Patents

Literature

88results about How to "Realize automatic lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

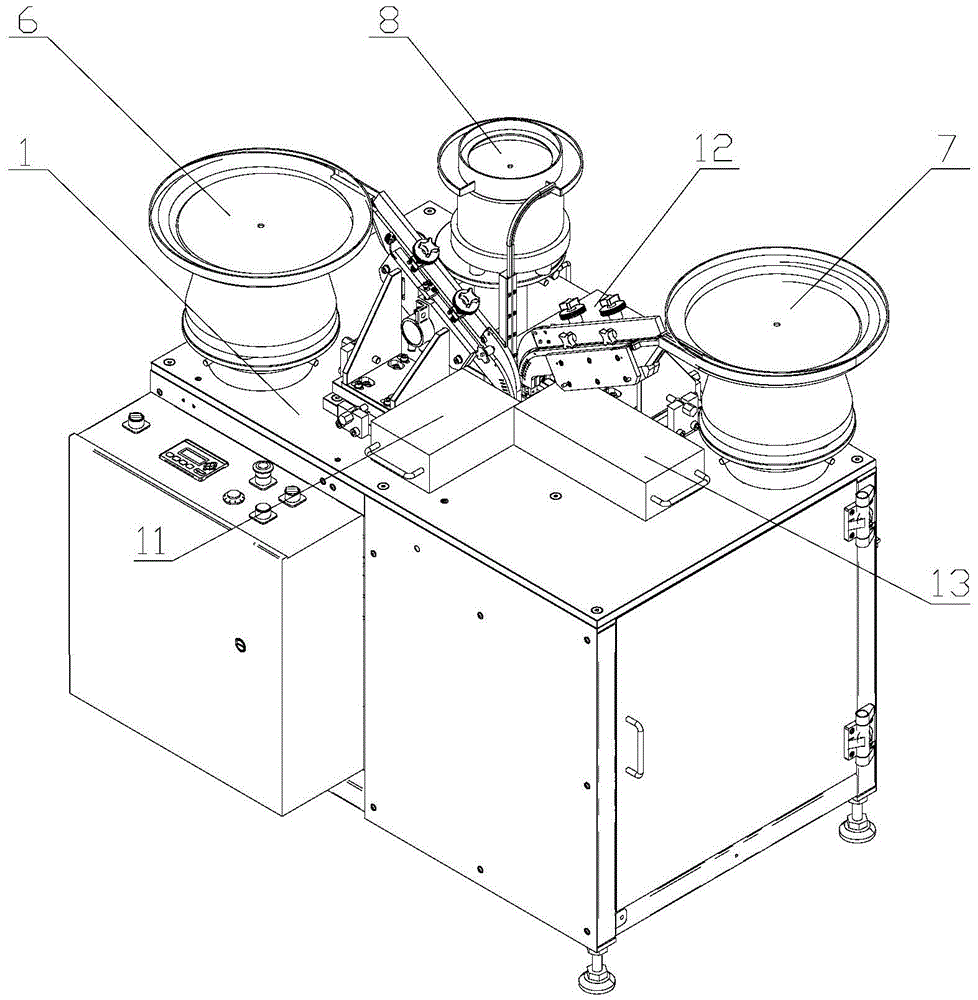

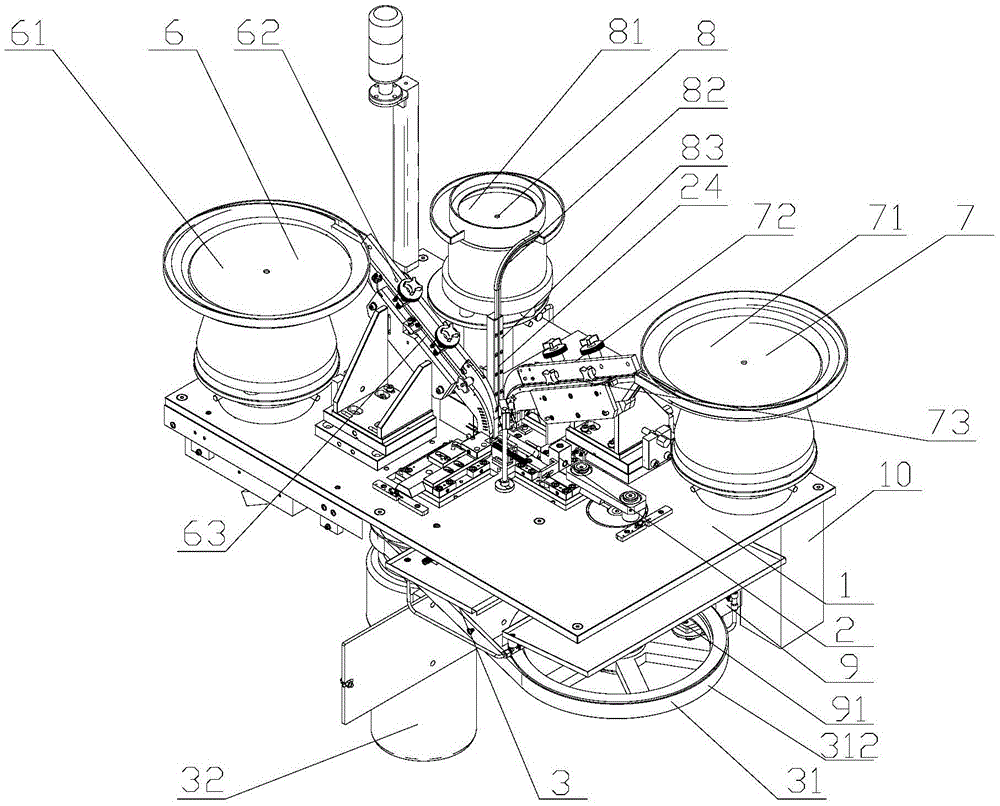

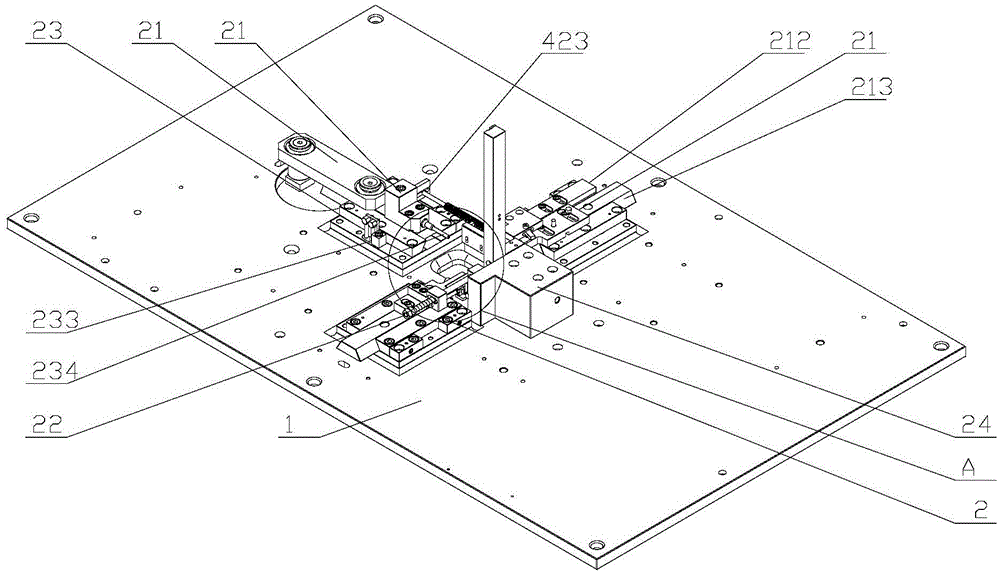

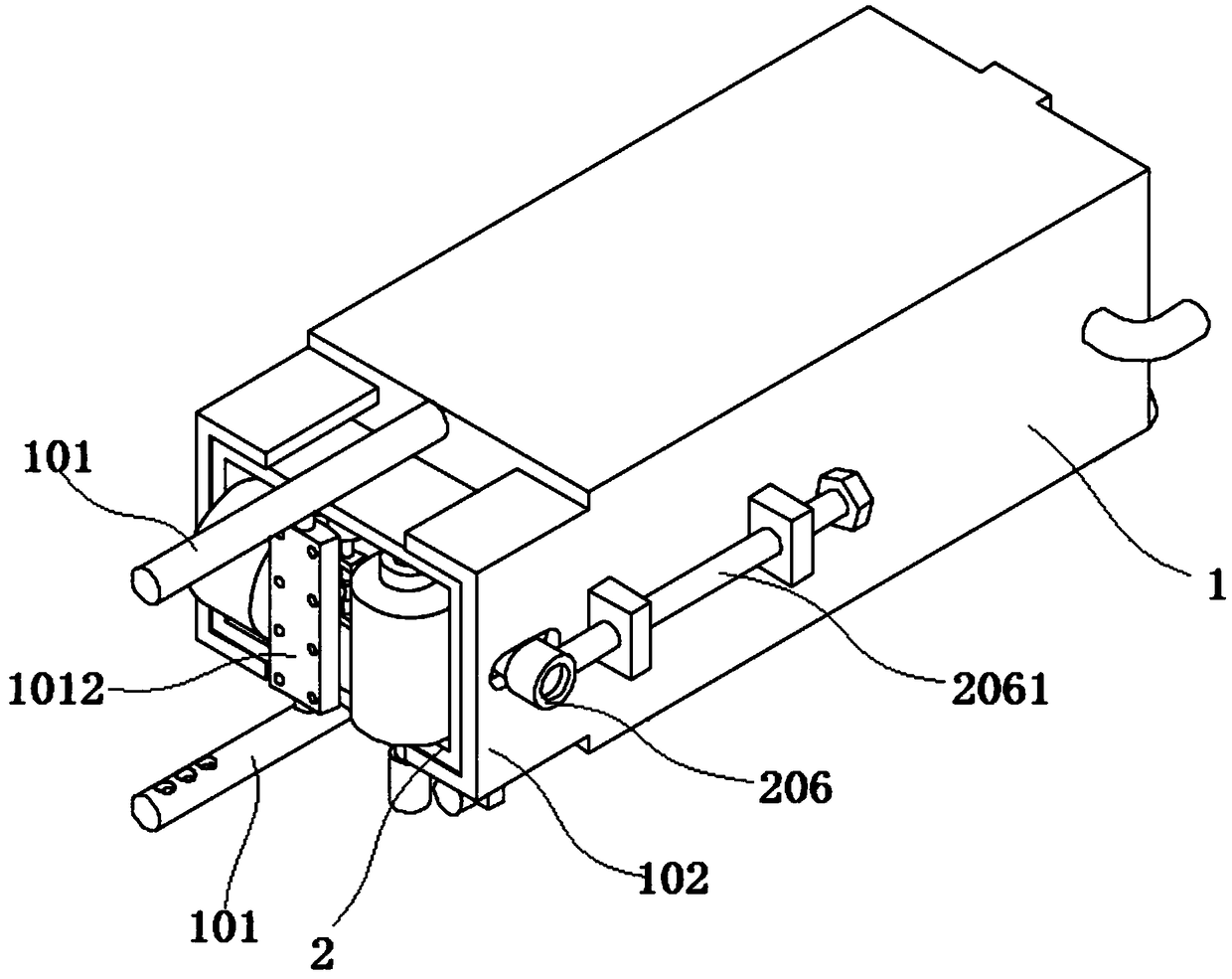

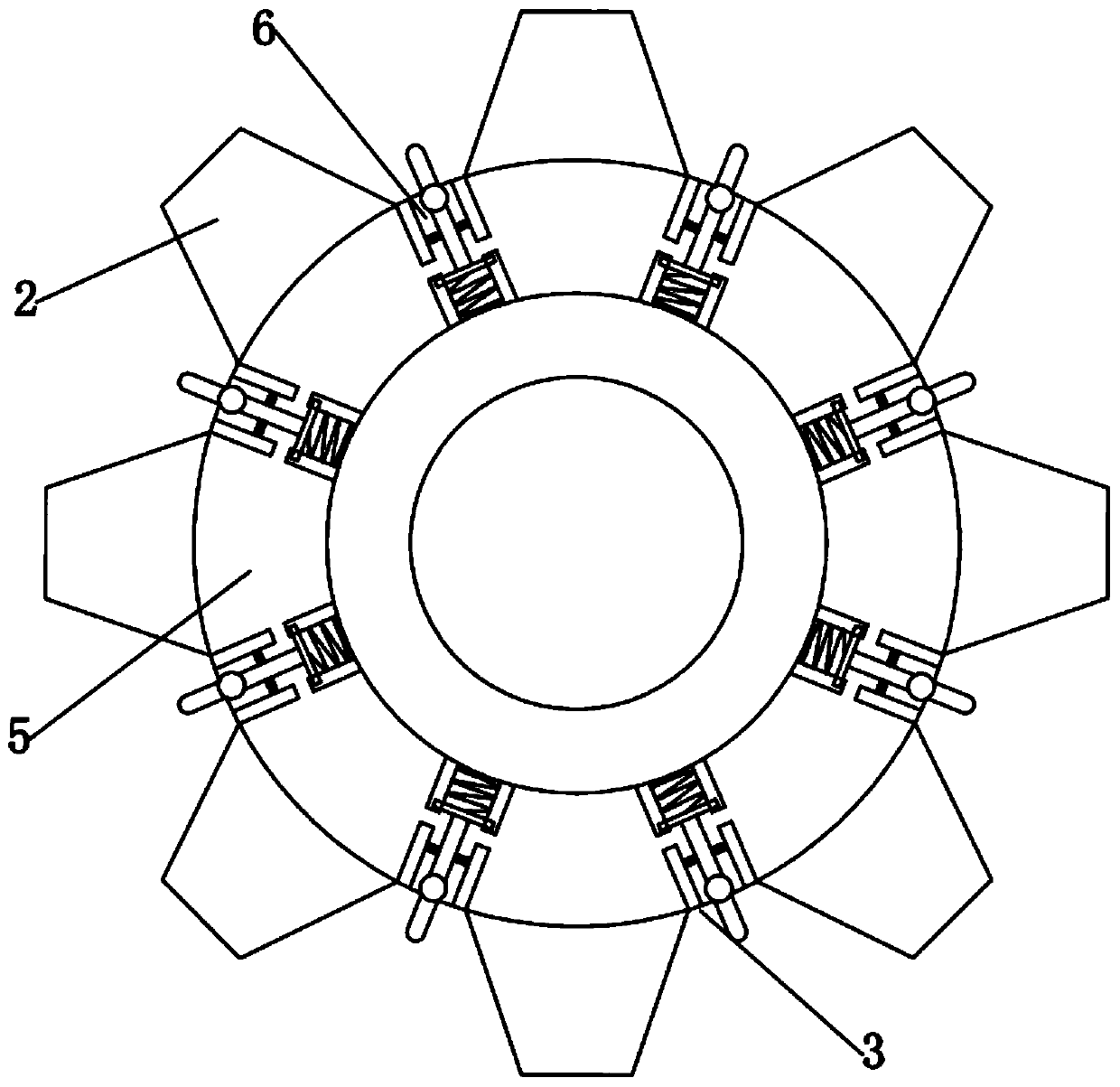

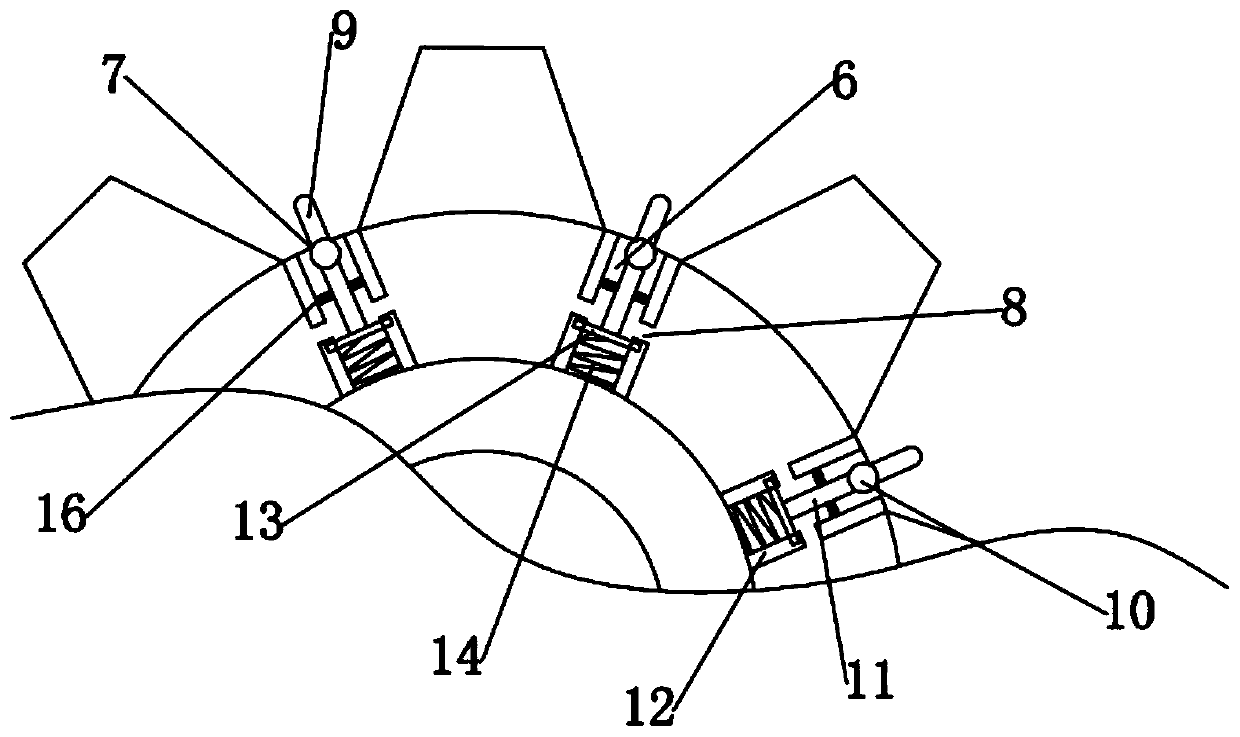

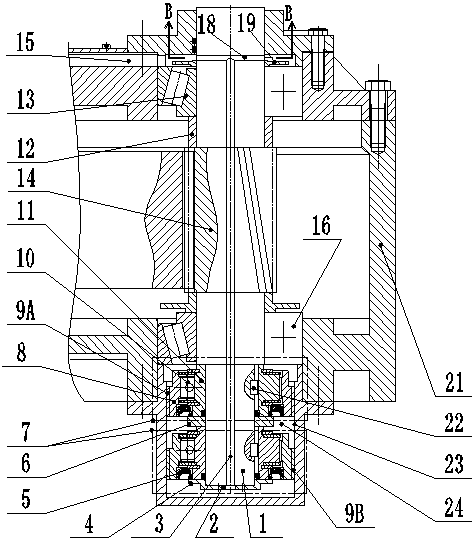

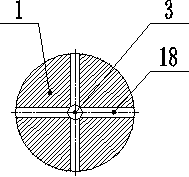

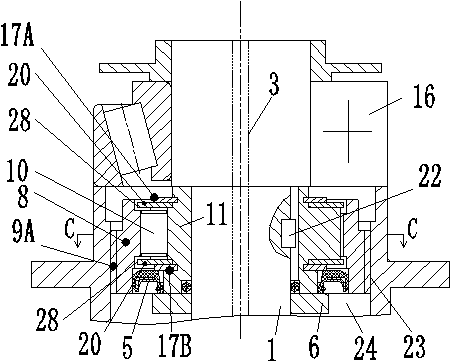

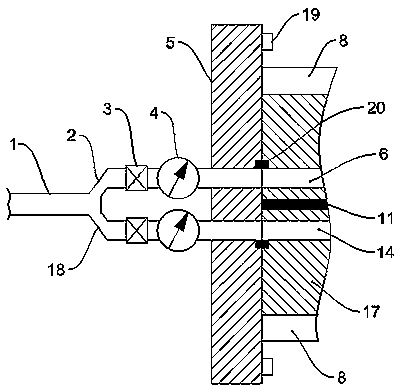

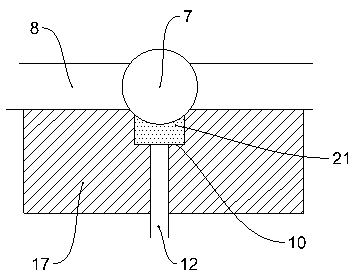

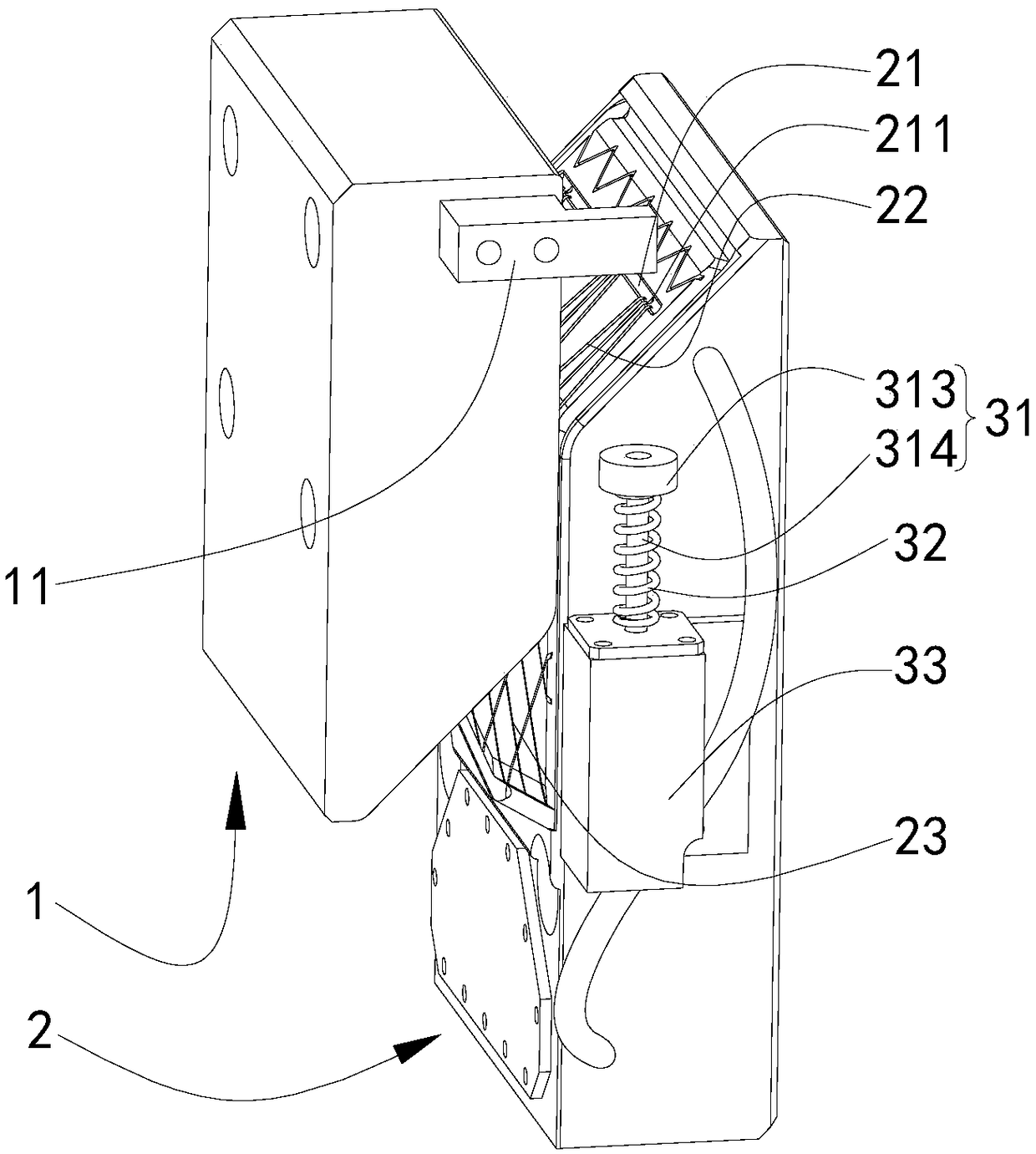

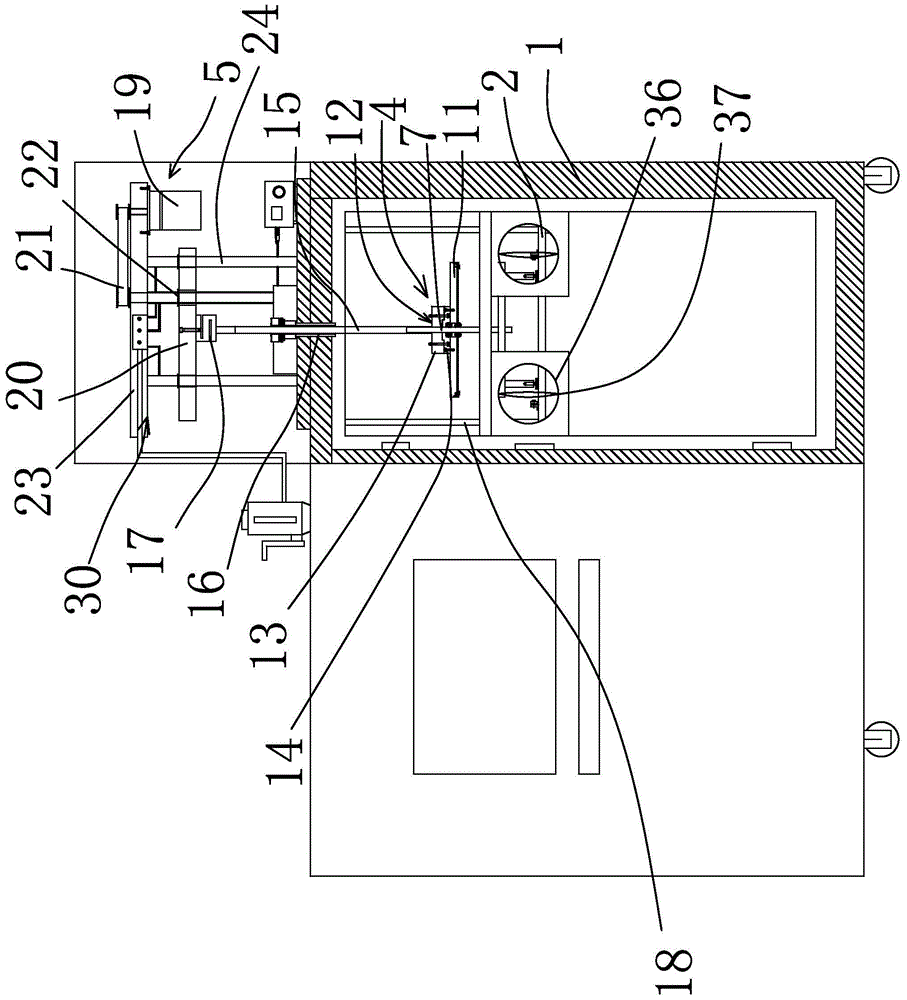

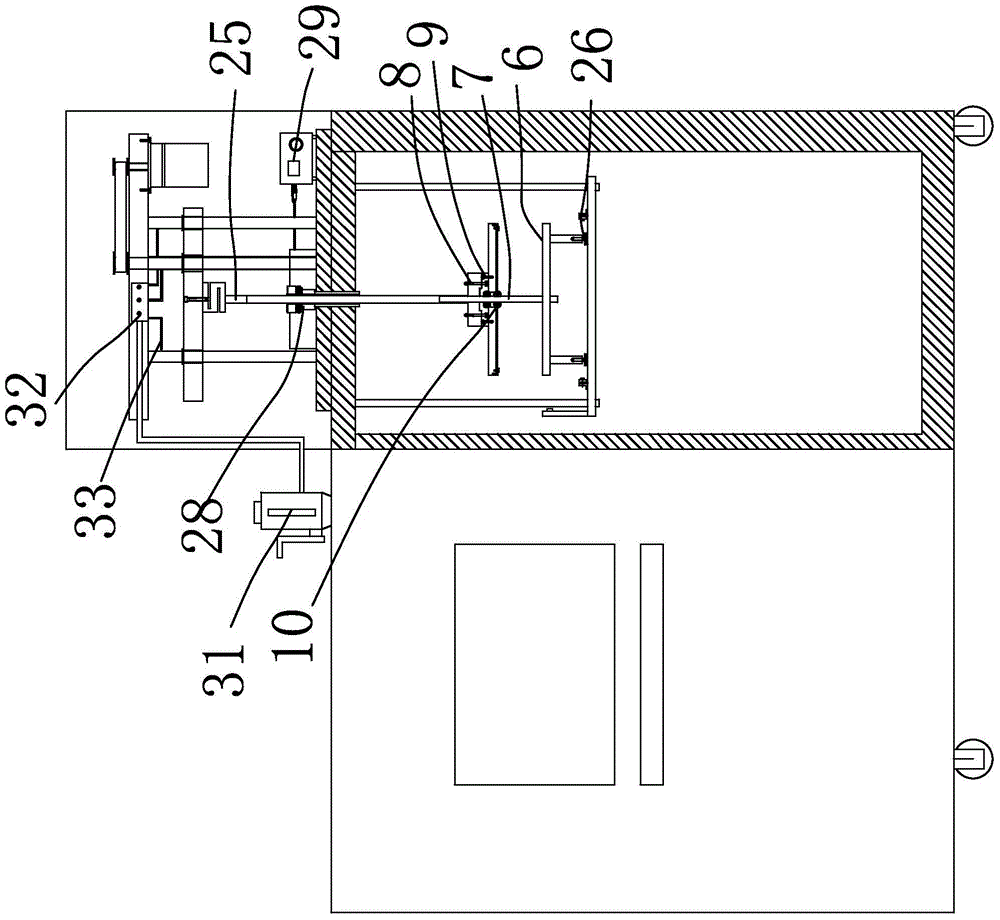

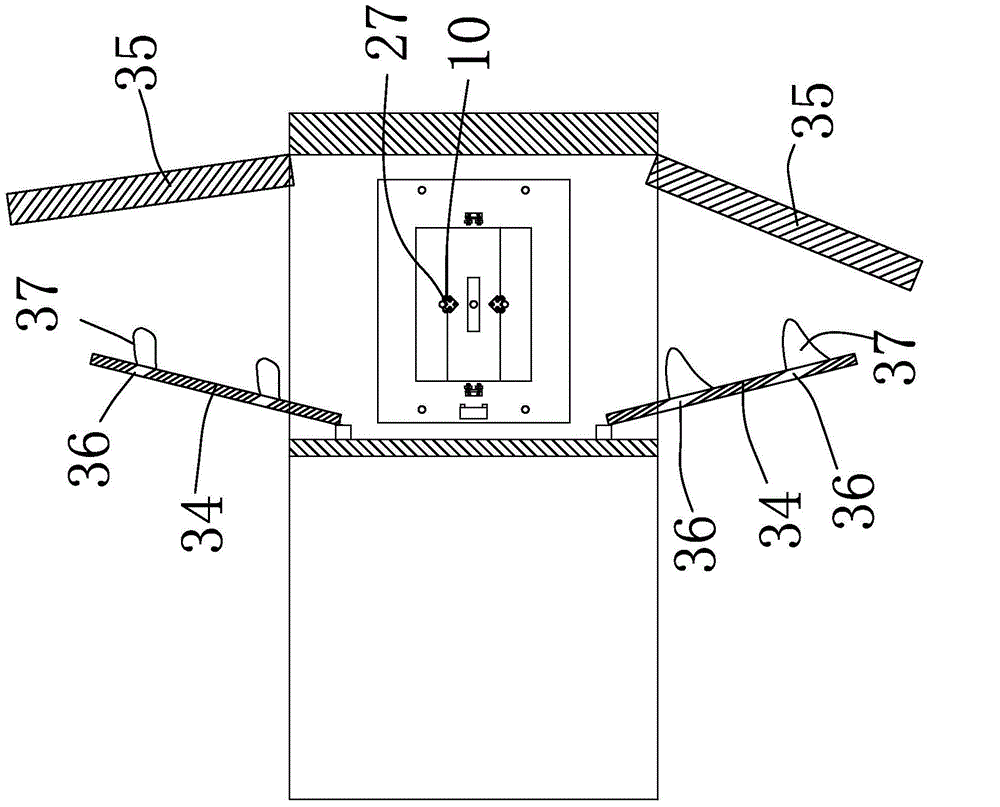

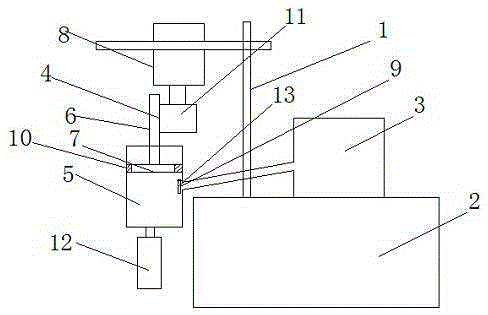

Rivet assembly equipment

PendingCN105618661AAvoid duplication of feedingAvoid stuck and other failuresDistributed structureElectric machinery

The invention discloses rivet assembly equipment. The rivet assembly equipment comprises an operation table, an executing mechanism and a power mechanism; the executing mechanism comprises a first distributing structure, a second distributing structure and a press-fitting structure; the first distributing structure comprises a first groove, a first base, a first support and a clamping jaw with a nail rod; the second distributing structure comprises a second groove, a second base, a second support and a clamping jaw with a nail head; the press-fitting structure comprises a crank rocker, a press-fitting groove, a press-fitting base, a press-fitting support and a pressing pin; the power mechanism comprises a rotation shaft and a motor, the rotation shaft comprises a main shaft, a flywheel, a rotation wheel, a first cam and a second cam, wherein the first cam is connected to the first support and the second cam is connected to the second support. The rivet assembly equipment has the advantages and the beneficial effects that the breakdown that the rivet assembly equipment is jammed because of repeated feeding of nail rods is avoided, the reliability of the rivet assembly equipment is improved, the uniformity of lubrication degree of sliding components is improved, and the work efficiency of rivet assembly is improved.

Owner:SHANGHAI TUOZHAN ELECTRICAL & MECHANICAL EQUIP

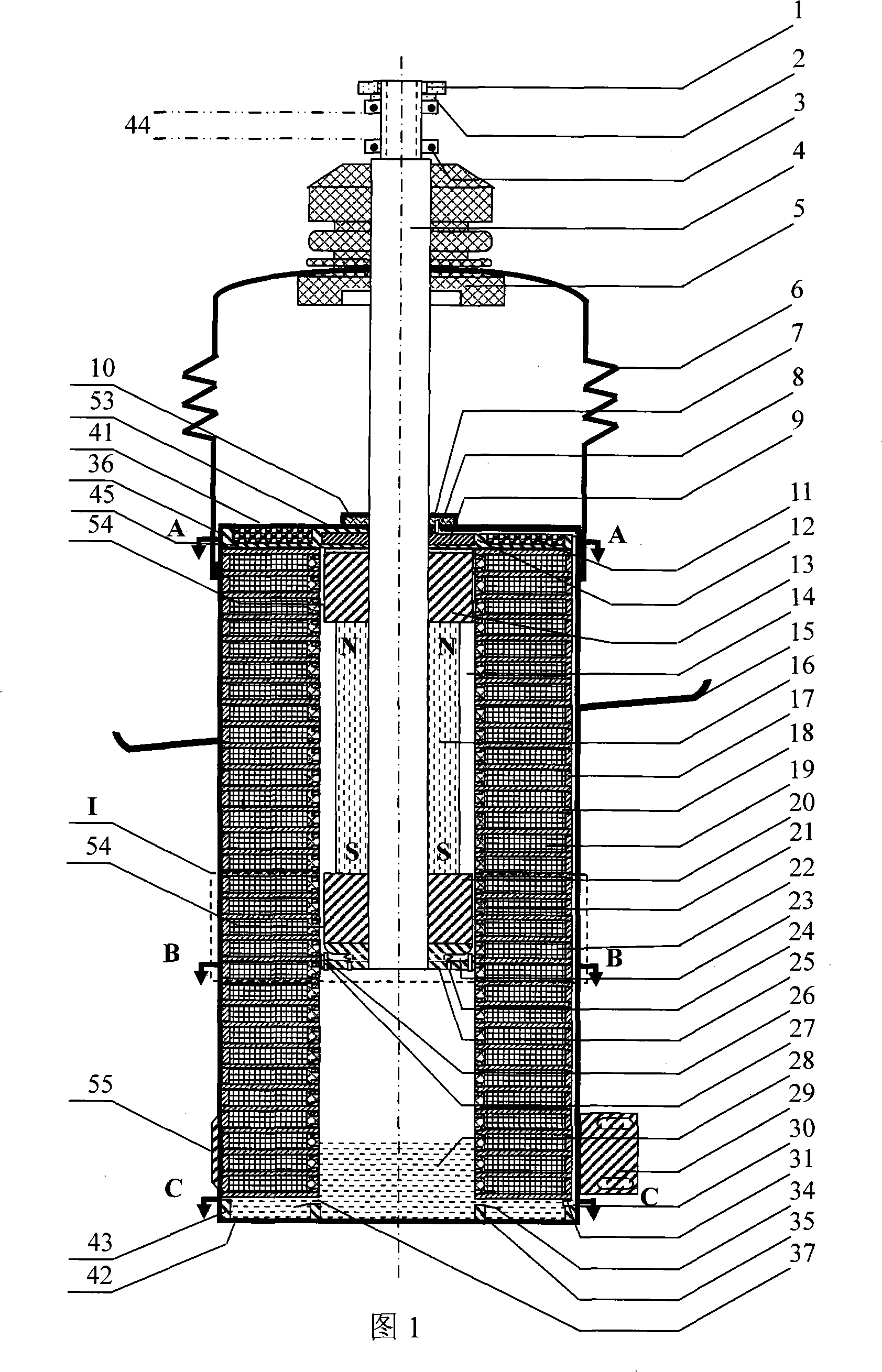

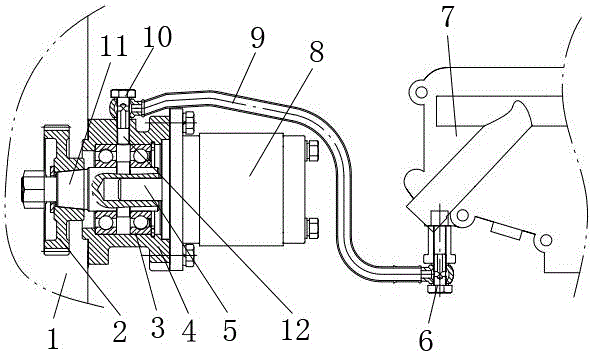

Oscillation damping power collector for automobile

InactiveCN101402309AAchieve dampingGo digitalProgramme controlAuxillary drivesVehicle frameEngineering

