Patents

Literature

60results about How to "Meet different process requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

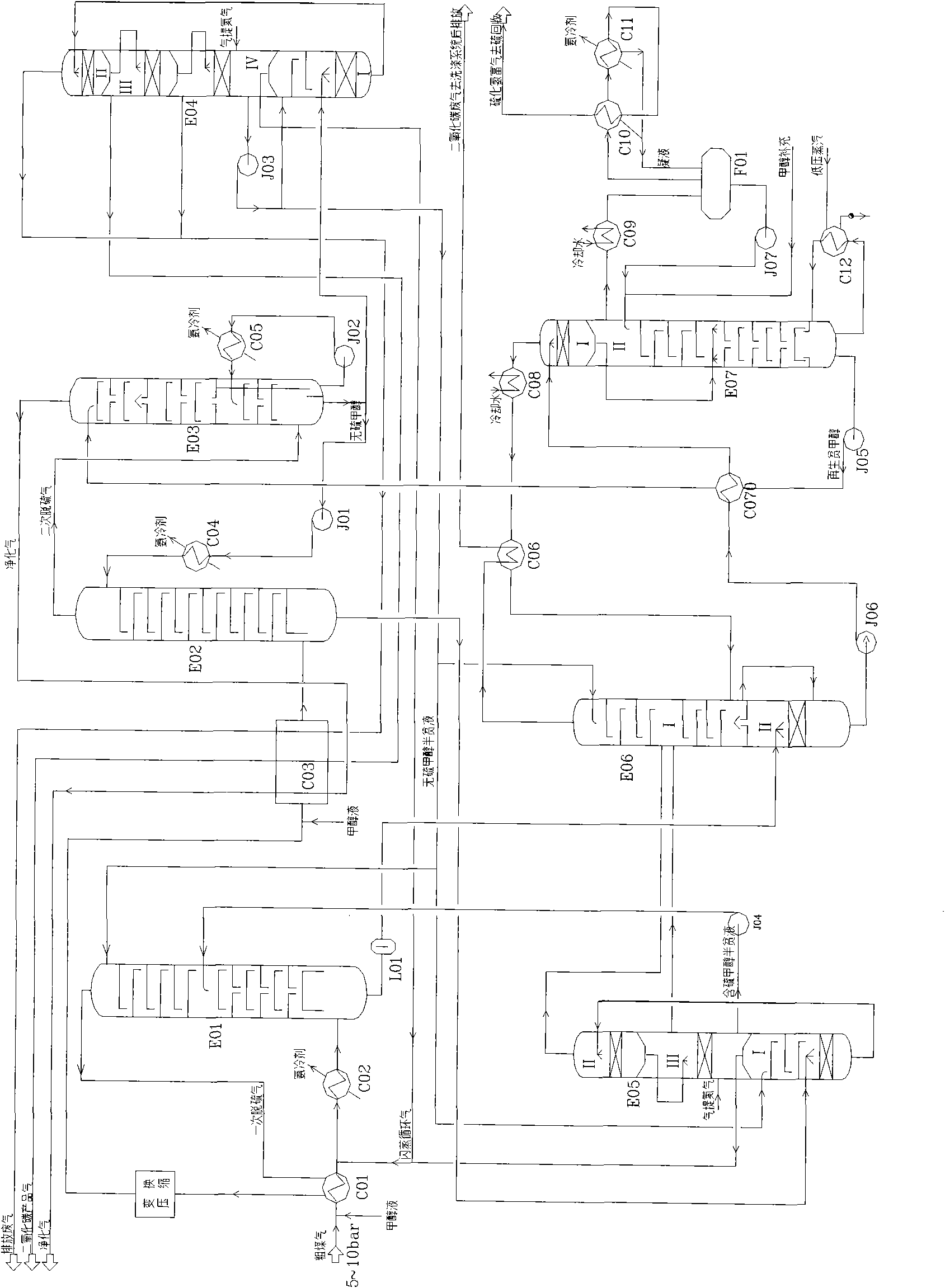

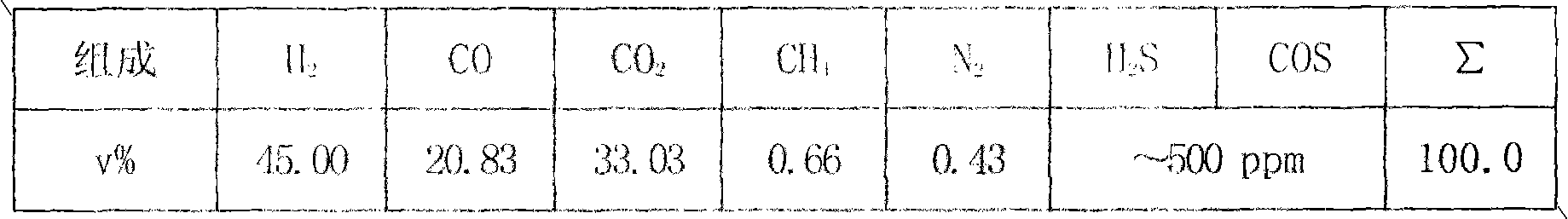

Purification process for removing sulphur and carbon dioxide in gas by using two-step method

ActiveCN101885993AMeet the requirements of concentration, etc.Suitable for purification requirementsCombustible gas purificationCo2 removalPurification methods

The invention discloses a purification process for removing sulphur and carbon dioxide in gas by using a two-step method. The purification method comprises six steps as follows: the crude desulphurization of low-pressure high-sulphur gas, desulphurization of high-pressure gas, CO2 removal, the regeneration of decarburization solution, the regeneration of desulfurization solution and H2S concentration, and heat regenerating system. The purification process has the advantages of low energy consumption, low operation strength, simple process and high purification.

Owner:SEDIN ENG

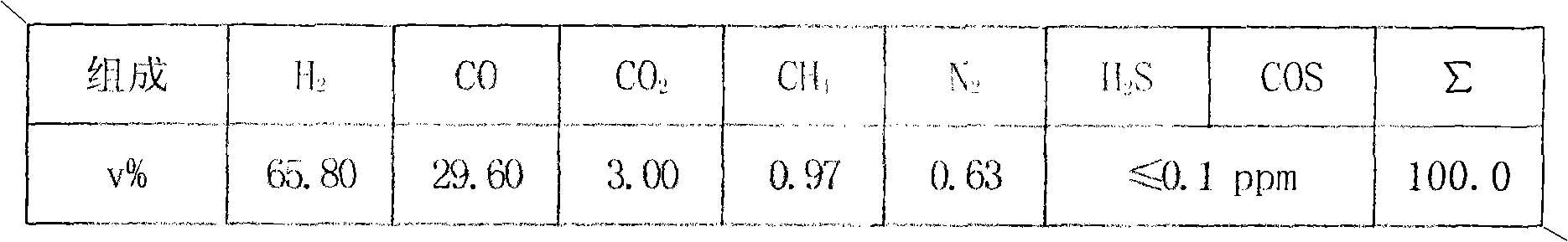

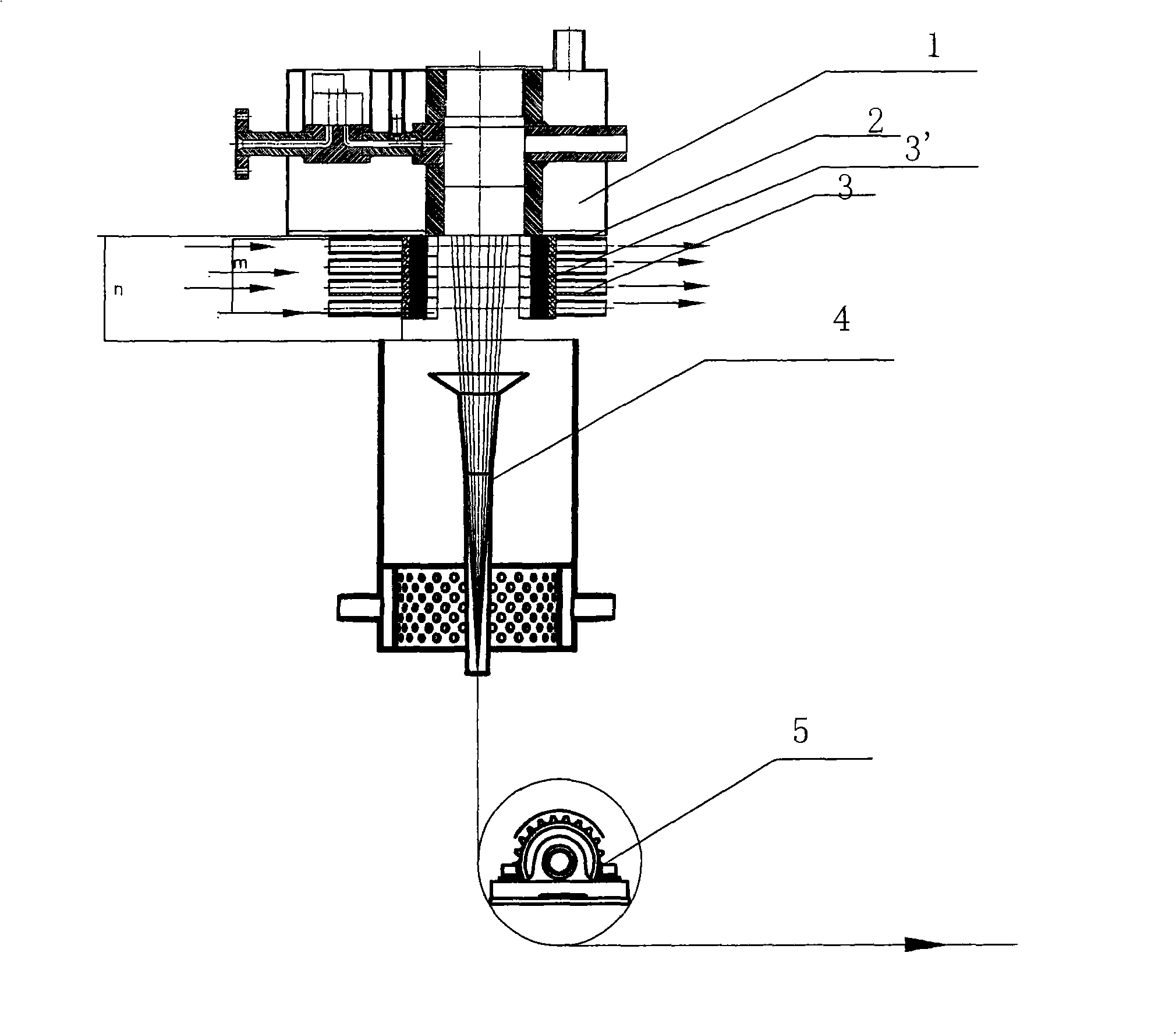

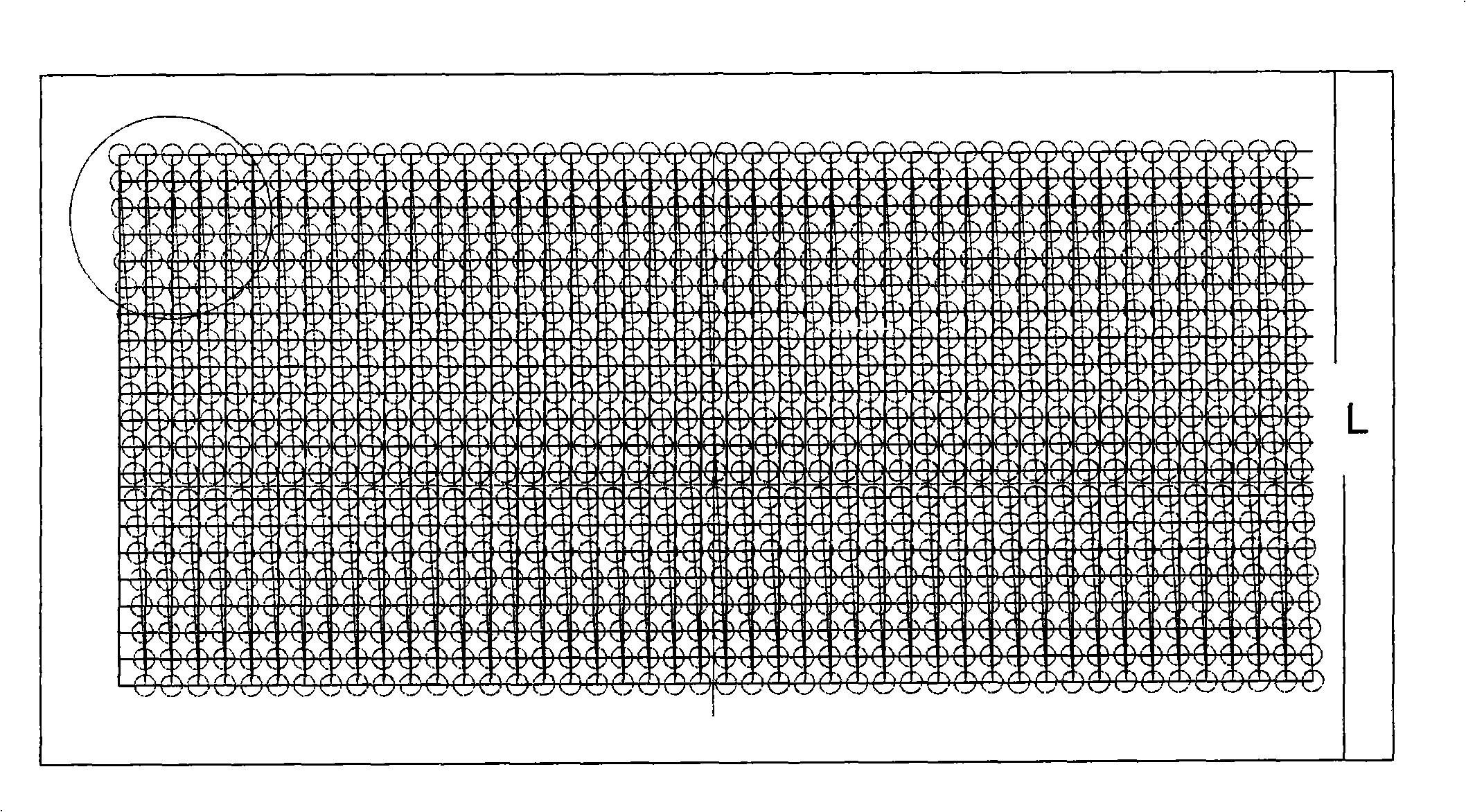

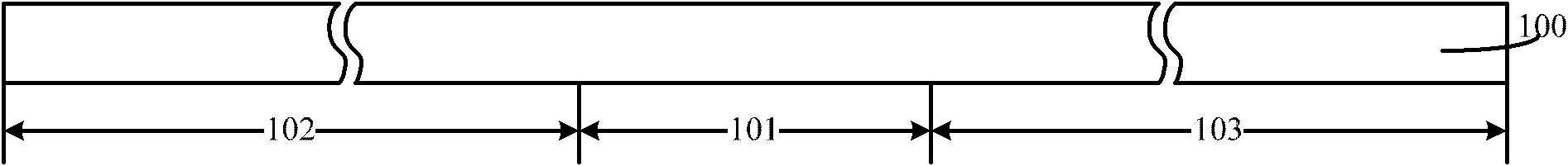

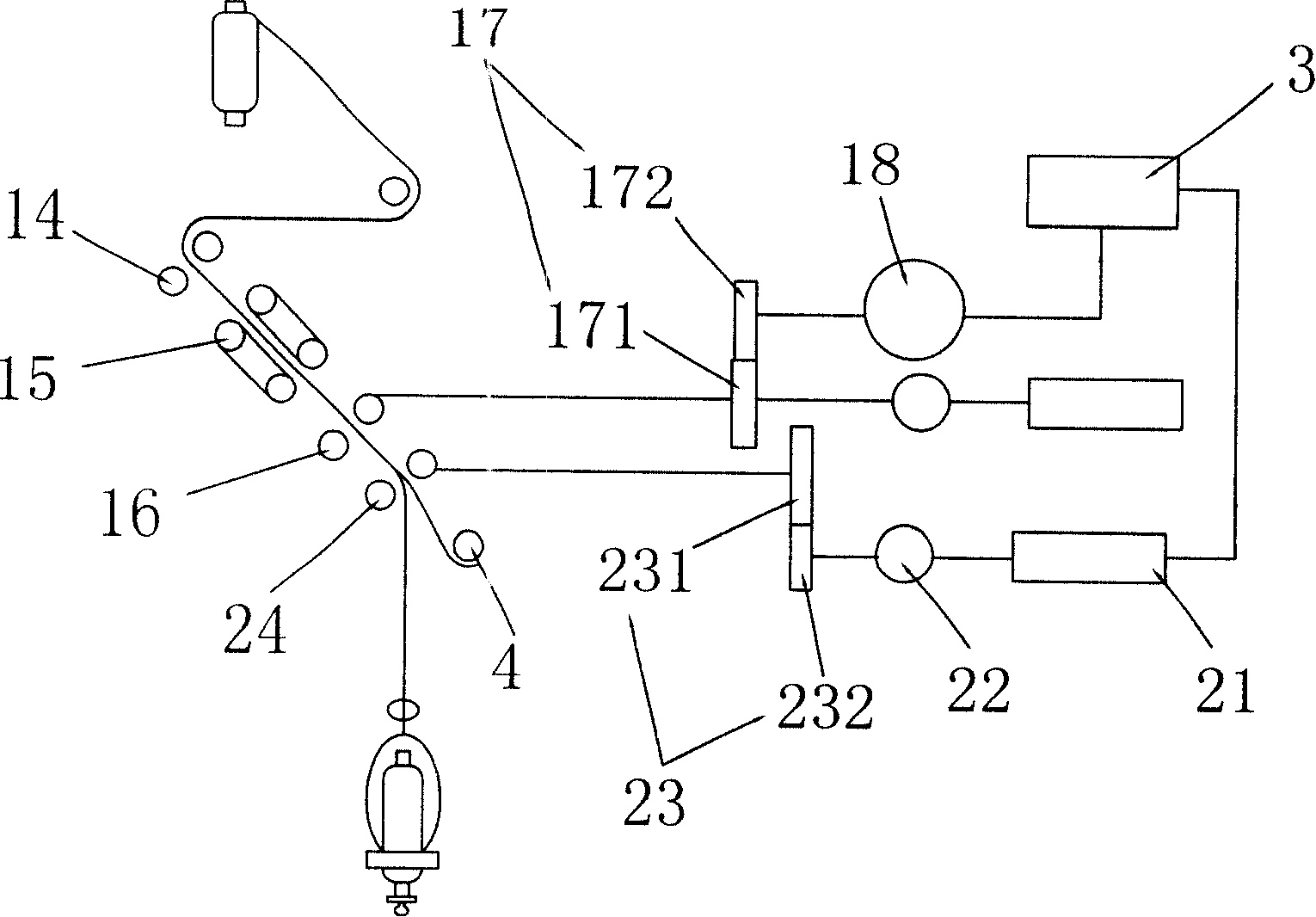

Spinning process of cellulose fibre and integration apparatus

ActiveCN101289762ACool evenlyChange flow rateSpinnerette packsArtificial filament physical treatmentOrganic solventCellulose fiber

The invention relates to a method for spinning cellulose fibers, comprising the following steps that: cellulose and organic solvent are mixed and dissolved, and mixture is obtained; the mixture enters into a section of air gap layer via a spinneret and ejected tows are blown and sucked by cooling air; the tows is brought into a precipitating bath via precipitating solution and led out by a spinning reel under the guidance of hauling equipment, wherein, the tows are blown and sucked by the cooling air by means of multi-layered laminar flow wind and the outlet velocity of the precipitating bath is between 20 and 150 meters per minute. The invention also relates to a device for completing the spinning method. By adoption of the spinning method and the spinning device, cellulose filaments or staple fibers obtained finally have uniform strength and elongation amount and the effect is also suitable for fibers with high or low size as well.

