Patents

Literature

1791results about How to "Small moment of inertia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

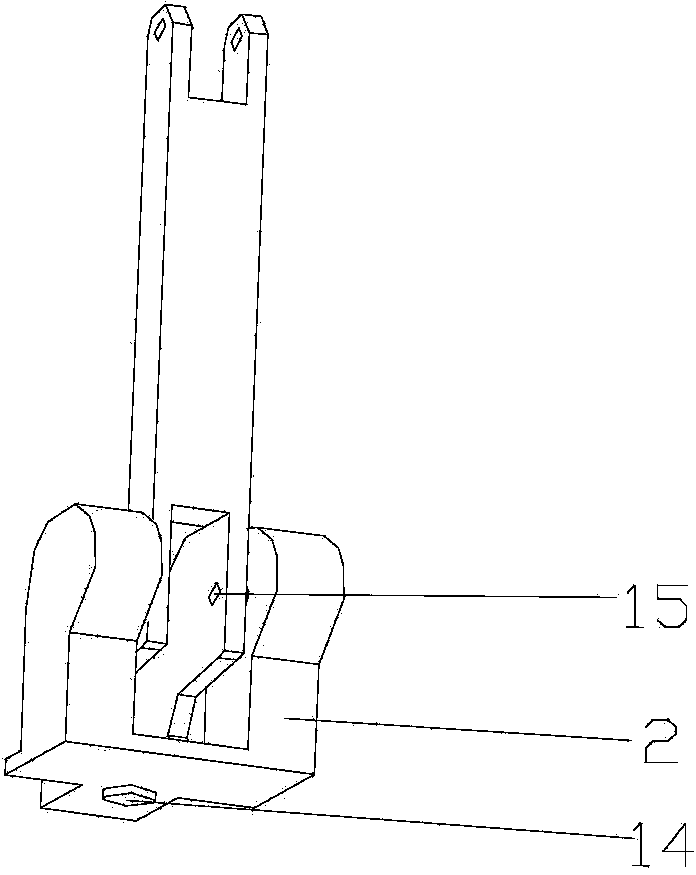

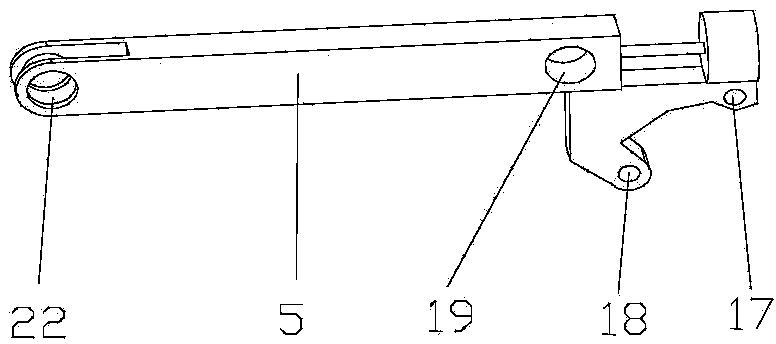

Upper limb rehabilitation training robot

ActiveCN102379793AAchieve the perfect matchImprove comfortChiropractic devicesMuscle exercising devicesThree-dimensional spaceFinger joint

The invention relates to an upper limb rehabilitation training robot which comprises a first joint, a second joint, a third joint, a fourth joint and a fifth joint; the five joints are sequentially connected serially; the movement of all the joints respectively corresponds to the unfolding / folding of shoulder joints, the bending / extension of the shoulder joints, the bending / extension of elbow joints, the internal rotation / external turning of forearms, the bending / extension of wrist joints and the bending / extension of fingers; all the joints of the robot are driven by independent motors; each joint is provided with a mechanical hard limit and an electric limit to protect the training of a patient; and the second joint and the fourth joint are respectively provided with a adjustment device capable of adjusting relative positions between the second joint and the third joint and between the third joint and the fifth joint. The upper limb rehabilitation training robot provides various rehabilitation movement for the turning of the shoulders, elbows and forearms as well as the wrist and finger joints of the upper limbs of the patient in a three-dimensional space, and can complete the upper limb rehabilitation training to the upper limbs of the patient with higher quality.

Owner:ANYANG SHENFANG REHAB ROBOTS CO LTD

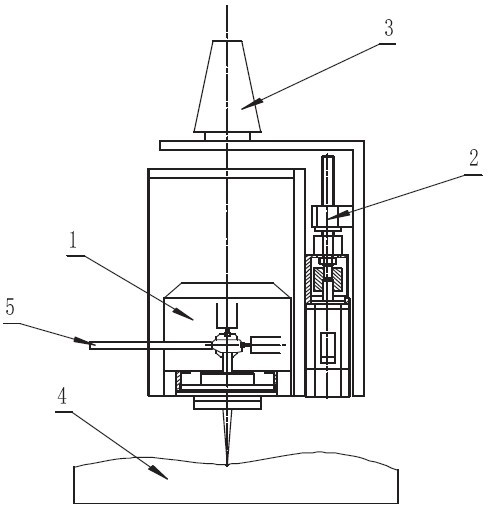

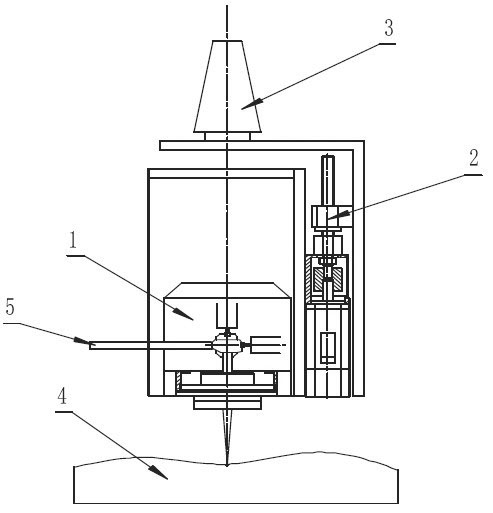

Laser machining method and device applicable for complicated curved surface

ActiveCN102151984AReduce the overall heightImprove energy consumptionLaser beam welding apparatusLaser etchingLaser processing

The invention provides a laser machining method applicable for a complicated curved surface. By adopting processing steps of dividing the complicated curved surface into curved surface sheets and establishing a coordinate system of each curved surface sheet, the subsequent processing steps of dividing sub blocks and machining pattern parallel projection can be implemented according to the coordinates of the curved surface sheets respectively, so the limit that a machining molded surface backing to a laser incident direction or a steep surface parallel to an optical axis direction cannot be machined because only one coordinate system is adopted to perform whole injection in the prior art can be overcome, the machining efficiency is improved and the machining applicable range is extended. The invention also provides a laser machining device. The laser machining device has a three-axis laser machining head structure provided with a two-axis laser polarization mirror and a Z-axis mobile mechanism, so the problem that the conventional system depends on a three-axis lathe is solved; therefore, a machining unit is independent and compact, and is easy to assemble and disassemble; the conventional five-axis linkage milling machine can be changed into a laser-etching machining lathe so that the functions are compatible; and the laser machining device has a significant practical value.

Owner:武汉飞能达激光技术有限公司

Controllable mechanism type fine-adjusting welding robot with multiple degrees of spatial freedom

ActiveCN103737578AIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorWelding/cutting auxillary devicesControl engineeringMachine

A controllable mechanism type fine-adjusting welding robot with multiple degrees of spatial freedom comprises three controllable fine-adjusting four-rod mechanism closed-loop subchains connected in parallel and an execution mechanism subchain in series connection. The four-rod mechanism closed-loop subchains can control a first connecting rod to move in the plane where the four-rod mechanism closed-loop subchains are located, and the spatial movement of a platform can be achieved through the movement of parallel connecting rods and a machine body. The spatial movement of a tail end executor can be controlled through the resultant movement of the three closed-loop subchains and the machine body, the movement inertia of the tail end executor is small, dynamics performance is good, reliability is high, the mechanism has the advantages of being compact in structure and easy to control, the connecting rods are used for control, rod pieces can be made into light rods, the work space of the mechanism is large, the gravity of the mechanism moves backwards, the mechanism is kept balanced, and the mechanism can act on more occasions.

Owner:GUANGXI UNIV

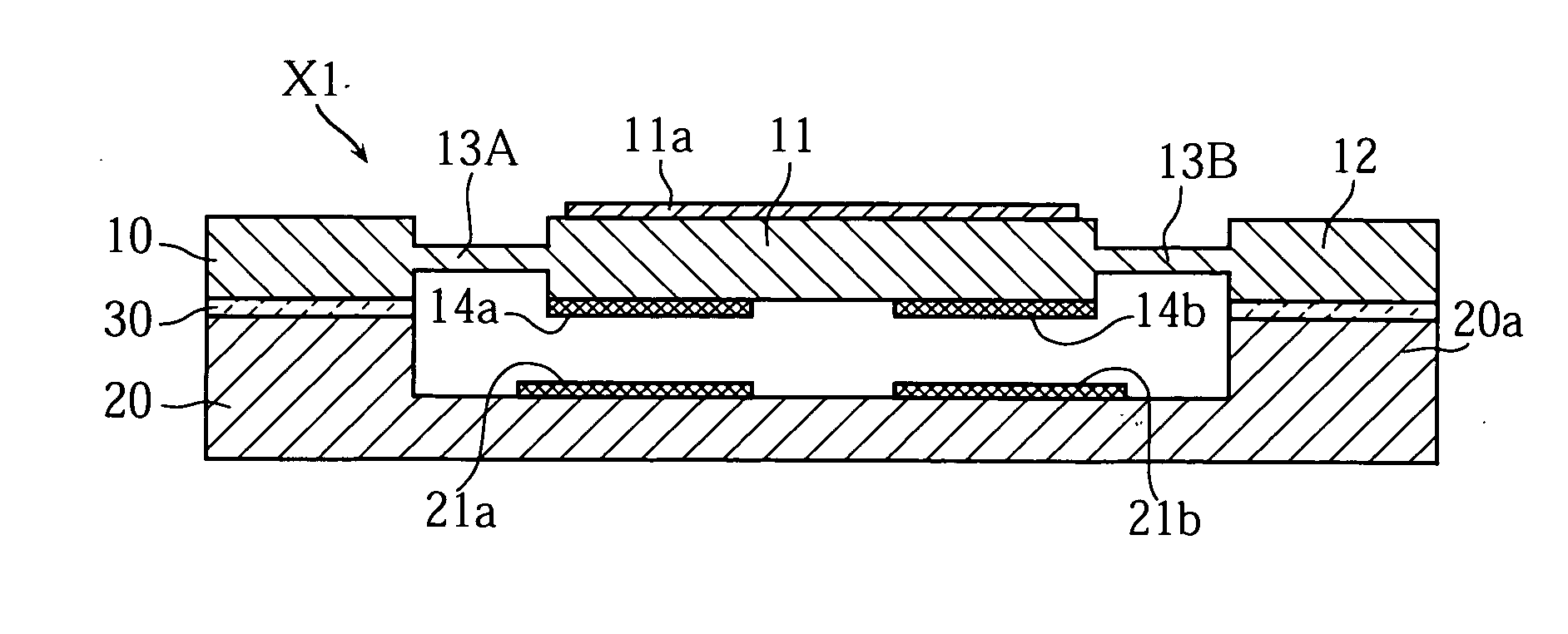

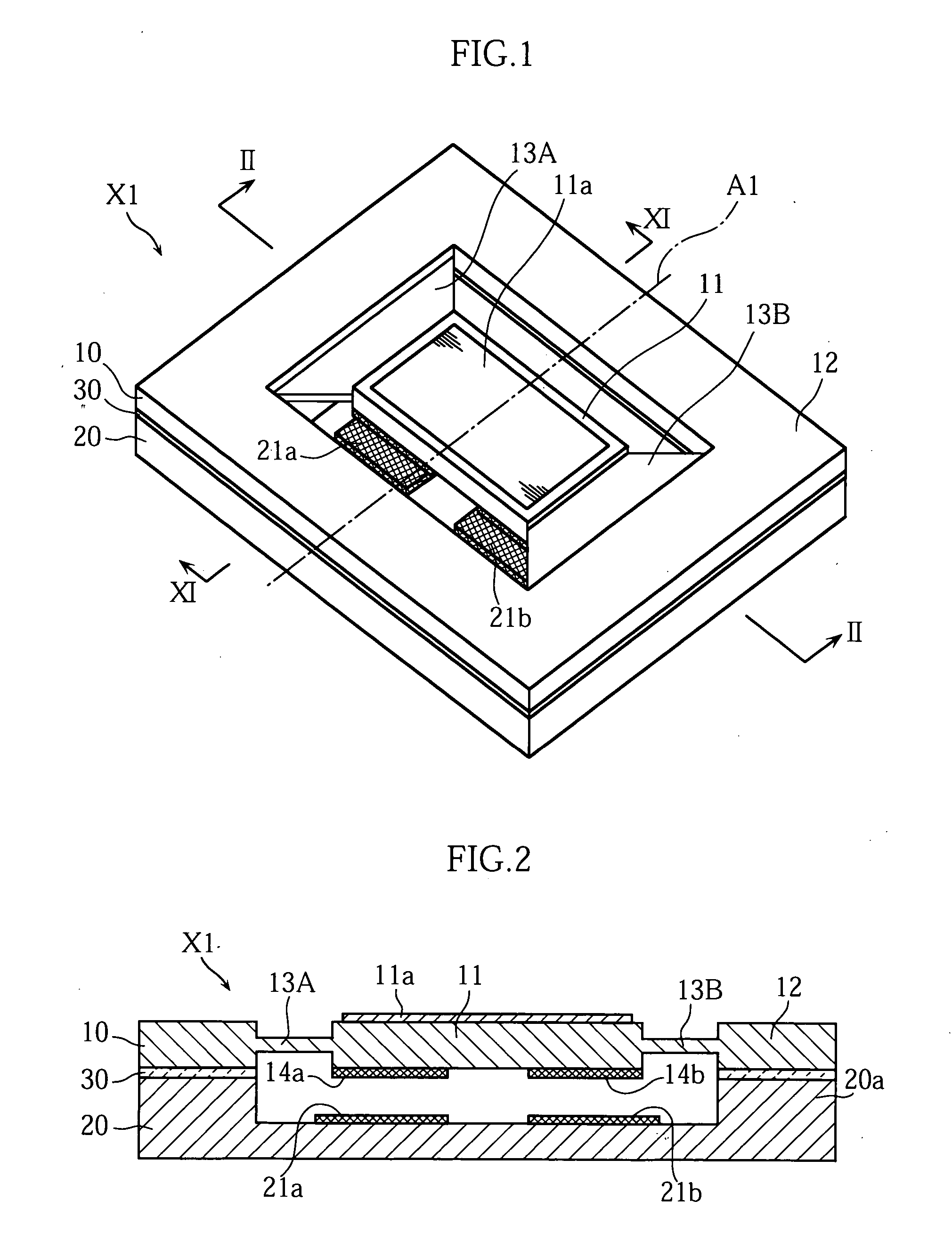

Micro-oscillation element

InactiveUS20050046504A1Improve rotational stiffnessInappropriate deformation can be preventedLaser detailsBathsEngineering

Owner:FUJITSU LTD

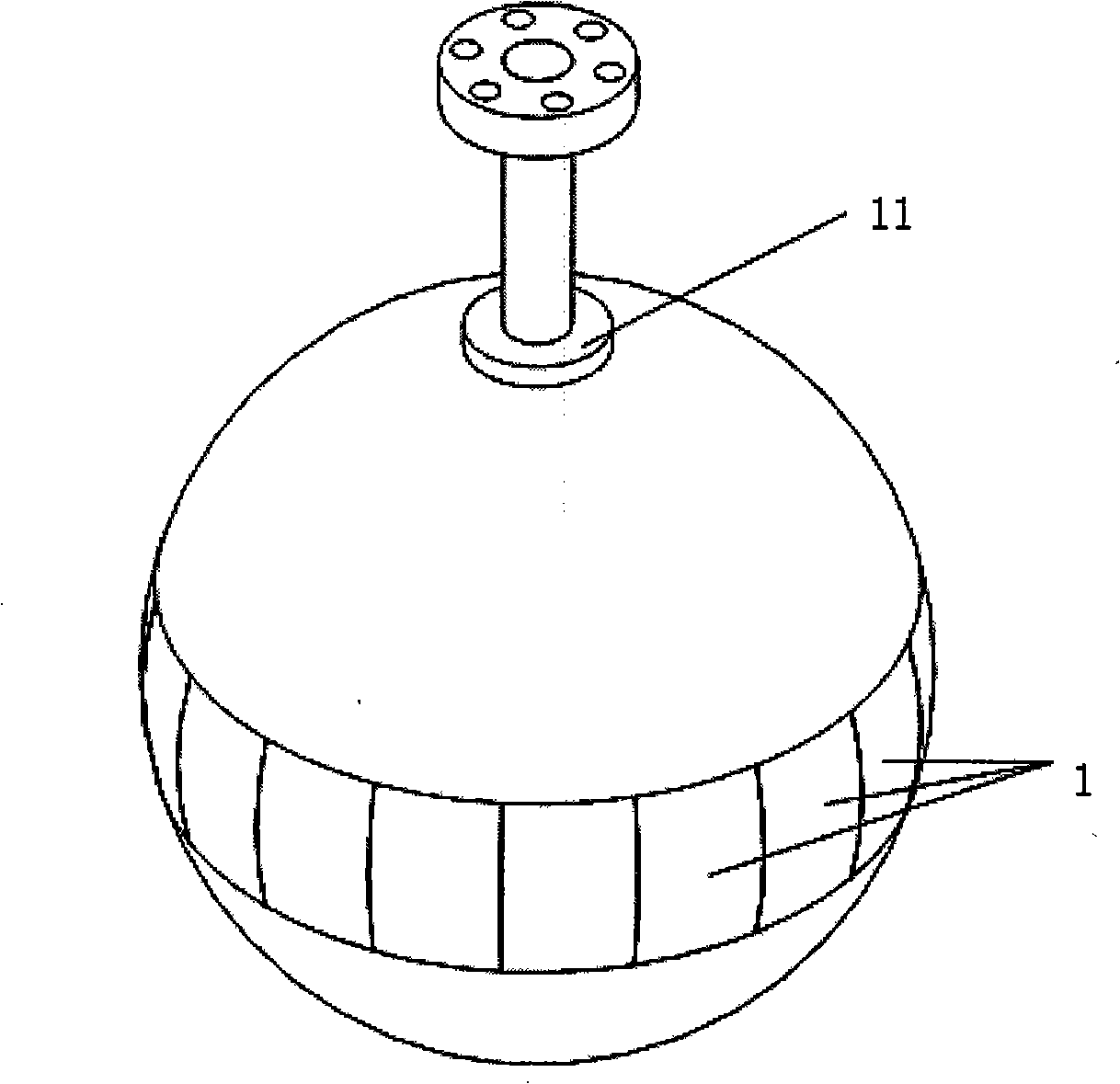

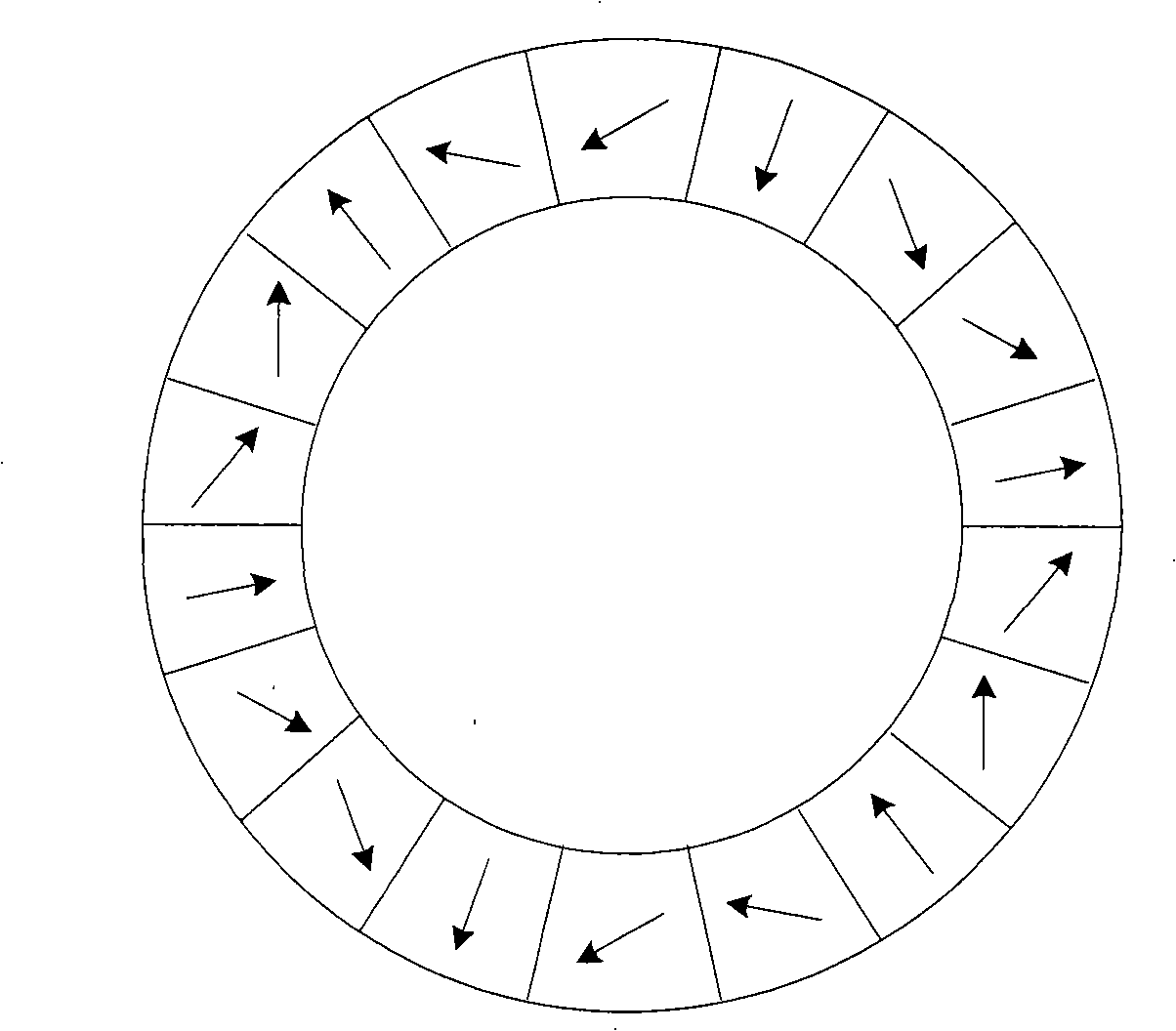

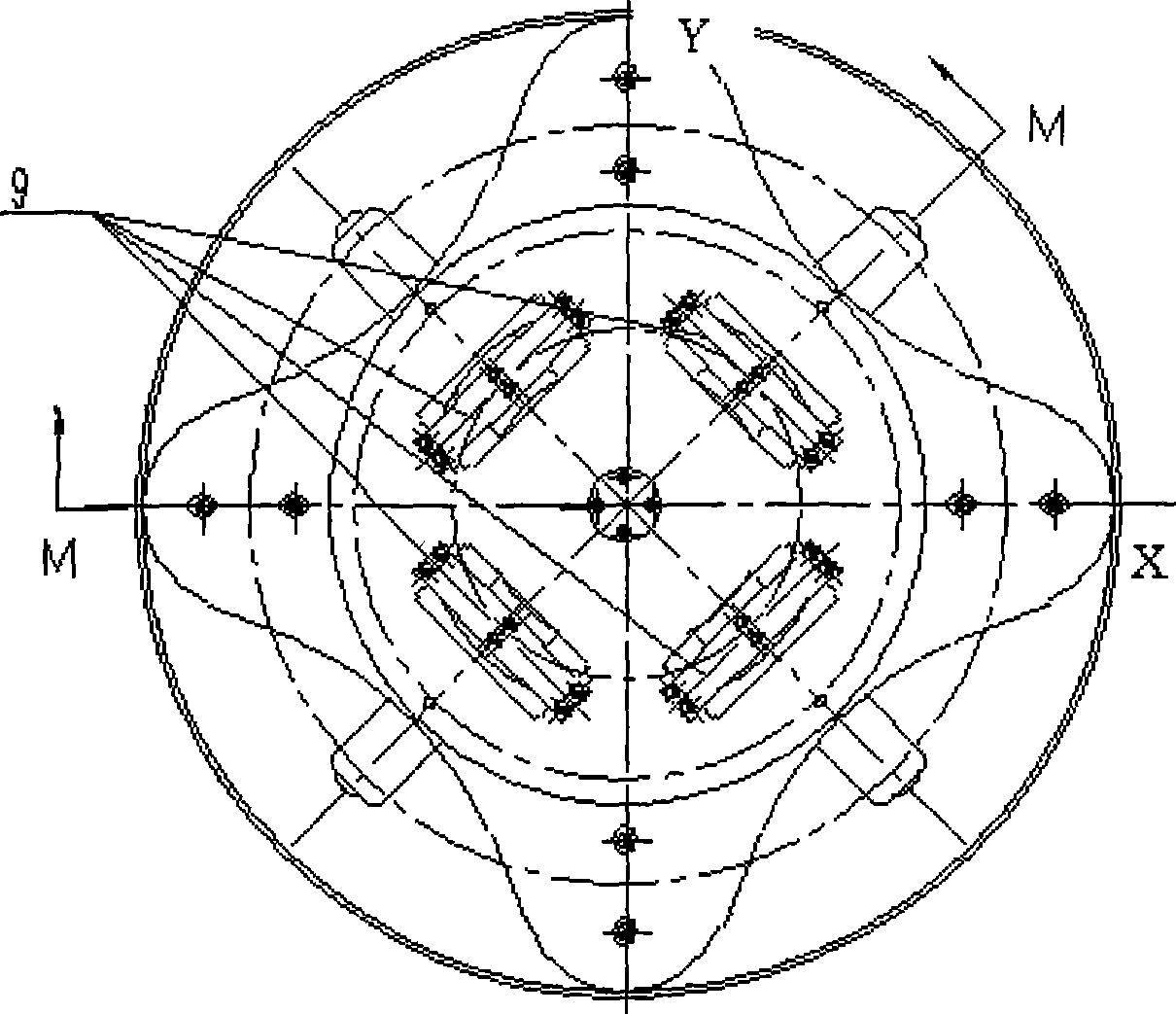

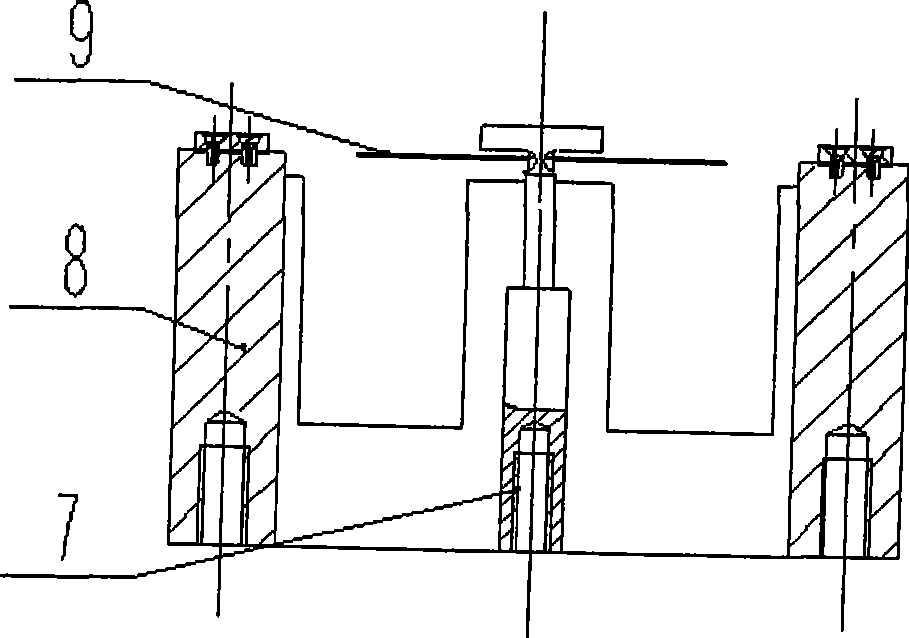

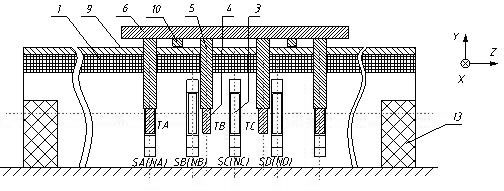

Three-freedom Halback array permanent magnetism sphericity synchronous motor

InactiveCN101282070AHigh positioning accuracySimple mechanical structureMagnetic circuit rotating partsSynchronous machine detailsFixed bearingSynchronous motor

The invention relates to a three-freedom degree Halbach array permanent magnetism spherical synchronous motor, belonging to spherical electric machine manufacturing technical field, which comprises a base, a support bearing positioned on the base, a spherical rotor body, an outside stator, an output shaft, the spherical rotor body comprises a hollow spherical rotor yoke made by non-guide magnetism materials and a Halbach array permanent magnetism body, the output shaft is through the upper of the hollow spherical rotor yoke and is fixingly connected with the hollow spherical rotor yoke, column-shaped slots are provided around a cycle of the hollow spherical rotor yoke equator, the Halbach array permanent magnetism body are fixed evenly on one cycle of the rotor yoke equator along the column-shaped slots, the contact surface of the rotor yoke lower and the support bearing is ring-shaped arc surface; the outer stator comprises a stator casing and multi-row coils, an adjustable fixing bearing is provided on the lower side of the stator casing cover. The spherical synchronous motor of the invention can realize three-freedom degree movement, has simple mechanical structure and improved dynamic and static performance of the drive system.