The invention relates to a vehicle damping kinetic energy collector, which is characterized by comprising a vehicle damping tray fixedly connected on an outer cylinder and a connecting plate connected with a wheel, wherein a stator is arranged in the outer cylinder; a vertically moving mover is arranged in the stator; the stator comprises a cavity which is arranged on a tooth magnetic plate and consists of a yoke magnetic ring and an inner ring; a plurality of stator units consisting of winding coils are arranged in the cavity, the plurality of the stator units are superposed in turn, and the winding coils of the plurality of the stator units under each electrode are connected forwards in the winding direction; the mover comprises a piston, a main magnetic lower guiding electrode, a permanent magnet and a main magnetic upper guiding electrode which are connected with a shaft sequentially from the bottom to the top; a turntable arranged on the outwards-extending end of the shaft is connected with a vehicle frame; a magnetism blocking plate is arranged on the topside of the stator; and an integrated controller is arranged in an outer enclosed cavity which is isolated by an upper internal pressure support ring between magnetism blocking rings under the magnetism blocking plate and an upper cylinder cover. The vehicle damping kinetic energy collector realizes current control through the intellectualization of damping information to collect vibration kinetic energy while achieving the flexible damping, thus the vehicle damping kinetic energy collector has the advantage of good adaptation to damping property, reduction of oil consumption, long service life and the like.

Owner:毕国忠

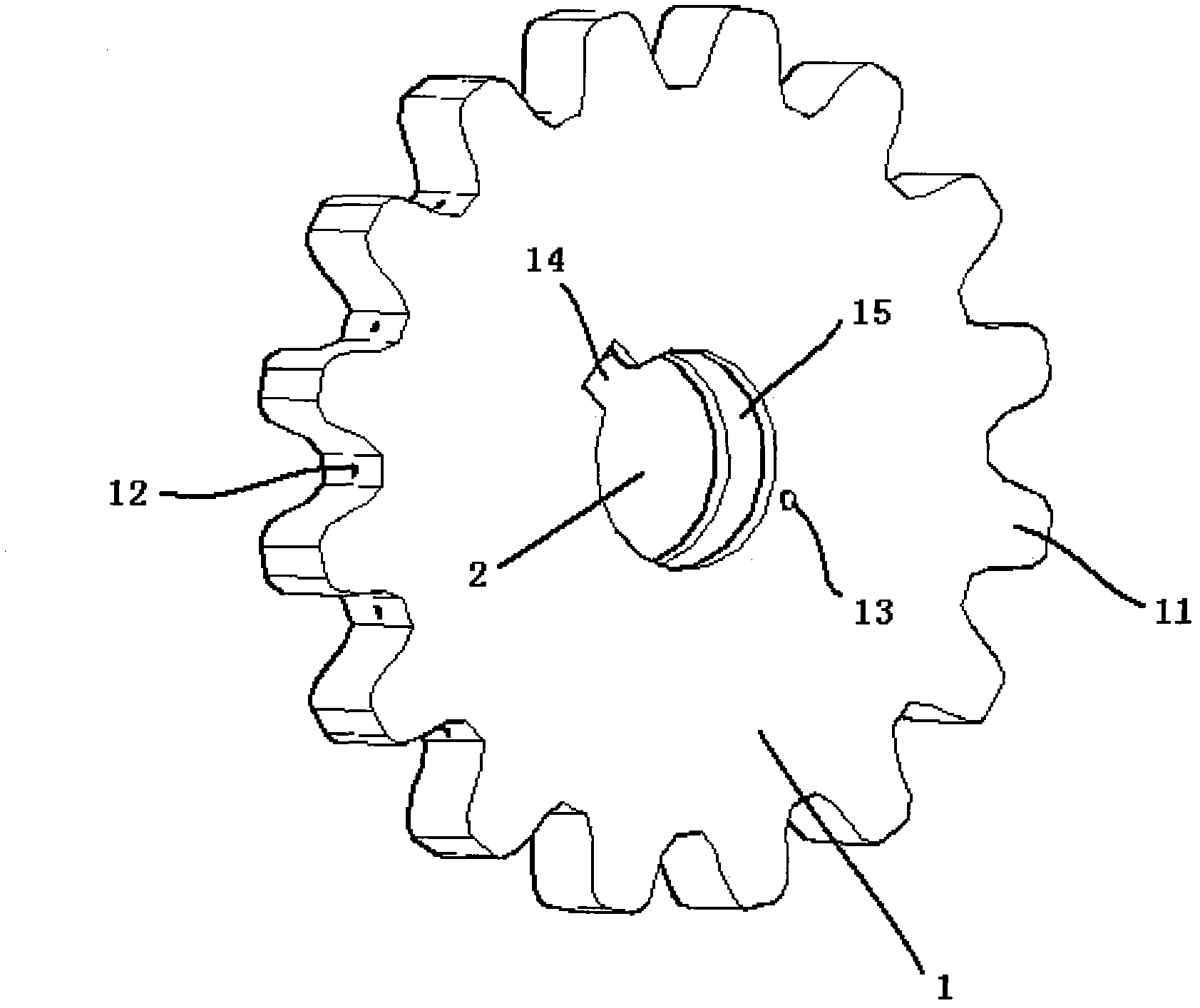

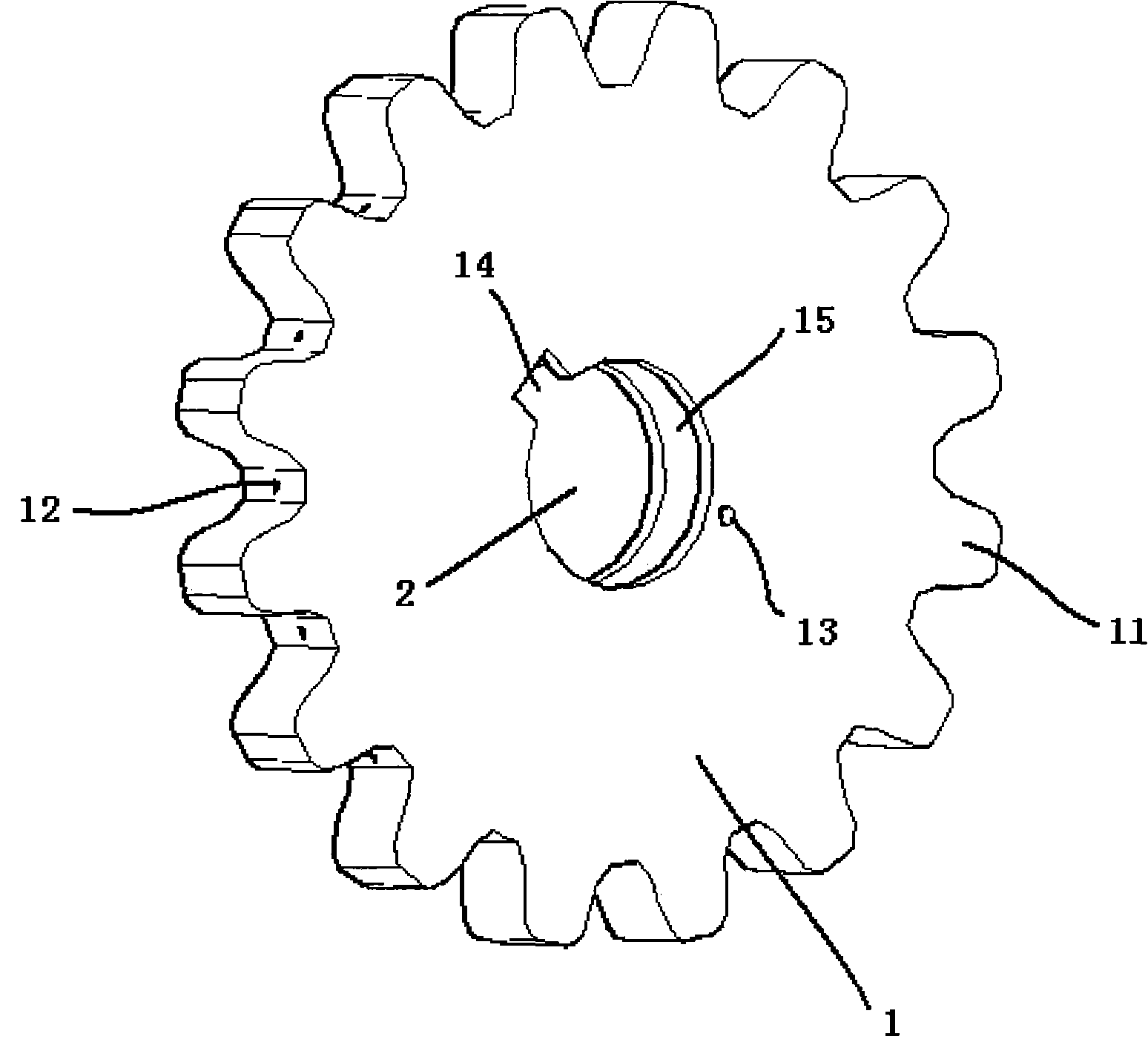

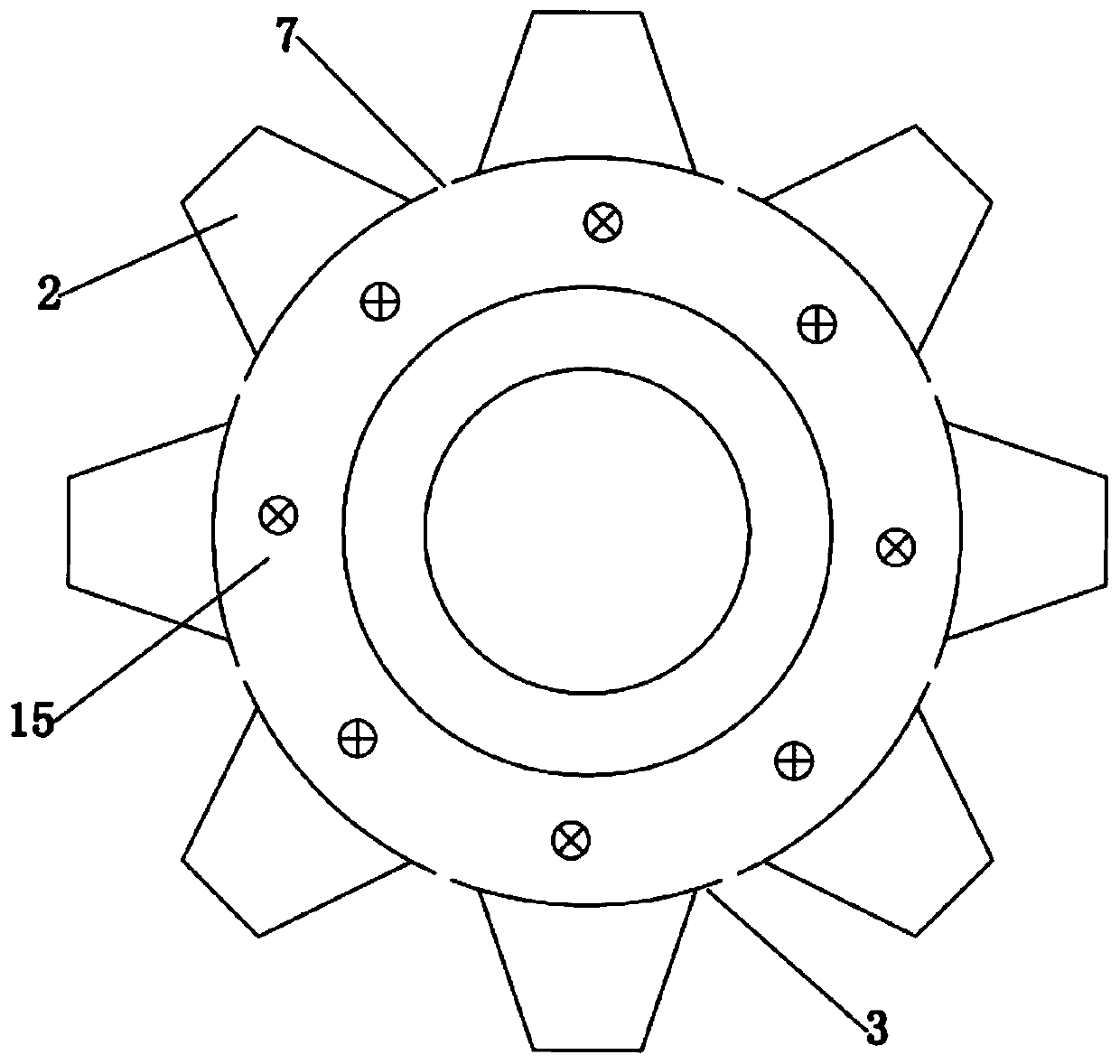

Oil-accumulating lubrication gear

InactiveCN102367865ASave lubricating oilEliminate manual lubricationPortable liftingGearing elementsGear transmissionLubrication

The invention provides an oil-accumulating lubrication gear, belonging to a mechanical part. The oil-accumulating lubrication gear comprises a gear body and a plurality of gear teeth, the center of the gear body is provided with a shaft hole matched with a shaft body, the shaft hole is provided with a key slot, the annular surface of the shaft hole is also provided with an annular inner groove, the annular inner groove is communicated with the surface of the gear body through a fluid injection hole, a plurality of lubrication channels are arranged between the annular inner groove and the root of each gear tooth, and permeable substances are arranged in the lubrication channels. The transmission of a gear pair can be realized effectively, and lubricating oil can be stored in the gear and can be automatically released to the surfaces of the gear teeth during the gear transmission process. Therefore, the lubricating oil can be saved, and the manual lubrication can be eliminated.