Owner:CHINESE TEXTILE ACAD

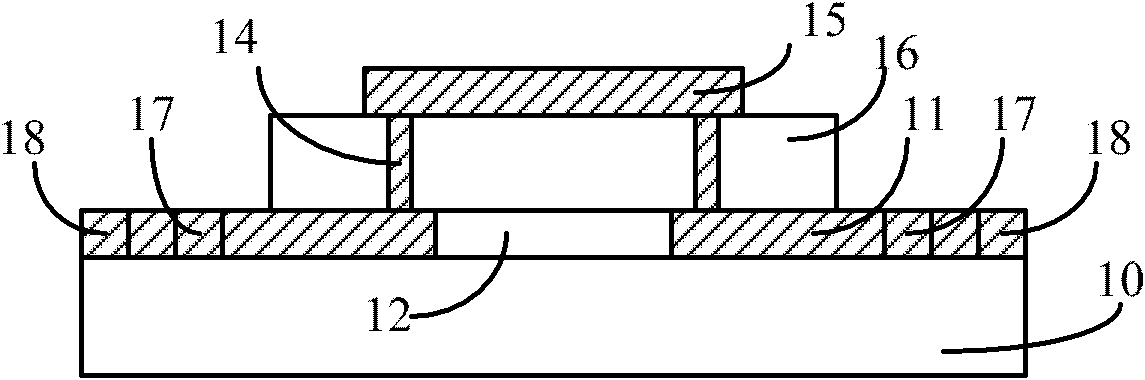

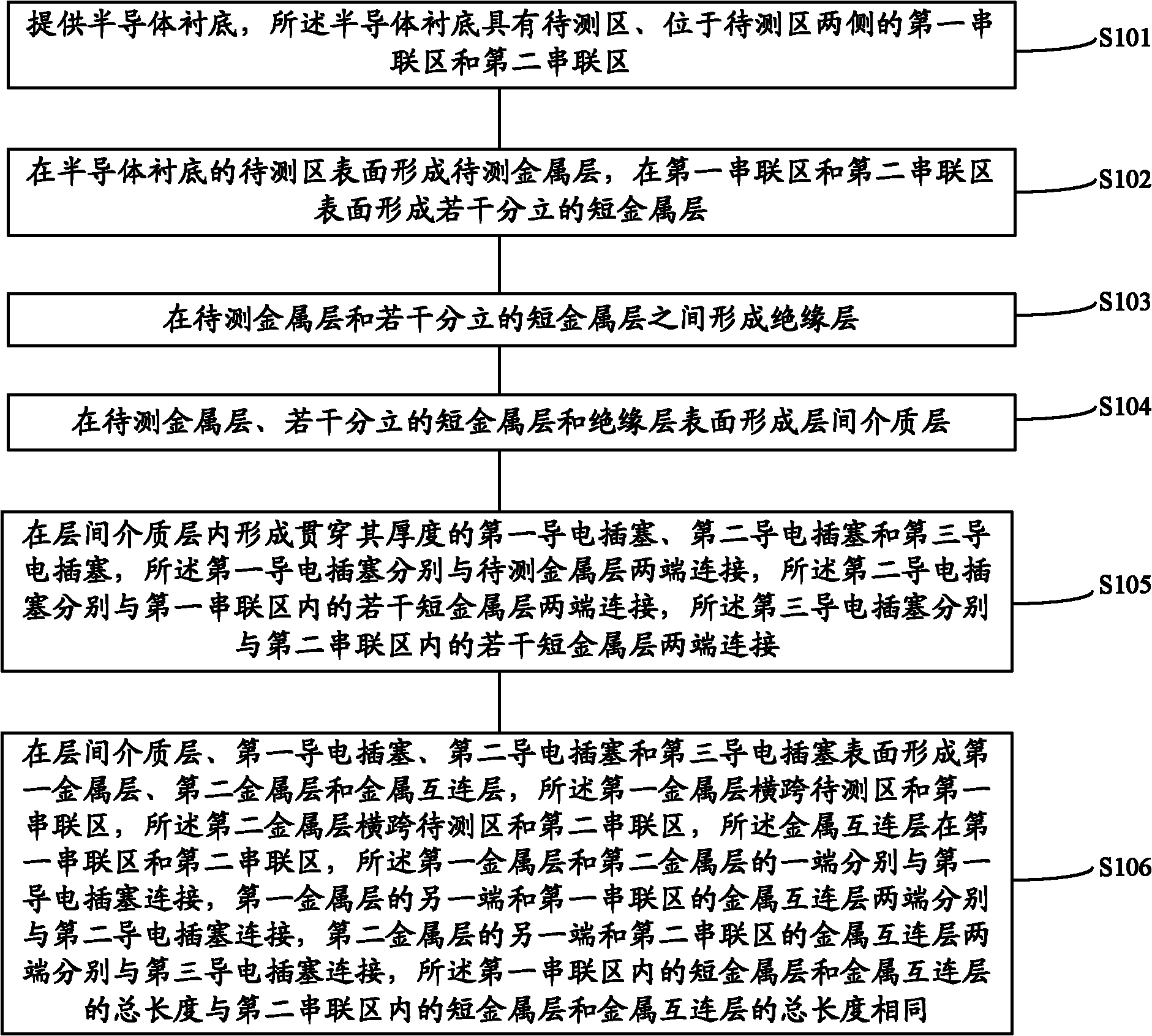

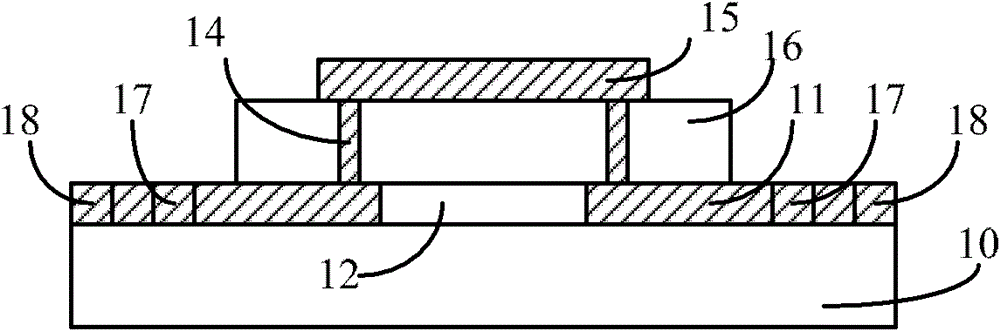

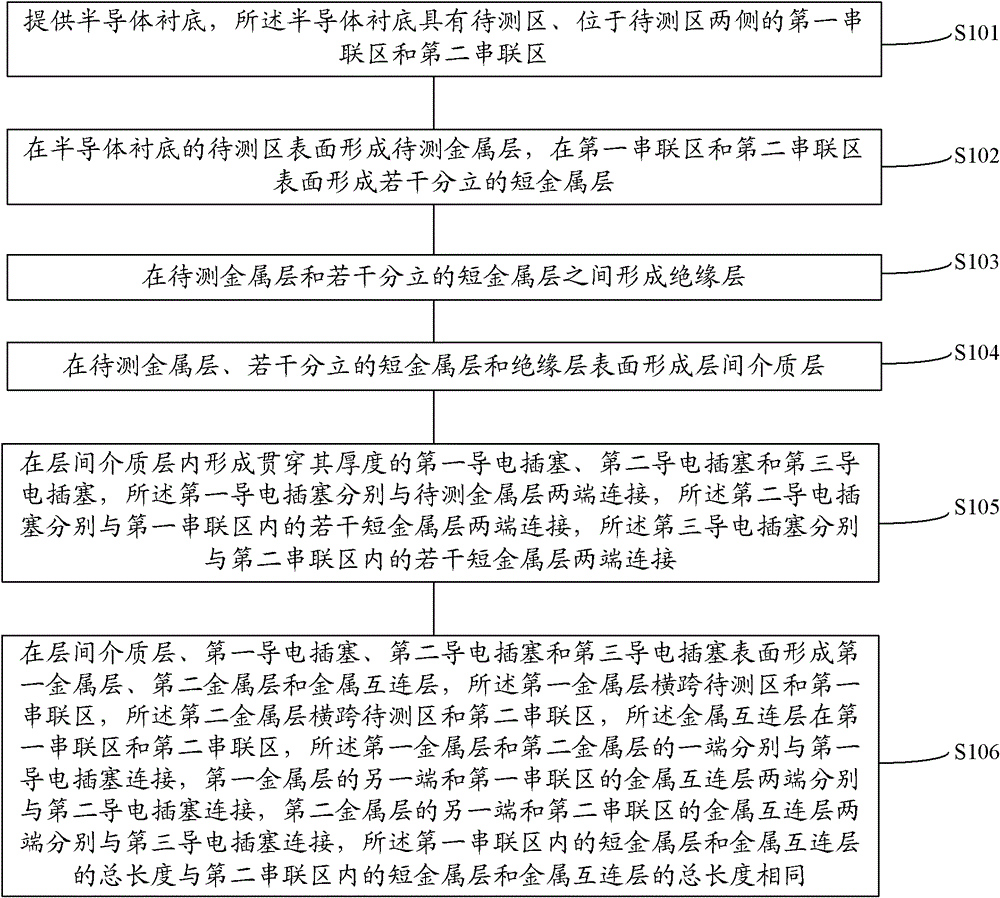

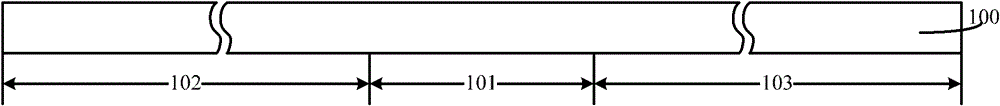

Semiconductor failure analysis structure, forming method of semiconductor failure analysis structure and failure time detection method thereof

ActiveCN103187403AImprove accuracyIncrease resistanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringFailure analysis

The invention provides a semiconductor failure analysis structure, a forming method of the semiconductor failure analysis structure and a failure time detection method thereof. The semiconductor failure analysis structure comprises a semiconductor substrate, a metal layer to be tested, a first metal layer, a second metal layer, a first conductive plug, a plurality of first resistance metal layers, a plurality of second resistance metal layers, a plurality of second conductive plugs and a plurality of third conductive metal layers. The semiconductor substrate is provided with an area to be tested, a first serial area and a second serial area. The metal layer to be tested, the first metal layer and the second metal layer are placed on the semiconductor substrate. The first conductive plug placed in an interlayer dielectric layer enables the first metal layer, the second metal layer and the metal layer to be tested to be connected in series. The plurality of first resistance metal layers are arranged in the first serial area. The plurality of second resistance metal layers are arranged in the second serial area. The plurality of second conductive plugs are placed in the interlayer dielectric layer of the first serial area. The plurality of third conductive metal layers are arranged in the interlayer dielectric layer of the second serial area. The first conductive plug, the second conductive plugs and the third conductive plugs enable the metal layer to be tested, the first metal layer, the second metal layer, the plurality of first resistance metal layers and the plurality of second resistance metal layers to be sequentially connected in series.

