Full-automatic tape-sticking machine

A glue sticking machine, fully automatic technology, applied in the direction of lamination device, lamination auxiliary operation, lamination system, etc., can solve the problem of unstable equipment operation, unguaranteed product quality, and elongated and thinned materials. and other problems, to achieve the effect of reducing labor intensity, good sensitivity and accuracy, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] Take the lamination of high-grade soft sealing rubber on this machine as an example.

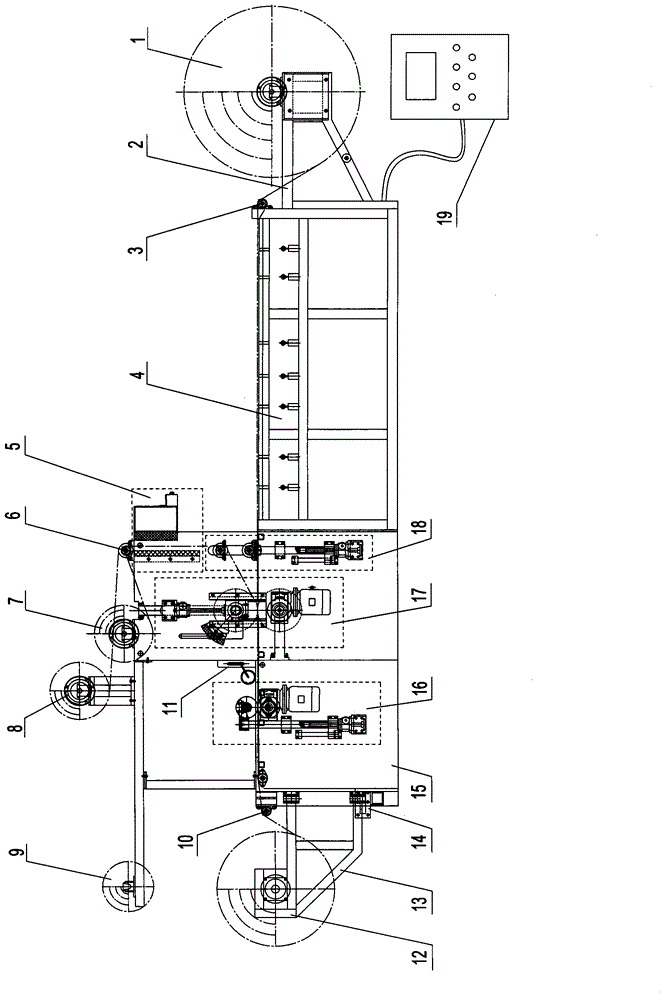

[0025] exist figure 1 Middle: the left side of the frame 15 is provided with a cantilever rotating bracket 2, the cantilever rotating bracket 2 is provided with a winding device 12, and the place where the cantilever rotating bracket 2 is connected with the frame 15 is also provided with a bracket locking and releasing device 14; Above the top winding device 12 of the frame 15, a packaging film unwinding device 9 is provided, and the right side of the packaging film unwinding device 9 is successively provided with a release paper unwinding device B8 and a release paper unwinding device from left to right. A7 and lead roller B6; the right side of the frame 15 is provided with an air cushion workbench 4, the air cushion workbench 4 is connected with the cantile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com