Owner:郑霞

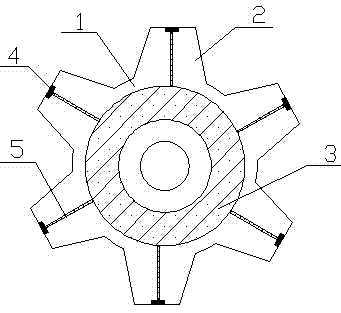

Self-lubricating gear

InactiveCN104265862AExtended service lifeRealize automatic lubricationPortable liftingGearing elementsEngineeringOil storage

The invention relates to the technical field of mechanical transmission, in particular to a self-lubricating gear. Functions of an existing gear are single, the existing gear does not have a self-lubricating function and is seriously abraded after working for a long time, and the service life of the existing gear is obviously shortened. The self-lubricating gear comprises a gear body and gear teeth mounted on the periphery of the gear body, an oil storage ring is arranged in the gear body, and oil outlet holes are formed in the ends of the gear teeth and connected with the oil storage ring through an oil lead pipe. The improved self-lubricating gear automatically lubricates, abrasion is avoided, and the service life of the gear is prolonged.

Owner:CHANGZHOU FUYUN CHEM

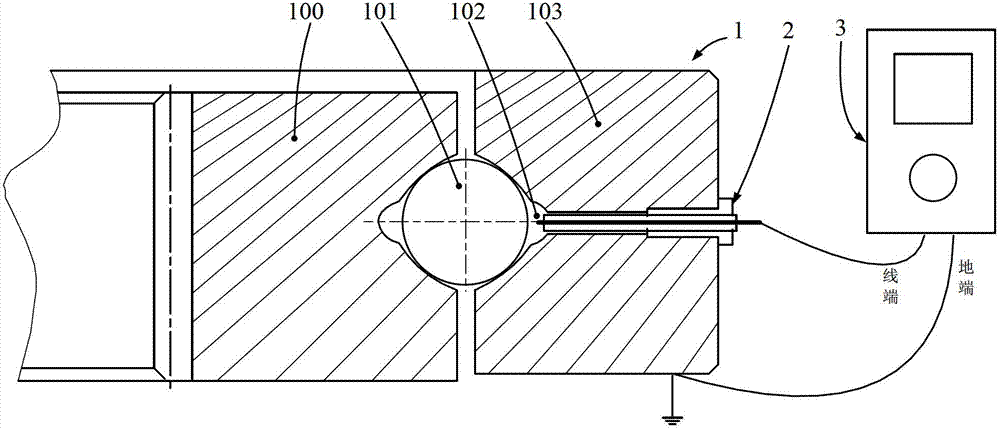

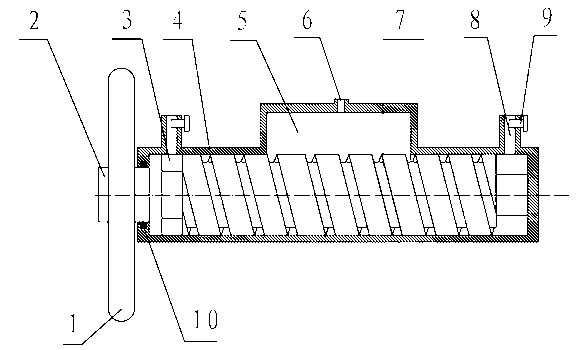

Slewing bearing wearing extent on-line measurement and lubricating grease automatic filling-up method

ActiveCN102853241AReal-time optimization of lubrication conditionsExtended service lifeLubrication elementsMaterial resistanceTransducerBearing wear

The invention relates to a slewing bearing wearing extent on-line measurement and lubricating grease automatic filling-up method. The method comprises the steps of utilizing the change of a lubricating grease insulating property to judge the change of metal particle content in a lubricating grease, and judging the wear condition of a slewing bearing raceway, so as to indirectly judge the generation and development of the damage of the raceway and be used for optimizing a lubrication condition of a slewing bearing, determining filling-up quantity and filling-up frequency of the lubricating grease according to the wear condition, and realizing the required lubrication of a self-adapting working condition. The method provided by the invention avoids the problem of separation of a wearing extent value of a micrometric displacement measuring method, the problem of self abrasion of a contact-type micrometric displacement transducer, and the problem of insufficient non-contact type micrometric displacement range and poor accuracy, can realize on-line measurement, avoids the problems that the regular fixed point filling-up has the problems of excessive pouring grease or shortage and the like, optimizes the lubrication condition of the slewing bearing, effectively improves the load-carrying capability of the slewing bearing, prolongs the service life, and fills up an industry blank; and the purposes can be realized just by general instrument and equipment such as electric control grease pouring pumps, insulation meters and measuring heads.

Owner:NANJING TECH UNIV

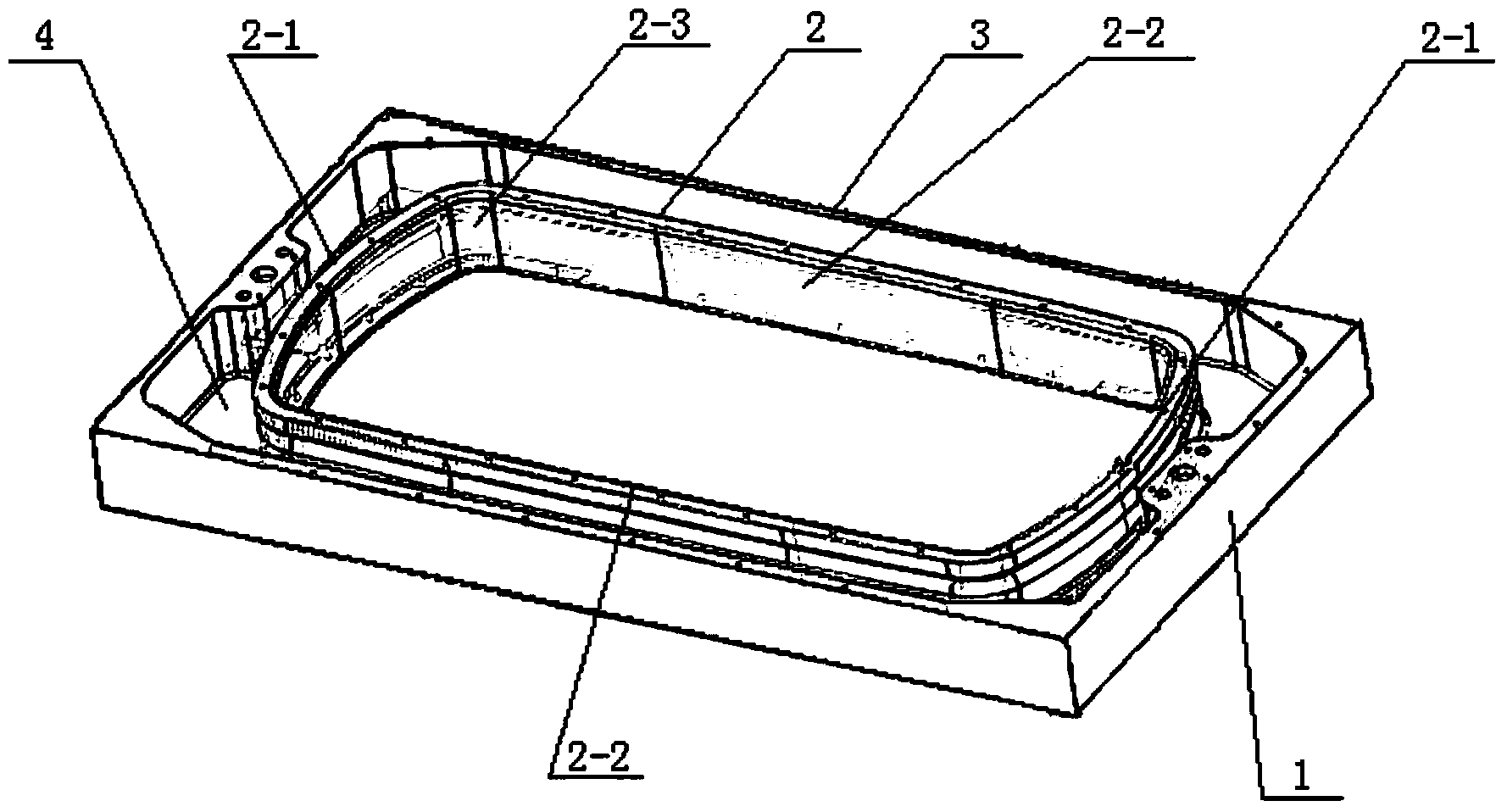

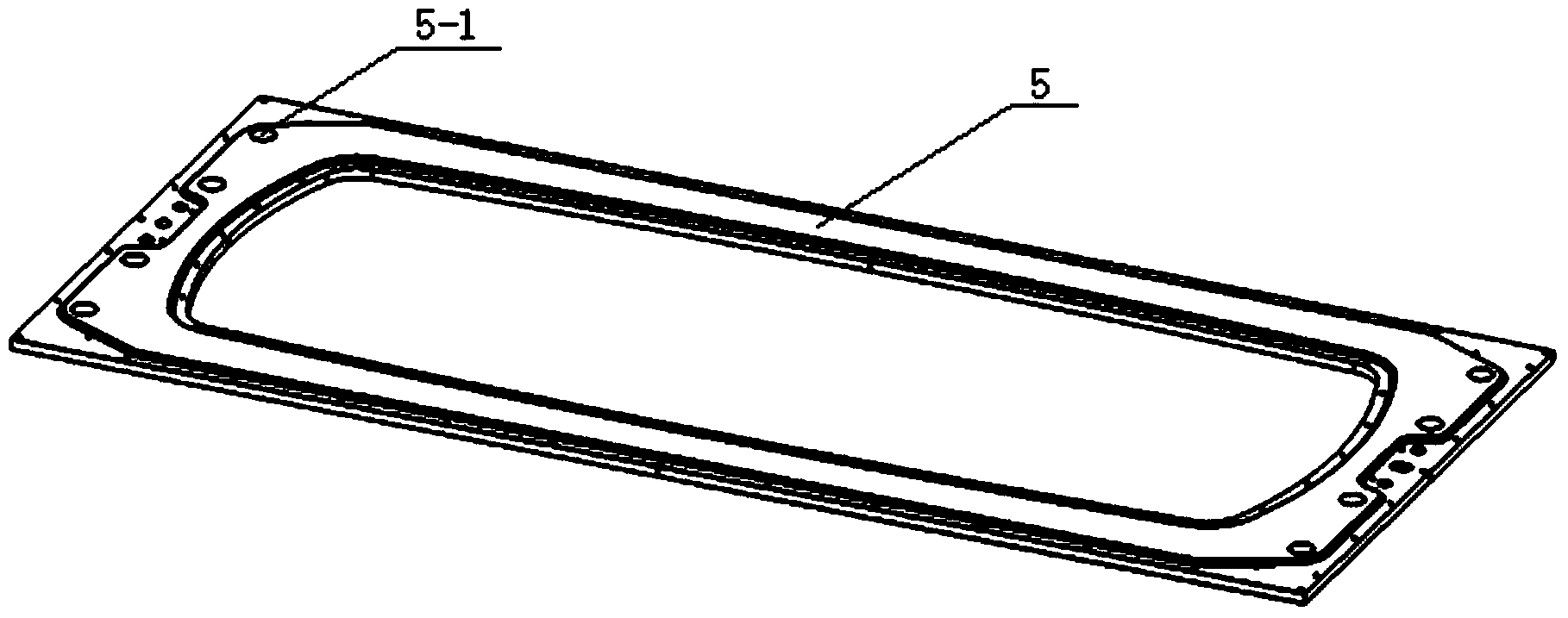

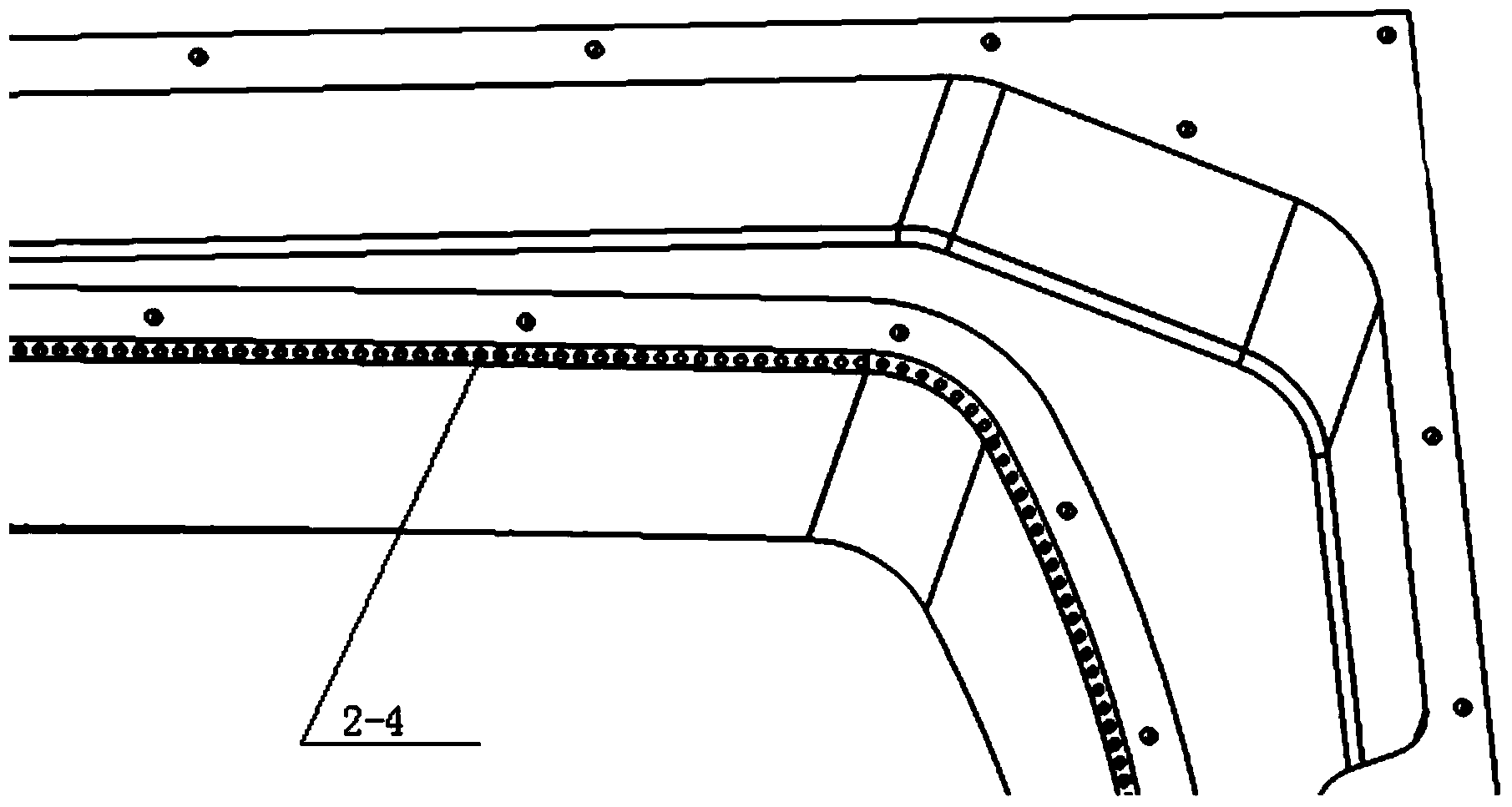

Crystallizer for preparing superhard aluminum alloy flat cast ingot and use method of crystallizer

The invention discloses a crystallizer for preparing a superhard aluminum alloy flat cast ingot and a use method of the crystallizer and relates to a tool for preparing the superhard aluminum alloy flat cast ingot and a use method of the tool.The crystallizer aims at solving the problem that superhard aluminum alloys produced by the existing casting tool have high possibility of crack rejects. The crystallizer for preparing the superhard aluminum alloy flat cast ingot comprises a crystallizer water chamber, a water chamber gland, a secondary water distribution plate and an oil gland, wherein the crystallizer water chamber comprises a water chamber internal wall, a water chamber external wall and a water chamber base; a plane is arranged at a junction between the internal surface and the upper surface of the water chamber internal wall; water outlet holes are formed in the plane; water inlet holes are formed at the two ends of the water chamber gland in a length direction; and a lubricating oil channel is arranged on the water chamber base and located close to the water chamber internal wall on the plane on the outer side of a cavity.The use method comprises the step of arranging a water baffle in a down direction of the cast ingot below the crystallizer when in use.The method reduces crack tendency.

