Patents

Literature

358results about How to "Easy stamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

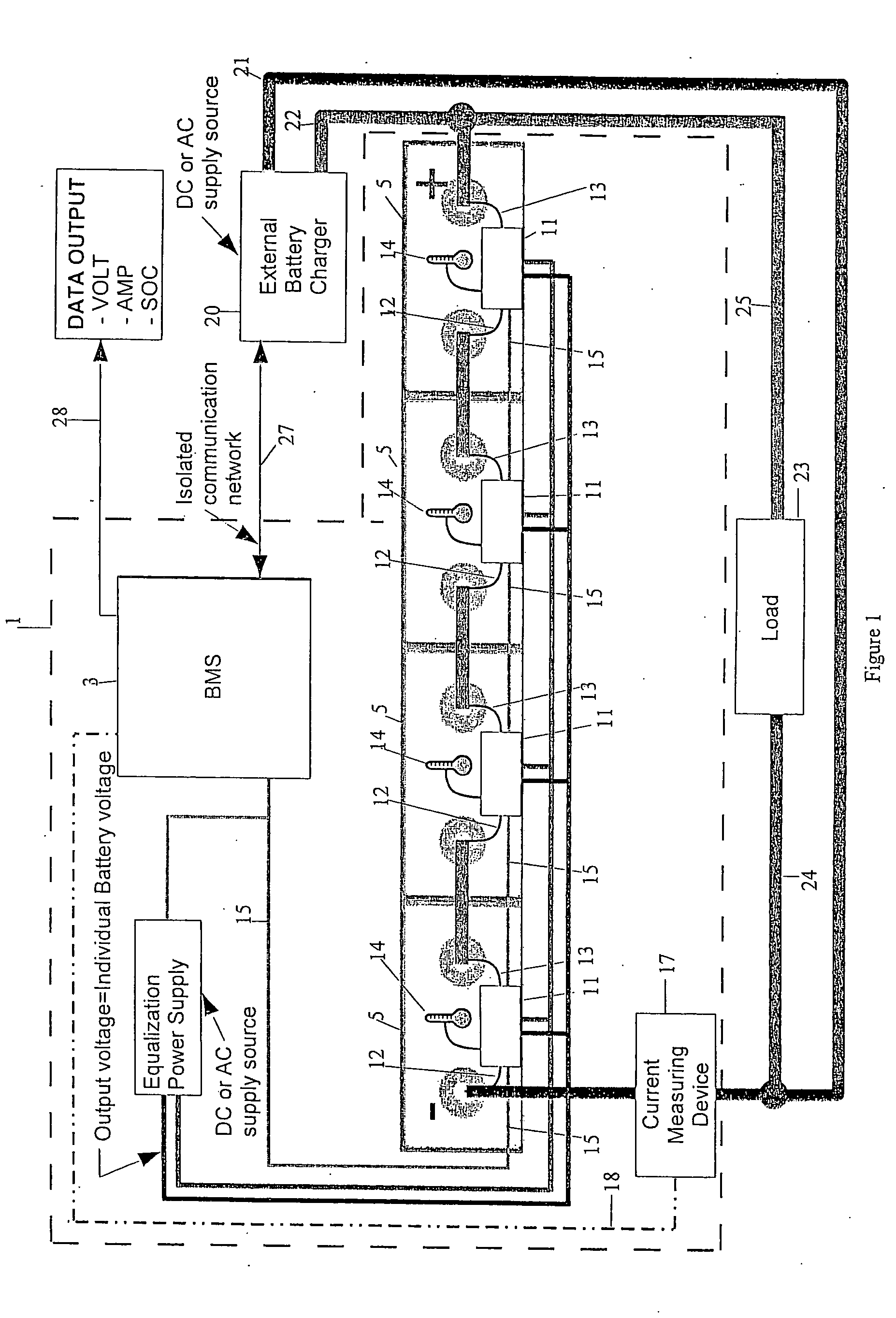

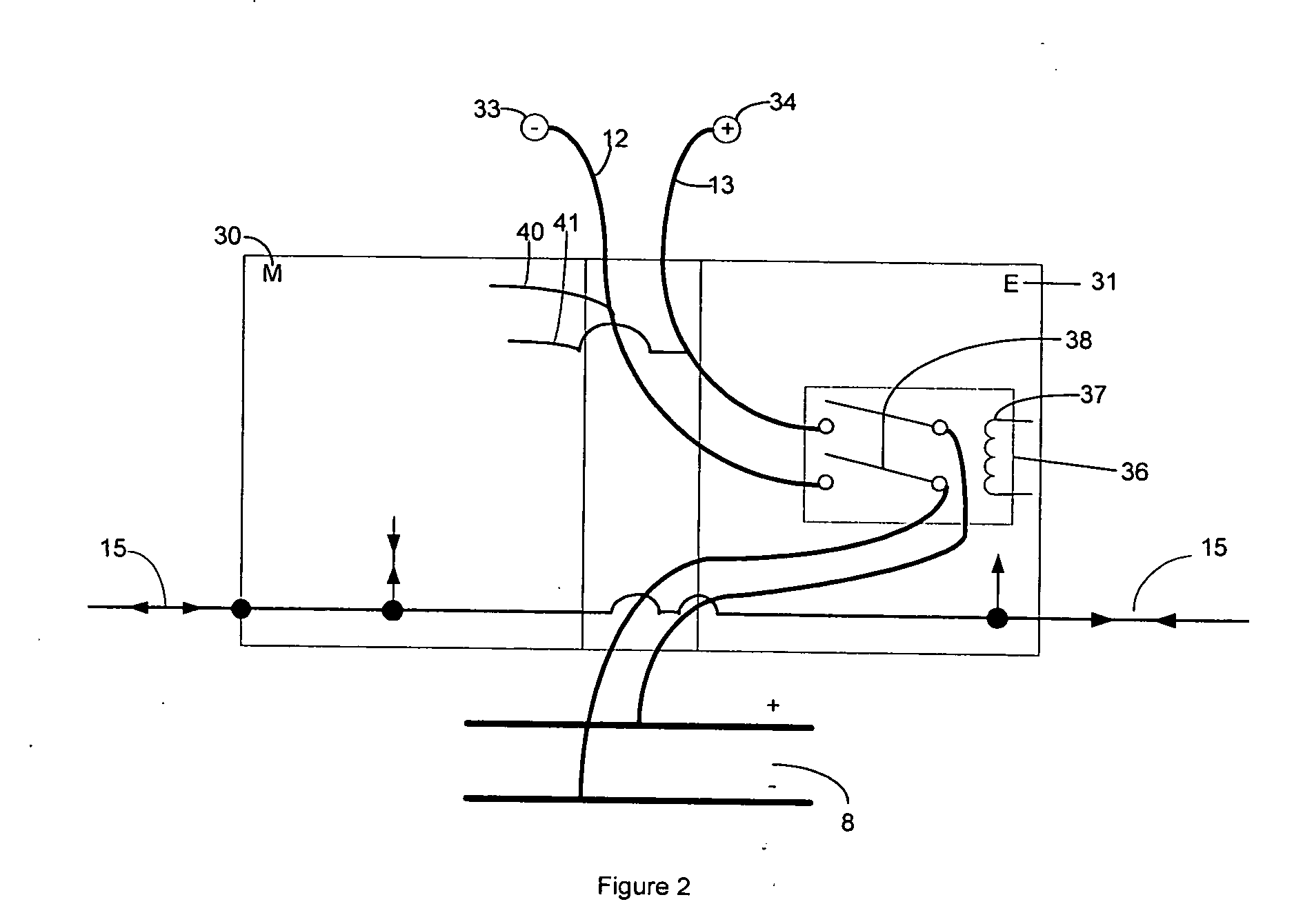

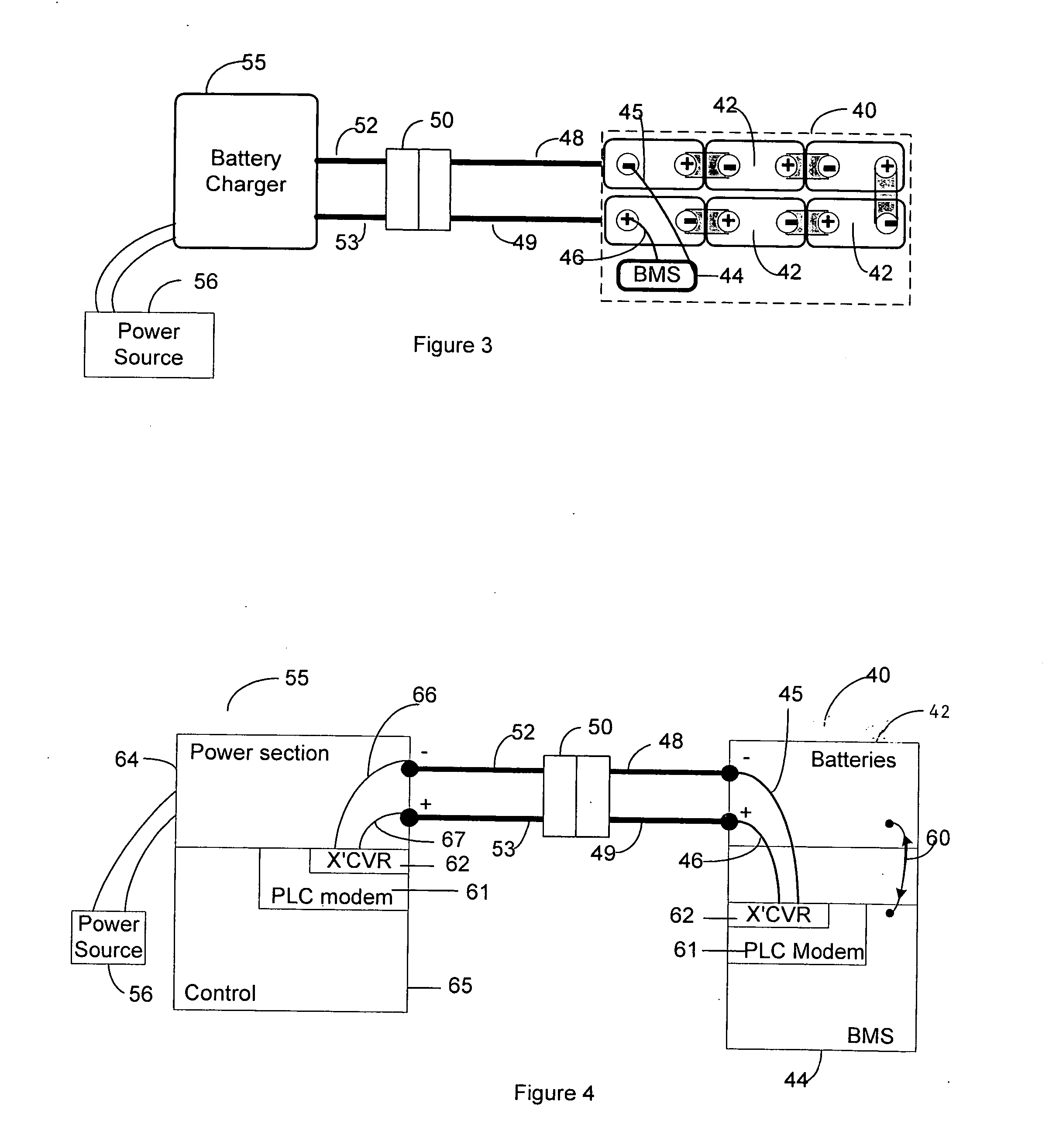

Battery management and equalization system for batteries using power line carrier communications

ActiveUS20060132089A1Easy to optimizeEliminate needCharge equalisation circuitElectric powerElectrical conductorBattery charge

A battery charging system uses power line carrier communications, for communicating battery state information associated with charging batteries, between a battery charger and a battery management system (BMS) located on the battery or battery pack. The power line carrier includes transmitters and receivers transmitting and receiving battery state information, such as current, voltage and temperature, as digital signals on existing cable conductors located between the battery / battery pack and the battery charger. The battery management system (BMS), which is physically located on the battery pack, receives the information from the power line carrier, in order to measure a variety of parameters relating to charging the battery, which may be a motor vehicle battery or a battery for operating machinery, such as fork lifts, bulldozers and other earth moving and product transportation vehicles.