Owner:TIANJIN UNIV

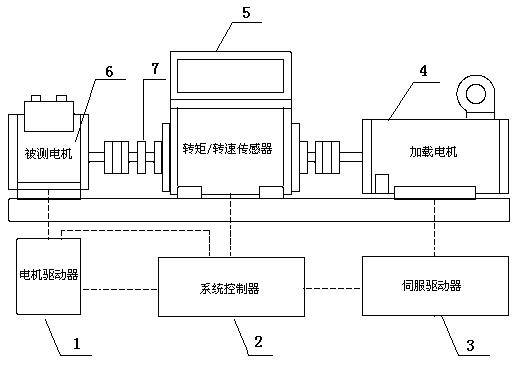

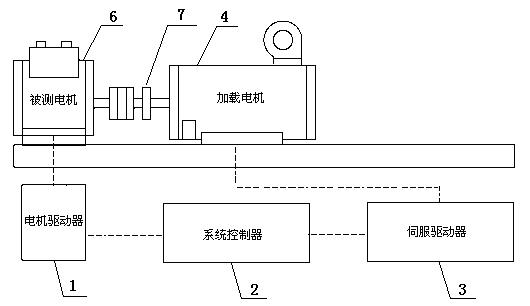

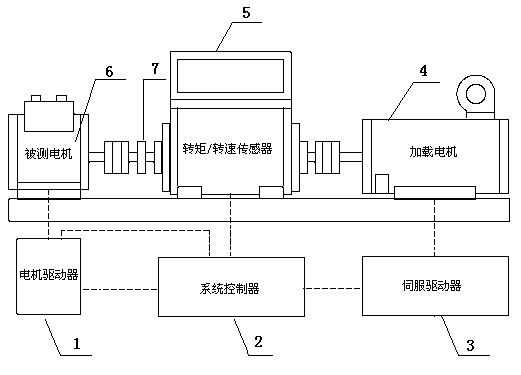

Dynamic loading methods based on servo motor

InactiveCN101793605ARealize dynamic characteristic testSimple structureEngine testingCurrent meterBrake torque

The invention relates to dynamic loading methods based on a servo motor, belonging to the field of motors and solving the problem that the properties of a direct-current motor can not satisfy the requirements of an electric loading system. The first method comprises the following steps of: transmitting a driving torque instruction value and an initial braking torque instruction value by utilizing a system controller according to the given loading spectrum to drive a measured motor to rotate; meanwhile, driving a loading motor to generate a braking torque for loading the measured motor; and then, feeding back the actual output torque value applied to the measured motor by the loading motor through adopting a torque / rotary speed sensor, and regulating the braking torque instruction value by utilizing the system controller according to a deviation so that the actual output torque value applied to the measured motor by the loading motor rapidly tracks the initial braking torque instruction value. The second method of the invention comprises the following steps of: calibrating the input and output torque relation curve of the loading motor by using the torque / rotary speed sensor, and then transmitting the driving torque instruction value and the braking torque instruction by using the system controller according to the given loading spectrum and the relation curve to load the measured motor.

Owner:HARBIN INST OF TECH

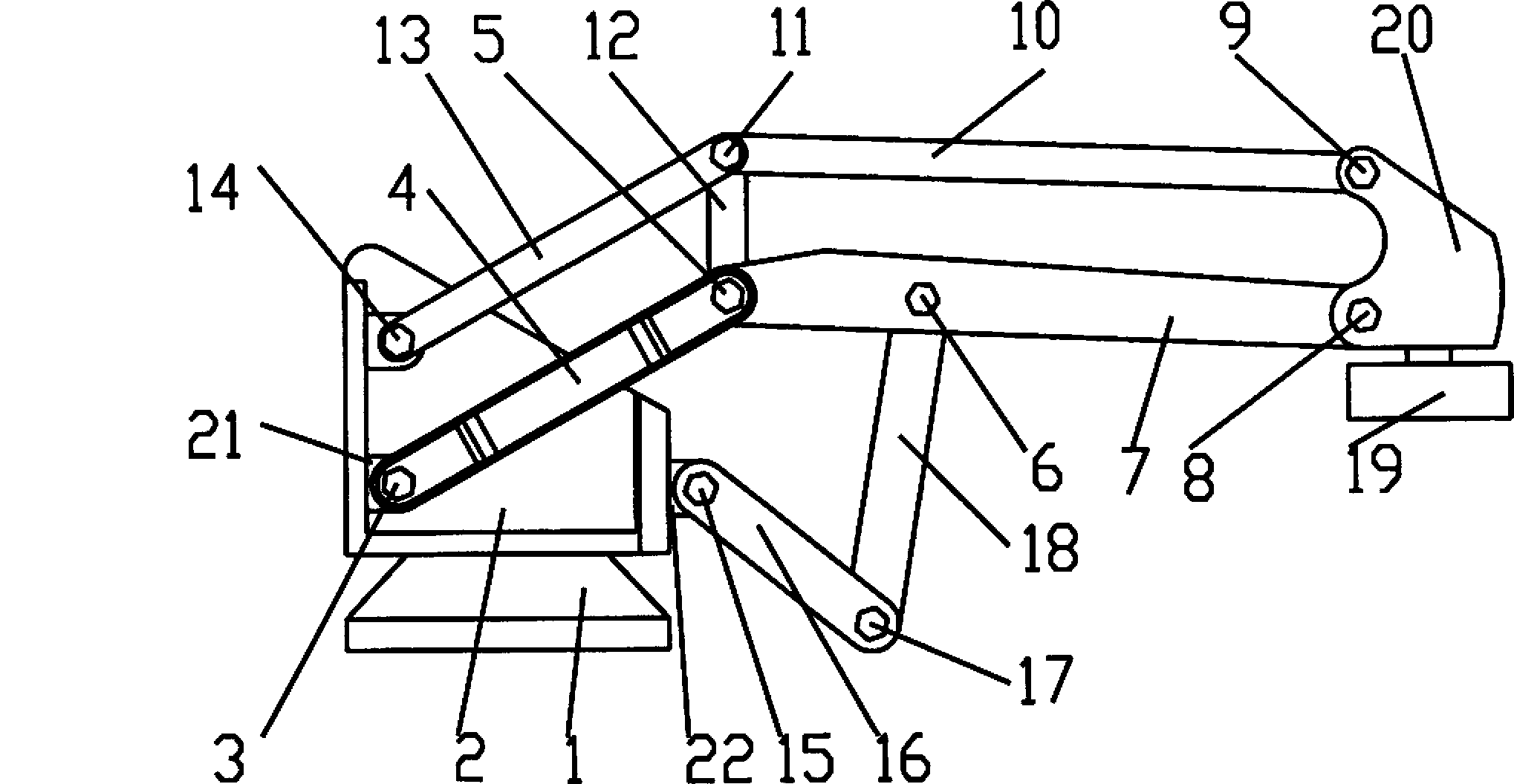

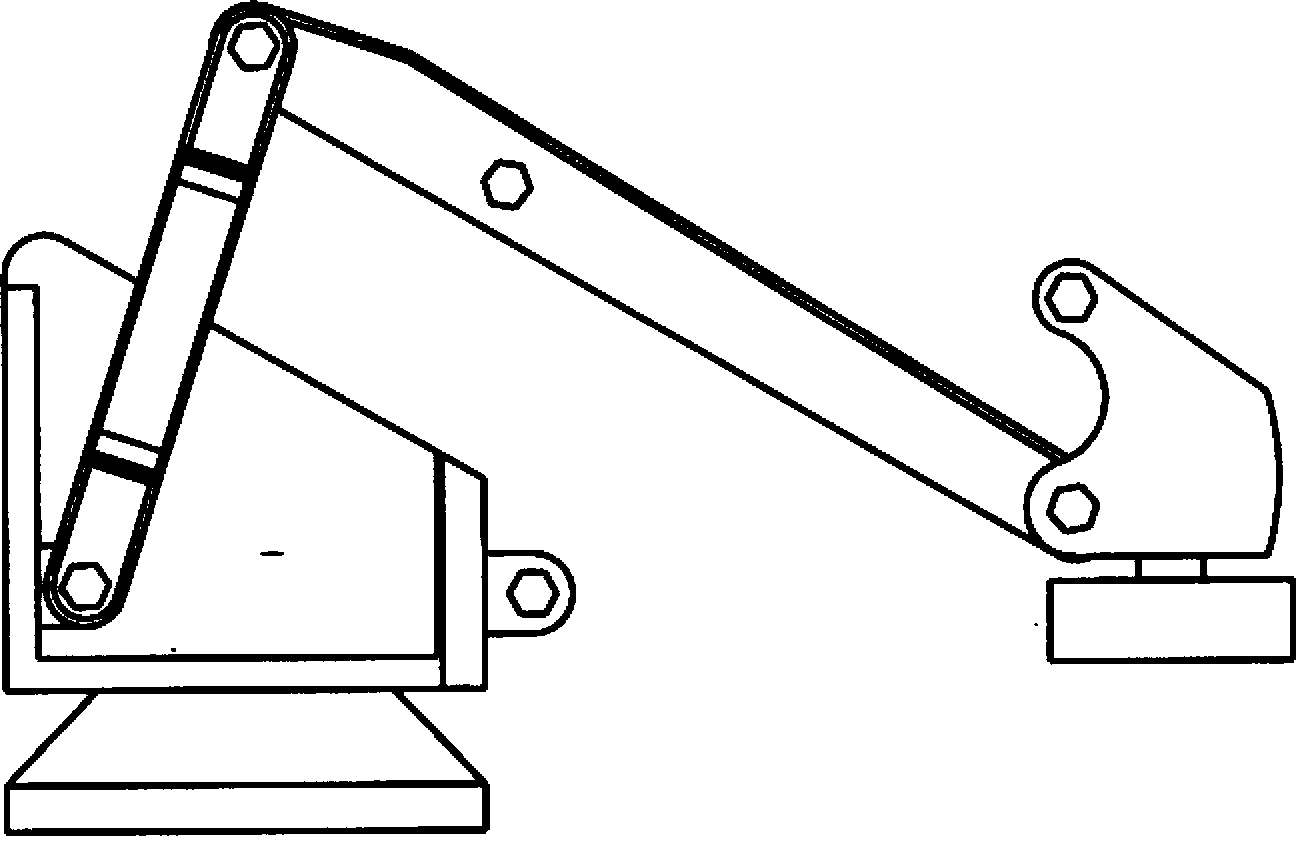

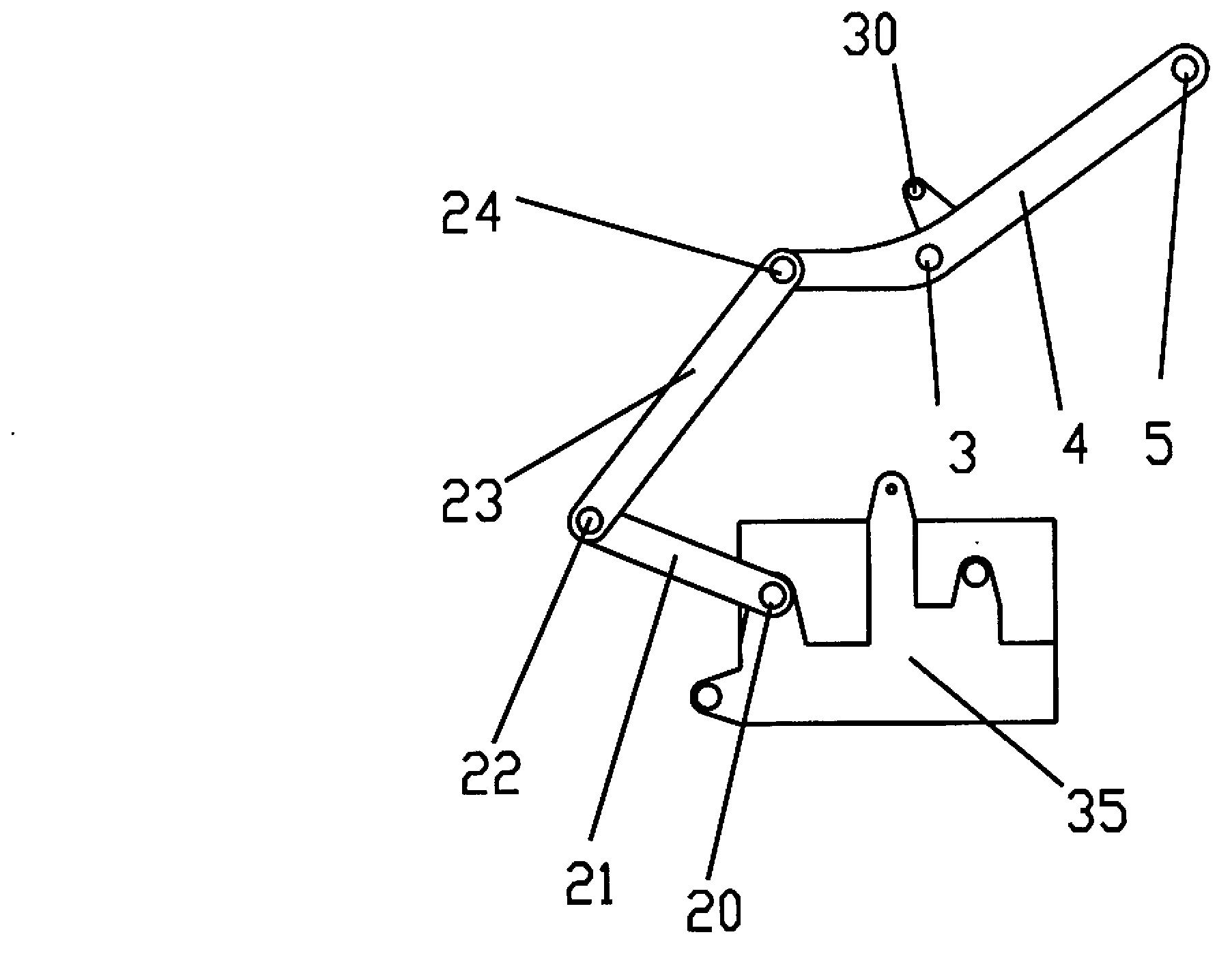

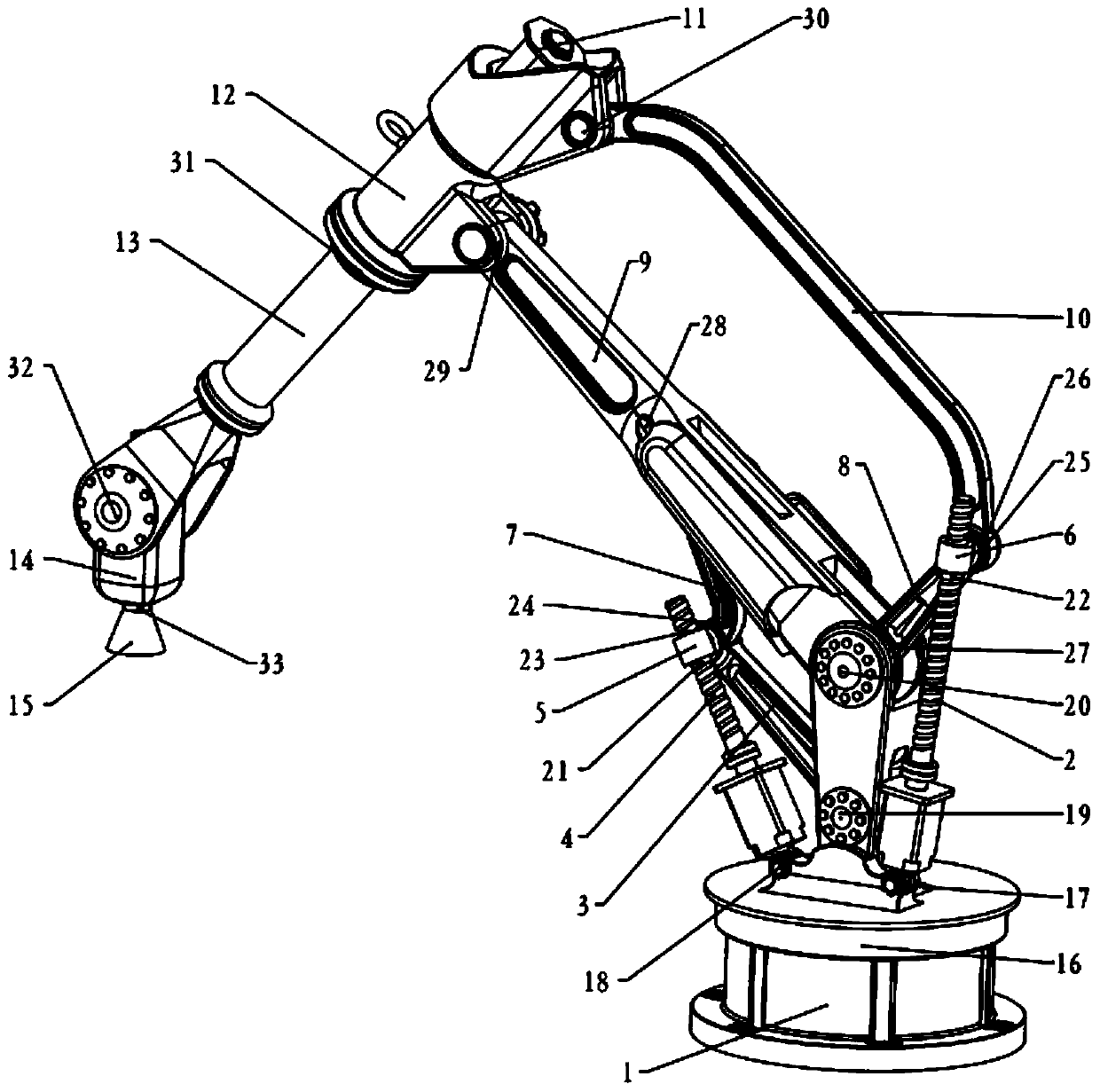

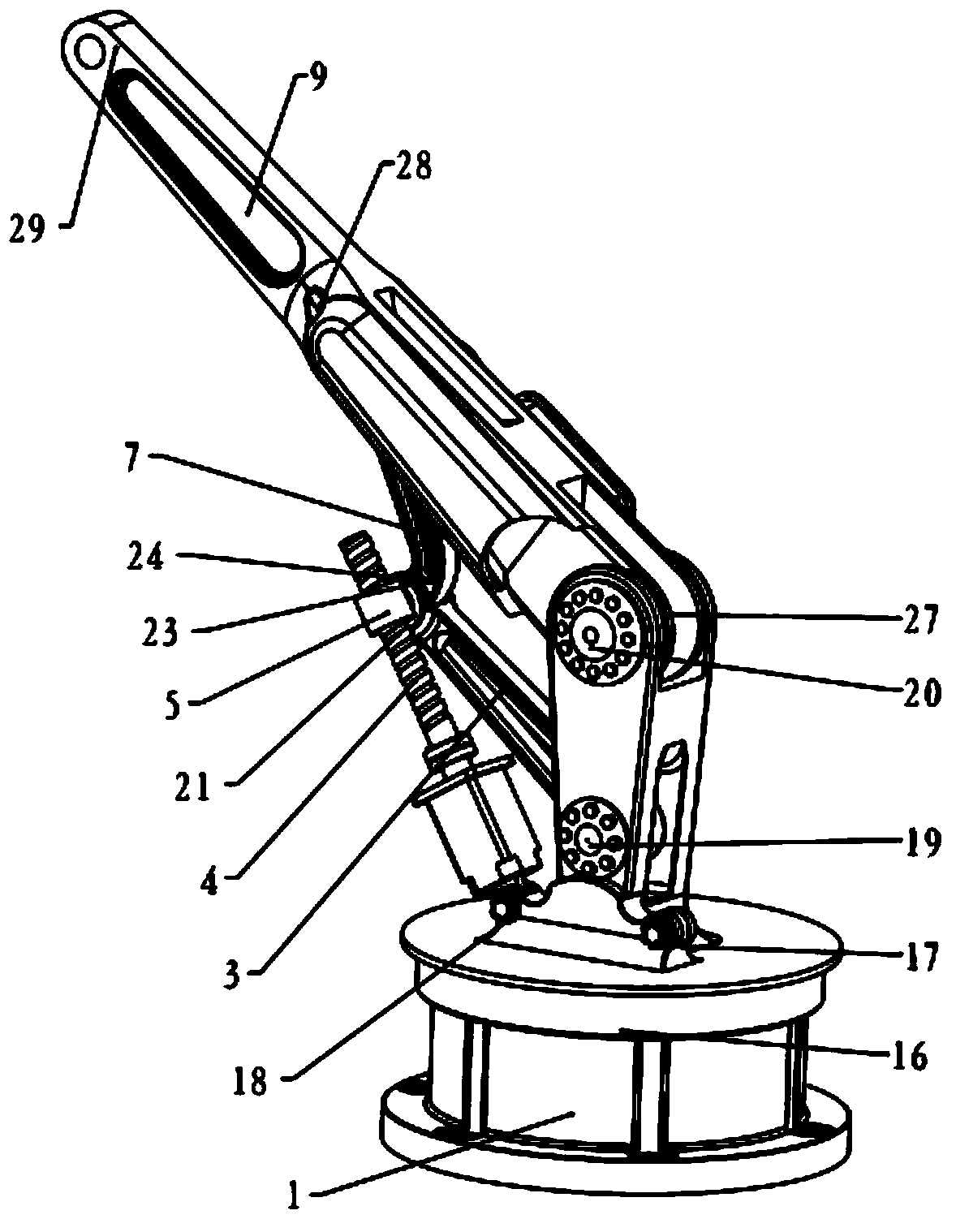

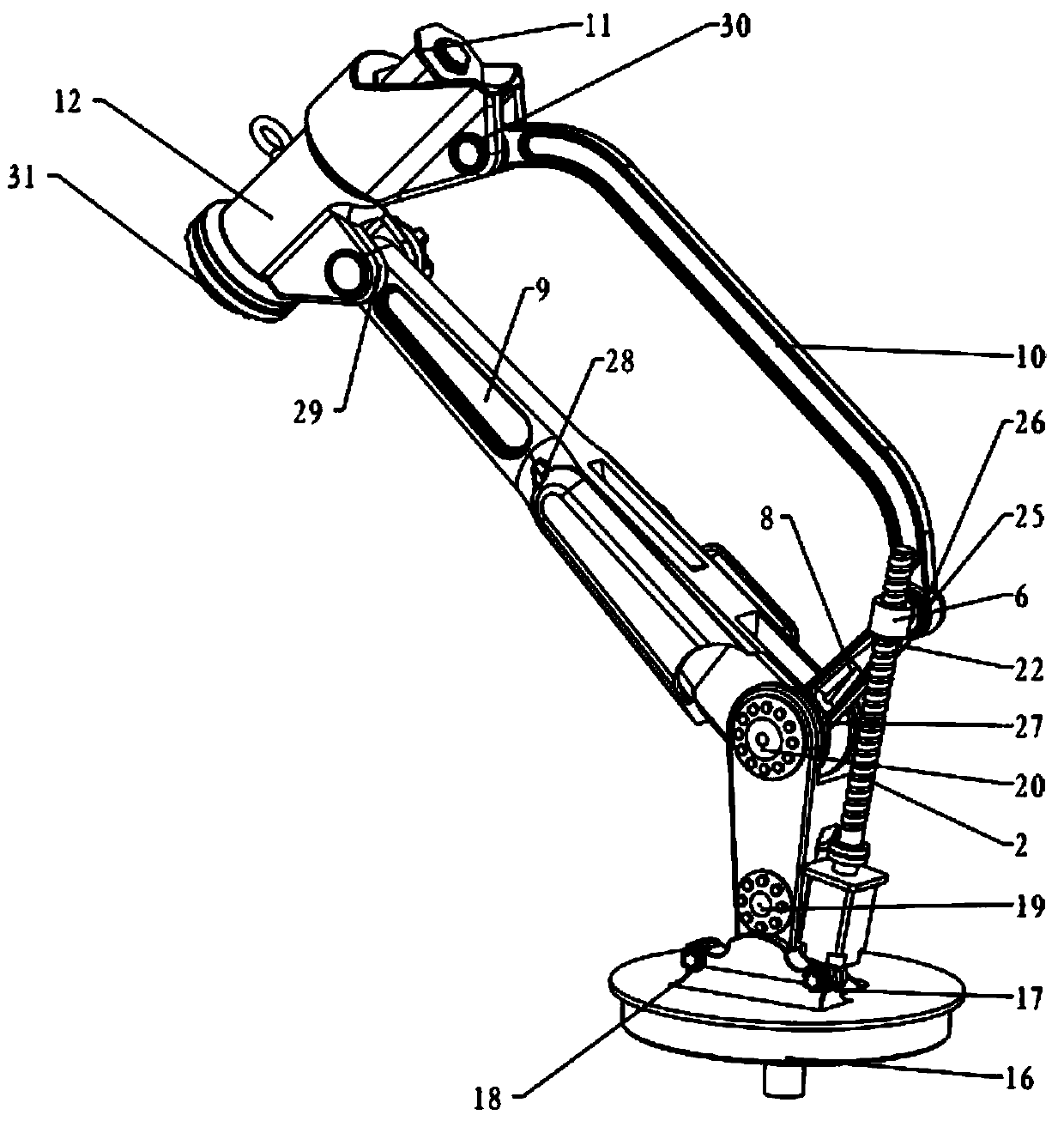

Controllable stacking robot

InactiveCN103009384AStrong flexible outputFlexible trajectoryProgramme-controlled manipulatorStacking articlesStack machineActuator

The invention relates to a controllable stacking robot, which comprises a large arm swinging branched chain, a small arm swinging branched chain, a gesture maintaining branched chain, a tail end actuator and a machine frame. The robot completes the tasks of transporting and stacking on a space as well as flexible and changeable trajectory output according to the combined movement of the large arm swinging branched chain and the small arm swinging branched arm. During a working process, according to two groups of parallelogram structures of the gesture maintaining branched chain, the tail end actuator can be guaranteed to maintain in a horizontal state all the time, all servo motors are arranged on the machine frame, rod pieces can be made into light rods, the robot has small movement inertia and excellent dynamic performance, and can be better satisfied with the requirement of transporting stacks at a high speed. According to the controllable stacking robot, by the adoption of a novel connecting rod mechanism, as a connecting transmission mechanism is simple in structure, the stress of each rod is improved, and the robot is more suitable for manufacturing a large-scale stacking machine.