Owner:NORTHEAST LIGHT ALLOY CO LTD

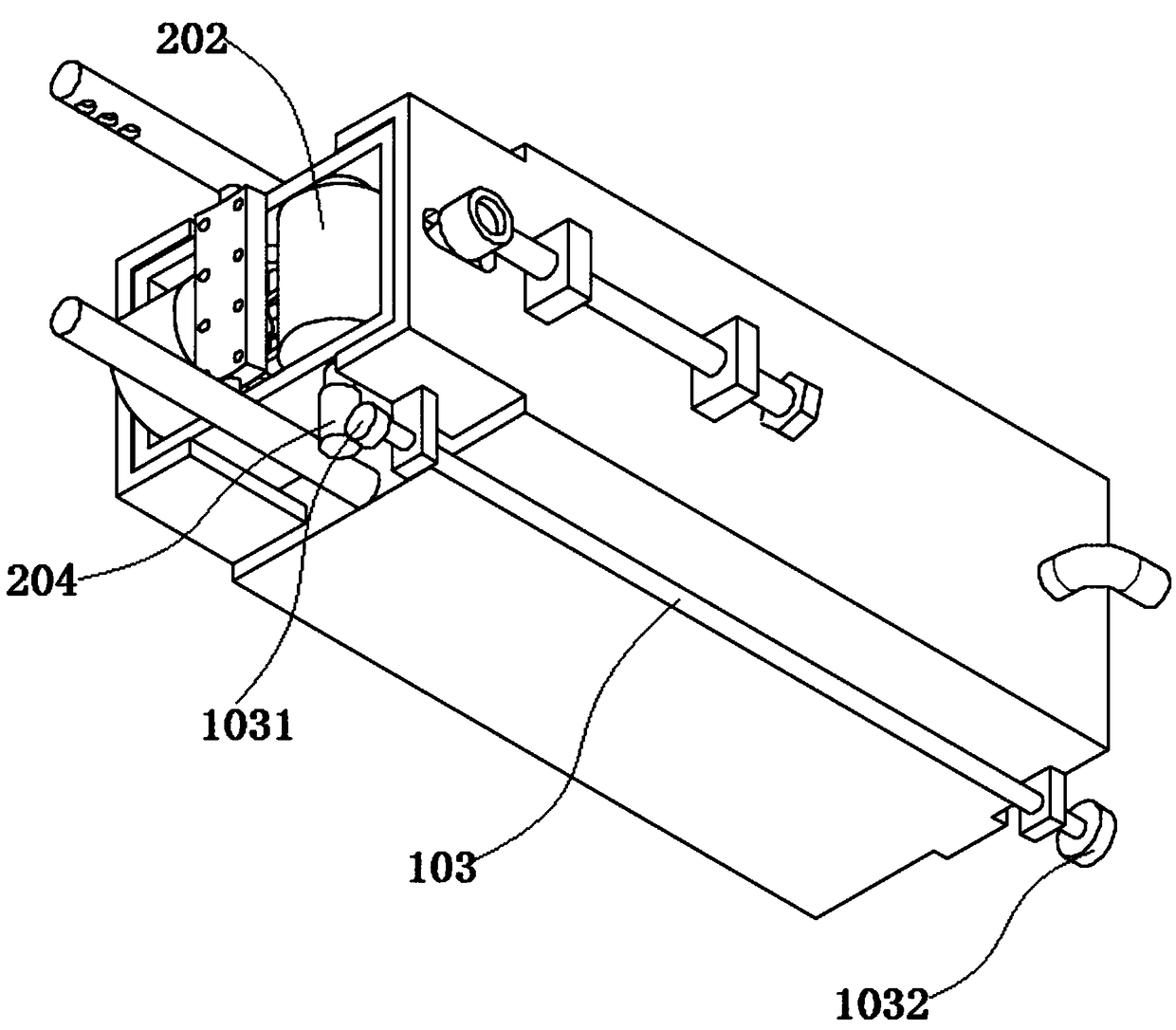

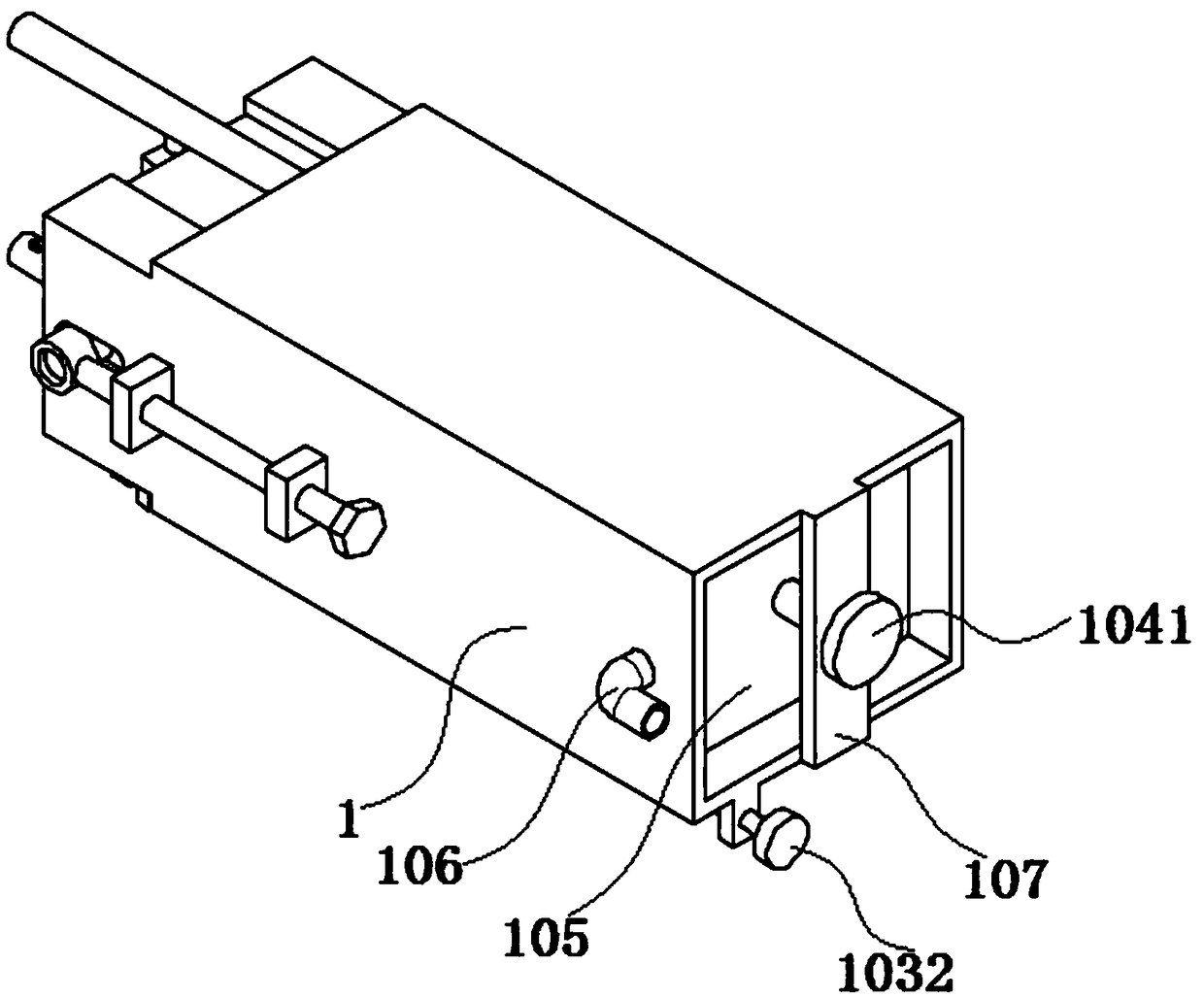

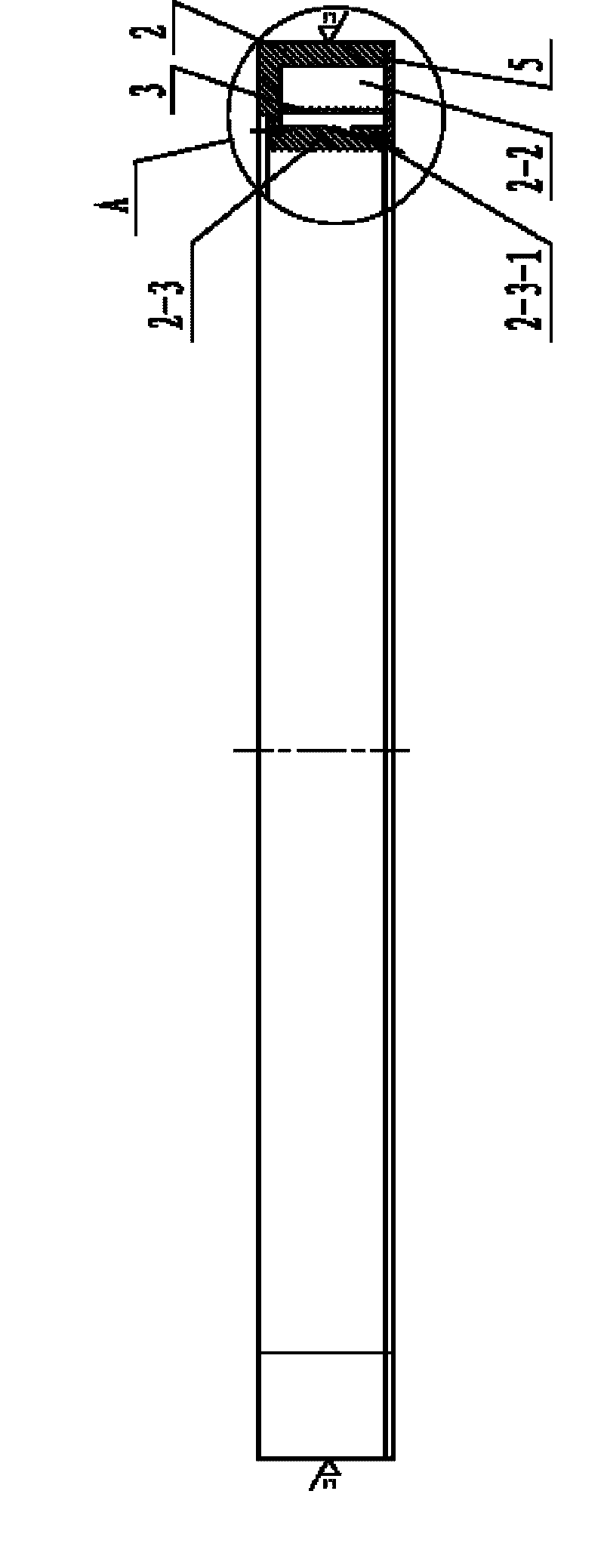

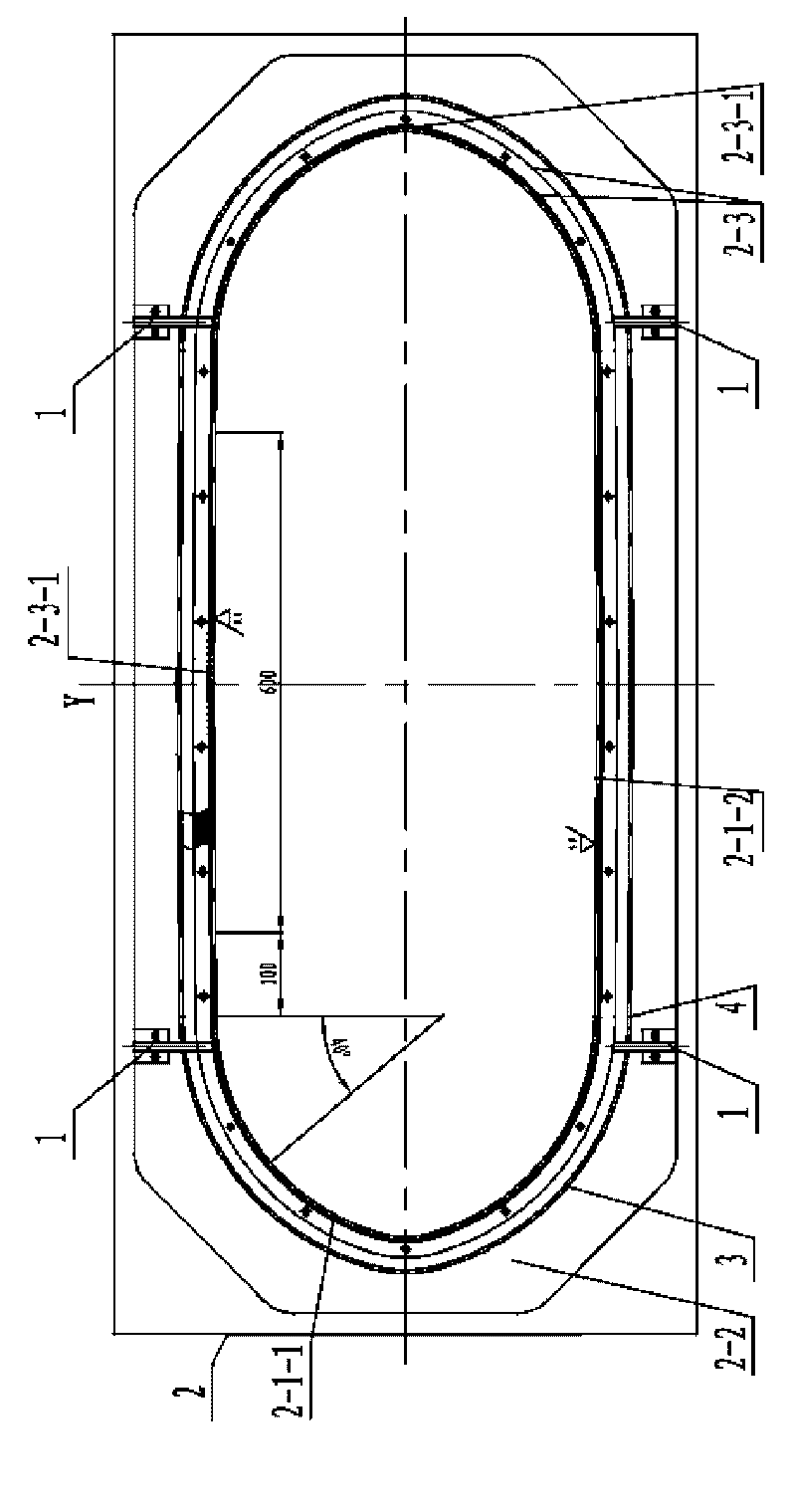

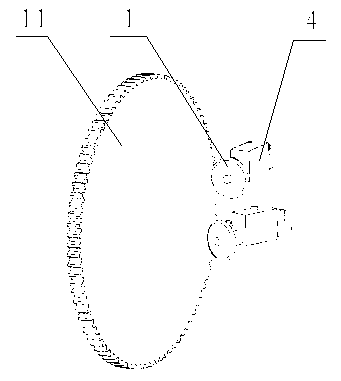

Track lubricating device for truck mounted crane

ActiveCN108799808AImprove efficiencyImprove work efficiencyCleaning using toolsConduits/junctionsFixed frameTruck

The invention discloses a track lubricating device for a truck mounted crane and relates to the technical field of cranes. The track lubricating device comprises a box body, one end of the box body isin sliding connection with a transmission device, oil injecting pipes are fixedly connected to one end of the box body side by side, the two oil injecting pipes communicate with an oil injecting box,and baffles are fixedly connected to one end of the box body side by side. The transmission device comprises a fixed frame, and a gear and a rolling brush are arranged in the fixed frame. The track lubricating device is provided with the box body and the transmission device; the gear of the transmission device and a gear of a rotation track are engaged to obtain power, the oil injection pipes andthe oil injecting box are used for lubricating the upper surface, lower surface and tooth surface of the track, and thus the problems that through an existing manual lubricating mode, the process iscomplicated and meanwhile incomplete lubricating is prone to occurring are solved; and the rolling brush is used for cleaning the rotation track, so that the problems that through an existing wiping mode of the rotation track, complexity and time consumption are caused, and working efficiency is low are solved.

Owner:启东启润康耐柯连接件有限公司

Integrated water tank type crystallizer used for casting 7 series extra super duralumin alloy

The invention provides an integrated water tank type crystallizer used for casting 7 series extra super duralumin alloy, relating to a crystallizer. The invention solves the problem that cast ingot produces cracks caused by stress concentration as the existing crystallizer is not even in water-cooling distribution. The cross section contour of the flat through hole is composed of two arc sections and two straight line sections, each arc section is formed by butt joint of two arcs in different diameters; the lower end face of all the side walls of crystallizer tank body is opened with an annular groove, the lower end face of the annular water feeding hole wall body between the annular groove and the flat through hole is opened with a plurality of osculums in uniform distribution, the lower end of each osculum is inclined toward the central axis of the flat through hole; and four clapboards are respectively arranged at the two ends of the annular groove and divide the annular groove into four regions. The crystallizer of the invention adopts four-section design and different diameters of osculums to control water flow, so that cooling of cast ingot is even, temperature is ensured to be consistent with stress field distribution, and cast ingot crack tendency is greatly reduced.

Owner:NORTHEAST LIGHT ALLOY CO LTD

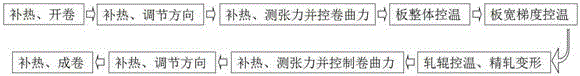

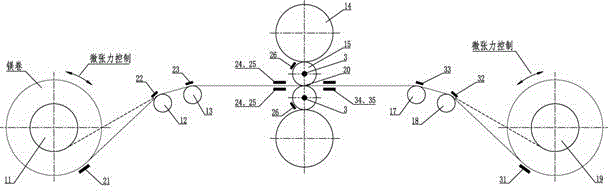

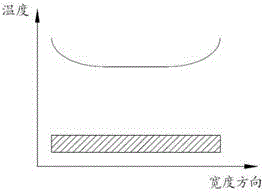

Temperature-controlled rolling technology of magnesium alloy coiled sheet

ActiveCN105834227AAvoid bumpingAvoid featuresTemperature control deviceMetal rolling arrangementsTemperature controlRolling mill

The invention discloses a temperature-controlled rolling technology of magnesium alloy coiled sheets. The steps comprise: (1) performing heating compensation on a magnesium coiled sheet and uncoiling the magnesium coiled sheet; (2) performing sheet heating compensation and adjusting turning directions of the magnesium alloy sheets; (3) measuring tension of the sheet and controlling a crimp force value; (4) performing integrated temperature control on a part which is to bite into the sheet; (5) performing gradient temperature control on the width direction of the part which is to bite into the sheet; (6) through a temperature-controlled roll, performing finishing rolling on the sheet and the sheet deforming; (7) measuring tension of the sheet and controlling a crimp force; (8) performing sheet heating compensation and adjusting turning directions of the magnesium alloy sheets; (9) performing sheet heating compensation and coiling the sheet in rolls; (10) if the thickness of the magnesium plate coil sheet does not reach the thickness (t0) of a target magnesium plate, reversely repeating the steps (1)-(9) on magnesium coiled sheets on a reversible temperature-controlled rolling mill according to the process steps, performing next temperature-controlled finish rolling processing; (11) if the thickness of the magnesium sheet reaches the thickness (t0) of the target magnesium plate, obtaining the magnesium alloy coiled sheet satisfying the thickness requirements.

Owner:BAOSHAN IRON & STEEL CO LTD

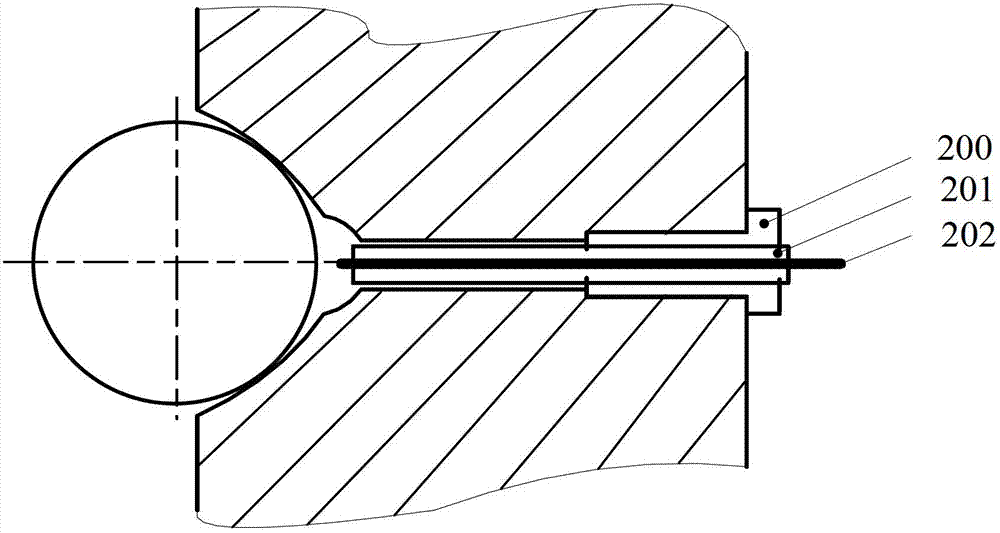

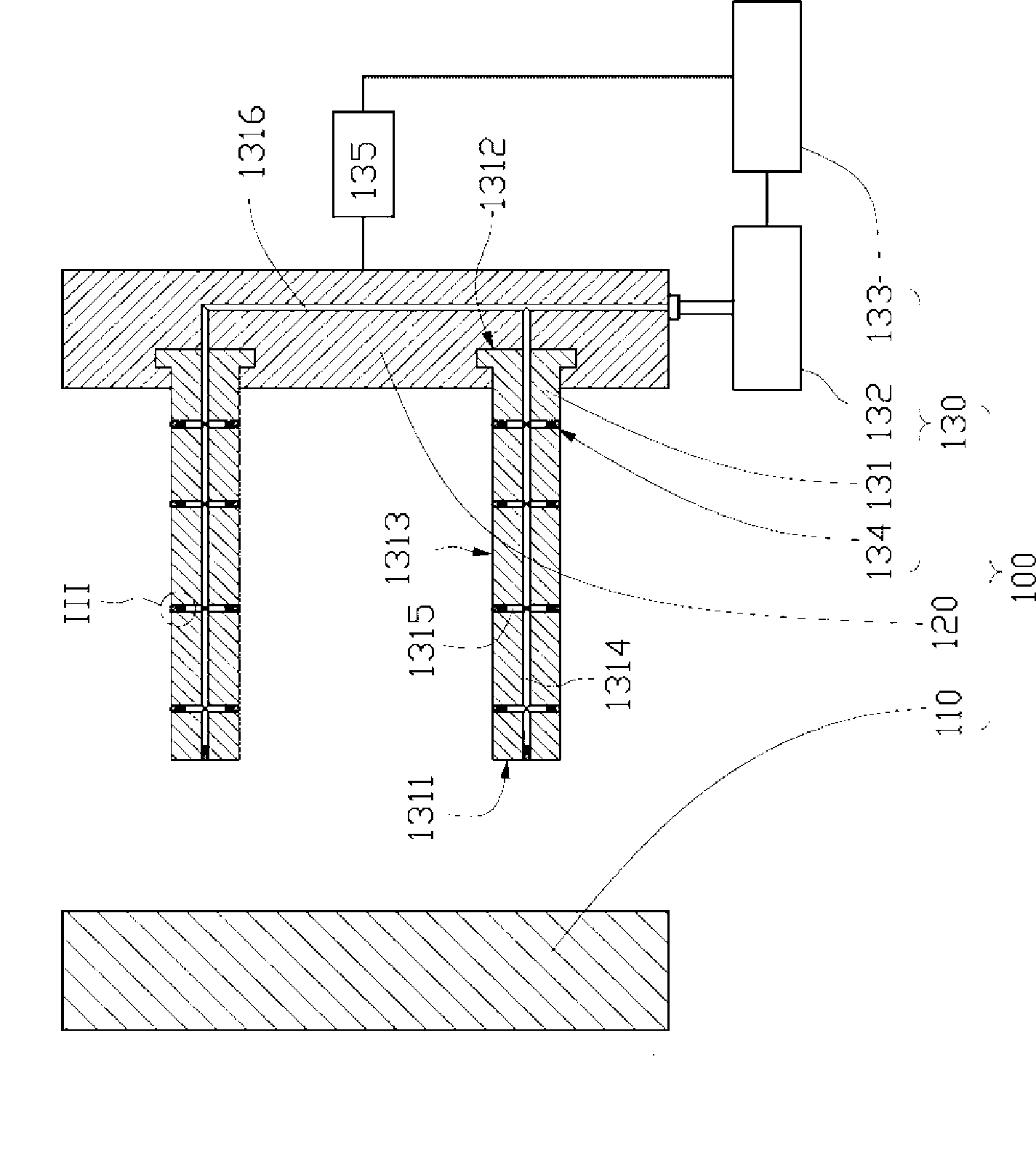

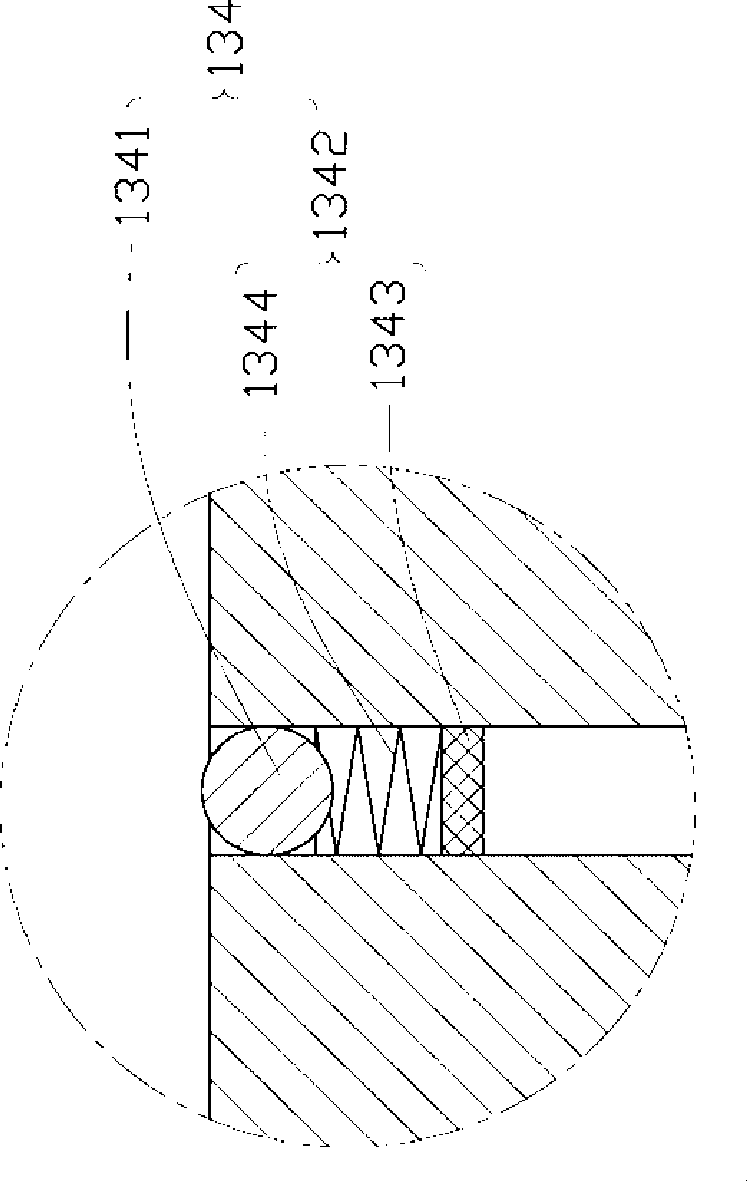

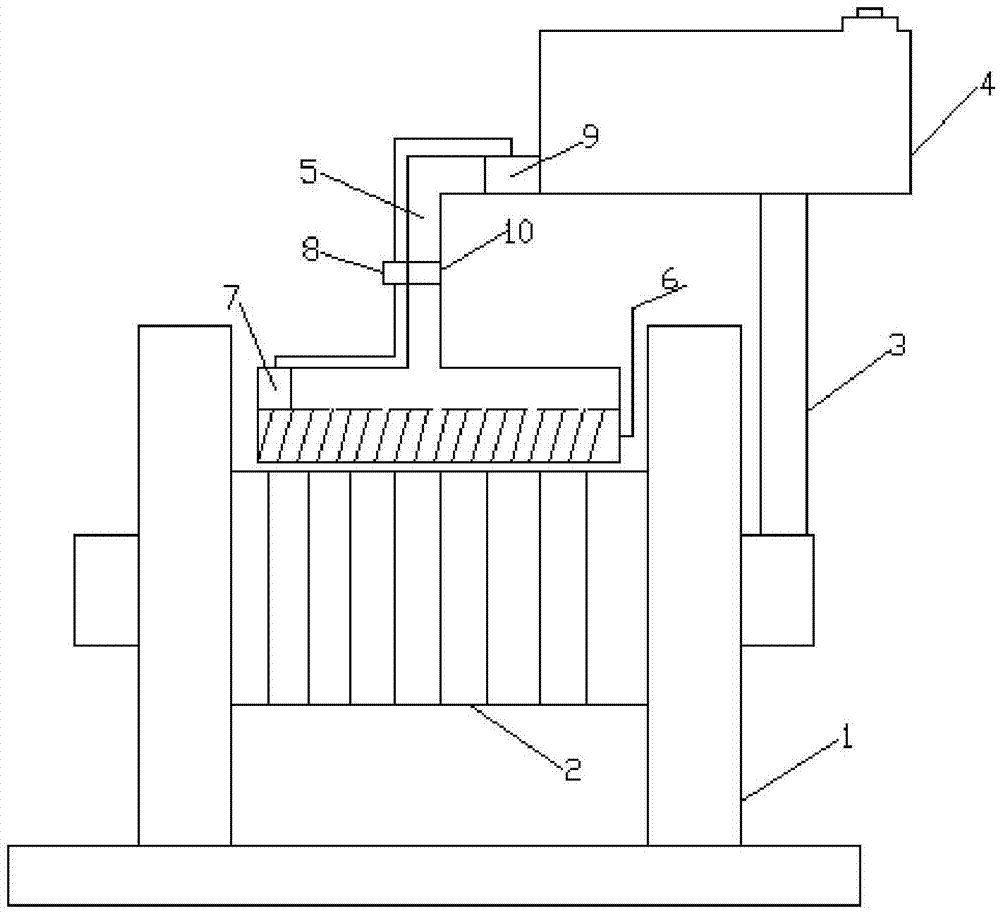

Automatic lubrication type guide pole device and mold positioning apparatus including the guide pole device

InactiveCN101462320ARealize automatic lubricationPrevent drynessEngine lubricationEngineeringLubrication

The invention relates to an automatic lubricating type guide pillar device and a die positioning device comprising the guide pillar device. The automatic lubricating type guide pillar device comprises a guide pillar, an oil supply device, and a control device. The guide pillar is provided with a first end face, a second end face opposite to the first end face, and a lateral surface positioned between the first end face and the second end face and connected with the first end face and the second end face. The guide pillar is provided with a first flow passage running through the first end faceand the second end face and a plurality of second flow passages running through the lateral surface, and each second flow passage is communicated with the first flow passage. The oil supply device iscommunicated with the first flow passage, and used for transporting lubrication oil to the first flow passage and each second flow passage. The control device is connected with the oil supply device,and used for controlling motion of the oil supply device. The die positioning device can automatically lubricate the guide pillar, and prevent the surface of the guide pillar drying and rusting, so as to improve production precision and prolong service life of a die.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Novel self-lubricating gear

