Patents

Literature

34results about How to "Reduce motion load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

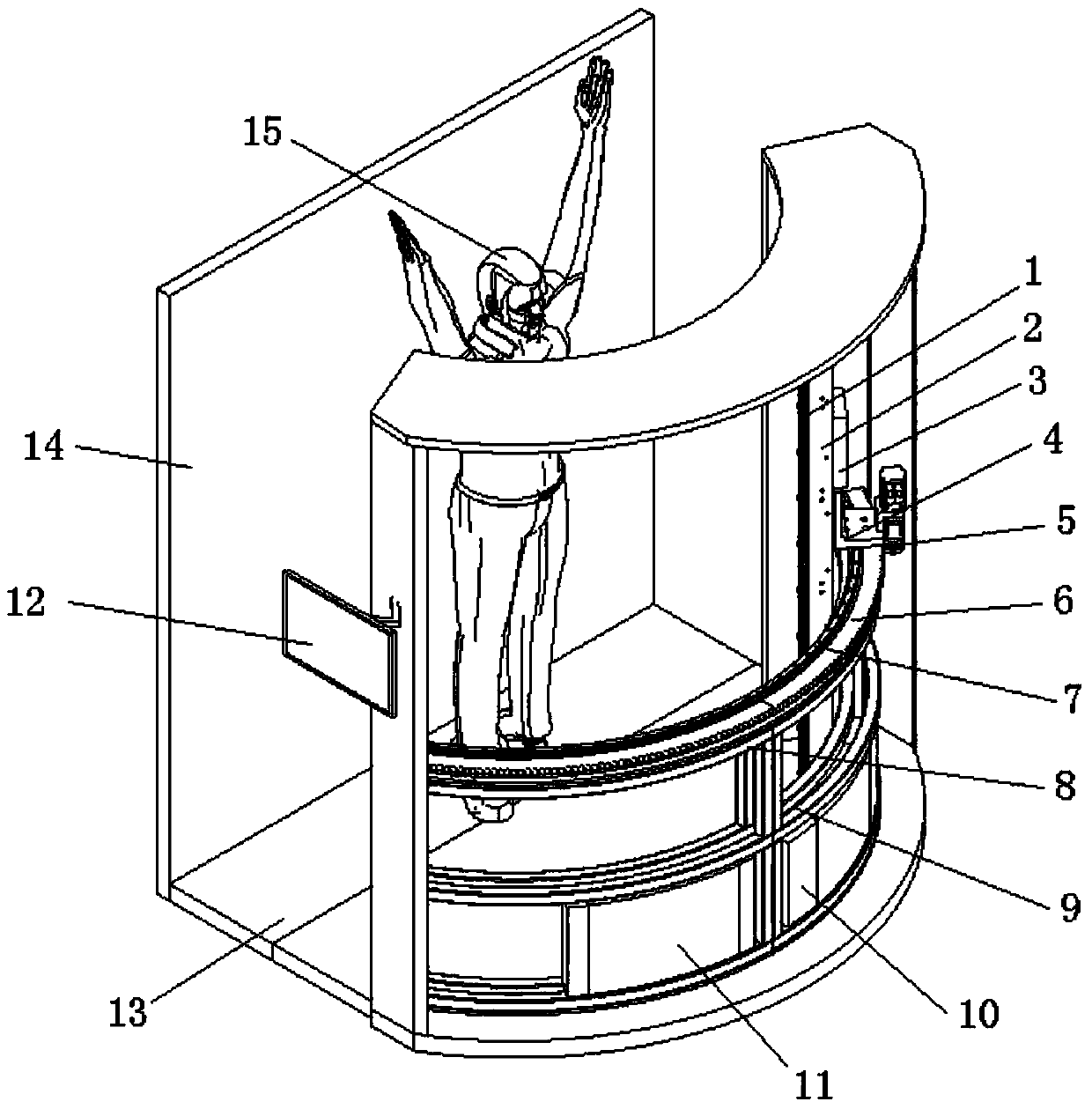

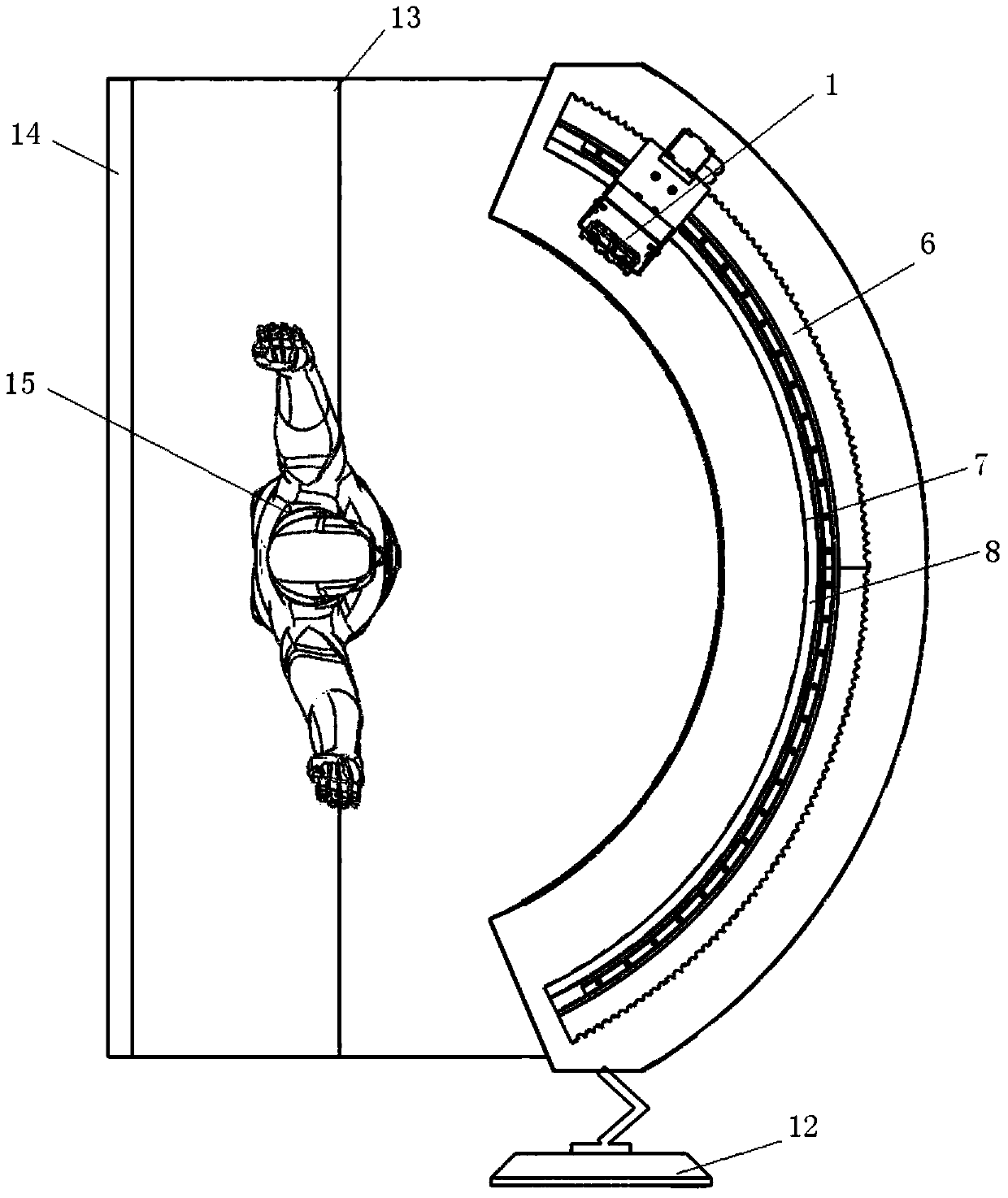

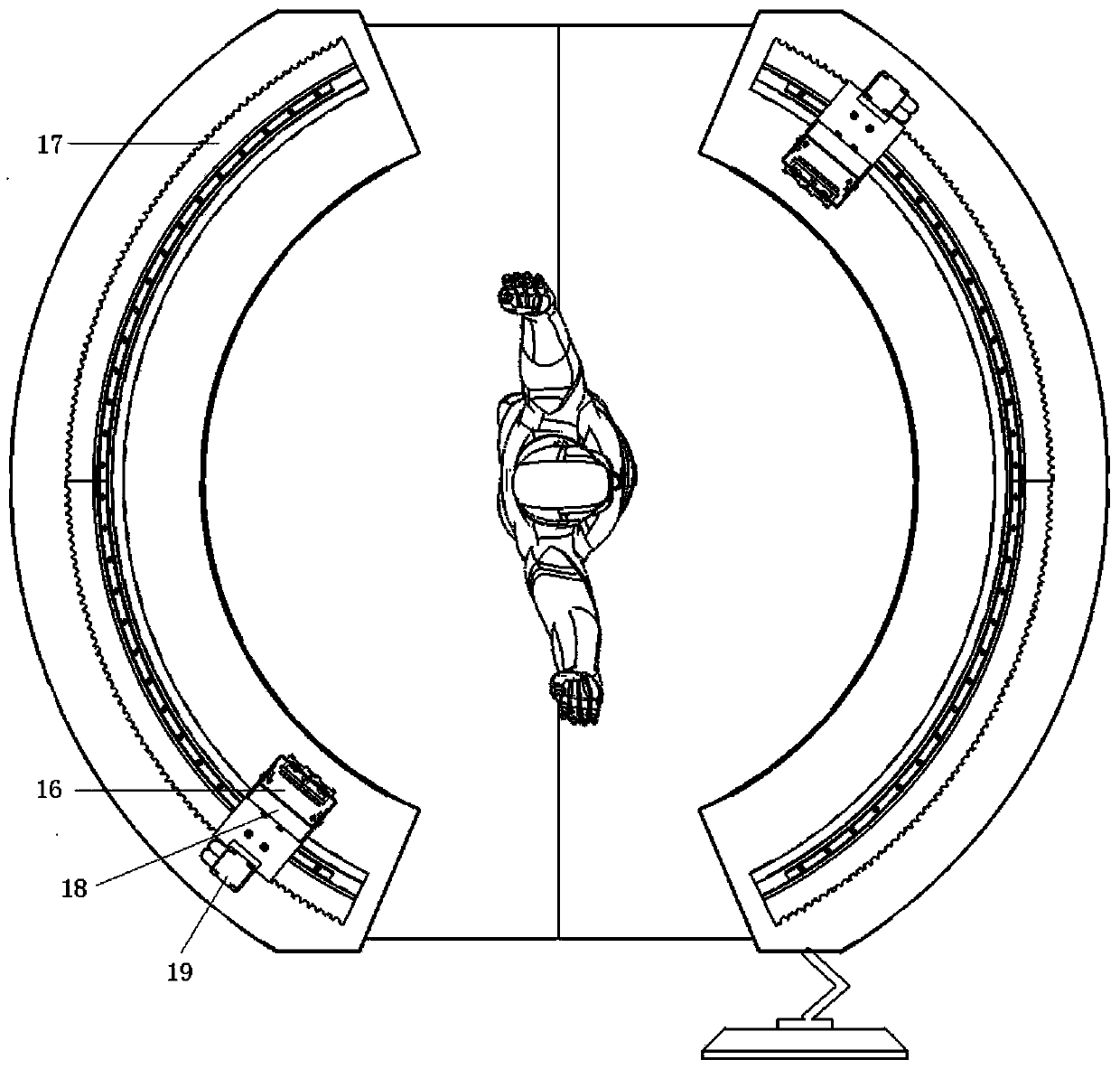

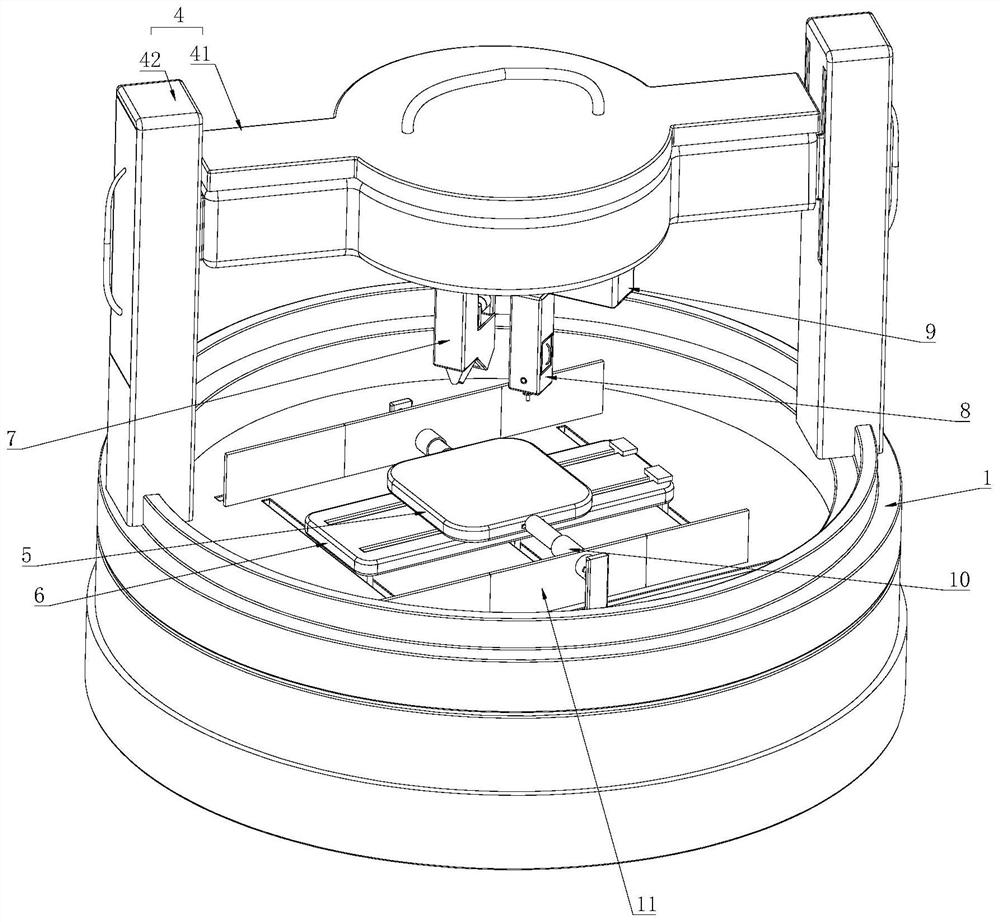

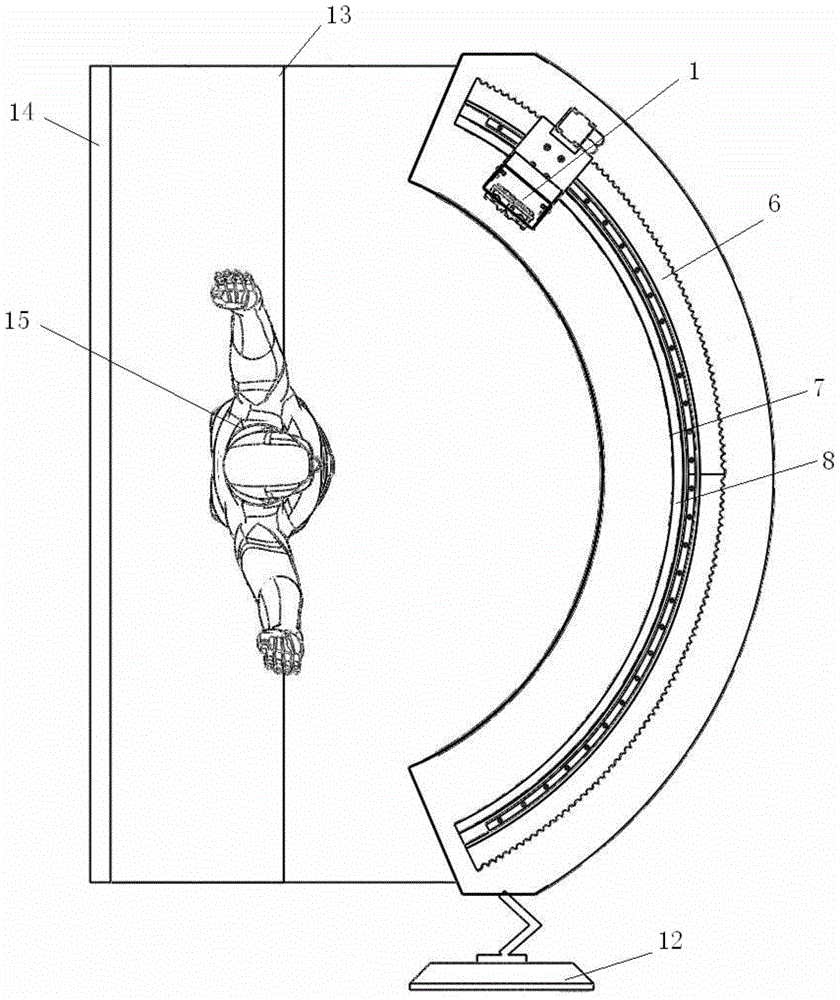

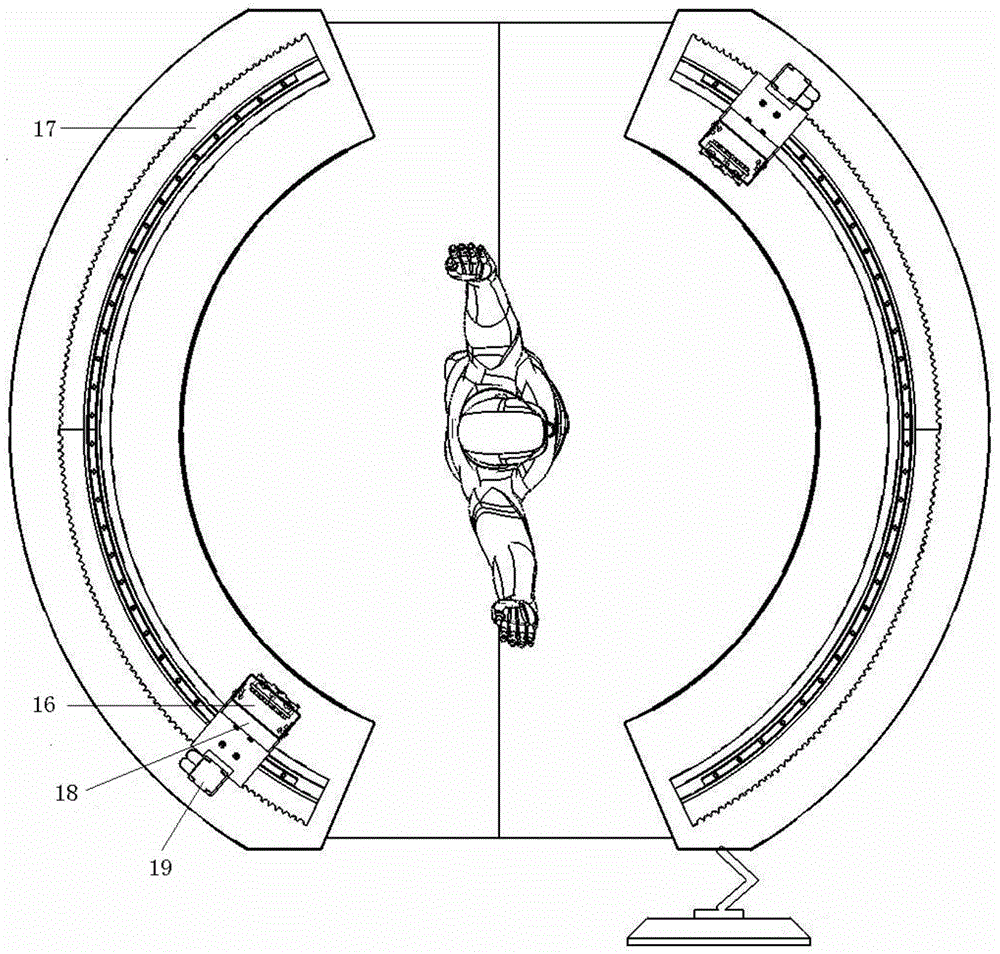

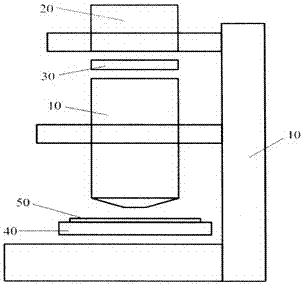

Virtual-axis millimeter-wave human body security check system

ActiveCN103698762AReduce motion loadSmall moment of inertiaRadio wave reradiation/reflectionHuman bodyTransceiver