Owner:SEMICON MFG INT (SHANGHAI) CORP

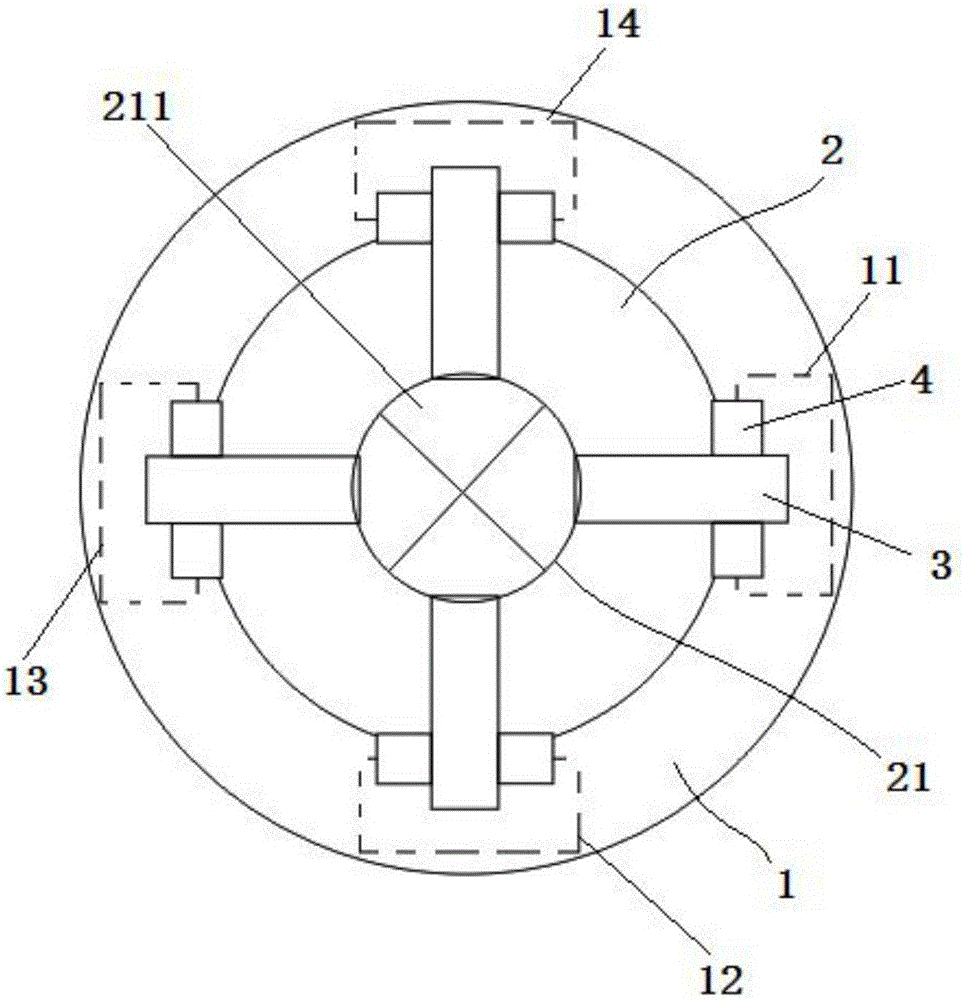

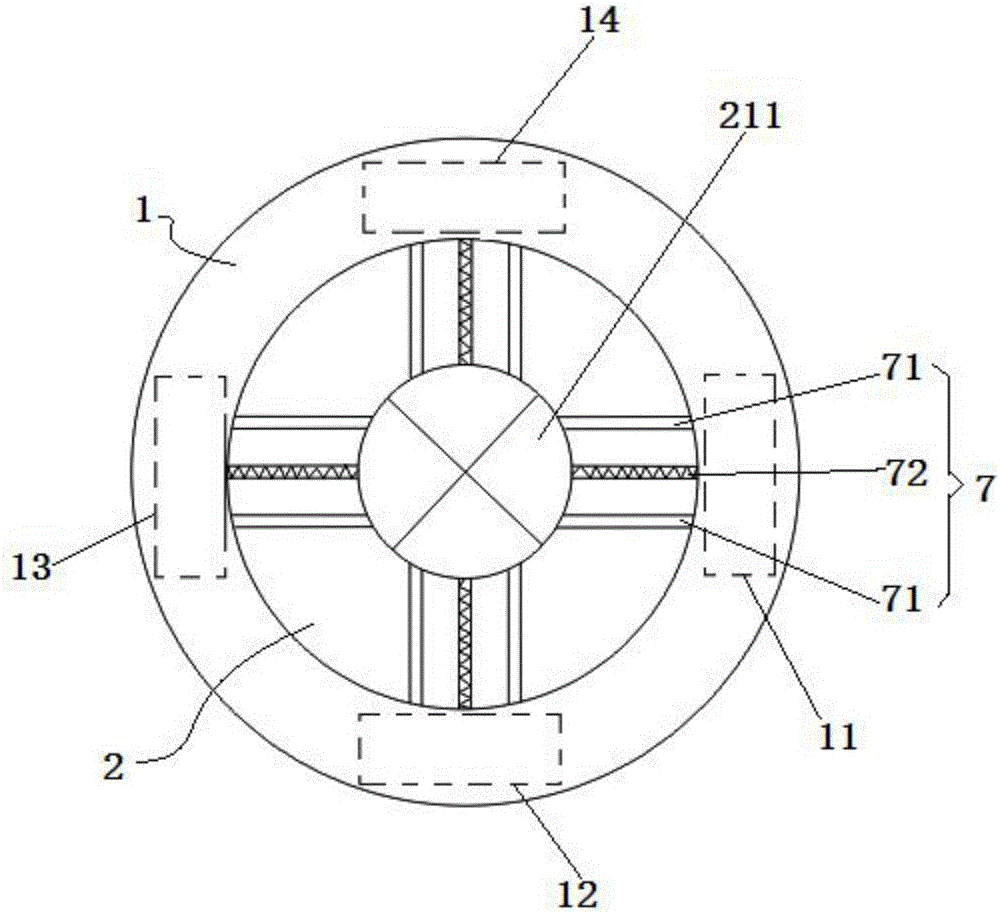

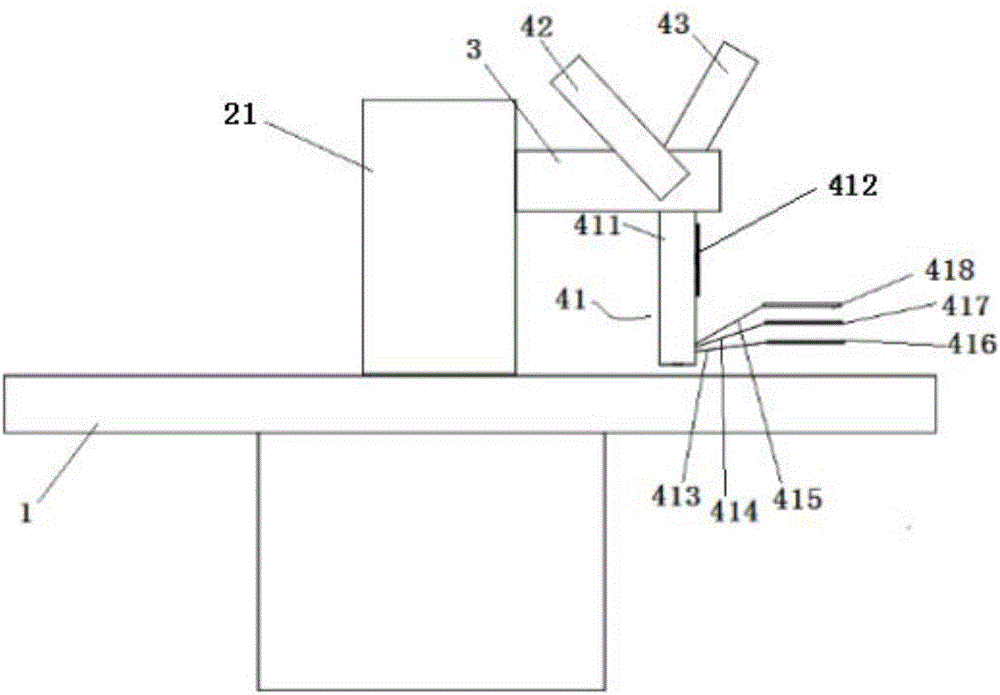

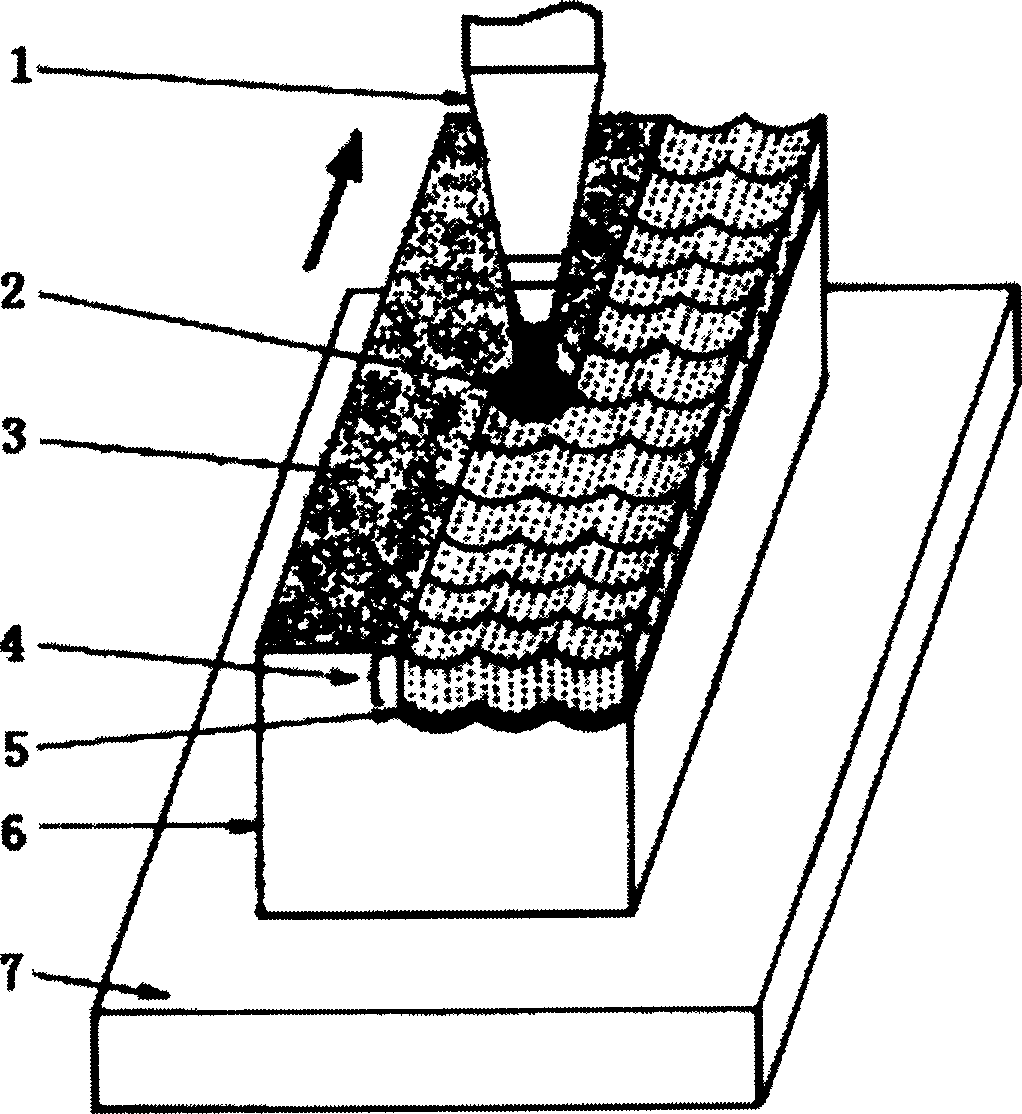

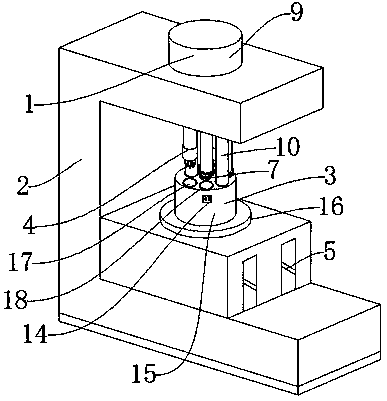

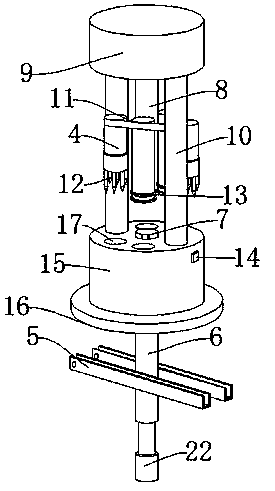

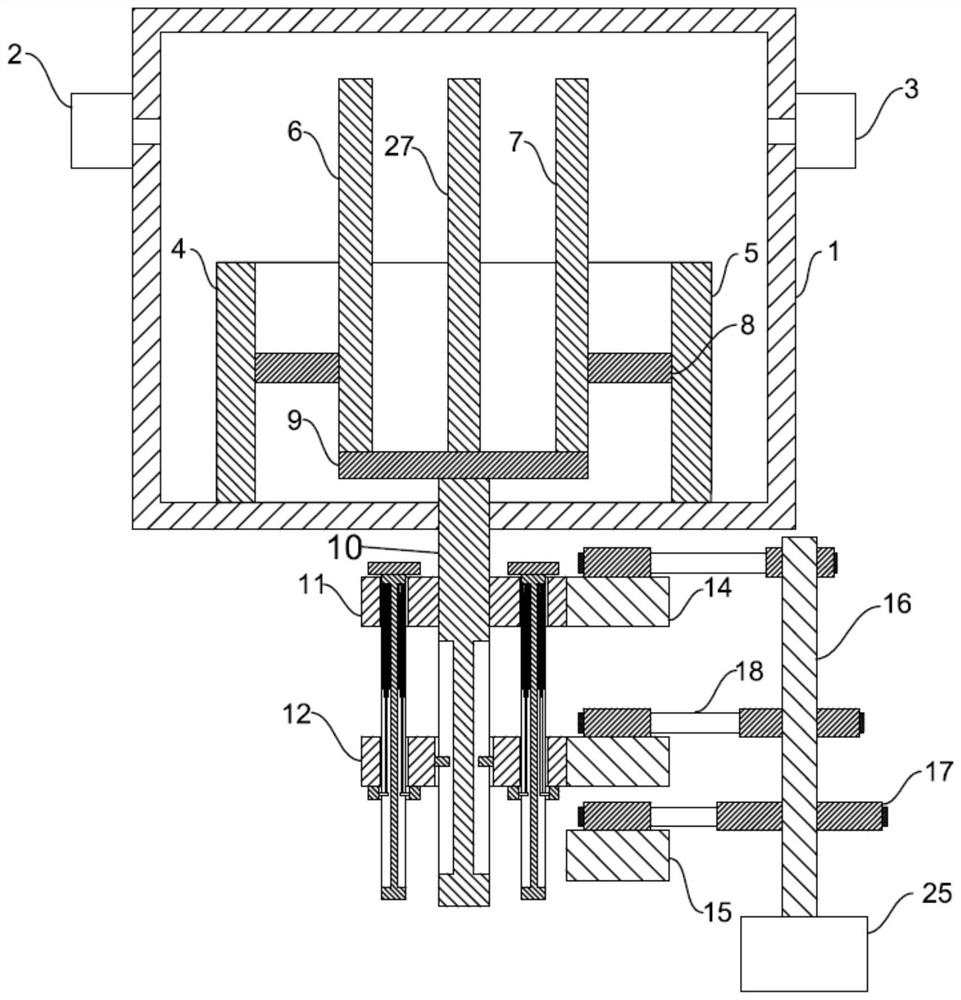

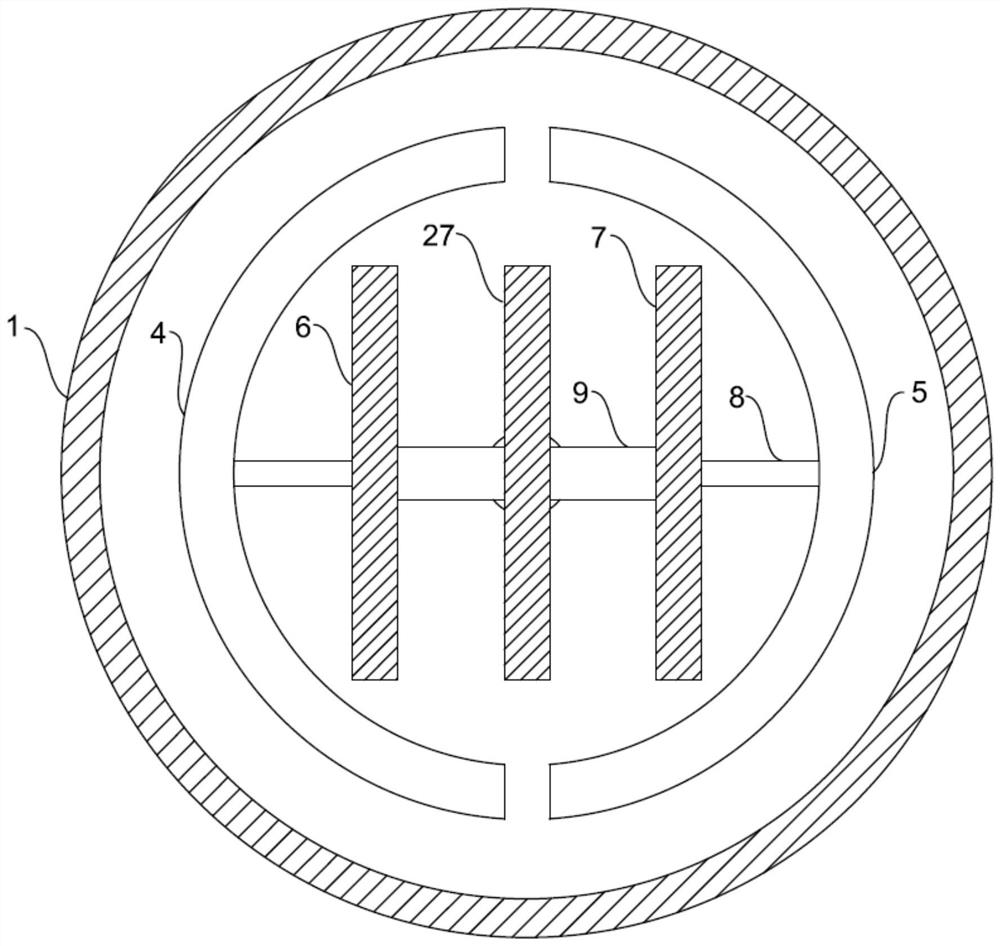

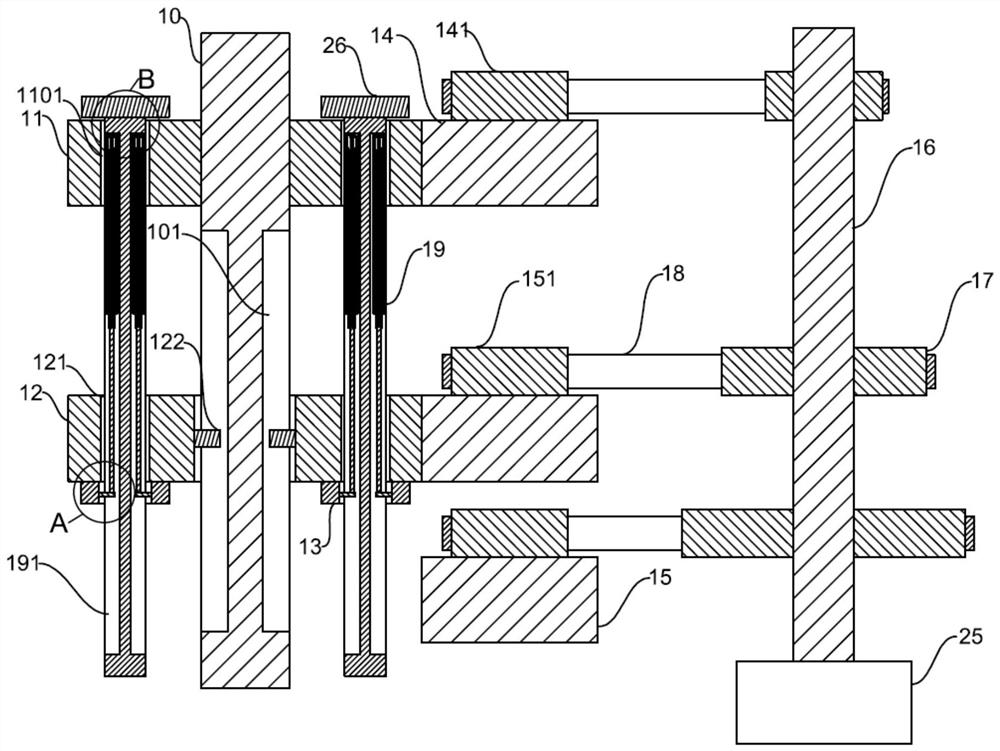

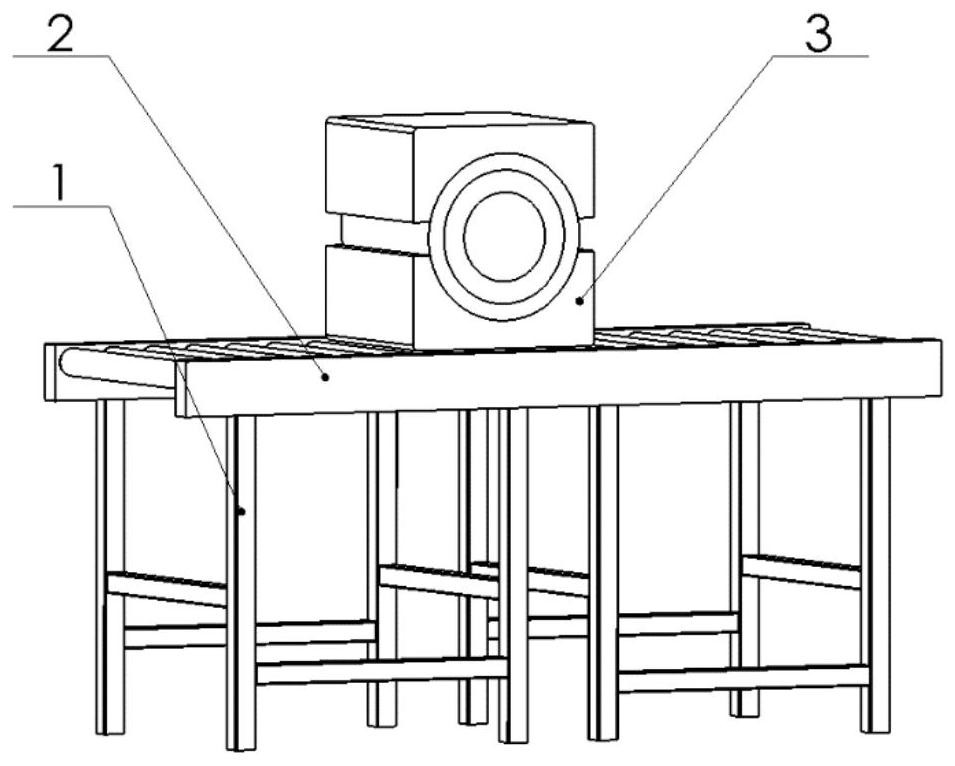

Multifunctional garment sewing machine

ActiveCN105887369AMeet different process requirementsImprove efficiencyWorkpiece carriersWork-feeding meansControl systemEngineering