InactiveCN110285204AAutomatic Lubrication AvoidanceSolve the inconvenience of operationPortable liftingGear lubrication/coolingOil storage

The invention discloses a novel self-lubricating gear. The novel self-lubricating gear comprises a gear body, wherein wheel teeth are uniformly arranged on the outer circumference of the gear body, tooth grooves are formed between the wheel teeth, an oil injection hole is formed in one side surface of the gear body, and an oil storage cavity is formed in the other side surface of the gear body; an upper oil outlet hole is formed in the middle of each tooth groove, oil storage columns with the same length as the tooth grooves are arranged on the inner side of the oil storage cavity, springs are fixedly connected to the interiors of the oil storage columns and the inner wall of the bottom end of the oil storage cavity, and inner oil outlet holes are formed in the two sides of the lower part of each oil storage column; and a sliding block is adapted to the inner side of each sliding groove, the other end of the each spring is connected below the corresponding sliding block, a lower pressing rod is fixedly connected above each sliding block, a rolling ball for blocking the corresponding upper oil outlet hole is fixedly connected to the top end of each lower pressing rod, and an upper pressing rod which is arranged on the outer side of the each upper oil outlet hole is fixedly connected to the top end of the corresponding rolling ball. Automatic lubricating of the gear can be realized, and the problems that in the prior art, the working efficiency and the service life of the gear are influenced due to the fact that lubricating in the gear working process is not in place and the operation is inconvenient when a gear meshing part is lubricated manually can be solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

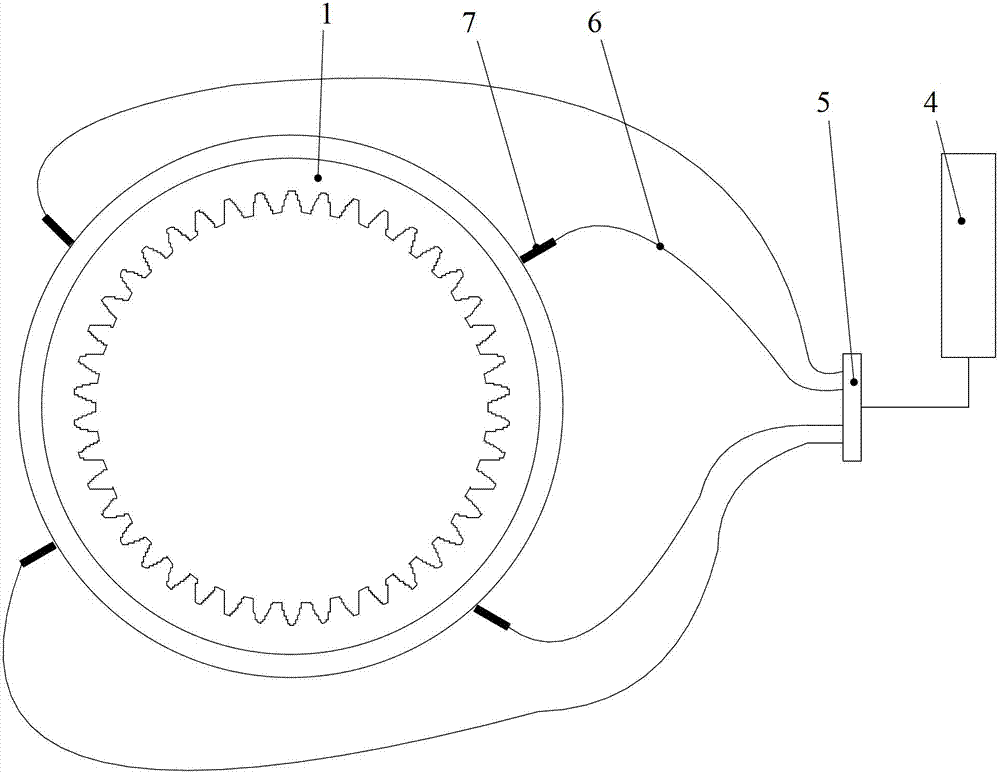

Exposed gear automatic lubricating device

InactiveCN103133672ARealize automatic lubricationAchieve lubricationGear lubrication/coolingEngineeringMechanical engineering

The invention discloses an exposed gear automatic lubricating device which comprises an airtight casing and a rotary shaft rotatably assembled in the casing. One end of the rotary shaft extends out of the casing, the extending portion is fixedly provided with a friction wheel in rotary fictional match with the end face of a gear. The peripheral face of the rotary shaft is provided with a helical structure which is axially screwed along the axial direction of the rotary shaft and used for conveying lubricating oil, the casing is provided with an adaptive hole section which is matched with the helical structure and used for achieving lubricating oil conveying along the axial direction of the rotary shaft when the rotary shaft rotates, and the casing is further provided with an oil storing cavity connected with the oil inlet end of the adaptive hole section and provided with an oil injecting hole, and an oil discharging cavity connected with the oil outlet end of the adaptive hole section and provided with an oil discharging hole. The exposed gear automatic lubricating device achieves lubricating oil supply by means of rotation of the gear, achieves automatic lubricating without other power, and is simple in structure and low in cost.

Owner:DONGHAI SILICON IND ENERGY SAVING TECHRES INST HENAN UNIV OF SCI & TECH

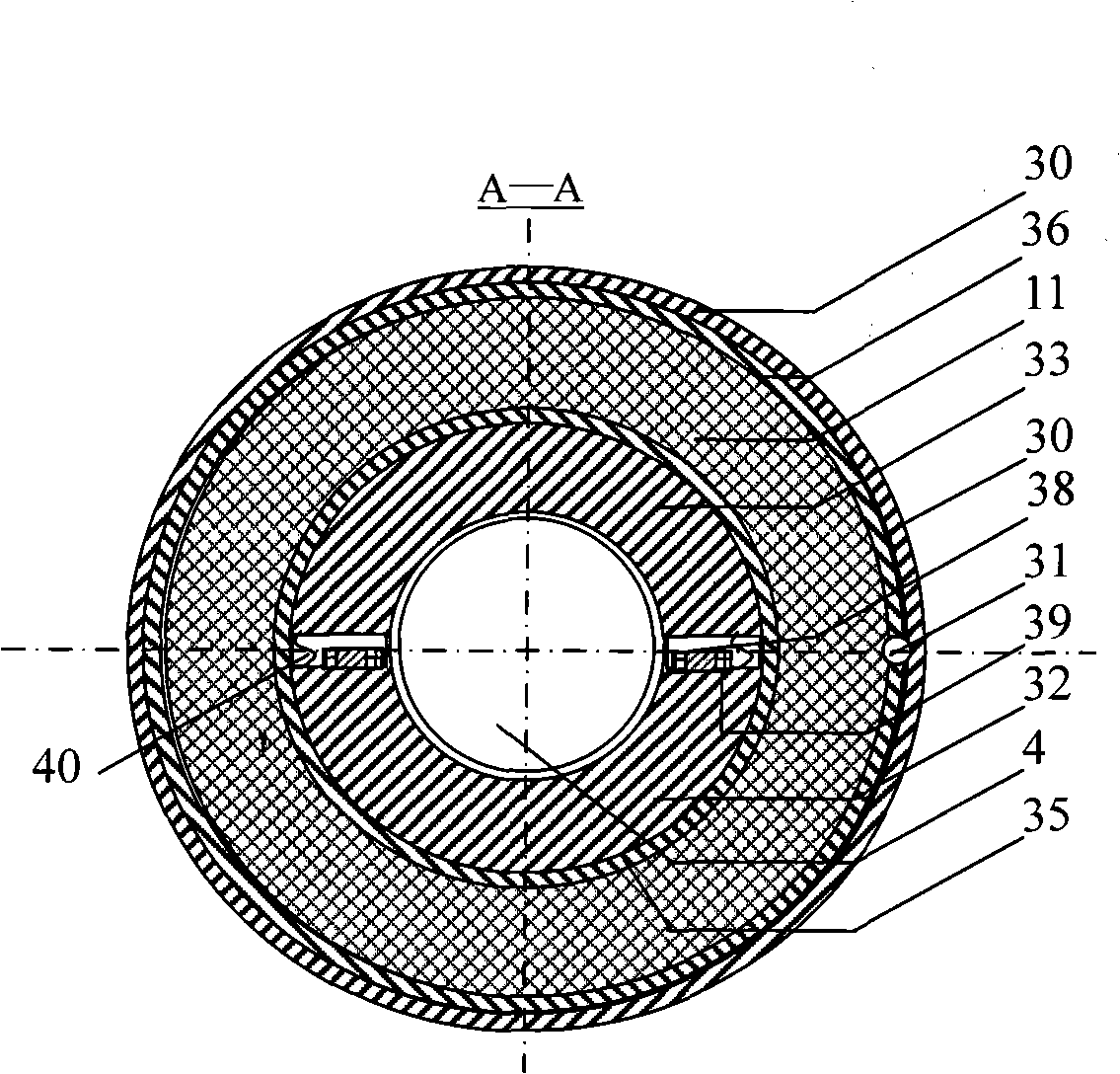

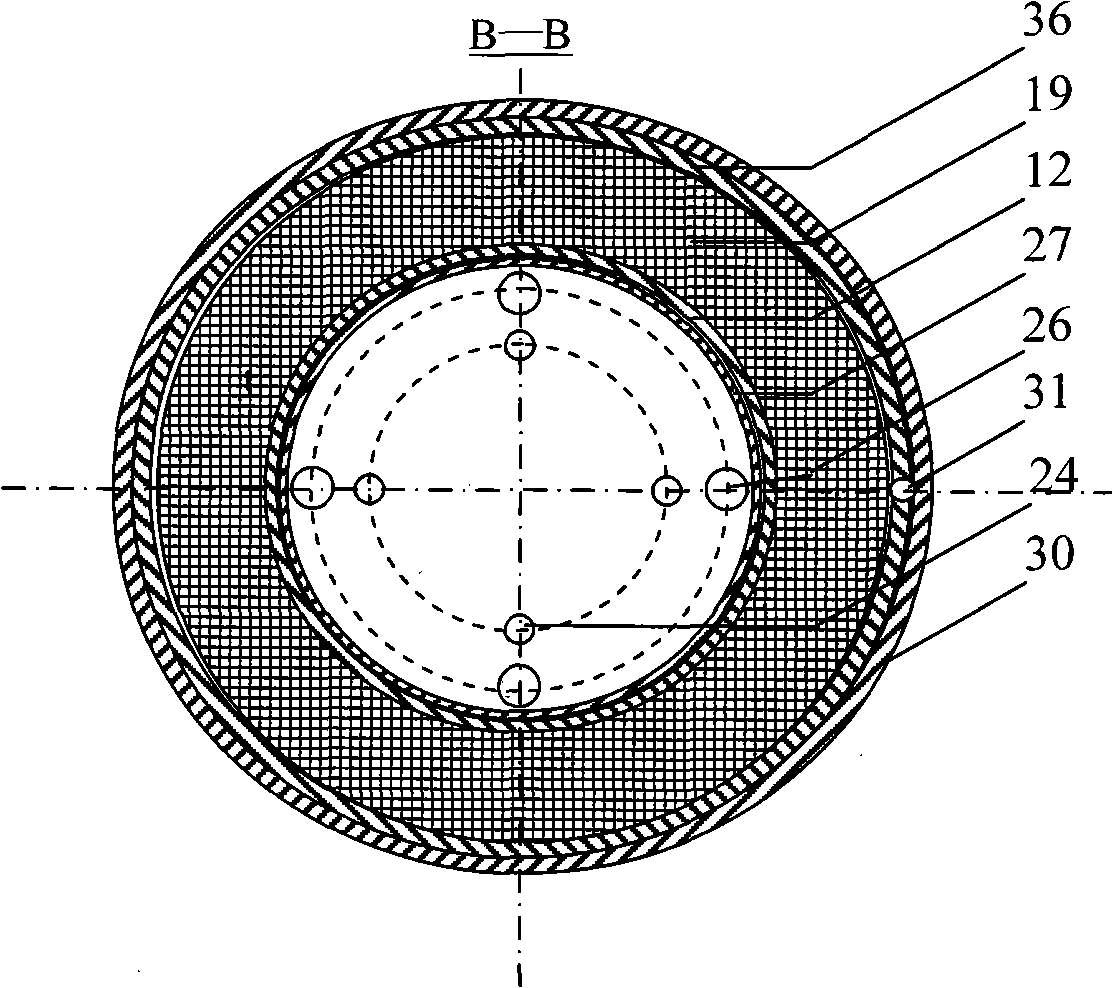

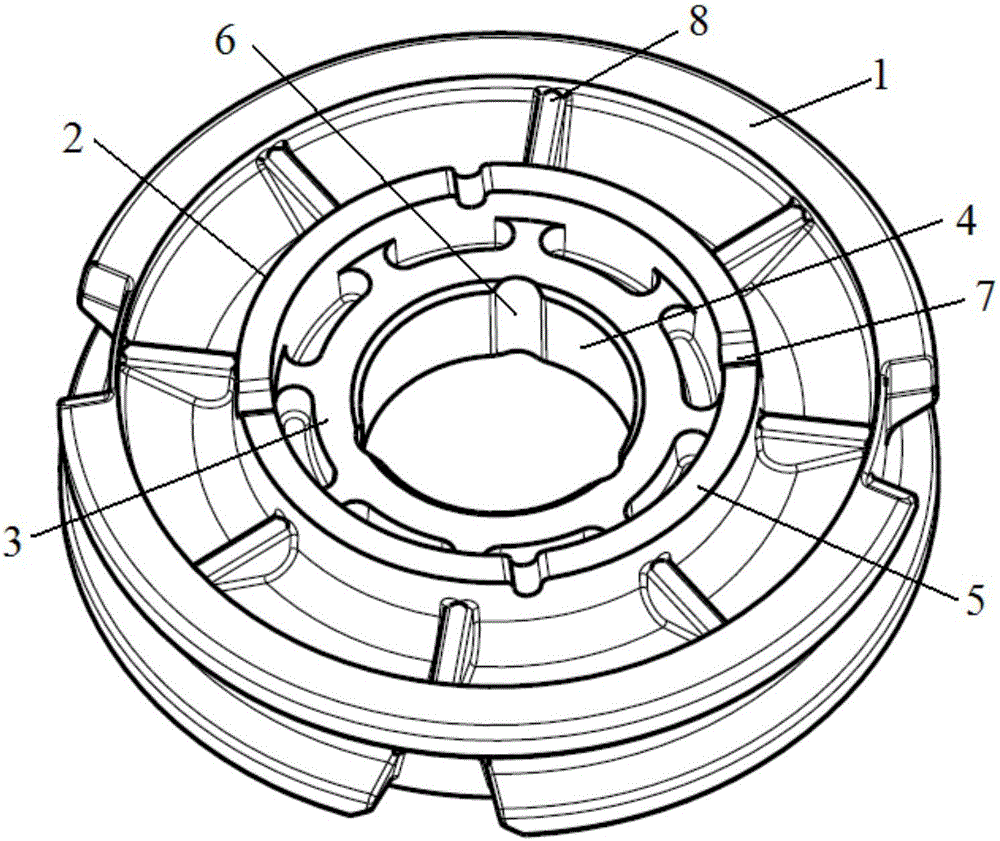

Automatic lubricating device of vertical speed reducer

InactiveCN103968051ASolve the problem of not easy to lubricateRealize automatic lubricationGear lubrication/coolingReduction driveEngineering

The invention discloses an automatic lubricating device of a vertical speed reducer. The automatic lubricating device comprises a machine box. The machine box is provided with an oil chamber and a vertical rotation shaft. The lower portion, extending into the oil chamber, of the rotation shaft is provided with two one-way rotation mechanisms in the vertical direction. Each one-way rotation mechanism comprises an inner ring body, an outer ring body and a middle body. The inner ring bodies are in key connection with the rotation shaft, and the outer ring bodies are arranged on the outer rings of the inner ring bodies in a spaced and sleeved mode. Wedge grooves with wedge-shaped sections are formed in the surfaces of the outer rings of the inner ring bodies. The middle bodies are arranged between the wedge grooves and the outer ring bodies. External threads are arranged on the surfaces of the outer rings of the outer ring bodies. The two one-way rotation mechanisms are installed oppositely. The rotation shaft is provided with an oil conveying hole, the bottom port of the oil conveying hole is communicated with the oil chamber, and the top port of the oil conveying hole is formed in the outer surface of the upper portion of the rotation shaft. The automatic lubricating device can solve the problem that a bearing and an accessory on the top of the vertical speed reducer can not be easily lubricated, and can lubricate the bearing and the accessory on the top of the vertical speed reducer automatically.

Owner:ZHENGZHOU UNIV

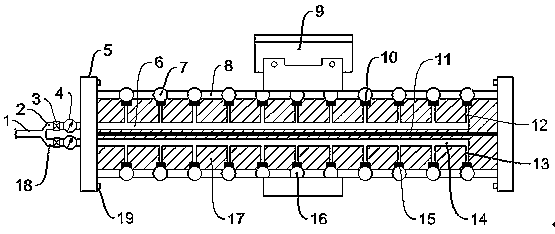

Permanent lubricating guide rail for industrial robot

ActiveCN108953374AEven oil supplyEasy to useLinear bearingsBearing componentsEngineeringMechanical engineering

The invention discloses a permanent lubricating guide rail for an industrial robot. The permanent lubricating guide rail comprises an air inlet main pipe, limiting stop blocks, an executing mechanismand a base, wherein the limiting stop blocks are mounted on the two ends of the base; clamp slots are formed in both upper and lower side surfaces of the base; a plurality of upper roll balls are uniformly mounted on the upper side of the base through a retainer I in a rolling manner, and a plurality of lower roll balls are uniformly mounted on the lower side of the base through a retainer II in arolling manner; the executing mechanism and the clamp slots are buckled one another and attached to the upper roll balls and the lower roll balls; a heating plate is arranged in the middle of the inner side of the base; a first oil passage and a second oil passage are formed in the upper side and the lower side of the heating plate respectively; upper grooves are formed in the lower sides of theupper roll balls; lower grooves are formed in the upper sides of the lower roll balls; the upper grooves and the lower grooves are filled with sponges; the oil inlet main pipe is arranged on the leftsides of the limiting stop blocks. The permanent lubricating guide rail has better lubricating effect on the roll balls, is higher in uniformity, and can effectively reduce waste of a lubricant, automatic lubrication is realized, and production efficiency is improved.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

Automatic lubricating device for guide rail

InactiveCN108006068AReduce wasteRealize automatic lubricationLinear bearingsLubrication containersFuel tankEngineering

The invention provides an automatic lubricating device for a guide rail. The automatic lubricating device for the guide rail comprises the guide rail and a sliding block matched with the guide rail. Afirst magnetic component is arranged on the side face of the sliding block. The magnetic pole direction of the first magnetic component is perpendicular to the side face of the sliding block. At least one through hole is formed in the guide rail and extends to the side face of the guide rail to be connected with a pipeline. The other end of the pipeline is connected with an oil storage tank. Theoil storage tank comprises an oil chamber and a pressure chamber. A partition plate is arranged between the oil chamber and the pressure chamber. A liquid level detection device is arranged in the oilchamber. A communication port is formed between the oil chamber and the pressure chamber. An elastic component and a second magnetic component are arranged in the pressure chamber. A guide componentis fixedly connected to the side face of the second magnetic component. A seal structure is arranged between the second magnetic component and the pressure chamber. The magnetic pole direction of thesecond magnetic component is perpendicular to the side face of the sliding block. A one-way valve, an electromagnetic valve, a hydraulic pump and an oil tank are further connected into the oil storagetank. The liquid level detection structure, the electromagnetic valve and the hydraulic pump are all connected with a PLC. By adoption of the structure, the adding quantity of lubricating oil can becontrolled, and all lubricating oil can be added between the guide rail and the sliding block without being wasted.