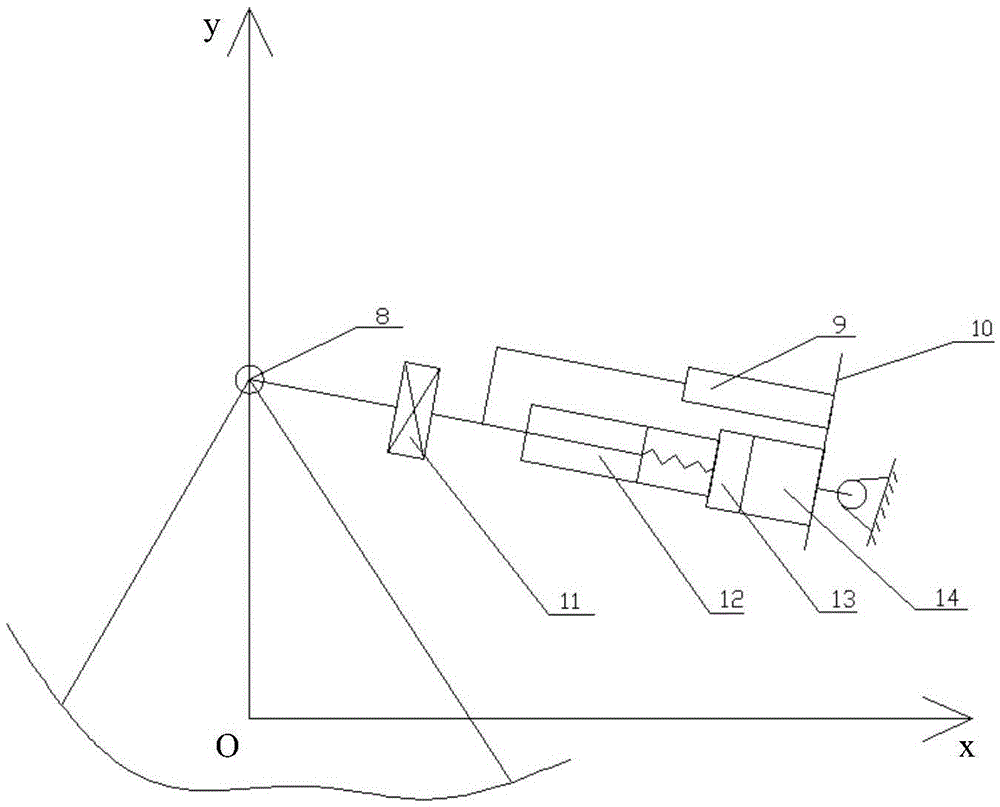

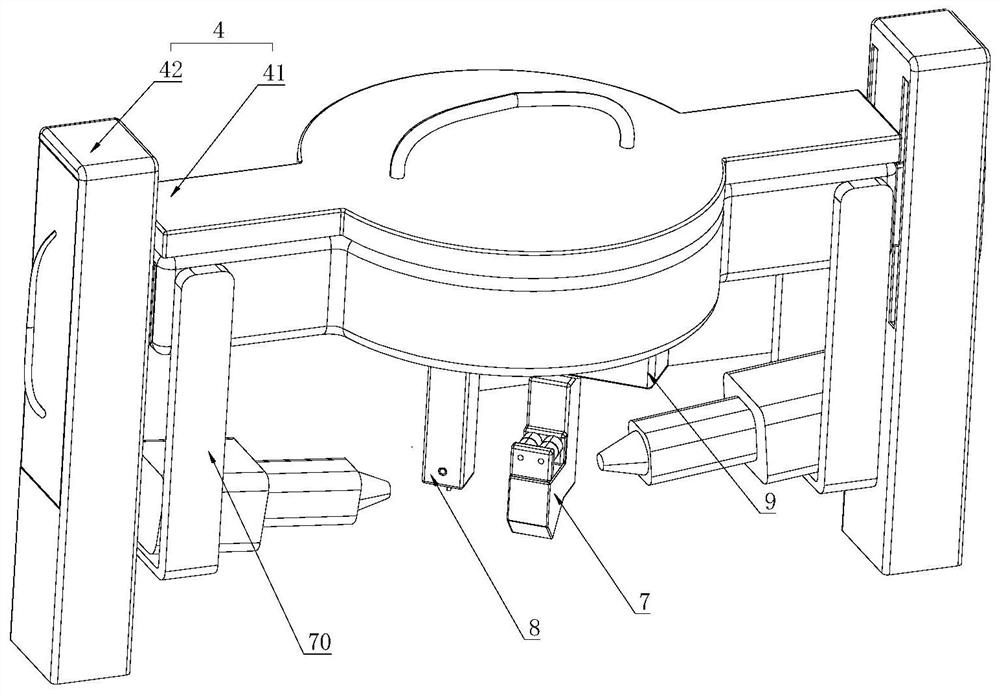

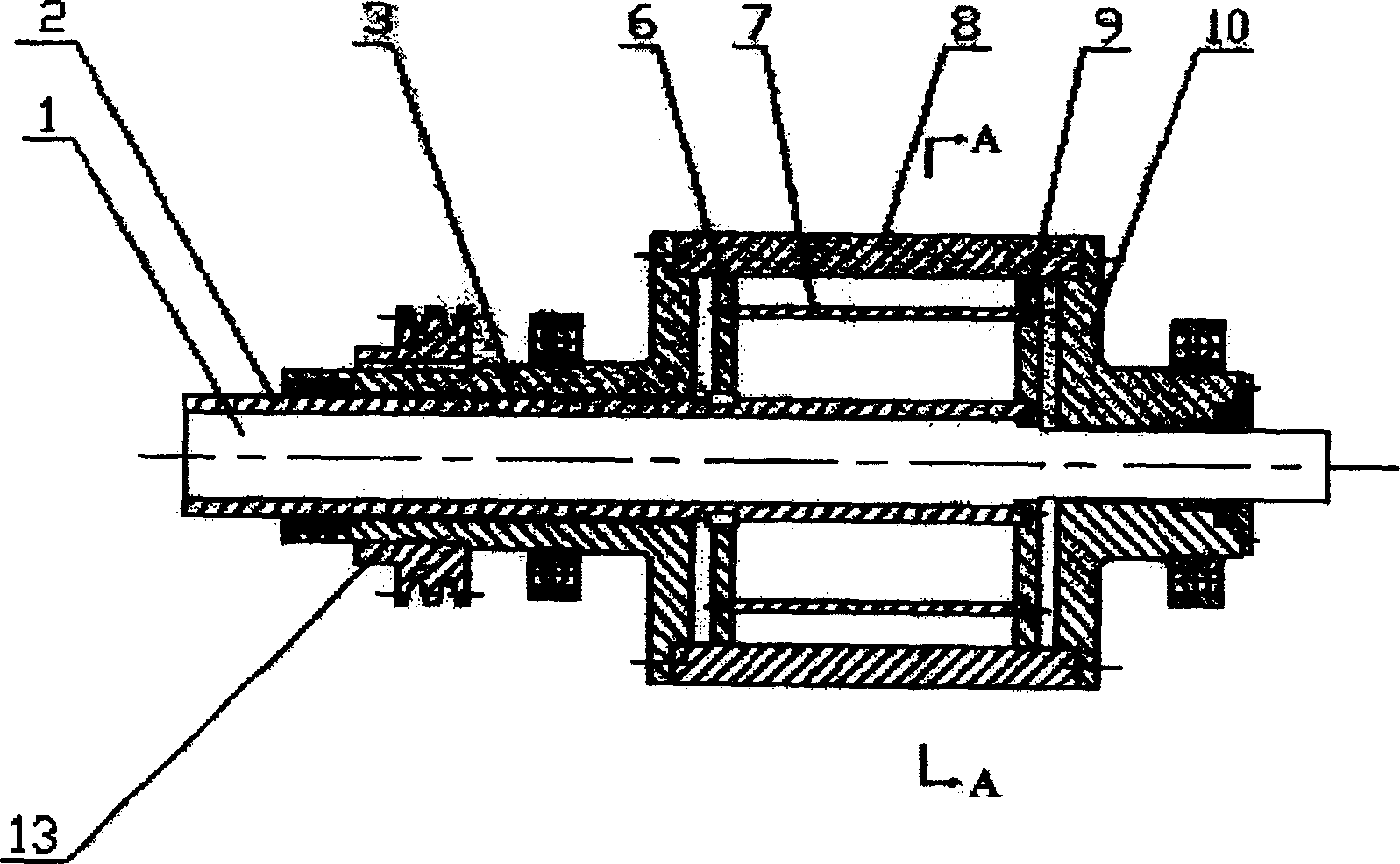

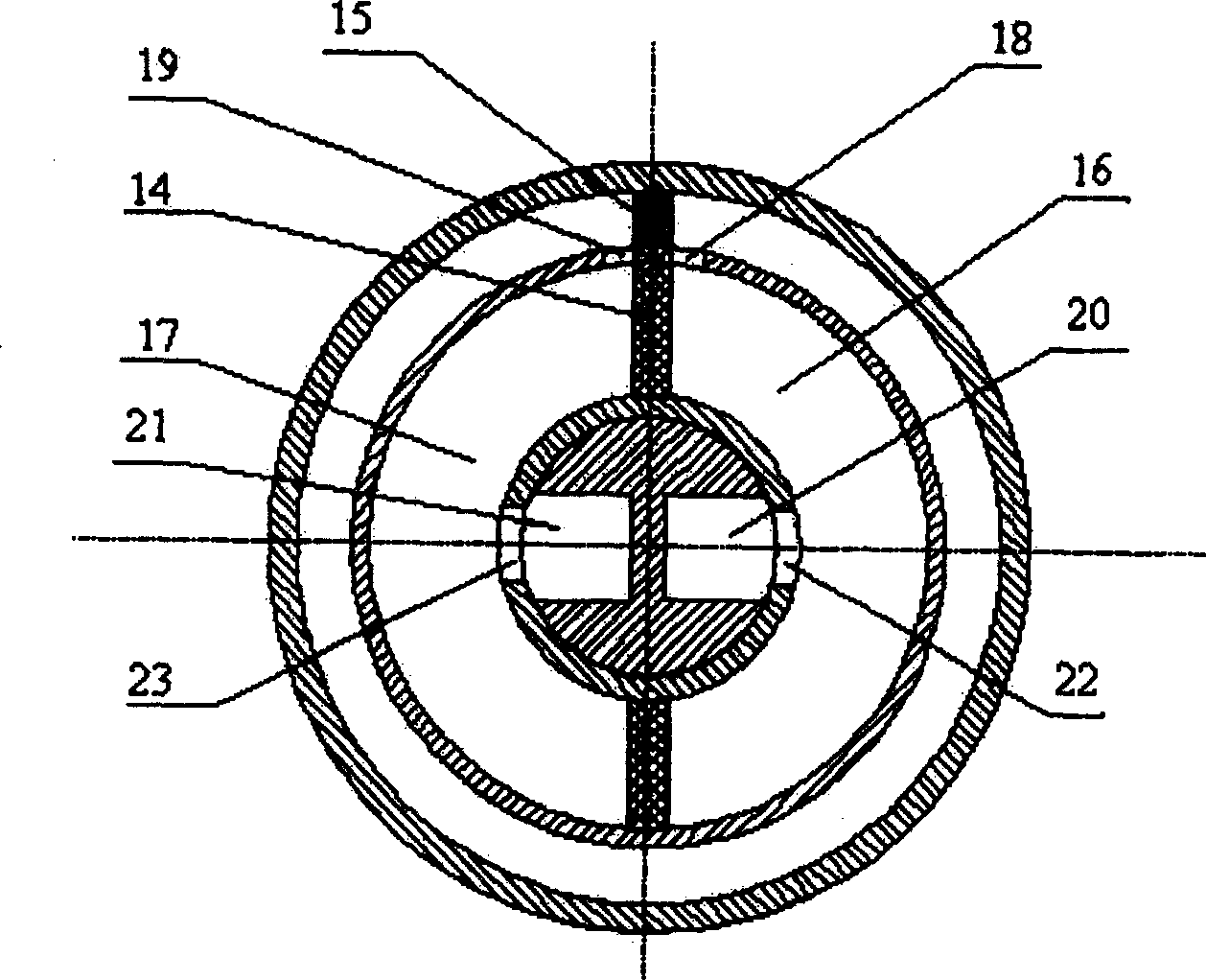

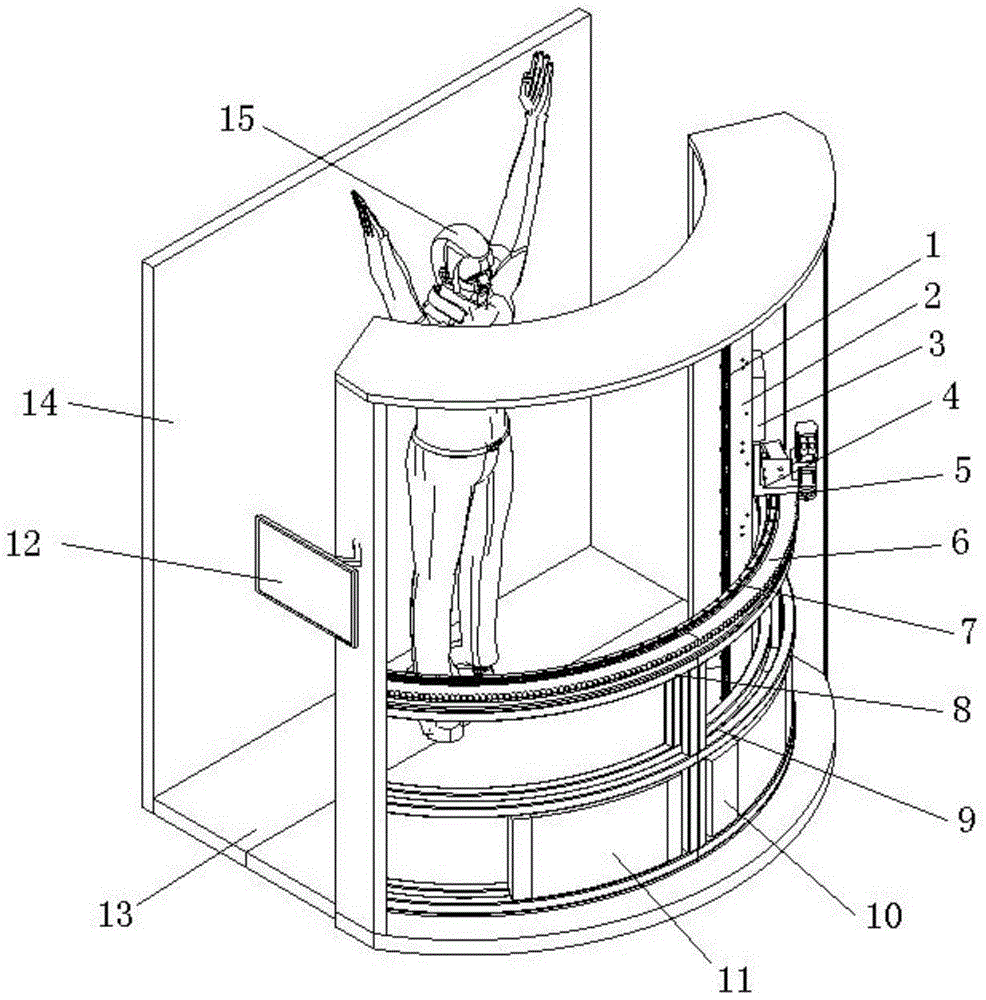

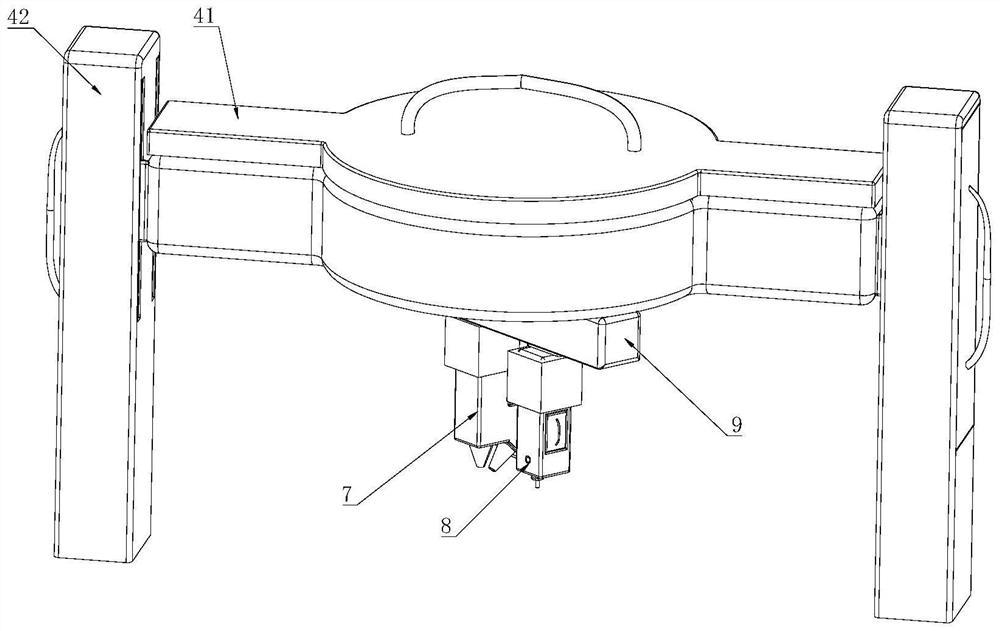

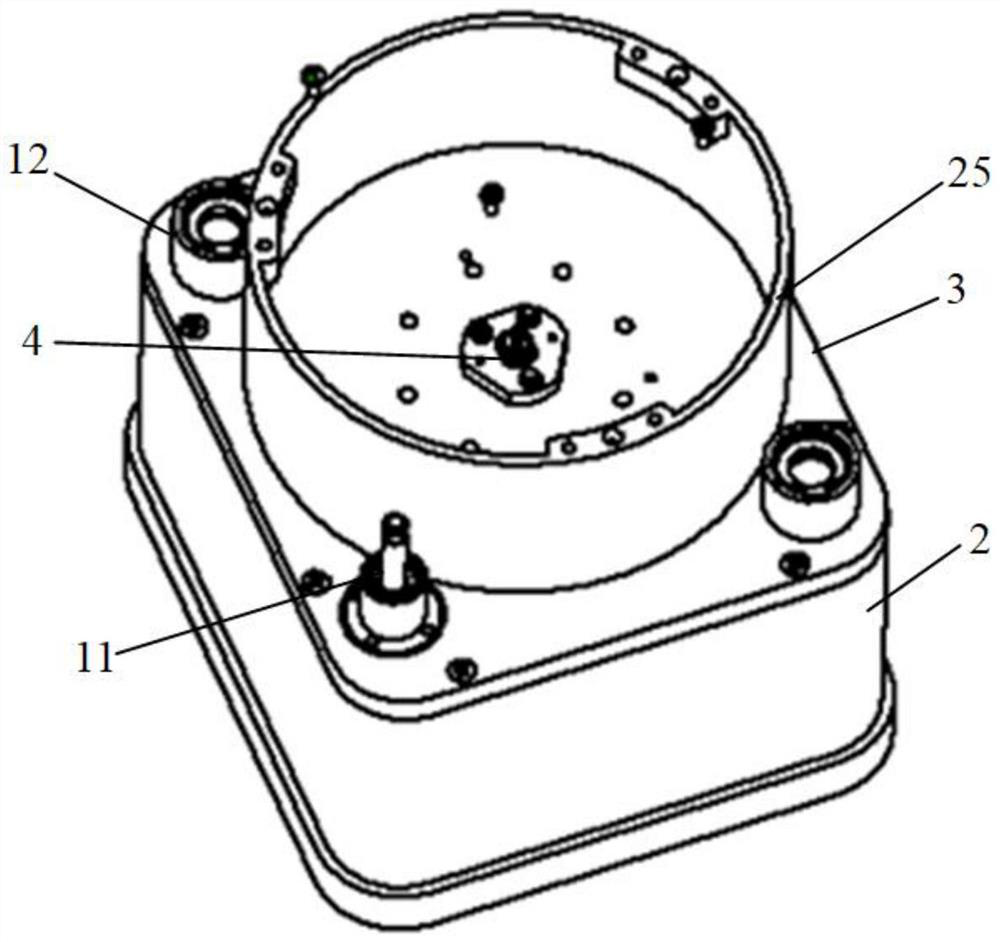

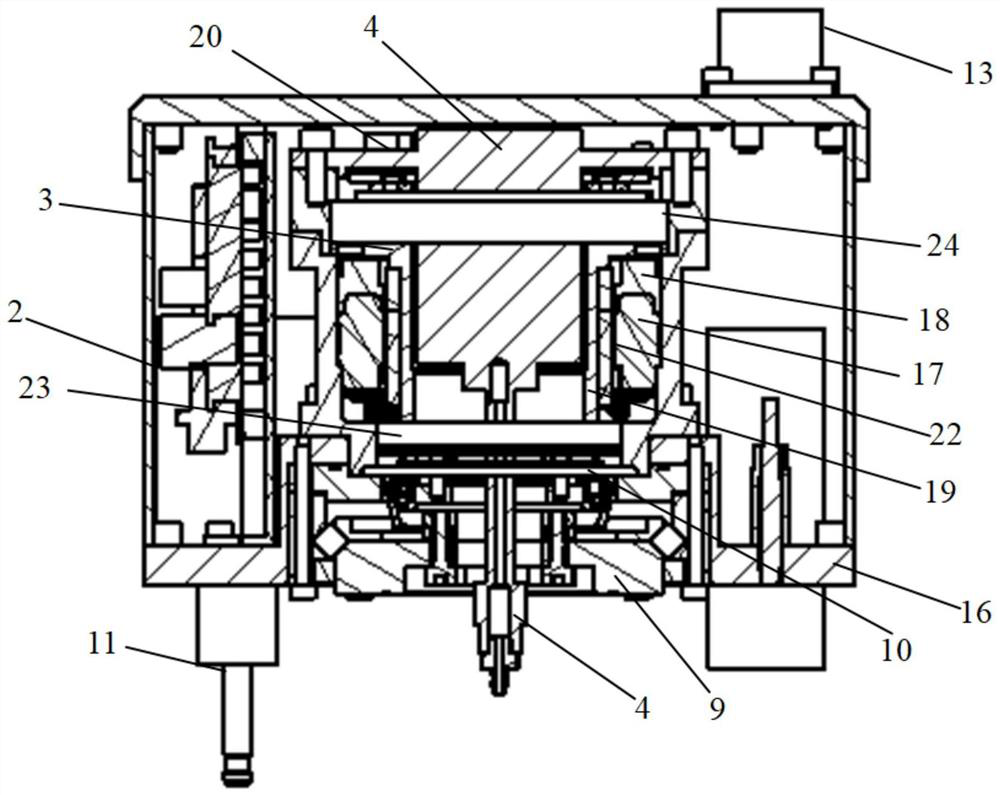

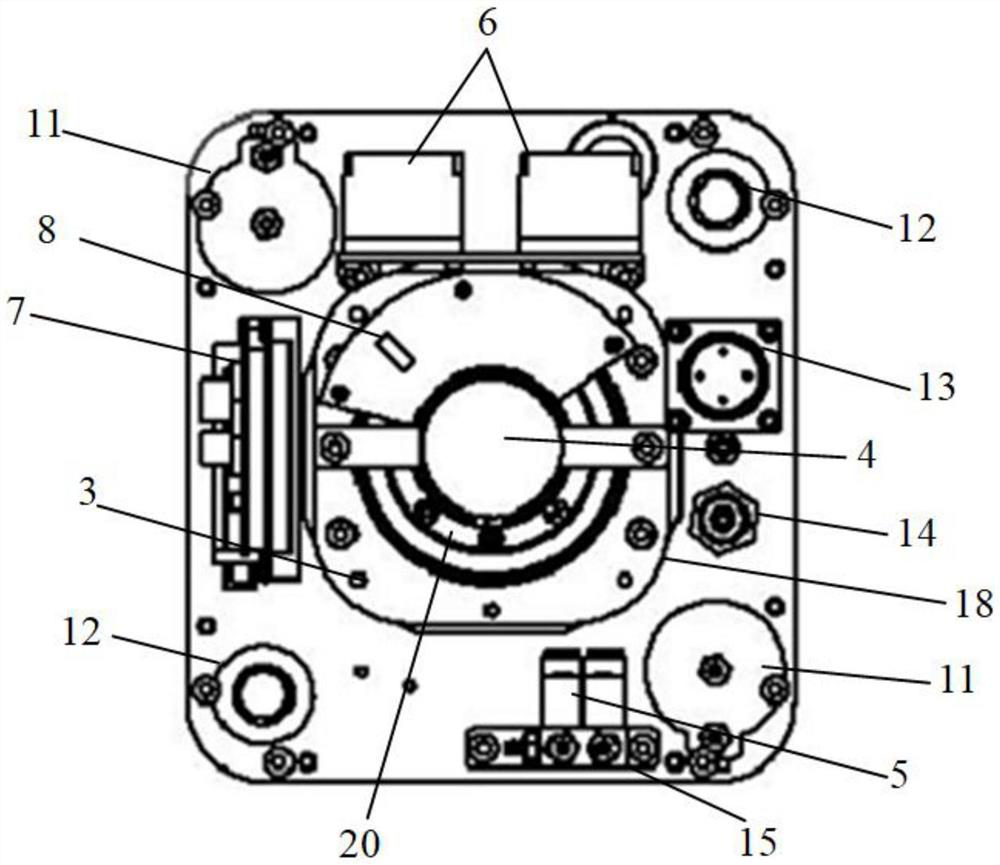

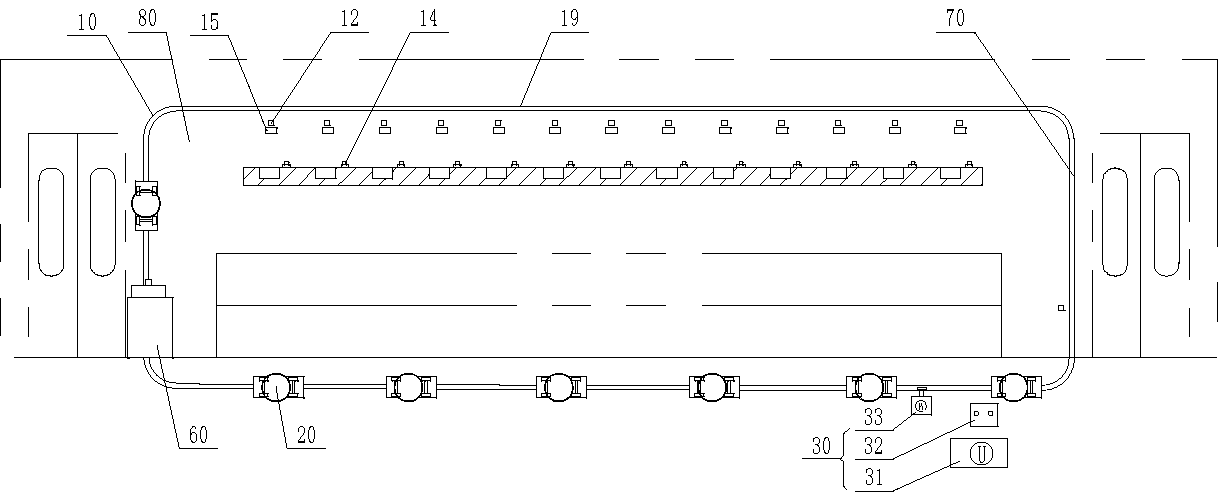

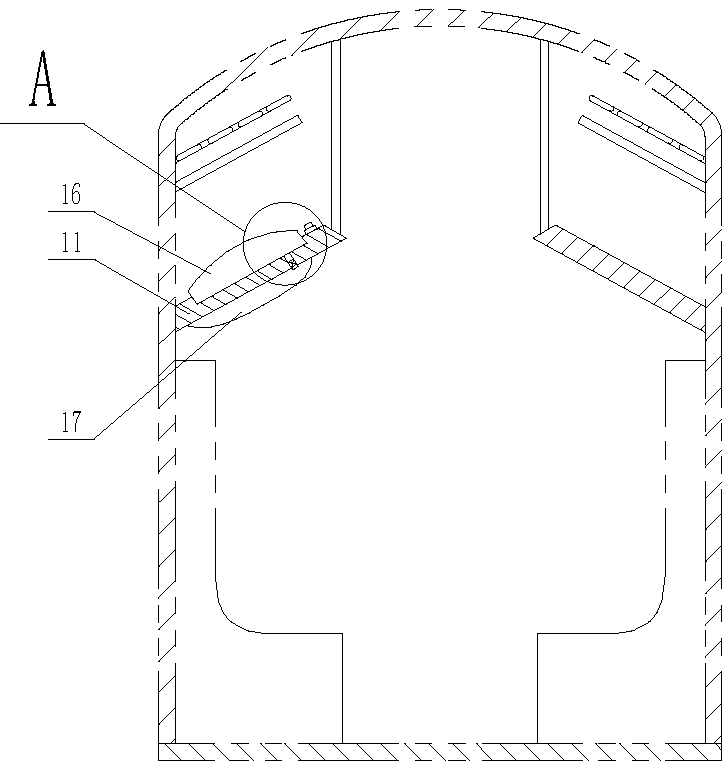

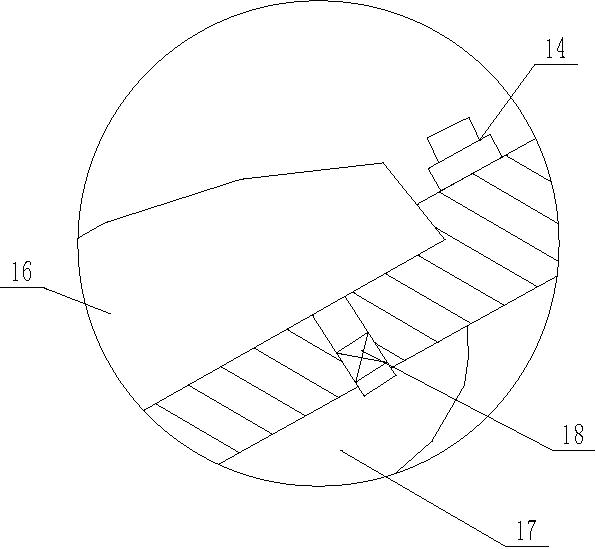

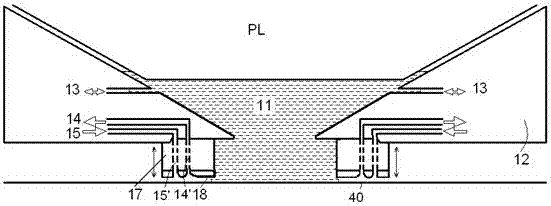

The invention relates to a virtual-axis millimeter-wave human body security check system. The system comprises a virtual-axis guide rail unit, a scanning unit, a scanning driving unit, a data processing unit and a display unit, wherein the virtual-axis guide rail unit comprises a first circular-arc-shaped guide rail; the scanning unit comprises a first group of millimeter-wave antenna arrays and a first millimeter-wave transceiver; the scanning driving unit is used for driving the first group of millimeter-wave antenna arrays to scan in a reciprocating virtual-axis circular-arc-shaped locus on the first circular-arc-shaped guide rail; the data processing unit is used for processing a detection signal from the scanning unit to form a human body image to be detected; the display unit is used for displaying the at least one human body image to be detected. In the human body security check system disclosed by the invention, a virtual-axis scanning way is used, the motion load does not need to be reduced, and the rotational inertia is reduced, so that the scanning speed is increased. The system is small in occupied space, and a single / double-module security check system can be assembled more flexibly according to the size of a practical space and the checked amount.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

