Dye sublimation transfer printing process for crossbow product

A dye-sublimation and crossbow technology, which is applied in printing, printing devices, copying/marking methods, etc., can solve the problems of pattern deformation, thermal sublimation transfer film damage, complex crossbow shape, etc., and achieve excellent durability and excellent anti-corrosion Scrape function, the effect that the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principles of the present invention will be described through examples. Other aspects, features and advantages of the present invention will become clear through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

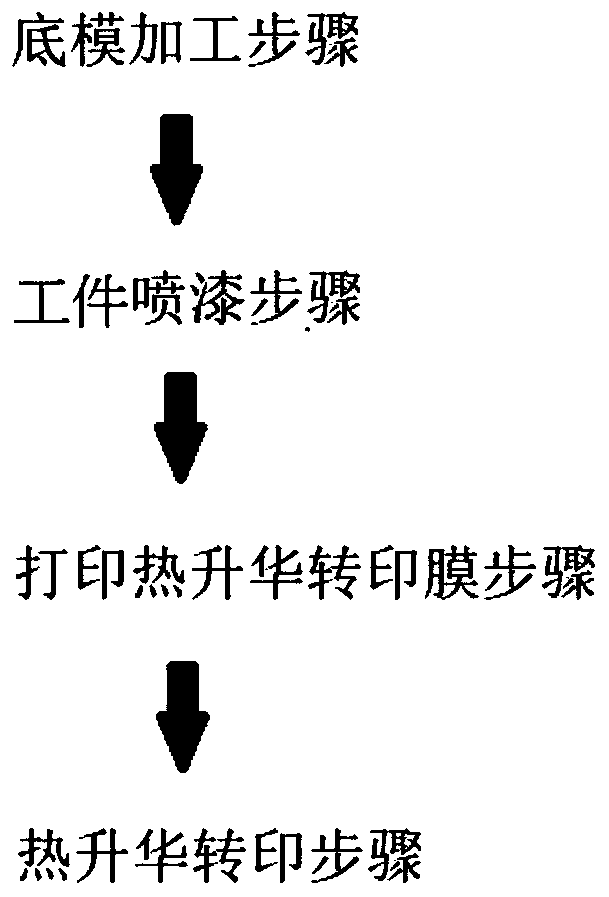

[0032] Such as figure 1 As shown, the thermal sublimation transfer process used for crossbow products of the present invention can produce different crossbow products and workpieces by changing the bottom mold design and thermal sublimation transfer parameters.

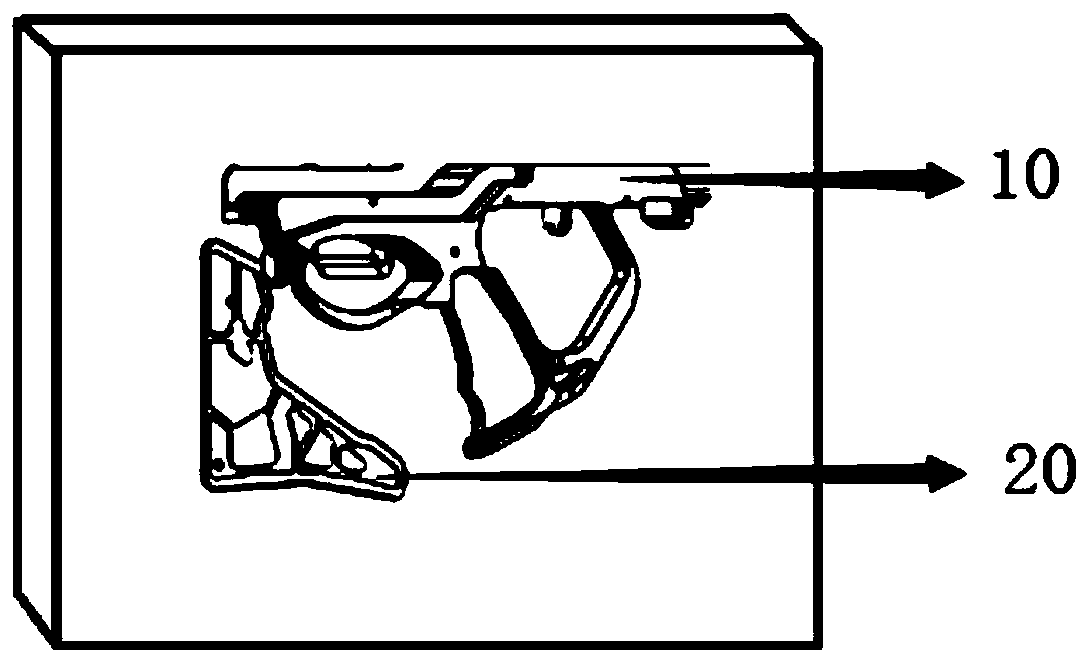

[0033] The production of the crossbow product with sublimation transfer pattern of the present invention includes crossbow body 10 and decorative sheet 20, crossbow body 10 is made of polyamide glass fiber composite material, and decora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com