Owner:JINHUA JINGYING TECH SERVICE CO LTD

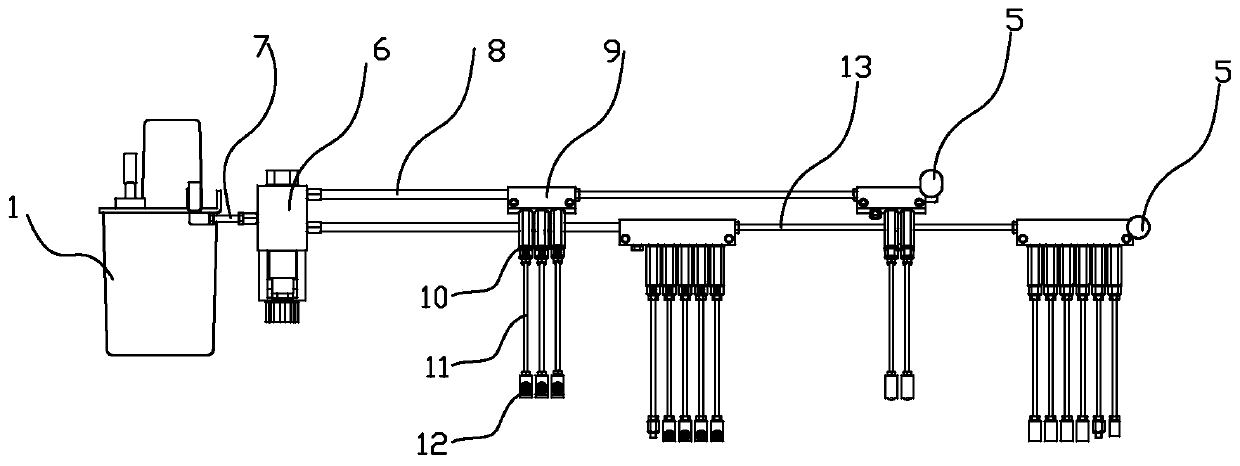

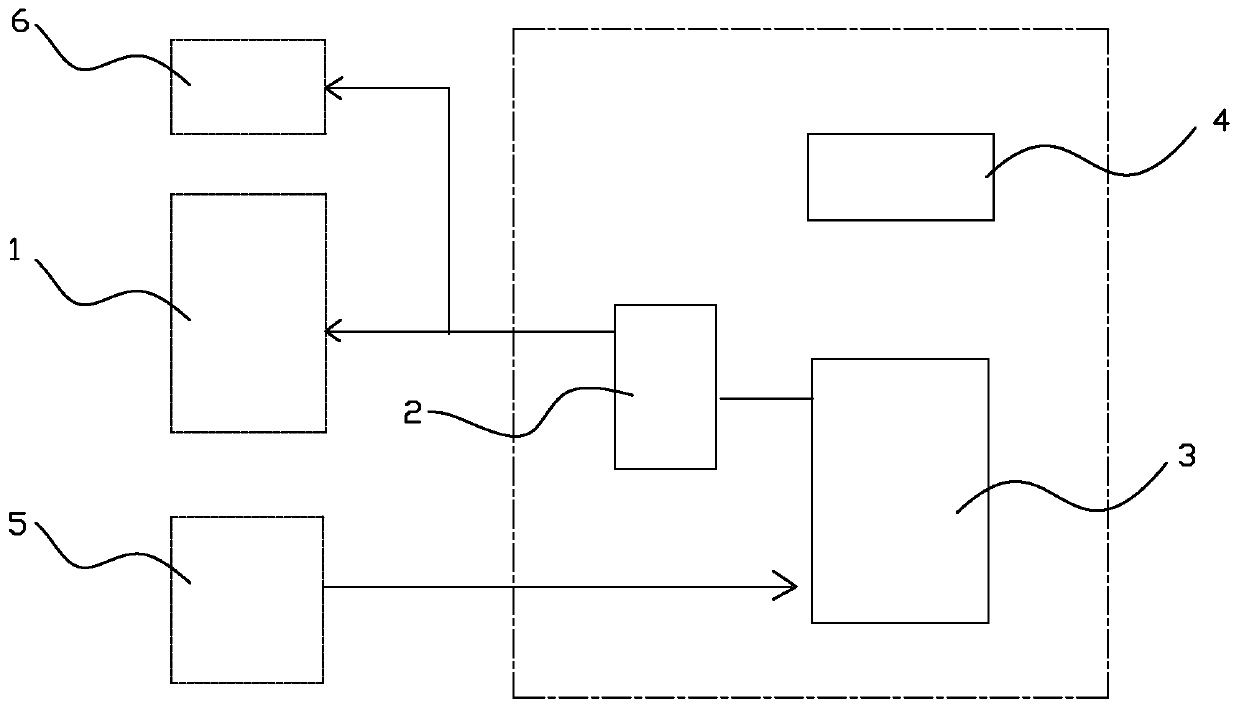

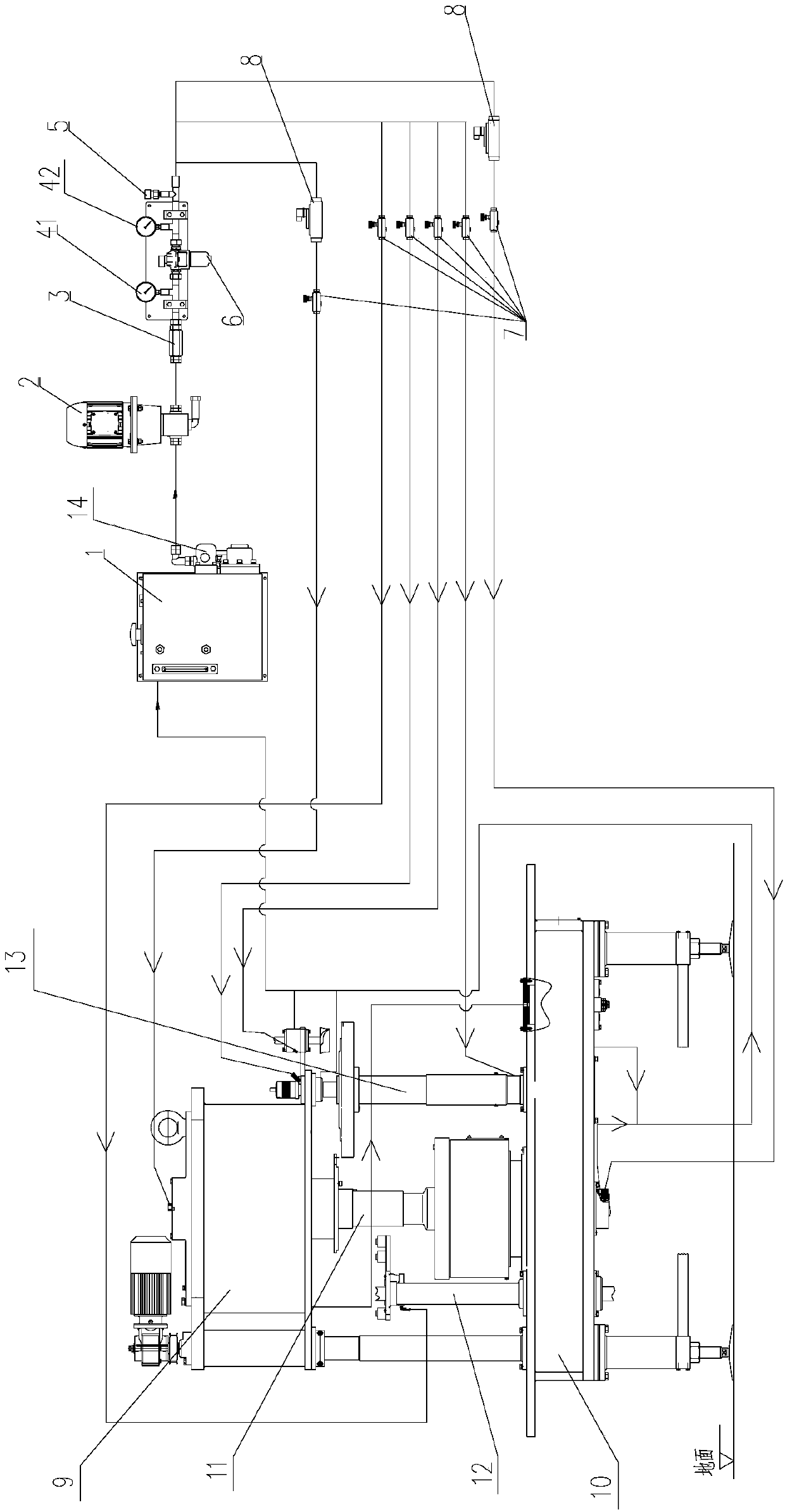

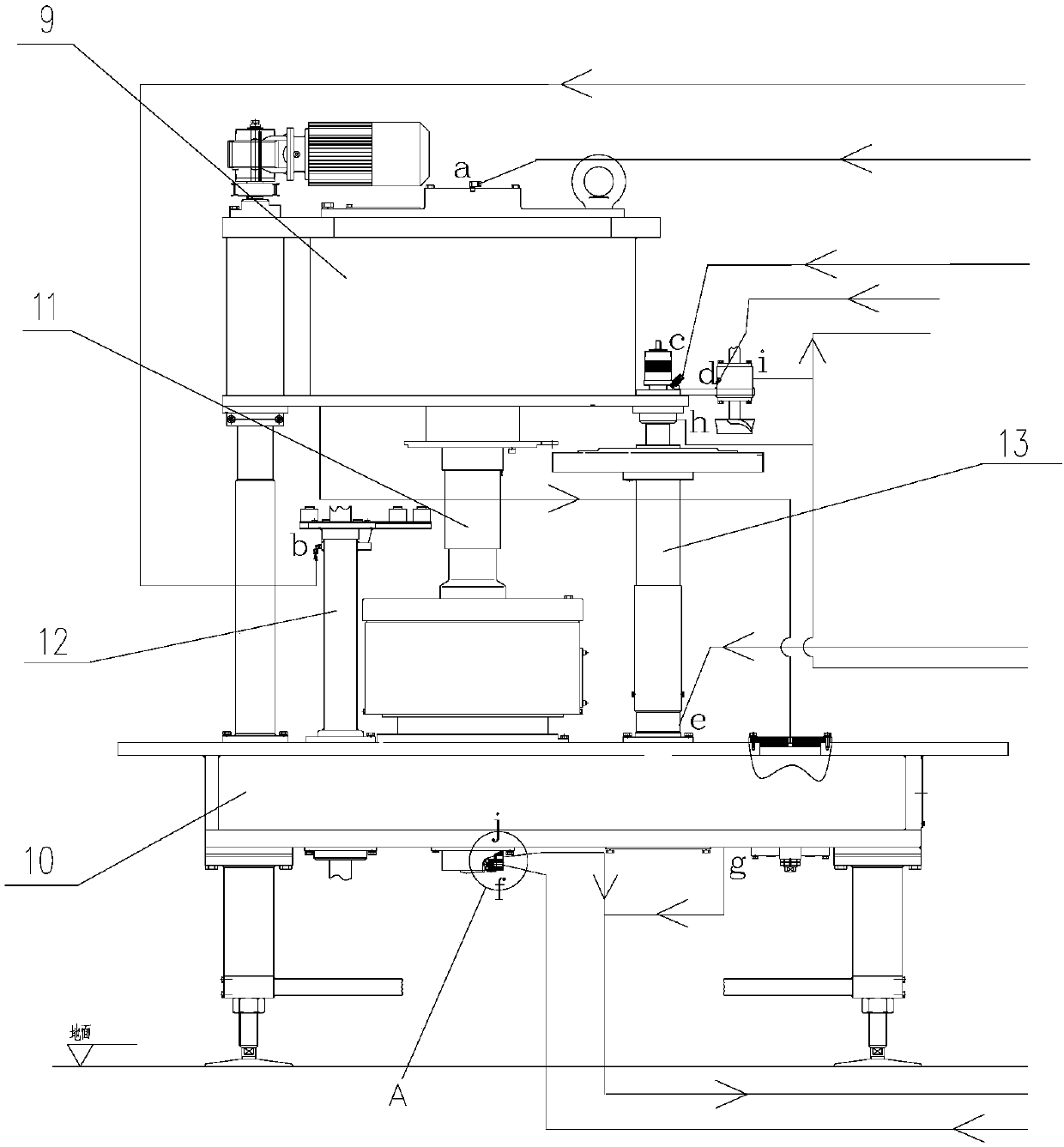

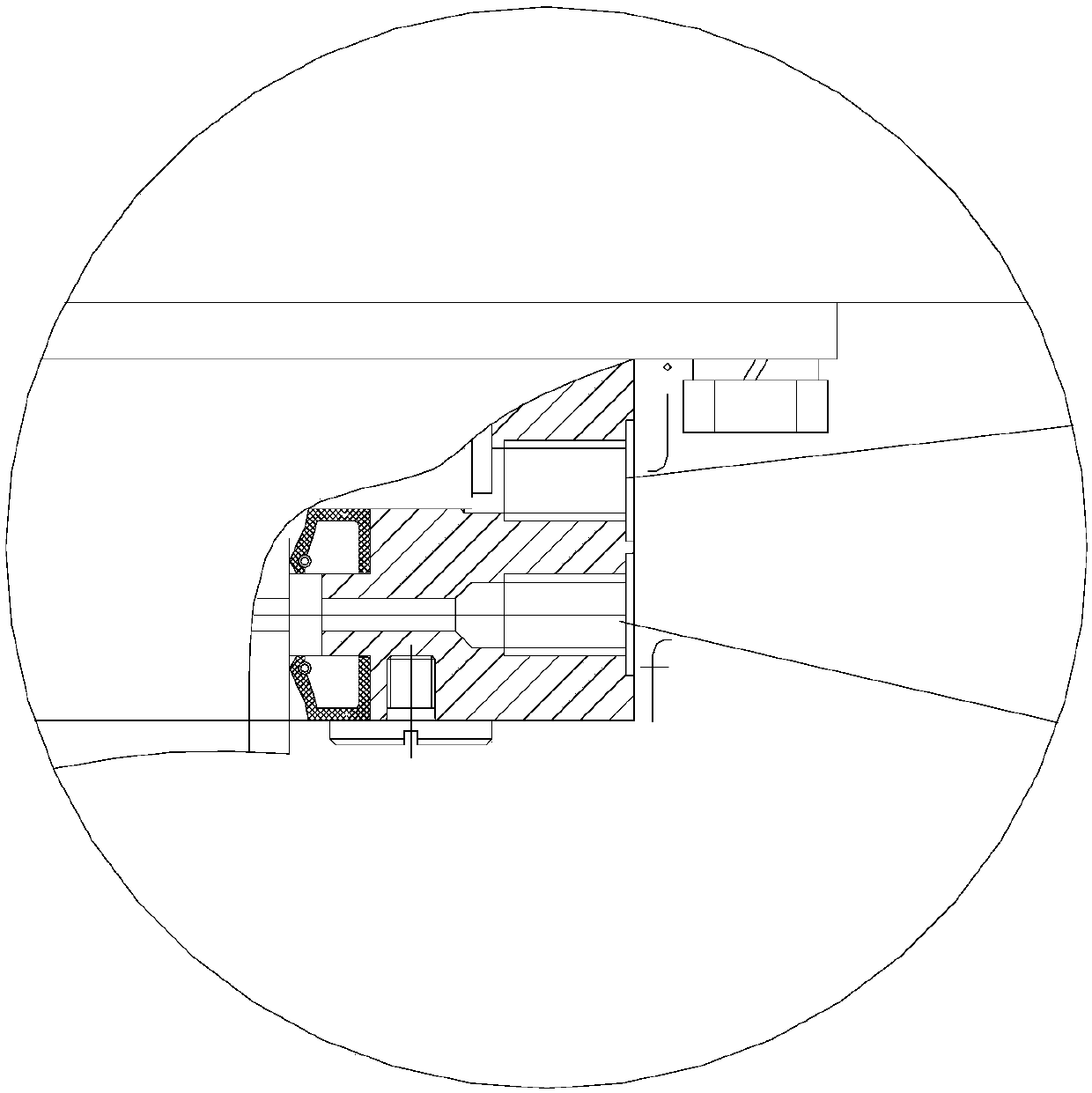

Double-path automatic oil supply lubricating device for weaving machine and using method thereof

PendingCN111237622ARealize automatic lubricationTime-consuming and laborious to solveProportioning devicesLoomsOil and greaseLubrication

The invention discloses a double-path automatic oil supply lubricating device for a weaving machine and a using method thereof. The double-path automatic oil supply lubricating device comprises an electric lubricating pump, a control device, an electromagnetic valve, a main oil conveying pipe, an oil conveying pipe I, an oil conveying pipe II, grease distribution assemblies and sensors, wherein the main oil conveying pipe is arranged at an outlet of the electric lubricating pump; an oil outlet of the main oil conveying pipe is connected with one end of the electromagnetic valve; the oil conveying pipe I and the oil conveying pipe II are arranged at the other end of the electromagnetic valve; pressure sensors are respectively arranged at the free ends of the oil conveying pipe I and the oilconveying pipe II; at least one grease distribution assembly is arranged on each of the oil conveying pipe I and the oil conveying pipe II; and the electromagnetic valve, the electric lubricating pump and the pressure sensors are respectively connected with the control device. According to the lubricating device, the problem that time and labor are wasted due to manual lubrication is solved, time-sharing control of different oiling points of the water-jet loom is realized, the oil supply period can be directly set through a screen, the lubricating pump is automatically started for lubricatingafter the set time point is reached, the operation is simple, and time and labor are saved.

Owner:SHANDONG RIFA TEXTILE MACHINERY

Winch with automatic lubricating device

InactiveCN106915701AEvenly lubricatedAvoid uneven lubricationWinding mechanismsEngine lubricationBristleFuel tank

The invention provides a winch with an automatic lubricating device and belongs to the field of mine operation equipment. The winch comprises a machine body and a roller and further provided with a lifting rod, an oil storage tank, a brush handle, brush bristles, a rotating speed sensor, a microprocessor, a flow velocity regulator and a height regulator. One end of the brush handle is connected with the brush bristles and the rotating speed sensor, and the other end of the brush handle is connected with the oil storage tank through the flow velocity regulator. The height regulator is mounted on the brush handle and connected with the microprocessor. The rotating speed sensor is connected with the flow velocity regulator through the microprocessor. According to the winch with the automatic lubricating device, full-automatic lubricating of a winch steel wire rope is achieved; and by means of combined using of the rotating speed sensor, the flow velocity regulator, the brush handle and the brush bristles, the steel wire rope is lubricated uniformly with a certain speed according to the rotating speed of the roller, and the existing problem of nonuniform lubricating of the steel wire rope is solved.

Owner:TIANJIN YASI DERUI TECH DEV CO LTD

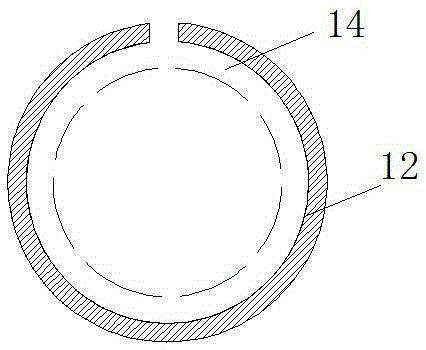

Pulley for automobile glass lifter

ActiveCN106337616AExtended service lifePlay a lubricating roleWing suspension devicesLubricationPulley

The invention discloses a pulley for an automobile glass lifter. The pulley comprises a pulley body which is provided with an oil storage structure. As for the pulley for the automobile glass lifter, through the arrangement of the oil storage structure, a lubrication effect is achieved when the pulley is in contact with other components, automatic lubrication is achieved, abrasion is reduced, and the service life of the pulley is prolonged.

Owner:WUHU MOTIONTEC AUTOMOTIVE

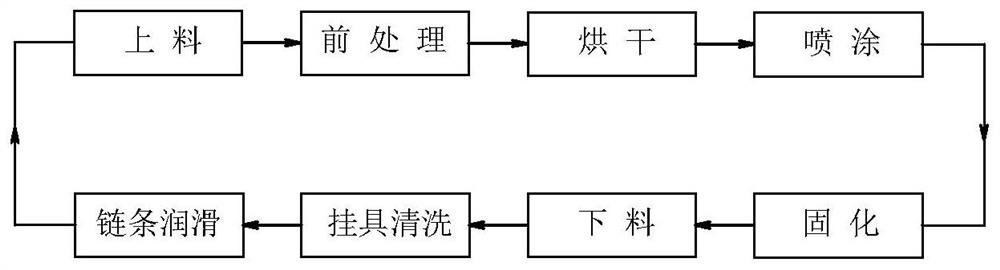

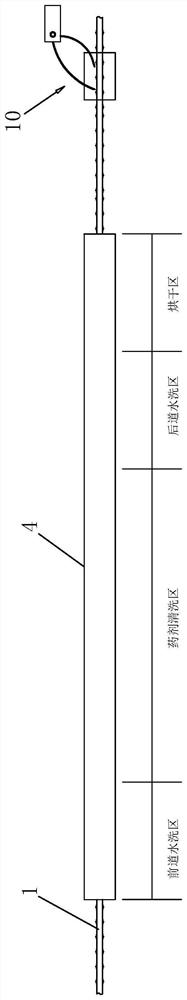

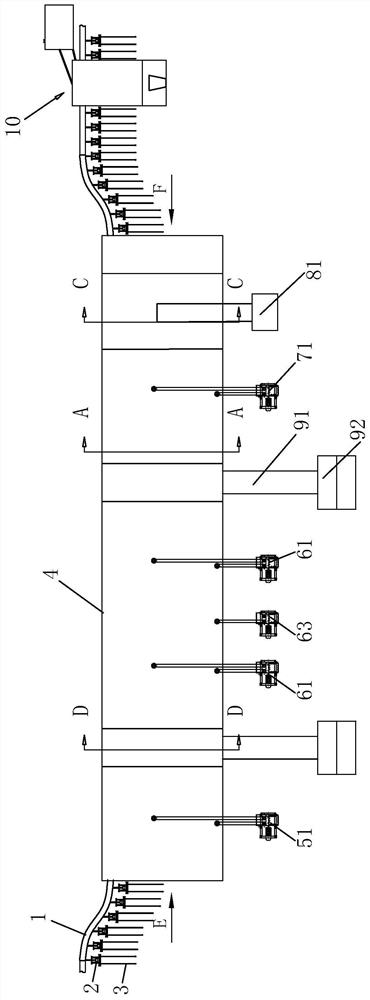

Online automatic cleaning equipment for hanging tool of spraying production line and cleaning method thereof

PendingCN113769950ALow costRealize online automatic cleaningSpraying apparatusCleaning using liquidsProcess engineeringWater spray

The invention discloses online automatic cleaning equipment for a hanging tool of a spraying production line and a cleaning method thereof. The equipment comprises a closed box body which is penetrated by a closed-loop chain guide rail and a conveying chain, wherein the interior of the closed box body is divided into a front-path washing area, a medicament cleaning area, a rear-path washing area and a drying area; the medicament cleaning area is provided with a medicament cleaning tank and a high-pressure medicament spraying device; the front-path washing area and the rear-path washing area are respectively provided with a washing tank and a high-pressure water spraying device; and the drying area is connected with drying equipment. The online automatic cleaning equipment for the hanging tool is arranged on the original spraying production line, so that the online automatic cleaning of the conveying chain and the spraying hanging tool is realized, the automatic cleaning can be realized without offline, the manual taking, replacing and cleaning of the hanging tool are replaced, the labor is greatly saved, and the production efficiency is improved; and the additional preparation of the spare hanging tool is not needed, so that the cost of the hanging tool is greatly saved, and the environmental protection property of the equipment is better.

Owner:SHANDONG HUAJIAN ALUMINUM GRP

Combined system of hydraulic pump and engine for multifunctional road sweeper

PendingCN106481797ARealize automatic lubricationOvercome troubleGear lubrication/coolingGear pumpGear wheel

The present invention relates to a combined system of a hydraulic pump and an engine for a multifunctional road sweeper. The combined system includes an engine and a hydraulic system. The engine comprises a transmission, and a lubrication system that comprises an oil out passage and an oil in passage. The hydraulic system comprises a gear pump. The gear pump is connected to the transmission by means of a drive mechanism. The drive mechanism comprises a drive shaft, a bearing, a bearing block and a drive gear, where an oil filling hole is formed in the bearing block; the bearing block is disposed on the transmission; the drive gear is located in the transmission to engage with gears of a gear set in the transmission; and an inner hole is formed in the other end of the drive shaft. A main shaft of the gear pump is disposed in an inner hole formed in the other end of the drive shaft. The gear pump is disposed on the bearing block. The combined system also includes an oil pipe, an oil pipe socket A, and an oil pipe socket B, where the oil pipe socket A is disposed on the oil filling hole formed in the bearing block of the drive mechanism; one end of the oil pipe is disposed on the oil pipe socket A; the oil pipe socket B is disposed on the oil out passage; and the other end of the oil pipe is disposed on the oil pipe socket B.

Owner:JINGSU YUEDA SPECIAL VEHICLE CO LTD

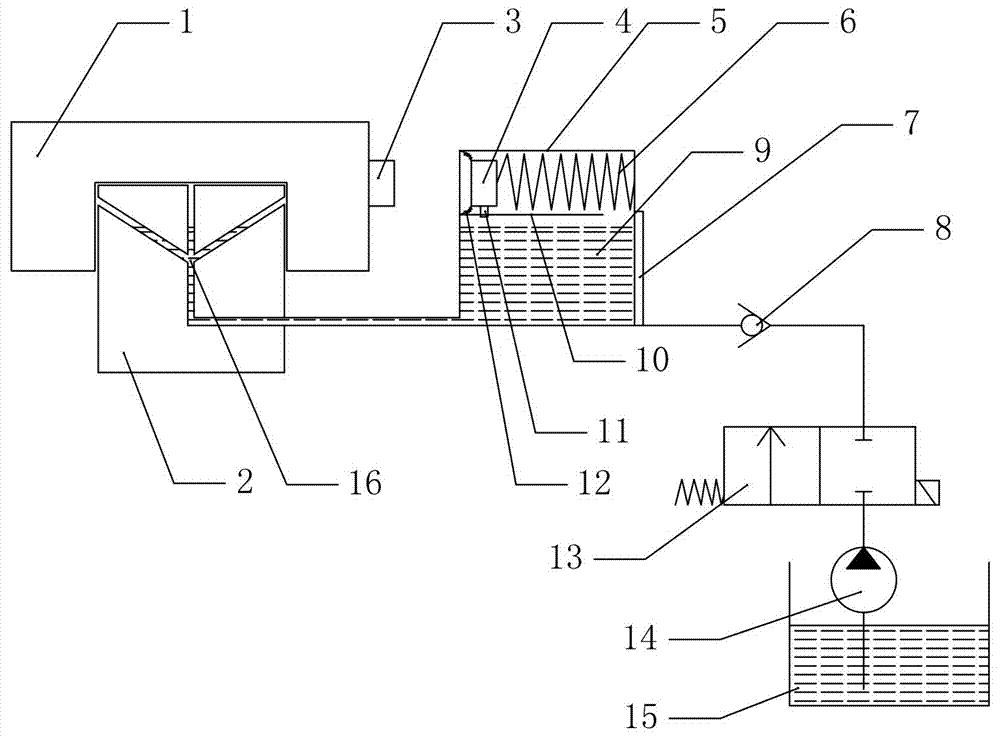

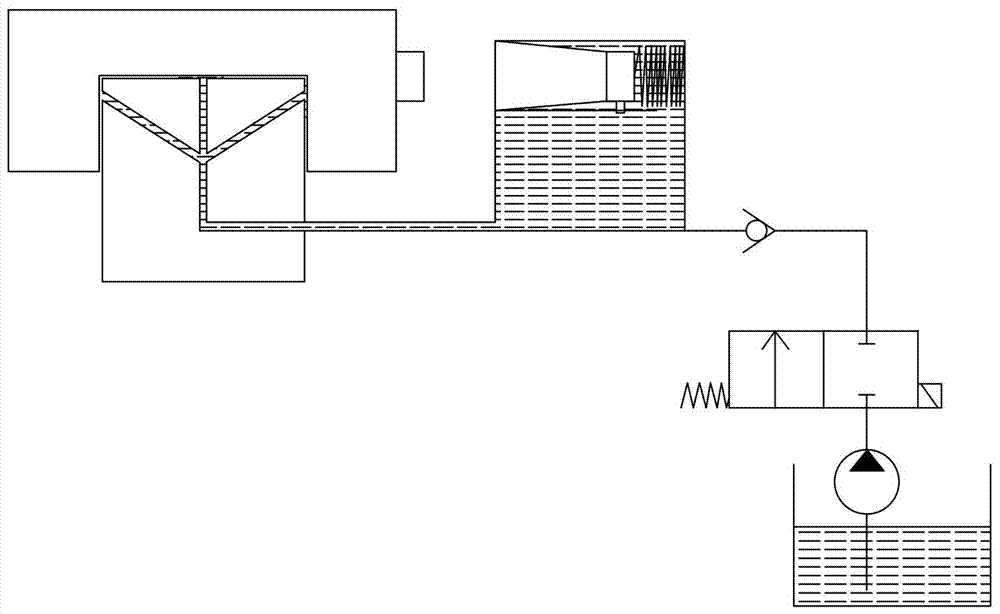

Fully-automatic thin oil lubrication system

PendingCN110360438ARealize automatic lubricationLess likely to dry outEngine pressureLubrication check valvesOil and greaseFuel tank

The invention relates to the field of packaging machinery, in particular to a fully-automatic thin oil lubrication system. The full-automatic thin oil lubrication system supplies oil to a capping machine, and comprises an oil tank and an oil pump, the thin oil is contained in the oil tank, the oil tank communicates with the capping machine, the thin oil in the oil tank is conveyed to an oil inletof the capping machine under the suction effect of the oil pump, and the thin oil enters an oil channel in the capping machine through the oil inlet, and flows in the oil channel and is used for lubricating the capping machine, and finally the thin oil flows back to the oil tank to be recycled through an oil outlet of the capping machine. According to the fully-automatic thin oil lubrication system, the problems that in the prior art, a capping machine adopts grease to lubricate, the lubricating effect is poor, and the effects of cooling and dirt discharging cannot be achieved are solved.

