Patents

Literature

77results about How to "Exhaust thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

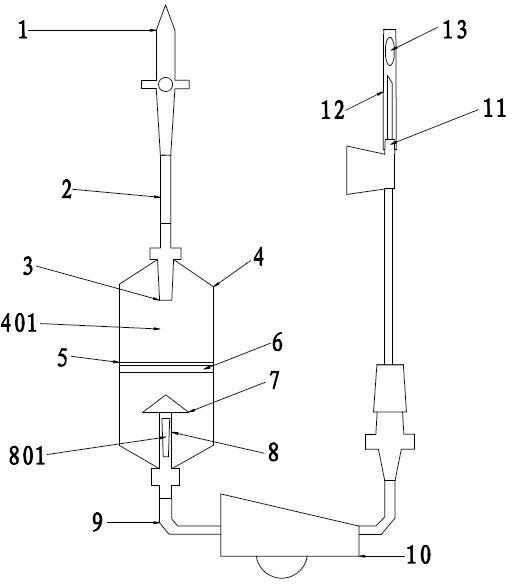

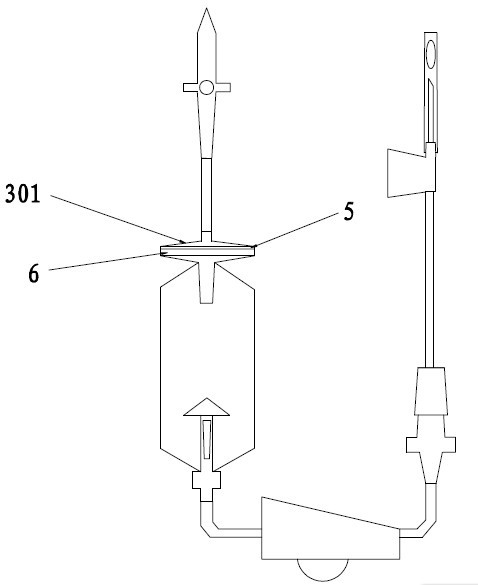

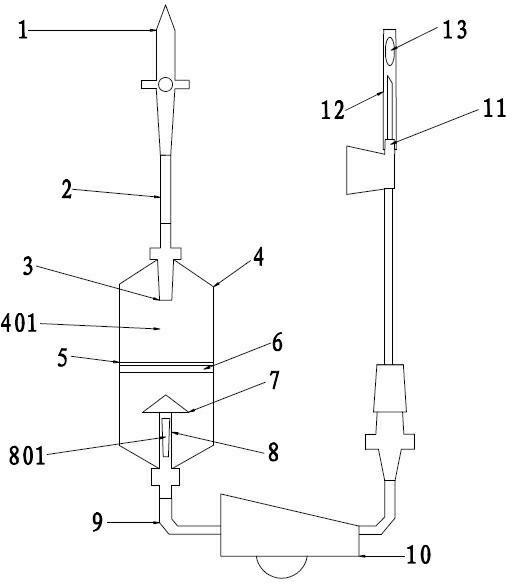

Infusion set

ActiveCN102350014ASave infusion operation timeSave operating timeInfusion devicesIntravenous needlesMedicine

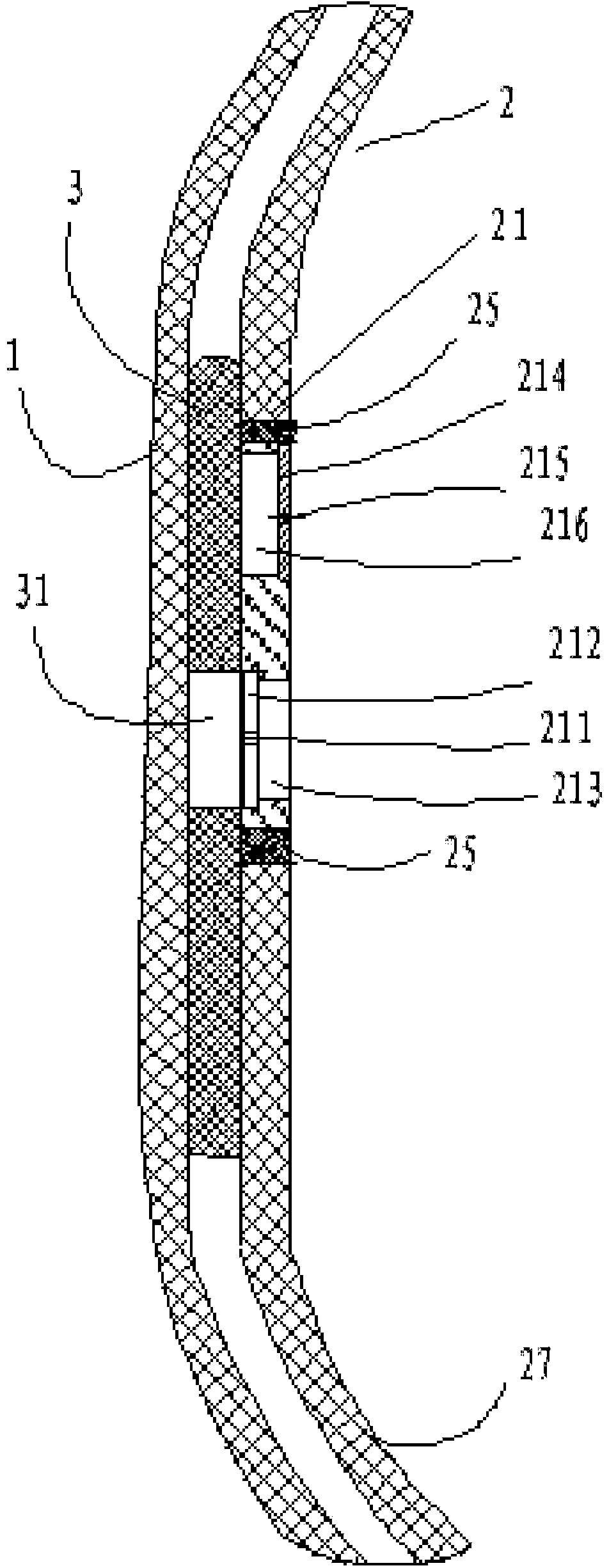

The invention relates to an infusion set and belongs to the technical field of medical apparatus and instruments. The infusion set comprises a puncture outfit, an upper conduit of a drop funnel, a drip tube, the drop funnel, a lower conduit of the drop funnel, a regulator and an intravenous needle which are sequentially connected. The liquid outlet end of the intravenous needle is sleeved with a sealing sleeve; an air exhaust pipe is arranged between the drop funnel and the lower conduit of the drop funnel; at least one air exhaust hole is formed at one end, which is positioned in an inner cavity of the drop funnel, of the air exhaust pipe; a liquid medicine passing membrane made from a material which is permeated by water is arranged above the air exhaust pipe; a group of pores are formed on the liquid medicine passing membrane; the liquid medicine passing membrane allows liquid medicine and gas to pass through but blocks insoluble granules with the diameter of greater than the diameter of the pores in the liquid medicine; the sealing sleeve seals the liquid outlet end of the intravenous needle; and an air filter is arranged on the sealing sleeve. The infusion set is simple in structure and has self-exhausting and automatic liquid-stopping functions.

Owner:ZHEJIANG KANGTAI MEDICAL DEVICES

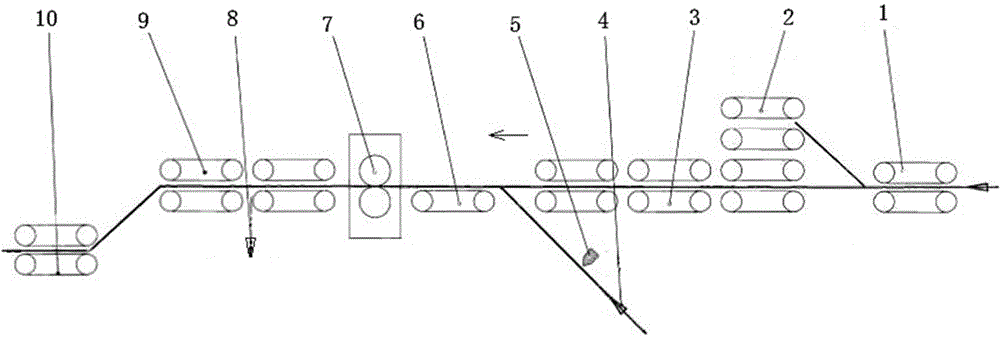

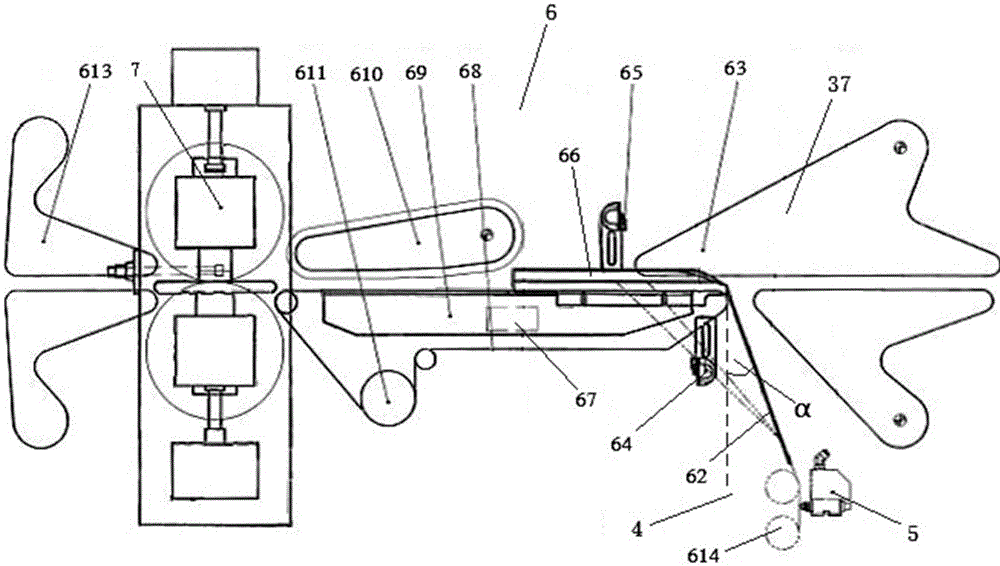

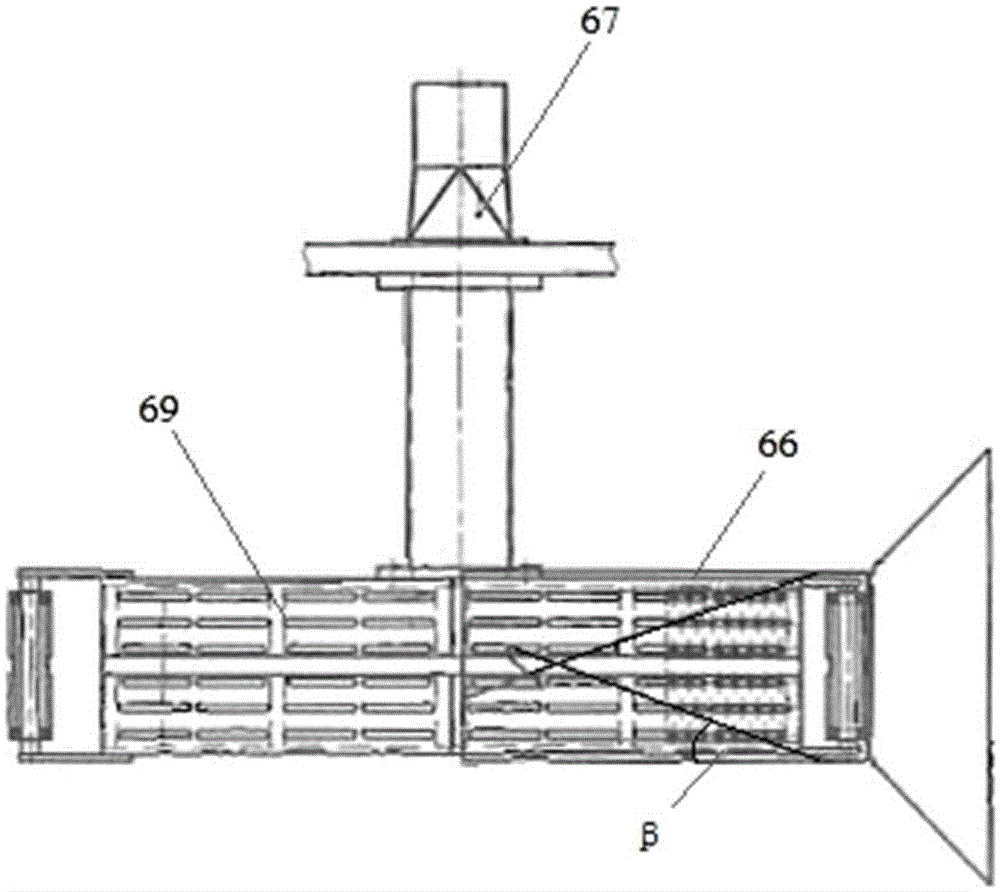

Automatic packaging mechanism for single-piece absorptive hygienic product

ActiveCN105083629AAdjust intervalImprove pass ratePaper article packagingWrappingMechanical engineeringFast speed

The invention belongs to the technical field of production equipment of absorptive hygienic products, and discloses an automatic packaging mechanism for a single-piece absorptive hygienic product. A packing system is sequentially provided with a multi-stage conveying unit, a film packaging and folding device and a heat sealing and cutting combination unit in the conveying direction. The multi-stage conveying unit sequentially comprises a front portion conveying unit, a middle conveying unit in the middle and a rear portion conveying unit which are operated independently. The middle conveying unit is provided with a synchronous conveying belt, baffles which protrude out of the surface of the conveying belt are evenly arranged on the surface of the conveying belt at intervals, and the hygienic product is conveyed on the portion, between the adjacent baffles, of the synchronous conveying belt. The automatic packaging mechanism for the single-piece absorptive hygienic product can be applied to single-piece packaging of the larger and thicker hygienic product such as sweat pants, has the beneficial effects of being high in packaging yield, low in size deviation, high in production speed and the like, and can adapt to high-speed development requirements of the hygienic products.

Owner:ZUIKO (SHANGHAI) CORP

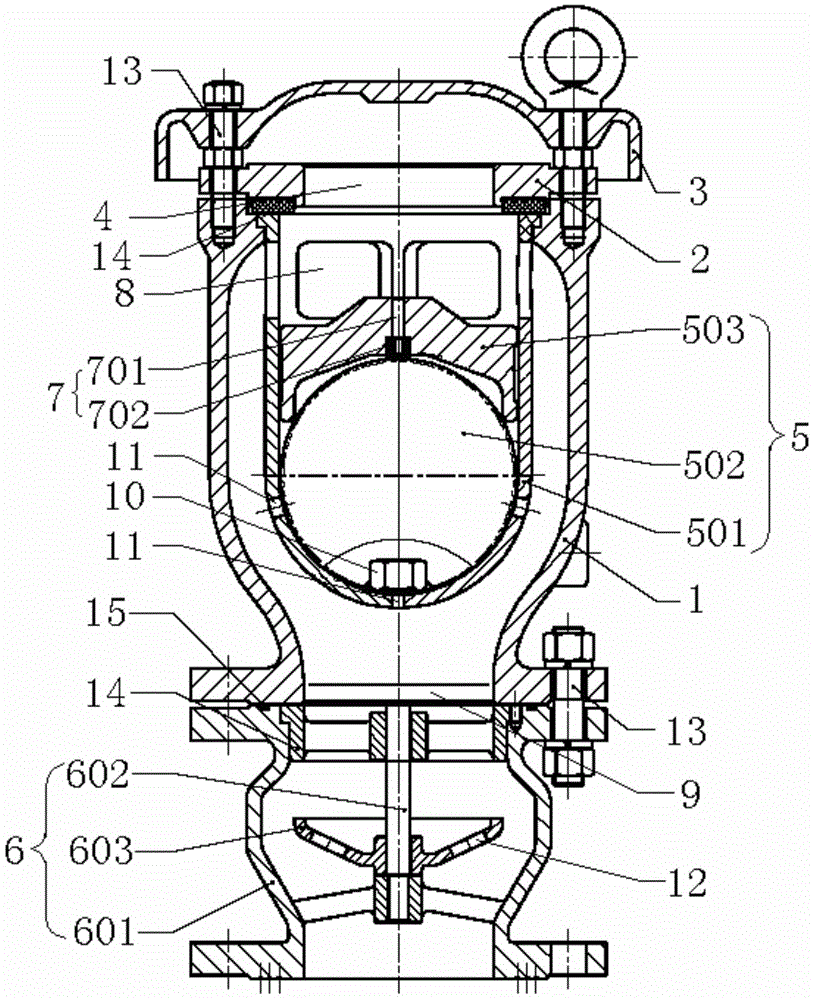

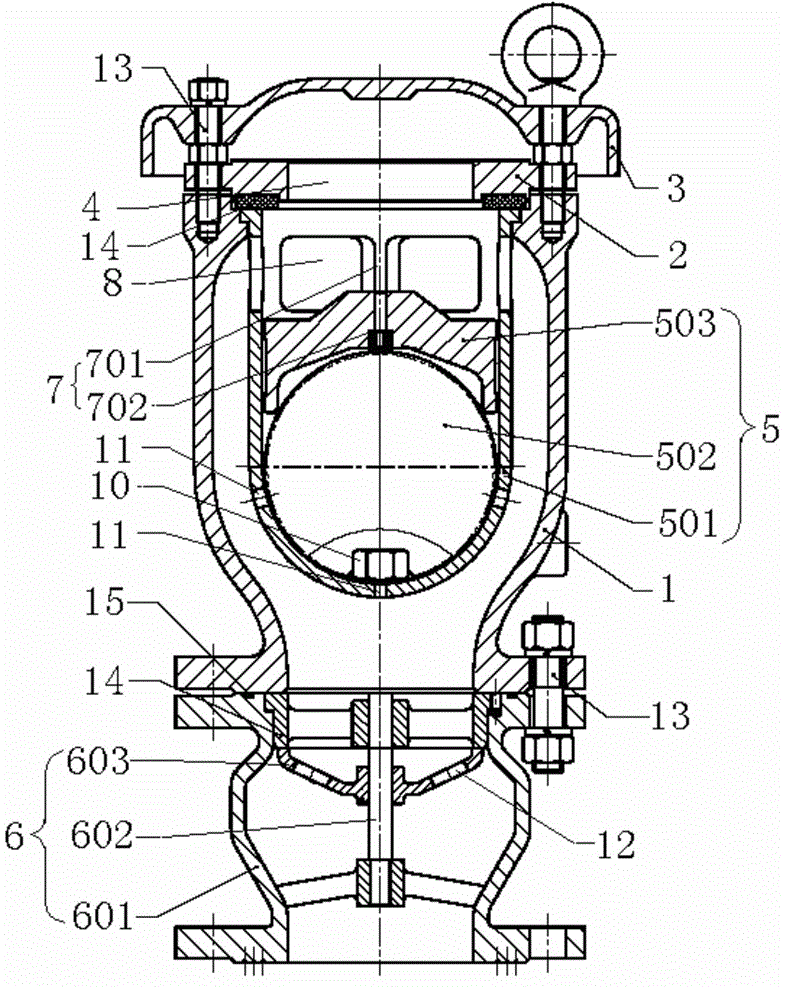

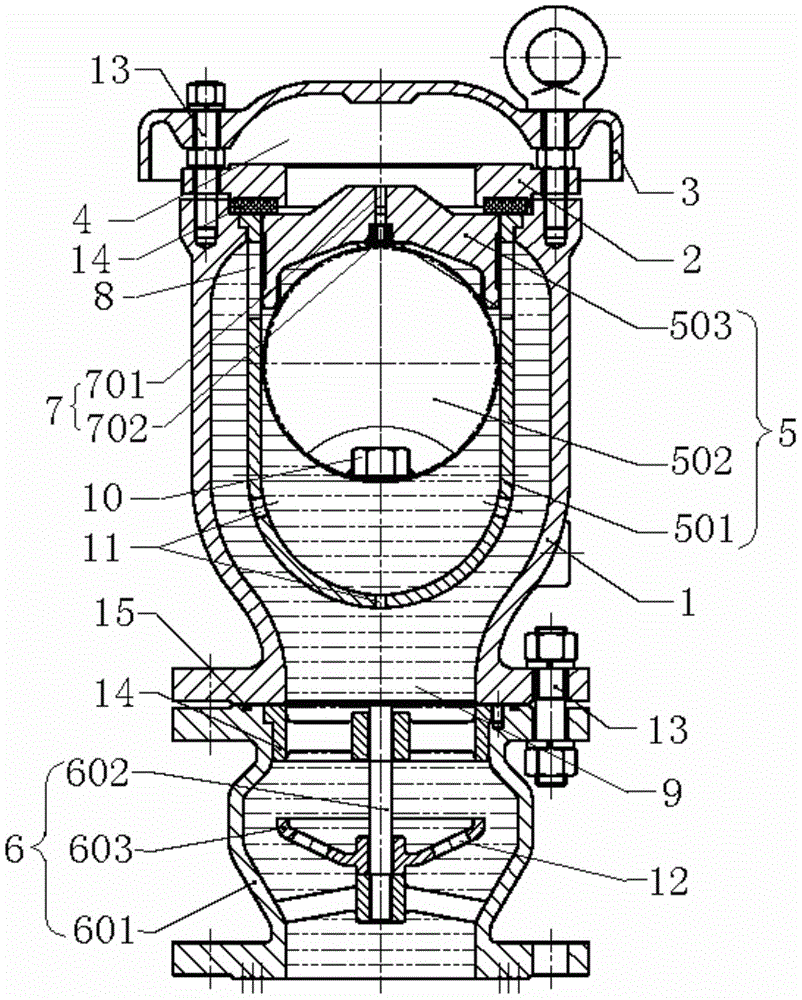

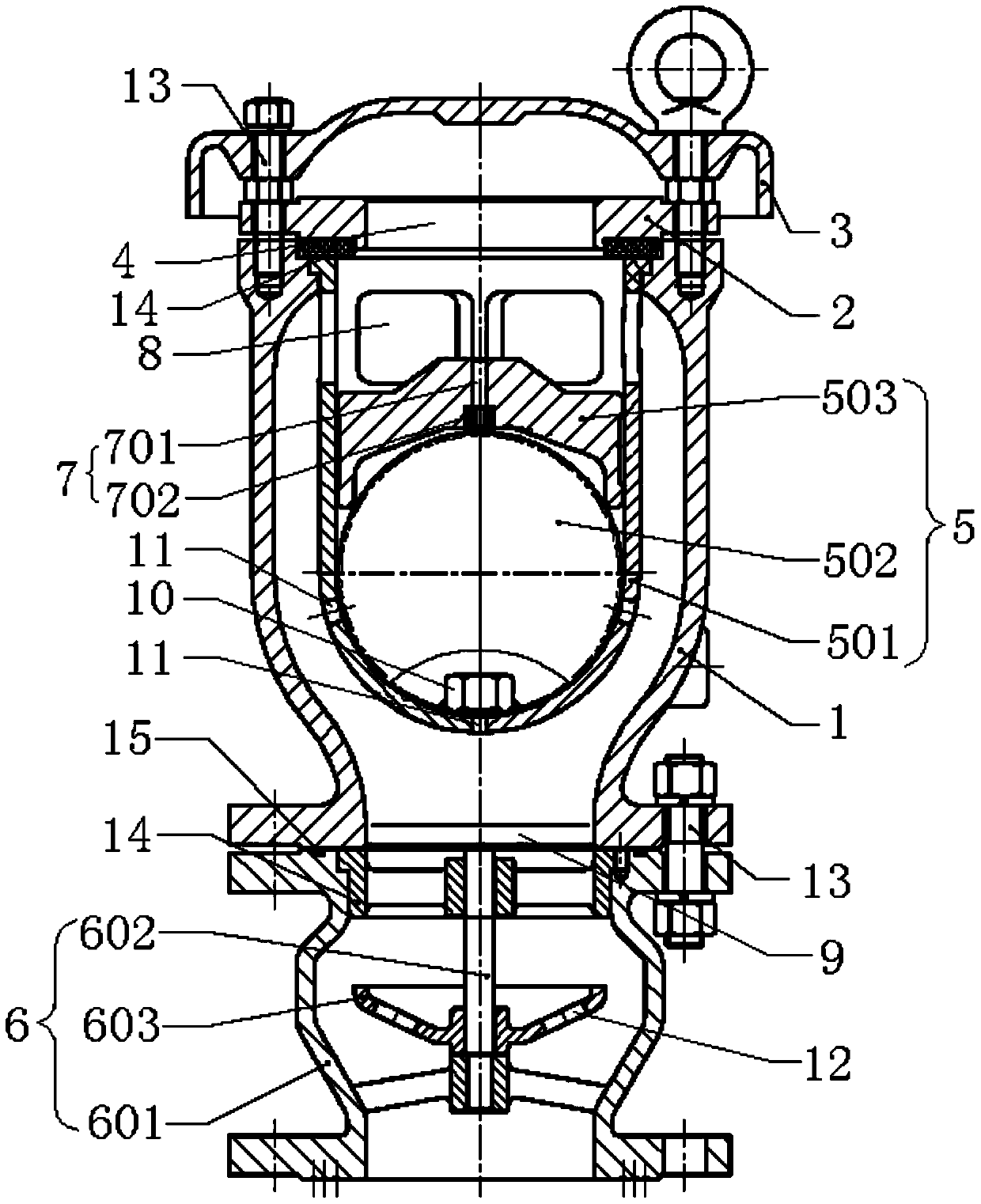

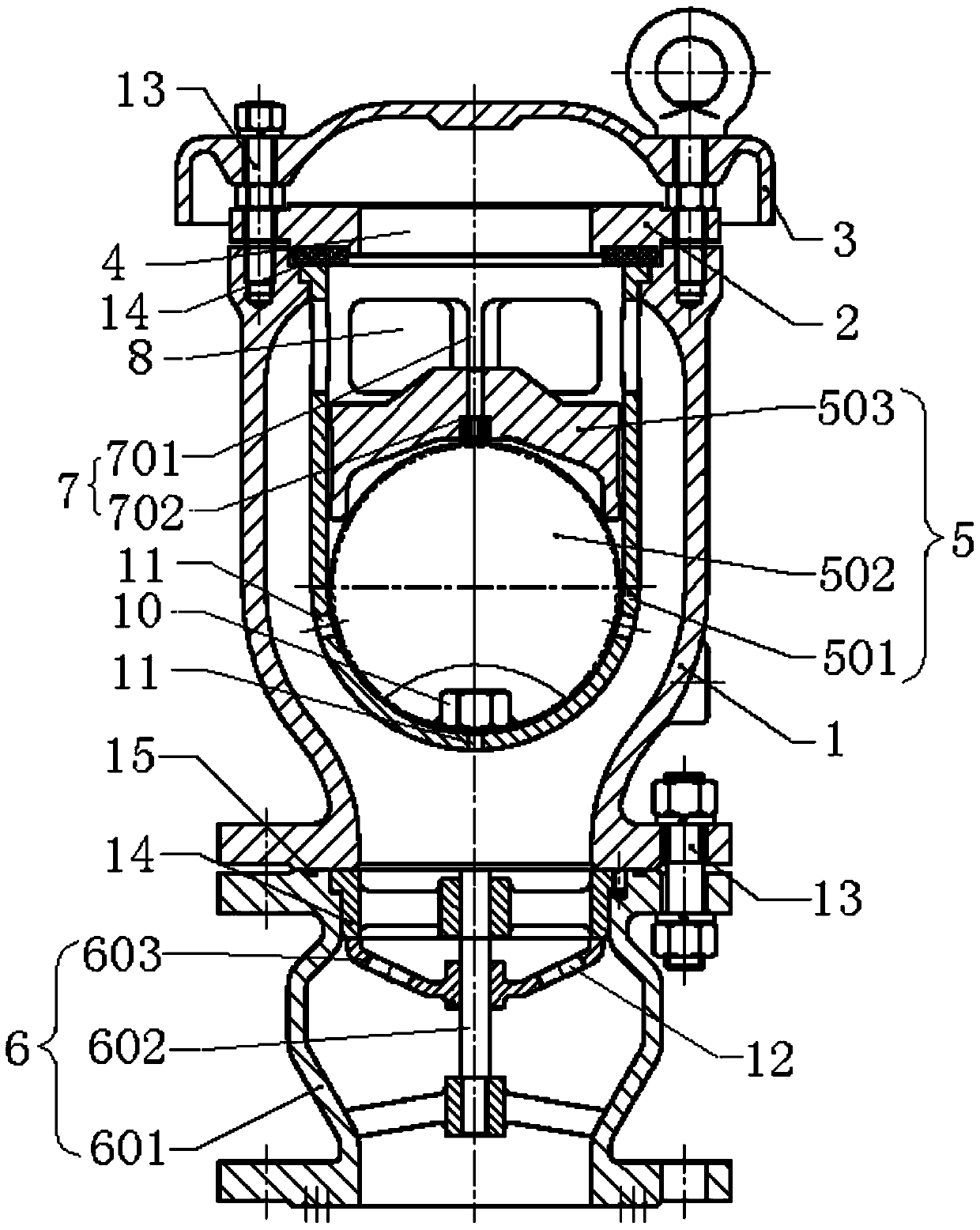

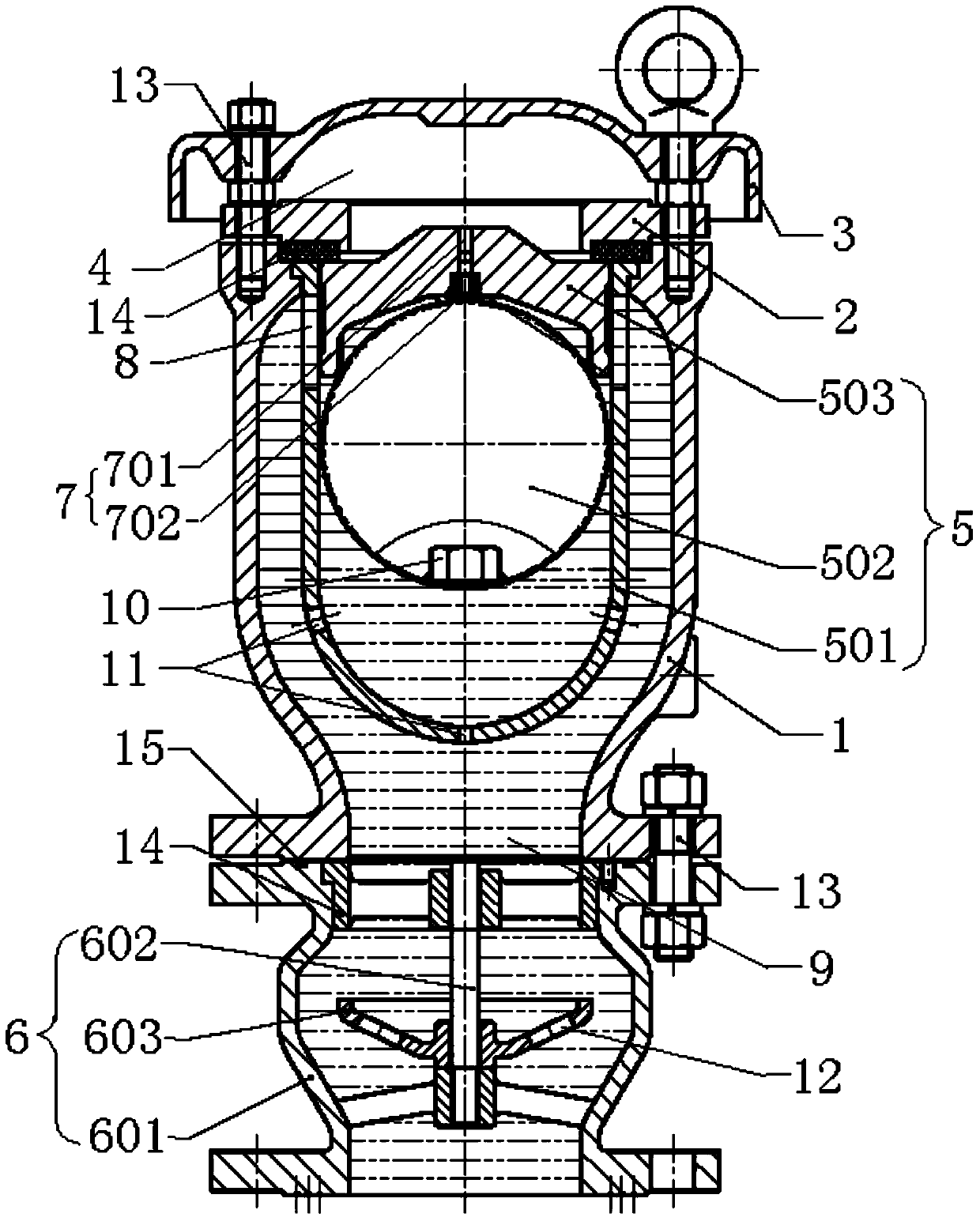

Water hammer air valve and water hammer gas discharging method during pipeline use

ActiveCN104896184AAvoid blowingAvoid air blockageValve members for absorbing fluid energyPipe elementsEngineeringWater hammer

The invention discloses a water hammer air valve and a water hammer gas discharging method during pipeline use. The water hammer air valve comprises a valve body, a bonnet and a protective cover, wherein the bonnet is provided with an opening, the protective cover is disposed on the opening, the valve body is provided with a valve opening for being communicated with a pipeline, a high-speed gas feeding and discharging device which is used for discharging gases stayed in the pipeline during water filling to the outside and shutting down the valve after pipeline water filling is completed is disposed in the inner cavity of the valve body, the output end of the high-speed gas feeding and discharging device is communicated with the outside through the opening of the bonnet, and the valve opening of the valve body is communicated with a bottom gas discharging throttling device for limiting the gas displacement of the pipeline to the inner cavity of the valve body; a trace gas discharging device for discharging mixed, residual and / or precipitated gases in the pipeline to the outside through the opening of the bonnet after the high-speed gas feeding and discharging device shuts down the valve is further disposed in the high-speed gas feeding and discharging device. By the water hammer air valve, water hammer reduction and pipeline safety protection are achieved, blowing blocking during high-speed gas discharging is avoided, and valve closing water hammer is eliminated.

