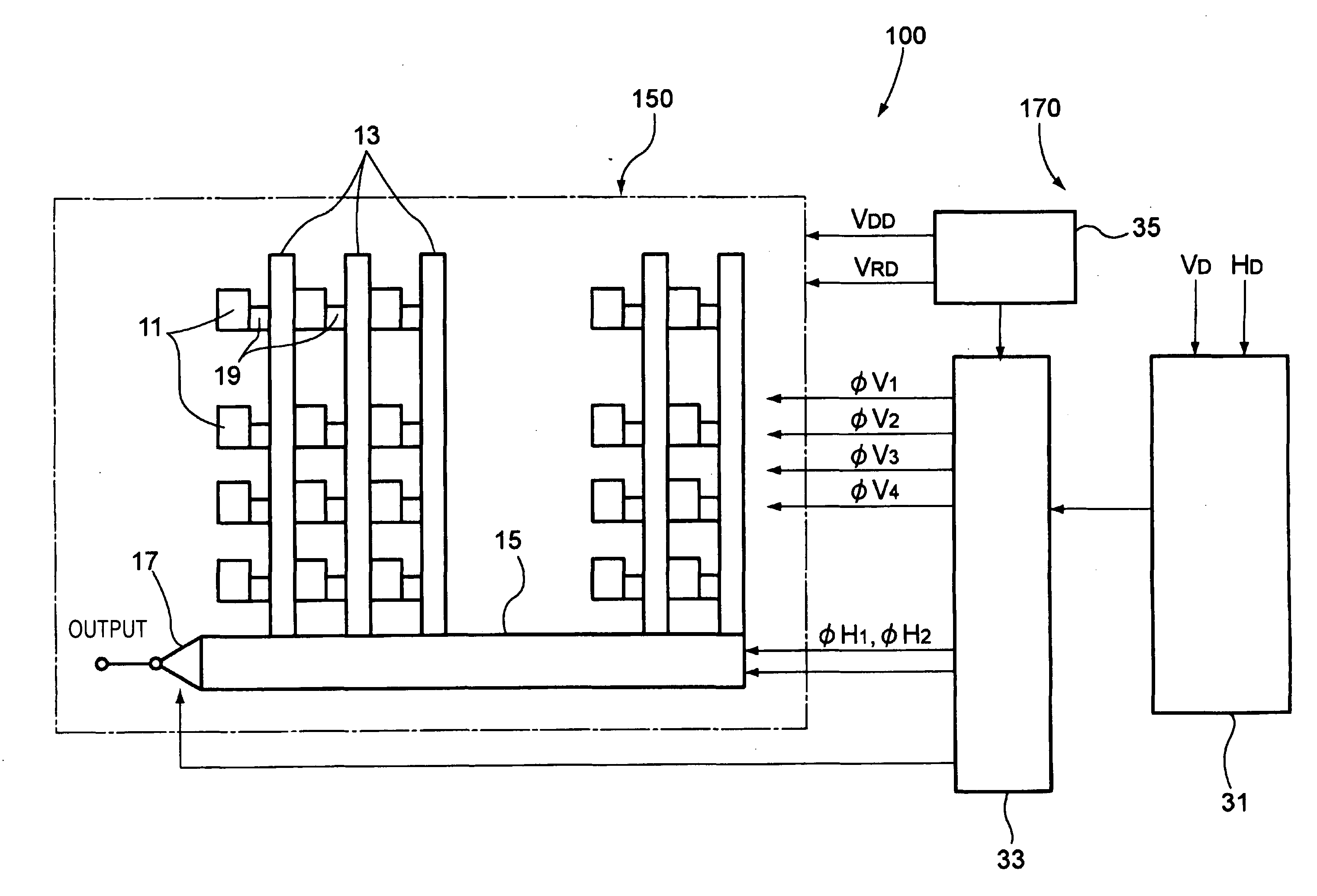

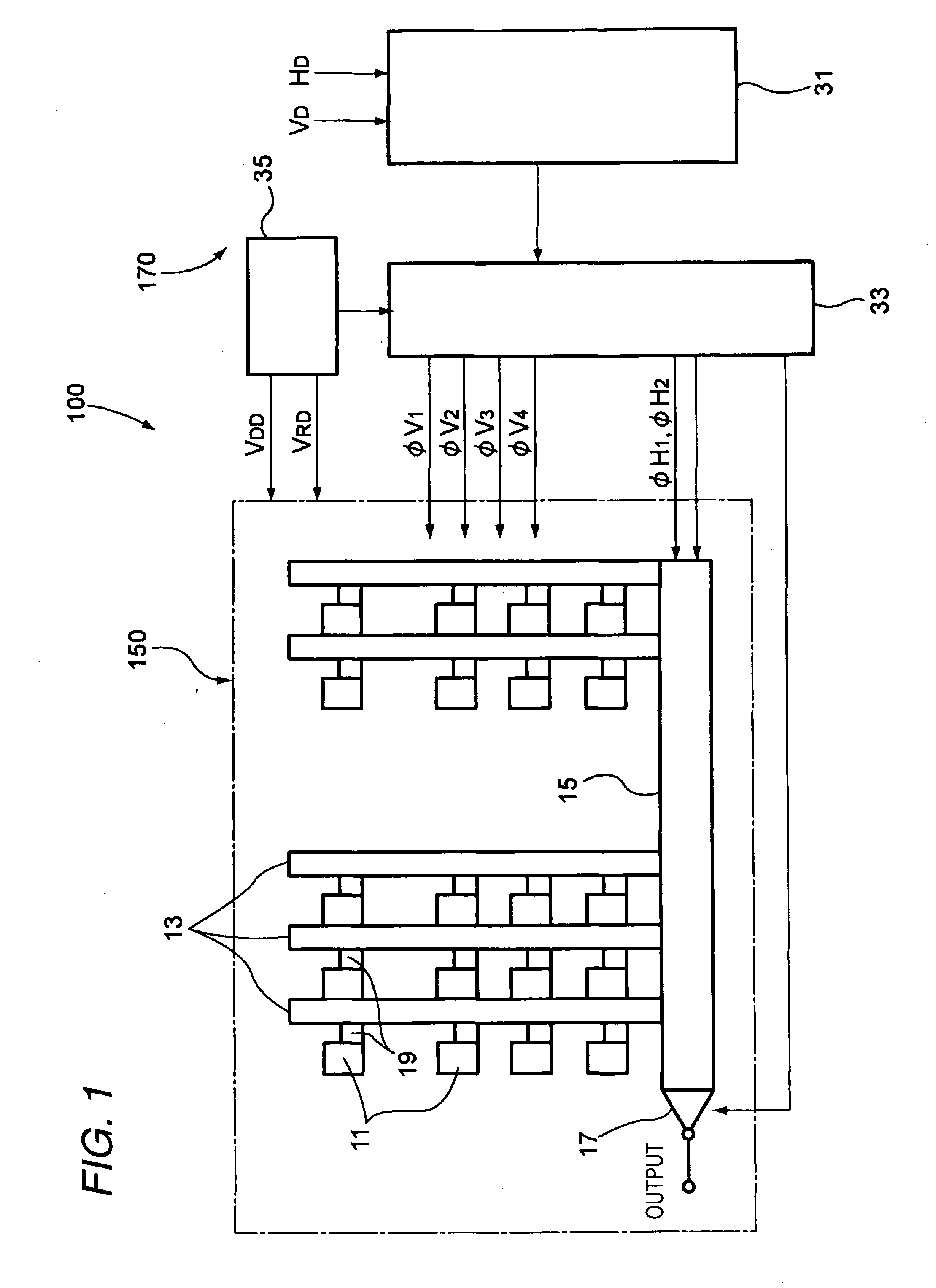

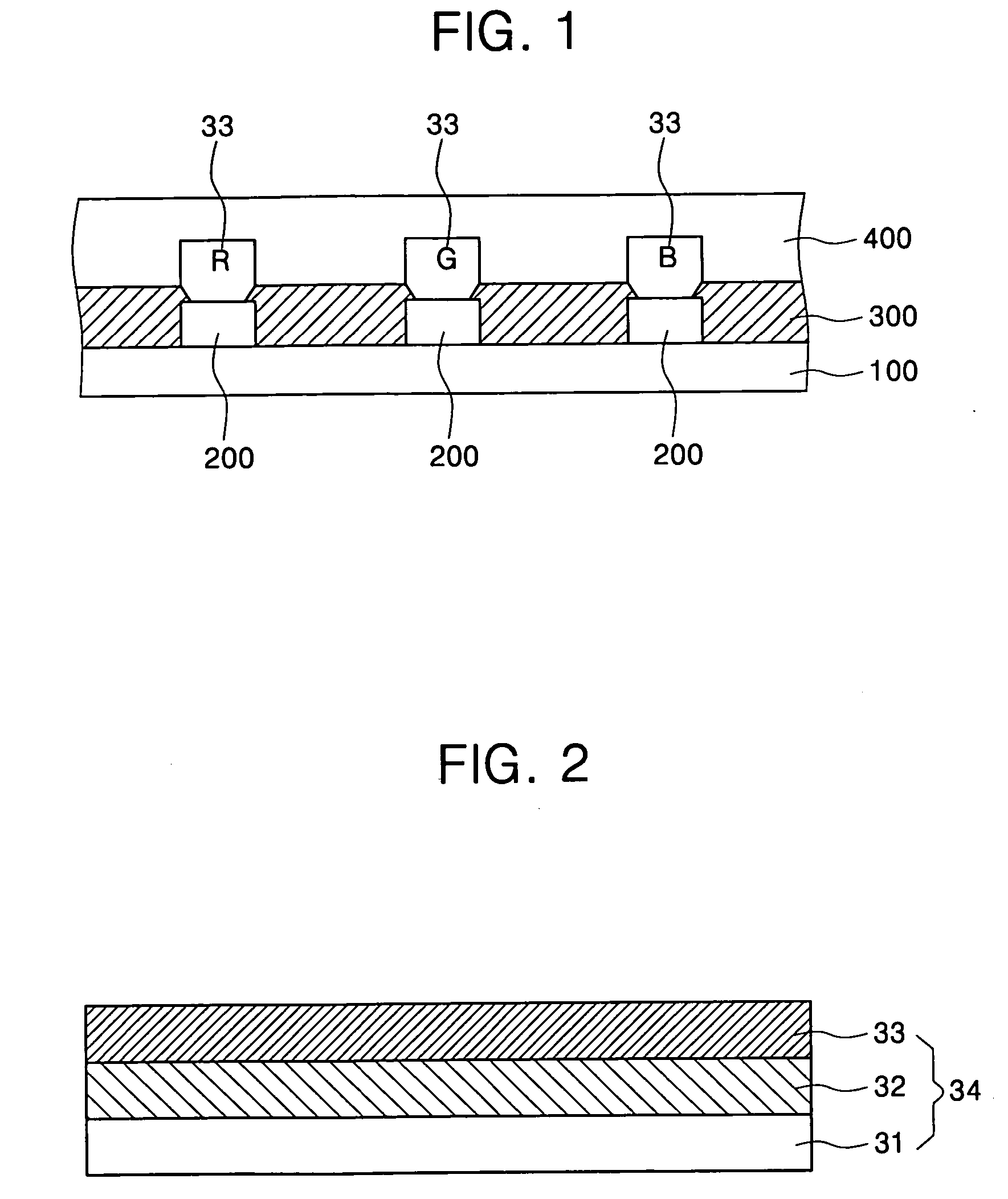

Solid state image pickup apparatus

InactiveUS7110030B1Transfer completelyTelevision system detailsTelevision system scanning detailsCapacitanceSolid-state

In the solid state image pickup apparatus, in order to achieve complete transfer of the charge from the photodiode to the floating diffusion area, there is provided a pickup apparatus having a photoelectric conversion element, a transfer switch consisting of a MOS transistor for transferring the signal charge generated in the photoelectric conversion element, a floating diffusion capacitance for receiving the signal charge through the transfer switch, and a reset switch consisting of a MOS transistor for resetting the potential of the floating diffusion capacitance, the device comprising at least a potential setting circuit for generating a voltage different from the power supply voltage, wherein the output of the potential setting circuit is applied as a pulse to the gate of the transfer switch and / or the gate of the reset switch.

Owner:CANON KK

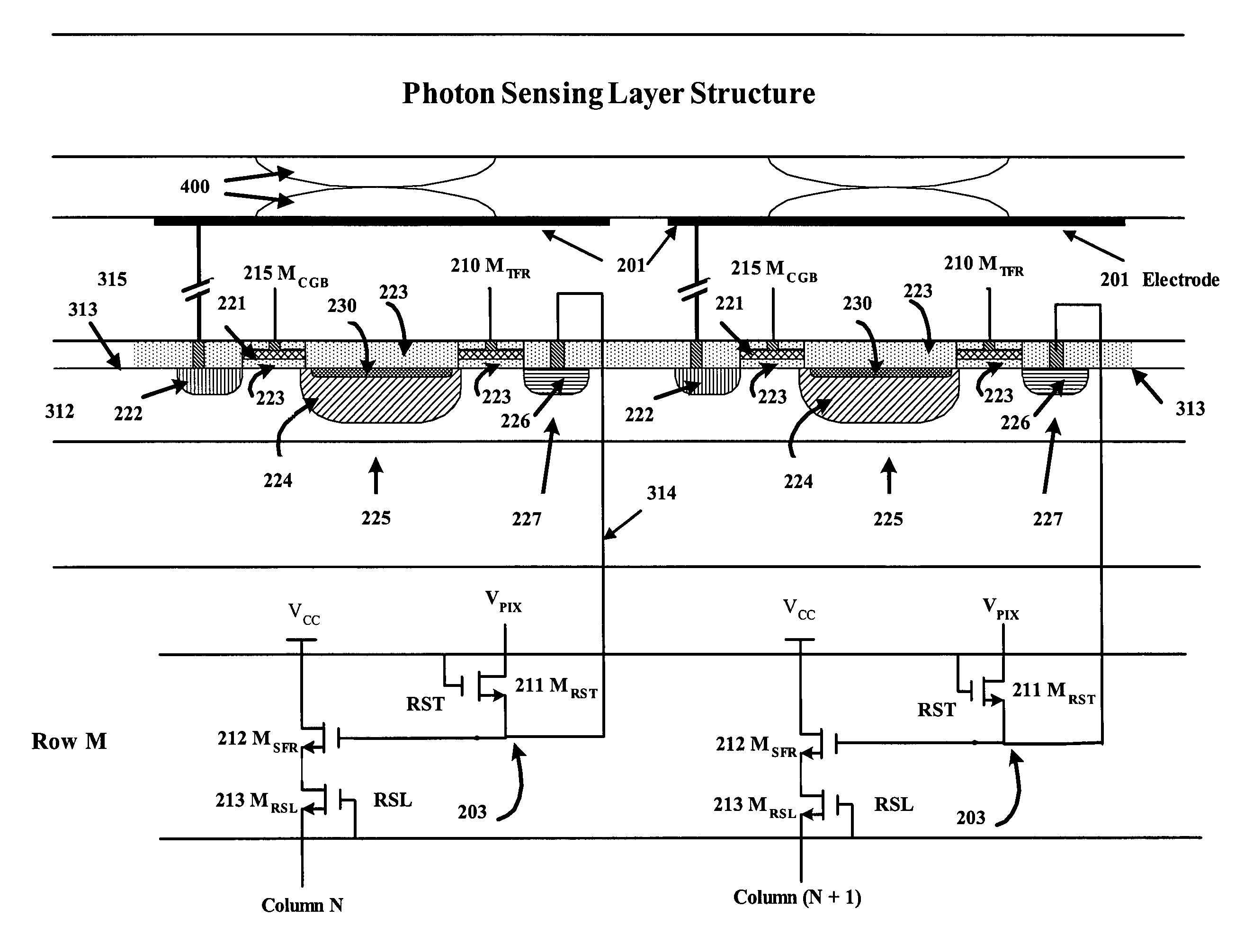

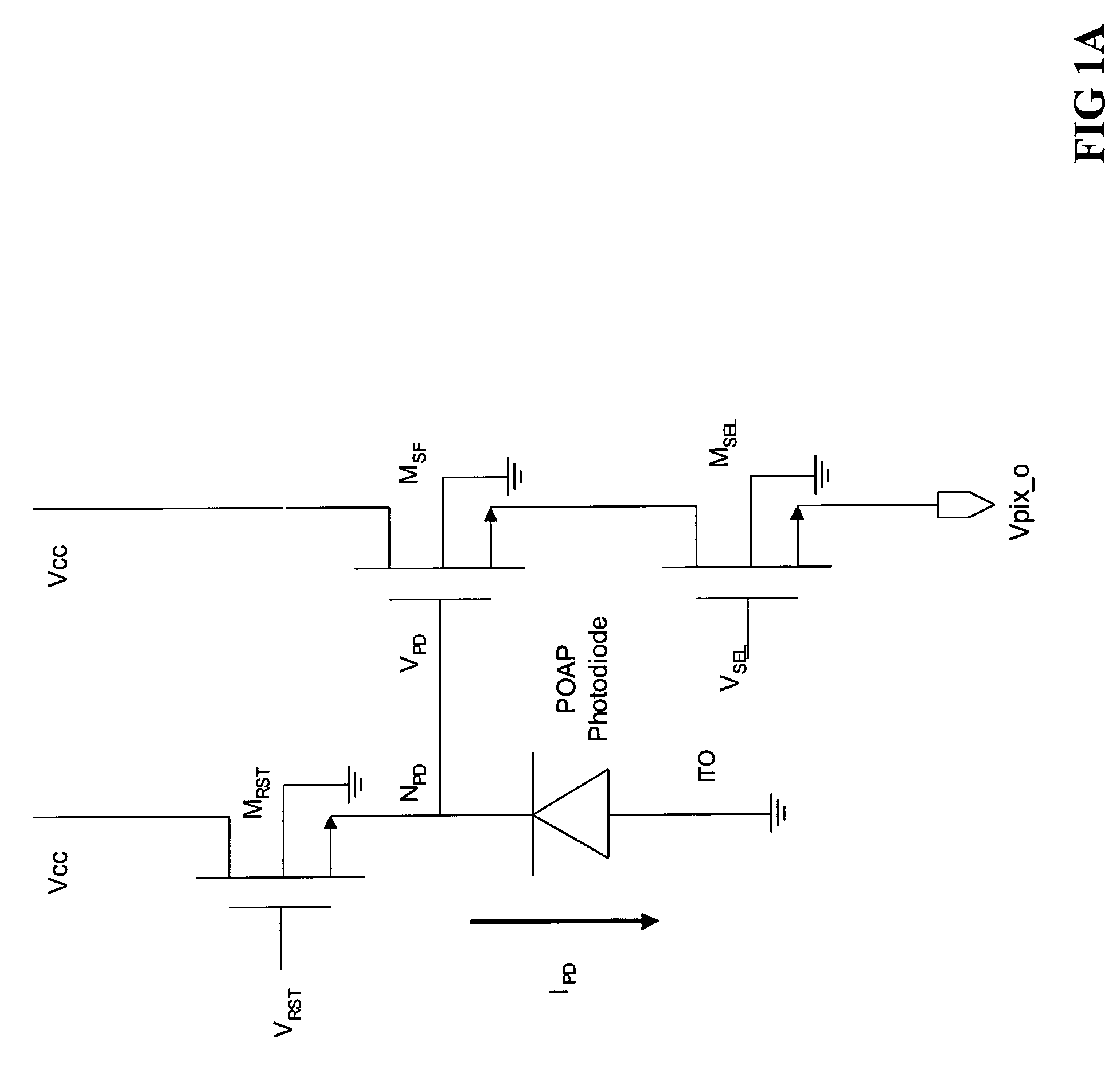

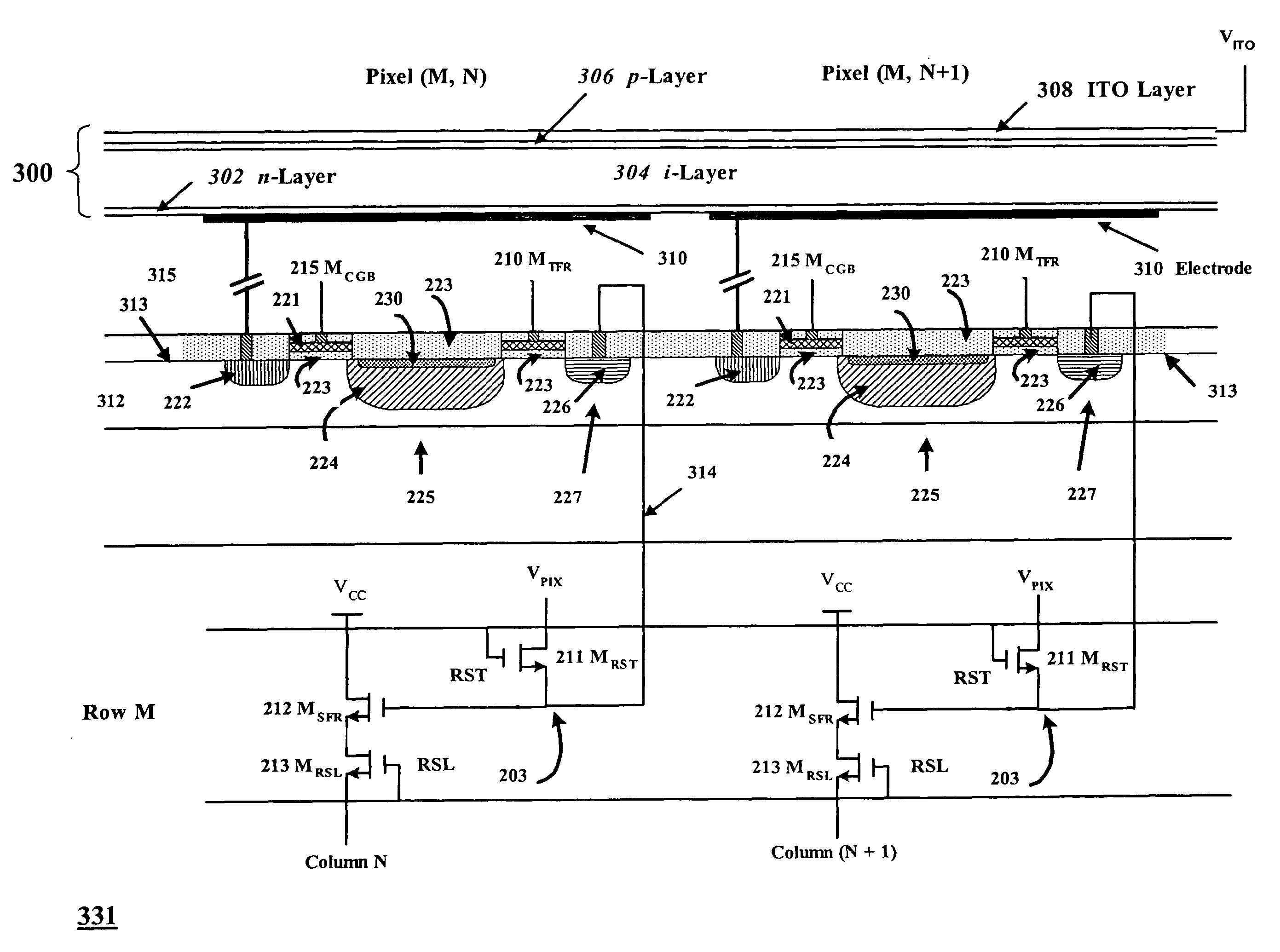

CMOS sensor with electrodes across photodetectors at approximately equal potential

InactiveUS7525168B2Minimize and eliminate currentMinimise currentTelevision system detailsTelevision system scanning detailsCMOS sensorPhotovoltaic detectors

A MOS or CMOS based active pixel sensor designed for operation with zero or close to zero potential across the pixel photodiodes to minimize or eliminate dark current. In preferred embodiments the pixel photodiodes are produced with a continuous pin or nip photodiode layer laid down over pixel electrodes of the sensor. In this preferred embodiment, the voltage potential across the pixel photodiode structures is maintained constant and close to zero, preferably less than 1.0 volts. This preferred embodiment enables the photodiode to be operated at a constant bias condition during the charge detection cycle. Setting this constant bias condition close to zero (near “short circuit” condition) assures that dark current is substantially zero.