Owner:POWER TECH HLDG LLC

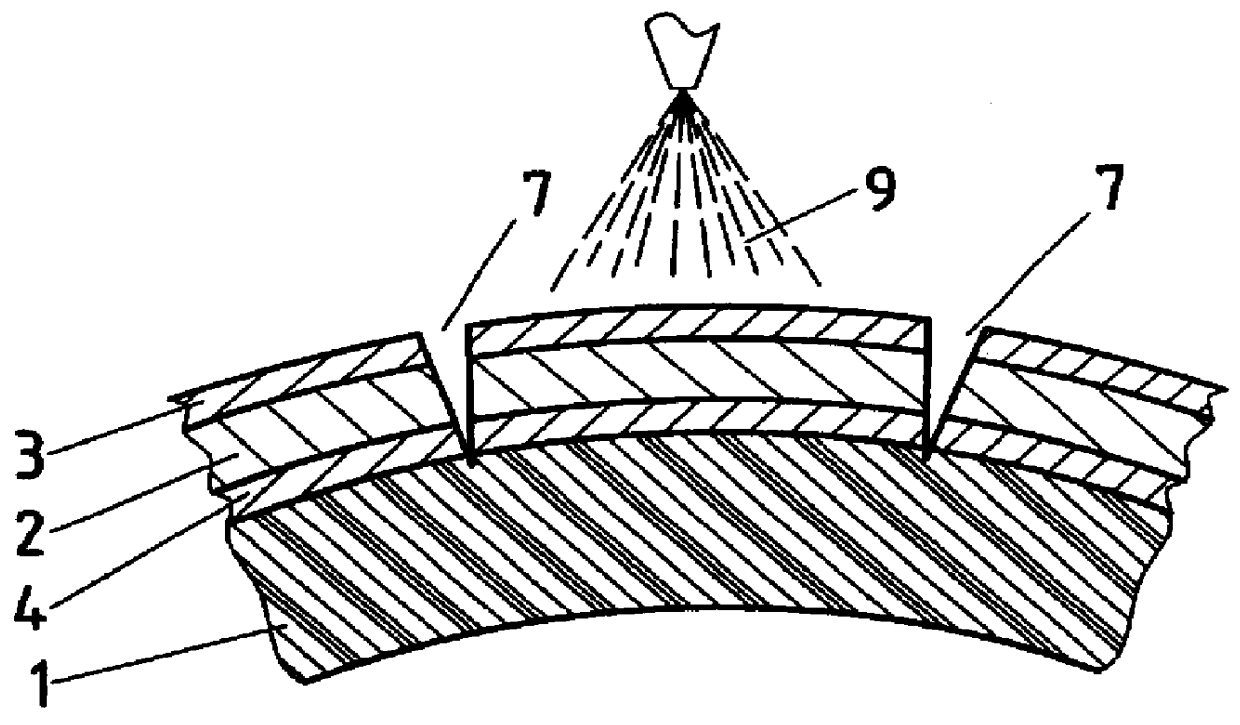

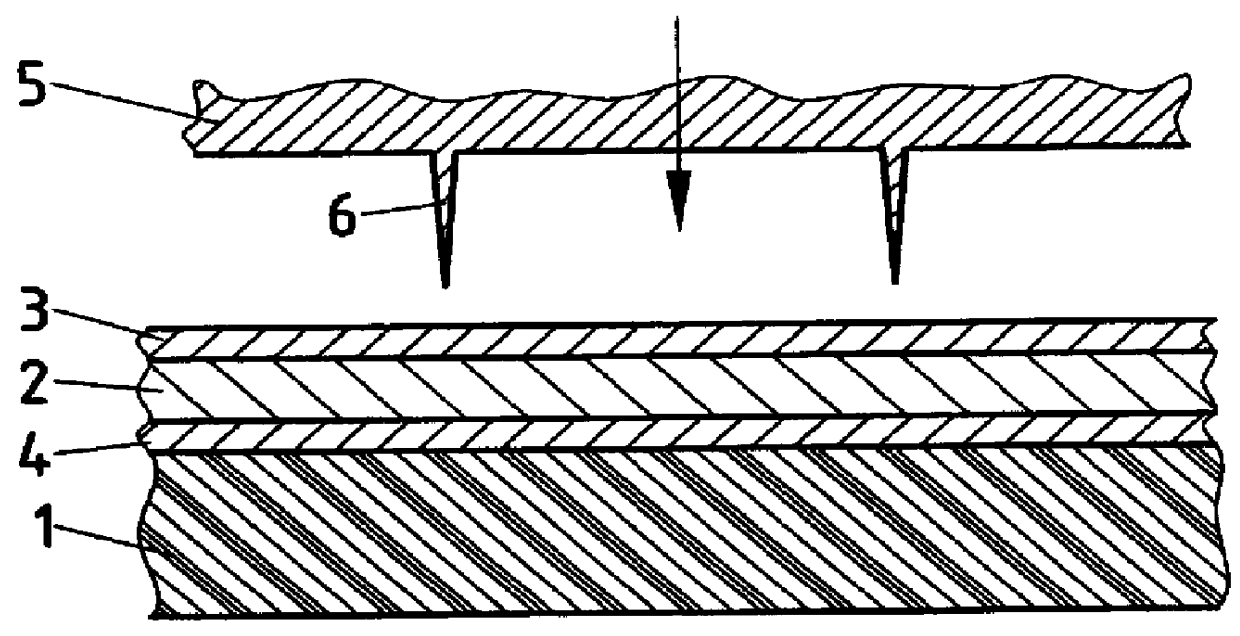

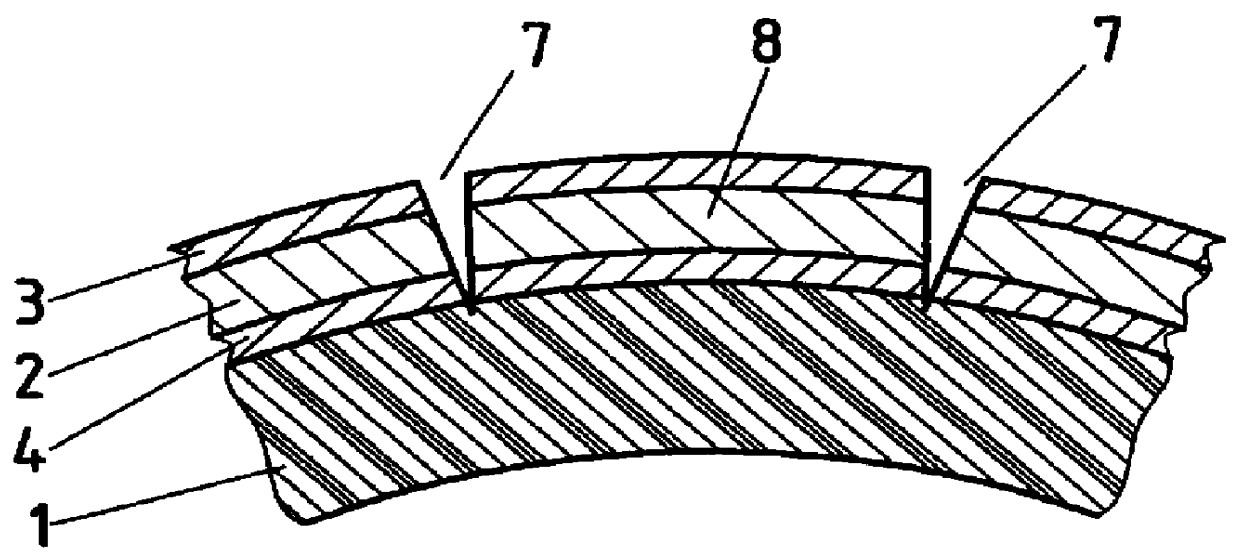

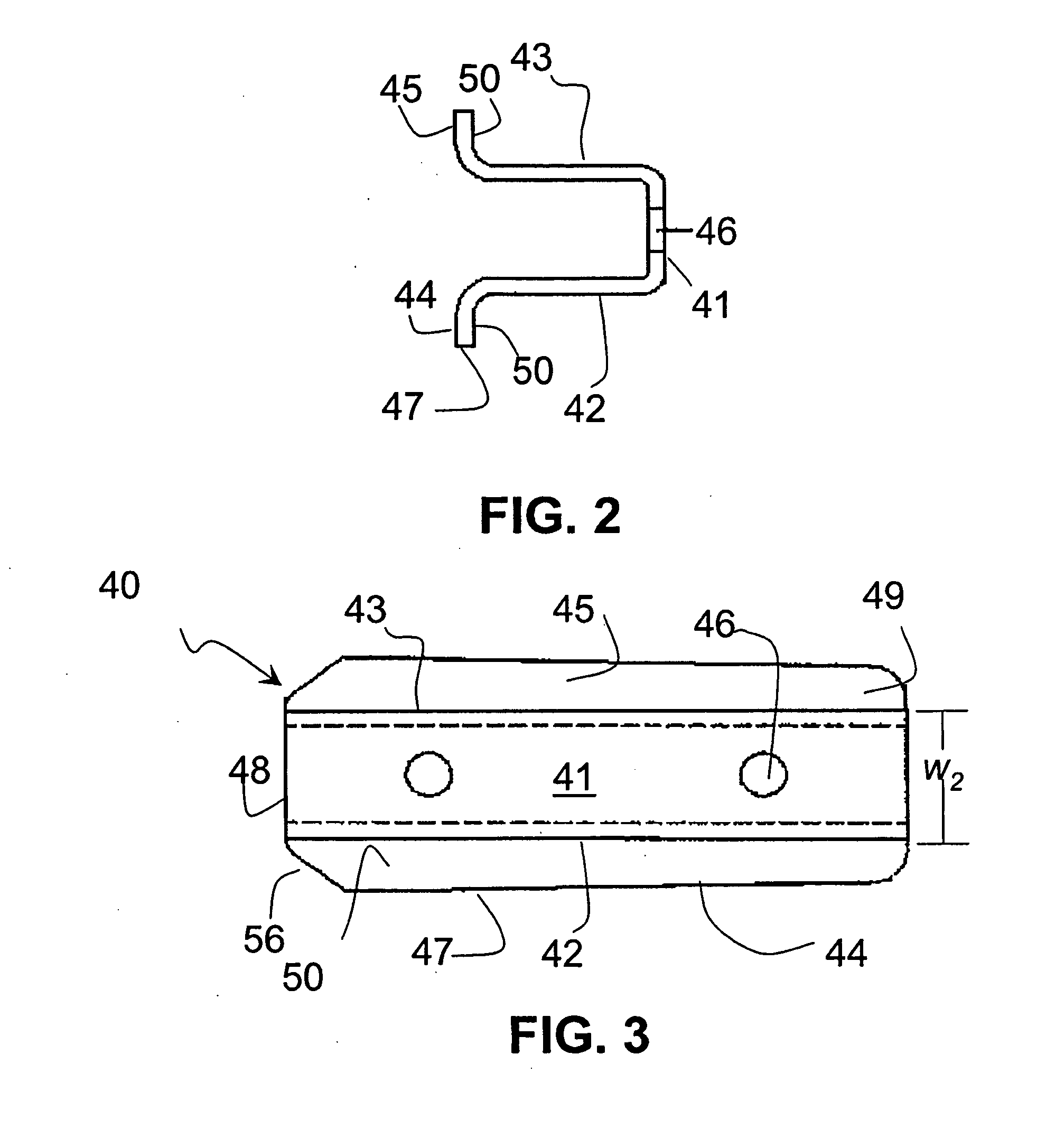

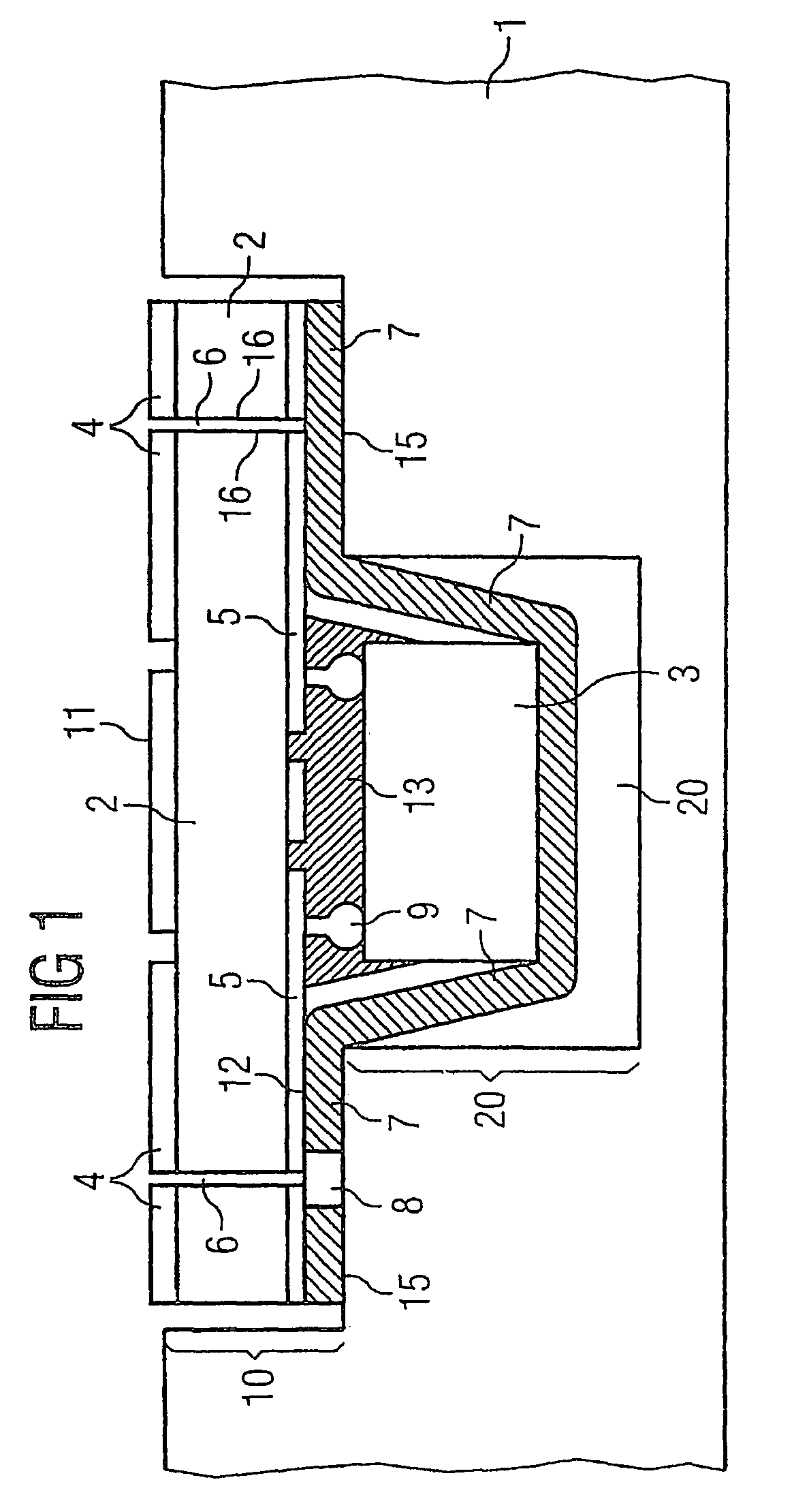

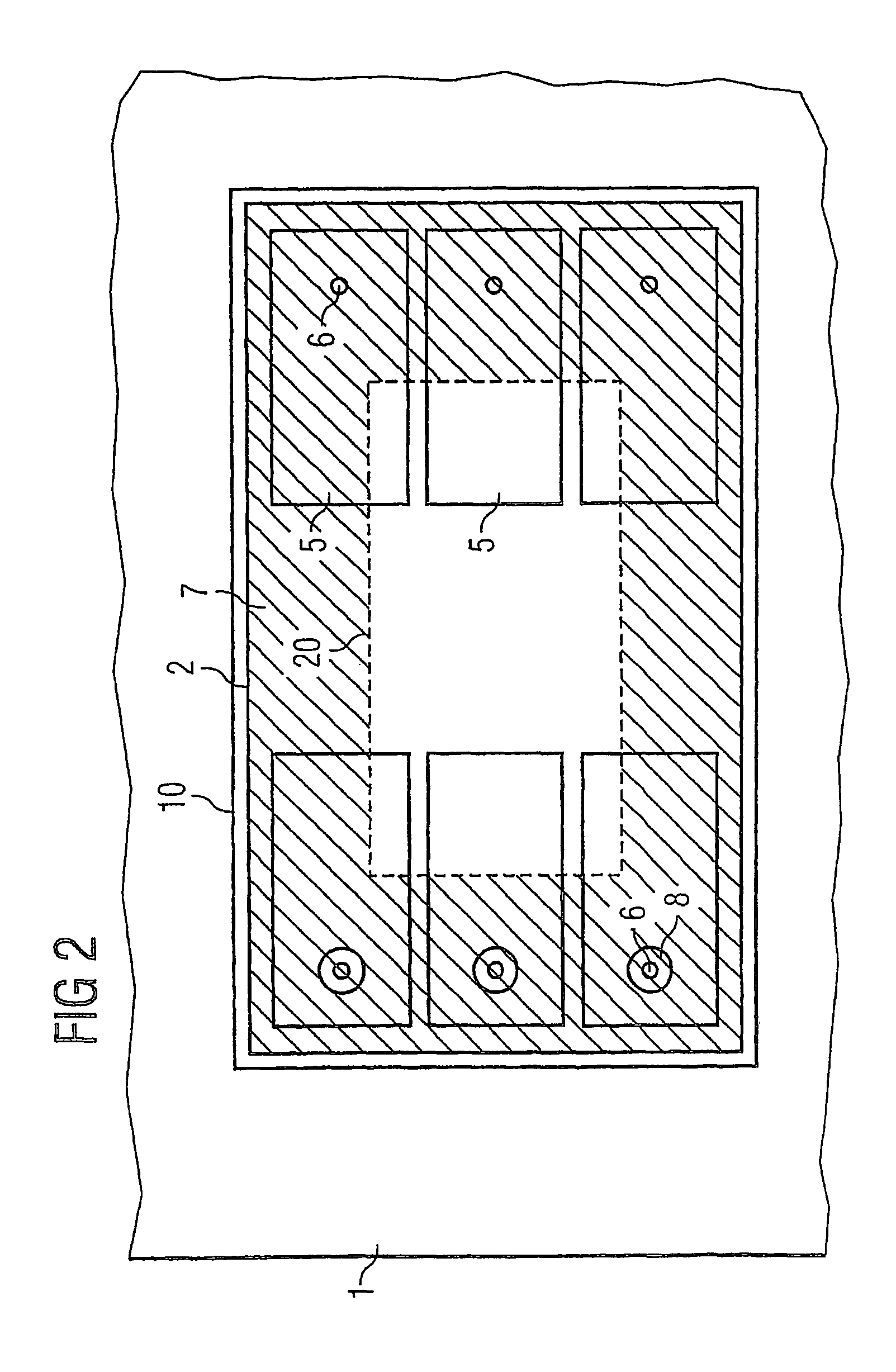

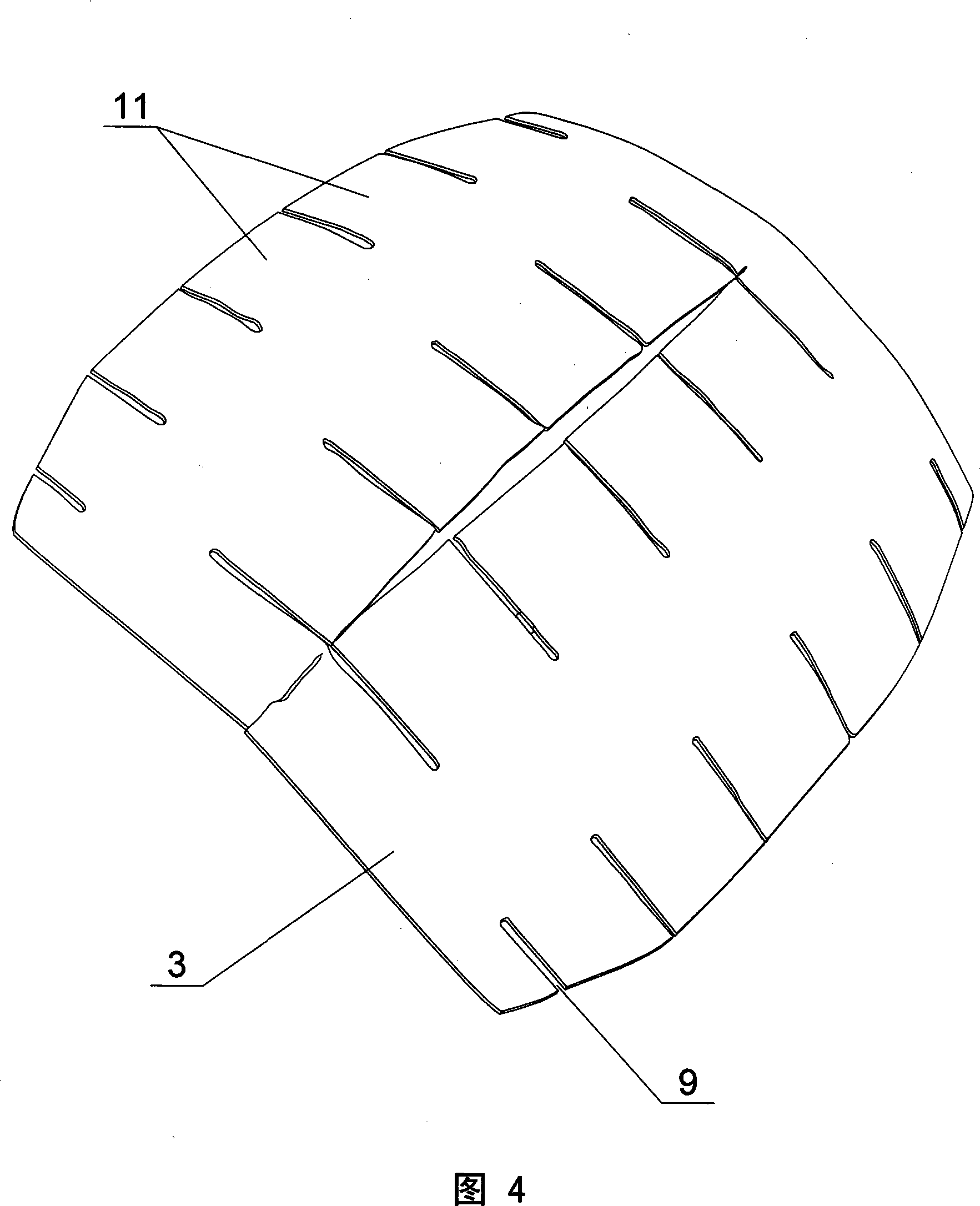

Method for producing a transponder coil

InactiveUS6161276AStamping of incisions considerably easierClean edgesConductive material mechanical removalTransmissionEdge surfaceDielectric substrate

PCT No. PCT / CH98 / 00231 Sec. 371 Date Oct. 25, 1999 Sec. 102(e) Date Oct. 25, 1999 PCT Filed Jun. 2, 1998 PCT Pub. No. WO98 / 56019 PCT Pub. Date Dec. 10, 1998A method of producing a transponder (20) comprising the following steps: demarcating the various turns (8) of a coil in a sheet (1), including a dielectric substrate covered by at least one conducting layer (2), by stamping said conducting layer with a stamping die (5) having sharp-edged surfaces (6) for contact with the superficial conducting layer (2; 2'''), connecting at least one electronic component (25) to the turns (8), and mounting at least one protective sheet (22; 27) covering the coil and the electronic component (25). To facilitate the stamping and to obtain clean incisions, the conducting layer is covered, before stamping, with a synthetic film. To prevent short circuits over the incisions, the incisions are preferably filled in with an adhesive, varnish or lacquer.

Owner:NAGRAVISION SA

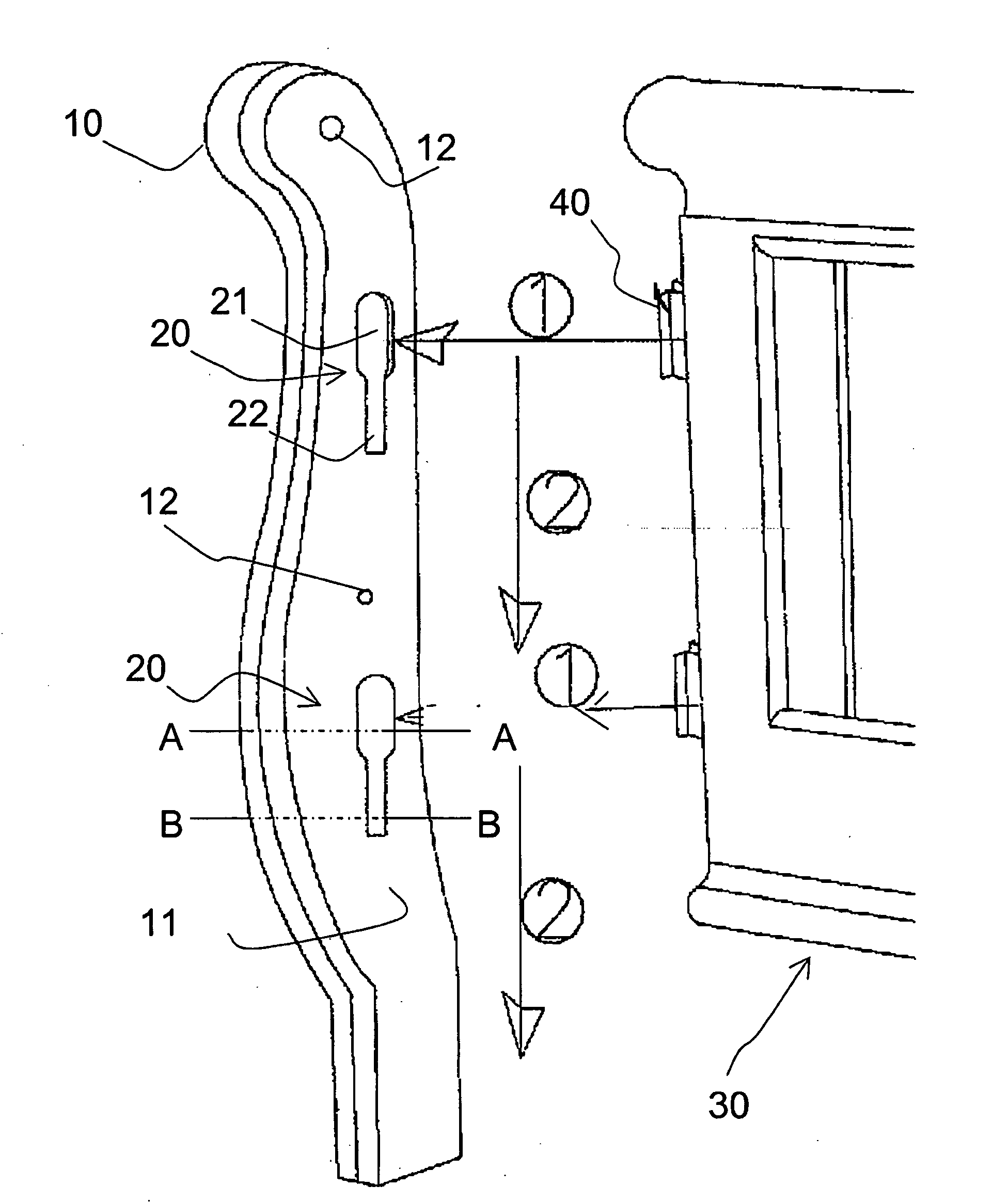

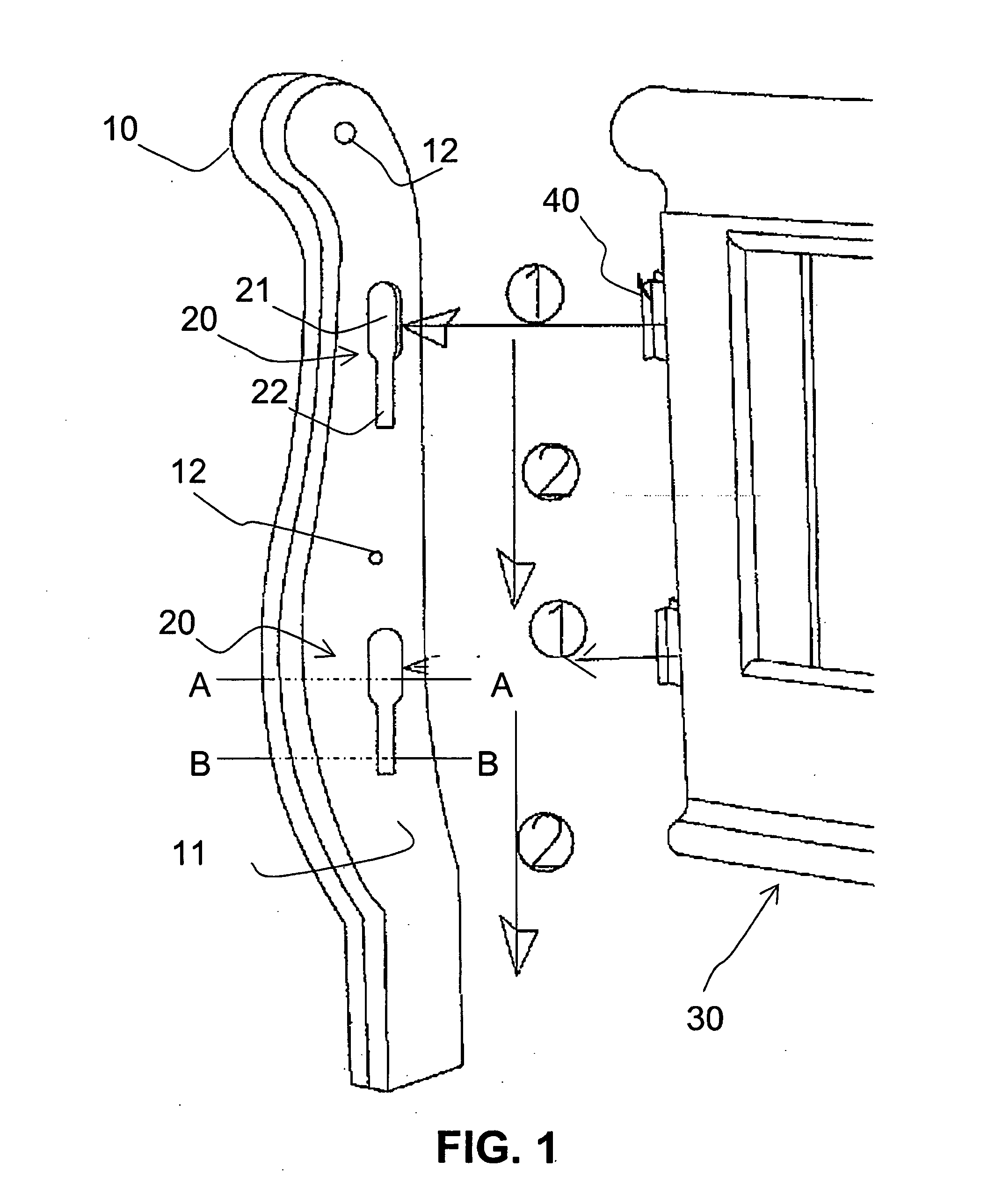

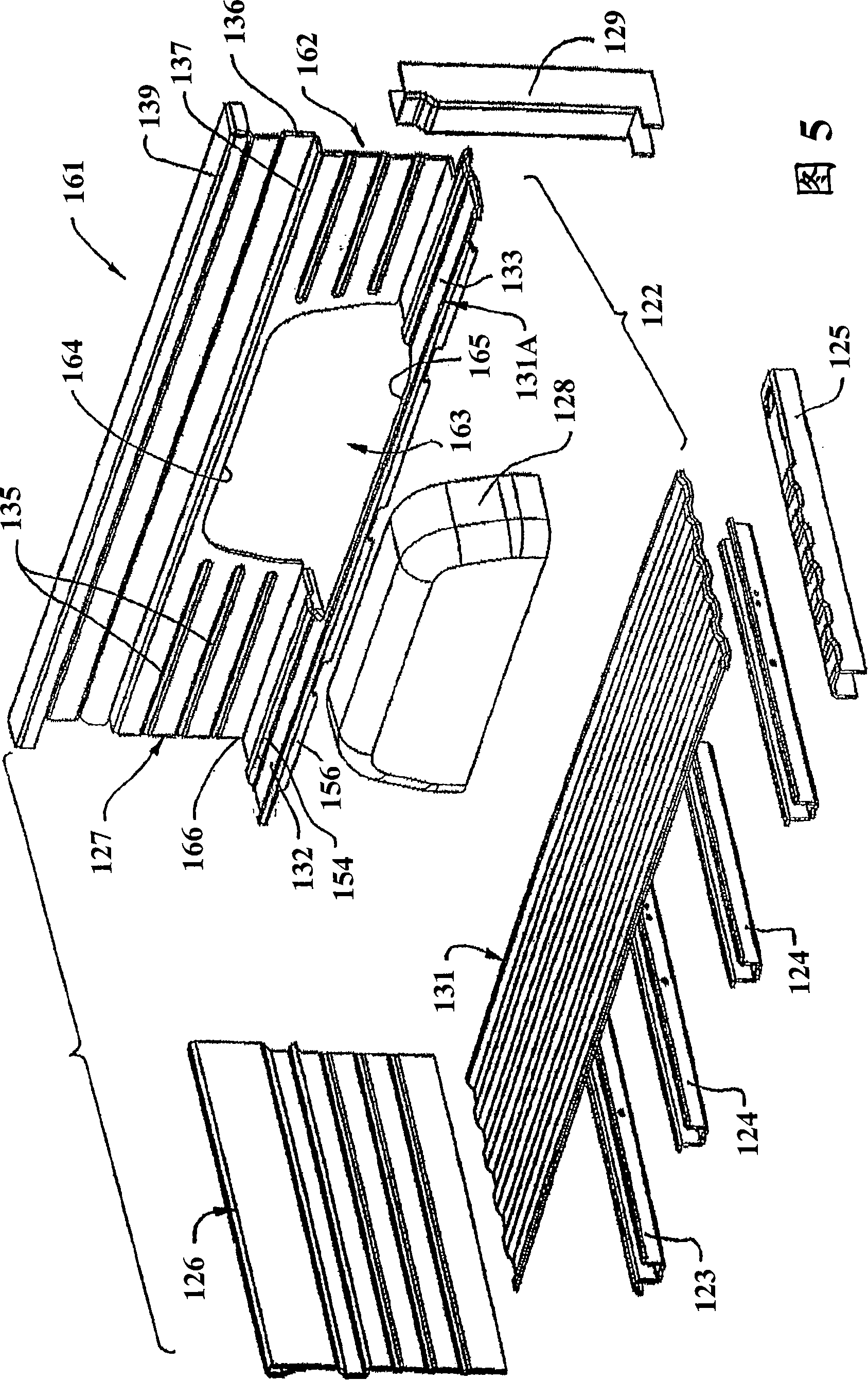

Apparatus and Method for Assembling Structural Components

InactiveUS20100003077A1Easy stampingWell formedRopes and cables for vehicles/pulleySheet joiningStructural elementEngineering

Owner:KELLEY SAM

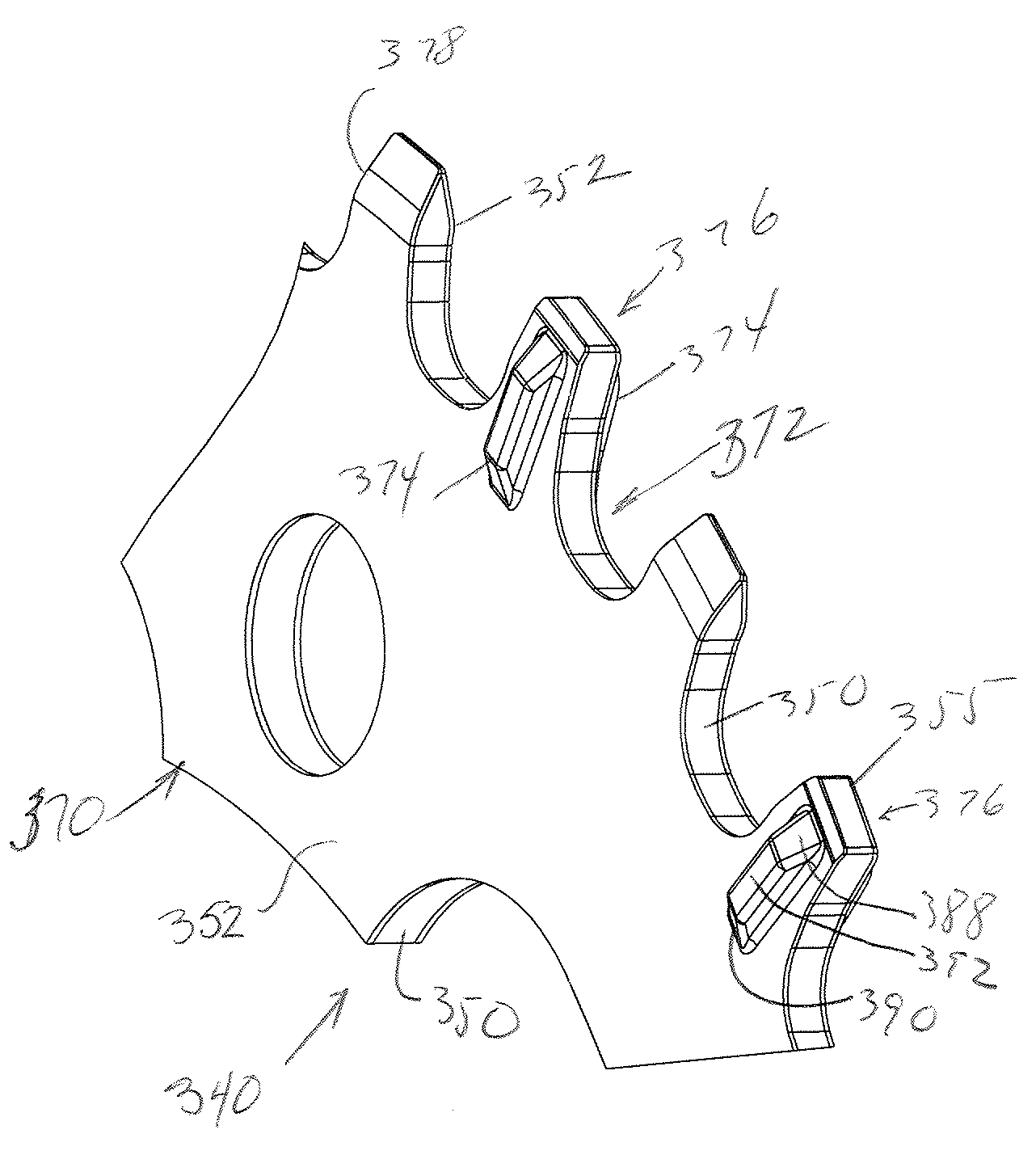

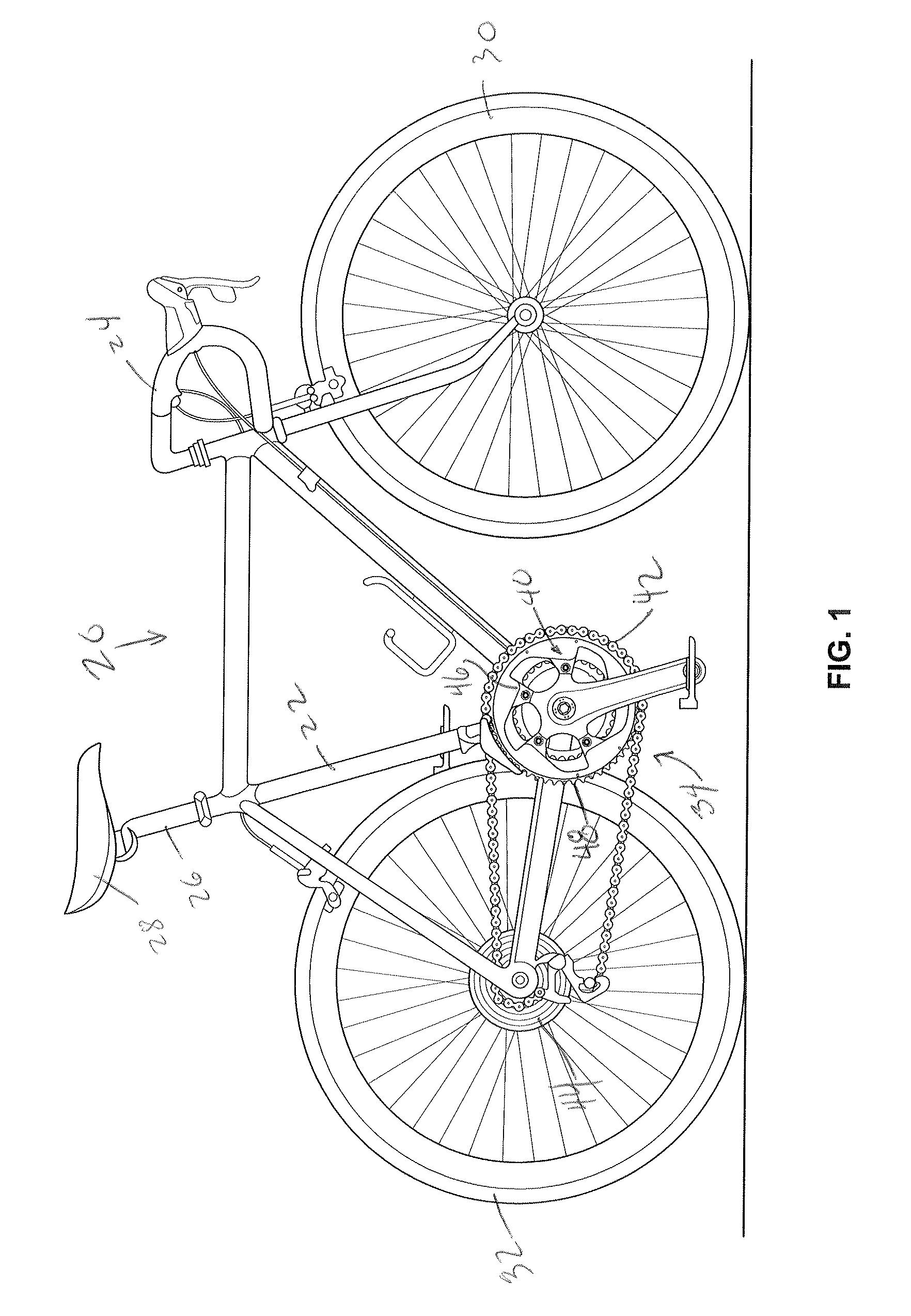

Clad chainring

ActiveUS9328814B2Easy stampingAvoiding and reducing machiningChain/belt transmissionPortable liftingWear resistanceMechanical engineering

A bicycle chainring, including a generally annular body formed of at least an inner material, the inner material including a first side and a second side opposite the first side and a plurality of teeth disposed about a periphery of the body. At least some of the plurality of teeth are formed of both the inner material and an outer material, the outer material disposed on one or both of the first and second sides, the outer material having a greater wear resistance relative to the inner material and a thickness greater than 0.1 millimeter.