Owner:ZHUZHOU SOUTHERN VALVE

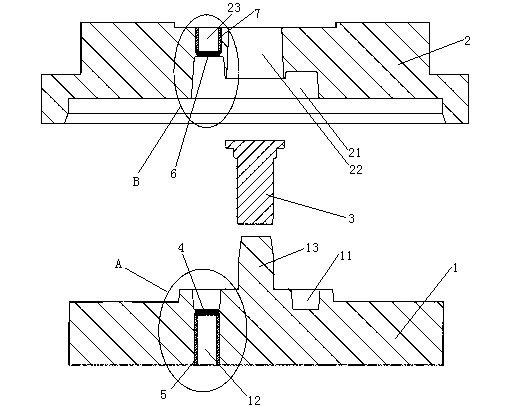

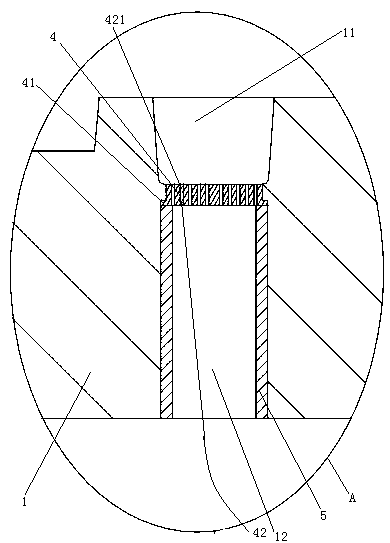

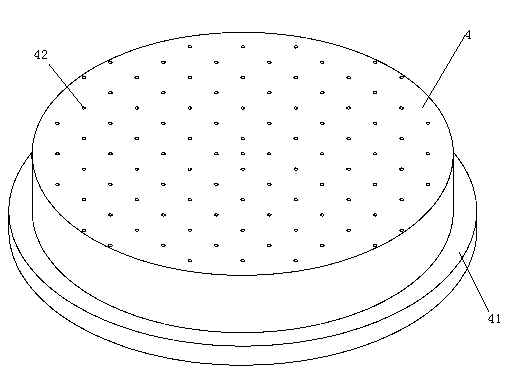

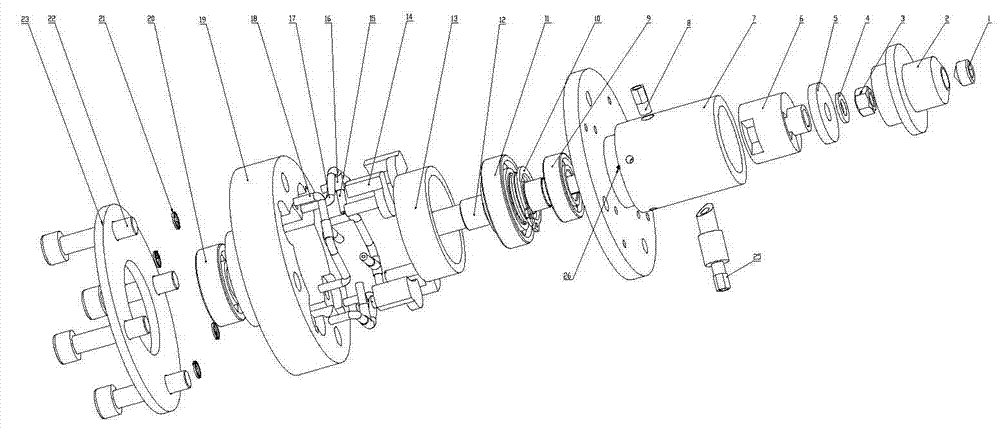

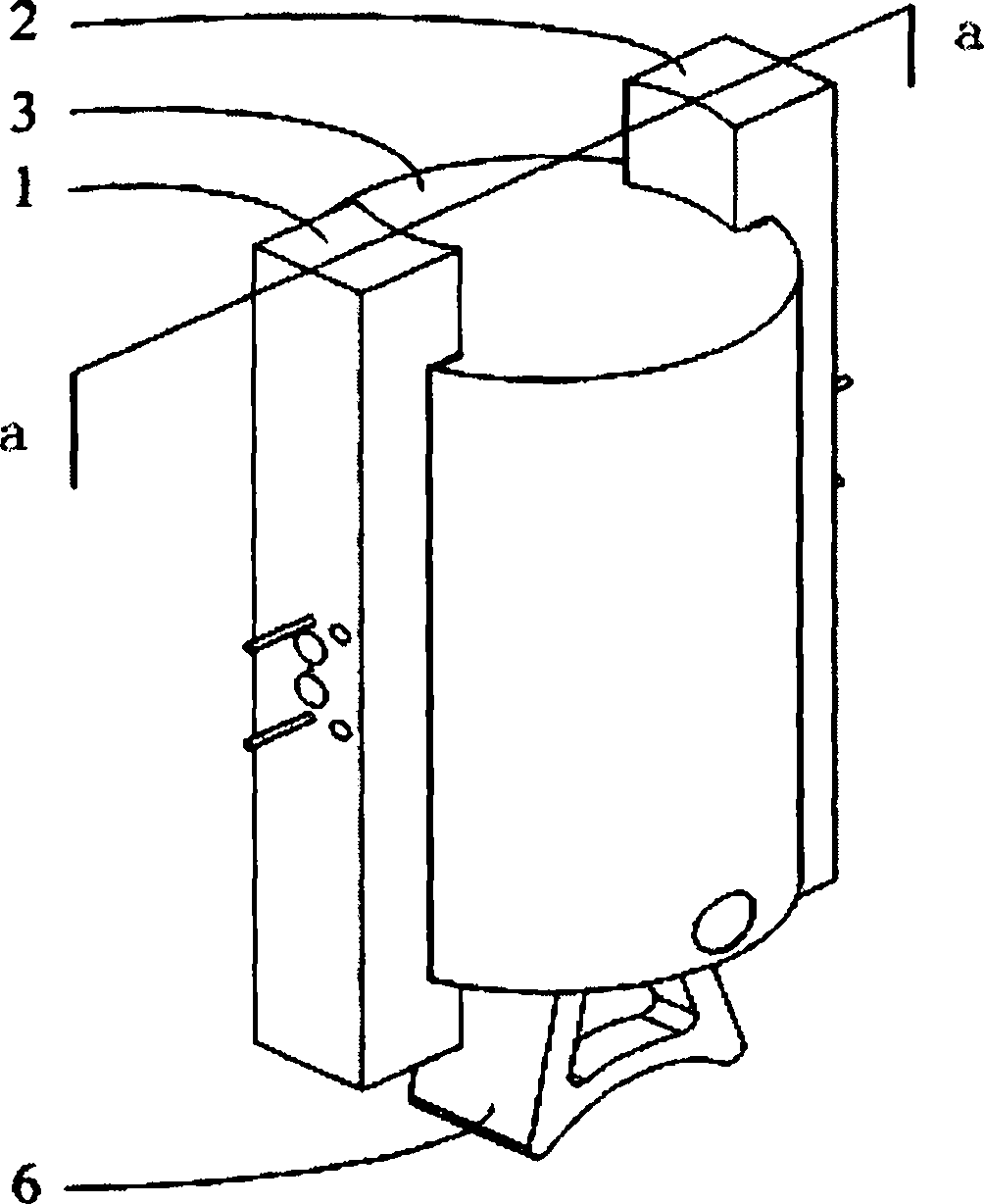

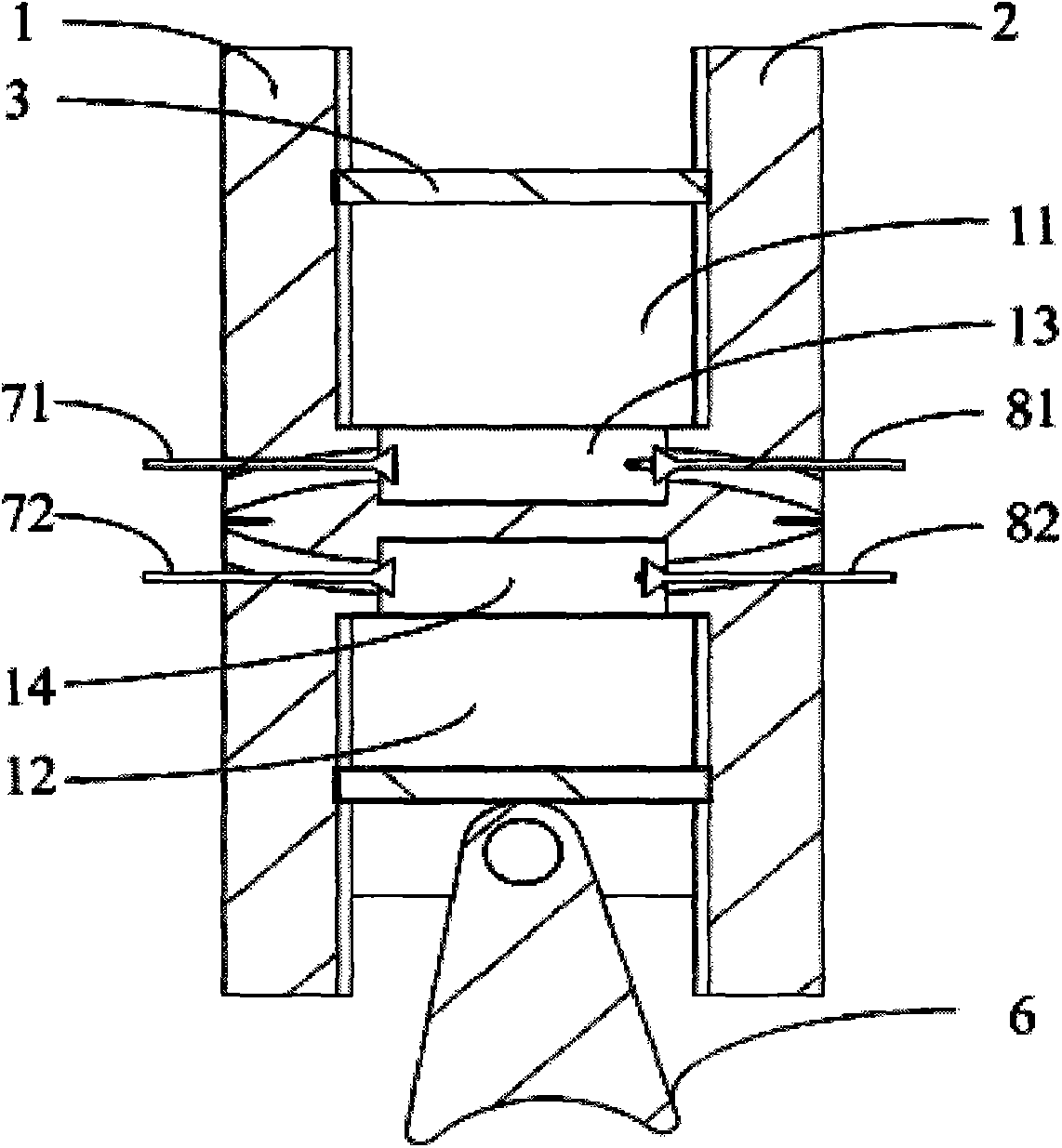

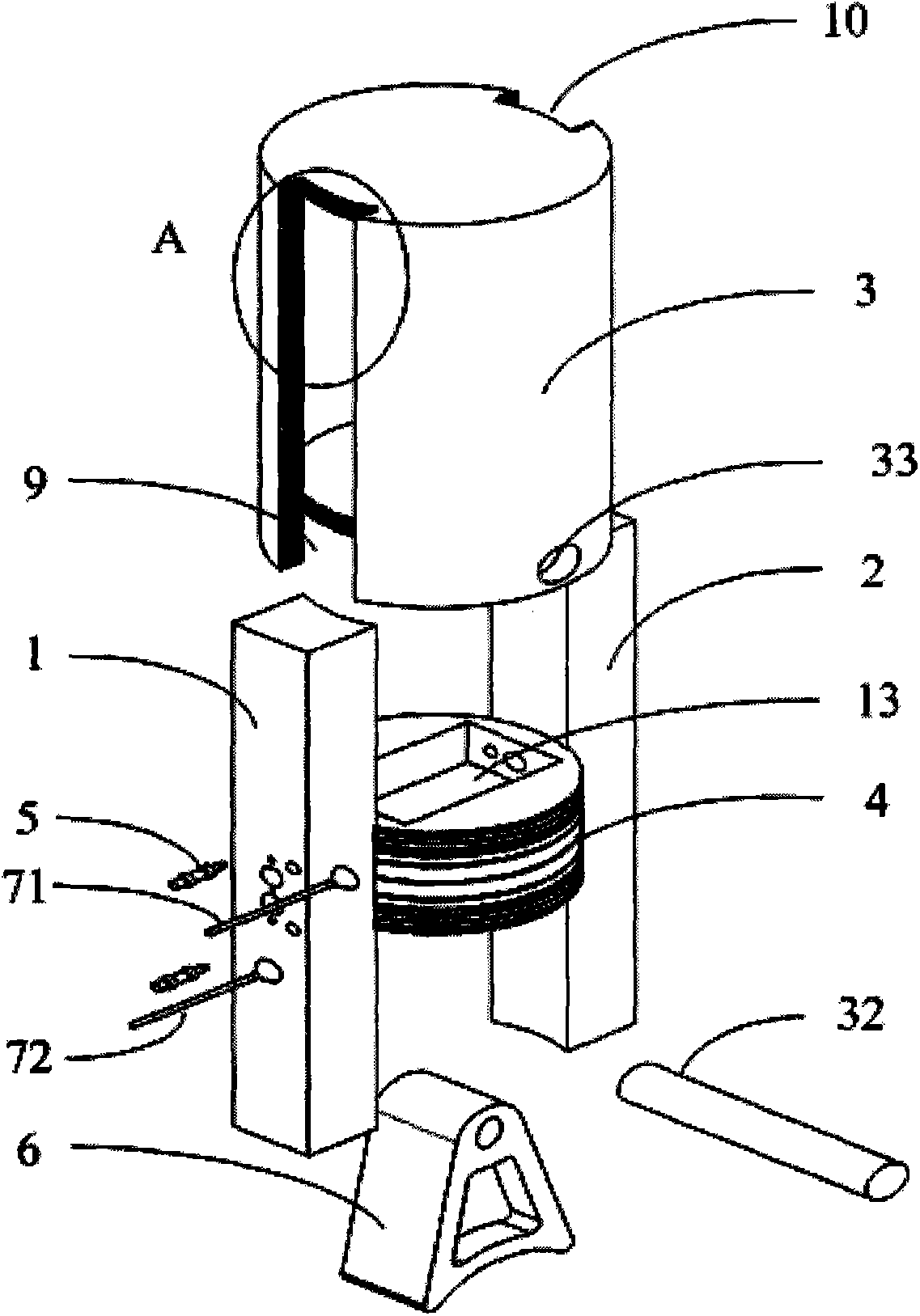

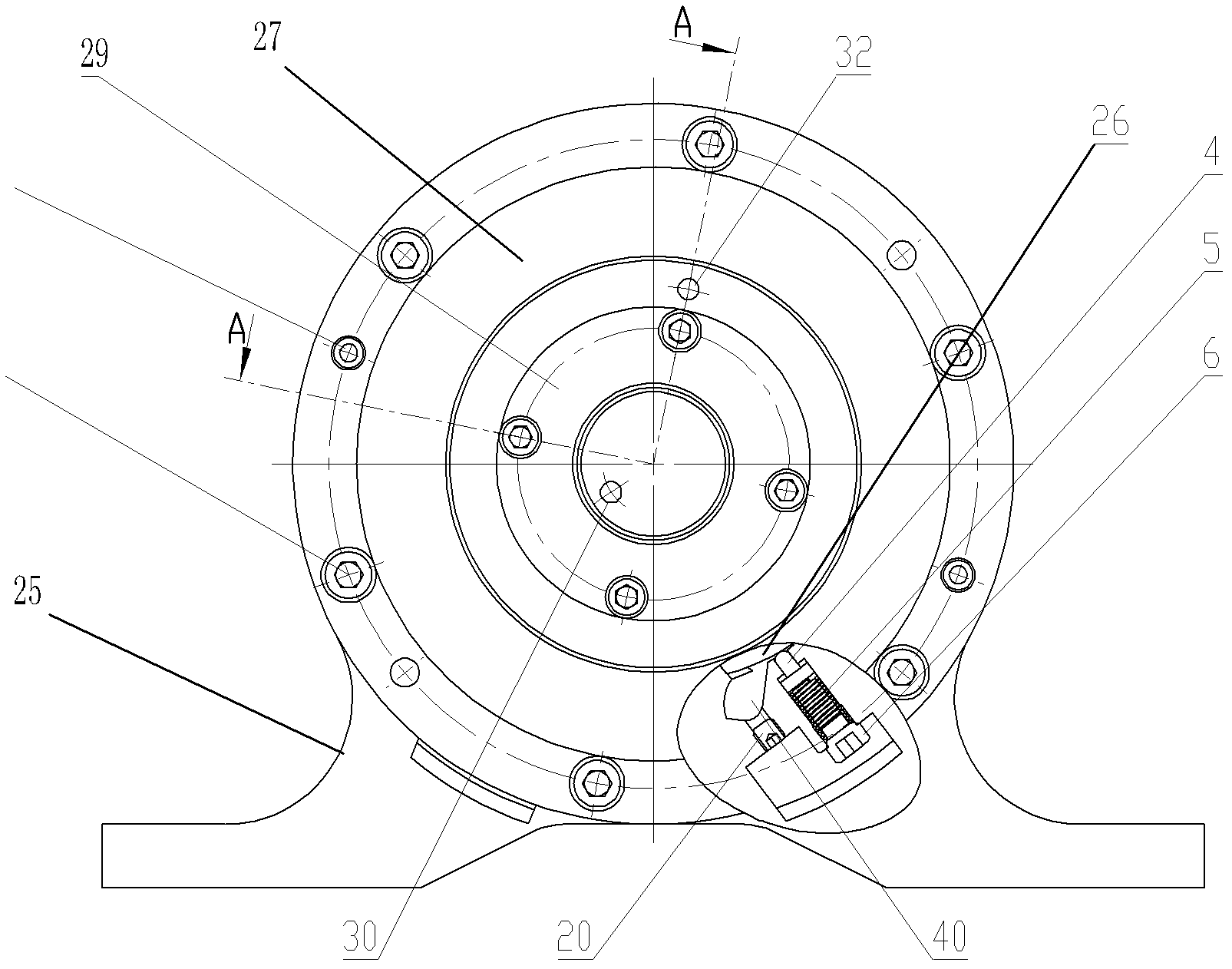

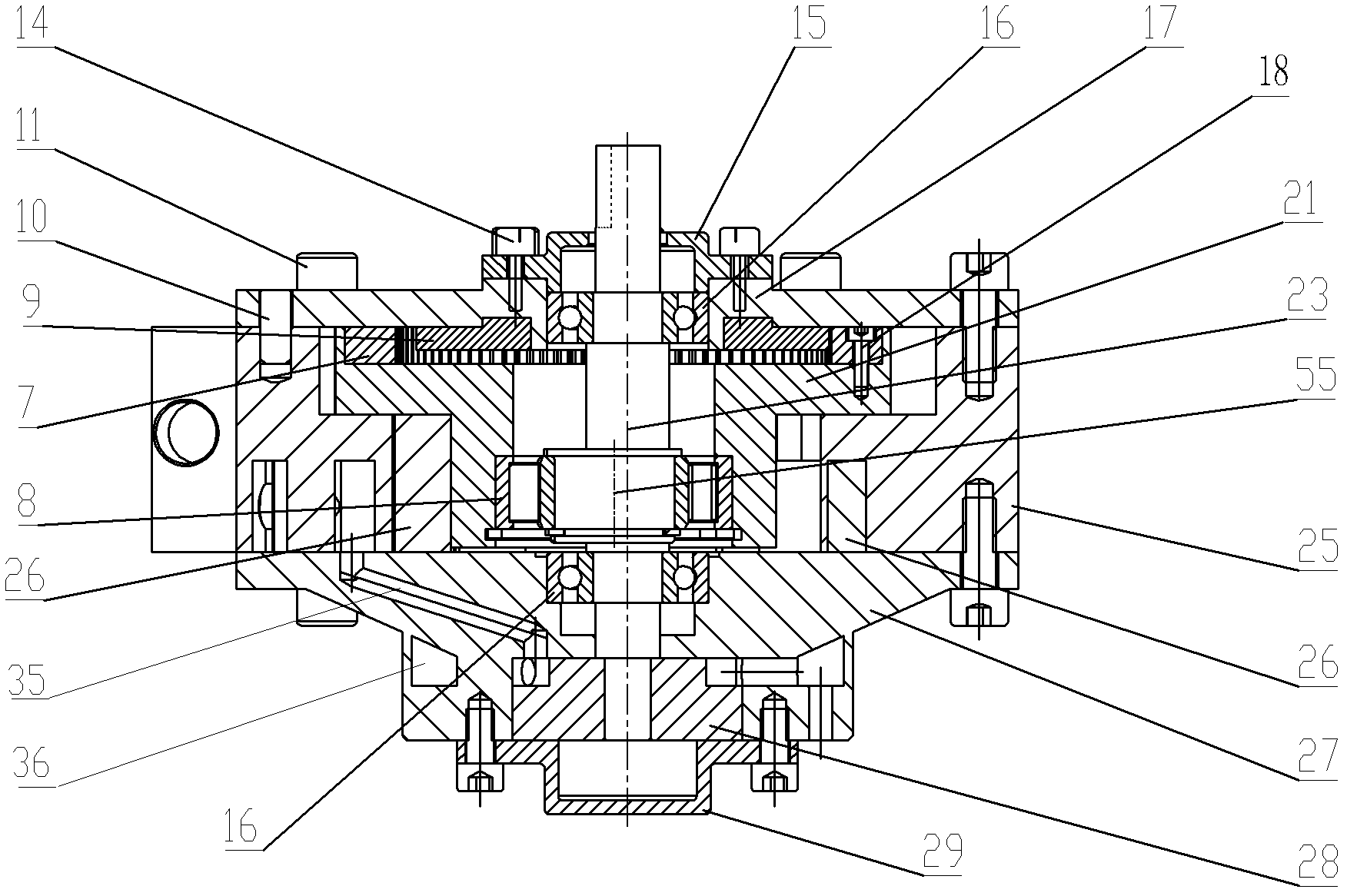

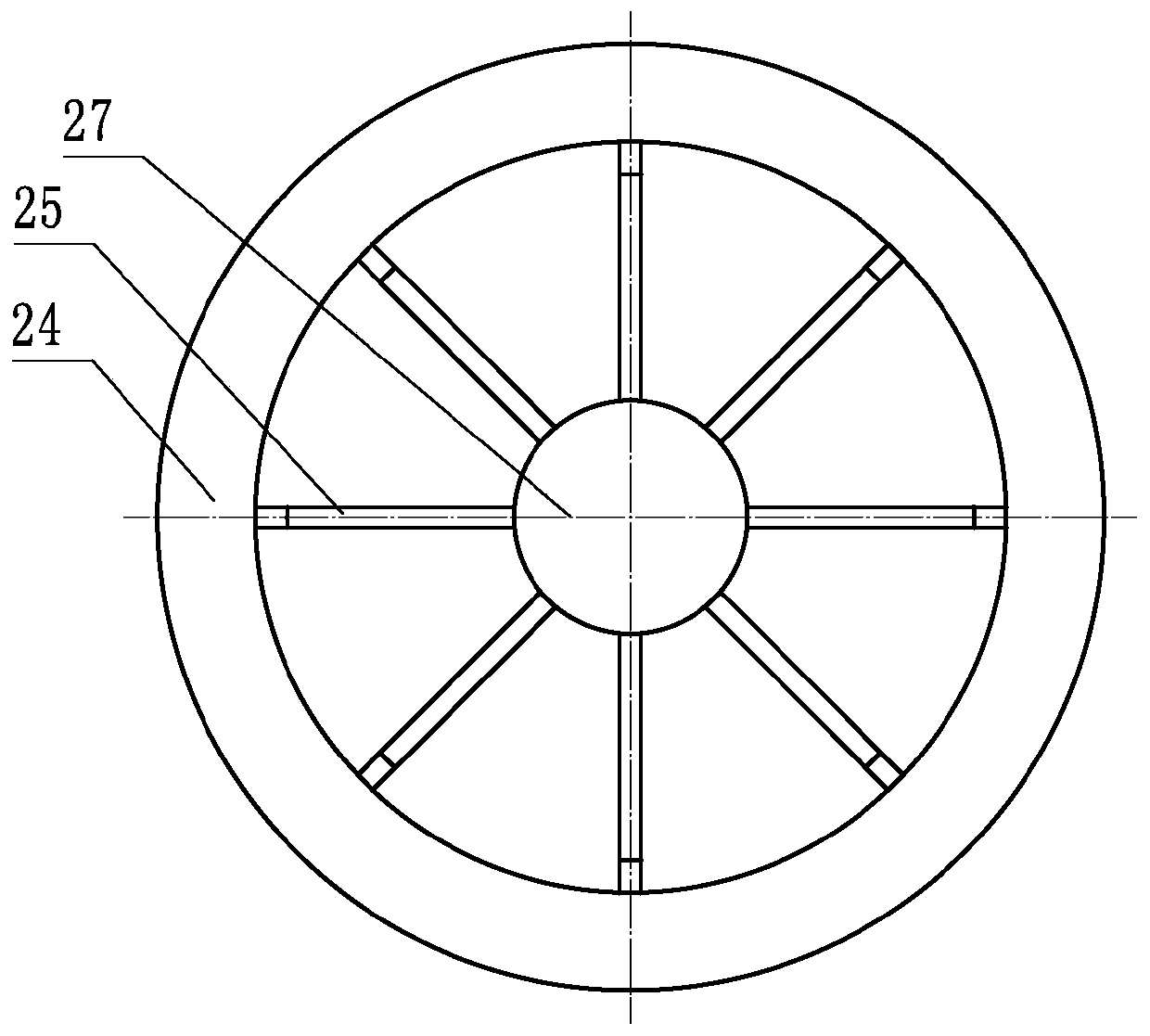

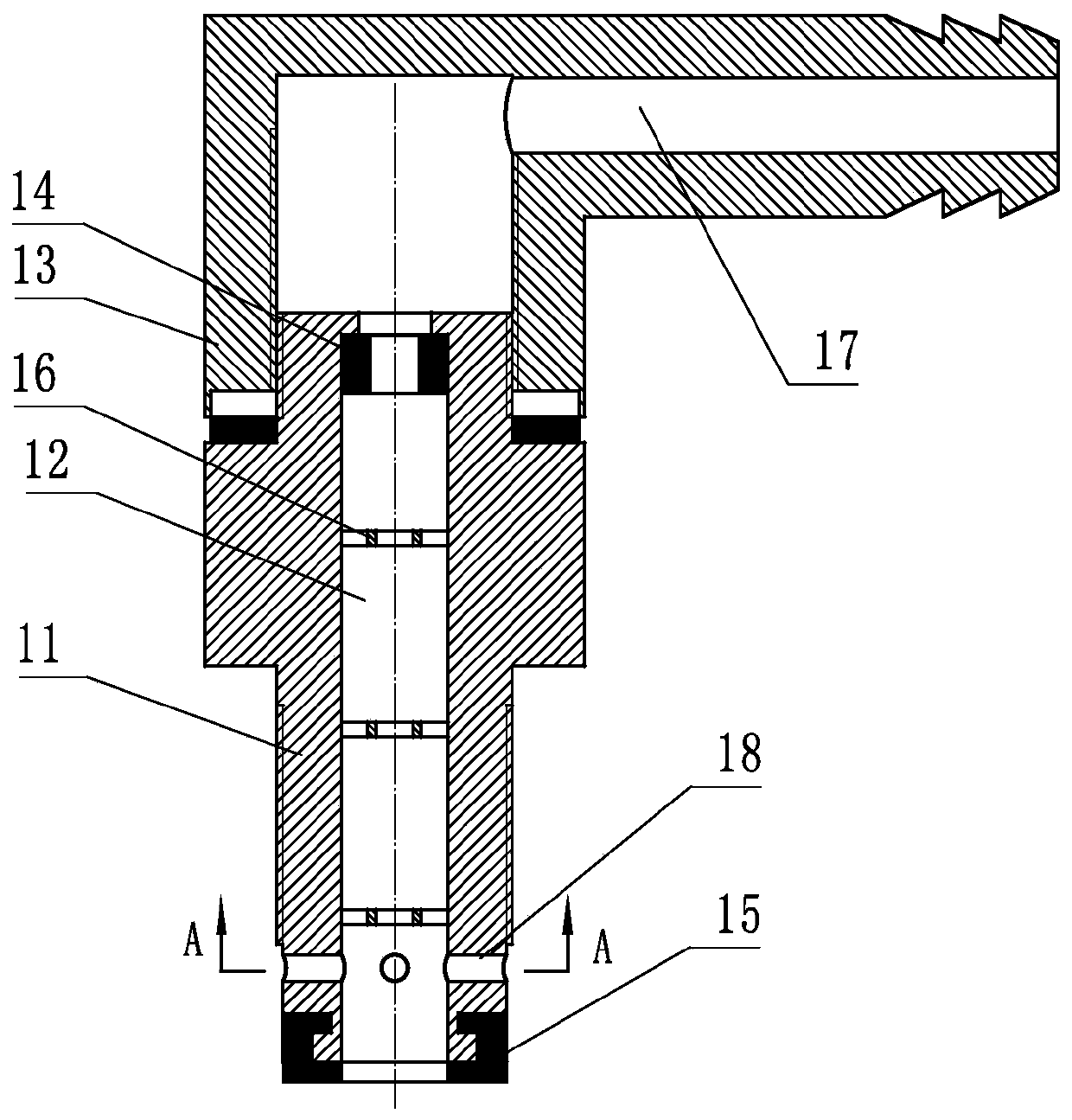

Centrifugal casting air discharging method for squirrel cage rotor and centrifugal casting die for implementing method