Owner:南京恒昌包装机械有限公司

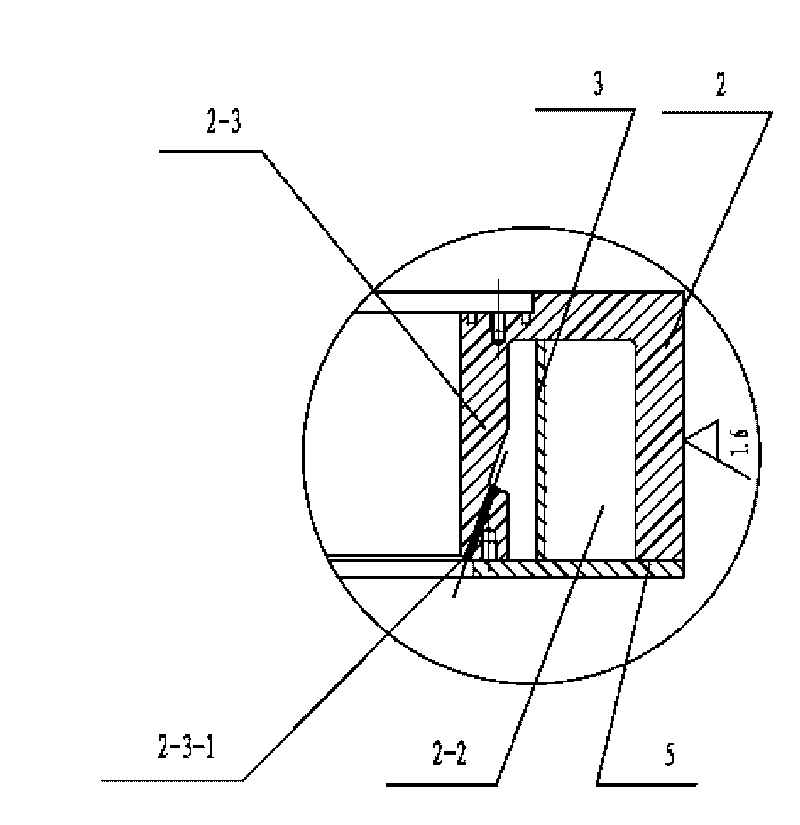

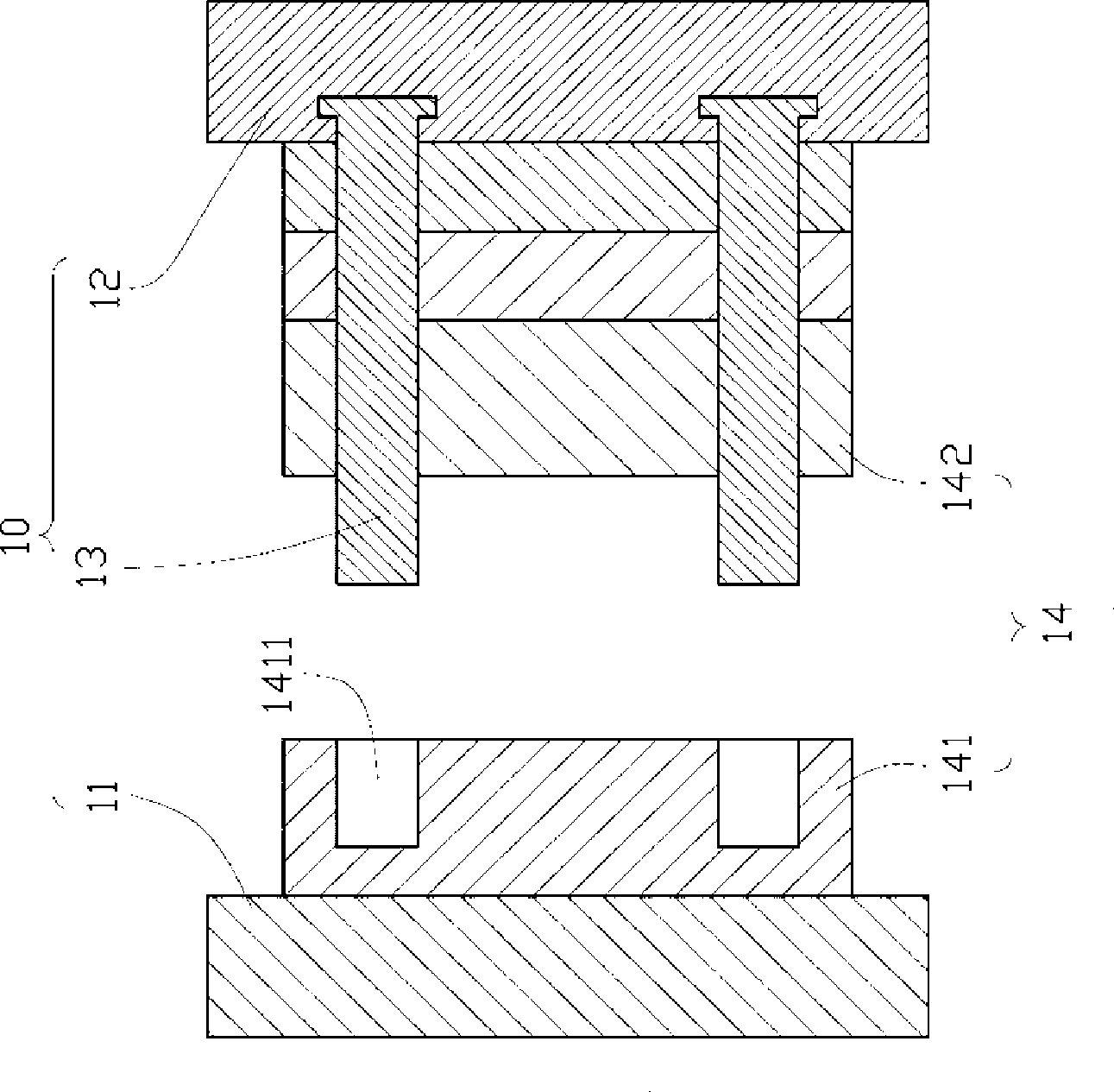

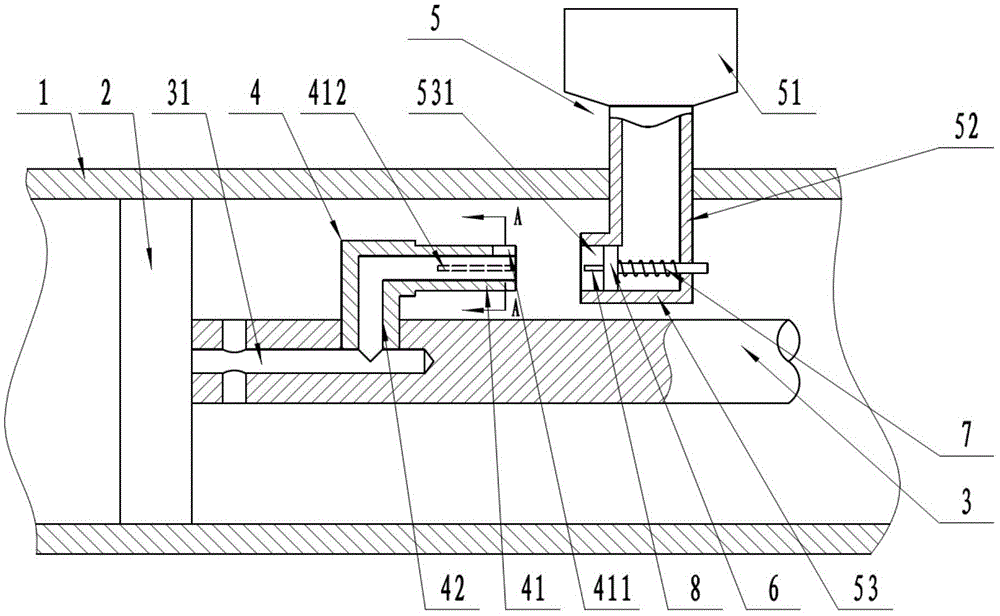

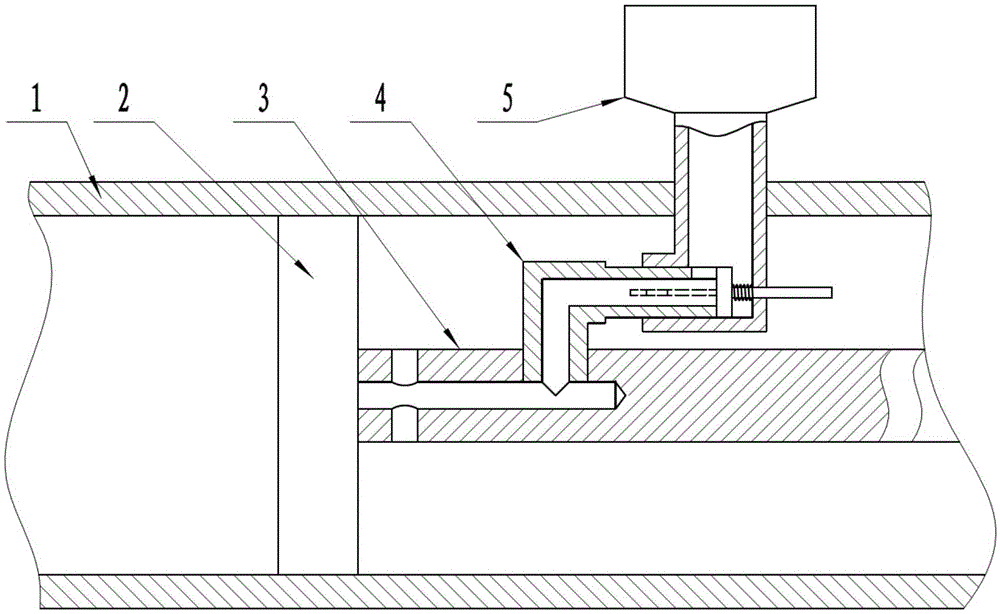

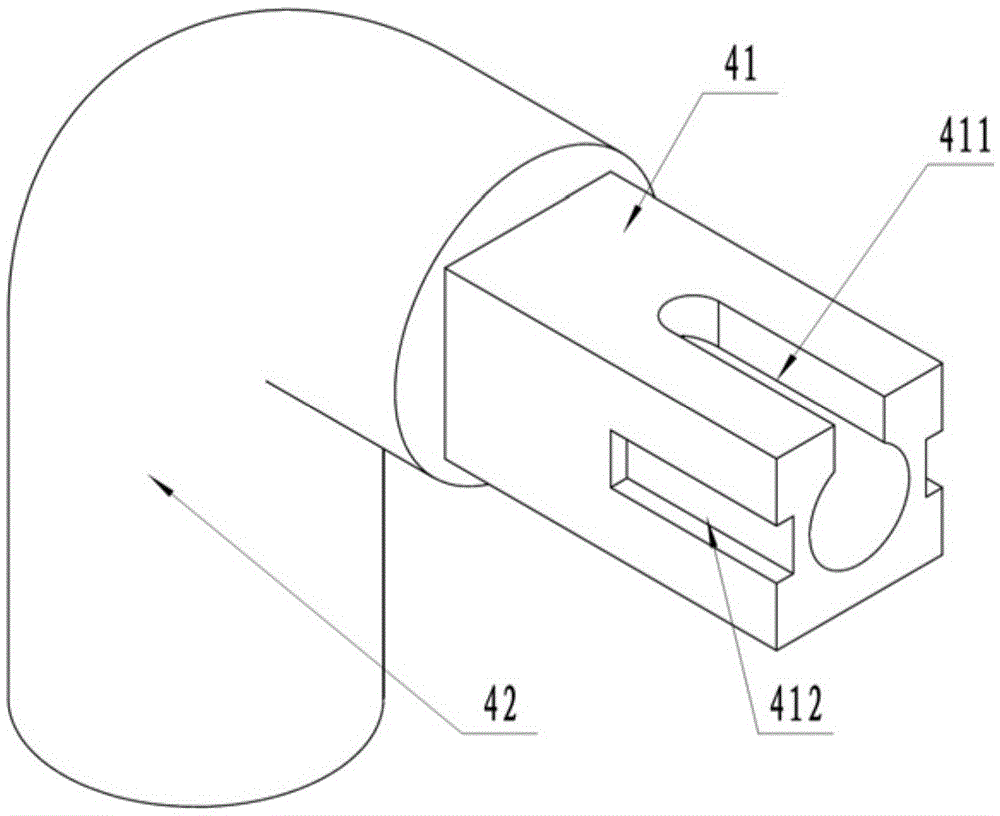

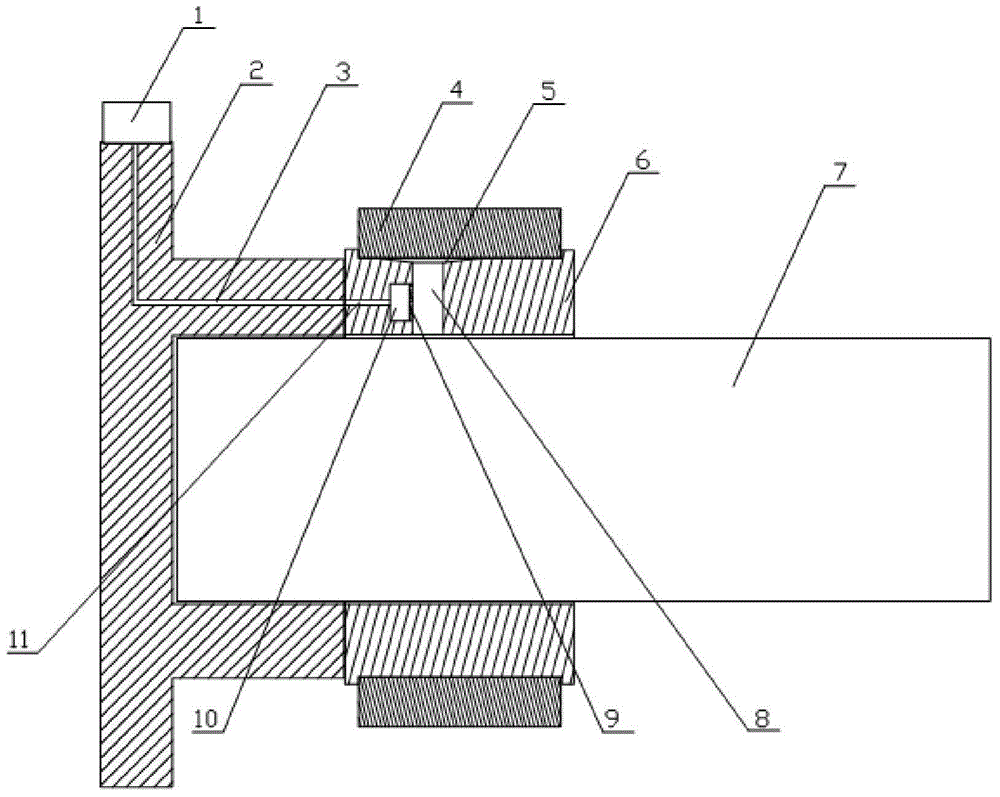

Self-oil-feeding type punching-mold guide component and punching mold

The invention provides a self-oil-feeding type punching-mold guide component and a punching mold and relates to the technical field of punching of rigid equipment or tools. By adoption of the self-oil-feeding type punching-mold guide component and the punching mold, the technical problem of how to feed oil for lubrication automatically on a guide sliding surface is solved. The self-oil-feeding type punching-mold guide component comprises an upper mold and a lower mold, wherein the contact surfaces of the upper mold and the lower mold are matched. The self-oil-feeding type punching-mold guide component also comprises an oil feeding device, wherein a stopping block is fixedly arranged on the side wall of the upper mold; an oil discharging groove, an oil dispersing groove and a lubricating oil groove communicated in sequence from top to bottom are arranged on the guiding sliding surface of the lower mold; the oil feeding device and the stopping block are arranged at the same side, are fixedly arranged on the side wall of the lower mold, and are respectively connected and communicated with the oil discharging groove and an oil tank for storing oil by pipelines; the stopping block can drive the oil feeding device to convey the oil from the oil tank to the oil discharging groove in the moving process of the upper mold and the lower mold, so that the oil flows through the oil dispersing groove and the lubricating oil groove to further realize self-oil-feeding lubrication.