The invention discloses a multifunctional garment sewing machine which comprises a rack and a control system, wherein a worktable and a rotating mechanism are arranged on the rack; a plurality of working areas are formed in the worktable; the rotating mechanism comprises a rotating disc; the rotating disc is arranged in the middle of the worktable; a first rotating shaft which rotates along the rotating disc is longitudinally arranged on the rotating disc; the first rotating shaft is composed of a plurality of equally divided intervals; the number of the intervals is equal to that of the working areas; the bottom of each interval is connected with the rotating disc by virtue of a Y-axis transmission mechanism so as to realize Y-direction movement of the intervals on the rotating disc; a second rotating shaft is transversely arranged on each interval; a plurality of working groups with different using functions are arranged on the second rotating shaft; the plurality of working groups are respectively uniformly and fixedly distributed on the second rotating shaft by taking the second rotating shaft as an axis and are positioned just above the worktable; and function switching of the working groups is realized by virtue of rotation of the second rotating shaft. According to the invention, the rotating mechanism is combined with the plurality of working groups, so that function selection diversity and automatic operation are realized.

Owner:南京润泽华针纺织科技发展有限公司

Coating powder for submerged arc surfacing of low-carbon steel and application method thereof

ActiveCN102152020AHigh hardnessImprove wear resistanceArc welding apparatusWelding/cutting media/materialsHigh resistanceHardness

The invention particularly relates to coating powder for submerged arc surfacing of low-carbon steel and an application method thereof. The coating powder contains C 7 wt% to 14 wt%, Cr 30 wt% to 65 wt%, Si 0.15 wt% to 3 wt%, Mn 1 wt% to 2 wt%, P 0.01 wt% to 0.04 wt%, S 0.01 wt% to 0.04 wt%, B 2 wt% to 6 wt%, and the balance of Fe. During the application, the coating powder is applied on the surface of a workpiece by 4 to 6 mm, and then the workpiece is subjected to submerged arc surfacing. The surfacing layer of the coating powder has high hardness, high resistance to abrasion and impact, and no cracks, impurities and pores, and filament-like stress releasing cracks generated on the surface of the surfacing layer can be prevented from dropping or stripping during the processing or application. Additionally, the process design of the coating powder is reasonable, and the parameters are easily controlled and the labor intensity is lower.

Owner:BIRTLEY TIANJIN IND EQUIP

Magnesium alloy surface SiC+Al pile up welding method

A technology for the build-up welding of SiC+Al on the surface of Mg alloy includes abrasing the surface of Mg-alloy workpiece for removing oxide, flushing with alcohol, drying in air, coating the mixture of SiC particles, Al particles and adhesive, baking, and tungsten arc build-up welding under protection of inertial gas. Its advantages are high hardness and antiwear-anticorrosion nature of welded surface and low cost.

Owner:SHANGHAI JIAO TONG UNIV

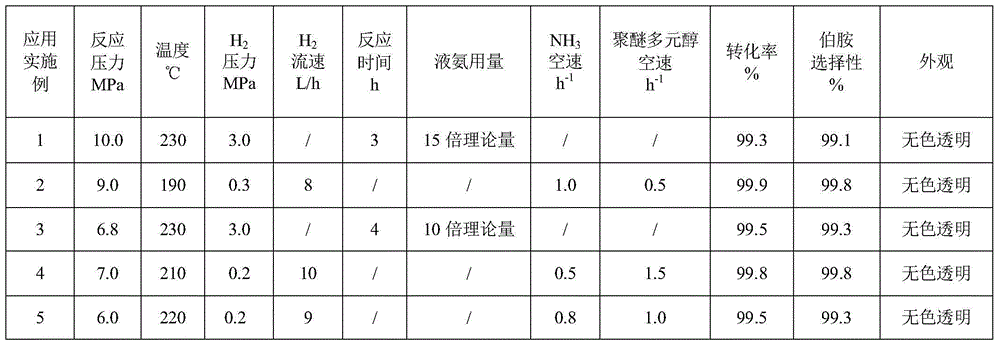

Catalyst for synthesis of amino-terminated polyether

ActiveCN104525212AImprove conversion rateLower reaction costMetal/metal-oxides/metal-hydroxide catalystsActive componentFixed bed

The invention discloses a catalyst for synthesis of amino-terminated polyether. The catalyst is load type, the carrier material has a porous structure, metal Ni and Co are taken as the main active components of the catalytic material, and any two of Cr, Fe and Mo are mixed in any proportion to serve as the assistant active component. The invention discloses a preparation method of the catalyst and application of the catalyst to synthesis of amino-terminated polyether. The catalyst provided by the invention is used for synthesis of amino-terminated polyether, and also has high conversion rate and high primary amine selectivity that are both greater than or equal to 99.0%. By using the catalyst provided by the invention, the reaction cost is lowered, and the catalyst has good catalytic effect in a batch kettle and a fixed bed reactor, and can meet different process requirements. By adding the catalyst, the reaction can be milder and more controllable, the temperature is lower than or equal to 230DEG C, the pressure is less than or equal to 10MPa, and the risk of the operation process is reduced.

Owner:HONGBAOLI GRP CO LTD +1

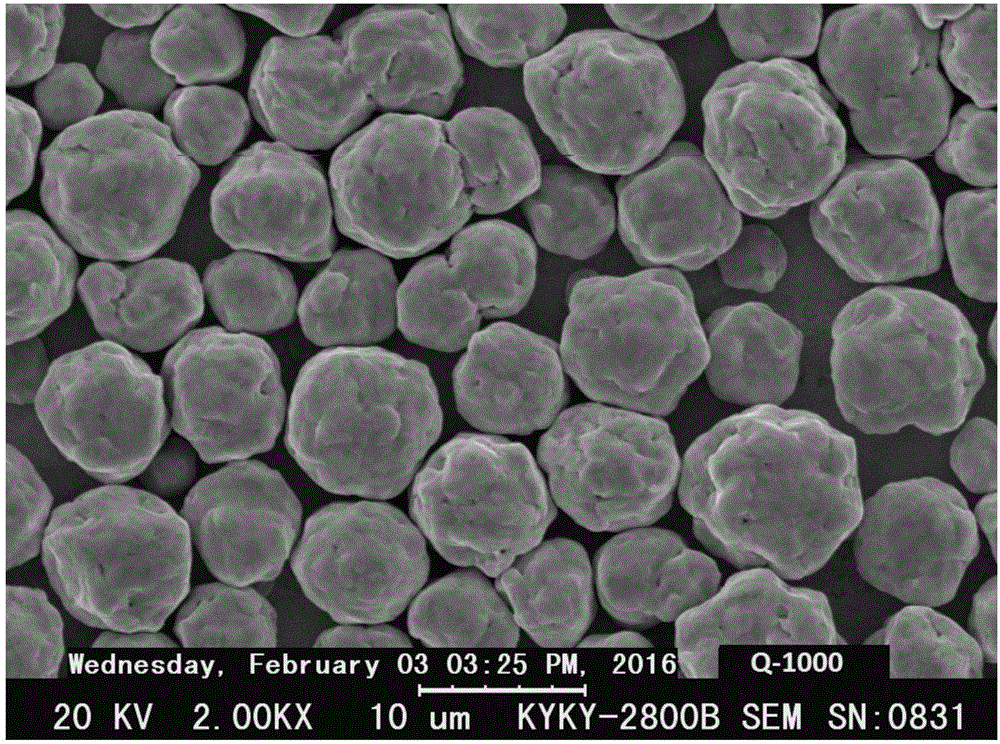

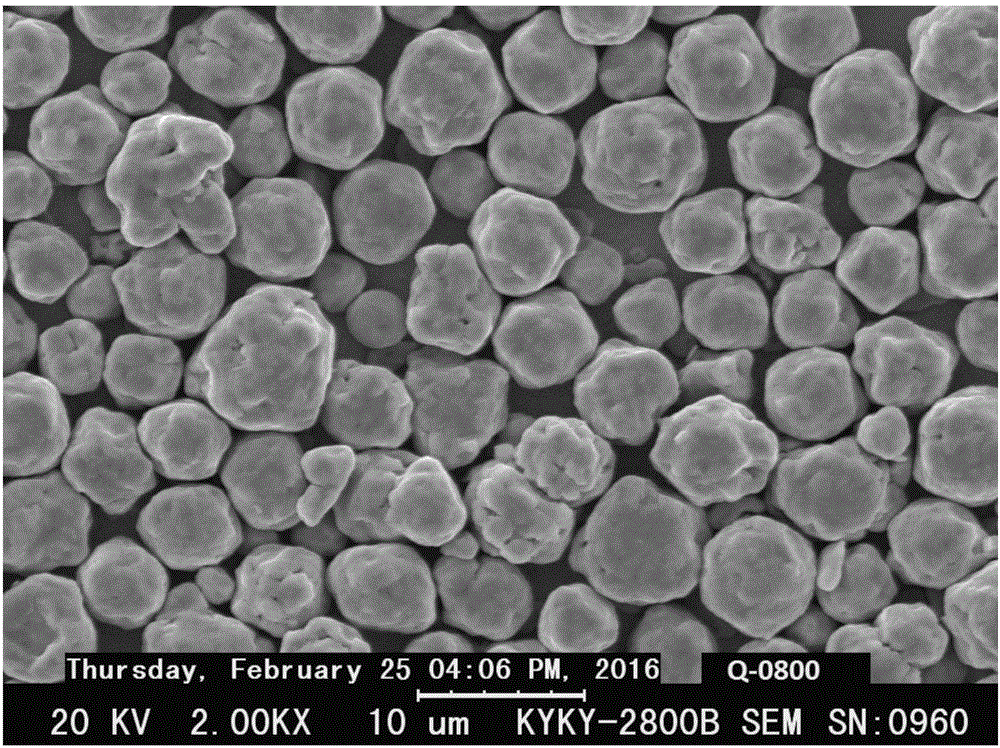

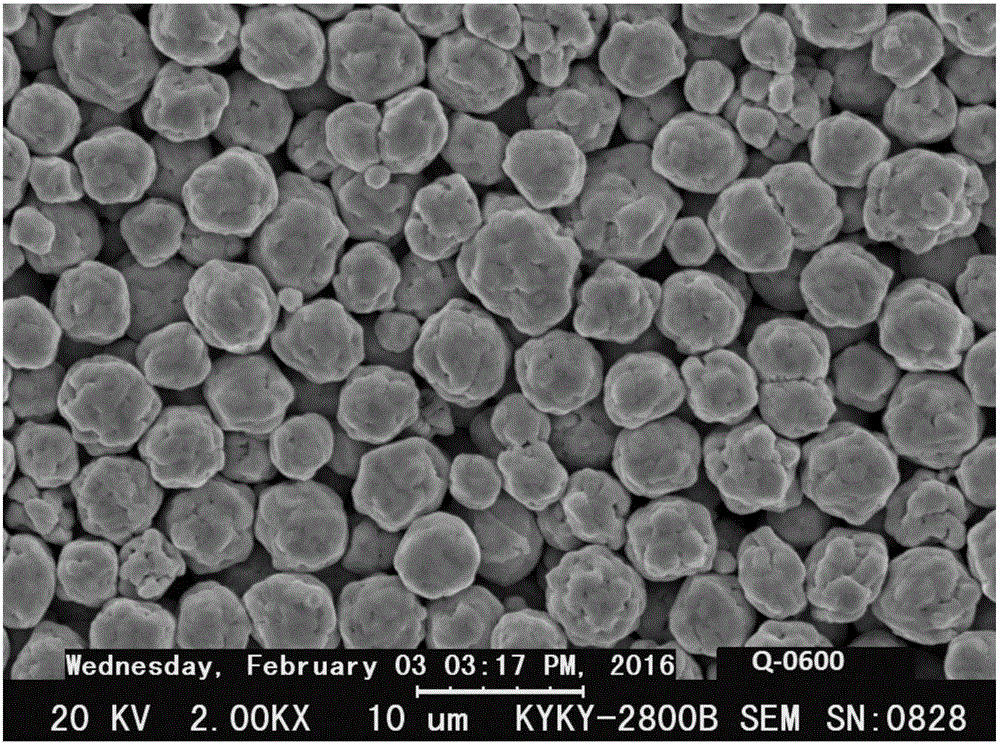

Large-grain-size spherical silver powder and preparation method thereof

InactiveCN106623978ANarrow particle size dispersionLarge particle sizeTransportation and packagingMetal-working apparatusMetallurgySlurry

The invention discloses a preparation method of large-grain-size spherical silver powder. The preparation method comprises the following steps: (1) weighing silver nitrate solid, adding water to dissolve, adding water to dilute and stirring uniformly to prepare a silver nitrate system; (2) weighing a reducing agent, adding water to dissolve, adding a dispersing agent, adding water to dilute and stirring uniformly to prepare a reduction system; (3) adjusting the temperature of the two system to be 5 to 60 DEG C, taking the reduction system as a parent body, and adding the silver nitrate system into the reduction system at a set stirring speed to react; and (4) after reaction is finished, cleaning silver powder until the electrical conductivity is less than or equal to 20 microseconds / centimeter, filtering and drying the silver powder. The silver powder prepared by the method has high tap density and small specific surface area; the granules of the silver powder have the characteristics of large grain size, narrow distribution range, high sphericity degree, smooth surface and the like; and the silver powder is mainly applied to pore filling of an electronic circuit and can be applied to electronic device end and thick film integrated circuit slurry.

Owner:广东羚光新材料股份有限公司

Method for dropping drop pills by vibration

InactiveCN104274319AReduce the amount of excipients and dosageIncrease production capacityPharmaceutical product form changeDropped headPreparation procedures

The invention relates to a preparation process of drop pills and particularly relates to a drop pill preparation method which has high drug loading capacity, and is simple in preparation procedure and high in production speed. The method comprises the following steps: (1) heating and fusing drugs and auxiliary base materials; (2) conveying fused drug liquid to a dropping head and dropping out the drug liquid by using a vibration dropping method; (3) cooling by low-temperature gas to obtain the drop pills.

Owner:TIANJIN TASLY PHARMA CO LTD

B4C+Al bead welding remelting method for magnesium alloy surface

InactiveCN1672849AControlling Surface Alloying QualityImprove mechanical propertiesArc welding apparatusAl powderHardness

The present invention relates to welding technology, and is B4C+Al bead welding re-melting method for magnesium alloy surface. The present invention has the following steps: 1) treating magnesium alloy workpiece surface via grinding, eliminating oxide, flushing with anhydrous alcohol and drying in the air; 2) mixing B4C and Al powder, and adding PVB via stirring to obtain coating material; 3) painting the compounded coating material onto the surface of magnesium alloy workpiece, and drying naturally or stoving; and 4) tungsten electrode arc welding and re-melting of the magnesium alloy workpiece surface under the protection of inert gas. The present invention can raise the surface hardness, wear resistance and corrosion resistance, and has simple equipment, easy operation, low production cost and other advantages.