ActiveCN103084557AImprove compactnessImprove processingAsynchronous induction motorsManufacturing dynamo-electric machinesElectric machineEngineering

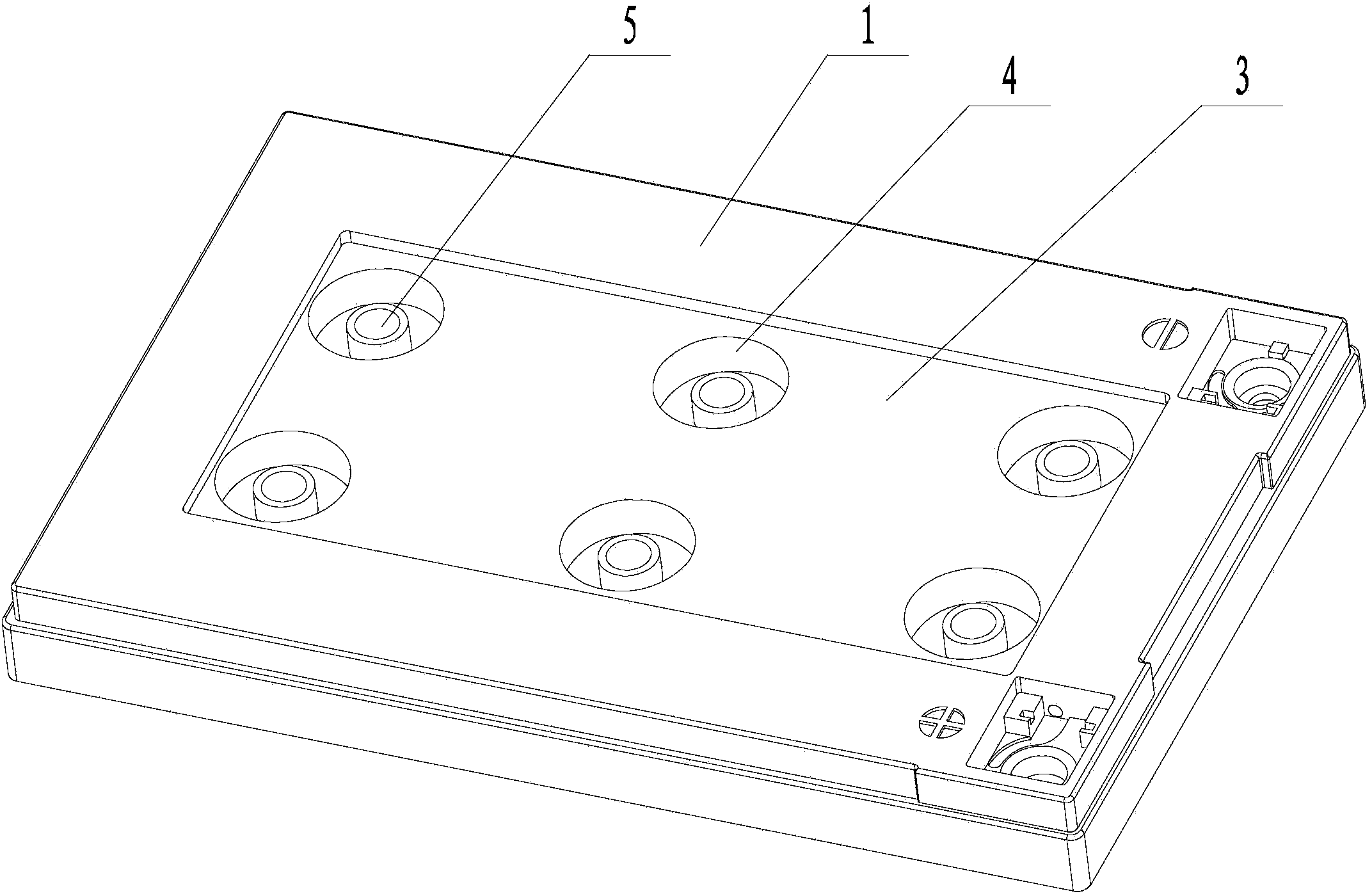

The invention relates to a squirrel cage rotor. A squirrel cage rotor centrifugal casting die comprises an upper die and a lower die; the upper die is provided with a rotor upper end annular cavity; the lower die is provided with a rotor lower end annular cavity; the bottom wall of the rotor lower end annular cavity is provided with a plurality of lower air discharging holes of which opening areas are less than three square millimeters; and air is discharged by the lower air discharging holes in a casting process. The invention provides a centrifugal casting air discharging method for the squirrel cage rotor, and the squirrel cage rotor centrifugal casting die. By the method, air can be discharged efficiently, conveniently and comprehensively; and by the method and the die, the problems of low production efficiency and complex equipment structure, and the problem that energy conversion efficiency of a motor is reduced due to low compactness of an aluminum cage, broken ribs and air bubble entrainment in the conventional air discharging method and the process that the squirrel cage rotor is cast by the centrifugal casting die can be solved.

Owner:HANGZHOU FUSHENG ELECTRICAL APPLIANCE

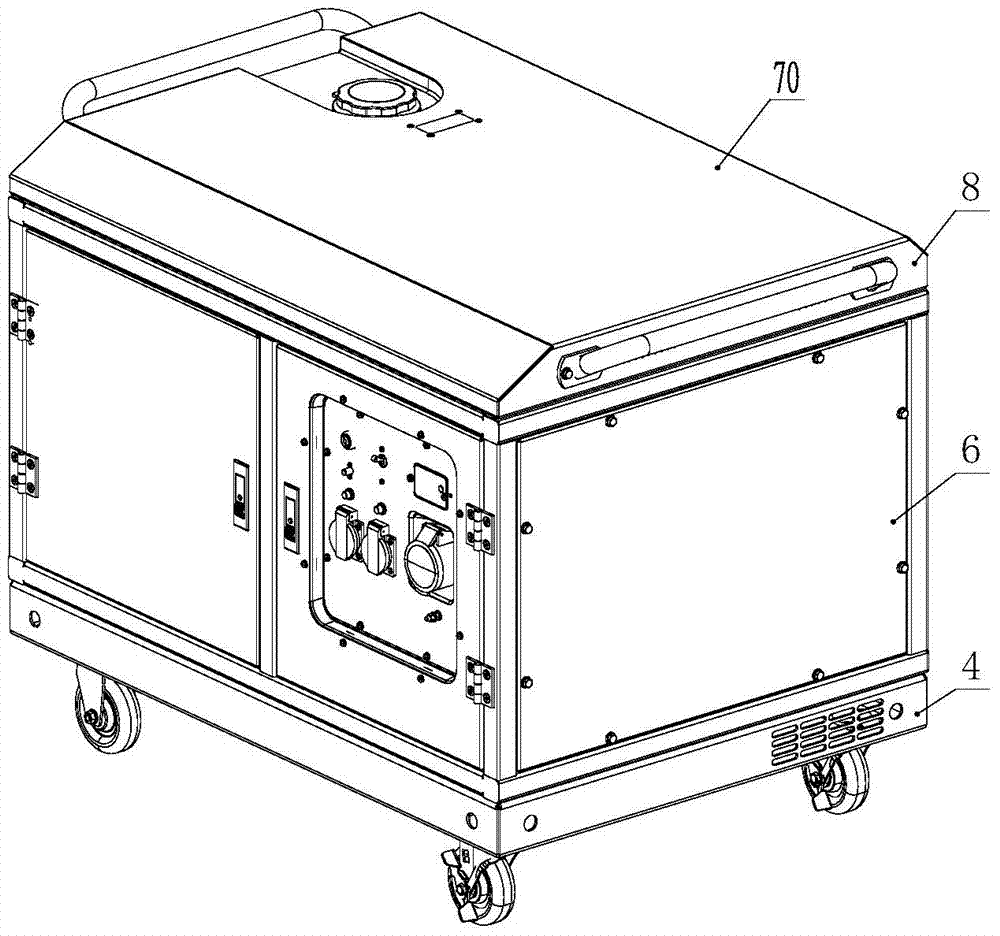

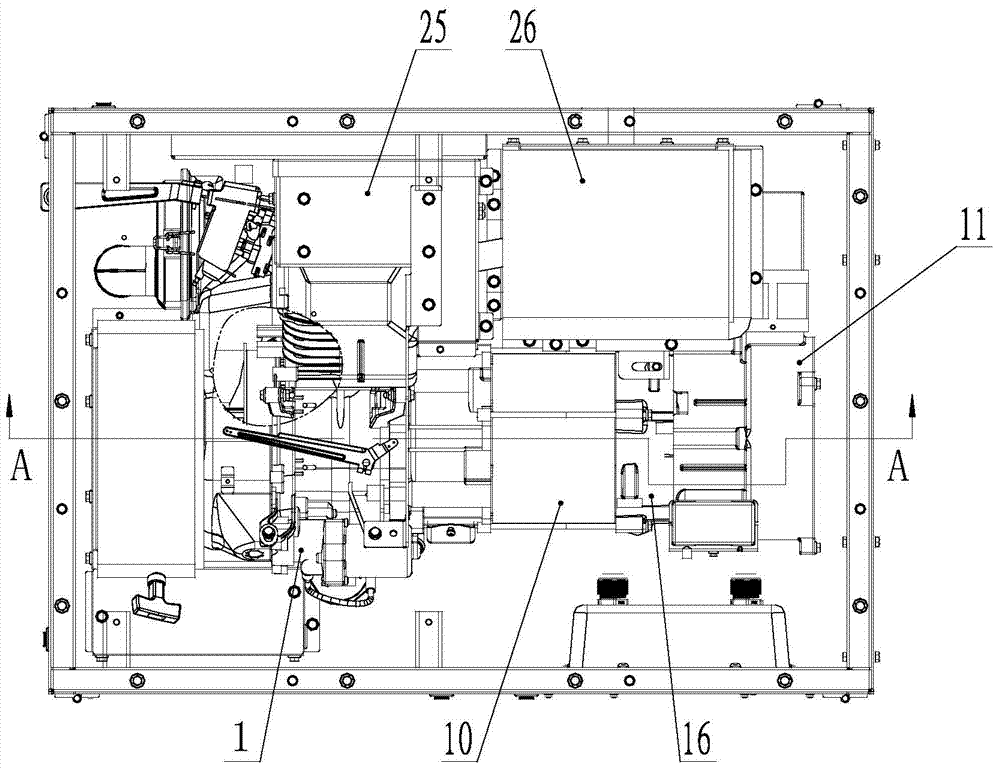

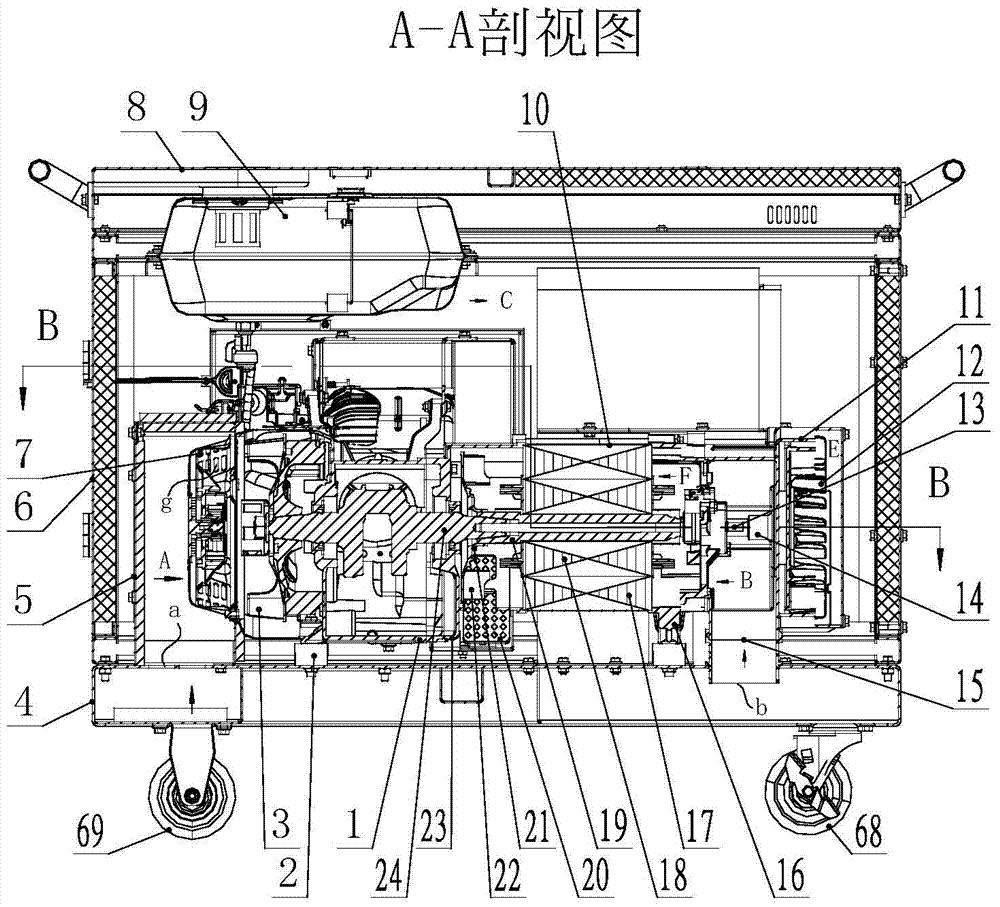

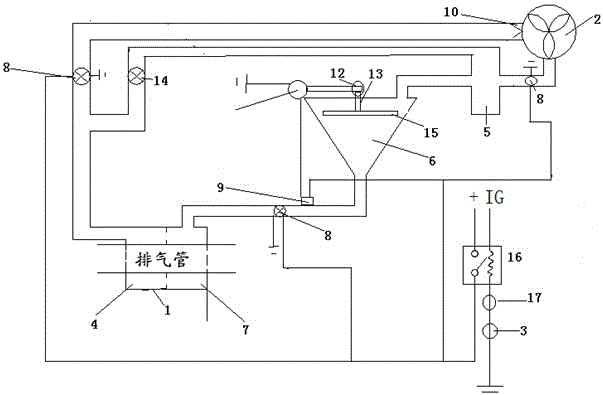

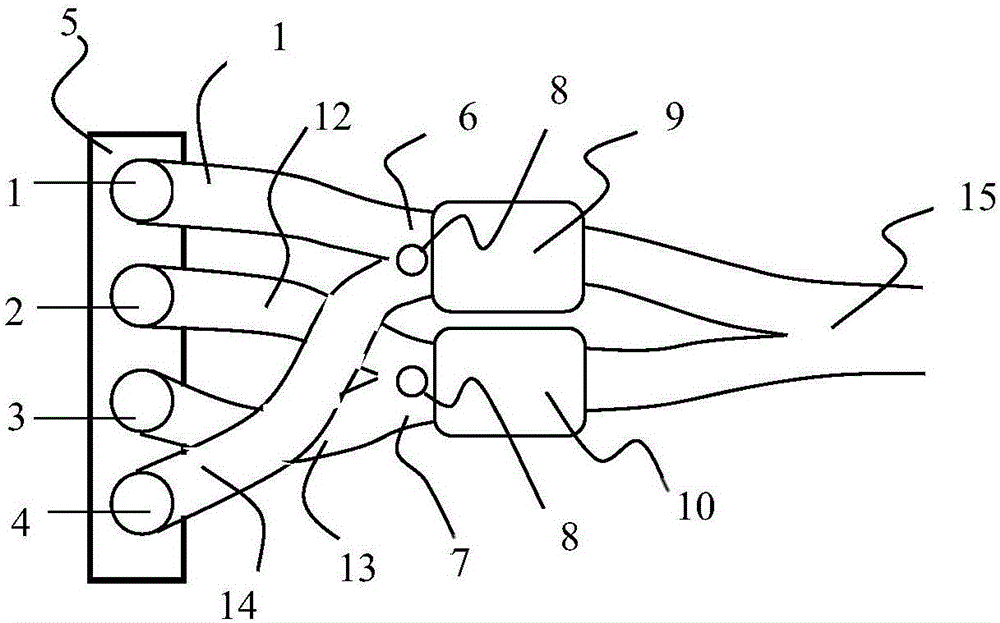

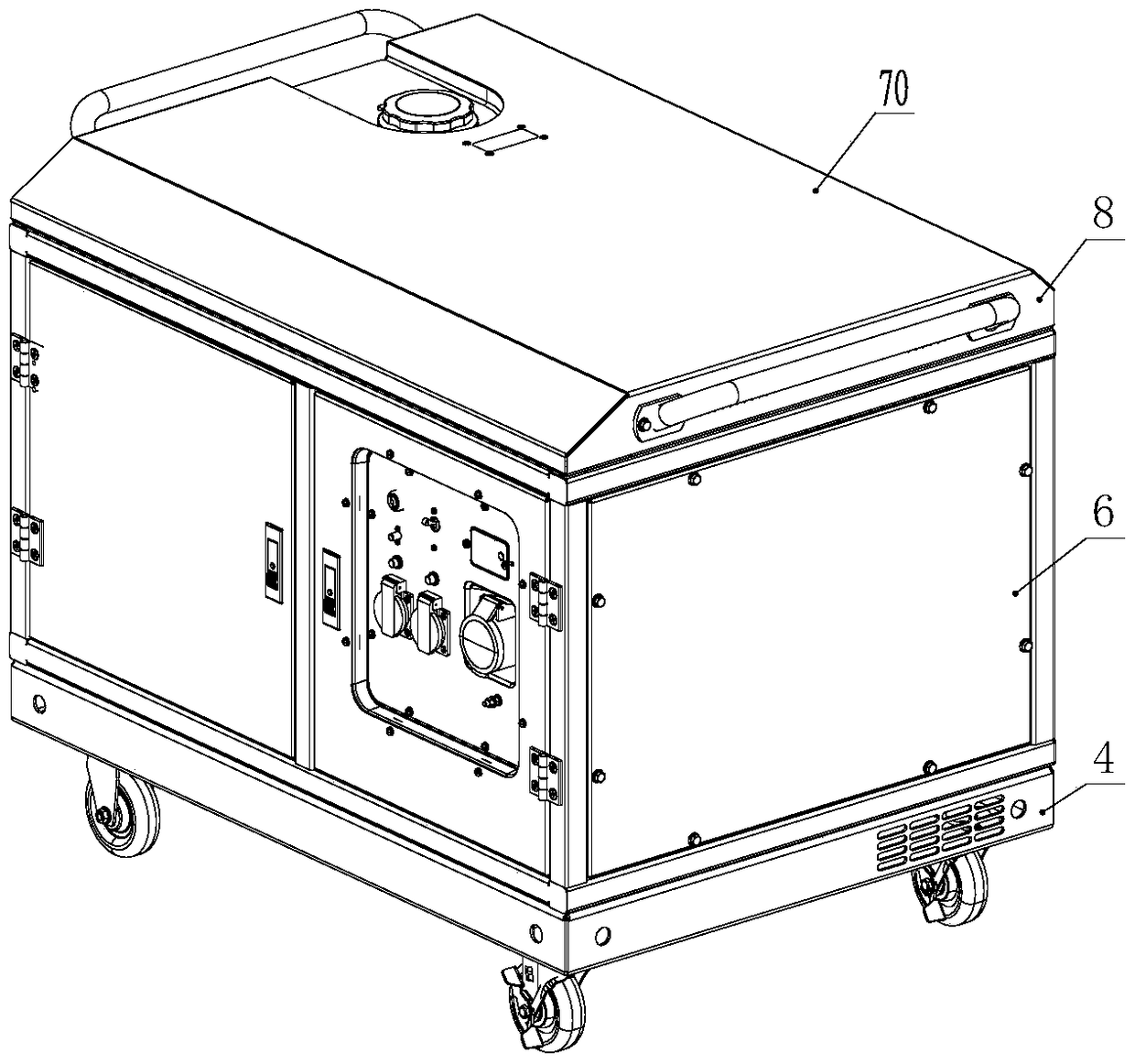

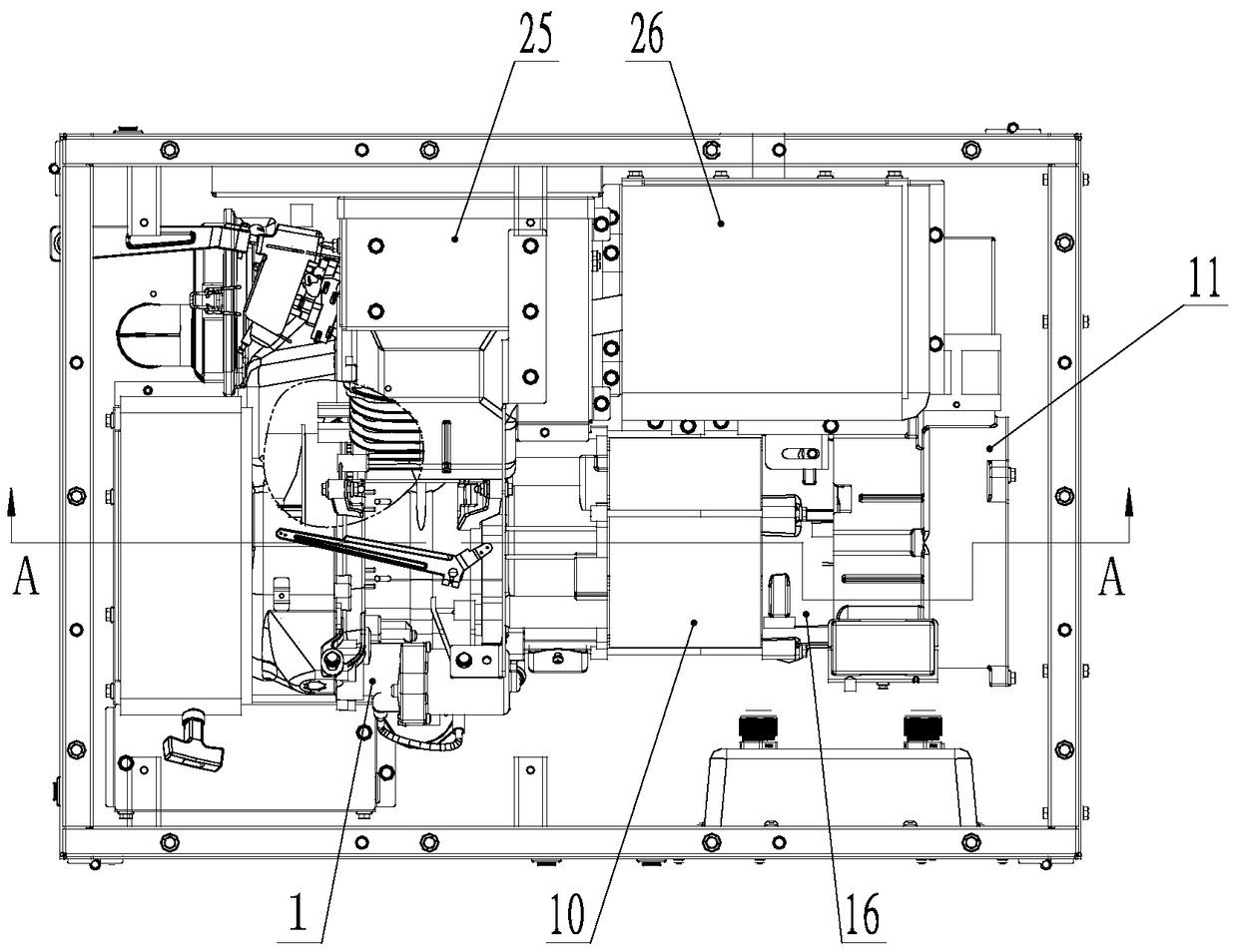

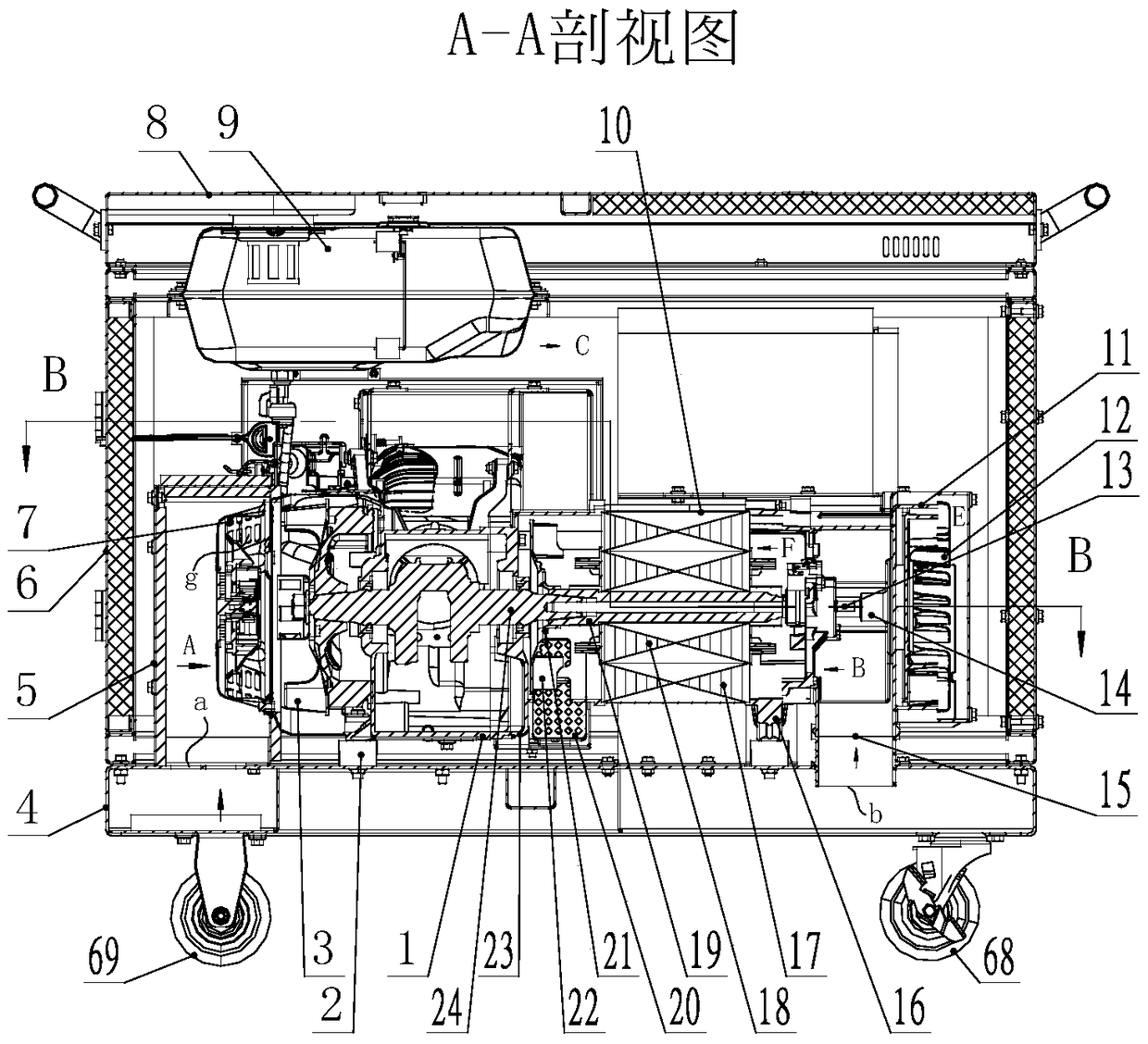

Generator set driven by engine

ActiveCN104847488ASolve the reflux problemBest Exhaust PathExhaust apparatusSilencing apparatusHeat balanceCylinder block

The invention discloses a generator set driven by an engine. The generator set comprises a sound proof box, an engine, a generator and an exhaust muffler, wherein the sound proof box is composed of an upper cover, side walls and a chassis; the engine is arranged on the chassis, and an engine cooling fan is arranged at the side inlet of the engine and guides cooling air into the engine; a cooling fan is arranged at the connection part of the generator and the engine to guide the cooling air into the generator; the exhaust muffler is arranged at the rear side of the generator and parallel to the axis of the generator; one end of the exhaust muffler is connected with the engine through an exhaust pipe; a hot air exhaust chamber is further arranged in the sound proof box, is composed of a side panel, a cover plate and an engine speed regulation base, and encircles an engine cylinder end, a cylinder body and one part of the exhaust pipe; an opening is formed in the rear side of the hot air exhaust chamber and is connected with a first ventilation hole at the side wall of the sound proof box. According to the generator set, the problems of noise and heat balance can be effectively solved, and the oil temperature of the engine can be obviously reduced beyond 30 degrees centigrade, thereby ensuring that reliable lubrication of the engine and the power level of the complete generator bring into correspondence with open-shelf products.