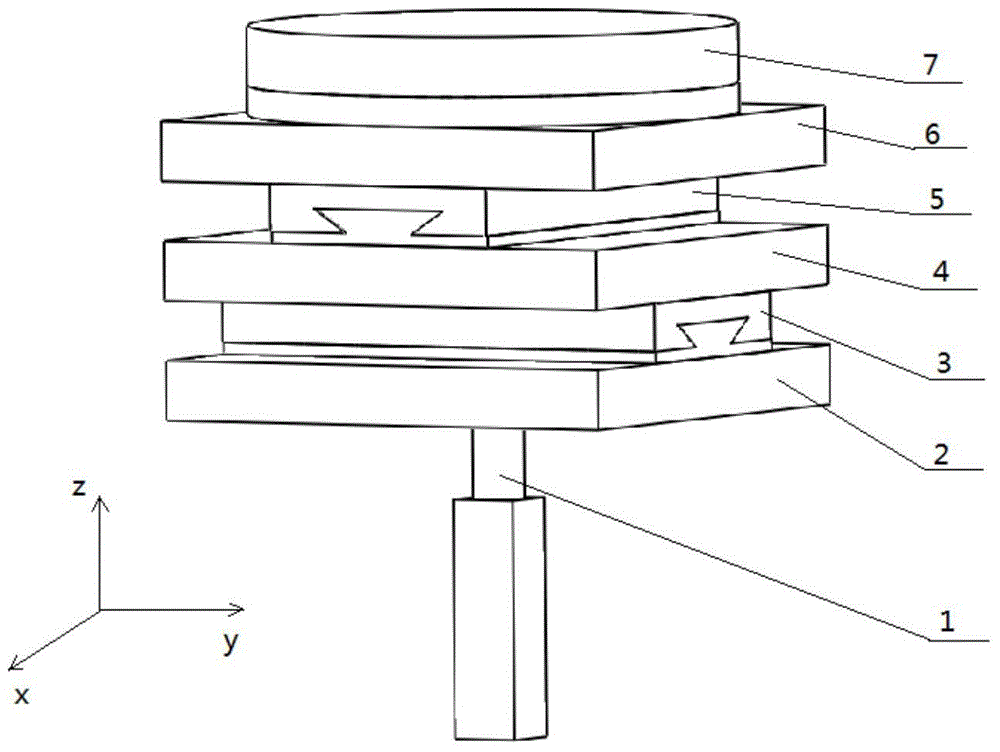

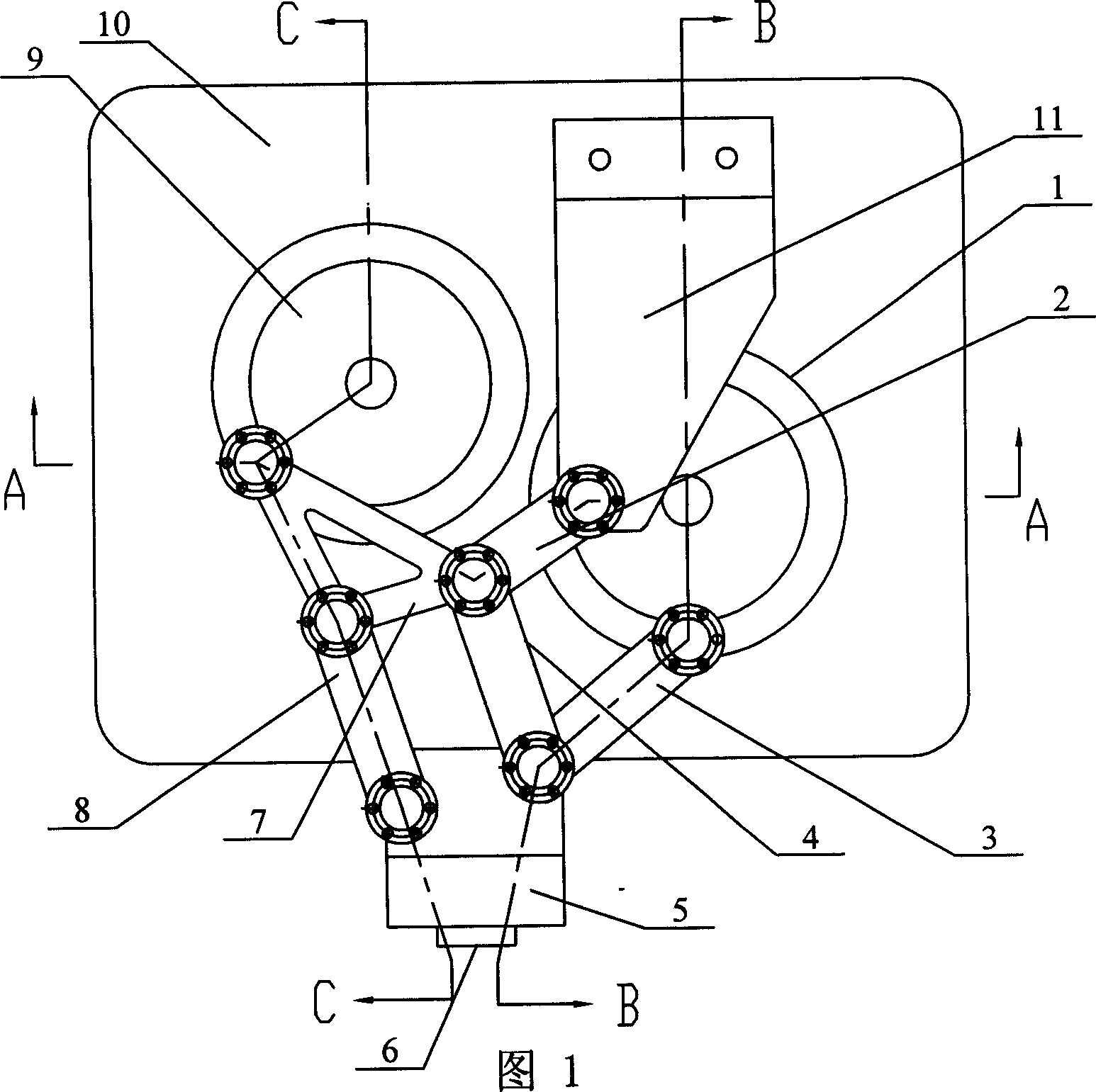

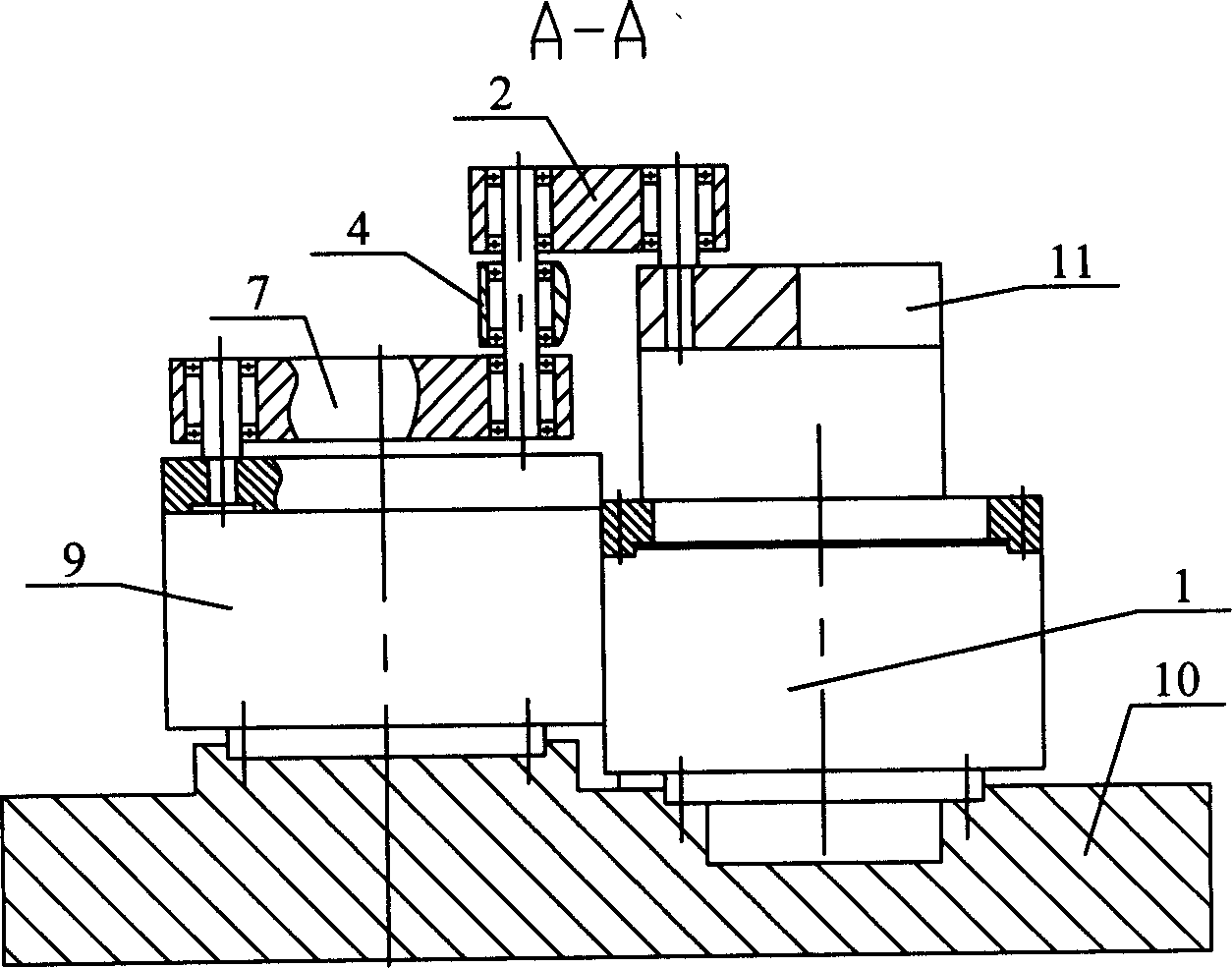

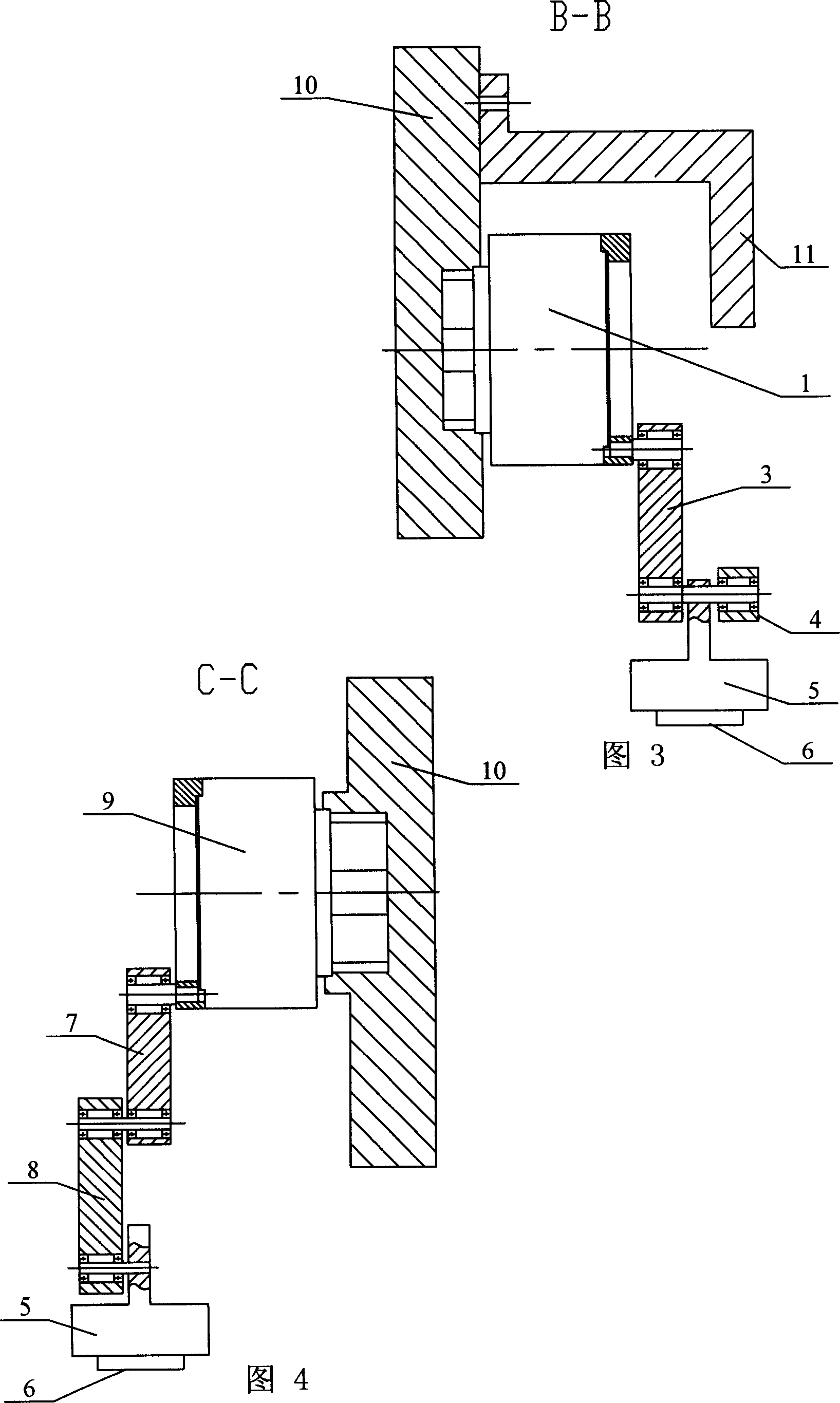

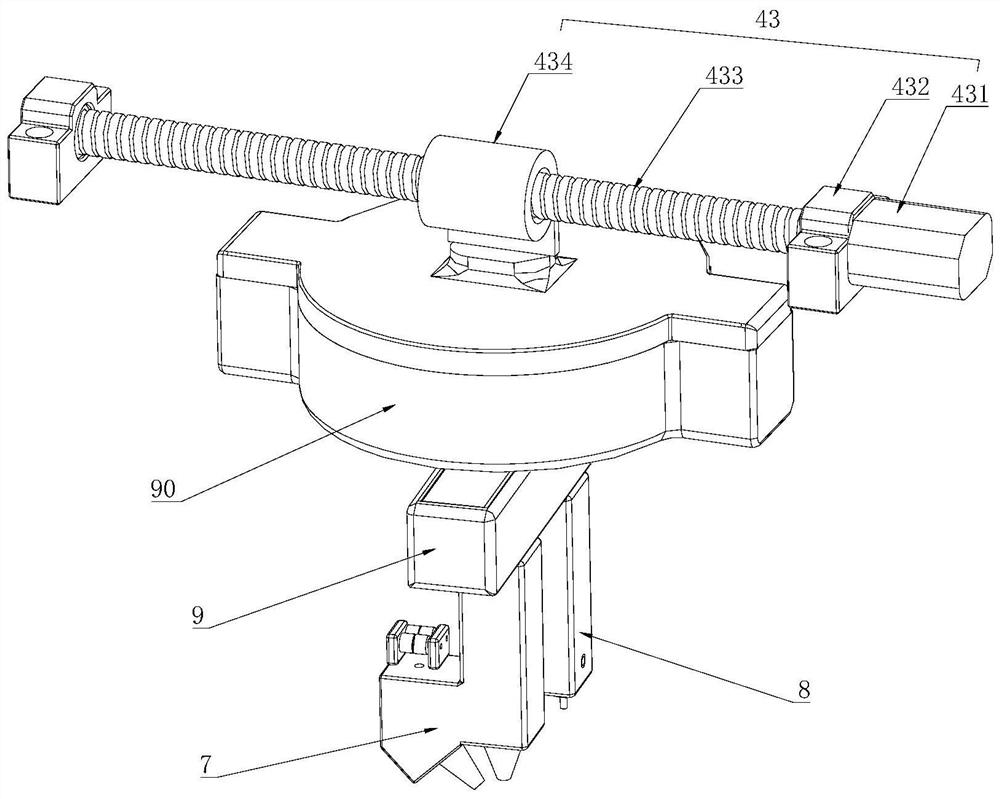

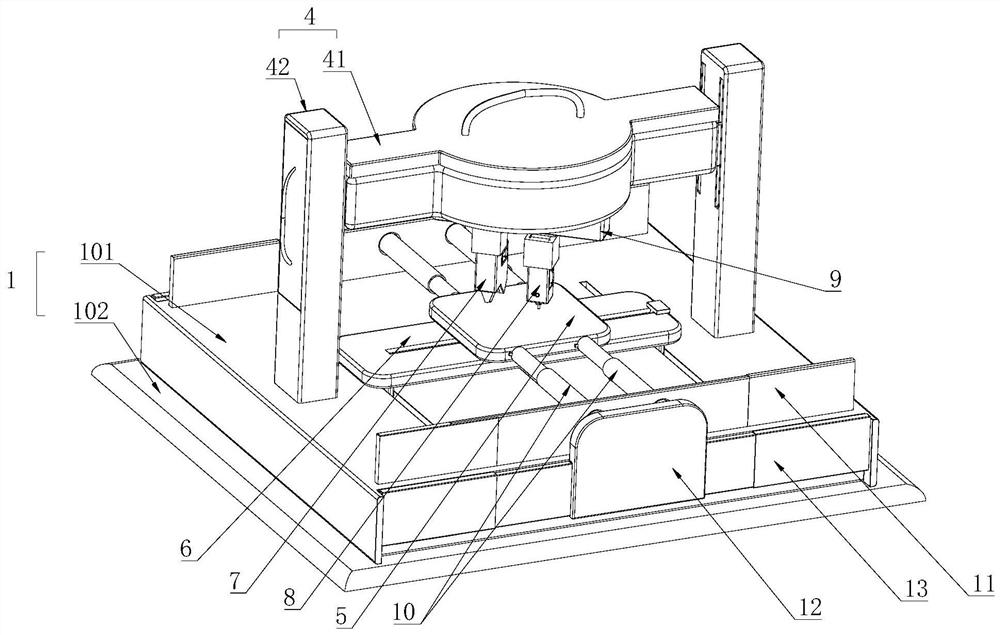

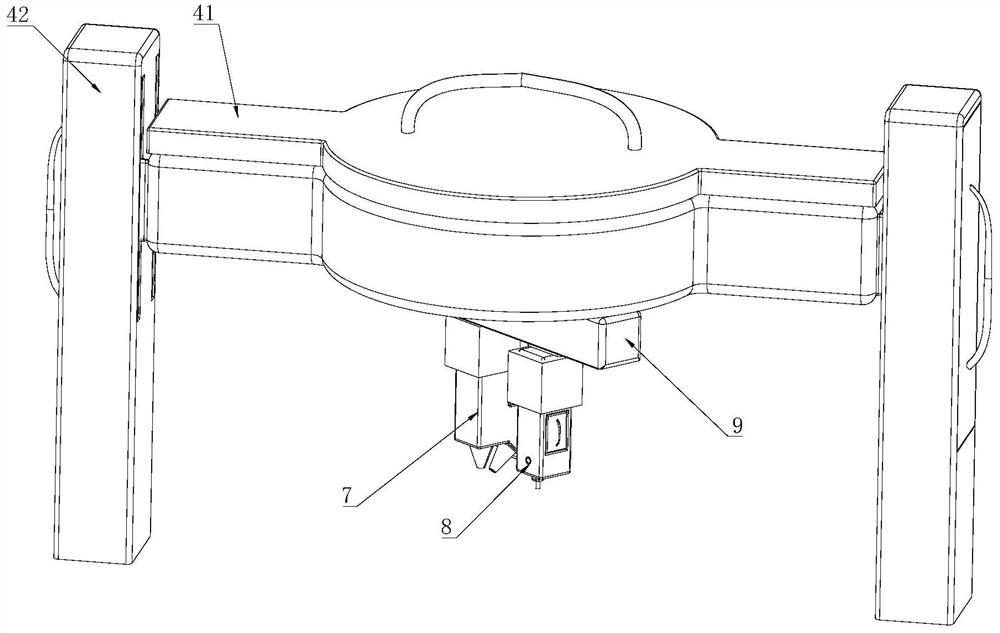

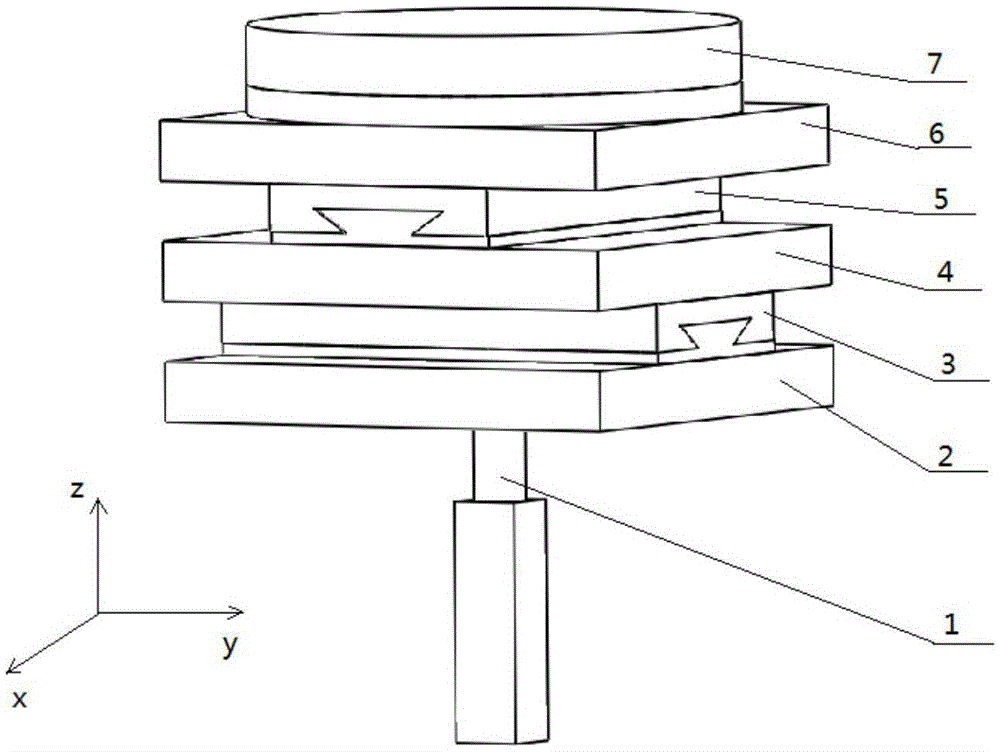

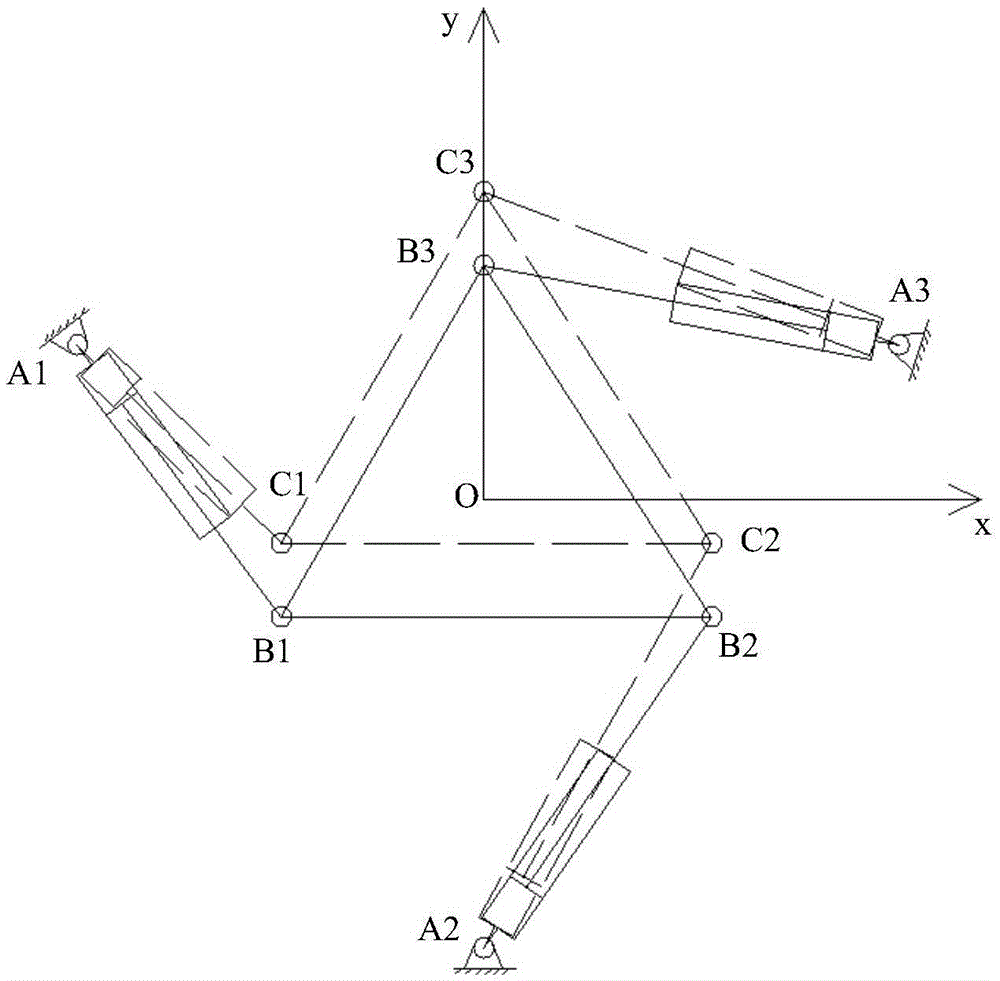

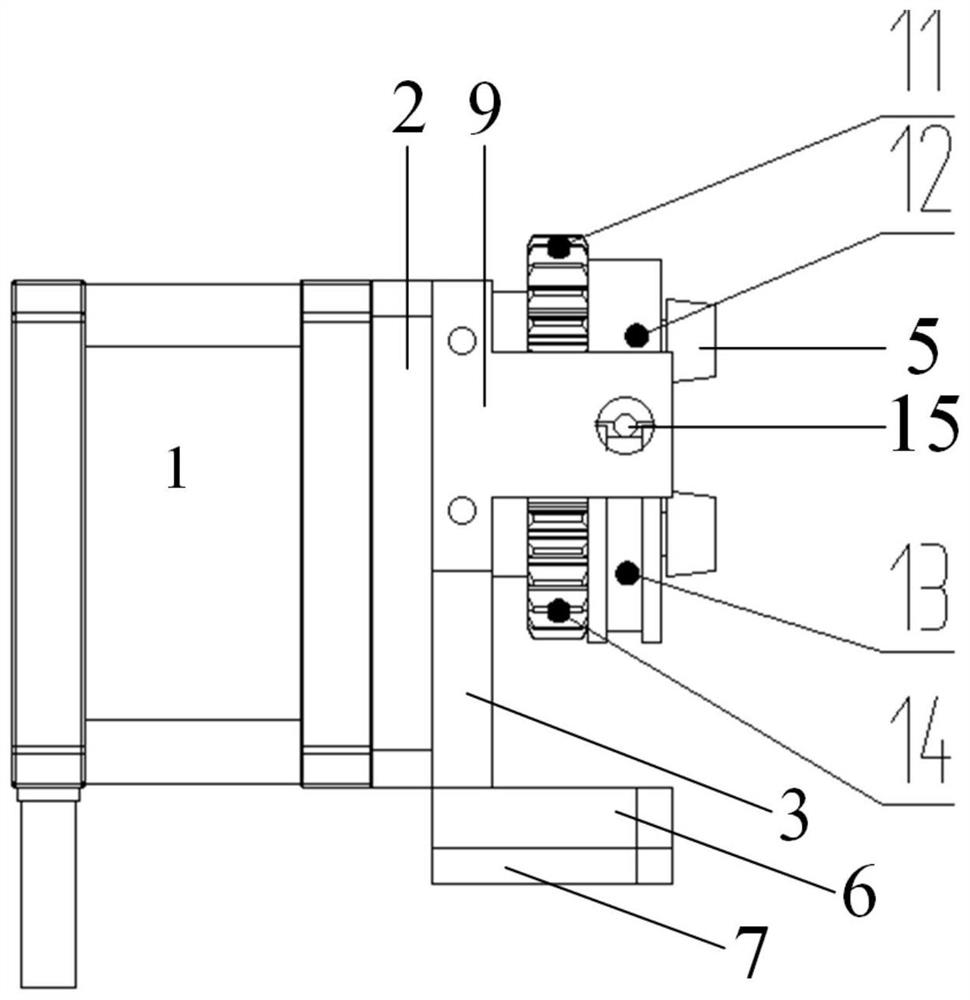

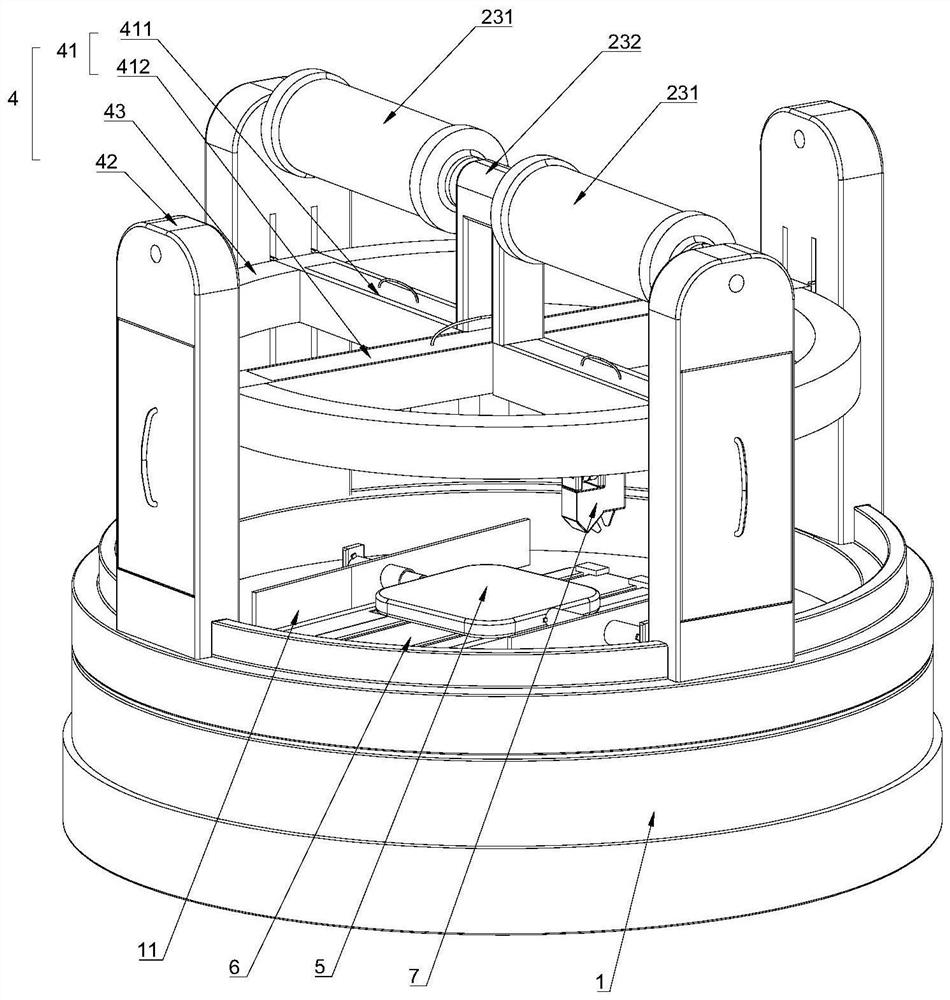

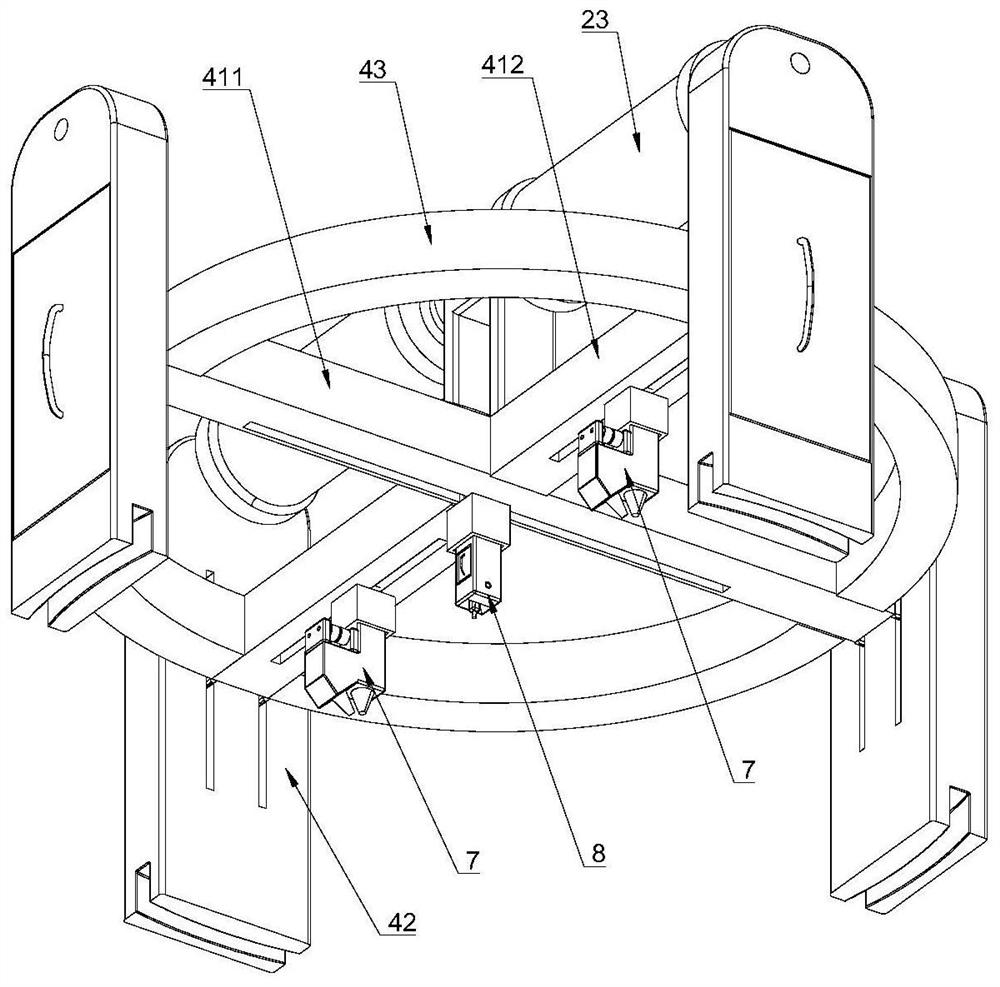

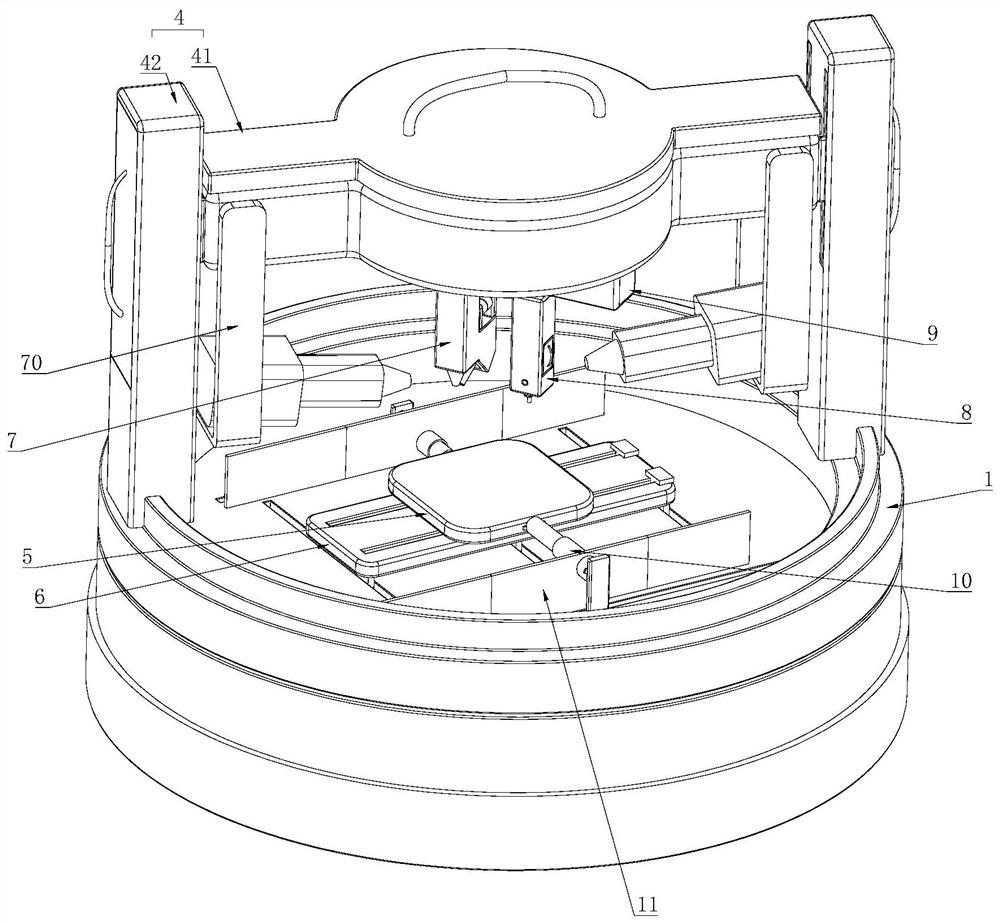

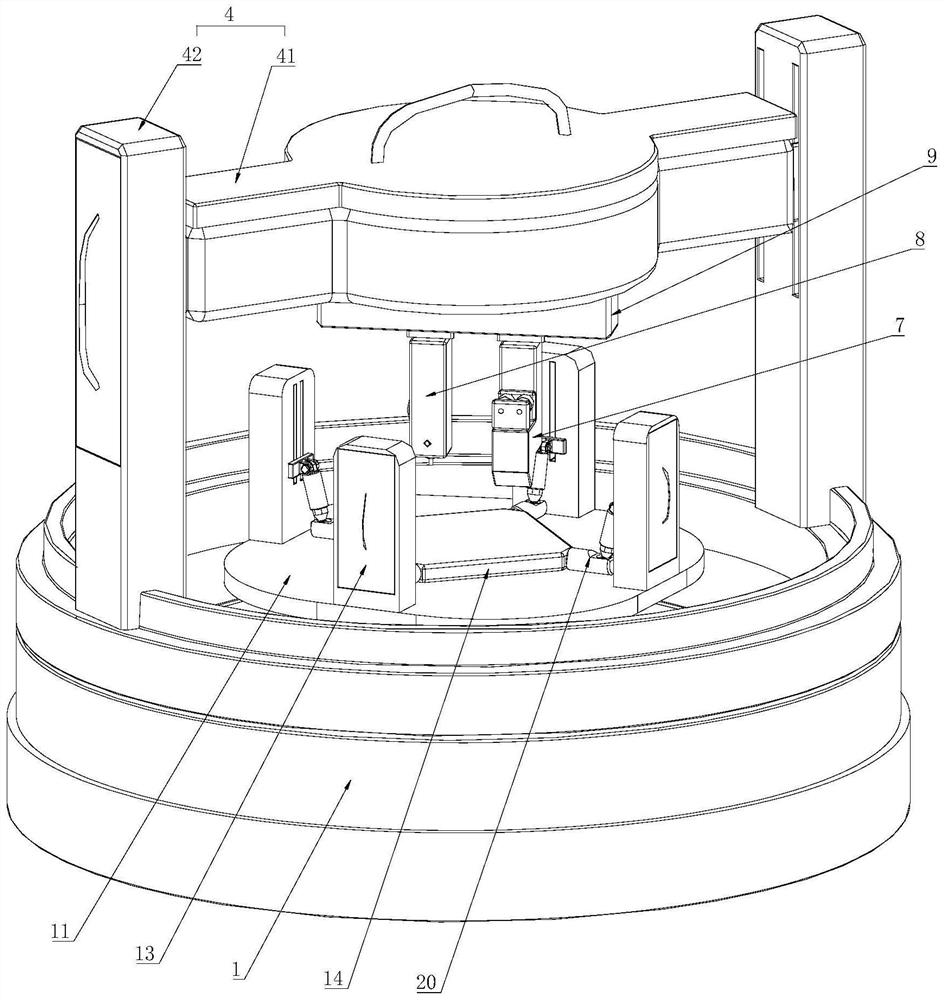

KC test stand driving loading device and method and application thereof

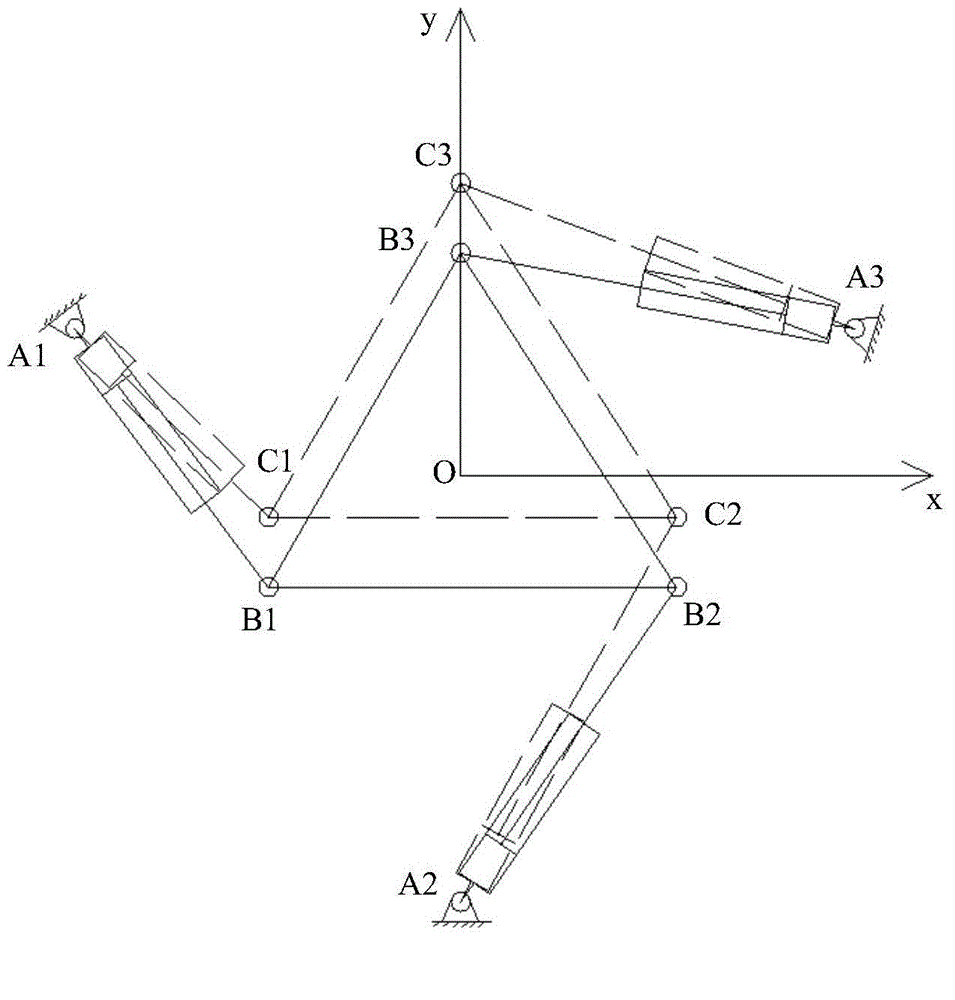

The invention discloses a KC test stand driving loading device comprising a vertical motion platform which is connected with a vertical driving mechanism and can be driven and loaded by the vertical driving mechanism to realize vertical motion, and a longitudinal, lateral and rotary motion driving platform which is arranged on the vertical motion platform. The longitudinal, lateral and rotary motion driving platform is respectively hinged with the power output members of three linear motion driving mechanisms via three driving connection points which are triangularly arranged on the longitudinal, lateral and rotary motion driving platform. The longitudinal, lateral and rotary motion driving platform is driven to perform translational motion along an x-axis and y-axis or rotary motion around a z-axis on the plane via linkage driving control of the three linear motion driving mechanisms. The invention also discloses a corresponding driving loading method and an application thereof. Accurate loading of a KC test stand can be realized so that error is low, motor power in a driving single-axis direction is relatively low, and more importantly, high-efficiency and accurate transmission can be realized in rotary loading and acting force and moment measurement is simple and accurate.

Owner:HUAZHONG UNIV OF SCI & TECH

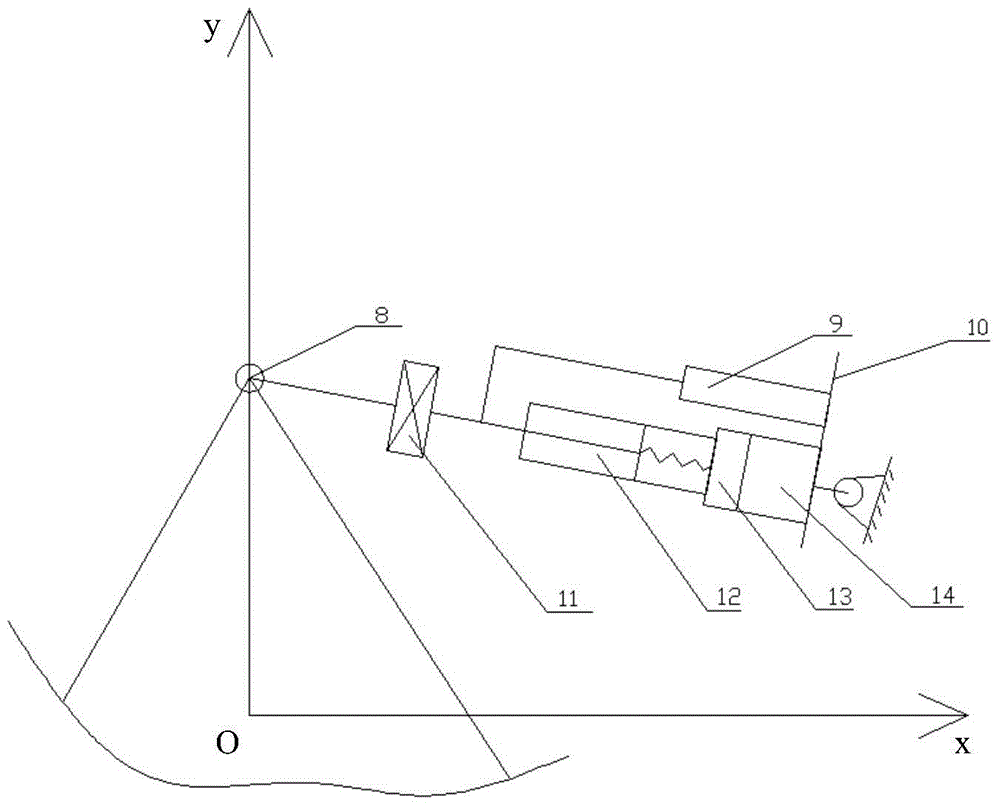

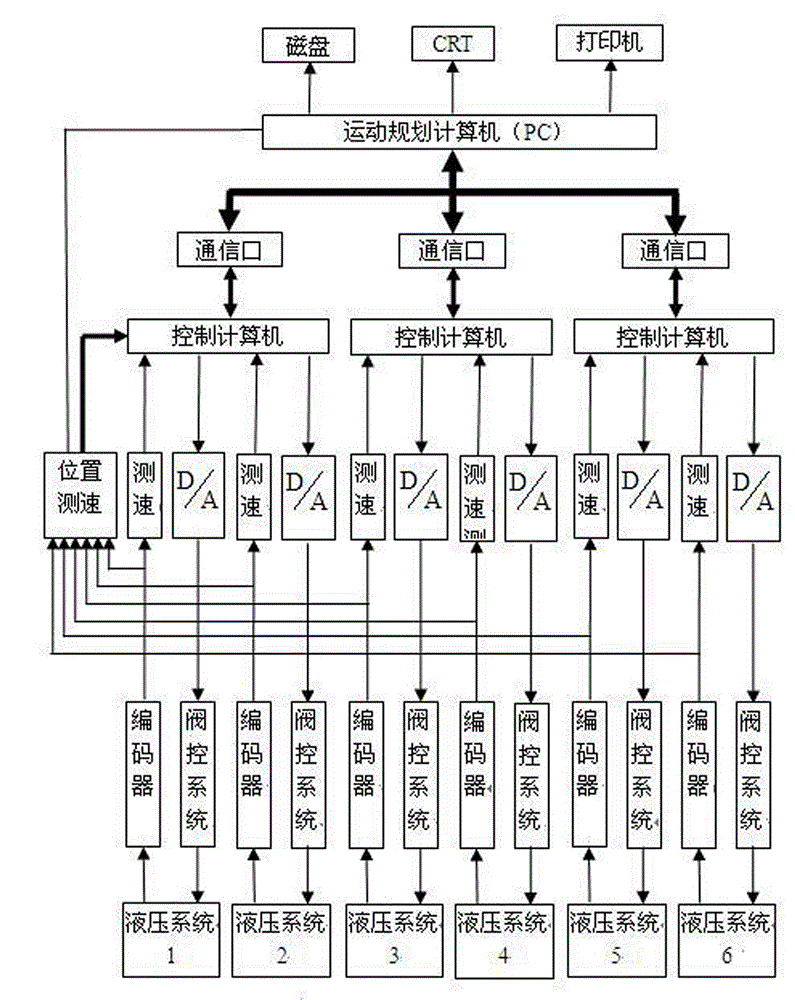

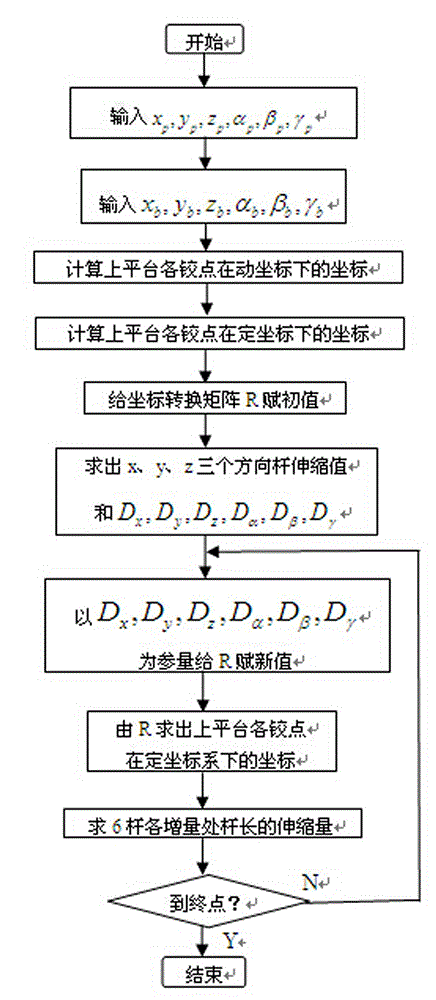

Hydraulic control system for parallel six-degree-of-freedom turntable

InactiveCN104564913AIncrease stiffnessStable structureFluid-pressure actuator componentsPosition controlMotion planning