Owner:SRAM CORPORATION

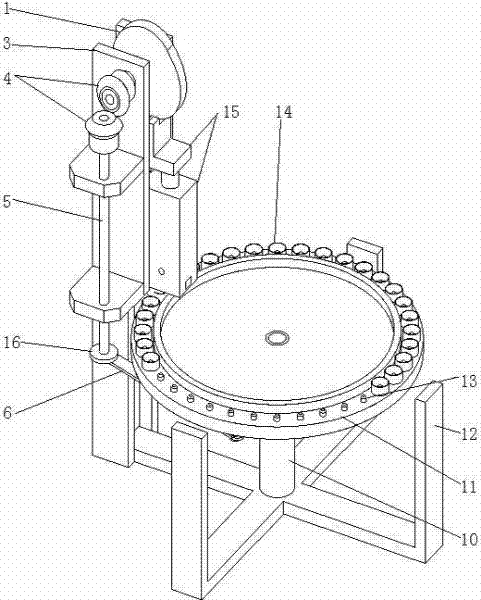

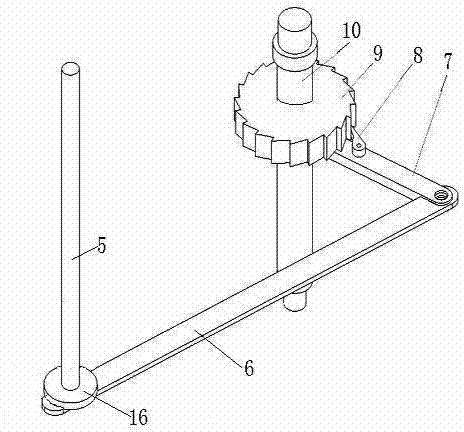

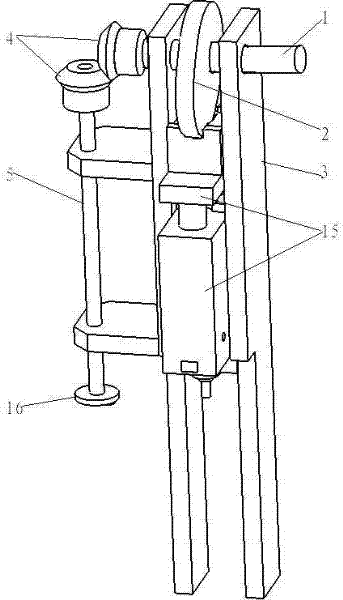

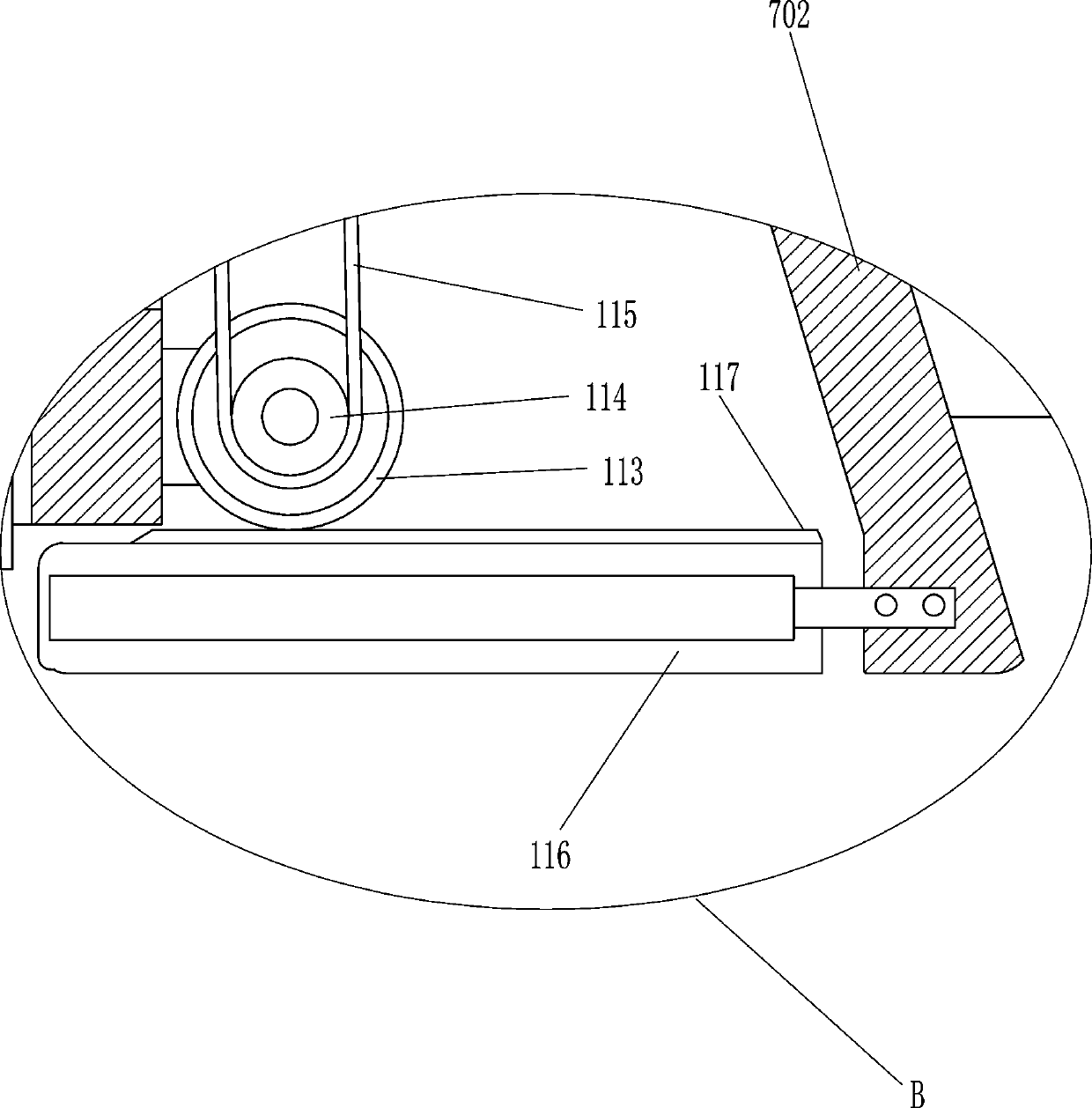

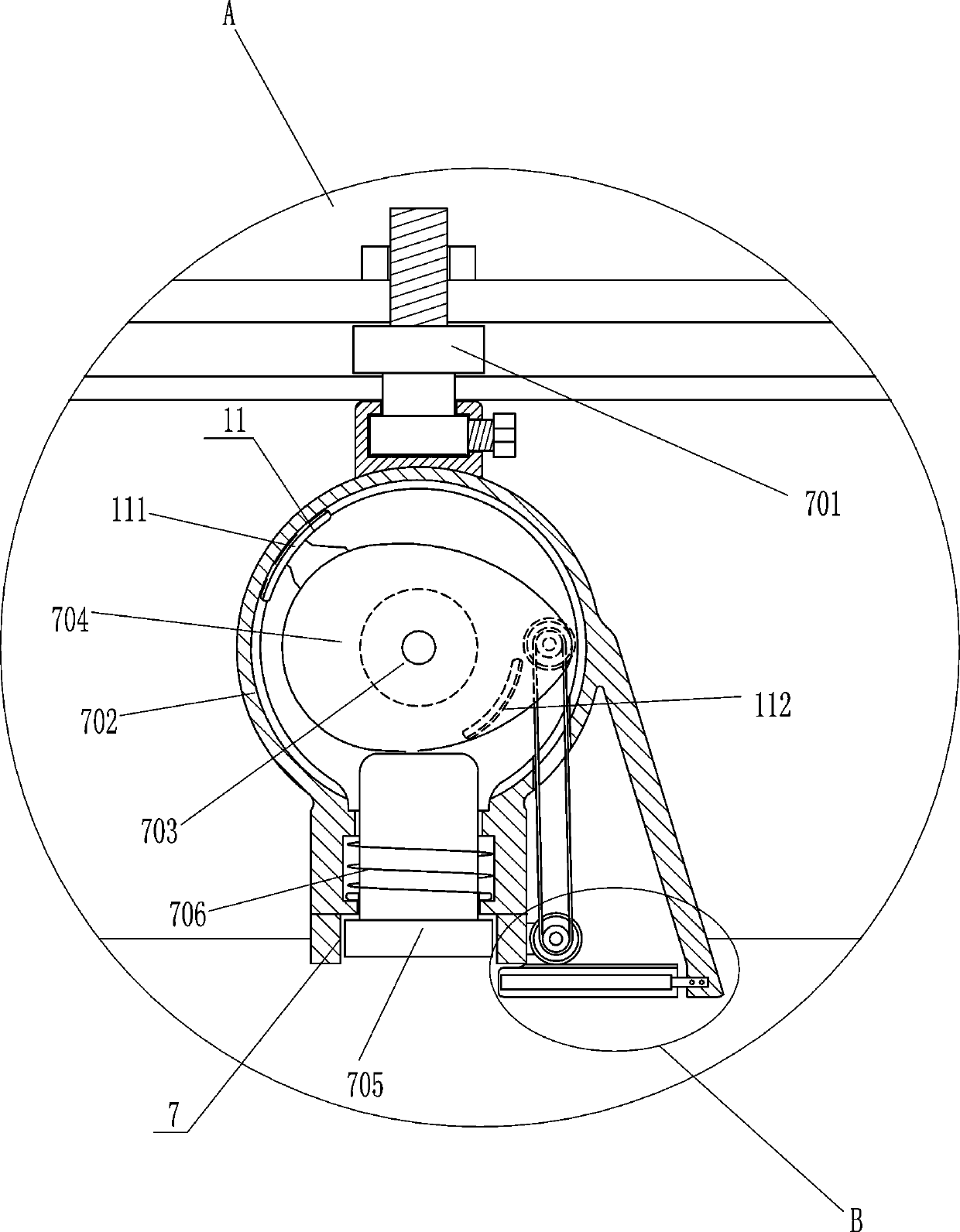

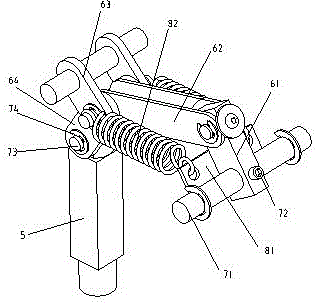

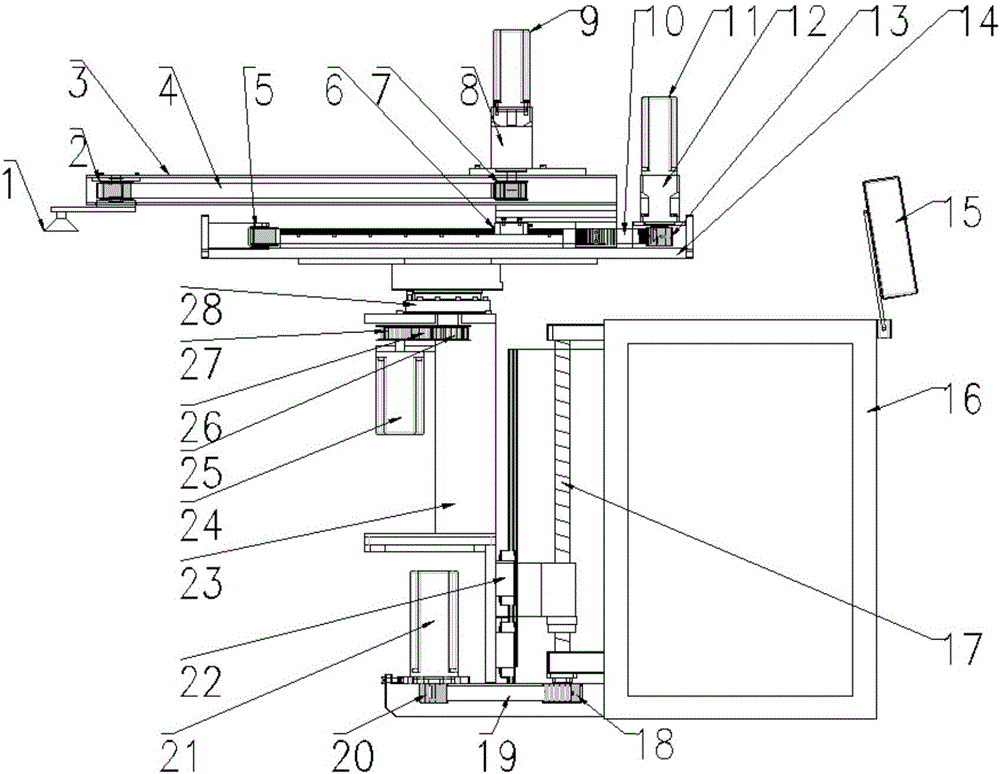

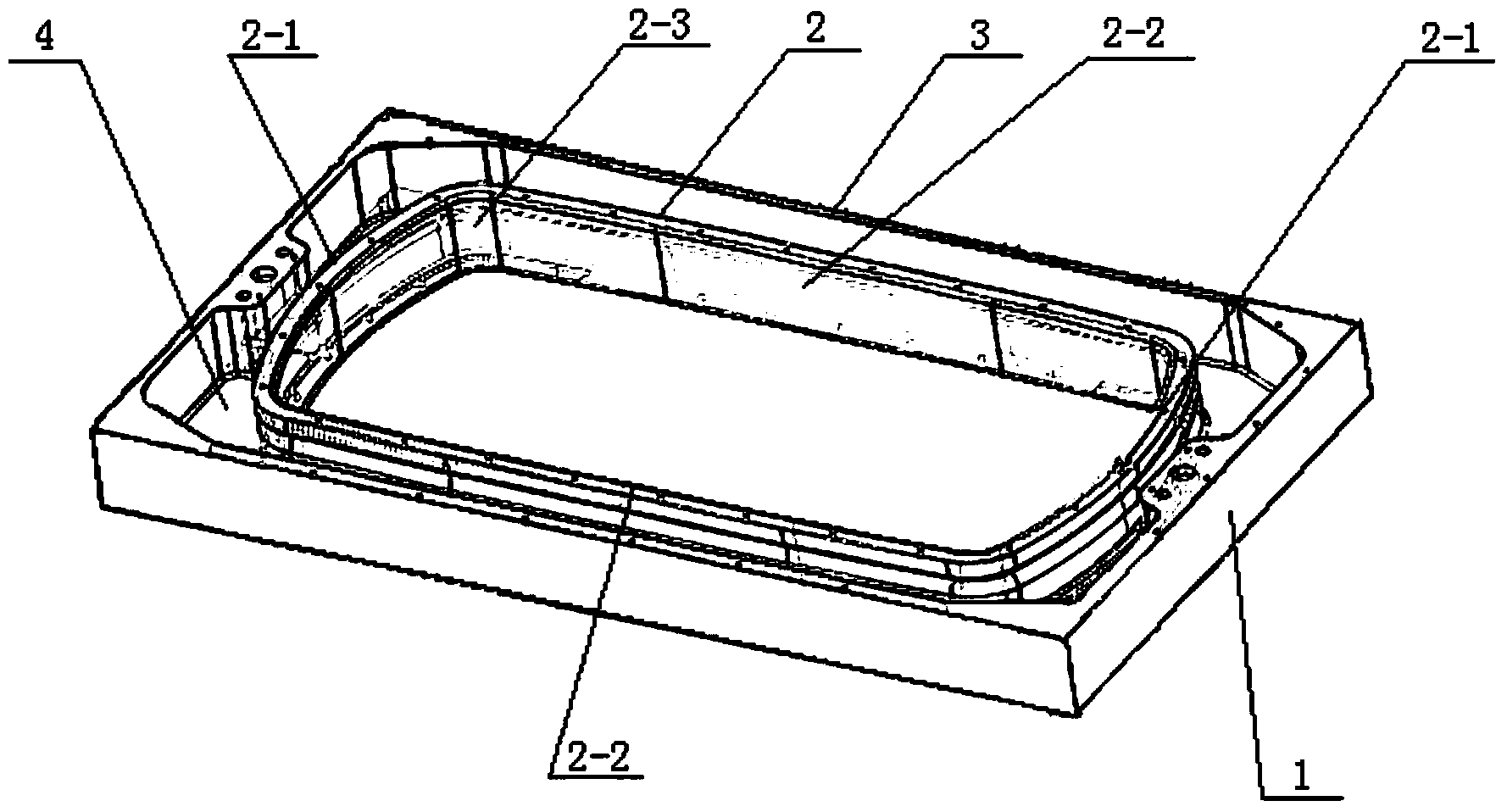

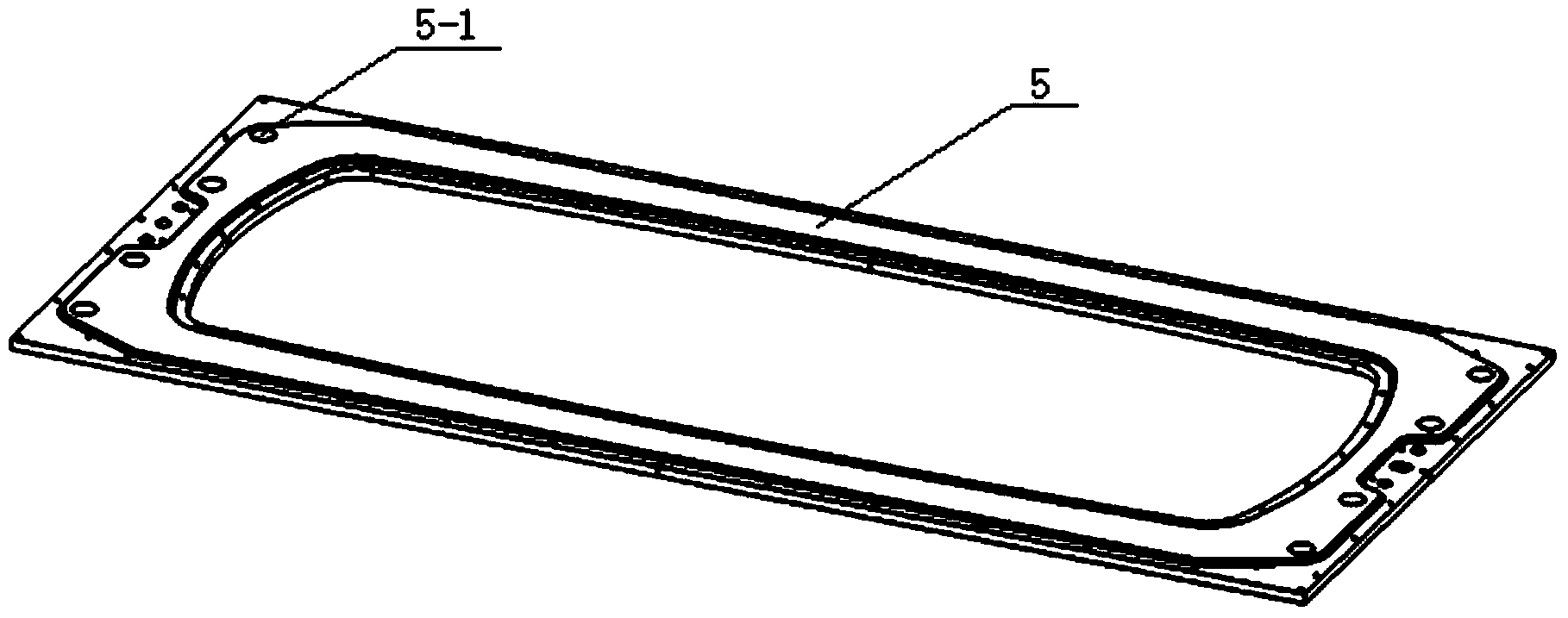

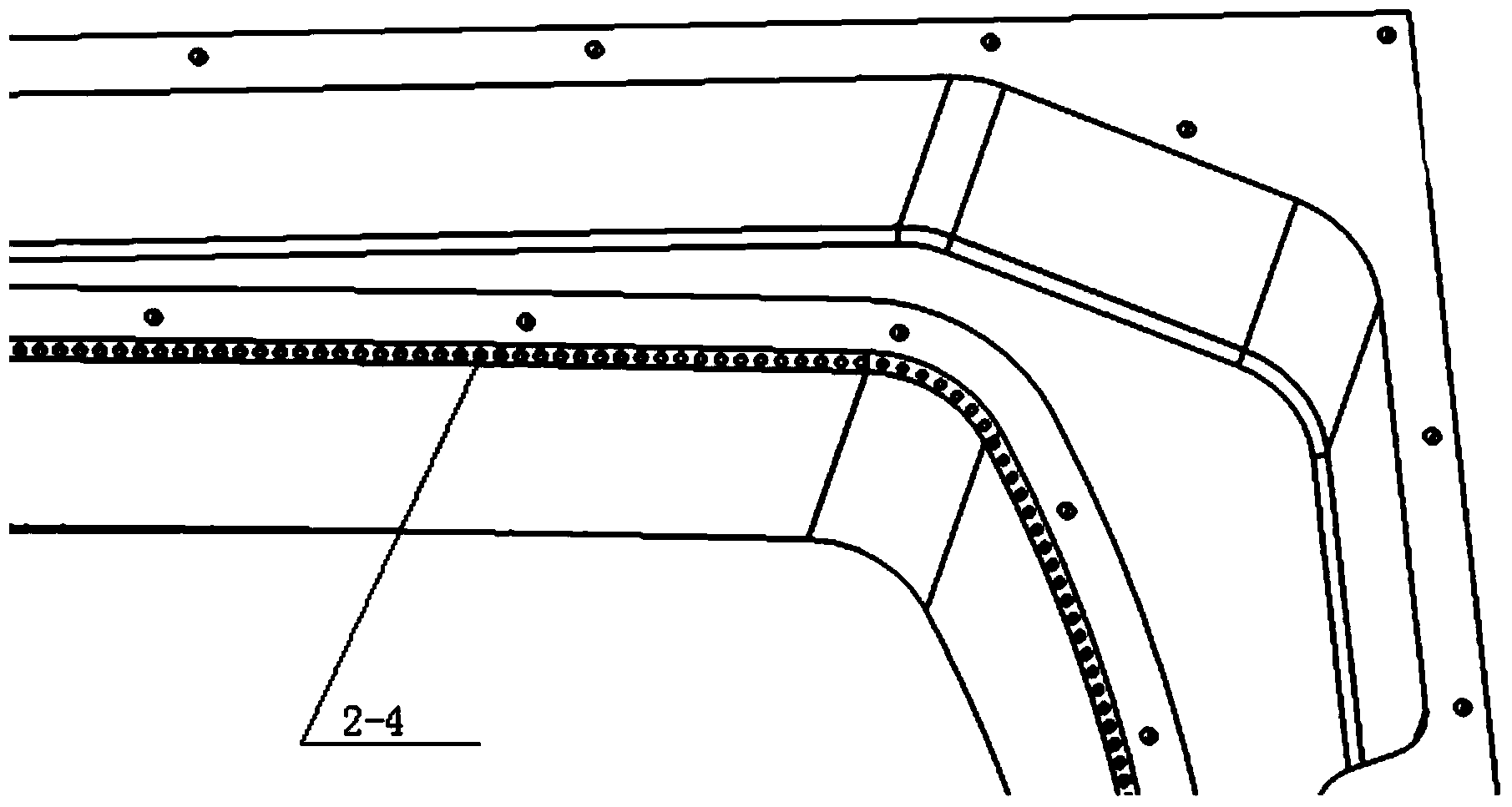

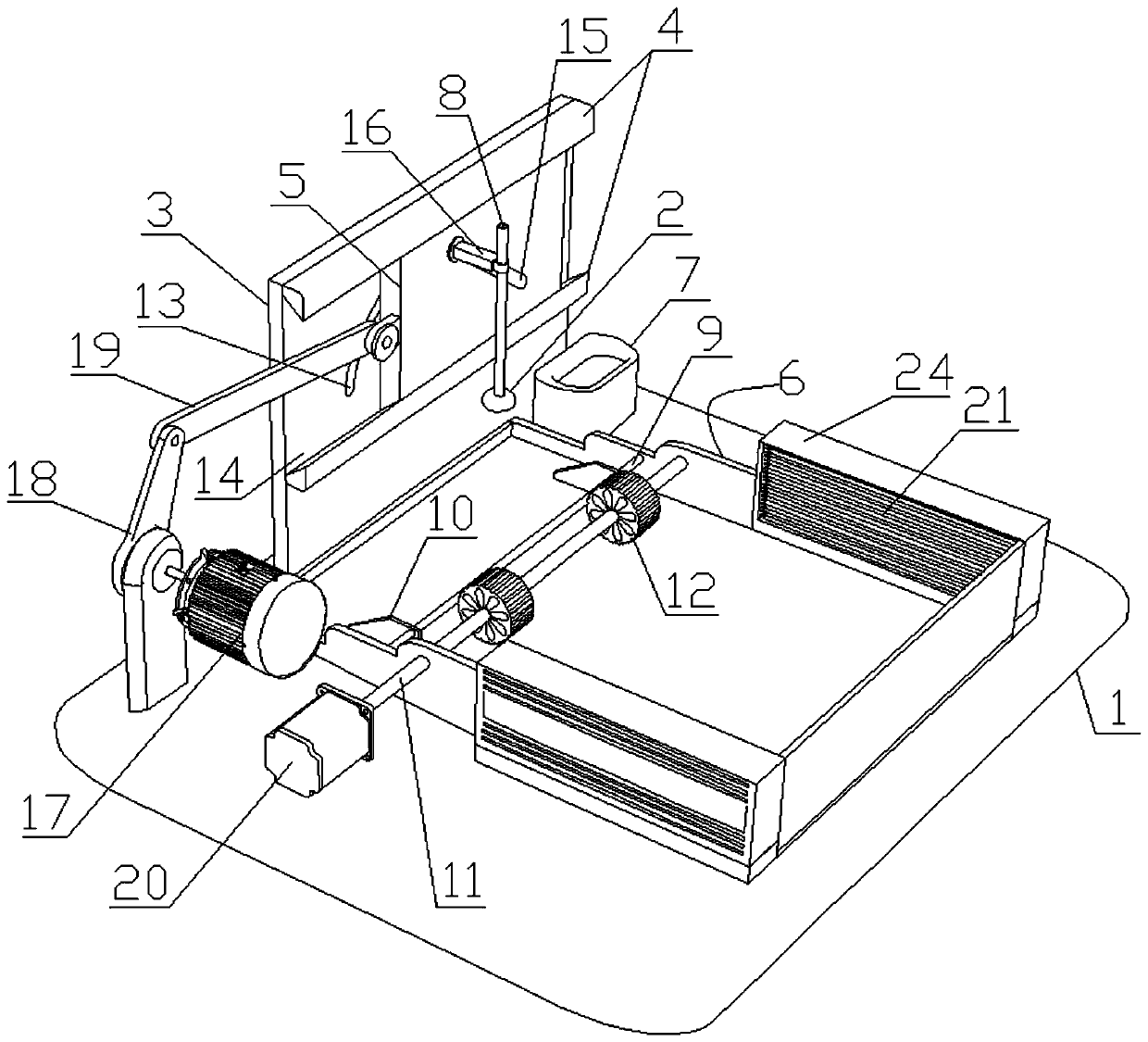

Linkage operation device for punched aluminum cover surface convex identifier

ActiveCN102350885AAchieve continuous mechanical stampingSave stamping timeStampingPunchingAgricultural engineering

The invention discloses a linkage operation device for a punched aluminum cover surface convex identifier. A cam mechanism and a cone pulley mechanism are arranged at the top of the device, a supporting part is arranged at the bottom of the device, and a cam is sleeved on a cam shaft and can rotate around the cam shaft; a cone pulley is horizontally arranged at one end of the cam shaft, the othercone pulley is vertically arranged at the upper end of a cone pulley shaft, and the two cone pulleys are mutually engaged; the lower end of the cone pulley shaft is connected with an eccentric wheel,the eccentric wheel is transversely and movably connected with one end of a connecting rod, the other end of the connecting rod is connected with one end of a swinging rod, and the other end of the swinging rod is connected with a ratchet pawl; and the bottom of a main shaft is vertically connected with a bracket, a ratchet corresponding to the ratchet pawl is fixedly arranged in the middle of the main shaft, the top of the main shaft is movably connected with a main turntable, and a plurality of positioning round pins for positioning an aluminum bottle cap are uniformly and fixedly arranged on the periphery of the upper surface of the main turntable at intervals. When the cam rotates for one circle for one-time punching, the main turntable rotates for one grid; and the turntable realizeslinkage operation, so the punching time is saved, and the production efficiency is improved.

Owner:溧阳常大技术转移中心有限公司

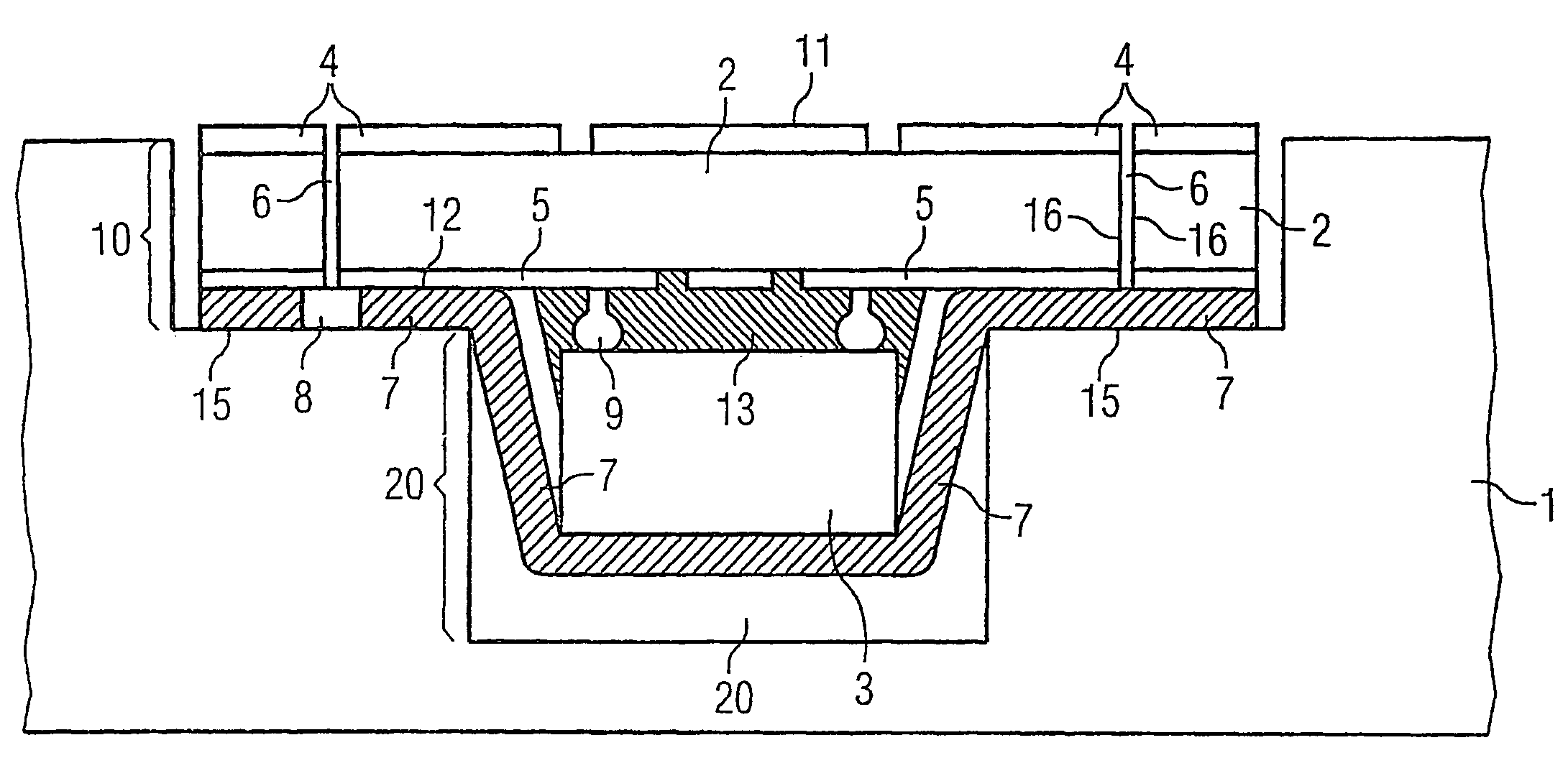

Making contact with semiconductor chips in chip cards

InactiveUS7019981B2Reliable contactLow costOther printing matterSemiconductor/solid-state device detailsSemiconductor chipEngineering

A chip card having a chip card body, a semiconductor chip and a carrier substrate, the carrier substrate being provided on both sides with surface contacts and with contact-hole lines electrically connecting the upper and lower surface contacts to one another. The contact-hole lines are arranged so close to the edge of the carrier substrate that their lower ends open out into a base of an outer cavity, where they are closed off, to thereby prevent moisture from penetrating into the inner cavity, in which the semiconductor chip is located, without it being necessary to produce a dedicated cover for the contact-hole lines.

