Patents

Literature

64results about How to "Exhaust stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

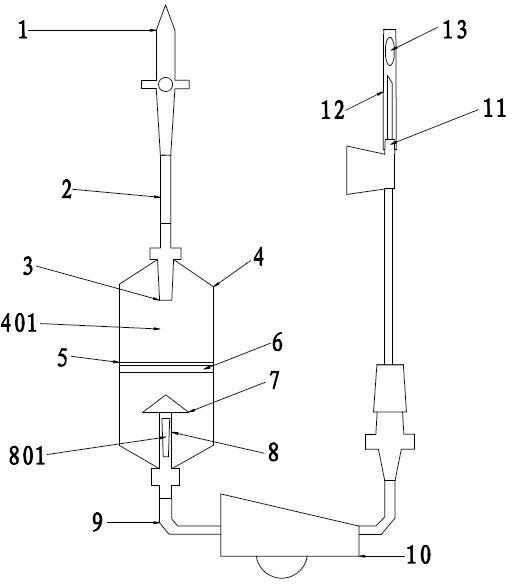

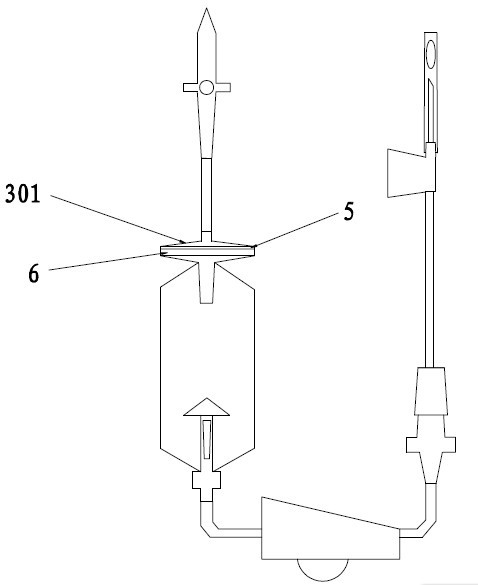

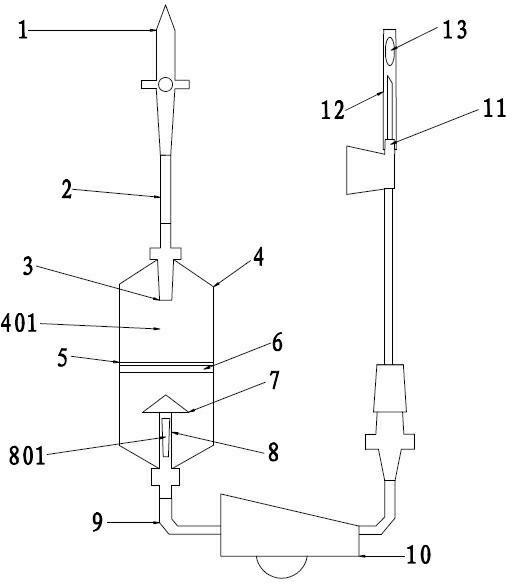

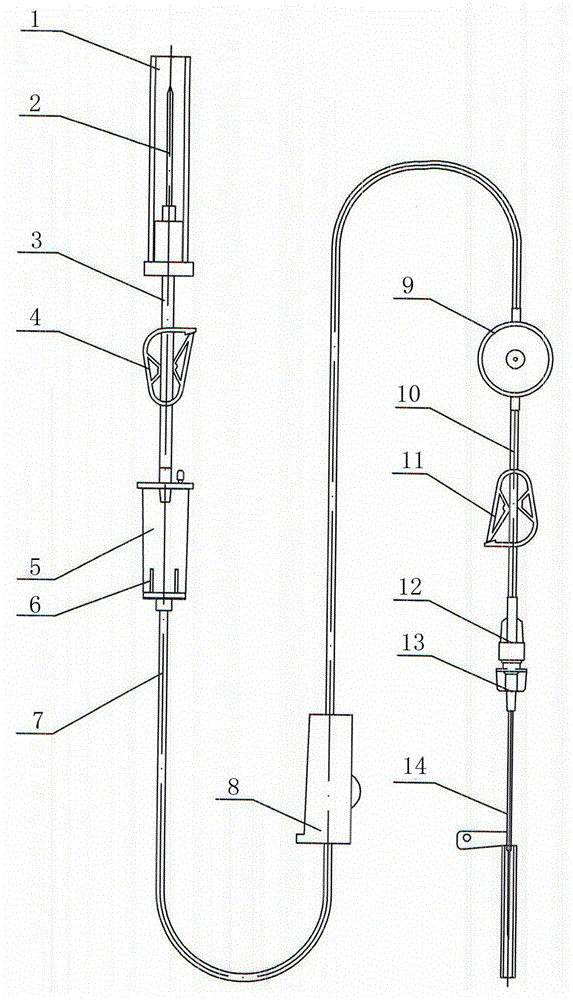

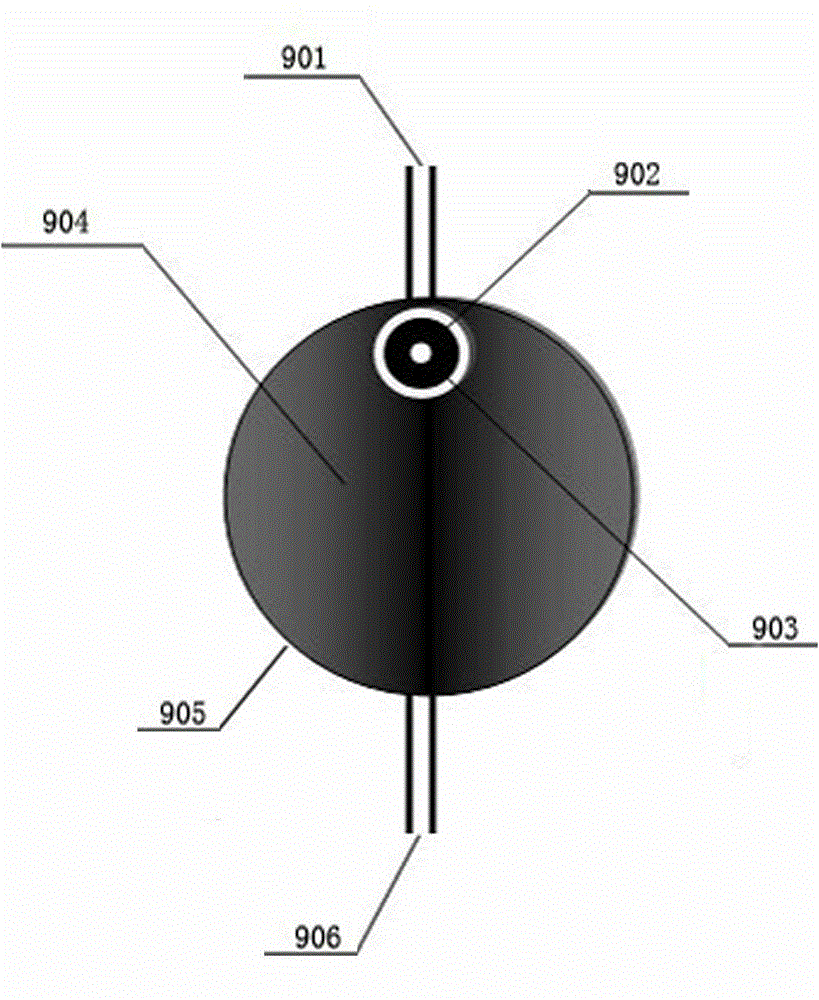

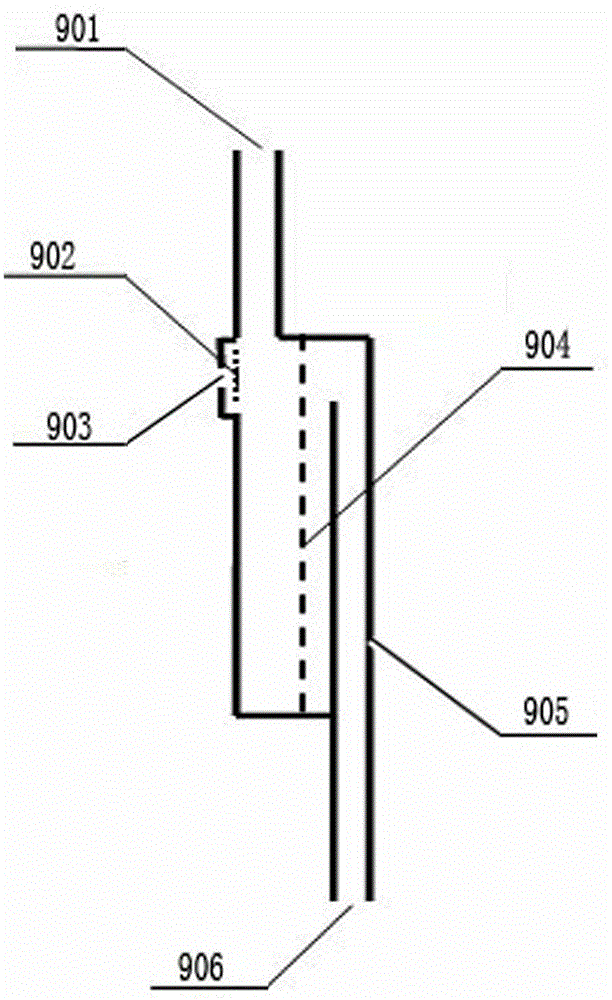

Infusion set

ActiveCN102350014ASave infusion operation timeSave operating timeInfusion devicesIntravenous needlesMedicine

The invention relates to an infusion set and belongs to the technical field of medical apparatus and instruments. The infusion set comprises a puncture outfit, an upper conduit of a drop funnel, a drip tube, the drop funnel, a lower conduit of the drop funnel, a regulator and an intravenous needle which are sequentially connected. The liquid outlet end of the intravenous needle is sleeved with a sealing sleeve; an air exhaust pipe is arranged between the drop funnel and the lower conduit of the drop funnel; at least one air exhaust hole is formed at one end, which is positioned in an inner cavity of the drop funnel, of the air exhaust pipe; a liquid medicine passing membrane made from a material which is permeated by water is arranged above the air exhaust pipe; a group of pores are formed on the liquid medicine passing membrane; the liquid medicine passing membrane allows liquid medicine and gas to pass through but blocks insoluble granules with the diameter of greater than the diameter of the pores in the liquid medicine; the sealing sleeve seals the liquid outlet end of the intravenous needle; and an air filter is arranged on the sealing sleeve. The infusion set is simple in structure and has self-exhausting and automatic liquid-stopping functions.

Owner:ZHEJIANG KANGTAI MEDICAL DEVICES

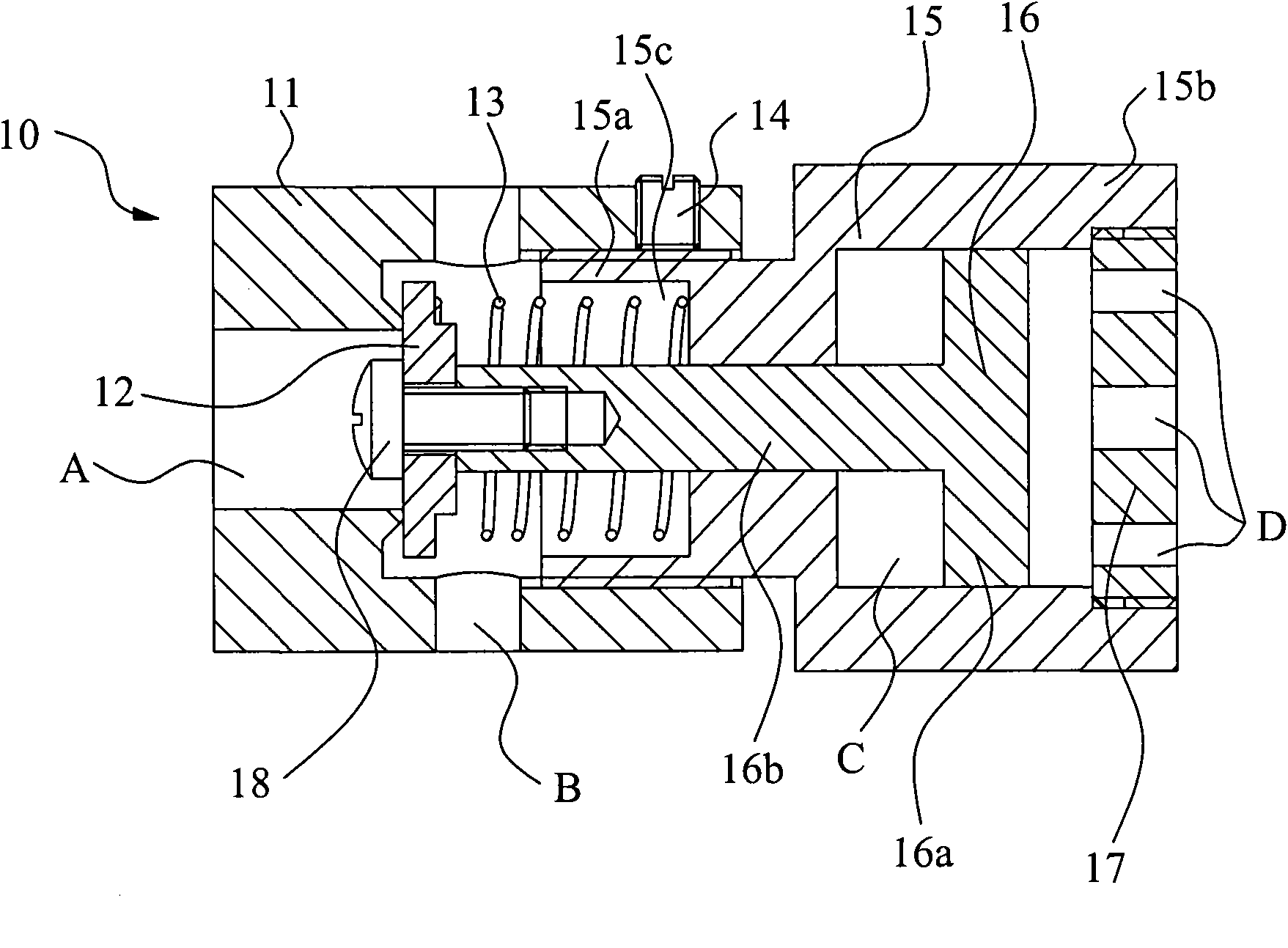

Airway pressure relief valve

InactiveCN101642598AExhaust stableProtection securityRespiratorsValve members for absorbing fluid energyMedicineAtmospheric air

The invention provides an airway pressure relief valve. The valve comprises a valve body, a damping cavity connected to the valve body, a piston and an elastic piece, wherein the valve body is provided with a first vent hole communicated with an airway of a patient and a second vent hole communicated with atmospheric environment; the damping cavity is internally provided with a damping air chamber communicated with the atmosphere; the piston passes through the damping cavity, the damping air chamber is formed in a chamber of the damping cavity through a first end of the piston, and the first end can move along the chamber of the damping cavity; the second end of the piston is positioned in the chamber of the damping cavity and seals up or opens the first vent hole along with the movement of the piston; and the elastic piece is arranged in the chamber of the valve body and presses the second end of the piston eccentrically. The airway pressure relief valve adopts a mode of mechanical control, has simple structure, and can control and maintain the safety pressure of the airway steadily. When pressure reaches the opening pressure of the relief valve, the relief valve can exhaust steadily without generating obvious and vigorous pressure fluctuation.

Owner:BEIJING AEONMED

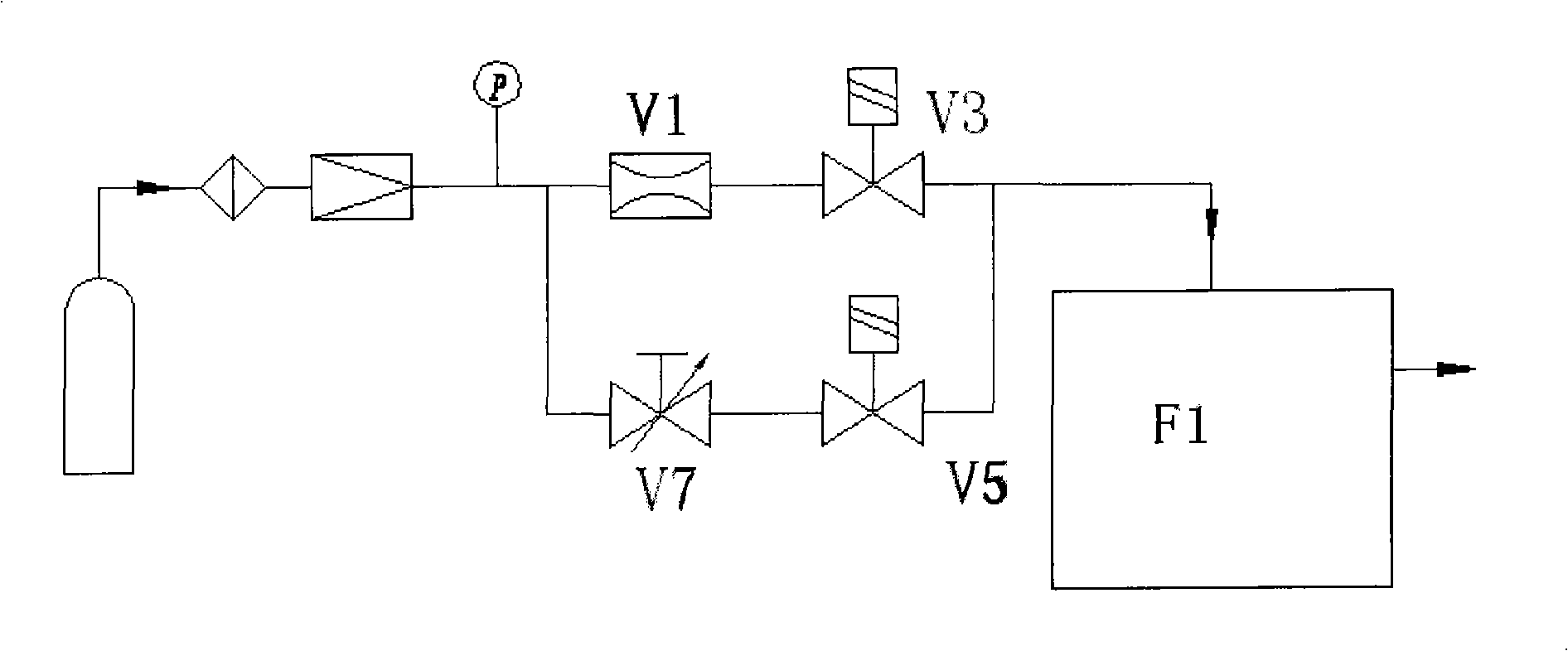

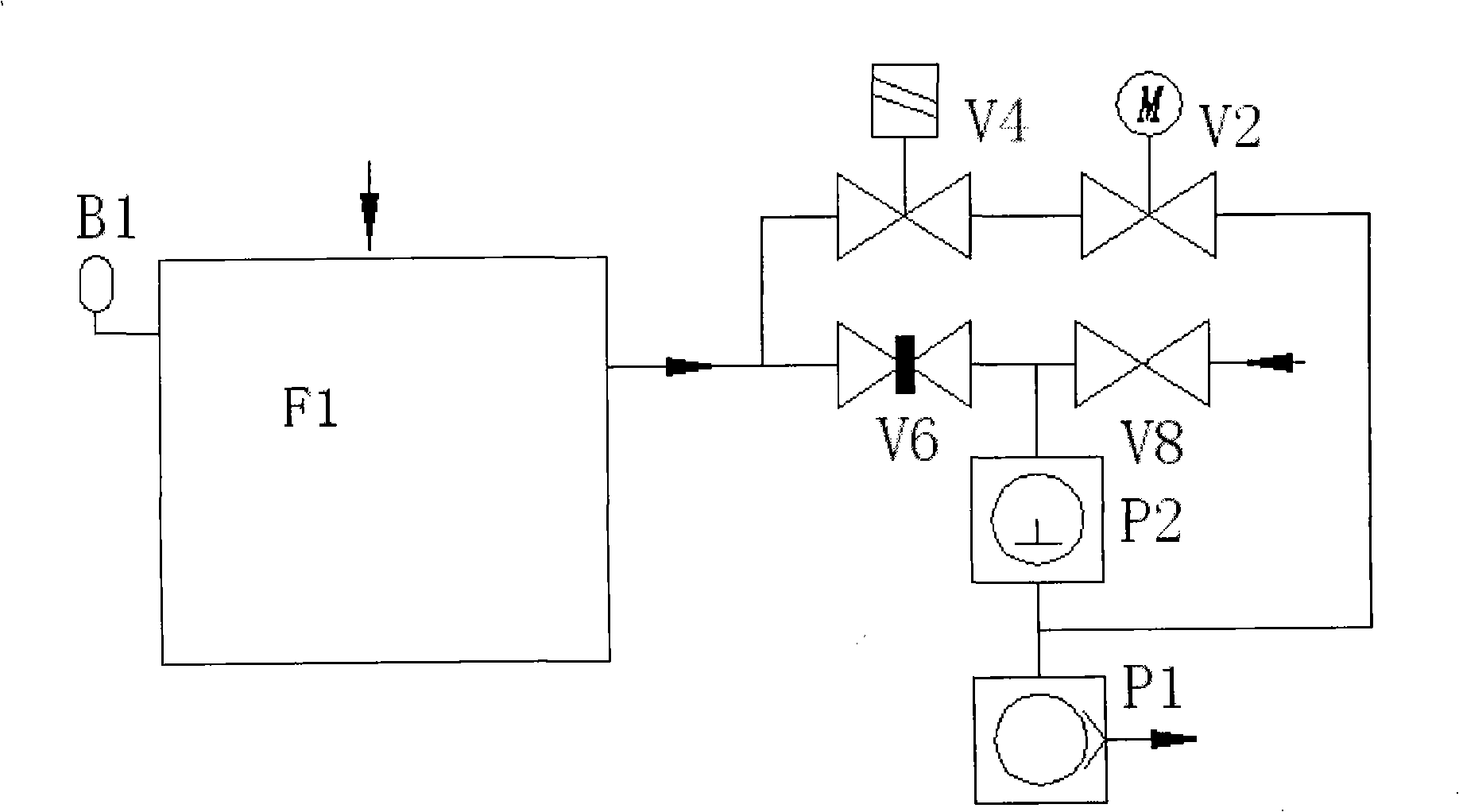

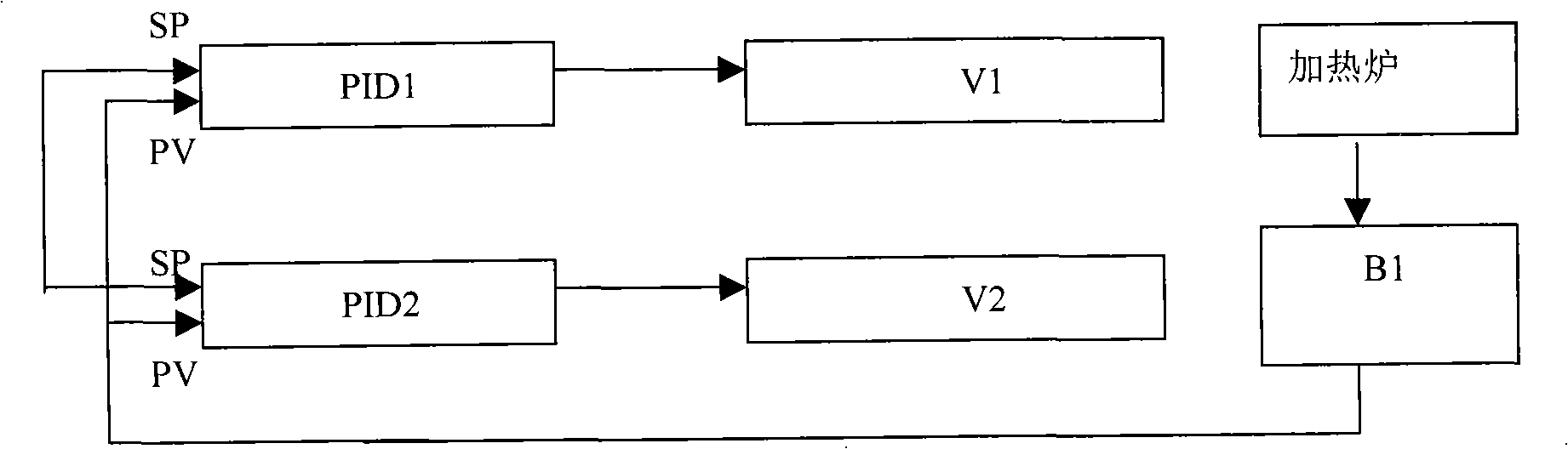

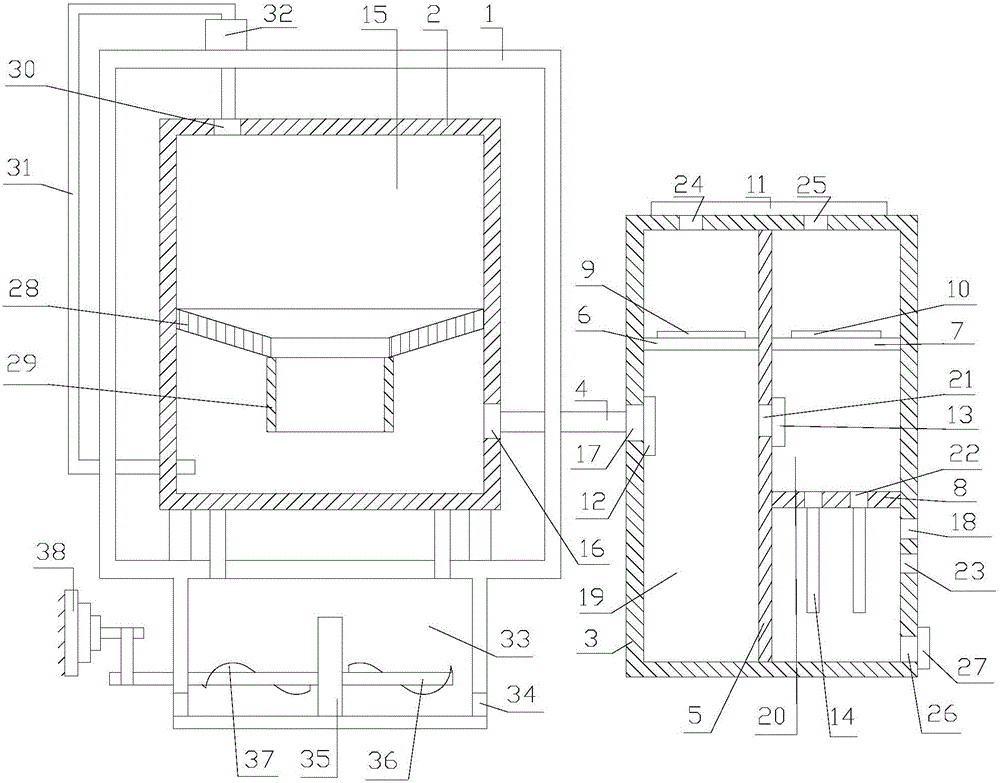

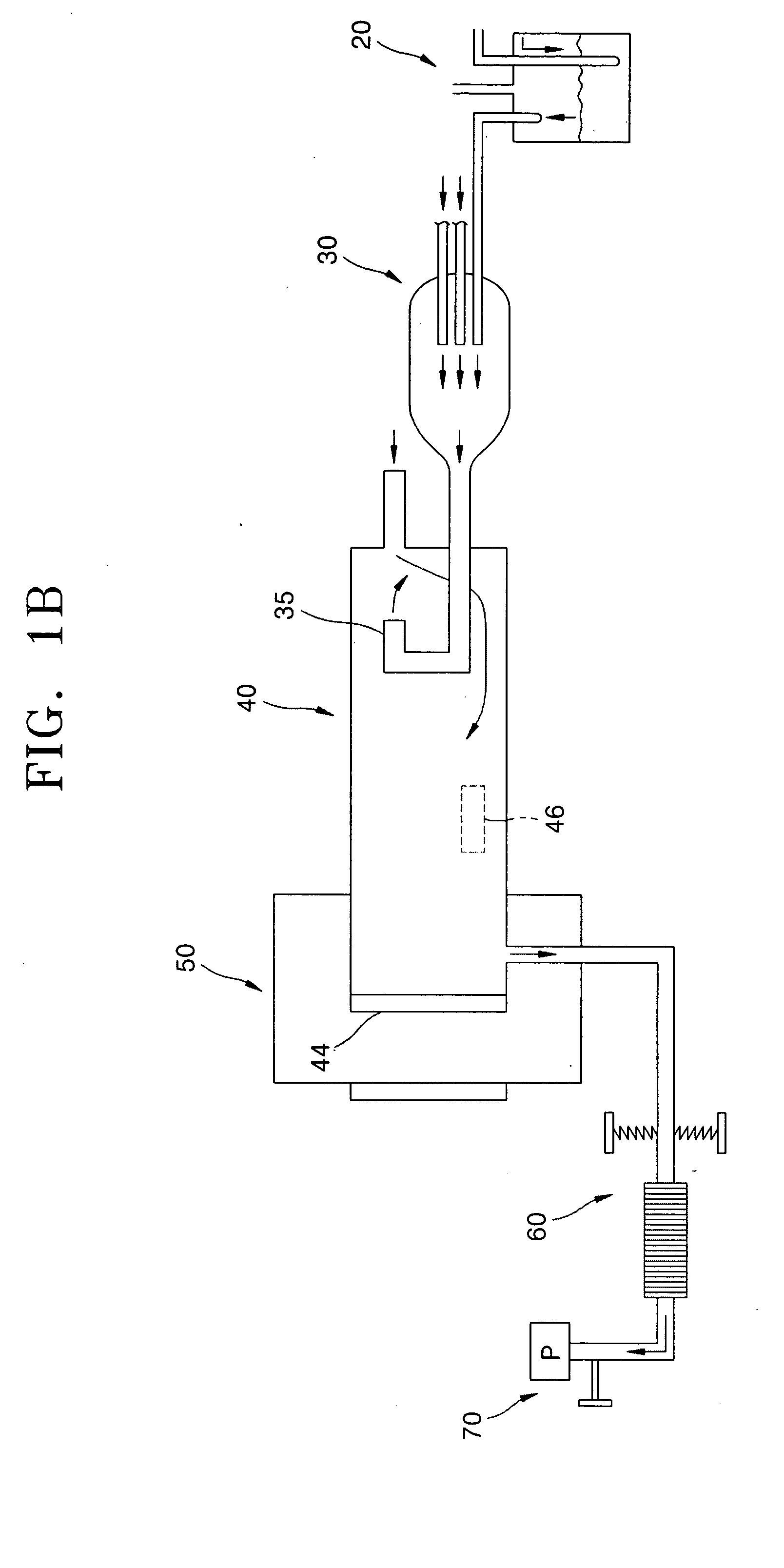

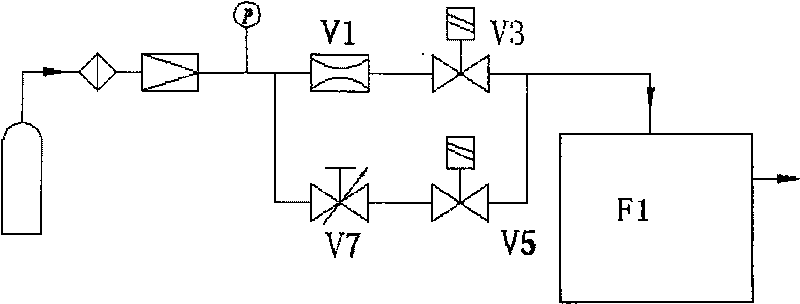

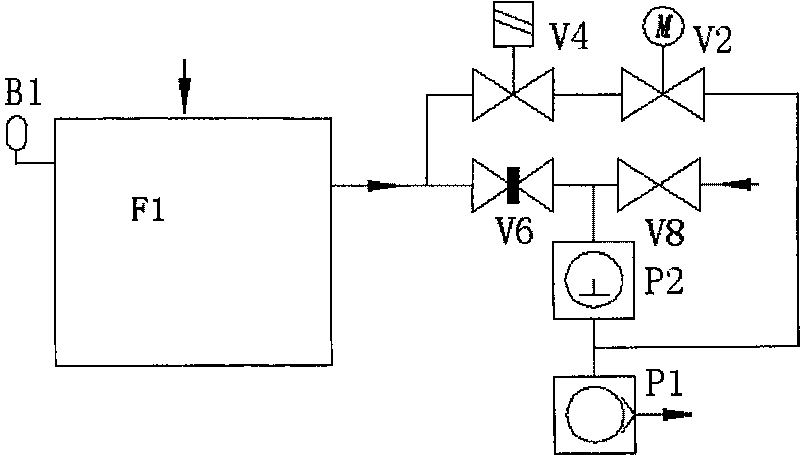

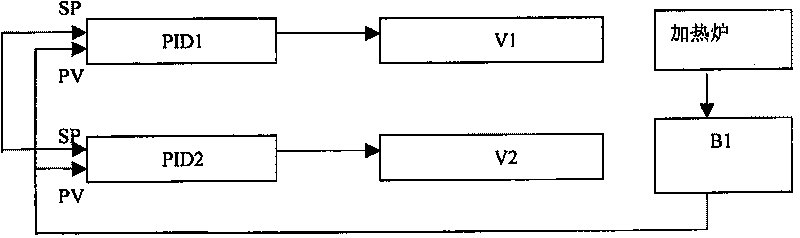

Vacuum pressure continuous control process for polysilicon ingot casting process and control system thereof