Owner:SUMEC MACHINERY & ELECTRIC

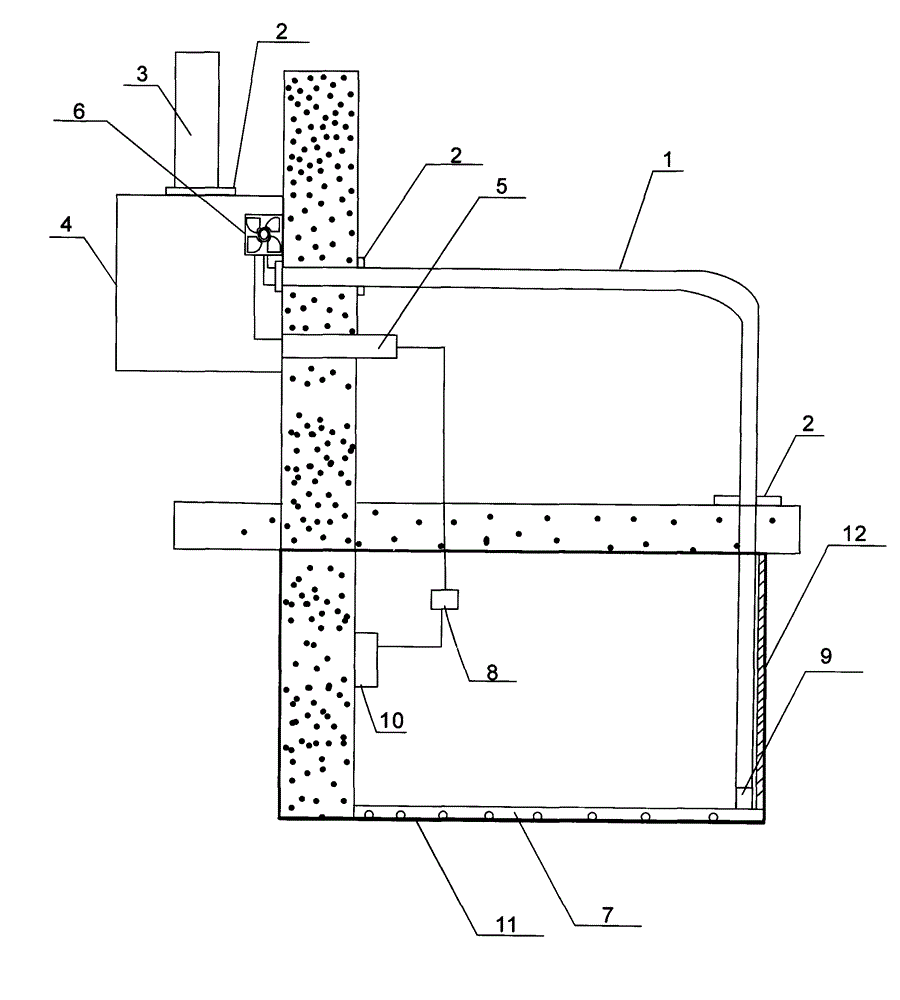

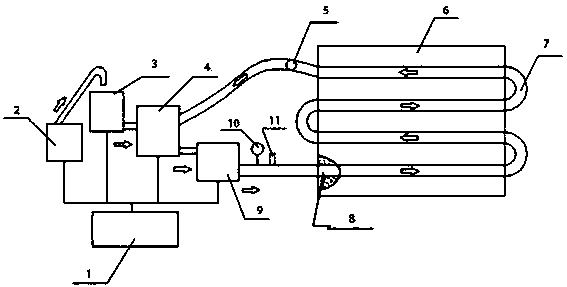

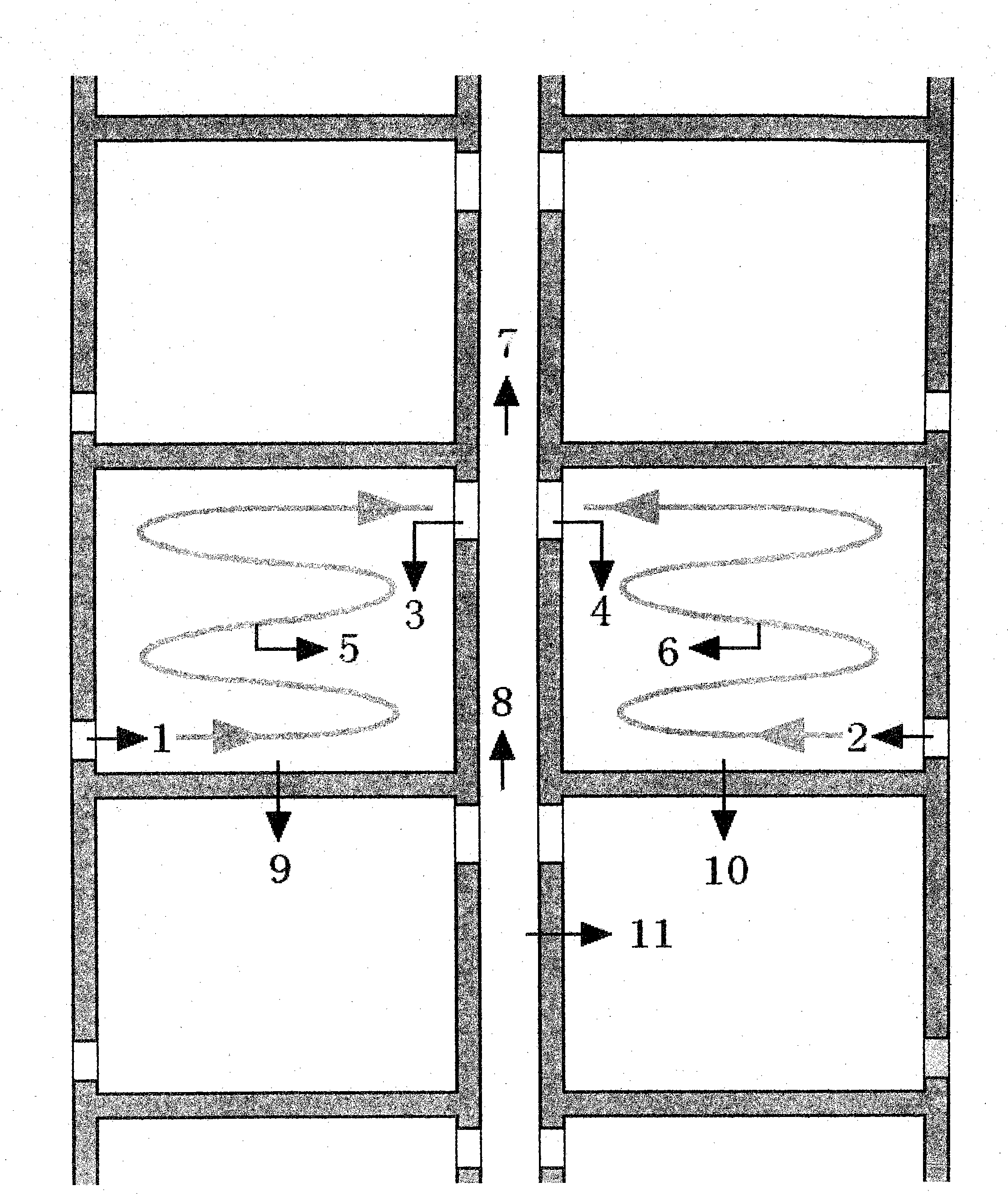

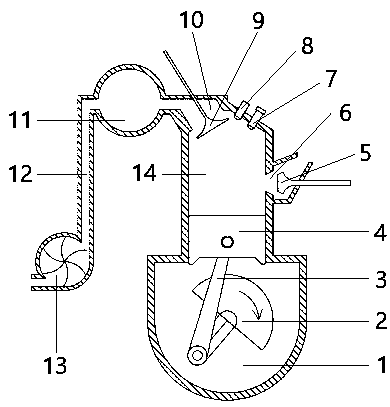

Radon removal system capable of being mounted in basement

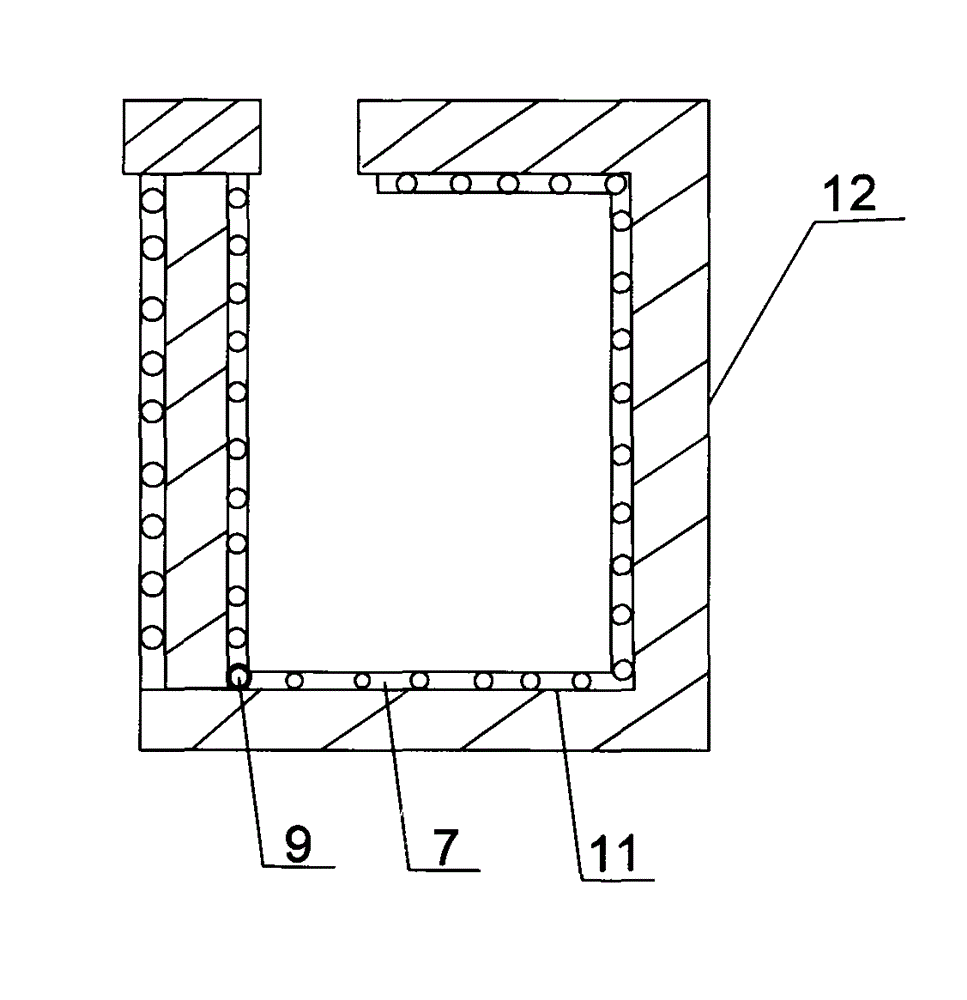

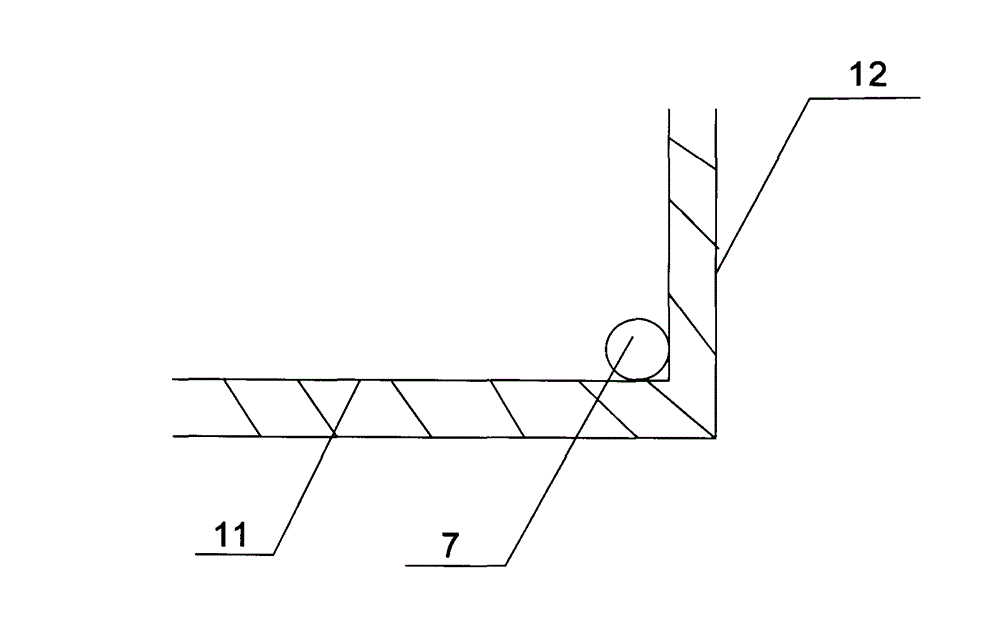

InactiveCN102914019APrevent penetrationExhaust thoroughlyLighting and heating apparatusVentilation systemsBasementFloor slab

The invention discloses a radon removal system capable of being mounted in a basement. A perforated pipe is laid at a vertical angle formed between a floor and a wall and is connected with a lead-out pipe; a right-angled pipeline passes through the floor slab to be connected with the lead-out pipe, the horizontal part of the right-angled pipeline pass through the sidewall and is connected with a fan on the outer wall, and the joints between the right-angled pipeline and the sidewall, the outer wall and the floor slab of the basement are respectively sealed by seals; the fan is placed in an outer cover, and an opening is formed at the upper end of the outer cover connected with an exhaust pipe through a seal; and the connection wire of the fan is connected with a converter through a protective hose, and the converter is then connected with a socket. The fan adopts a DC motor, and the converter converts AC into DC to be supplied to the fan, so that the operating security can be improved; the laid perforated pipe can effectively adsorb radon gathered on the surface of the floor; and owing to the seals, radon penetration is prevented.

Owner:WUXI IMPRINT NANO TECH

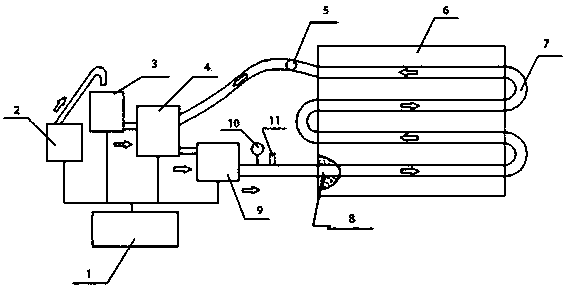

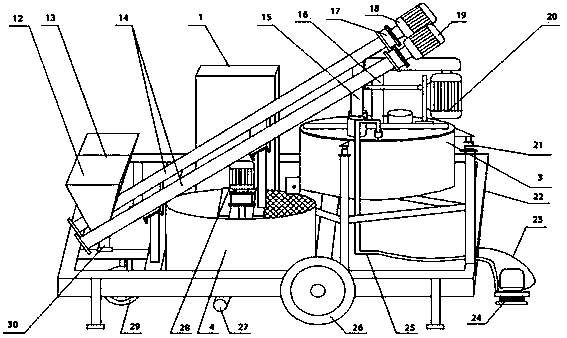

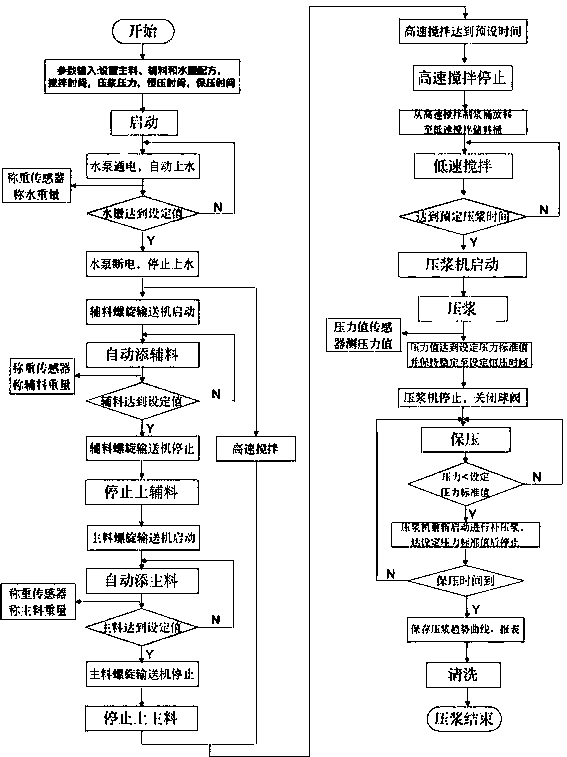

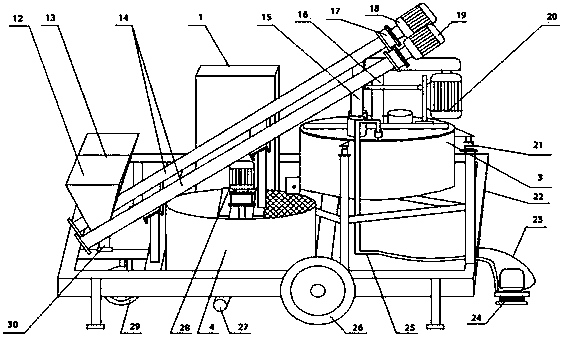

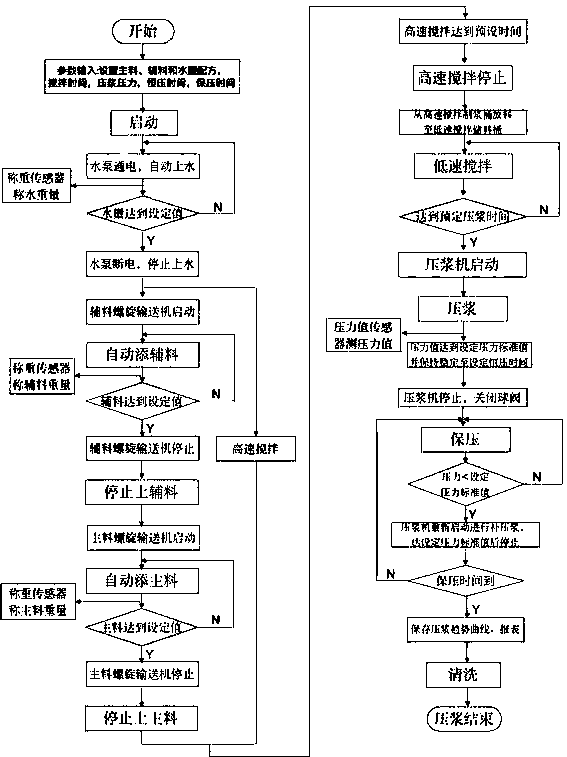

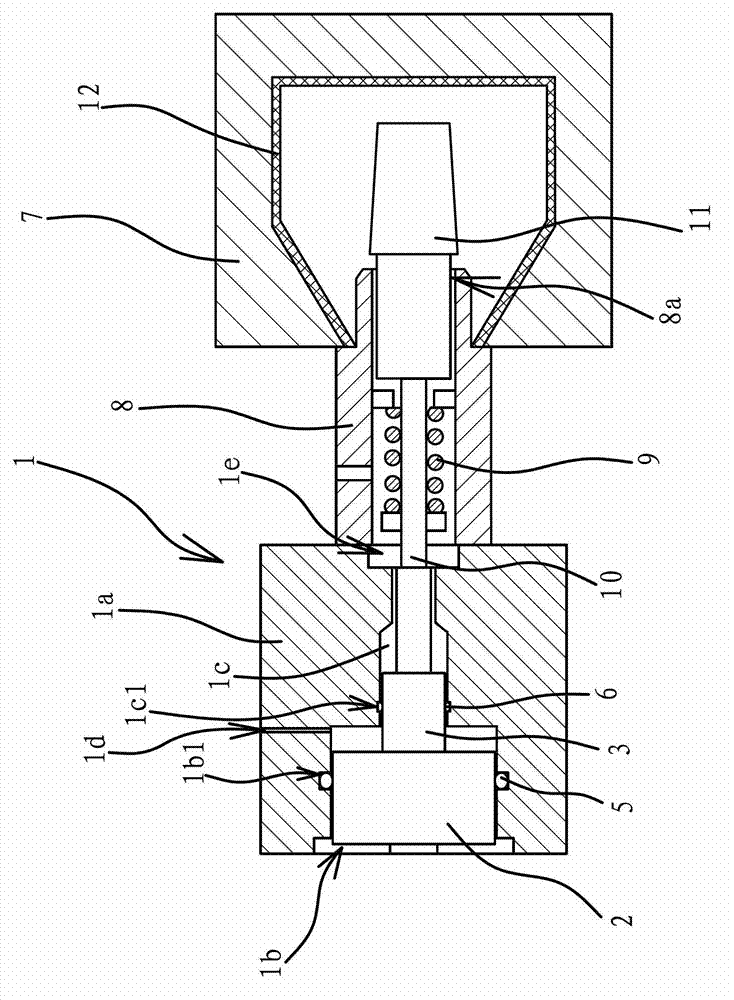

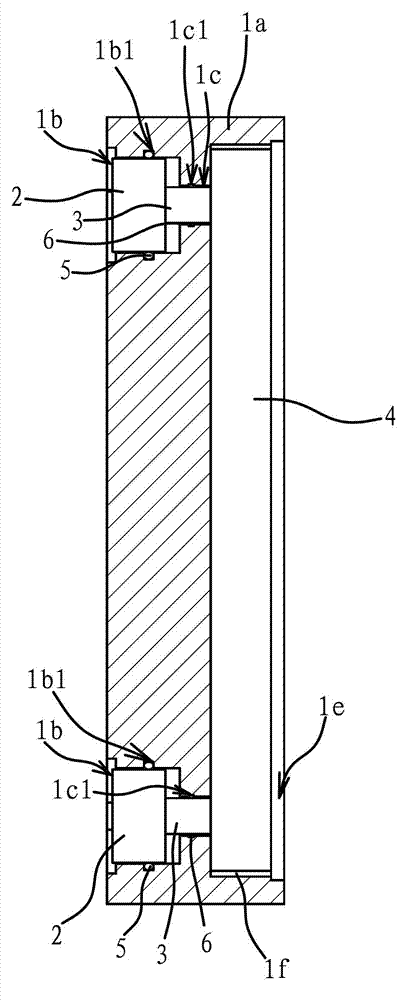

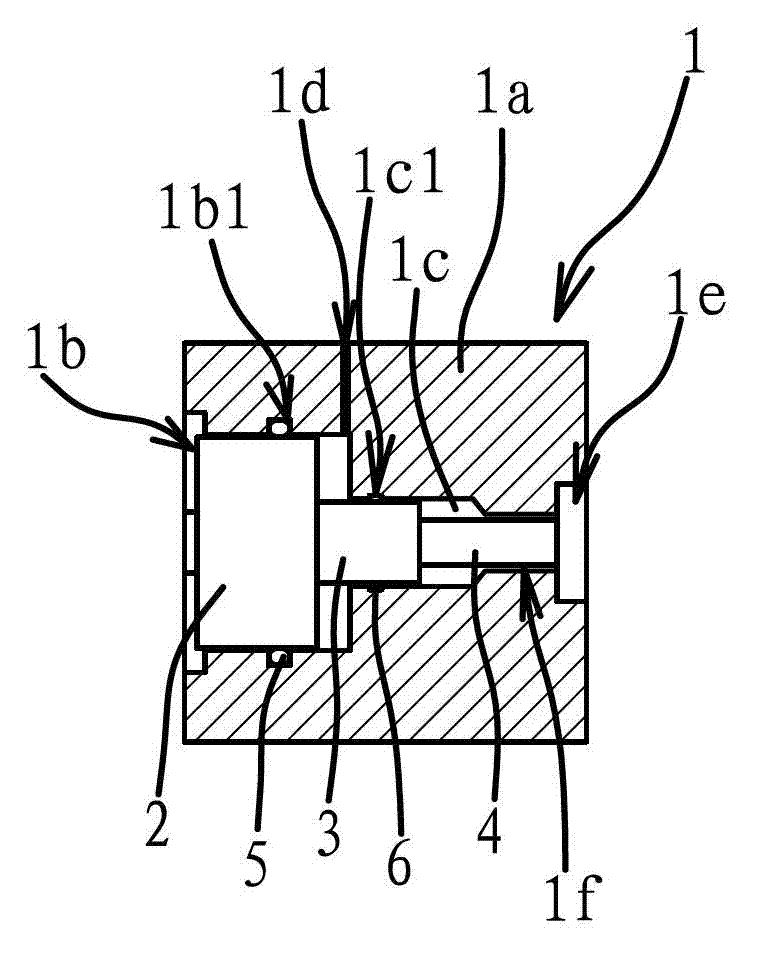

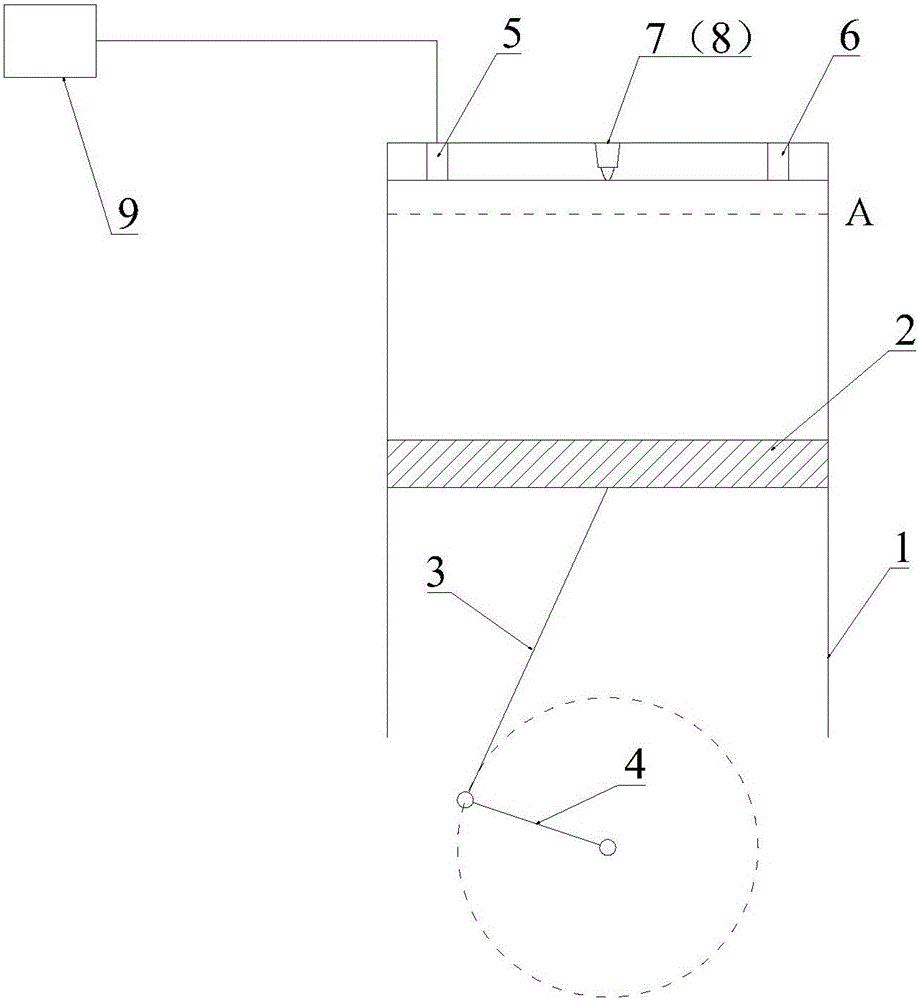

Intelligent pulping and grouting system

InactiveCN103711317AExhaust thoroughlyPrecise pressure controlBridge erection/assemblyBuilding material handlingPulp and paper industryLoad cell

An intelligent pulping and grouting system used for prestressed engineering comprises a high-speed stirring pulping barrel, a low-speed stirring pulping barrel, a loading system and a grouting system. The loading system is provided with a water inlet pipe, an auxiliary material feeding motor and a main material feeding motor. The intelligent pulping and grouting system is further provided with a weighting sensor, a pressure sensor and a control center which are used for monitoring the weight of water, auxiliary material and main material and comparing those with preset values in real time, controlling the adding amount of the water, auxiliary material and main material, controlling the high speed stirring time and low speed stirring time, monitoring the pressure, constant pressure time and pressure maintaining time of a pulp inlet and comparing those with preset values in real time, and controlling the actions of an automatic grouting machine. The intelligent pulping and grouting system has the advantages that pressure can be controlled accurately, gas in pipelines can be exhausted thoroughly, filling and compaction of grouting can be guaranteed, the whole grouting process is controlled through the computer control center, loading is performed automatically according to the preset proportion, pulping and grouting are performed automatically, and grouting data are recorded automatically.