Owner:SHANGHAI HAOHUA MOLD

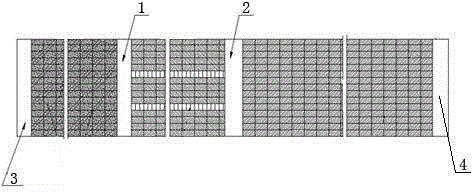

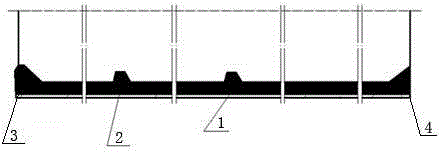

Castable kiln structure of cylindrical heat rotary equipment

Disclosed is a castable kiln structure of cylindrical heat rotary equipment. The castable kiln structure is characterized in that a kiln body is divided into a low-temperature feeding region, a high-temperature heat reaction region and an outlet and flow port. Retaining rings are arranged on regional boundaries of the low-temperature feeding region, the high-temperature heat reaction region and the outlet and flow port. The retaining rings protrude out of a kiln liner, so that the materials are enabled to turn over and change operation orbits through the retaining function of the protrusion height of the retaining rings when materials enter different temperature regions. The shortcomings that the kiln liner shaking during operation of a traditional bricked kiln liner to be separated from a steel casing to produce slip frequency with the same is free of overall strength, the kiln liner can be loosened and disintegrated instantly and cannot be maintained rapidly in a small range, and the like are effectively overcome, so that service life of the cylindrical kiln liner is prolonged by one to several times as compared with that of the bricked kiln liner, working cavities inside the kiln liner can be optionally changed according to technological requirements, damages to certain parts of the kiln liner do not cause affect to the service life of the whole kiln, and rapid maintenance in the small range can be achieved.

Owner:洛阳市洛华粉体工程特种耐火材料有限公司

Heating forming machine for honeycomb biomass cured fuel

The invention discloses a heating forming machine for a honeycomb biomass cured fuel. The heating forming machine for the honeycomb biomass cured fuel comprises a charge device, a box body, a formingdevice, a stamping chipping-sweeping device, a finished product conveying device and a power transmission device, wherein the charge device comprises a charge hopper and a material barrel; the material barrel is arranged below the charge hopper; the forming device is arranged below the material barrel; a piston rod is arranged at the inner side of the material barrel and at the lower end of the box body; and the forming device comprises a forming die, a tray, a spiral heating wire and a power connector. The heating forming machine for the honeycomb biomass cured fuel has the following beneficial effects: the biomass cured fuel produced by the cured fuel forming machine is honeycomb, and high in burn-off rate and calorific value; the cured fuel forming machine is simple in structure, stablein mechanism running, reliable in working, low in noise in a production process, and capable of meeting the environmental protection requirement; the overall system is high in adaptive capacity, andcapable of meeting different process requirements; wearing parts are easy to install, detach and change; and equipment parts are simple to machine.

Owner:ZAOZHUANG UNIV

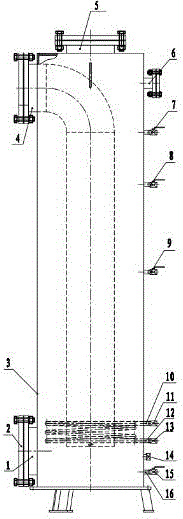

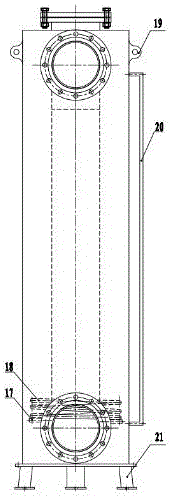

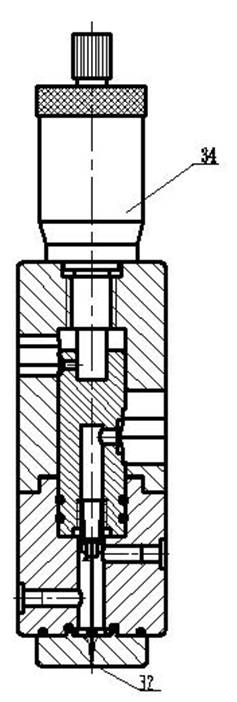

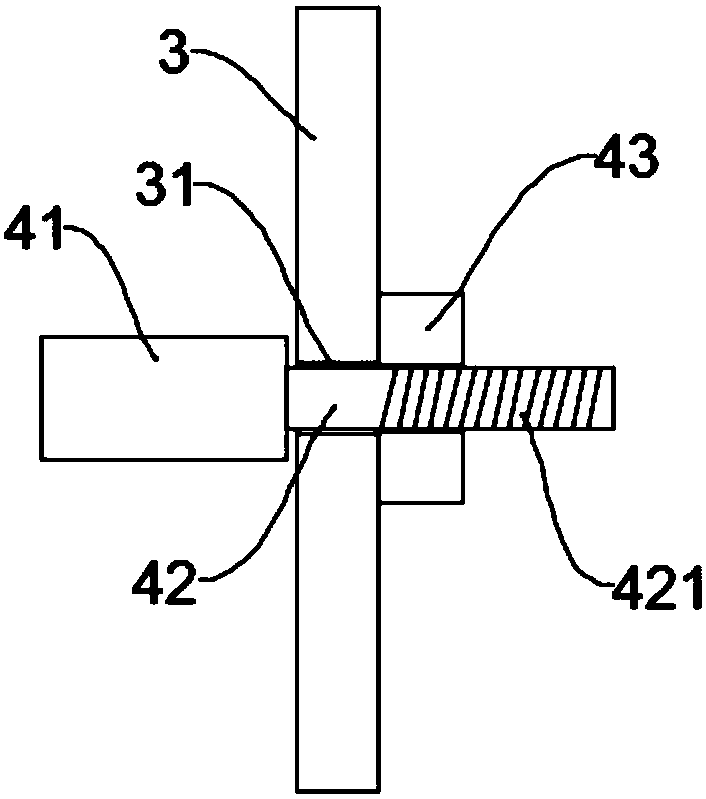

Safe diffusing device for gas transmission and using method

InactiveCN106089501AConcentration effectAvoid incomingInternal combustion piston enginesFuel supply apparatusPressure stabilizationEngineering

The invention belongs to the technical field of gas power generation sets, and provides a safe diffusing device for gas transmission and a using method. The safe diffusing device for gas transmission is provided with a hollow cylinder (3) with the two ends closed, an air inlet pipe (4) is arranged in the hollow cylinder (3), and the diameter of the air inlet pipe (4) is smaller than that of the hollow cylinder (3); the air inlet pipe (4) is provided with a straight pipe section, and a gap is formed between an air outlet of the lower end of the straight pipe section and the bottom face of the hollow cylinder; a bent pipe section bent toward one side is arranged at the upper end of the straight pipe section, an outlet of the bent pipe section is located at the upper end of one side wall face of the hollow cylinder (3), and water for carrying out water seal on gas exists in the gap between the air inlet pipe (4) and the hollow cylinder (3); a water level control valve is installed on one side wall face of the hollow cylinder (3), and a diffusing opening (5) is formed in the upper end face of the hollow cylinder (3). Constant pressure diffusion at multiple pressure levels is achieved to meet different process requirements, and the function of pressure stabilization and overpressure diffusion is achieved.

Owner:HENAN DIESEL ENGINE IND

Continuous vacuum magnetron sputtering coating device and coating production line

ActiveCN112251728ASolve the problem of excessive accumulation, which can easily cause ignition between polesDifferent coating thicknessVacuum evaporation coatingSputtering coatingSputteringTarget surface

The invention discloses a continuous vacuum magnetron sputtering coating device and a coating production line. The continuous vacuum magnetron sputtering coating device comprises an alternate coatingunit and a variable-speed rotating unit, a first sputtering target and a second sputtering target which are opposite to each other are movably arranged between a positive electrode power connection annular plate and a negative electrode power connection annular plate, and gear teeth of a first driven rotating gear and gear teeth of a second driven rotating gear are complementary; and a plurality of variable-speed rotating wheels with different sizes are fixedly connected to a driving rotating rod, empty grooves are formed in the two sides of an adjusting rod, and adjusting mechanisms are fixedly arranged in the empty grooves. When the continuous vacuum magnetron sputtering coating device is used, the positive electrode power connection annular plate and the negative electrode power connection annular plate are arranged, so that the two sides of a part to be coated are alternately coated, and positive ions accumulated on a target surface are neutralized; and through the arrangement of the multiple variable-speed rotating wheels with the different sizes, multiple second driving rotating gears and the adjusting mechanisms, the coating thicknesses of the two sides of the part to be coated are different, different process requirements are met, and the application range of the device is widened.

Owner:凯盛信息显示材料(洛阳)有限公司

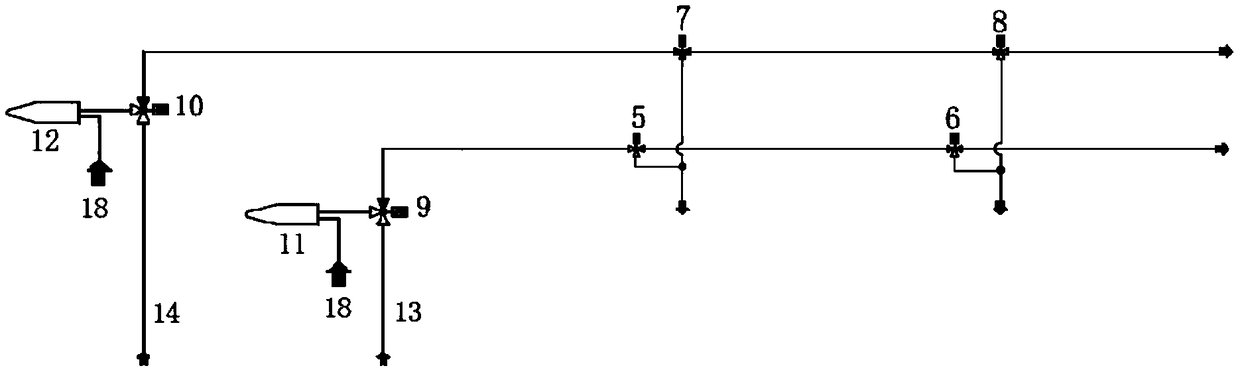

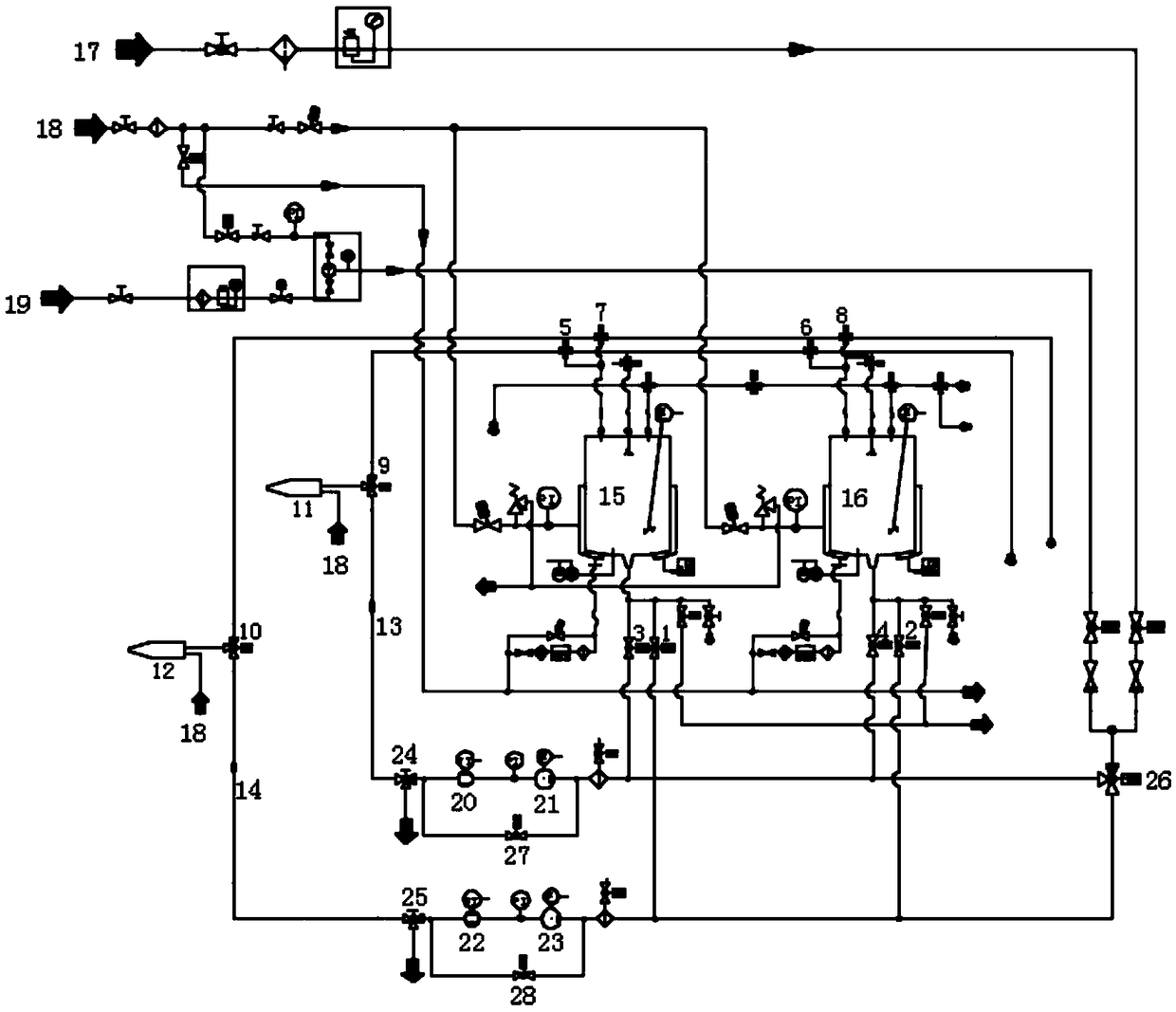

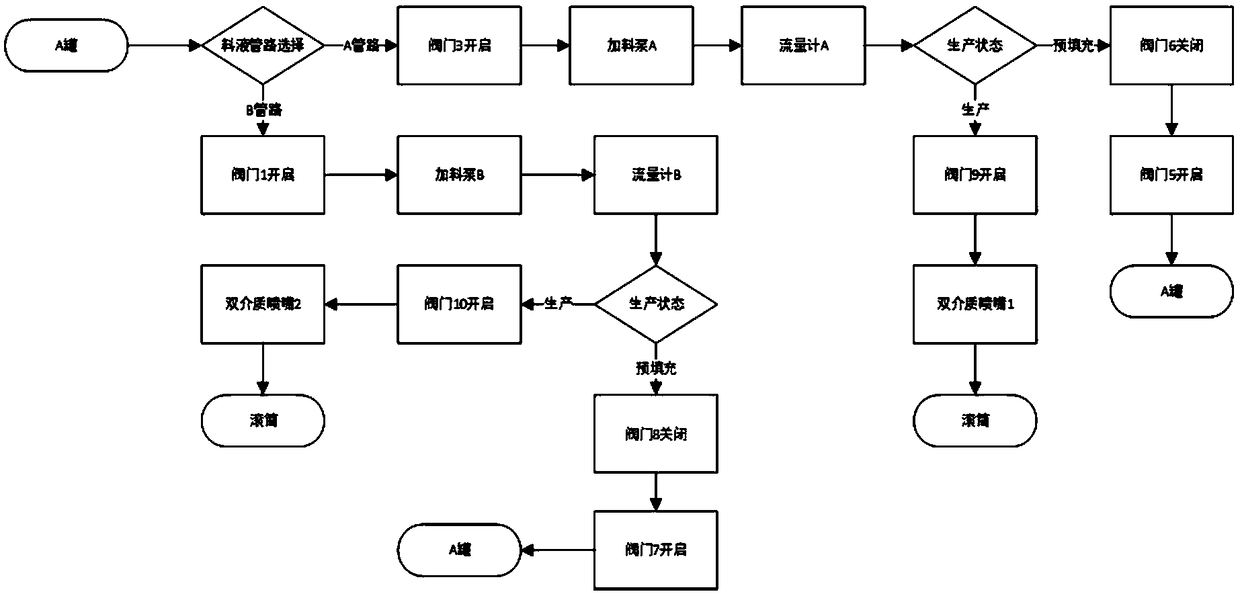

Tobacco primary processing secondary charging and water replenishing control system and method

PendingCN108887730AEnsure continuous production of equipmentMeeting Diversity RequirementsTobacco preparationTobacco treatmentSteel tubeContinuous production

A tobacco primary processing secondary charging and water replenishing control system is characterized in that two independent charging and water replenishing pipelines are designed after an originalpipeline exits from a flowmeter, a first pneumatic three-way valve, a second pneumatic three-way valve, a fifth pneumatic three-way valve and double-medium nozzles A and B are newly added, and are connected together by a stainless steel tube, and by the pipeline, two independent charging and water replenishing pipelines can be formed; the first pneumatic three-way valve and the second pneumatic three-way valve are switched over for a feeding tank of a feed liquid pipeline loop; and the fifth pneumatic three-way valve is switched over for production and pre-filling pipelines. Quantified water replenishing and proportional water replenishing are designed and meet different process requirements; double charging pipelines are selected in production, and can be used flexibly, the pipelines canbe switched over if equipment fails in production, and continuous material feeding in production is realized; and continuous production of the equipment and completeness of a blade assembly formula can be ensured.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

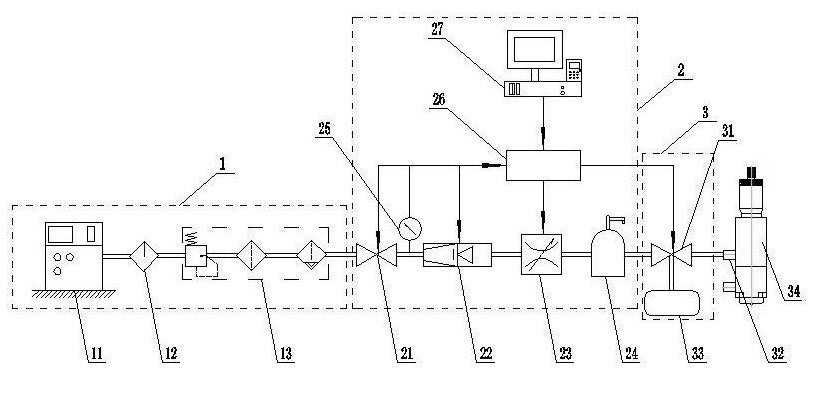

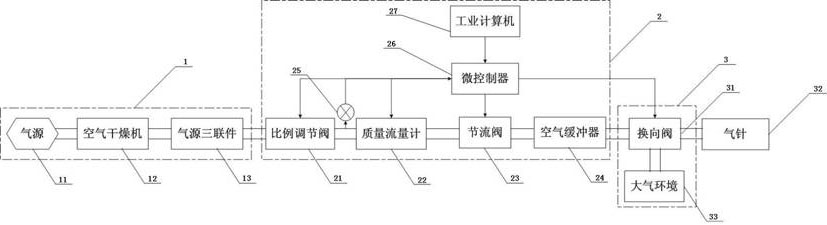

Auxiliary gas control system for double-fluid ejector

InactiveCN102151626AEasy to operateEasy to maintainLiquid spraying apparatusProcess engineeringProduct gas

The invention relates to an auxiliary gas control system for a double-fluid ejector, which comprises a gas source device, a gas pressure-flow adjustment unit, a gas reversing unit and the double-fluid ejector, wherein the gas source device, the gas pressure-flow adjustment unit, the gas reversing unit and the double-fluid ejector are orderly connected through a gas pipe; and an outlet of the gas reversing unit is connected with a gas needle of the double-fluid ejector through a gas pipe so as to realize the gas supply of the double-fluid ejector. Through a microcontroller in the gas pressure-flow adjustment unit, a proportion control valve and a mass flow meter are controlled to adjust the pressure and the flow of the gas so that the technological parameter requirements are satisfied; and through the microcontroller, the action of the gas reversing valve is controlled so that the pulsation and continuous gas supply are realized and different technological requirements are satisfied. The auxiliary gas control system for the double-fluid ejector is suitable for the spot gluing technologies such as time-pressure type spot gluing, double-fluid ejection spot gluing, mechanical ejection spot gluing and the like.