Owner:E PHOCUS

Hybrid imaging sensor with approximately equal potential photodiodes

InactiveUS20090256156A1Minimize and eliminate dark currentMinimize and eliminate currentTelevision system detailsSolid-state devicesPotential differenceEngineering

A hybrid MOS or CMOS image sensor. The sensor includes photon-sensing elements comprised of an array of photo-sensing regions deposited in the form of separate islands on or in a substrate. Pixel circuitry is created on and / or in the substrate at or near the edge of or beneath the photon-sensing elements. The photo-sensing elements may be comprised of multiple photo-sensing semiconductor layers or be created in a single photon-sensing semiconductor layer. Special circuitry is provided to keep the potential across the pixel photon-sensing element at or near zero volts to minimize or eliminate dark current. The potential difference is preferably less than 1.0 volt. The circuitry also keeps the small potential difference across the photodiodes constant or approximately constant throughout the charge collection cycle. In preferred embodiments the substrate is a crystalline substrate and the photon-sensing elements are separated from the substrate by a dielectric material except for a hole at the bottom through which the material of the photon-sensing element can be grown epitaxially from the substrate.

Owner:E PHOCUS

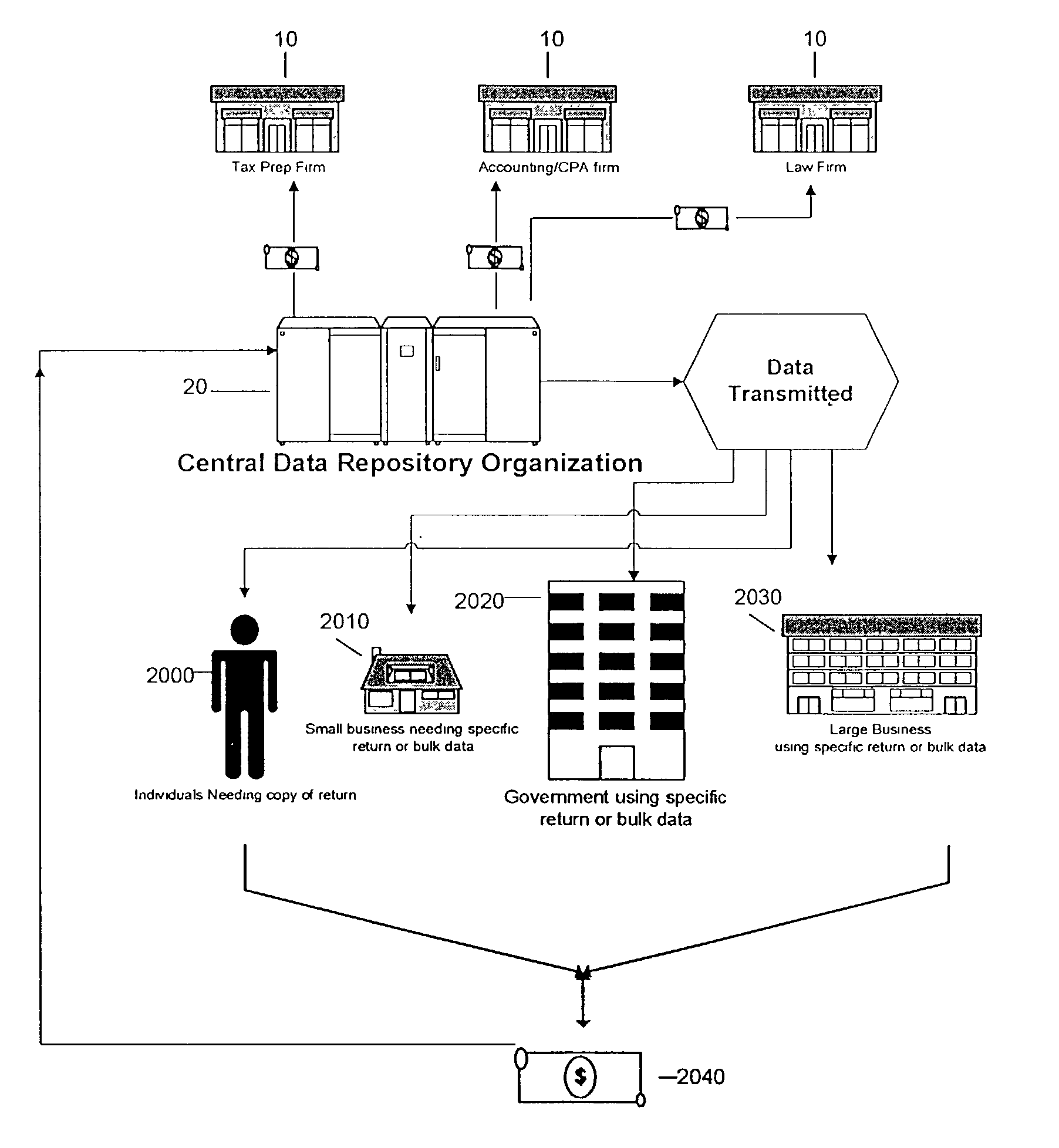

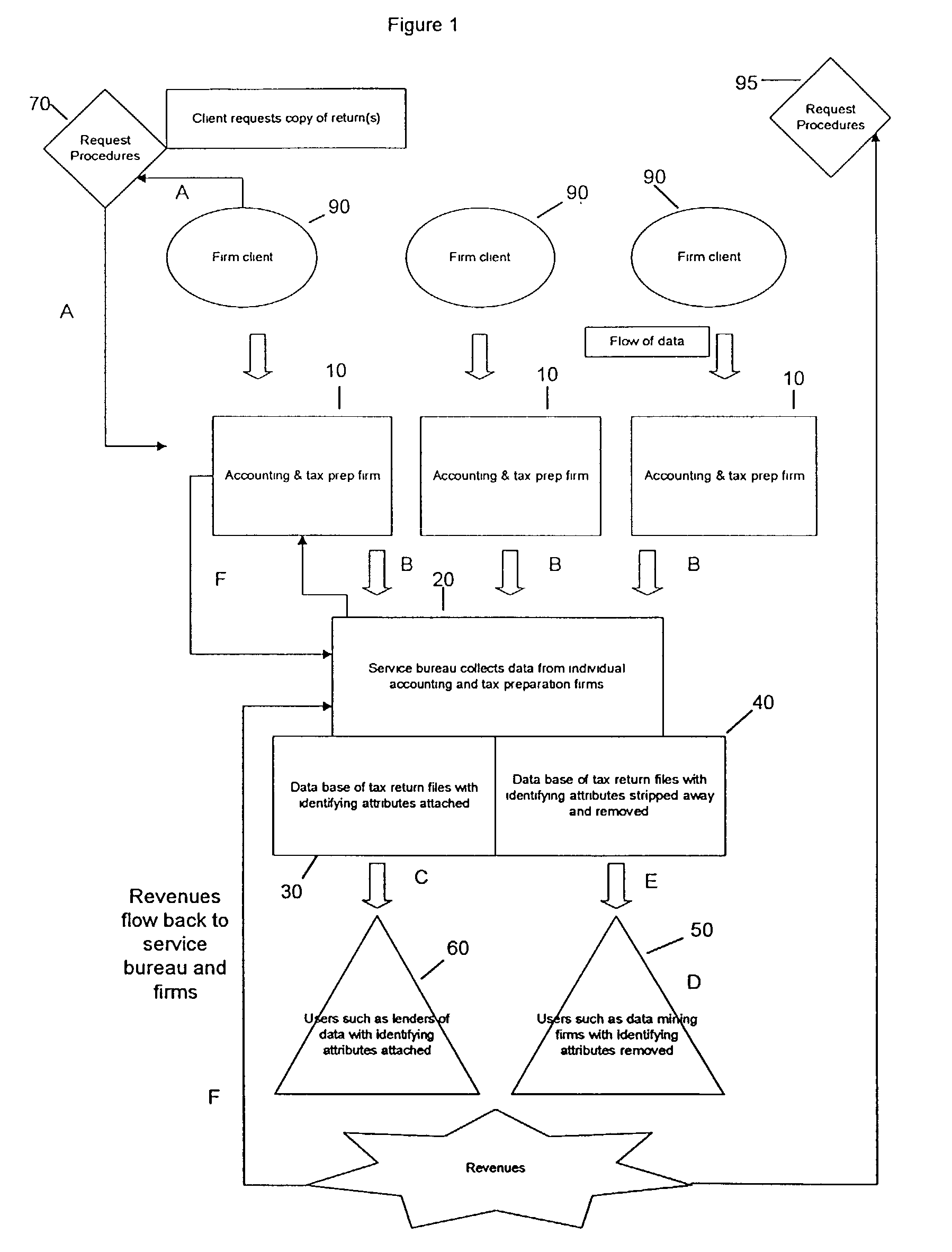

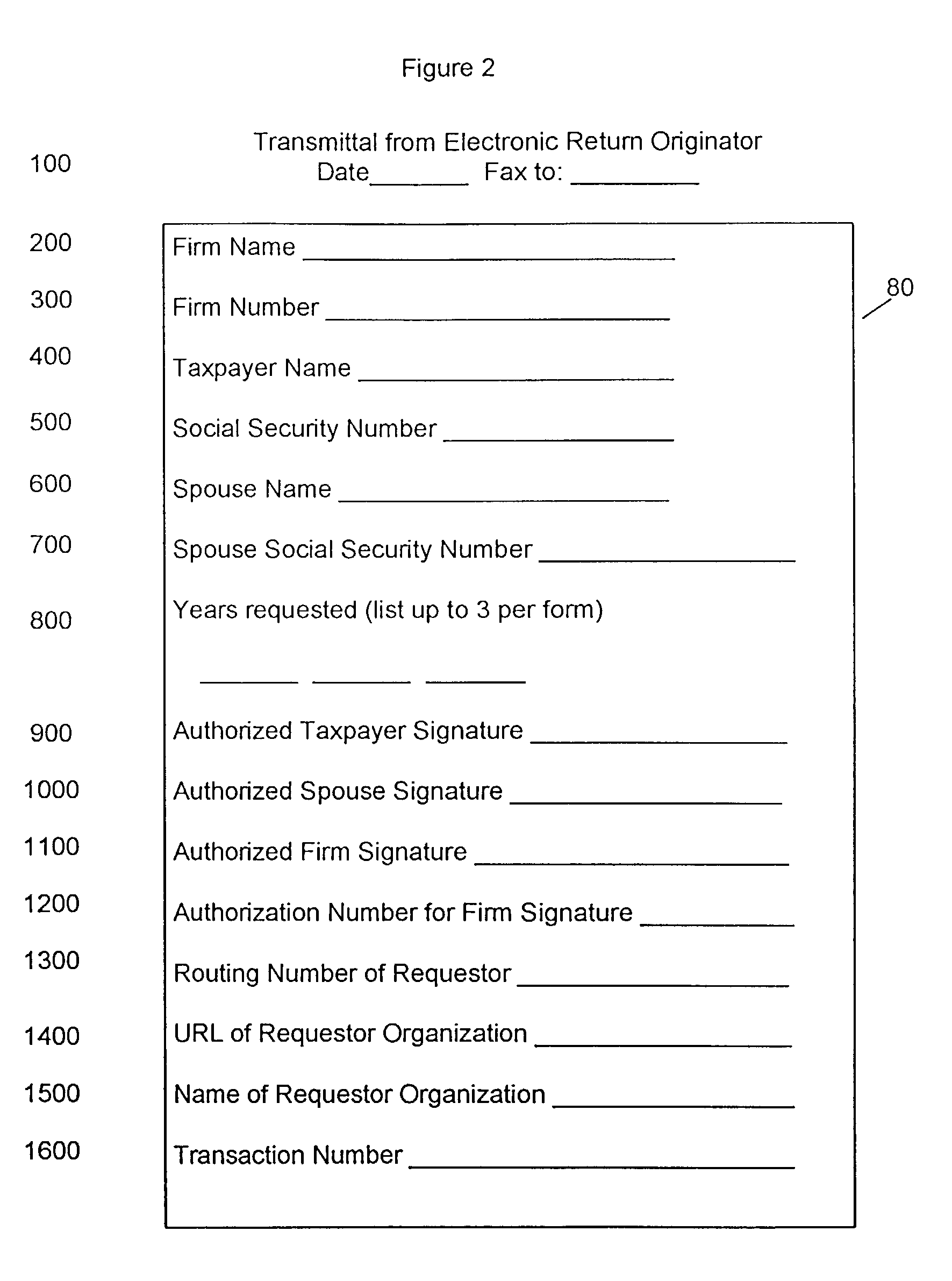

Method and system for aggregation and exchange of electronic tax information

InactiveUS7257553B1Improve confidentialityAllocating expenseComplete banking machinesFinanceComputer scienceQualitative property

A process that arranges information warehoused at individual accounting and tax preparation firms at a central location for the purpose of marketing information. Data contained at these firms have qualitative and quantitative characteristics that are different from data archived at the Internal Revenue Service or other tax authorities. This fact makes the data valuable as data in two ways. First the data can be exchanged to provide new revenue streams. Secondly, these data, if grouped into data warehouses of other firms, has value as pure data, not just customer lists. These data may be sold or rented creating additional revenue streams for their originators. The purchasers of this bulk data are interested in using this data in the field of data mining. Data mining is a technique of analyzing vast amounts of information to uncover relationships to predict events and has wide application in many areas of the economy.

Owner:REVENUE REALIZATION

Hot stamping foil applied to overlapping hot stamping on gold stamping layer and preparation method of hot stamping foil

ActiveCN103465668AImprove trimming effectTransfer completelyDuplicating/marking methodsPolyurea/polyurethane coatingsHot stampingCellulose

The invention discloses a hot stamping foil applied to overlapping hot stamping on a gold stamping layer and a preparation method of the hot stamping foil. When overlapping hot stamping is carried out on an existing hot stamping foil, the defects that the transferring is incomplete, the hot stamping is not carried out on some portions due to omission, scumming is caused, powder falls off, and the edge of a hot stamping layer is not clear can happen. The hot stamping foil is composed of a base membrane layer, a release layer, a color coating layer, a vacuum aluminum coated layer and a gumming layer. The gumming layer is prepared by raw materials which comprise, by weight, 1-6 parts of chloroethylene-vinyl acetate resin, 1-10 parts of polyvinyl alcohol, 1-10 parts of acrylic ester, 1-5 parts of nitrocellulose, 1-5 parts of fumed silica, 20-70 parts of ethyl acetate, 10-50 parts of ethyl alcohol and 1-5 parts of propyl acetate. According to the hot stamping foil applied to the overlapping hot stamping on the gold stamping layer, the hot stamping foil has the good stamping performance and the good trimming performance, the overlapping hot stamping layer is complete in transferring, the edge is smooth and free of burrs, the adhesion is firm, the phenomena of dusting, powder falling and the like do not exist, the hot stamping effect is strong in third dimension, and the anti-fake performance is more outstanding.

Owner:云南玉溪东魅包装材料有限公司

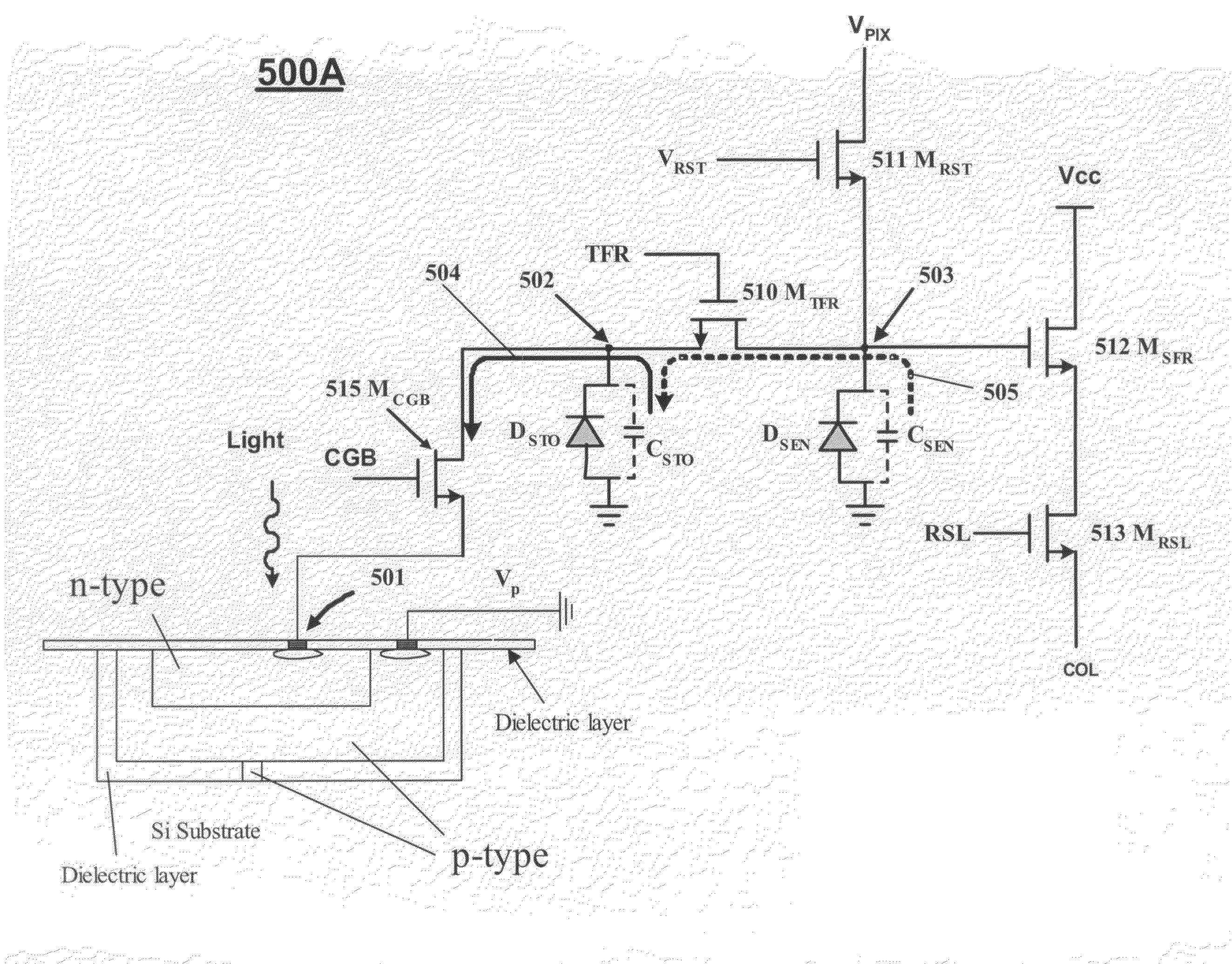

CDS capable sensor with photon sensing layer on active pixel circuit

InactiveUS7786543B2Remove noiseTransfer completelyTelevision system detailsTelevision system scanning detailsCMOS sensorCapacitance

A MOS or CMOS based active pixel sensor with special sampling features to substantially eliminate clock noise. The sensor includes an array of pixels fabricated in or on a substrate, each pixel defining a charge collection node on which charges generated inside a photodiode region are collected, a charge integration node, at which charges generated in said pixel are integrated to produce pixel signals, a charge sensing node from which reset signals and the pixel signals are sensed. In preferred embodiments the sensor includes a continuous electromagnetic radiation detection structure located above the pixel circuits providing a photodiode region for each pixel. The sensor includes integrated circuit elements adapted to maintain voltage potentials of the charge integration nodes substantially constant during charge integration cycles. The sensor also includes integrated circuit elements having electrical capacitance adapted to store charges providing an electrical potential at the charge integration node. In preferred embodiments this is a pinned diode.

Owner:E PHOCUS

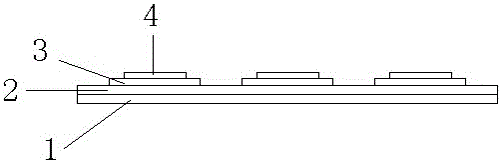

High-precision overlay gold stamping paper and manufacturing method thereof

ActiveCN104924790AHigh precisionThere is no phenomenon of inaccurate ironingPaper/cardboard layered productsOther printing apparatusHot stampingProcess engineering

The invention provides a piece of high-precision overlay gold stamping paper and a manufacturing method thereof. When printing and overprinting are conducted through two existing types of alumite, the printing and stamping accuracy is not high, the printing deflection is large, and waste is prone to happening. The high-precision overlay gold stamping paper sequentially comprises a tipping base paper layer (1), a printing layer (2), a first gold stamping layer (3) and an overlay stamping layer from bottom to top. The manufacturing method includes the following steps of firstly, printing a piece of tipping paper; secondly, designing a pattern; thirdly, manufacturing an overlay gold stamping plate; fourthly, preparing hot stamping; fifthly, conducting the first time of hot stamping; fifthly, conducting overlay stamping; sixthly, conducting checking and unwinding. In the post-printing gold stamping and overlay stamping process, no inaccurate printing phenomena exist, the transverse and longitudinal overlay stamping accuracy is 0.01 mm, the printing accuracy is greatly improved, and the gold stamping plate does not need to be aligned multiple times. Due to the fact that positioned overlay stamping is conducted at a specific position of a tipping paper ink layer, products are more personalized, and meanwhile the anti-counterfeit function is achieved.