InactiveCN101311341AReduce consumptionStable controlPolycrystalline material growthSingle crystal growth detailsFurnace temperatureVacuum pressure

The invention discloses a vacuum pressure continuous control method used for a polysilicon ingot casting process. A vacuum mode is adopted in furnace heating step; then the melting, growing, annealing and cooling steps are carried out; the gas voltage regulation mode is adopted; under the voltage regulation mode, two modes of gas inlet regulation and gas outlet regulation are adopted to regulate the furnace pressure. At the same time, the invention also discloses a control system for realizing the control method. The method can be used for the polysilicon ingot casting production, can steadily control the vacuum furnace pressure, can guarantee stable gas inlet and gas outlet at the same time, can save the input gas consumption, and is simple and practical and has ideal control effect.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

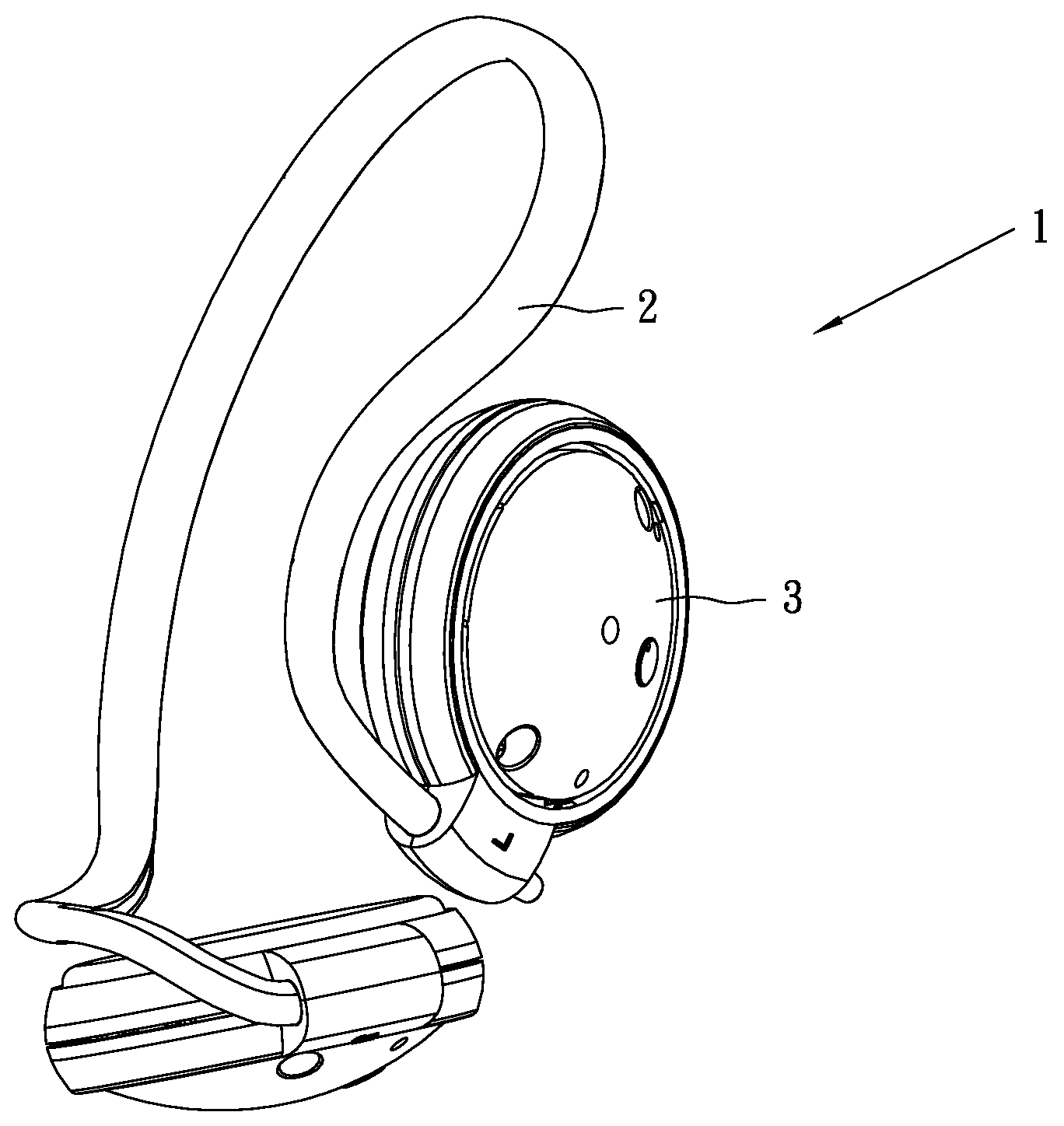

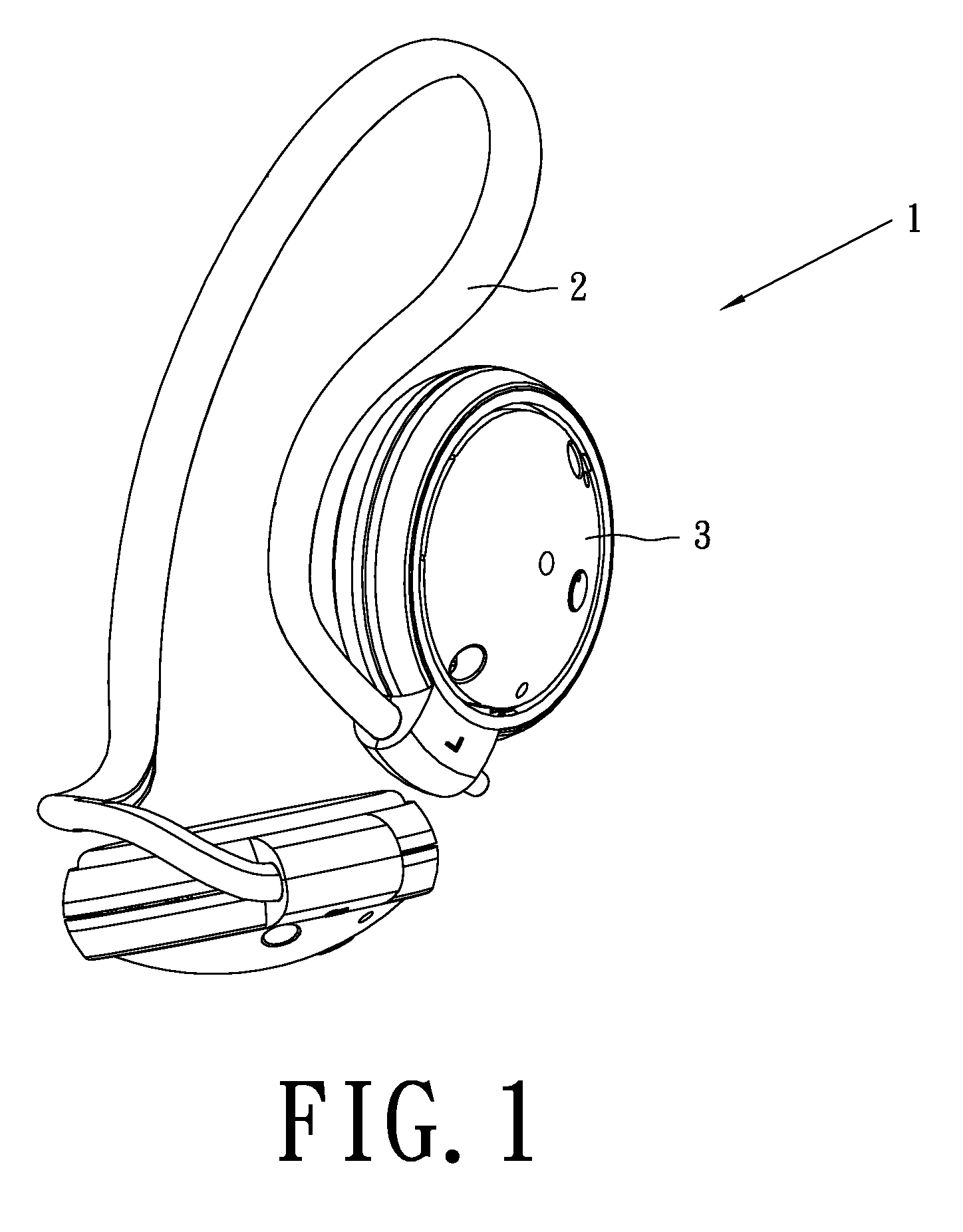

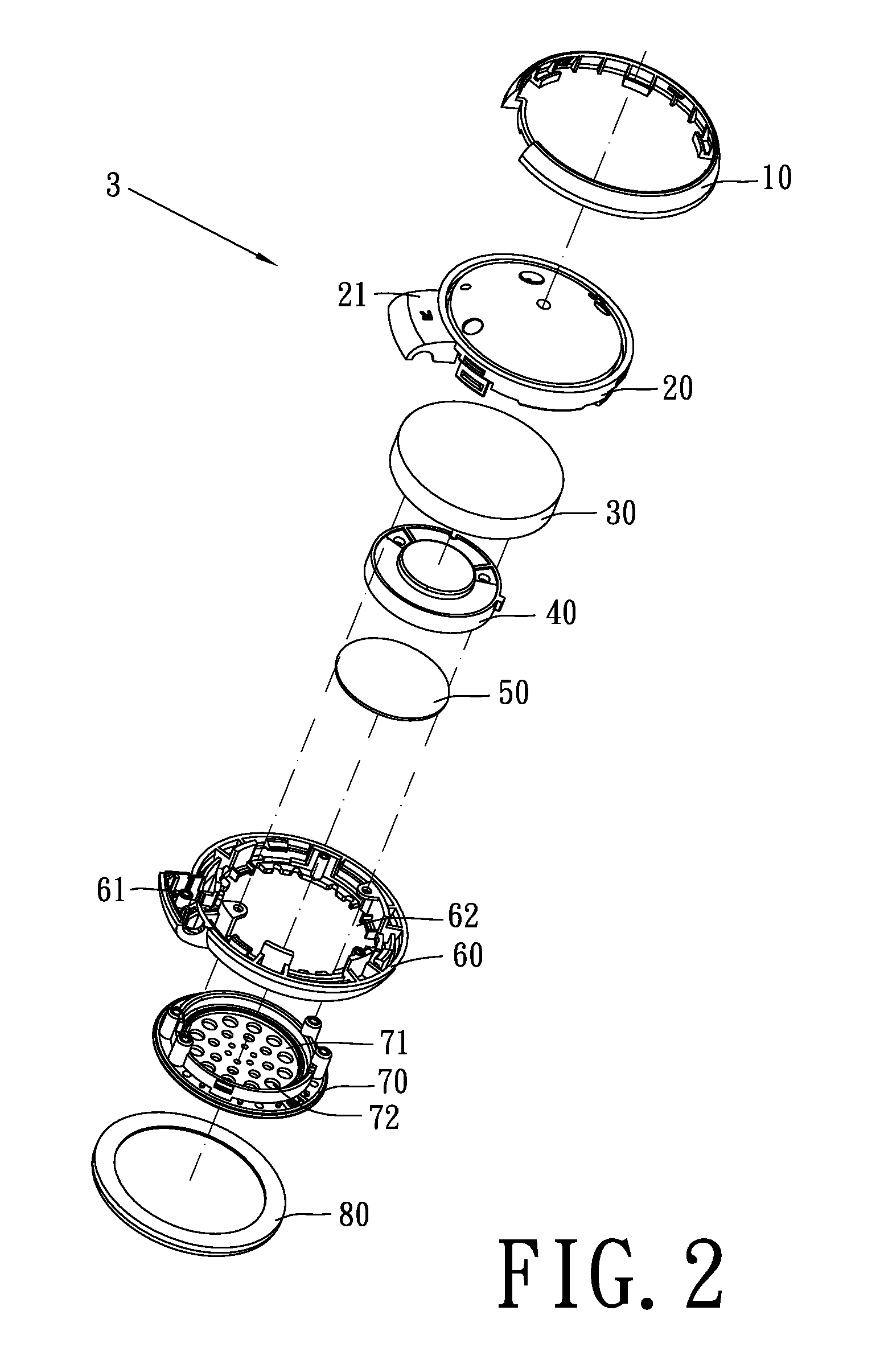

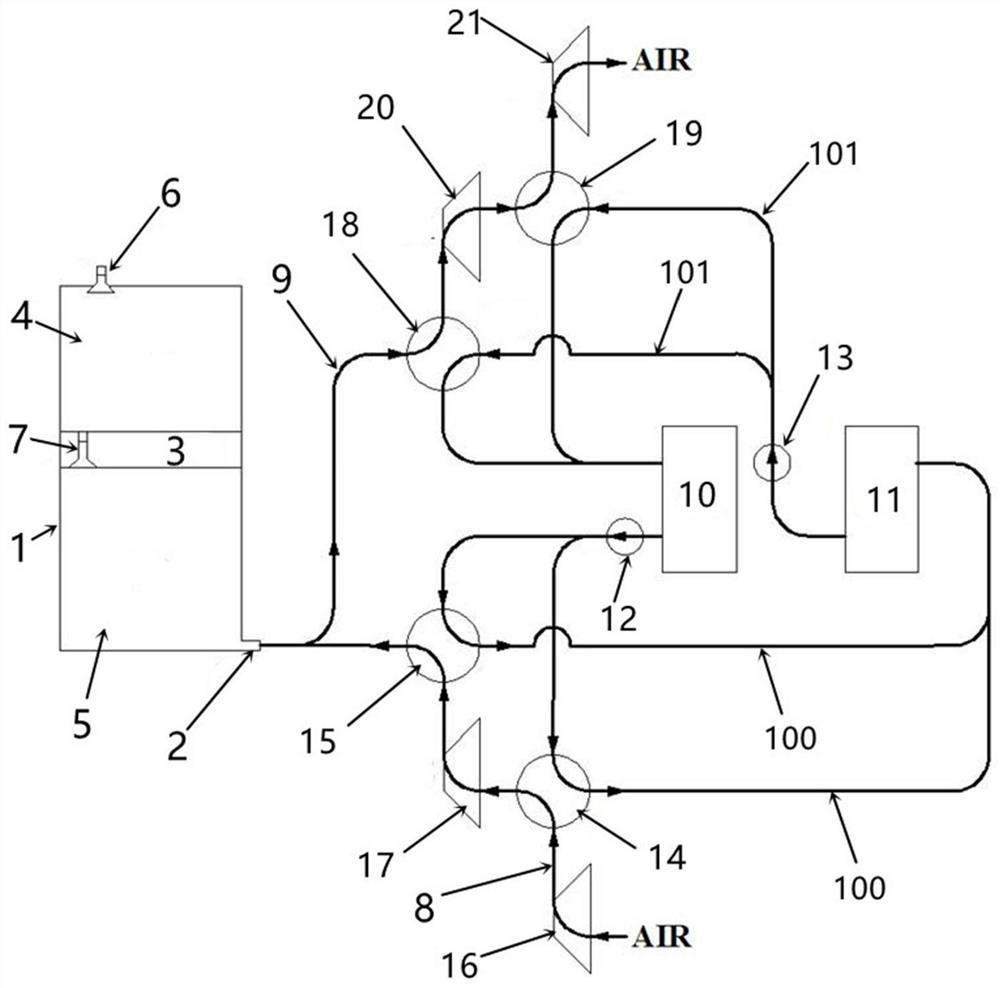

Headphone

InactiveUS20090285433A1Exhaust stableHigh-quality audioEarpiece/earphone attachmentsTransducer casings/cabinets/supportsEngineeringHeadphones

Owner:MERRY ELECTRONICS CO LTD

Compressed air energy storage system and method

PendingCN112922814AReduce power consumptionReduce mechanical lossHeat storage plantsSteam engine plantsEngineeringInlet pressure

The invention relates to the technical field of energy storage, in particular to a compressed air energy storage system and method.The compressed air energy storage system comprises an air cavity and an inflation and deflation pipe orifice, a piston capable of moving up and down is arranged in the air cavity and divides the air cavity into an upper low-pressure cavity and a lower high-pressure cavity, and the low-pressure cavity is provided with a low-pressure communication opening capable of communicating with the outside. The piston is provided with a high-pressure communicating opening capable of communicating the low-pressure cavity with the high-pressure cavity, the inflation and deflation pipe orifice communicates with the bottom of the high-pressure cavity, and the inflation and deflation pipe orifice is externally connected with a cooling compression device used for inflation and a heating expansion device used for deflation. According to the compressed air energy storage system and method, the problems that in the compressed air energy storage system, the air inlet pressure of the expansion machine is unstable, and throttling losses exist can be solved.

Owner:TSINGHUA UNIV +2

Device for treating household garbage

The invention discloses a device for treating household garbage. The device comprises an outer shell, an inner shell, a box, a first connecting pipe, a first baffle plate, a first moving piece, a second moving piece, a second baffle plate, a forward magnetostrictive film, a reverse magnetostrictive film, a coil, a first one-way film, a second one-way film and multiple cooling pipes; the inner shell is positioned on the inner side of the outer shell; a combustion cavity is formed in the inner shell; a feeding port is formed in the top wall of the inner shell; a first exhaust hole is formed in the side wall of the inner shell; the feeding port and the first exhaust hole are both communicated with the combustion cavity; the box is positioned on the outer side of the outer shell; an accommodating cavity is formed in the box; an intake hole and a second exhaust hole are formed in the side wall of the box; a first end of the first connecting pipe is connected with the first exhaust hole, and a second end of the first connecting pipe is connected with the intake hole; the first baffle plate is positioned in the accommodating cavity for dividing the accommodating cavity into a first abdominal cavity and a second abdominal cavity; and an exhaust hole is formed in the first baffle plate. The device is excellent in garbage treatment effect.