Owner:SHANGHAI UNIV

Central transmission thickener driving device

PendingCN112354224AHigh mechanical strengthWith overload protection functionSedimentation separationControl engineeringReducer

The invention discloses a central transmission thickener driving device, which comprises a fixed seat, a rotating frame, a slewing bearing , low-speed large-torque speed reducers, guide wheel sets, aguide pipe shaft and a rake lifting oil cylinder, wherein the guide pipe shaft is fixed to the upper portion of the fixed seat, the rotating frame is installed on the fixed seat through the slewing bearing and connected to the guide pipe shaft in a sleeving mode, the low-speed large-torque speed reducers are installed on the rotating frame, connected with the slewing bearing and drive the slewingbearing to rotate, the at least two low-speed large-torque speed reducers are symmetrically arranged; the guide wheel sets and the rake lifting oil cylinder are fixed to the upper portion of the speedreducer box body, guide grooves are formed in the guide pipe shaft, the guide wheels of the guide wheel sets are located in the guide grooves, and at least two guide wheel sets are symmetrically arranged. According to the invention, hydraulic multi-point driving is adopted, stepless speed regulation is achieved, the mechanical strength is high, the stability is good, the overload protection function is achieved, and different technological requirements are met; and the equipment is high in operation stability, low in operation failure rate, low in maintenance frequency, long in service life and low in overall operation cost.

Owner:HUAIBEI MINSHENG MINING MACHINERY

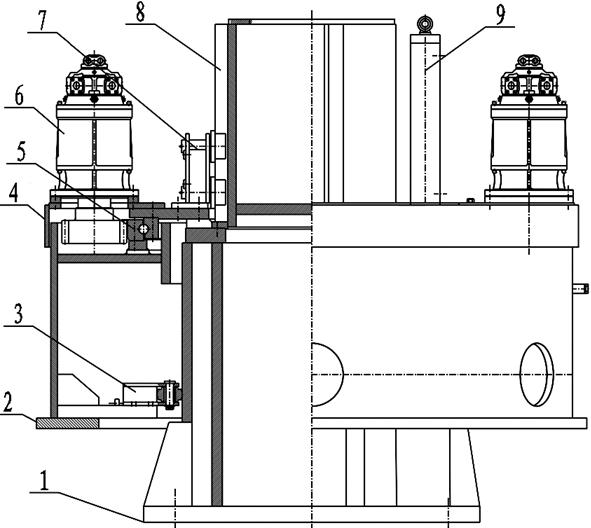

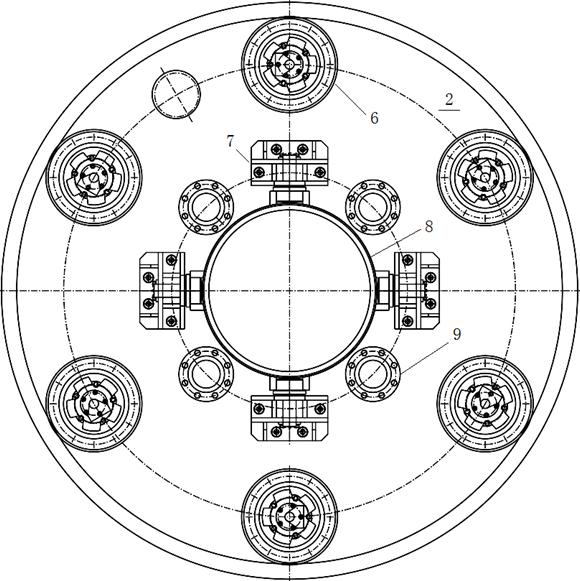

Bidirectional synchronous loading hydraulic forming equipment for aero-engine sealing ring

ActiveCN112246951AEnsure consistent qualityEnsure quality stabilityMetal working apparatusNumerical controlLoop controlControl manner

The invention discloses bidirectional synchronous loading hydraulic forming equipment for an aero-engine sealing ring. The bidirectional synchronous loading hydraulic forming equipment comprises an automatic die filling system, a main machine system, an ultrahigh pressure system and a numerical control system, wherein the main machine system comprises two servo hydraulic cylinders of which the displacement synchronous control precision can reach + / -0.02 mm, and a die locking hydraulic cylinder; the ultrahigh pressure system not only drives the hydraulic cylinder, but also provides a bulging pressure of 100MPa at most; the pressure can be dynamically adjusted along with feeding displacement of the servo hydraulic cylinders, so that the requirement for bidirectional synchronous loading hydraulic forming of special-shaped section members made of difficult-to-deform materials such as high-temperature alloy is met; and the numerical control system is based on a control mode of an upper computer and a lower computer and has intelligent functions such as database and parameter analysis. According to the bidirectional synchronous loading hydraulic forming equipment, closed-loop control isadopted, and the functions of precise load application, servo drive / hydraulic constant-load composite control, load / pressure real-time detection, forming error intelligent compensation and the like are integrated, so that integration and automation of the bidirectional loading bulging process are achieved, and product quality consistency and stability are guaranteed.

Owner:BEIHANG UNIV +1

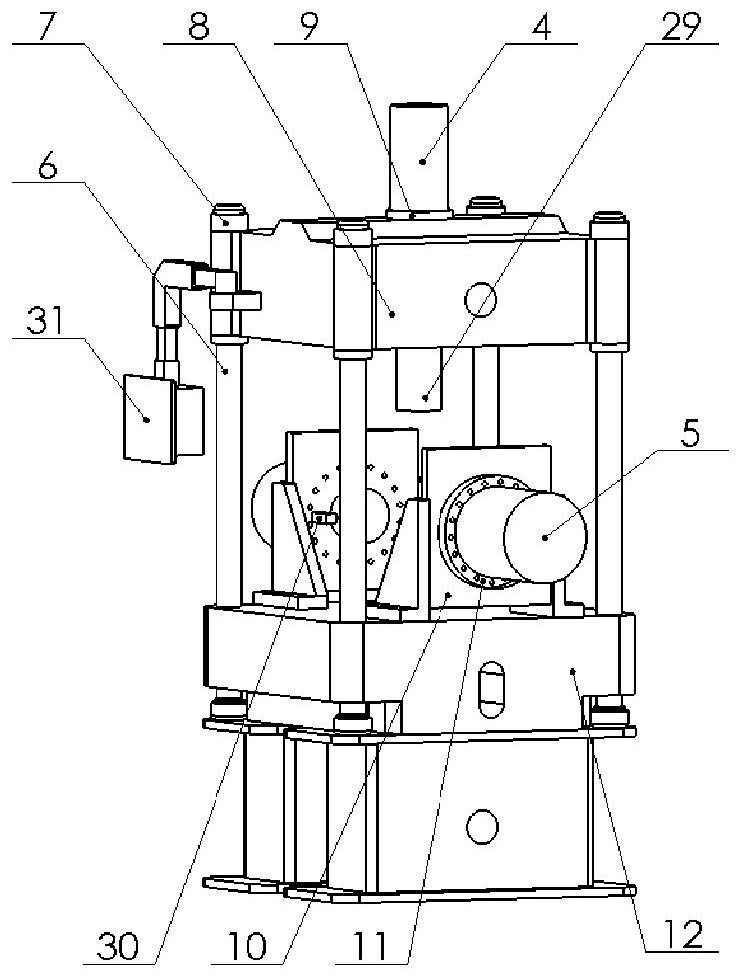

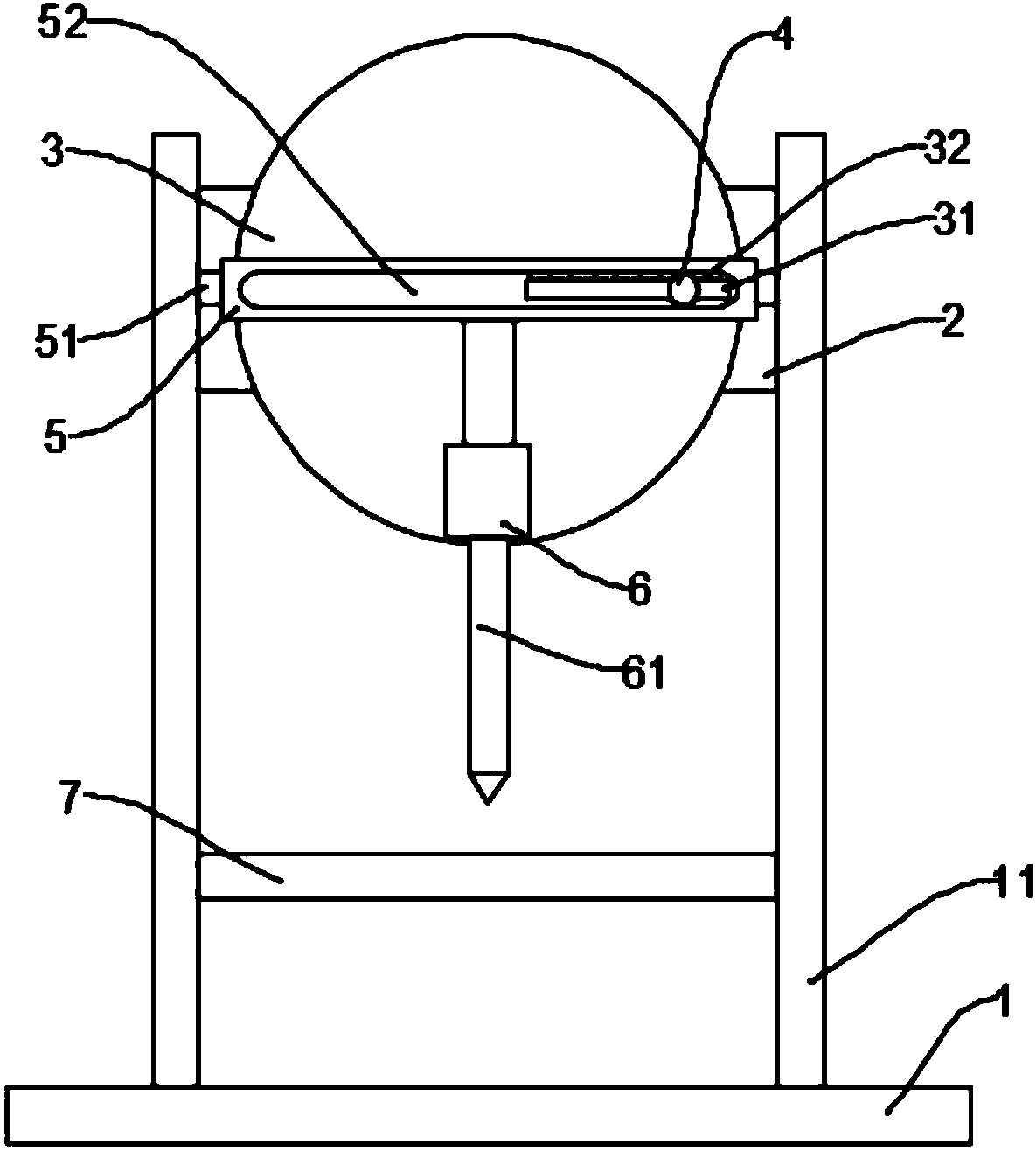

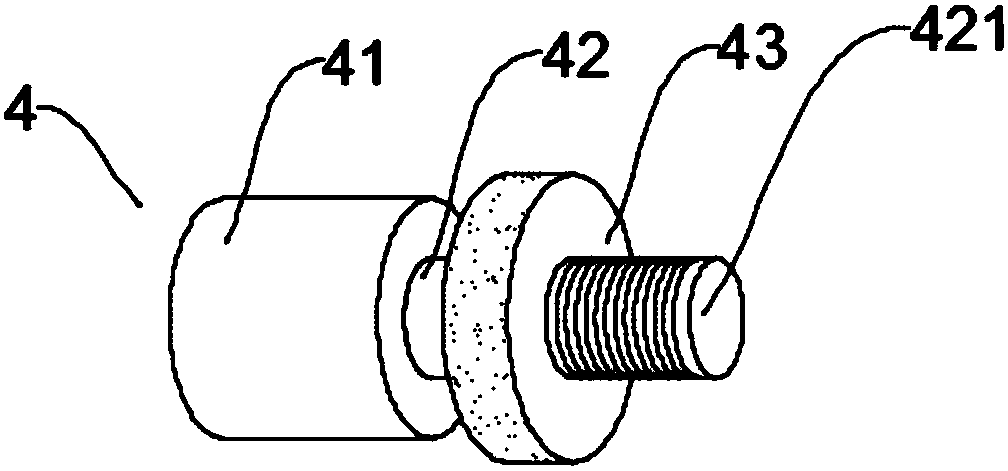

Novel adjustable drilling device

The invention discloses a novel adjustable drilling device. The novel adjustable drilling device comprises a pedestal, a rotary table, an adjusting slider, a T-shaped rod, a motor and a workbench. Vertical frames are symmetrically fixed to the left side and the right side of the top of the pedestal. A mounting plate is fixed between upper frame bodies of the vertical frames on the two sides. The rotary table is connected to the front side of the mounting plate in a rotating mode. The rotary table is provided with an adjusting hole in the radius direction, and the adjusting hole is connected with the adjusting slider in a matched mode. The T-shaped rod is arranged on the front side of the rotary table. The motor is installed at the tail end of a vertical rod body of the T-shaped rod. The workbench is fixed between the vertical frames on the two sides and is further located at the position below a rotating rod. The novel adjustable drilling device is novel in structure, the drilling depth can be adjusted by changing the position of the adjusting slider on the rotary table, and therefore different technological requirements are met, and the using flexibility of the device is improved;moreover, the adjusting slider can be operated conveniently and rapidly; and meanwhile, scale marks are arranged, and workers can accurately control the drilling depth.

Owner:孙梦思

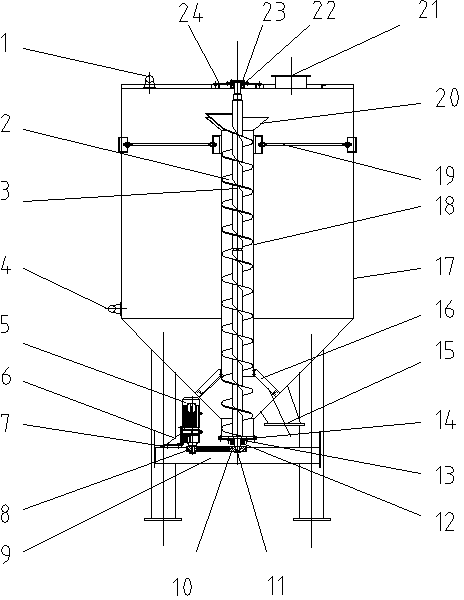

Tobacco sheet stem powder raw material pretreatment mixing and stirring device

InactiveCN103877897AMeet uniformityWell mixedRotary stirring mixersTransportation and packagingVertical mixingEngineering

The invention relates to a tobacco sheet stem powder raw material pretreatment mixing and stirring device which is a device for blending and stirring the prepared dry materials to be uniformly mixed before tobacco sheet stem powder raw materials are leached, belonging to the technical field of tobacco machinery. The device is mainly characterized by comprising a vertical mixing spiral shaft arranged in a tank body, a reducing motor outside the tank body, a feeding and discharging material level detector on the tank body, and a frame, wherein the reducing motor fixed on the frame drives a spindle in the vertical mixing spiral shaft; when the tobacco sheet stem powder raw materials are mixed, the tobacco stems and tobacco powder are vertically conveyed to the upper part of the tank through the vertical mixing spiral shaft, the materials are thrown to the periphery through the effects of spiral stirring blades which extend outwards and a throwing hopper, and the materials drop along the interior of the tank. When sliding to the bottom of the tank body, the tobacco stems and tobacco powder are lifted upwards by the vertical mixing spiral shaft again. The tobacco stems and tobacco powder are repeatedly recycled until the materials are uniformly mixed. The device is simple in structure and convenient to operate, and the batching uniformity can be met.