Owner:INFINEON TECH AG

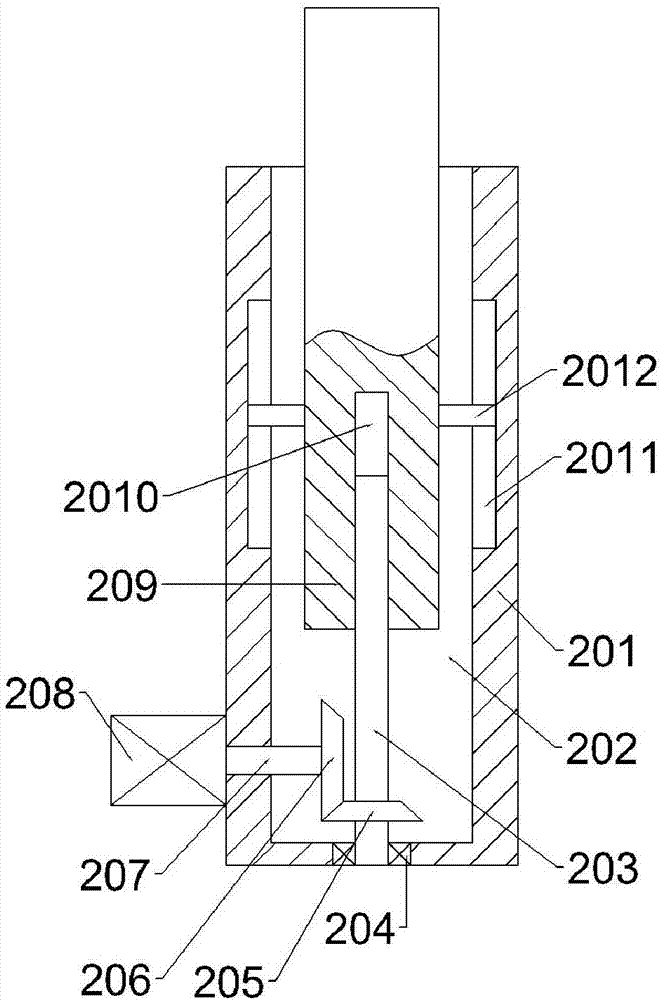

Punching and grinding integrated device

InactiveCN108500129AImprove efficiencyEasy to processEdge grinding machinesShaping toolsPunchingEngineering

The invention belongs to the technical field of punching device, and specifically discloses a punching and grinding integrated device. The device comprises a worktable, a controller, a punch and a sliding barrel, wherein a groove is formed in the upper surface of the worktable, and an infrared emitter is arranged in the groove; an empty cavity is formed in the worktable, and two pushing columns are connected into the empty cavity in a sliding manner; L-shaped clamping plates are arranged on the pushing rods; a piston is connected into the sliding barrel in a sliding manner, and the punch is fixed to the piston; a water inlet pipe, a water draining pipe and a communicating pipe are connected to the sidewall of the sliding barrel; an inner concave cavity is formed in the lower surface of thepunch, and a plunger piston is connected into the inner concave cavity and a motor is arranged in the inner concave cavity; a telescoping rod is connected to an output shaft of the motor and is connected to the plunger piston; a chute is formed in the sidewall of the plunger piston; a grinding bump is connected into the chute in a sliding manner; an infrared receiver is embedded into the lower surface of the plunger piston; and the infrared receiver and the infrared emitter are electrically connected to a controller. According to the technical scheme, the device is capable of punching, grinding and processing a workpiece, and the processing efficiency is improved.

Owner:宁波鑫神泽汽车零部件有限公司

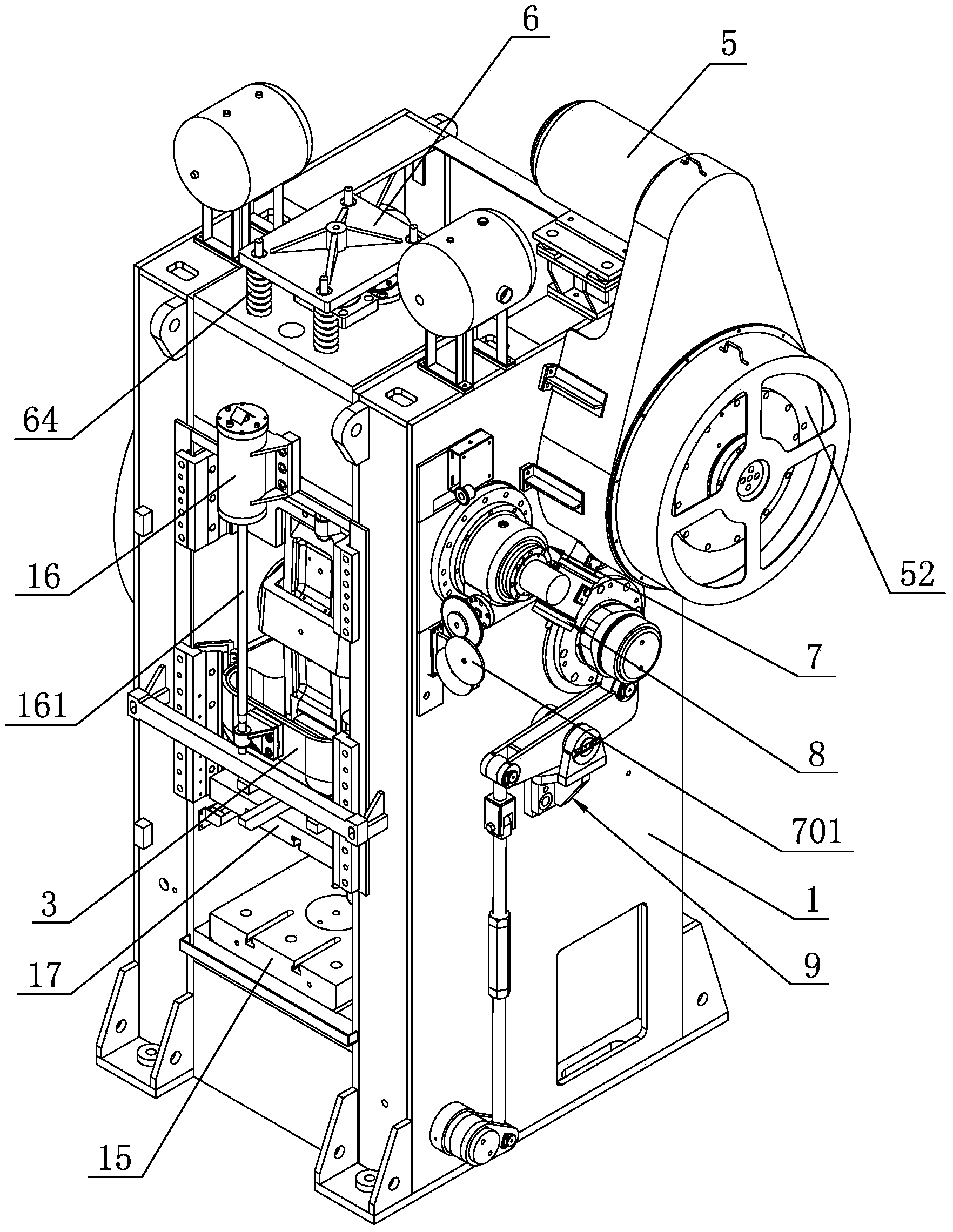

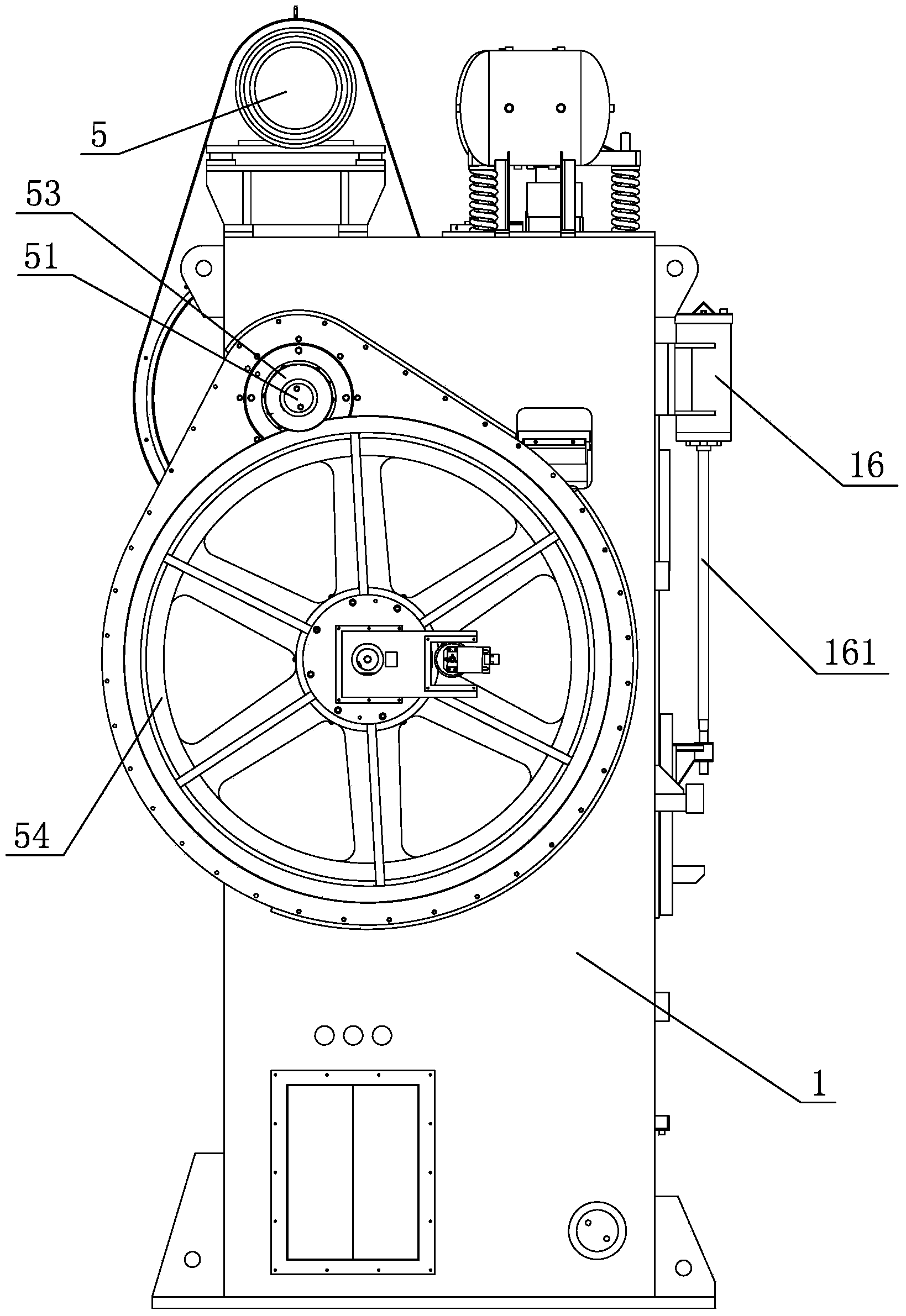

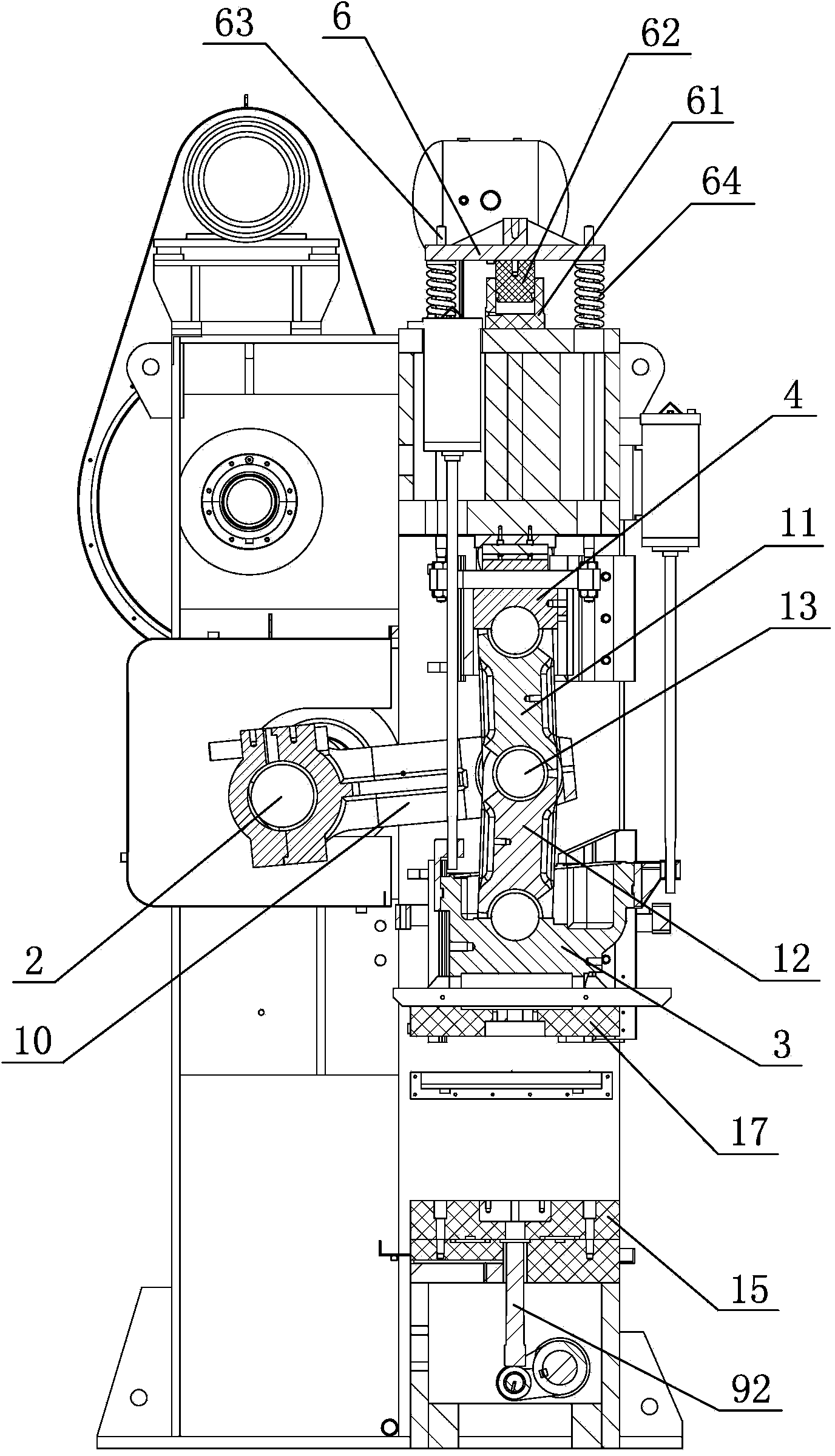

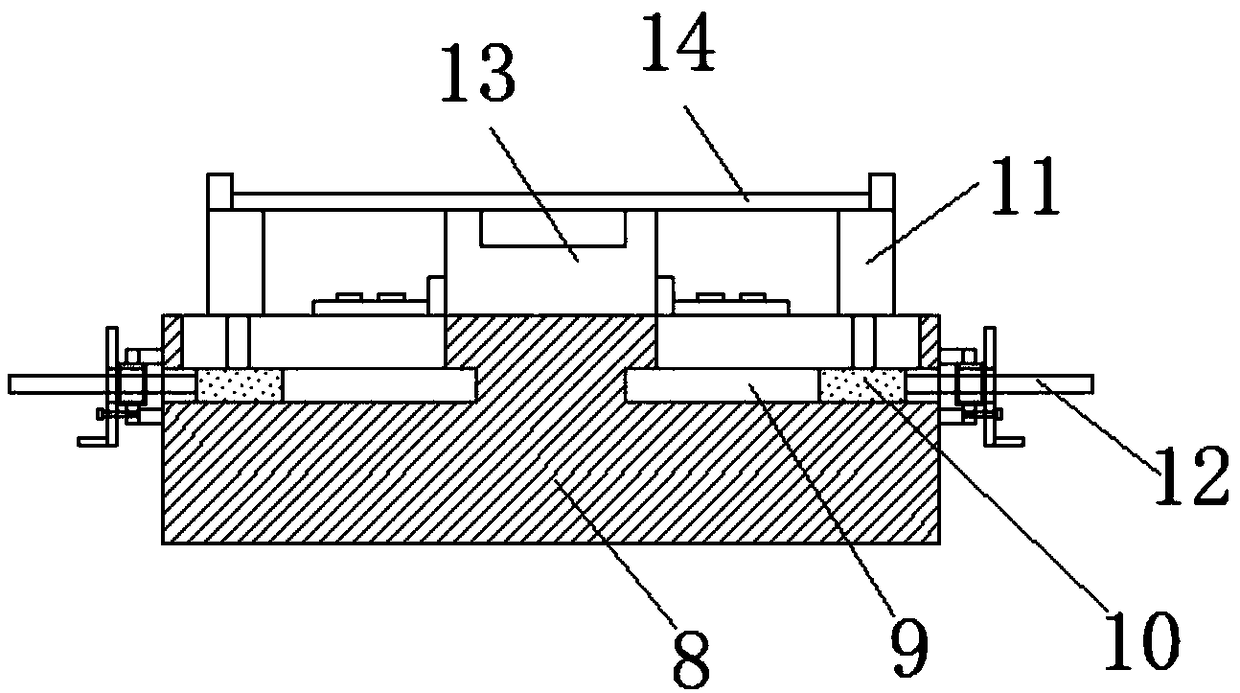

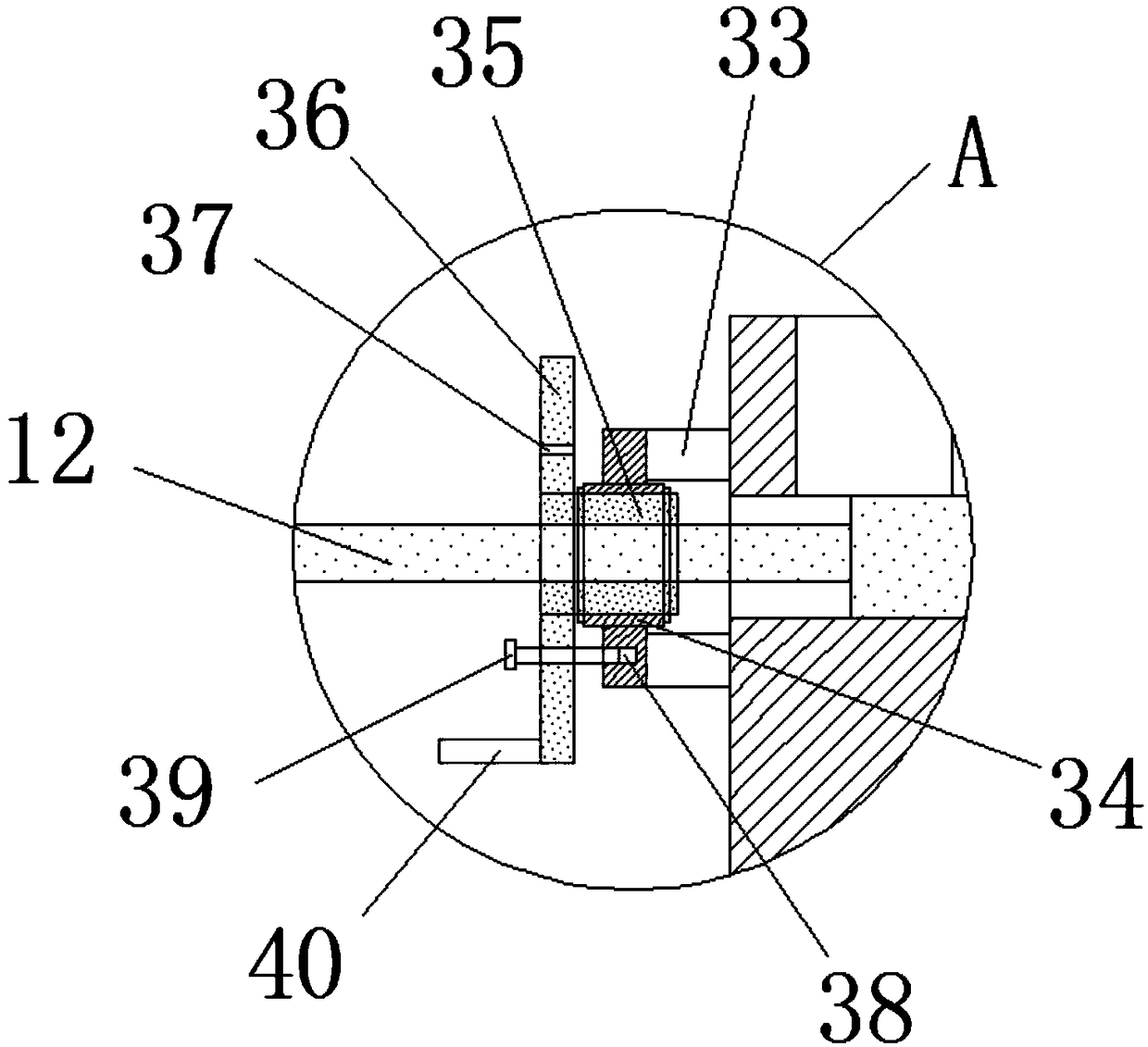

Connecting rod punch press

ActiveCN104226768AReduce connection gapsGuaranteed stabilityPress ramEjection devicesPunch pressDynamic balance

The invention discloses a connecting rod punch press, comprising a rack, a crankshaft, a lower slide block, and a crankshaft rotation drive device, wherein the lower slide block is in sliding fit with the rack. The connecting rod punch press is characterized in that an upper slide block is arranged inside the rack; the upper end of the rack is provided with a dynamic balance connecting mechanism of the upper slide block; a first link transmission mechanism is arranged among the crankshaft, the lower slide block and the upper slide block; the rack is provided with an upper slide block adjusting mechanism which is used for adjusting the height of the mold. The connecting rod punch press has the advantages that the upper slide block is arranged inside the rack, the rack is provided with the upper slide block adjusting mechanism which is used for adjusting the height of the mold, and the upper and lower positions of the upper slide block can be adjusted through the adjusting mechanism, thus the height of the mold of the connecting rod punch press is adjusted, meanwhile, the internal structure of the lower slide block is also reduced, the structure of the lower slide block is simplified, the condition that the lower slide block can bear good punching, and does not deform when the connecting rod punch press is used for punching at high temperature is ensured, the punching stability of the punch press and the accuracy of a punched product are ensured, and the connecting rod punch press can be applicable to high-temperature punching.

Owner:NINGBO CITY COSTON PRECISION MACHINERY

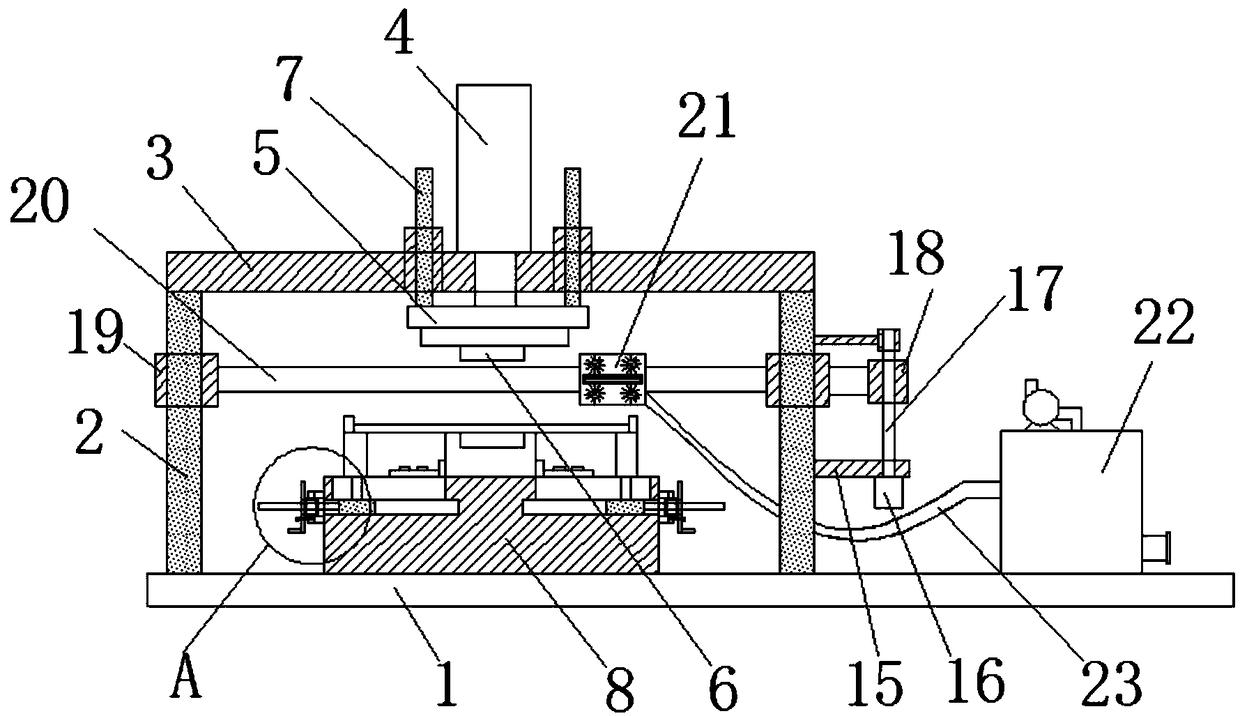

Sheet metal stamping device

PendingCN108637118AImprove stamping accuracyImprove yield rateShaping toolsMetal-working feeding devicesElectric machineryEngineering

The invention discloses a sheet metal stamping device. A cylinder rod of an air cylinder is connected to the left side of a movable frame, a first bracket is arranged on the right side of a support column, a first motor is installed at the bottom of the first bracket, a second threaded rod is connected to an output shaft of the first motor, a first threaded sleeve is in threaded connection to theouter side of the second threaded rod, and the first threaded sleeve is fixedly connected with the outer side of a movable barrel. According to the sheet metal stamping device, a plurality of stampingsupport seats are arranged, so that different shapes of sheet metal pieces of different sizes can be positioned, supported and clamped by the device, the different sheet metal pieces are convenientlystamped, and the stamping precision of the sheet metal pieces is increased; according to the sheet metal stamping device, a stamping head is brushed by a first bristle brush wheel and a second bristle brush wheel, and brushed chippings are sucked by a hollow plate, so that the stamping head is kept clean, the rate of finished products of the sheet metal pieces is increased, and the surfaces of the sheet metal pieces are prevented from being scratched and damaged by the chippings.