Owner:湖南未名环保科技有限公司

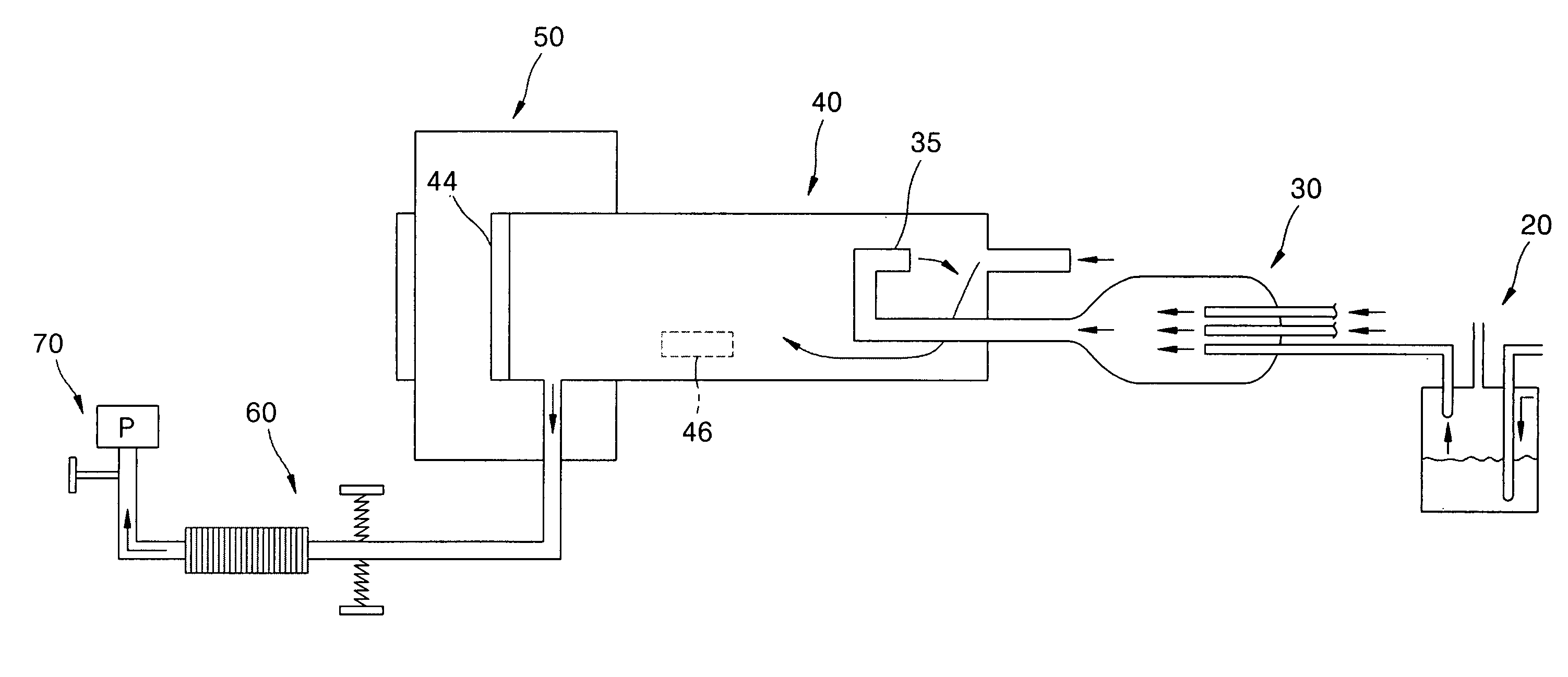

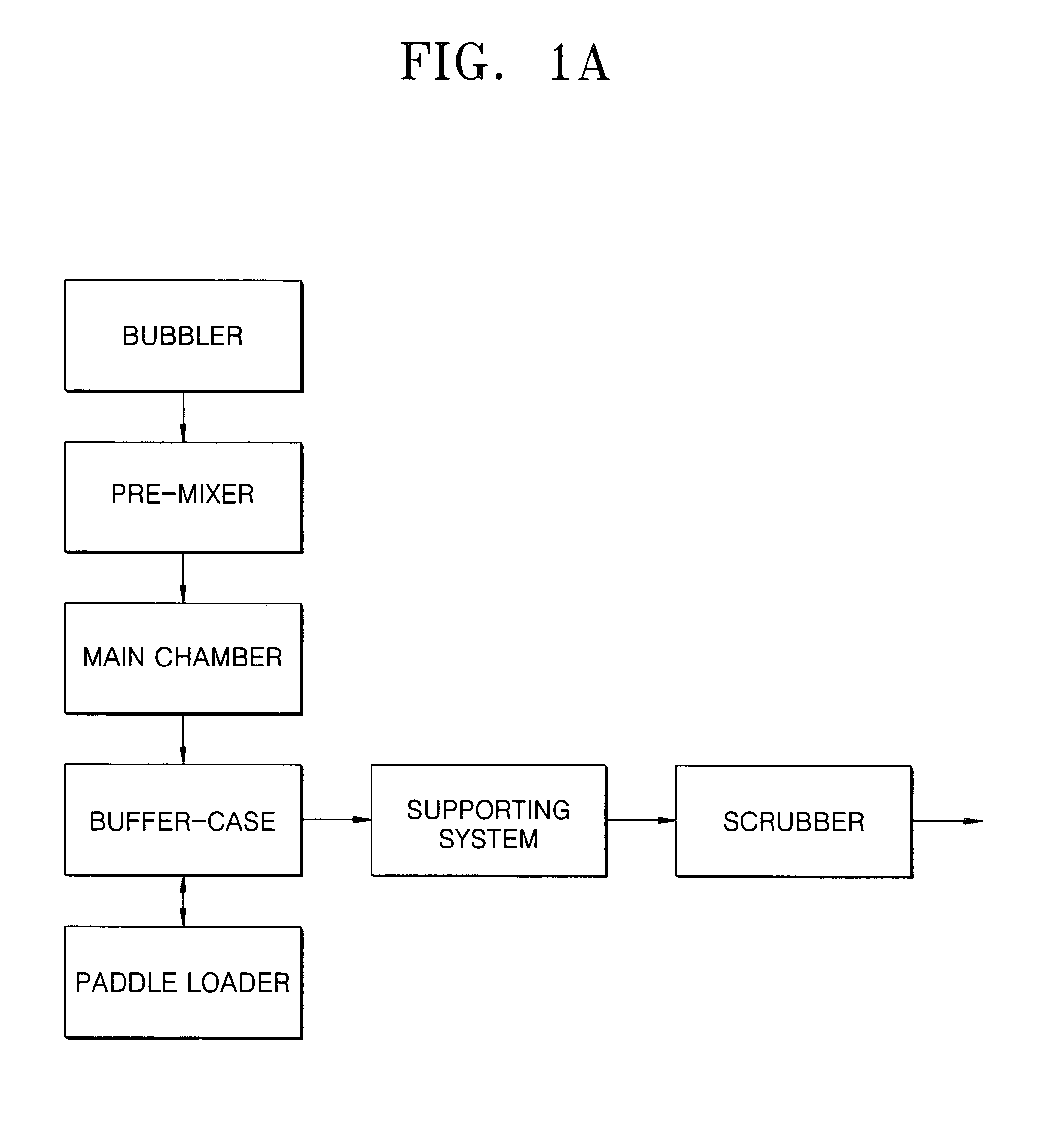

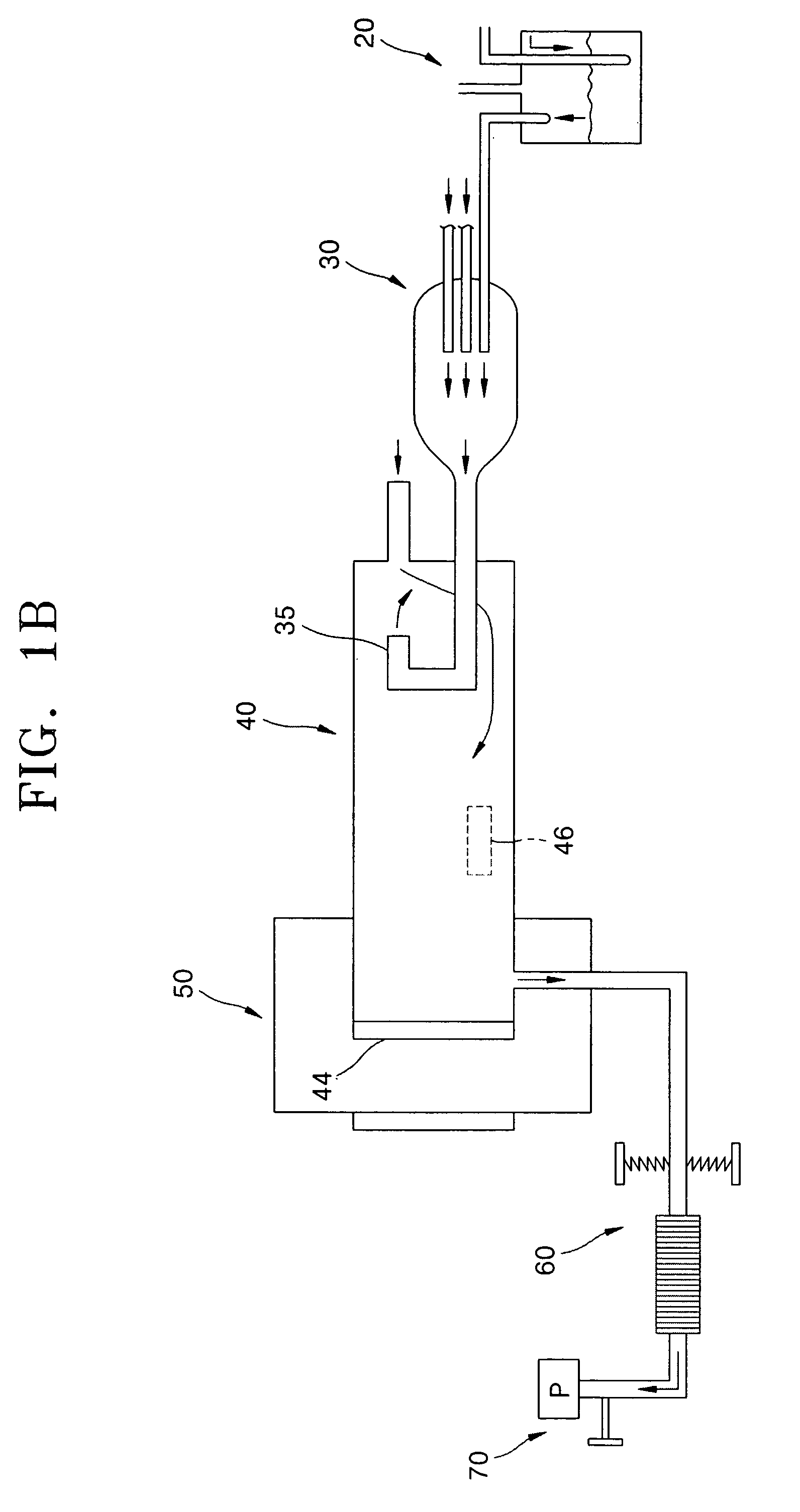

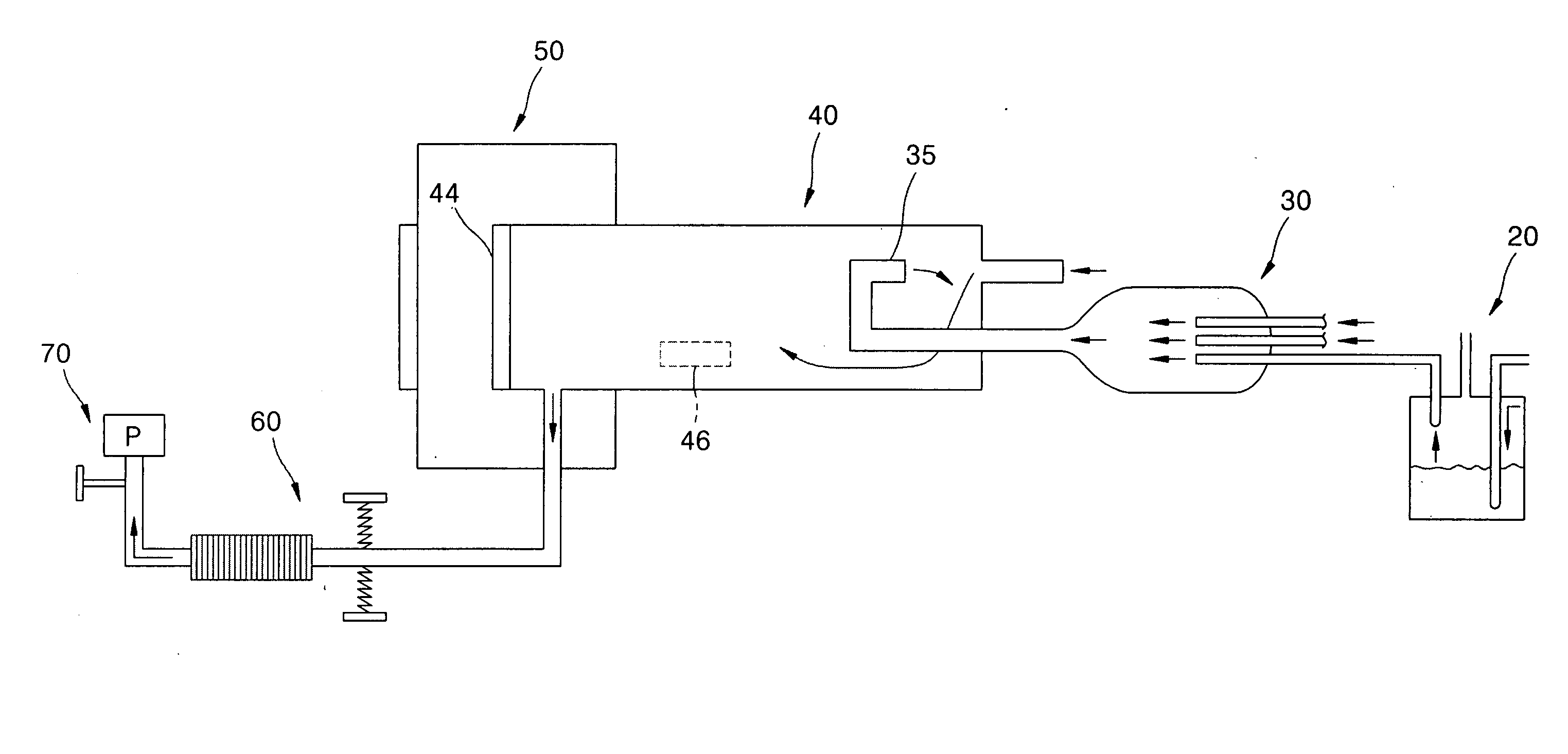

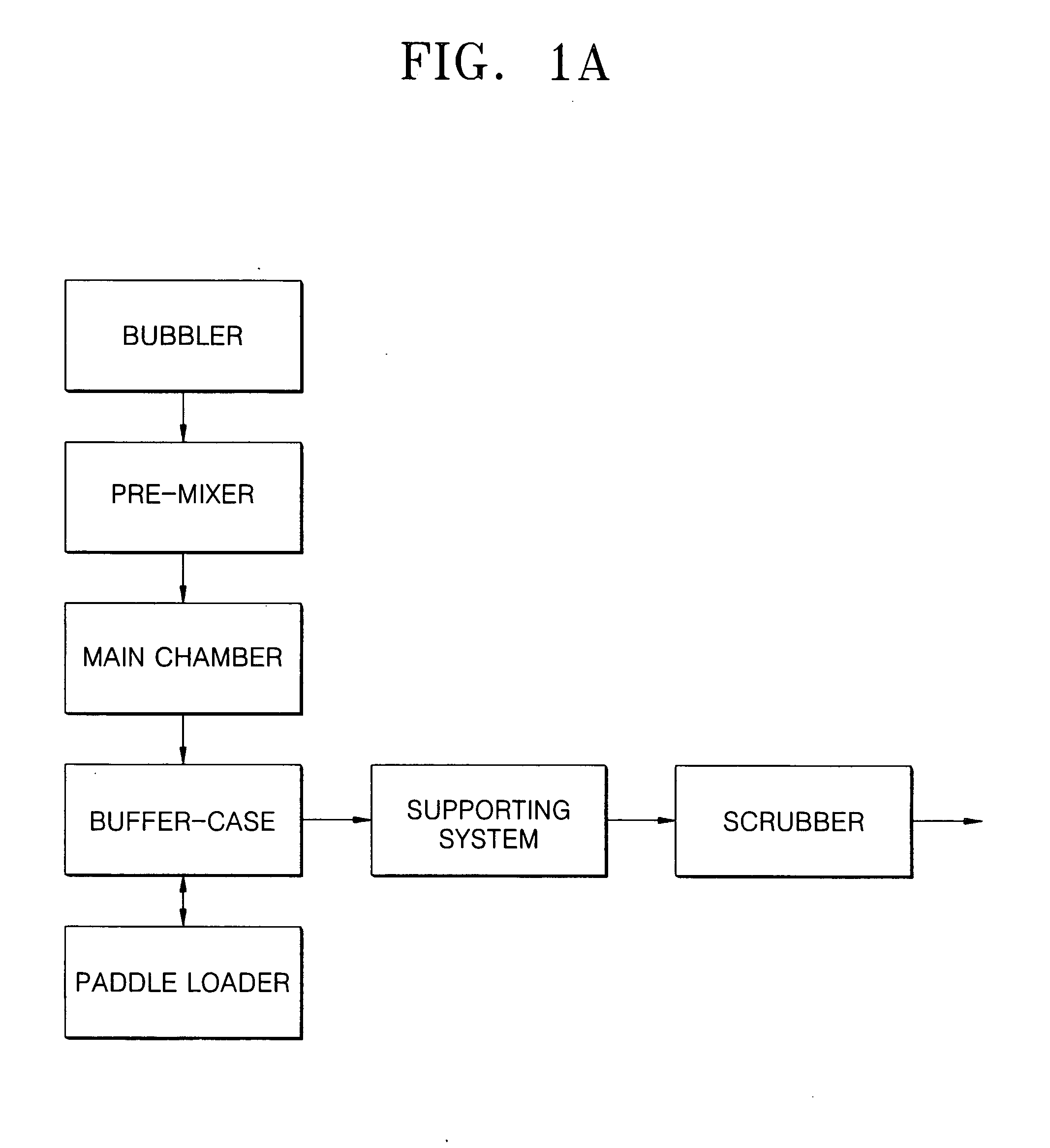

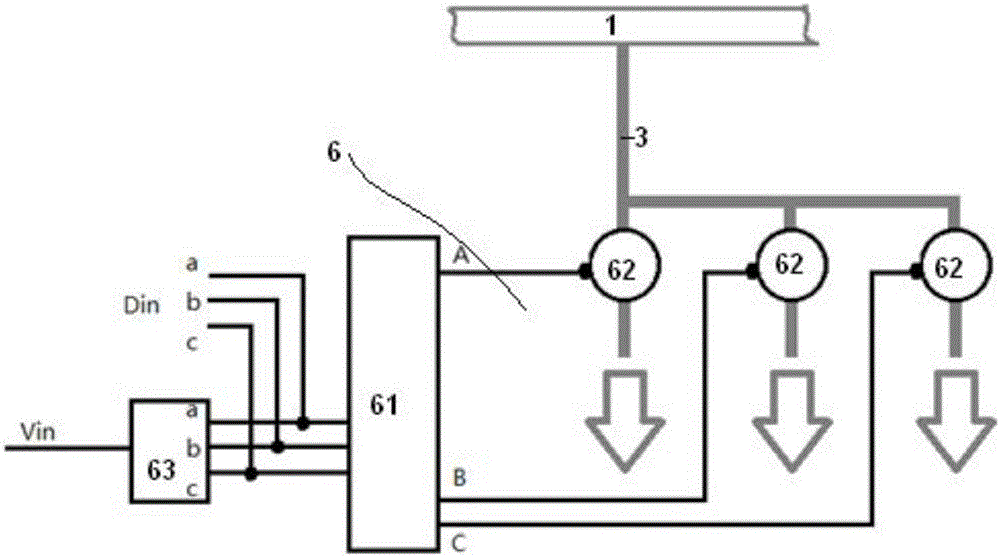

Diffusion system

InactiveUS7452423B2Speed efficientExhaust stableAfter-treatment apparatusDiffusion/dopingDiffusionReactive gas

Provided is a diffusion system for forming a doping layer in a wafer. The diffusion system includes a bubbler for generating a doping gas; a premixer, which premixes the doping gas with reactive gases and preheats the gas mixture; a main chamber, in which the gas mixture reacts to the wafer; a buffer case, which externally isolates an exhaust port and a door for loading and unloading the wafer into and out or the main chamber; and a used gas exhaustion system, which exhausts a used gas after the reaction is finished in the main chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

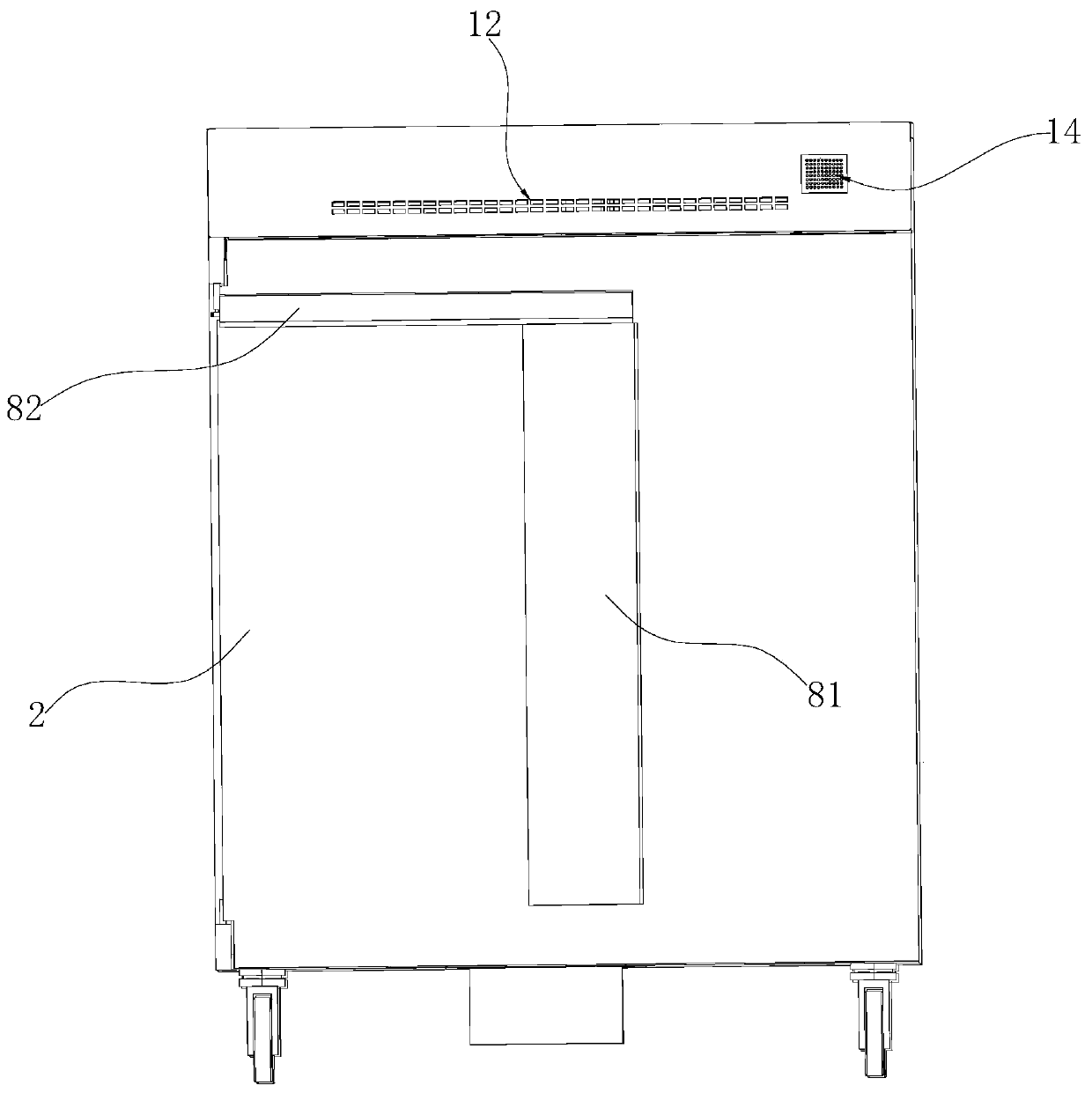

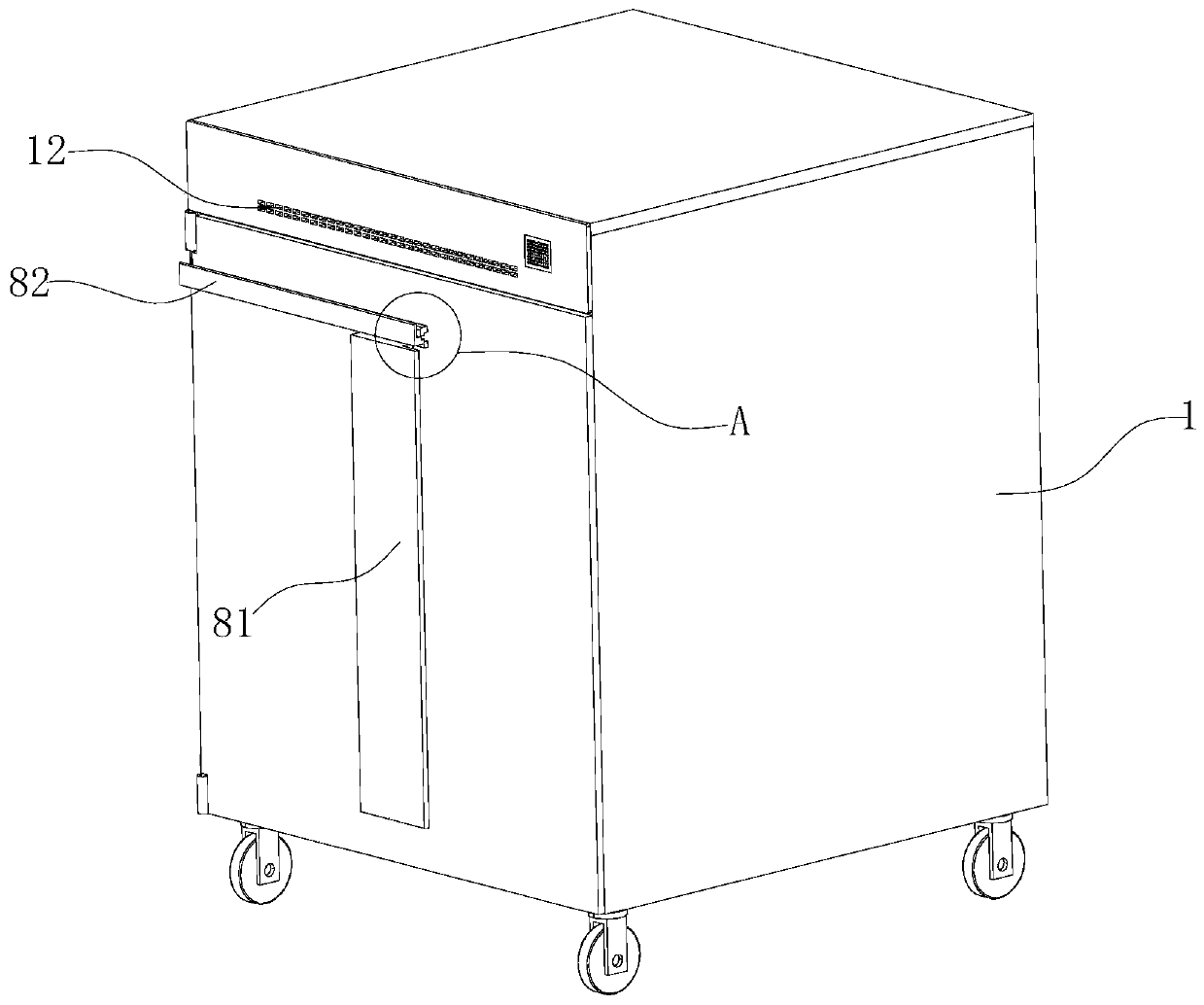

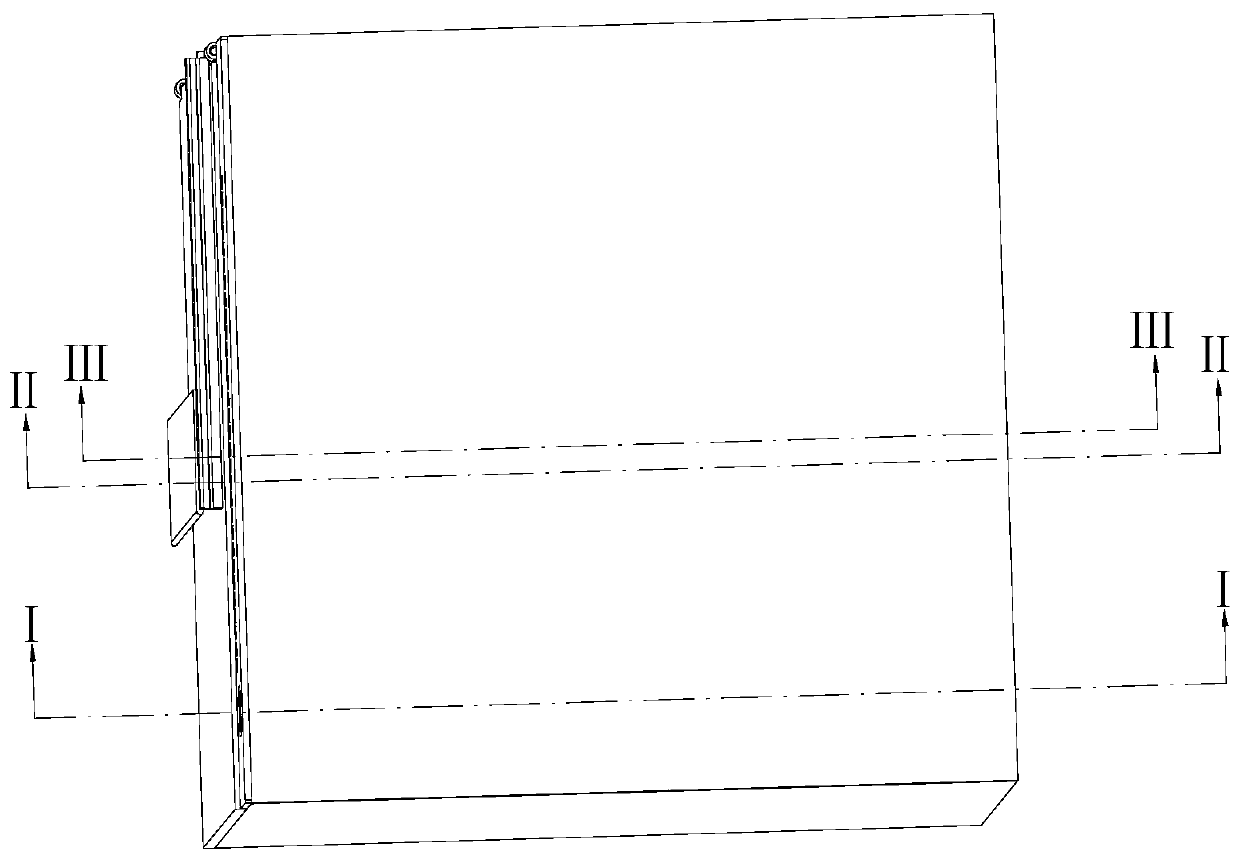

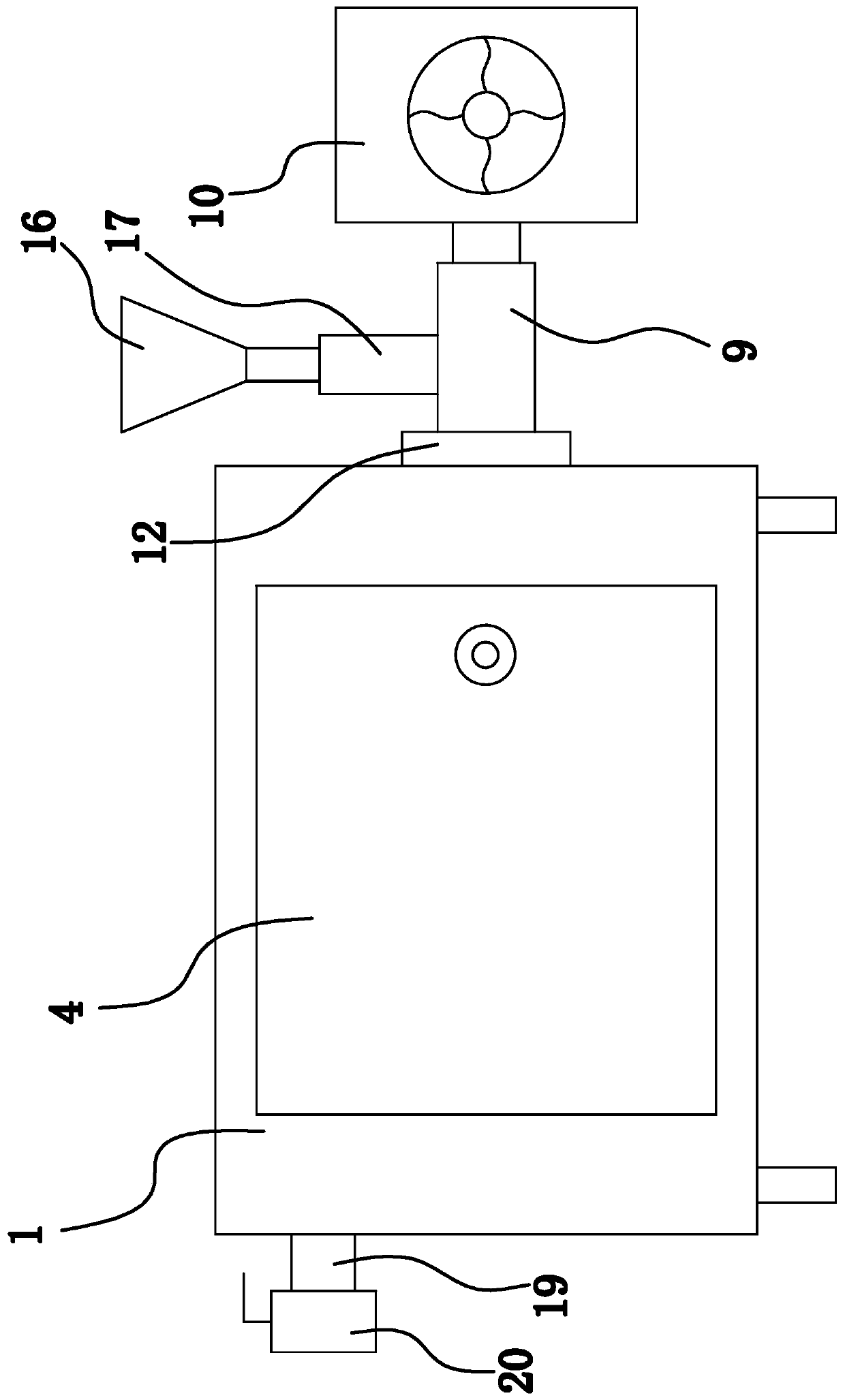

Novel disinfection cabinet

The invention relates to a novel disinfection cabinet, which comprises a cabinet body with a disinfection cavity. The cabinet body is internally provided with an airflow passage outside the disinfection cavity, a fan in forward and reverse rotation and a negative ion generator capable of generating disinfection gas are arranged in the airflow passage, and the airflow passage is provided with a first port communicated with the outside and a second port communicated with the disinfection cavity. The airflow passage has air inlet and outlet functions at the same time; in an air inlet state, external air can be mixed with disinfection gas generated by the negative ion generator prior to entering the disinfection cavity, and mixed gas entering the disinfection cavity can be quickly and uniformly distributed in the disinfection cavity, so that disinfection effects are improved. By integration of the air inlet and outlet functions, the disinfection cabinet is structurally simple and compact;the disinfection gas is dynamically pumped into the disinfection cavity and uniformly distributed in the disinfection cavity, and accordingly the disinfection effects are improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Technology of manufacturing large power xenon lamp

InactiveCN104103472AImprove yieldShort installation timeCold cathode manufactureCooking & bakingSilica gel

A technology of manufacturing a large power xenon lamp disclosed by the present invention is characterized by comprising the following steps of a, preparing an xenon lamp electric arc tube; b, shaping molybdenum wires into an electric arc tube supporting support according to the dimension requirements of different specifications, and electrically welding gettering sheets on the support; c, placing the electric arc tube with the support in a corresponding quartz outer tube, and using an outer tube clamping and sealing machine to heat the quartz tube to clamp and seal into a lamp tube; d, filling silica gel or lamp holder fixing powder in a lamp holder, and welding the clamped and sealed electric arc tube with a lamp pin or a lead; e, fixing the shaped electric arc tube on the filled lamp head, placing in a baking oven to heat to 90 to 150 DEG C to dry and detect. The technology of the preset invention is simple, is convenient to operate, and possesses a good popularization value.