Owner:YUNNAN YUXI TIPPING PAPER FACTORY

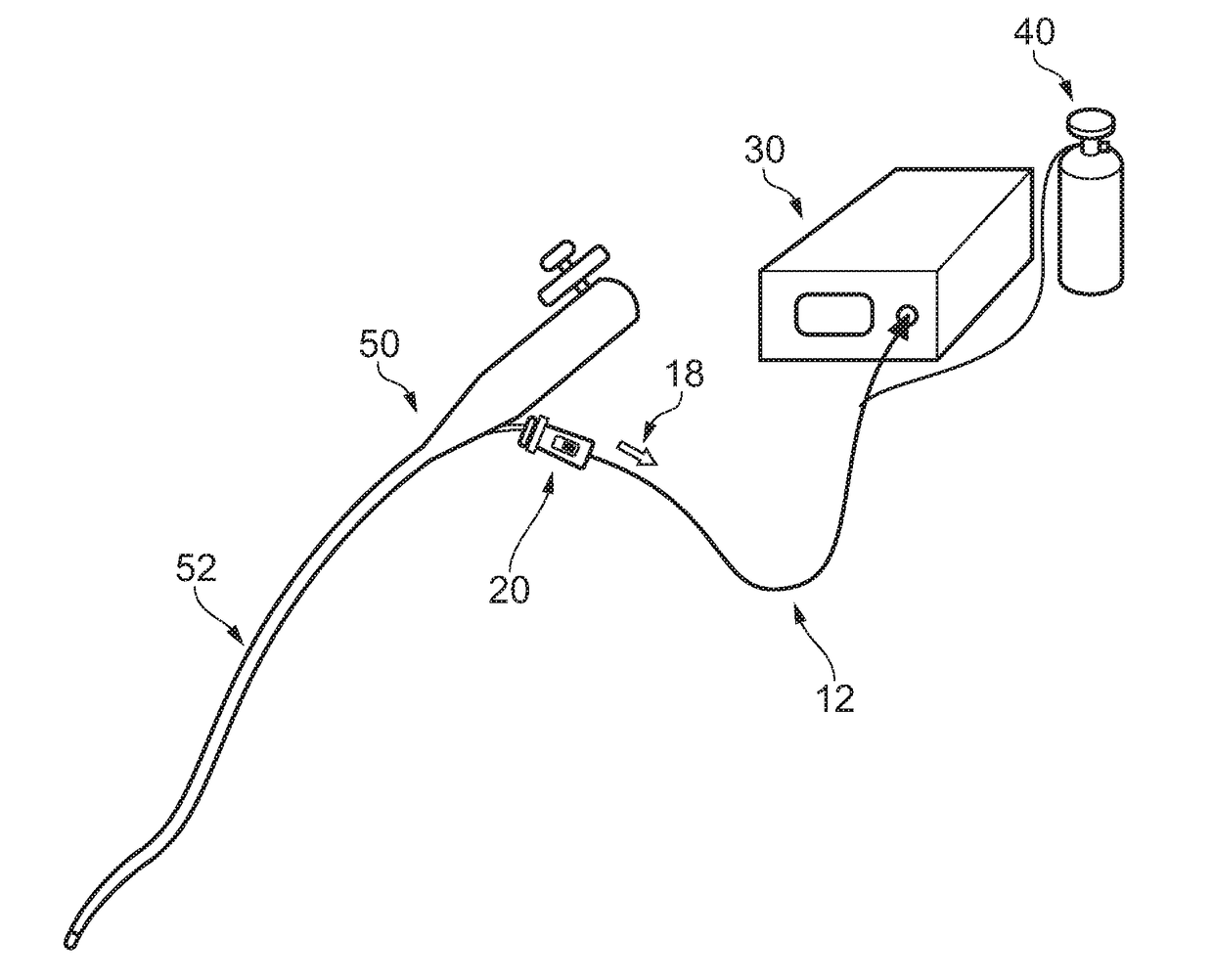

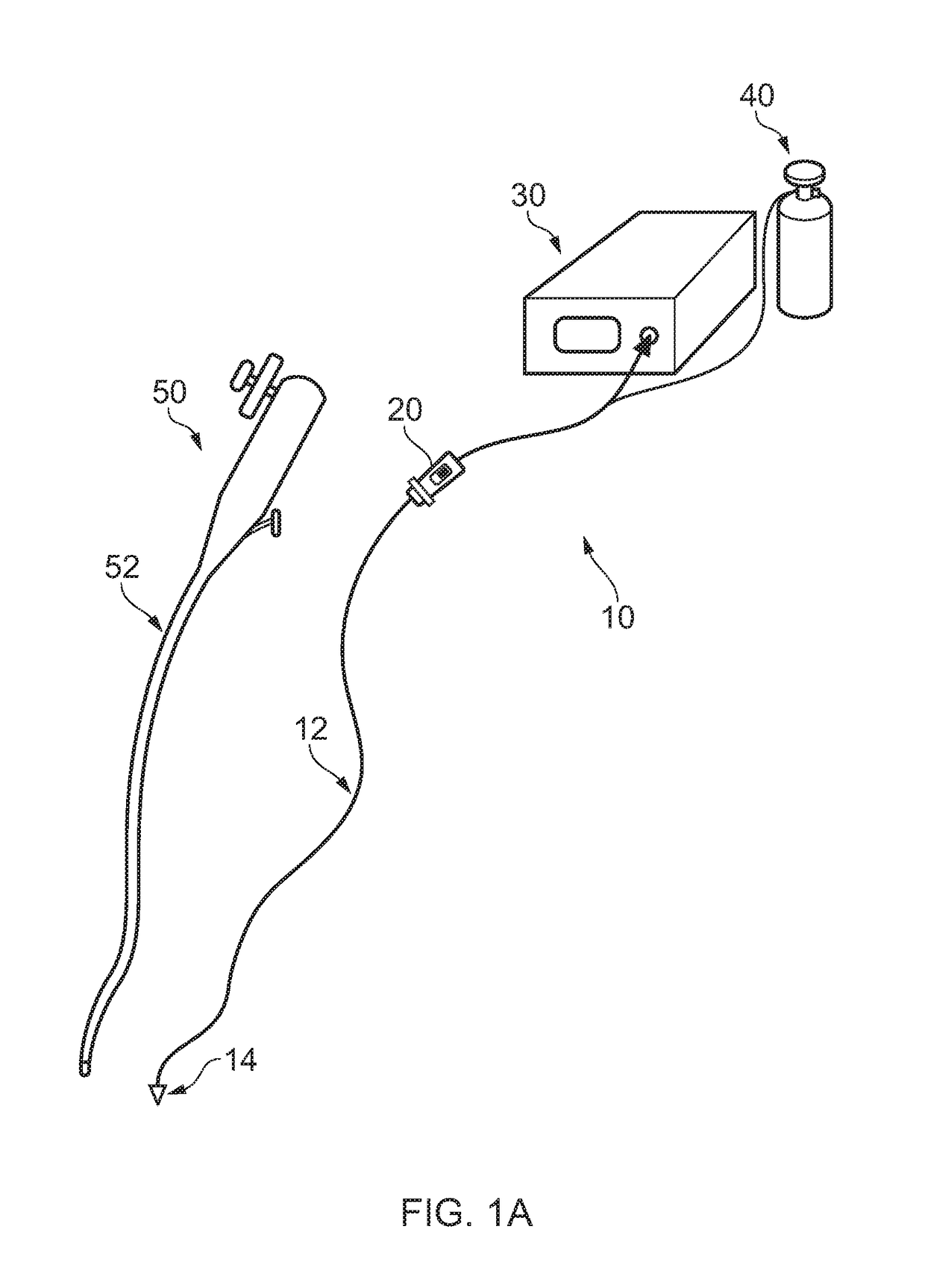

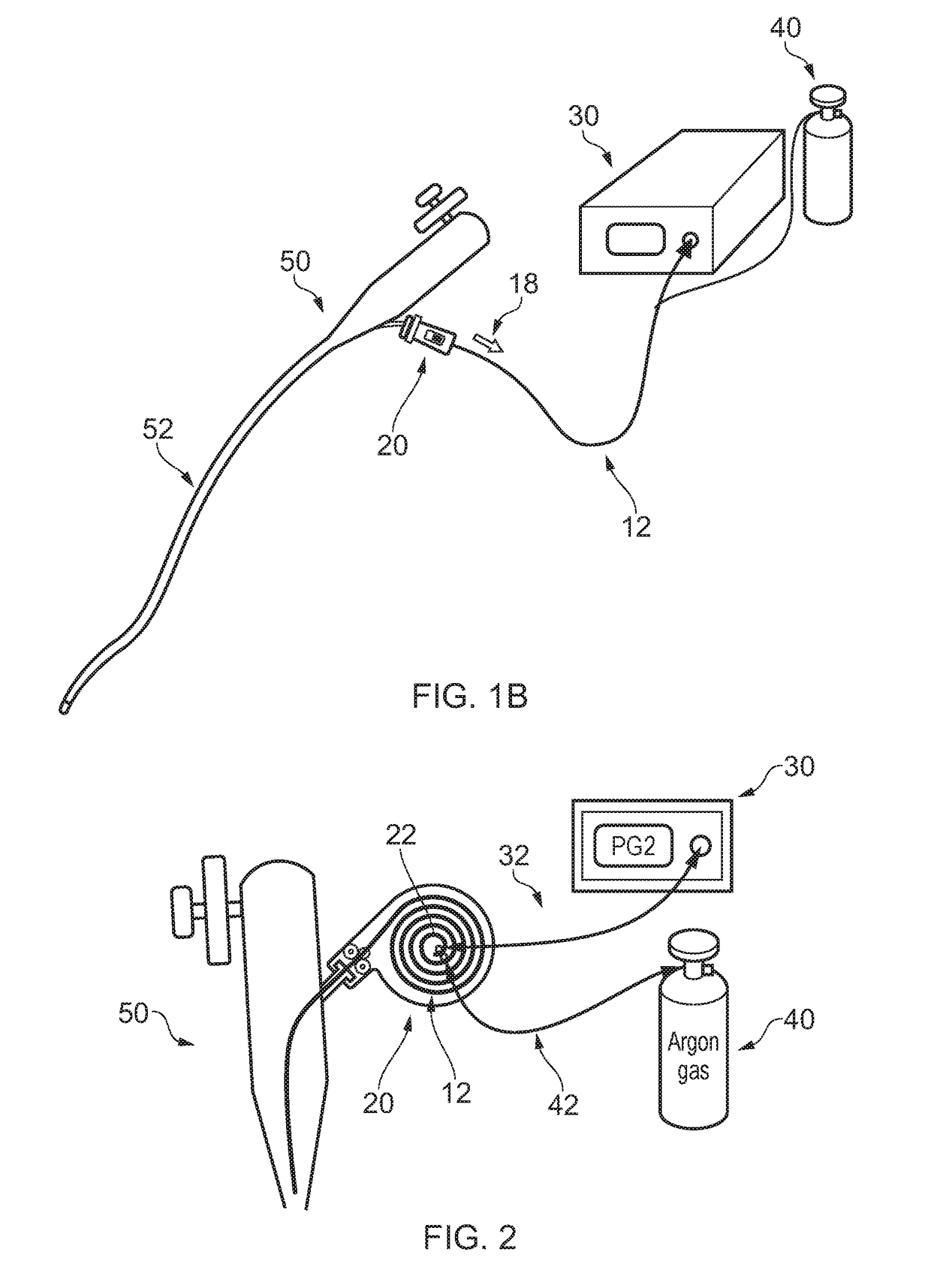

Apparatus for sterilizing an instrument channel of a surgical scoping device

ActiveUS20180318459A1Improvement factorTransfer completelyElectric discharge tubesSurgeryBiomedical engineeringElectric field

Sterilization apparatus comprising a sterilization instrument configured to be inserted through the instrument channel of a surgical scoping device and a withdrawal device for withdrawing the sterilization instrument from the instrument channel at a predetermined rate. The sterilization instrument comprises an elongate probe having a probe tip with a first electrode and a second electrode arranged to produce an electric field from received RF and / or microwave frequency EM energy. In operation the instrument may disinfect an inner surface of the instrument channel by emitting energy whilst being withdrawn through the channel.

Owner:CREO MEDICAL LTD

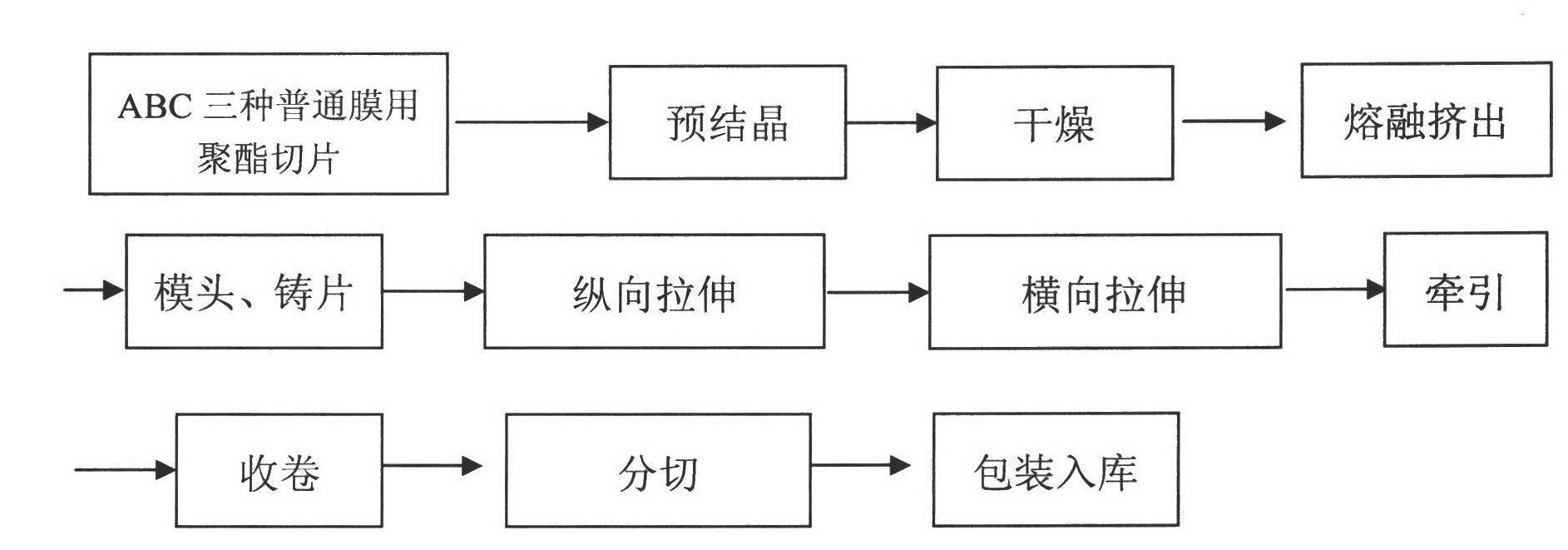

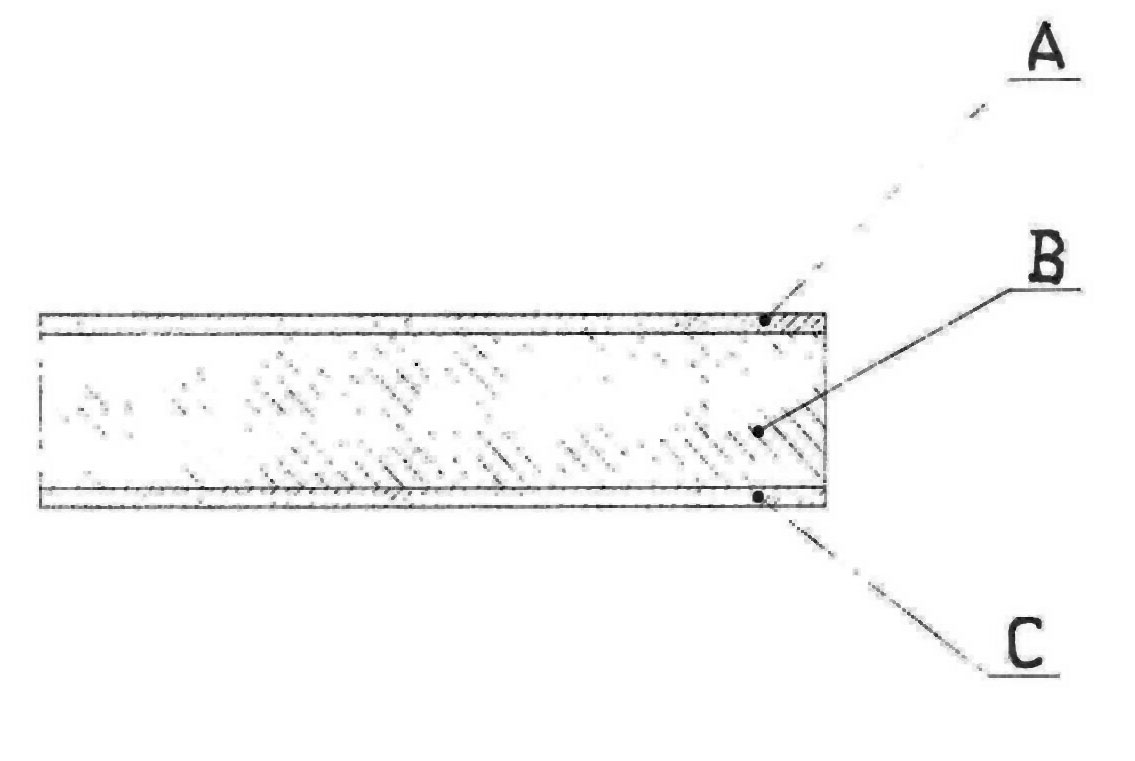

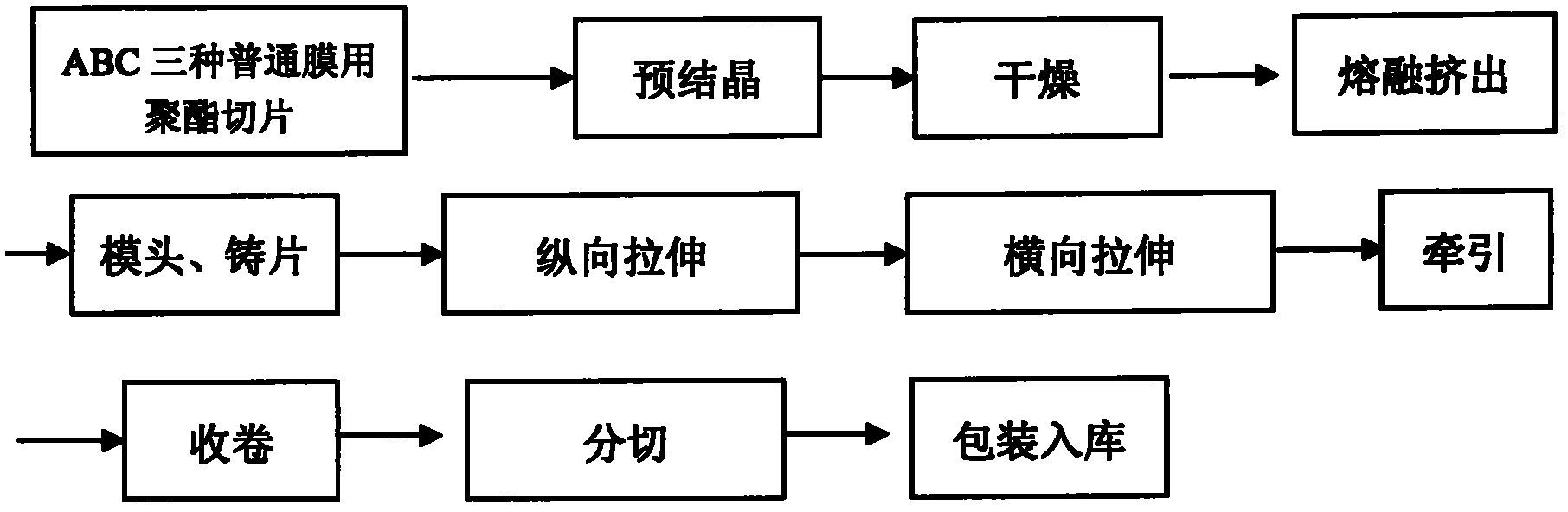

Shrinking-proof polyethylene terephthalate (PET) laser transfer base film and method for preparing same

ActiveCN102582189AReduce coefficient of frictionMeet the requirements of producing high-grade positioning laser transfer base filmSynthetic resin layered productsFlat articlesPolyethylene terephthalate glycolPolyethylene terephthalate

The invention discloses a shrinking-proof PET laser transfer base film and a method for preparing the same. The weight ratio of components of raw materials of layer A, layer B and layer C are as follows: layer A: 75% of polyester used for films, 25% of a caking inhibiter; layer B: 85% of film polyester, 15% of a thermal stability caking inhibiter; and layer C: 80% of film polyester, 20% of the caking inhibiter. The method for preparing the shrinking-proof PET laser transfer basement film comprises the steps of cutting materials into pieces and mixing the materials; performing fusion and extrusion; performing die head piece casting; drawing longitudinally; drawing transversely; performing traction and side shearing; winding; slitting and finishing products. Compared with conventional laser transfer base films, the shrinking-proof PET laser transfer base film has the advantages that the shrinking-proof performance is excellent, the thermal stability is good, the stamping effect is good, the transfer is complete, and the thickness is uniform. The shrinking-proof PET laser transfer base film can meet requirements of users for production of high-end positioning laser transfer base films and is applicable to manufacture of laser transfer aluminum plating packaging materials which have certain anti-counterfeiting functions.

Owner:JIANGSU SHUANGXING COLOR PLASTIC NEW MATERIALS

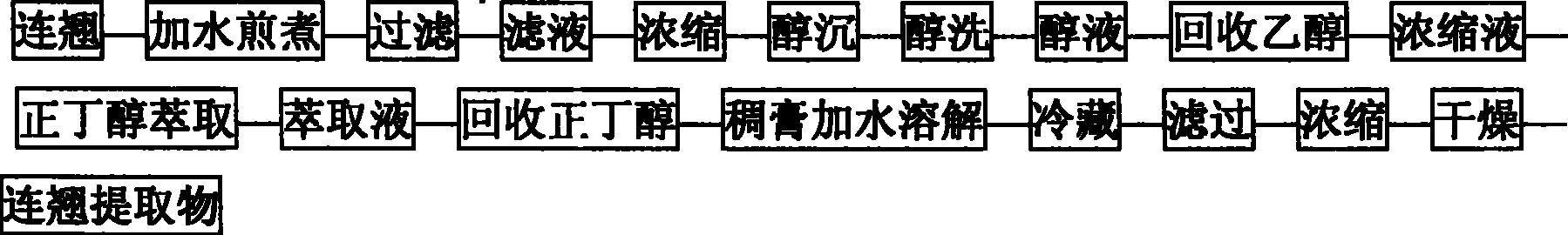

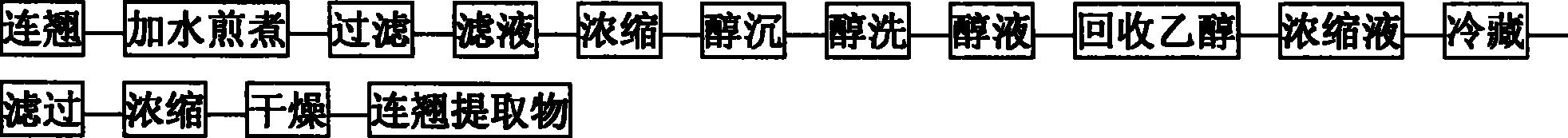

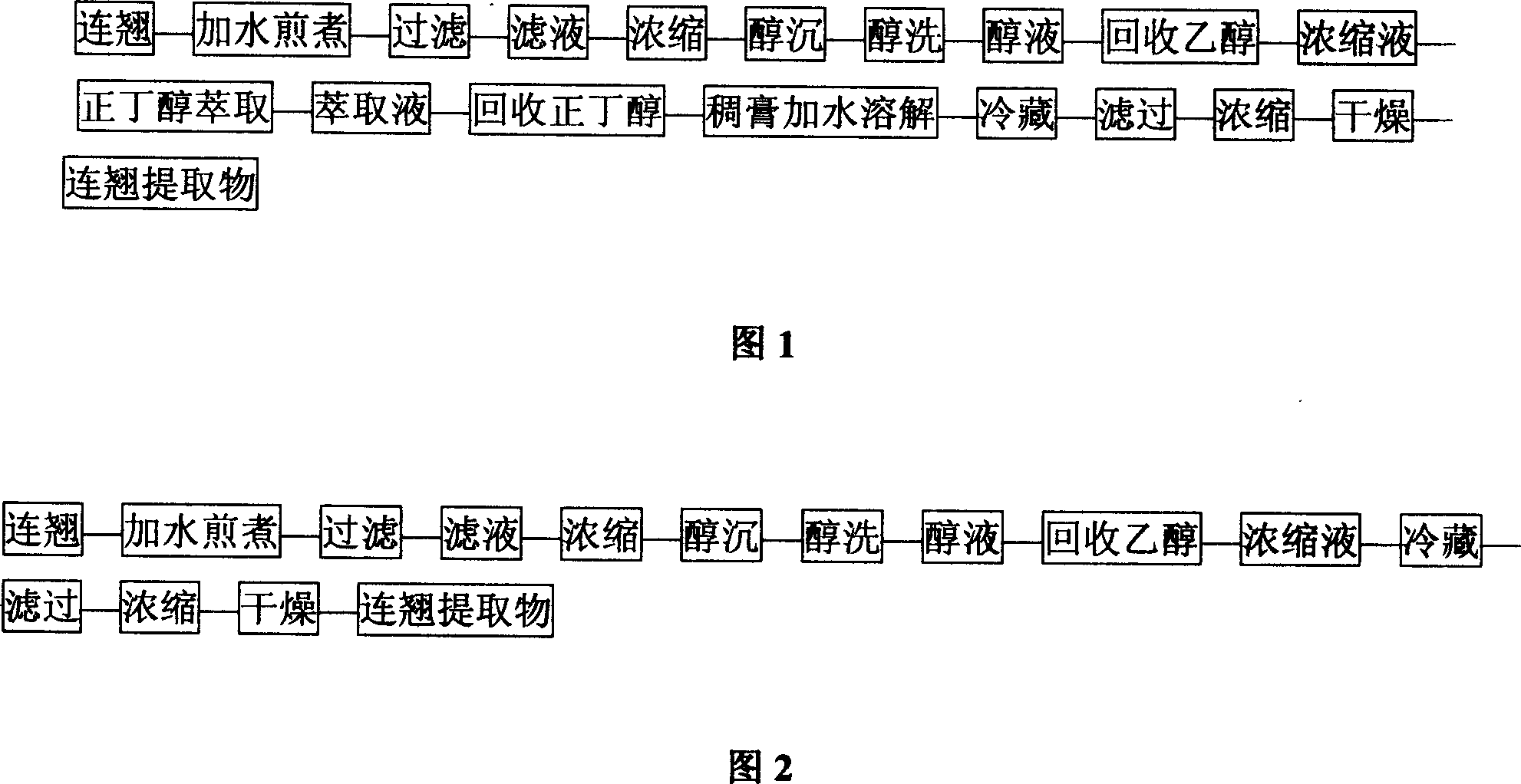

Method for preparing forsythia suspense extraction

The invention provides a preparation method of Fructus Forsythiae extract, and belongs to the field of preparative technique of Chinese traditional medicine. The inventive method comprises decocting Fructus Forsythiae with water for extraction, preliminary purifying through alcohol precipitation, and refining through water satured n-butanol extraction method. Compared with present technology, theinvention obtains efficient extract with phillyrin as main ingredient, avoids the loss of phillyrin in each operation, especially guarantee extraction rate of phillyrin, completely transfers effective ingredient, improves purity, thus, the invention has simple operation, and can provide technological conditions in favor of industrial production.

