Crystallizer for preparing superhard aluminum alloy flat cast ingot and use method of crystallizer

A hard aluminum alloy and crystallizer technology, which is applied in the field of preparing superhard aluminum alloy flat ingots, can solve the problems of superhard aluminum alloys that are prone to cracks and waste products, reduce cracking defects, facilitate forging, improve surface quality and The effect of internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

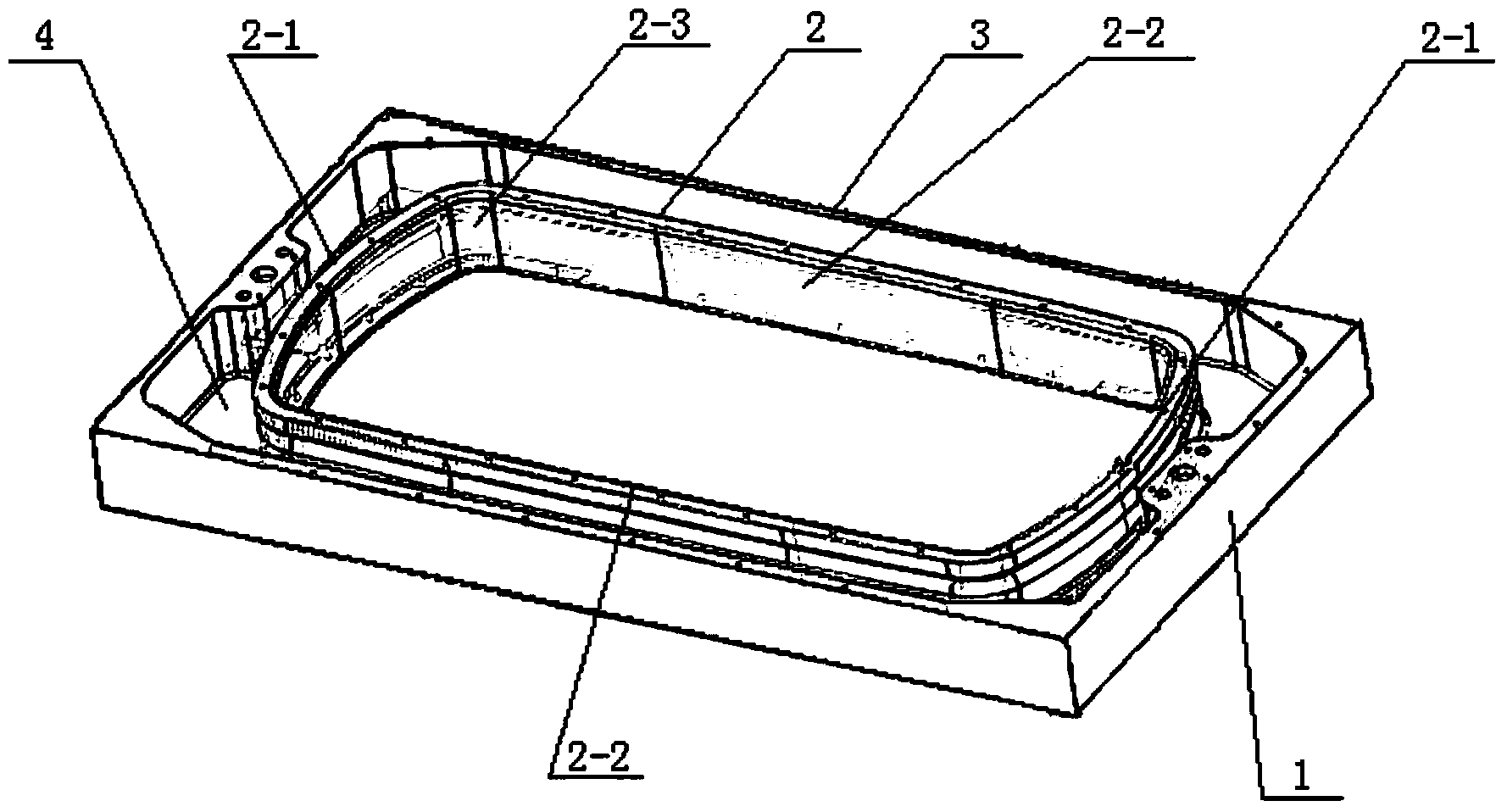

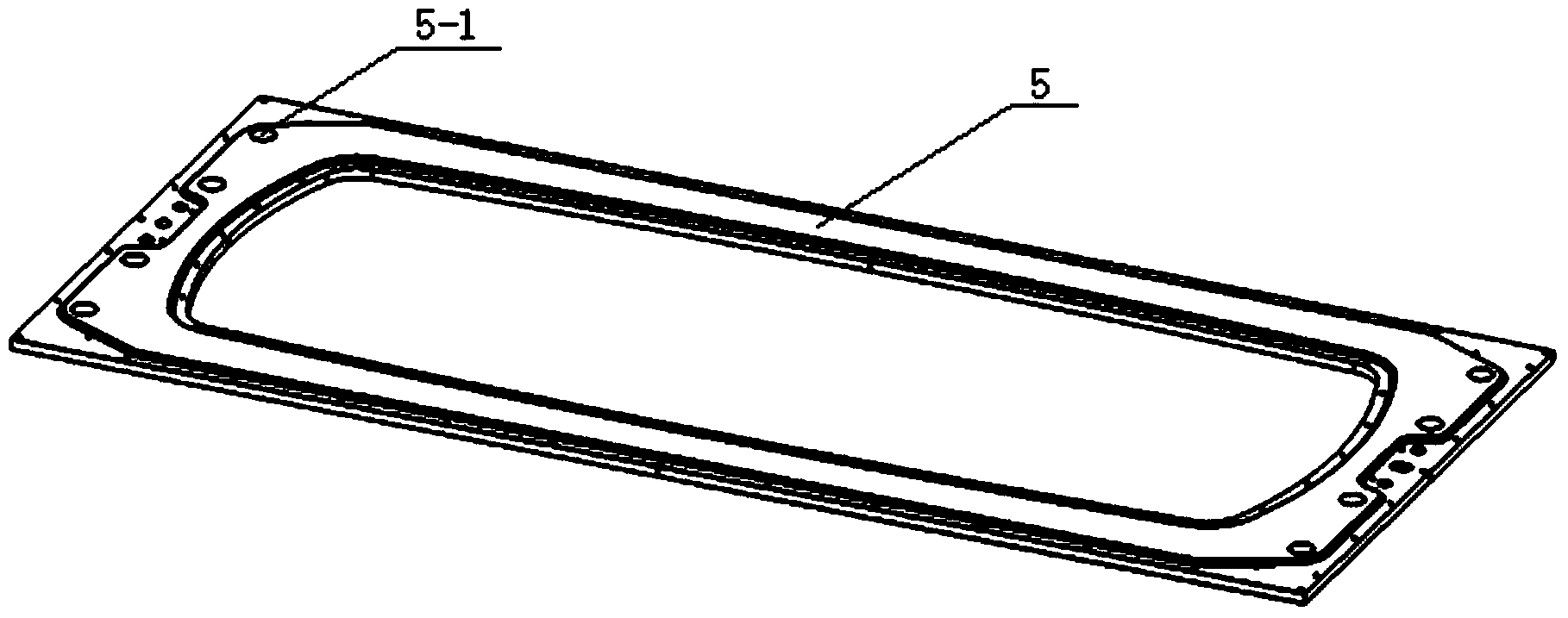

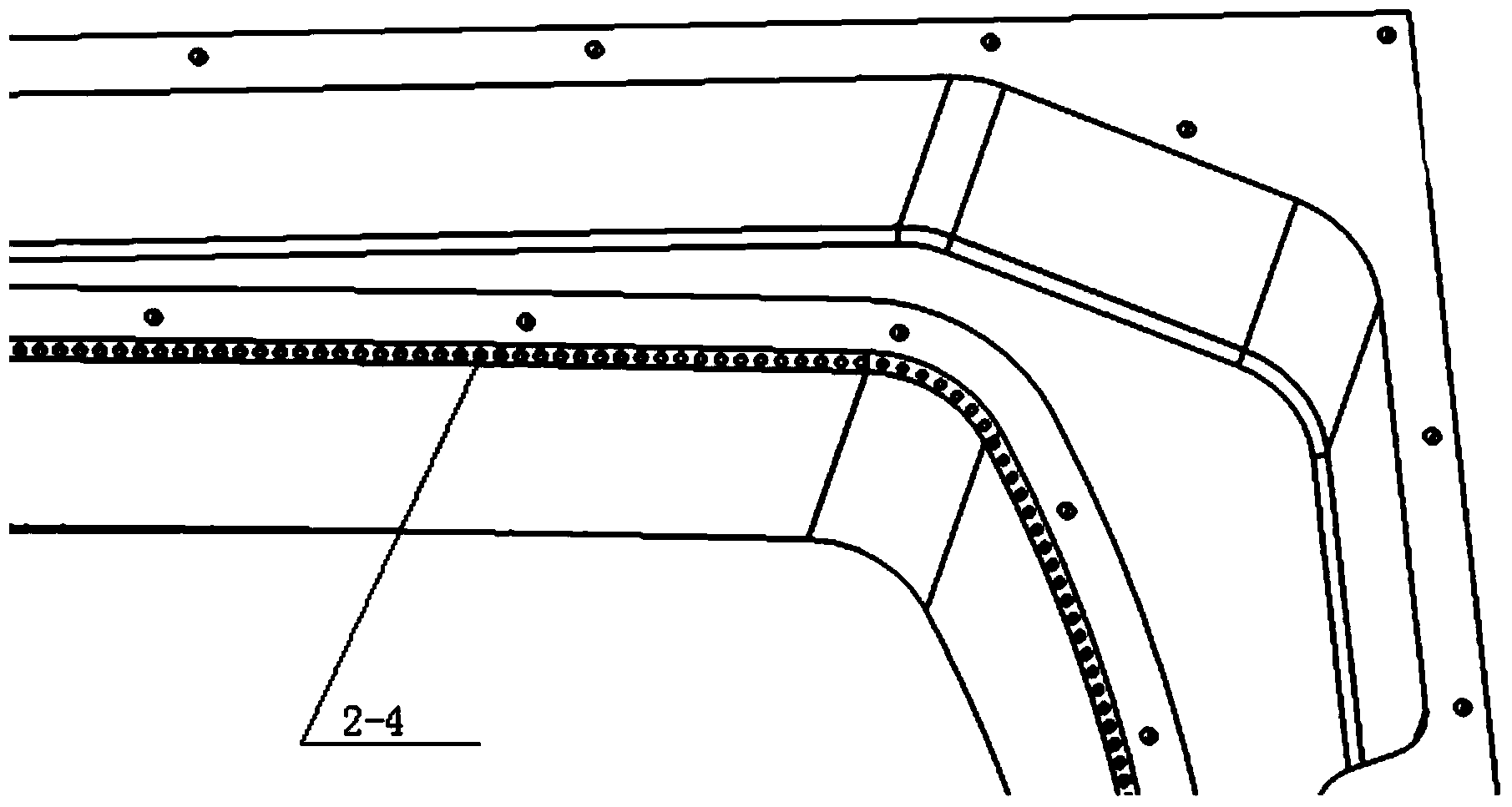

[0021] Embodiment 1: A crystallizer for preparing superhard aluminum alloy flat ingots according to this embodiment includes a crystallizer water chamber 1, a water chamber gland 5, a secondary water distribution plate 6 and an oil pressure lid 7; Crystallizer water chamber 1 comprises