Owner:GUANGDONG CHANGSHENG LIGHTING TECH

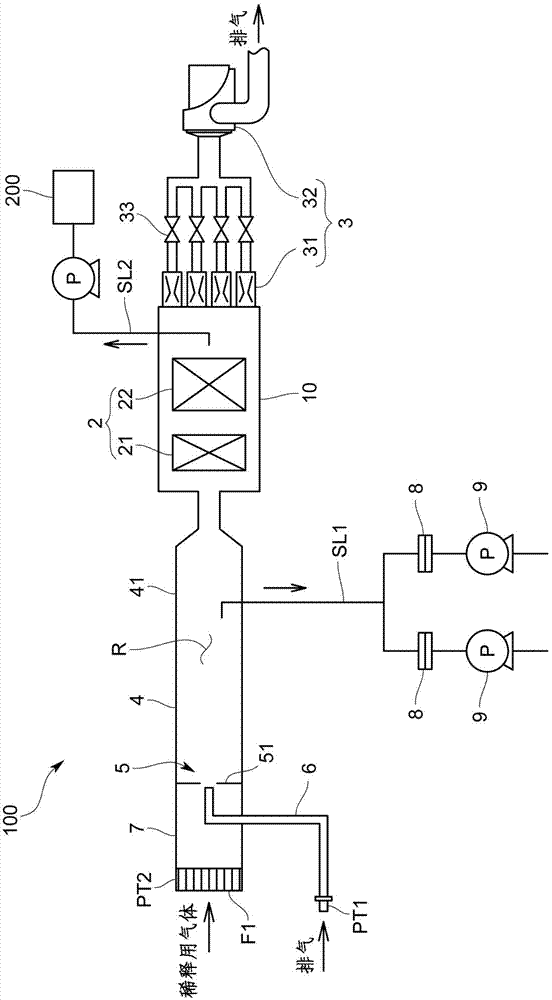

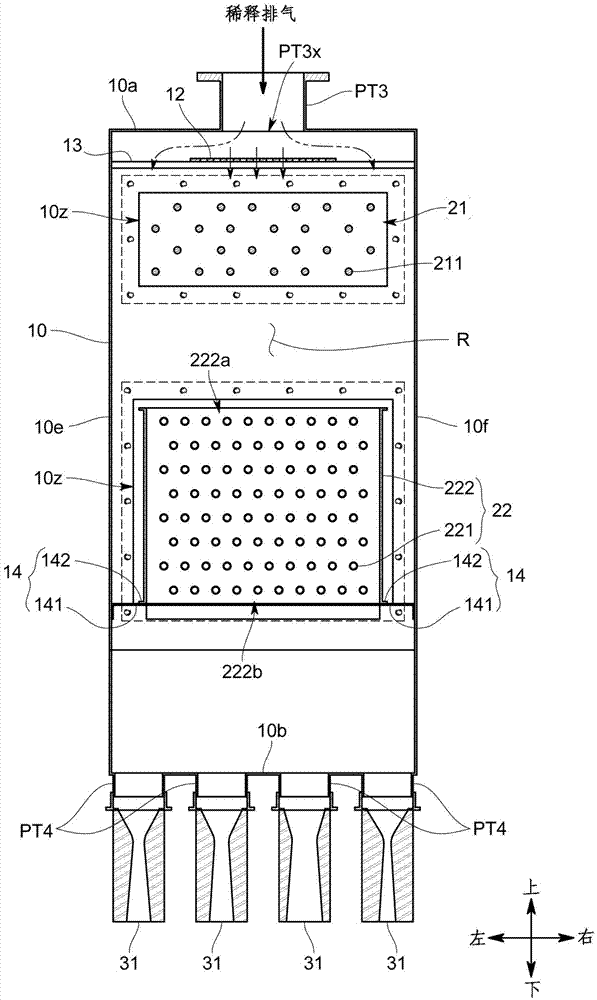

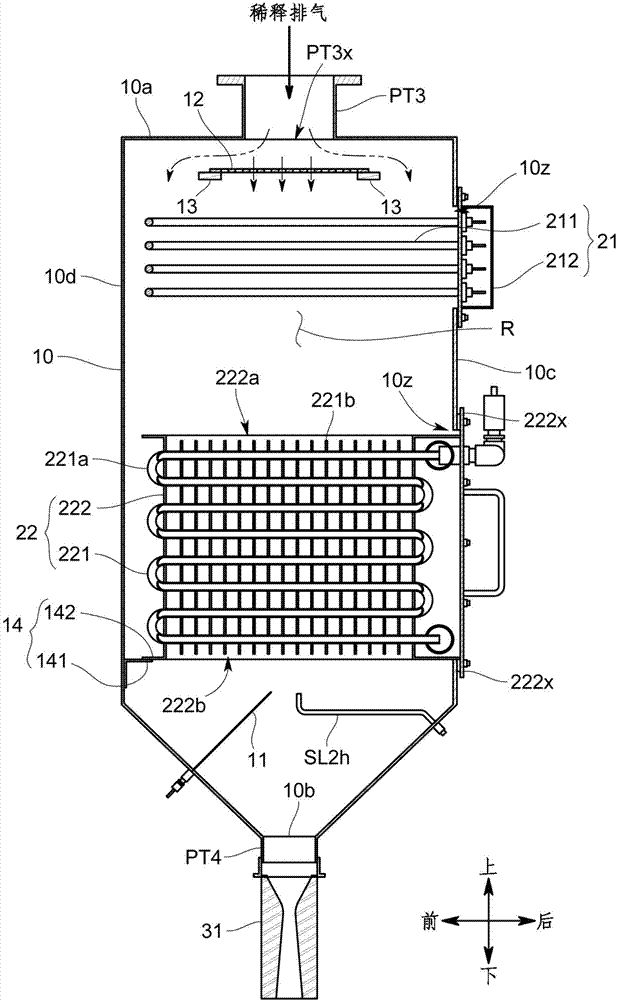

Exhaust gas sampling apparatus

InactiveCN104215476AUniform temperatureExhaust stableWithdrawing sample devicesPreparing sample for investigationProduct gasProcess engineering

The present invention is one that downsizes an exhaust gas sampling apparatus such as a CVS as well as uniforming temperature of diluted exhaust gas passing through a flow rate controller such as a critical flow venturi, and has a casing 10 formed with a gas introduction port PT3 for introducing the diluted exhaust gas and a gas lead-out port PT4 for leading out the diluted exhaust gas, in which a temperature regulating mechanism 2 is contained in the casing 10, the flow rate controller 31 is fluidly connected to the gas lead-out port PT4, and between the gas introduction port PT3 and the temperature regulating mechanism 2, a dispersion structure 12 that disperses the diluted exhaust gas introduced from the gas introduction port PT3 is provided.

Owner:HORIBA LTD

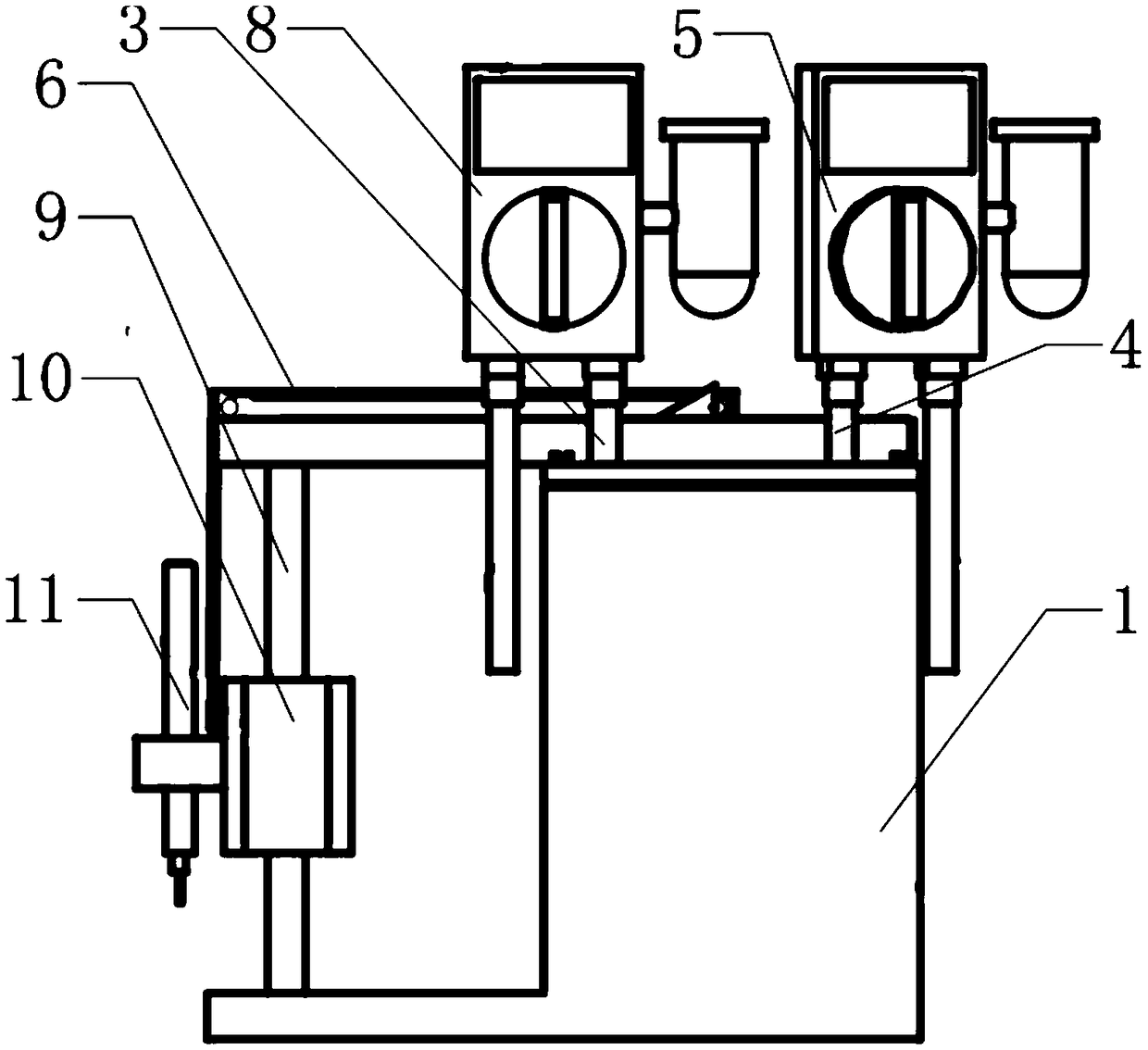

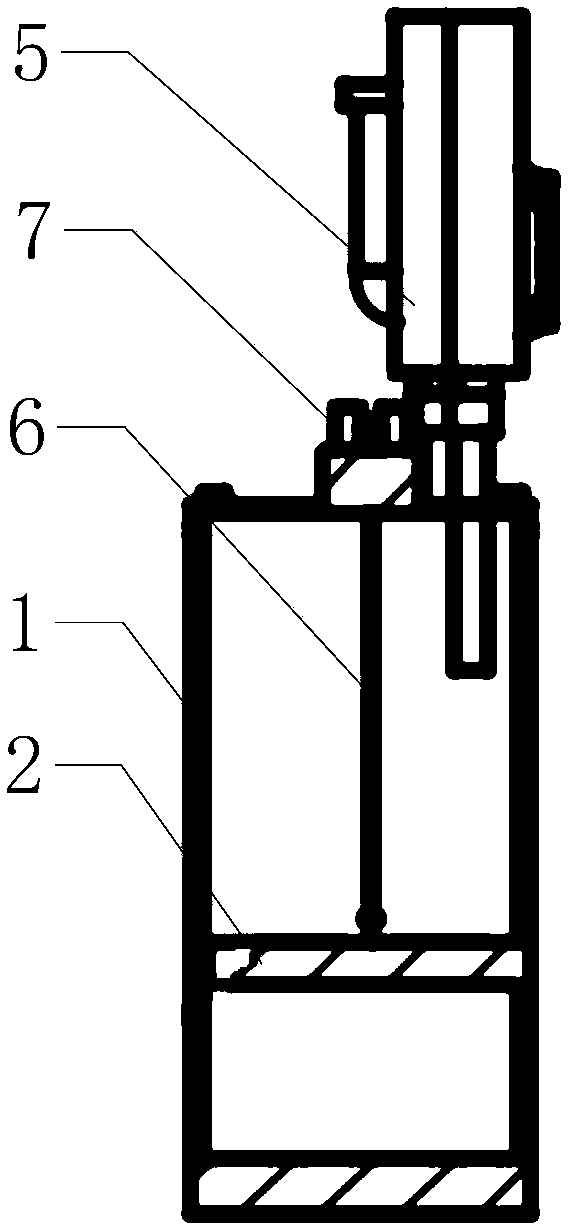

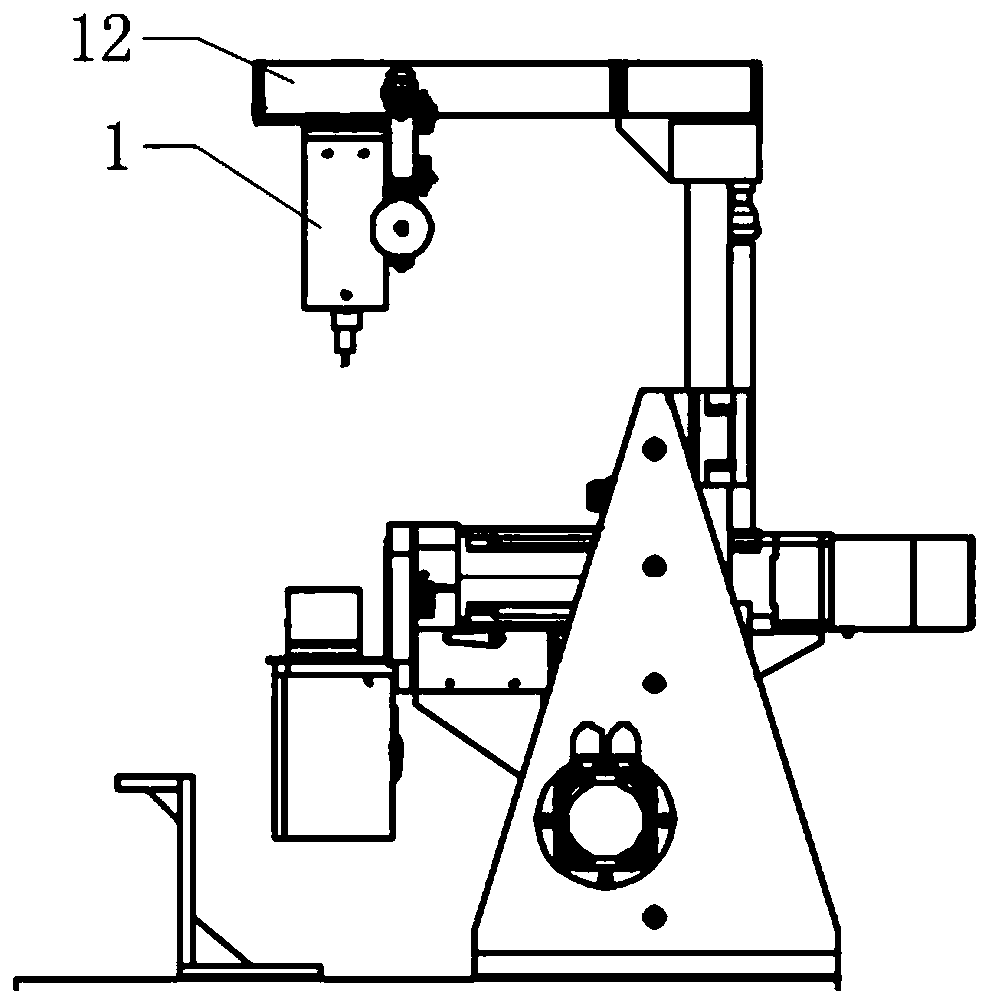

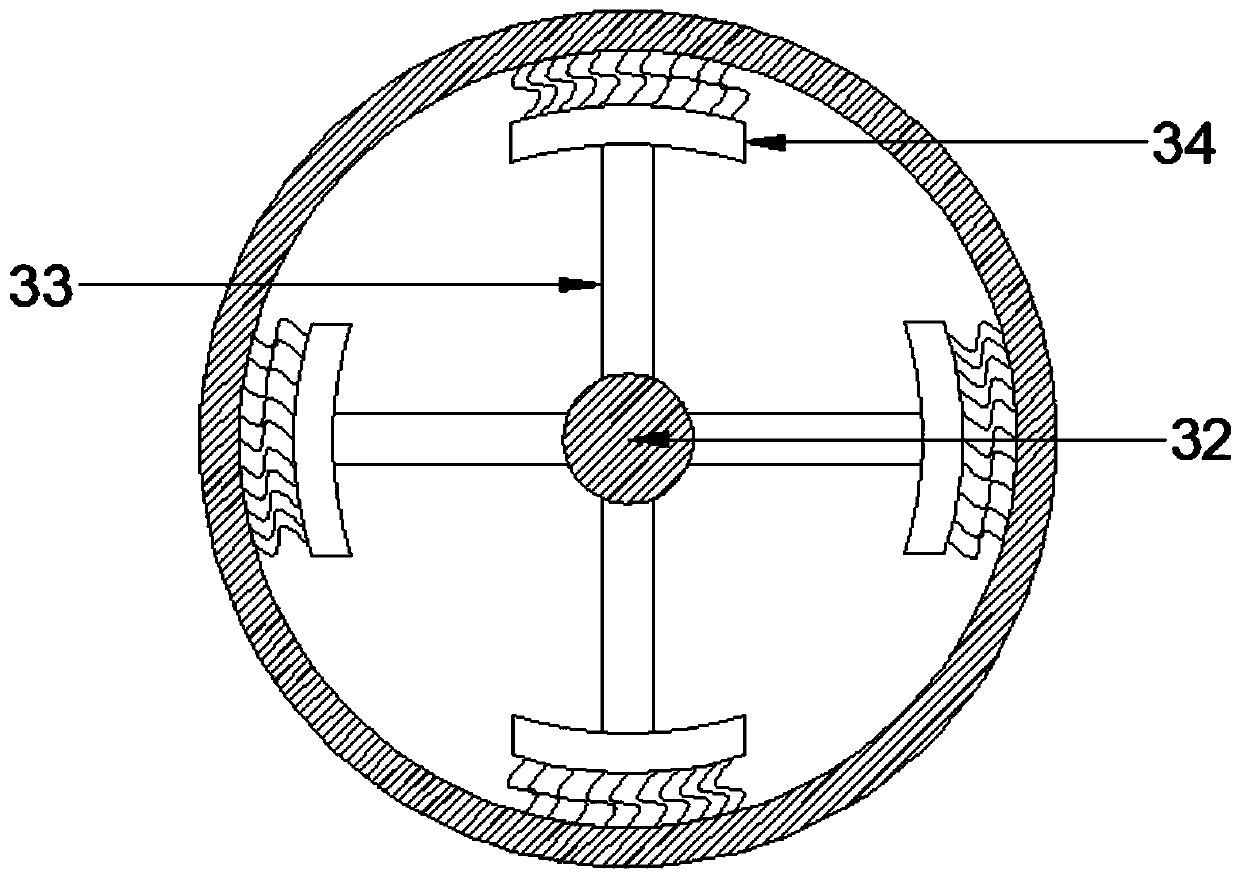

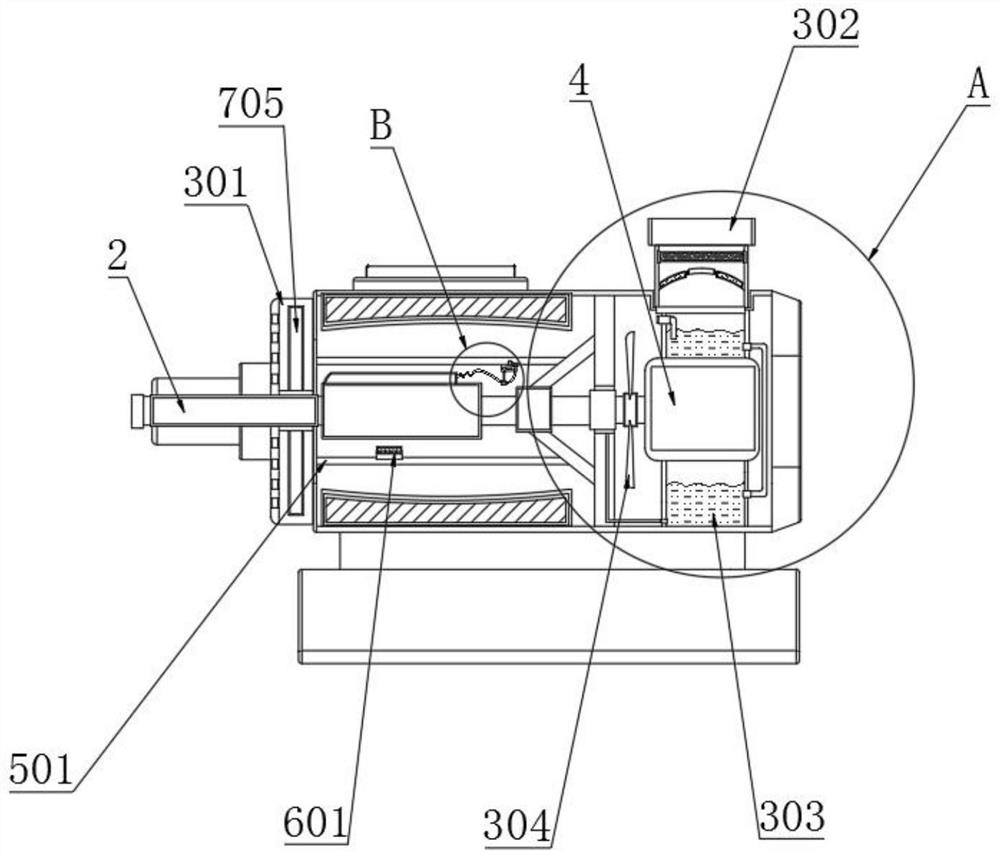

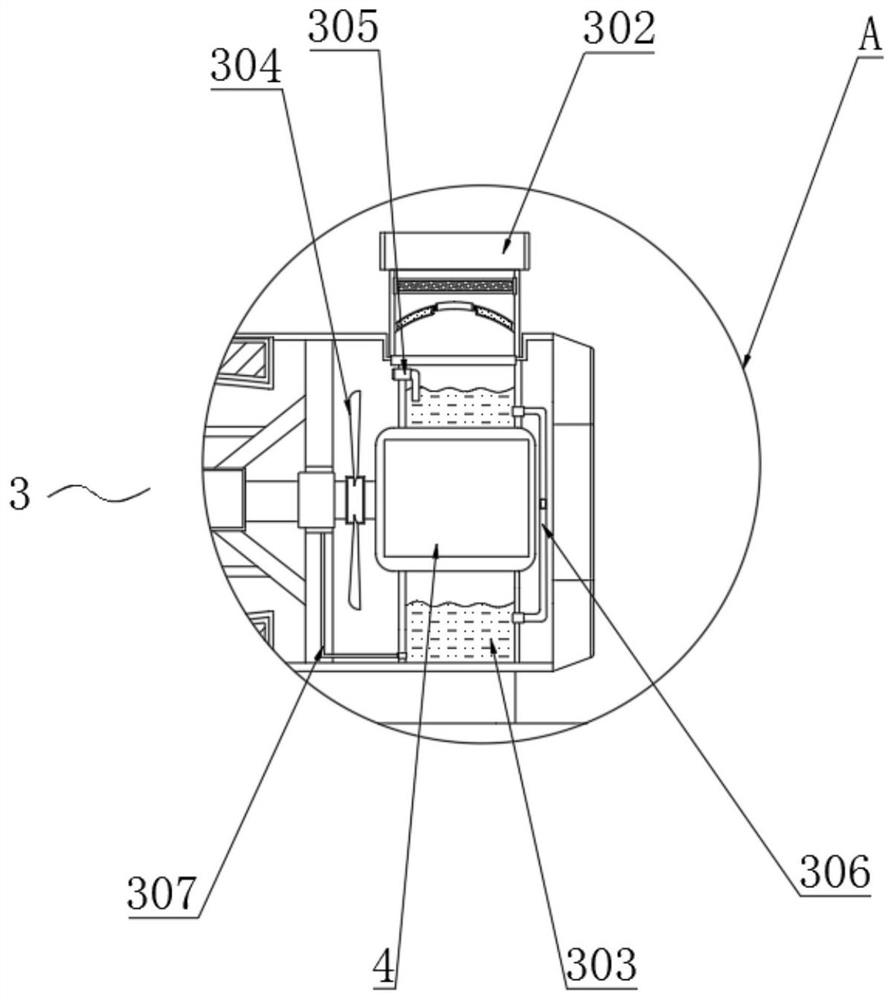

Polishing machine tool and constant-pressure device thereof

InactiveCN109176226AExhaust stableKeep the pressure constantOptical surface grinding machinesGrinding feed controlPull forceContact pressure

The invention discloses a constant-pressure device of a polishing machine tool. The constant-pressure device comprises a sealed gas cylinder and a polishing module which is in contact with a polishingworkpiece and can vertically move, wherein a piston platform is arranged in the gas cylinder; the piston platform can vertically move in the gas cylinder, is connected with the polishing module through a connector to transmit tensile force; a through hole for allowing the connector to pass through is formed in the gas cylinder; a gas outlet of the gas cylinder is used for stably discharging gas;a gas inlet of the gas cylinder is equipped with an inlet adjustable pressure-stabilizing valve; and the inlet adjustable pressure-stabilizing valve adjusts gas inlet amount according to the positionof the piston platform, so that pressure in the gas cylinder is kept constant. Real-time automatic compensation for contact pressure is realized through gas pressure change rule, so that constant-pressure polishing is realized, the polishing process for the workpiece is improved, the structure is simple, the control process is simplified, influences, on polishing, of a complex structure are reduced, and problems such as low workpiece polishing precision and a great rejection rate caused by conventional manual polishing equipment operation are avoided. The invention further discloses the polishing machine tool comprising the constant-pressure device.