The invention relates to a hydraulic control system for a parallel six-degree-of-freedom turntable. The hydraulic control system mainly comprises a motion planning computer, a direct control computer, a communication interface, a position and speed detecting part, a D / A (Digital / Analog) conversion and power amplifier and an electro-hydraulic servo valve. The main functions of all parts of a turntable control system are as follows: the motion planning computer is used for directly receiving an outside control command and parameter, monitoring the motion of a robot in real time, displaying information and sending various control commands to subordinate; the computer is directly controlled to receive the commands and the corresponding given information for the position and speed sent by the higher-level computer; the state value of the monitored object is detected in real time; the communication interface is an important part for transferring information between two-level computers; through the interface, a given value for a motion speed at a certain moment and necessary information for coordination and control of the two levels of computers are supplied to a speed control computer by a position control computer; the electro-hydraulic servo valve can control the flux and the flow direction through an electric signal, so that the speed, direction and size of the joint motion can be controlled.

Owner:HEILONGJIANG ZHENMEI BROADCAST COMM EQUIP

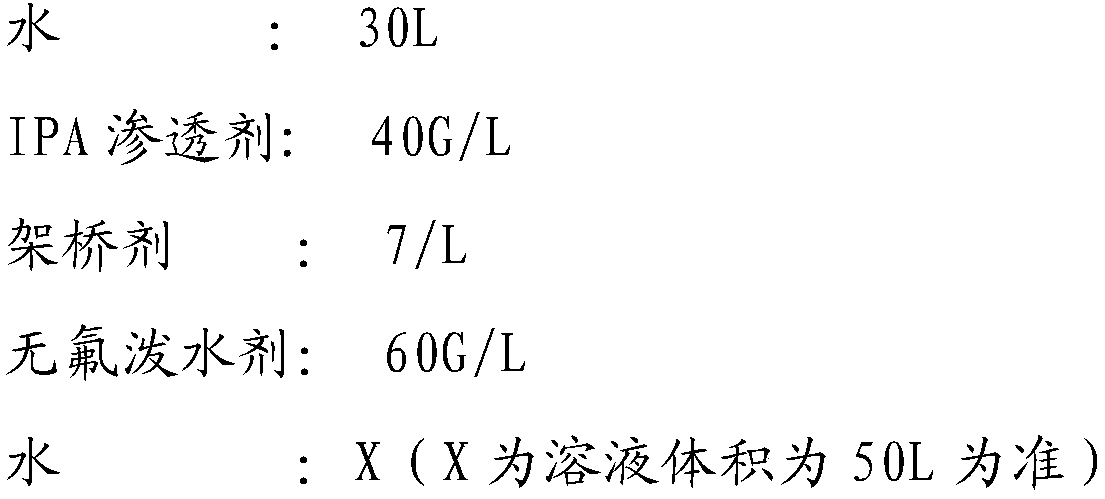

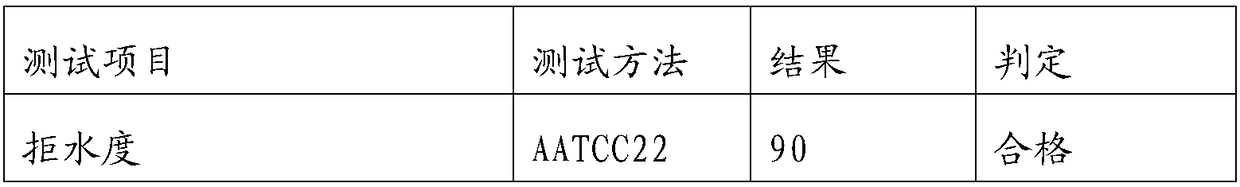

Manufacturing process for novel functional fabric

ActiveCN108914622AReduce motion loadEasy to storeDyeing processArray data structureMoisture permeability

The invention discloses a manufacturing process for a novel functional fabric. The manufacturing process mainly comprises the following steps: 1) water spraying of a dyed fabric for setting; 2) calendering before sizing; and 3) one-knife PU resin functional coating treatment: performing one-knife PU resin functional coating treatment on a calendered surface, wherein a functional coating comprises,by mass, 60-70 parts of two-component polyurethane resin, 25-30 parts of one-component polyurethane resin, 5-10 parts of AC glue, 1-3 parts of a silicon-series dry agent, 1-2 parts of a bridging agent and a solvent X, and the usage amount of the solvent X is added with the viscosity of a rubber compound of 15000 CPS as the criterion. According to the invention, a one-knife coating process is adopted, so the novel functional fabric has the functions of low water pressure, high moisture permeability and UV resistance, and further has the advantages of light weight, thinness, easy storage, comfortable wearing, reduced environmental pollution, etc.