water inner wall 2, water outer wall 3 and water chamber base 4, and described crystallizer water chamber 1 is integral structure; The water inner wall 2 of described crystallizer water chamber 1 is made of facet 2-1. The three parts of the large surface 2-2 and the transitional surface 2-3 of the large and small surfaces are butted to form an overall structure; the small surface 2-1 is arc-shaped; the transitional surface 2-3 of the large and small surfaces is A circular arc whose radian is smaller than that of the facet 2-1; the junction of the inner surface and the upper surface of the water inner wall 2 of the crystallizer water chamber 1 is set as a plane, and the water outlet hole 2-4 is se...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the crystallizer for preparing superhard aluminum alloy slab ingot is made of 2A50 alloy, which has been forged and heat-treated. The forging heating temperature is 400-480°C, the heat treatment parameters are: heating temperature: 549-515°C, holding time: 160min-200min, quenching water temperature: 50-60°C; aging temperature: 152-160°C, holding time: 5h~7h. Others are the same as the first embodiment.

[0029] In this embodiment, 2A50 aluminum alloy with high plasticity in hot state, easy forging and stamping, good process performance and good machinability is used, forged by a 5000-ton hydraulic press and heat-treated as the blank material of the crystallizer, reducing the cost of casting. The coarse-grained layer on the surface of the ingot improves the surface quality and internal quality of the ingot.

specific Embodiment approach 3

[0030] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the radian of the small surface 2-1 is R800-1000 mm. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com