Owner:GUANGDONG UNIV OF TECH

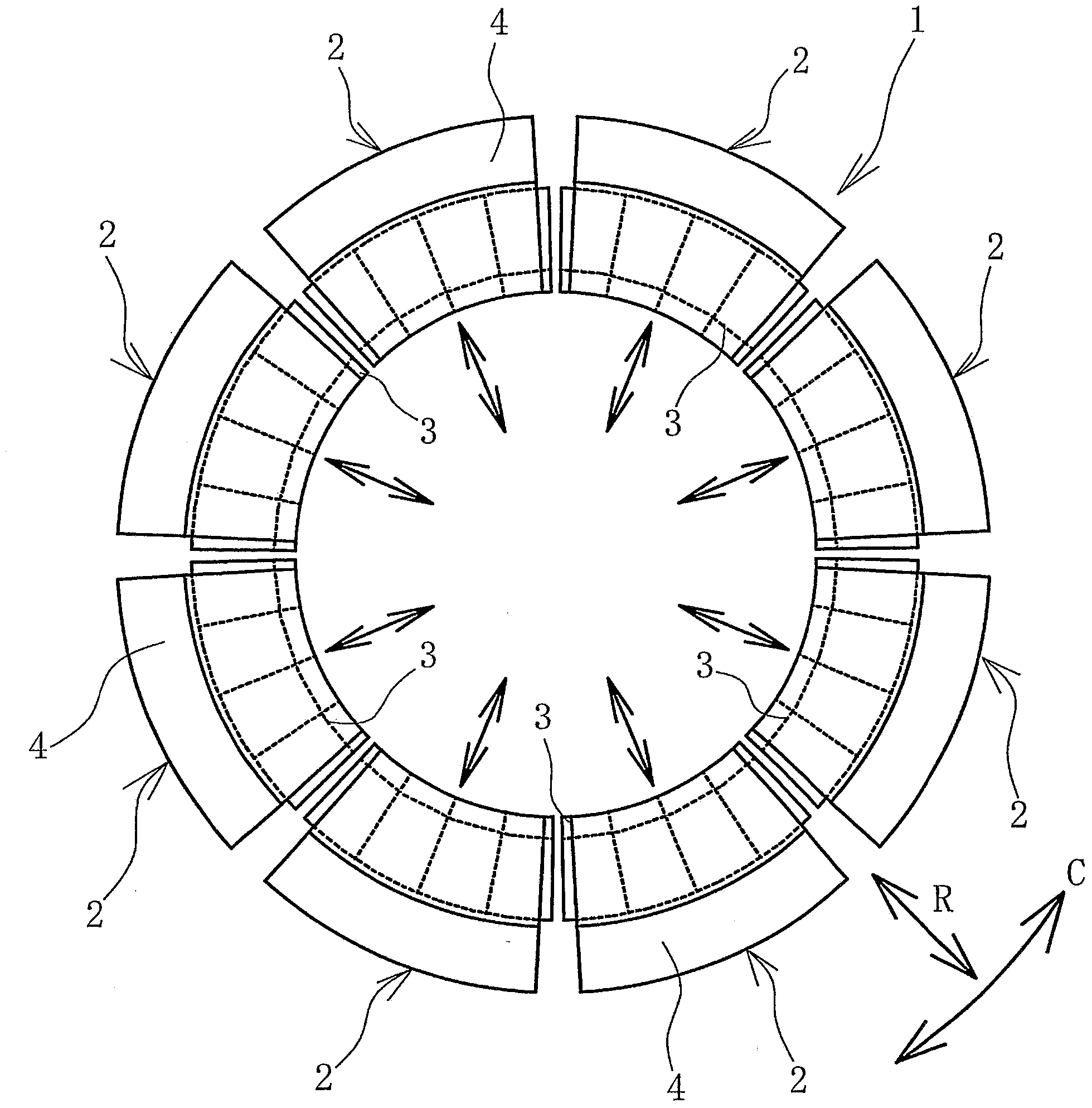

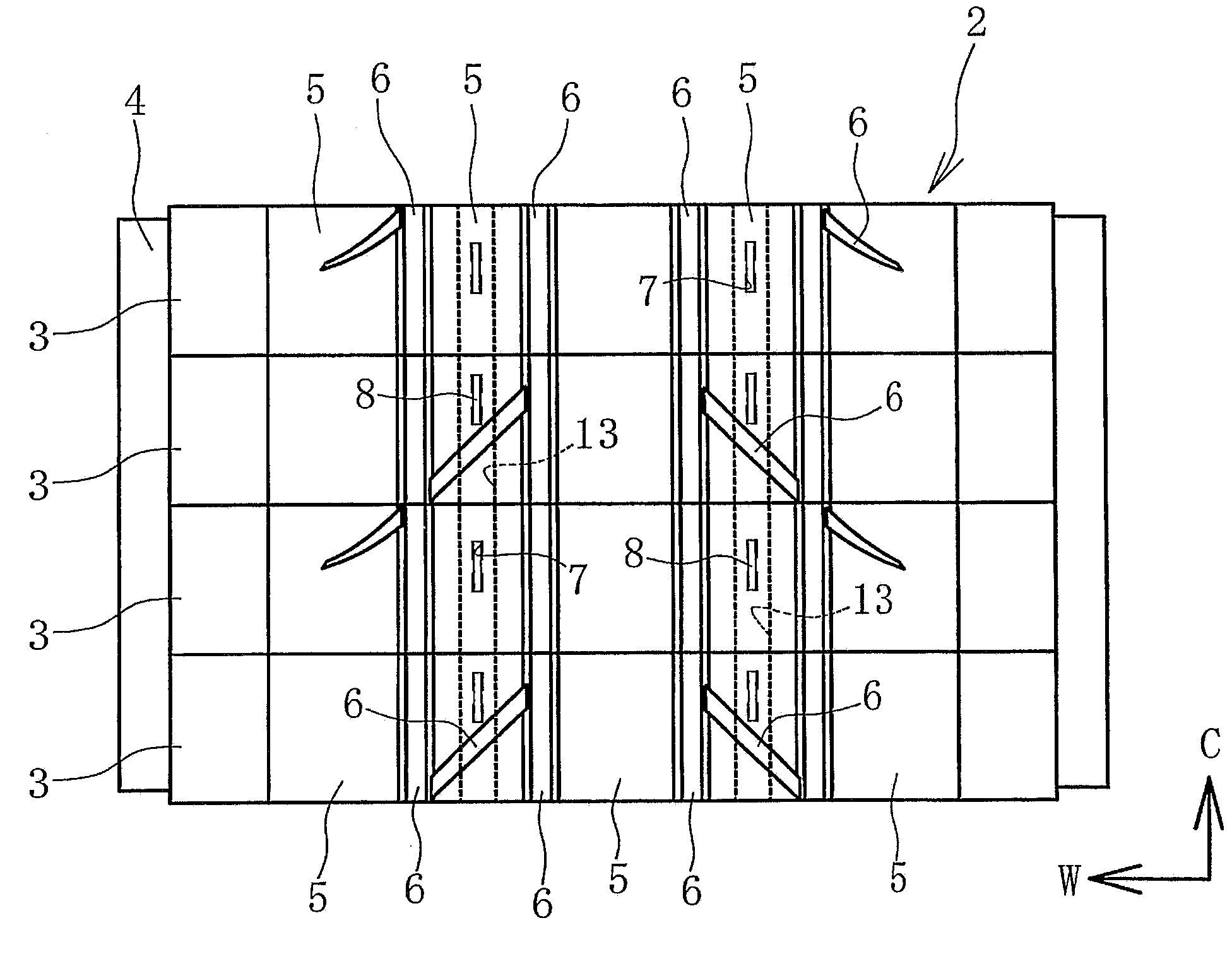

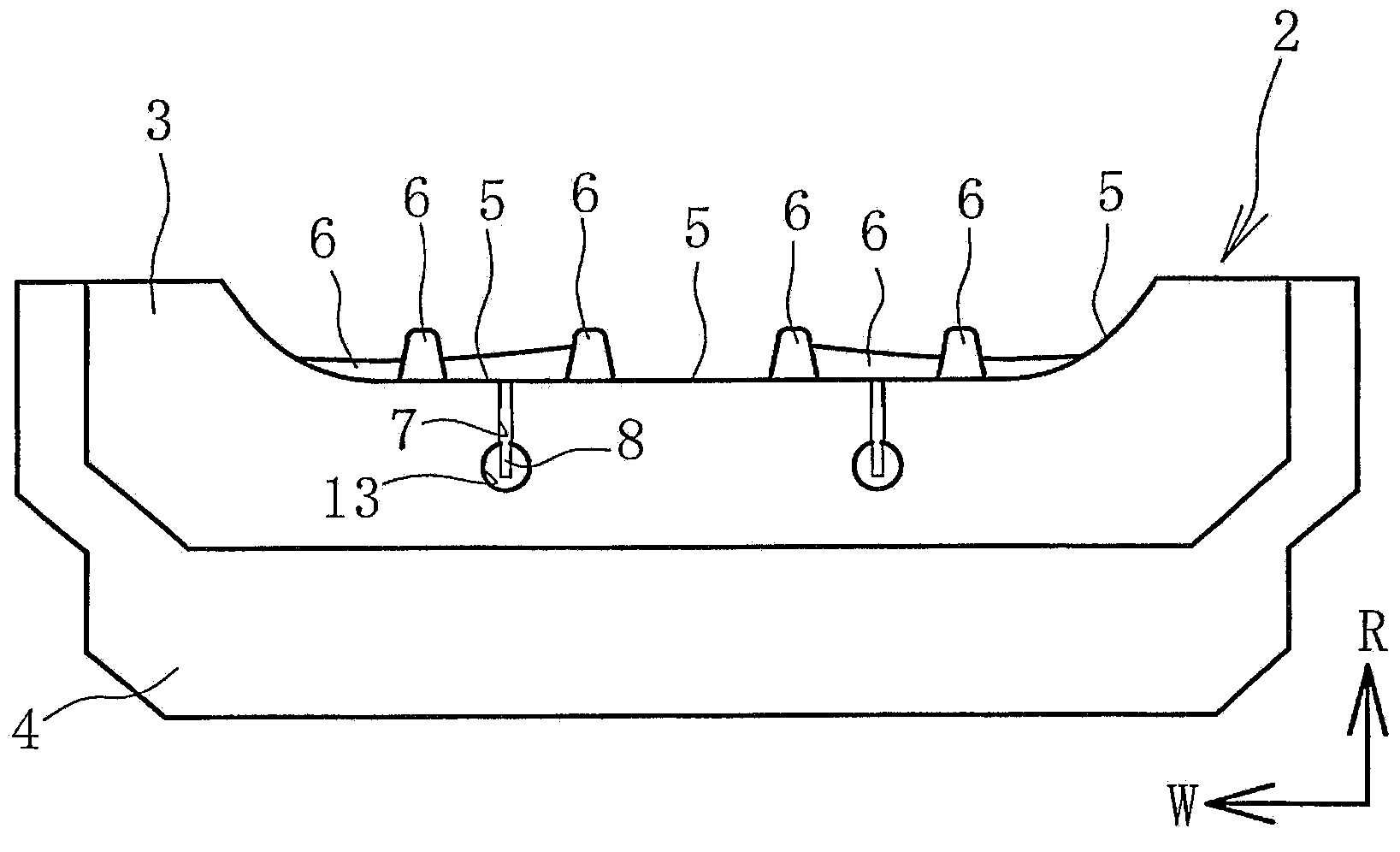

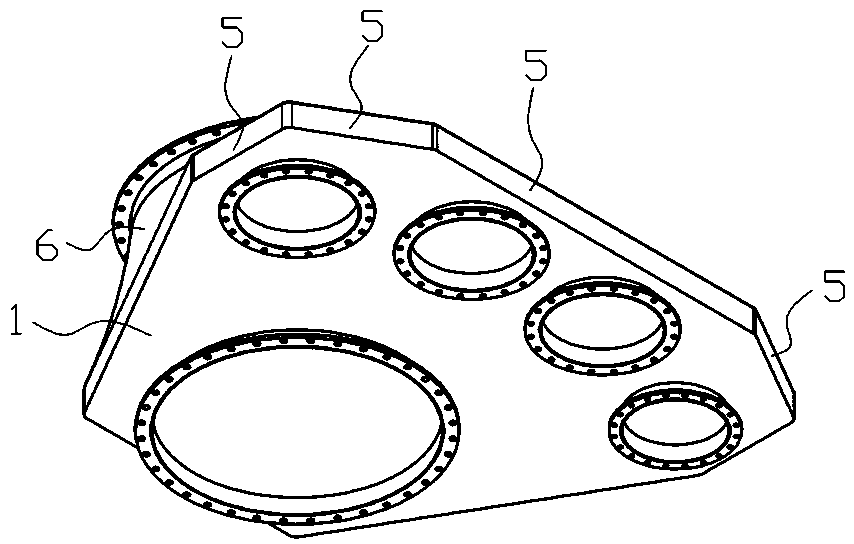

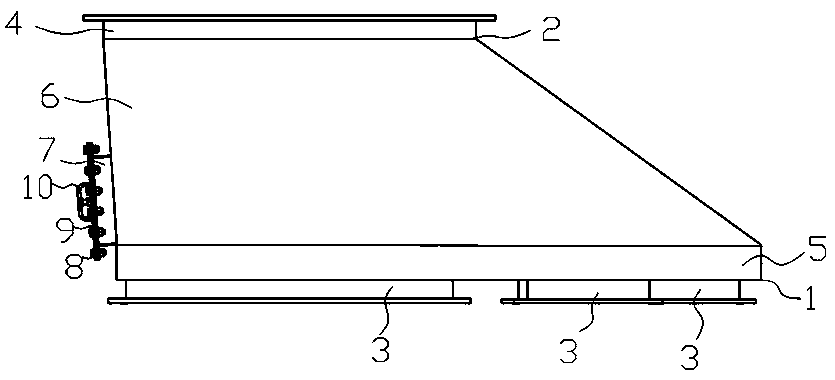

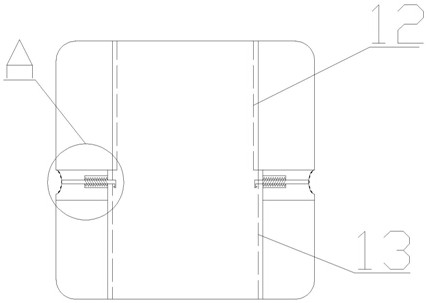

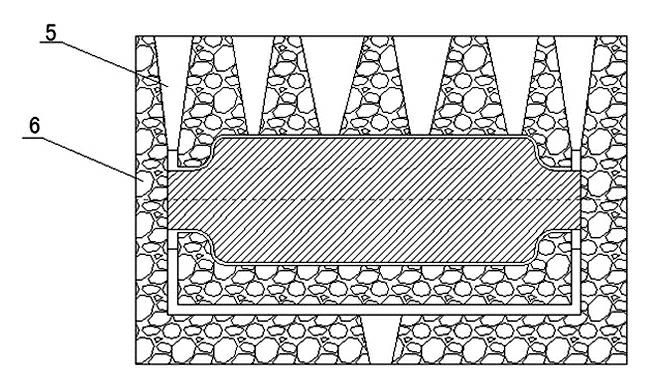

Tire vulcanization mold and manufacturing method therefor

Provided are a tire vulcanization mold, which can secure stable exhausting while embedding blades securely in the tire mold surface, and a manufacturing method therefor. In addition to providing protruding sections (9) that protrude in the thickness direction midway in the vertical direction of a blade (8), a communicating section (12), which extends from below the protruding sections (9) to above the protruding sections (9) and which passes through the blade (8) in the thickness direction, is provided. The initial thickness (t3) of the exhaust grooves (7) provided in the tire mold surface (5) is formed to be thinner than the thickness (T) of the protruding section (9). By inserting and positioning the lower end of a blade (8) in an exhaust groove (7) and pressing the positioned blade (8) in the depth direction of the exhaust groove (7) to embed same while spreading the exhaust groove (7) in the thickness direction using the protruding sections (9), minute gaps (g) are formed between the portions (10) above the protruding sections (9) of the embedded blade (8) and the exhaust groove (7), and the minute gaps (g) and the exhaust hole (13) communicate through the communicating section (12).

Owner:THE YOKOHAMA RUBBER CO LTD

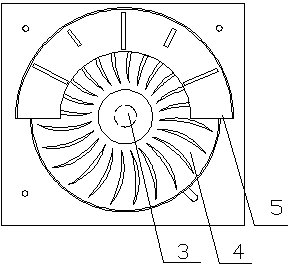

Casting method of turbofan

The invention relates to the technical field of turbofan casting and in particular relates to a casting method of a turbofan. The technological process of the casting method comprises the steps of material inspection, production of precoated sand, core producing / modeling, core setting, mould assembling, smelting, pouring, mould disassembling, casting head knocking, coarse polishing, clearing, burnishing, elaborate polishing, appearance inspection, oiling, warehousing inspection, packaging and delivery, wherein in the core setting step, a core III is set into a lower mould firstly, and then a core II and a core I are set into the lower mould sequentially; in the pouring steps, molten iron is poured in a suspended manner through a traveling crane to enter from an upper mould and is poured at the periphery while oppositely poured at two sides, and then exhaust gas is ignited by open fire by a worker. The casting method adopts a flat mould pouring method, and the core head part of the mud core II extends and is pressed and fixed by the mud core I, so that scrap caused by upward floating of the mud cores can be effectively prevented. According to an existing pouring process, the molten iron enters from the periphery, and the top end is open for exhaust, so that the mould filling of the molten iron can be relatively stable and is conducive to exhaust.

Owner:溧阳市双盛机械制造有限公司

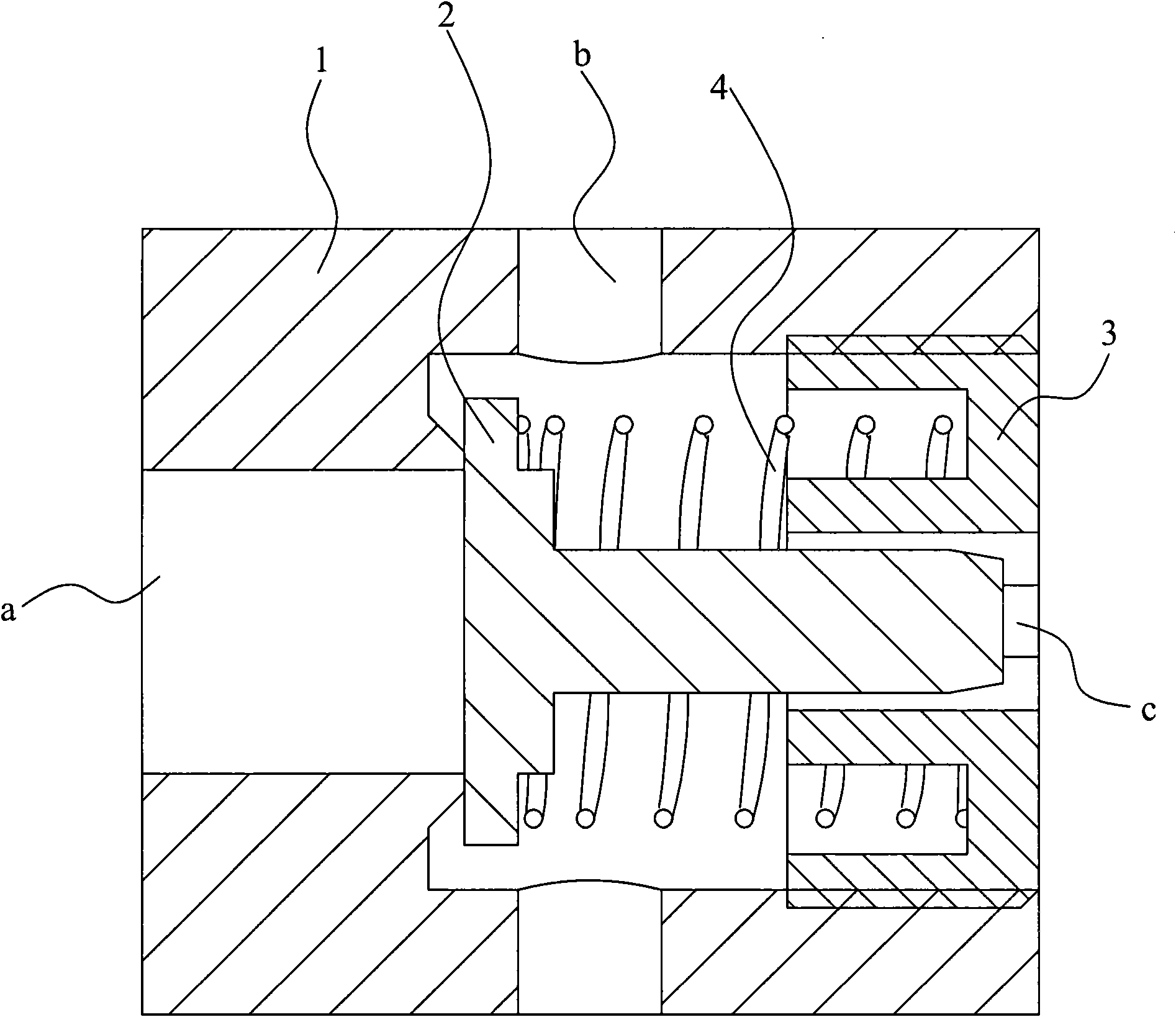

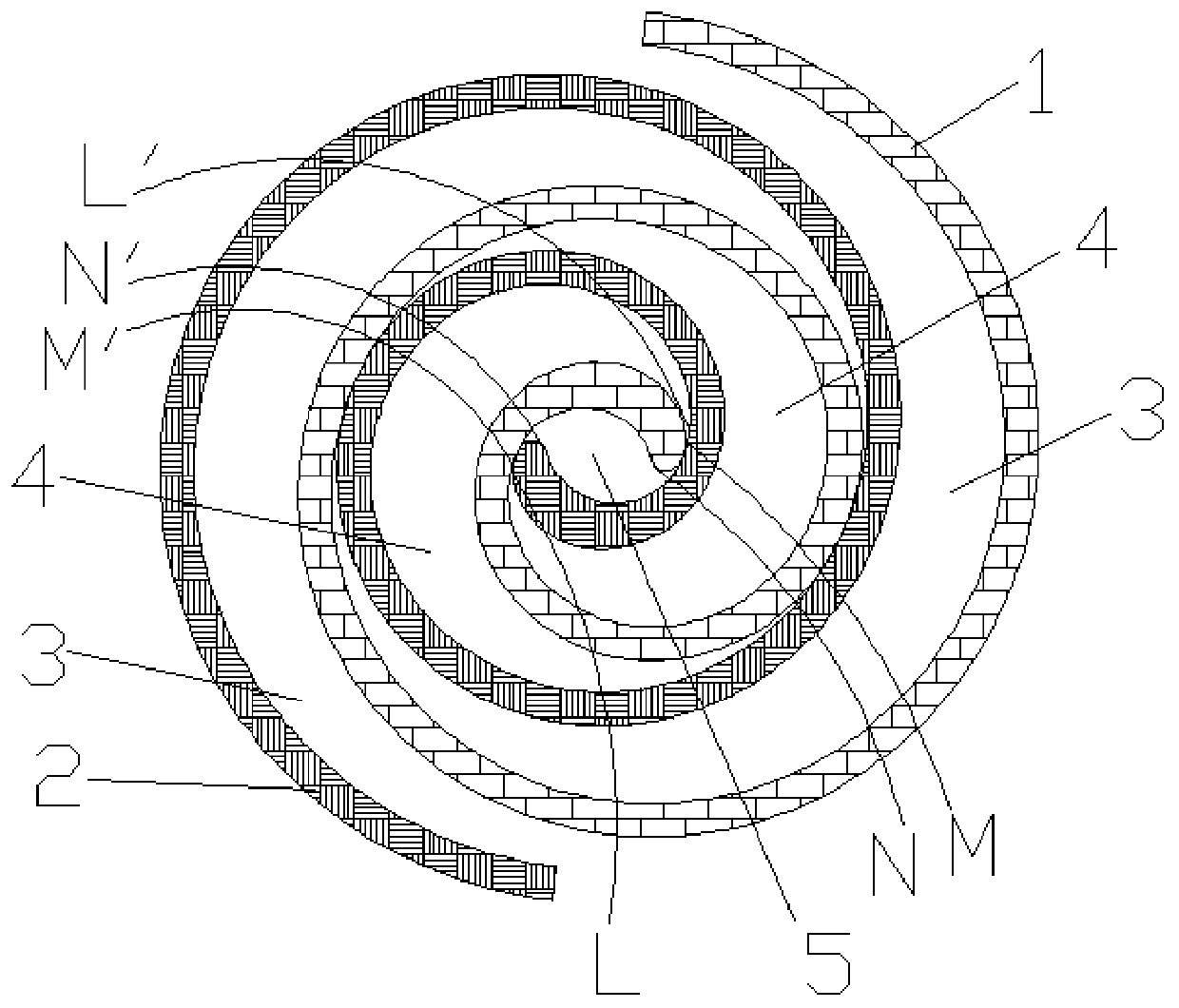

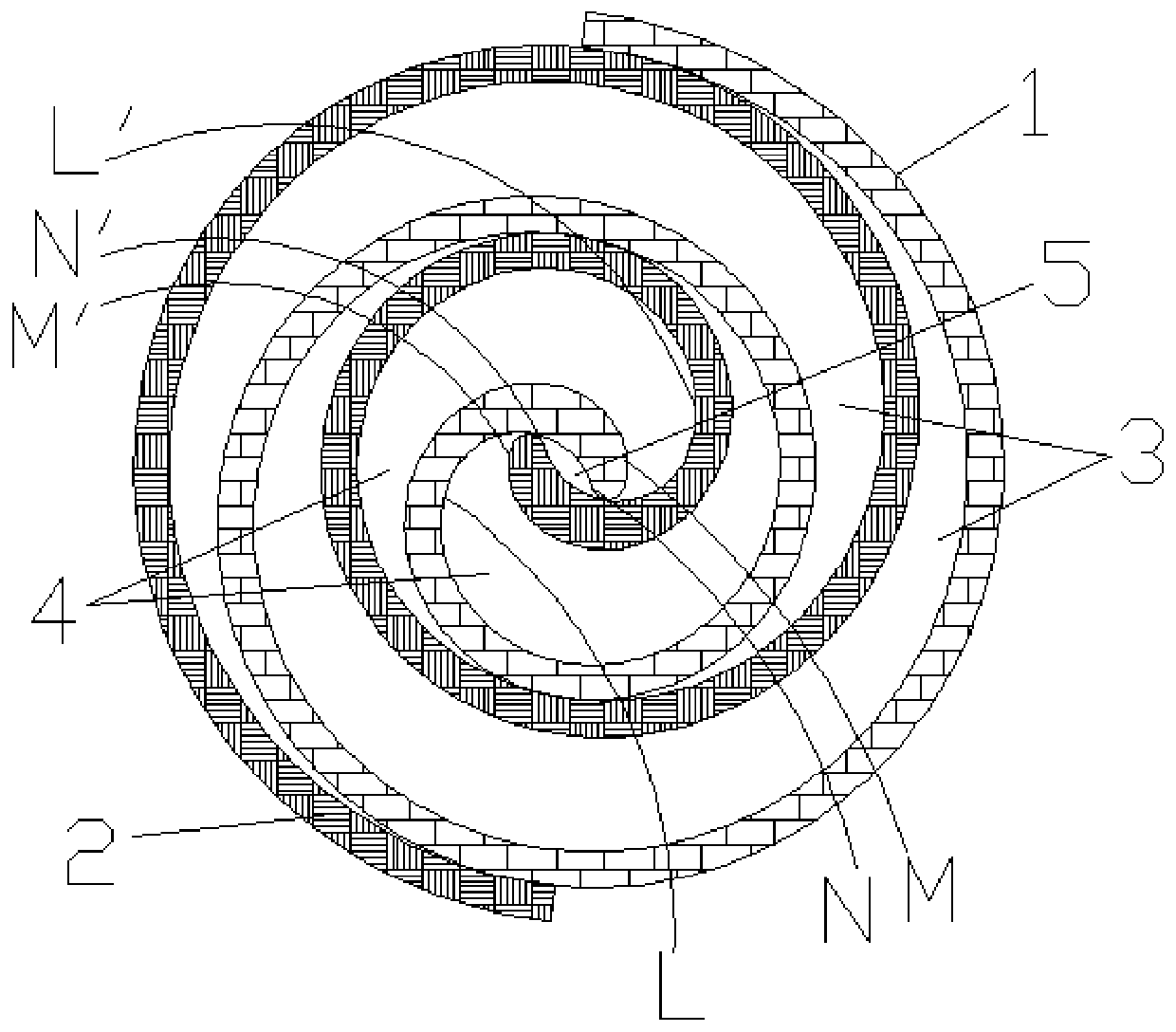

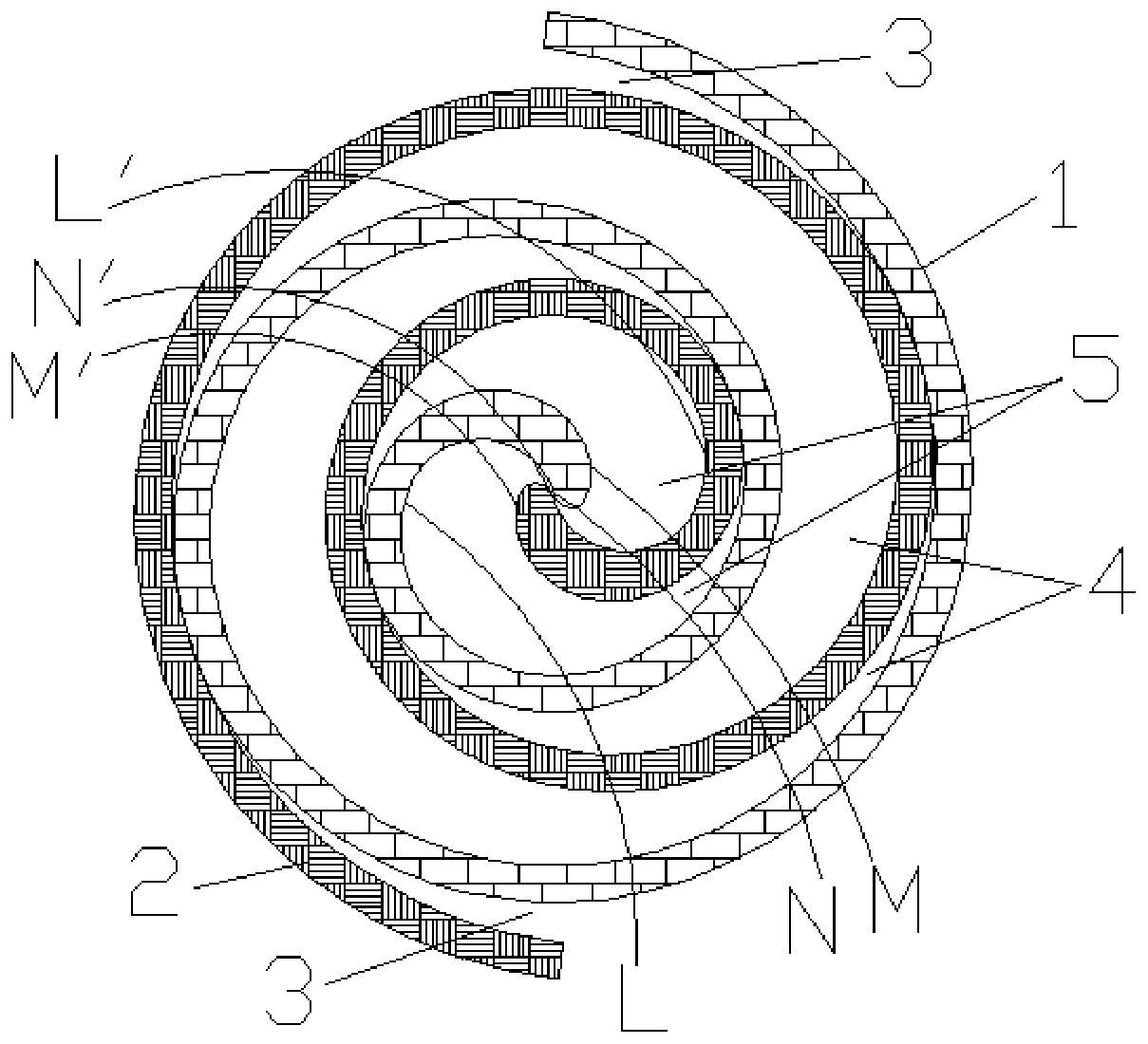

Scroll type linear tooth head structure of scroll compressor and correcting method thereof

PendingCN110030191AUniform pressureExhaust stableGeometric CADPump componentsBusiness efficiencyMechanical engineering

The invention provides a scroll type linear tooth head structure of a scroll compressor. The scroll type linear tooth head structure of the scroll compressor is characterized in that gas is exhaustedthrough static scroll plates and a movable scroll plate; when a gas suction chamber is closed, a first clearance is formed between a first center head part section and a second center inner circular arc section, a second clearance is formed between a second center head part section and a first center inner circular arc section, and scroll teeth of the static scroll plates between the gas suction chamber and an intermediate pressure chamber are engaged with scroll teeth of the movable scroll plate; the static scroll plates and the movable scroll plate are capable of sucking air and compressing;and when the gas suction chamber is gradually opened, the scroll teeth of the static scroll plates between the gas suction chamber, the intermediate pressure chamber and the gas exhausting chamber are engaged with the scroll teeth of the movable scroll plate. The invention also provides a correcting method of the scroll type linear tooth head structure of the scroll compressor. According to the scroll type linear tooth head structure of the scroll compressor and the correcting method, the tooth head parts are engaged through gradual clearances, so that the pressure of a compressing chamber and the pressure of a gas exhausting hole are close to each other or equal to each other while the compressing chamber communicates with the gas exhausting hole; the compressing process can be subjectedto smooth transition, the mechanical noise and electromagnetic noise caused by suddenly changed pressure can be reduced, and thus the energy efficiency ratio can be increased.