Owner:GUANGXI UNIV

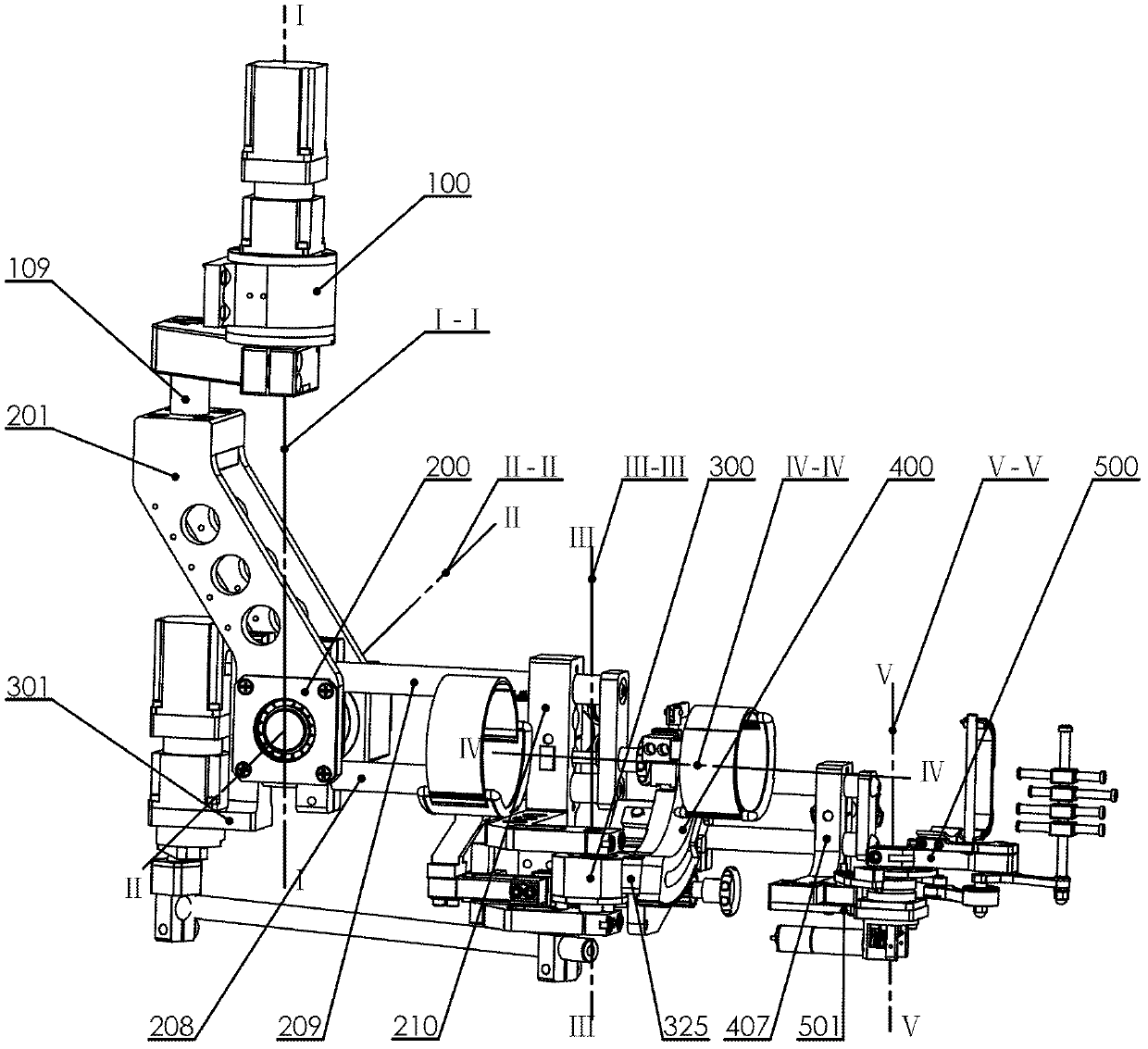

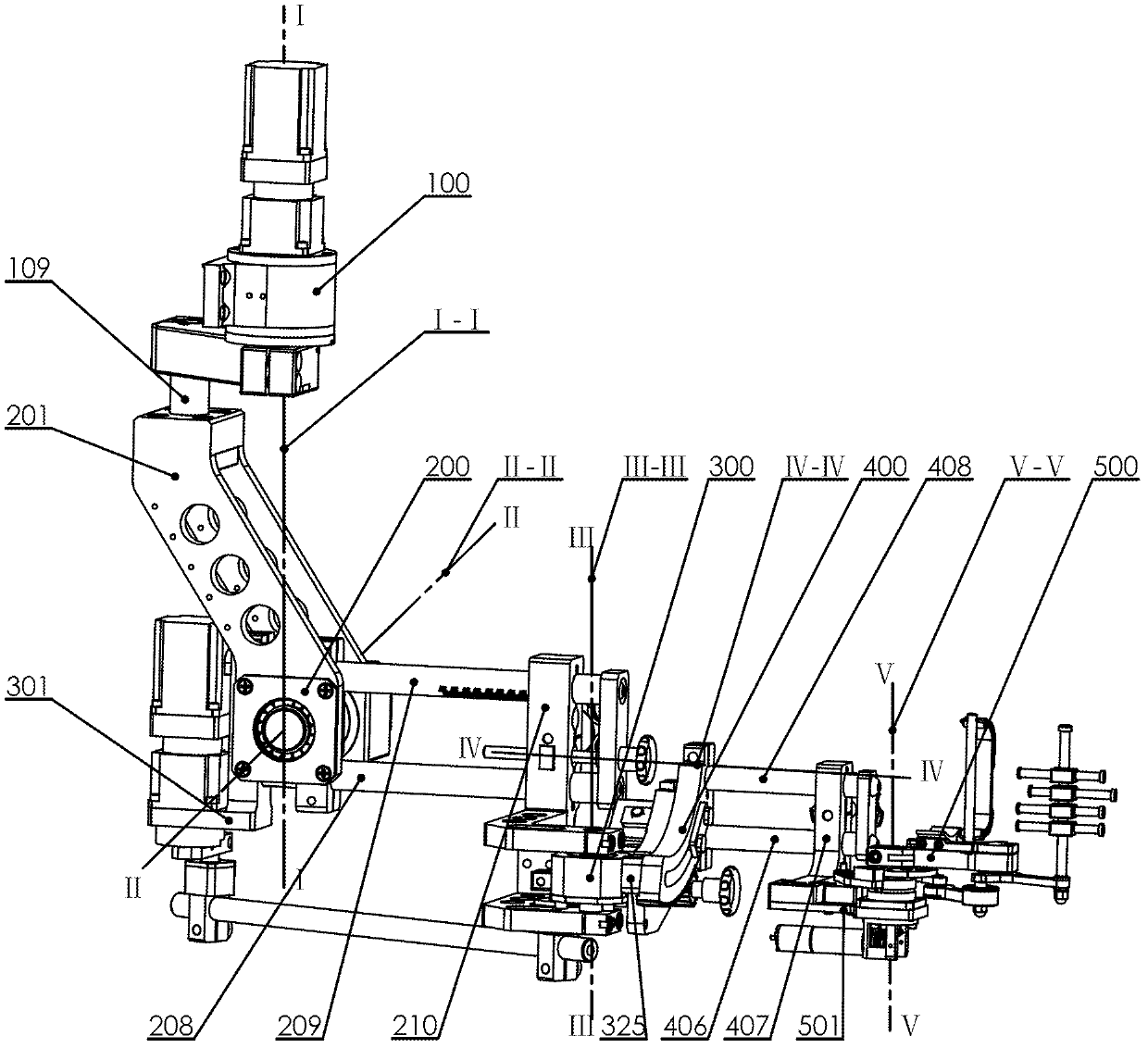

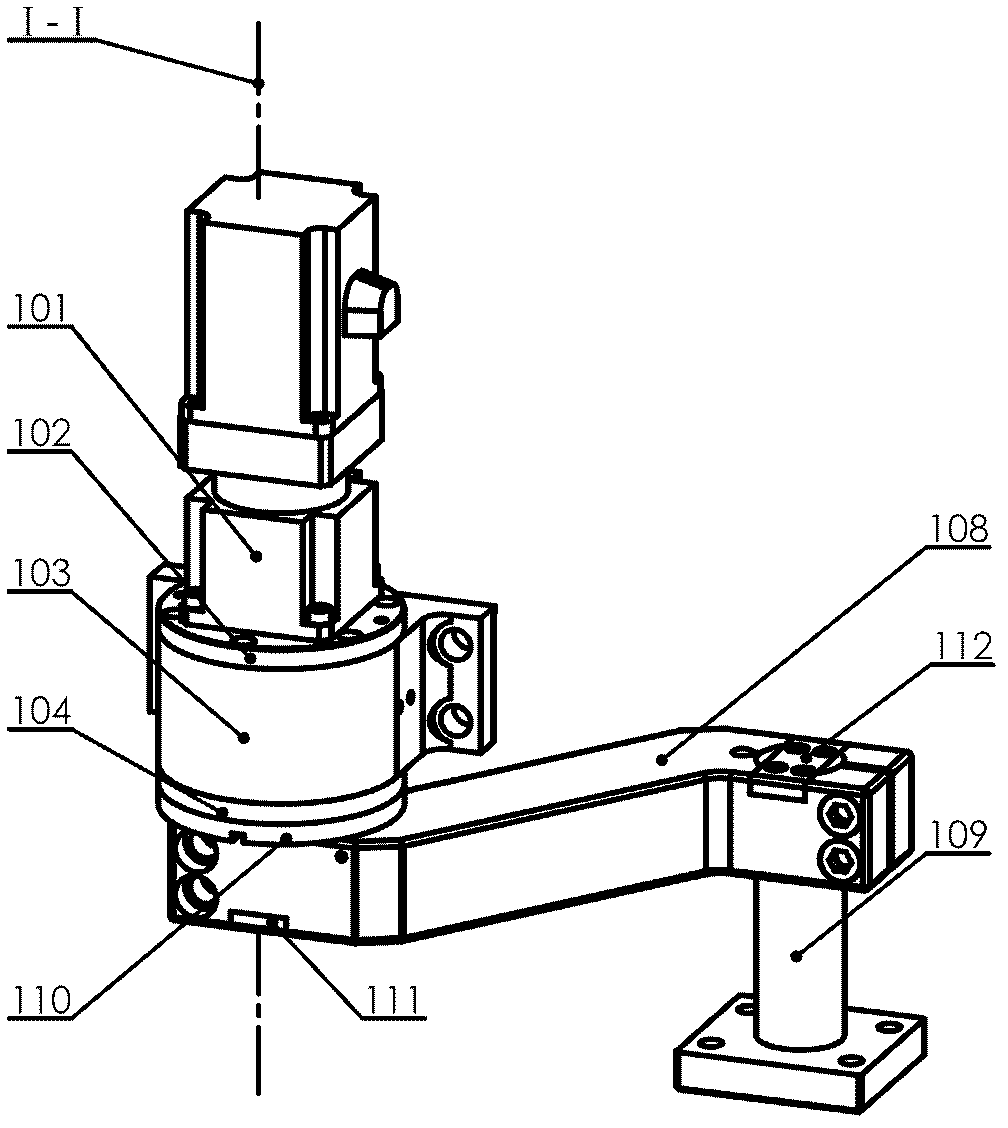

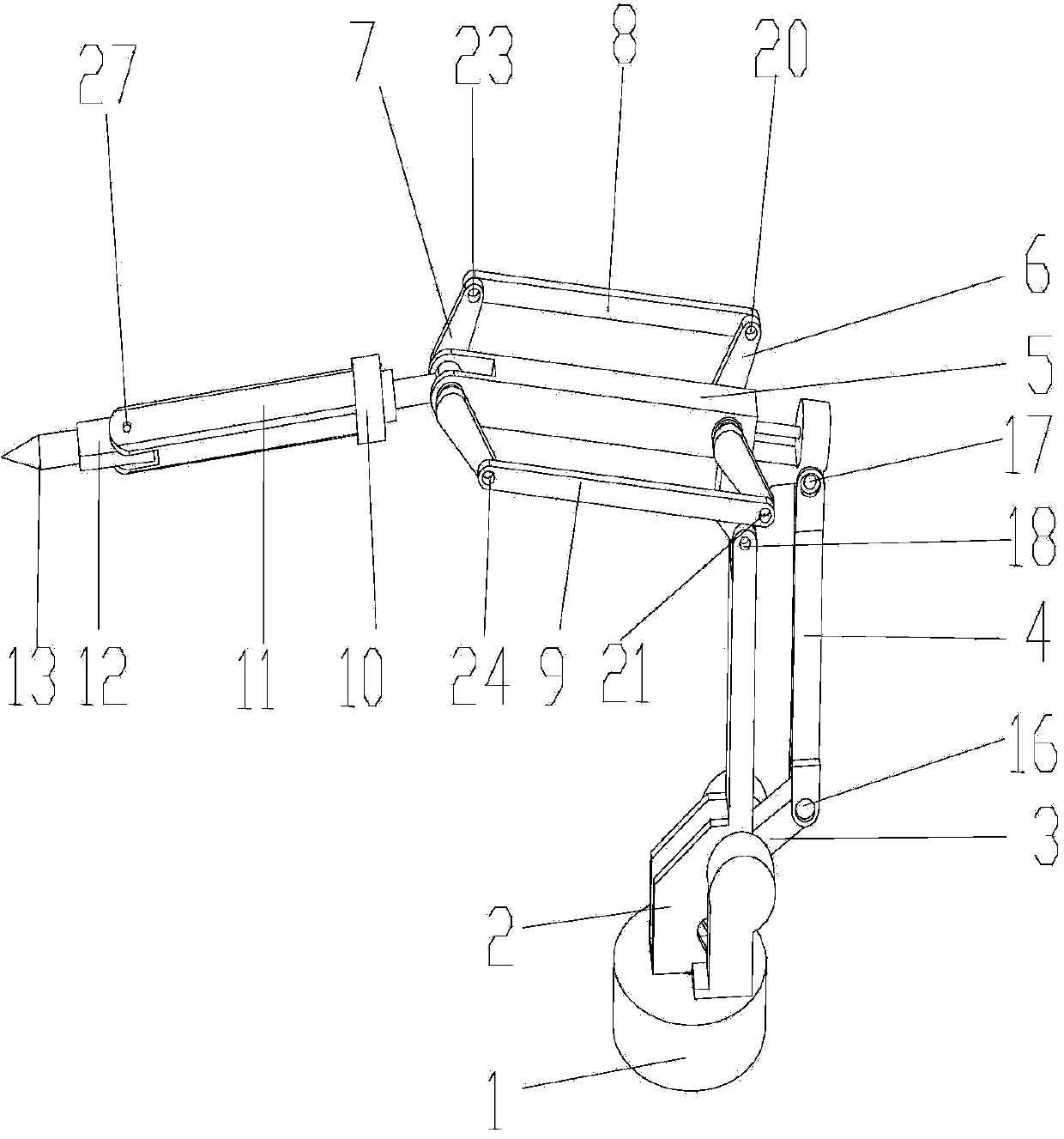

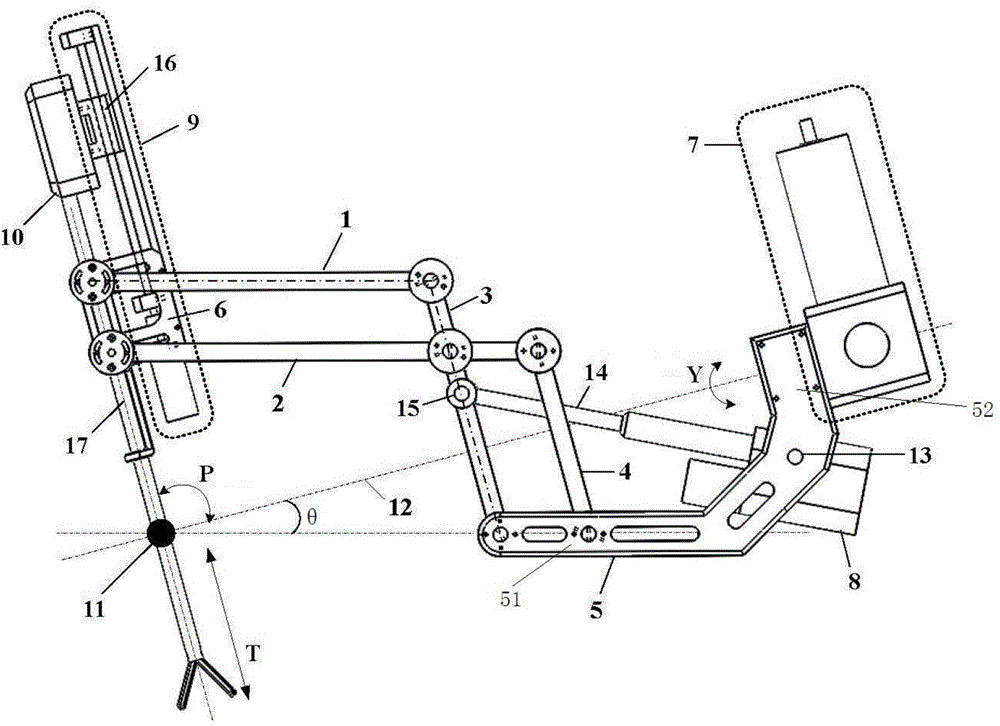

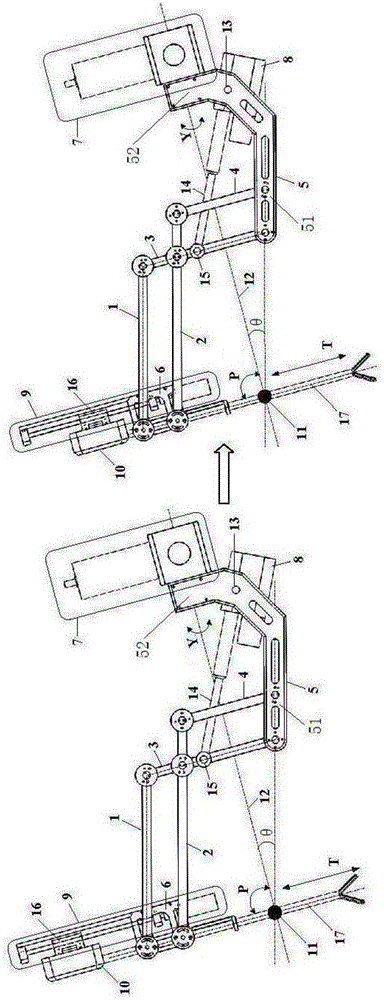

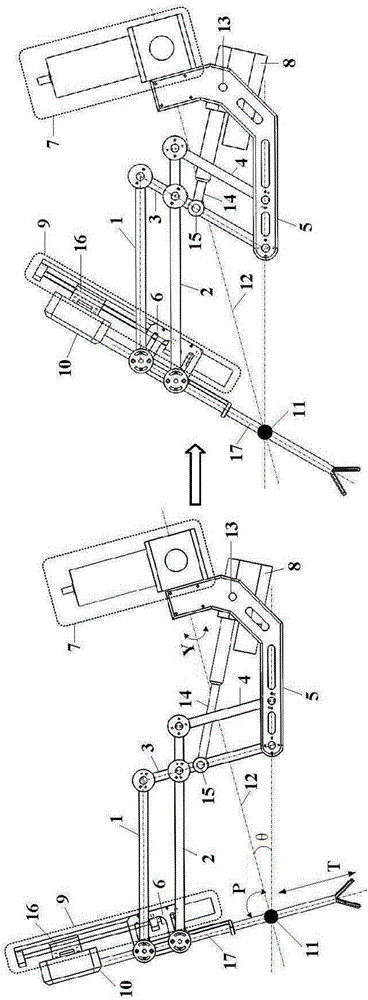

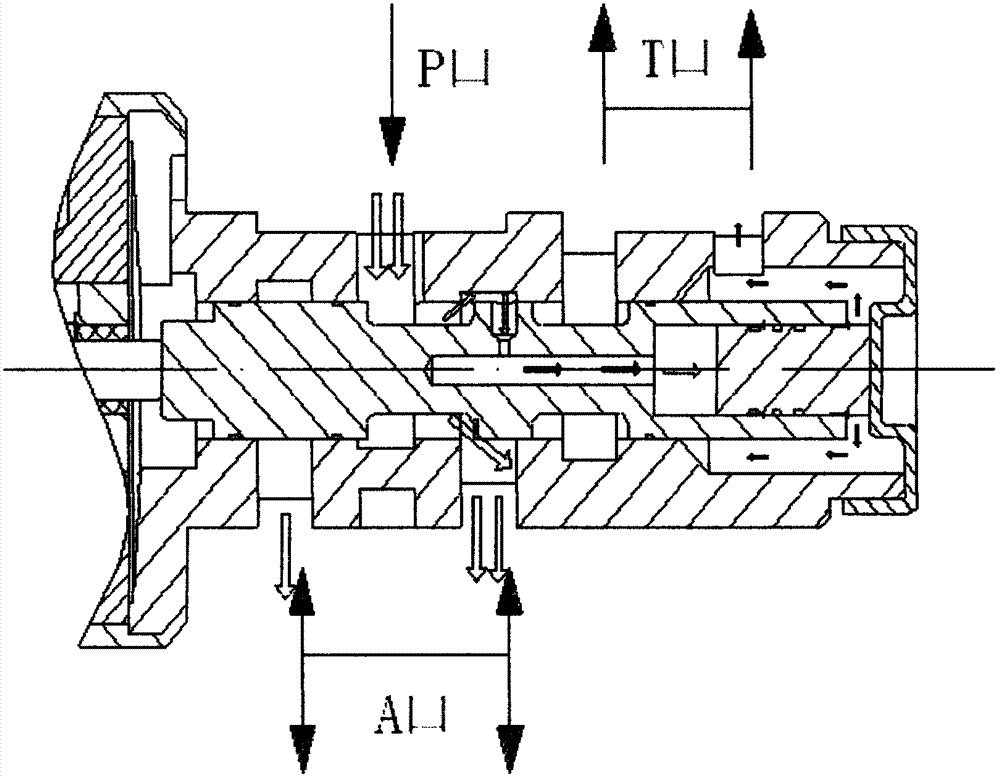

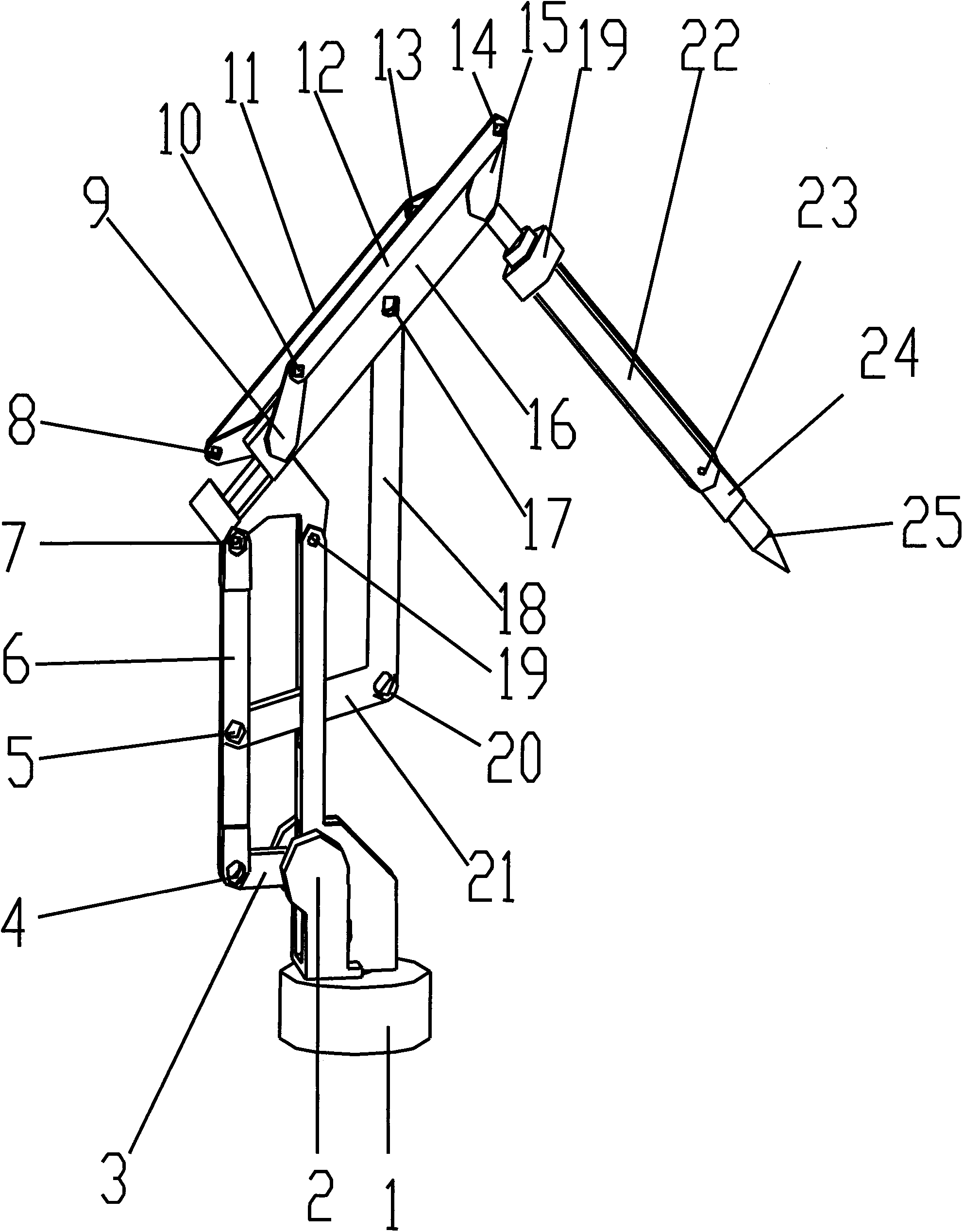

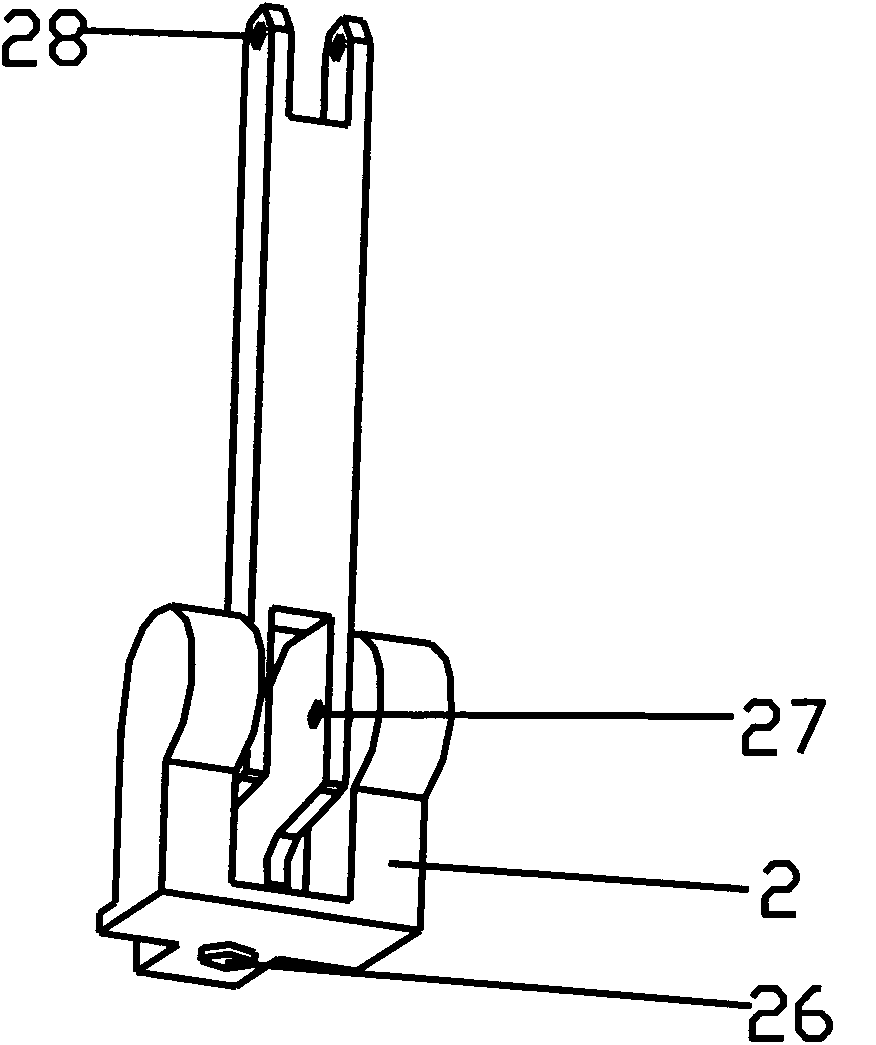

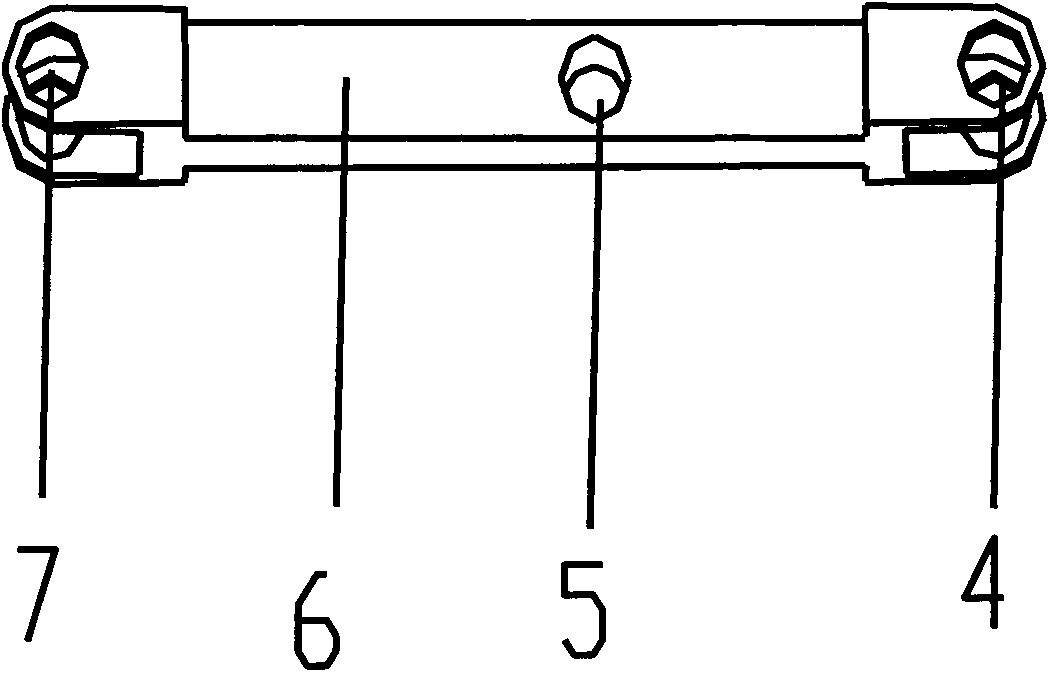

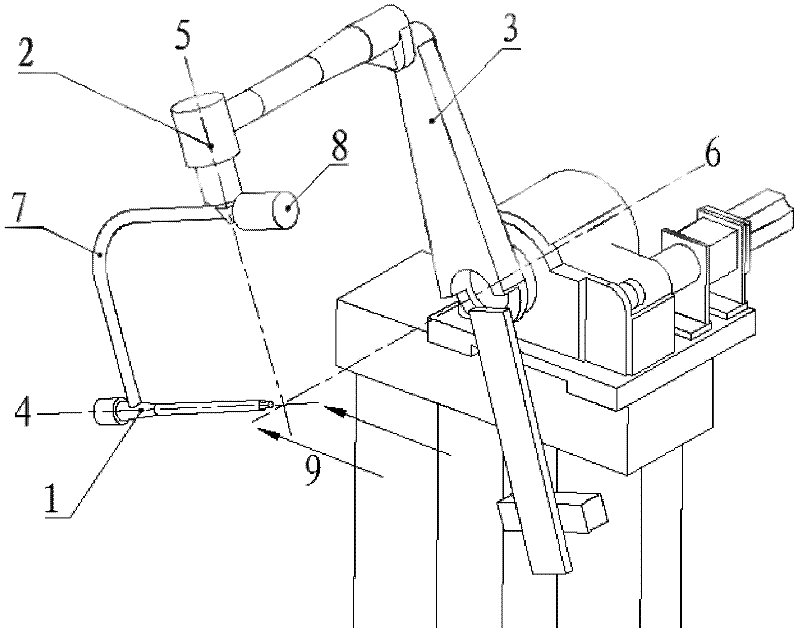

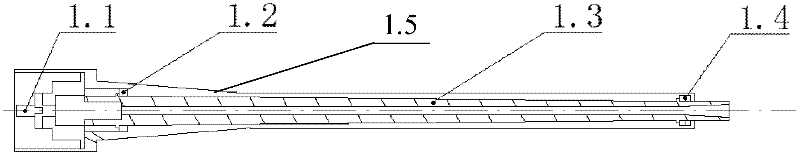

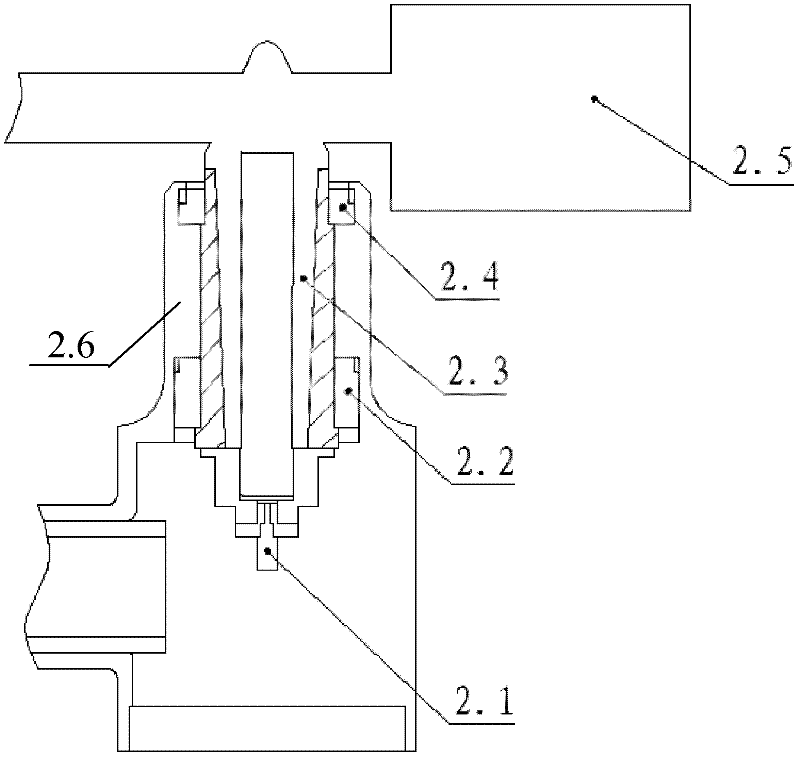

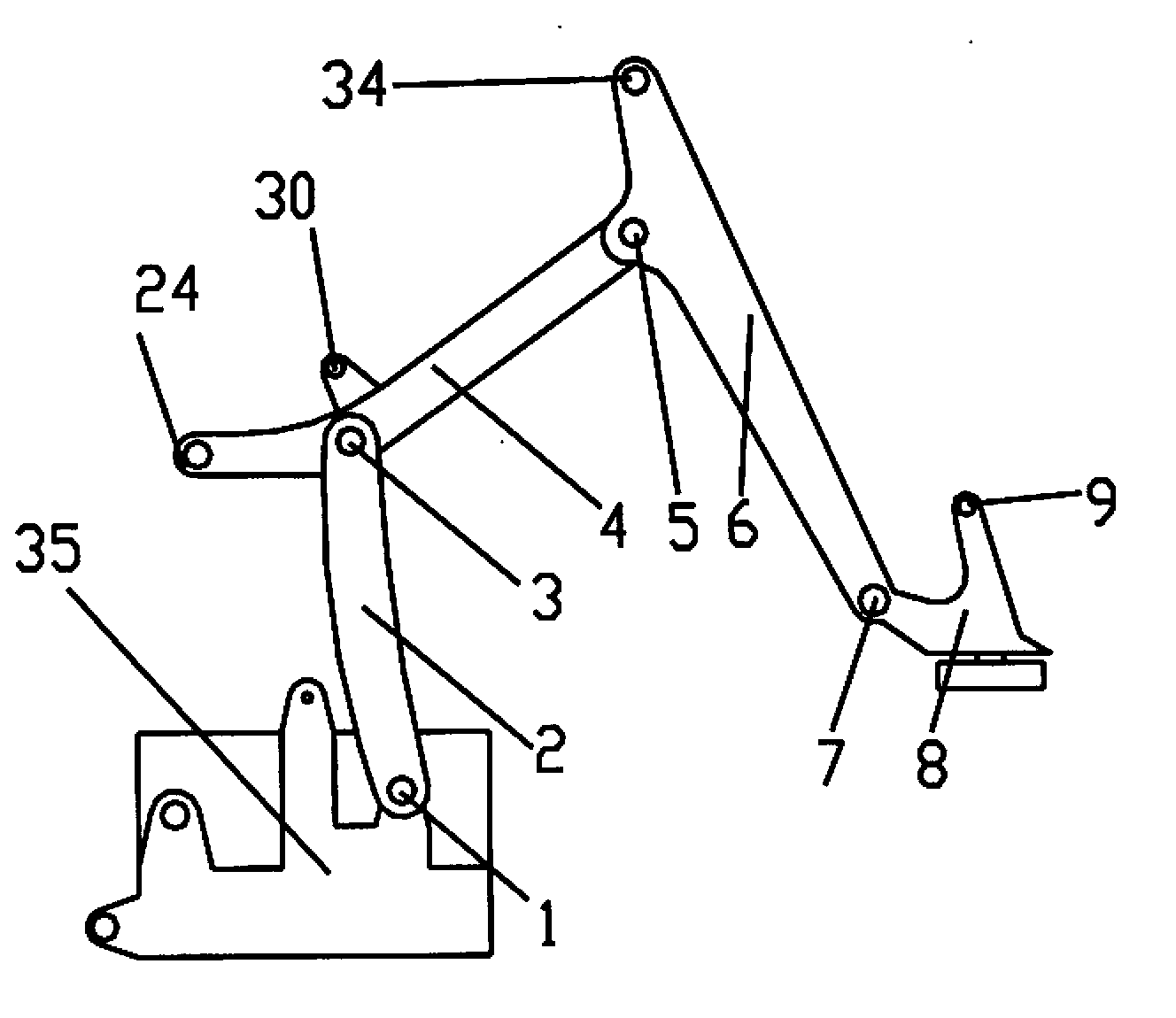

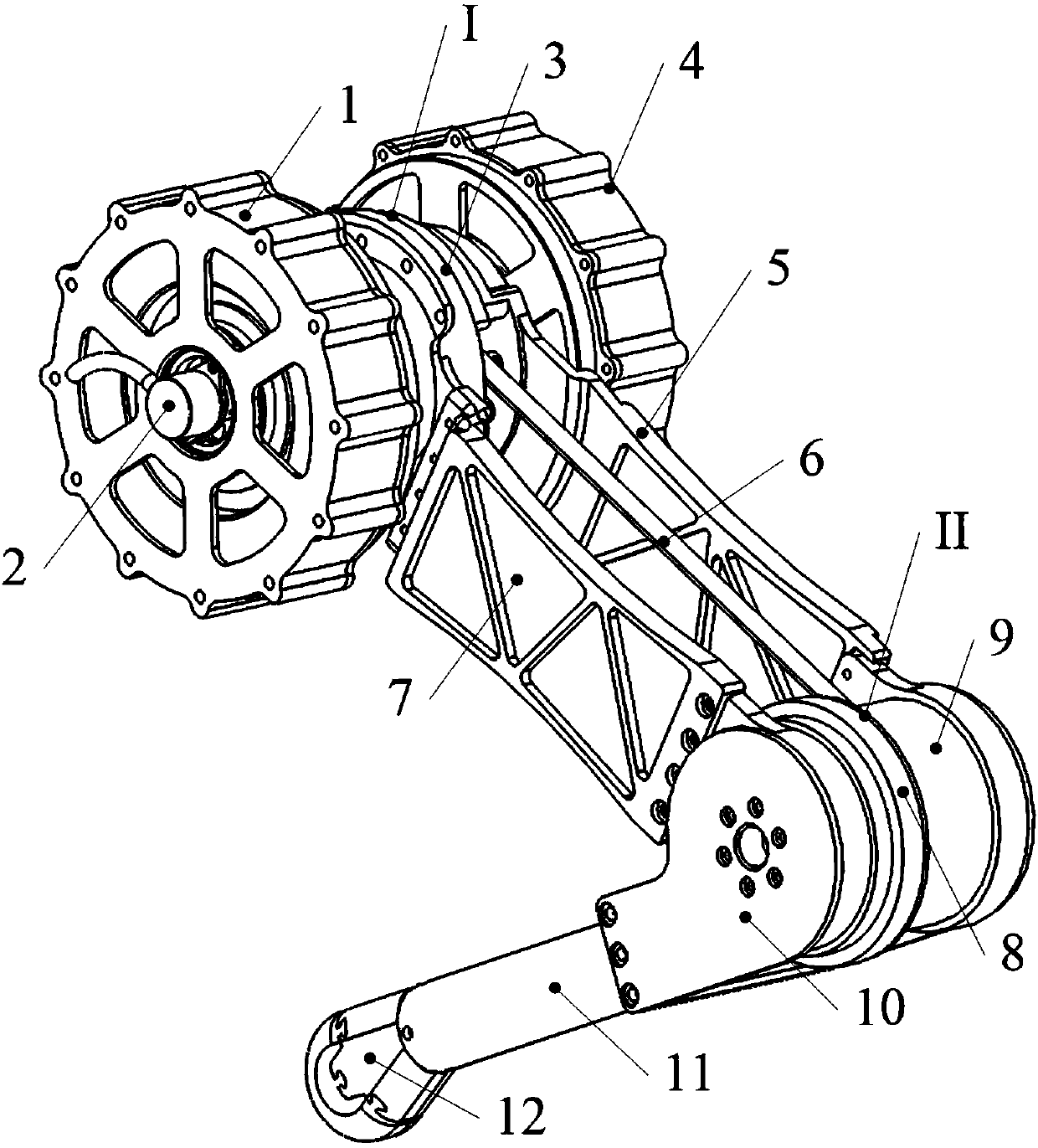

RCM mechanism for mechanical arm of laparoscopic minimally invasive surgical robot

InactiveCN104546147AReduced output torque requirementsSmall moment of inertiaDiagnosticsSurgeryLinear displacementPush and pull

The invention discloses an RCM mechanism for a mechanical arm of a laparoscopic minimally invasive surgical robot. The RCM mechanism disclosed by the invention comprises a connecting rod I, a connecting rod II, a connecting rod III, a connecting rod IV, a connecting rod V, a connecting rod VI, a linear motion output mechanism I, a linear motion output mechanism II, a rotation output mechanism and surgical instruments, wherein the six connecting rods form double parallelogram mechanisms. According to the RCM mechanism, motions of the surgical instruments including linear displacement freedom degree T, deflection freedom degree P and rotation freedom degree Y are correspondingly realized through the driving actions of the linear motion output mechanism I, the linear motion output mechanism II and the rotation output mechanism respectively; requirements of various freedom degrees to moment / torque of a driving mechanism are reduced through the double parallelogram mechanisms and the manner that the rotary centre axis of the rotation freedom degree Y and the connecting rod II form a certain included angle theta; the connecting rod III is directly pushed and pulled through the linear motion output mechanism II, so that the output moment / torque requirements to a freedom degree driving mechanism are reduced; and thus, the light weight and the miniaturization of the mechanical arm of the laparoscopic minimally invasive surgical robot are realized.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

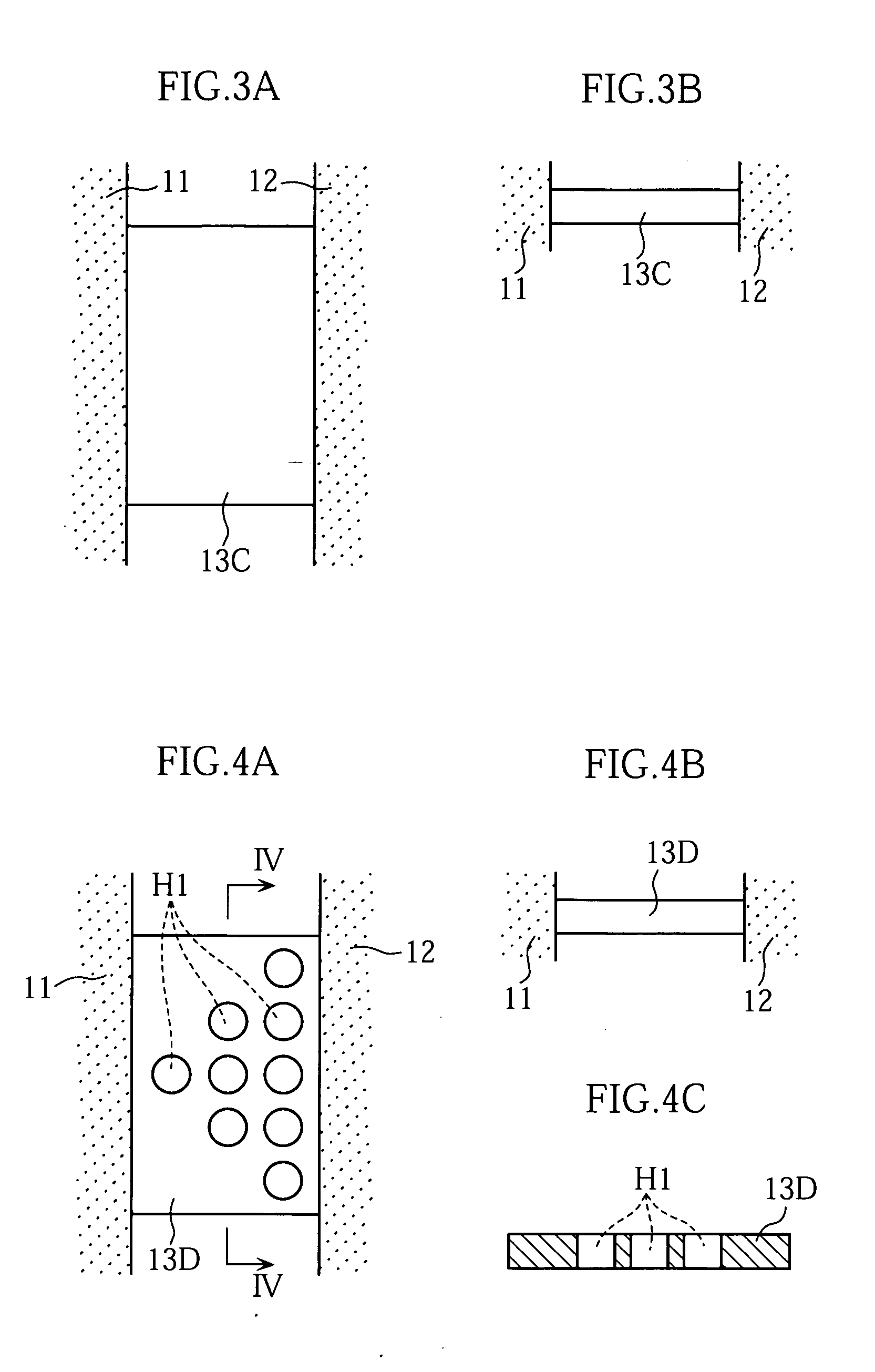

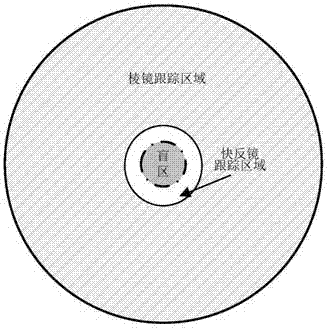

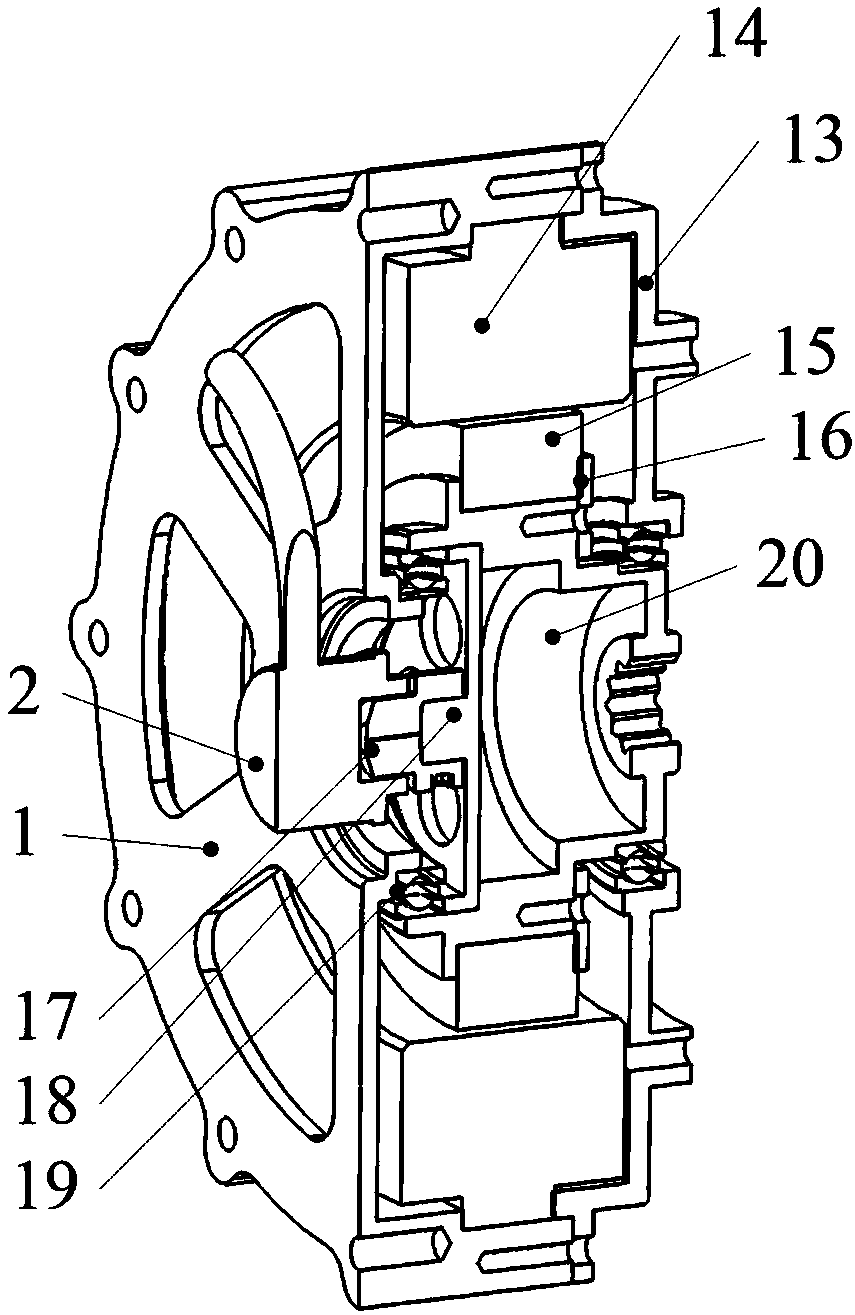

Bidimensional large-diameter fast control reflection mirror