Owner:LIUZHOU QIAN BRIDGE ENG MATERIALS

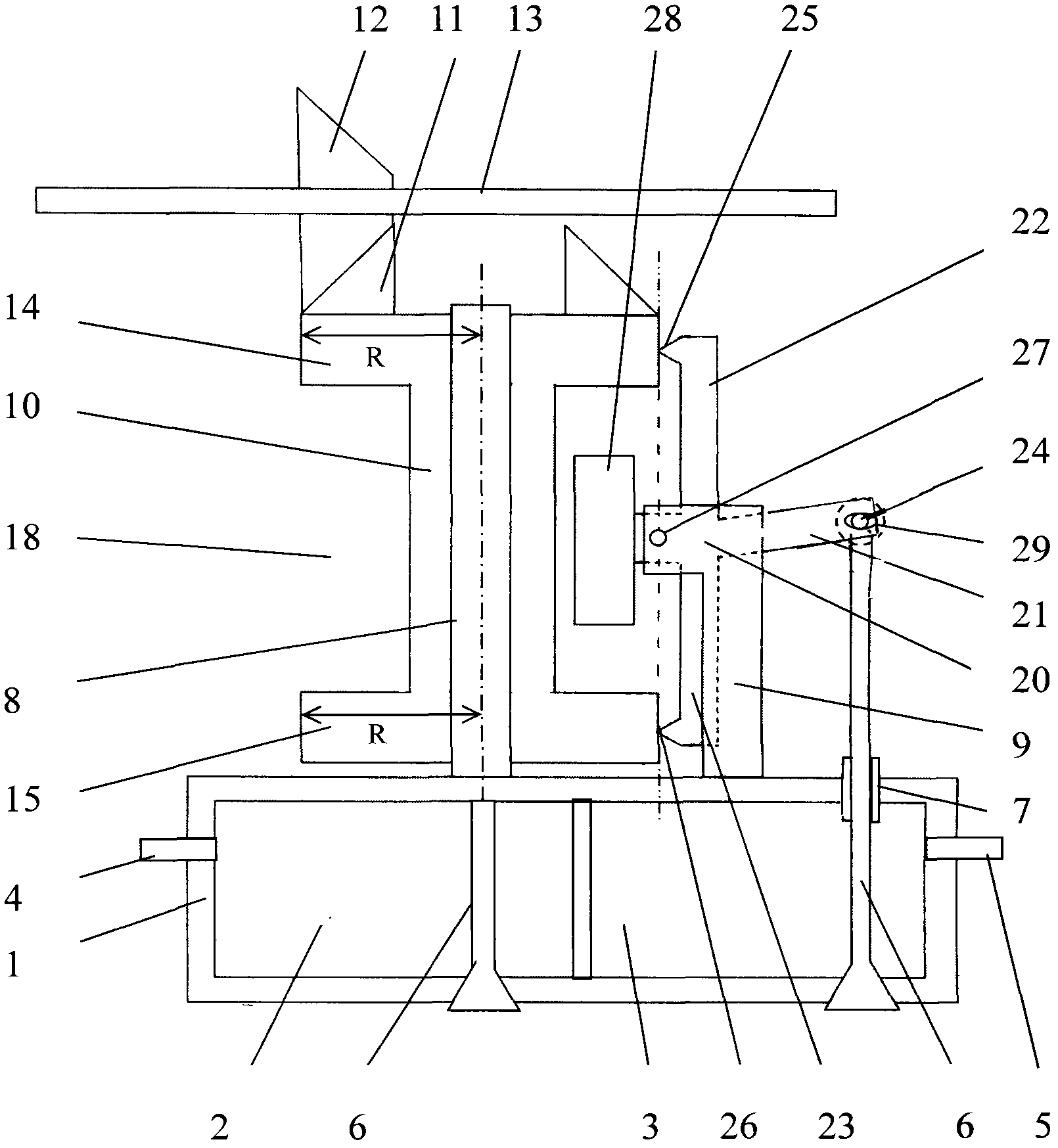

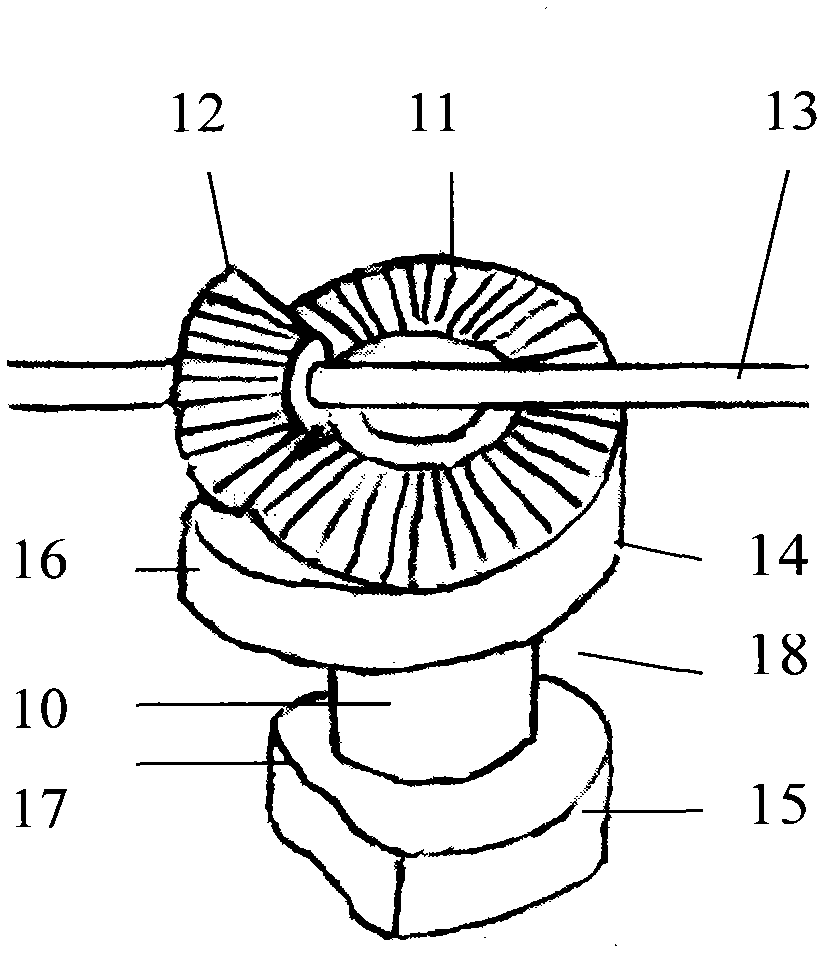

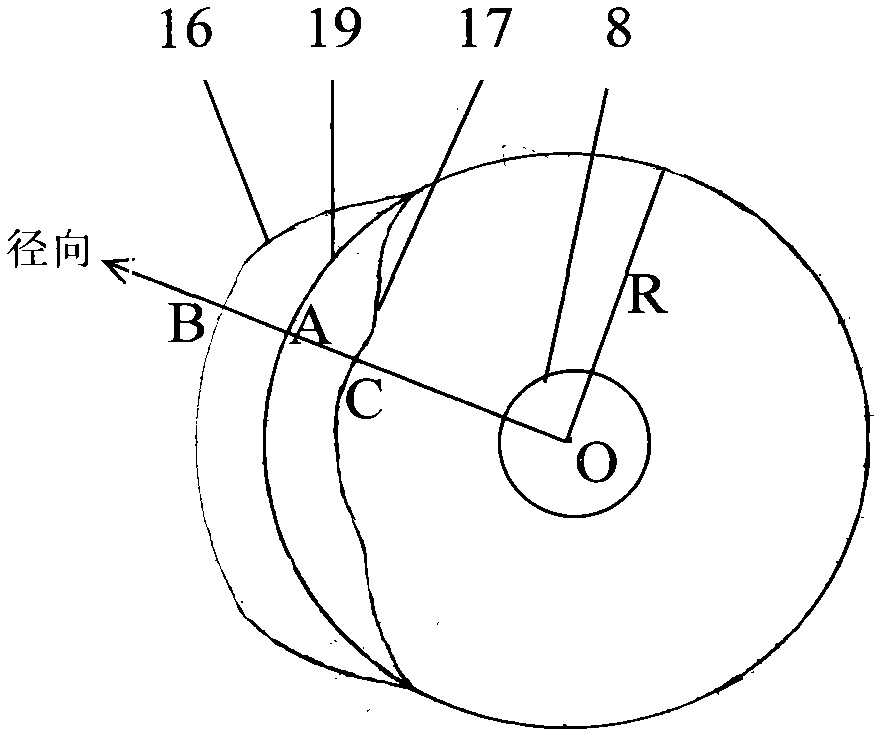

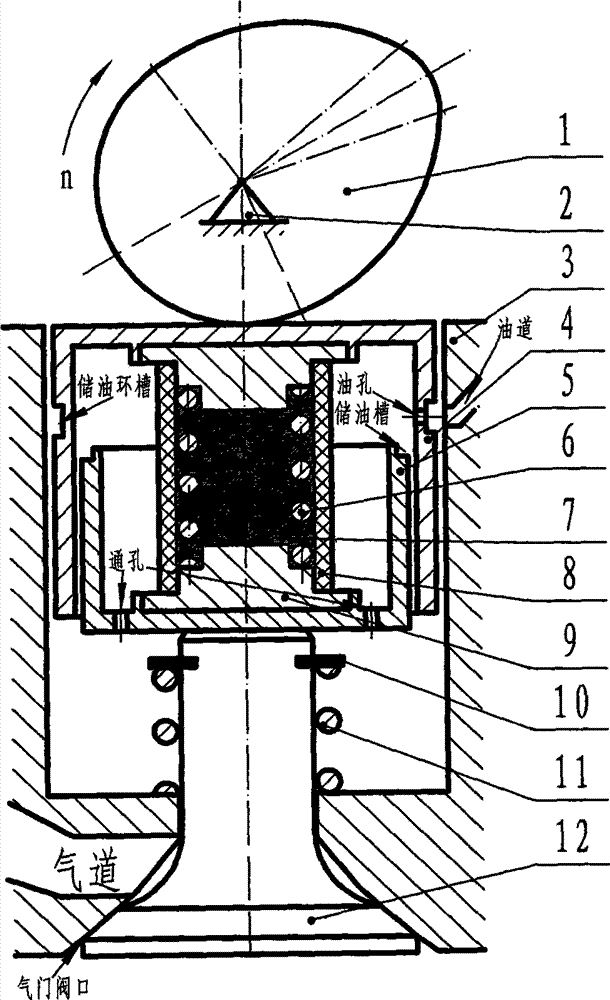

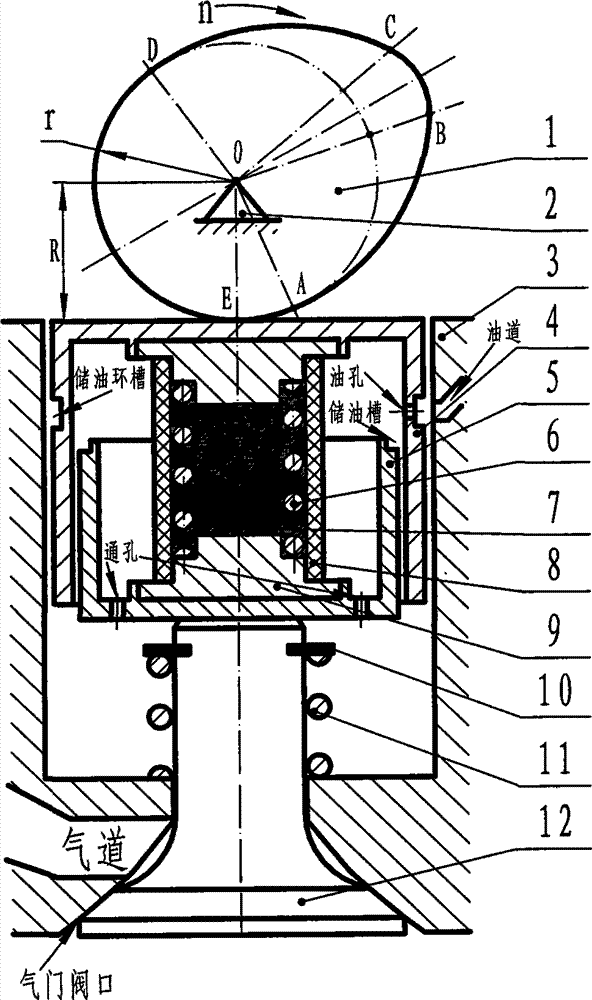

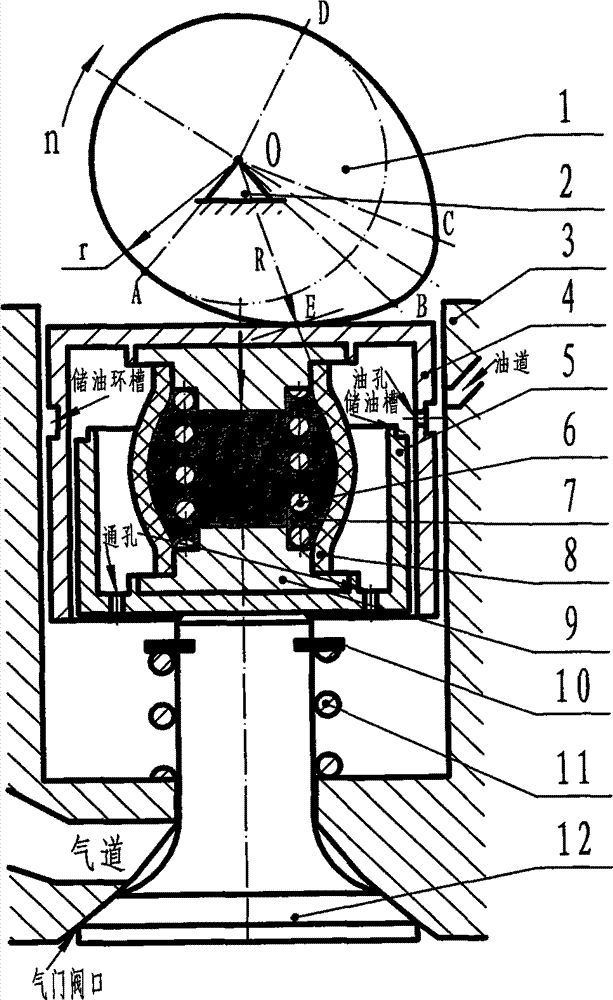

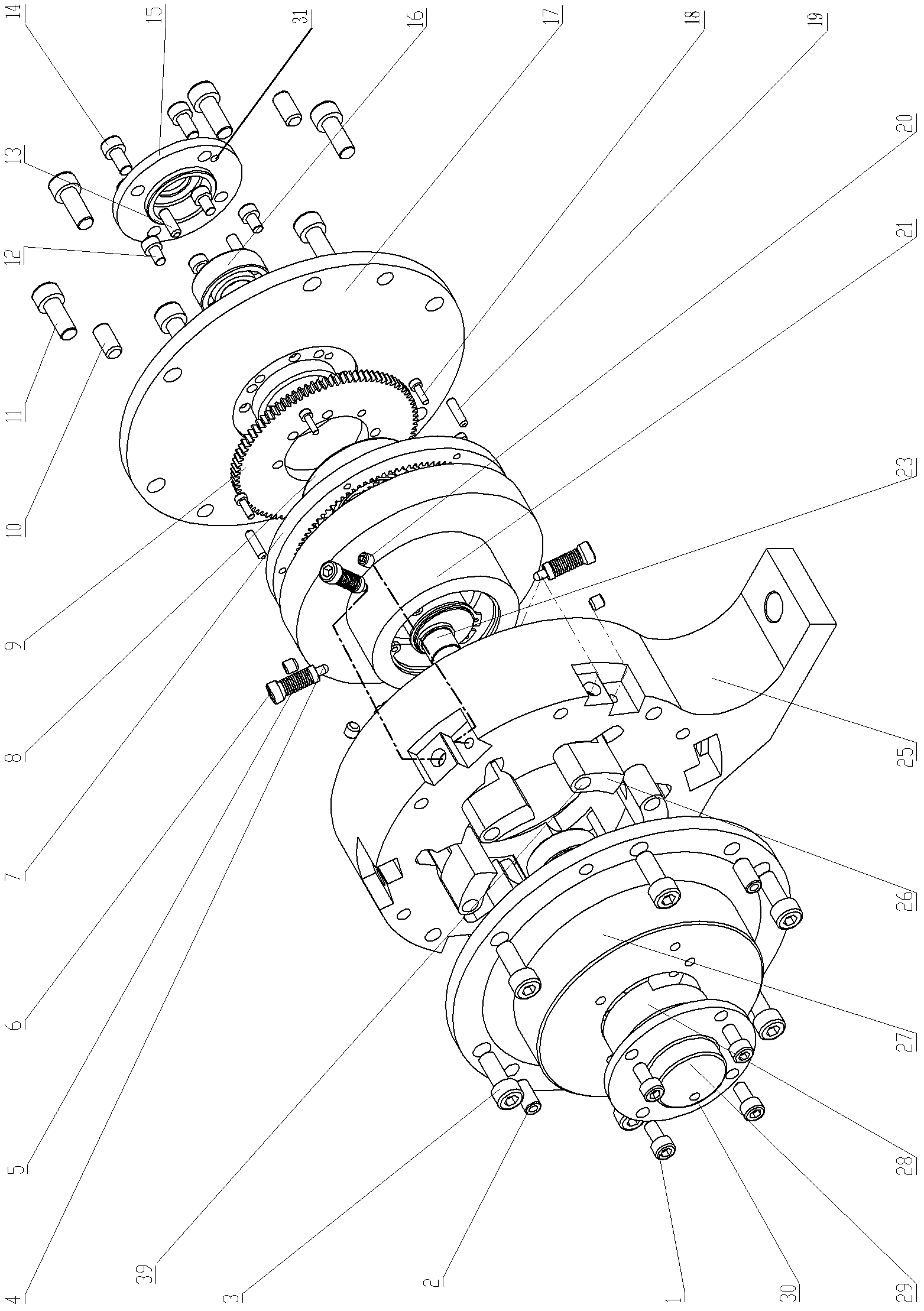

Concave-convex wheel rocker arm type valve distribution mechanism and matched internal combustion engine

ActiveCN102619583ASimple structureEasy to manufactureValve drivesMachines/enginesExternal combustion engineRadial position

The invention discloses a concave-convex wheel rocker arm type valve distribution mechanism. The concave-convex wheel rocker arm type valve distribution mechanism comprises a cylinder cover, wherein a vertical shaft and two rocker arm frames are arranged on the cylinder cover; a concave-convex wheel is arranged on the vertical shaft; conical teeth are arranged at the top of the concave-convex wheel; conical gears are arranged on the conical teeth and are located on a horizontal shaft; the gear ratio of the conical teeth to the conical gears is 2 to 1; the two rocker arm frames are respectively arranged on two radial positions of the concave-convex wheel; the inclined angle between the two radial positions is 90 DEG; and T-shaped rocker arms are arranged on the rocker arm frames. An internal combustion engine matched with the concave-convex wheel rocker arm type valve distribution mechanism is provided with concave-convex wheel rocker arm type valve distribution mechanisms with the same number as cylinders; the horizontal shafts of the valve distribution mechanisms are integrally connected, are located on shaft frames and are connected with crankshafts through driven chain wheels, chains and drive chain wheels; and the driven chain wheels have the same tooth number as the drive chain wheels. The concave-convex wheel rocker arm type valve distribution mechanism is simple in structure and convenient to manufacture, is reliable in performance and can tightly close and easily open the valve, is less in internal consumption, high in efficiency and more oil-saving, and can fully open the valve for conveniently sucking and exhausting air.

Owner:广西东兴市富佳五金皮具有限公司

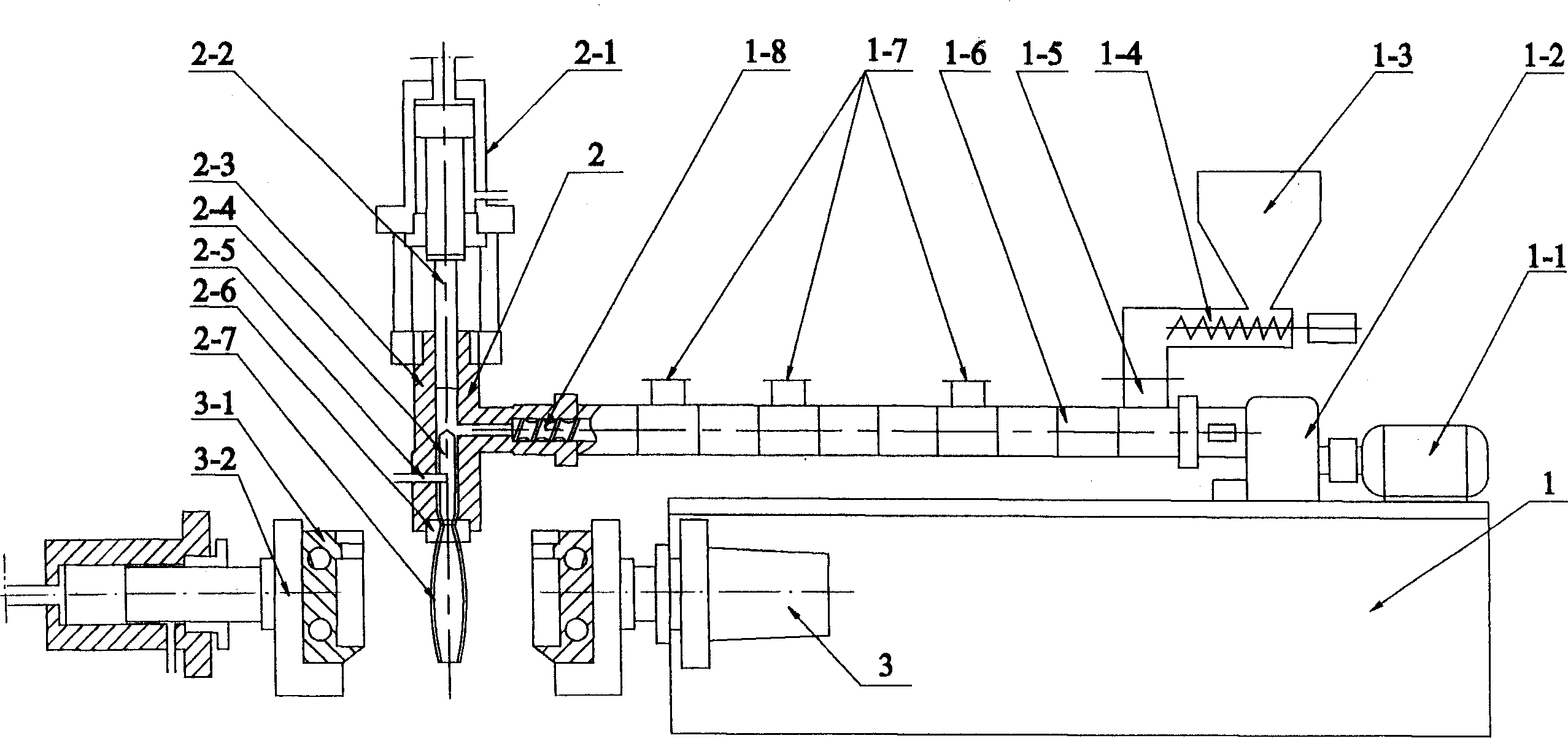

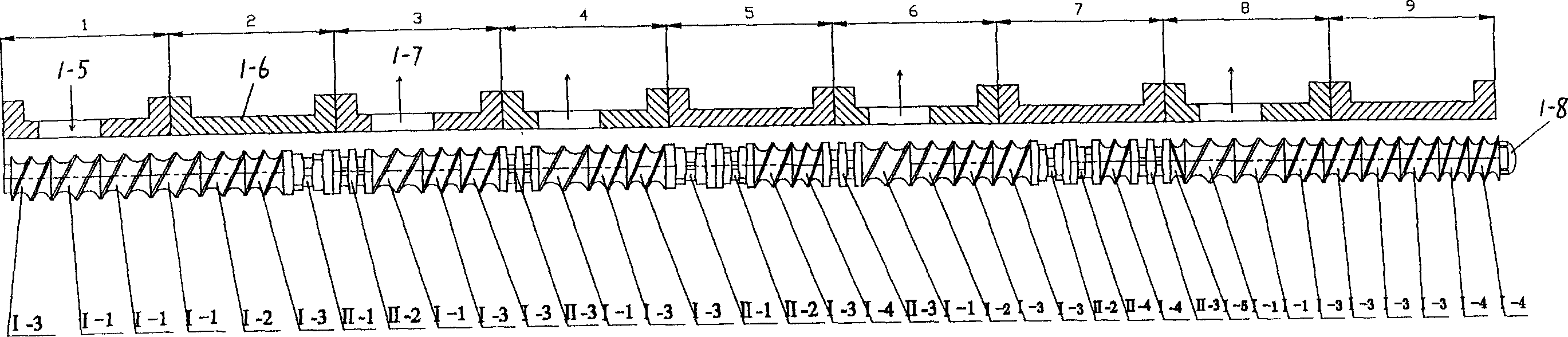

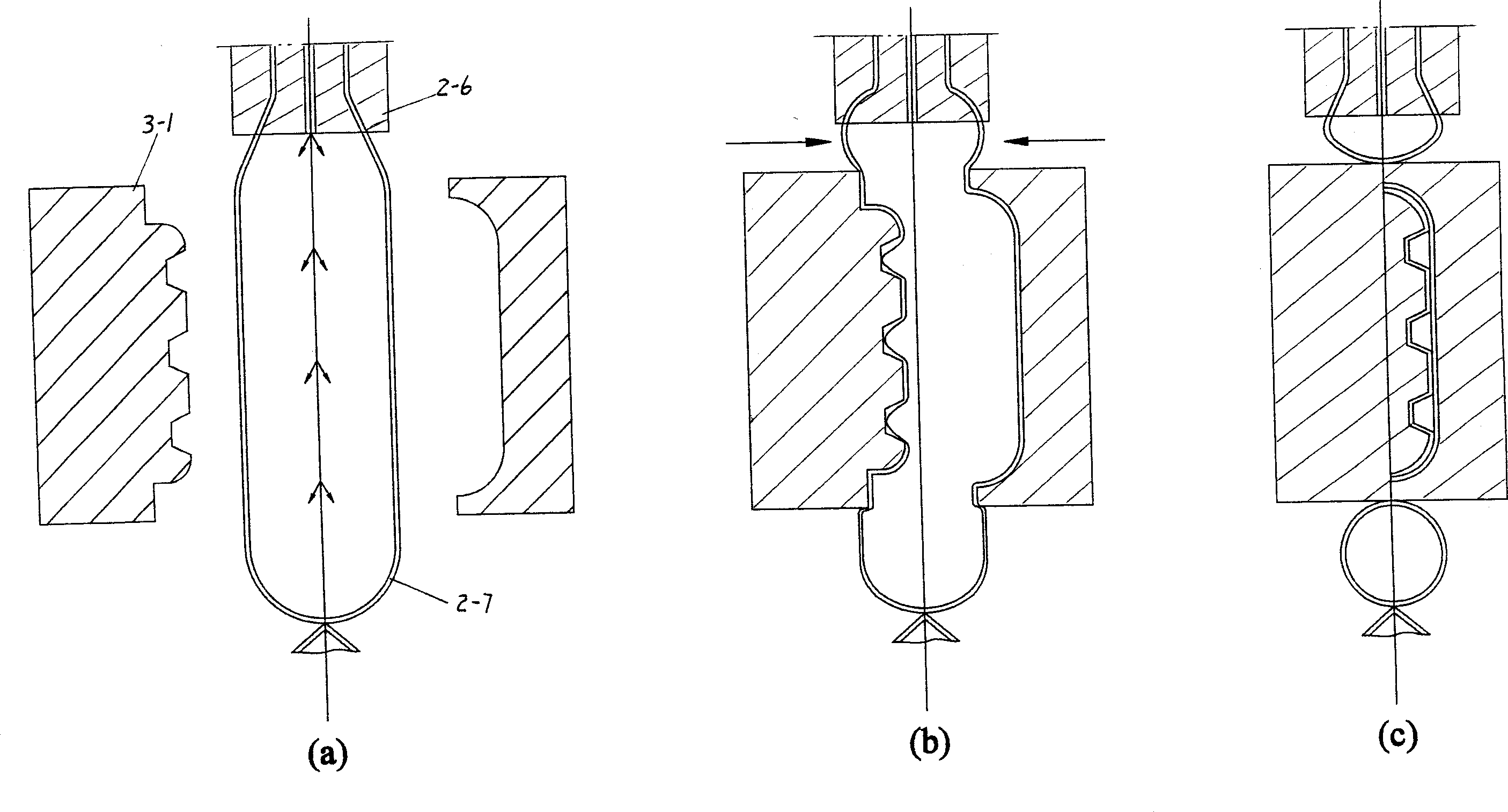

Composite wood-plastic material blow molding machine

The composite wood-plastic material blow molding machine is one parallel double screw extruder provided with storage cylinder and mold closing device. The parallel double screw extruder has outlet communicated with the storage cylinder, and the storage cylinder has outlet over the mold closing device. The composite wood-plastic material blow molding machine has the functions of deairing, mixing, forming at low temperature and low pressure and eliminating residual stress, and is used in forming composite wood-plastic material product in high quality.