Owner:FUJIAN SUNTION TEXTILE SCI & TECH

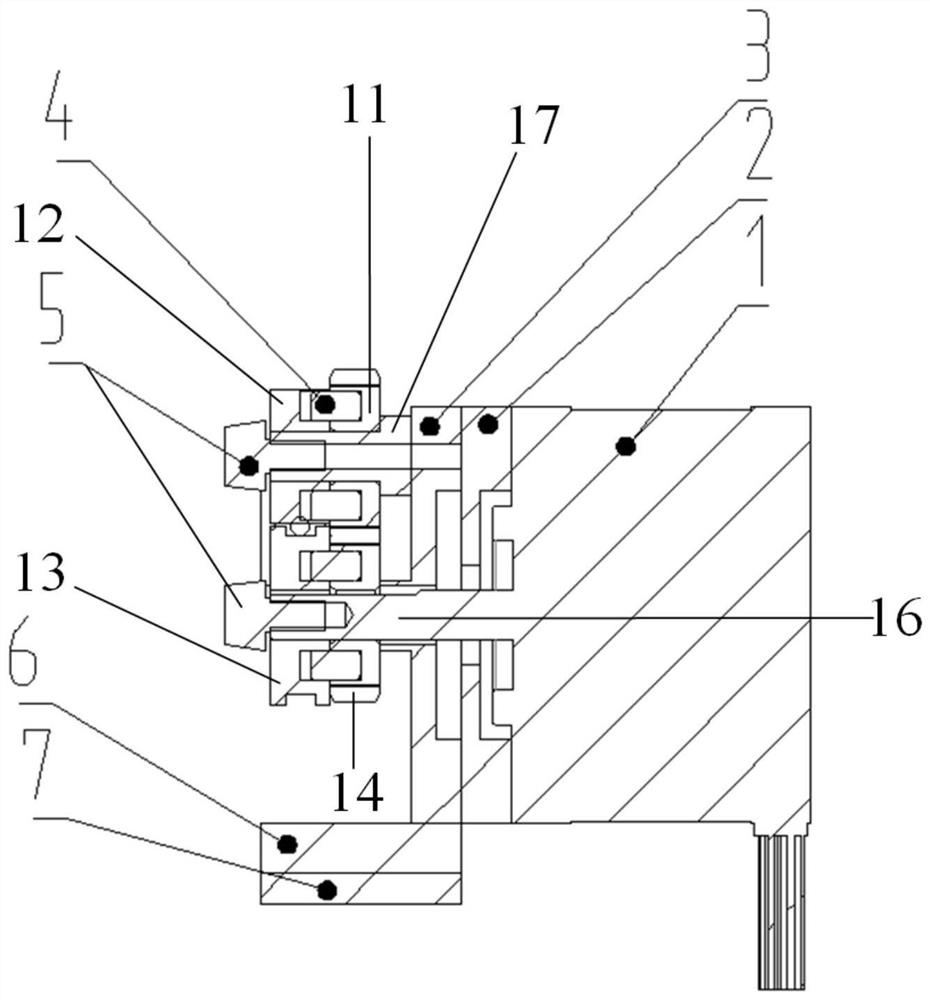

Label winding and sticking device

ActiveCN1751970AGuaranteed accuracyEnsure consistencyLabellingHot-melt adhesiveElectrical and Electronics engineering

A label rolling and sticking apparatus is composed of label sticking unit, transmission unit for driving said label sticking unit, label rolling unit under said label sticking unit, label conveying unit at the side of label rolling unit, label-sucking sleeve pipe in the label feeding die under said label sticking unit, label-sucking mandrel in said label-sucking sleeve pipe, and shaping die sleeve above label feed die and surrounding said sleeve pipe.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

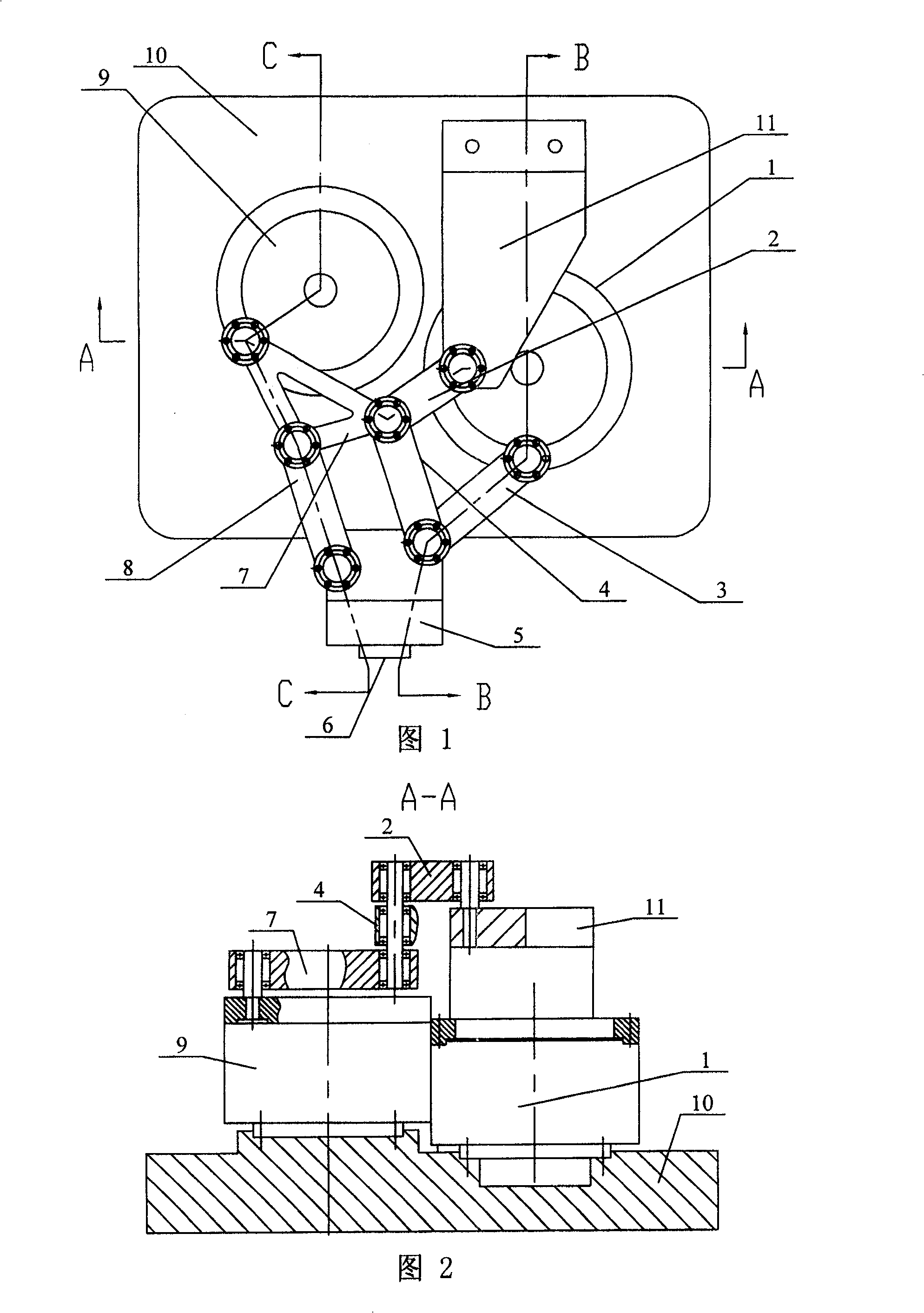

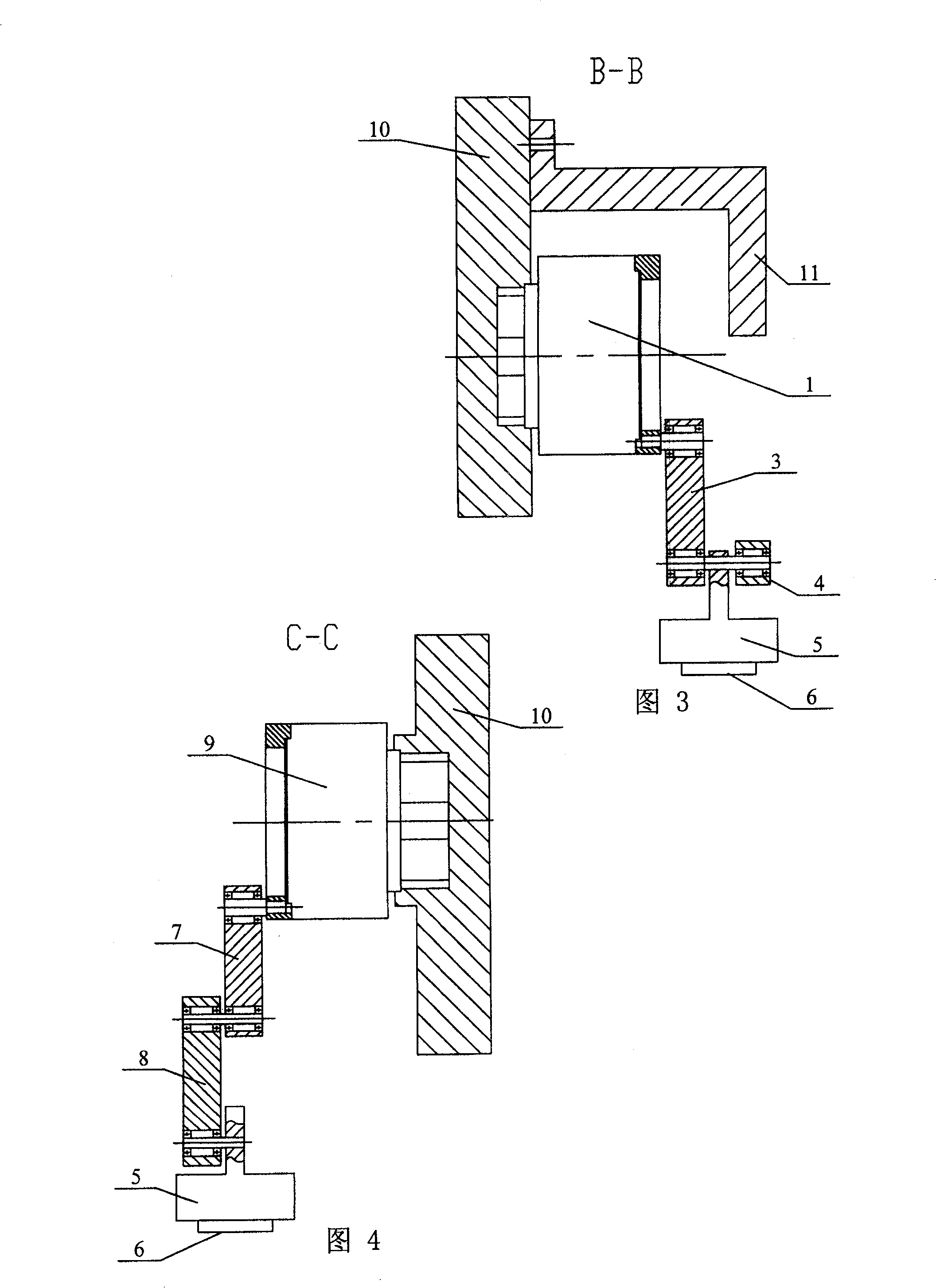

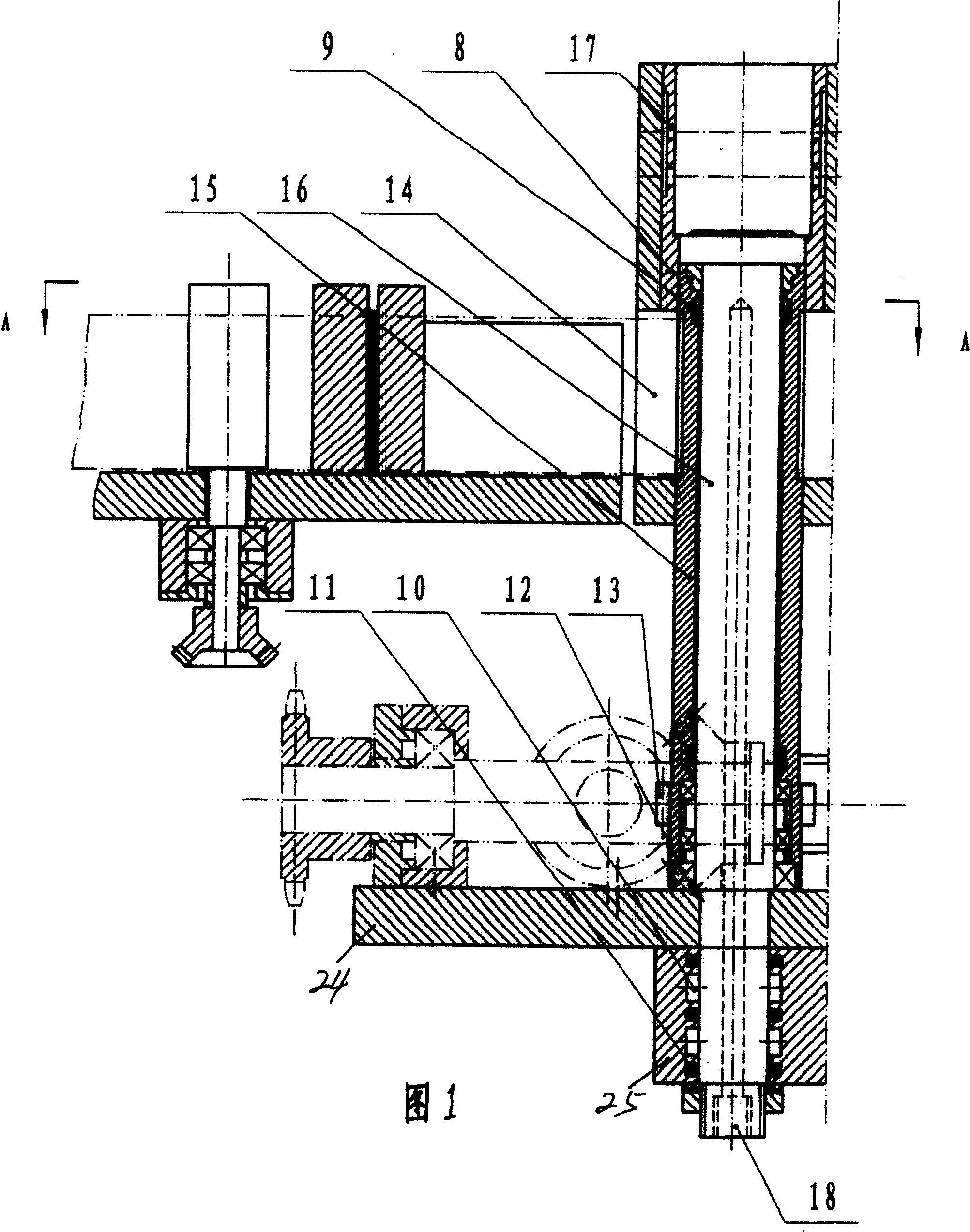

Direct-driving three-freedom serial-parallel mixed precision positioning mechanism

InactiveCN1581362ACompact structureHigh positioning accuracyInstrumental componentsMarine engineeringHinge joint

The positioning mechanism includes following parts ad connections: bent plate is fixed on a side of machine foundation, base of No.1 motor and base of No.2 motor are fixed on the foundation; one end of No.1 connecting rod is hinge-jointed to bent plate, and another end of No.1 connecting rod is connected to one end of No.3 and No.4 connecting rods respectively; one end of No.2 connecting rod is hinge-jointed to output end of No.1 motor, another ends of No.3 and No.2 connecting rods are hinge-jointed to output module from upper to lower respectively. The invention also contains No.5 connecting rod, and other connections etc. Rectilinear motion module is fixed to output module. Advantages are: compact structure, high positioning accuracy, and good dynamic performance.

Owner:HARBIN INST OF TECH

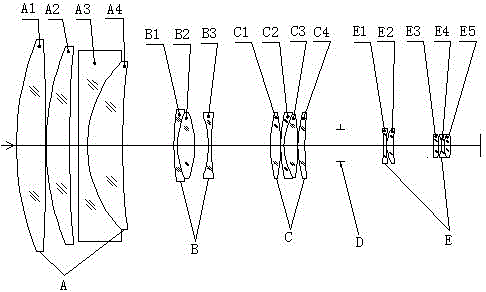

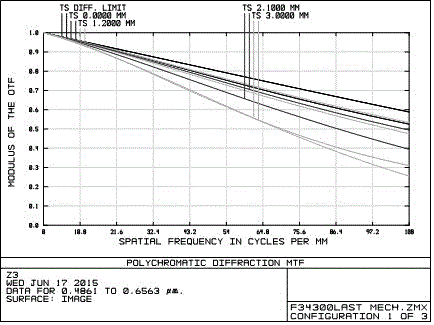

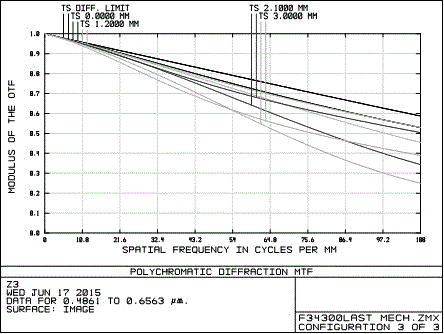

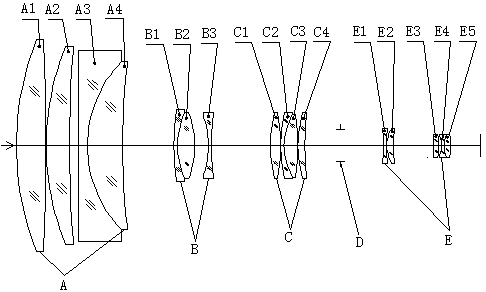

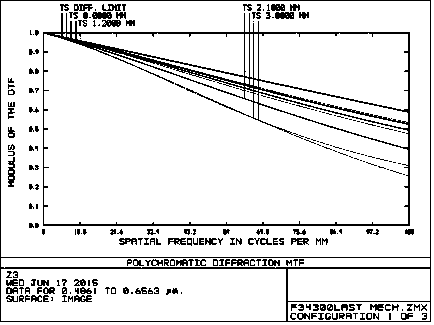

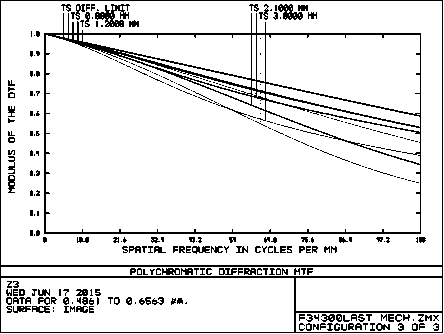

High definition continuous zooming pick-up lens capable of rapidly switching field of view at low temperature

The invention relates to a high definition continuous zooming pick-up lens capable of rapidly switching field of view at low temperature. The pick-up lens is provided with along the light incoming direction: a front fixed lens group having a positive focal power, a zoom lens group having a negative focal power, a compensation lens group having a positive focal power, and a rear fixed lens group having a iris diaphragm and a negative focal power; the front fixed lens group is provided with a double-convex lens, a positive meniscus lens and a first gluing group which is composed by sealing a negative meniscus lens and a second positive meniscus lens; the zoom lens group is provided with a second gluing group which is composed by sealing a second negative meniscus lens and a second double-convex lens and also a double-concave lens; the compensation lens group is provided with a third double-convex lens, a third gluing group which is composed by sealing a third negative meniscus lens and a fourth meniscus lens, and also a third positive meniscus lens; the rear fixed lens group is provided with a double-concave lens, a fourth positive meniscus lens, a planoconvex lens, and a fourth gluing group which is composed by sealing a third double-concave lens and a fifth double-convex lens. The pick-up lens enables rapid switching at low temperature.

Owner:FUJIAN FORECAM OPTICS CO LTD

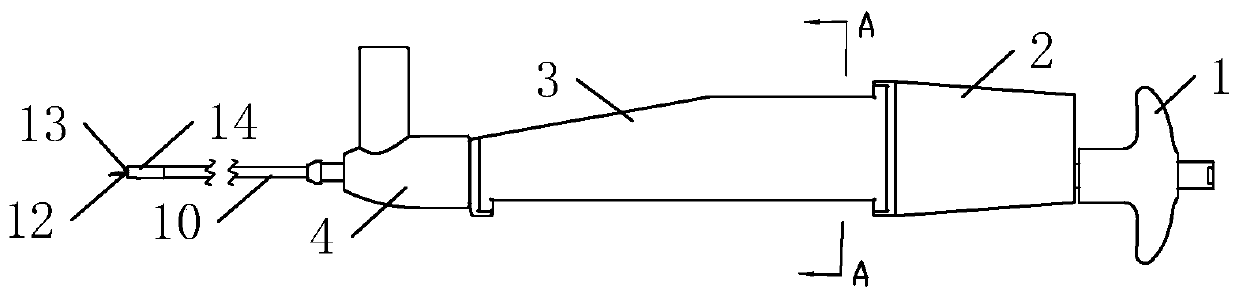

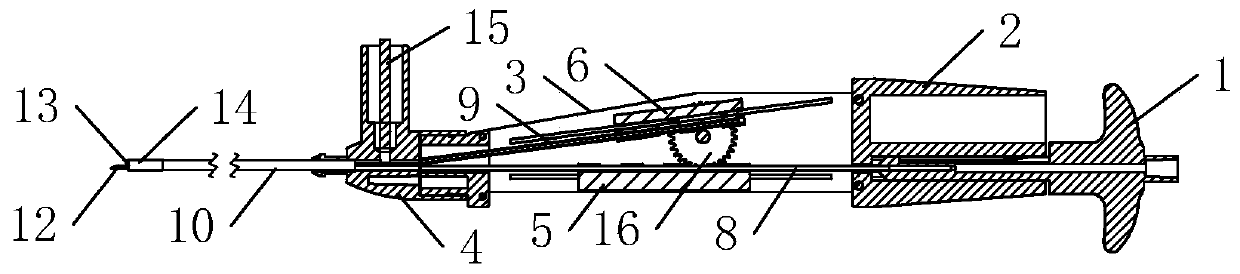

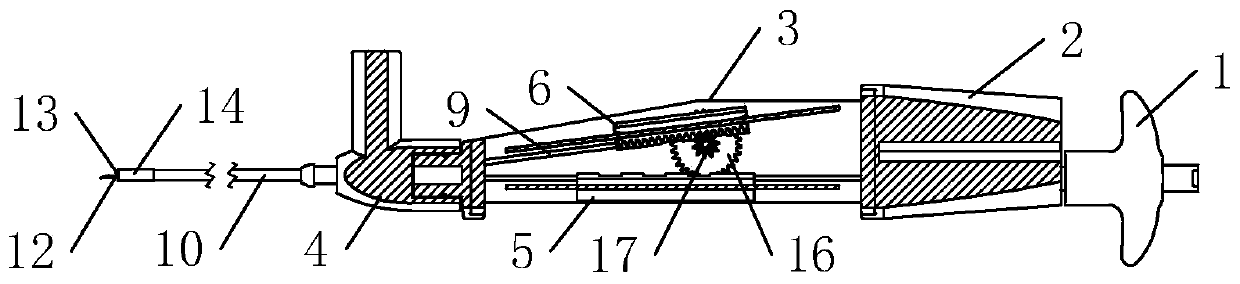

Linkage structure of an endoscope apparatus

ActiveCN110236669AAvoid the holding partReduce distractionsEndoscopesMedical devicesEngineeringEndoscope

The invention discloses a linkage structure of an endoscope apparatus. The linkage structure comprises a handle part, a sheath pipe, a flow guiding pipe, a traction wire, a cutting knife and an injection needle, wherein the handle part comprises a first handle, a second handle, an injection pipe and an electrode pipe; the electrode pipe and the injection pipe are arranged in a handle side cover of the handle part; an end cap is also arranged at the front end of the handle side cover; an electrode is fixed to the end cap; the electrode pipe and / or the traction wire penetrates through the end cap; an electrode is in contact conductance with the electrode pipe and / or the traction wire through an electric brush; the flow guiding pipe penetrates through the handle and is fixedly connected with an injection handle; the injection handle moves backwards and forwards to drive the flow guiding pipe to move backwards and forwards; the electrode is fixed on the end cap at the front end of the handle part; besides, an injection opening of the injection pipe is formed in the rear end of the handle part; a driven piece does not have load brought by other connection, so that when the apparatus is used, the grasping part can be sufficiently avoided, the interference to an operator is reduced, the movement load of the apparatus mechanisms is reduced, and the difficulty of realizing the technology is reduced.