Owner:QINGDAO JINNUO AUTOMOBILE MOLD CO LTD

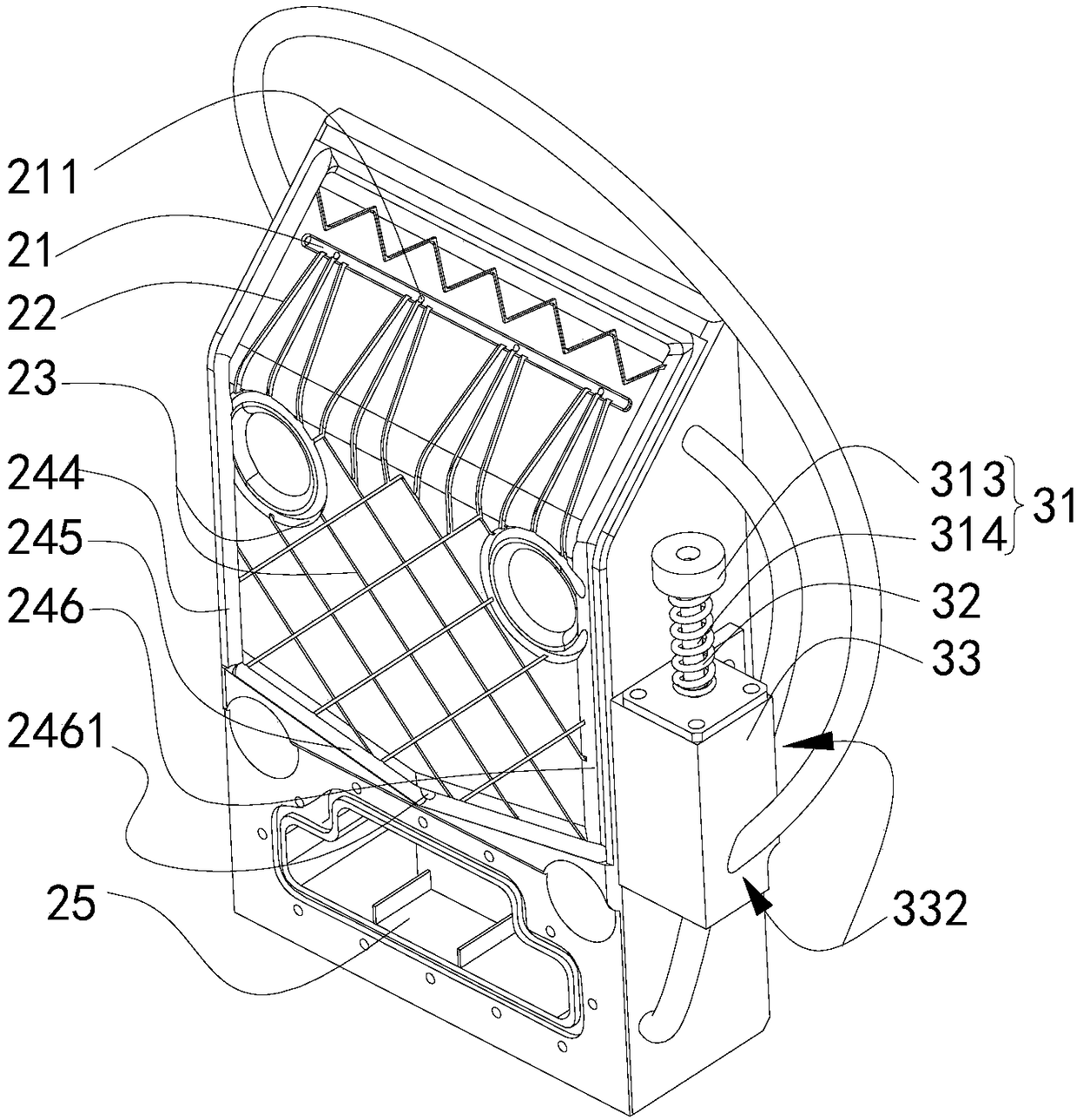

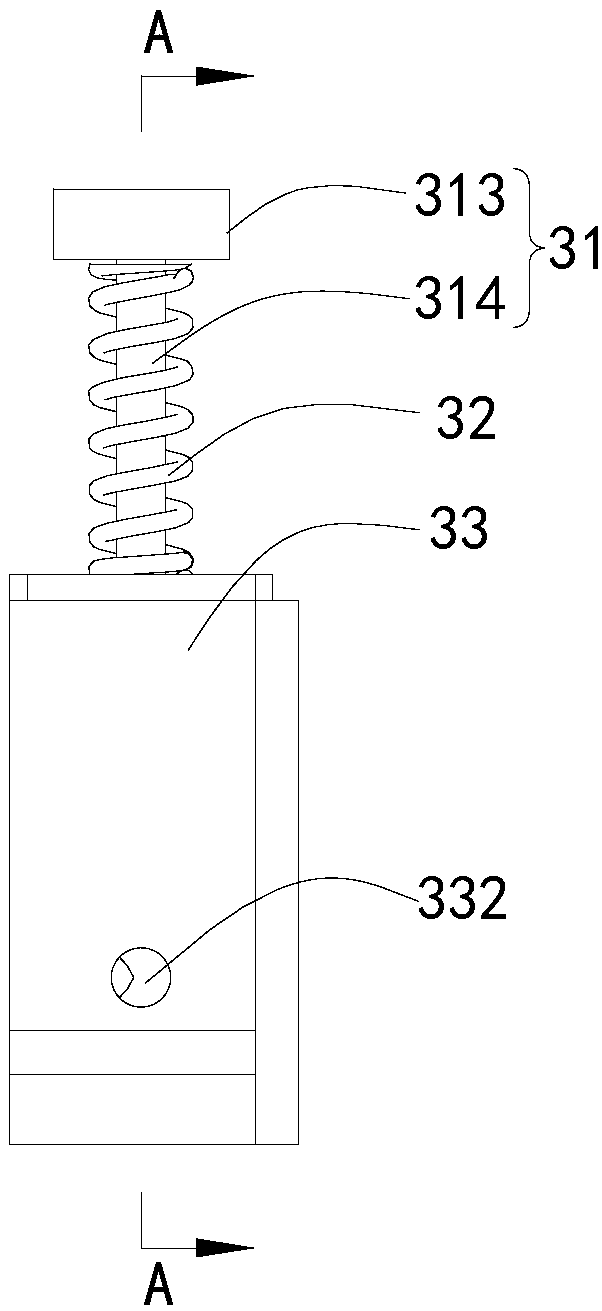

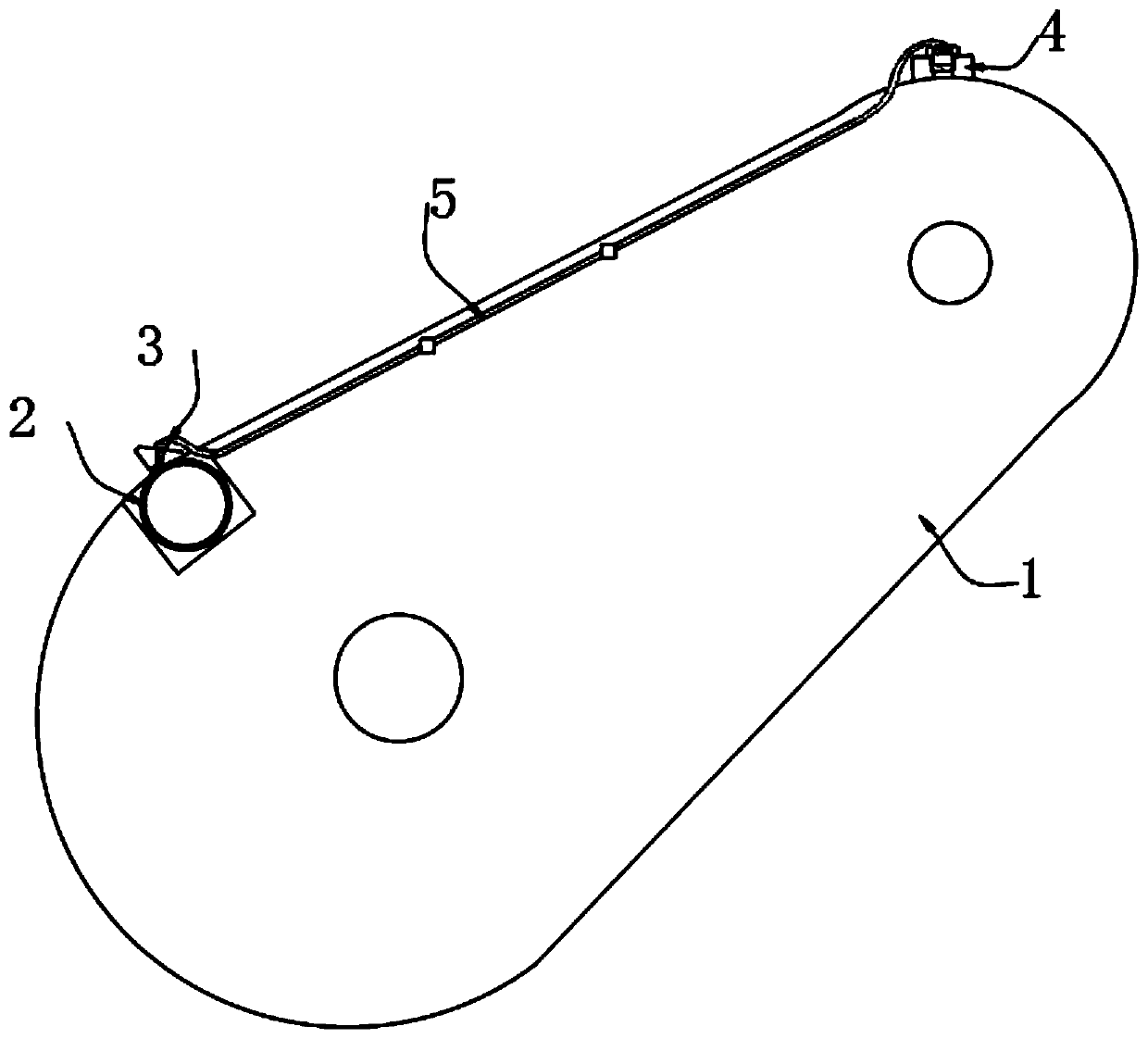

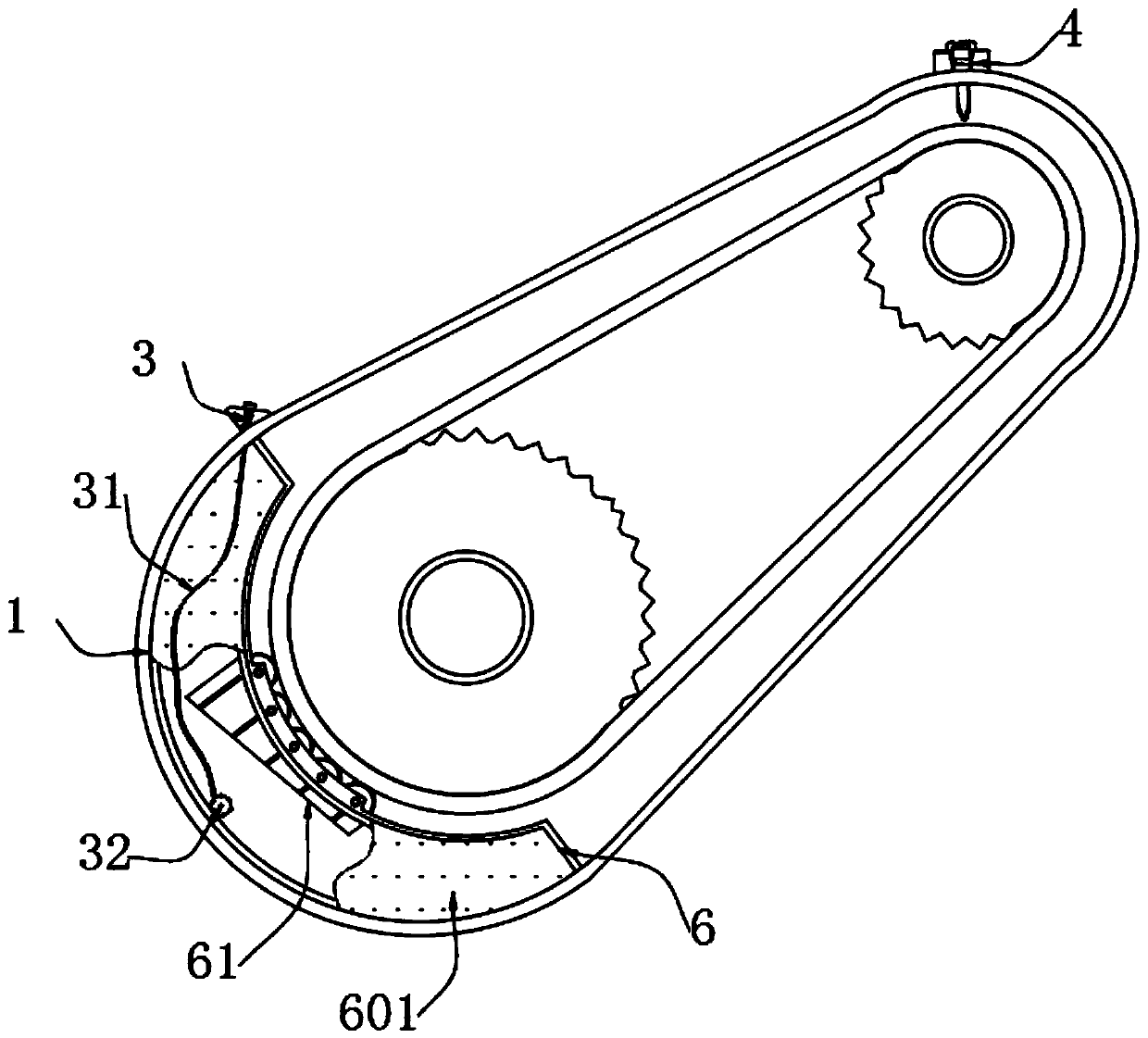

Chain transmission mechanism protective cover for warp knitting machine

The invention belongs to the technical field of warp knitting machine accessories, and particularly relates to a chain transmission mechanism protective cover for a warp knitting machine. The chain transmission mechanism protective cover comprises a cover shell, a plunger pump is screwed and fixed on the outer side of the cover shell, an oil storage tank is fixedly arranged at the bottom end in the cover shell, an oil storage cavity is formed in the oil storage tank, a mounting plate is fixedly arranged at the top end of the oil storage tank, and a plurality of oil collecting rollers are rotationally connected with the inner side of the mounting plate through rotating shafts. The oil storage tank is additionally arranged in the cover shell and used for storing lubricating oil, the lubricating process that the lubricating oil is conveyed to the transmission chain from the oil storage tank and then drips into the oil storage cavity after lubricating the transmission chain is completed incombination with the additional use of the plunger pump, an oil suction valve, a oil conveying pipe and an oil injection valve, thus a circulating oil conveying process is achieved, the lubricating oil in the oil storage cavity can be recycled and conveyed repeatedly and circularly, use of the lubricating oil is saved, the use cost is reduced, the transmission chain can be evenly coated with thelubricating oil, manual coating is not needed, and the workload of workers is reduced.

Owner:嘉兴博睿创业服务有限公司

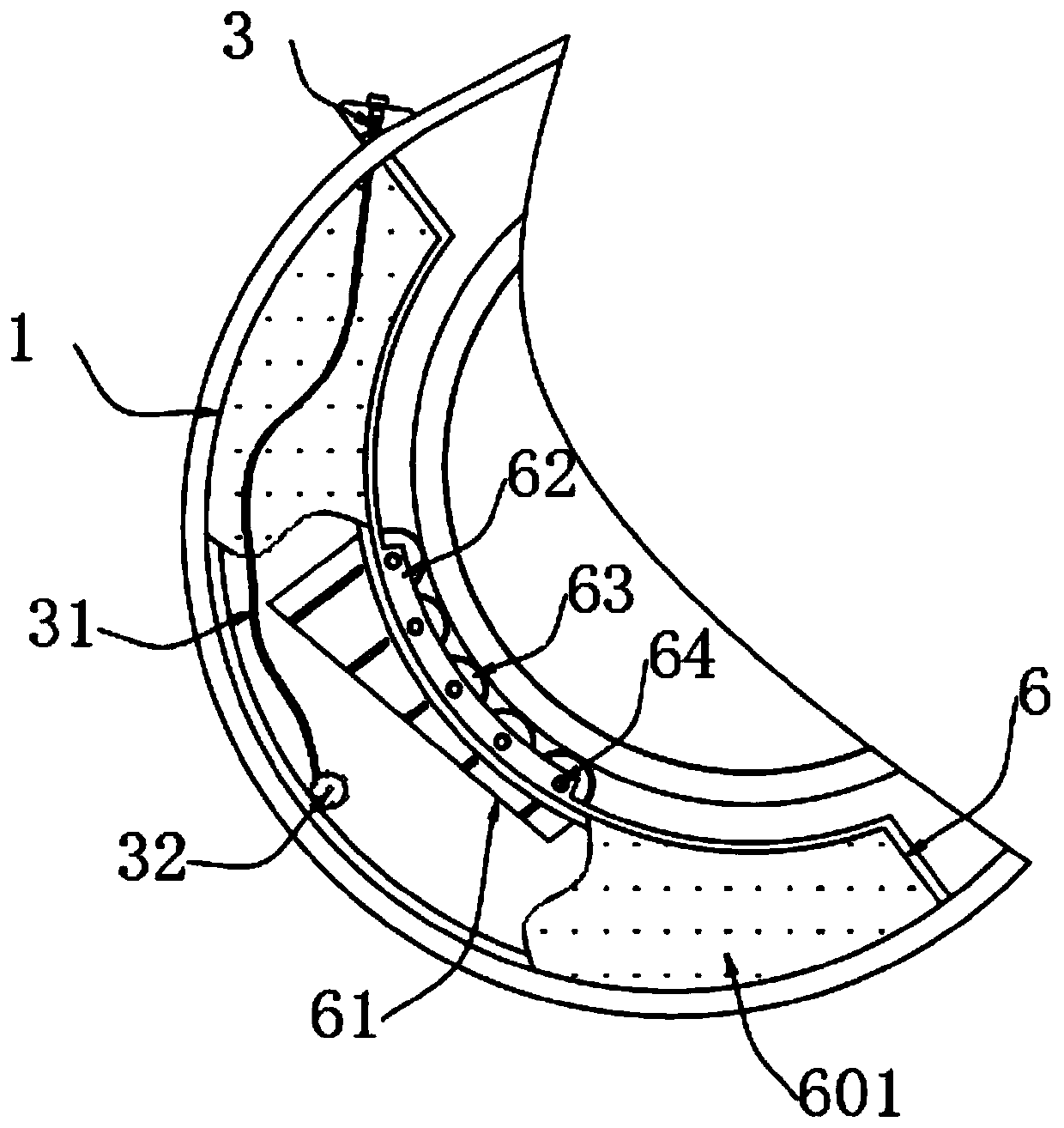

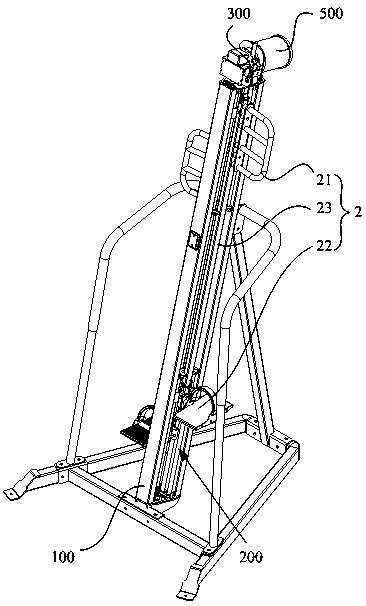

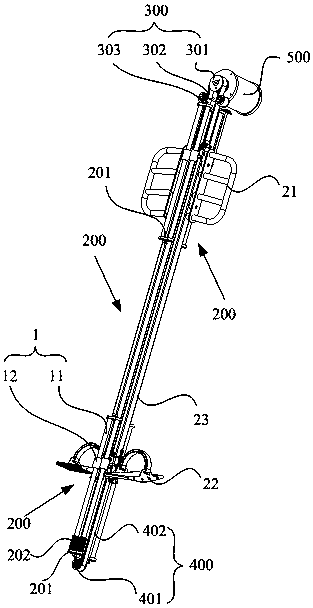

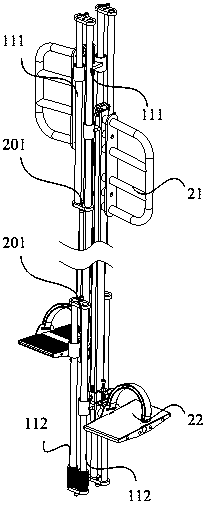

Guide sleeve assembly with self-lubricating function, sliding guide mechanism and fitness equipment

PendingCN110090417ASmooth slidingImprove experienceMagnetic springsSport apparatusLubricationOil storage

The invention discloses a guide sleeve assembly with the self-lubricating function, a sliding guide mechanism and fitness equipment. The guide sleeve assembly comprises an outer sleeve; an inner sleeve arranged in the outer sleeve and capable of sliding relative to the outer sleeve; an oil storage component arranged in the outer sleeve and arranged at the end of the inner sleeve, wherein the lubricating oil is absorbed in the oil storage component; and two installation limiting pieces arranged at the corresponding ends of the outer sleeve. The inner sleeve and the oil storage component are arranged between the two installation limiting pieces. The inner sleeve is used for sliding in the outer sleeve to extrude the oil storage component to release the lubricating oil. The guide sleeve assembly can realize self-lubrication to reduce the friction. Meanwhile, the guide sleeve assembly ensures the smooth guide sliding so as to improve the experience of a sporter.

Owner:SHANDONG RELAX HEALTH IND

High/low-temperature durable double-door testing machine for measuring automotive water cut long-term compressive load

InactiveCN104089830APrevent crashNo condensation and icing phenomenonVehicle testingMaterial strength using tensile/compressive forcesTest efficiencyWater vapor

The invention belongs to the technical field of vehicle inspection devices and provides a high / low-temperature durable double-door testing machine for measuring an automotive water cut long-term compressive load. The testing machine comprises a closed box, wherein a testing worktable plate, a lower platform fixture fixing mechanism and an upper platform moving mechanism are respectively arranged in the box; a driving mechanism is arranged on the box; two sealing doors, namely an inner sealing door and an outer sealing door respectively, are arranged in the box; an operating hole is formed in the inner sealing door; a closing membrane is arranged in the operating hole. The high / low-temperature durable double-door testing machine has the advantages that due to the design of double doors, samples can be replaced through the operating hole in the glass door by both hands at high and low temperature under the condition that the temperature is guaranteed, a phenomenon that the test conditions in the test box are influenced by an external environment when the closing membrane is separated from the external environment to replace the samples is avoided, and a phenomenon that the high temperature suddenly drops and the low temperature suddenly rises is avoided. Moreover, water vapor enters the box to be condensed in the process of replacing the samples at low temperature, and the test efficiency is improved.

Owner:NINGBO XINTAI MACHINERY

Automatic and high-efficient lubrication equipment for copper alloy wires

InactiveCN105351719ARefueling stableImprove lubrication efficiencyEngine lubricationEngineeringLubrication

The invention relates to automatic and high-efficient lubrication equipment for copper alloy wires. The automatic and high-efficient lubrication equipment comprises a bracket, a mould box, a lubrication grease container and a lubrication device, wherein the bracket is arranged on the top of the mould box; the lubrication device is arranged below the bracket; the lubrication grease container is fixed on the top of the mould box through bolts; the lubrication device comprises a cylinder, a screw rod, a lubrication ring, a pressure plate and a motor; the motor is arranged on the bracket; the inner side of the cylinder is provided with a grease inlet; the grease inlet is communicated with the lubrication grease container; the pressure plate is arranged in the cylinder; the screw rod is connected to the top of the pressure plate; the outer side of the pressure plate is provided with a sealing ring; a worm wheel is arranged on the upper part of the screw rod in a matched manner; the worm wheel is arranged on the motor; and the lubrication ring is arranged below the cylinder and is located on the outer side of the mould box. The automatic and high-efficient lubrication equipment is simple in structure, convenient for lubrication and high in safety.

Owner:WUHU CHUJIANG ALLOY COPPER

Automatic lubrication device arranged between material barrel and plunger chip

The invention provides an automatic lubrication device arranged between a material barrel and a plunger chip. The automatic lubrication device comprises the material barrel and the inside plunger chip. A plunger rod is connected to one side of the plunger chip, and a channel is formed inside the plunger rod. A right-angled oil guide pipe comprises a butt joint end and a connecting end, wherein the butt joint end is horizontally arranged, and the connecting end is connected with the plunger rod. An oil inlet groove is formed in the top of the butt joint end, and the oil inlet groove, the oil guide pipe and the channel are communicated with one another. An oil storage part is arranged on the material barrel, and the oil guide pipe is located between the plunger chip and the oil storage part. The oil storage part comprises an oil storage chamber, an oil conveying pipe and a butt joint block, wherein the upper end of the oil conveying pipe is communicated with the oil storage chamber, the lower end of the oil conveying pipe is communicated with the butt joint block, a butt joint groove is formed inside the butt joint block, and a piston is arranged inside the butt joint groove. When the return stroke is conducted, the butt joint end and the connecting end enter the butt joint groove, an oil circuit is automatically formed through connection, and a lubricating agent passes through the channel, is perpendicularly sprayed to the inner wall of the material barrel, and then lubricates the plunger chip. When the stroke is conducted, the butt joint end leaves the butt joint groove, the butt joint groove is plugged by the piston, and automatic lubrication of the plunger chip is achieved. The production efficiency is improved, the structure is simple, no electric control systems need to be added, and the cost is low.

Owner:辽宁天海津城装备制造有限公司

Water turbine bearing lubricating device

InactiveCN104633427ARealize automatic lubricationHydro energy generationMachines/enginesWater turbineOil storage

The invention relates to the technical field of bearing lubricating, in particular to a water turbine bearing lubricating device. The water turbine bearing lubricating device comprises a rotating shaft, a bearing bush arranged outside the rotating shaft in a sleeving mode, an end cover arranged at one end of the rotating shaft and a bearing clamped on the bearing bush, and further comprises an oil tank, a first oil injecting channel, an oil discharging groove, an oil discharging hole, a filtering net, an oil storage chamber and a second oil injecting channel arranged in the bearing bush in a penetrating mode. The oil tank is fixed to the outer edge of the end cover, the first oil injecting channel is arranged in the end cover in a penetrating mode, one end of the first oil injecting channel is connected with the oil tank, and the other end of the first oil injecting channel is aligned and connected with the second oil injecting channel. The oil storage chamber is arranged at one end of the second oil injecting channel, and the filtering net is arranged in the oil storage chamber. The oil discharging hole is formed in the bearing bush in a penetrating mode in the radial direction of the bearing bush, and the oil discharging groove is formed in the end, close to the bearing, of the oil discharging hole. By means of the lubricating device, manual participation is not needed, and automatic lubricating can be achieved.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

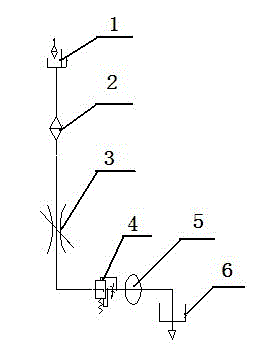

Automatic lubrication system for slideway and riding wheel of cabling machine

InactiveCN102748573ARealize automatic lubricationReduce heatRope making machinesLubrication check valvesPipe fittingControl valves

The invention relates to an automatic lubrication system for a slideway and a riding wheel of a cabling machine. The automatic lubrication system is mainly formed by serially and sequentially connecting an oil storage box, a filter, a one-way throttle valve, a flow control valve, a pipe fitting and an oil dripping mouth, so that the automatic lubrication of the slideway and the riding wheel of the cabling machine is realized. The phenomenon that manual oiling is not timely and disconnected is changed, so that the automatic oil dripping and lubricating for 24 hours is realized, the labor input is reduced, and the operation quality of equipment is enabled to be at a good state.

Owner:GUIZHOU WIRE ROPE

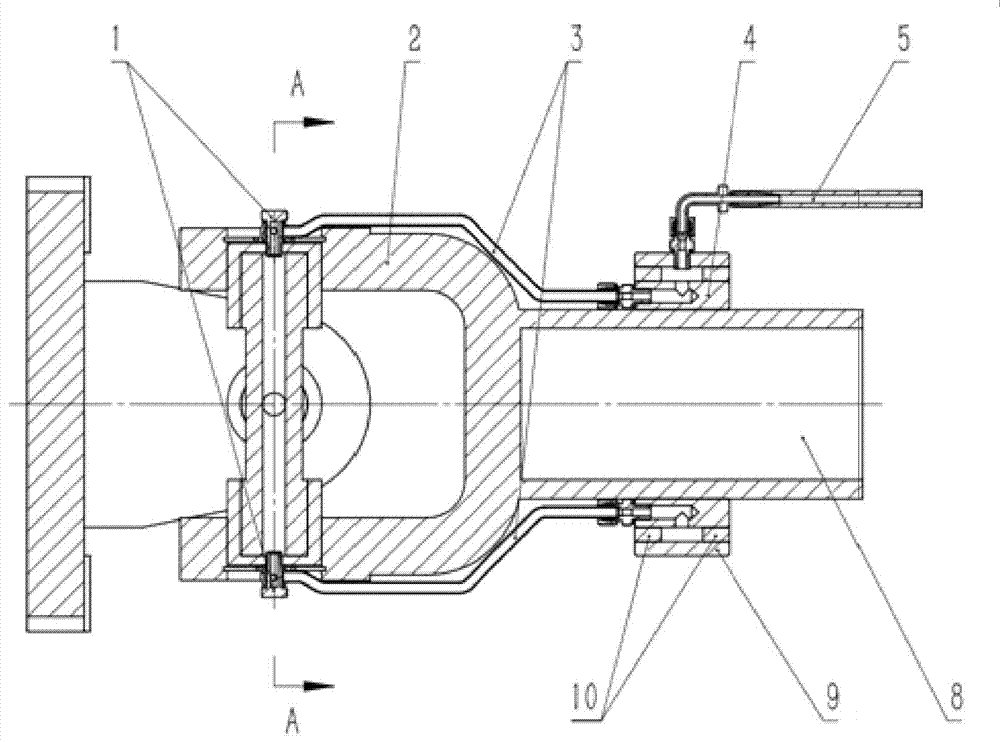

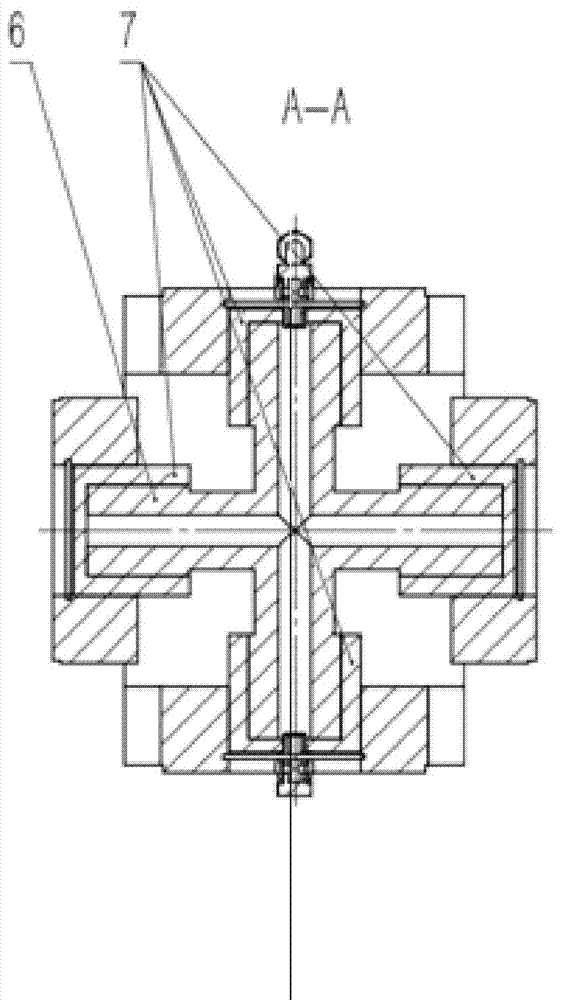

Centralized lubrication structure of universal joint

PendingCN107289034ARealize automatic lubricationRealize timing and quantitative fillingYielding couplingBearing componentsNeedle roller bearingRotational axis

The invention discloses a centralized lubrication structure of a universal joint. The structure comprises parts and components including oil seals, oil sealing sleeves, a shaft sleeve, an oil pipe, the universal joint, oil pipe joints and the like, wherein the shaft sleeve is fixed to a position, which is close to the universal joint, of a driving shaft, and the shaft sleeve is in tight fit with a shaft and rotates at equal speed along with the shaft; an oil pipe joint mounting hole is formed in the shaft sleeve and is used for connecting the oil pipe joint. Two oil seals are assembled on the shaft sleeve at an interval, the oil sealing sleeves are assembled on the oil seals, the oil sealing sleeves are opened for installing the oil pipe joint and then is connected with the oil pipe, and the oil seals and the oil sealing sleeves are fixed and cannot rotate along with the shaft. An oil filling port is formed in an end cover of a needle bearing and is used for installing the oil pipe joint, the oil pipe joint of the shaft sleeve is connected with the oil pipe joint at the end cover of the needle bearing by the metal oil pipe, and the shaft sleeve is fixedly connected with a rotary shaft of the universal joint. According to the centralized lubrication structure, manpower is saved, the lubricating efficiency is improved, and the service life of the universal joint is prolonged.

Owner:付琨

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com