Owner:SHANGHAI KAIBAO PHARMA

Method for preparing forsythia suspense extraction

ActiveCN101085043AAvoid lostGuaranteed ExtractionAntiviralsDermatological disorderAlcoholAdditive ingredient

The invention provides a preparation method of Fructus Forsythiae extract, and belongs to the field of preparative technique of Chinese traditional medicine. The inventive method comprises decocting Fructus Forsythiae with water for extraction, preliminary purifying through alcohol precipitation, and refining through water satured n-butanol extraction method. Compared with present technology, the invention obtains efficient extract with phillyrin as main ingredient, avoids the loss of phillyrin in each operation, especially guarantee extraction rate of phillyrin, completely transfers effective ingredient, improves purity, thus, the invention has simple operation, and can provide technological conditions in favor of industrial production.

Owner:SHANGHAI KAIBAO PHARMA

Full-aqueous release coating for electrochemical aluminum hot stamping foil and preparation method of coating

ActiveCN110105861ASolve concentrationSolve quality problemsWax coatingsDuplicating/marking methodsHot stampingSolvent

The invention provides a full-aqueous release coating for an electrochemical aluminum hot stamping foil and a preparation method of the coating. When a release coating in an alcohol-water system is inuse, because the volatilization of ethyl alcohol and demulsification of a wax emulsion cause the quality defects such as concentration rising, which affects the release tightness of a product, and the utilization rate of the release coating in the alcohol-water system is low, a large amount of waste is caused. The full-aqueous release coating is prepared from, by weight, 80-98 parts of purified water, 1-5 parts of an aqueous polyurethane emulsion, 0.1-1 part of an aqueous acrylic emulsion, 0.1-1 part of a polyurethane crosslinking agent, 1-5 parts of an aqueous wax emulsion, 0.1-0.5 part of awetting agent and 0.1-1 part of a defoaming agent. The release coating improves the water resistance, solvent resistance, temperature resistance and mechanical properties of coating film; the recoating performance of the release coating is good, and coating requirements of subsequent colored layer coating can be met; the release effect is excellent, a hot stamping layer is transferred completely,and the release tightness is adjusted by adjusting the addition amount of a release agent.

Owner:云南玉溪东魅包装材料有限公司

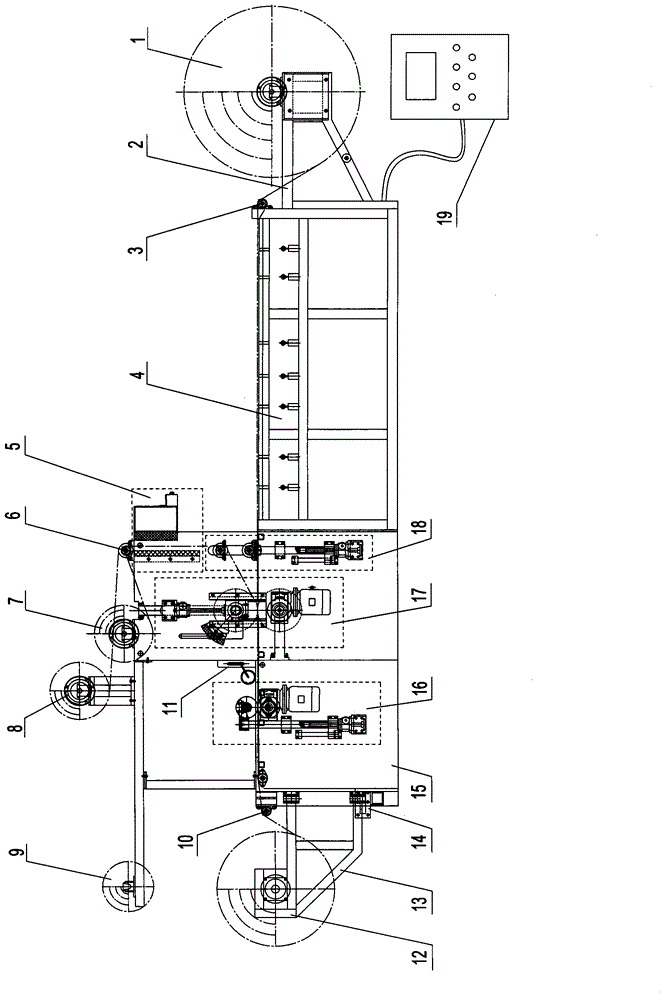

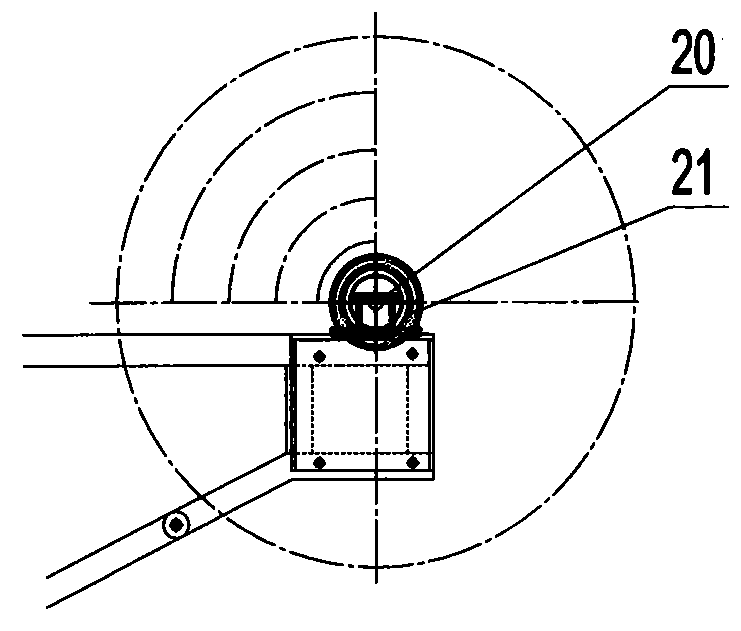

Full-automatic tape-sticking machine

ActiveCN103935109ATransfer completelySmooth transferLamination plant layoutLamination ancillary operationsVibration attenuationNumerical control

A full-automatic tape-sticking machine relates to tape-sticking equipment of foam and rubber products for sound absorption, vibration attenuation and external protection. A pulling pressing automatic lifting numerical control device, a meter counter, a pressing fitting automatic lifting numerical control device, a material-guiding pressing roller automatic lifting numerical control device and a preheating drying tunnel device are arranged in a rack; a winding device and a support locking and loosing device are arranged on the left side of the rack; a packaging film unwinding device and a release paper unwinding device are arranged on the top of the rack; and an air cushion workbench and an unwinding device are arranged on the right side of the rack. The machine adopts computer closed-loop control and a human-computer interface, and realizes automation of the whole process. Through the preset two times of heating, release paper cannot wrinkle when fitted to the material, and the rubber on the release paper can be totally transferred to a material required to be fitted; the air cushion workbench is adopted, so that the equipment can be used for fitting high-end sealing materials with elasticity. Therefore, the machine has high automation degree, the production efficiency is increased, the product quality is guaranteed, the rejection rate is effectively reduced, and the manual labor intensity is reduced.

Owner:YANCHENG XIEHE MACHINERY

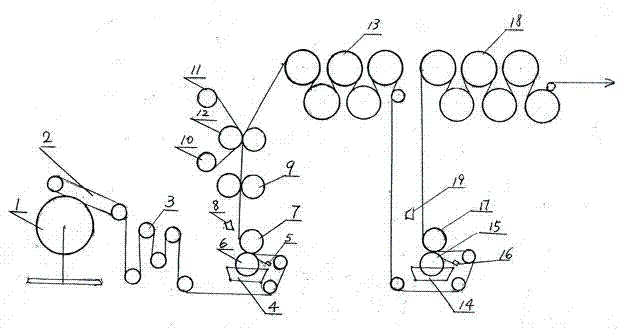

Reactive dye printing and dyeing transfer device and method without steaming and washing

ActiveCN102285210ATransfer completelyNo damage strengthTransfer printingPulp and paper industryWater soluble

The invention relates to a device and a method for printing and dyeing and transferring a steaming-free water-scrubbing-free reactive dye, which is used for machinery for transfer-printing in dyeing and finishing industries. According to the invention, the device comprises a tensionless conveying guide belt and a tension-regulating guide roller group; any shell fabric is fed into a repeatedly-wetting fluid bath device with a scraper; after the shell fabric is wetted, the shell fabric enters a transfer-printing pressing roller group and a first group of baking drums; the shell fabric is subjected to fixation through a meshed concave roller of a fixating fluid bath with a scraper and a pressing roller fixating group and enters a second group of braking drums while a softening agent is added; and the outlet product enters a product reel. In the invention, a water-soluble transfer-printing technique is adopted, thus the method is energy-saving and has low investment; through only once hot-pressing transferring at the highest temperature of 100 DEG C and then baking, the shell fabric can be fully fixated without waste material, waste gas and water scrubbing, thus the device and the method for printing and dyeing and transferring of the steaming-free water-scrubbing reactive dye satisfy with the standard 100 of ecological textiles.

Owner:邹恒余

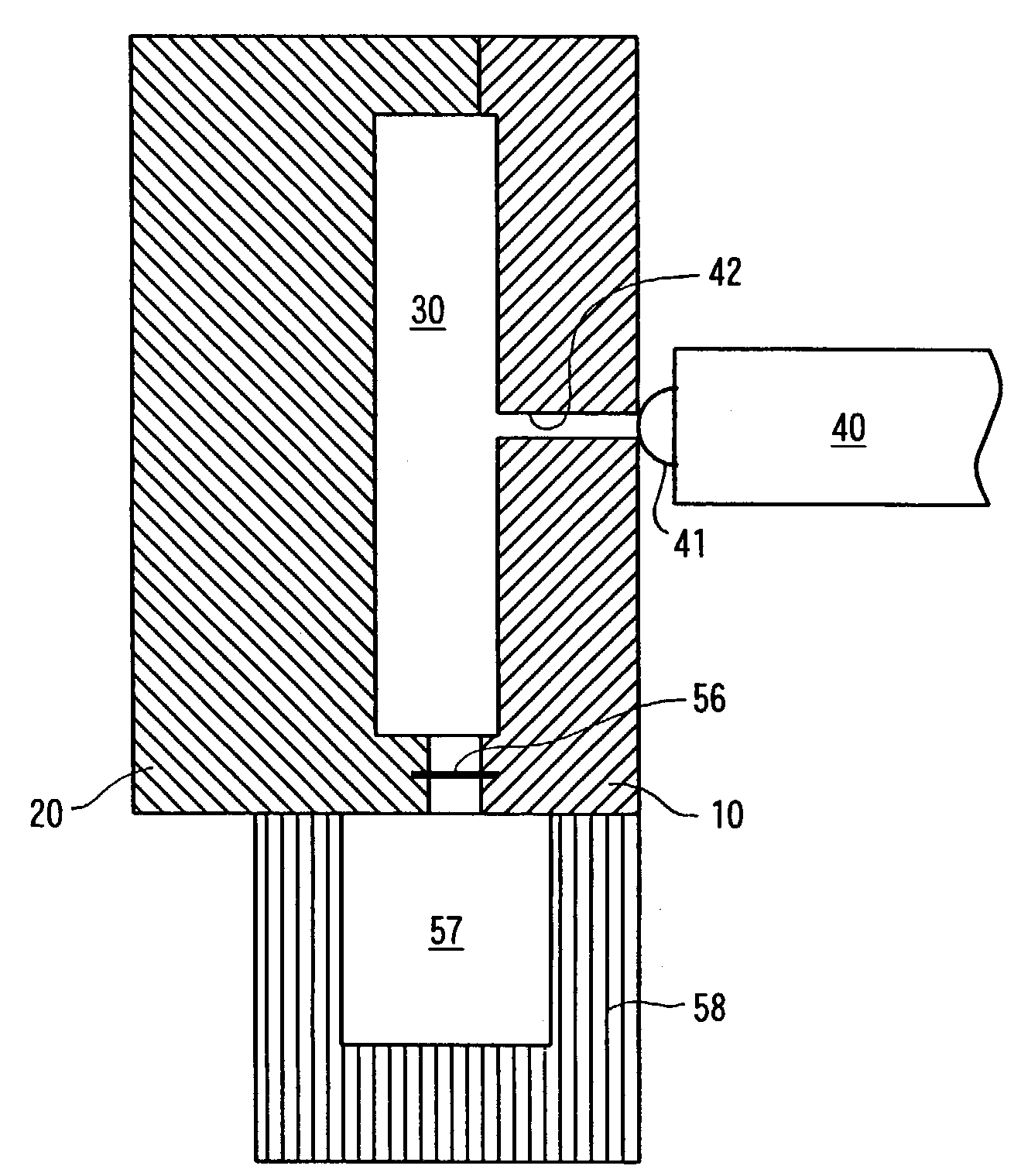

Method for formation of polymer

InactiveUS7077986B2Good transferabilityTransfer completelyLaminationLamination apparatusPolymer scienceShell molding

Objects of the present invention are to provide a method for molding polymers to be able to mold products each of which has an outer shape transferred accurately from the shape of the inside of a mold, exhibits high dimensional accuracy and is uniform in the thickness of its surface skin layer and the expansion ratio in its foamed inside.A molten polymer 60 is injected into a cavity 30 and simultaneously gas is pressed to the inside of the molten polymer 60 to contact the polymer close to the surface of the mold, and then gas is exhausted while maintaining the shape inside the mold, to thereby mold a polymer formed product in which a surface skin layer 61 and a foamed inside 62 having cushioning property are formed in one piece.