Owner:徐凌秀

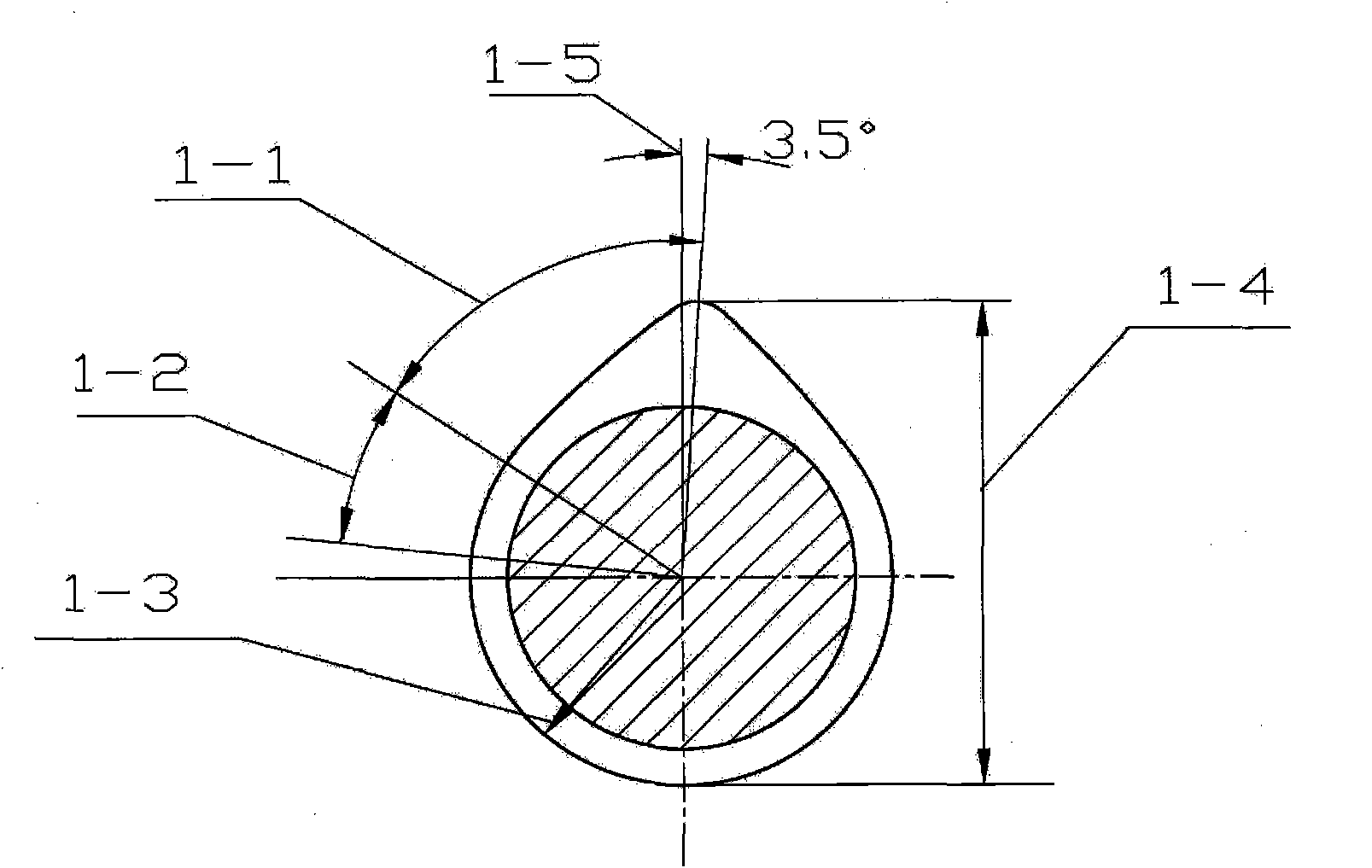

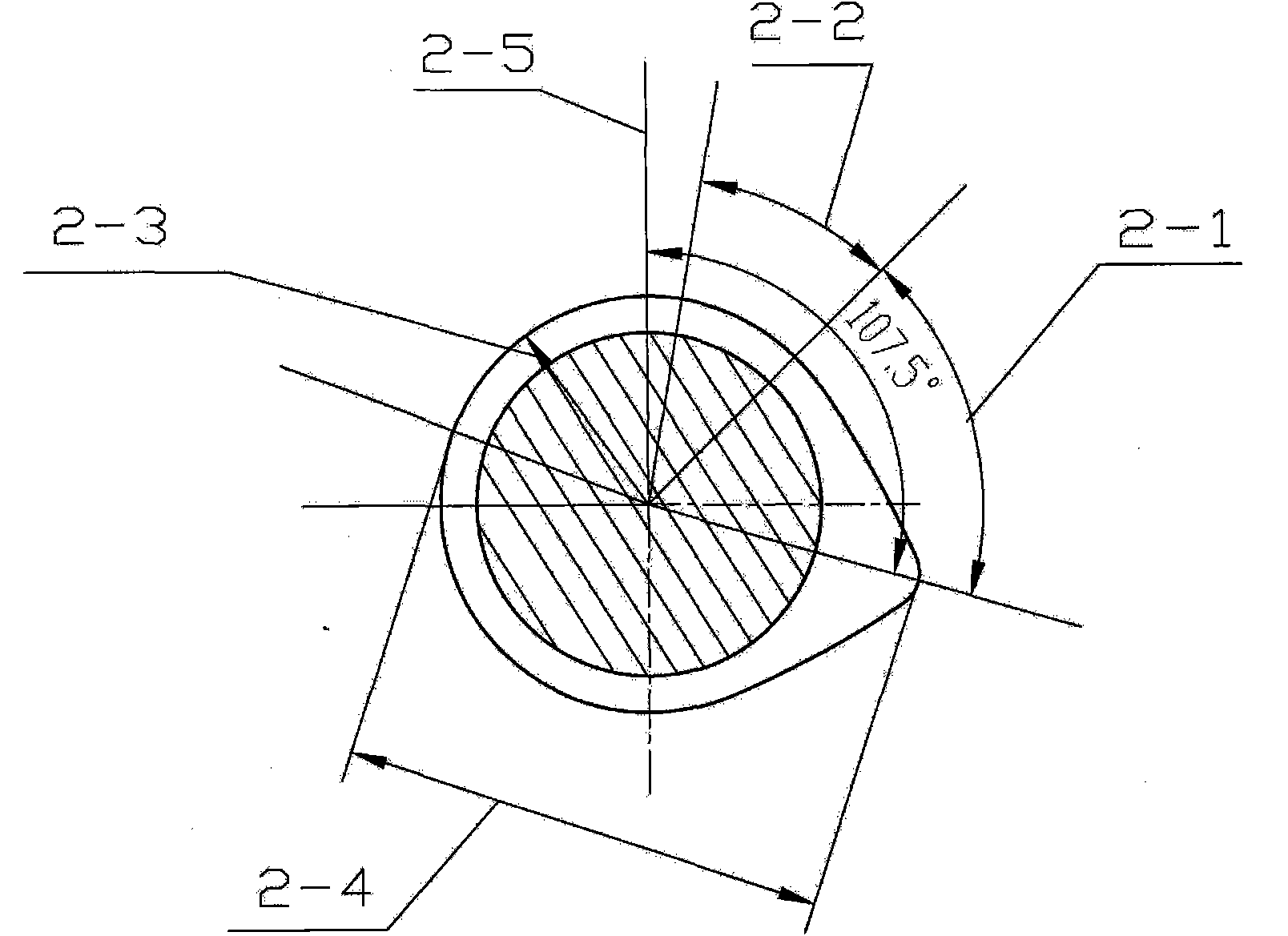

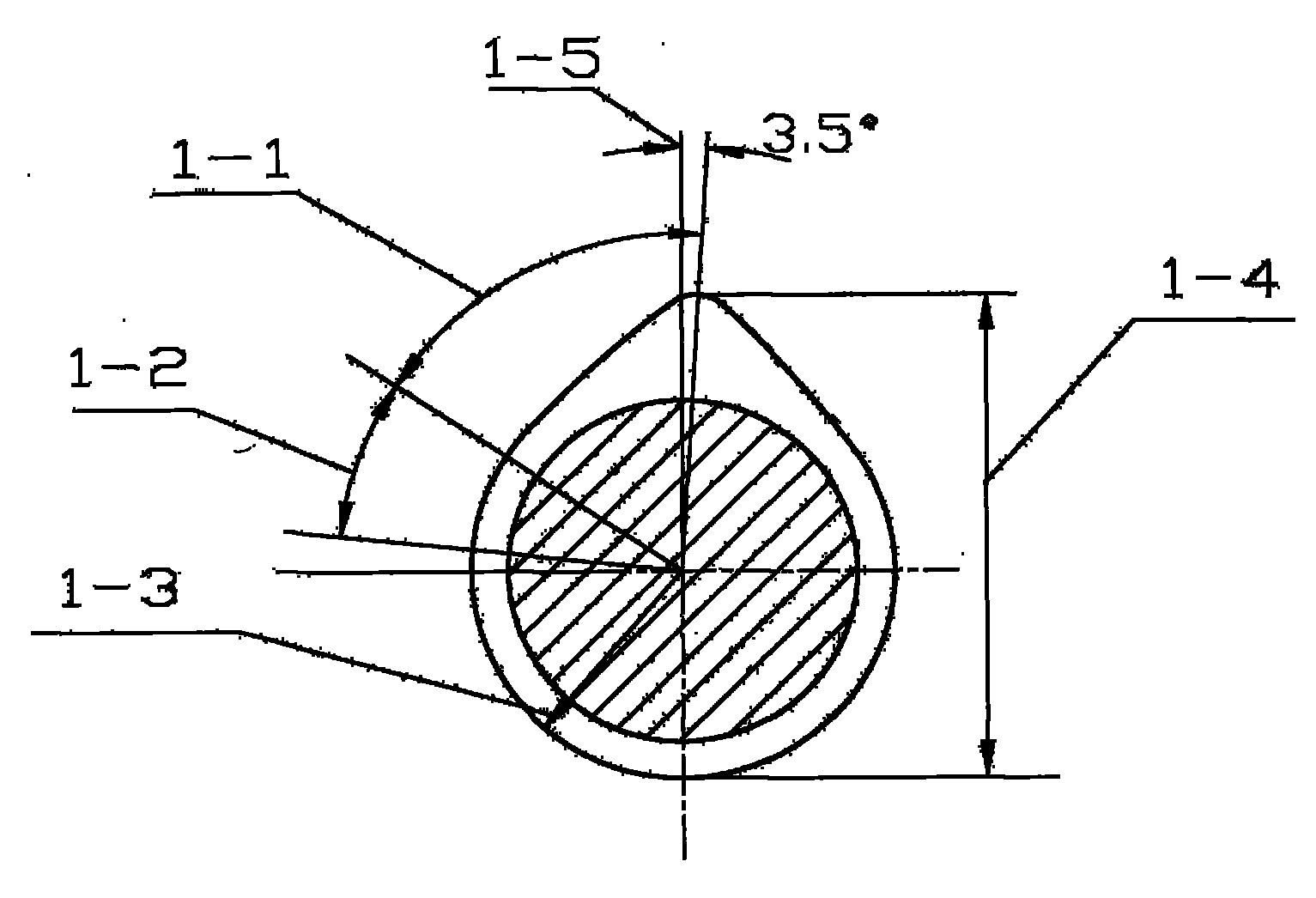

Cam with symmetrical profile lines

The invention relates to a cam with symmetrical profile lines, comprising an intake cam and an exhaust cam. The angle of the working section of the intake cam is 54.2 degrees, the angle of the transition section of the intake cam is 25 degrees, the radius of the arc section of the intake cam is 20.6 mm, the overall height of the profile of the intake cam is 48.09 mm, the angle from the central line of the intake cam to the central line of a key slot is 3.5 degrees, the angle of the working section of the exhaust cam is 60.5 degrees, the angle of the transition section of the exhaust cam is 29 degrees, the radius of the arc section of the exhaust cam is 20 mm, the overall height of the profile of the exhaust cam is 47.916 mm, and the angle from the central line of the exhaust cam to the central line of a key slot is 107.5 degrees. The performance indexes of a diesel engine are improved by improving the profile line of the cam. The rated power of a test diesel engine is 103Kw / 2800r / min, and the power is raised from 88Kw to 103Kw at the same rotating speed; the torque is raised from 343N.m to 385N.m at the same rotating speed and the fuel consumption rate under the rated power is less than or equal to 245g / (Kw.h). Accordingly, the cam with symmetrical profile lines obviously improves the performance of the diesel engine.

Owner:DONGFENG CHAOYANG DIESEL ENGINE

Piston engine valve timing and variable lift driving system

ActiveCN104121054AAvoid damageAvoid failureValve arrangementsMachines/enginesLow speedEffective length

The invention discloses a piston engine valve timing and variable lift driving system. On the basis of the shear thickening fluid critical speed phase change characteristic and the cam speed change curve driving rule, the effective length of a shear thickening tappet changing in the same direction as change of rotation speed of a cam is adaptively obtained according to the change of the rotation speed of the cam (or the rotation speed of an engine), the opening advance angle, the lift and the closing delay angle of a valve are automatically adjusted, and thus the dynamic property, the strengthening degree, the low temperature startability, the low speed stability, the economical efficiency and the exhaust cleanliness of the engine are improved. According to the technical scheme, the system is free of electronic control, simple in mechanical structure, reliable in work, convenient to arrange, low in cost, easy to maintain, smooth in engine power output and capable of being widely applied to driving valves of various piston engines.

Owner:范永建

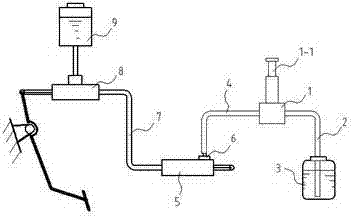

Exhaust method of hydraulic operation system of vehicle clutch

The invention discloses an exhaust method of a hydraulic operation system of a vehicle clutch; the method solves the problem of difficult exhaust of gas in the hydraulic operation system of the vehicle clutch; the exhaust method applies an oil conveying pump of a diesel engine; an oil sucking port of the oil conveying pump is tightly connected with an oil sucking pipe, and is inserted into a brake liquid bottle; an oil outlet is tightly connected with an oil outlet pipe, and is inserted on a unscrewed air release screw plug of a separate pump booster; then, a hand oil pump on the oil conveying pump is pressed; brake liquid in the brake liquid bottle upwards enters a clutch oil storage tank by an oil pipe to exhaust air in a pipeline system from the oil storage tank; and after the brake liquid in the oil storage tank reaches the oil level and has no bubbles, the air in the pipeline system is totally exhausted. The exhaust method applies the oil conveying pump of the diesel engine to pump the brake liquid in the operation process, exhausts in the gas flowing direction from low place to high place, and has such characteristics as simple method, quick exhaust and thorough exhaust.

Owner:JIANGXI COPPER

Control method of intelligent pulping and grouting system

ActiveCN103711316AExhaust thoroughlyPrecise pressure controlBuilding material handlingLow speedPre stress

A control method of an intelligent pulping and grouting system includes a weighting step, a step of setting weights of water, auxiliary material and main material, a step of controlling adding the water, auxiliary material and main material, a step of controlling the high speed stirring time, and a step of controlling the low speed stirring time; setting standard low speed stirring time; when the low speed stirring time is equal to the standard low speed stirring time, allowing a control center to sending signals for stopping low speed stirring; an automatic grouting step; when the pressure maintaining time reaches a standard value of the constant pressure time, allowing the control center to store grouting data automatically and generate grouting trend curves automatically. The control method has the advantages that pressure can be controlled accurately, gas in pipelines can be exhausted thoroughly, filling and compaction of grouting can be guaranteed, the whole grouting process is controlled through the computer control center, loading is performed automatically according to the preset proportion, pulping and grouting are performed automatically, and grouting data are recorded automatically.

Owner:LIUZHOU QIAN BRIDGE ENG MATERIALS

Air blowing pre-ventilation device of injection blowing molding machine

The invention provides an air blowing pre-ventilation device of an injection blowing molding machine, which belongs to the technical field of thermoplastic molding, and solves the problem that the exhausting of the existing air blowing pre-ventilation device of the injection blowing molding machine is not complete, and thus a product is easy to crack and deform. The air blowing pre-ventilation device provided by the invention comprises a double-diameter air cylinder comprising a cylinder body; the cylinder body is provided with a cavity I and a cavity II, which are communicated with each other; the diameter of the cavity I is more than that of the cavity II; the cavity I and the cavity II are internally and respectively provided with a piston I and a piston II, which are respectively matched with the cavity I and the cavity II; and the outer side of the piston II is communicated with the outer side of the cylinder body. The air blowing pre-ventilation device of the injection blowing molding machine has the advantages of short air exhausting time and more complete air exhaustion.

Owner:ZHEJIANG SHUOKANG PACKING

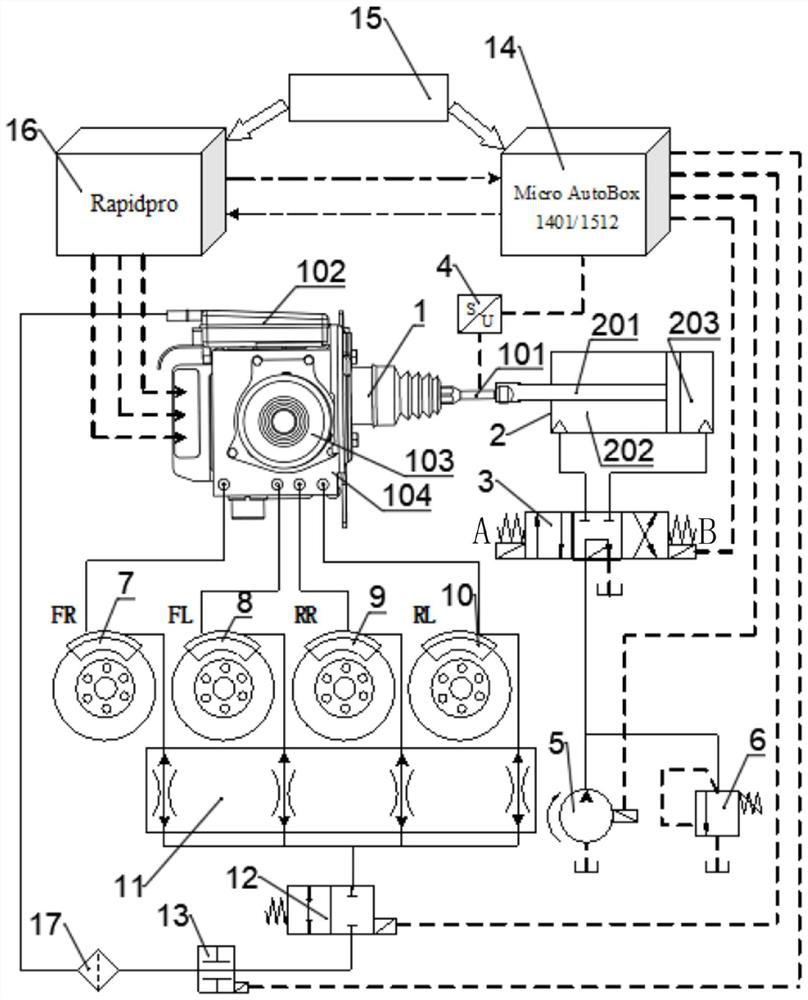

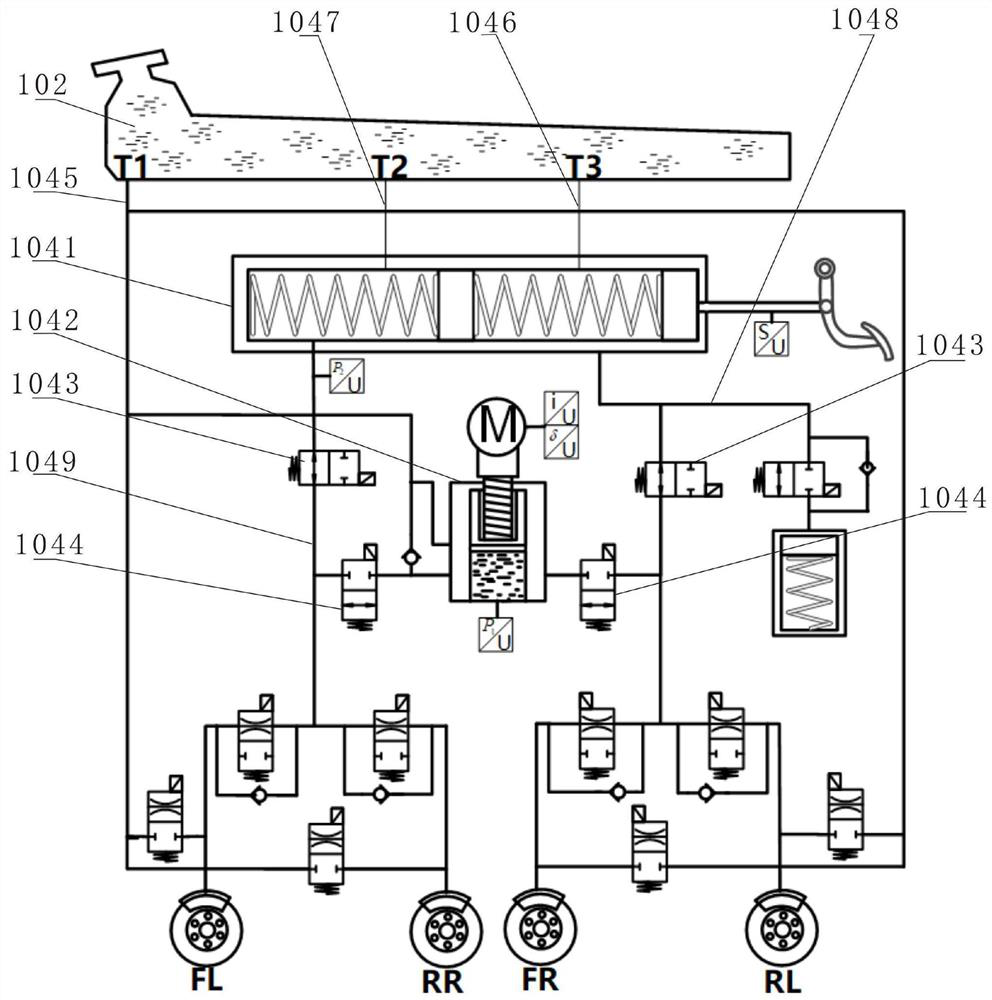

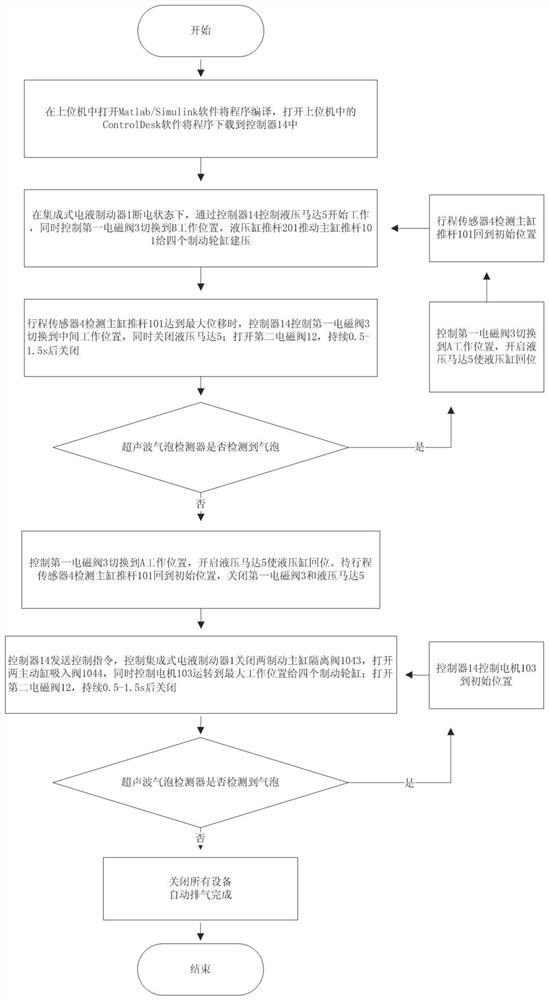

Automatic exhaust device and method for integrated electro-hydraulic brake system

PendingCN112693440APrevent system overloadImprove securityAir treatment devicesBrake safety systemsElectric machineryAutomotive engineering

The invention discloses an automatic exhaust device of an integrated electro-hydraulic brake system, which comprises an integrated electro-hydraulic brake, a hydraulic cylinder, a first electromagnetic valve, a travel sensor, a hydraulic motor, a brake wheel cylinder, a flow distributing and collecting valve, a second electromagnetic valve, a bubble detector and a controller, the integrated electro-hydraulic brake comprises a hydraulic unit, a liquid storage tank, a main cylinder push rod and a motor, a brake master cylinder, a master cylinder, a plurality of integrated electro-hydraulic brake electromagnetic valves and a hydraulic pipeline are integrated in the hydraulic unit, and the brake master cylinder and the master cylinder are decoupled. The invention further discloses an automatic exhaust method of the integrated electro-hydraulic brake system. Aiming at the problem that air in a hydraulic pipeline is difficult to exhaust completely due to decoupling of a brake main cylinder and a driving cylinder of an integrated electro-hydraulic brake system, automatic and thorough exhaust of the integrated electro-hydraulic brake system is realized by controlling a hydraulic cylinder, a motor and an integrated electro-hydraulic brake electromagnetic valve; and a perfect solution is provided for automatic exhaust of a completely-decoupled integrated electro-hydraulic brake system.

Owner:JILIN UNIV

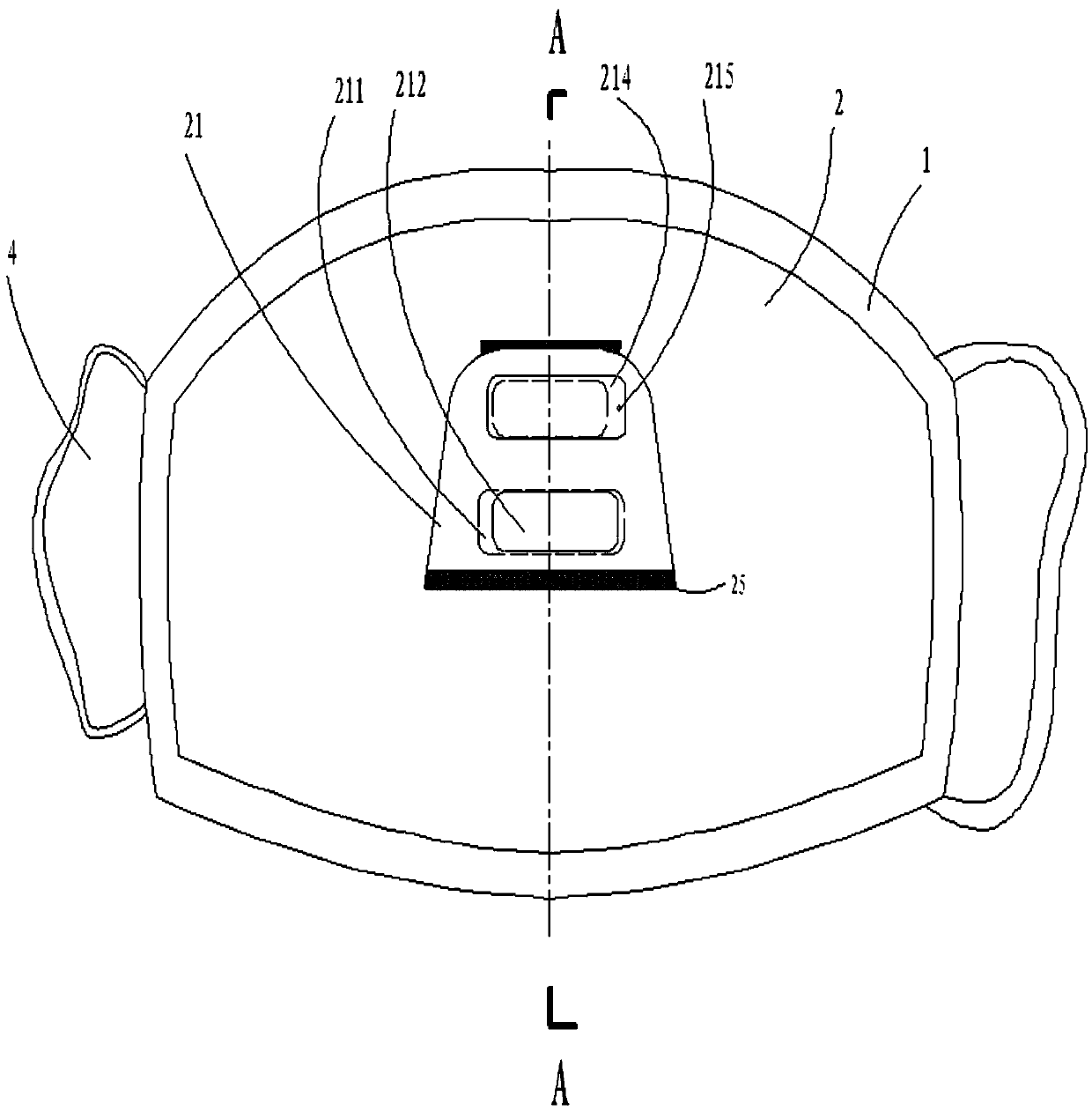

Dust-proof filter mask

InactiveCN103585722AKeep healthyCompact structureFire rescueRespiratory apparatusInhalationRespirator

The invention discloses a dust-proof filter mask which comprises a mask body and fixing bands. The mask body and the fixing bands are connected. The mask body comprises a breathable outer layer, a filter layer and an inner layer, the breathable outer layer, the filter layer and the inner layer are connected in sequence from outside to inside, the inner layer comprises an edge part and a middle part which are connected with each other, the middle part comprises an upper flat plate body, the upper flat plate body corresponds to the position of the nostrils, a nostril air inlet one-way valve is arranged on the upper portion of the upper flat plate body, and a nostril air outlet one-way valve is arranged on the lower portion of the upper flat plate body. The nostril air inlet one-way valve comprises a nostril air inlet valve groove and an air inlet rectangular hole which are matched with each other, the air inlet rectangular hole is covered with a nostril air inlet valve sheet, the nostril air outlet one-way valve comprises an air outlet valve groove and an air outlet rectangular hole, the air outlet rectangular hole is covered with a nostril air outlet valve sheet, and the air outlet valve sheet is connected with the air outlet valve groove in the left side or the right side of the air outlet rectangular hole. The dust-proof filter mask is low in inhalation and exhalation resistance and suitable for being used by a wearer requiring the mask with a plurality of layers and the large inhalation resistance of the mask, and guarantees the body health of a user.