Owner:JIANGSU WELL ELECTRIC

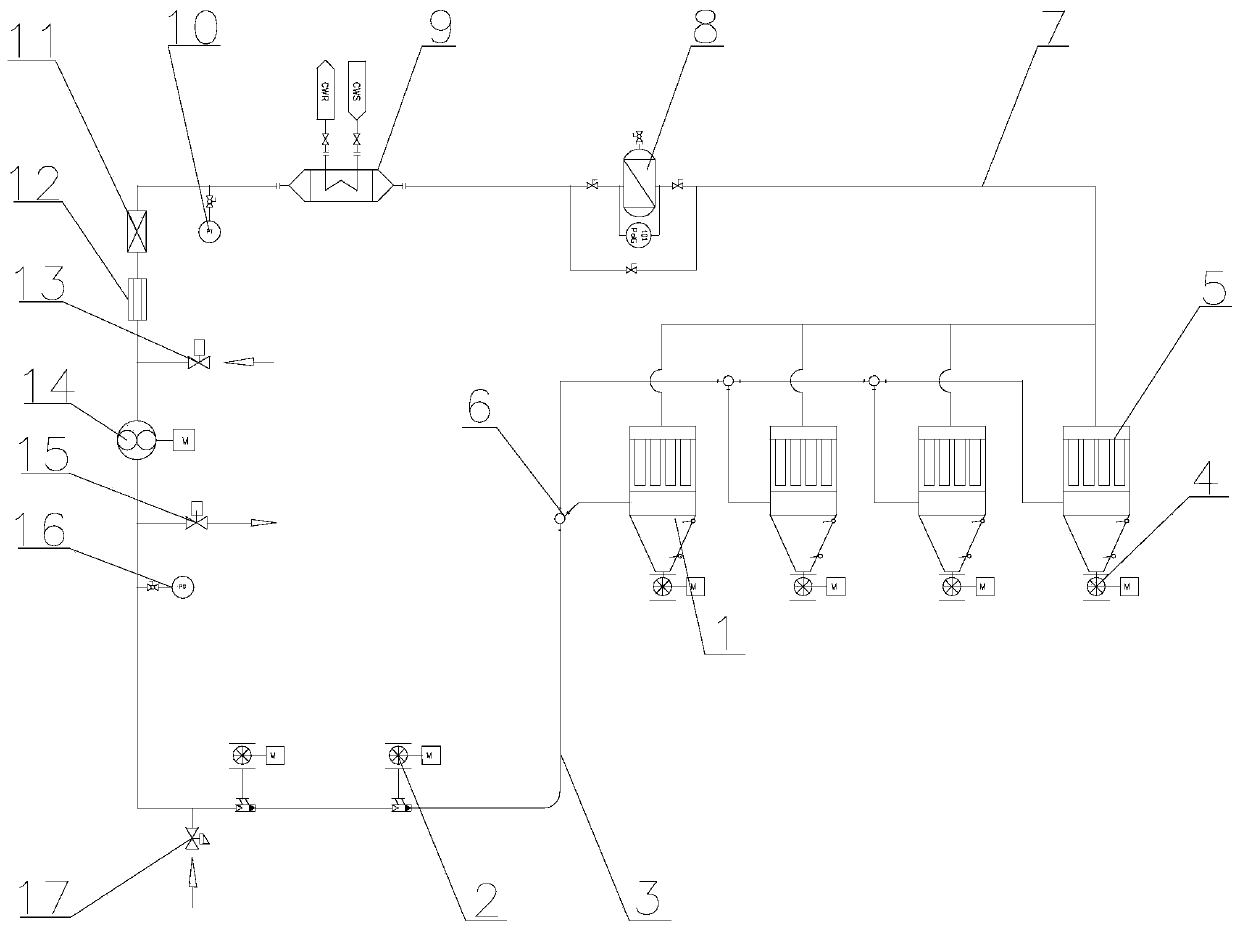

Closed gas flow conveying device for battery-grade lithium hydroxide

PendingCN111392429AAvoid reactionQuality assuranceBulk conveyorsLithium hydroxideProcess engineering

The invention discloses a closed gas flow conveying device for a battery-grade lithium hydroxide. The closed gas flow conveying device for the battery-grade lithium hydroxide comprises a conveying pipeline, a second material gas separator, a return pipeline and a booster fan; the conveying pipeline is arranged at one end of the booster fan and is connected to one end of the booster fan; the conveying pipeline is connected with a first unloading valve of a material supply system through a tee joint; a lithium hydroxide material in the material supply system enters the conveying pipeline throughthe first unloading valve; the second material gas separator is arranged at an end part of the conveying pipeline; the conveying pipeline is connected to one side of the second material gas separator; and the return pipeline is arranged above the second material gas separator. According to the closed gas flow conveying device for the battery-grade lithium hydroxide, a completely closed mode is adopted for conveying a battery-grade lithium hydroxide material; nitrogen gas which does not contain carbon dioxide and water is taken as a conveying medium for conveying a product from one process tothe other process; and the battery-grade lithium hydroxide material is prevented from reacting with the carbon dioxide and the water in the air, so that the product quality is ensured.

Owner:SHANDONG ZHANGQIU BLOWER

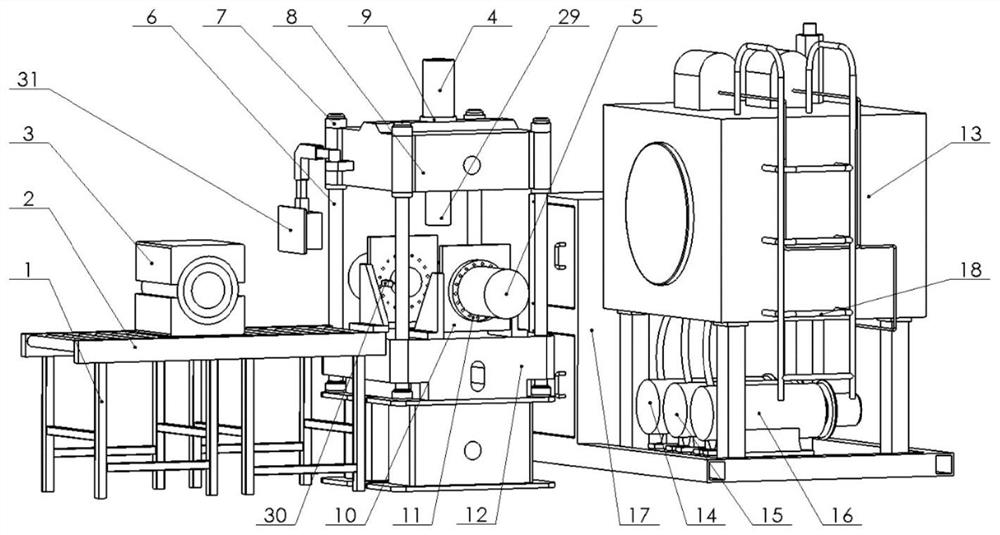

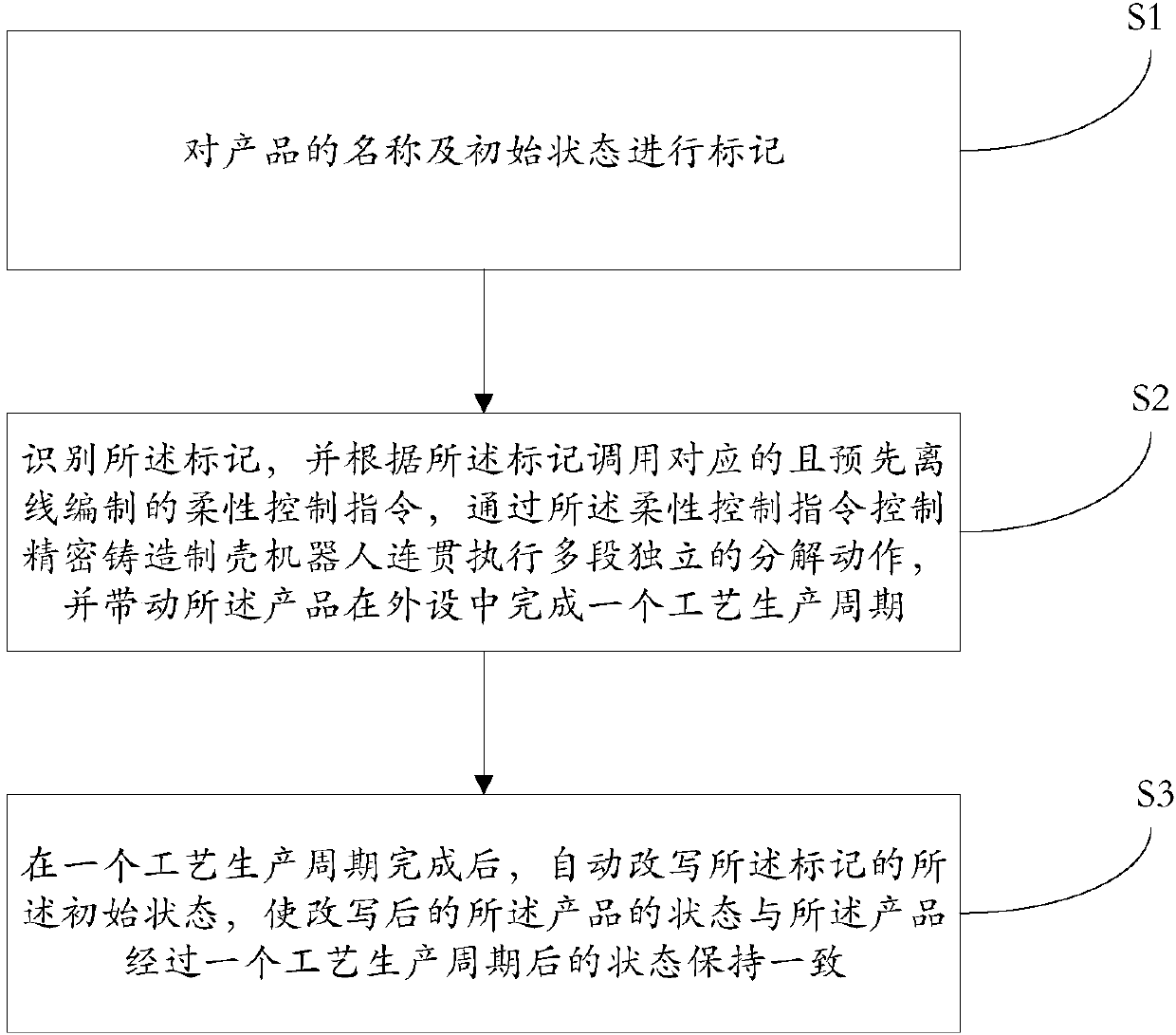

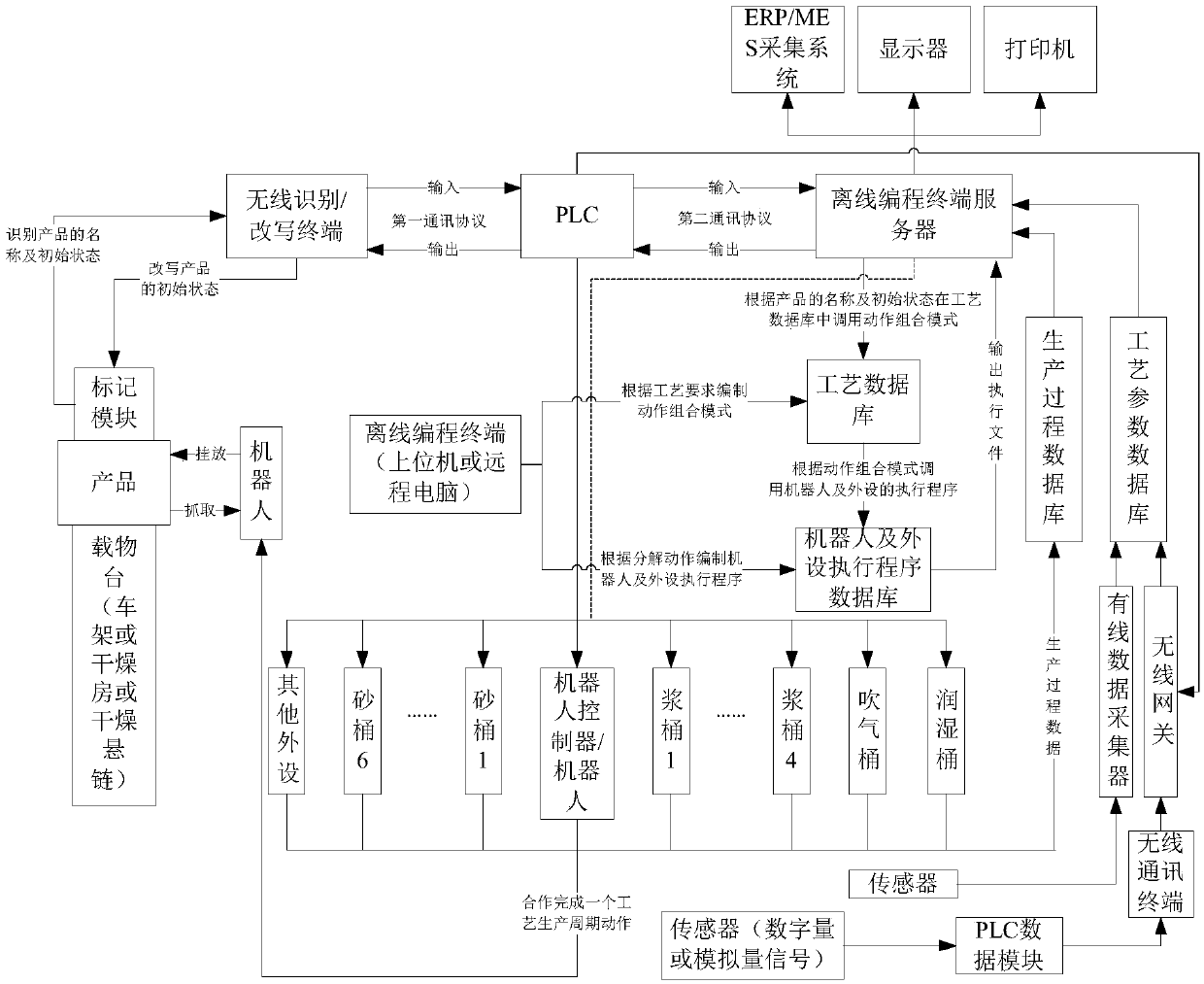

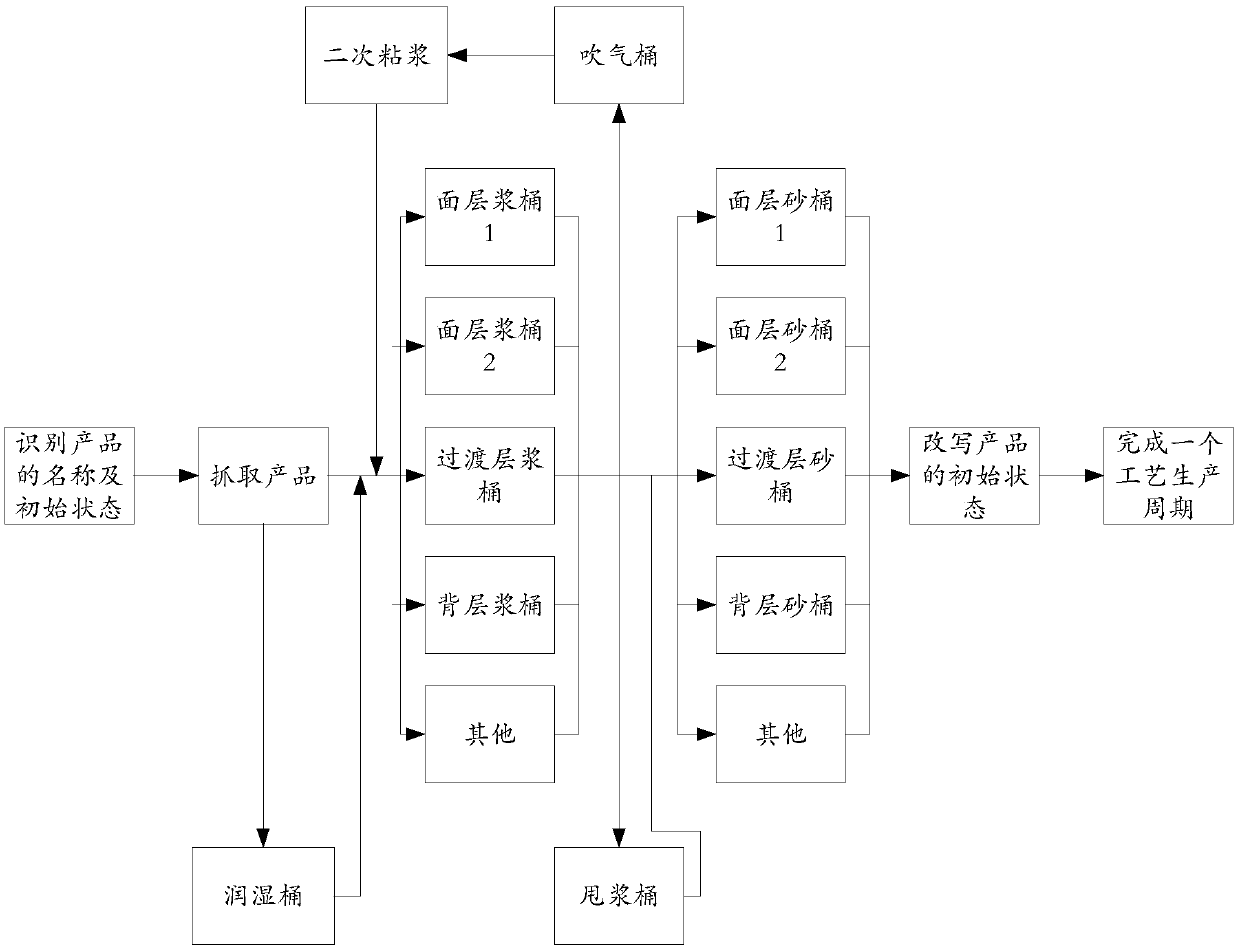

Flexible intelligent control method and system for precision shell casting robot

ActiveCN107774929ARealization of offline programmingImprove flexibilityProgramme-controlled manipulatorMoulding machinesComputer scienceIntelligent control

The invention relates to a flexible intelligent control method and system for a precision shell casting robot. The method includes steps: marking a product name and an original state; recognizing markers, calling corresponding off-line pre-compiled flexible control instructions according to the markers, controlling the precision shell casting robot to continuously execute multiple independent segment actions according to the flexible control instructions, and driving products to finish a process production cycle peripherally; after a process production cycle is completed, and automatically rewriting the product original state in the markers to keep the rewritten product state uniform with the product state after the process production cycle. By control of the precision shell casting robotfor continuously executing multiple independent segment actions according to the flexible control instructions, product process flexibility is realized, and application of one precision shell castingrobot to small-batch production of various products can be realized.