A two-dimensional large caliber fast control reflection mirror is suitable for various optical systems to drive and stabilize the light beam. The problem to be solved is that, the requirement of the reflection mirror caliber larger than 250 mm is satisfied driven by a straight-line drive device, the inclination angle range and the resonance frequency of the fast control reflection mirror can be effectively improved and increased. The invention compares four blocks of distributed spring sheets to the central spherical hinge to implement the flexible rotation around the dual shafts of the reflection mirror and rigid fastening of the rest freedom degrees; the light weighting of the rotating body and the minimum of the rotational inertia around the shaft can be implemented by improving the reflection mirror fixing mode, uniting the rotating centers of the dual shafts and the gravity centers of the rotating body and light weighting design of the supporting frame and the reflection mirror; the compact whole structure and the small appearance size can be implemented by reasonable arrangements of the straight-line drive device and the micro-displacement position sensor.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

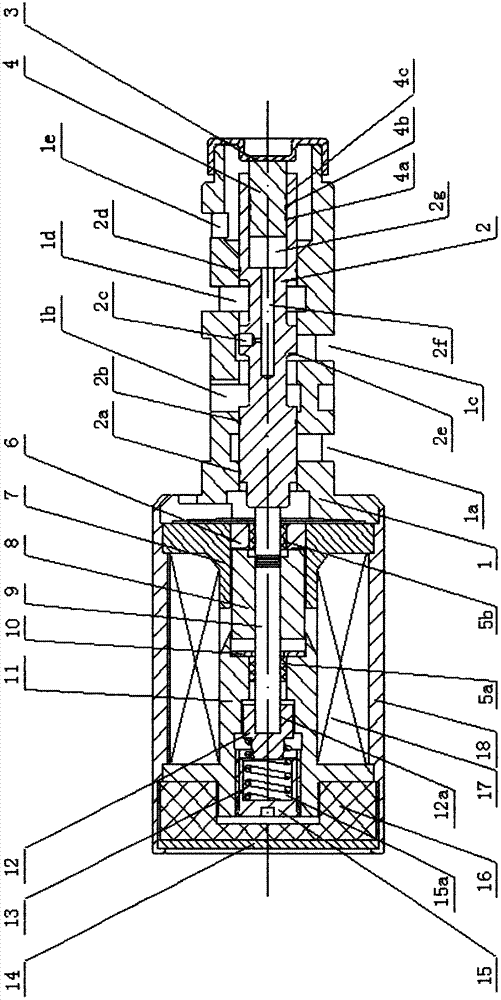

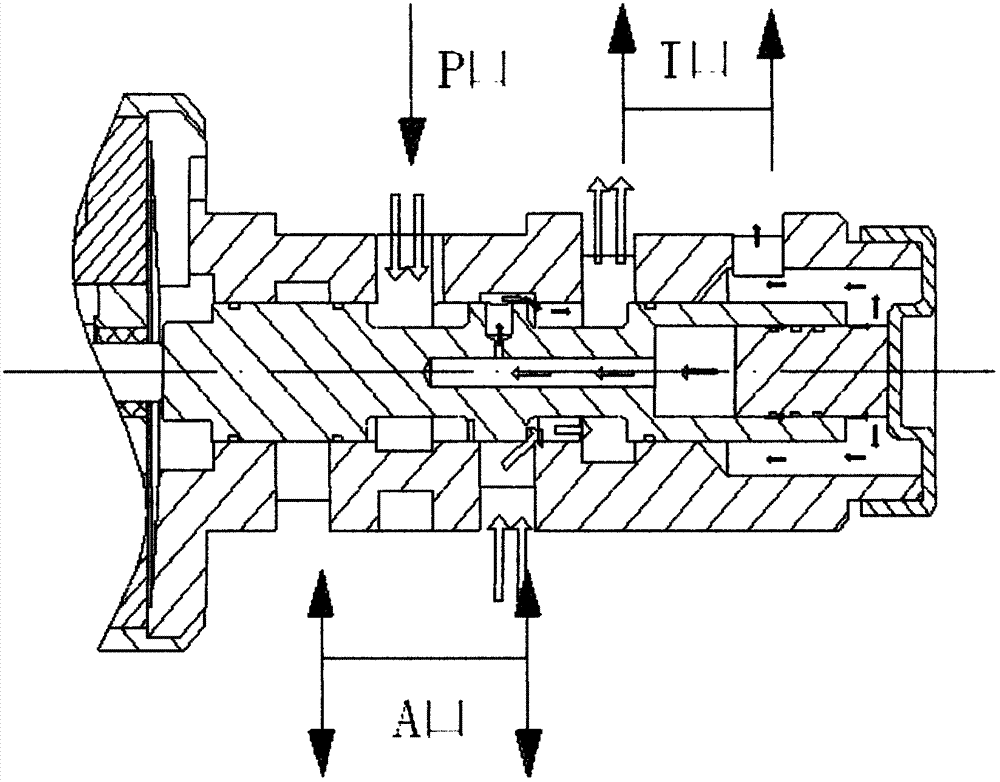

Two-position three-way inverse proportion decompression electromagnetic valve for AT (Automatic Transmission)

InactiveCN103032619ALight in massQuick responseOperating means/releasing devices for valvesMultiple way valvesAutomatic transmissionEngineering

The invention relates to a two-position three-way inverse proportion decompression electromagnetic valve for an AT (Automatic Transmission). The two-position three-way inverse proportion decompression electromagnetic valve is mainly formed by a main valve and a proportion electromagnet, wherein the main valve is formed by a valve body, a valve core which is positioned at the inner part of the valve body, a valve seat which is sleeved on the valve body and an inner valve core which is positioned at the inner part of the valve core and close to one side of the valve seat, and the proportion electromagnet is formed by a sliding bearing, a bearing seat, a pole shoe, an armature, a top rod, a stroke gasket, a stop iron, a spring seat, a regulating spring, a baffle plate, a regulating screw, a baffle plate cushion, a coil and a yoke iron. According to the two-position three-way inverse proportion decompression electromagnetic valve disclosed by the invention, the problems such as lower response speed, larger pressure fluctuation, short service life, large leakage rate and high manufacturing cost of an existing inverse proportion decompression electromagnetic valve for the AT are solved, and the two-position three-way inverse proportion decompression electromagnetic valve disclosed by the invention has the advantages of high response speed, small pressure fluctuation, long service life , small leakage rate, lower manufacturing cost and the like.