Owner:范媛媛

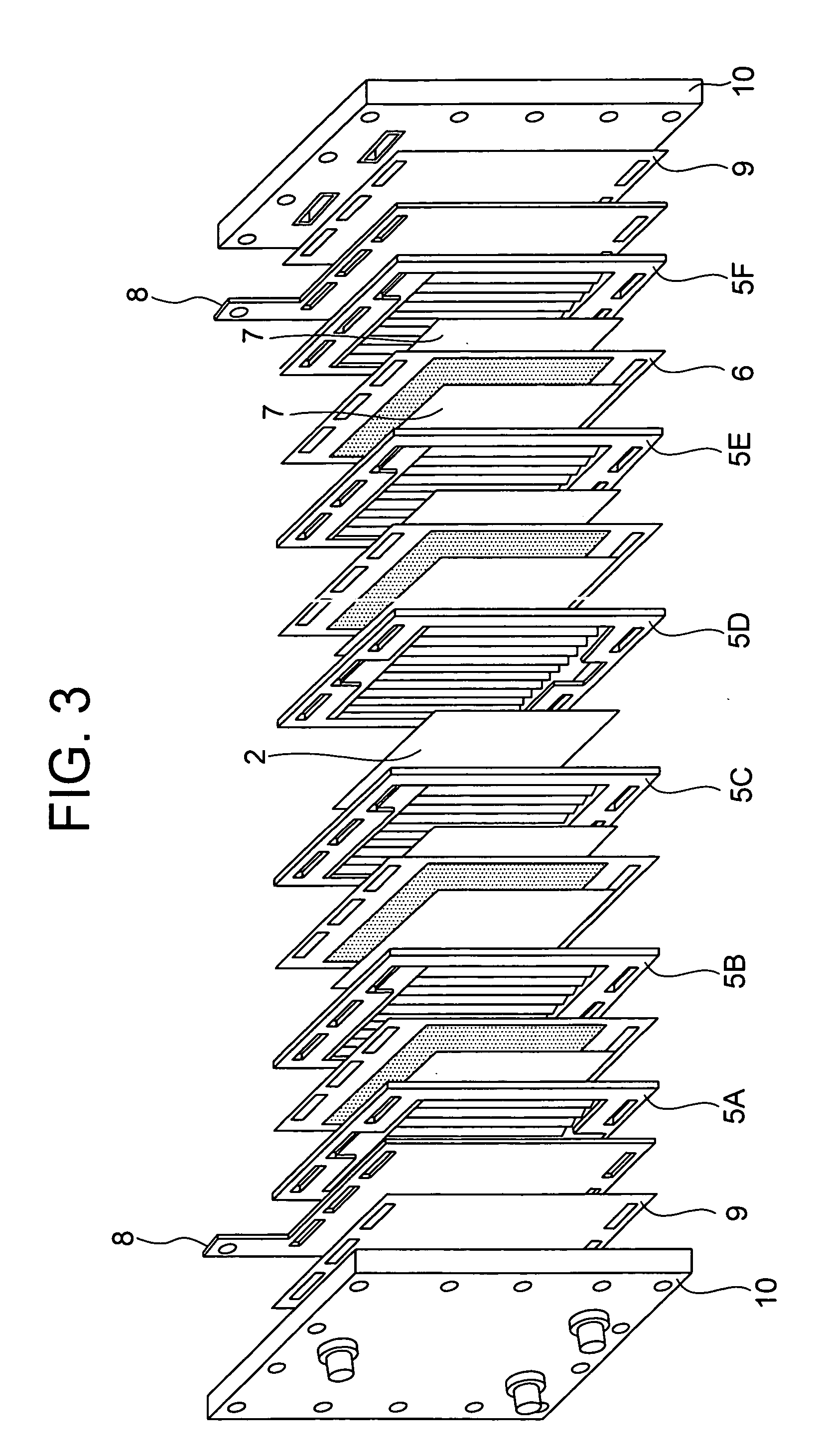

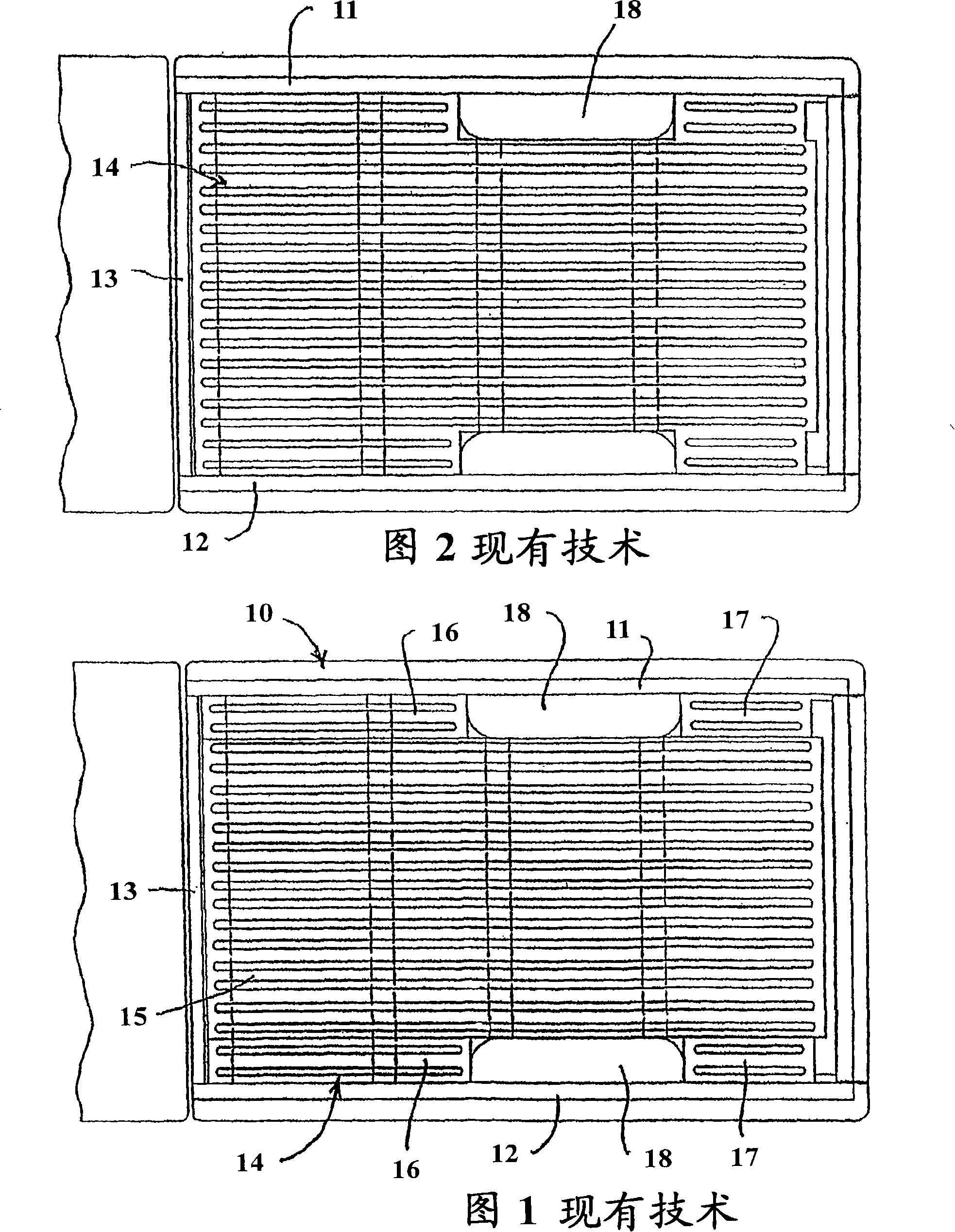

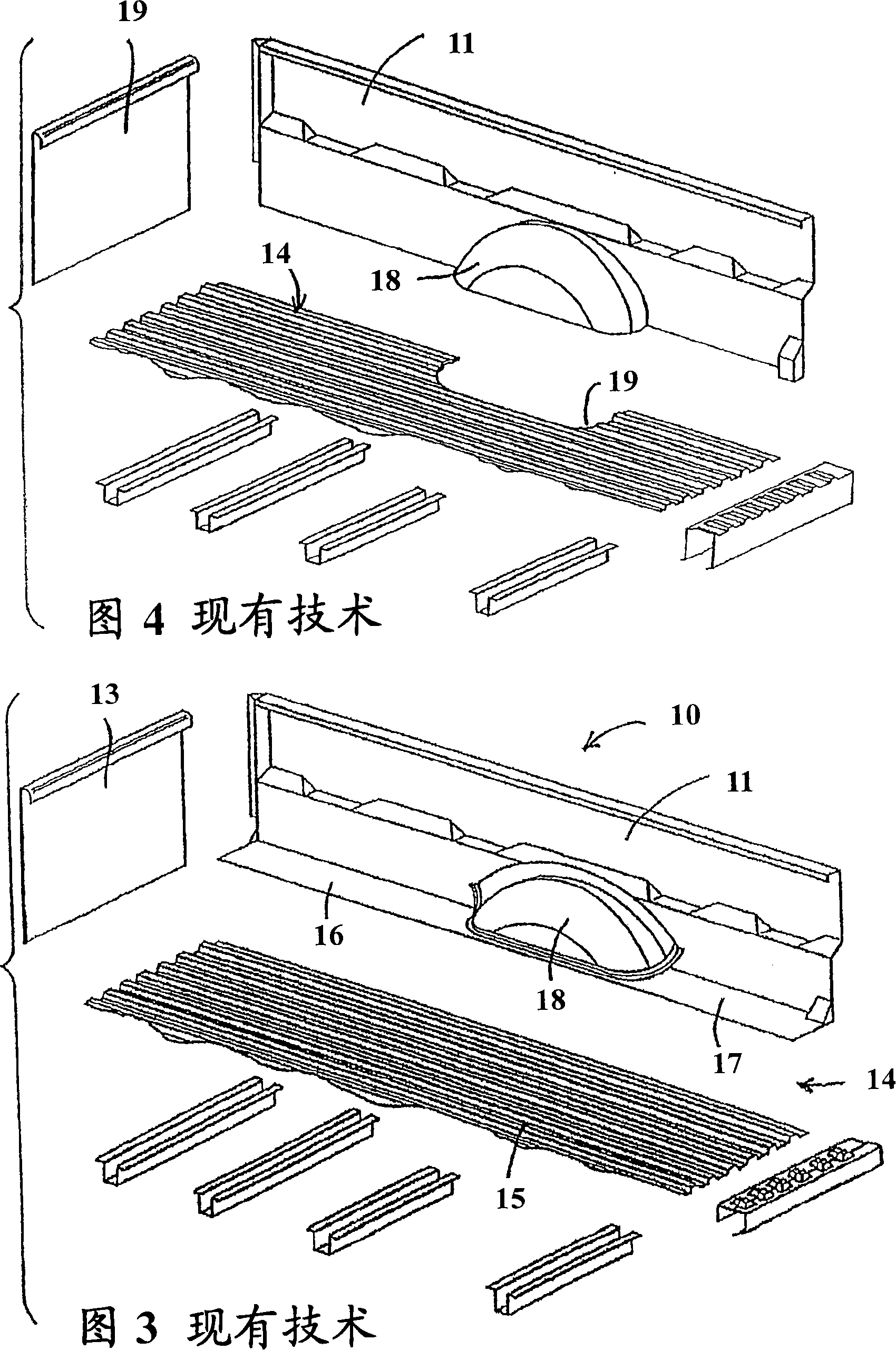

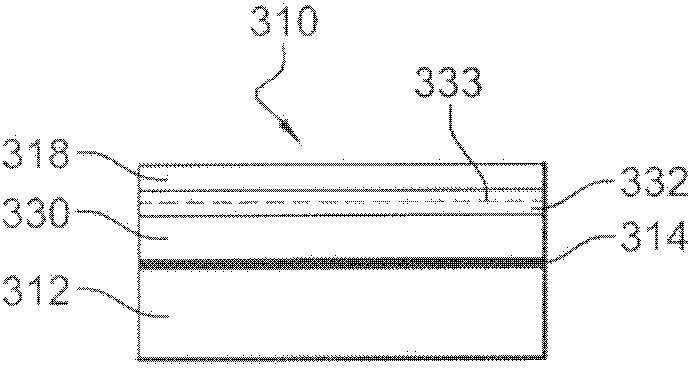

Fuel cell and separator for cooling used therein

InactiveUS20050106444A1Improve cooling effectReduce contact resistanceFuel cells groupingCell electrodesFuel cellsEngineering

It is an object of the present invention to reduce contact resistance of a fuel cell cooling section of stamped metal and thereby to improve output capacity of the fuel cell. The present invention provides a fuel cell having a stack structure of several unit cells, each containing electrolyte membrane electrodes, gas diffusion layer provided on each side of the electrode and metallic separator having corrugated passages and coming into contact with each gas diffusion layer, and a separator for cooling provided in the stack structure, wherein the separator for cooling is provided with an elastic and / or compressive and electroconductive intermediate sheet held between the passage planes, and a gasket in the portion other than the passage plane.

Owner:HITACHI LTD

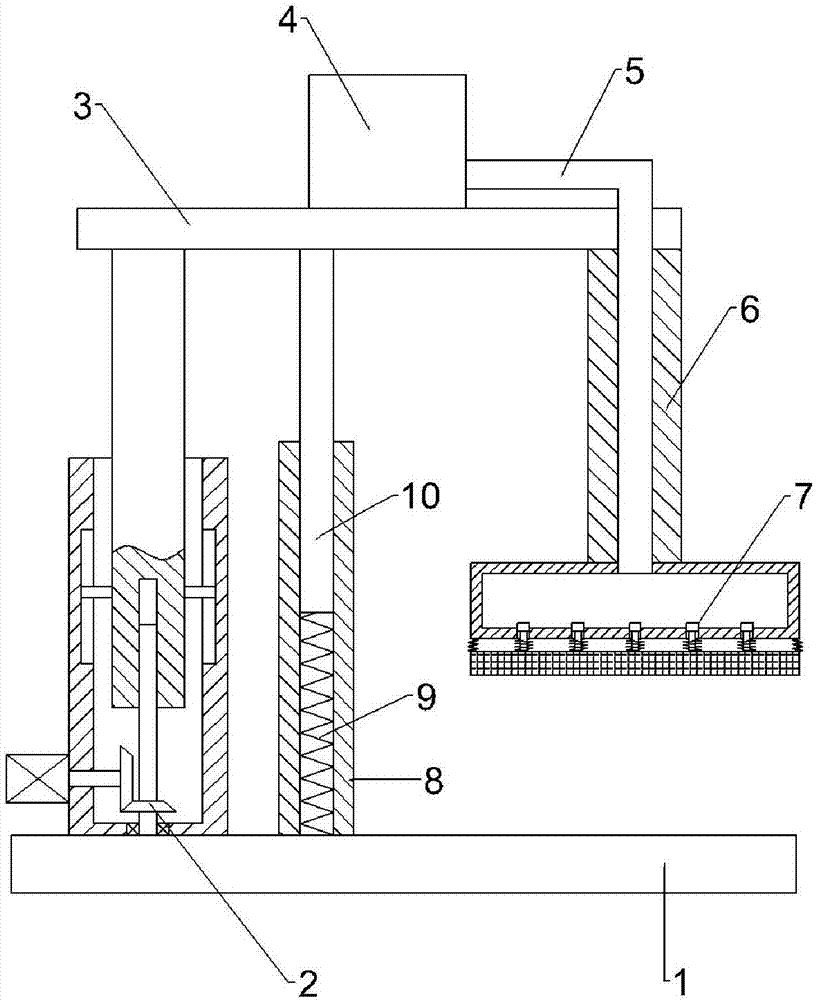

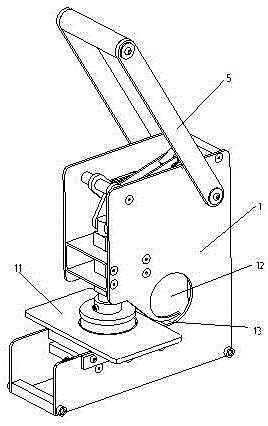

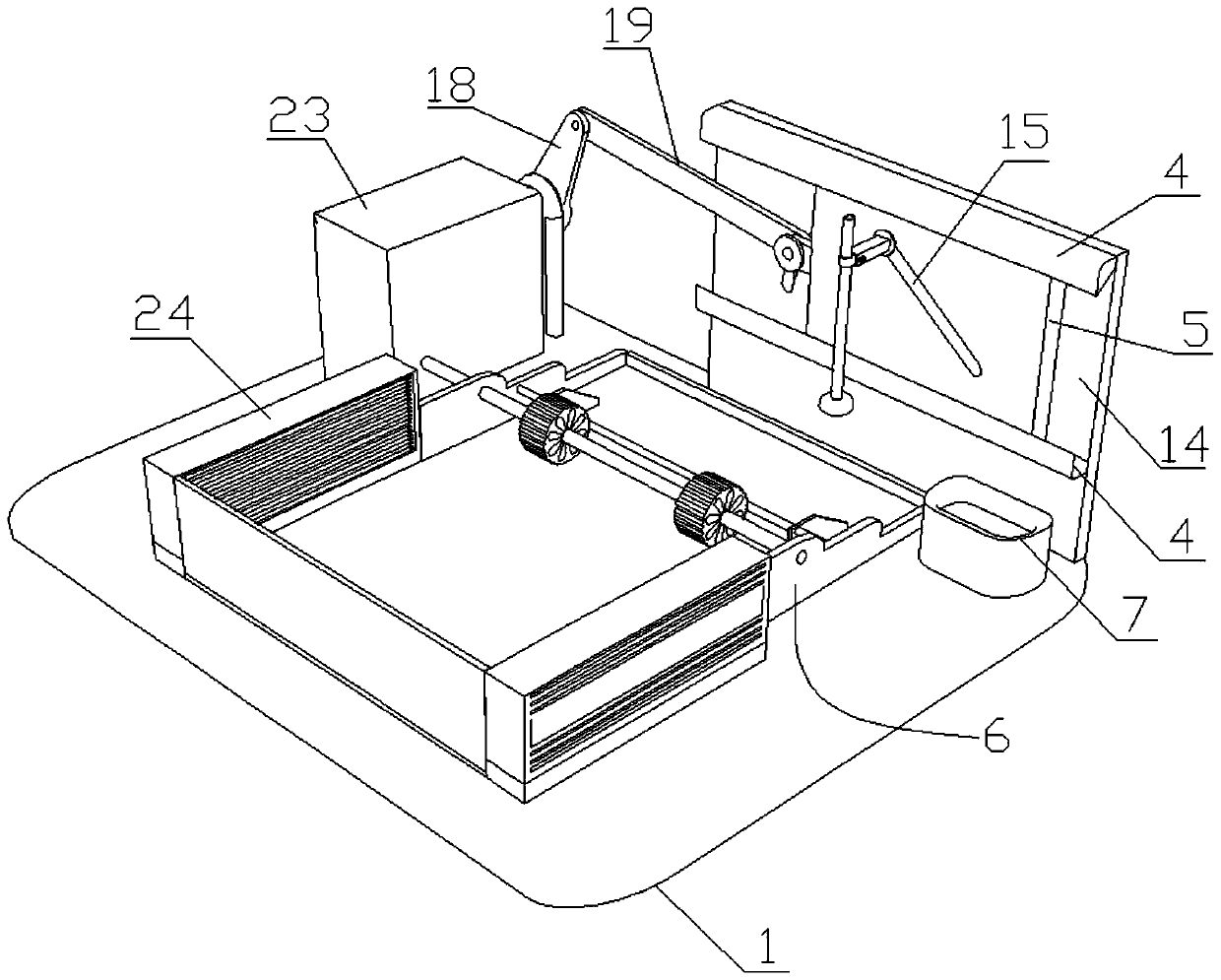

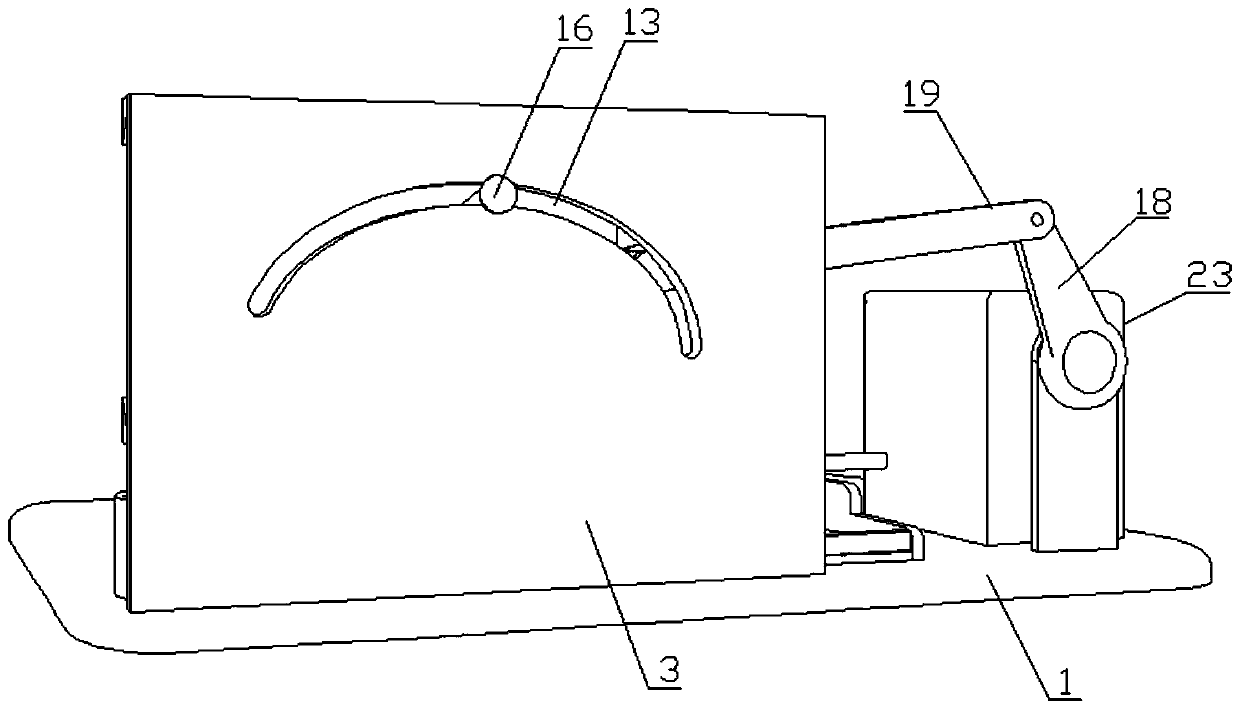

Automatic stamping machine facilitating inkpad adding

The invention relates to a stamping machine, in particular to an automatic stamping machine facilitating inkpad adding. The technical aim of the automatic stamping machine facilitating inkpad adding is that the contamination of a stamp with the inkpad can be facilitated, the stamping efficiency is ensured, people do not need to frequently take or place data files, it is ensured that the data filesare clean, and inkpad adding is facilitated. The automatic stamping machine facilitating inkpad adding includes a base, a bracket, a sliding block, an outer shell, a mounting plate, a first spring and the like; the bracket is mounted on the right side of the top of the base, the sliding block is arranged on the bracket in a sliding manner, the left end surface of the sliding block is connected with the outer shell, the mounting plate is slidably arranged in the outer shell, the mounting plate can be slide up and down in the outer shell, and the first spring is connected between the mounting plate and the outer shell. The data files can be quickly stamped through the function of the stamping mechanism, the left, right, front and back positions of the stamping mechanism can be adjusted before stamping, and all parts of the data files can be conveniently stamped.

Owner:中迪环境工程有限公司

Medium-strength and high-ductility titanium alloy

InactiveCN101476059AReduced cold workabilityImproved cold working propertiesForeign matterElectric arc furnace

The invention belonging to a low cost titanium alloy for sports products and other civil industries, relates to mezzo-forte high-ductility titanium alloy.The invention is characterized in that the components of the mezzo-forte high-ductility titanium alloy are aluminum of 2-4.5% by weight, molybdenum is 0.1-1.5% by weight, zirconium is 0.5-2% by weight, Fe is 0.1-1.5% by weight, and the rest is Ti and ineluctable foreign matters; the sum of each component content of the raw material is 100%. The manufacturing process comprises the following steps: batching according to a certain weight percentage, batch mixing and pressing to form consumable electrodes, performing a second smelting in the vacuum consumable arc furnace, and then making casting ingot into casting ingot boards.Because of the solution strength effect of aluminum, zirconium, molybdenum, vanadium, iron and the like, the titanium alloy of the invention can remain a definite strength level, the cost of the raw materials of the alloy can be reduced, cold working performance of the alloy is improved, the cold deformation amount is increased, the process flow is shortened, and correspondingly, the processing cost of the materials is reduced, processing performances of winding, bending, press forming and the like of the materials are improved, and shaping requirements of users can be further satisfied.

Owner:BAOJI TITANIUM IND CO LTD

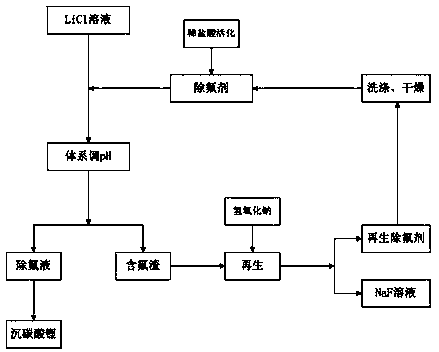

Method for deeply removing fluorine from LiCl solution recovered from waste batteries

InactiveCN111139367AEasy stampingSolve corrosiveWaste accumulators reclaimingProcess efficiency improvementLithium carbonateProcess engineering

The invention discloses a method for deeply removing fluorine from an LiCl solution recovered from waste batteries. According to the method, the LiCl solution is used as a raw material for preparing battery-grade lithium carbonate. The method comprises the following steps of A, preparing the raw material; B, activating a fluorine removal agent; C, adjusting a pH of the system; D, removing the fluorine from the LiCl solution; and E, regenerating the fluorine removal agent. According to the method, deep fluorine removal can be achieved through adding a small amount of the fluorine removal agentinto the LiCl solution, and then the LiCl solution is regenerated and reused through a sodium hydroxide solution. The method is good in fluorine removal effect, simple and rapid, and the fluorine removal agent can be regenerated and reused for multiple times, so that the production cost is greatly reduced; and meanwhile, the method has the advantages of short process flow, high fluorine removal efficiency, simplicity in operation, greenness, environmental friendliness and the like, and large-scale industrial production can be realized.

Owner:江西赣锋循环科技有限公司

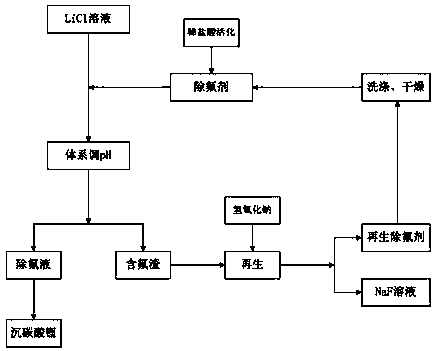

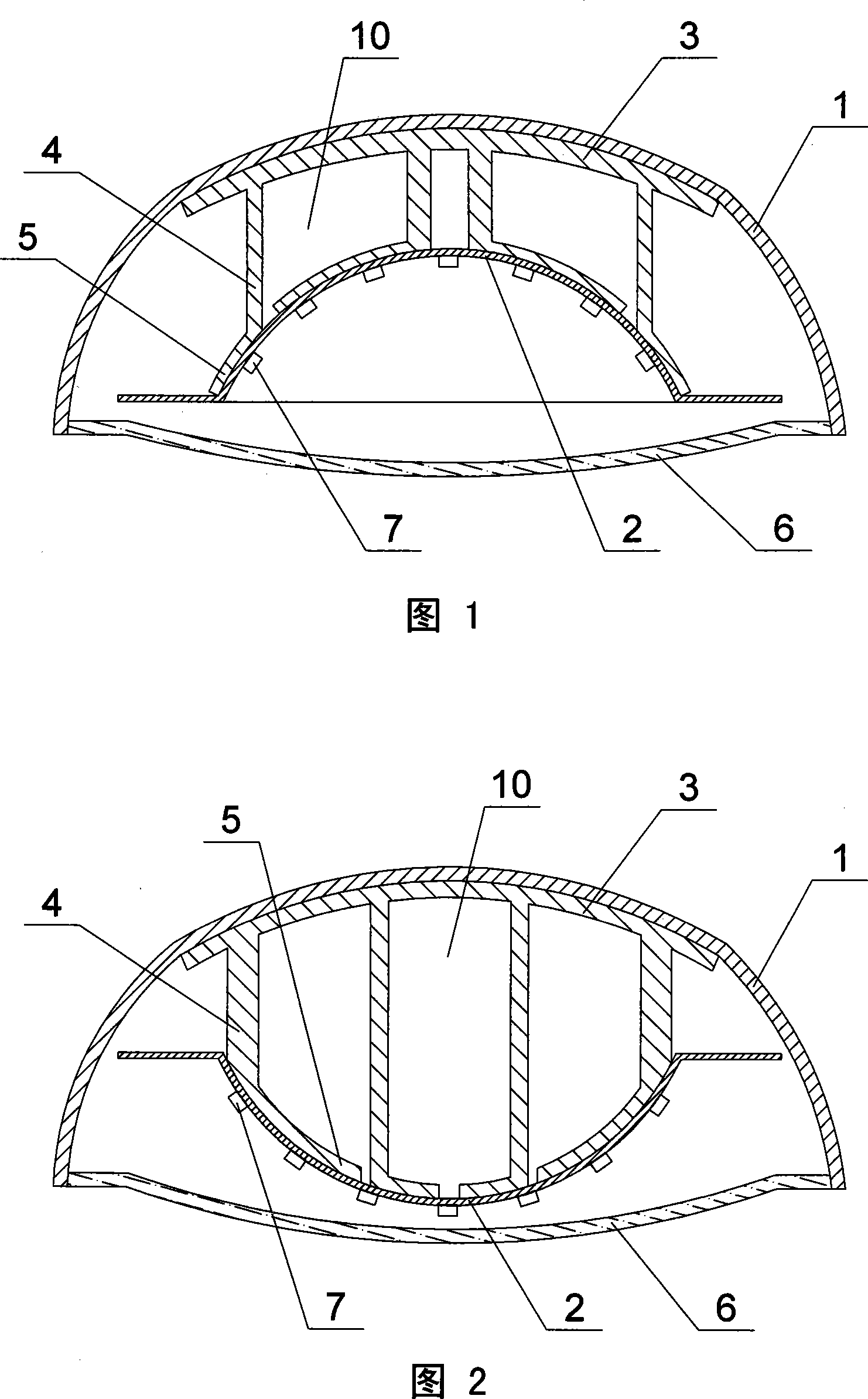

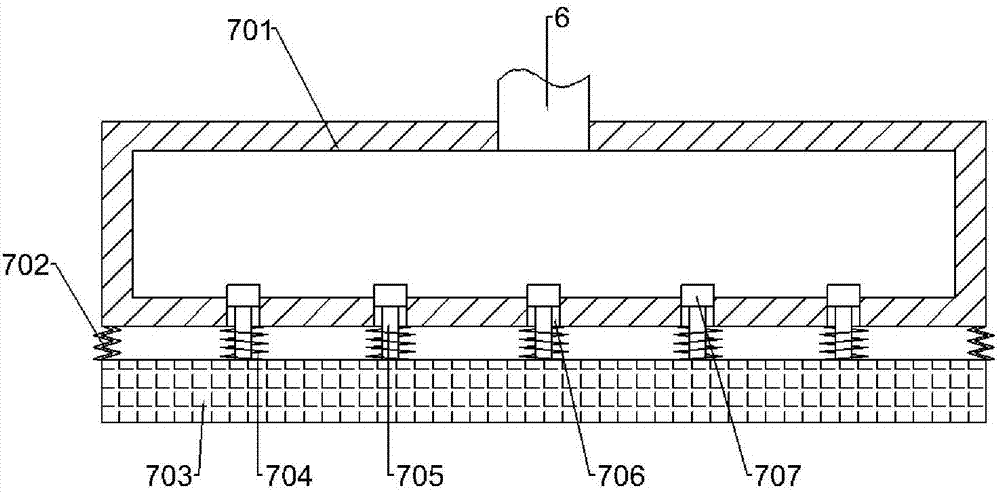

Integral heat dissipation LED road lamp

InactiveCN101144603AImprove overall lifespanImprove cooling effectPoint-like light sourceLighting heating/cooling arrangementsHeat conductingEngineering

The invention discloses an LED street lamp, with the purpose of providing an integrated heat radiating LED street lamp which has good heat radiation effect, and prolongs the service life effectively. The invention comprises a metal rear cover (1), a base plate (2), a non light tight front cover (6), and a plurality of LEDs (7), wherein, a plurality of LEDs (7) are installed in the base plate (2), and are arranged in the cavity surrounded by the rear cover (1) and the front cover (6) together with the base plate (2), a heat radiator is arranged between the base plate (2) and the rear cover (1), the heat radiator comprises a heat conducting back plate (3), a plurality of heat conducting ribs (4), wherein, the heat conducting back plate (3) and the inner surface of the rear cover (1) contact tightly and have adaptive shapes, and the upper part and the lower part of the heat conducting ribs (4) are respectively connected with the back plate (3) and the base plate (2). The invention can be widely applied to the outdoor illumination field.

