Novel stamping robot

A robot and a new type of technology, applied in metal processing equipment, feeding devices, safety equipment, etc., can solve problems such as unsafety, work-related accidents, and handicapping due to broken hands, so as to achieve less material consumption, reduce consumable materials, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

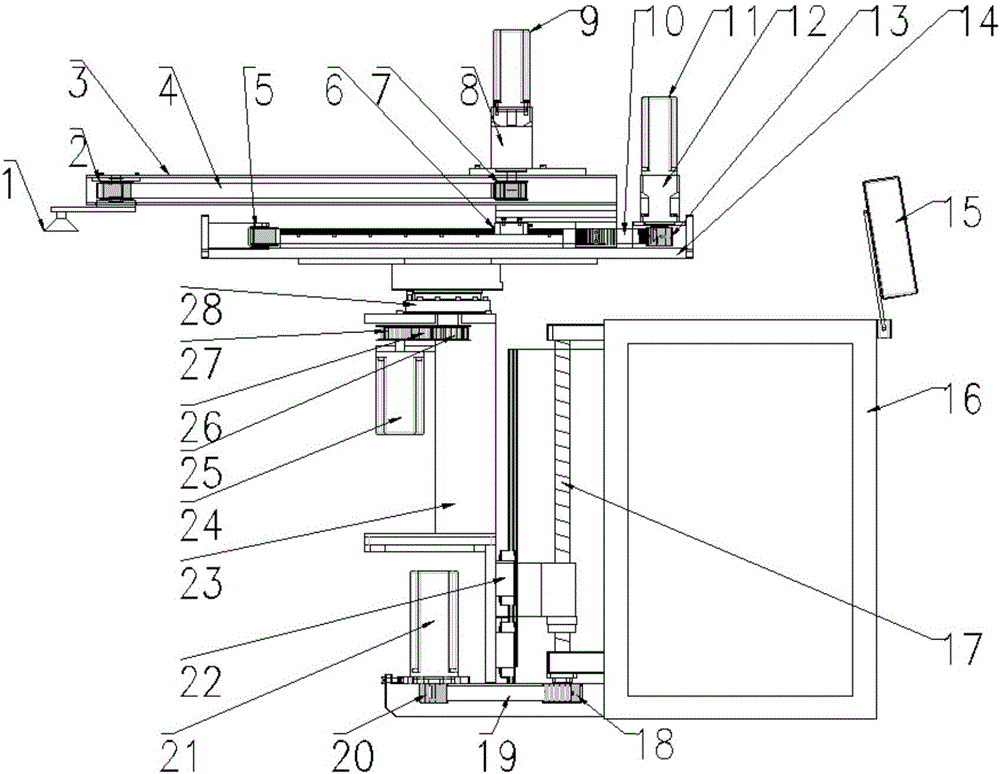

[0014] figure 1 Show the specific embodiment of a kind of novel stamping robot of the present invention: a kind of novel stamping robot, comprise fuselage main body 16 and the arm main body 3 above fuselage main body 16, wherein said fuselage main body 16 is provided with controller 15, controls Device 15 links to each other with fuselage main body 16, and one side of fuselage main body 16 is provided with elevating mechanism, and elevating mechanism comprises fuselage motor 21, fuselage screw rod 17 and fuselage linear guide 22, wherein fuselage screw rod 17 is fixed on fuselage main body On the outer side wall of 16, the bottom of fuselage motor 21 and fuselage screw rod 17 passes through fuselage main synchronous wheel 20, fuselage from synchronous wheel 18, and the mechanism between fuselage main synchronous wheel 20 and fuselage from synchronous wheel 18 The body timing belt 19 is connected, wherein the body motor 21 is connected with the main synchronous wheel 20 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com