Owner:JSR CORPORATIOON

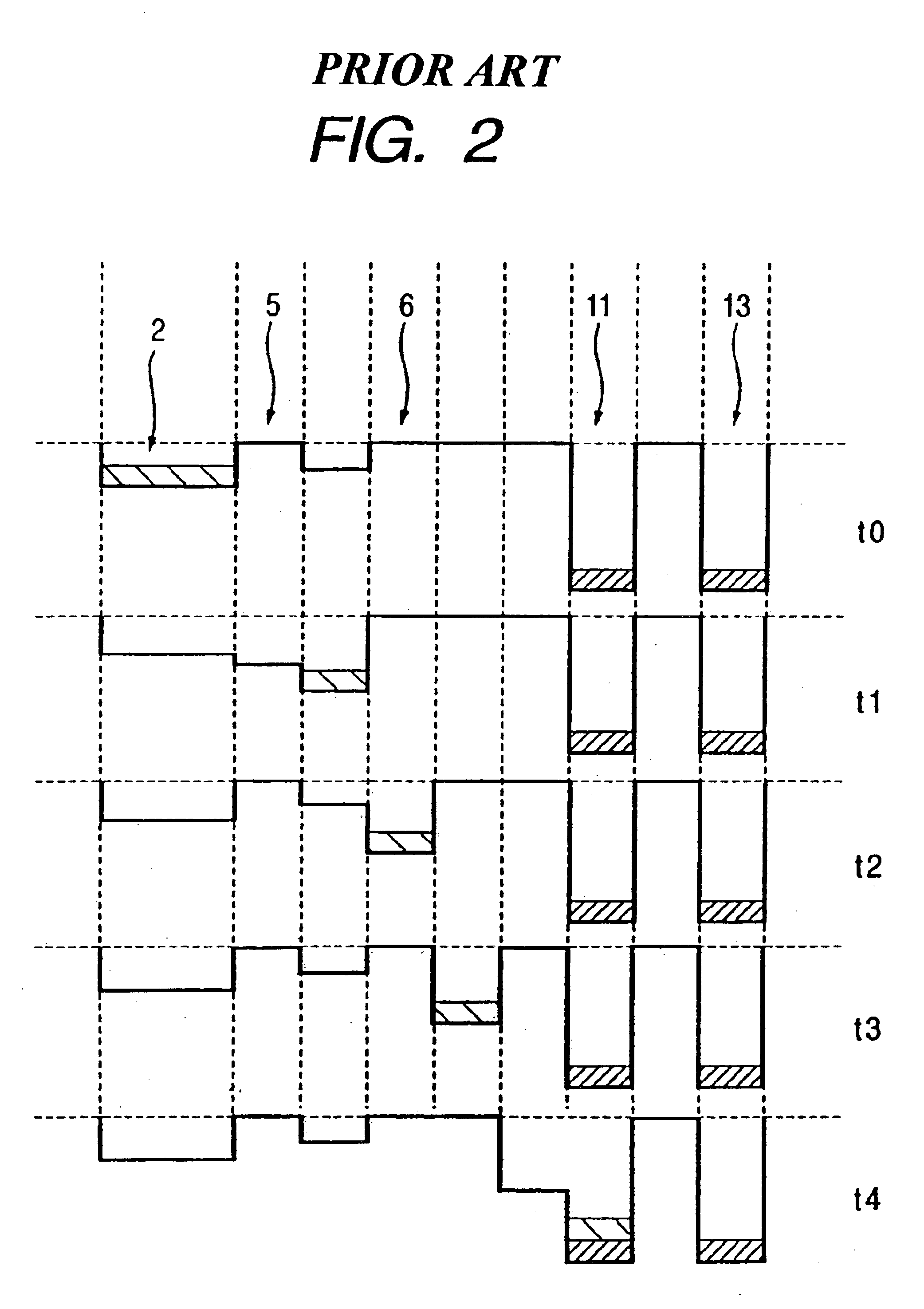

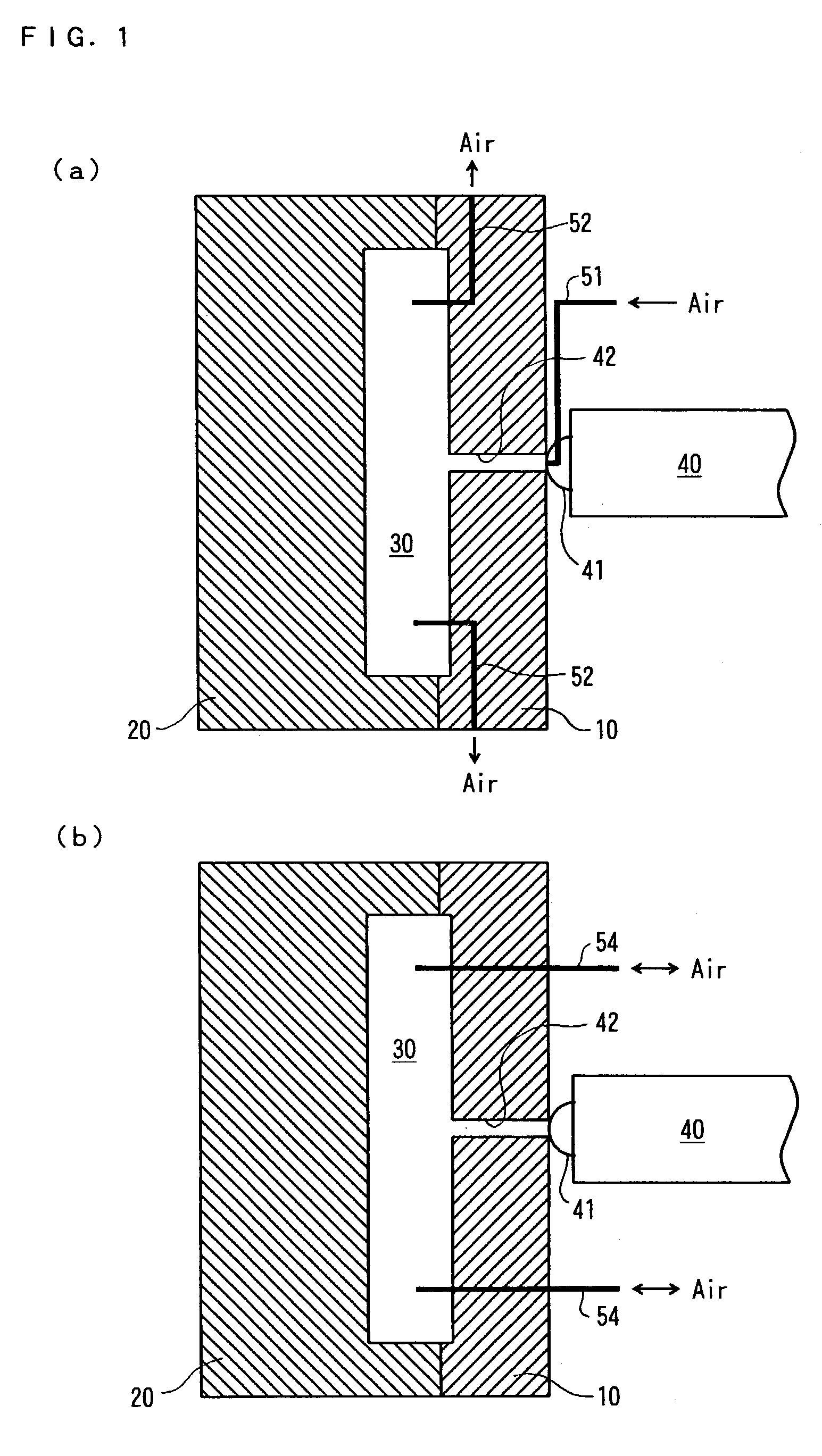

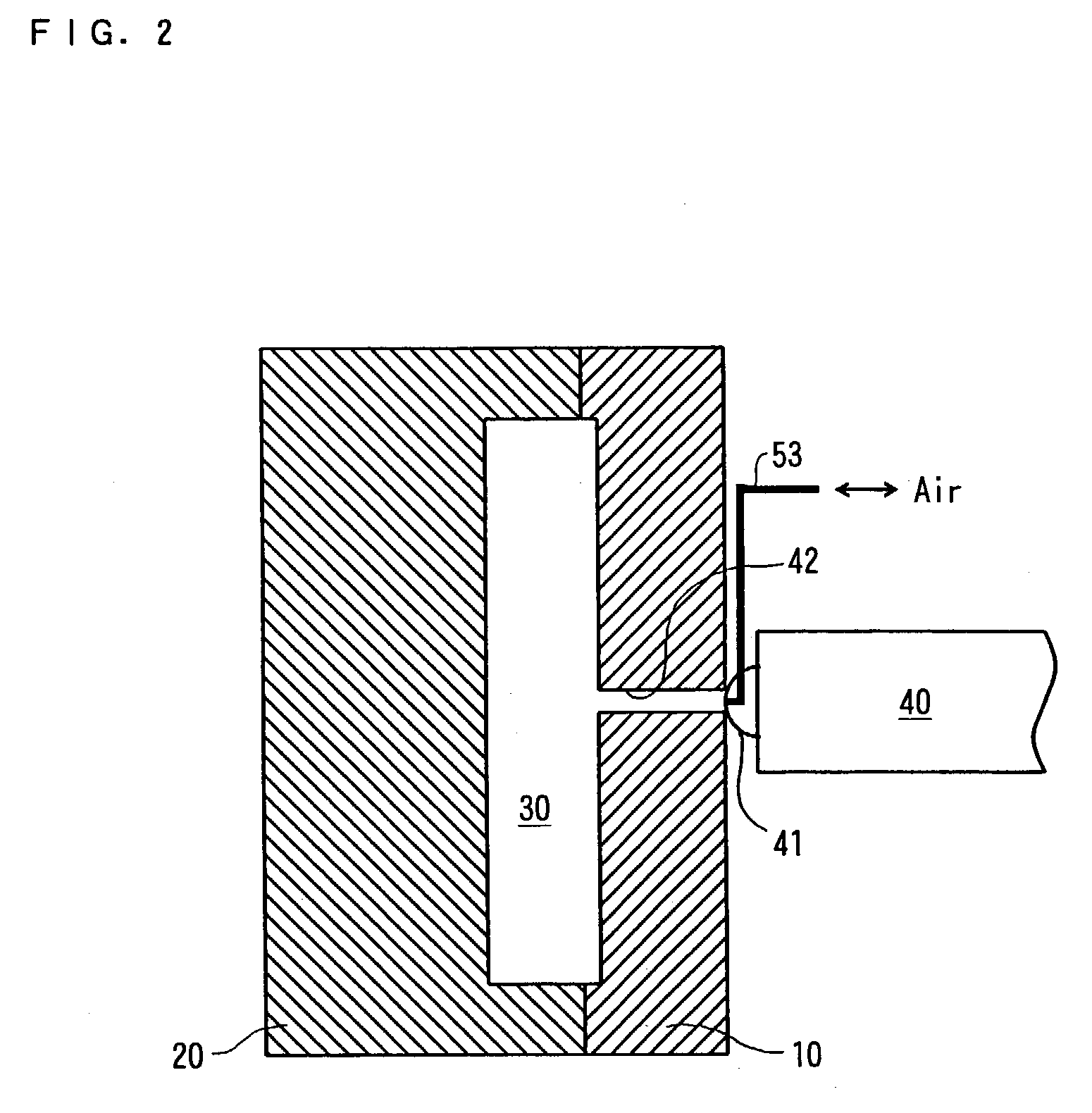

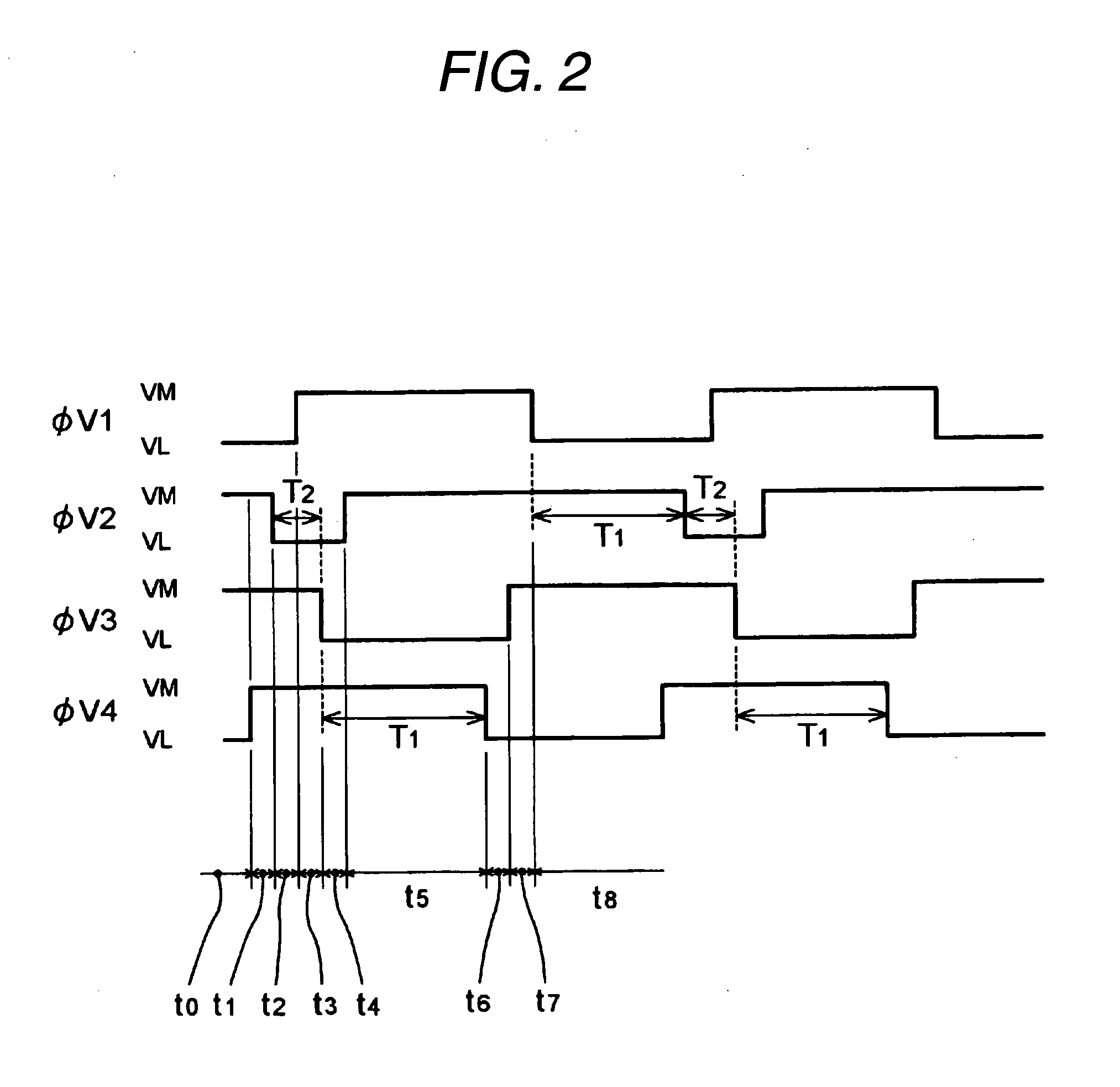

Method for driving solid-state imaging device and solid-state imaging device

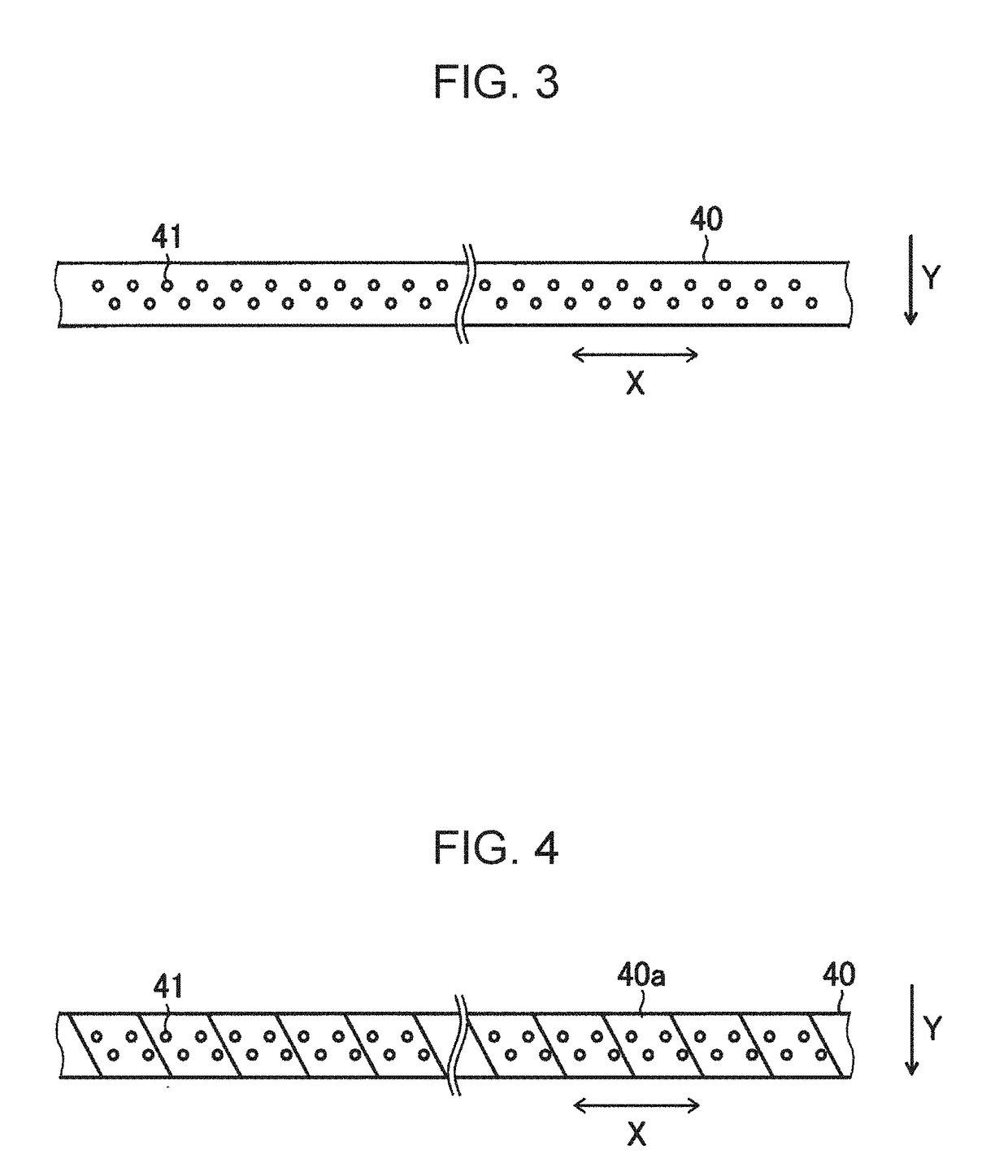

InactiveUS20060268141A1Extension of timeShorten the timeTelevision system detailsTelevision system scanning detailsEngineeringPhotoelectric conversion

A method for driving a solid-state imaging element, which includes photoelectric conversion parts; vertical charge-transfer paths transferring signal charges from the photoelectric conversion parts in the vertical direction, each of the vertical charge-transfer paths including pairs of a first and second electrodes; and a horizontal charge-transfer path transferring the signal charge in a horizontal direction, is provided and includes applying driving pulses to the first and second electrodes to transfer the signal charge in the vertical direction. The transferring of the signal charge in the vertical charge-transfer paths is performed in such a way that when the signal charge is transferred from an electrode whose length is longer, a charge transfer time is lengthened, and that when the signal charge is transferred from an electrode whose length is shorter, a charge transfer time is shortened.

Owner:FUJIFILM CORP

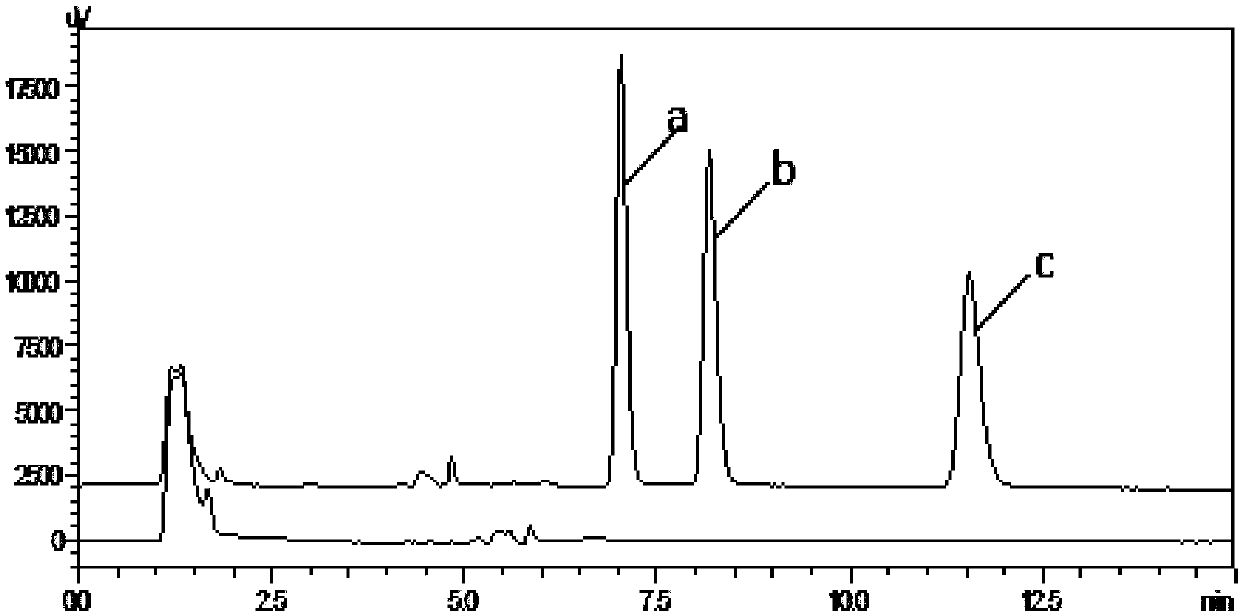

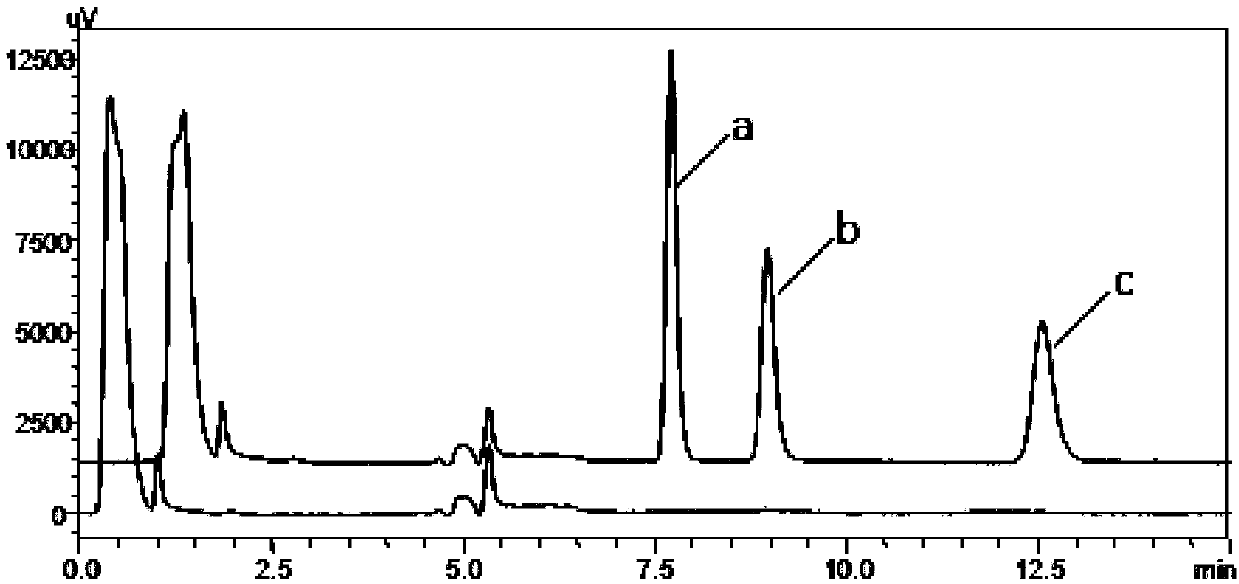

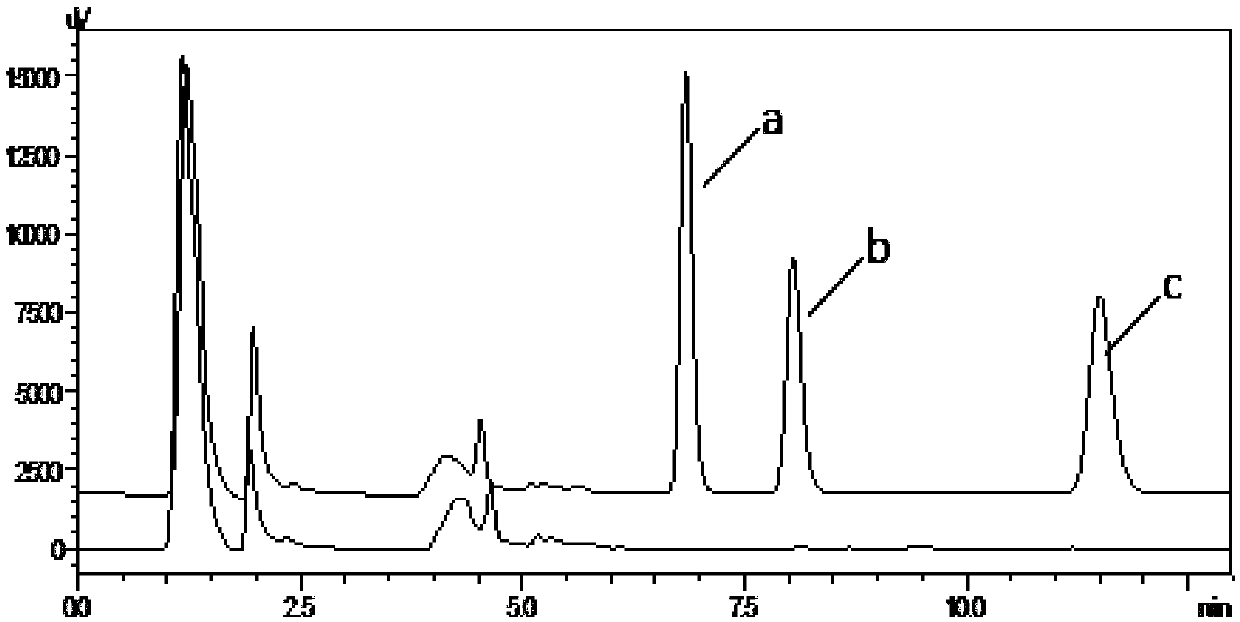

Method based on two-dimensional liquid chromatography to detect gelsemine, koumine and gelsenicine in biological specimen at same time

ActiveCN108614052ATransfer completelyEasy to handleComponent separationQualitative propertyLiquid phase

The invention discloses a method based on two-dimensional liquid chromatography to detect gelsemine, koumine and gelsenicine in a biological specimen at same time. The method comprises the steps of 1)pretreating the biological specimen to obtain a solution under test; 2) injecting the solution under test into a 2D-LC-UV system for detection; 3) subjecting detection results to quantitative analysis. The method has the advantages that, for instance, specimen pretreatment is simple, detection sensitivity is higher than that of common chromatography, false positives can be effectively eliminated,instrument stability is high, and the method is applicable to the qualitative and quantitative detection of gelsemine, koumine and gelsenicine in various biological specimens (blood, urine and muscle) and also applicable to the inspection of in-vitro specimens and suspicious material evidences.