Owner:珠海泰坦新能源系统有限公司

Two-piece side and floor panel arrangement for box assembly

InactiveCN101193789AEasy to manufactureReduce weightSuperstructure subunitsLoading-carrying vehicle superstructuresRear quarterEngineering

A vehicle box assembly (210) having a horizontal floor (211), and upright side panels (211) adjacent opposite side edges of the floor. The floor (211) and side panels (212) are defined by two similar L-shaped members each defining one of the side panels (212) and each defining a floor section (216) integrally and monolithically joined to the respective side panel (217) and extending generally perpendicularly therefrom. The floor sections (216) of the two panel members have lengthwise-extending edge flanges (224) which are joined together in the lengthwise extent of the floor. The panel members are preferably roll-formed so that the floor section has a transversely protruding reinforcing rib (221) extending lengthwise thereof, and the side panel has a channel-like edge rail extending lengthwise along the free edge thereof. The panel members each have a wheel well opening (228) formed therein. The panel members are transversely bent along a lengthwise region to define the L-shape.

Owner:PULLMAN IND

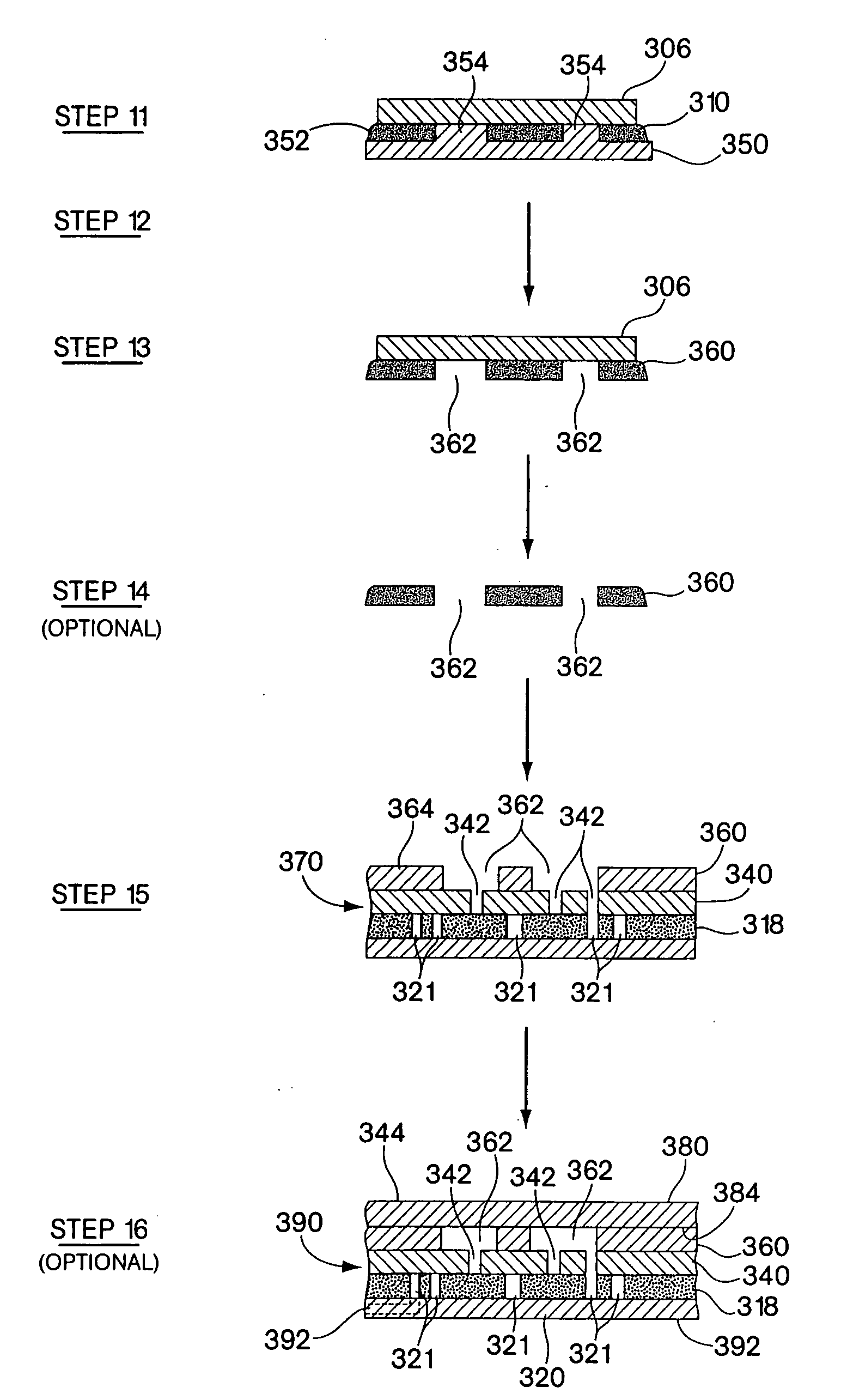

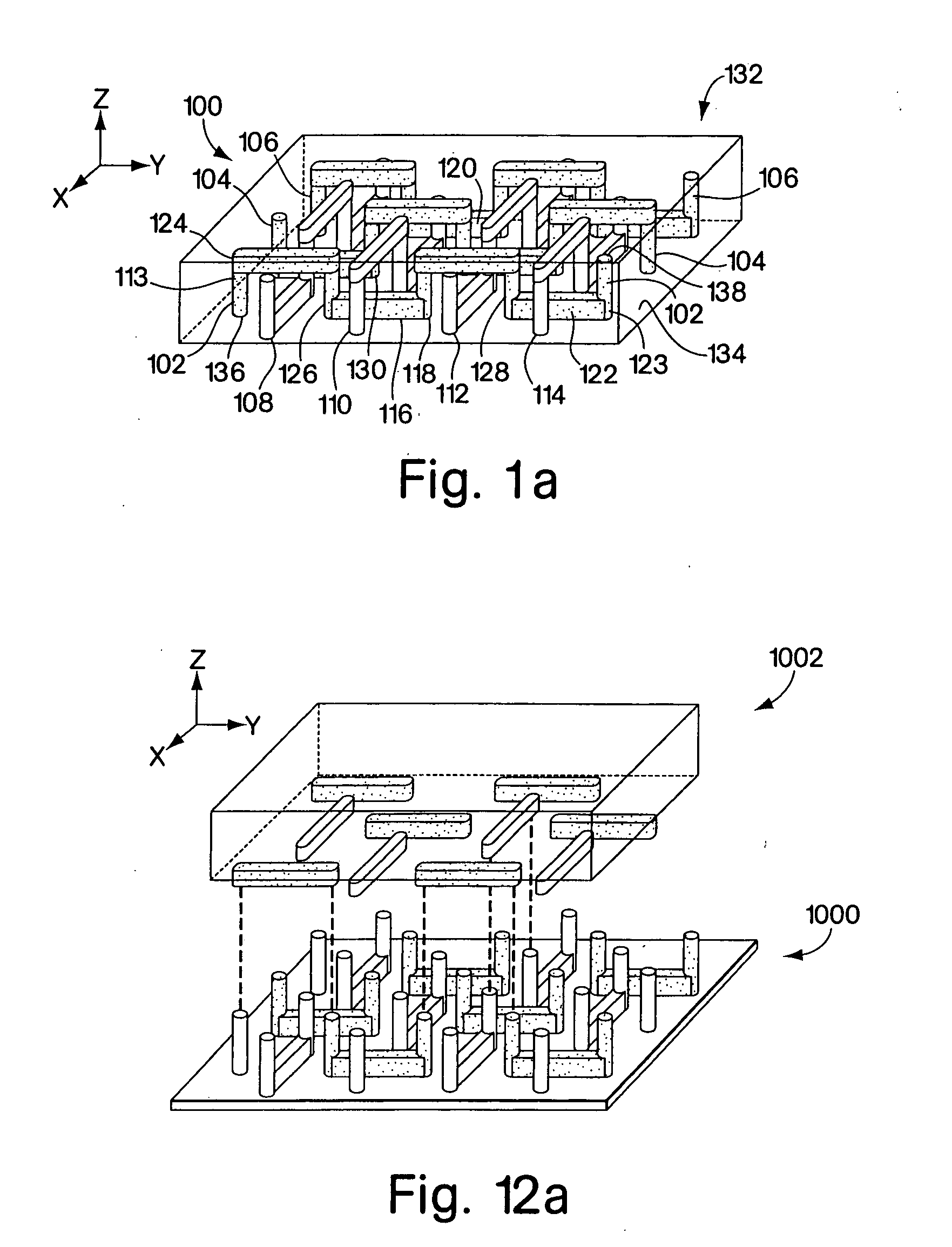

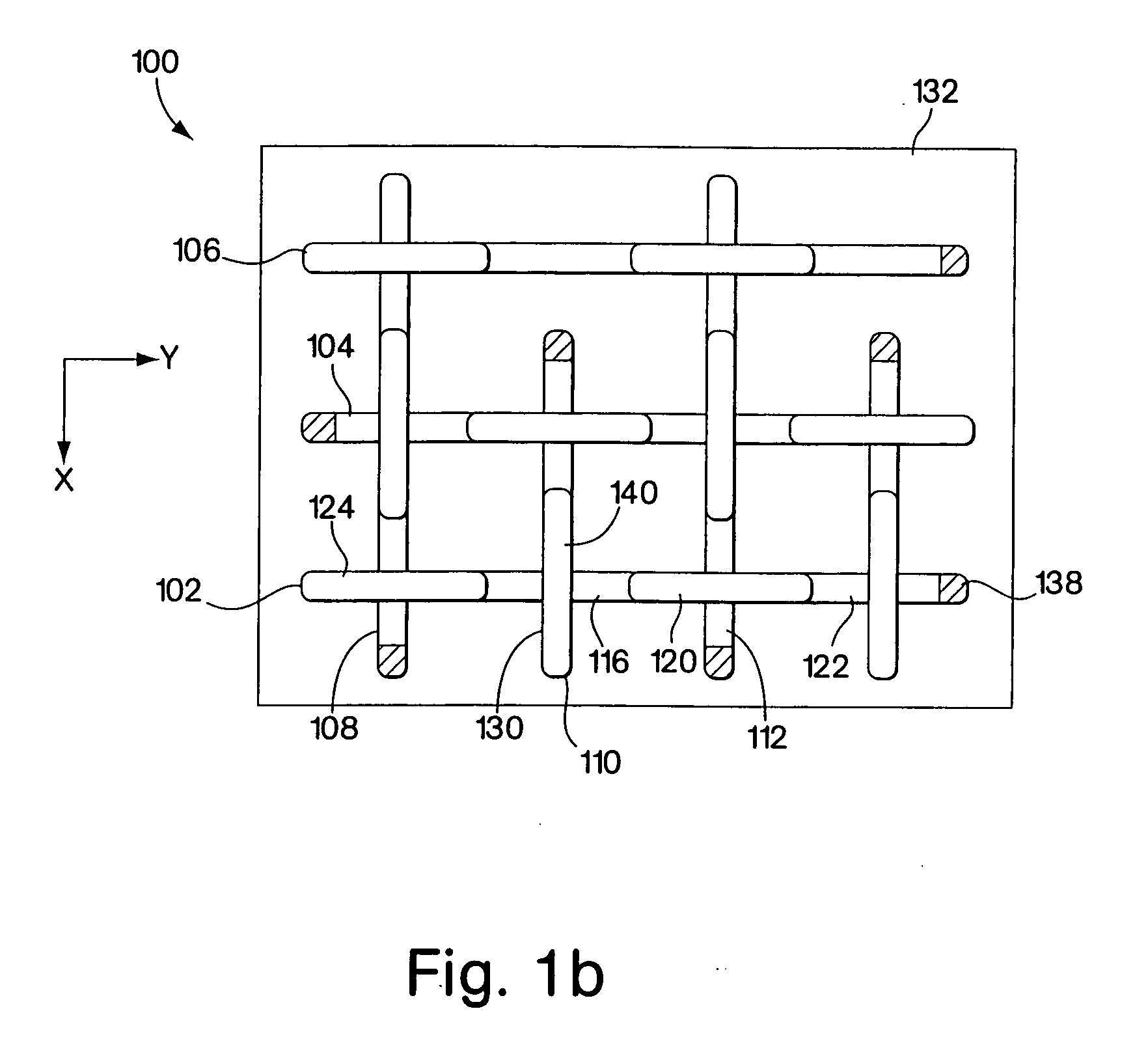

Microfluidic systems including three-dimensionally arrayed channel networks

InactiveUS20080124663A1Conveniently routedEasy stampingFixed microstructural devicesVolume/mass flow by thermal effectsChannel networkNetwork structure

The present invention provides, in certain embodiments, improved microfluidic systems and methods for fabricating improved microfluidic systems, which contain one or more levels of microfluidic channels. The inventive methods can provide a convenient route to topologically complex and improved microfluidic systems. The microfluidic systems provided according to the invention can include three-dimensionally arrayed networks of fluid flow paths therein including channels that cross over or under other channels of the network without physical intersection at the points of cross over. The microfluidic networks of the invention can be fabricated via replica molding processes, also provided by the invention, utilizing mold masters including surfaces having topological features formed by photolithography. The microfluidic networks of the invention are, in some cases, comprised of a single replica molded layer, and, in other cases, are comprised of two, three, or more replica molded layers that have been assembled to form the overall microfluidic network structure. The present invention also describes various novel applications for using the microfluidic network structures provided by the invention.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

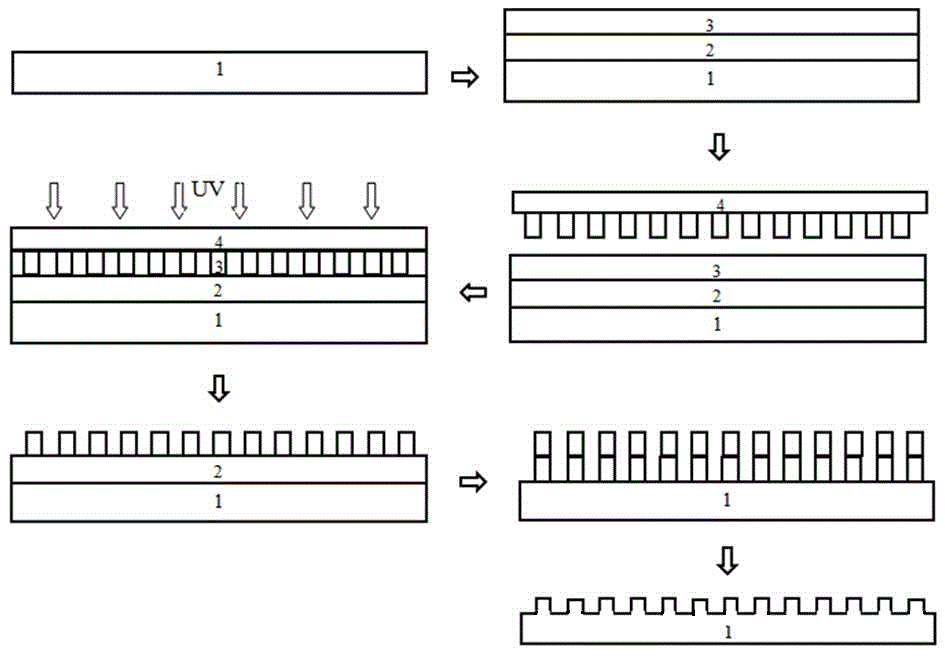

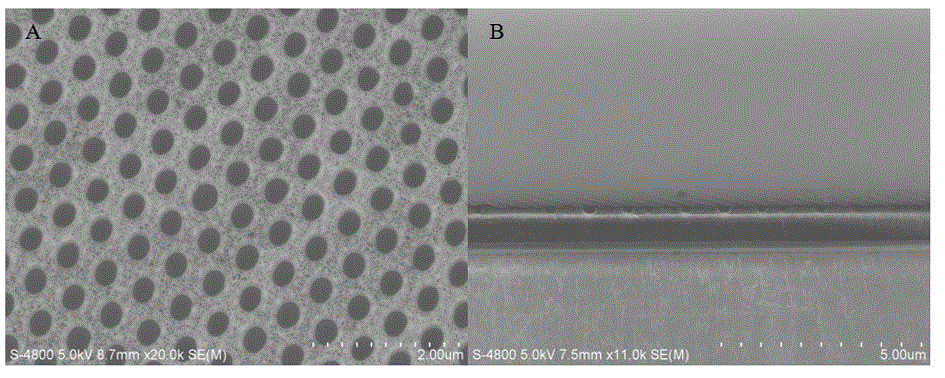

Preparation method of lubricating film

InactiveCN103984204ALow costHigh resolutionDecorative surface effectsPhotomechanical apparatusMicro nanoPhotoresist

The invention discloses a preparation method of a lubricating film. The preparation method comprises the steps of pretreating a film layer on the surface of a substrate; carrying out spin coating on a photoresist, heating, and then carrying out ultraviolet-curing to form a middle layer; forming an ultraviolet-cured nano embossing rubber layer; pressing a soft embossing template in the ultraviolet-cured nano embossing rubber layer, exposing under an ultraviolet lamp; etching to remove ultraviolet-cured nano embossing rubber left on an unexposed place, exposing the middle layer; etching the middle layer by taking the ultraviolet-cured nano embossing rubber layer as a mask layer, and exposing a thin film layer, etching the film layer by using the ultraviolet-cured nano embossing rubber layer and the middle layer as mask layers so as to form a micro-nano structure on the film layer; and removing the ultraviolet-cured nano embossing rubber layer and the middle layer to obtain the required lubricating thin film. According to the preparation method, by using a soft embossing and nano embossing compounding technology, the required pattern is effectively transferred on the film, and the lubricating film with the micro-nano structure can be prepared on an irregular non-plane. The preparation method has the characteristics of high efficiency, low cost and high resolution.

Owner:SUZHOU JINFU TECH

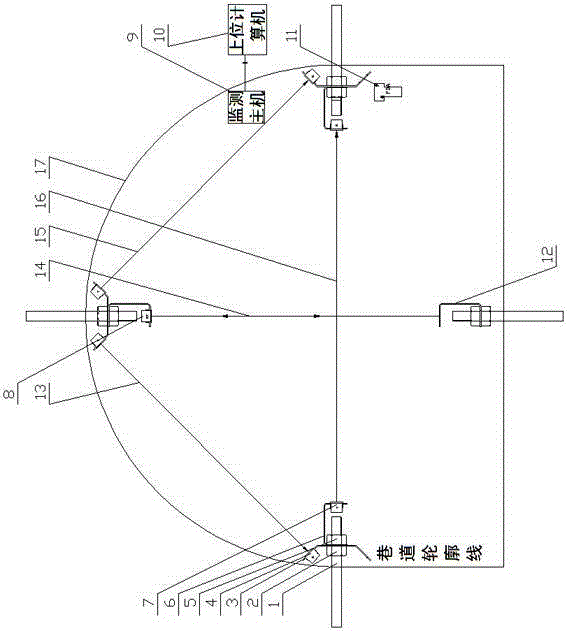

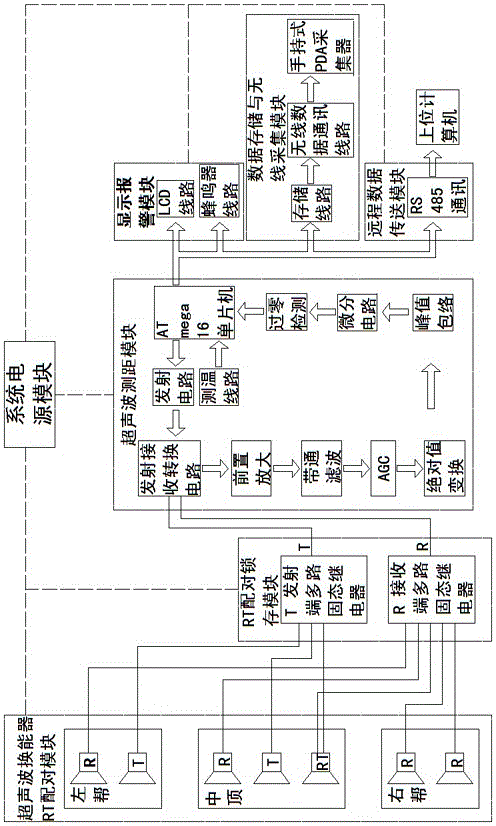

Ultrasonic multi-point roadway surface displacement monitoring device

InactiveCN105004291AFlexible settingsHigh sampling frequencyUsing subsonic/sonic/ultrasonic vibration meansAcoustic wave reradiationTransducerEngineering

The invention relates to an ultrasonic multi-point roadway surface displacement monitoring device, which comprises a split type receiving transducer R and a transmitting transducer T which are arranged at the left side of a roadway, two split type transmitting transducers T and a receiving and transmitting integrated transducer RT which are arranged at the middle top of the roadway, and two split type receiving transducers R which are arranged at the right side of the roadway, thereby forming an upper triangular left side measuring line, a center line top bottom measuring line, an upper triangular right side measuring line and an upper triangular horizontal measuring line. Each split type receiving / transmitting transducer or integrated transducer adopts a four-core cable to be laid to a monitoring host along the roadway, and the monitoring host is connected with a remote upper computer through an RS485 or a wireless Zigbee. An RT matching latch module, an ultrasonic ranging module, a display alarm module, a data storage and wireless acquisition module, a remote data transmission module and a power supply module which are connected with the ultrasonic receiving / transmitting transducers are arranged inside the monitoring host. The ultrasonic multi-point roadway surface displacement monitoring device utilizes the ultrasonic ranging principle, and is stable in monitoring.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

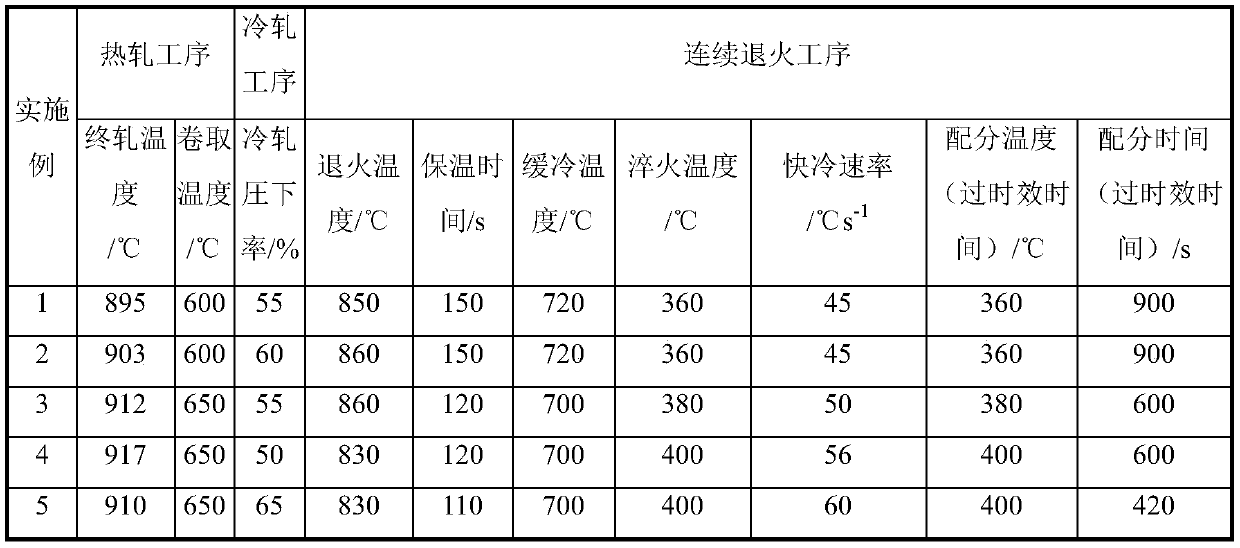

800 MPa grade high-strength plastic product Q&P steel plate and preparation method thereof

ActiveCN110129673AEasy to implementEasy to controlProcess efficiency improvementProduction lineCold formed

The invention discloses a 800 MPa grade high-strength plastic product Q&P steel plate and a preparation method thereof, and belongs to the technical field of cold-rolled automobile steel production. The steel plate comprises the following chemical components of, in percentage by weight, 0.38%-0.42% of C, 0.10%-0.30% of Si, 0.80%-1.20% of Mn, 2.80%-3.20% of Al, less than or equal to 0.020% of P, less than or equal to 0.0030% of S, less than or equal to 0.0060% of N, the balance Fe and inevitable impurity elements. The preparation method comprises the following steps of smelting; continuous casting; hot rolling; acid pickling; cold rolling; and continuous annealing, specifically, heating a cold-rolled plate to 830-860 DEG C during continuous annealing, then slowly cooling to 700-730 DEG C, finally, rapid cooling cold-rolled plate to 350-400 DEG C at 40-60 DEG C per second cooling rate to carry out overaging distribution treatment. The Q&P steel plate has advantages that the mechanical property is excellent, the yield strength is larger than or equal to 480 MPa, the tensile strength is larger than or equal to 800 MPa, the elongation percentage is greater than or equal to 25%, the n isgreater than or equal to 0.20, the yield ratio is less than or equal to 0.75, and the cold forming property is good. The Q&P steel plate and the preparation method have low requirements on process equipment, and are suitable for production of an existing continuous annealing production line.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