Owner:兰溪市中元贸易有限公司

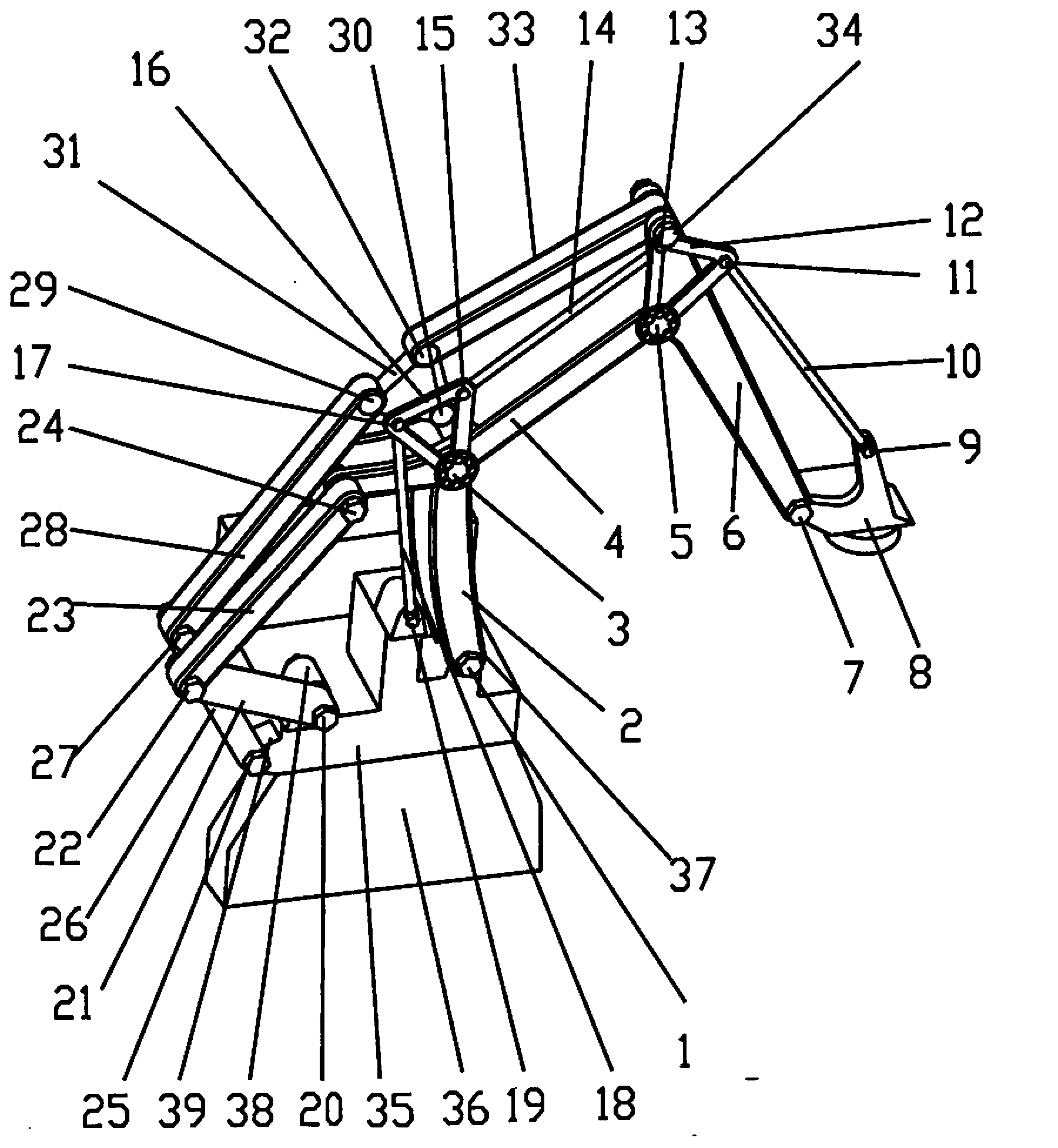

Controllable multi-degree of freedom welding robot

InactiveCN103707289AIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorWelding/cutting auxillary devicesClosed loopEngineering

A controllable multi-degree of freedom welding robot comprises four controllable four-link-mechanism closed-loop executing mechanism subchains which are in parallel connection and an executing main chain in series connection. A main chain connecting rod can be controlled by the controllable four-link-mechanism closed-loop executing mechanism subchain to move within the surface with the controllable four-link-mechanism closed-loop executing mechanism subchains. The spatial motion of a moving platform can be achieved by the motion of a first connecting rod and a body. According to this arrangement, the spatial motion of an end effector can be achieved, motion inertia is small, dynamics performance is good and reliability is high. The controllable multi-degree of freedom welding robot has the advantages of being compact in structure and easy to control. The rods can be made as light rods, work spaces for mechanisms are large, gravity centers of the mechanisms are moved backwards to keep balance. The controllable multi-degree of freedom welding robot can be widely used.

Owner:GUANGXI UNIV

Device for simulating free yawing/rolling movement under pitching movement of aircraft

An experimental device for simulating free yawing / rolling movement of an aircraft in two degrees of freedom in an air tunnel mainly comprises a free yawing support rod and a free rolling support rod which are fixedly connected with a pitching mechanism. The experimental device is mainly characterized in that the central axis of the free yawing support rod and the central axis of the free rolling support rod are perpendicular to that of a pitching movement device, the three axes are intersected at one point, a rotary shaft of the yawing support rod is connected with the rolling support rod through a connecting rod and drives the rolling support rod to yaw, a rolling rotary shaft of the rolling support rod is fixedly connected with a model, and the rotary shaft of the yawing support rod and the rotary shaft of the rolling support rod are supported by bearings in the corresponding support rods and can freely move without being restrained. In order to realize yawing of the yawing support rod, a counterweight block needs to be placed on the connecting rod between the yawing support rod and the rolling support rod, and the centers of mass of the connecting rod and the rolling support rod are adjusted onto the axis of the yawing rotary shaft.

Owner:BEIHANG UNIV

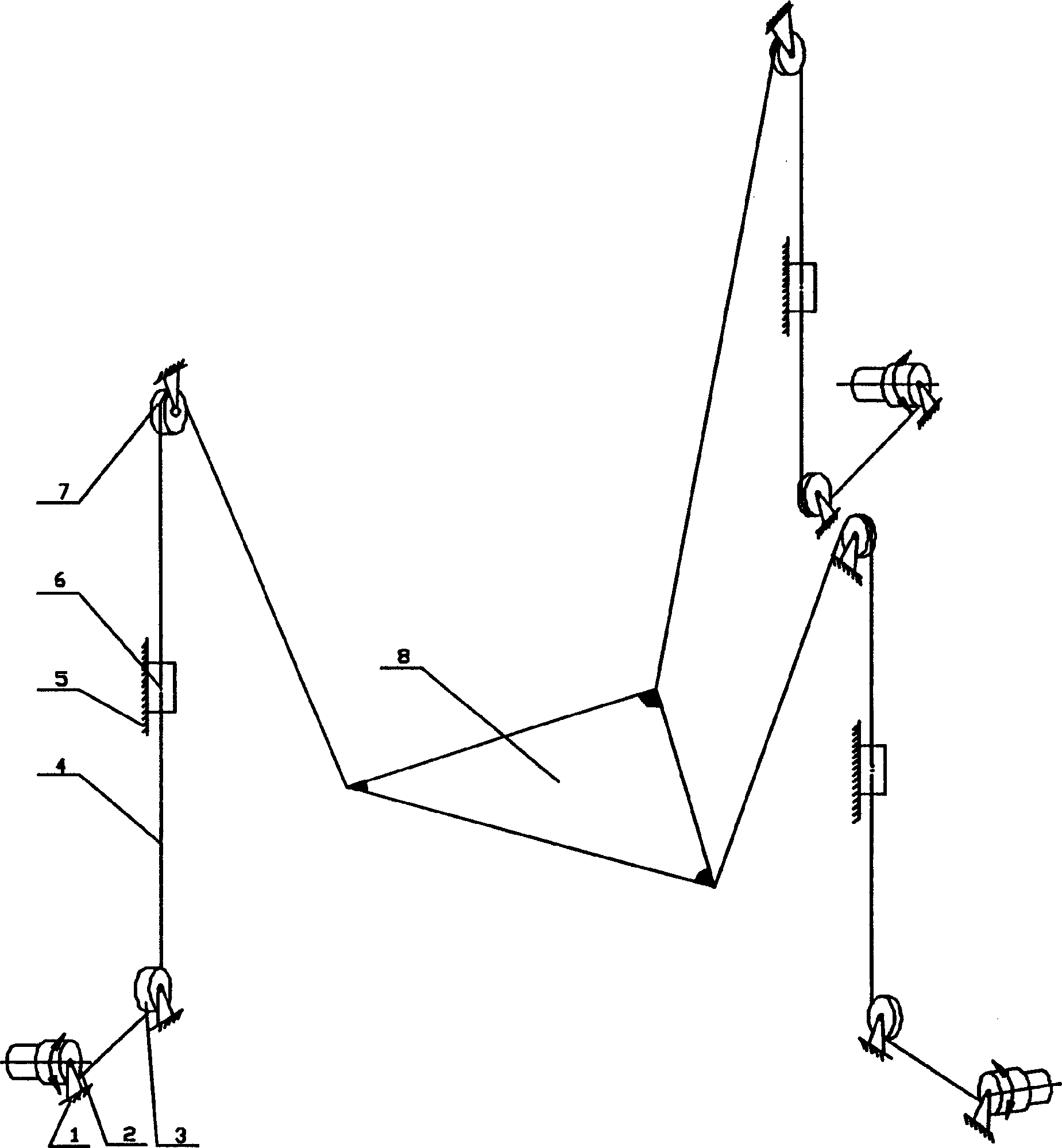

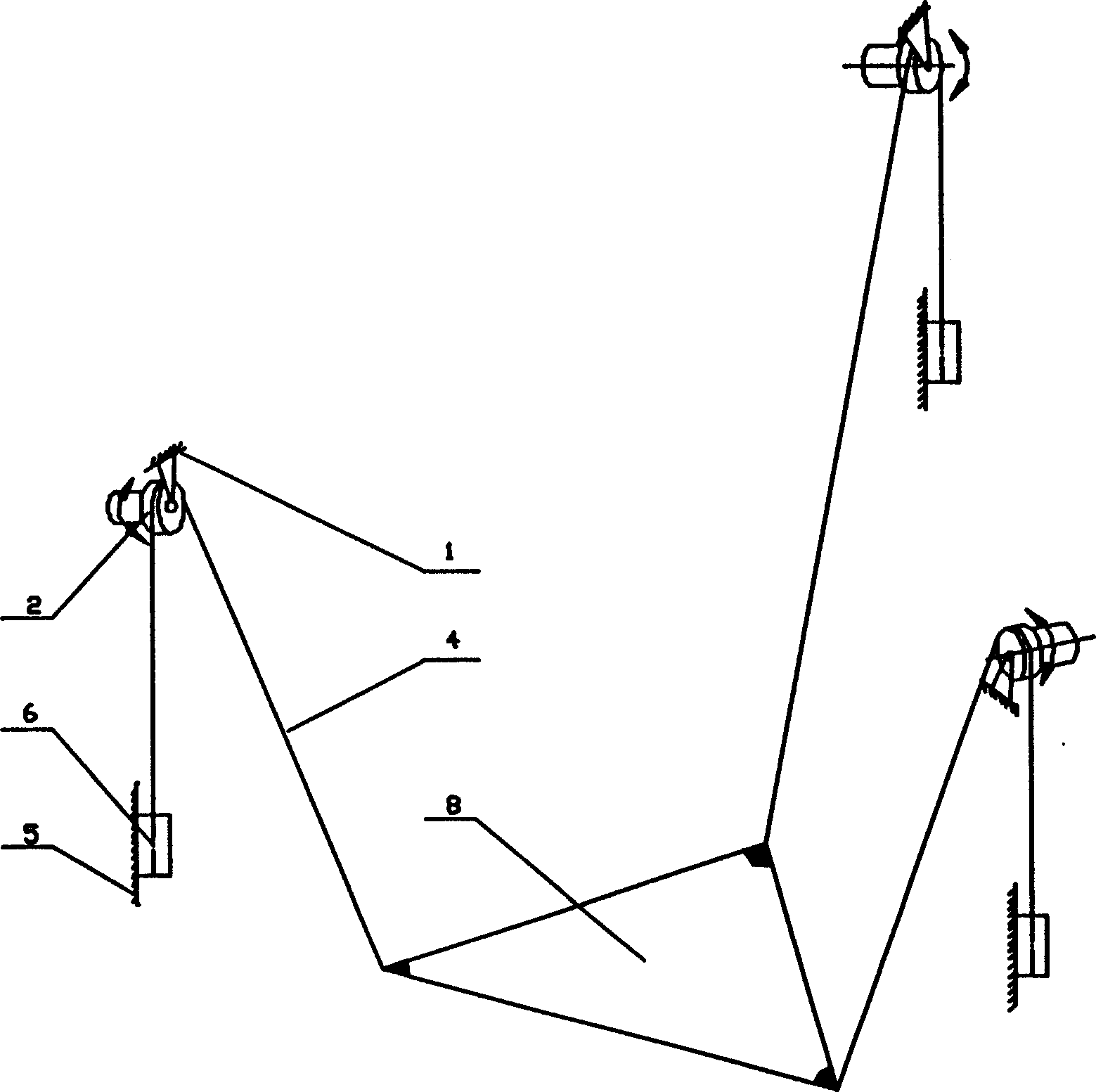

Three-freedom parallel mechanism driven by flexible rope

A flexible cable driven three-freedom parallel mechanism is composed of three drive units and moving platform. The said driven unit comprises base, reel installed along with motor and vertical column. The steel wire cable wound on the said reel passes through lower static pulley, counterweight and upper static pulley and then fixed to the moving platform. The steel wire cables for threed drive units are all fixed to the moving platform to form a triangle. Its advantages are big working space and high stressing performance and speed.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

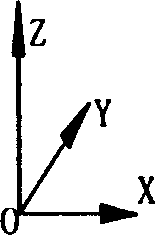

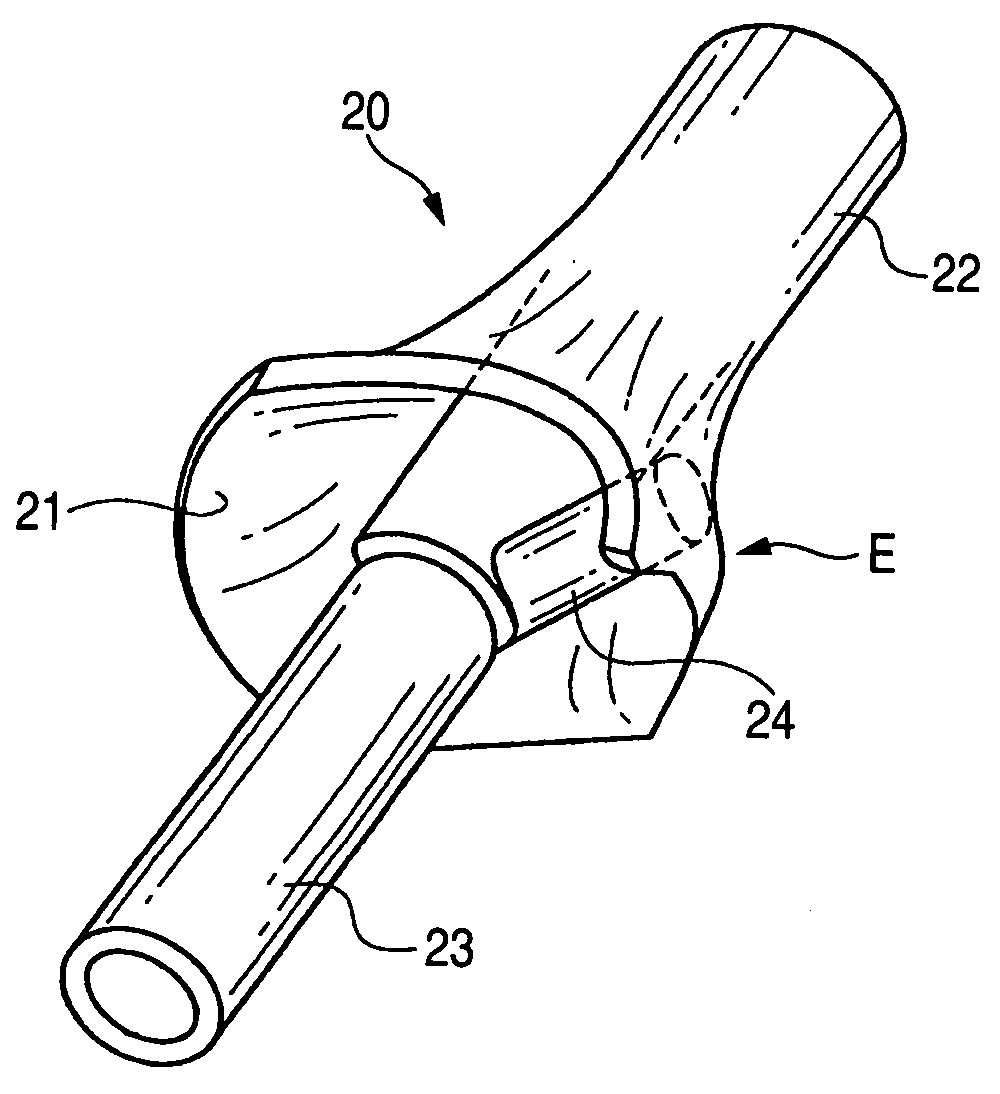

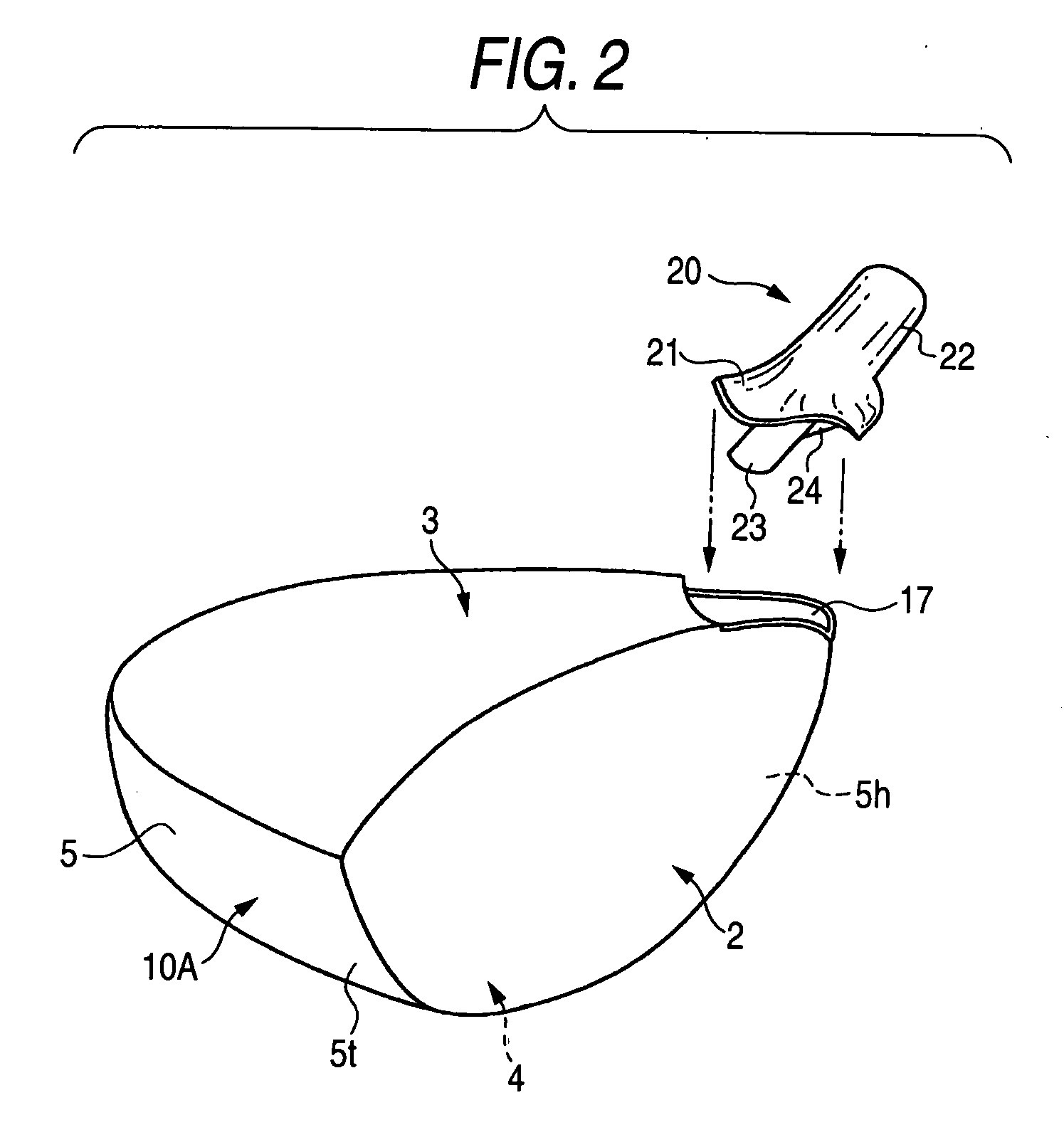

Golf club head

A weight material is provided on a heel side of a hosel portion in a golf club head. A convex portion E is provided on the heel side of the head. The weight material is disposed within the convex portion. The weight material is made of high specific gravity metal such as tungsten, and welded on both a lower column and a skirt portion.

Owner:BRIDGESTONE SPORTS

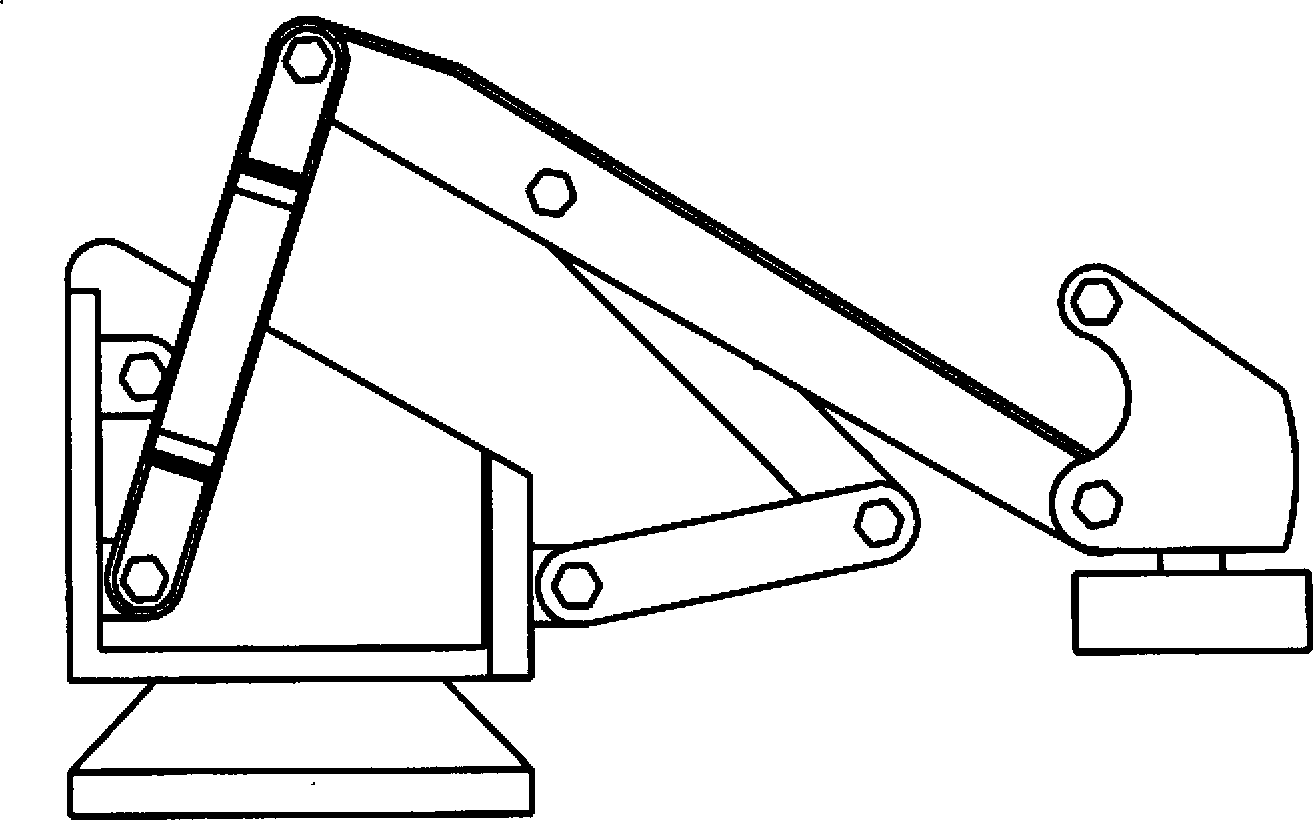

Large-work-space controllable-mechanism stacker crane

InactiveCN103056875AStrong flexible outputLarge working spaceProgramme-controlled manipulatorStacking articlesPalletizerEngineering

The invention relates to a large-work-space controllable-mechanism stacker crane. The stacker crane comprises a large-arm swing branch chain, a mid-arm swing branch chain, a small-arm swing branch chain, a posture keeping branch chain, an end executor and a rack. A robot completes carrying stacking operations with large work space and flexible changeable track output through the combined movement of the large-arm swing branch chain, the mid-arm swing branch chain and the small-arm swing branch chain. Three groups of parallelogram structures of the posture keeping branch chain can guarantee that the end executor keeps a horizontal state constantly in a working process, and all servo motors are mounted on the rack, bars can be made into light bars, the robot moving inertia is small, the dynamic performance is good, and requirements for high-speed and heavy-duty carrying and stacking can be well met. According to the stacker crane, a novel connection rod mechanism is utilized, so that the carrying and stacking work space is large, the connection rod transmission mechanism is simple, stresses on the bars are improved, and the manufacture of large stacker crane is applicable.