Owner:HUNAN AGRICULTURAL UNIV

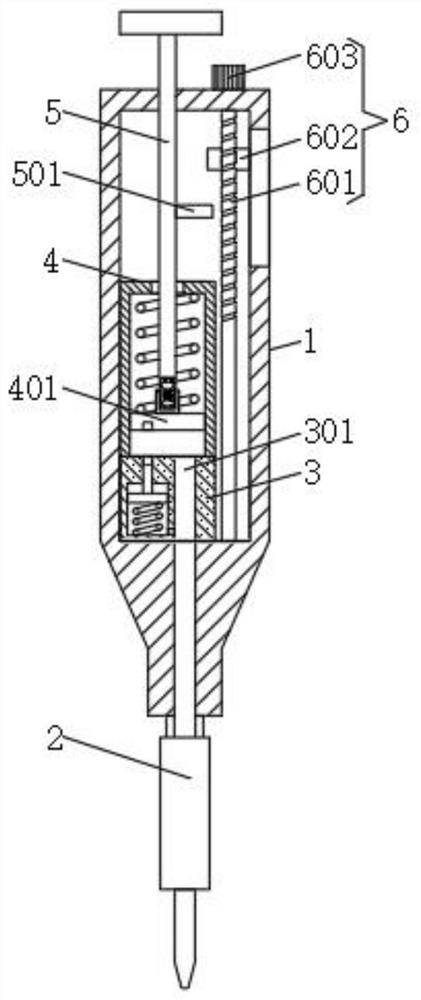

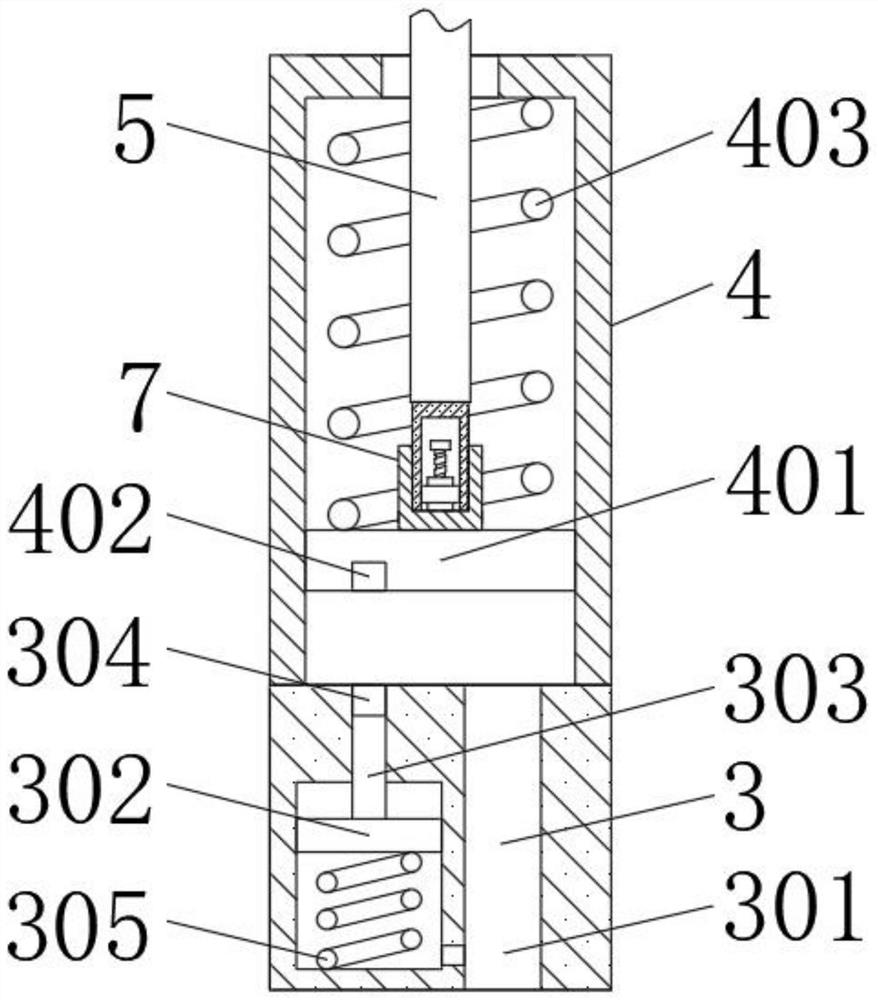

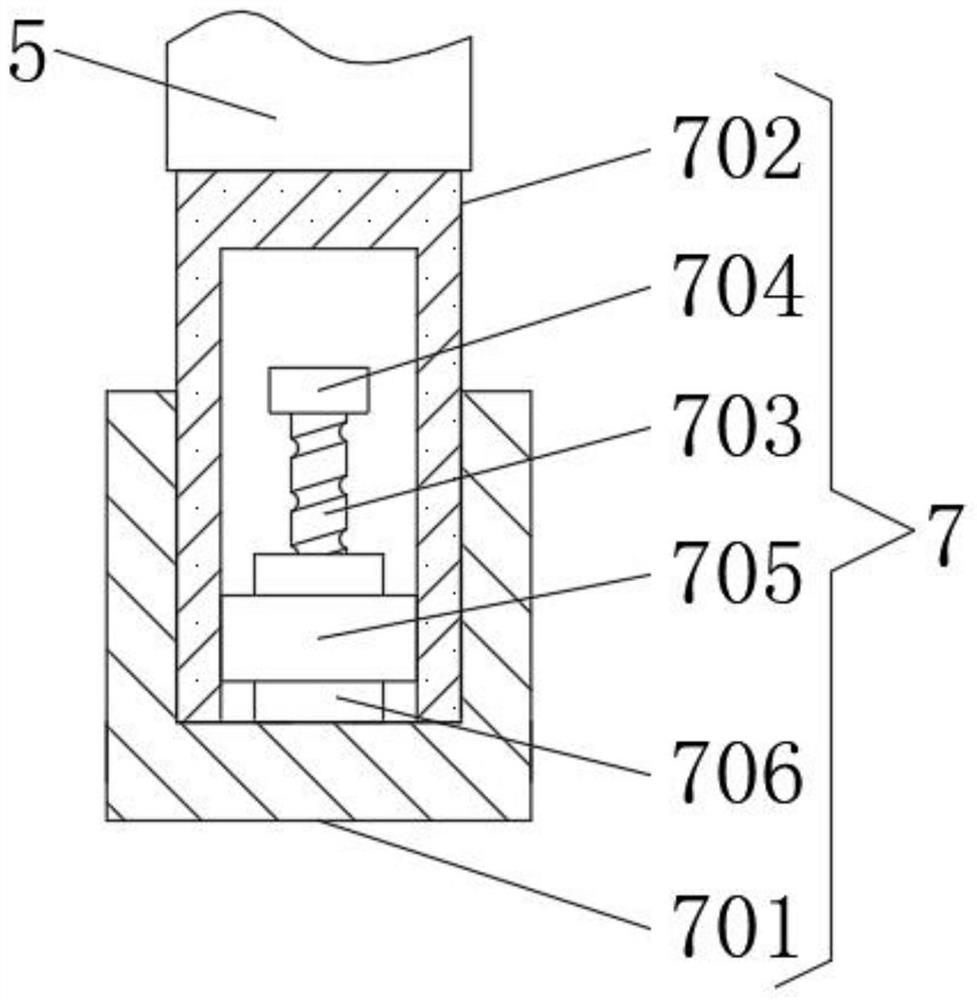

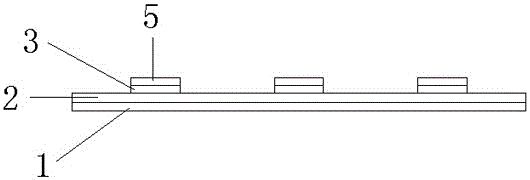

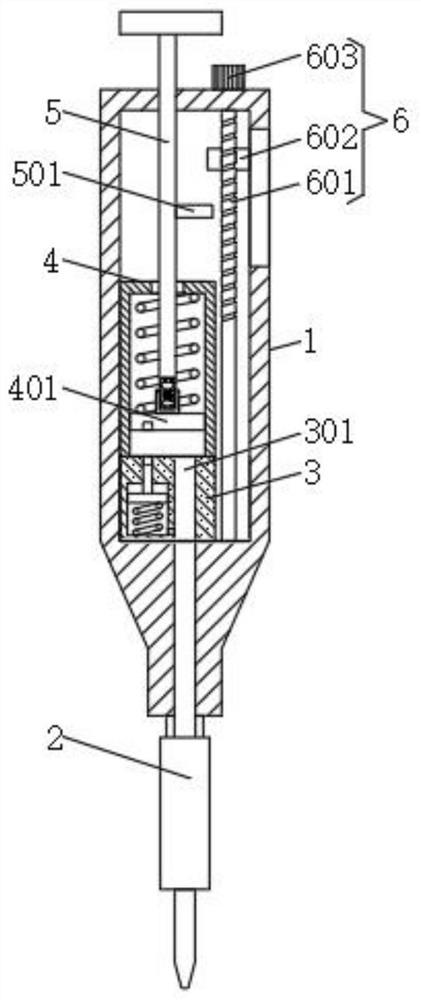

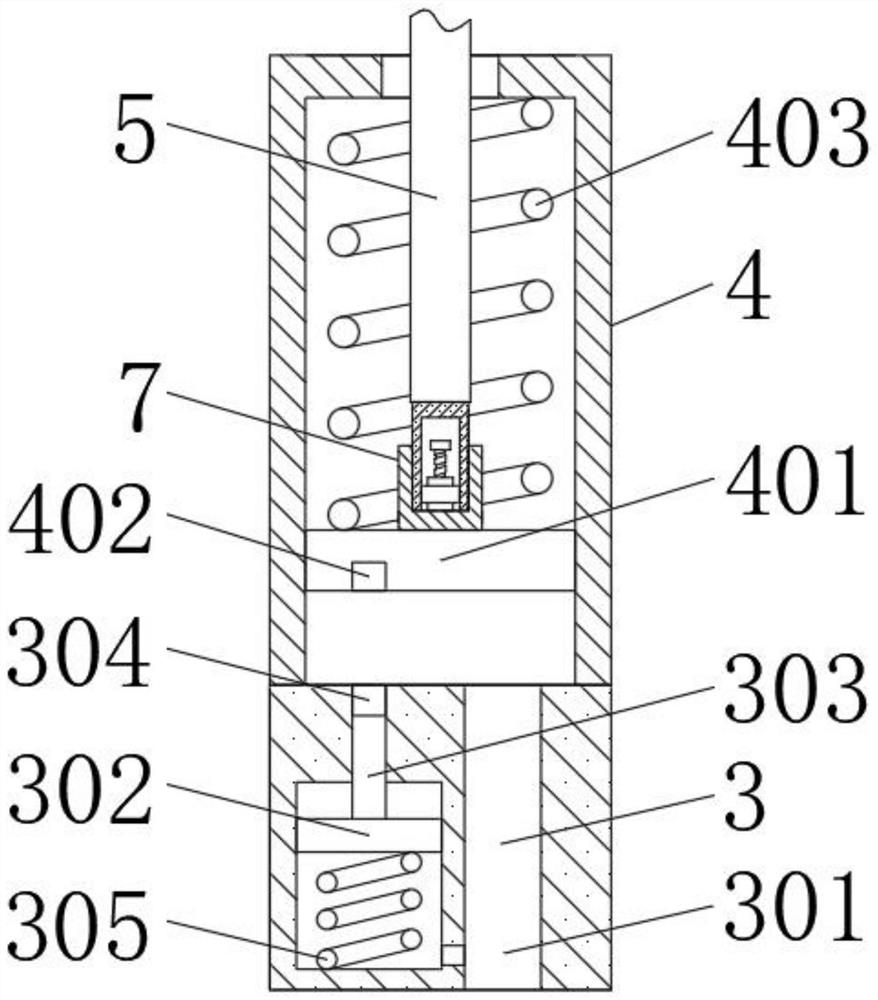

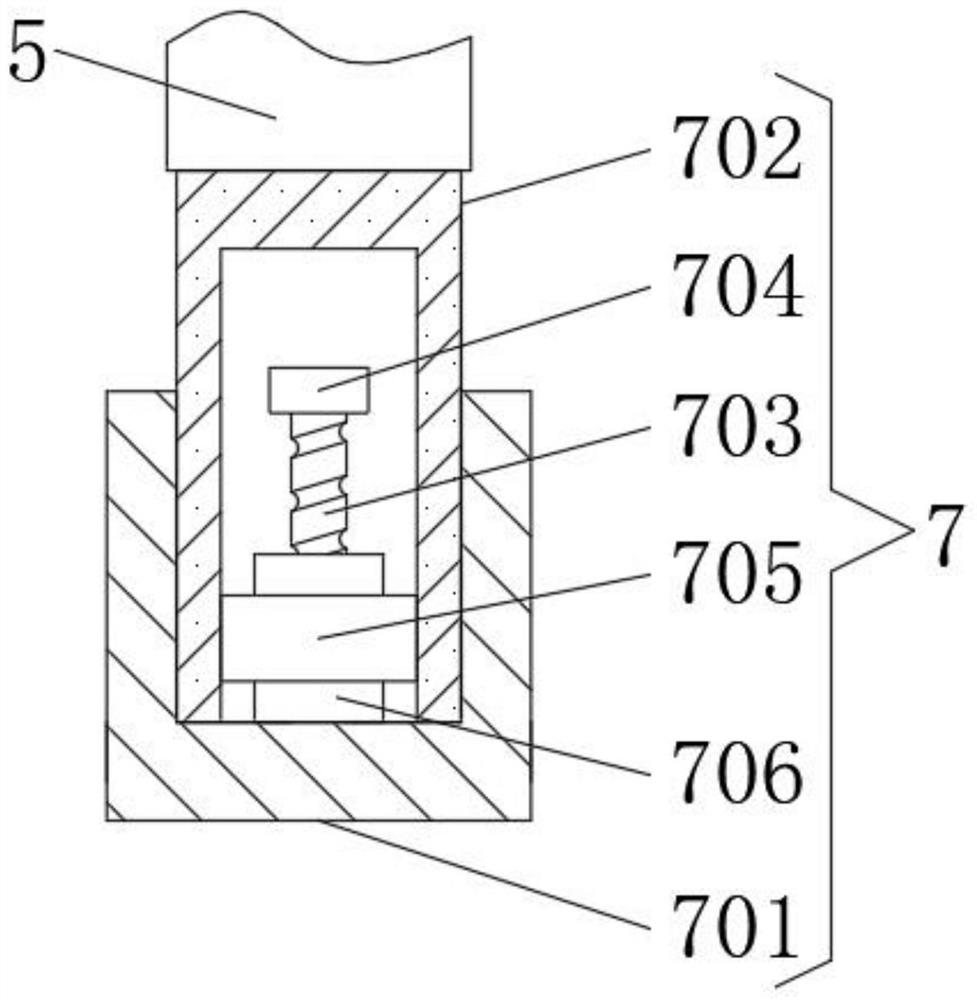

Delayed pressure supplementing pipettor for biomedical laboratory

The invention relates to the field of biomedical experiment instruments, and discloses a delayed pressure supplementing pipettor for a biomedical laboratory. The delayed pressure supplementing pipettor comprises a pipettor tube body, the bottom of the pipettor tube body is communicated with a pipetting needle tube, and the bottom of the inner cavity of the pipettor tube body is provided with a positioning pressure supplementing tube; a through groove communicated with the pipetting needle tube is formed in one side of the positioning pressure supplementing tube, and an inner groove is formed in the other side of the positioning pressure supplementing tube. According to the delayed pressure supplementing pipettor for the biomedical laboratory, through the structural design of the positioning pressure supplementing tube below the negative pressure suction tube, in cooperation with a self-rotating connecting mechanism between a push shaft and a pressure pumping piston, in the process thatthe pipettor is used for quantitatively transferring a solution, an upper magnetic plate is used for acting on a lower magnetic plate firstly, so that the lower magnetic plate moves downwards; and after the upper magnetic plate rotates to the other side, the lower magnetic plate moves upwards and resets under the action of the elastic force, and thus the exhaust is more thorough before the solution is extracted, and the accuracy of the solution transfer amount is improved.

Owner:重庆市开州区华兰生物单采血浆有限公司

Content determination method of haw and corium stomachium galli preparation

ActiveCN101167909AReduce the amount of dissolutionEasy to operateAnthropod material medical ingredientsComponent separationAlcoholFiltration

The invention relates to a content measuring method of a Chinese patent drug. The steps of the invention are that the chromatographic condition and the systematical employment and suitability test are the first step. The preparation of the solution for comparison is the second step of the invention. 3. After extracting by methyl alcohol, the extract solution of the preparation specimen is concentrated to the low alcoholic solution or the alcoholic-free solution. 4. After the purge process 3, the concentration solution of the extract solution is transferred to the macroreticular resin of a neutral alumina pole, wherein the lower portion is neutral alumina, and the upper portion is pre-treated macroreticular resin. The upper portion and the lower portion are washed by water and a grain alcohol solution of 10-25% sequentially, then the pole is eluted by the grain alcohol solution of 50-95%, and the eluent is collected and evaporated to dryness, further the residue is dissolved and has the constant volume and the filtration. The sequent filtration solution is achieved as the specimen solution. 5. According to the measuration, the solution for comparison of 10 mul and the specimen solution of 20 mul are precisely extracted separately, and the liquid chromatograph is injected, after measuring, the aim is achieved.

Owner:云南神威施普瑞药业有限公司

High-precision overprinting hot stamping tipping paper and its manufacturing method

ActiveCN104924790BHigh precisionThere is no phenomenon of inaccurate ironingPaper/cardboard layered productsOther printing apparatusHot stampingPulp and paper industry

The invention provides a piece of high-precision overlay gold stamping paper and a manufacturing method thereof. When printing and overprinting are conducted through two existing types of alumite, the printing and stamping accuracy is not high, the printing deflection is large, and waste is prone to happening. The high-precision overlay gold stamping paper sequentially comprises a tipping base paper layer (1), a printing layer (2), a first gold stamping layer (3) and an overlay stamping layer from bottom to top. The manufacturing method includes the following steps of firstly, printing a piece of tipping paper; secondly, designing a pattern; thirdly, manufacturing an overlay gold stamping plate; fourthly, preparing hot stamping; fifthly, conducting the first time of hot stamping; fifthly, conducting overlay stamping; sixthly, conducting checking and unwinding. In the post-printing gold stamping and overlay stamping process, no inaccurate printing phenomena exist, the transverse and longitudinal overlay stamping accuracy is 0.01 mm, the printing accuracy is greatly improved, and the gold stamping plate does not need to be aligned multiple times. Due to the fact that positioned overlay stamping is conducted at a specific position of a tipping paper ink layer, products are more personalized, and meanwhile the anti-counterfeit function is achieved.

Owner:YUNNAN YUXI TIPPING PAPER FACTORY

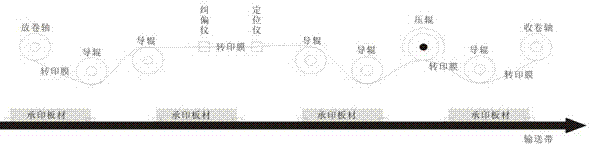

Process for preparing positioning transfer decoration surface

InactiveCN103029471AFast transferTransfer completelyPrinting after-treatmentInk transfer from master sheetControl parametersLight wave

The invention discloses a process for preparing a positioning transfer decoration surface. The process comprises the following steps: mounting a transfer film printed with decorative patterns and an identification cursor on a positioning transfer machine; putting a printing plate on a conveyer belt of the positioning transfer machine and fixing the printing plate; inputting corresponding control parameters, and manually adjusting the positions of the section of the front end of the printing plate on the conveyer belt and the pressing contact point of a pressing roller; starting the positioning transfer machine for performing continuous production, decorating the transfer film to control accurate, rapid and safe transfer printing between the decoration surface and the printing plate through positioning of a cursor positioning instrument and a light wave correction instrument on the positioning transfer machine and the conveyer belt which is provided with a servo motor and has accurate measurement, and the prepared decoration surface is high in color and pattern simulation degree and high in decoration property; and the positioning transfer decoration surface can be produced in batches and is high in production efficiency, low in energy consumption, small in field occupied area, environment-friendly, diversified in patterns and wide in base material range, and the application amount of the woods is reduced.

Owner:JIAOZUO ZHUOLI STAMPING MATERIAL CO., LTD.