Owner:ANREI MEDICAL HZ

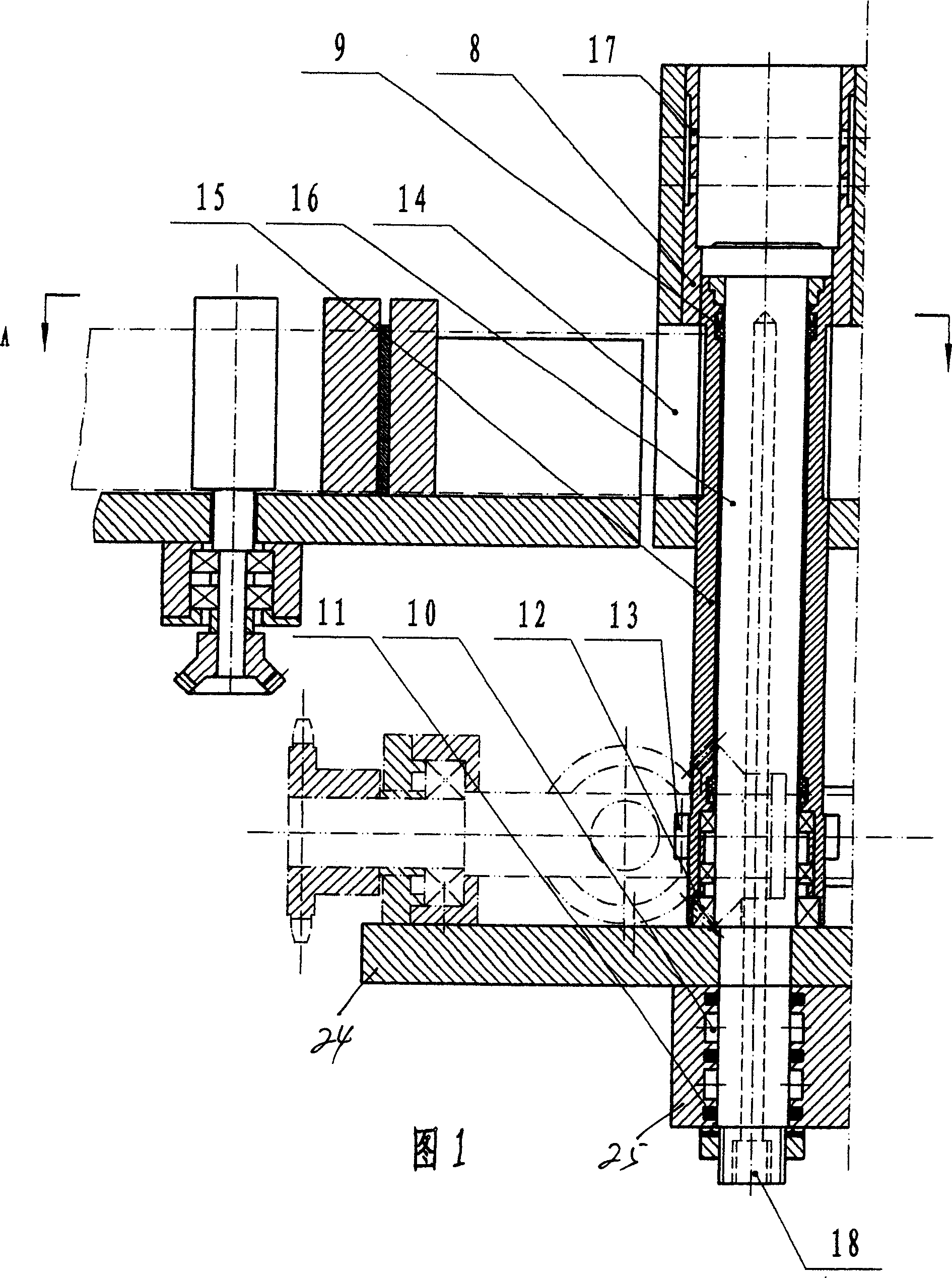

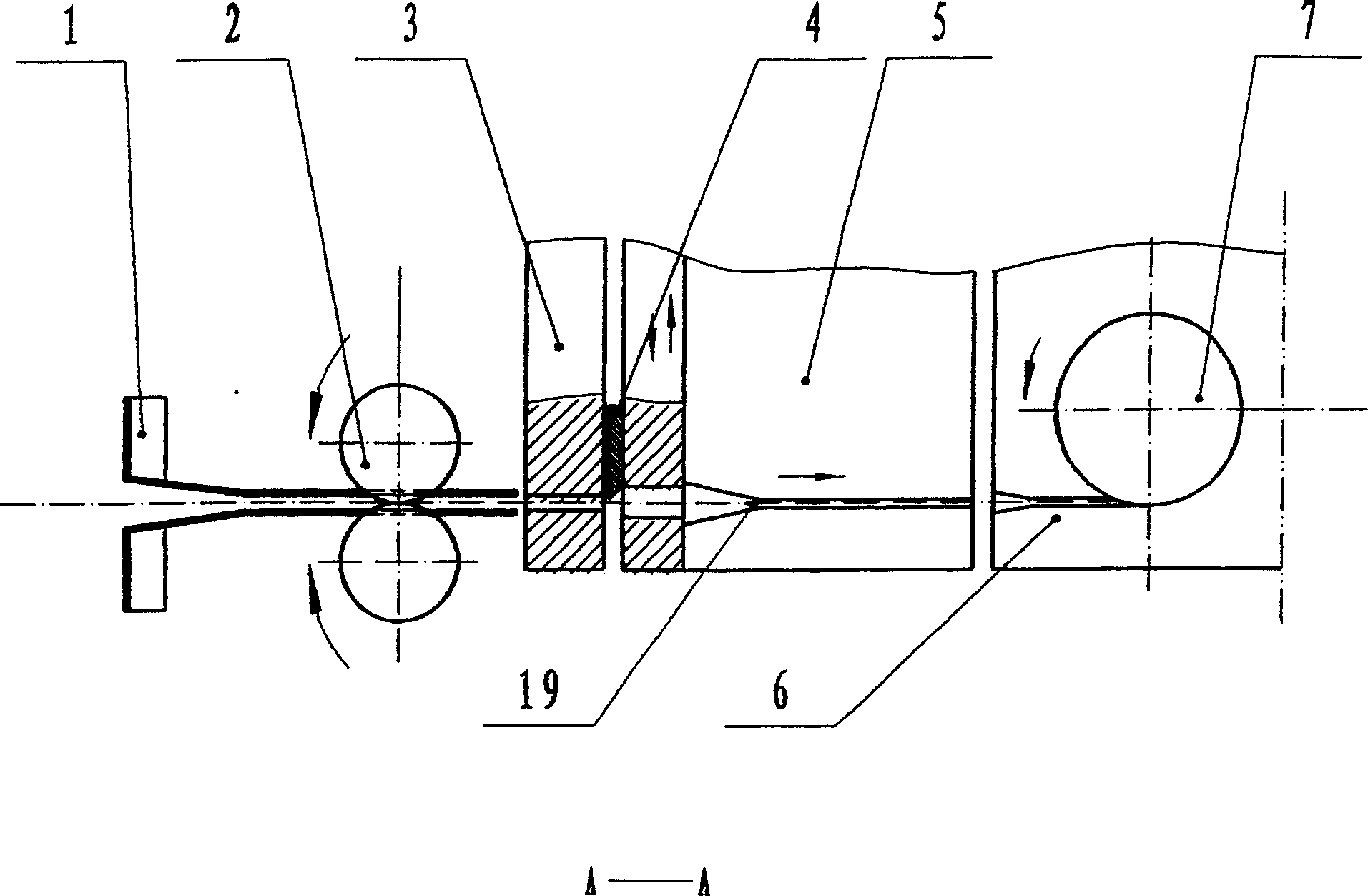

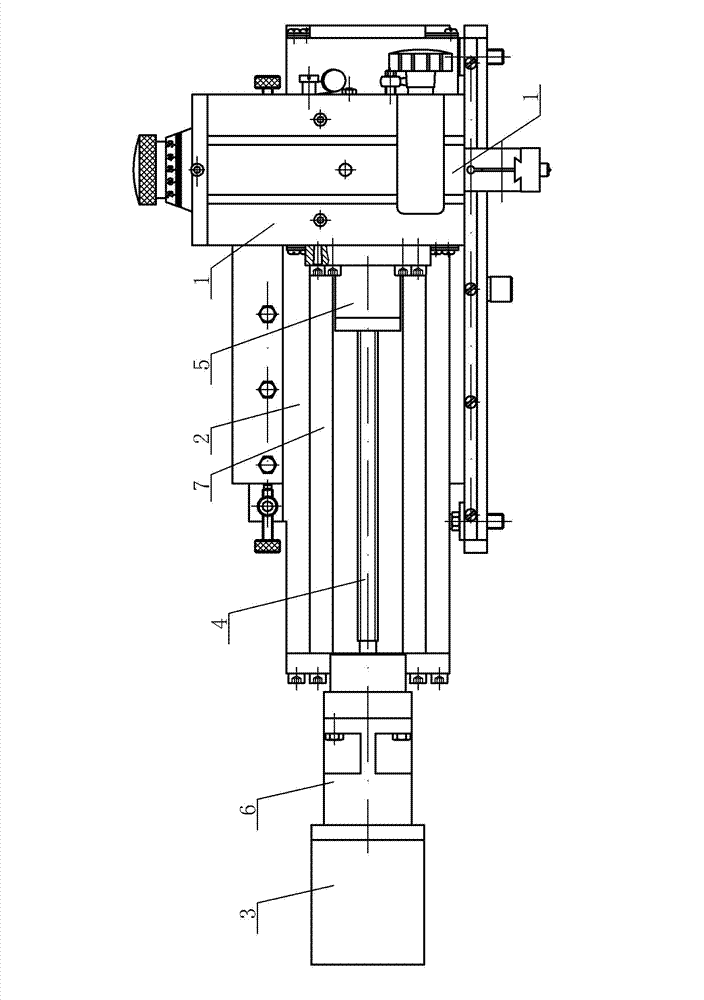

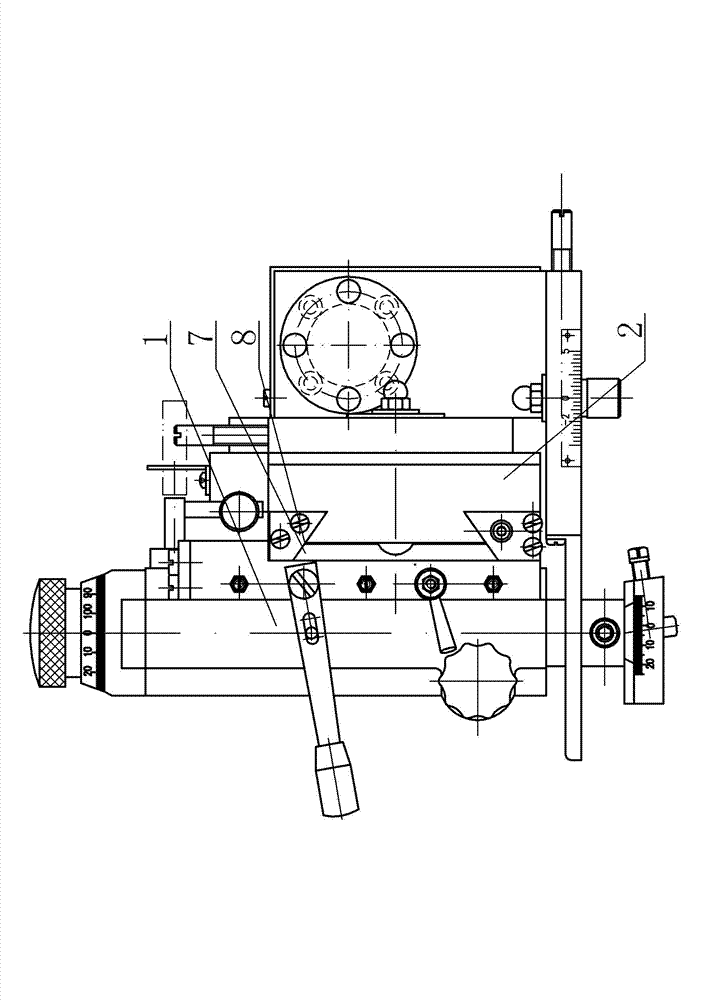

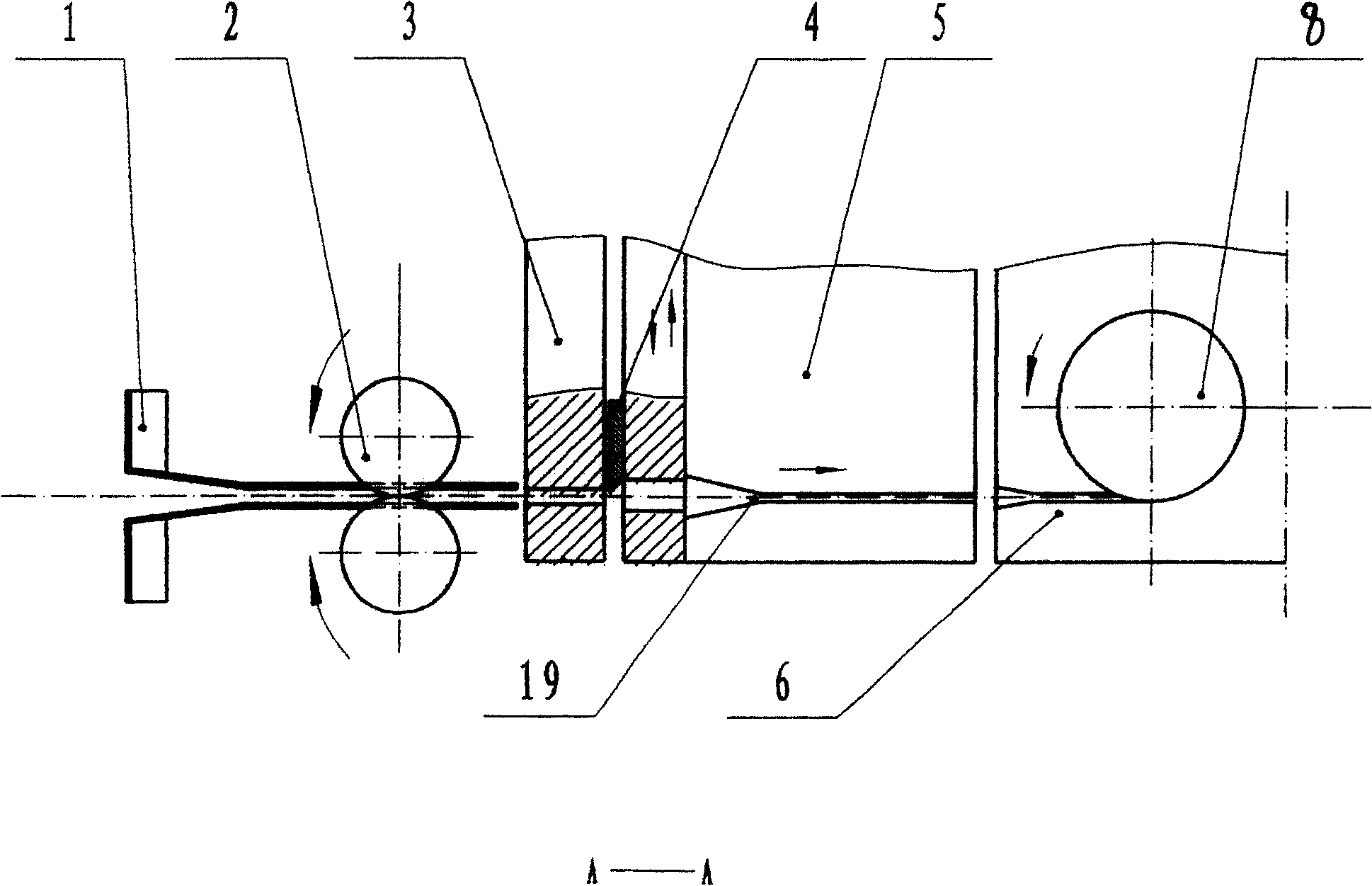

Guide wheel dresser feeding structure of air valve rod-part numerical control centerless grinding machine

InactiveCN102785134APrecise feedingGuaranteed feed accuracyRevolution surface grinding machinesAbrasive surface conditioning devicesCenterless grindingBall screw

The invention provides a guide wheel dresser feeding structure of an air valve rod-part numerical control centerless grinding machine, which can guarantee the straight feed accuracy of a guide wheel dresser, guarantee the feed precision of the guide wheel dresser, reduce the movement load of a ball screw and can ensure the long working service life of the ball screw. The guide wheel dresser feeding structure comprises a guide wheel dresser, a base, a servo motor, a ball screw and a screw nut, wherein the guide wheel dresser is supported on the base, the servo motor drives the ball screw, the ball screw is connected with the screw nut in a threading way, one end of the screw nut is tightly connected with the guide wheel dresser, and the guide wheel dresser feeding structure is characterized in that the upper end surface of the base is provided with a dovetail straight lead-rail groove, the bottom of the guide wheel dresser is provided with a dovetail lead rail, the dovetail lead rail is embedded inside the dovetail straight lead rail groove, the servo motor is connected with the input end of a reducer, and the output end of the reducer is connected with the input end of the ball screw.

Owner:WUXI JIANHE NUMERICAL CONTROL MACHINE TOOL

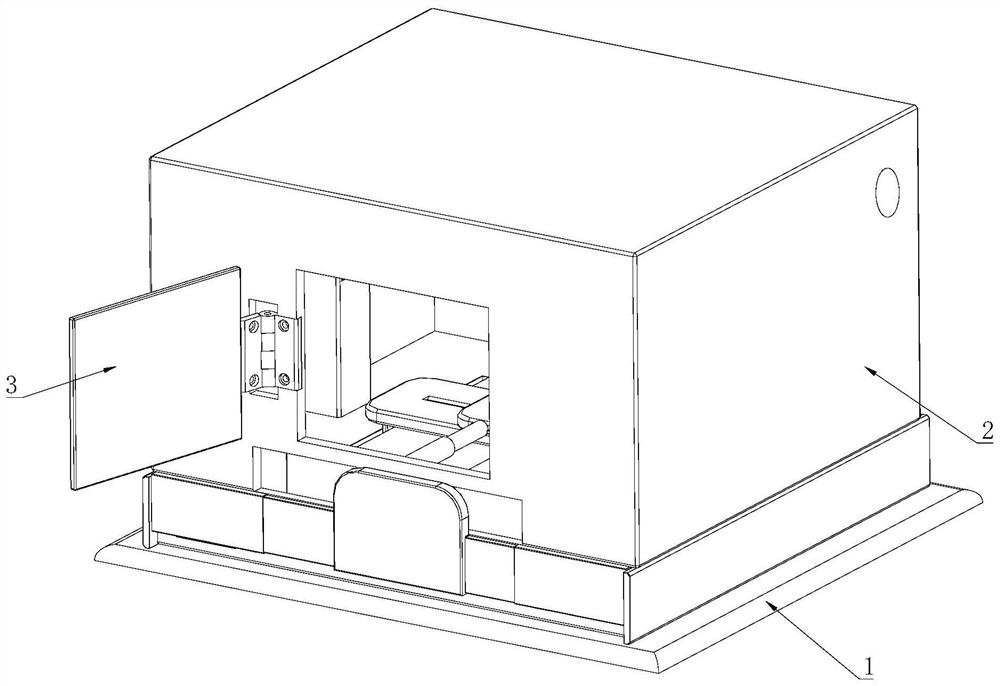

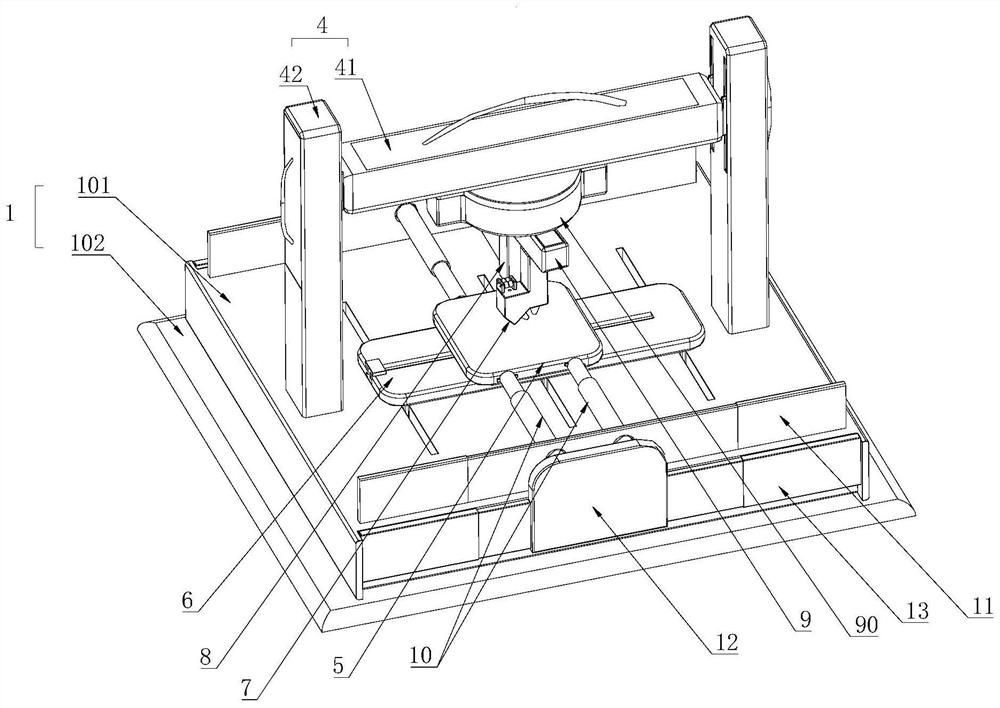

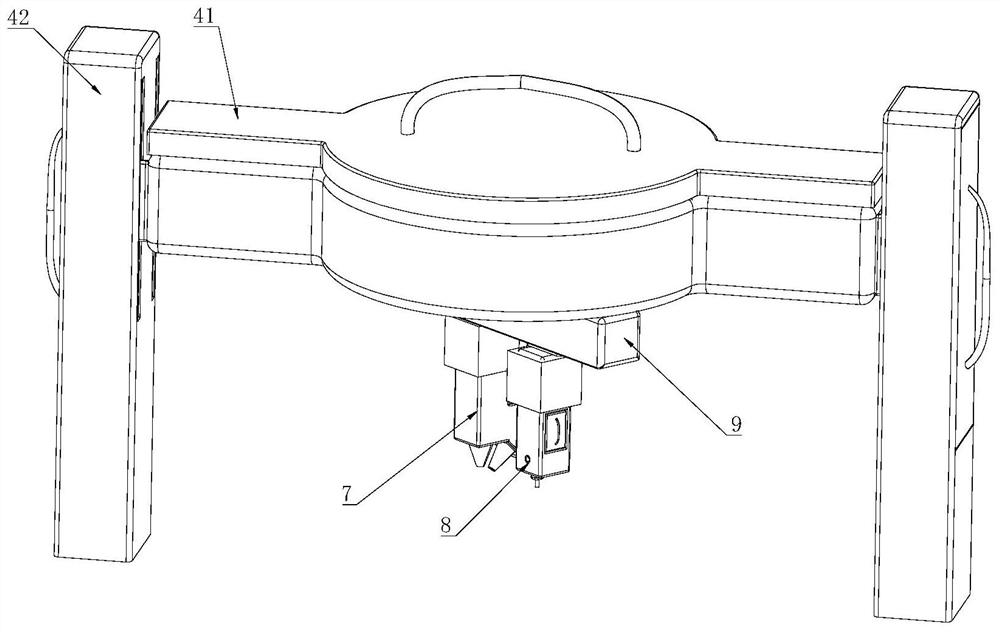

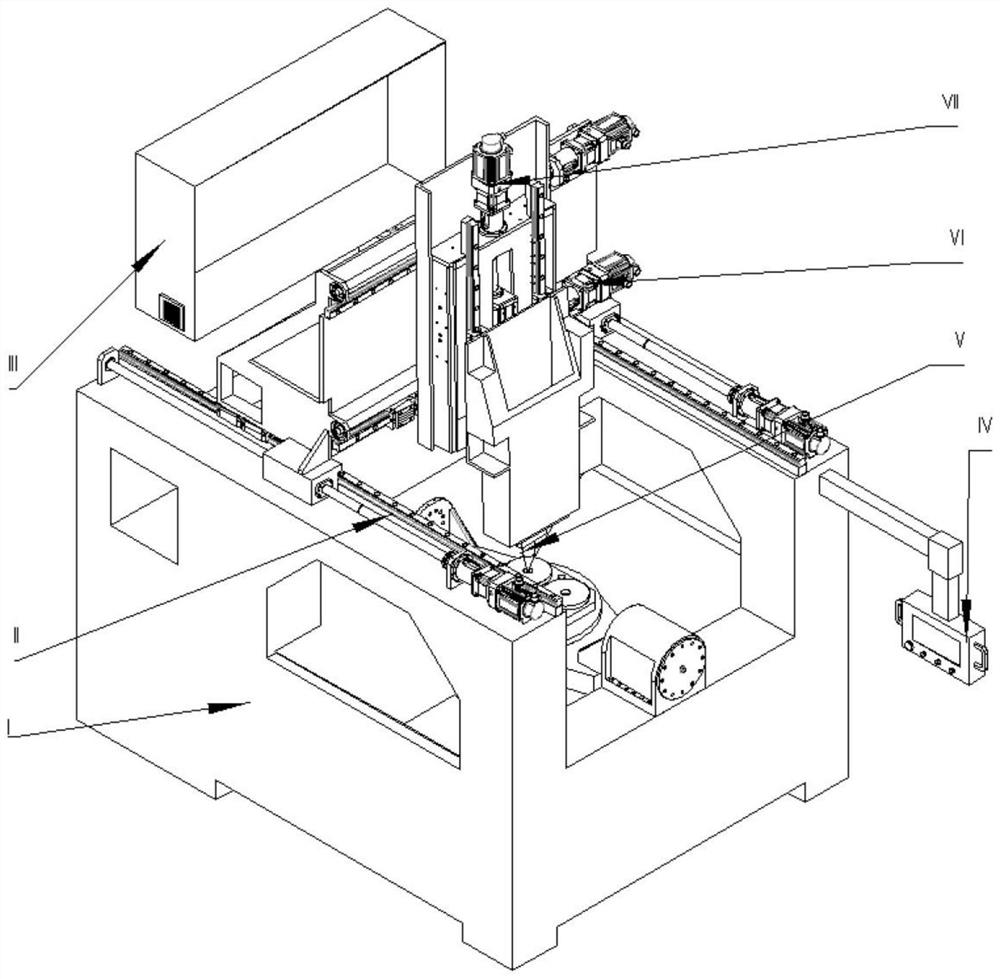

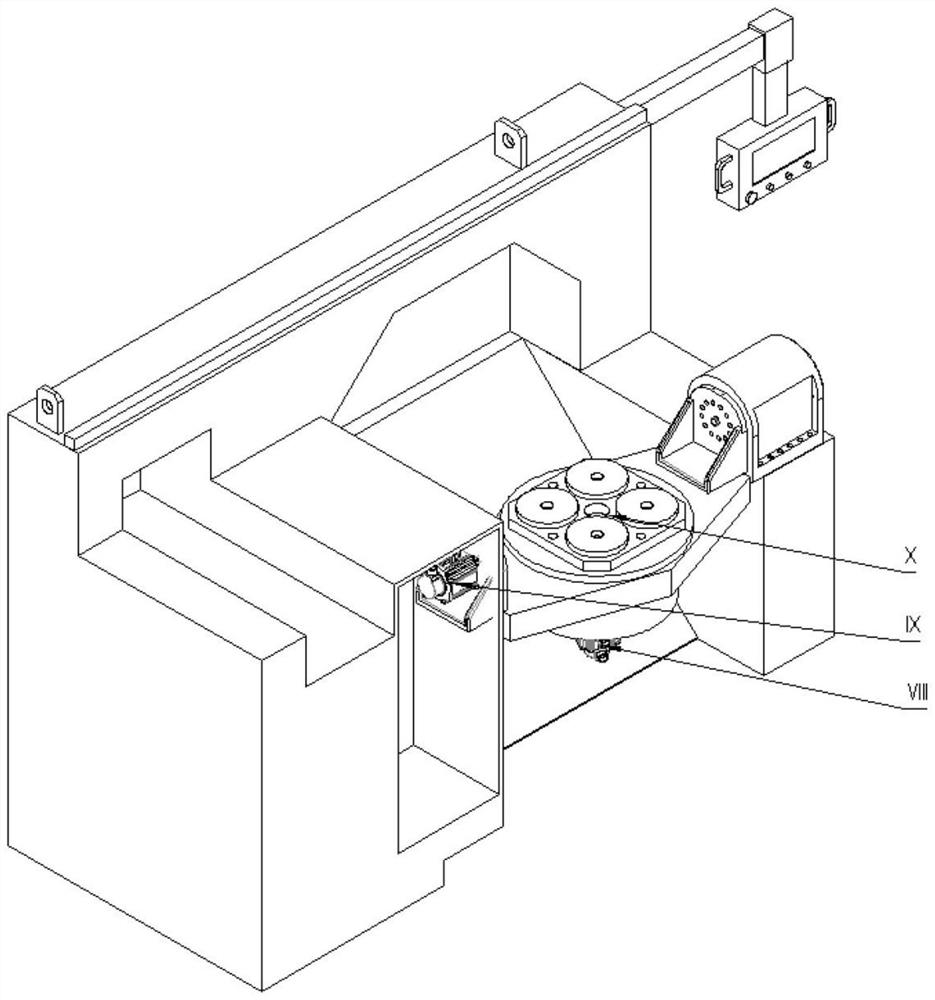

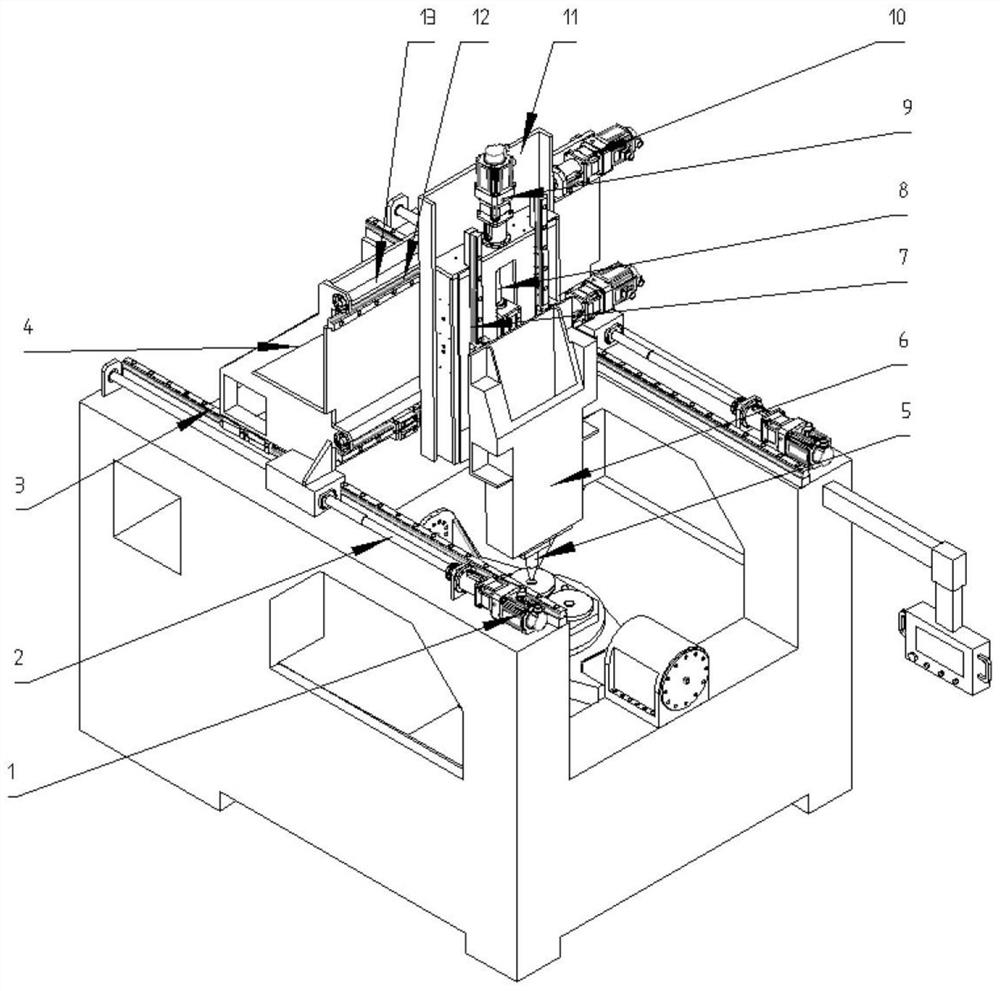

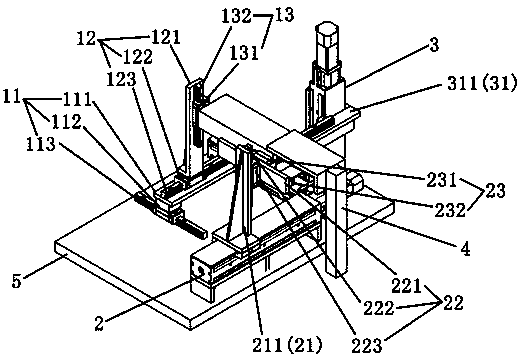

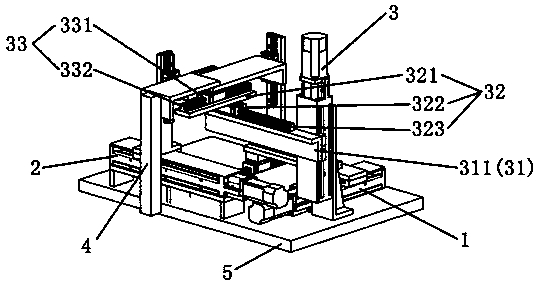

Additive and subtractive double-station synchronous machining method and device for spatially asymmetric component

InactiveCN114453748AUnshackleImprove production flexibilityAdditive manufacturing apparatusGrinding drivesGrindingGantry crane

The material increasing and decreasing double-station synchronous machining device comprises a fixed base, a gantry crane, a material increasing module, a grinding and cutting material module and a composite workbench, the gantry crane comprises a gantry crane cross beam and gantry crane stand columns, a rotating cross beam is arranged below the gantry crane cross beam, a first horizontal driving mechanism is arranged in the gantry crane cross beam, and a second horizontal driving mechanism is arranged in the gantry crane cross beam; the rotating cross beam is driven by the first horizontal driving mechanism to horizontally move relative to the gantry crane cross beam; a linkage cross beam is arranged below the rotating cross beam, a rotating driving mechanism is arranged in the rotating cross beam, the linkage cross beam is driven by the rotating driving mechanism to rotate, the material adding module and the grinding and cutting module are installed on the lower portion of the linkage cross beam, and a second horizontal driving mechanism is arranged in the linkage cross beam. And the second horizontal driving mechanism drives the material adding module and the grinding and cutting module to horizontally move. According to the invention, one-time additive and subtractive machining of the component with the variable cross section can be realized.