Owner:泰铂(上海)环保科技股份有限公司

Diffusion system

InactiveUS20050092244A1Speed efficientExhaust stableAfter-treatment apparatusDiffusion/dopingDiffusionReactive gas

Provided is a diffusion system for forming a doping layer in a wafer. The diffusion system includes a bubbler for generating a doping gas; a premixer, which premixes the doping gas with reactive gases and preheats the gas mixture; a main chamber, in which the gas mixture reacts to the wafer; a buffer case, which externally isolates an exhaust port and a door for loading and unloading the wafer into and out or the main chamber; and a used gas exhaustion system, which exhausts a used gas after the reaction is finished in the main chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

Vacuum pressure continuous control process for polysilicon ingot casting process and control system thereof

InactiveCN101311341BReduce consumptionStable controlPolycrystalline material growthSingle crystal growth detailsFurnace temperatureVacuum pressure

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

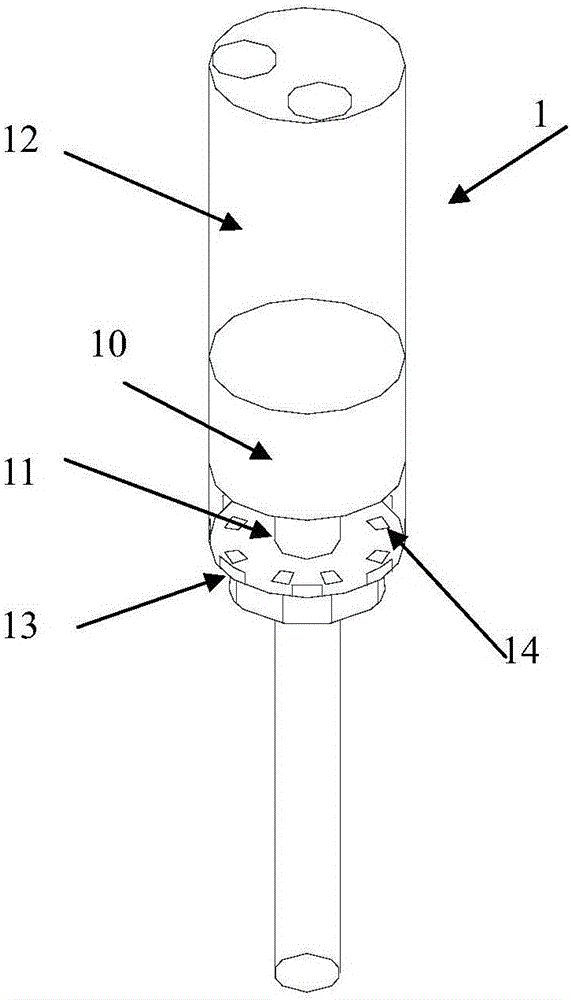

Disposable infusion apparatus with precise filter capable of exhausting gas automatically

InactiveCN105233360ASimple structureImprove safety and reliabilityInfusion devicesIntravenous needlesMedical equipment

The invention provides a disposable infusion apparatus with a precise filter capable of exhausting gas automatically, and belongs to the field of medical equipment. The disposable infusion apparatus with the precise filter capable of exhausting gas automatically comprises a cap bag, a bottle inserting plastic needle, a first infusion tube section, a first water stopping valve, a flat-bottom drip chamber, a gas exhausting tube, a second infusion tube section, an adjusting valve, the precise filter capable of exhausting gas automatically, a third infusion tube section, a second water stopping valve, a Luer, a Luer fitting and an intravenous needle, wherein the gas exhausting tube is arranged in the flat-bottom dripping chamber; the cap bag sleeves the bottle inserting plastic needle; the bottle inserting plastic needle is connected with the flat-bottom dripping chamber through the first infusion tube section; the first water stopping valve sleeves the first infusion tube section; the flat-bottom dripping chamber is connected with the precise filter capable of exhausting gas automatically through the second infusion tube section; the adjusting valve is mounted on the second infusion tube section; the precise filter capable of exhausting gas automatically is connected with the Luer through the third infusion tube section; the second water stopping valve sleeves the third infusion tube section; the Luer is connected with the Luer fitting in a clamping mode; and the Luer fitting is connected with the intravenous needle.

Owner:徐州一佳医疗器械有限公司

Hybrid cylinder, hybrid engine and control method

InactiveCN105840297AImprove power output smoothnessReduce the temperatureCombustion enginesPump installationsEngineeringInternal combustion engine

The invention discloses a hybrid cylinder. The hybrid cylinder comprises a cylinder body which is divided into an oil chamber and a piston of an air chamber which are distributed from top to bottom; first side air holes are formed in the bottom of the side wall of the air chamber; through the first side air holes, compressed air is injected into the air chamber or internal air is discharged to a compressed air collecting part; first bottom air holes are formed in the bottom of the air chamber; and through the first bottom air holes, air discharge in the later stage of compression is realized. The hybrid cylinder provided by the invention has the advantages that the oil chamber and the air chamber of an internal combustion engine are integrally arranged from top to bottom, so that the high temperature of the oil chamber during work time and the compressed air injected into the air chamber are effectively utilized for expansion work, and the expansion work of the compressed air can be achieved while the temperature of the cylinder body of the hybrid cylinder is lowered, that is, the compressed air is utilized for auxiliary work during an exhaust stroke of the oil chamber, thereby effectively improving the overall efficiency; and meanwhile, the internal energy of the first half of the downward movement of the piston is huge after ignition of the oil chamber, so that the internal energy can be sufficiently utilized to compress air in the air chamber for preparation and storage of the compressed air, and the engine power can be output more stably.

Owner:张昭贵 +1

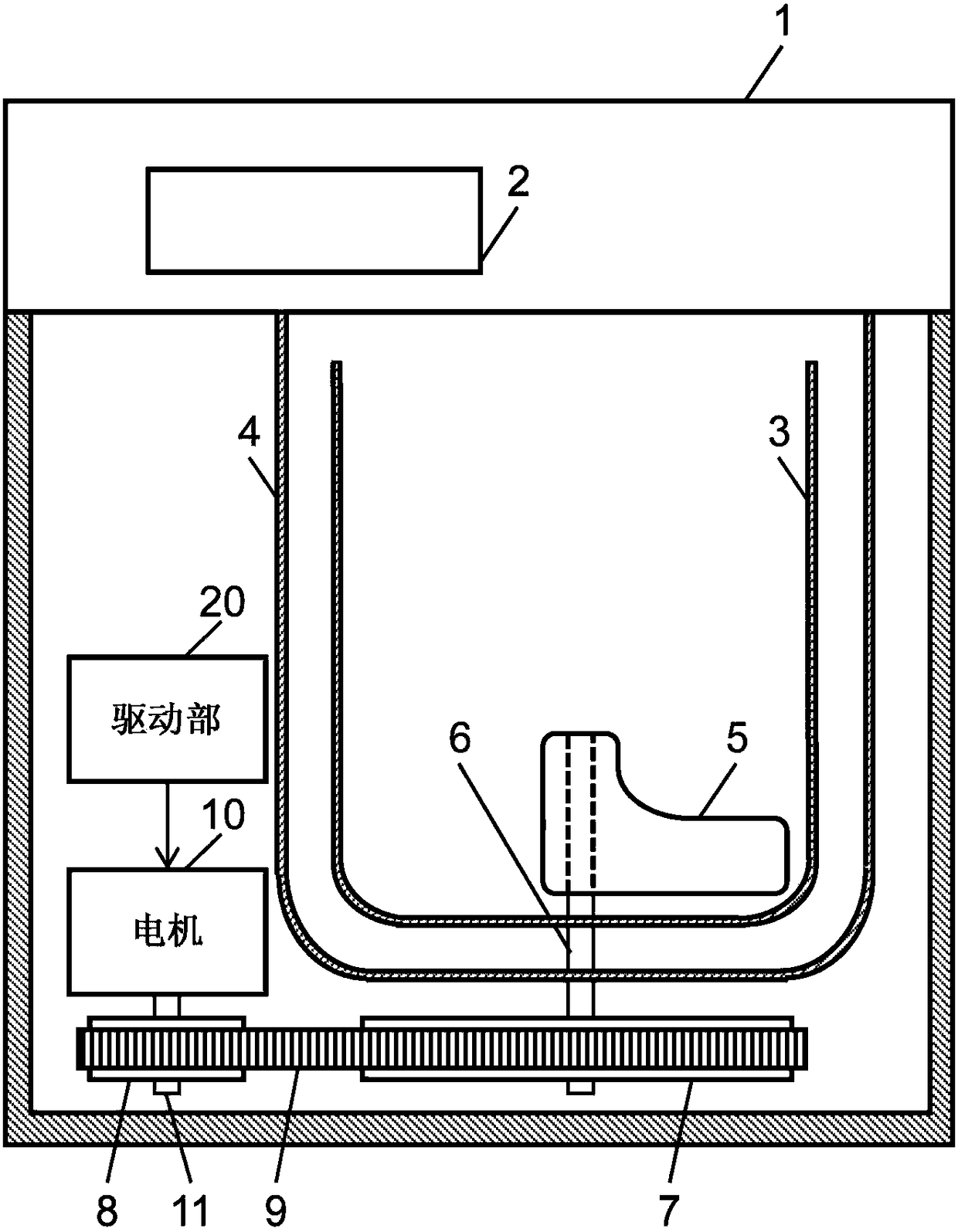

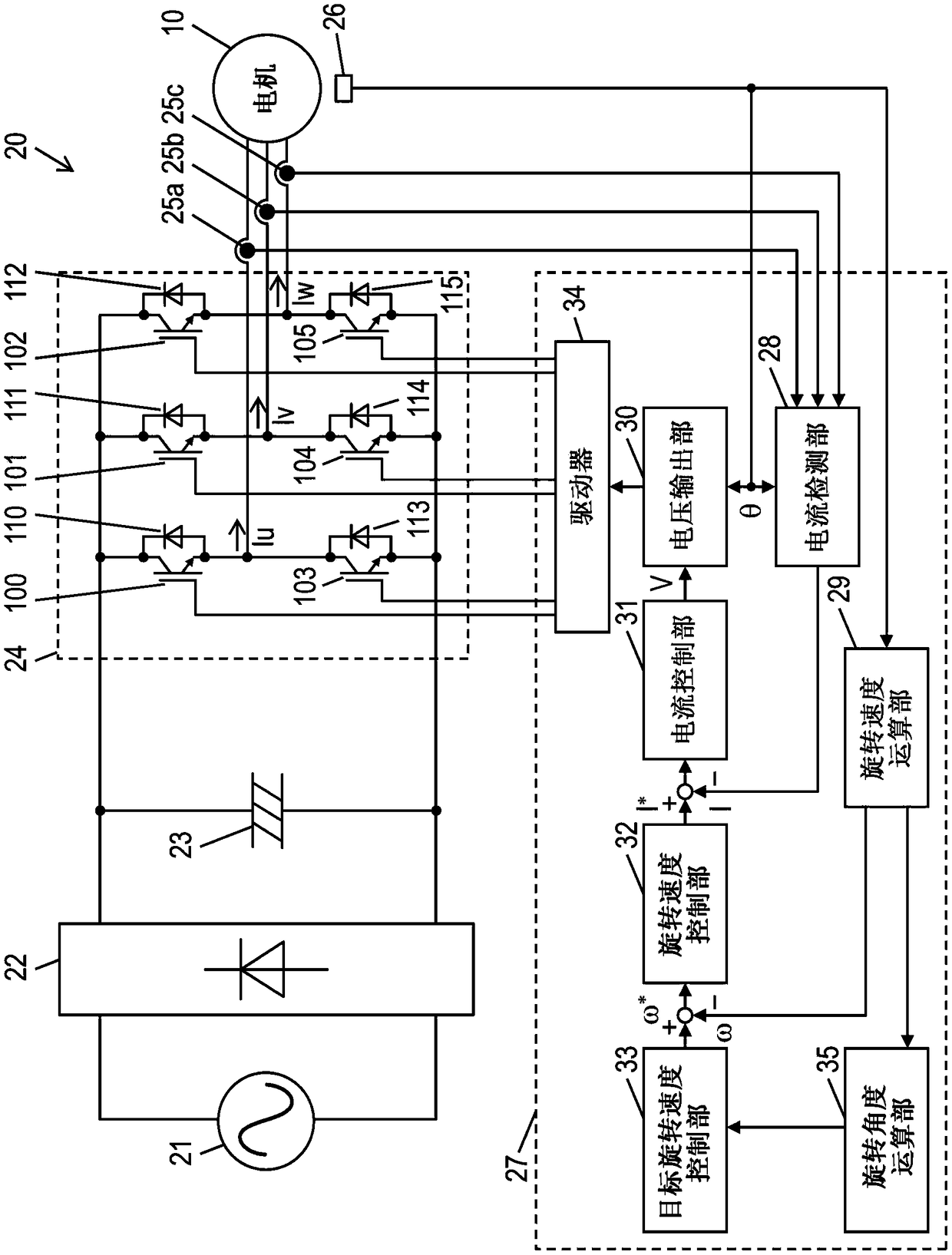

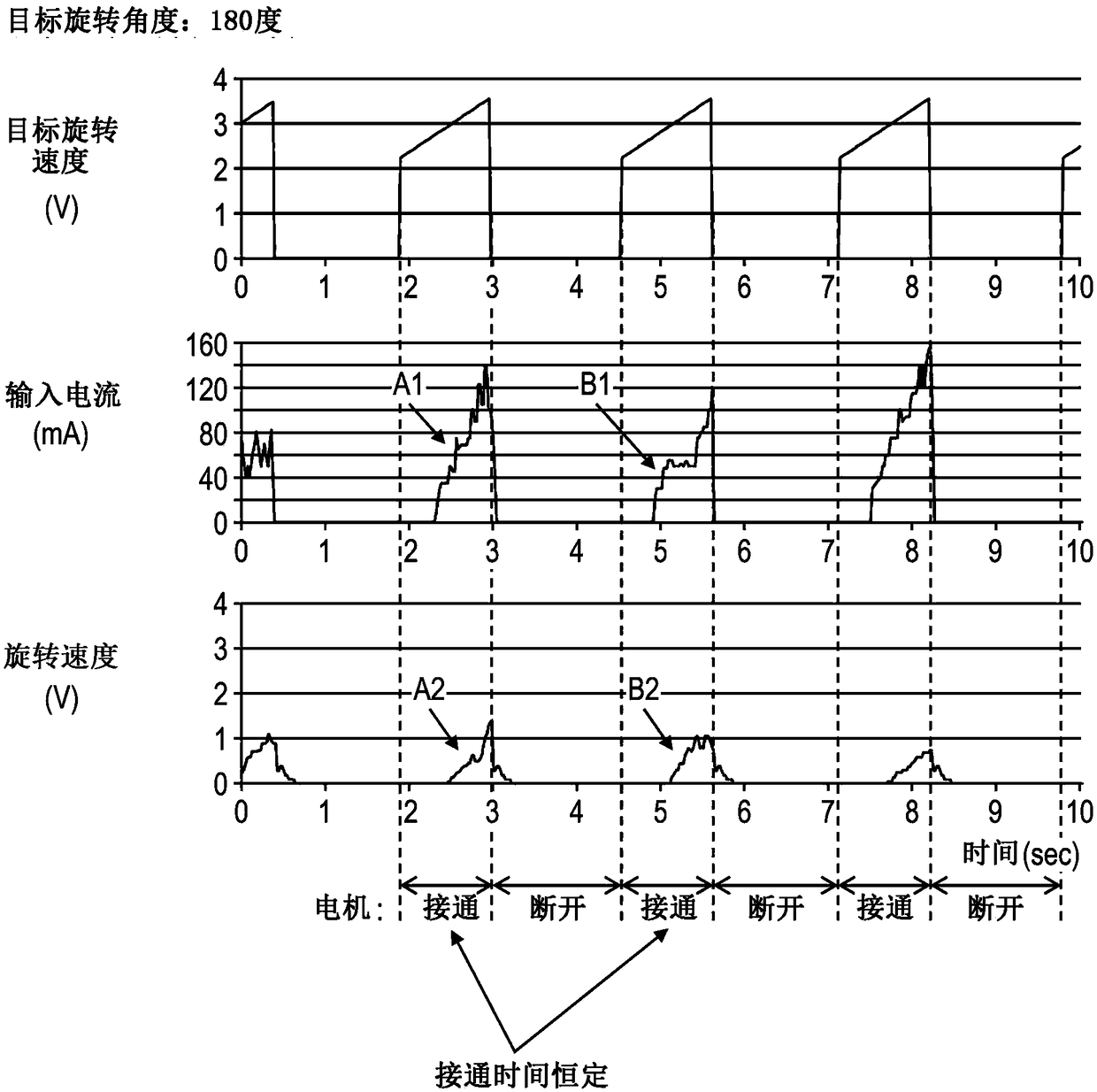

Automatic bread maker

Provided is an automatic bread maker, comprising a container, stirring blades, a motor, a pulse output part, an inverter part and a control part. Bread stuff is put into the container. The stirring blades are disposed in the container in a rotatable manner. The motor enables the stirring blades to rotate. The pulse output part outputs a pulse signal based on the rotation angle of the motor. The inverter part drives the motor. The control part controls the inverter part based on the pulse. In an air exhausting process, the control part calculates the rotating speed of a motor based on the pulsesignal, and controls the inverter part so that the rotating speed can be the target rotating speed. The control part calculates the rotating speed of the motor based on the pulse signal, and controlsthe inverter part so that the rotating angle can be the target rotating angle. In the air exhausting process, the damage of bread dough can be prevented, and air exhaust can be stably conducted.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

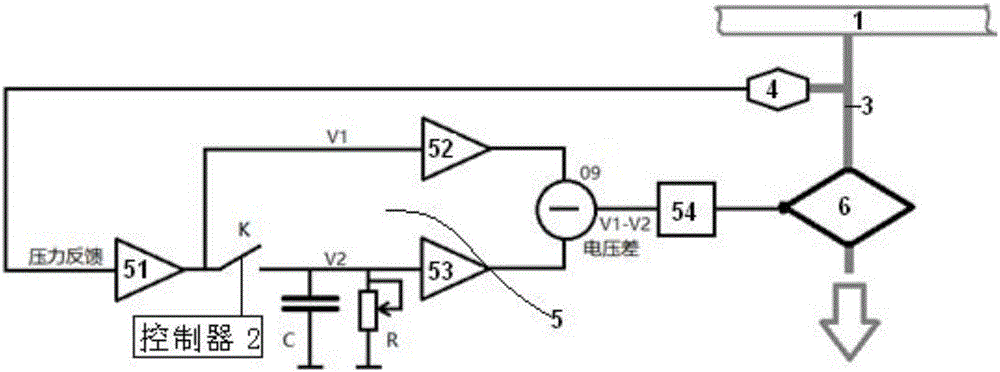

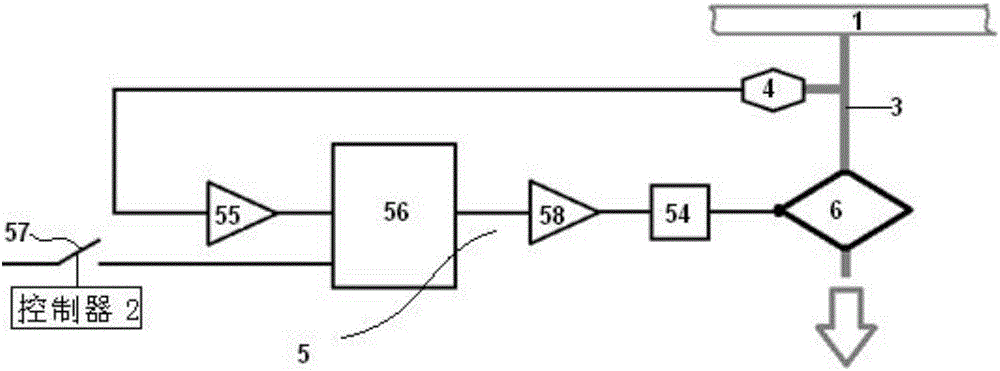

Air discharging control device and method for train braking

ActiveCN106483992AExhaust stableStable exhaust air speed controlFluid pressure control using electric meansElectricityDriver circuit

The invention discloses an air discharge control device and method for train braking. The control device comprises a train pipe arranged on a train, a controller, a pipeline communicated with the train pipe, a pressure sensor arranged in the pipeline, a pressure feedback control circuit and a flow control body arranged in front of an air exhaust opening of the pipeline; the flow control body comprises a driving circuit and m electric-control switch valves in parallel connection, and m>=2; and the signal input end of the pressure feedback control circuit is electrically connected with the signal output end of the pressure sensor, the pressure feedback control circuit is electrically connected with the controller and a drive circuit, and the driver circuit is connected with the electric-control switch valves. The control device and method are characterized in that the air discharge speed can be controlled stably and adjusted continuously.

Owner:HANGZHOU CHUANGLIAN ELECTRONICS TECH

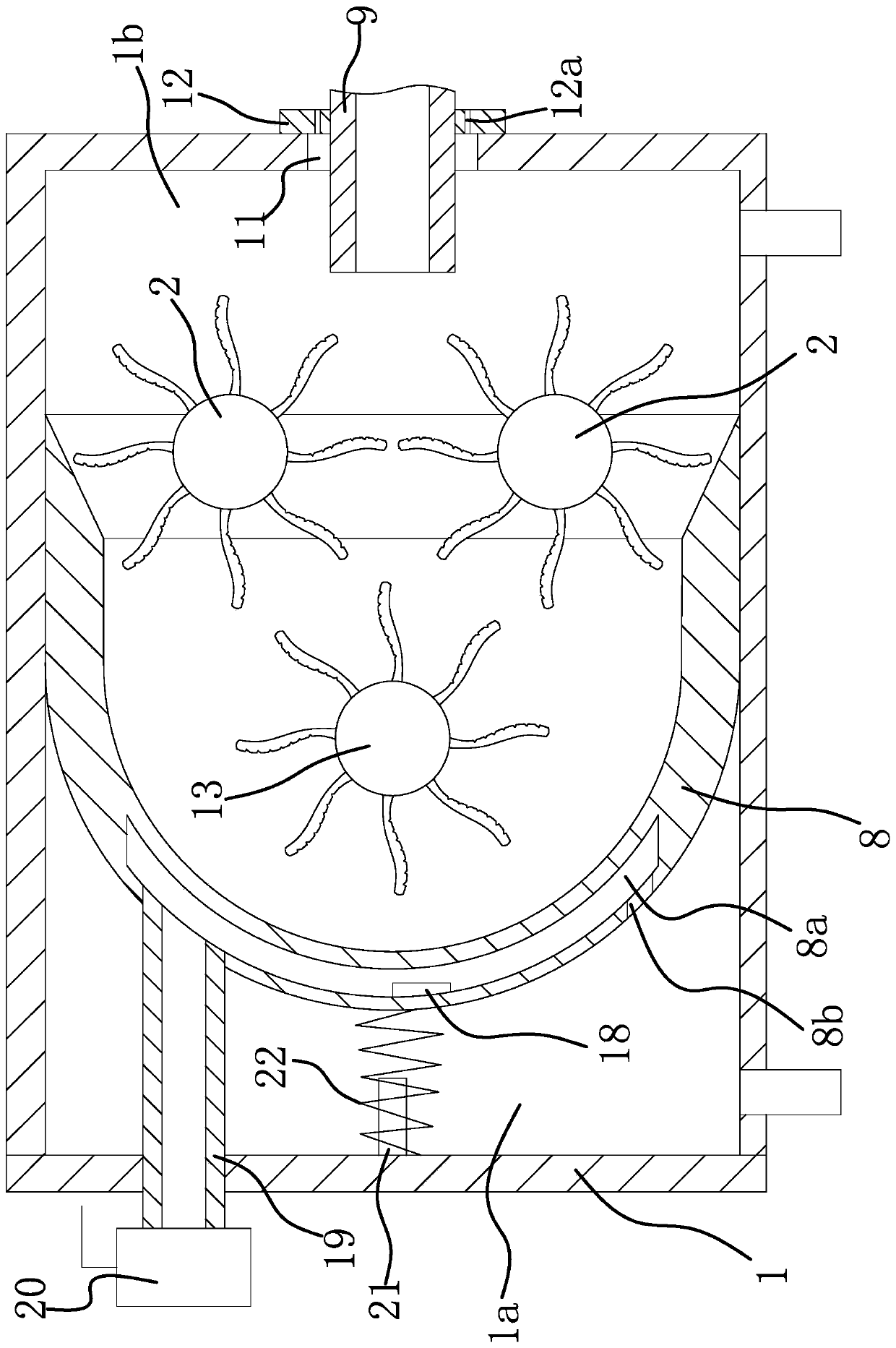

Environmental-friendly particle food drying and stirring device

InactiveCN110030796AIncrease contact timeFully contactedDrying solid materials with heatDrying gas arrangementsEnvironmental resistanceDrying

The invention provides an environmental-friendly particle food drying and stirring device which comprises a tank, first stirring blades arranged in the tank, and a motor arranged outside the tank. Thetwo first stirring blades are arranged; the motor simultaneously drives the two first stirring blades to rotate through a transmission mechanism; a baffle plate is fixed into the tank and divides aninner cavity of the tank into a left cavity and a right cavity; the cross section of the baffle plate in the vertical direction is in a U shape; an opening part of the baffle plate is arranged rightwards; the two first stirring blades are located in the baffle plate; an installation hole is formed in the right side of the tank in a penetrating way; a discharge pipe is fixedly arranged in the installation hole; the right end of the discharge hole stretches out of the installation hole and is connected with a first hot air blower; an exhaust passage for communicating the right cavity and the outside is formed between the outer side wall of a discharge pipe and the hole wall of the installation hole; a hopper is arranged right above the right end of the discharge pipe and is located between the first hot air blower and the tank; a feeding pipe is vertically fixed between the hopper and the discharge pipe; and two ends of the feeding pipe communicate with the hopper and the feeding pipe. The environmental-friendly particle food drying and stirring device provided by the invention has the advantage of good drying effect.