Owner:GUANGXI UNIV

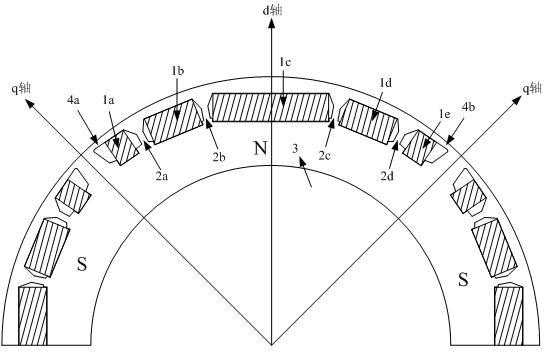

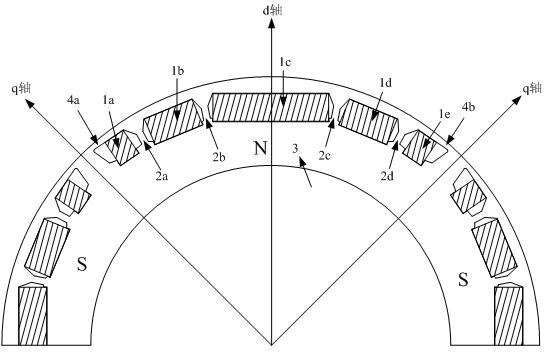

Double-channel fault tolerant type flux switch permanent magnet motor and control method thereof

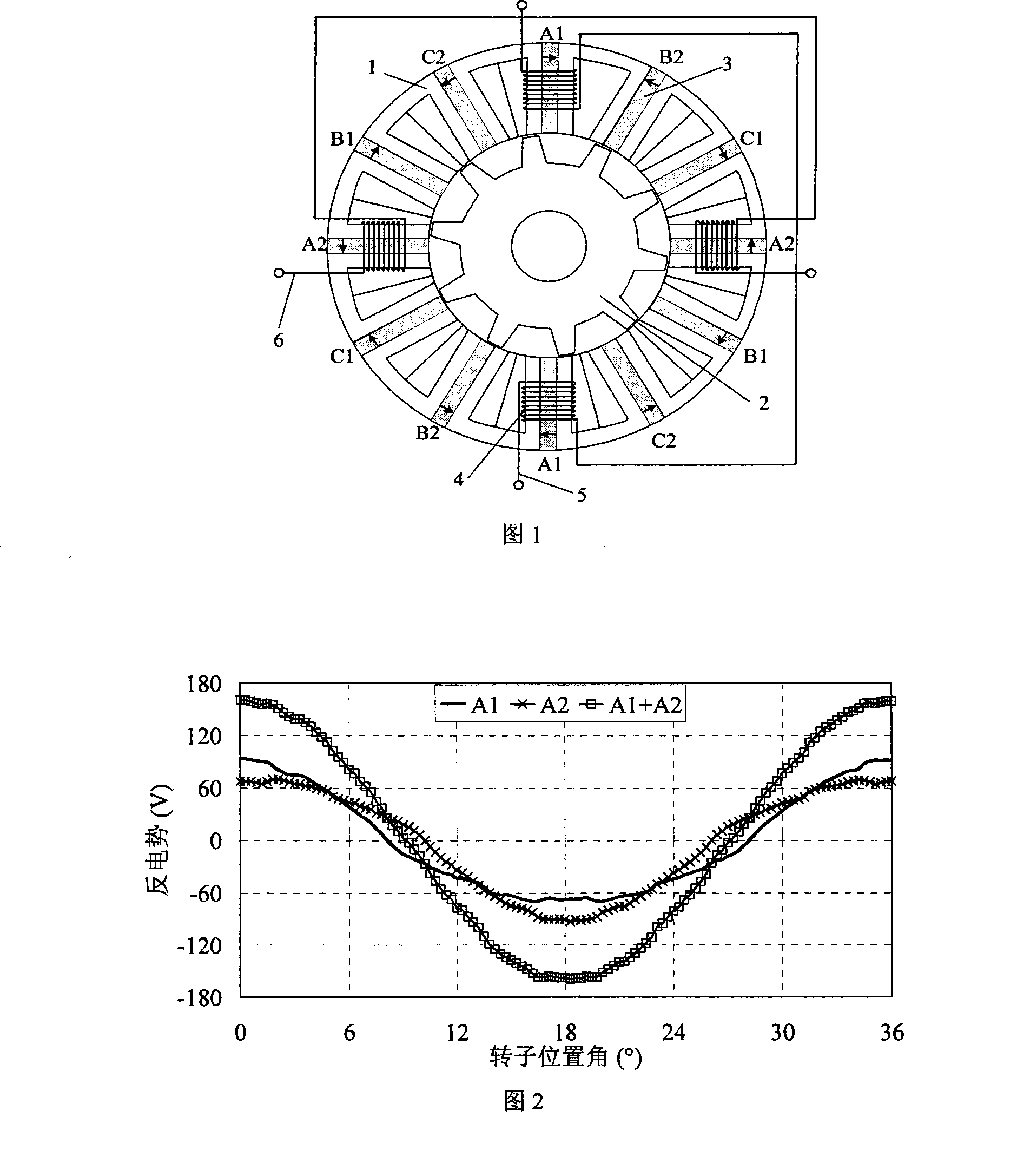

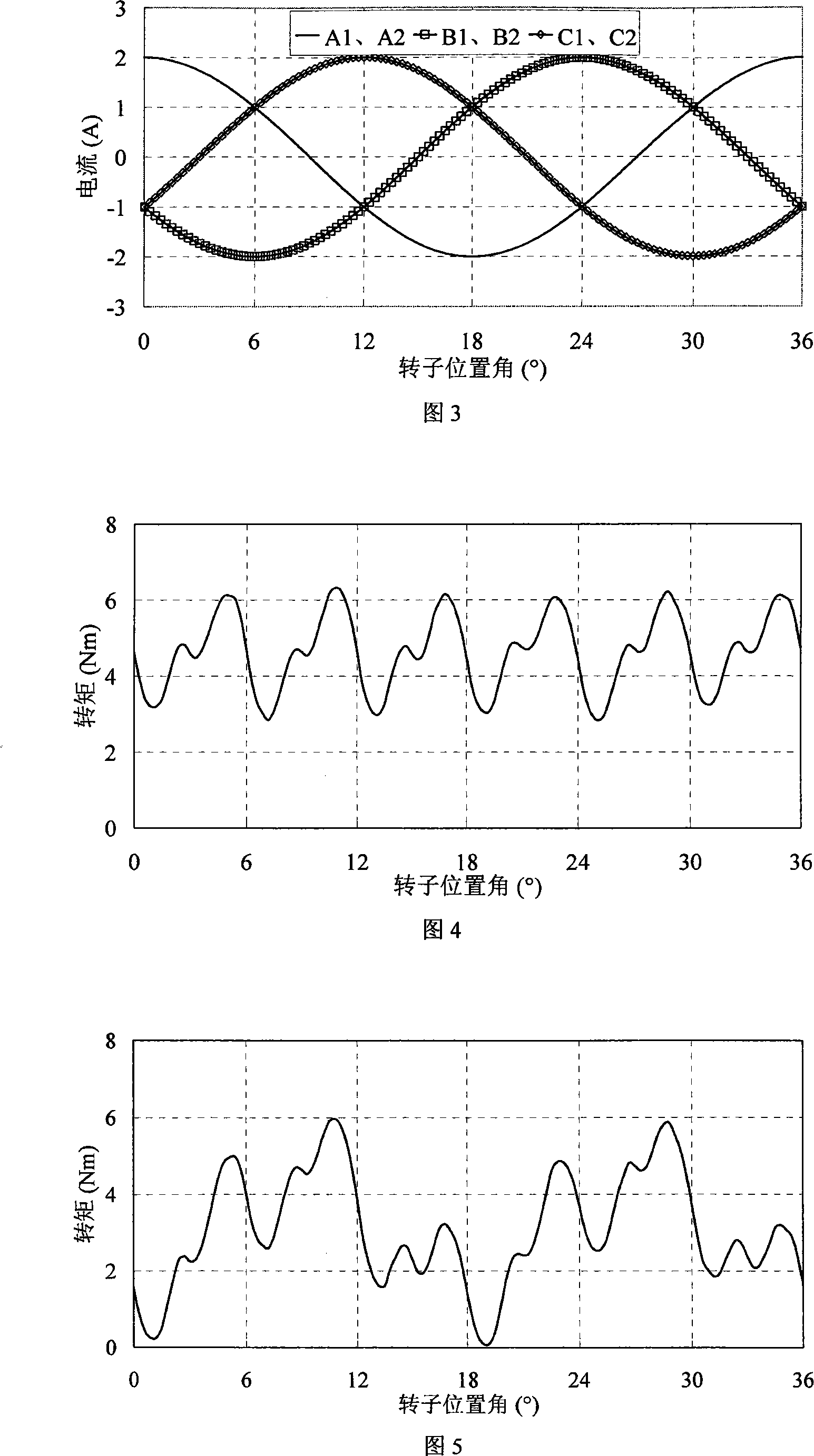

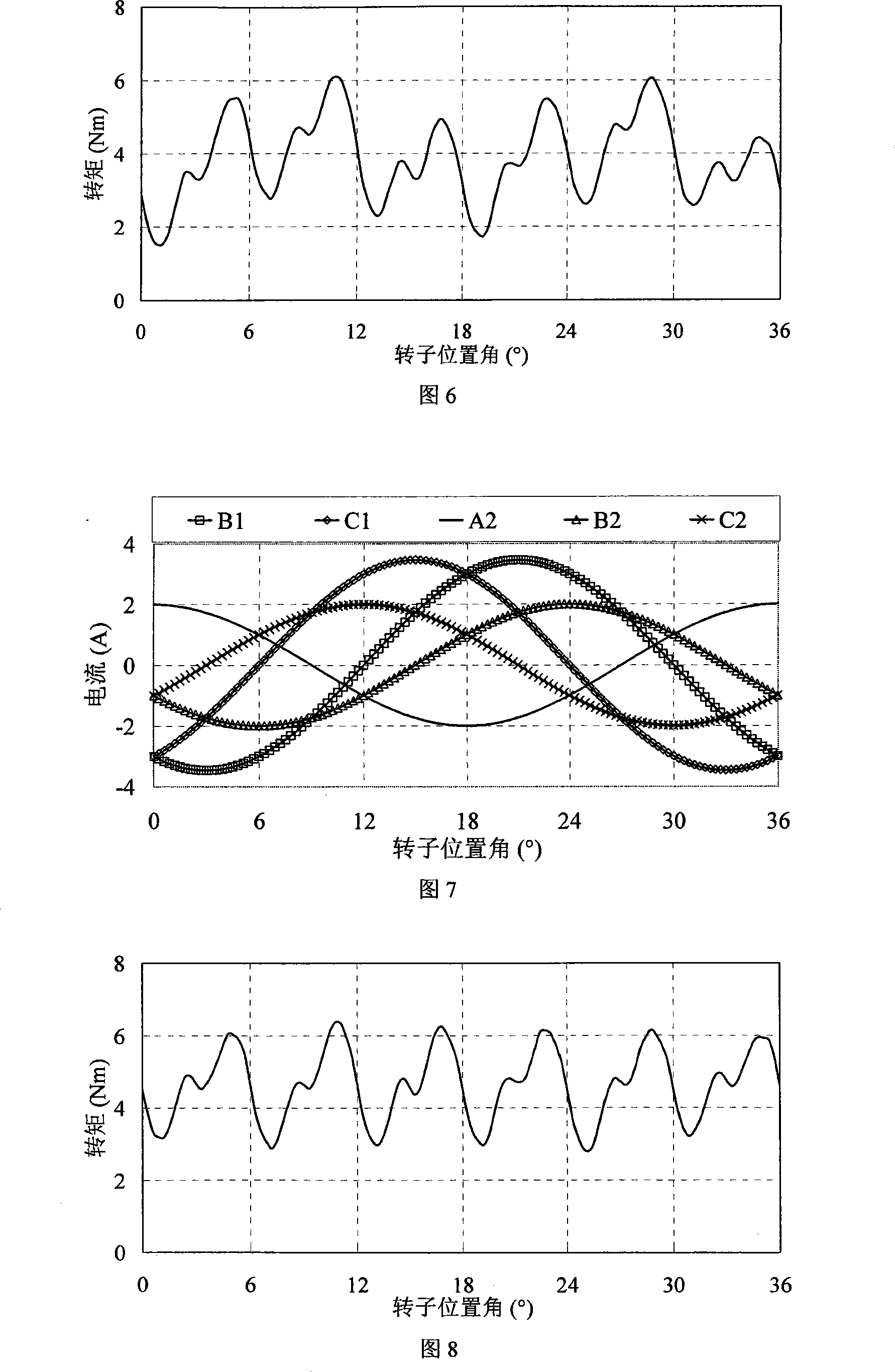

InactiveCN101159391AImprove reliabilityImprove power densityTorque ripple controlMagnetic circuit rotating partsFault tolerancePhase currents

A dual-channel fault tolerant flux switch permanent magnet motor is a novel stator permanent magnet motor. The fault tolerant motor adopts a doubly salient structure, and the inner loop of the stator (1) is provided with salient poles evenly. Permanent magnets (3) are arranged onto the circle of the stator in pairs, which can be cooled easily; the rotor (2) adopts a simple salient structure, without windings nor permanent magnets. The fault tolerance motor integrates the advantages of a switch magnet resistance motor and a rotator permanent magnet fault tolerance motor, and has the advantages of high credibility, high power density, and preferable operating capacity when a failure occurs. The invention provides a fault tolerance strategy, and can improve the electromagnetic performance of the motor when a failure occurs by adjusting the phase and amplitude of non-fault phase current; the invention can accomplish the torque output in the approximately normal running status and have high theory and practical value.

Owner:SOUTHEAST UNIV

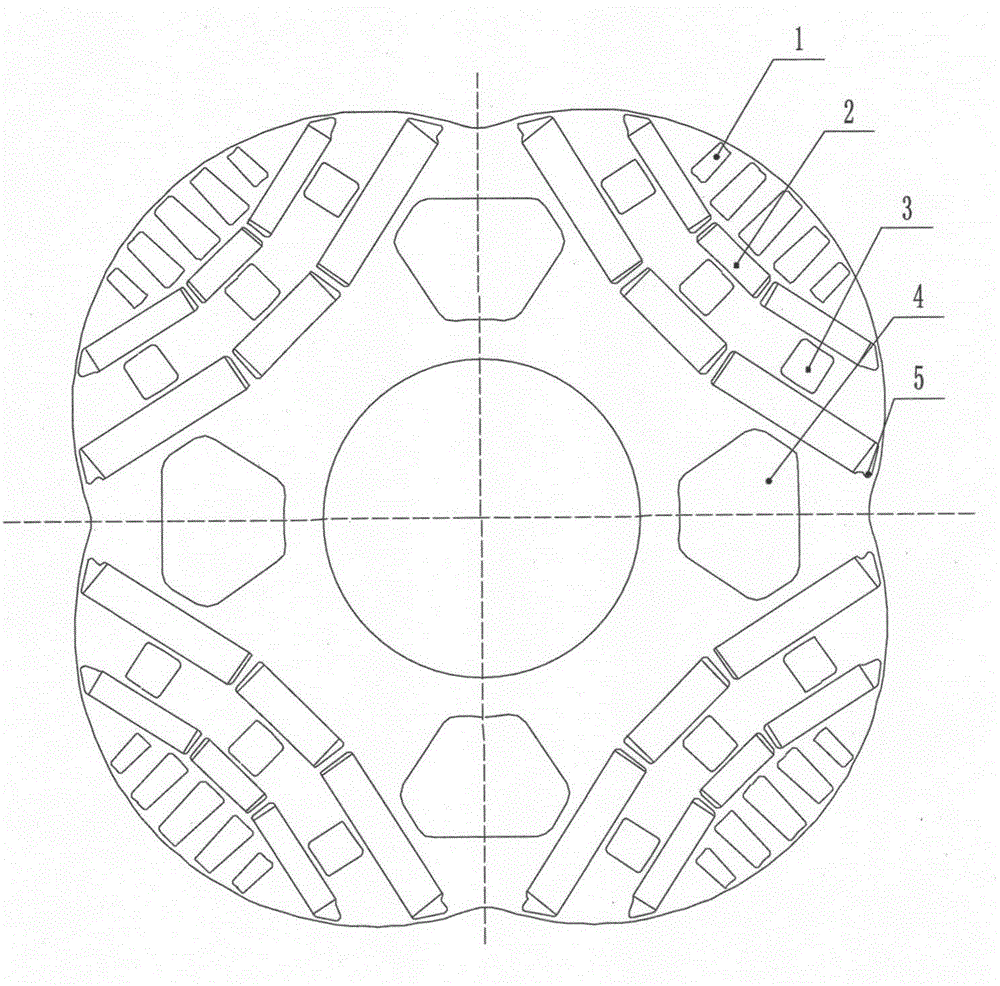

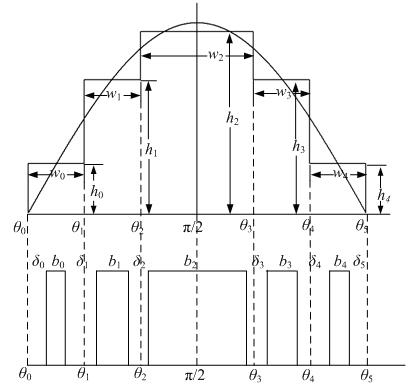

Rotor punching structure for permanent-magnet servo motor

ActiveCN104882981AImprove back EMF waveformReduce additional stray lossMagnetic circuit rotating partsPunchingCoupling

The invention provides a rotor punching structure for a permanent-magnet servo motor, and the structure comprises a rotor punching body. The peripheral surface of the rotor punching body is provided with permanent magnet tanks, and the interior of each permanent magnet tank is provided with a permanent magnet in an embedded manner. The external circle of the rotor punching body above the permanent magnet tanks is not concentric with the internal circle of a stator. The rotor punching body above the permanent magnet tanks is provided with magnetic isolation holes which are arranged horizontally, and the rotor punching body below the permanent magnet tanks is provided with an axial cooling channel. The permanent magnet tanks are radially arranged in a layered manner, and magnetic isolation tanks are respectively disposed between the adjacent permanent magnet tanks. Magnetic isolation bridges are disposed among the magnetic isolation tanks and the permanent magnet tanks. Through the improvement of the rotor punching structure and the control of the direction of a magnetic field, the nonlinear impact, caused by the coupling of quadrature-axis and direct-axis magnetic circuits, on motor parameters is reduced, and the space of a rotor punching is used fully for placing permanent magnets as many as possible. Moreover, the capability of resistance to demagnetizing and the overbearing capability of the permanent-magnet servo motor are improved, and the operation performance of the permanent-magnet servo motor is effectively improved.