Owner:江西应用科技学院

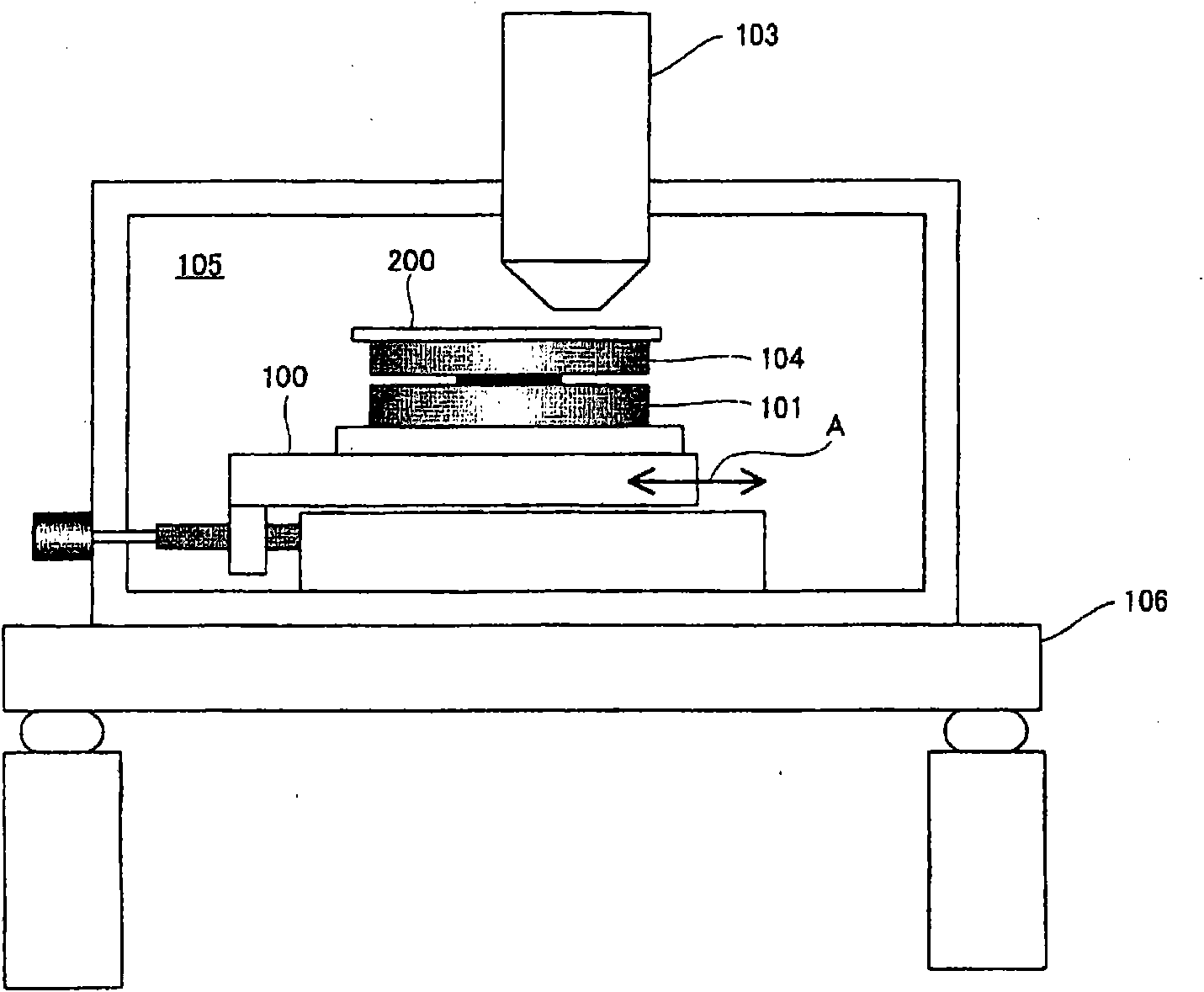

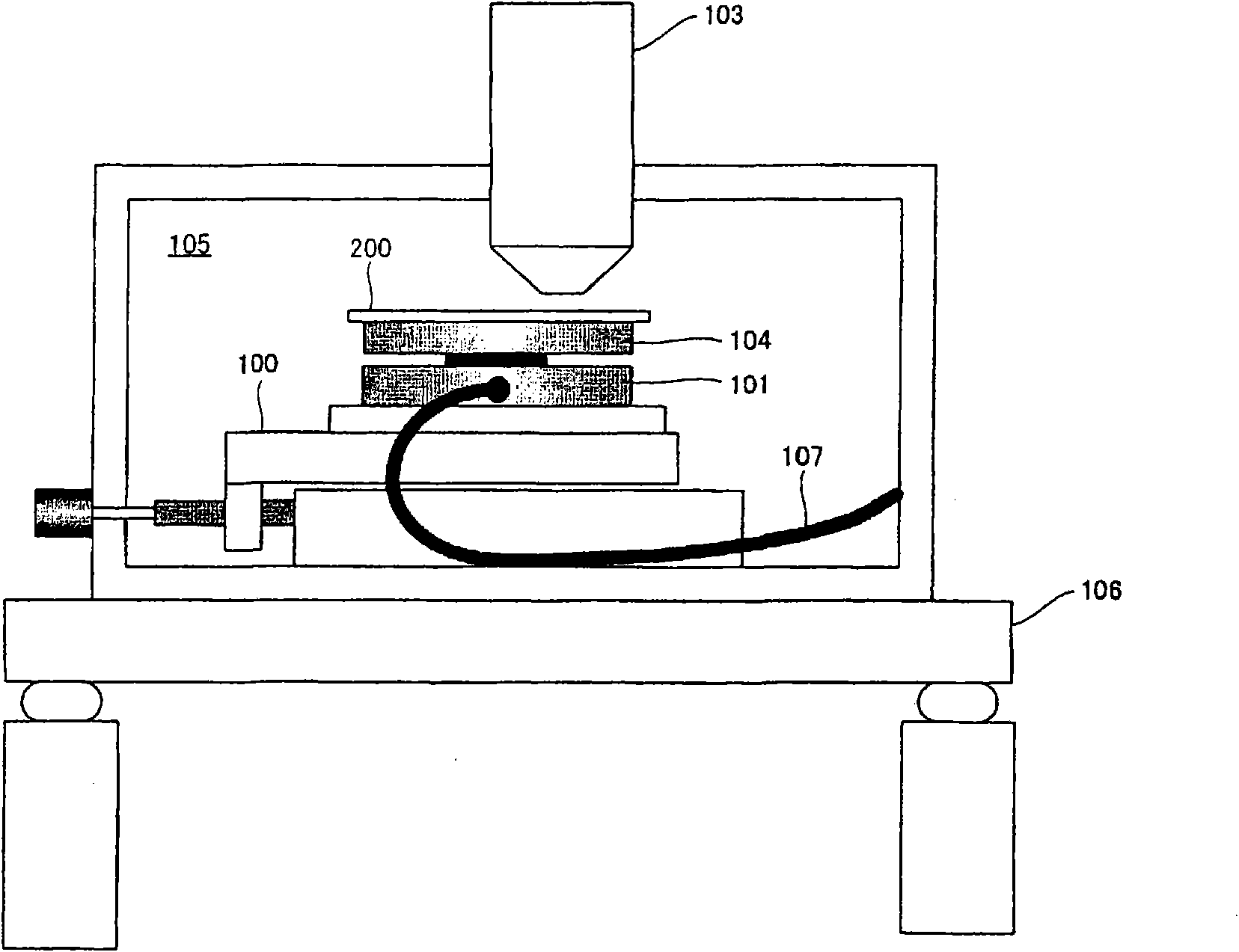

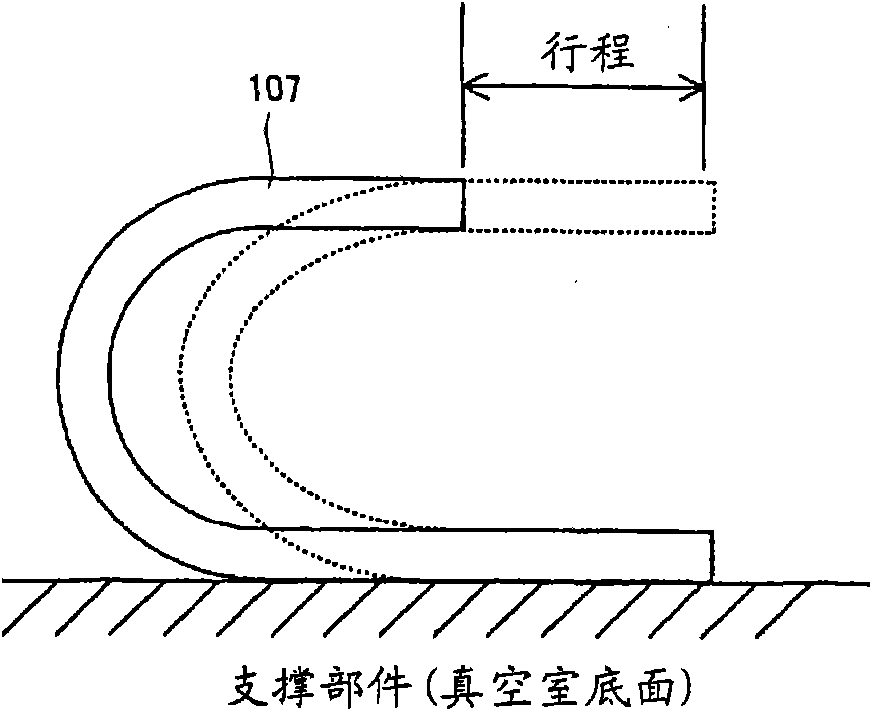

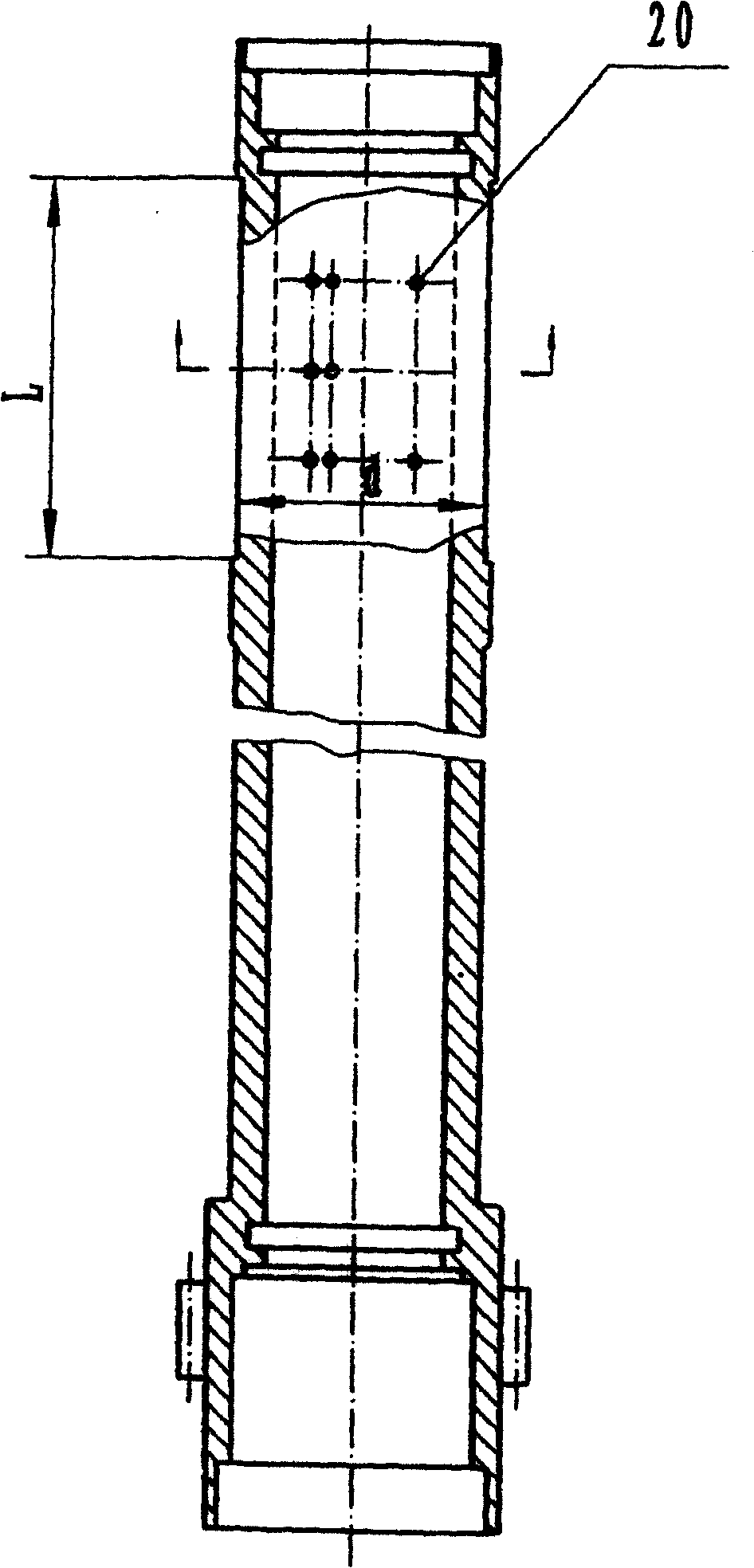

Electron beam drawing apparatus and stage mechanism thereof

InactiveCN101641742AReduce motion loadRecord information storageLarge fixed membersRotary stageLinear motion

A positioning mechanism including a rotary stage and a linear motion stage is contained in a vacuum chamber and a pipe is connected to the positioning mechanism from the outside of the vacuum chamber.A space extending below the positioning mechanism is formed in the vacuum chamber. The pipes connecting the positioning mechanism and a vacuum partition wall to each other are so disposed in a generally U-shape that the pipes can be deformed in correspondence with the movement of the linear motion stage without contacting with the inner wall of the vacuum chamber in the space.

Owner:NUFLARE TECH INC

Additive and subtractive double-station synchronous machining method and device for complex structural part

InactiveCN114453982AMeet the requirements of multi-directional processingGet rid of the bondageGrinding carriagesGrinding drivesStructural engineeringGantry crane

The invention discloses an additive and subtractive material double-station synchronous machining device for complex structural parts, which comprises a fixed base, a gantry crane, an additive material module, a subtractive material module and a composite workbench, the gantry crane comprises a gantry crane cross beam and a gantry crane stand column, and the gantry crane cross beam is located above the composite workbench; the gantry crane stand columns are located at the two ends of the gantry crane cross beam and fixed to the fixing bases, the material adding module and the material reducing module are located on the gantry crane cross beam and conduct material adding and reducing machining on parts on the composite workbench, and the device comprises a linkage cross beam and a rotation driving mechanism located in the gantry crane cross beam. The material adding module and the material reducing module are installed on the lower portion of the linkage cross beam and can horizontally move relative to the linkage cross beam, and the linkage cross beam is driven by the rotation driving mechanism to rotate. The structure is compact, and the machining mode is flexible and variable.

Owner:江西应用科技学院

A kind of driving and loading device, method and application of kc test bench

Owner:HUAZHONG UNIV OF SCI & TECH

Blister machine table automatic backing plate

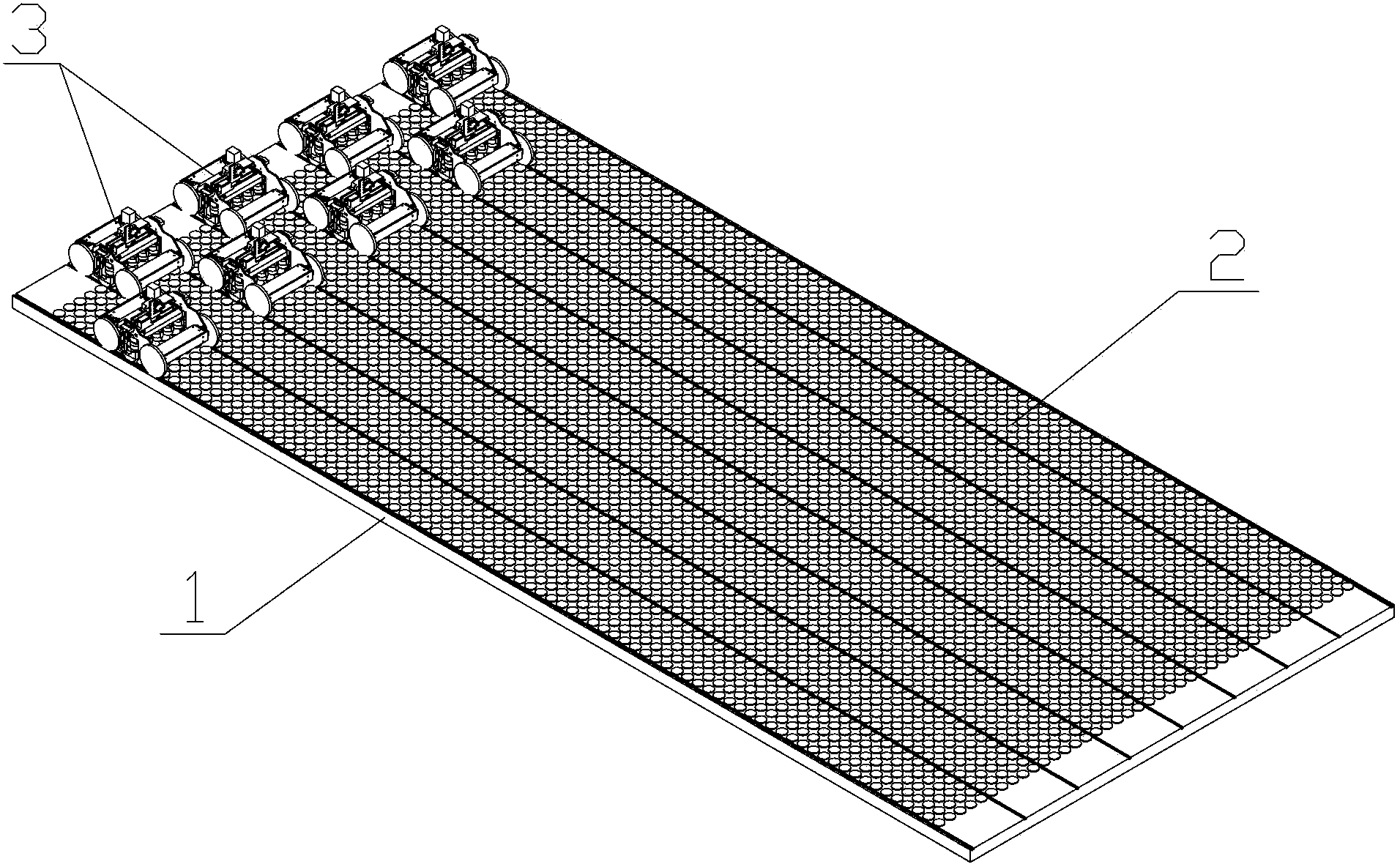

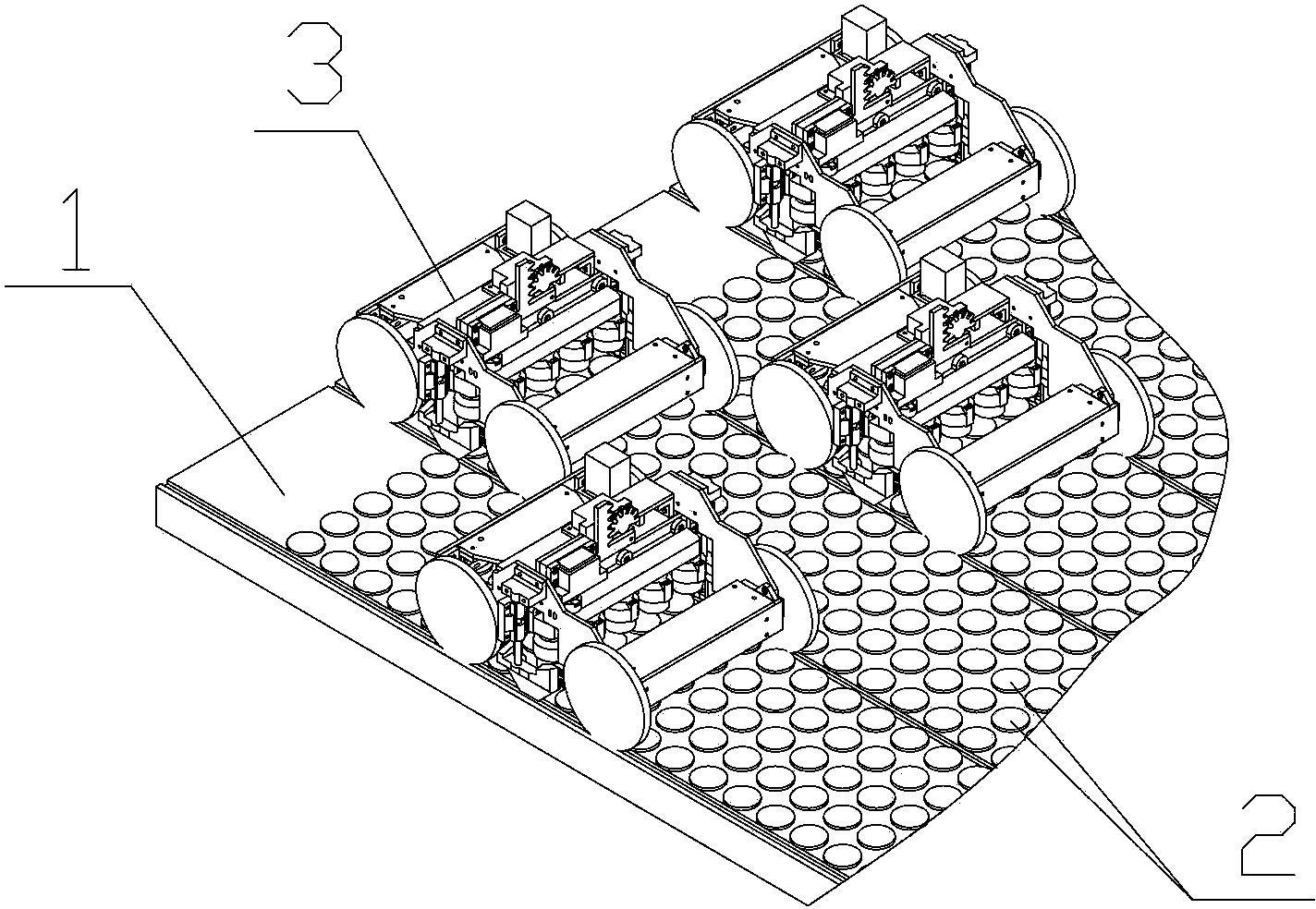

The invention discloses an automatic base plate for a vacuum forming machine worktable. The automatic base plate comprises a base plate, a plurality of supporting units arranged on the base plate, and at least one manipulation robot, wherein each supporting unit comprises a supporting seat and a supporting rod which is arranged in the supporting seat and can move up and down; the supporting rod can be stopped and supported at a lifting position when the supporting rod moves upwards so as to form a lifting state, and when the supporting rod moves downwards, the supporting rod can be stopped and supported at a descending position so as to form a descending state; the manipulation robot is a movable trolley and comprises a frame, a traveling device, and a lifting device, a positioning device and a controller which are arranged on the frame; the lifting device comprises a lifting frame and a lifting motor; an operation head is arranged on the lifting frame; and the operation head acts on the supporting rod and lift up or put down the supporting rod to an ascending position or a descending position along with the lifting frame. According to the automatic base plate, the state of the supporting units can be actively changed, and the automatic base plate has the advantages of simple structure, light weight and the like.

