Automatic bread maker

A bread machine, automatic production technology, applied in the direction of toasting equipment, household utensils, applications, etc., can solve the problems of excessive gas discharge, bread dough damage, gas cannot be discharged smoothly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

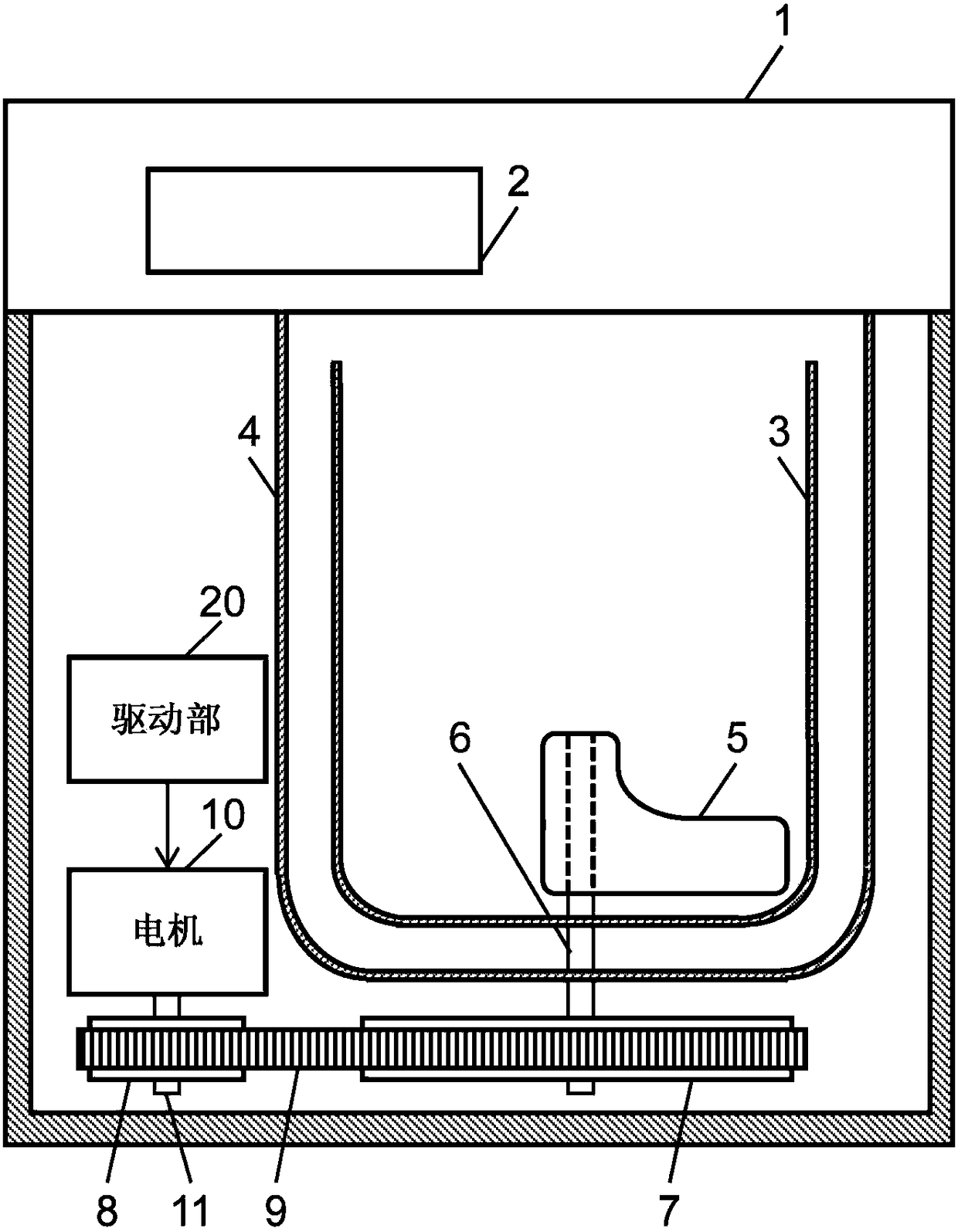

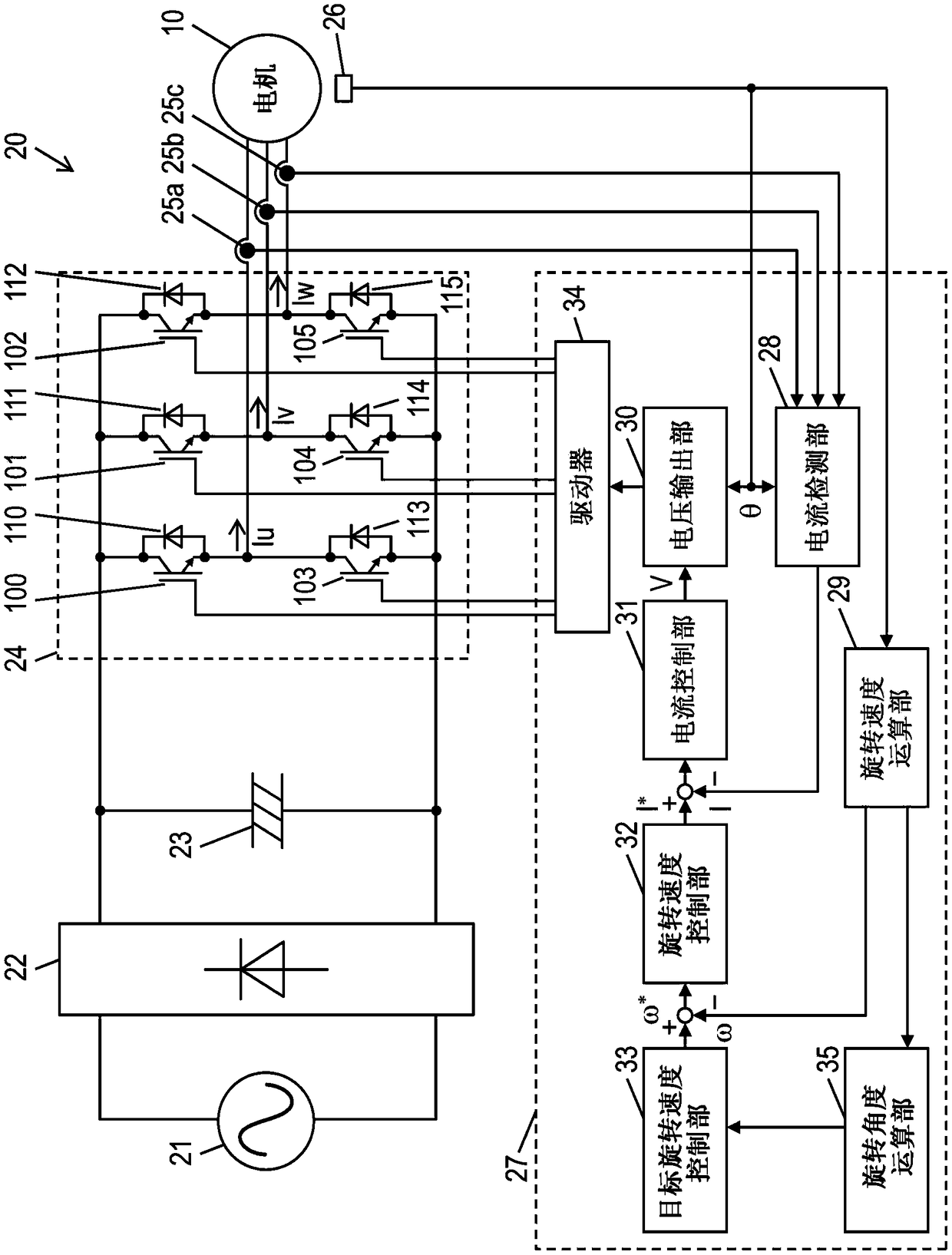

[0033] figure 1 It is a partially cutaway sectional view showing a schematic structure of automatic bread maker 1 according to Embodiment 1 disclosed herein. The automatic bread maker 1 has an operation unit 2 , a container 3 , a baking chamber 4 , a stirring blade 5 , a rotating shaft 6 , pulleys 7 and 8 , a belt 9 , a motor 10 , and a driving unit 20 .

[0034] The operation part 2 is provided on the upper part of the main body of the automatic bread maker 1 . The operation unit 2 is provided with a plurality of operation keys for performing operations such as start / stop of bread making, and a display unit for displaying operation contents. The display unit also displays progress status, scheduled end time, and the like. The plurality of operation keys may include operation keys for inputting the quantity of bread ingredients.

[0035] Put bread ingredients into container 3. The container 3 is housed in the baking chamber 4 . A heater (not shown) is arranged in the baki...

Embodiment approach 2

[0106] Hereinafter, Embodiment 2 of the automatic breadmaker disclosed here is demonstrated.

[0107] In the initial stage of the kneading process, the bread ingredients are not sufficiently kneaded. Therefore, in the initial stage of the stirring process, the stirring blade 5 is rotated at a relatively low rotational speed (for example, 60 rpm) to suppress scattering of the bread ingredients.