Owner:HANGZHOU FUYANG FUSHIDE FOOD CO LTD

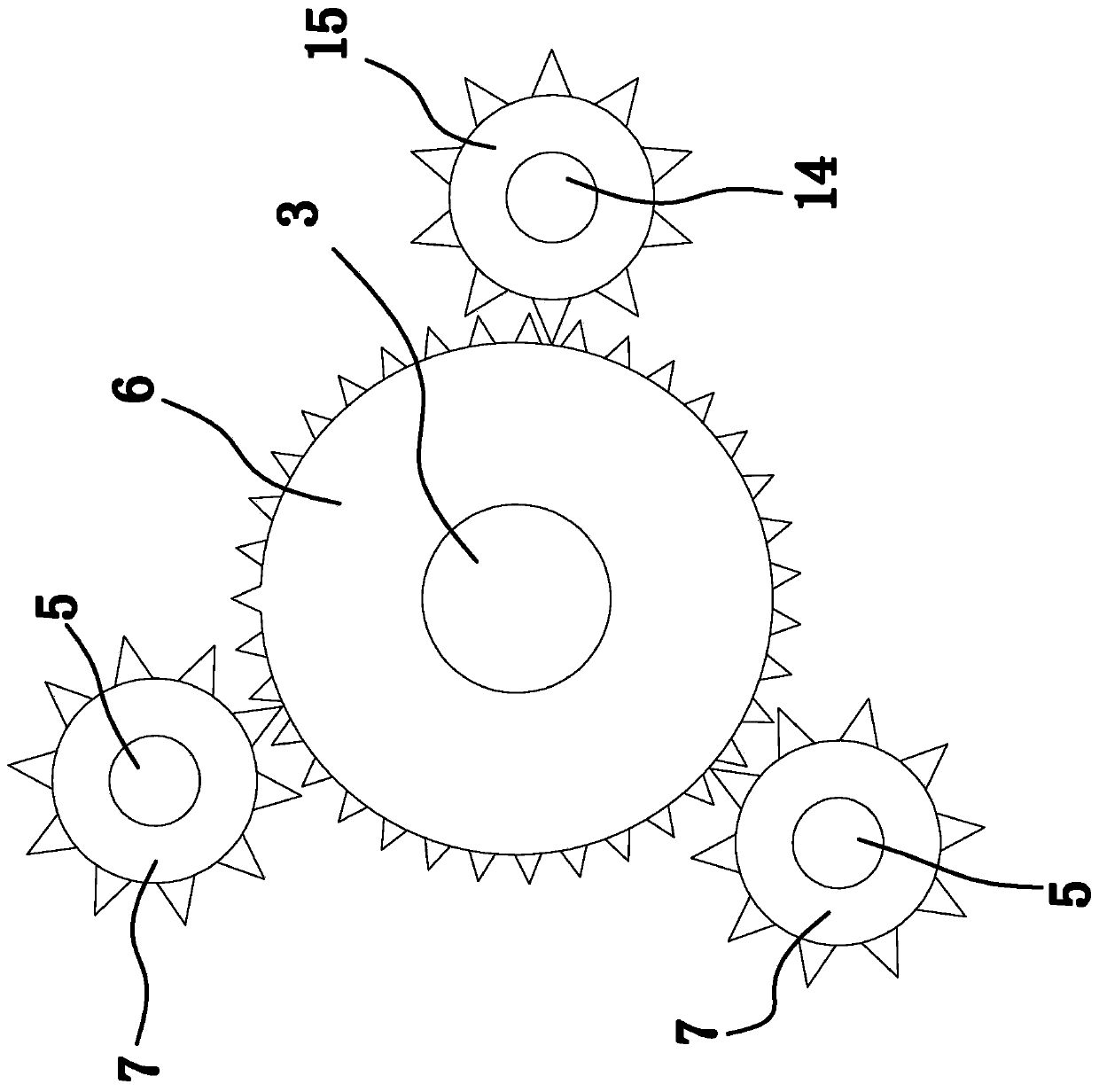

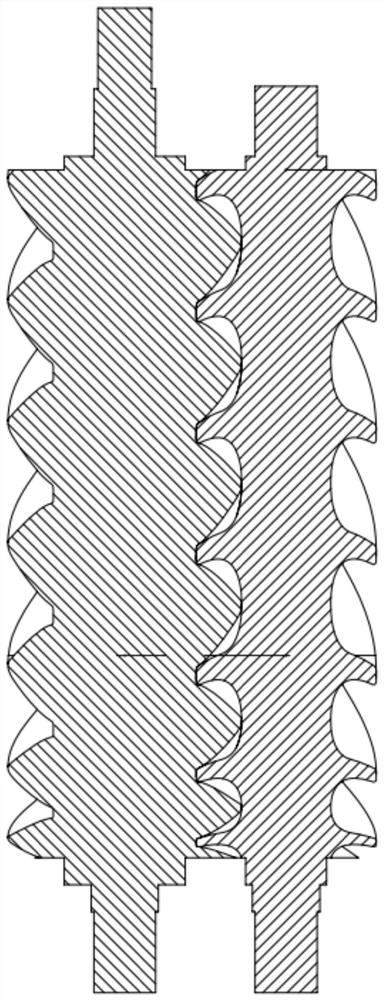

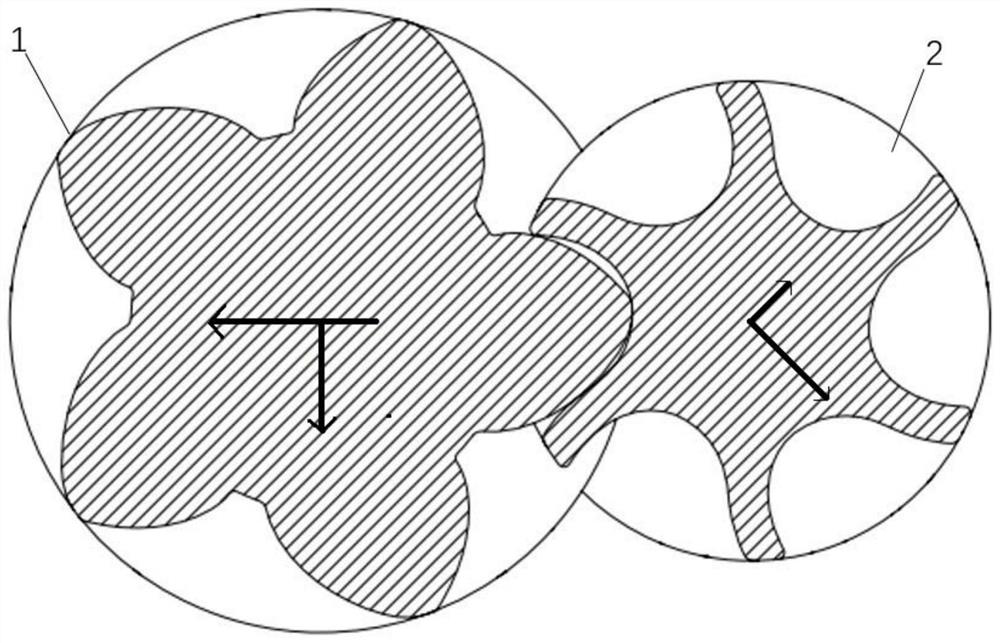

Two-section type gradient pitch double-screw compressor rotor

PendingCN113586448ASmooth compression and exhaustReduce loadRotary piston pumpsRotary piston liquid enginesAir volumeClassical mechanics

The invention discloses a two-section type gradient pitch double-screw compressor rotor. The two-section type gradient pitch double-screw compressor rotor comprises a male rotor, a female rotor, male rotor journals and female rotor journals, wherein the male rotor is connected with bearings on the two sides of a compressor shell through the male rotor journals. the female rotor is connected with the bearings on the two sides of the compressor shell through the female rotor journals; and the male rotor journals are connected with a coupler through male rotor shaft heads. The first section close to the air suction side adopts the equal pitch, and a complete contact line is formed on the section, so that the problem that the working volume is reduced due to the gradient pitch is avoided, and the air volume of a compressor is ensured. The pitch of the second section of screw close to the exhaust side is gradually reduced, so that the internal compression with the changed pitch is increased in the compression process, the area of an exhaust orifice is increased, the flow loss during exhaust is reduced, the exhaust noise is reduced, and the efficiency of the compressor is improved.

Owner:XI AN JIAOTONG UNIV

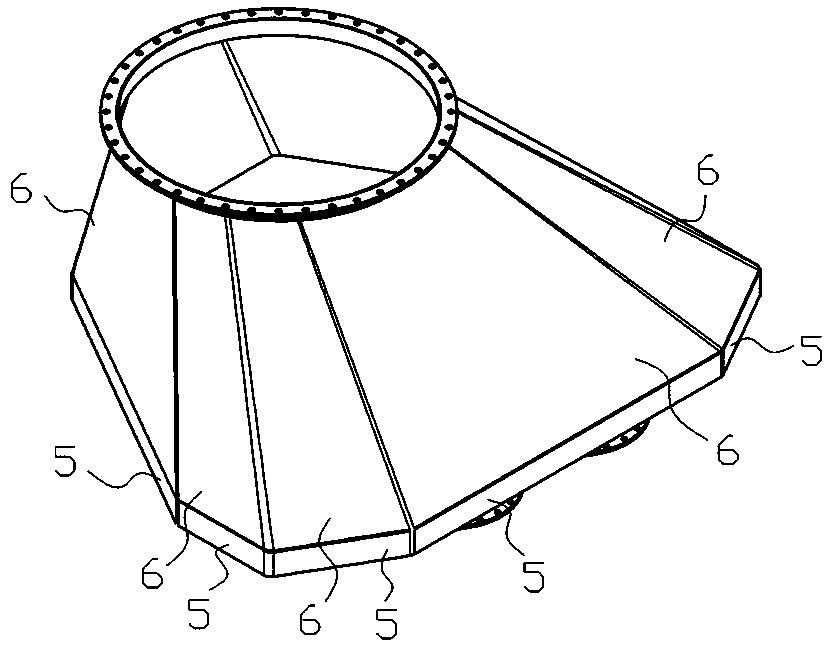

Environmentally friendly air dust removal equipment for chemical workshop and using method thereof

ActiveCN108816533BEasy to removeAdd automatic cleaning functionReversed direction vortexChemical industryDust control

The invention discloses environment-friendly air dedusting equipment for chemical industry workshop and a using method thereof. The environment-friendly air dedusting equipment comprises a support table, wherein two cyclone dedusting tanks which are arranged in parallel are arranged on the top surface of the support table in a penetrating way; two air pumps are arranged at two sides of the top surface of the support table; air exhaust ends of the air pumps are connected with air inlets; the air inlets are formed in the top parts of the outer side walls of the cyclone dedusting tanks along tangential positions of the side walls of the cyclone dedusting tanks; separating cavities are arranged in the cyclone dedusting tanks; air exhaust pipes are vertically arranged at the central positions of the separating cavities; the side walls of the top parts of the air exhaust pipes are rotationally arranged on the top surfaces of the cyclone dedusting tanks in the penetrating way; dust falling openings are formed in the bottom surfaces of the cyclone dedusting tanks; a sewage discharging hopper is arranged under the dust falling openings; multiple air paddle plates are fixedly arranged on theside walls of the top parts of the air exhaust pipes; dust scraping devices are arranged at the inner parts of the air exhaust pipes in a sleeving way; openings in the top parts of the air exhaust pipes penetrate through a secondary filter tank; the secondary filter tank is internally provided with a detachable push-pull filter net. According to the environment-friendly air dedusting equipment disclosed by the invention, a self cleaning function can be realized by driving the air exhaust pipes through wind power.

Owner:JIANGXI LONGZHENG SCI & TECH DEV

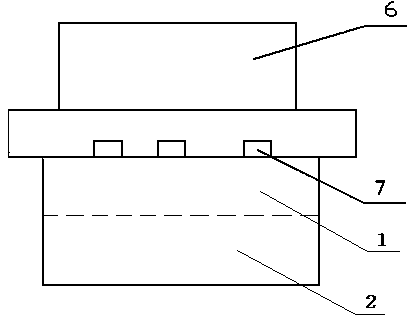

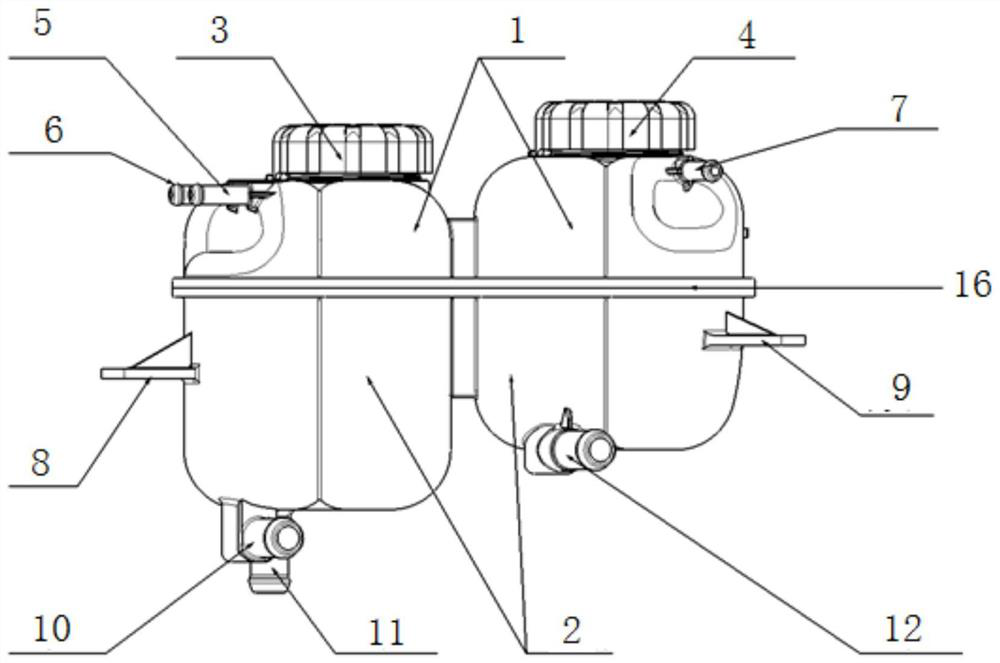

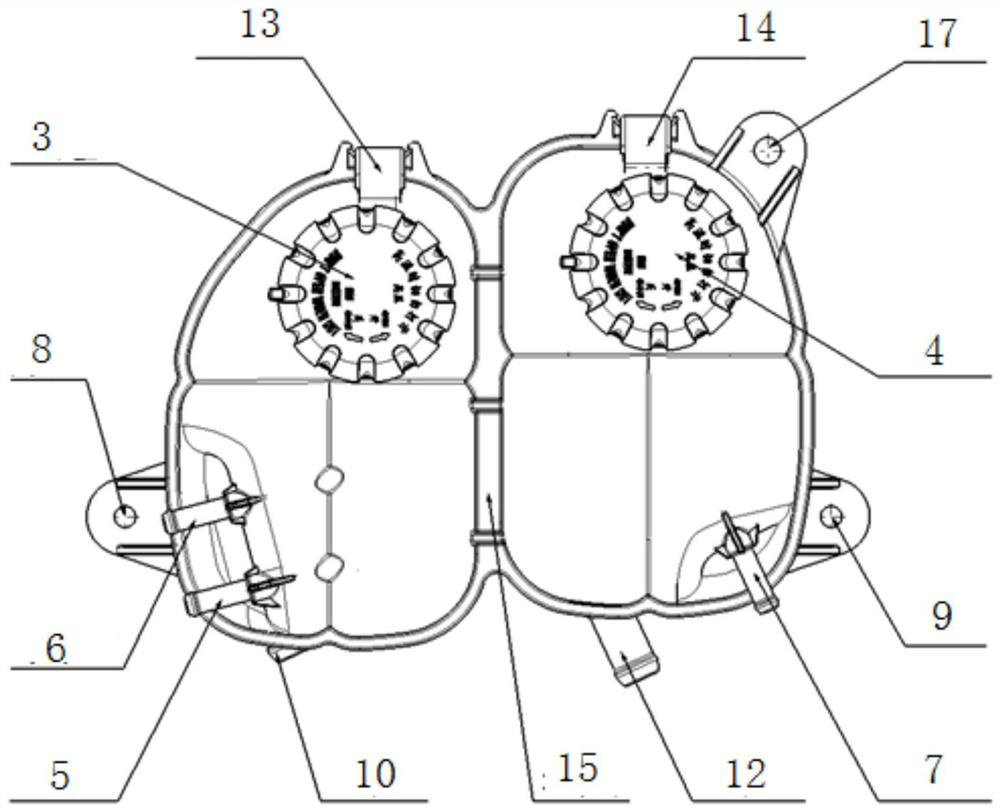

Integrated double-cavity liquid storage tank for new energy vehicle

InactiveCN112277610ASimple structureEasy to implementAir-treating devicesElectric propulsion mountingNew energyLiquid storage tank

The invention discloses an integrated double-cavity liquid storage tank for a new energy vehicle. The integrated double-cavity liquid storage tank for the new energy vehicle comprises an upper shell and a lower shell, the upper shell and the lower shell are each provided with two independent cavities, and after the upper shell and the lower shell are welded through a hot plate, the cavities of theupper shell and the lower shell are in butt joint to form two independent liquid storage cavities; a pressure cover is assembled at the top of each of the two liquid storage cavities; the two liquidstorage cavities are respectively provided with an overflow port, an air return port and a water replenishing port; the integrated double-cavity liquid storage tank is connected with a whole vehicle through a support. By means of the structure, water supplementing of 2-3 cooling circulation loops, exhausting of residual air in the system and stabilization of system pressure can be achieved, the structure is simple, implementation is easy, the arrangement space is saved, assembling is convenient, and cost reduction and light weight are achieved.

Owner:FAW CAR CO LTD

Inlet flow mixing pipe of desulfurizing tower

PendingCN111086618AExhaust stableEasy to ventPropulsion power plantsOutboard propulsion unitsInterior spaceMixed flow

The invention relates to an inlet flow mixing pipe of a desulfurizing tower. The inlet flow mixing pipe comprises a bottom sealing plate and a connecting plate located above the bottom sealing plate,wherein the bottom sealing plate and the connecting plate are connected into a whole through a peripheral plate, the bottom sealing plate, the connecting plate and the peripheral plate define an internal space allowing waste gas to be exhausted into, a powder generator air inlet hole, a host machine air inlet hole and a boiler air inlet hole are formed in the bottom sealing plate, an air outlet hole is formed in the connecting plate, air inlet pipes are arranged at the power generator air inlet hole, the host machine air inlet hole and the boiler air inlet hole, an air outlet pipe is arrangedat the air outlet hole, and the center of the host machine air inlet hole, the center of the air inlet pipe arranged at the host machine air inlet hole, the center of the air outlet hole in the connecting plate and the center of the air outlet pipe are located on the same straight line. The inlet flow mixing pipe of the desulfurizing tower is small in back pressure, stable in air discharge, smallin occupied space and simple in structure.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

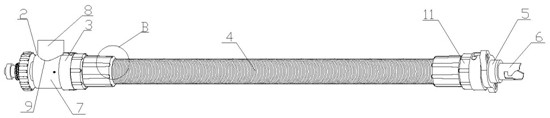

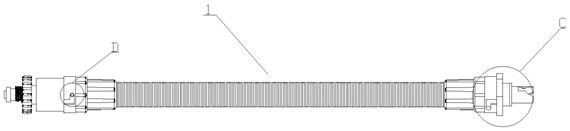

Portable inflation connector

PendingCN113048307AExhaust stableConform to transmissionHose connectionsPipe connection arrangementsStructural engineeringMechanical engineering

The invention discloses a portable inflation connector, which comprises an inflation connector body, and the inflation connector body comprises an input connector assembly, an O-shaped ring, a transfer connector, a corrugated hose, a gasket and an output connector; the input connector assembly comprises a cylindrical pipe and a cylindrical branch pipe; a through hole I is arranged on the side wall of the cylindrical pipe; one end of the cylindrical branch pipe is connected into the through hole I; the transfer connector is provided with a transfer connector I and a transfer connector II; the corrugated hose is arranged between the transfer connector I and the transfer connector II; an internal thread section I and an internal thread section II are arranged in the transfer connector I and the transfer connector II; the diameter of the internal thread section II is larger than that of the internal thread section I; a locking device is arranged on the side wall of the internal thread section II; and O-shaped rings are arranged at one end of the transfer connector I and one end of the transfer connector II, and the other end of the transfer connector I is connected with the cylindrical pipe. By arranging an input connector, the transfer connector I and the transfer connector II, the stability of the connectors is improved, and the connectors are convenient to carry and easy to use.