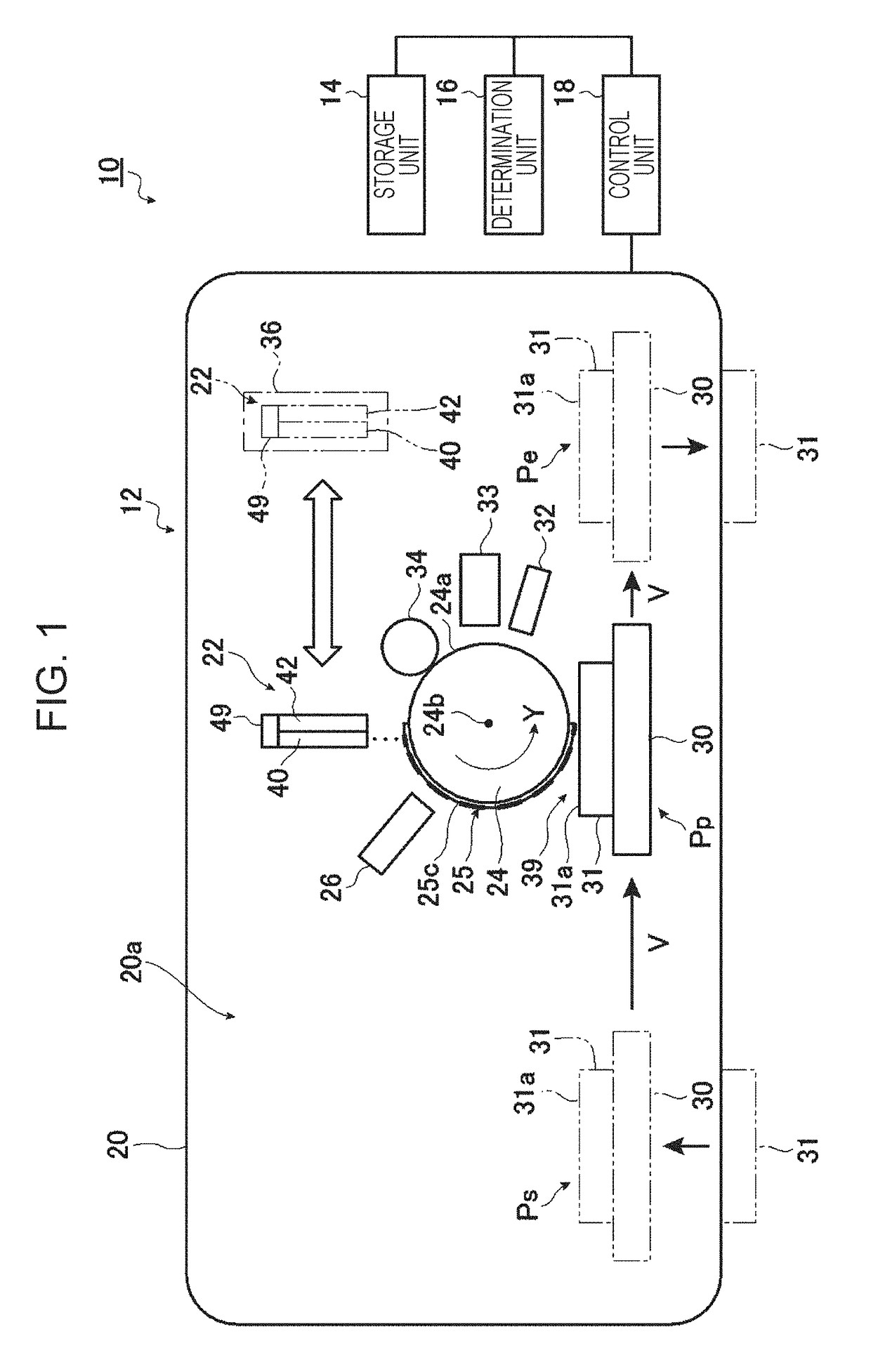

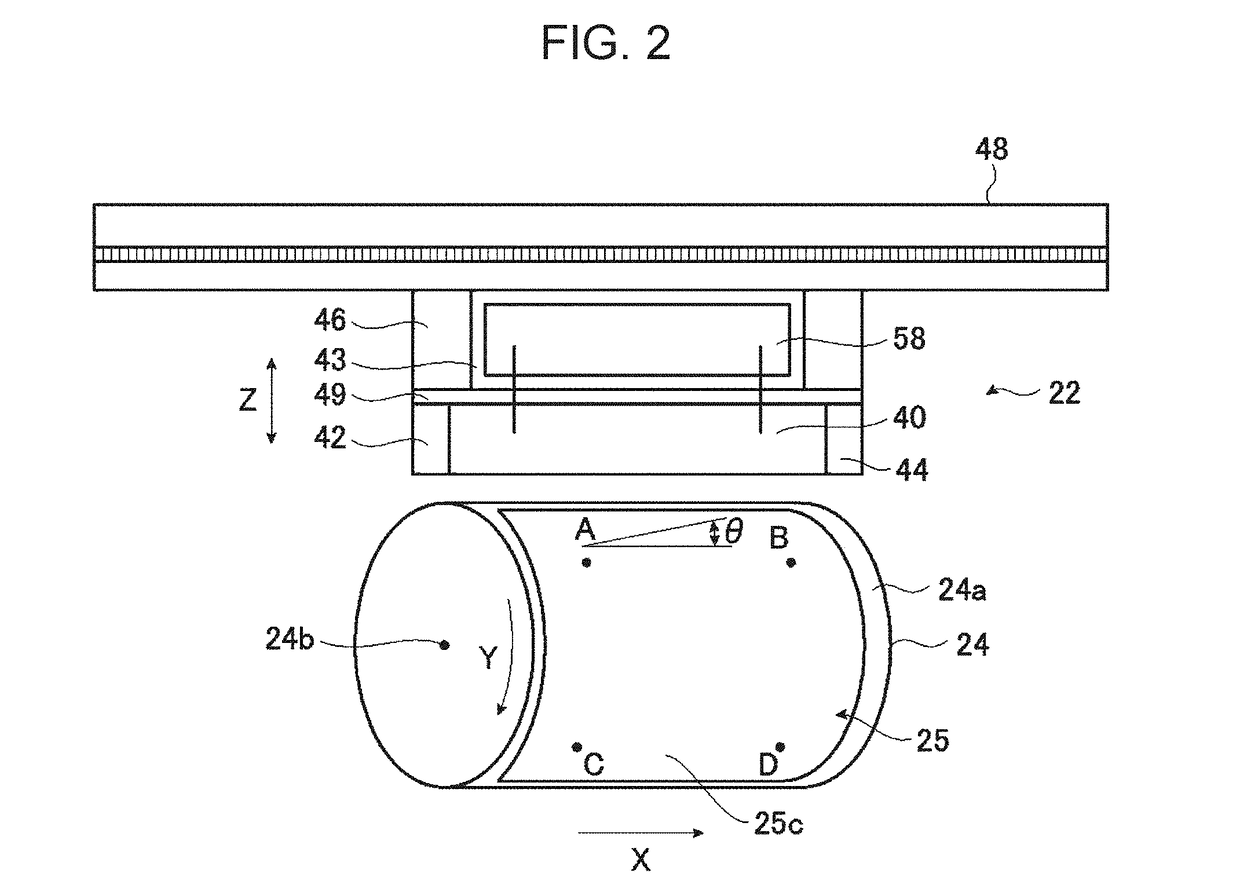

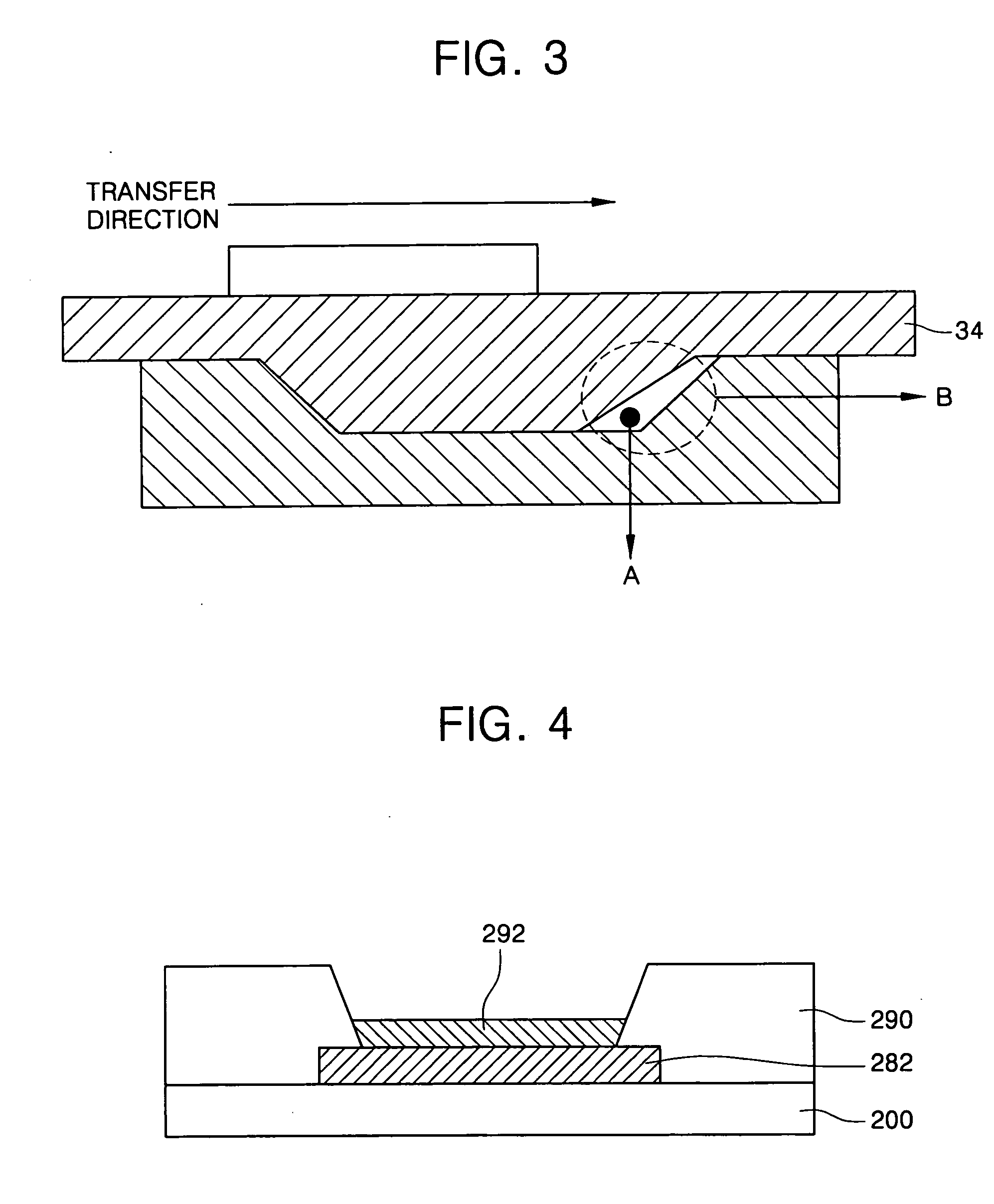

Printing plate, method for manufacturing printing plate, and printing method

InactiveUS20190023051A1Efficiently useHigh-resolution printingDuplicating/marking methodsPlate printingPrinting inkEngineering

Provided are a printing plate, a method for manufacturing a printing plate, and a printing method that allow for high-resolution printing and efficient use of printing ink. The printing plate has an image area and a non-image area. The image area is formed by a layer containing silicone rubber. The non-image area is formed by a layer containing a fluorine compound on a surface of the layer containing silicone rubber. The height difference between a surface of the image area and a surface of the non-image area is 100 nm or less. The method for manufacturing a printing plate has the steps of subjecting a region of a surface of a layer containing silicone rubber to chemical treatment or physical treatment to form hydroxyl groups, the region being a region that becomes a non-image area; and binding a fluorine compound to the region, having the hydroxyl groups formed thereon, of the surface of the layer containing silicone rubber to form a non-image area. The printing method has an ink-applying step of applying a printing ink to an image area and a transfer step of transferring the printing ink from the image area to a substrate.

Owner:FUJIFILM CORP +1

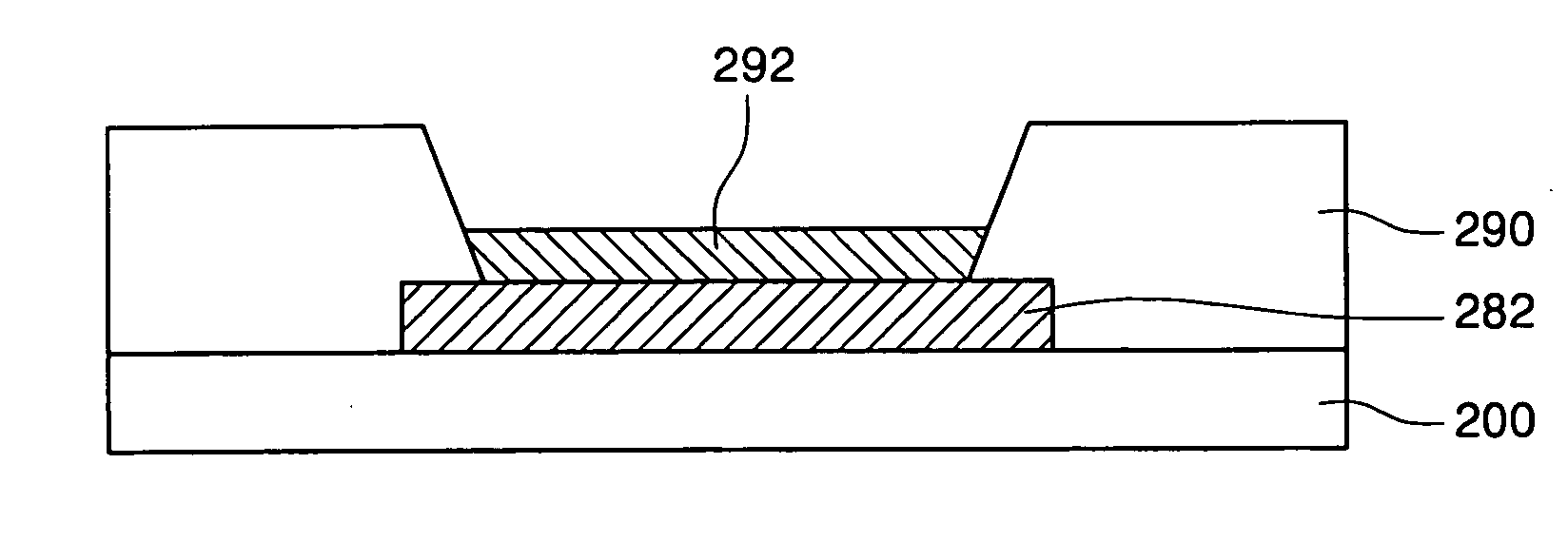

Organic light emitting display (OLED) and its fabrication method

ActiveUS20060145147A1Transfer completelyAvoid failureBatteries circuit arrangementsElectroluminescent light sourcesOptoelectronicsLaser

An Organic Light Emitting Display (OLED) and its fabrication method has a pixel defining layer provided on a first electrode which is formed with a gas vent groove to allow gas to vent when the pixel defining layer is being formed, so that gas is not left in a pixel but vented when a donor film is laminated by a Laser-Induced Thermal Imaging (LITI) method, thereby decreasing edge open failures.

Owner:SAMSUNG DISPLAY CO LTD

Inkjet printing method and inkjet printing equipment for realizing method

PendingCN109624540AStay uncuredTransfer completelyTransfer printingOther printing apparatusUV curingEngineering

The invention provides an inkjet printing method. The method adopts a rotating roller plated with chromium on the surface as a middle transfer printing body; an inkjet printing head is firstly adoptedto spray UV gloss oil to the surface of the cooled middle transfer printing body; a multi-color inkjet printing head is adopted to spray UV ink on a gloss oil layer; then, the middle transfer printing body with the gloss oil layer and an image layer pass through a first UV curing device, so that the image layer is primarily cured; meanwhile, the surface temperature of the middle transfer printingbody is increased for transfer printing of the image layer and the gloss oil layer from the middle transfer printing body onto a printed substrate; and finally, the printed substrate with images passes through second and third UV curing devices in sequence, so that the image layer and the gloss oil layer are thoroughly cured, wherein the gloss oil layer and the image layer contain light initializing agents sensitive to different wave sections of light. The inkjet printing method can guarantee thorough and clean transfer printing of the images on printed matters at each time, and meanwhile, guarantees high definition of the images. The invention further provides inkjet printing equipment for realizing the method.

Owner:SHANTOU DONGFENG PRINTING CO LTD

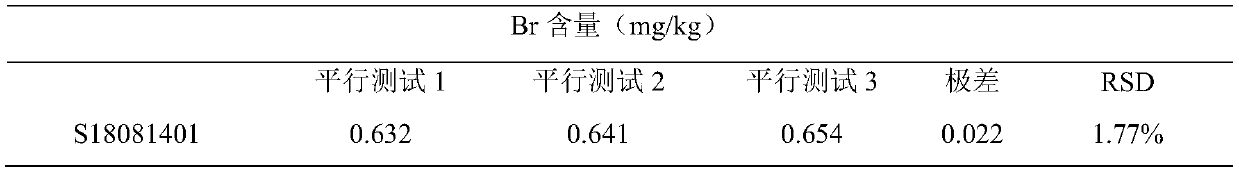

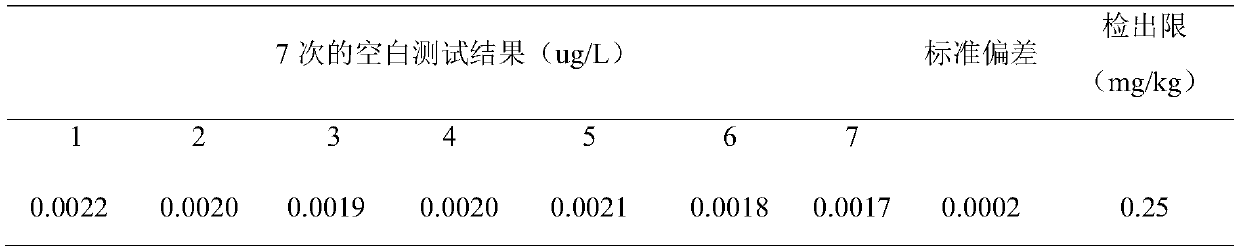

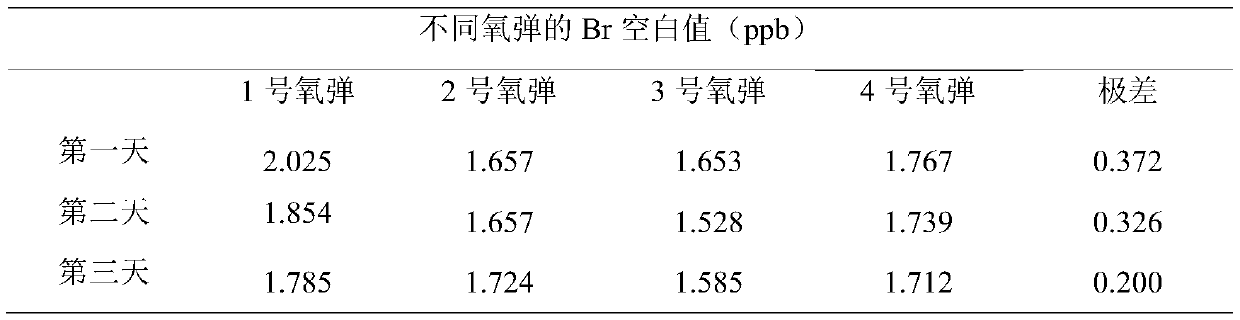

Method for measuring bromine content in organic photoelectric material based on oxygen bomb combustion method

InactiveCN111380942ABackground blank stableFully absorbedPreparing sample for investigationMaterial analysis by electric/magnetic meansBrominePhysical chemistry

The invention discloses a method for determining the bromine content in an organic photoelectric material based on an oxygen bomb combustion method, which uses a pretreatment mode of oxygen bomb combustion and combines a single quadrupole inductively coupled plasma mass spectrometer for detection, and comprises the following steps: 1, sample pretreatment: absorbing and fixing the volume after oxygen bomb combustion; 2, making a standard curve; 3, measuring the content of bromide ions in the sample; 4, calculating. The method is simple to operate, good in precision, high in sensitivity and capable of effectively detecting the content of trace bromine ions in the material.

Owner:GUANGDONG AGLAIA OPTOELECTRONICS MATERIALS

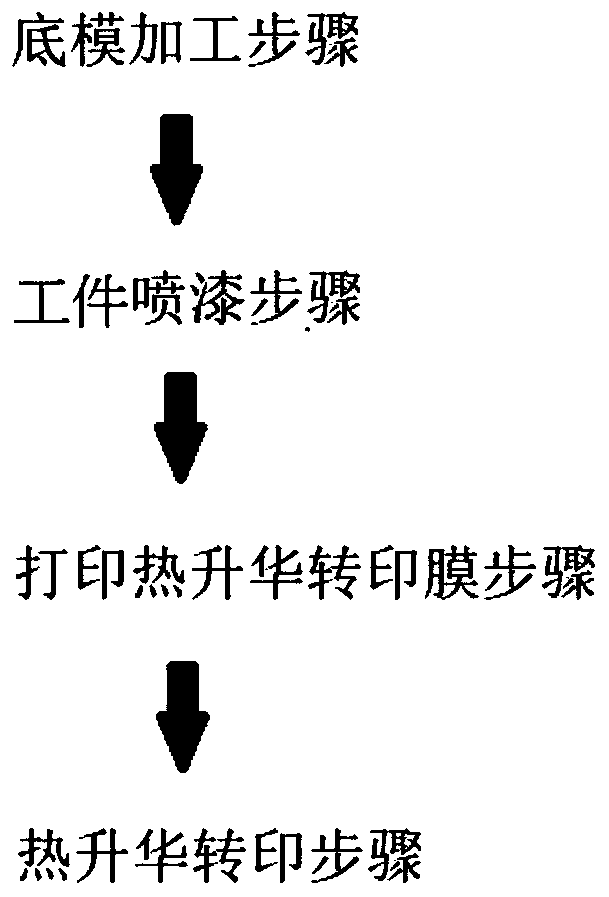

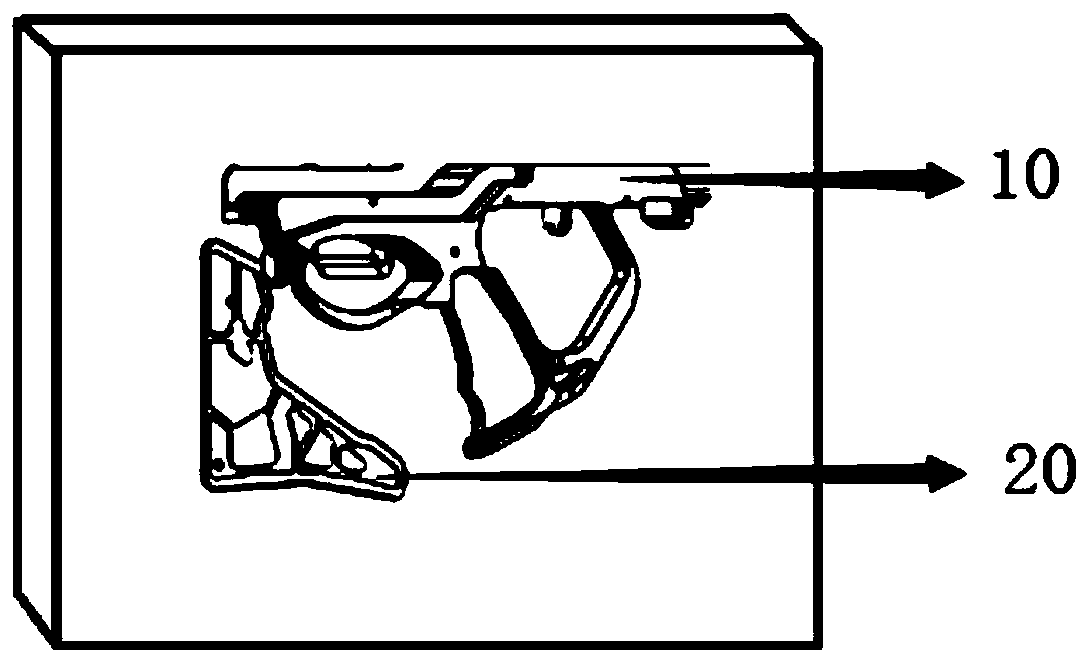

Dye sublimation transfer printing process for crossbow product

InactiveCN110053388AQuick updateIncreased durabilityDuplicating/marking methodsOther printing apparatusEngineeringTransfer printing

The invention discloses a dye sublimation transfer printing process for a crossbow product. The process comprises the following steps: spraying a paint layer to a crossbow workpiece; fixing positionsof the workpiece and a dye sublimation transfer printing film by using a bottom mold; and transfer printing a pattern of the dye sublimation transfer printing film to the crossbow product in dye sublimation transfer printing processes of four stages through a dye sublimation transfer printer. The process comprises the following steps: a bottom mold processing step, a workpiece paint-spraying step,a dye sublimation transfer printing film printing step and a dye sublimation transfer printing step. The process can be applied to appearance production of the crossbow product, can customize and replace the style quickly without leading to pollution, the steps are reduced and the production efficiency and the yield are improved. According to the crossbow product with the dye sublimation transferprinting pattern, the appearance pattern of the crossbow product is clear and the color is bright, a camouflage pattern can be decorated, and the crossbow product has excellent durability and scratchresistance and is suitable for outdoor use.