Owner:张秀霞

Lead-acid storage battery cover

ActiveCN104393213AGuaranteed safe operationAvoid bloatingCell sealing materialsAtmospheric pressureElectrical and Electronics engineering

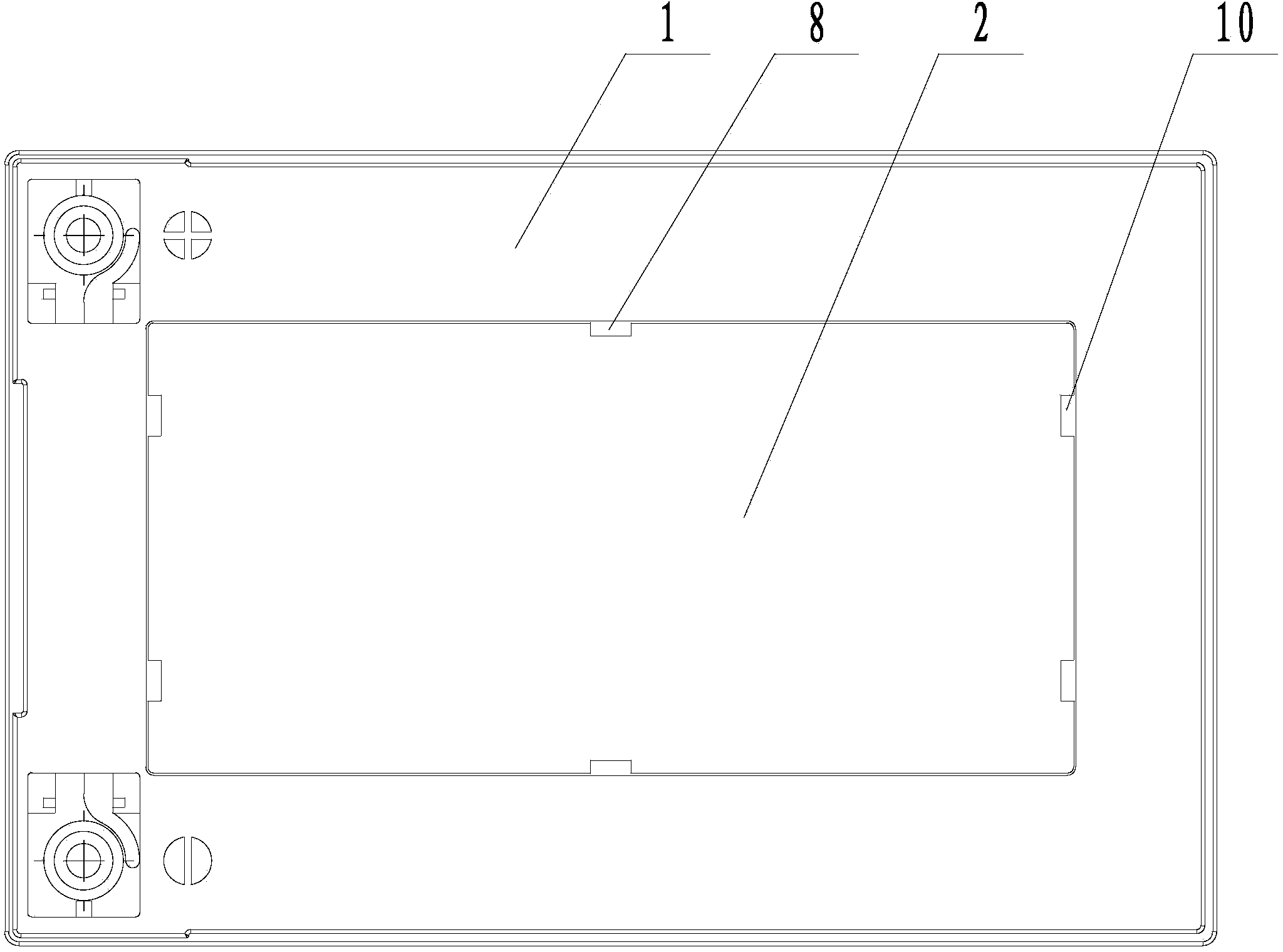

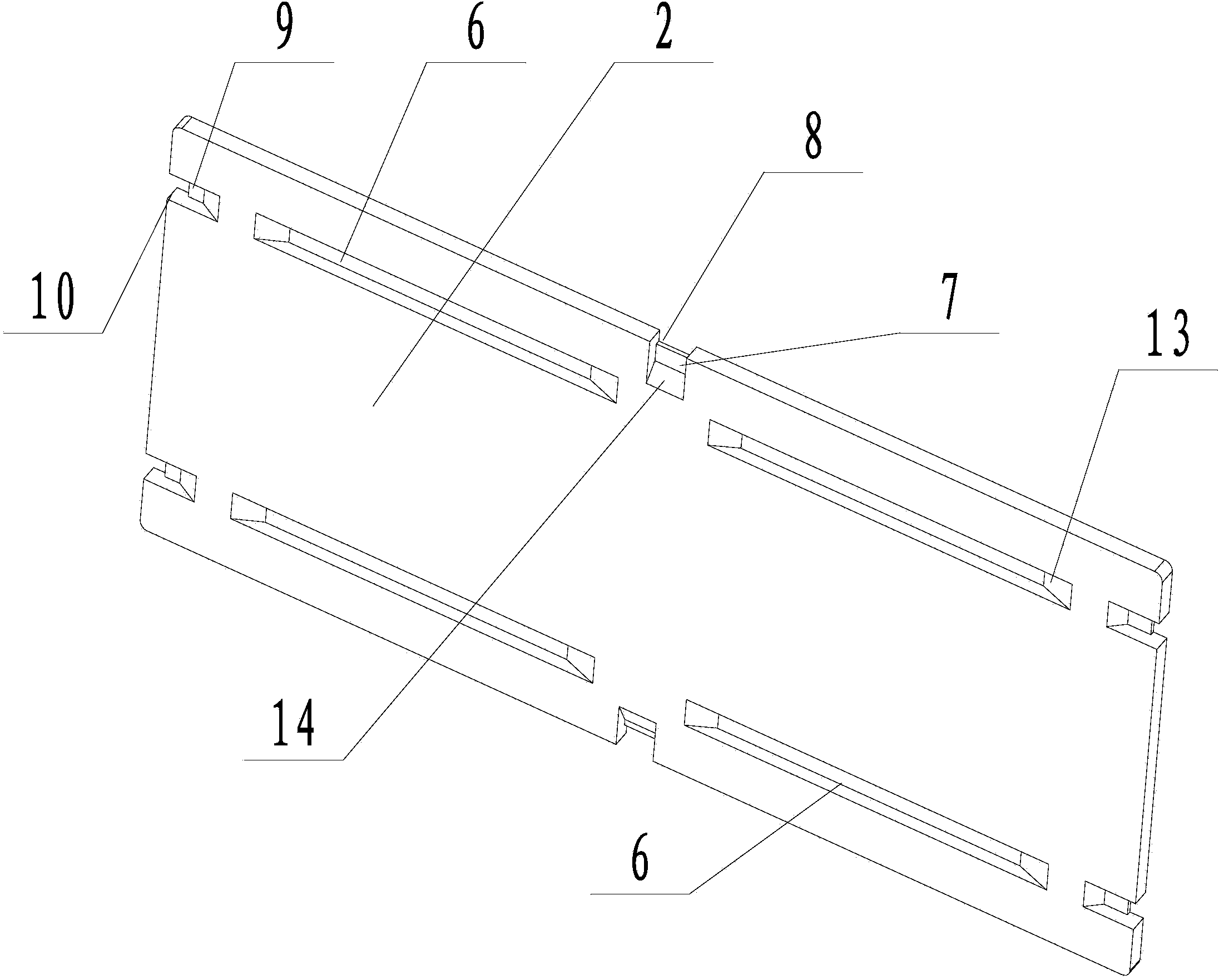

The invention discloses a lead-acid storage battery cover and aims at solving the defect that a storage battery is expanded, and even burst in a serious condition, as the gas inside a storage battery cannot be immediately discharged and the air pressure of the interior of the storage battery is increased because a glue is easy to block an exhaust passage when a cover sheet is adhered on a cover body. The lead-acid storage battery cover comprises a cover body and a cover sheet, wherein a cover sheet mounting slot is formed in the upper end face of the cover body, a plurality of rows of accommodating slotted holes are formed in the bottom of the cover sheet mounting slot, the interior of each accommodating slotted hole is provided with an injection hole, the cover sheet is adhered in the cover sheet mounting slot, an air discharge duct is arranged between every two adjacent accommodating slotted holes in the same row, the air discharging ducts are formed in the lower end face of the cover sheet, two ends of each air discharging duct are respectively communicated with the two adjacent accommodating slotted holes, a long-side air discharging groove is arranged between every two adjacent air discharging ducts in the same row in the lower end face of the cover sheet and is arranged at the edge of the cover sheet, and long-side air outlets communicated with the long-side air discharging grooves are formed in the position, close to the long-side air discharging grooves, of the edge of the cover sheet.

Owner:ANHUI YONGHENG STORAGE BATTERY

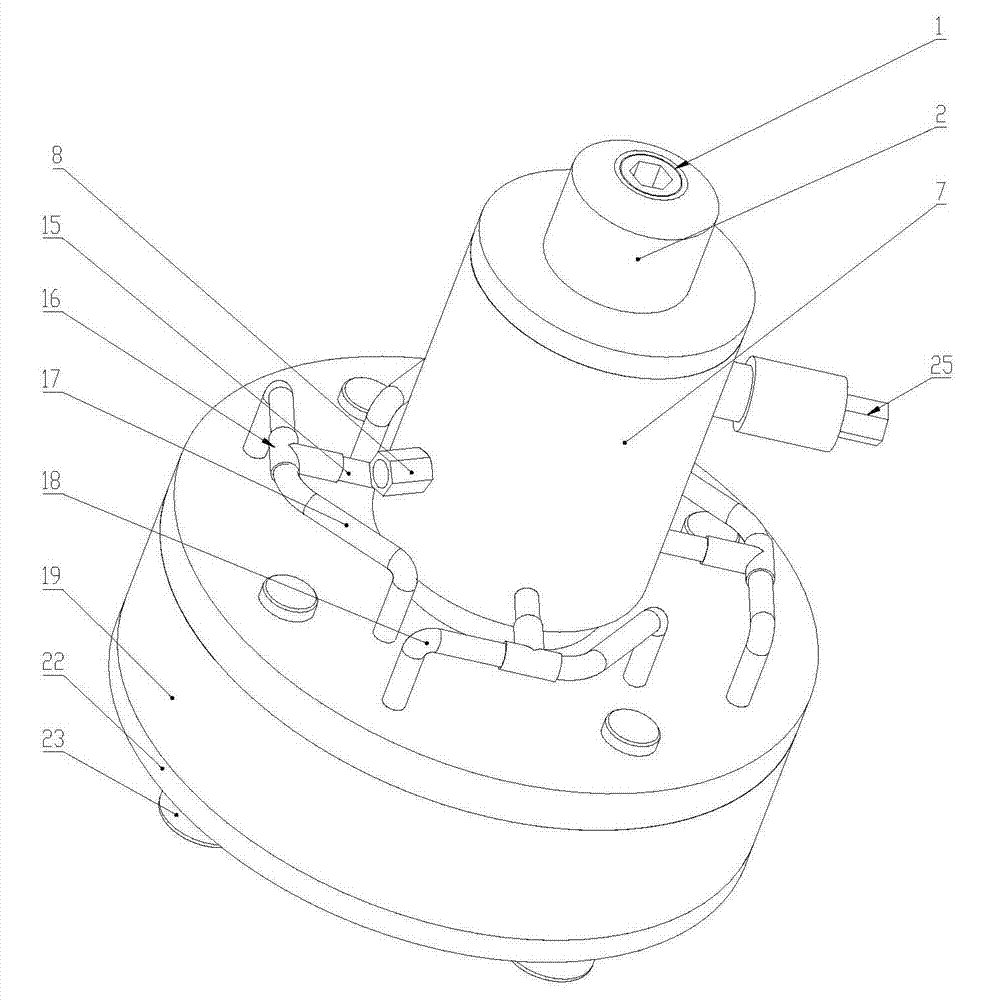

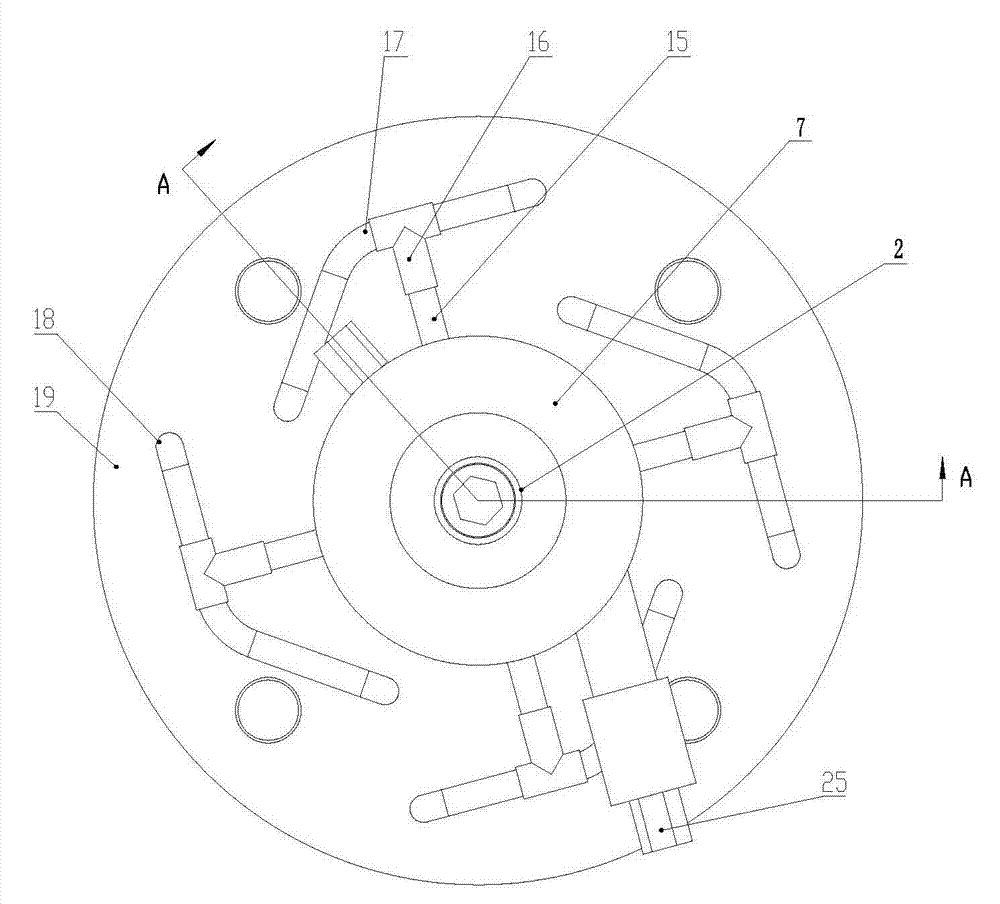

Swing arm rotation type compressor

InactiveCN103114997AReduce friction lossReduce leakageOscillating piston pumpsOscillating piston liquid enginesRotary valveMoving parts

The invention discloses a swing arm rotation type compressor which comprises a housing, a main shaft and an air guide pipe for communicating a two-stage compression chamber with an air inlet cavity or an air outlet cavity of a rotary valve, wherein the upper end surface of the housing is covered with an upper bearing sealing seat with a gland; an eccentric shaft section is formed in the middle of the main shaft; the inner circle of a rotary sleeve arranged in an inner cavity of the housing is connected with the eccentric shaft section of the main shaft through a sleeve bearing; the main shaft on the upper side and the lower side of the rotary sleeve is connected with the upper bearing seat and the housing through a pair of upper and lower rolling bearings; the rotary valve with the air inlet cavity and the air outlet cavity is arranged on the main shaft on the outer side of the upper bearing; the rotary valve is axially fixed by a locking nut through a valve plate and a gasket; an air inlet connector communicated with the air inlet cavity of the rotary valve and an air outlet connector communicated with the air outlet cavity of the rotary valve are arranged on the outer wall of the upper bearing seat; multiple sets of swing arm mechanisms contacted with the outer circle of the rotary sleeve are arranged along the inner circumferential direction of the housing; and the swing arm mechanisms, the housing, the rotary sleeve and the upper bearing seat form the two-stage compression chamber. According to the swing arm rotation type compressor, the functions of air suction, compression, air discharge and residual air expansion can be effectively achieved, multiple times of sequential compression operation can be finished by rotating the main shaft for a circle, the two-stage compression operation can be performed in each compression process, and the compressor is very small in frictional loss between moving parts, energy-saving, efficient and wide in application range.

Owner:SHENZHEN SAILANGKEN SCI & TECH

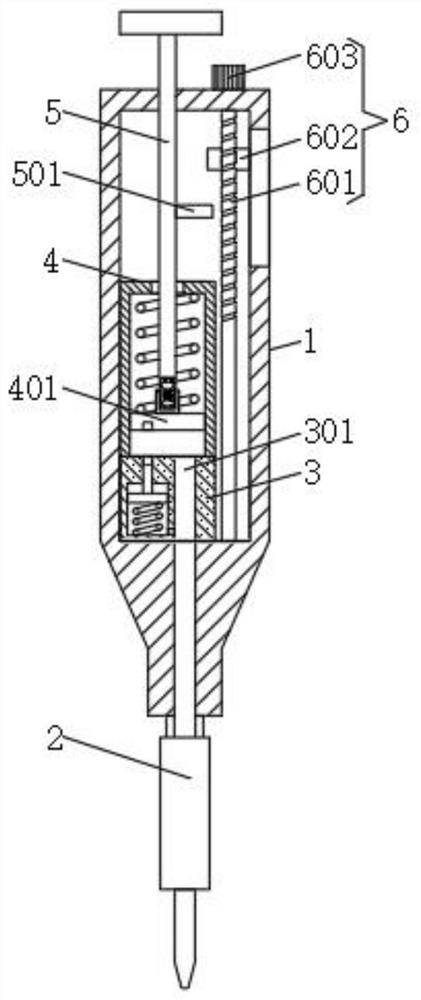

Delayed pressure supplementing pipettor for biomedical laboratory

The invention relates to the field of biomedical experiment instruments, and discloses a delayed pressure supplementing pipettor for a biomedical laboratory. The delayed pressure supplementing pipettor comprises a pipettor tube body, the bottom of the pipettor tube body is communicated with a pipetting needle tube, and the bottom of the inner cavity of the pipettor tube body is provided with a positioning pressure supplementing tube; a through groove communicated with the pipetting needle tube is formed in one side of the positioning pressure supplementing tube, and an inner groove is formed in the other side of the positioning pressure supplementing tube. According to the delayed pressure supplementing pipettor for the biomedical laboratory, through the structural design of the positioning pressure supplementing tube below the negative pressure suction tube, in cooperation with a self-rotating connecting mechanism between a push shaft and a pressure pumping piston, in the process thatthe pipettor is used for quantitatively transferring a solution, an upper magnetic plate is used for acting on a lower magnetic plate firstly, so that the lower magnetic plate moves downwards; and after the upper magnetic plate rotates to the other side, the lower magnetic plate moves upwards and resets under the action of the elastic force, and thus the exhaust is more thorough before the solution is extracted, and the accuracy of the solution transfer amount is improved.

Owner:重庆市开州区华兰生物单采血浆有限公司

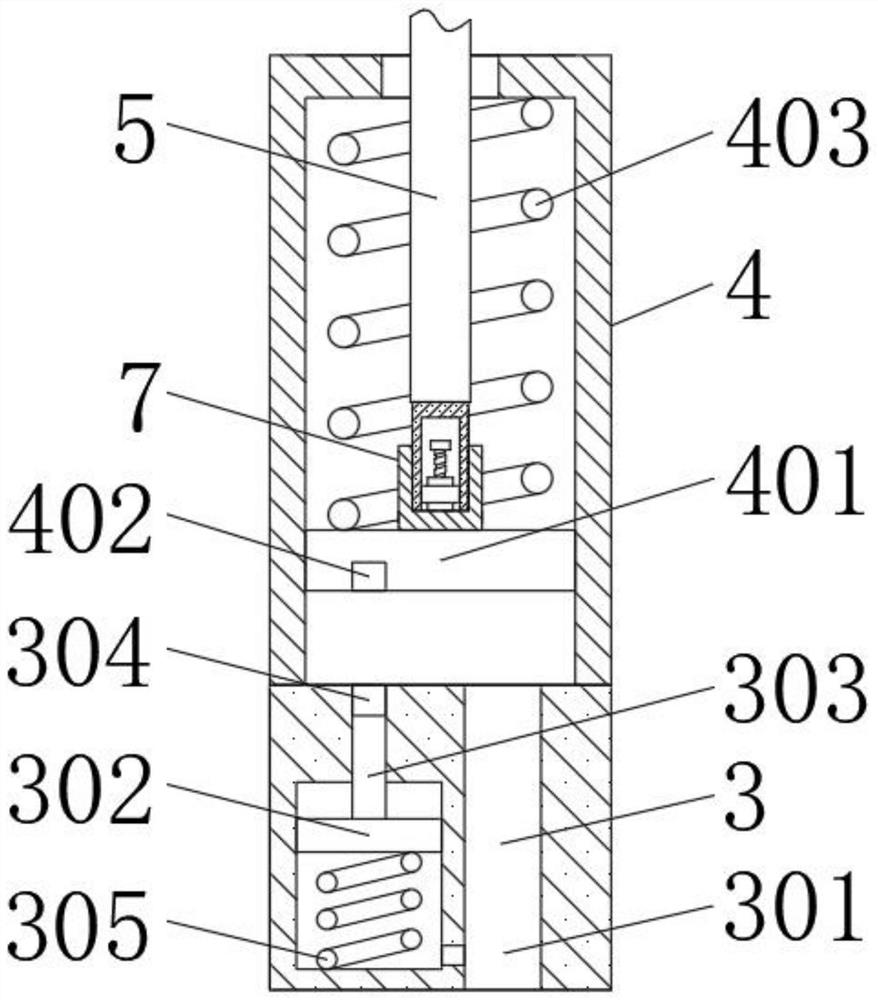

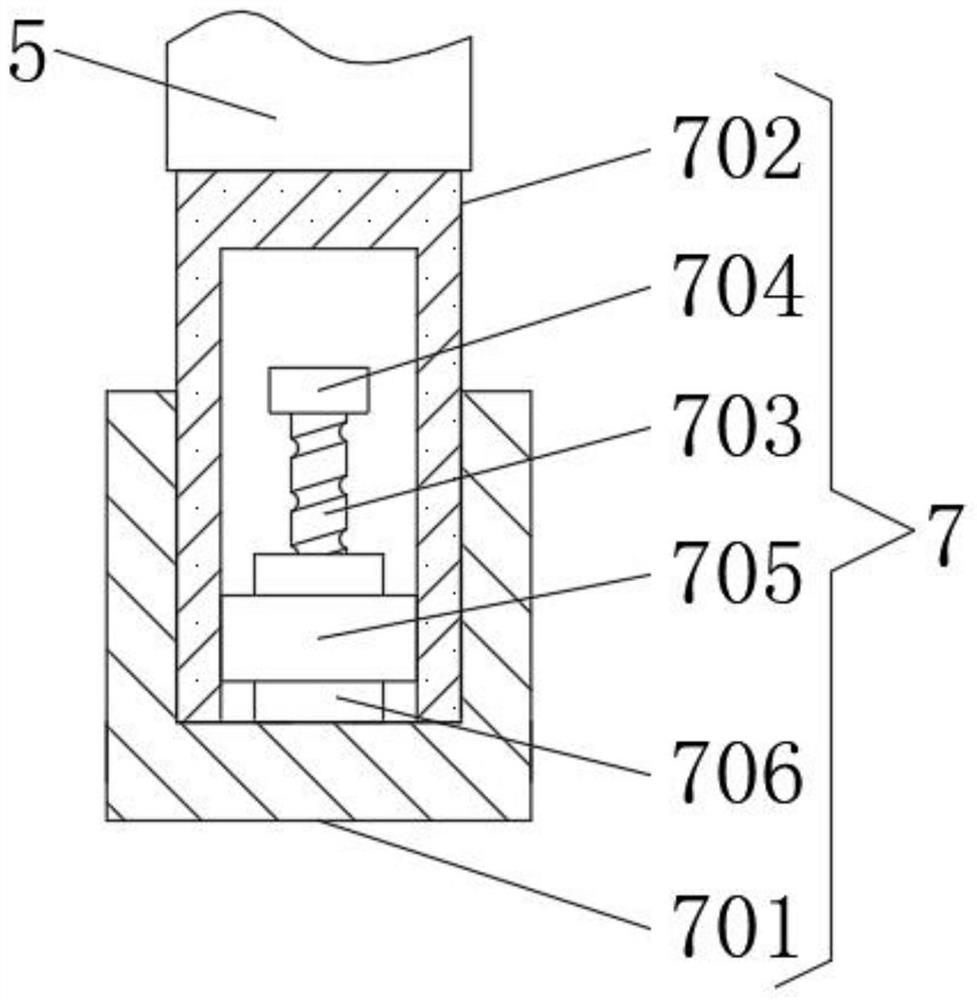

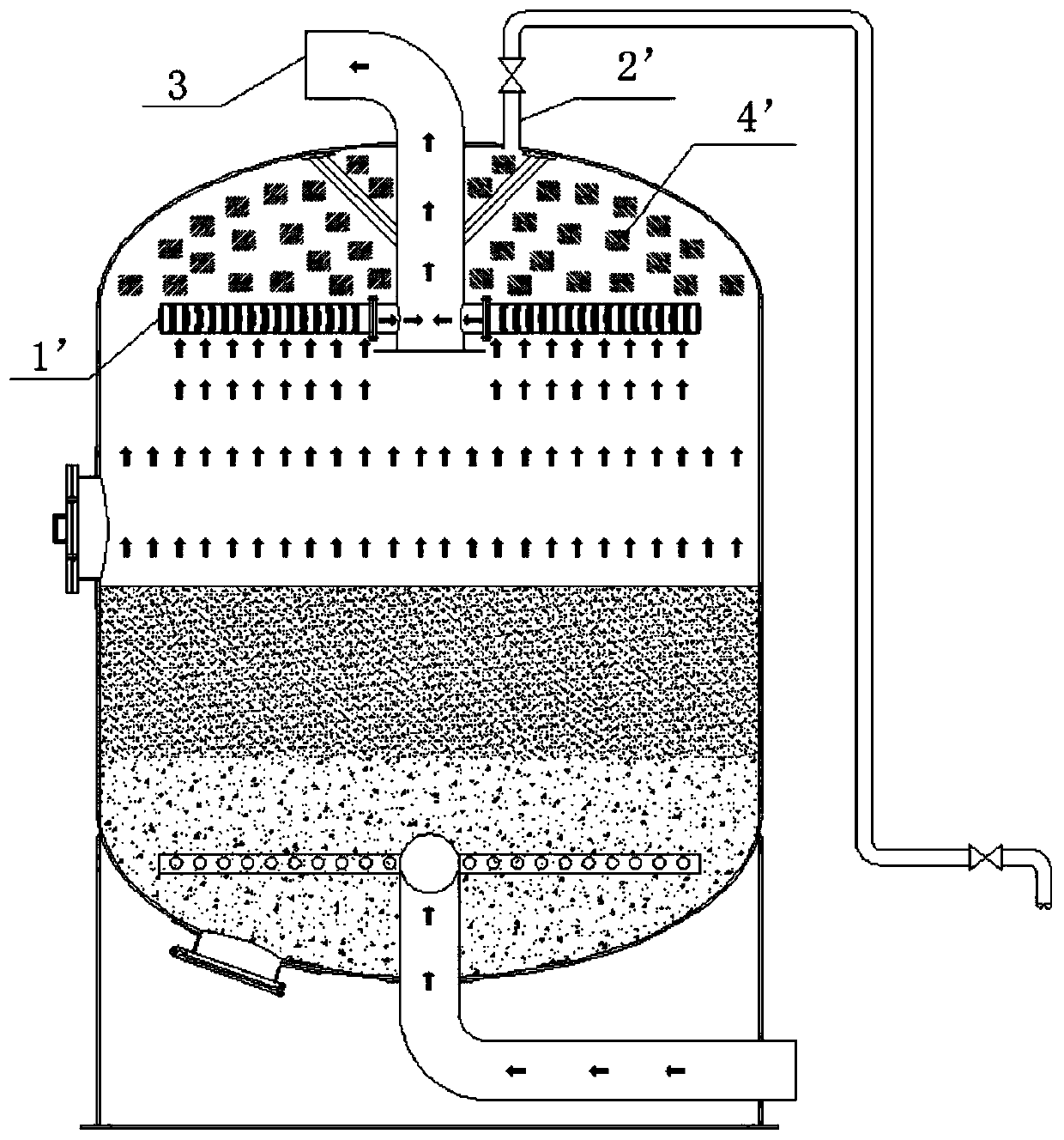

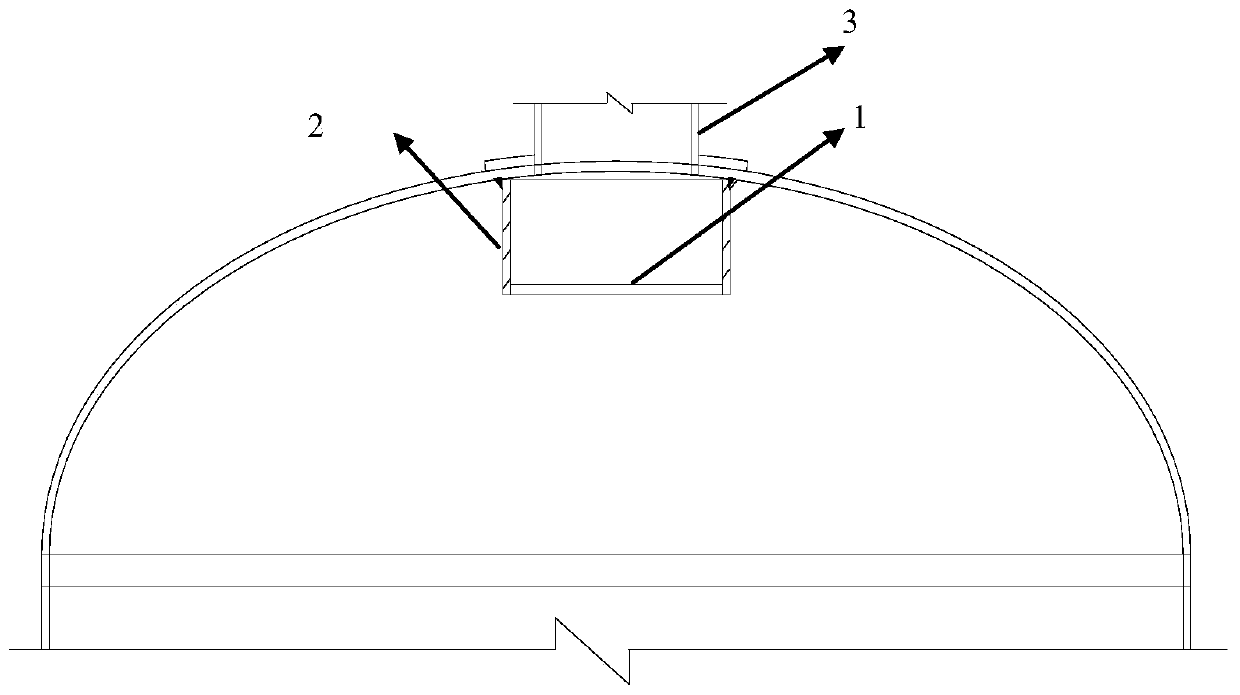

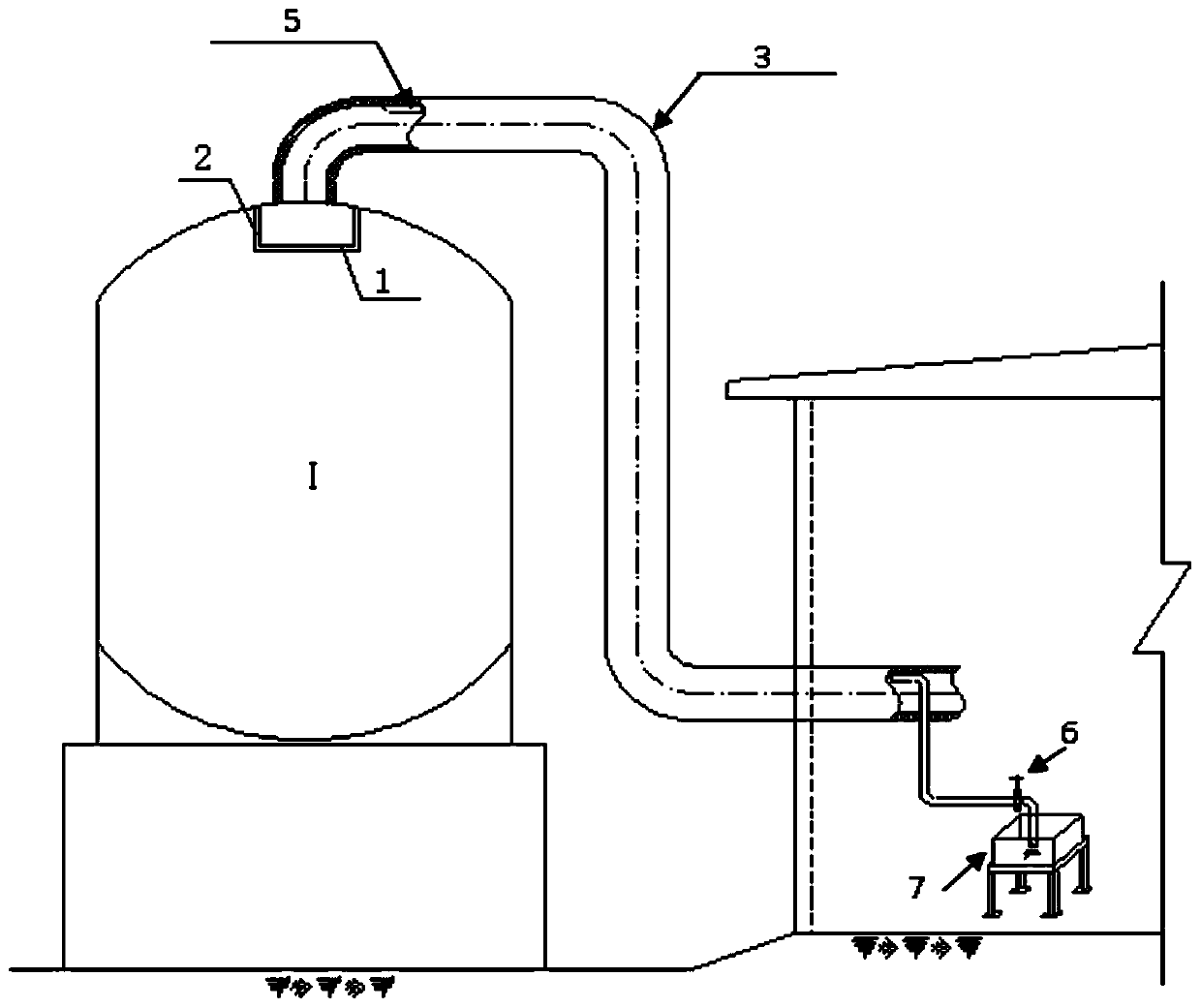

Water distribution and exhaust device for pressure filtration tank, pressure filtration tank and water distribution and exhaust method