[0108] When a predetermined time elapses in the kneading step, the kneading of the bread dough proceeds to a certain extent. At this point, the rotation speed of the stirring blade 5 is increased (for example, 250 rpm).

[0109] When the rotational speed of the stirring blade 5 is increased, the stirring blade 5 rotates while the bread dough sticks to the stirring blade 5 , so-called idling of the stirring blade 5 may occur. When the idling of the kneading blade 5 occurs, the bread dough cannot be kneaded sufficiently.

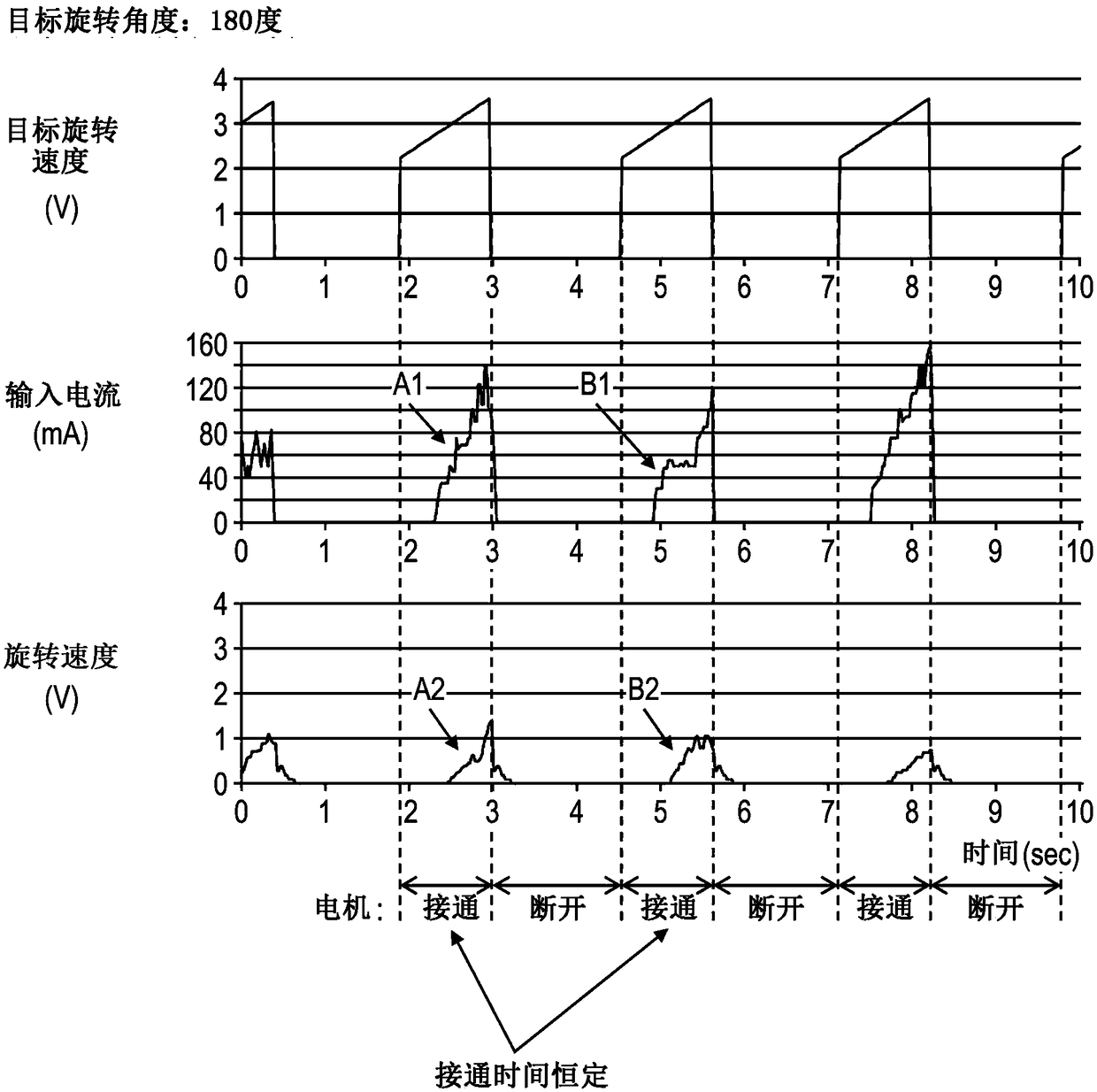

[0110] Figure 5 It is a waveform chart of the target rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com