Owner:ZENGCHENG HUACHANG PLASTIC HARDWARE MOLD

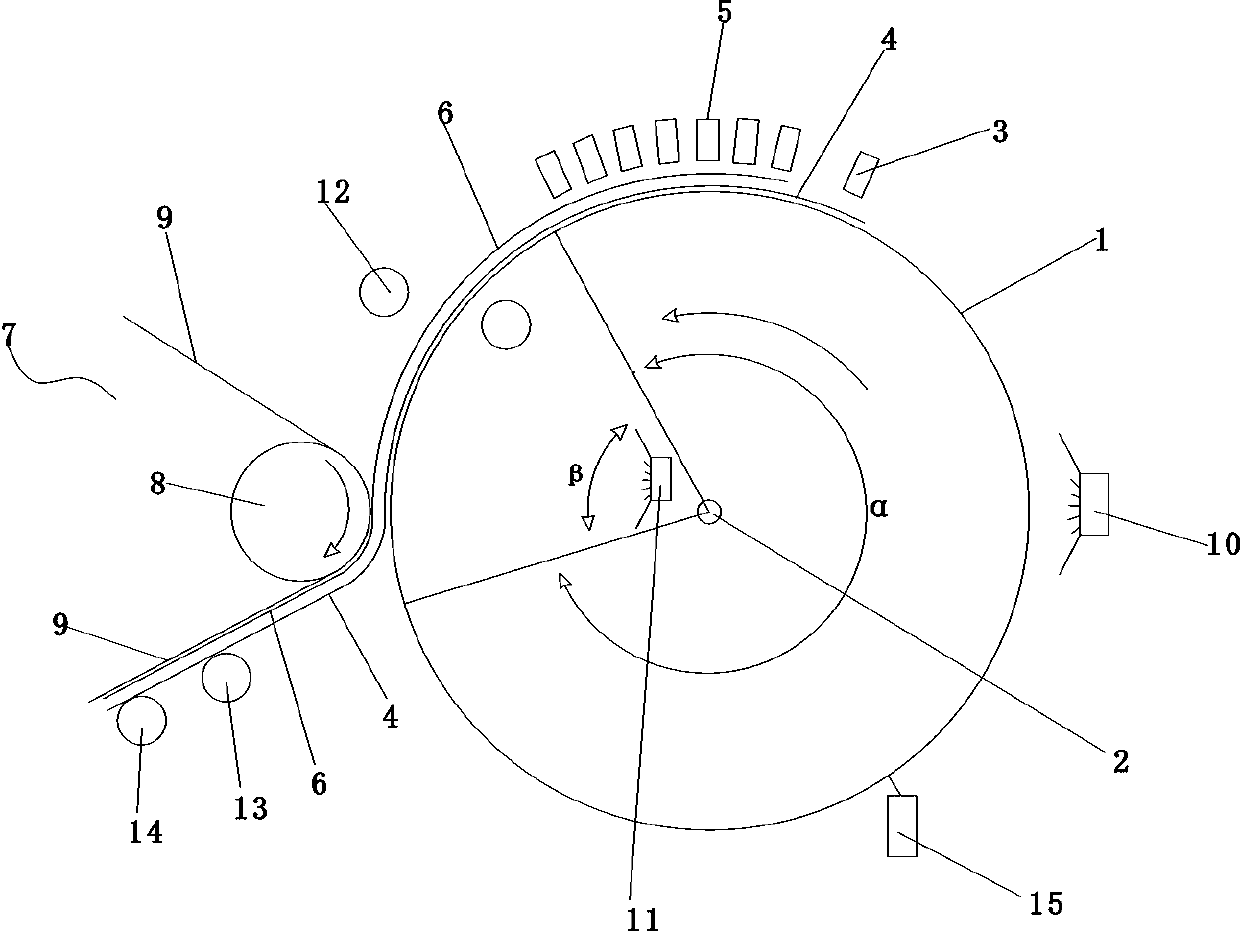

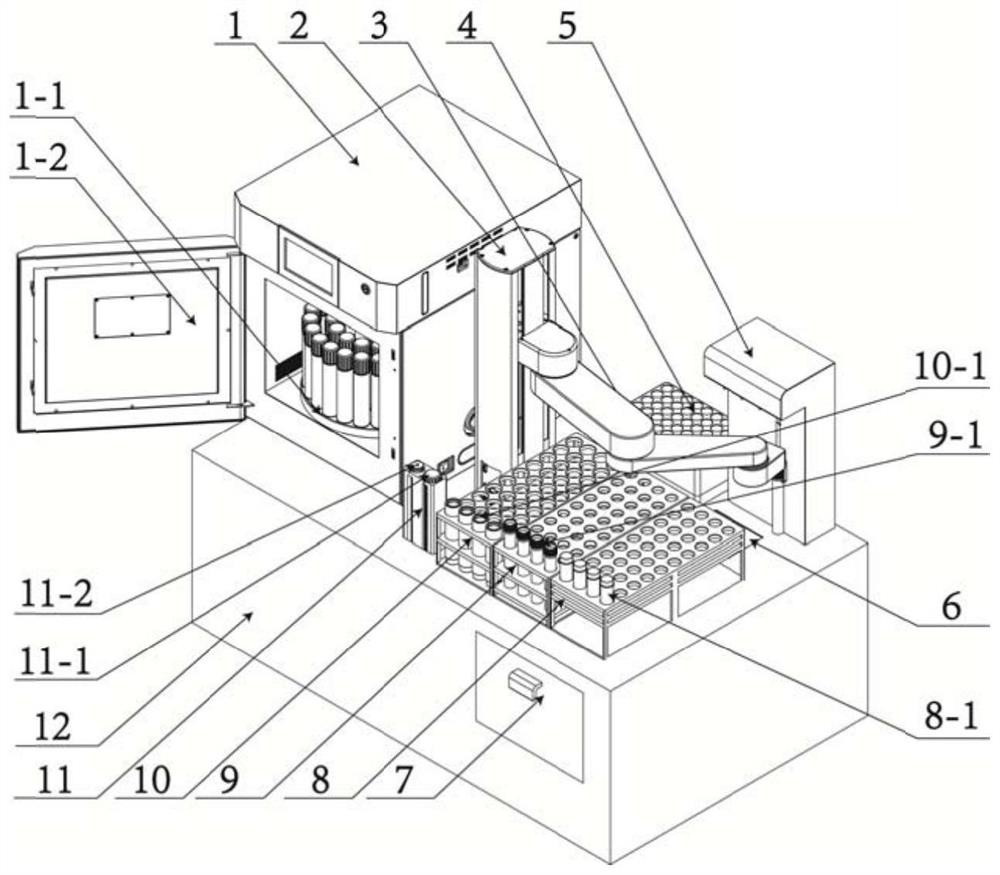

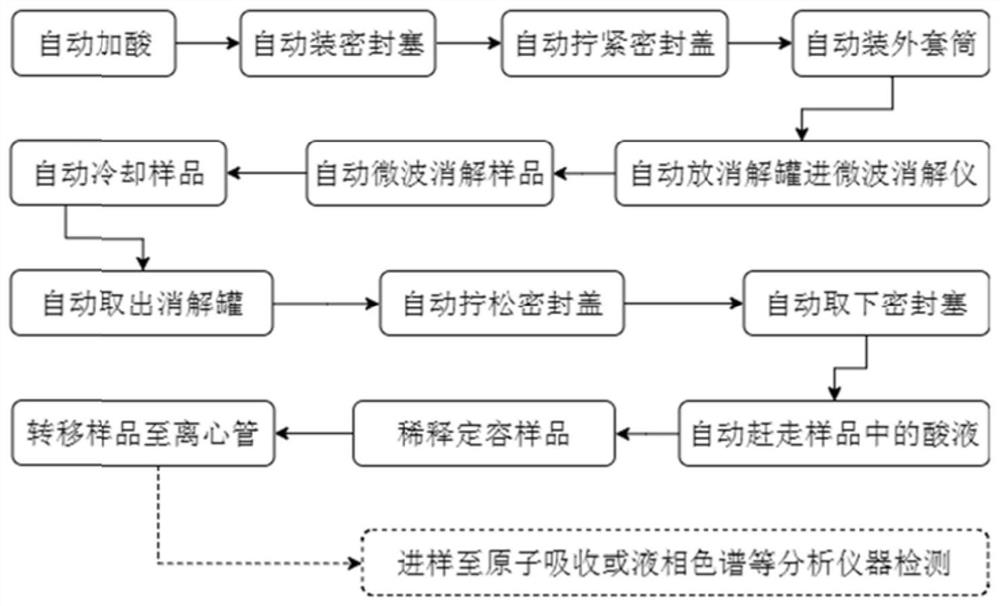

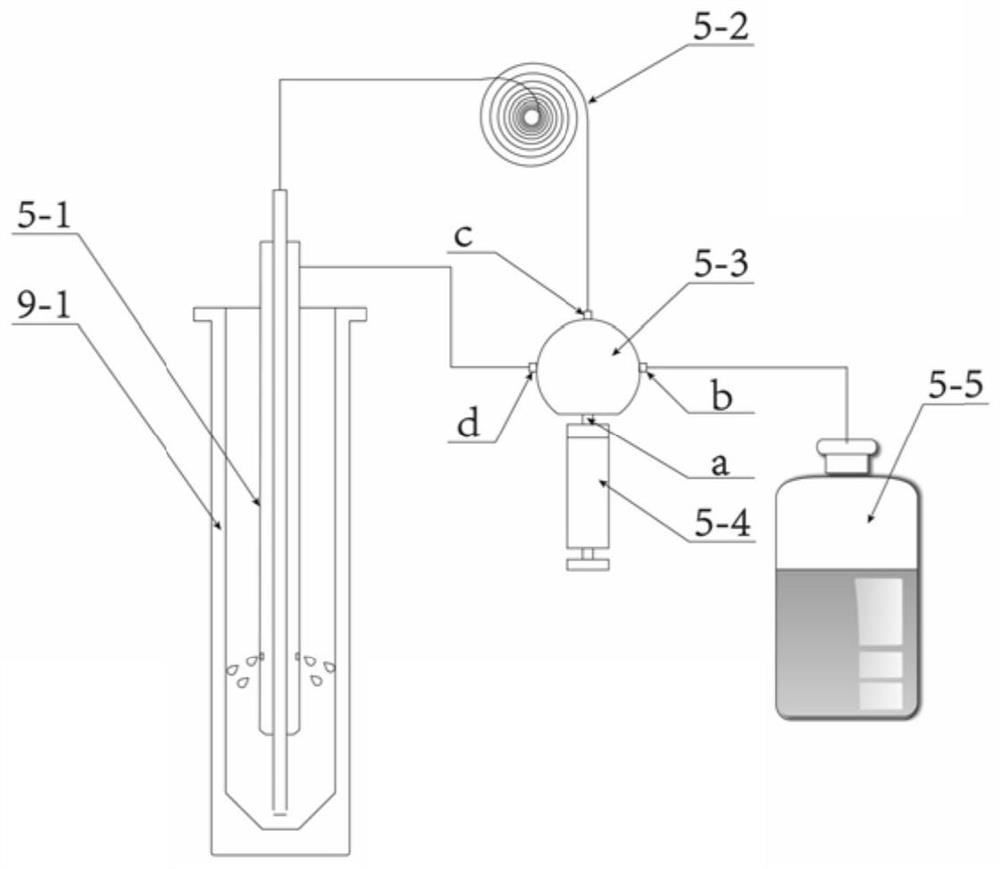

A fully automated sample pretreatment platform centered on microwave digestion

ActiveCN110631890BReduce harmGuaranteed parallelismPreparing sample for investigationRobotic armProcess engineering

A fully automatic sample pretreatment platform with microwave digestion as the core belongs to the field of analytical instruments. A microwave digestion cooling system, transportation device, cap screwing device, acid removal device, acid addition device, centrifuge tube rack module, digestion tank rack module, outer sleeve rack module and automatic sealing cap sealing plug device are installed on the platform; The storage port and the extraction port are set on the platform box; a turntable is set in the microwave digestion cooling system, and a safety door is set on one side of the microwave digestion cooling system; the centrifuge tube rack module, the digestion tank rack module and the outer sleeve rack module are placed in sequence. Placed on the platform; centrifuge tubes are loaded in the centrifuge tube rack module; digestion tanks with samples placed in the digestion tank rack module are loaded; outer sleeves are placed in the outer sleeve rack module; The cap sealing plug device is loaded with a sealing cap and a sealing plug; the transportation device is a mechanical arm that can move controllably in three directions; the acid adding and constant volume device is provided with multiple acid adding channels for selection.

Owner:PREEKEM SCI INSTR

A time-delayed pressurization pipette for biomedical laboratory

The invention relates to the field of biomedical experimental instruments, and discloses a time-delayed pressurization pipette for biomedical laboratories, which includes a pipette body, and a pipette needle is connected to the bottom of the pipette body. The bottom of the inner cavity of the pipette tube is provided with a positioning and pressure-increasing tube, one side of the positioning and pressure-increasing tube is provided with a through groove communicating with the pipette needle, and the other side of the positioning and pressure-increasing tube is provided with an inner groove. The biomedical laboratory uses a time-delayed pressure-replenishing pipette, through the structural design of positioning the pressure-replenishing tube under the negative pressure suction tube, and the self-rotating connection mechanism between the push shaft and the pumping piston, the pipette is used for quantitative transfer. During the solution process, the upper magnetic plate is used to act on the lower magnetic plate first, so that the lower magnetic plate moves down until the upper magnetic plate rotates to the other side, and the lower magnetic plate moves upward and resets under the action of the elastic force, so as to facilitate the extraction of the solution. , The exhaust is more thorough, which improves the accuracy of the solution transfer volume.

Owner:重庆市开州区华兰生物单采血浆有限公司

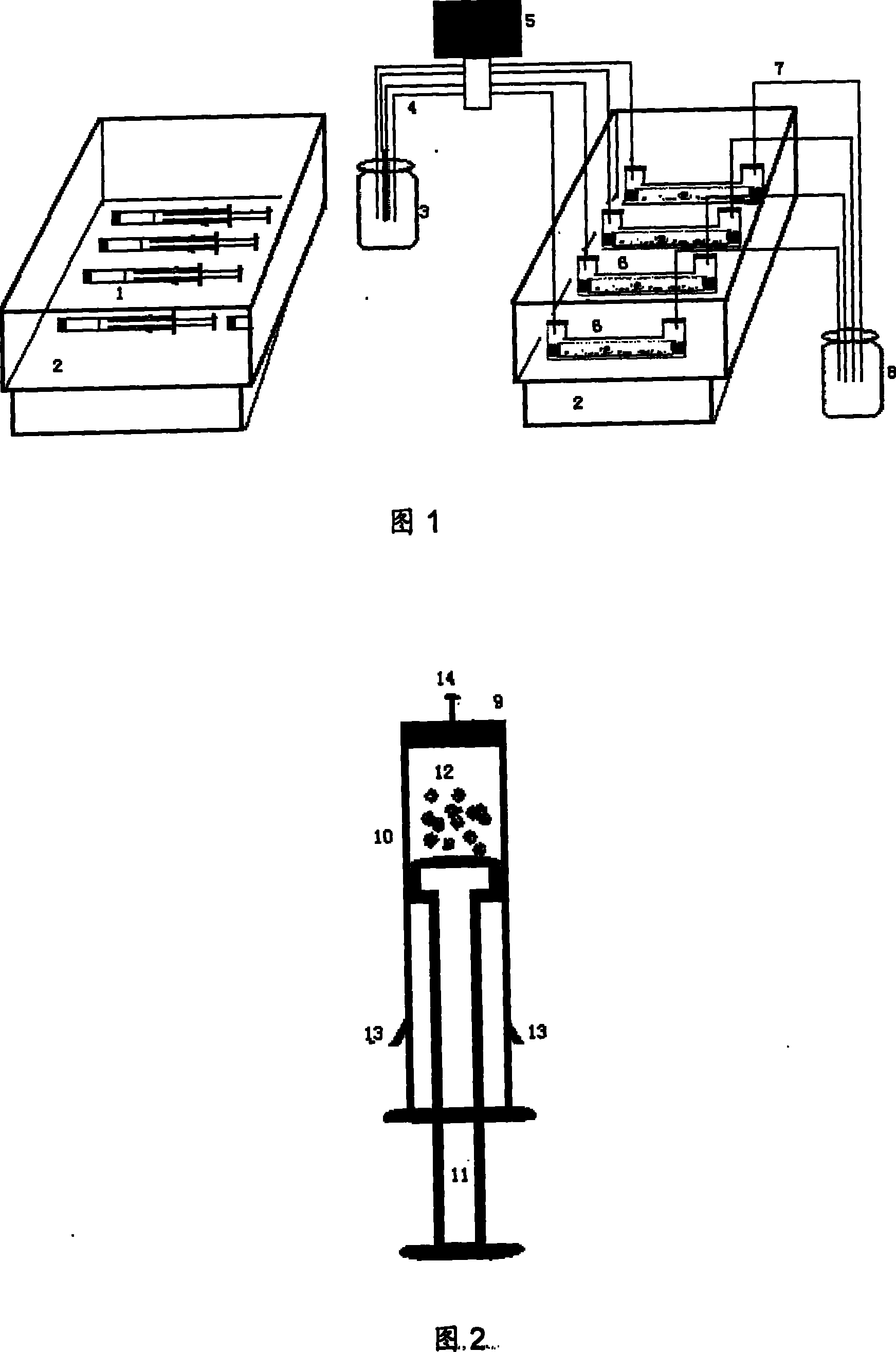

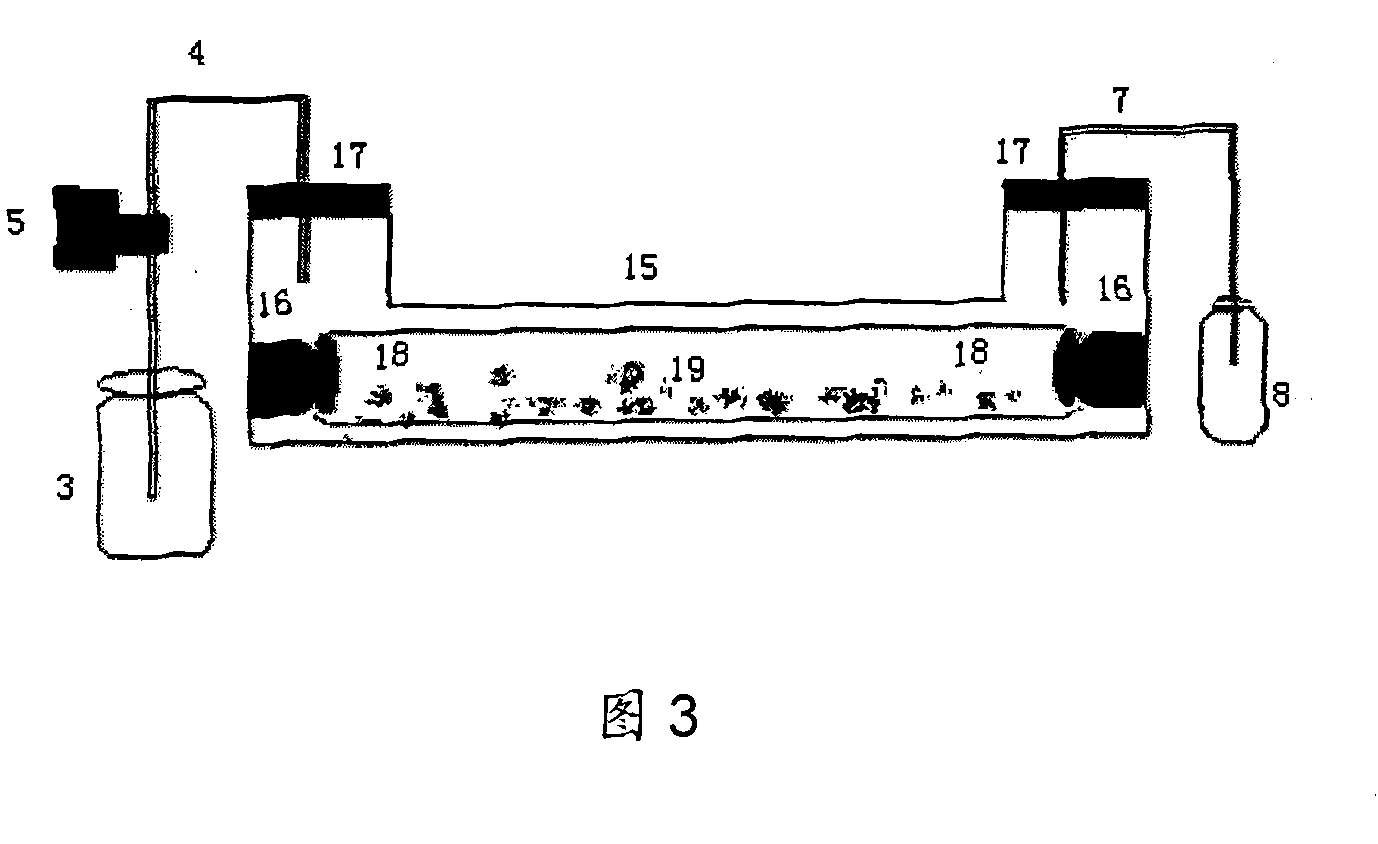

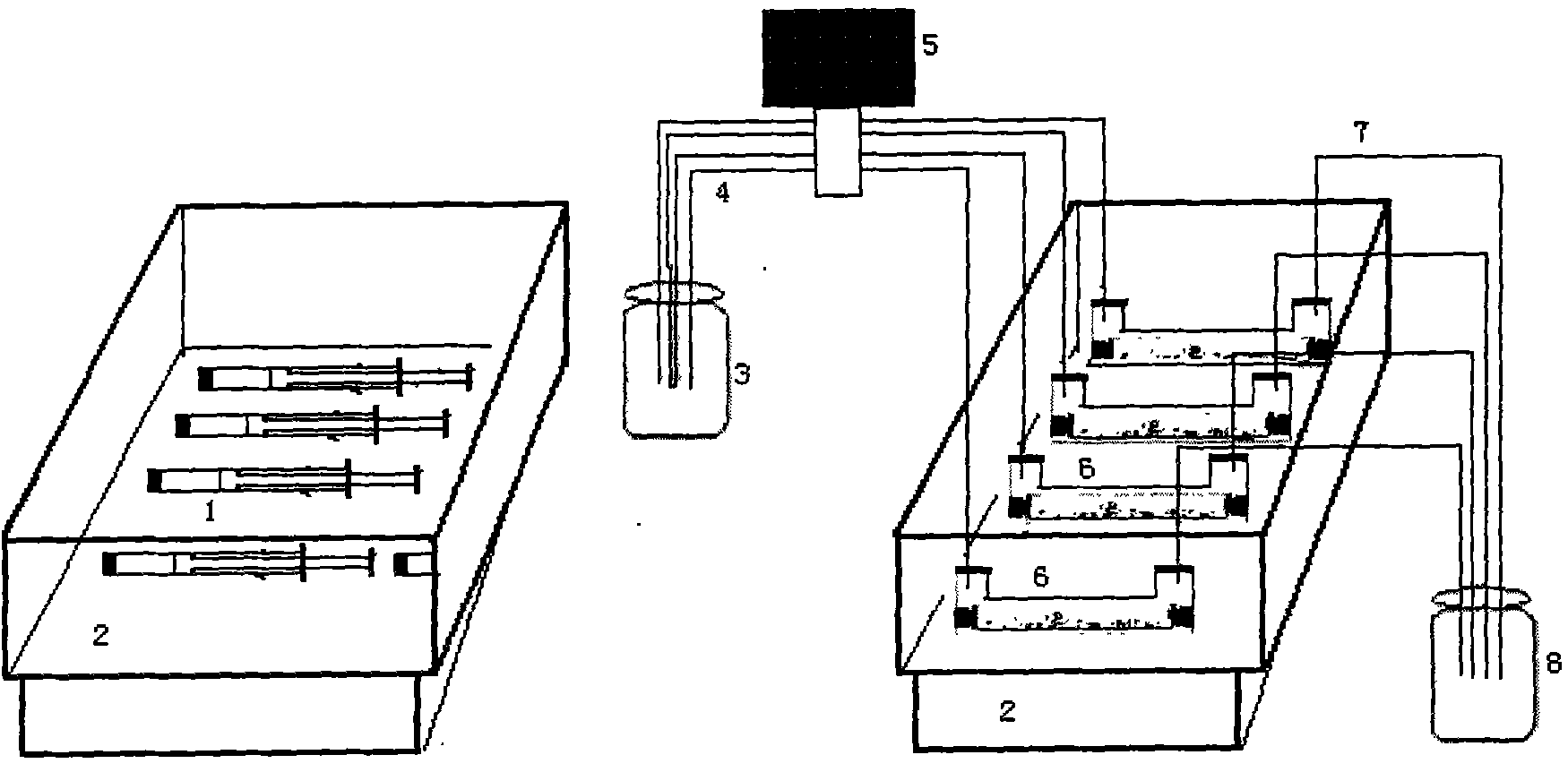

Broiler external digestion simulating device

The present invention provides an in vitro simulator which can simulate digestion and absorption processes of feed nutrient in the chicken alimentary tract, including maw and peptic digest chamber, small intestine digesting chamber and constant temperature system etc. The feed nutrient is completed by the maw and peptic digest chamber under the digesting course of the maw and peptic; chyme is converted to the small intestine digesting chamber continuously digested after the period of maw and peptic digestion, completing the digestion of the nutrient in the small intestine and the absorption of the digested nutrient, finally achieving the simulation of the digestion and absorption processes of the feed nutrient in the chicken alimentary tract in vitro; the constant temperature system provides heat preservation and vibrating mixture functions for the digestion course of the chyme in the maw, peptic digest chamber, small intestine digesting chamber, simulating the environment temperature of the chicken alimentary tract, gastrointestinal peristalsis and chyme mixture. The chicken in vitro simulating digestion device of the invention has a lower cost, simple operation, quick performance and better palingenesis.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

Manicuring method

InactiveCN108618341ANail Polish DistributionNail polish evenly distributedManicure/pedicureEngineeringCircular segment

The invention relates to a manicuring method, which comprises the following steps: (1) applying a layer of base coat to the surfaces of cleaned fingernails; (2) applying a layer of nail polish I to the surfaces of the fingernails; (3) fully applying a nail polish II to the interior of each manicure pattern of a transfer sample plate; (4) scraping and flattening the nail polish II on each manicurepattern via a scraper; (5) pressing a transfer side of the transfer stamp on each manicure pattern; (6) pressing the nail polish II on the transfer side onto the nail polish of the step (2); and (7) finally, applying a layer of top coat. According to the manicuring method provided by the invention, grooves, which are 2-3mm deep and are matched with the manicure patterns, are arranged in the manicure patterns of the transfer sample plate; the scraper keeps an included angle, which is 30-60 degrees, with the manicure patterns; the scraper is used for conducting scraping and flattening on the manicure patterns for 2-4 times; and the transfer side of the transfer stamp is an arched side. With the application of the manicuring method provided by the invention, the manicure patterns can be rapidly, clearly and completely transferred to the fingernails; and the manicuring method, which is convenient and rapid, can be completed within several minutes.

Owner:李绍瑾

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com