PendingCN110694314ASimple structureReduce manufacturing costWaste water treatment from quariesTreatment involving filtrationFiltrationOil field

The invention discloses a water distribution and exhaust device for a pressure filtration tank, the pressure filtration tank and a water distribution and exhaust method. The water distribution and exhaust device comprises a water distribution structure and an exhaust structure; the water distribution structure is arranged at the top end of the interior of a pressure filtering tank, and is composedof a bottom blocking plate and side blocking plates; a cylinder with an upper opening and a lower opening is formed by the side blocking plates; a plurality of through holes are uniformly distributedin the surface of the cylinder; the bottom blocking plate is arranged at the bottoms of the side blocking plates, and a container with an upper opening and a sealed bottom is formed by the bottom blocking plate and the side blocking plates; the upper opening of the side blocking plates and an top end opening of the pressure filtering tank are in sealing connection, and is communicated with a filtering inlet water dry pipe arranged at the top end opening of the pressure filtering tank. The water distribution and exhaust device is low in manufacturing cost; no blockage is caused, no pressure build-up is induced, no dead water area is formed, uniform water distribution is achieved, thorough exhaust is achieved, no freezing during operation in winter is caused, the treatment efficiency of oilfield pressure filter tanks is improved, and the service life is prolonged.

Owner:DAQING OILFIELD CO LTD +1

Waterproof hammer air valve and waterproof hammer exhaust method during use of pipeline

ActiveCN104896184BEliminate water hammer on valve closingStructure sensitiveValve members for absorbing fluid energyPipe elementsWater hammerValve opening

The invention discloses a water hammer air valve and a water hammer gas discharging method during pipeline use. The water hammer air valve comprises a valve body, a bonnet and a protective cover, wherein the bonnet is provided with an opening, the protective cover is disposed on the opening, the valve body is provided with a valve opening for being communicated with a pipeline, a high-speed gas feeding and discharging device which is used for discharging gases stayed in the pipeline during water filling to the outside and shutting down the valve after pipeline water filling is completed is disposed in the inner cavity of the valve body, the output end of the high-speed gas feeding and discharging device is communicated with the outside through the opening of the bonnet, and the valve opening of the valve body is communicated with a bottom gas discharging throttling device for limiting the gas displacement of the pipeline to the inner cavity of the valve body; a trace gas discharging device for discharging mixed, residual and / or precipitated gases in the pipeline to the outside through the opening of the bonnet after the high-speed gas feeding and discharging device shuts down the valve is further disposed in the high-speed gas feeding and discharging device. By the water hammer air valve, water hammer reduction and pipeline safety protection are achieved, blowing blocking during high-speed gas discharging is avoided, and valve closing water hammer is eliminated.

Owner:ZHUZHOU SOUTHERN VALVE

Two-stroke engine

The invention provides a two-stroke engine. A piston is arranged between two air cylinder guide rails, piston grooves are formed in the air cylinder guide rails, and the piston slides along the air cylinder guide rails. An air cylinder is arranged in the piston and fixed to the air cylinder guide rails through openings of the piston grooves, and the air cylinder is matched with the air cylinder guide rails to divide an inner cavity of the piston into two independently sealed air chambers; the two opposite sides, located on the two air chambers, of the air cylinder are respectively provided with a groove, an air inlet channel, an ignition placement channel, an air inlet valve placement channel, an air exhaust channel and an exhaust valve placement channel are arranged between the side walls of the grooves and the air cylinder guide rails, an air inlet valve is arranged in the air inlet valve placement channel, an ignition device is arranged in the ignition placement channel, and an exhaust valve is arranged in the exhaust valve placement channel. The power of the working volume of the air cylinder is higher, air inlet is full, exhaust is complete, and fuel is saved; ignition efficiency is high, the spreading speed of sparks is high, lubricating and cooling are easier to conduct, machine oil consumption is small, mechanical loads and thermal loads are small, and the service life of the engine is longer.

Owner:张雨

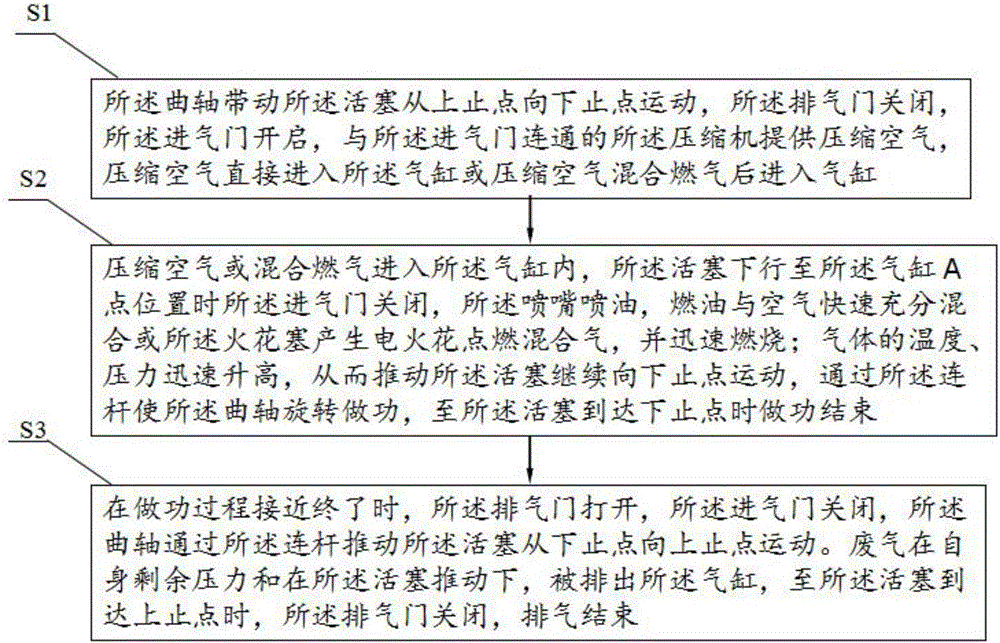

Two-stroke engine transformed from four-stroke engine and working method of two-stroke engine

InactiveCN105927378AImprove powerImprove efficiencyInternal combustion piston enginesCombustionFour-stroke engine

The invention relates to a two-stroke engine transformed from a four-stroke engine. Compared with a traditional multi-stroke engine, the method that the inlet gas is compressed externally is adopted, so that the compression stroke of the engine is omitted, and accordingly the four-stroke engine has the possibility of the two-stroke mode. Compared with the four-stroke engine, two strokes are omitted, so that the power performance is better, the structure is simple, the size is small, and the weight is low; compared with the traditional engine, the compression stroke is omitted, advanced ignition is not needed, and therefore the knocking phenomenon is eliminated; and the independent combustion chamber space is omitted, exhaust is thorough, and the combustion efficiency is substantially improved.

Owner:苏喜清

A car engine exhaust waste heat boosting drive system

InactiveCN103978897BExhaust thoroughlyIncrease output powerAuxillary drivesInternal combustion piston enginesImpellerInternal combustion engine

The invention discloses an exhaust gas residual heat boosting driving system for an automobile engine. The exhaust gas residual heat boosting driving system comprises a boiler, a driving impeller and a temperature switch, wherein the chamber inlet end of the driving impeller is communicated with a gasifying pot of the boiler through a main pipeline; the chamber outlet end of the driving impeller is communicated with the inlet end of a condenser; one outlet end of the condenser is communicated with the inlet end of a gravity pressure water tank through a pipeline; the other outlet end of the condenser is communicated with the main pipeline through a bypass pipeline; the outlet end of the gravity pressure water tank is communicated with a preheating pot of the boiler; a cut-off electromagnetic valve is arranged on the main pipeline, a pipeline between the driving impeller and the condenser, and a pipeline between the outlet end of the gravity pressure water tank and the preheating pot respectively; a driving device is arranged on the top of the gravity pressure water tank; all the cut-off electromagnetic valves and a pressure switch arranged at the bottom of the gravity pressure water tank are connected with an external power supply through relays. By adopting the exhaust gas residual heat boosting driving system, the output power of an internal combustion engine can be increased.

Owner:CHANGSHA VOCATIONAL & TECHN COLLEGE

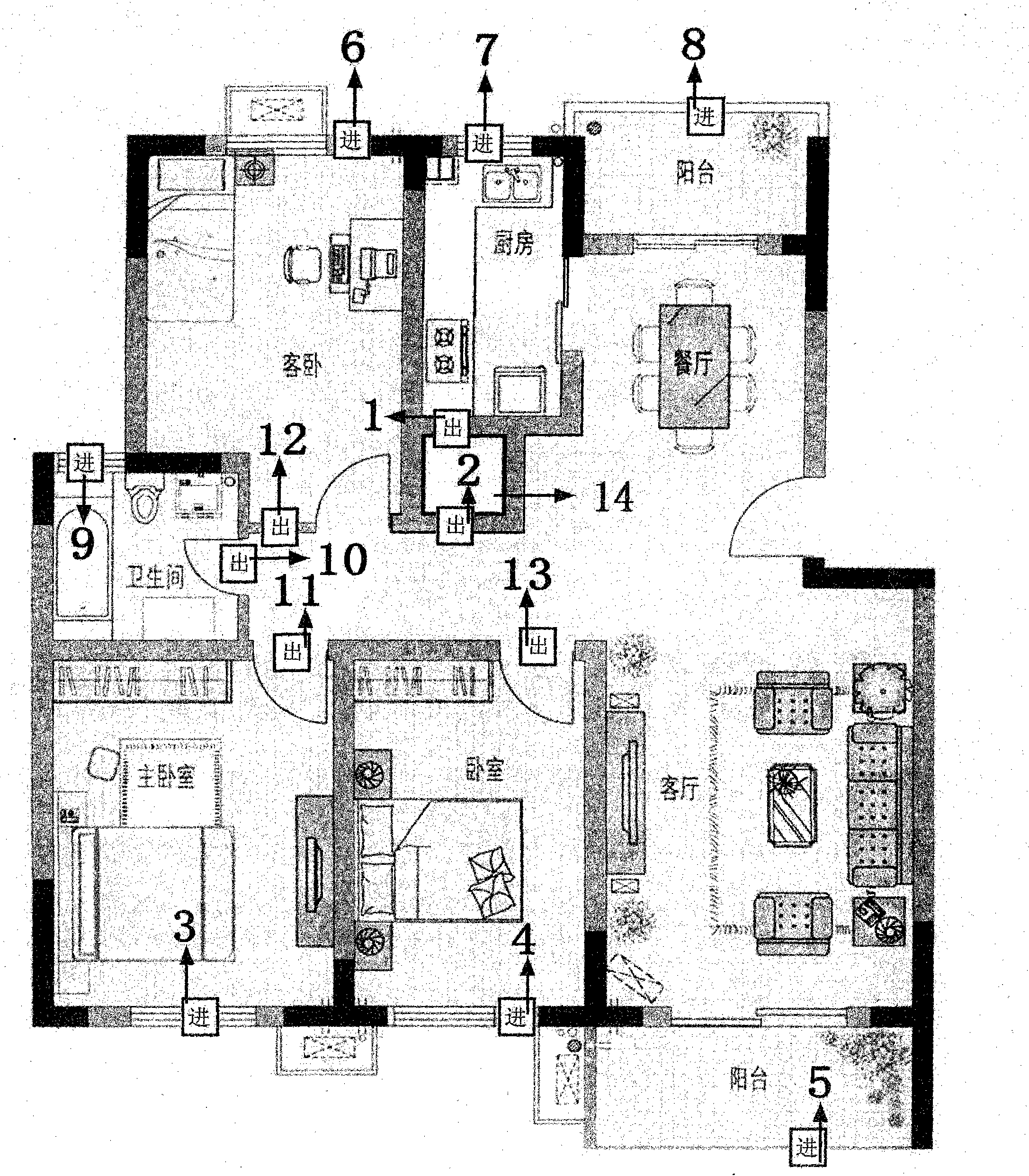

Method for realizing ventilation, air change, temperature and humidity adjustment and firefighting of building by using embedded chimney

InactiveCN103850448ASmooth dischargeImprove the fire effectVertical ductsDwelling buildingFirefightingSitting room

The invention discloses a method for realizing ventilation, air change, temperature and humidity adjustment and firefighting of a building by using an embedded chimney. During construction of the building, a vertical chimney which ranges from a bottom floor to a top floor and is over three meters higher than the top floor is built close to the center of each living unit of the building, and at least one side of the chimney faces a relatively open space which is easy for exhausting smoke such as a shared atrium or living room or corridor and the like of the unit; an exhaust opening which can be opened and closed freely and only exhausts towards the chimney is formed close to the top of the building on each layer of the chimney; an exhaust opening is formed at a position closest to the chimney on the top of each room leading to the shared atrium or living room or corridor of the building; an air inlet leading to the outside is formed in the lowermost part of the outer wall of the room. At normal times, an exhaust hole of a proper size is formed in the exhaust opening in each layer of the chimney by using the chimney effect, and one or more air inlets leading to the outside are opened, so the natural ventilation and air change and temperature and humidity adjustment are realized for reach room on each floor of the building; in case of fire, the exhaust opening on a certain layer of the chimney is opened fully to suck smoke gas produced by the combustion of big fire outside, so that the firefighting aim is fulfilled.

Owner:胡永生

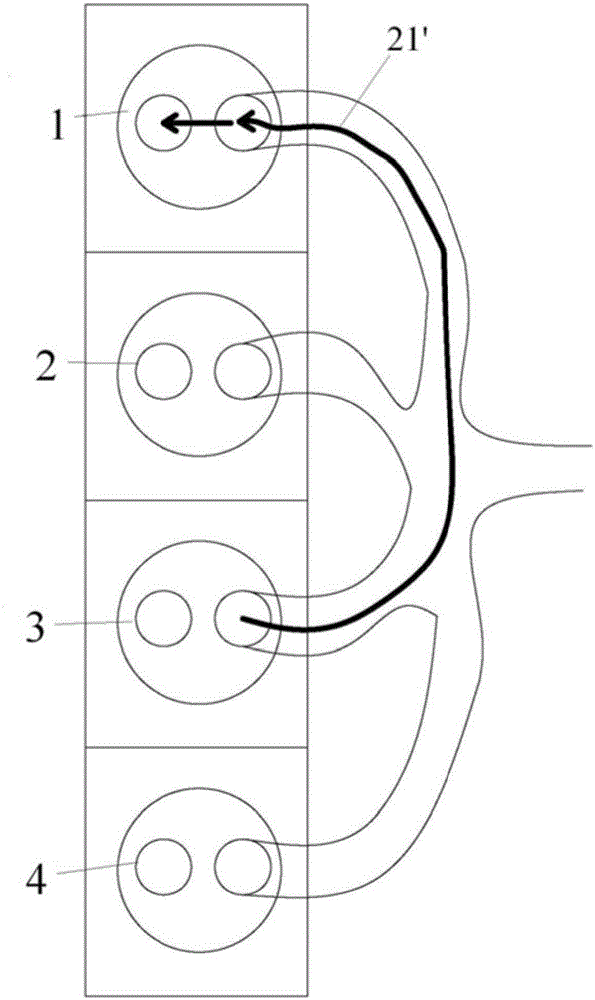

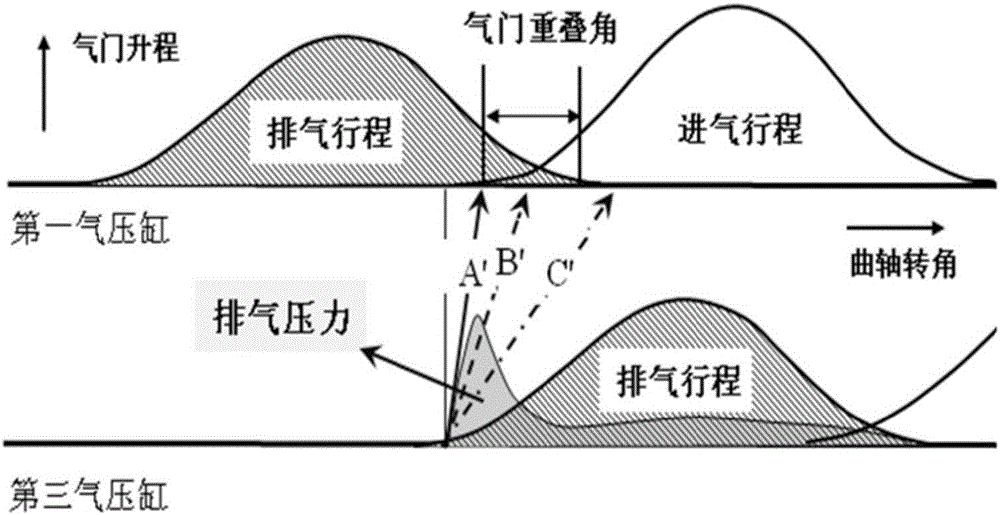

Exhaust structure capable of reducing exhaust disturbance between air cylinders of engine

InactiveCN106321210AReduce the temperatureResidue reductionExhaust apparatusSilencing apparatusDetonationExhaust fumes

The invention discloses an exhaust structure capable of reducing exhaust disturbance between air cylinders of an engine. The exhaust structure comprises an exhaust branch pipe communicated with each air cylinder, every two exhaust branch pipes are intersected to form an intersection pipe, each intersection pipe is communicated with a catalysis device, and exhaust openings of all the catalysis devices are intersected to form a main exhaust opening. According to the exhaust structure capable of reducing the exhaust disturbance between the air cylinders of the engine, the exhaust disturbance can be reduced, exhaust is more thorough, the residual amount of waste gas in the air cylinders is reduced, the air inlet amount is improved, meanwhile, the temperature of mixed gas in the air cylinders is reduced, and detonation is reduced; meanwhile, exhausts of the two sets of air cylinders are provided with the independent catalysis devices, the oil break and cylinder stop function of the two sets of air cylinders of the engine can be achieved, and the oil consumption rate is reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Swinging wing engine

InactiveCN102305129AImprove efficiencyIncrease profitInternal combustion piston enginesGear wheelRotary valve

The invention discloses a swinging wing engine. The swinging wing engine comprises a shell, a rotor and an output shaft which is coaxial with the shell. An eccentric shaft section is arranged in the middle of the output shaft; the inner circle of the rotor is connected with the eccentric shaft section through a rotator bearing; one end face of the rotor is embedded into an inner gearing phase gear; one end face of the shell is connected with an upper end cover and the inner surface of the upper end cover is provided with an outer gearing phase gear which is meshed with the inner gearing phasegear; the inner circle of the upper end cover is connected with the output shaft through a bearing; an upper bearing cover is connected with the upper end cover; other end face of the shell is connected with a distribution valve; the inner circle of the distribution valve is connected with the output shaft through the other bearing; a rotary valve which is connected with the output shaft is arranged in the inner circle of an outer end of the distribution valve; a lower bearing cover is connected with the distribution valve; a plurality of groups of swinging wing driving mechanisms which drivethe output shaft to rotate are arranged on an end face of the shell which is connected with the distribution valve along the inner circle of the shell; and the distribution valve and the rotary valveare also provided with air intake and exhaust passages which ensures the swinging wing driving mechanisms act; and the upper bearing cover is also provided with intracavity air overflow ports.

Owner:SHENZHEN SAILANGKEN SCI & TECH

Two-stroke internal combustion engine and working method thereof

InactiveCN110905657AImprove efficiencyExhaust thoroughlyInternal combustion piston enginesExhaust valveTop dead center

The invention discloses a two-stroke internal combustion engine and a working method thereof. The structure of the internal combustion engine comprises a crankshaft, a crankshaft box, a piston, a cylinder, a connecting rod and an air booster; the crankshaft is positioned in the crankshaft box, the crankshaft is positioned in the cylinder, and the piston is connected with the crankshaft through theconnecting rod; an air inlet is formed in the top end of the cylinder, an air inlet valve is arranged in the air inlet, the air inlet is connected with the air booster through an air inlet pipeline;and an exhaust port is formed in the side wall of the cylinder, the position of the exhaust port on the side wall is positioned between a top dead center and a bottom dead center, and the exhaust portis provided with an exhaust valve. The two-stroke internal combustion engine has the beneficial effects that the exhaust is thorough, the working stroke of the piston is larger than the compression stroke, and the efficiency of the internal combustion engine can be improved; and a cycle has only two strokes, and the power performance is good.

Owner:谭智

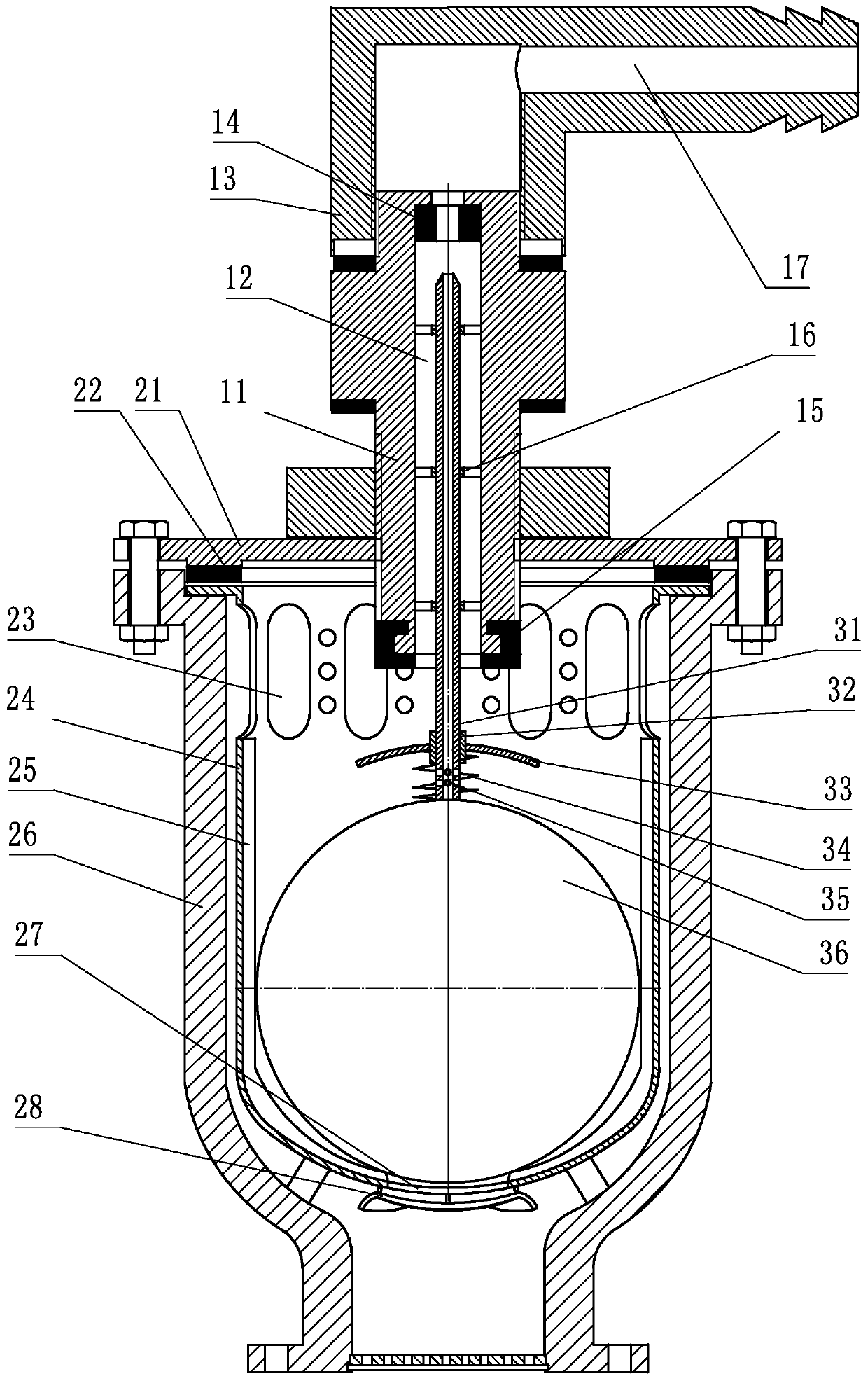

Precise composite suction and exhaust valve

PendingCN110822157AEnsure safetyReasonable structureOperating means/releasing devices for valvesPipe elementsExhaust valveEngineering

The invention discloses a precise composite suction and exhaust valve. The precise composite suction and exhaust valve comprises a valve body (26), a valve cover (21), a valve column (11), a float sealing piece (15), a valve column end cover (13), a floating ball outer barrel (24), a guide exhaust pipe (31), a floating ball gland (33) and a floating ball (36), wherein a first exhaust hole (12) anda guide mechanism (16) are arranged in the middle of the valve column (11); the guide exhaust pipe (31) is fixedly arranged on the floating ball (36); the floating ball gland (33) is connected to theguide exhaust pipe (31) through a sliding sleeve (32); and a return spring (34) is arranged between the floating ball gland (33) and the floating ball (36). Compared with the prior art, a split structure is adopted for the precise composite suction and exhaust valve, the precise composite suction and exhaust valve is more reasonable in structure, is not prone to blockage failure, can perform micro-exhaust through a secondary exhaust hole after a large amount of exhaust is finished, is more thorough in exhaust, is particularly suitable for occasions requiring precise exhaust, and can effectively guarantee the safety of facilities such as water delivery pipelines or containers.

Owner:奎屯耐特阀门科技有限公司

An engine-driven generator set

ActiveCN104847488BSolve the reflux problemSufficient air volumeExhaust apparatusSilencing apparatusCylinder headHeat balance

An engine-driven generator set, comprising: a soundproof box, the soundproof box is composed of an upper cover, a side wall and a chassis, and the chassis is provided with: an engine, and a cooling air guide to the engine is provided at the side inlet of the engine. Engine cooling fan; generator, the connection between the generator and the engine is provided with a cooling fan that guides the cooling air to the generator; the exhaust muffler is arranged on the rear side of the generator, parallel to the axis of the generator; the exhaust One end of the muffler is connected to the engine through an exhaust pipe; a hot air exhaust chamber is also provided in the soundproof box, and the hot air exhaust chamber is composed of a side plate, a cover plate and an engine speed control seat, and the engine cylinder head , the cylinder body and part of the exhaust pipe are enclosed inside; the rear side of the hot air exhaust chamber is provided with an opening, and the opening is connected to the first exhaust hole on the side wall of the soundproof box. The invention effectively solves the problems of noise and heat balance, can significantly reduce the temperature of the engine oil by more than 30°C, and ensures the reliable lubrication of the engine and the power level of the whole machine is consistent with that of the open-shelf product.

Owner:SUMEC MACHINERY & ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com