Owner:GUANGZHOU YUANFANG COMP SOFTWARE ENG

High-definition continuous zoom camera lens with fast field of view switching in low temperature environment

The invention relates to a high definition continuous zooming pick-up lens capable of rapidly switching field of view at low temperature. The pick-up lens is provided with along the light incoming direction: a front fixed lens group having a positive focal power, a zoom lens group having a negative focal power, a compensation lens group having a positive focal power, and a rear fixed lens group having a iris diaphragm and a negative focal power; the front fixed lens group is provided with a double-convex lens, a positive meniscus lens and a first gluing group which is composed by sealing a negative meniscus lens and a second positive meniscus lens; the zoom lens group is provided with a second gluing group which is composed by sealing a second negative meniscus lens and a second double-convex lens and also a double-concave lens; the compensation lens group is provided with a third double-convex lens, a third gluing group which is composed by sealing a third negative meniscus lens and a fourth meniscus lens, and also a third positive meniscus lens; the rear fixed lens group is provided with a double-concave lens, a fourth positive meniscus lens, a planoconvex lens, and a fourth gluing group which is composed by sealing a third double-concave lens and a fifth double-convex lens. The pick-up lens enables rapid switching at low temperature.

Owner:FUJIAN FORECAM OPTICS CO LTD

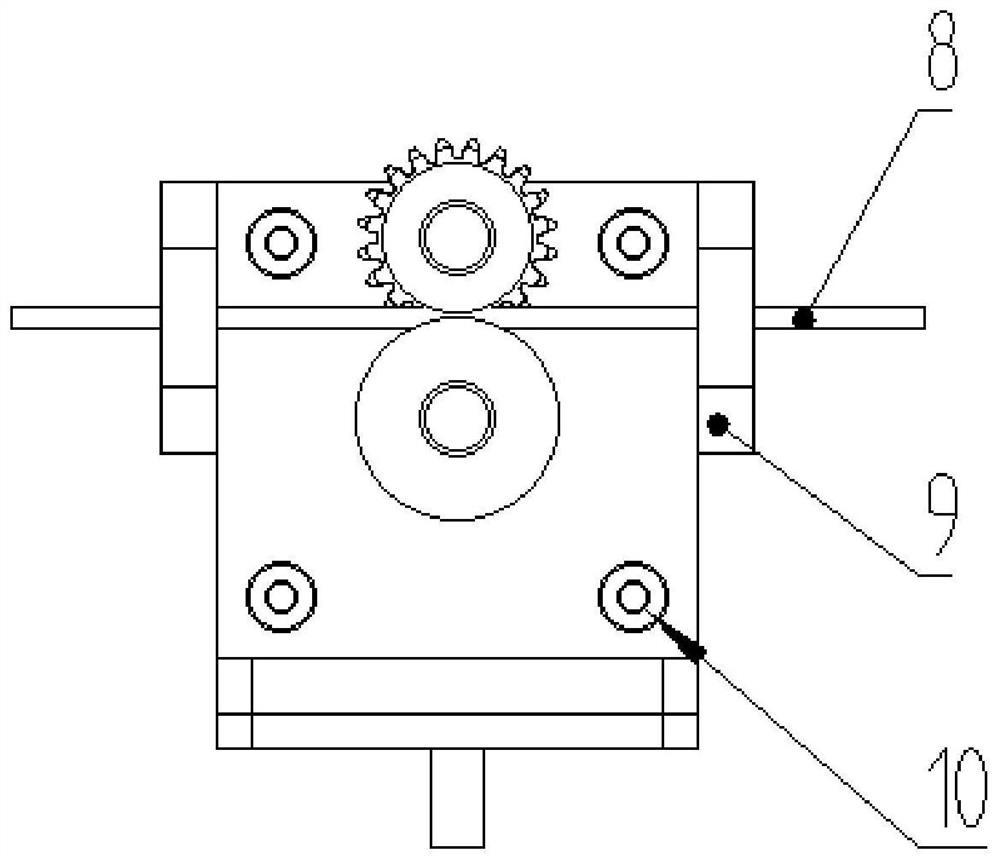

Laser cladding wire feeding device

InactiveCN112064009AReduce the probability of interferenceReduce volumeMetallic material coating processesDrive wheelGear wheel

The invention provides a laser cladding wire feeding device. The laser cladding wire feeding device comprises a motor, a motor installation flange, a driven wheel, a wire pressing wheel, a wire feeding wheel and a driving wheel, wherein the motor installation flange is installed on the motor; a motor shaft of the motor penetrates through the motor installation flange; a protruding shaft column isarranged on the motor installation flange; the driving wheel and the wire feeding wheel are coaxially installed on the motor shaft side by side and are driven by the motor shaft so as to rotate synchronously; the driven wheel and the wire pressing wheel are coaxially installed on the protruding shaft column side by side and rotate synchronously; the driven wheel and the driving wheel are in meshing transmission connection through a gear; and the driving wheel transmits rotation of the motor shaft to the driven wheel. The device provided by the invention is simple and clear in structure and easy to disassemble and assemble, the addition of the load of other mechanisms does not need to be considered during installation, the installation space of the whole mechanism is saved, the risks of metal wire bending and unsmooth wire feeding can be reduced, the wire feeding stability is improved, the wire replacement time is shortened, the production efficiency is improved, and the development ofthe laser cladding technology is promoted.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

Direct-driving three-freedom serial-parallel mixed precision positioning mechanism

InactiveCN100478133CCompact structureHigh positioning accuracyInstrumental componentsMetal working apparatusMarine engineeringComputer module

The positioning mechanism includes following parts ad connections: bent plate is fixed on a side of machine foundation, base of No.1 motor and base of No.2 motor are fixed on the foundation; one end of No.1 connecting rod is hinge-jointed to bent plate, and another end of No.1 connecting rod is connected to one end of No.3 and No.4 connecting rods respectively; one end of No.2 connecting rod is hinge-jointed to output end of No.1 motor, another ends of No.3 and No.2 connecting rods are hinge-jointed to output module from upper to lower respectively. The invention also contains No.5 connecting rod, and other connections etc. Rectilinear motion module is fixed to output module. Advantages are: compact structure, high positioning accuracy, and good dynamic performance.

Owner:HARBIN INST OF TECH

Additive and subtractive double-station synchronous machining method and device for thin-wall shell parts

InactiveCN114453600AMeet the requirements of multi-directional processingGet rid of the bondageGrinding carriagesAdditive manufacturing apparatusEngineeringGantry crane

The invention discloses a material increasing and decreasing double-station synchronous machining device for thin-wall shell components, which comprises a fixed base, a gantry crane, a material increasing module, a material grinding and cutting module, a composite workbench and the like, the fixed base comprises an inner base and an upper base, the upper base can rotate relative to the inner base, and a gantry crane upright post is fixed on the upper base; the composite workbench is arranged at the inner base; the device further comprises a linkage cross beam which is located below the gantry crane cross beam and can rotate relative to the gantry crane cross beam. The material adding module and the grinding and cutting module are mounted at the lower part of the linkage cross beam and can horizontally move relative to the linkage cross beam; the composite workbench comprises an upper workbench body and a lower workbench body, and the upper workbench body and the lower workbench body can horizontally move relative to the inner base. The invention has the advantages of compact structure and the like.

Owner:江西应用科技学院

Space thin-wall part material increasing and decreasing multi-station synchronous machining method and device

ActiveCN113909676AMeet the requirements of multi-directional processingGet rid of the bondageIncreasing energy efficiencyOther manufacturing equipments/toolsStructural engineeringGantry crane

The invention discloses a space thin-wall part material increasing and decreasing multi-station synchronous machining device. The space thin-wall part material increasing and decreasing multi-station synchronous machining device comprises a fixed base, a gantry crane, a material increasing module, a grinding and material decreasing module, a composite workbench and the like. The fixed base comprises an inner base, an upper base and a lower base. The inner base and the upper base are located on the lower base. The upper base is arranged on the outer side of the inner base in a sleeving manner and rotates relative to the inner base. A gantry crane stand column is fixed to the upper base. The composite workbench comprises an upper workbench body and a lower workbench body. The upper workbench body and the lower workbench body can horizontally move. The gantry crane comprises a gantry crane cross beam and the gantry crane stand column. The gantry crane cross beam comprises a first cross beam body and a second cross beam body. The grinding and material decreasing module and the material increasing module horizontally move relative to the first cross beam body and the second cross beam body correspondingly. The space thin-wall part material increasing and decreasing multi-station synchronous machining device has the beneficial effects of being compact in structure and the like.

Owner:HUNAN UNIV

Multi-station synchronous near-net forming method and device for thin-wall shell components

InactiveCN114454037AMeet the requirements of multi-directional processingGet rid of the bondageAdditive manufacturing apparatusGrinding carriagesGantry craneWorkbench

The invention discloses a multi-station synchronous near-net forming device for thin-wall shell parts, which comprises a fixed base, a gantry crane, a material adding module, a grinding material reducing module, a laser material reducing module, a composite workbench and the like, the fixed base comprises an inner base and an upper base, the upper base can rotate relative to the inner base, a gantry crane upright post is fixed on the upper base, and the gantry crane upright post is fixed on the composite workbench; the composite workbench is arranged at the inner base; the device further comprises a linkage cross beam which is located below the gantry crane cross beam and can rotate relative to the gantry crane cross beam. The material adding module and the grinding and cutting module are mounted at the lower part of the linkage cross beam and can horizontally move relative to the linkage cross beam; the composite workbench comprises an upper workbench body and a lower workbench body, and the upper workbench body and the lower workbench body can horizontally move relative to the inner base. The invention has the advantages of compact structure and the like.

Owner:江西应用科技学院

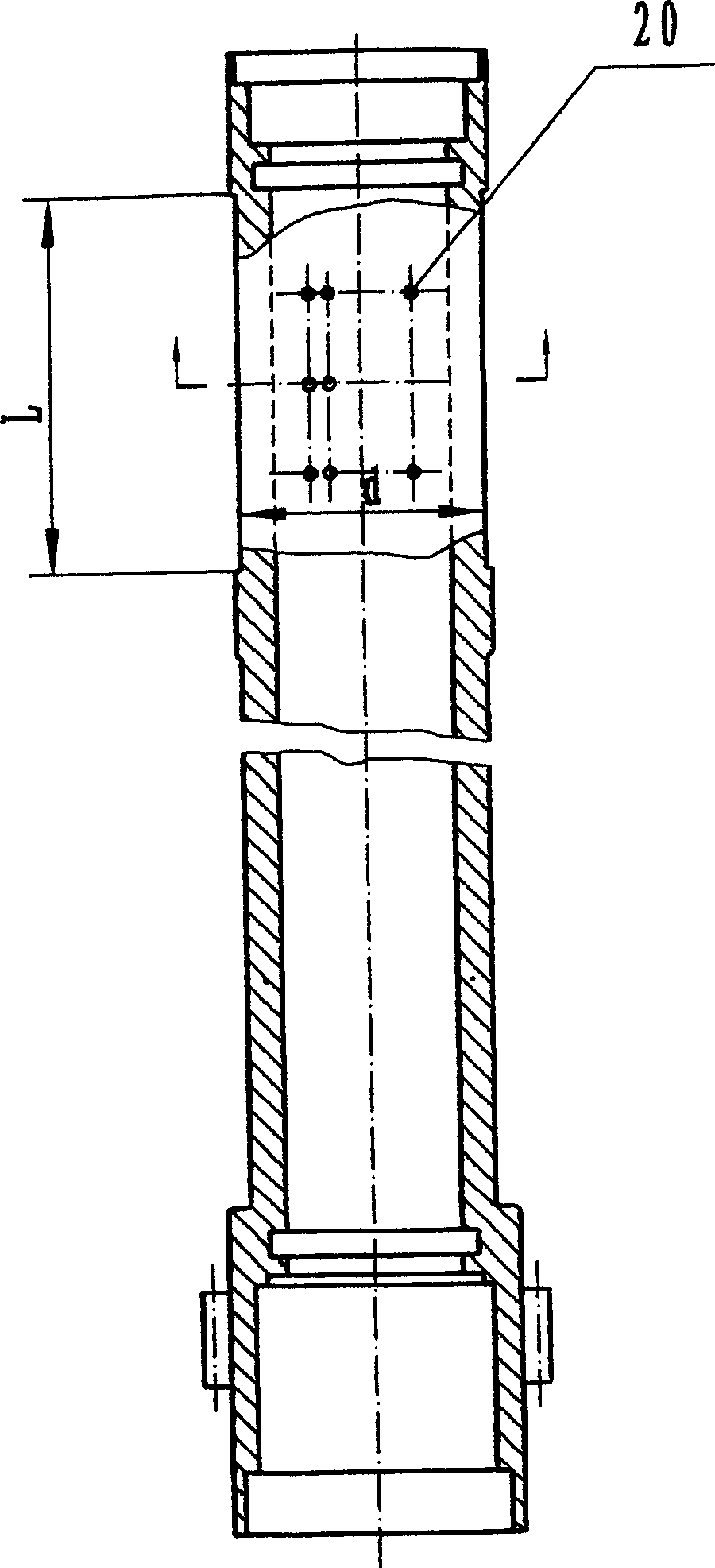

Water cooling roller for preparing rapid hardening metal thin band

InactiveCN1276807CReduce motion loadAdjust cooling intensityRollsMetal rolling arrangementsThin metalMaterials science

Owner:SOUTHEAST UNIV

A virtual axis millimeter wave human body security inspection system

ActiveCN103698762BReduce motion loadSmall moment of inertiaRadio wave reradiation/reflectionHuman bodyTransceiver

The invention relates to a virtual-axis millimeter-wave human body security check system. The system comprises a virtual-axis guide rail unit, a scanning unit, a scanning driving unit, a data processing unit and a display unit, wherein the virtual-axis guide rail unit comprises a first circular-arc-shaped guide rail; the scanning unit comprises a first group of millimeter-wave antenna arrays and a first millimeter-wave transceiver; the scanning driving unit is used for driving the first group of millimeter-wave antenna arrays to scan in a reciprocating virtual-axis circular-arc-shaped locus on the first circular-arc-shaped guide rail; the data processing unit is used for processing a detection signal from the scanning unit to form a human body image to be detected; the display unit is used for displaying the at least one human body image to be detected. In the human body security check system disclosed by the invention, a virtual-axis scanning way is used, the motion load does not need to be reduced, and the rotational inertia is reduced, so that the scanning speed is increased. The system is small in occupied space, and a single / double-module security check system can be assembled more flexibly according to the size of a practical space and the checked amount.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

Rapid forming method and device for space curved surface

InactiveCN114453830AUnshackleImprove production flexibilityOther manufacturing equipments/toolsGrindingGantry crane

The invention discloses a rapid forming device for a spatial curved surface, which comprises a fixed base, a gantry crane, a material adding module, a material grinding and cutting module, a composite moving table, a fixed supporting seat and the like, an upper base of the fixed base can rotate relative to an inner base, a vertical column of the gantry crane is fixed on the upper base, and the composite moving table and the fixed base are arranged at the inner base; a linkage cross beam capable of rotating relative to the gantry crane cross beam is arranged below the gantry crane cross beam; the material adding module and the grinding and cutting module are mounted at the lower part of the linkage cross beam and can horizontally move relative to the linkage cross beam; an upper moving table and a lower moving table of the composite moving table can horizontally move relative to an inner base, a first stand column is fixed to the upper moving table, and a workbench can incline relative to the first stand column. The invention has the advantages of compact structure and the like.

Owner:江西应用科技学院

Direct drive transmission mechanism of heat exchanger tube plate crawling robot

PendingCN114227715AReduce radiation dose levelsHigh rotation accuracyManipulatorElectric machineryEngineering

The invention provides a heat exchanger tube plate crawling robot direct drive transmission mechanism which comprises a machine-mounted box, a motor is arranged in the machine-mounted box, a harmonic reducer is arranged on a top cover of the machine-mounted box, the motor is directly connected with the harmonic reducer, and the harmonic reducer directly drives a load. According to the direct-drive transmission mechanism of the heat exchanger tube plate crawling robot, a transmission chain of the positioning robot is reduced, and the complexity of a transmission part is reduced, so that the rotation precision of the positioning robot is improved, the inspection efficiency is improved, the service life of a probe is prolonged, and the radiation dose level of operators is reduced.

Owner:RES INST OF NUCLEAR POWER OPERATION +1

device for securing luggage

InactiveCN106360934BImprove space utilizationReduce the risk of fallingRailway componentsLuggageMagnetic polesDrive motor

The invention belongs to the field of bearing tools on light rails, and in particular discloses a device for fixing a trunk. The device comprises an annular track, walk trolleys and a power device which are fixed on the carriage wall of a light rail vehicle, wherein each walk trolley comprises a bearing basal body, a drive gear, and a sucker used for fixing the trunk; the annular track comprises a left vertical track section, an upper horizontal track section, a right vertical track section, a lower horizontal track section and an arc-shaped track section; an oblique support plate is mounted on the carriage wall of the light rail vehicle just below the upper horizontal track section; a plurality of touch rods arranged at equal distances are mounted on the carriage wall of the light rail vehicle between the upper horizontal track section and the oblique support plate, an electromagnet block with the magnetic pole being opposite to that of a permanent magnet block is further mounted on the carriage wall of the light rail vehicle, and a gravity sensor is mounted on the oblique support plate; the power device comprises a drive motor, a drive power supply and a controller which are connected through leads. After the scheme is adopted, the problems that trunks can not be conveniently placed on the existing light rails, and the trunks can be easily damaged are solved.

Owner:CHONGQING JIAOTONG UNIVERSITY

Label winding and sticking device

ActiveCN100457557CGuaranteed accuracyEnsure consistencyLabellingHot-melt adhesiveElectrical and Electronics engineering

A label rolling and sticking apparatus is composed of label sticking unit, transmission unit for driving said label sticking unit, label rolling unit under said label sticking unit, label conveying unit at the side of label rolling unit, label-sucking sleeve pipe in the label feeding die under said label sticking unit, label-sucking mandrel in said label-sucking sleeve pipe, and shaping die sleeve above label feed die and surrounding said sleeve pipe.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

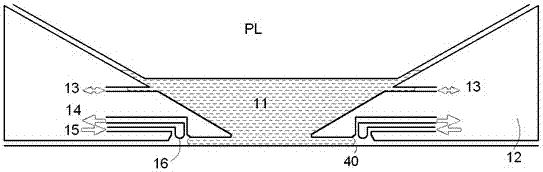

An immersion lithography machine immersion liquid flow field maintenance anti-collision system

ActiveCN105988294BSatisfy functionGuaranteed functionPhotomechanical exposure apparatusMicrolithography exposure apparatusCushioningLithographic artist

The invention discloses an immersion liquid flow field maintenance anti-collision system for an immersion photolithography machine, which is characterized in that it includes: a liquid supply device for providing liquid between a projection objective lens and a base table; a base located on the base table and immersed in the liquid; a buffer telescopic device, the buffer telescopic device is located between the liquid supply device and the base, is used to realize the sealing of the liquid, and can move in the direction of the optical axis.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

A fast and precise measurement method for distributed plane six-degree-of-freedom pose

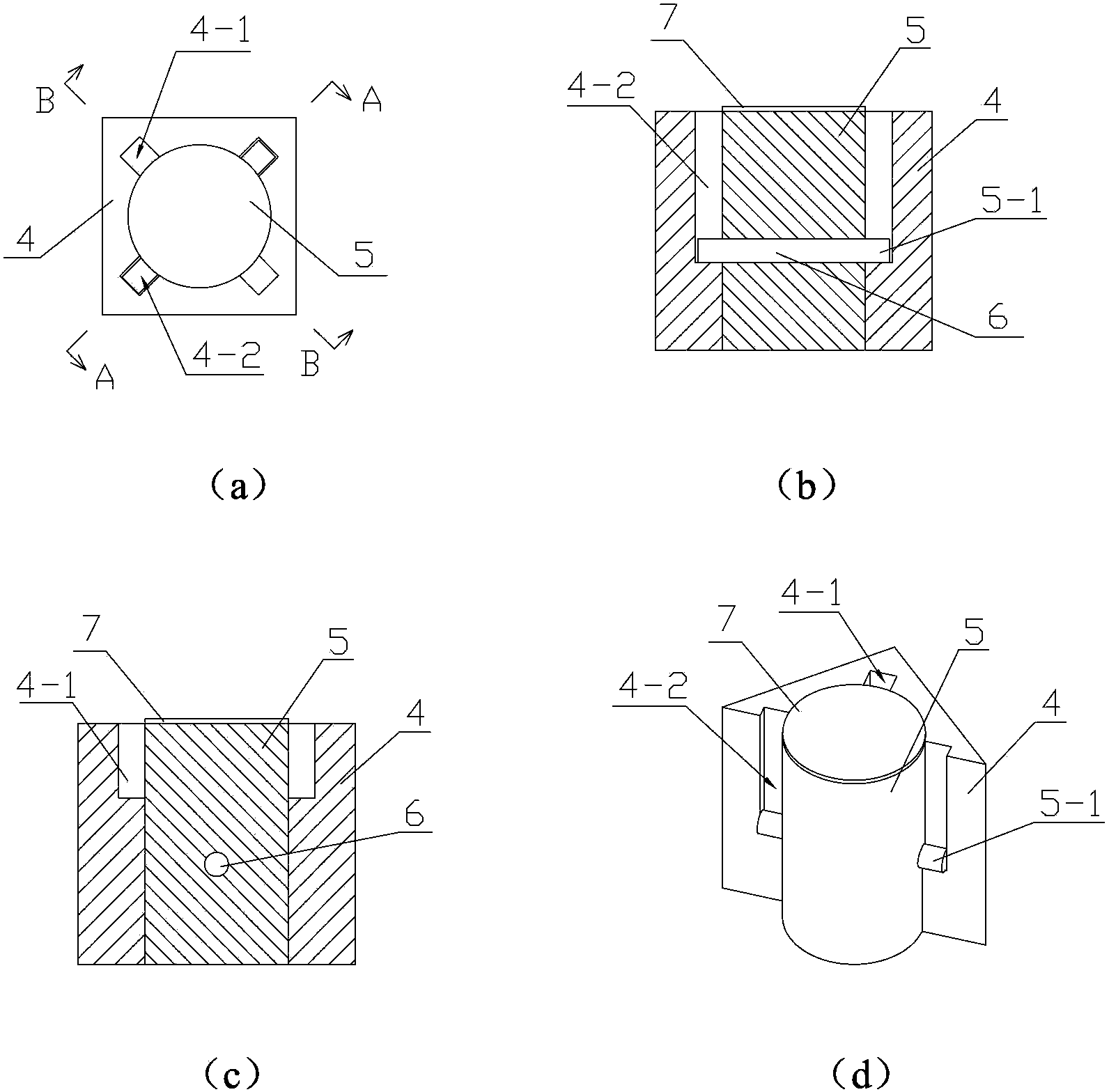

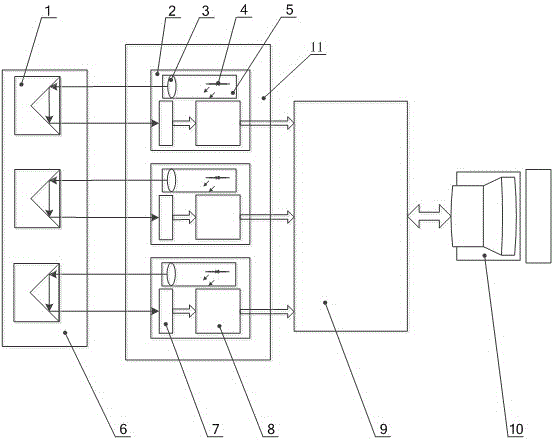

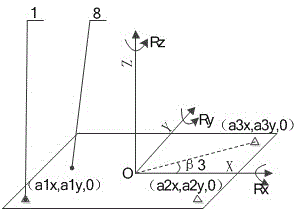

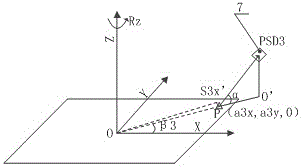

ActiveCN103134428BReduce motion loadSimple structureUsing optical meansDegrees of freedomPhase sensitive

The invention discloses a distributed rapid precise plane six-degree of freedom pose measuring device and a measuring method and belongs to the technical field of semiconductor fabrication equipment, and particularly relates to the distributed rapid precise plane six-degree of freedom pose measuring device. According to the distributed rapid precise plane six-degree of freedom pose measuring device, laser diodes are introduced to serve as light sources and two-dimension Phase-Sensitive Detectors (PSDs) are introduced to serve as photoelectric elements. The light source portion and the two-dimension PSDs are integrated, and therefore the size is reduced, the weight is lightened, and installation is convenient. In addition, three cube-corner prisms are arranged on a motion platform, and therefore motion load of the motion platform is reduced. To sum up, the distributed rapid precise plane six-degree of freedom pose measuring device is simple in structure and very appropriate for six-degree of freedom pose measurement on the high-speed motion platform. According to the distributed rapid precise plane six-degree of freedom pose measuring device, the cube-corner prisms arranged on the platform to be measured serve as position sensing elements, a three-dimensional coordinate system formed by the cube-corner prisms and the PSDs is converted into a motion coordinate system of the platform to be measured through transformation of coordinate systems, and therefore six-degree of freedom information can be obtained. And therefore the measuring method is easy and convenient to operate and adjustment of light paths is easy.

Owner:HARBIN INST OF TECH

Dual-drive five-axis gantry machining center equipment and working method

PendingCN113059369AImprove running stabilityEasy to useFeeding apparatusLarge fixed membersControl engineeringMachine

The invention discloses dual-drive five-axis gantry machining center equipment and a working method. The operation stability of a machine can be effectively improved, the machining and debugging difficulty is reduced, the motion load of a third shaft is effectively relieved, the stability and precision of a machine tool are improved, and the use of the whole machine is improved. According to a first shaft driving system, two first servo motors distributed on the two sides of a rack assembly drive a first lead screw to drive a first fixing frame to do reciprocating positioning motion in the X-axis direction; two second servo motors distributed on the upper portion and the lower portion of the first fixing frame drive a second lead screw to drive a second fixing frame to do reciprocating positioning motion in the Y-axis direction; a third servo motor distributed on the second fixing frame drives a third lead screw to drive a machine head assembly to do reciprocating positioning motion in the Z-axis direction; a fourth servo motor fixed on the rack assembly drives a working platform to do circular motion; and a fifth servo motor fixed on the working platform drives a to-be-machined workpiece fixing frame to do circular motion.

Owner:湖南金岭机床科技集团有限公司

Three-shaft linkage device

The invention discloses a three-shaft linkage device and relates to the technical field of vacuum suction. The three-shaft linkage device comprises a driving device, a guiding sliding assembly and a working component, wherein the driving device is connected with the guiding sliding assembly, and the guiding sliding assembly is connected with the working component. According to the three-shaft linkage device, a certain guiding device is added between the connection of each driving shaft, so that the driving device of each shaft is independent, and no load is generated on other shafts; due to the existence of a guiding connecting device, each shaft can be in linkage, so that a mechanism greatly reduces the motion load during the movement, high-speed motion can be achieved, there is almost noload, the efficiency of each shaft is greatly improved, and thus the production efficiency is effectively improved.

Owner:恩纳基智能科技无锡有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com