Owner:SHANGHAI MOTOR SYST ENERGY SAVING ENG TECH RES CENT +2

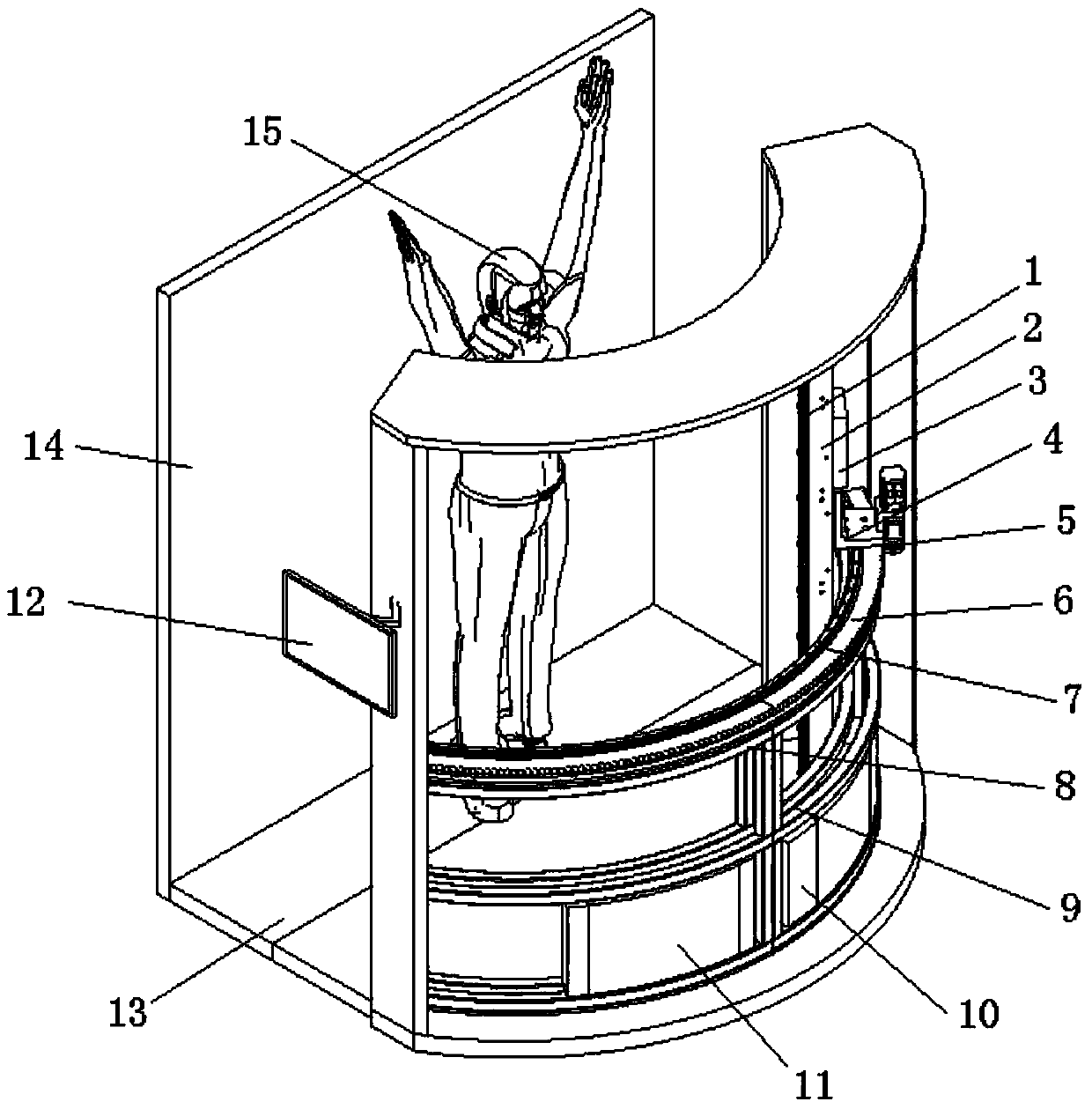

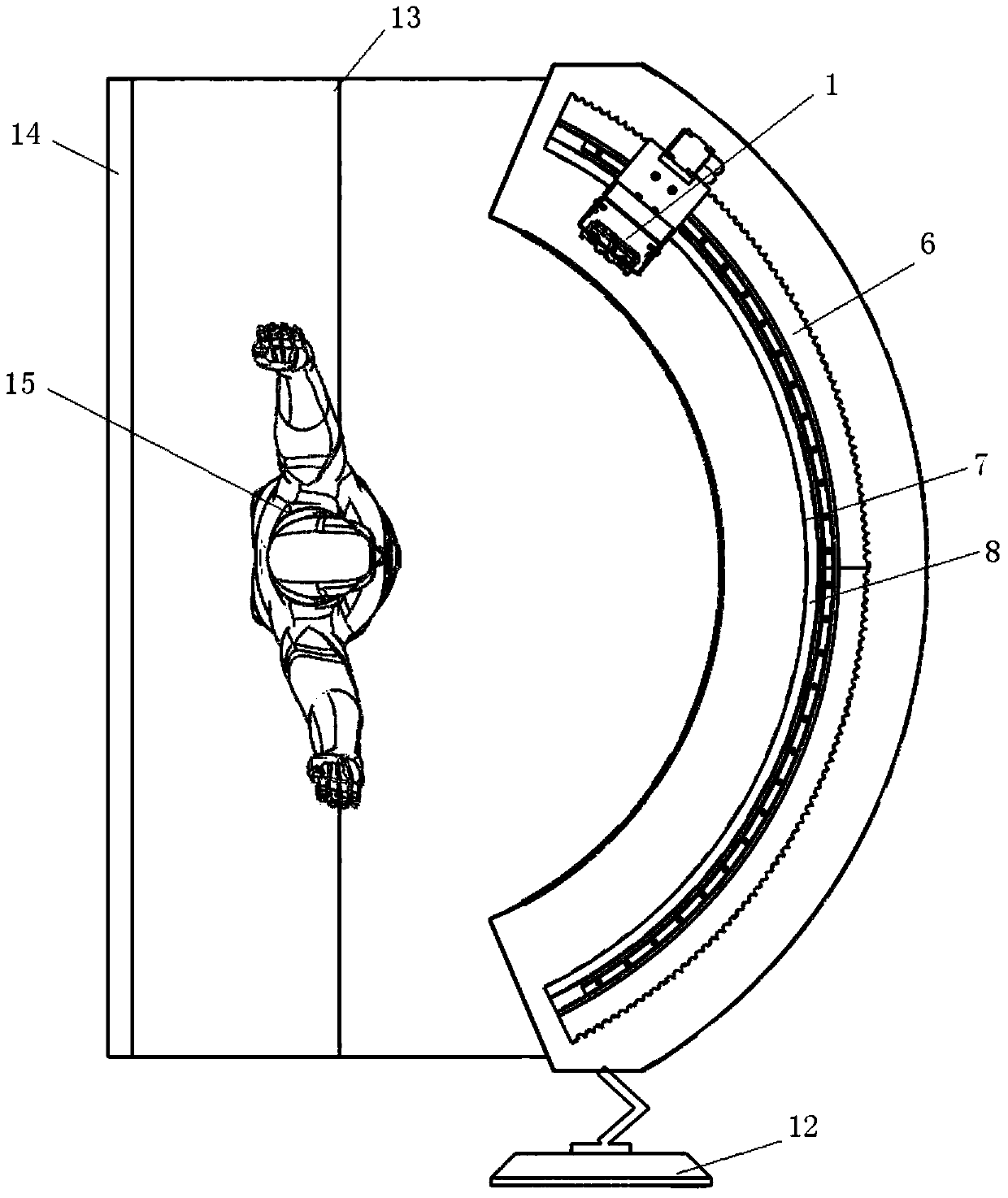

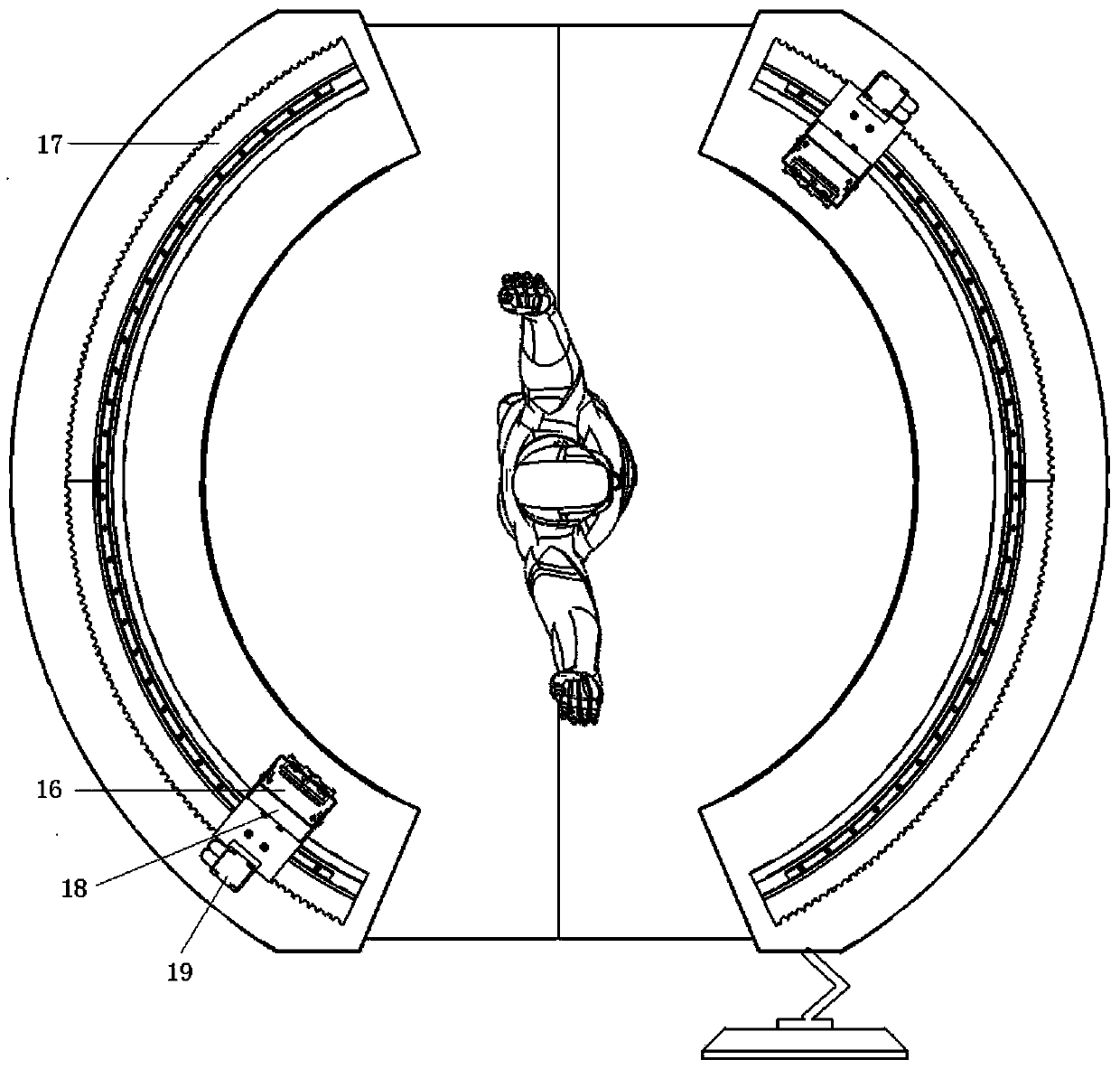

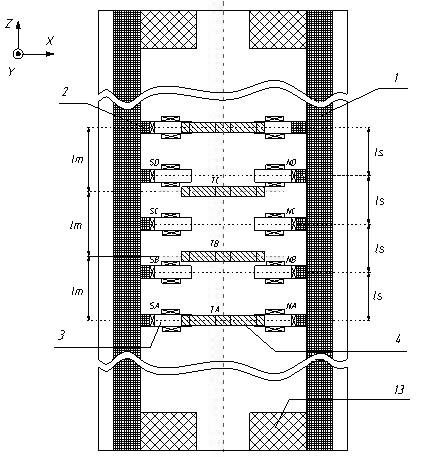

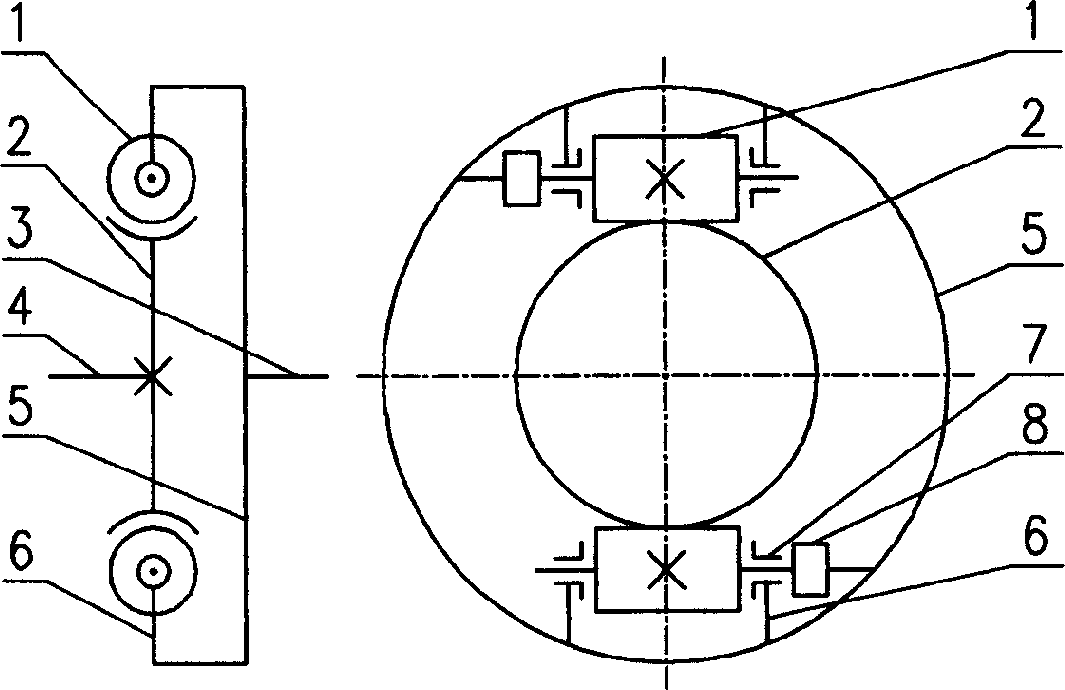

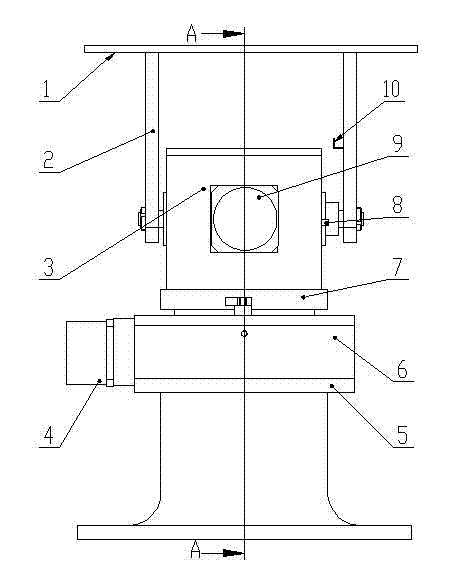

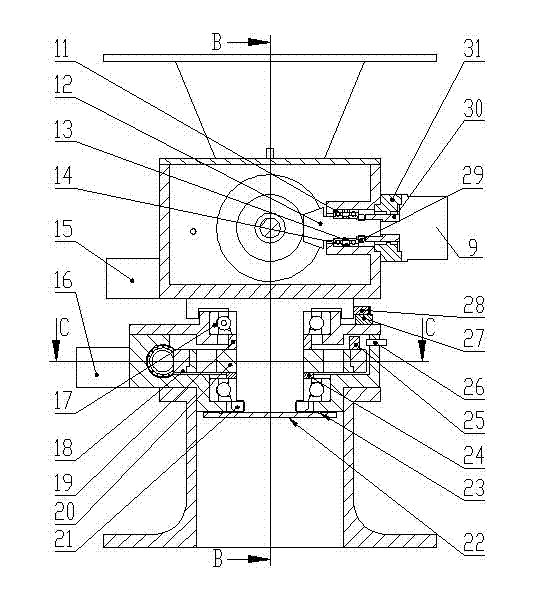

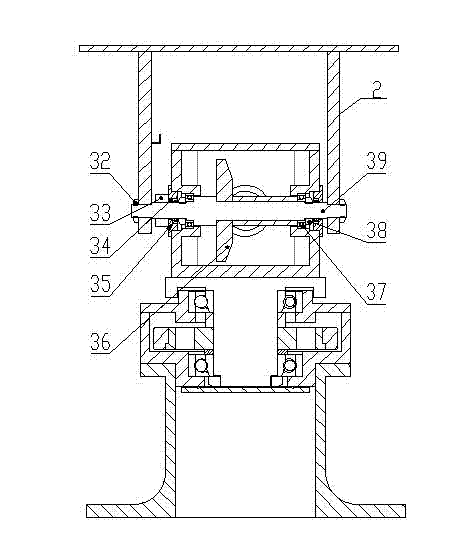

Virtual-axis millimeter-wave human body security check system

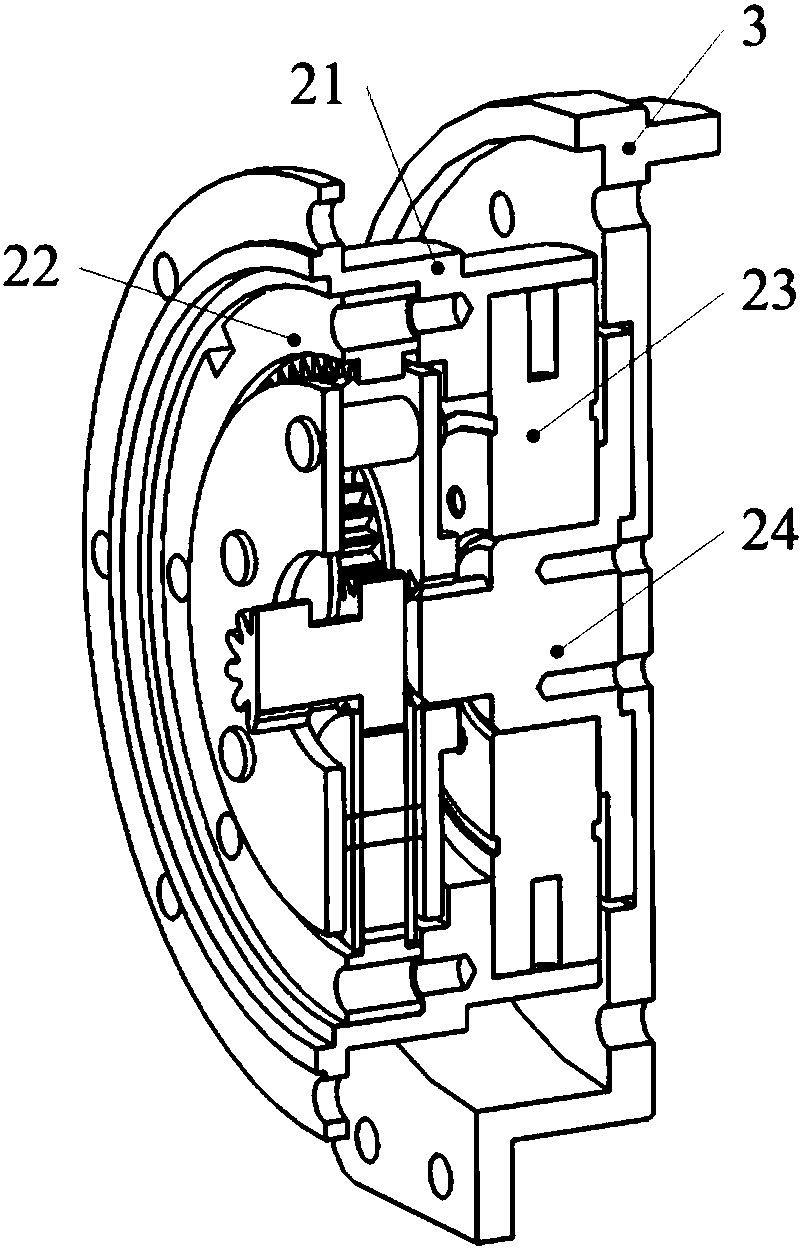

ActiveCN103698762AReduce motion loadSmall moment of inertiaRadio wave reradiation/reflectionHuman bodyTransceiver

The invention relates to a virtual-axis millimeter-wave human body security check system. The system comprises a virtual-axis guide rail unit, a scanning unit, a scanning driving unit, a data processing unit and a display unit, wherein the virtual-axis guide rail unit comprises a first circular-arc-shaped guide rail; the scanning unit comprises a first group of millimeter-wave antenna arrays and a first millimeter-wave transceiver; the scanning driving unit is used for driving the first group of millimeter-wave antenna arrays to scan in a reciprocating virtual-axis circular-arc-shaped locus on the first circular-arc-shaped guide rail; the data processing unit is used for processing a detection signal from the scanning unit to form a human body image to be detected; the display unit is used for displaying the at least one human body image to be detected. In the human body security check system disclosed by the invention, a virtual-axis scanning way is used, the motion load does not need to be reduced, and the rotational inertia is reduced, so that the scanning speed is increased. The system is small in occupied space, and a single / double-module security check system can be assembled more flexibly according to the size of a practical space and the checked amount.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

Rotor of built-in permanent magnet motor and magnetic steel structural parameter determining method thereof

InactiveCN102157998AHigh mechanical strengthIncrease stiffnessMagnetic circuit rotating partsElectric machinePermanent magnet motor

The invention relates to a rotor of a high-quality and high-speed built-in permanent magnet motor and a magnetic steel structural parameter determining method thereof. In the invention, the whole section magnetic steel of each electrode of the rotor of a conventional built-in permanent magnet motor is divided into multiple sections of magnetic steel which have the same polarity and different widths; the multiple sections of the magnetic steel are respectively arranged in a rotor core; and reinforcing ribs with the function of magnetic isolation are arranged among the multiple sections of the magnetic steel. By reasonably modulating and determining the width and distribution of each section of the magnetic steel, the air gap magnetic density waveform approaches sine distribution; harmonic components are reduced to the greatest extent; the eddy current loss of the magnetic steel and the torque pulsation of the motor are simultaneously reduced; and the electromagnetic performance of the motor is enhanced. Furthermore, the multiple sections of the magnetic steel are arranged in the circumference along the rotor; the highest rotating speed of the safe operation of the rotor is greatly enhanced on machinery; the radial thickness which is needed by the magnetic circuit of the rotor is obviously reduced on the structure; the rotational inertia and weight of the rotor are reduced; the dynamic response of the motor is improved; and the requirements of a high-speed driving system on the performance of the motor are met.

Owner:SHANGHAI UNIV

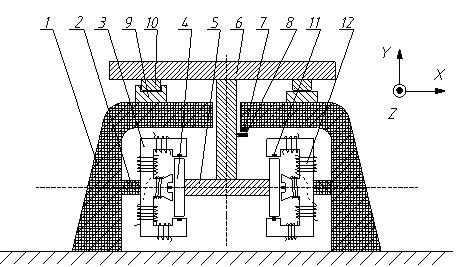

Magnetic suspension bilateral magnetic resistance driving type direct linear transmission device

InactiveCN102185459AIncrease profitSimple mechanical structurePropulsion systemsMagnetic holding devicesEngineeringStator

The invention discloses a magnetic suspension bilateral magnetic resistance driving type direct linear transmission device, which mainly comprises a linear bilateral long base, a bilateral long stator linear magnetic resistance motor, a movement bearing table, a stator base fixed connecting rod, a rotor inter-phase connecting rod, a linear movement displacement sensing ruler, an auxiliary support guide rail pair, a suspended air gap detection sensor, a radiating fan and the like. A magnetic suspension support magnetized loop is multiplexed with a linear magnetic resistance motor stator and rotor magnetized loop, a base is not needed to be used for magnetizing, a moving component is not provided with a permanent magnet and does not need an external power supply, and the transmission device has the advantages of simple and compact structure, low manufacturing cost, high power-to-volume ratio, high electromagnetic thrust, short magnetic circuit path, high inter-phase sealing property, high fault-tolerant capability, zero friction operation and the like.

Owner:NANTONG UNIVERSITY

Single-leg robot jumping mechanism driven through connecting rod

The invention discloses a single-leg robot jumping mechanism driven through a connecting rod. The single-leg robot jumping mechanism comprises a machine body, a thigh and a shank which are hinged in sequence. The thigh is provided with a jumping drive device for driving the shank to rotate. The hinged position of the machine body and the thigh is provided with a direction drive device for driving the thigh to rotate. The upper end of the shank is provided with a shank ejector plate hinged to the lower end of the thigh. A drive rod is arranged between the shank ejector rod and the jumping drive device. The drive device and the shank ejector rod are hinged to the two ends of the drive rod respectively, and an elastic energy storing piece is arranged between the thigh and the shank ejector plate. The direction drive device can drive the thigh to rotate to achieve the direction control. The jumping drive device and the direction drive device are close to the machine body, the rotational inertia of the thigh relative to the machine body is reduced, the energy consumption of a first drive motor can be reduced, and the moving stability and agility of robot movement are improved. The stability of a robot is improved through balancing fly wheels. The energy can be stored and buffering can be achieved through the elastic energy storing piece and balancing pieces.

Owner:HANGZHOU YUNSHENCHU TECH CO LTD

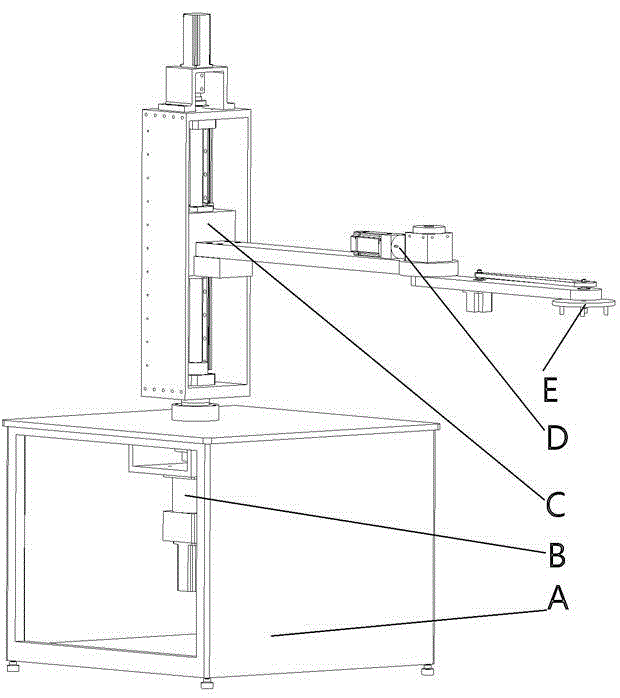

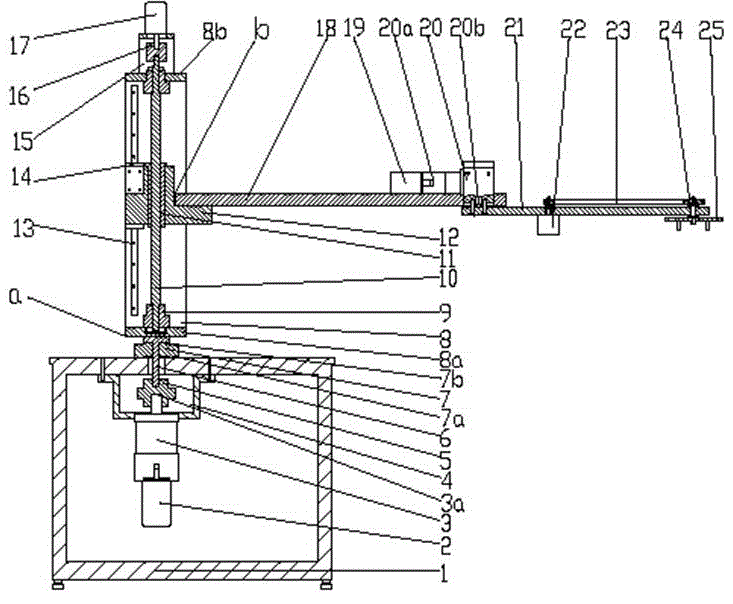

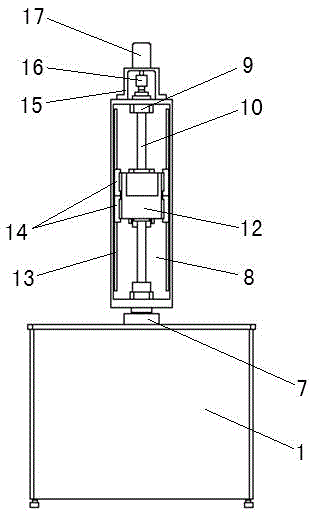

Quasi-SCARA (Selective Compliance Assembly Robot Arm) industrial robot

InactiveCN103978482ALower the altitudeSmall moment of inertiaProgramme-controlled manipulatorEngineeringVertical motion

The invention relates to a quasi-SCARA (Selective Compliance Assembly Robot Arm) industrial robot, which comprises a base, a whole arm rotating mechanism, a vertical motion mechanism, a forearm rotating mechanism and an actuating station rotating mechanism; the whole arm rotating mechanism is fixedly arranged on the base; the vertical motion mechanism is arranged on the whole arm rotating mechanism; the whole arm rotating mechanism drives the vertical motion mechanism to rotate; the forearm rotating mechanism is fixedly arranged on the vertical motion mechanism; the vertical motion mechanism drives the forearm rotating mechanism to move vertically; the actuating station rotating mechanism is arranged on the forearm rotating mechanism; the forearm rotating mechanism drives the actuating station rotating mechanism to rotate; so that a tandem type industrial robot structure is formed. Compared with an SCARA robot, the quasi-SCARA industrial robot has the advantages that the lifting movement of the robot is moved from the fourth joint to the second joint, the robot is small in size in the vertical direction due to the special flat design of the forearm rotating mechanism and the actuating station rotating mechanism, and thus the robot is more suitable for operations of carrying objects and the like in a narrow space.

Owner:FUZHOU UNIV

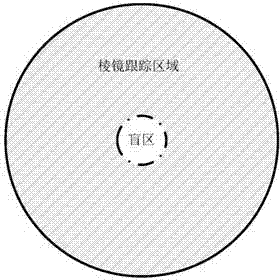

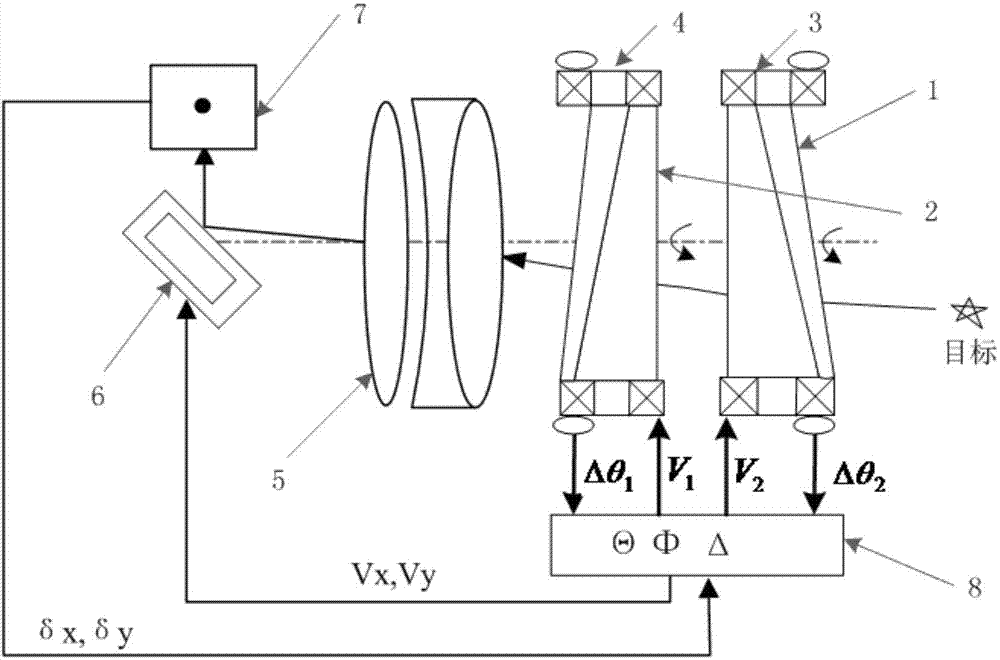

Compound axis tracking system based on rotary biprism

The invention provides a compound axis tracking system based on a rotary biprism. The system can be used for tracking a fast-moving target with high precision. The device comprises a rotary biprism tracking control device, an imaging assembly, a fast reflecting mirror tracking device and a detector. According to the system, the rotary biprism is controlled to quickly track the moving target, namely, the target enters the image assembly and then is imaged to the detector, a fast reflecting mirror is controlled to deflect according to the miss distance of the target on the detector in order to stably close the target in a detection center, and as a result, high-precision tracking of the fast-moving target can be realized.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

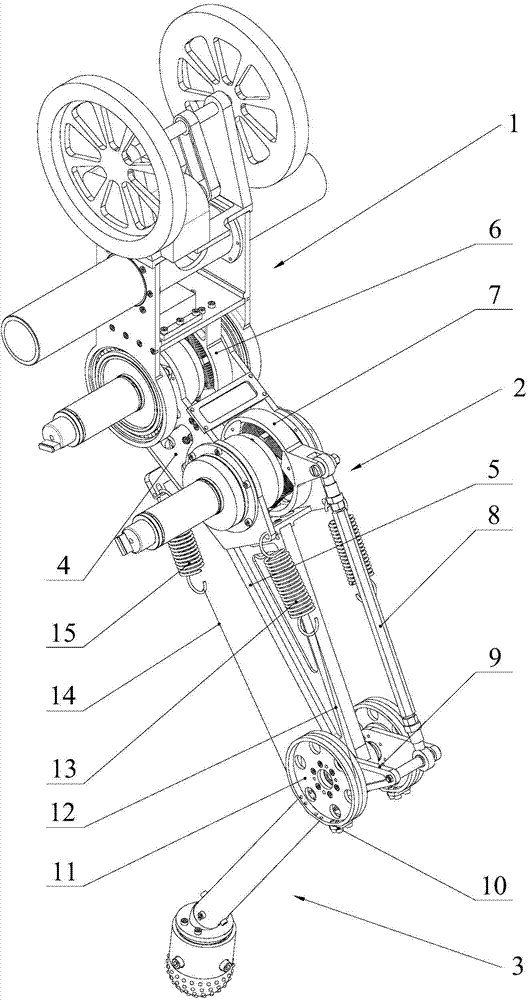

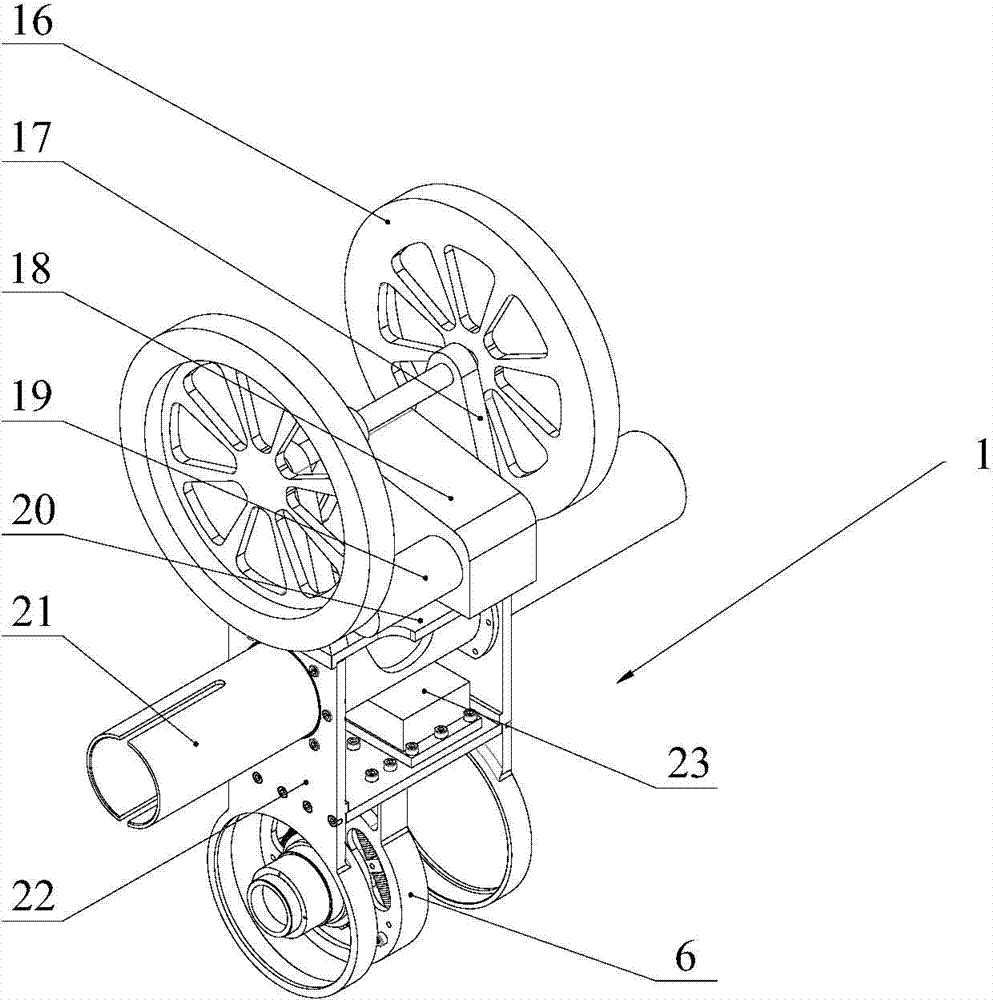

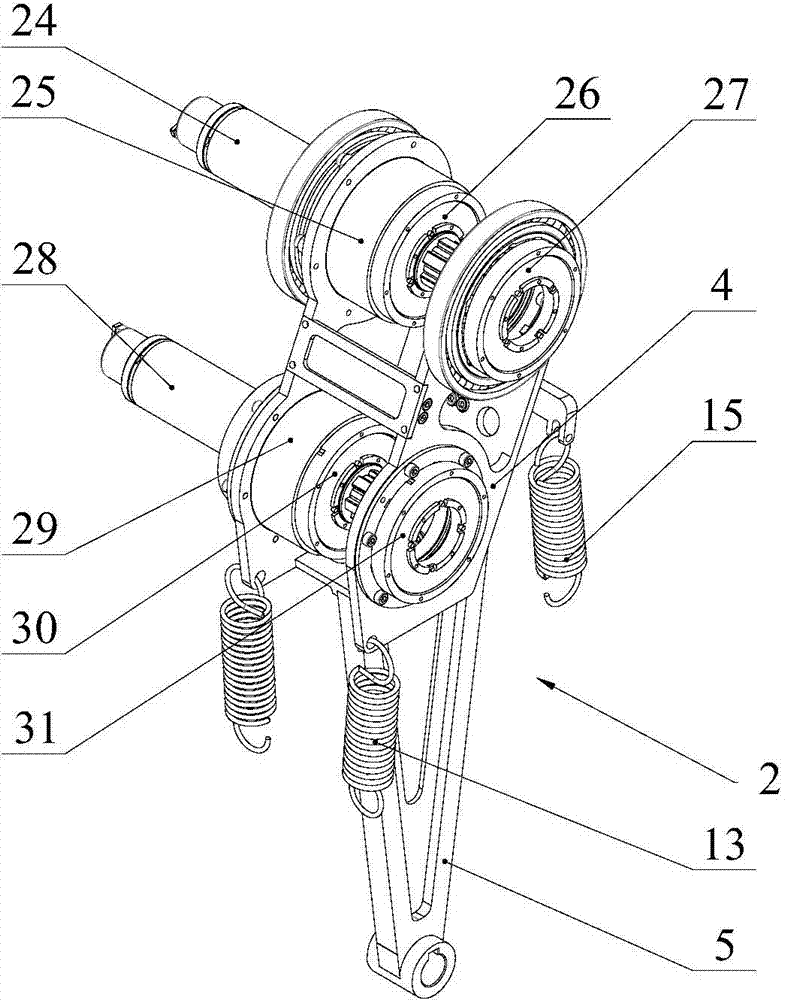

Single leg structure of electric quadruped robot

PendingCN107651041ALight in massSmall moment of inertiaVehiclesThighPhysical medicine and rehabilitation

The invention relates to a single leg structure of an electric quadruped robot. The single leg structure comprises a hip joint, a knee joint, a thigh connecting rod, a shank connecting rod and a foot,the hip joint comprises a first hip joint body and a second hip joint body, the second hip joint body is connected with the power output end of the first hip joint body, the knee joint is connected with the power output end of the first hip joint body through the thigh connecting rod, the knee joint is in rigid connection with the second hip joint body, the power output end of the second hip joint body is connected with power input end of the knee joint through the transmission mechanism, the shank is fixedly connected to the power output end of the knee joint, and the foot is connected to the shank. According to the structure, the low quality and low rotating inertia of the thigh and the shank is guaranteed, the good motion performance is achieved, the structure is simple and compact, itis guaranteed that the knee joint and the hip joint of the single leg have the good reverse drive characteristic, and the single leg structure can be used for assembling the electric quadruped robotwhich is capable of bouncing and high in load deadweight ratio.