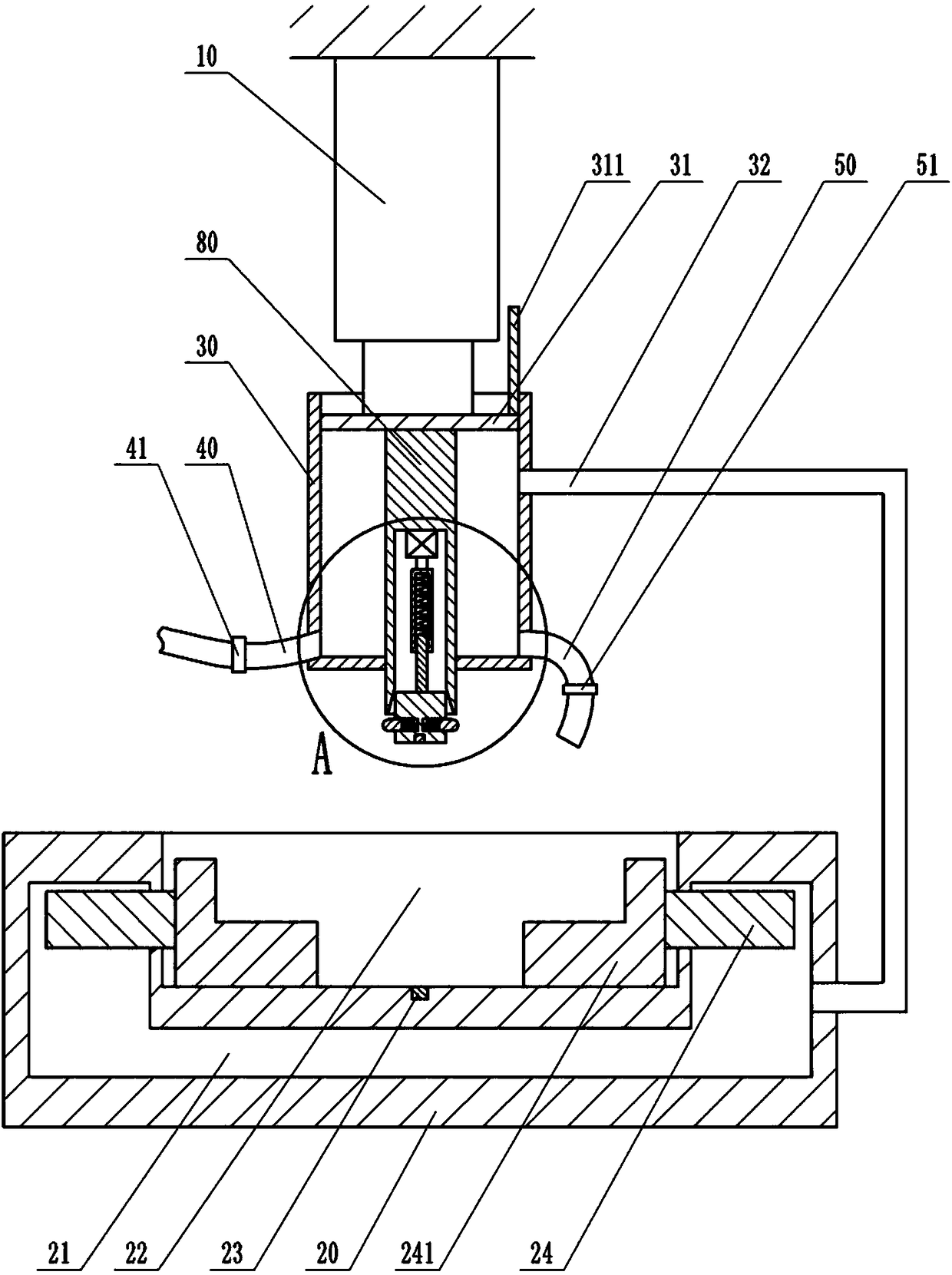

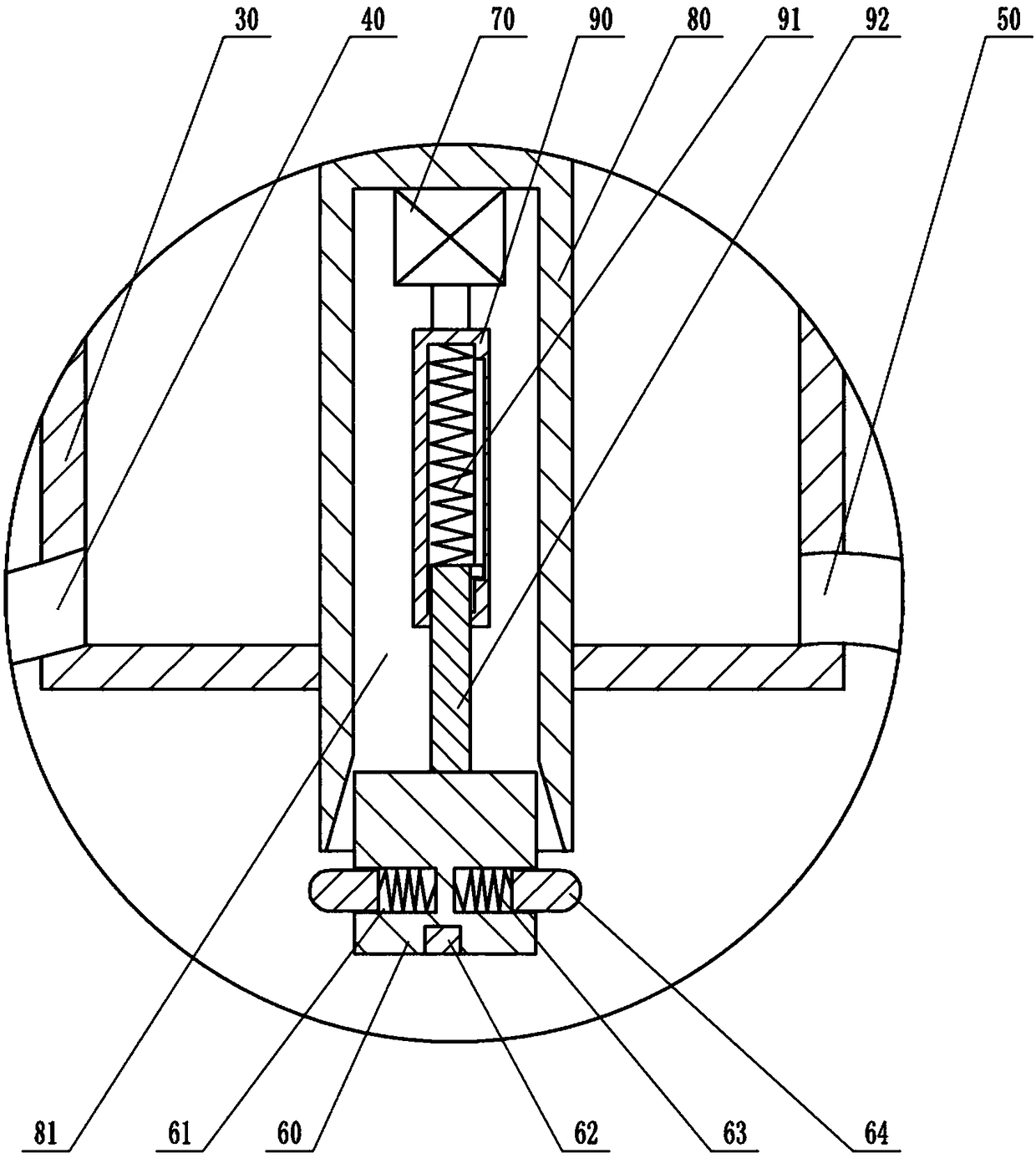

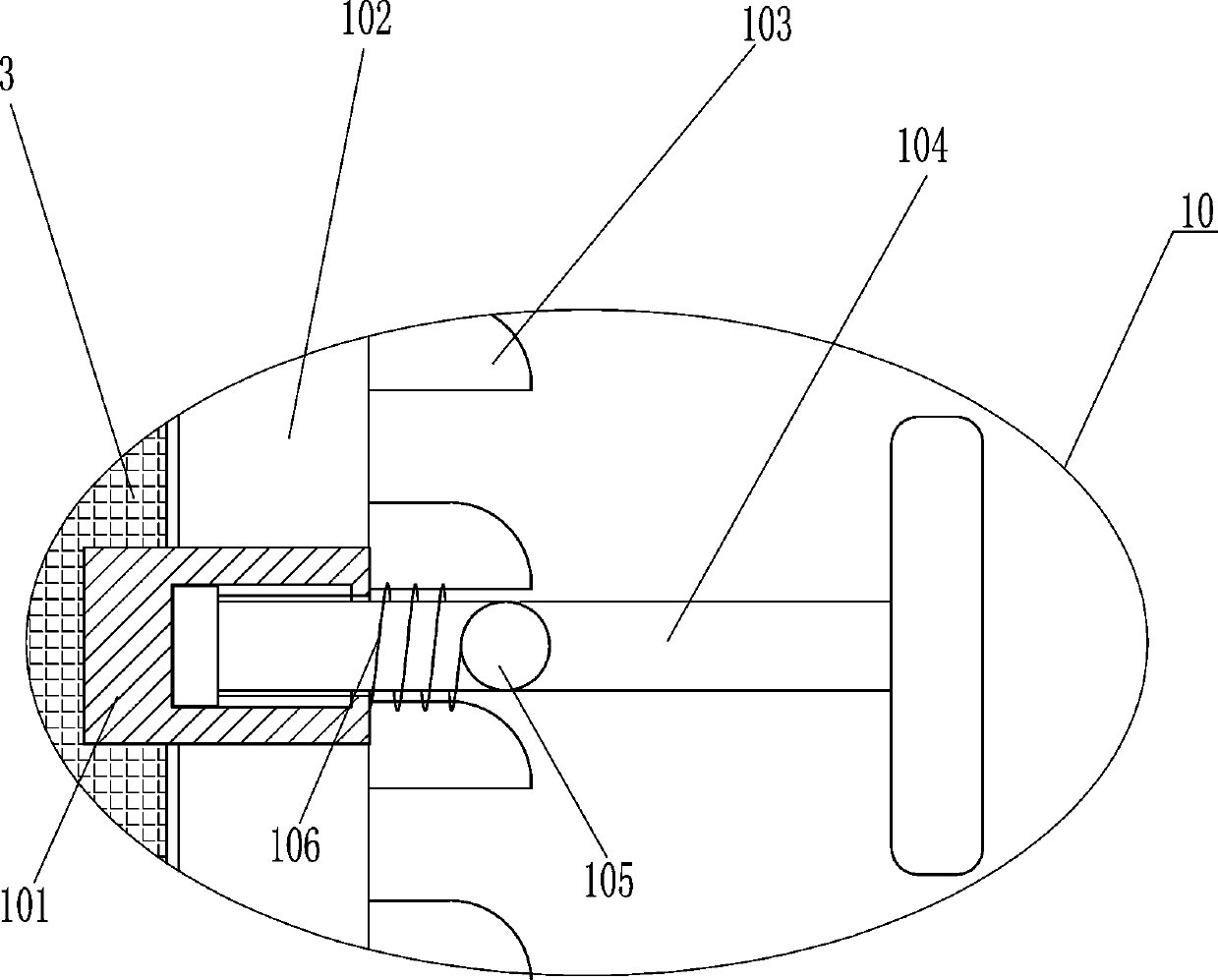

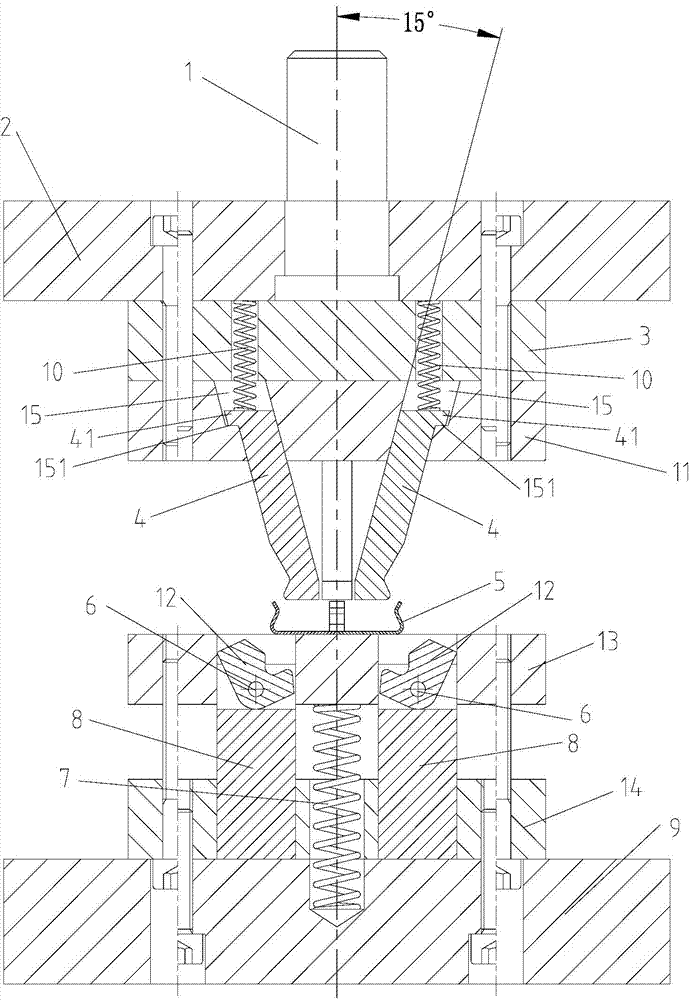

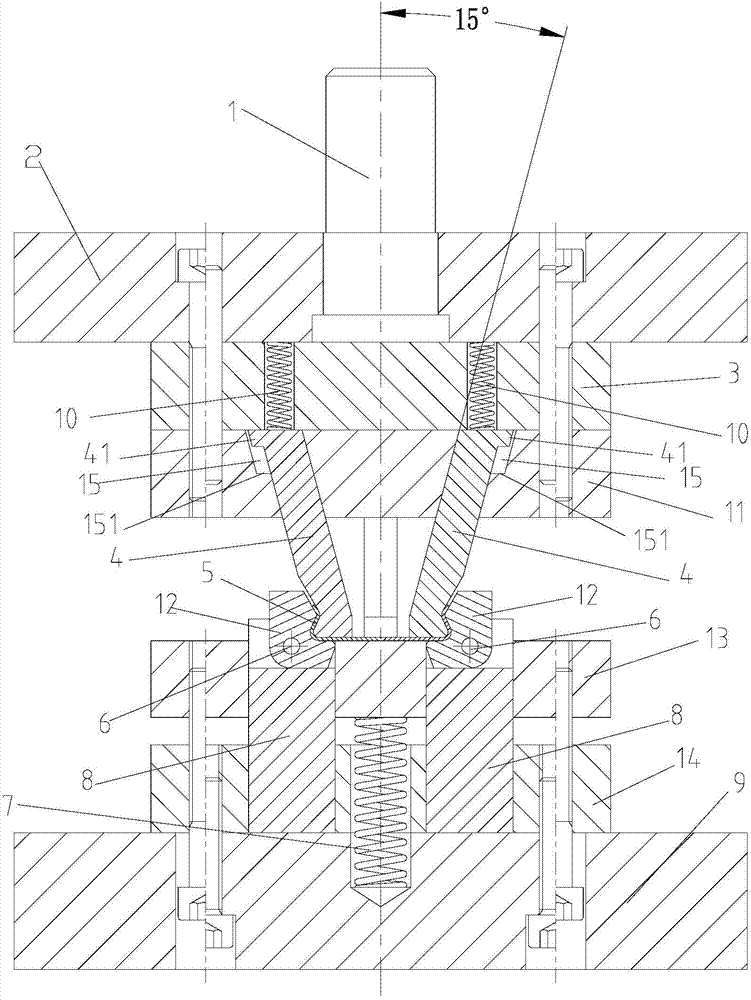

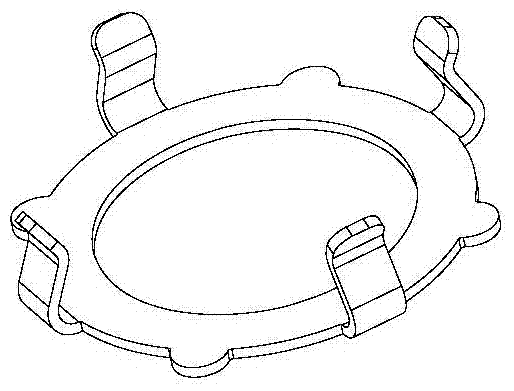

Stamping die used for stamping inverted-pothook-shaped structure

ActiveCN103611816AReduce molding processSmooth movementShaping toolsEjection devicesEngineeringMechanical engineering

The invention discloses a stamping die used for stamping an inverted-pothook-shaped structure. The stamping die comprises an upper die and a lower die; the lower die comprises a bottom board and a support fixing board arranged on the bottom board, and the support fixing board is fixedly provided with a support; the support is further provided with a swing block which is movably connected to the support. The swing block is provided with a formed surface matched with the inverted-pothook-shaped structure of a stamped part. An upper die guide board is provided with a set of inclined top blocks which can move vertically, and a formed surface which is matched with the swing blocks to form the inverted-pothook-shaped structure is arranged below the inclined top blocks. The lower die is further provided with a blank locating board which is arranged on the support in a sleeved mode, an elastic part is arranged between the blank locating board and the support fixing board, and the elastic part can be elastic rubber or a spring. According to the stamping die, the inverted-pothook-shaped structure can be formed at a time, the number of stamping procedures of the inverted-pothook-shaped structure is reduced, and production cost is lowered. The stamping die can be widely applied to the stamping field of the inverted-pothook-shaped structure.

Owner:HUANGSHAN AOTESI ELECTRICAL CO LTD

Office stamping equipment with uniform printing ink distribution function

InactiveCN108001056ARealize stamping workTo achieve the purpose of stampingStampingArchitectural engineeringPrinting ink

The invention provides office stamping equipment with a uniform printing ink distribution function. The office stamping equipment with the uniform printing ink distribution function comprises a bottomplate. A lifting device is fixedly connected to the left portion of the upper side of the bottom plate. The lifting device comprises a support column. The bottom end of the support column is fixedlyconnected with the upper side of the bottom plate. A groove with an upward opening is formed in the support column. A threaded rod is arranged in the groove. The bottom end of the threaded rod is rotationally connected with the bottom of the support column. A driven bevel gear is fixedly connected to the lower portion of the threaded rod. The left side of the driven bevel gear is engaged with a driving bevel gear. A rotary shaft is fixedly connected to the left end of the driving bevel gear. The left end of the rotary shaft penetrates the support column. The left end of the rotary shaft is fixedly connected with an output shaft of a motor. A lifting column is arranged in the portion, above the threaded rod, of the groove. A threaded groove with a downward opening is formed in the lower portion of the lifting column. The top of the threaded rod is in threaded connection with the threaded groove. The top end of the threaded rod is fixedly connected with a mounting plate. The office stamping equipment has the beneficial effects of being reasonable in structural design, convenient to stamp and the like and has a certain application and popularization value.

Owner:苏州汇恒网络科技有限公司

Steel printing machine

The invention discloses a steel printing machine which comprises a base, a supporting table installed on the base, an acting shaft which is assembled on the base in a sliding manner and can move vertically on the base, a printing die comprising an upper printing die body and a lower printing die body, and a driving mechanism. The upper printing die body is connected to the lower end of the acting shaft, and the lower printing die body is installed on the supporting table. The driving mechanism is movably connected with the acting shaft so that when the driving mechanism acts, the acting shaft moves vertically on the base, and therefore the upper printing die body is driven to move in the direction away from the lower printing die body or in the direction towards the lower printing die body, and impressing of paper between the upper printing die body and the lower printing die body is achieved. The steel printing machine can be used for well impressing the paper, in addition, labor is saved, the steel printing writing effect is good, and stress is even.

Owner:张锁柱

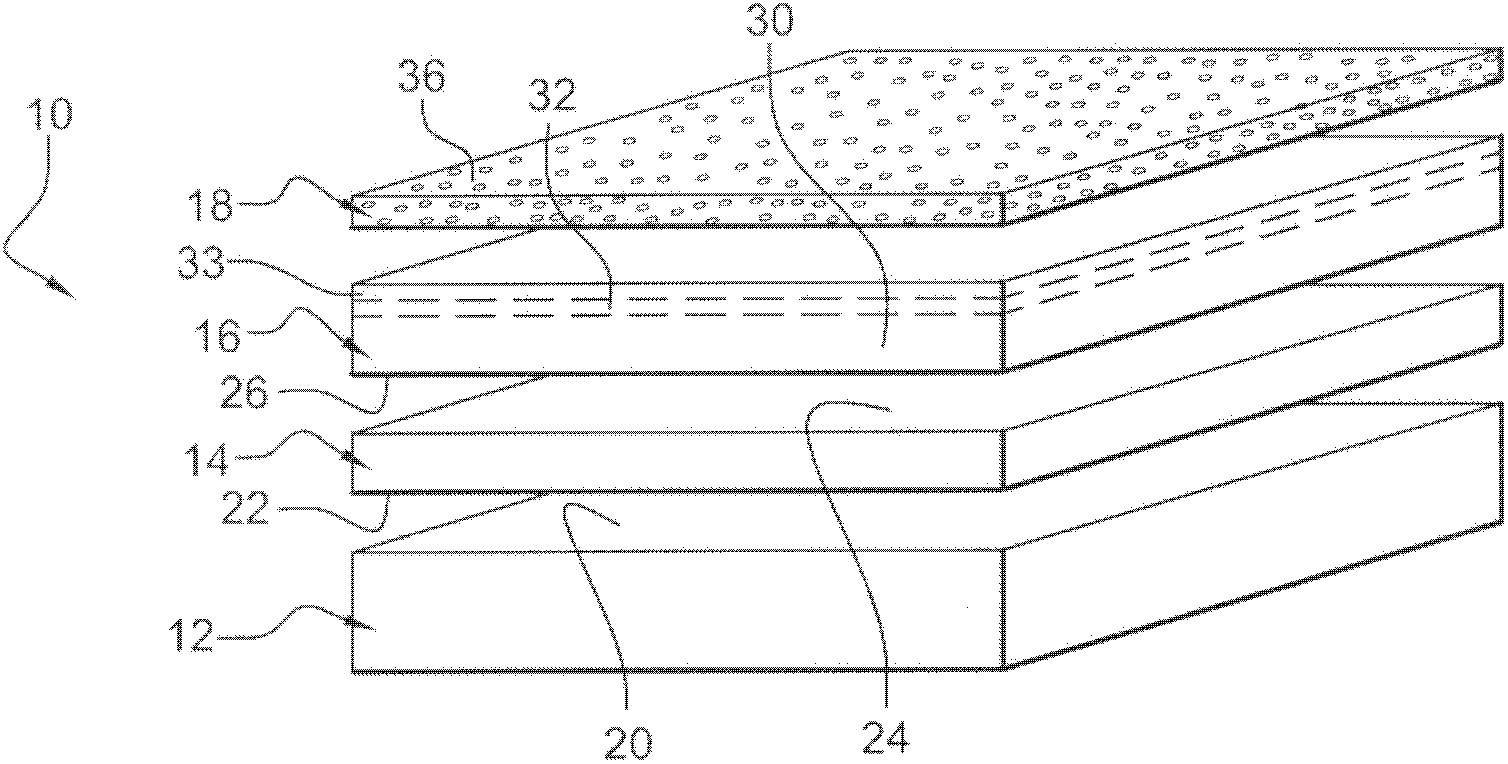

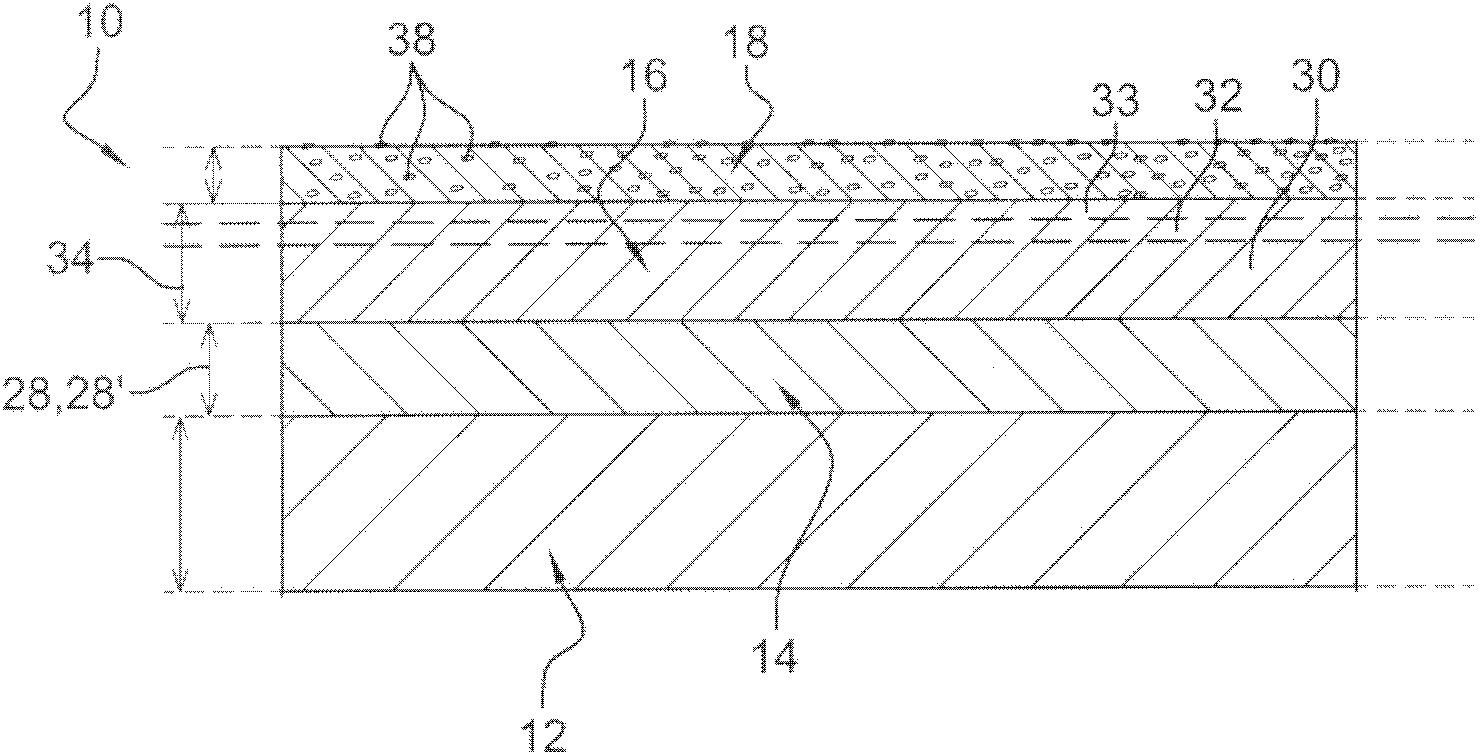

Multilayer printable sheet with a soft or silky touch and manufacturing method thereof

InactiveCN102405135AImprove scratch resistanceConvenient coatingSignboardsFlexible coversVarnishMaterials science

The invention relates to a multilayer printable sheet (10), including a bottom support layer (12), an intermediate metal layer (14) and a top layer (16) made of transparent or translucent plastic material, a top surface of said layer of plastic material being covered with a coating layer (18) made of a transparent or translucent matte varnish with a soft or silky touch.

Owner:ARJO WIGGINS FINE PAPERS LTD

Edible Utensil and Method of Producing The Same

InactiveUS20140272010A1Easy and economical to manufactureEliminate wasteDough treatmentFrozen sweetsFood science

Owner:DELAPRYM LAURIE L

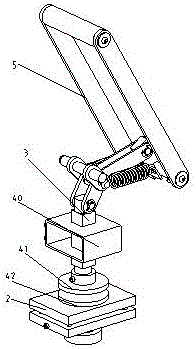

Novel stamping robot

InactiveCN106311922AImprove securitySmall moment of inertiaMetal-working feeding devicesShaping safety devicesMaterial consumptionInertia

The invention discloses a novel stamping robot and relates to the field of automatic machines. The novel stamping robot comprises a robot body and an arm body above the robot body. The robot body is provided with a controller. A lifting mechanism is arranged on one side of the robot body. The lifting mechanism is fixed to the rear side wall of the robot body. A rotating mechanism is arranged on the lifting mechanism. A front-back telescopic mechanism is arranged above the rotating mechanism and is provided with a workpiece correcting mechanism. A suction cup is arranged below the workpiece correcting mechanism. The robot is suitable for stamping equipment, safety can be improved, in addition, the rotation angle can reach 360 degrees, and therefore stamping is more convenient. The robot is mainly composed of the rotating mechanism, the lifting mechanism, the front-back telescopic mechanism and the workpiece correcting mechanism; the rotating inertia of the robot during rotation is small, so that the requirement for the equipment strength of the robot is greatly lowered, material consumption is less, stability is higher, the requirement for the rated power of a motor is lowered, and energy can be effectively saved.

