Water cooling roller for preparing rapid hardening metal thin band

A thin metal, water-cooled roll technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of scrapped water-cooled rolls, difficult processing and assembly, and difficult connection and assembly, so as to reduce motion load and change Cooling process, effect of reducing power demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

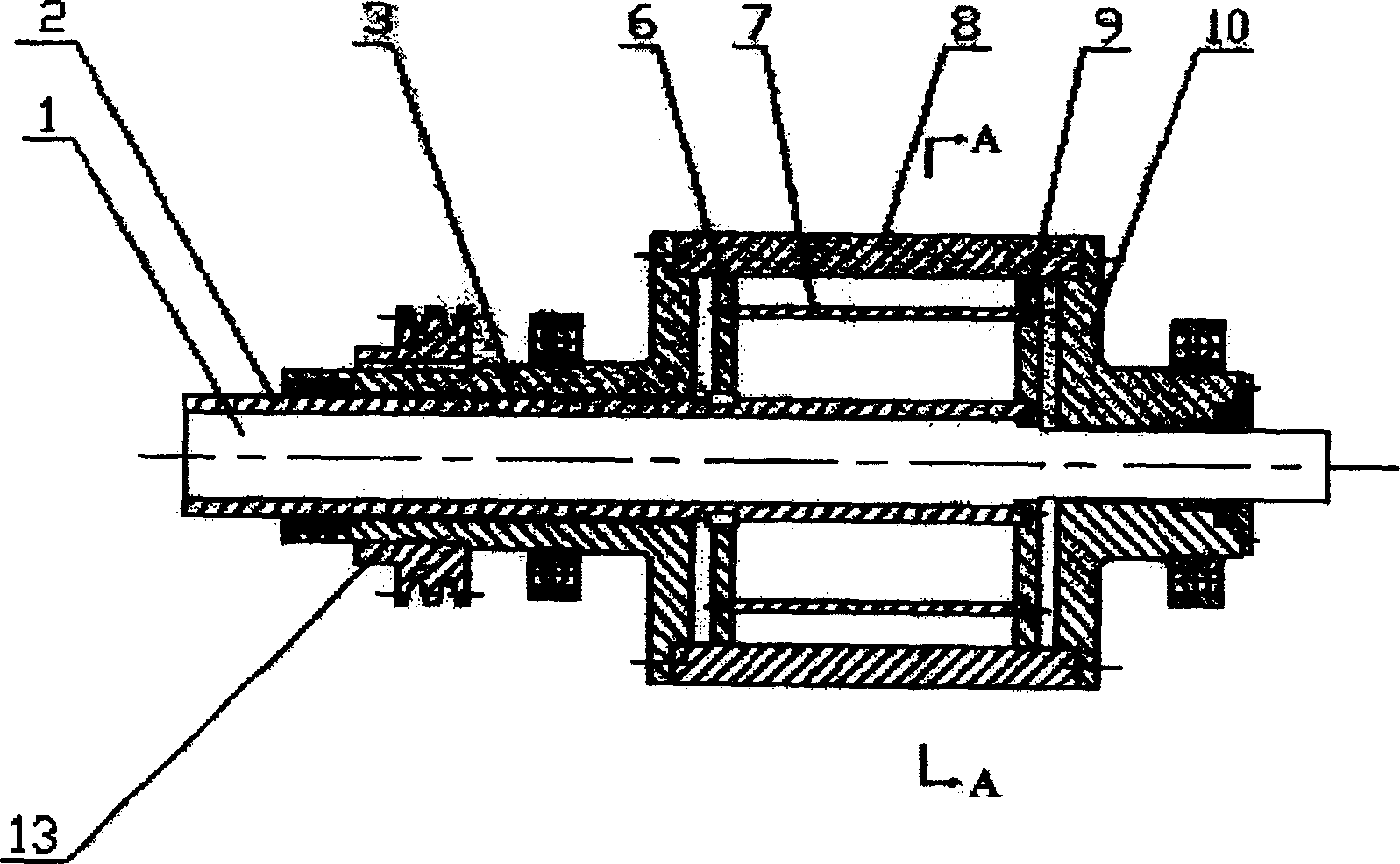

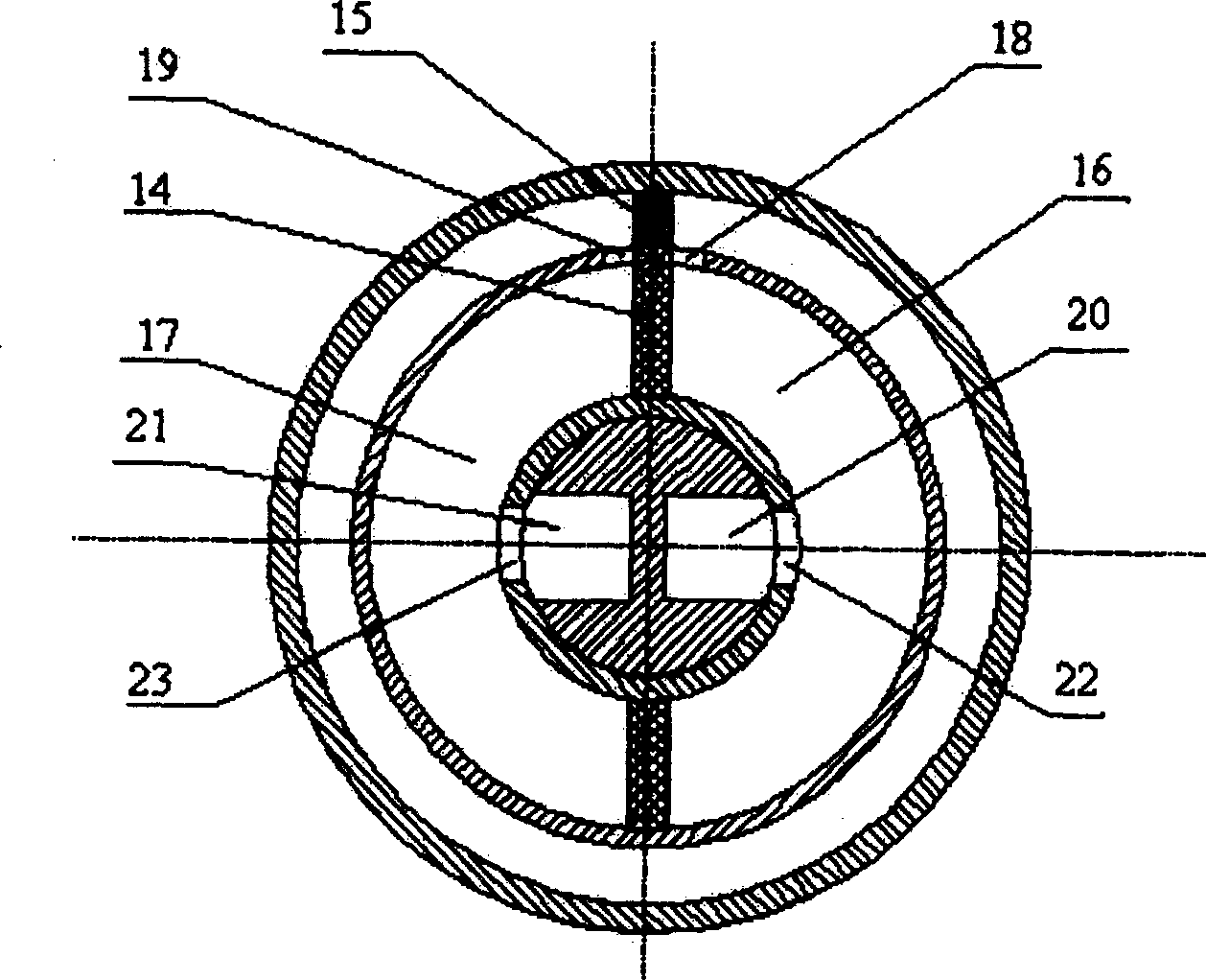

[0012] A water-cooled roll for preparing quick-setting metal thin strips for forming thin metal strips. It consists of a main shaft 1, roll body supports 3 and 10, and a roll body 8. The roll body 8 is fixedly connected to the roll body supports 3 and 10 respectively. The body supports 3 and 10 are set on the main shaft 1 and are connected in rotation with the main shaft 1. The inner cylinder 7 is provided in the roller body 8, and the two ends of the inner cylinder 7 are respectively provided with cover plates 6 and 9. The cover plates 6 and 9 They are respectively fixedly connected with the main shaft 1, and a water baffle 14 is provided in the inner cylinder 7, and the inner space of the inner cylinder 7 is divided into a water outlet cavity 16 and a water return cavity 17 by the water baffle plate 14, the inner cylinder 7 and the cover plates 6 and 9 , a water outlet hole 18 is provided on the water outlet chamber 16, a water return hole 19 is provided on the water return c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com