Owner:SHANDONG UNIV

Six-freedom-degree industrial robot with ball screw pair transmission

InactiveCN103737577ARealize two-dimensional translationRealize three-degree-of-freedom attitude adjustmentProgramme-controlled manipulatorBall screw driveDrive motor

The invention relates to a six-freedom-degree industrial robot with ball screw pair transmission. Waist whole circle rotating is achieved through a waist swing mechanism, a shoulder swing mechanism and an elbow swing mechanism form a two-freedom-degree parallel mechanism to achieve two-dimensional horizontal moving, and ball screws are driven by motors arranged on a swing platform respectively. Three mutual-orthometric rotating shafts connected through a front arm rotating mechanism, a wrist swing mechanism and a tool clamping base swing mechanism are driven independently by three motors respectively, and three-freedom-degree gesture adjusting of an executing tail end tool is achieved. The advantage of the large working space of a serial mechanism is kept, ball screw transmission is used, the rigidness of the mechanism is guaranteed, the positions of the driving motors are lowered, good dynamic characteristics are obtained, bearing capacity is large, high-speed or superspeed operation can be easily achieved, and the six-freedom-degree industrial robot has the advantages that side gaps do not exist, rigidness is high, micro-motion feeding can be conveniently achieved, accumulated errors are small, motion accuracy is high, positive and athwart kinematics solving is convenient, and control is convenient.

Owner:GUANGXI UNIV

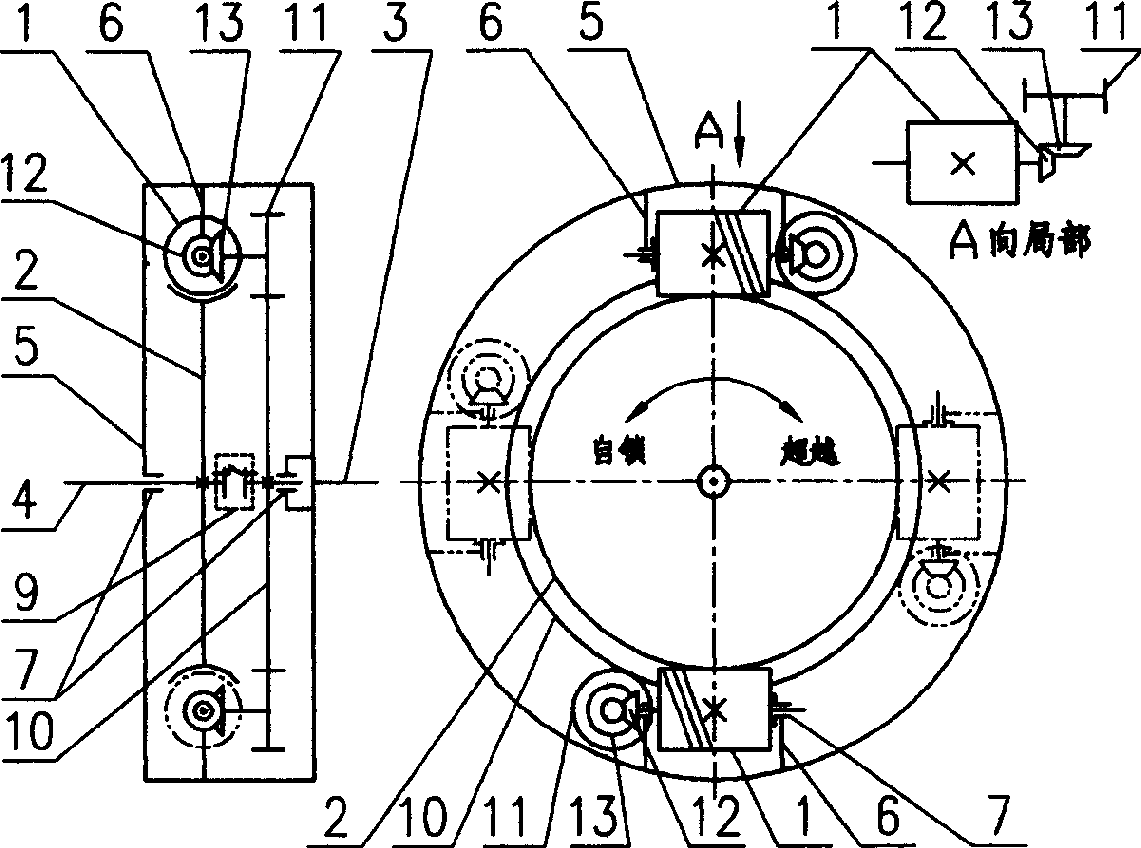

Stepless tooth engagement control type high efficiency and high power clutch

InactiveCN1629508AImprove efficiencyDoes not affect transmission efficiencyFreewheel clutchesAutomatic transmissionMachine tool

Owner:王国斌

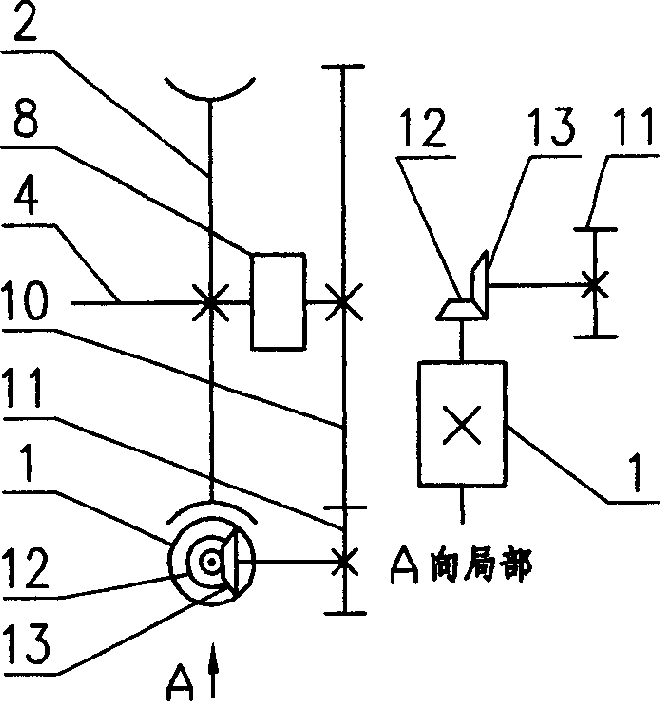

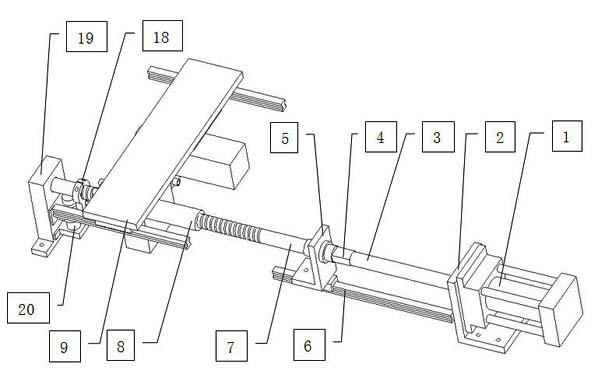

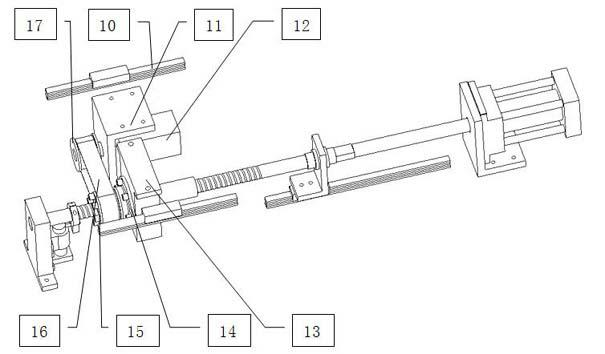

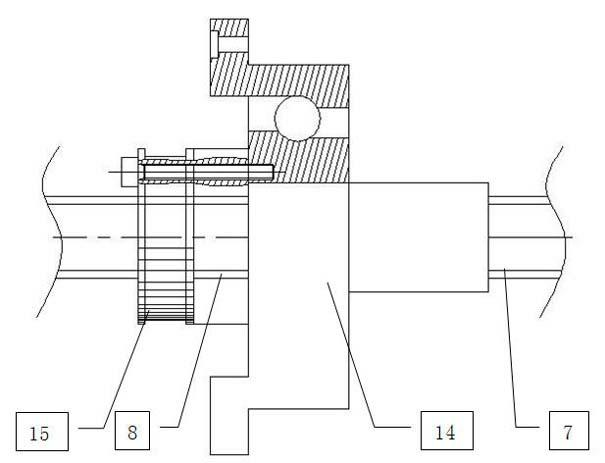

Experiment table for studying friction mechanism of precision ball screw pair

InactiveCN102095541AIncrease frictionAvoid distortionForce measurementWork measurementDrive wheelFriction torque

An experiment table for studying the friction mechanism of a precision ball screw pair comprises a ball screw pair, and a torque sensor connected with the screw for acquiring the friction torque of the ball screw pair, wherein the ball screw pair includes a flange-type nut, a screw support and an axial sliding support respectively arranged on both ends of the screw, one end of an axial force sensor is connected with one end of the screw on the same side of the axial sliding support; the other end of the axial force sensor is connected with the piston rod of an oil cylinder; an angular contact bearing is sheathed on the flange-type nut; a connection block is arranged on the outer side of the angular contact bearing; an axial sliding support is connected with the connection block; a motor is placed on the axial sliding support; the power output of the motor is transmitted to the flange-type nut through a belt drive device; and the flange-type nut, the inner ring of the angular contact bearing and the driven wheel of the belt drive device are fixedly connected with one another.

Owner:SOUTHEAST UNIV

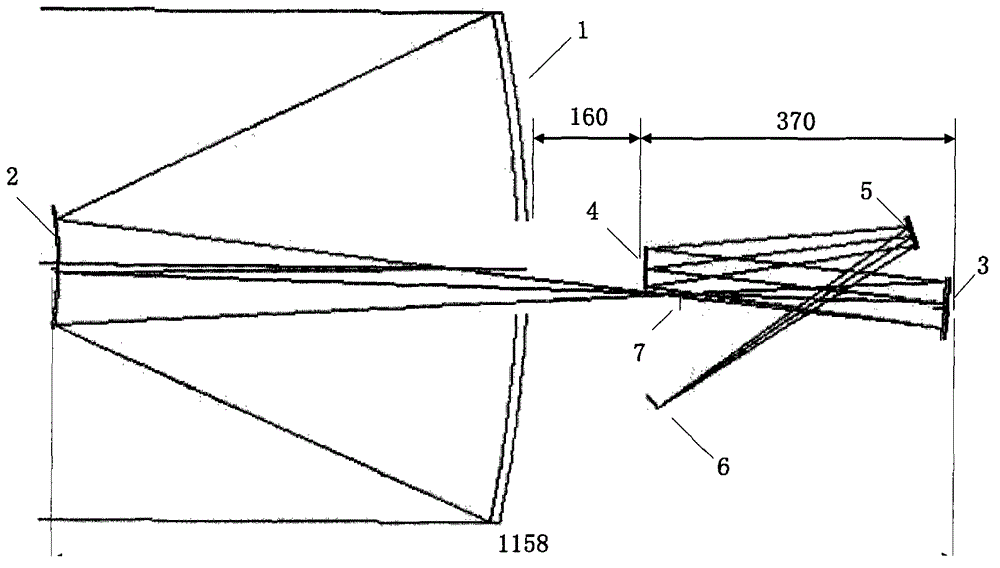

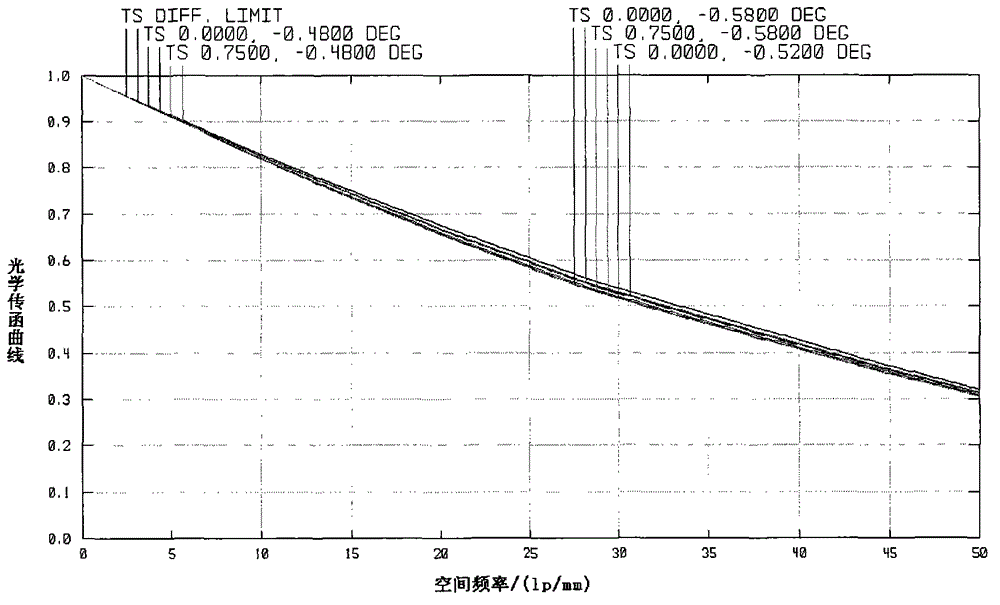

Coaxial four-reflector ultra-low distortion optical system

ActiveCN102866487ACompact structureImprove structural stabilityMirrorsPicture taking arrangementsLow distortionPlane mirror

The invention relates to a coaxial four-reflector ultra-low distortion optical system, which comprises a primary mirror, a secondary mirror, a third mirror, a fourth mirror, a plane mirror and a receiving image plane, wherein optical axes of the primary mirror, the secondary mirror, the third mirror, the fourth mirror and the plane mirror are in a same straight line; the plane mirror is located between the third mirror and the fourth mirror; the primary mirror and the secondary mirror constitute a classical R-C system and form a primary real image, which continues imaging when passing through the third mirror and the fourth mirror and deflects to the receiving image plane through the plane mirror; the primary mirror, the secondary mirror and the third mirror constitute a coaxial TMA system and assume most of focal power; the fourth mirror assumes smaller part of focal power, accounting for 10-20% of the total focal power, in the imaging of the optical system; and an aperture diaphragm of the optical system is located on the primary mirror and the fourth mirror is placed at an exit pupil of the system. The optical system of the invention can be used to realize high image quality, low distortion and high stability and greatly reduce the processing difficulty of a large-aperture primary mirror and is suitable for high-precision satellite-borne stereo mapping cameras.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Automatic solar tracking device

ActiveCN102778896AImprove calculation accuracyRealize closed-loop controlControl using feedbackPosition angleControl system

The invention relates to an automatic solar tracking system which tracks the sun accurately in real time and is used for efficiently collecting and using solar energy. The automatic solar tracking device comprises a solar energy photovoltaic array, an adjusting device connected with the solar energy photovoltaic array and used for adjusting the position of the solar energy photovoltaic array, a stand column for supporting the adjusting device and a control system. The adjusting device is composed of a pitch angle adjusting assembly and a position angle adjusting assembly, wherein the pitch angle adjusting assembly is connected with the position angle adjusting assembly through a vertical shaft, the position angle adjusting assembly is arranged on the stand column, and the control system is used for performing closed loop control on the adjusting device. The accuracy in solar tracking of the automatic solar tracking device is smaller than 0.1, the energy consumption only occupies for 0.5% of the electric energy production of the driving photovoltaic array, and the automatic solar tracking system has the advantages of being long in service life, intact in protection function and the like.

Owner:LUOYANG NORMAL UNIV

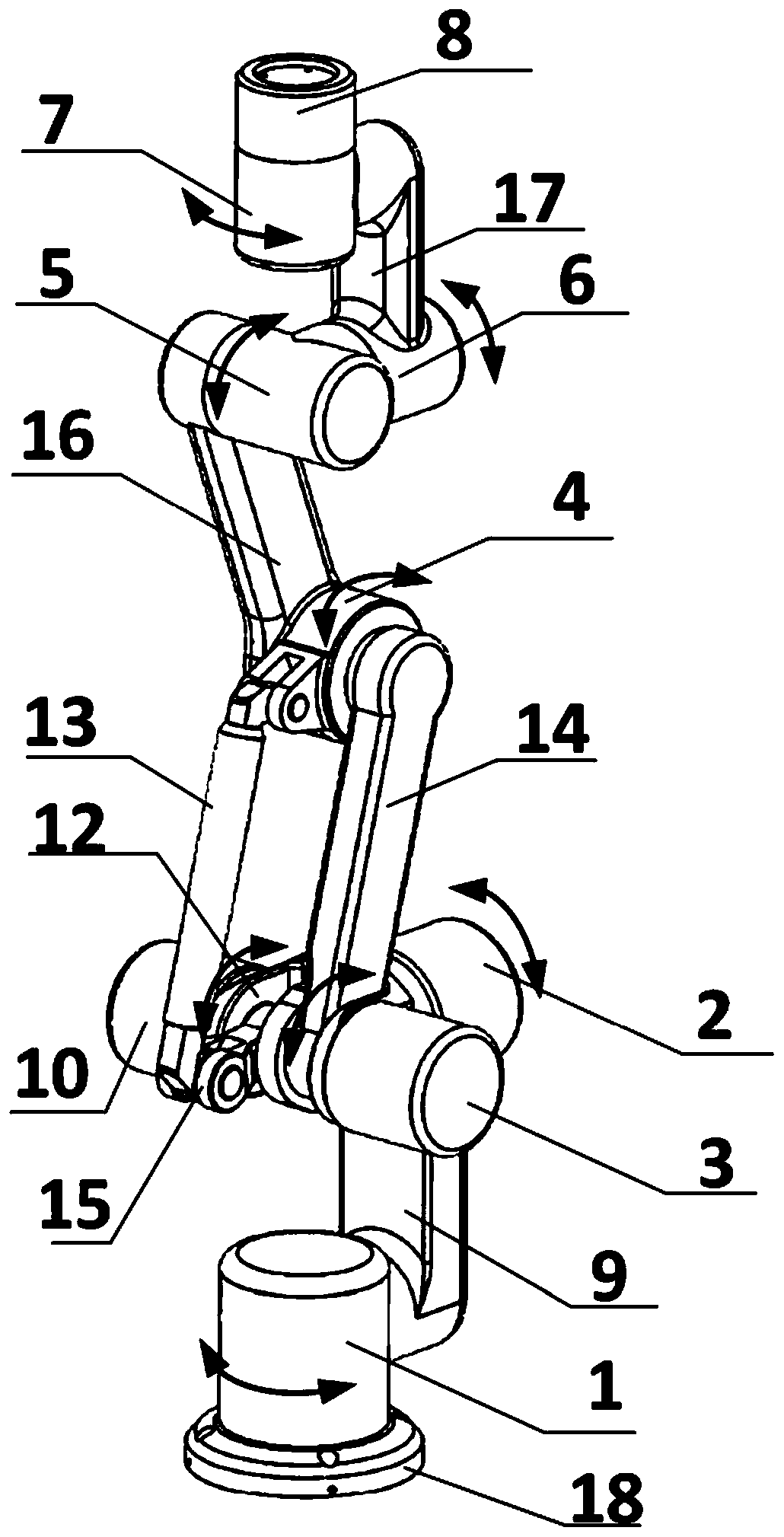

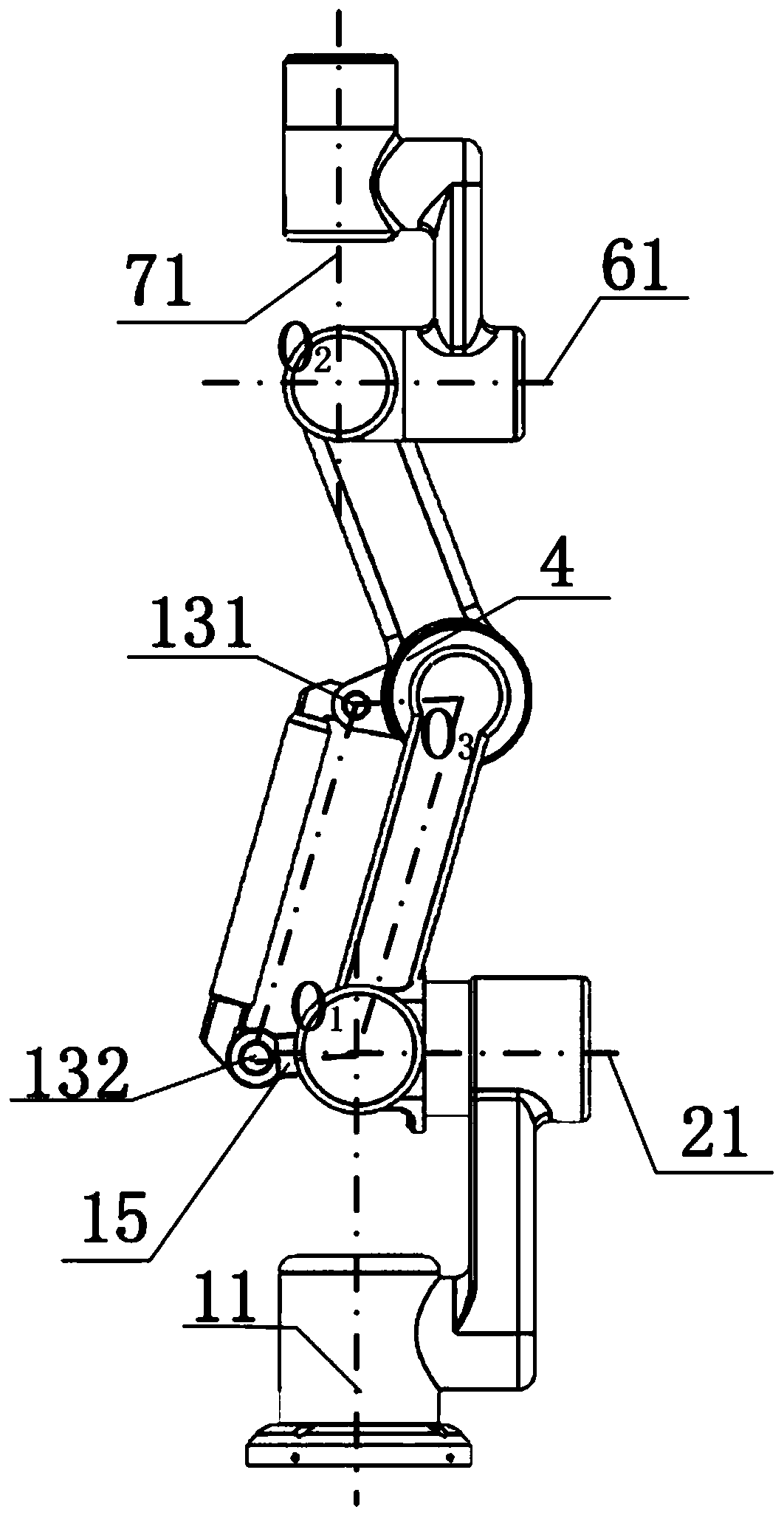

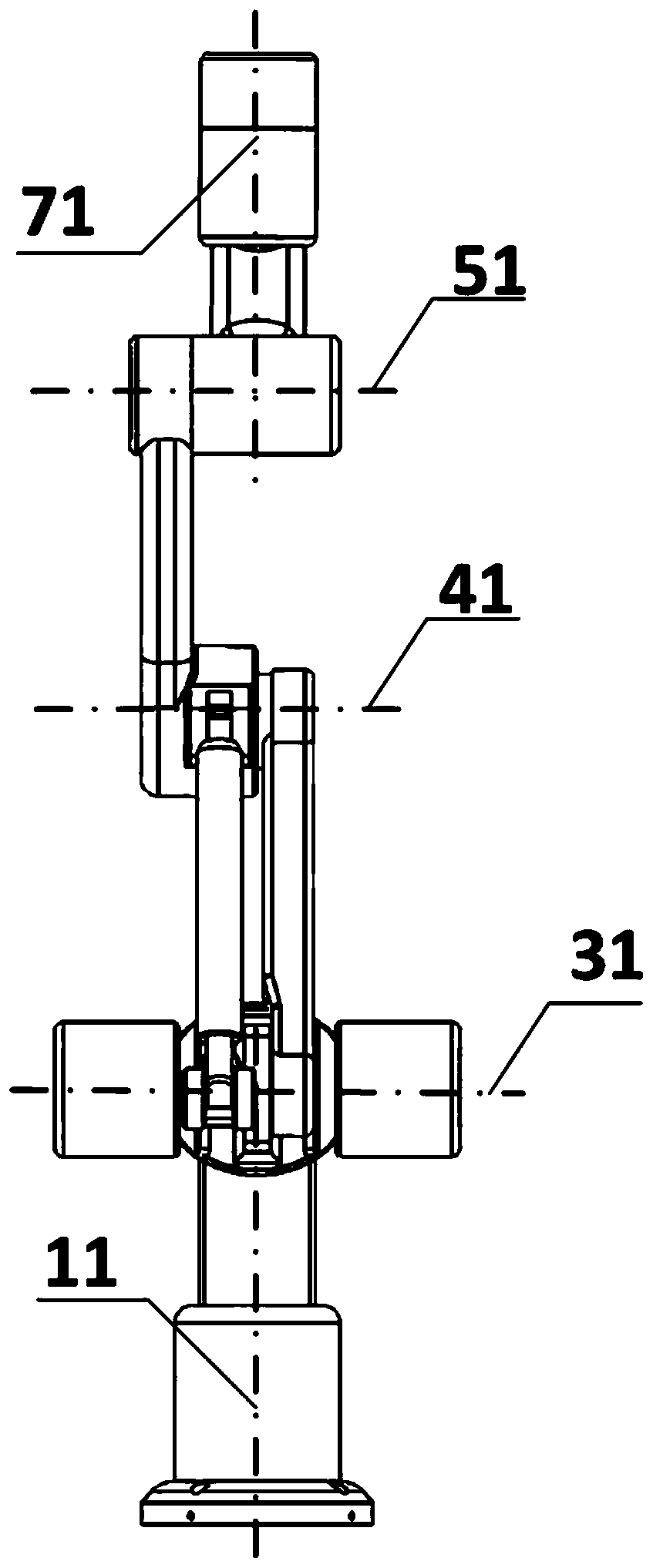

Seven-degree-of-freedom series-parallel hybrid mechanical arm and robot

ActiveCN111360787ASmall moment of inertiaReduce load torqueProgramme-controlled manipulatorLoad torqueControl engineering

The invention provides a seven-degree-of-freedom series-parallel hybrid mechanical arm. The seven-degree-of-freedom series-parallel hybrid mechanical arm comprises a base, a first joint, a first link,a second joint, a connection support, a third joint, a second link, a fourth joint, a fifth link, a fifth joint, a sixth joint, a sixth link, a seventh joint and an end executer connection flange which are sequentially connected, wherein a third link and a fourth link are further arranged between the third joint and the fourth joint, one end of the fourth link is connected with the fourth joint,the other end of the fourth link is connected with the third link, and the third link is connected with a motor shell body of the fourth joint; the third link, the fourth link, the fourth joint and the second link form a parallel four-link transmission mechanism; and the axis of the third joint, the axis of the fourth joint and the axis of the fifth joint are mutually parallel. The new configuration of the seven-degree-of-freedom series-parallel hybrid mechanical arm is high in operation flexibility in a common reachable range of a main movement space; and meanwhile, the load torque of the motor in the vicinity of the base is reduced, and the rotational inertia of the whole mechanical arm is reduced.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com