Owner:佛山市顺德区天本模具制造有限公司

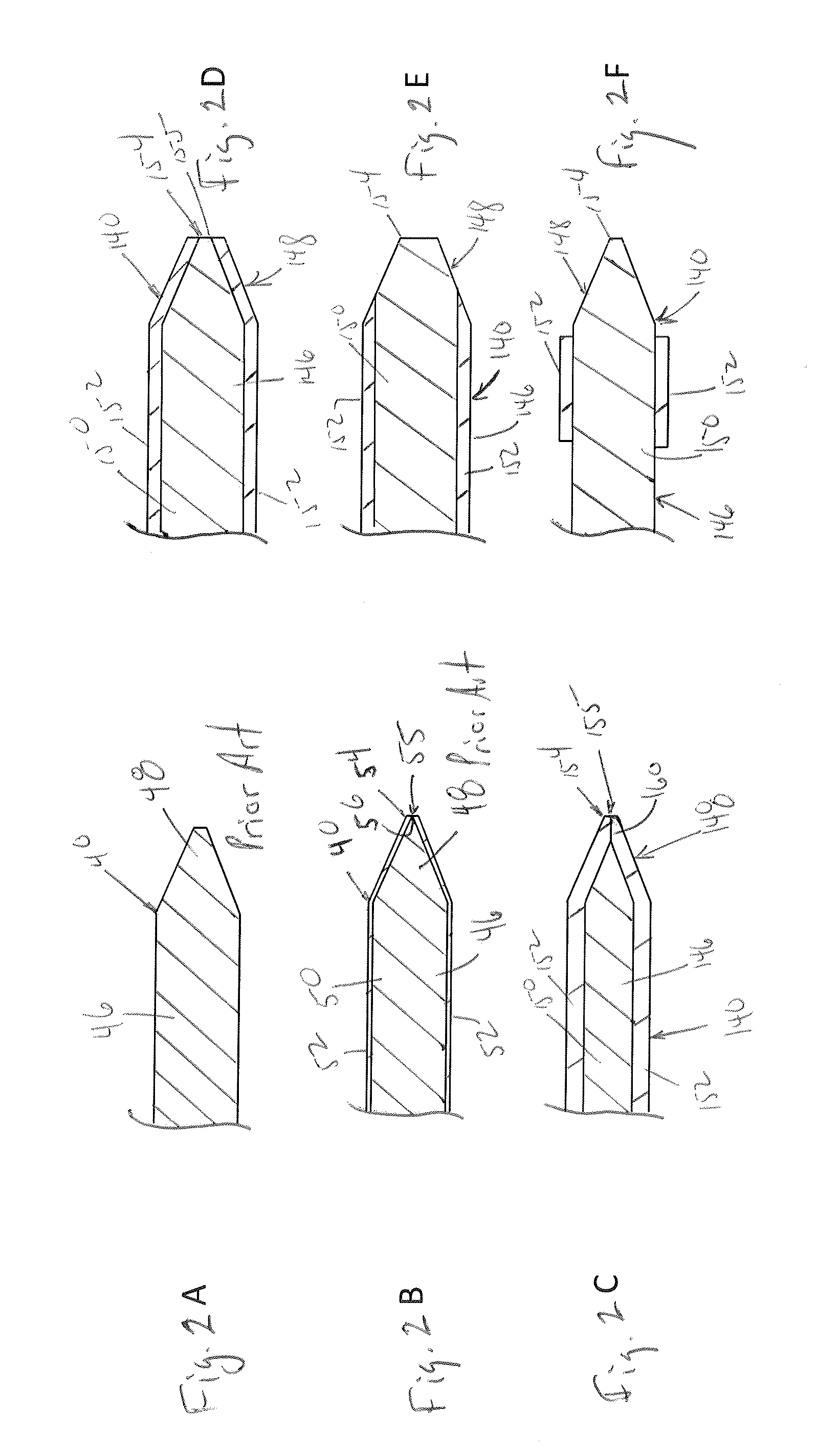

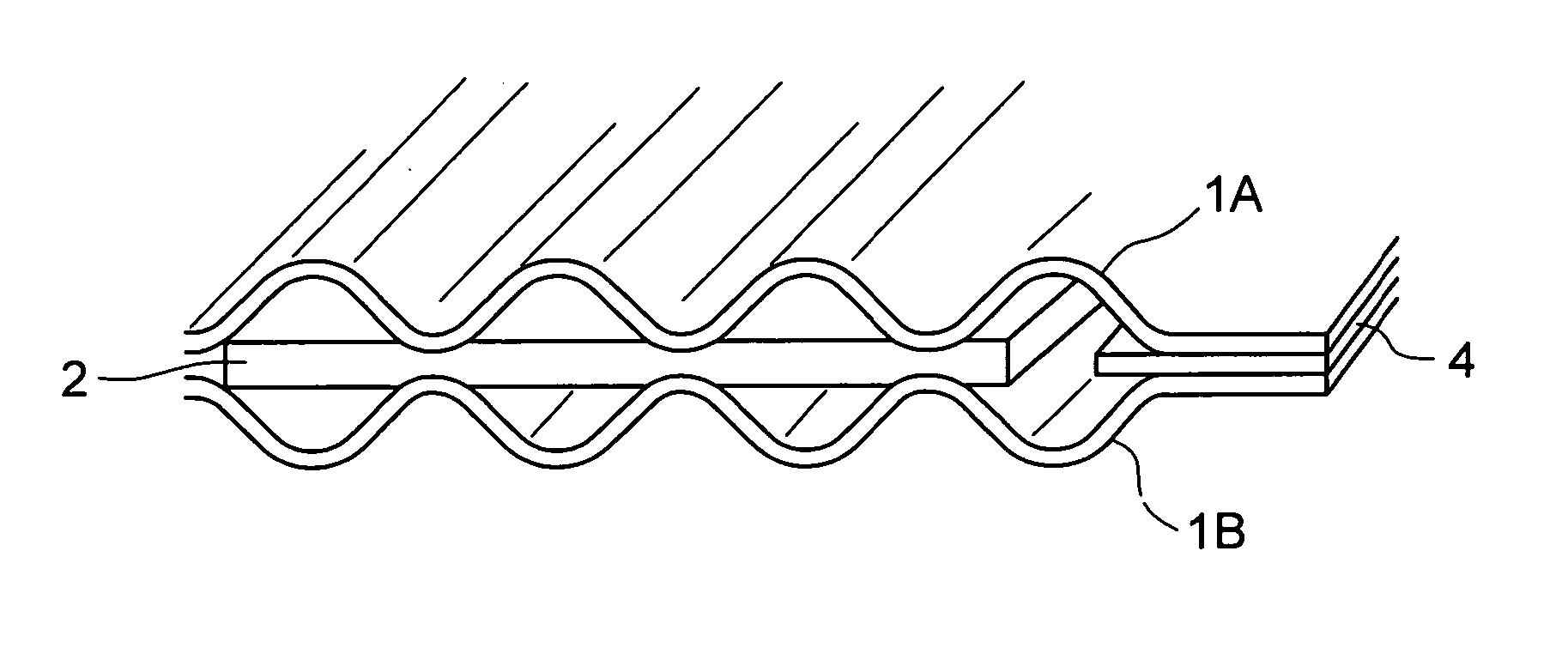

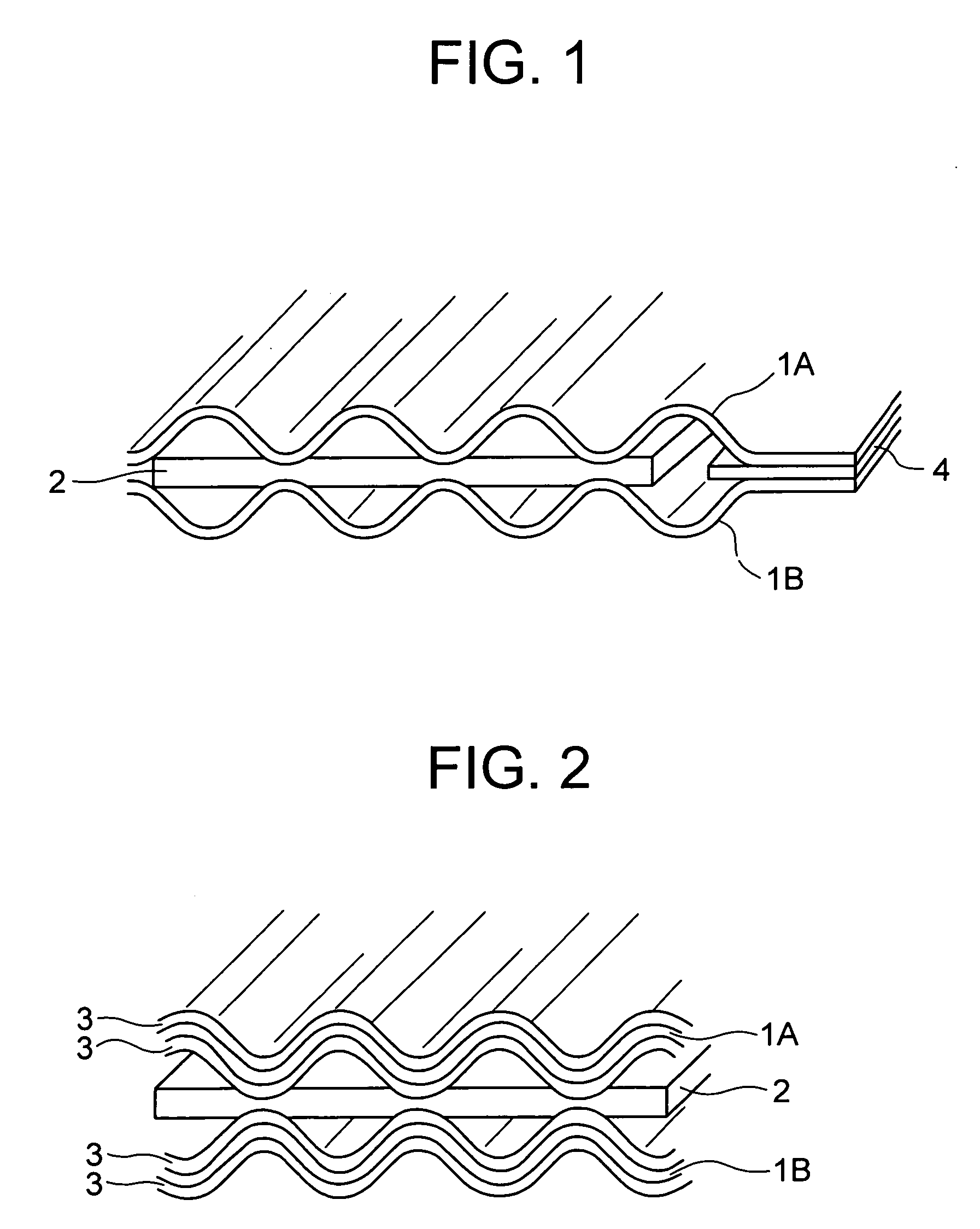

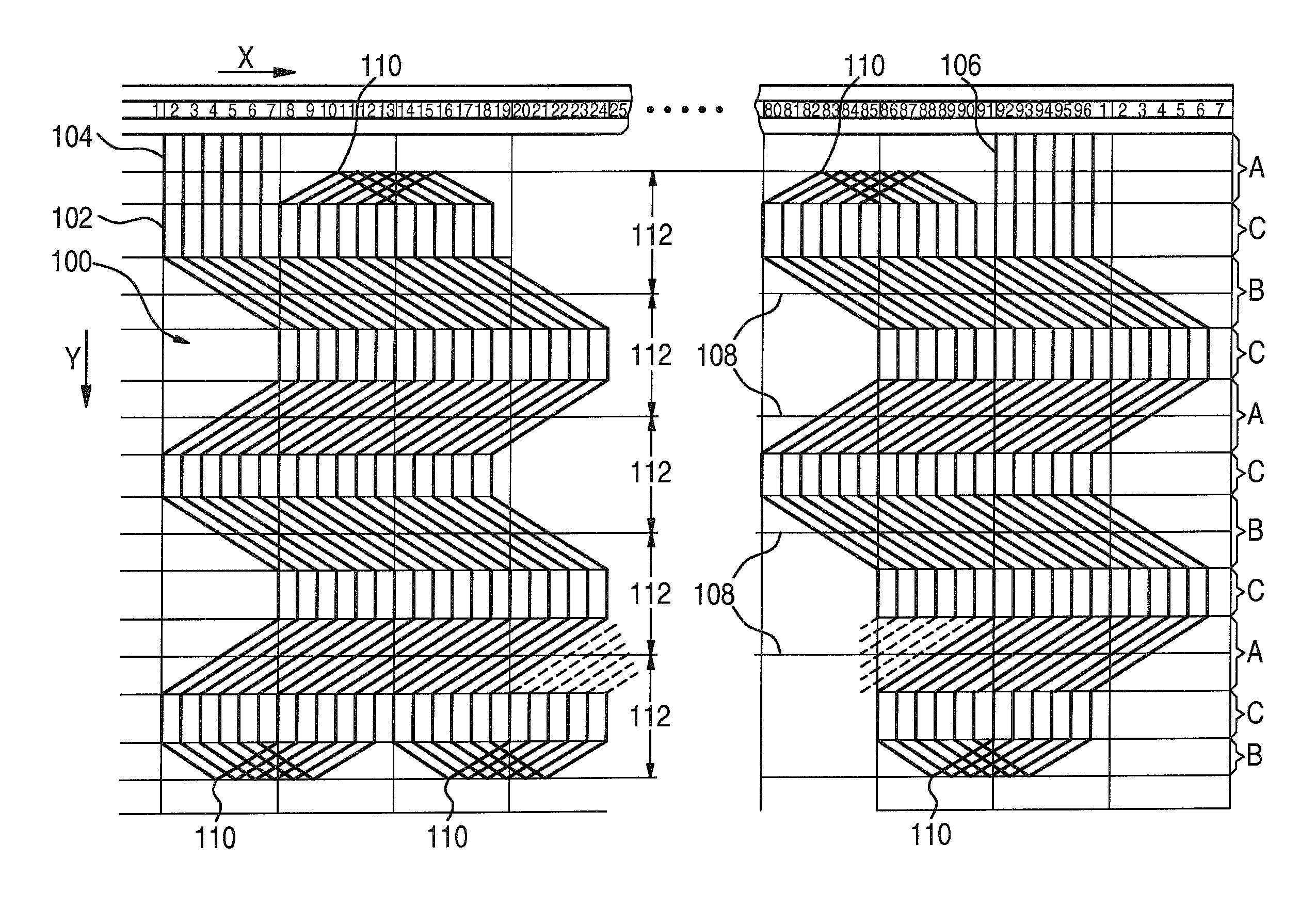

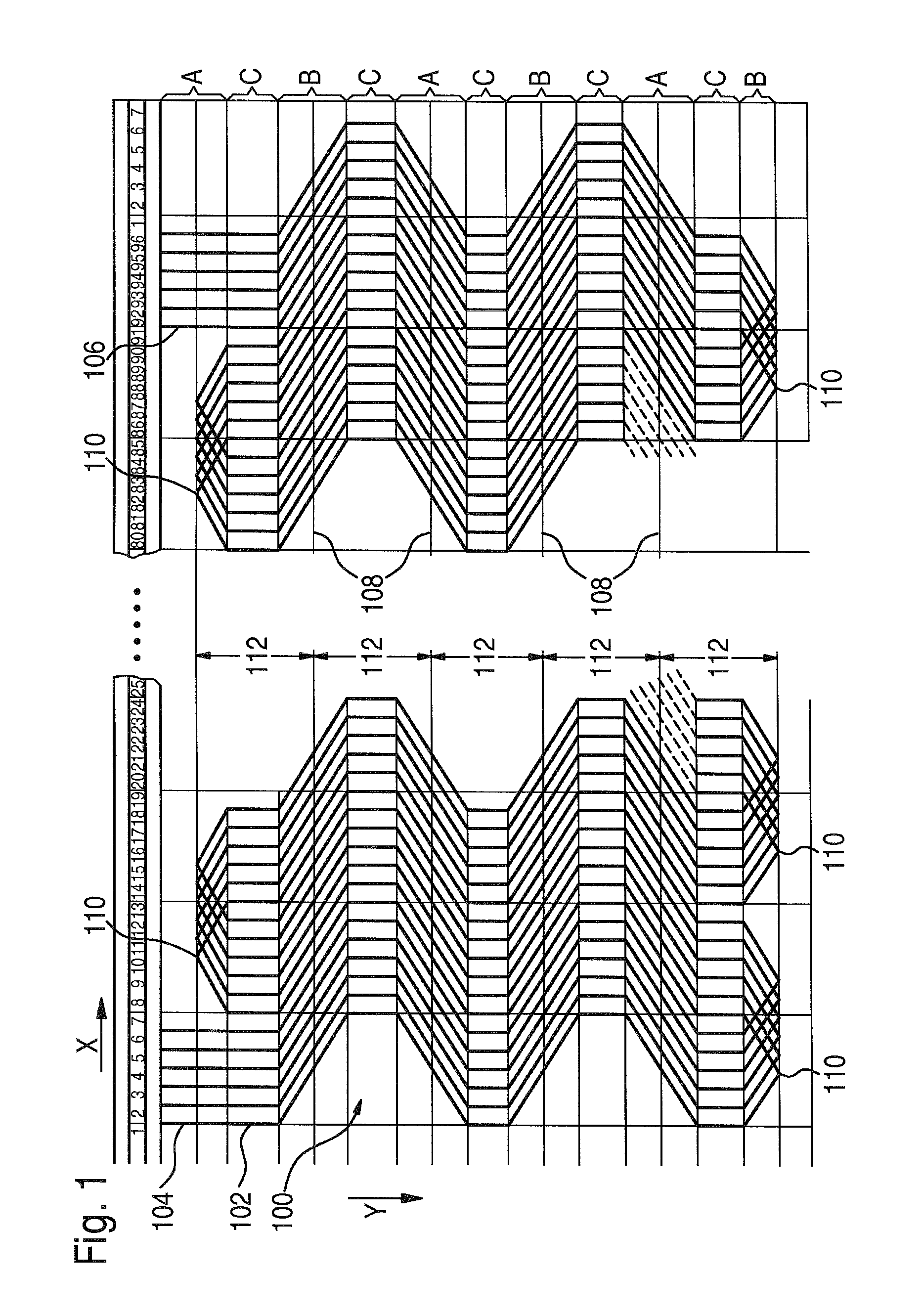

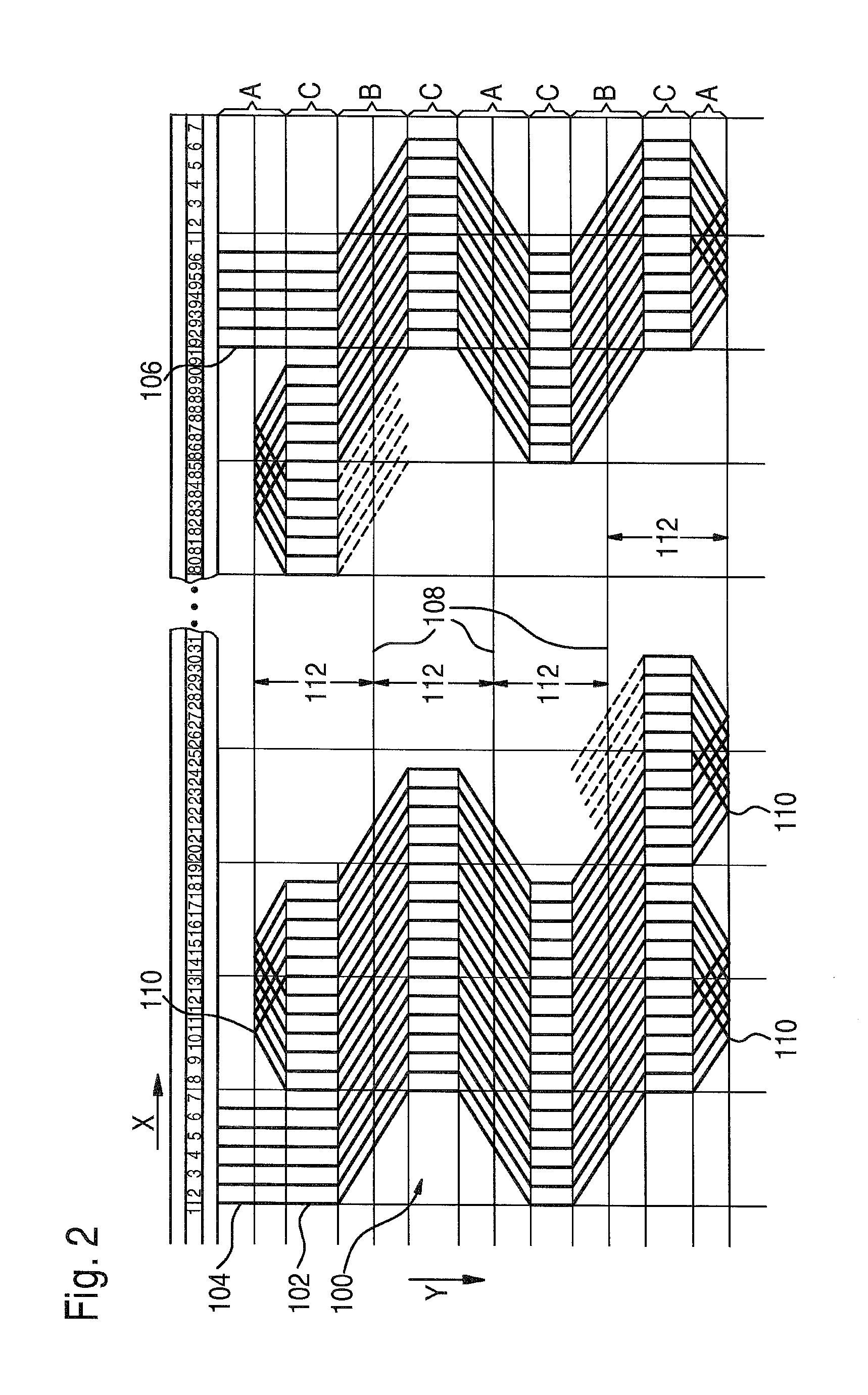

Method of producing a stator winding for an electrical machine

InactiveUS8966742B2Offset easilyEasy stampingSynchronous machinesAsynchronous induction motorsWave shapeConductor Coil

A method of producing a stator winding for a stator of an electrical machine includes positioning a phase winding segment of the stator winding in a same plane in a serpentine manner in a first direction (X) and in a shape of a wave in a second direction (Y) transverse to the first direction. The method includes bending regions (A, B, C) of the phase winding segment toward one another along a folding line to form a lap winding including positioning regions (C) parallel to each other connected by regions (B) where the regions (B) cross the at least one folding line (108). The phase winding is formed with a continuous wire.

Owner:SEG AUTOMOTIVE GERMANY GMBH

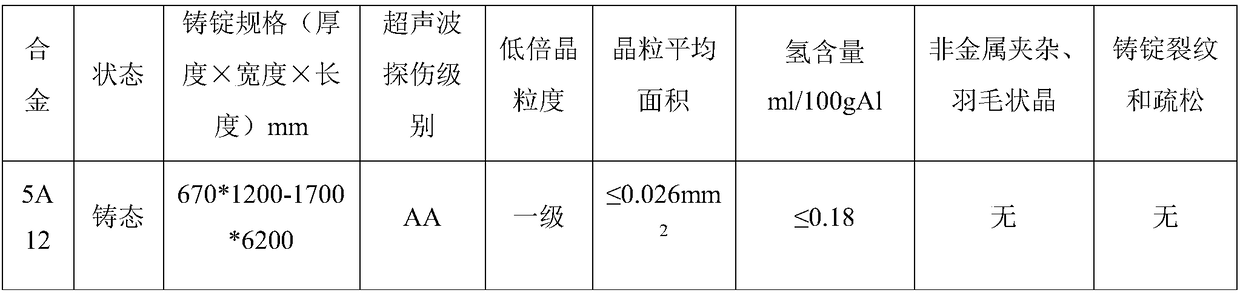

5A12 aluminum alloy cast ingot as well as production method and application thereof

The invention discloses a 5A12 aluminum alloy cast ingot as well as a production method and application thereof and relates to the technical field of alloy processing. The 5A12 aluminum alloy cast ingot is prepared from the following alloy elements in percentage by mass: smaller than or equal to 0.15 percent of Si, 0.1-0.2 percent of Fe, smaller than or equal to 0.05 percent of Cu, 0.5-0.6 percent of Mn, 8.8-9.3 percent of Mg, smaller than or equal to 0.1 percent of Cr, smaller than or equal to 0.1 percent of Ni, smaller than or equal to 0.1 percent of Zn, 0.07-0.09 percent of Ti, 0.001-0.002percent of Be, 0.01-0.02 percent of Sb, smaller than 0.05 percent of other impurity elements and the balance of Al. The production method comprises the following steps of smelting, burdening, refining, still standing and casting of aluminum alloy scraps and an aluminum ingot for remelting to obtain the large-specification 5A12 aluminum alloy cast ingot with the width being 1200-1700mm. By adopting the production method provided by the invention, the technical problems that production of the large-specification 5A12 aluminum alloy cast ingot is high in equipment technical requirements and complex in broad width casting technology and can product a circular cast rod only in the prior art are solved.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD

Crystallizer for preparing superhard aluminum alloy flat cast ingot and use method of crystallizer

The invention discloses a crystallizer for preparing a superhard aluminum alloy flat cast ingot and a use method of the crystallizer and relates to a tool for preparing the superhard aluminum alloy flat cast ingot and a use method of the tool.The crystallizer aims at solving the problem that superhard aluminum alloys produced by the existing casting tool have high possibility of crack rejects. The crystallizer for preparing the superhard aluminum alloy flat cast ingot comprises a crystallizer water chamber, a water chamber gland, a secondary water distribution plate and an oil gland, wherein the crystallizer water chamber comprises a water chamber internal wall, a water chamber external wall and a water chamber base; a plane is arranged at a junction between the internal surface and the upper surface of the water chamber internal wall; water outlet holes are formed in the plane; water inlet holes are formed at the two ends of the water chamber gland in a length direction; and a lubricating oil channel is arranged on the water chamber base and located close to the water chamber internal wall on the plane on the outer side of a cavity.The use method comprises the step of arranging a water baffle in a down direction of the cast ingot below the crystallizer when in use.The method reduces crack tendency.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Automatic seal machine

The invention discloses an automatic seal machine. A supporting vertical plate is fixedly connected to the front end of a supporting bottom plate, and the middle of the supporting vertical plate is provided with an arc-shaped through groove; a pair of guide rails are fixedly connected with the supporting vertical plate in a spaced mode, and a transverse slide groove is formed between the two guiderails; a slide plate is transversely and slidably arranged in the transverse slide groove and provided with an inclined through groove with the left side higher than the right side; a bearing frame is fixedly connected to an upper end surface of the supporting bottom plate; an inkpad box is fixedly connected to the right side of the front end of the bearing frame; a connection rod is vertically arranged on the rear side of the supporting vertical plate, the lower end of the connection rod is fixedly connected with the upper end of a seal, the upper portion of connection rod is vertically andfixedly connected with a guide transverse beam, and the guide transverse beam is in sliding fit with the inclined through groove and the arc-shaped through groove; an output shaft of a first driving motor is vertically and fixedly connected with one end of a crank, the other end of the crank is hinged to one end of a rocker, and the other end of the rocker is hinged to the left end of the slide plate; and the front end of the interior of the bearing frame is provided with a pair of paper baffles adjustable in distance and further provided with a pair of paper rubbing wheels driven by the motor. The automatic seal machine can automatically achieve large-batch seal operation.

Owner:XUZHOU UNIV OF TECH

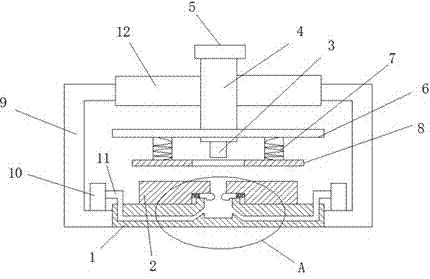

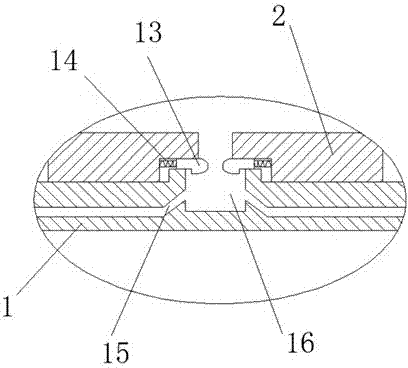

Air conditioner fin cold-punching die capable of preventing waste material jumping

InactiveCN107030200AEasy stampingPrevent jumpingShaping toolsMetal-working feeding devicesPunchingEngineering

The invention discloses an air conditioner fin cold-punching die capable of preventing waste material jumping. The air conditioner fin comprises a base, a lower female die is arranged over the top of the base, and supporting rods are fixedly connected to the two sides of the base respectively; a guiding plate is fixedly connected to the tops of the supporting rods, a first installing hole penetrating through the guiding plate is formed in the top of the guiding plate, and a guiding block is slidably installed in the first installing hole; a connecting block is fixed to the top of the guiding block, an upper male die is fixed to the bottom of the guiding block, a connecting plate is fixedly connected to the outer side of the end, close to the upper male die, of the guiding block in a sleeving mode, two first springs are fixed to the bottom of the connecting plate, a material pressing plate is fixed to the bottoms of the first springs, and an exhaust fan is fixed to the end, close to the base, of each supporting rod. According to the air conditioner fin cold-punching die capable of preventing waste material jumping, through cooperative use of the structures such as L-shaped rods and second springs, waste materials attached to the upper male die can be scraped off, and the condition that the punching work is influenced due to the fact that the upper male die brings out of the waste materials is avoided.

Owner:滁州市东华模具制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com