Owner:江西鼎峰装备科技有限公司

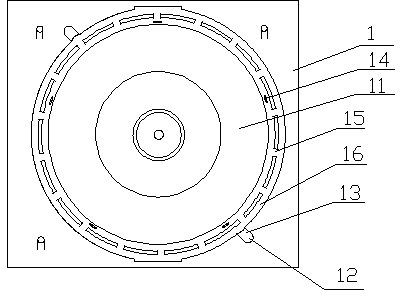

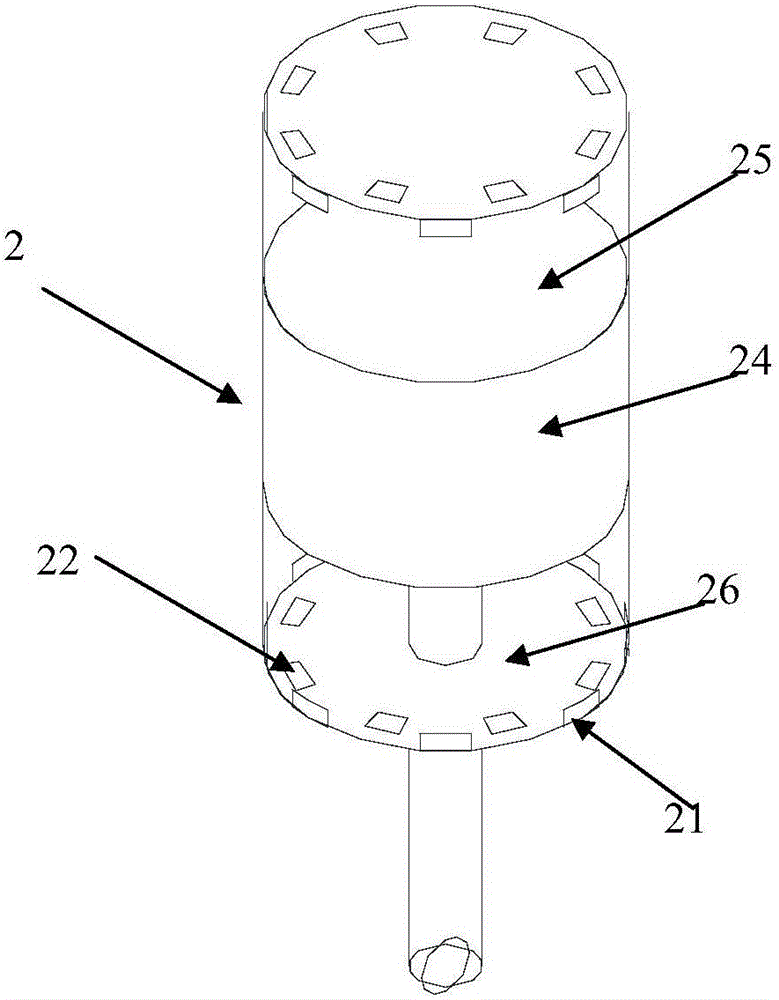

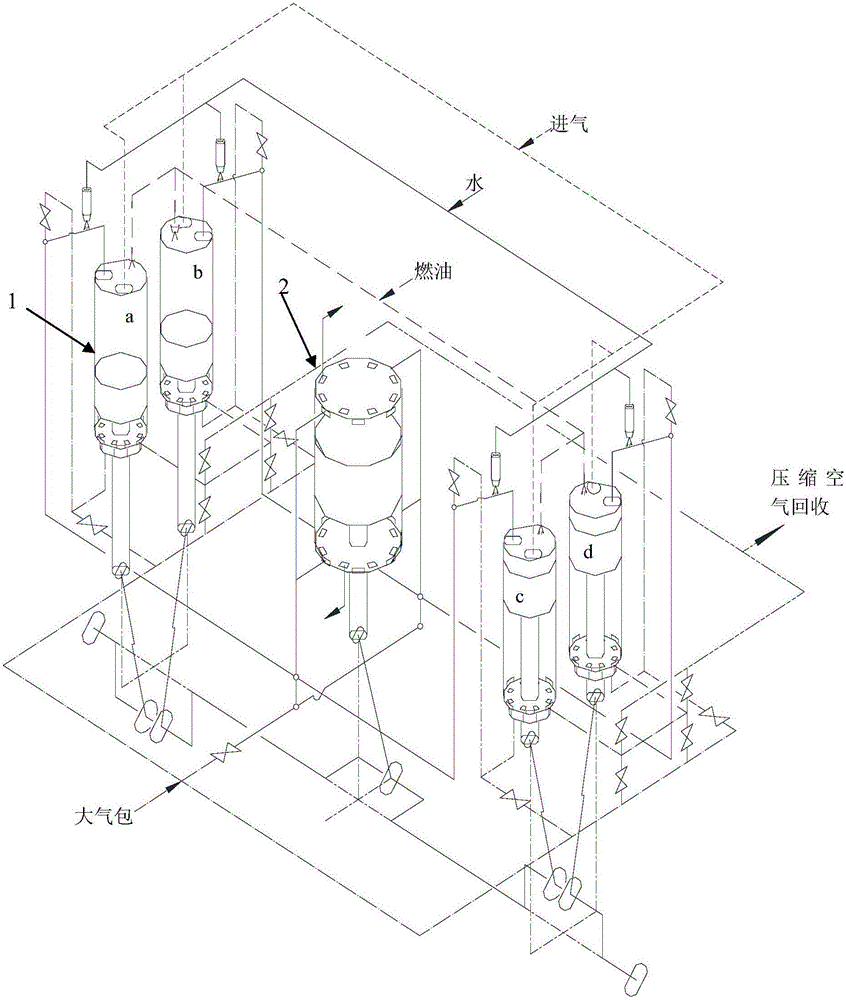

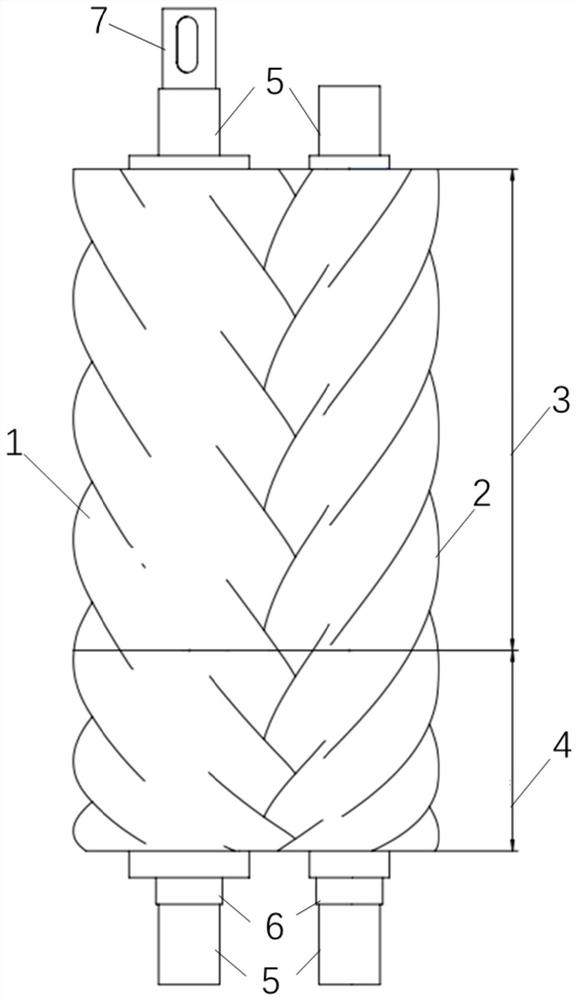

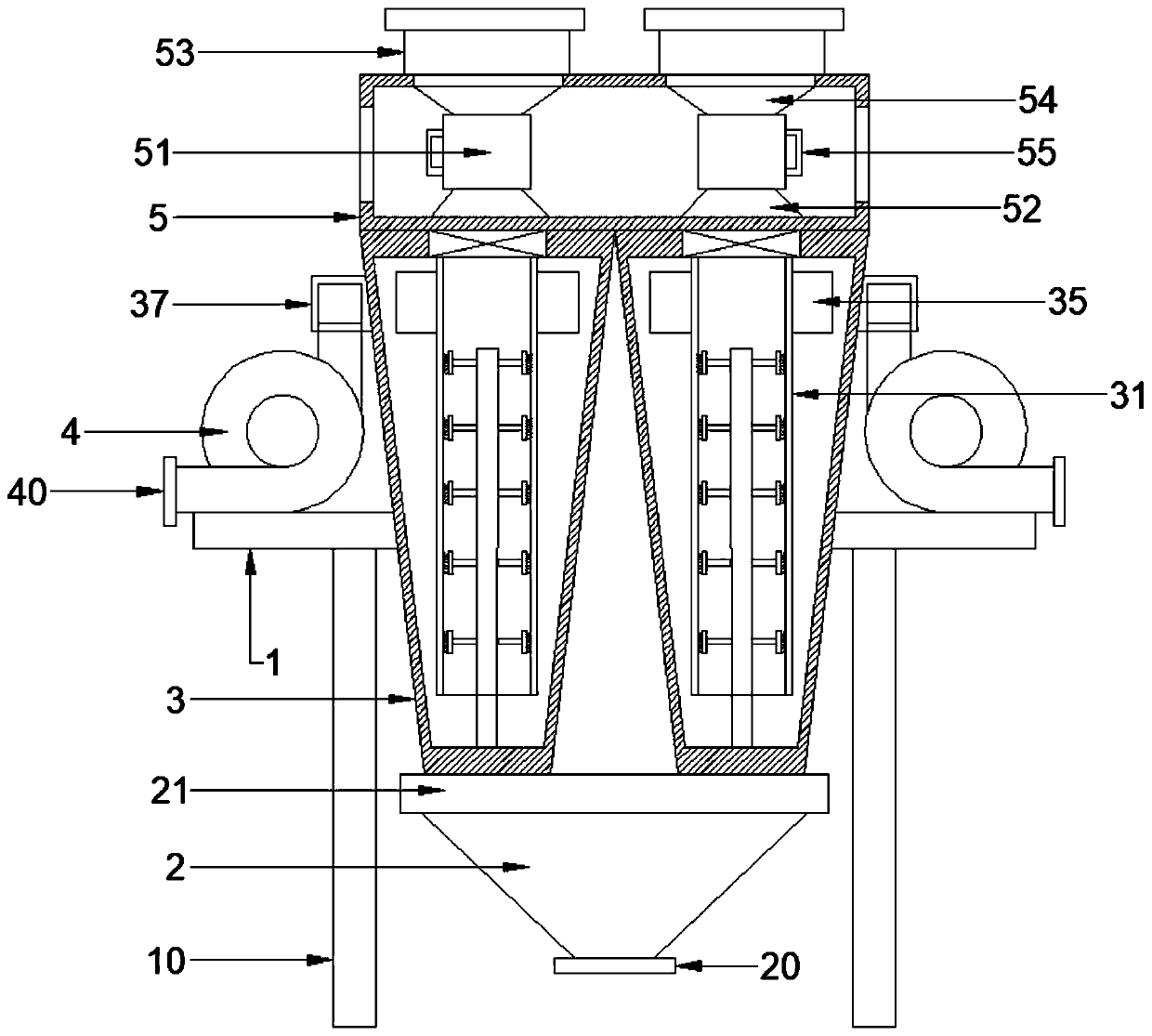

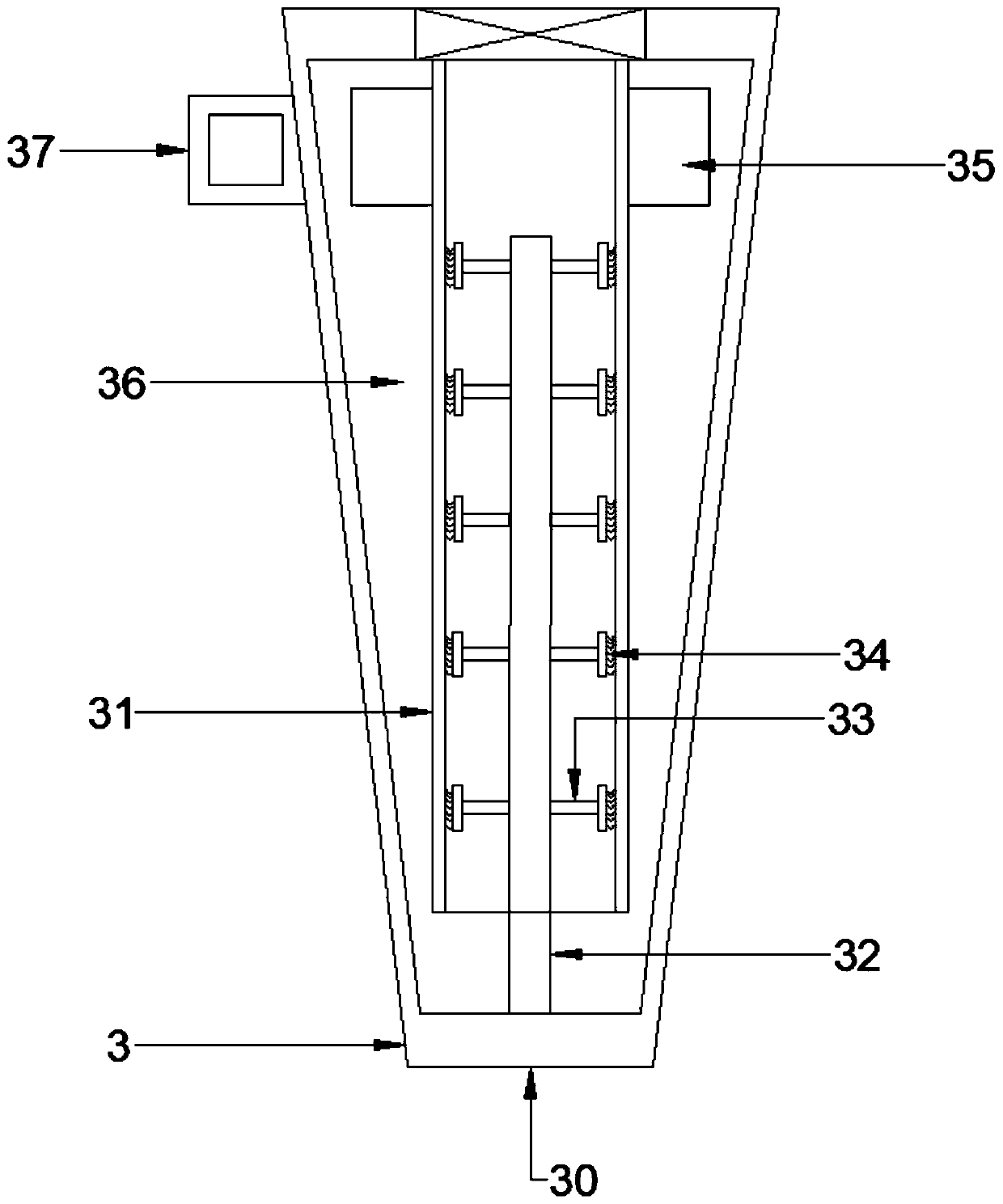

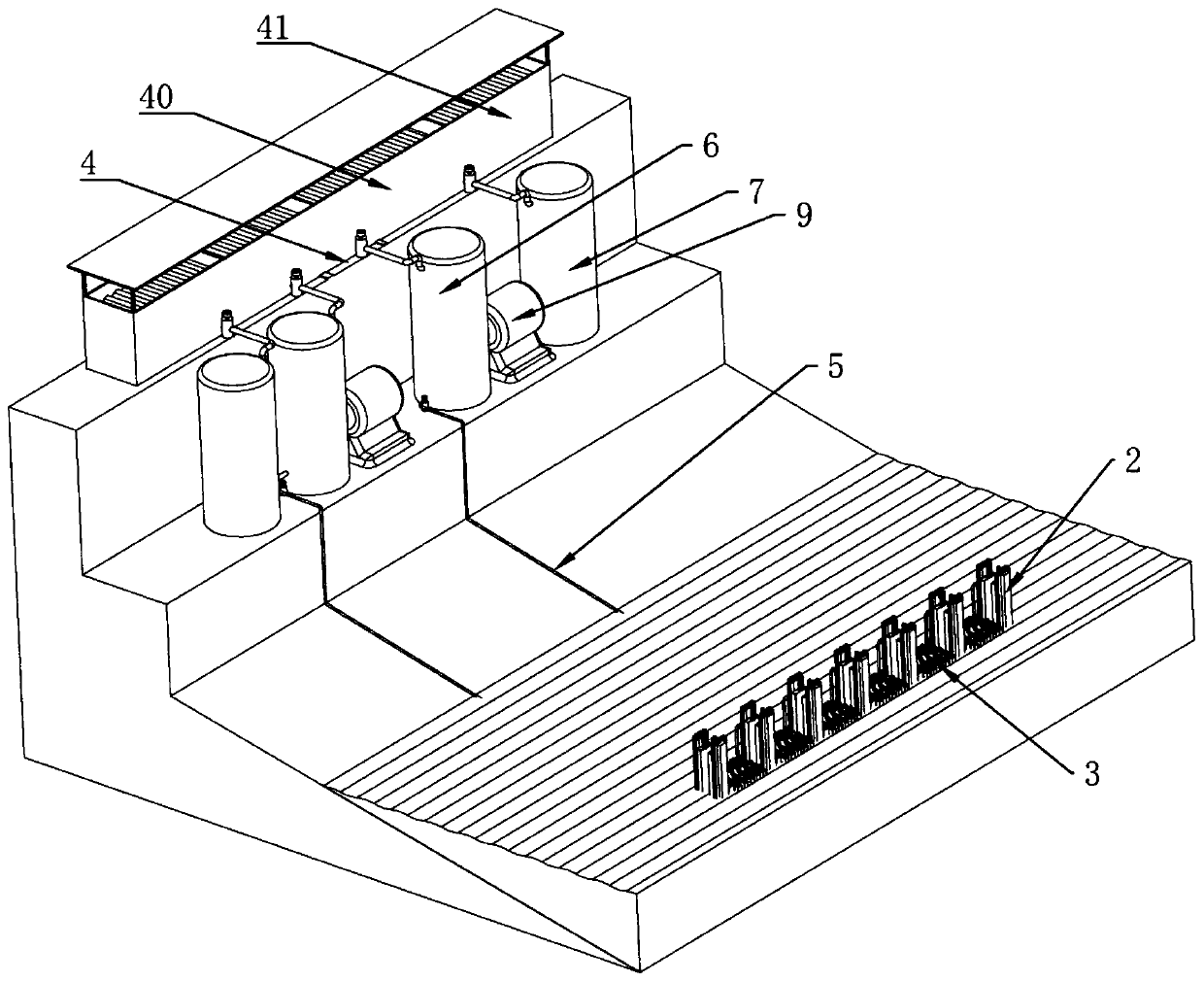

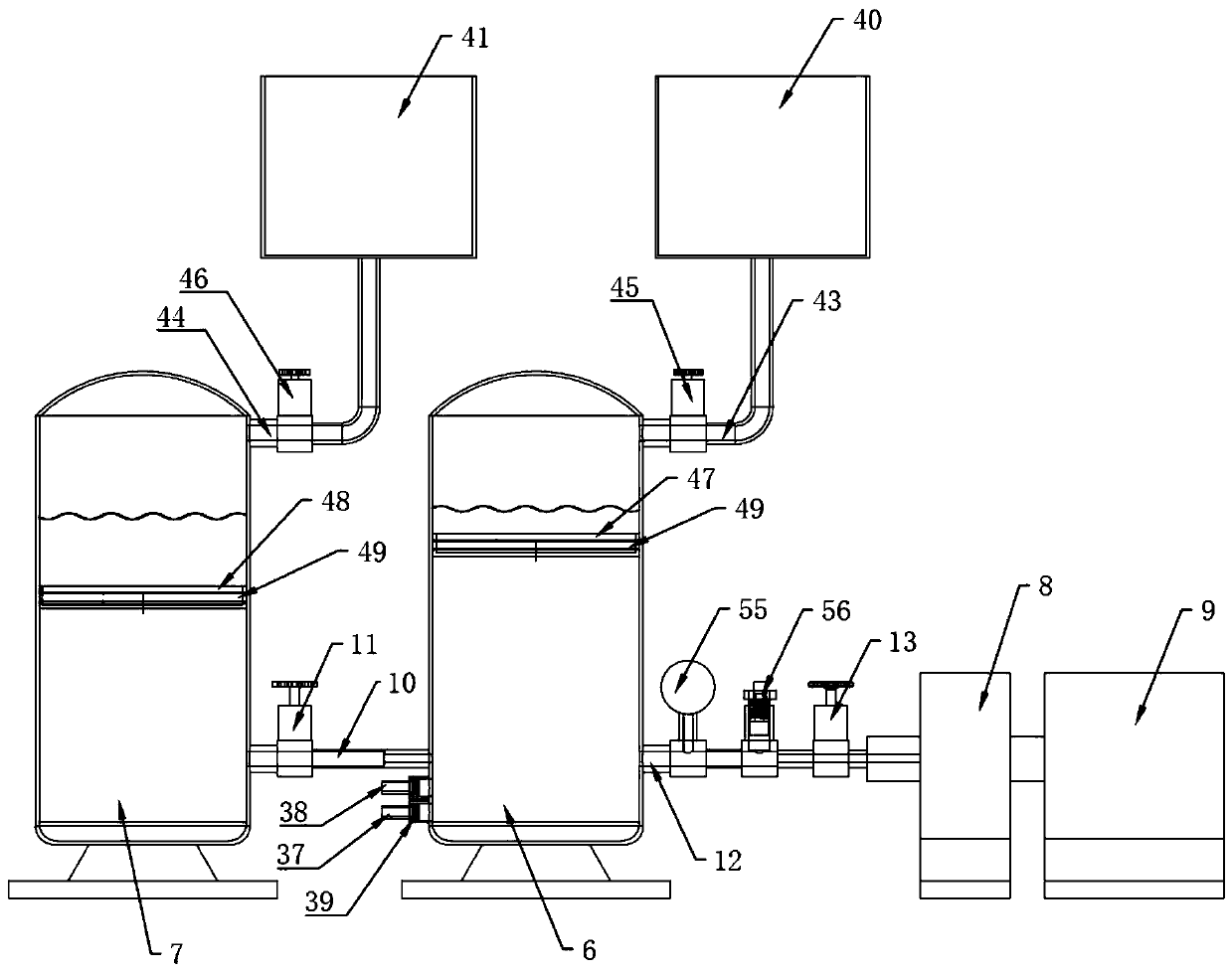

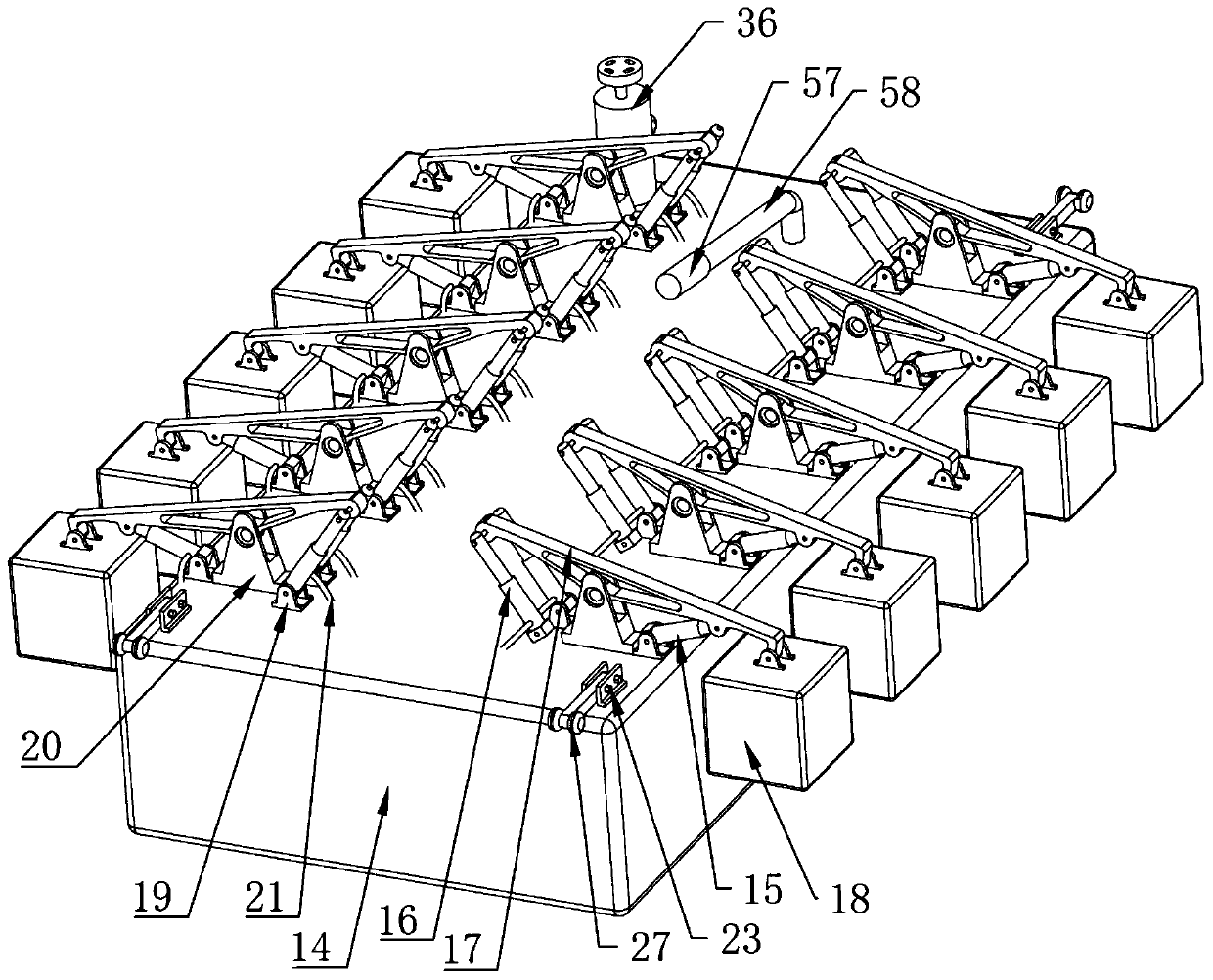

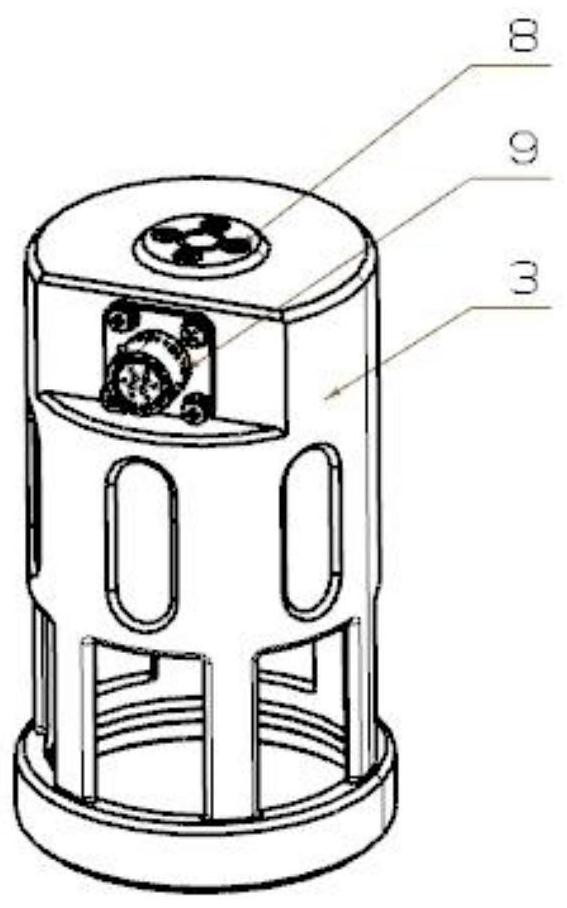

An energy storage wave power station

ActiveCN109944732BFull use of valueExhaust stableMachines/enginesEngine componentsPower stationSea waves

An accumulating wave power station, comprising a fixed column (1), a wave energy transmitting and stabilizing mechanism (2) mounted on the fixed column; a wave energy collecting mechanism (3) mounted on the wave energy transmitting and stabilizing mechanism; a transmission channel (5) provided on the wave energy transmitting and stabilizing mechanism; and an accumulating and applying mechanism (4) to which the wave energy collecting mechanism is connected via the transmission channel. The accumulating and applying mechanism comprises a pressure-stabilizing and gas-accumulating tank (6), a pressurized gas-accumulating tank (7), a pneumatic actuating apparatus (8), and an electricity-generating apparatus (9). The wave energy collecting mechanism comprises a gas-accumulating floating tank (14), a first multimodal gas compressor (15), a second multimodal gas compressor (16), a lever (17), and a float (18). The accumulating wave power station produces stable gas accumulation and gas discharge to serve as power driving the pneumatic actuating apparatus to drive the electricity-generating apparatus to generate electricity, and is provided with the characteristics of stable electricity generation, inexpensive manufacturing costs, high practicability, and convenient installation and maintenance.

Owner:陈伟晓

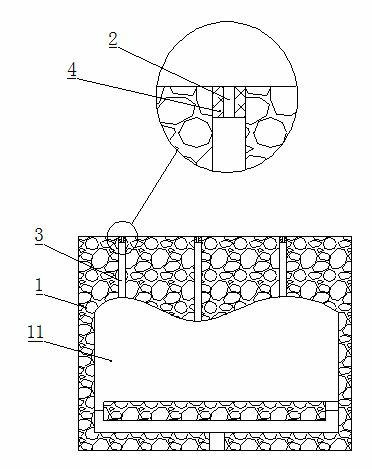

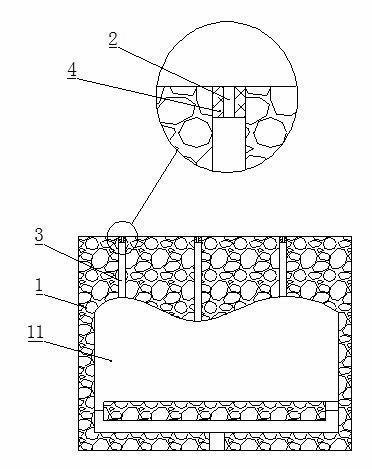

Low-pressure casting filling-mold air exhaust structure for sand mold and setting method for low-pressure casting filling-mold air exhaust structure

The invention relates to a method for setting a low-pressure casting filling-mold air exhaust channel for a sand mold. The method comprises the following steps of: vertically drilling at least one deep hole for communicating the highest point of a cavity and the outside in the sand mold; downwards smearing a section of pasty fire resistant material layer in an orifice at the upper end of the deephole; drilling a small-aperture shallow hole communicated with the deep hole in the fire resistant material layer; and heating and hardening the fire resistant material layer, wherein when aluminum liquid rises steadily, the air in the cavity is exhausted from the small-aperture shallow hole; and when the aluminum liquid continuously rises through the deep hole in the sand mold and overflows fromthe small-aperture shallow hole, the aluminum liquid overflowing the plane of the sand mold is solidified quickly due to the relatively small aperture of the small-aperture shallow hole. Therefore, the air can be exhausted steadily during mold filling; after mold filling, the cavity is closed quickly, so that pressurization, pressure retention and crystallization are realized conveniently, and a reliable guarantee is supplied for improving the quality of a product. Furthermore, the height of a cover box sand mold is effectively reduced to 100 to 120 millimeters, the sand using amount of a cover box is reduced greatly, and the cost is saved.

Owner:NANTONG L S LIGHT METAL FORMING

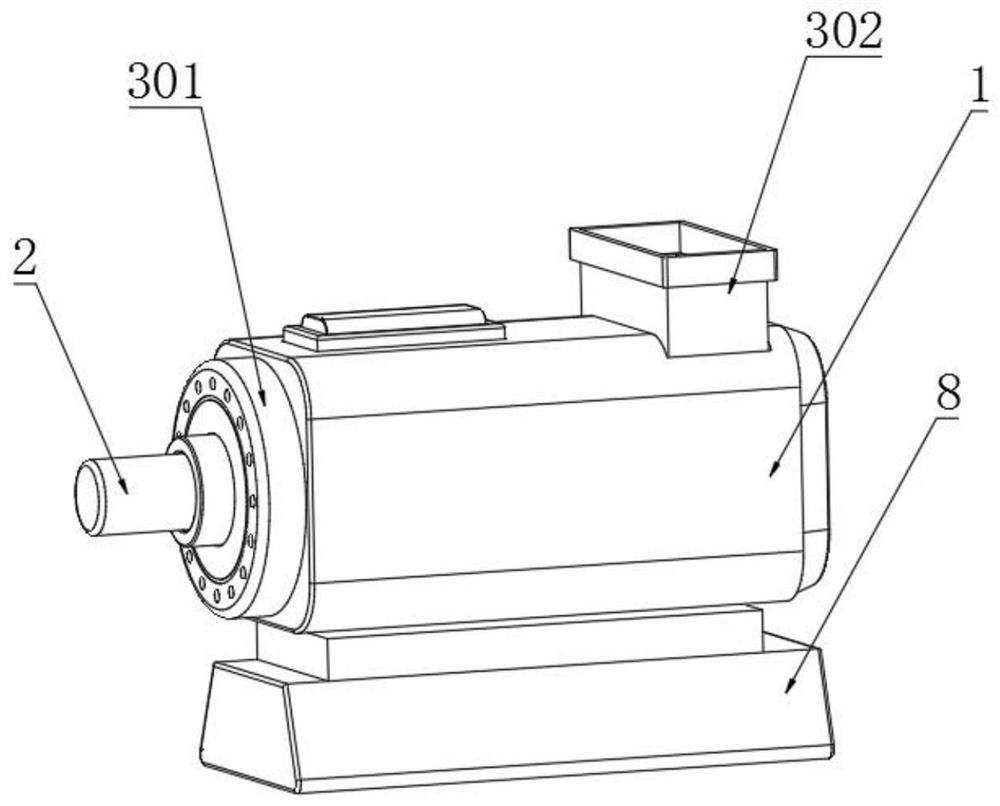

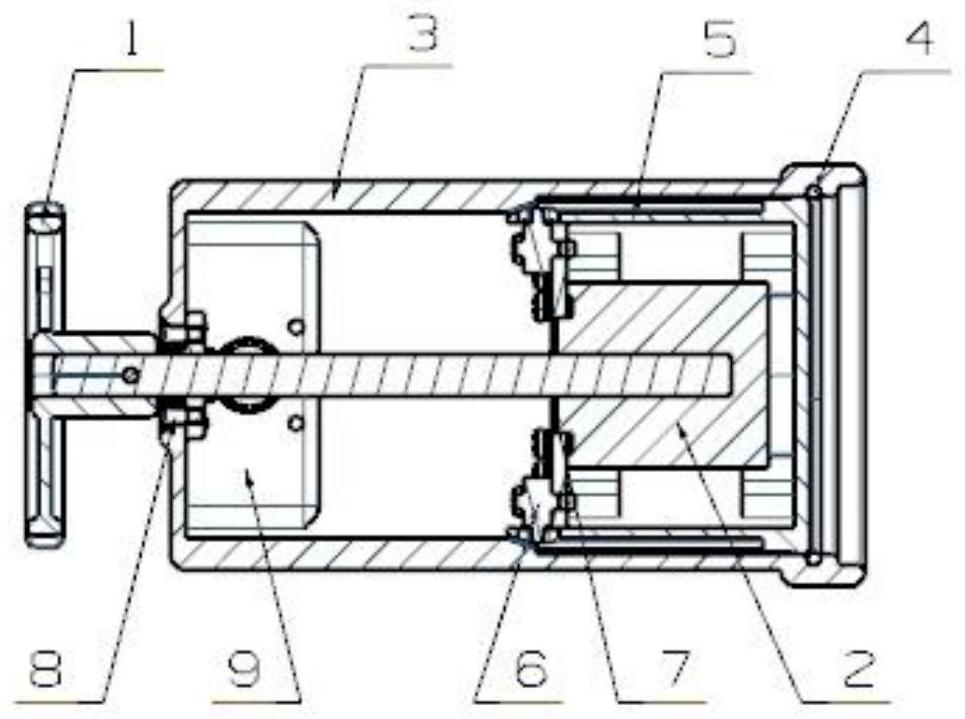

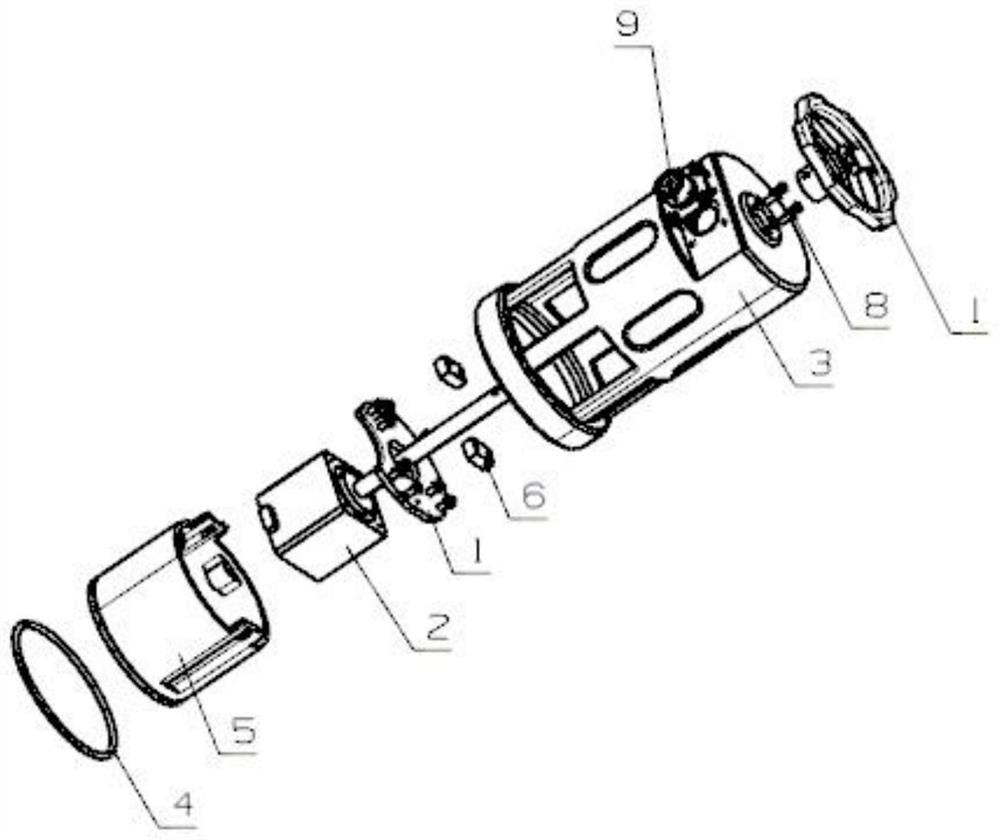

Self-ventilation traction motor

ActiveCN112134411ARealize automatic lubricationAchieve ventilation and heat dissipationCooling/ventillation arrangementMotorsDrive shaftElectric machinery

The invention discloses a self-ventilation traction motor. The motor comprises a shell, a driving shaft and a rotor; the rotor is connected with one side of the interior of the shell, the driving shaft is connected with one end of the rotor, an air inlet cover is connected with one side of the exterior of the shell, an air outlet cover is embedded into the top end of one side of the outer wall ofthe shell, and liquid storage hoppers are arranged on the two sides of the outer wall of the rotor respectively. Blades are connected to the top end of the exterior of the driving shaft in a sleevingmode, air inlet pipes are installed at the top ends of one sides of the outer walls of the liquid storage hoppers in an embedded mode, and pressure balancing pipes are installed on one sides of the outer walls of the two liquid storage hoppers. The blades are driven by the driving shaft to rotate, so that external gas is fed into the shell from the air inlet cover; and heat generated in the shellis absorbed. Meanwhile, lubricating oil liquid is injected into the rotary connecting position of the driving shaft from the liquid inlet pipe through the pressure balancing pipes, so that the ventilation and heat dissipation performance of the interior of the traction motor is achieved, and automatic lubrication of the connecting position of the driving shaft is achieved.

Owner:浙江江宇电机有限公司

Overpressure exhaust device

PendingCN113147318AAdjust the overpressure valueFunctionalAir-treating devicesOperating means/releasing devices for valvesElectric machineryEngineering

The invention provides an overpressure exhaust device which comprises a hand wheel, a lead screw stepping motor, a valve body, a sealing ring, a valve element, a position switch, a supporting plate, a circular ring nut and an electric connector. Wherein the valve body, the circular ring nut and the electric connector form a valve body assembly, and the valve element, the supporting plate, the lead screw stepping motor and the position switch form a valve element assembly. Through the threaded fit of the lead screw and the circular ring nut fixed on the valve body, the rotating motion of the lead screw is changed into the linear motion of the valve element assembly in the cavity of the valve body assembly, and the adjustment of the overpressure value in the sealed cabin is realized by adjusting the opening degree of the exhaust windows in the valve element assembly and the valve body assembly.

Owner:BEIJING NORTH VEHICLE GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com