Owner:WUHAN ZONKING METAL PRODS

Semiconductor failure analysis structure and formation method, method of detecting failure time

ActiveCN103187403BImprove accuracyIncrease resistanceSemiconductor/solid-state device testing/measurementIndividual semiconductor device testingElectrical resistance and conductanceFailure analysis

The invention provides a semiconductor failure analysis structure, a forming method of the semiconductor failure analysis structure and a failure time detection method thereof. The semiconductor failure analysis structure comprises a semiconductor substrate, a metal layer to be tested, a first metal layer, a second metal layer, a first conductive plug, a plurality of first resistance metal layers, a plurality of second resistance metal layers, a plurality of second conductive plugs and a plurality of third conductive metal layers. The semiconductor substrate is provided with an area to be tested, a first serial area and a second serial area. The metal layer to be tested, the first metal layer and the second metal layer are placed on the semiconductor substrate. The first conductive plug placed in an interlayer dielectric layer enables the first metal layer, the second metal layer and the metal layer to be tested to be connected in series. The plurality of first resistance metal layers are arranged in the first serial area. The plurality of second resistance metal layers are arranged in the second serial area. The plurality of second conductive plugs are placed in the interlayer dielectric layer of the first serial area. The plurality of third conductive metal layers are arranged in the interlayer dielectric layer of the second serial area. The first conductive plug, the second conductive plugs and the third conductive plugs enable the metal layer to be tested, the first metal layer, the second metal layer, the plurality of first resistance metal layers and the plurality of second resistance metal layers to be sequentially connected in series.

Owner:SEMICON MFG INT (SHANGHAI) CORP

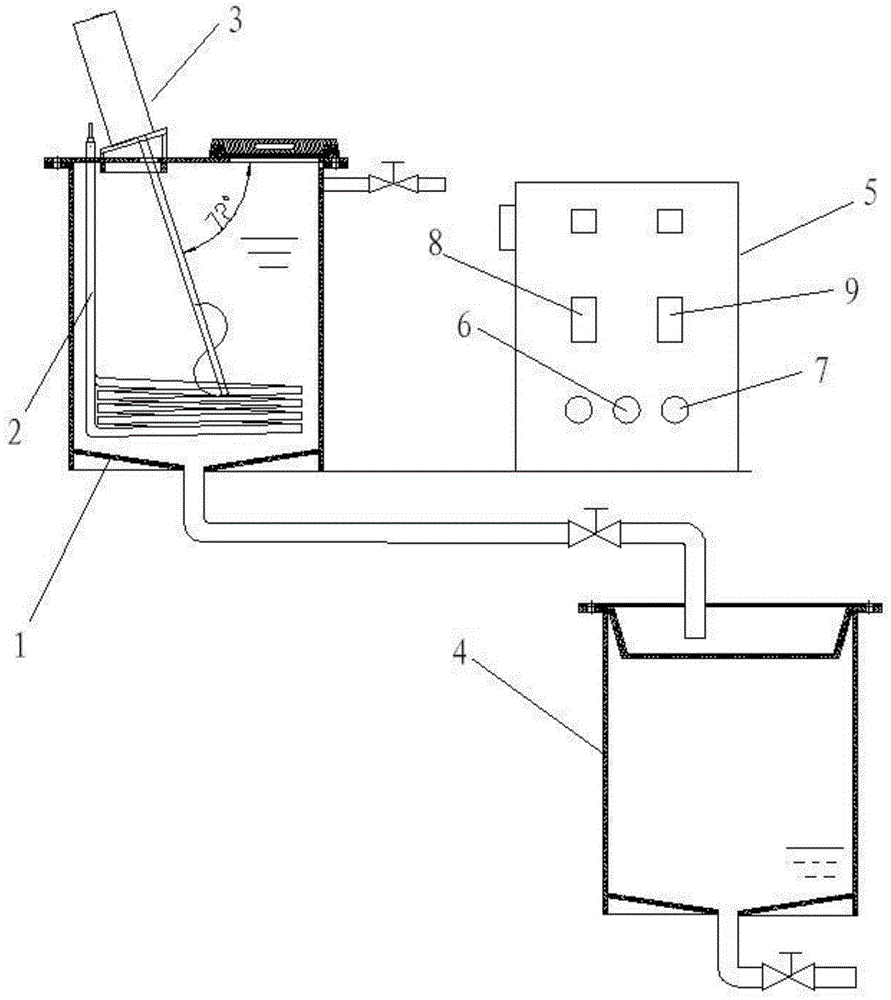

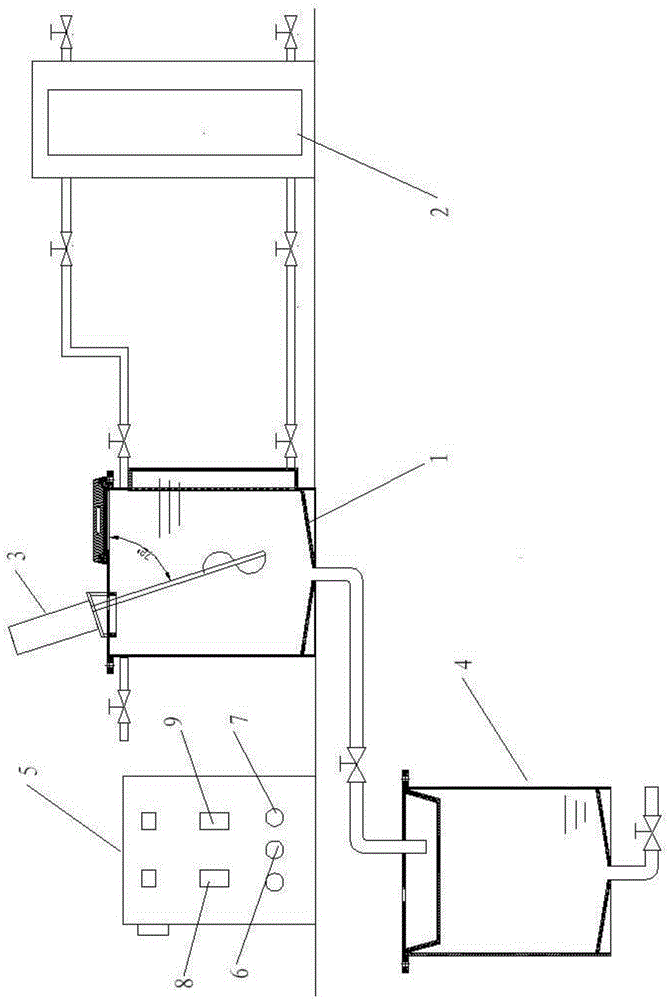

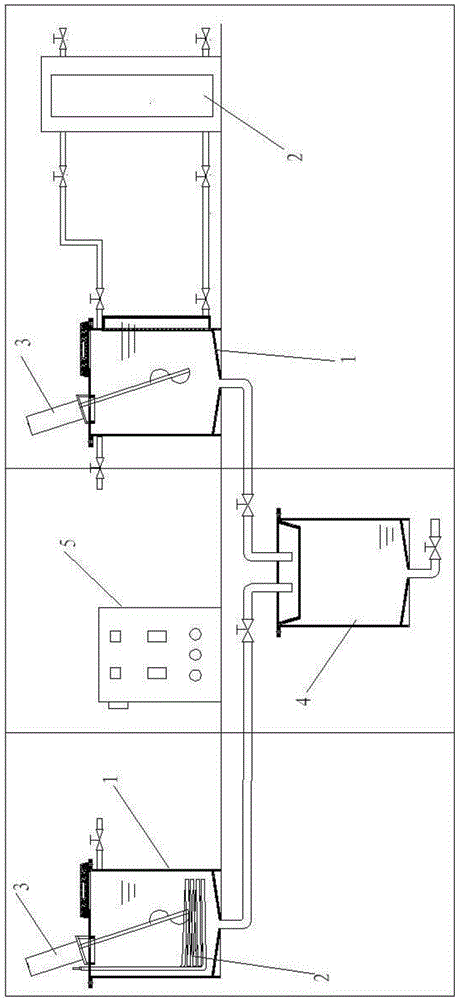

Acid leaching equipment for high-silica glass fiber

The invention discloses acid leaching equipment for high-silica glass fiber. According to the acid leaching equipment, the technical problems that high-silica glass fiber products produced by virtue of acid leaching in a traditional semi-automatic or manual process in the prior art cannot meet requirements, and the acid leaching production process of glass fiber cottons such as alkali glass fiber cottons cannot be smoothly and efficiently finished by virtue of existing equipment are solved. According to the adopted technical scheme, the acid leaching equipment comprises an acid reaction bucket, a heater, a stirrer and a filter bucket. According to the acid leaching equipment, a suspension liquid mixture, added in the acid reaction bucket, of acid and glass fiber cottons or chopped fibers is heated to a high temperature not higher than 100 DEG C and is continuously stirred to enable glass fibers to be in adequate contact with acid liquid to generate chemical reaction, the acid liquid automatically flows from a high liquid level into the filter bucket to be filtered, and then the acid liquid and the glass fibers are separated, thereby finishing the acid leaching production process of the high-silica glass fibers.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

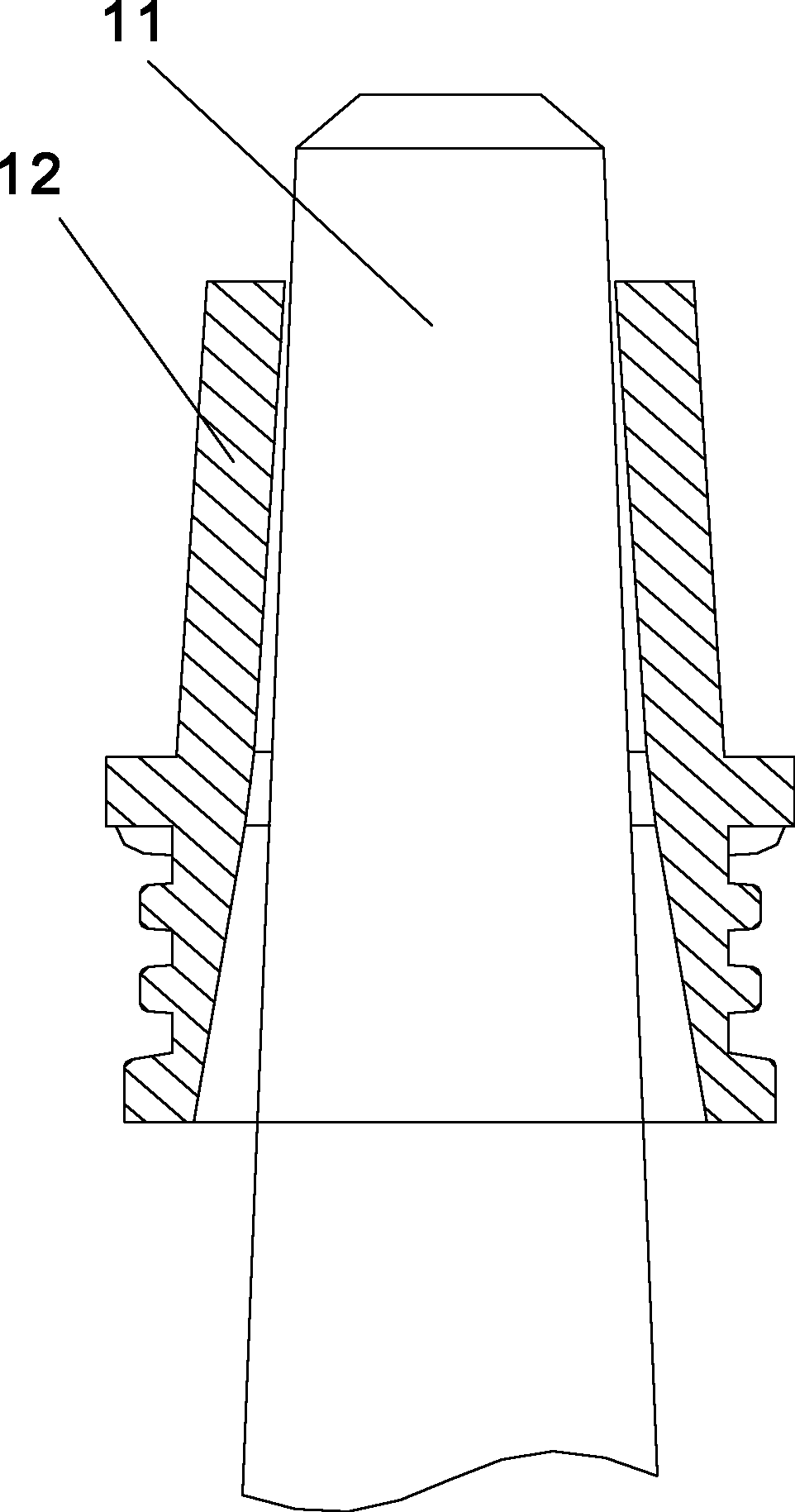

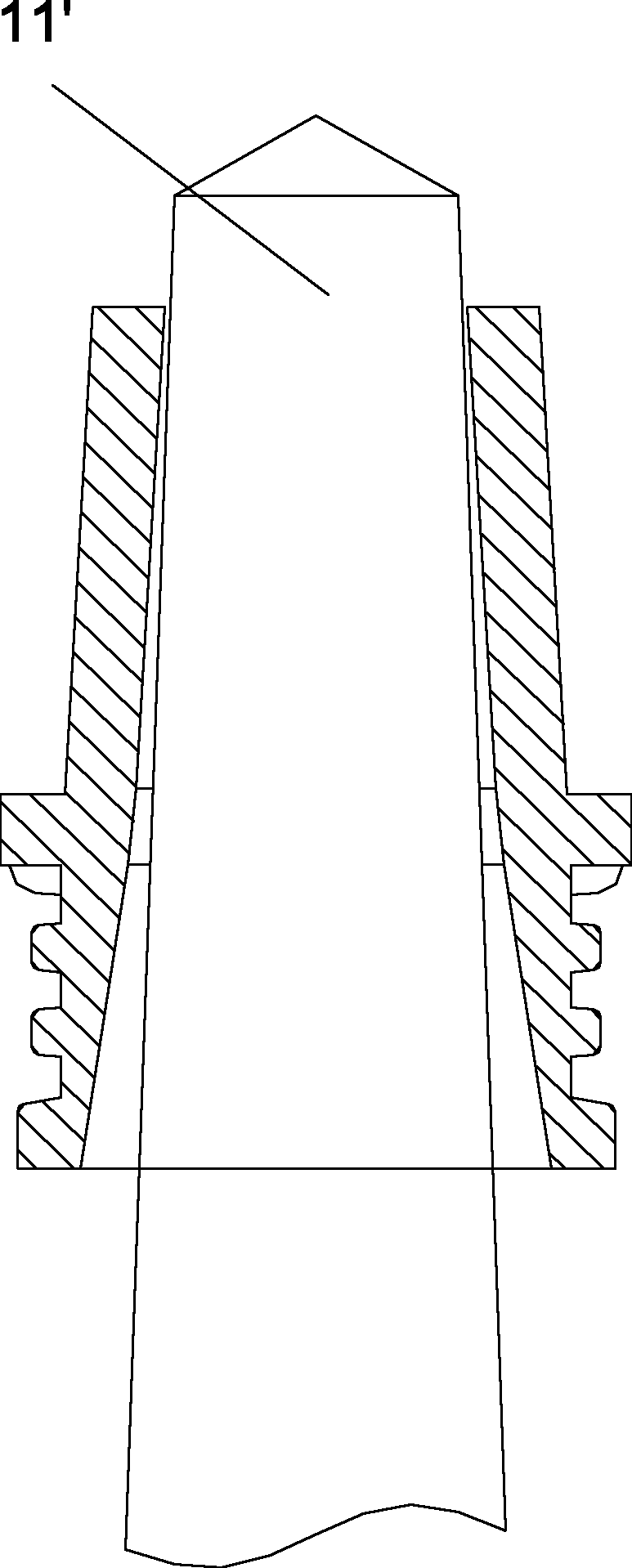

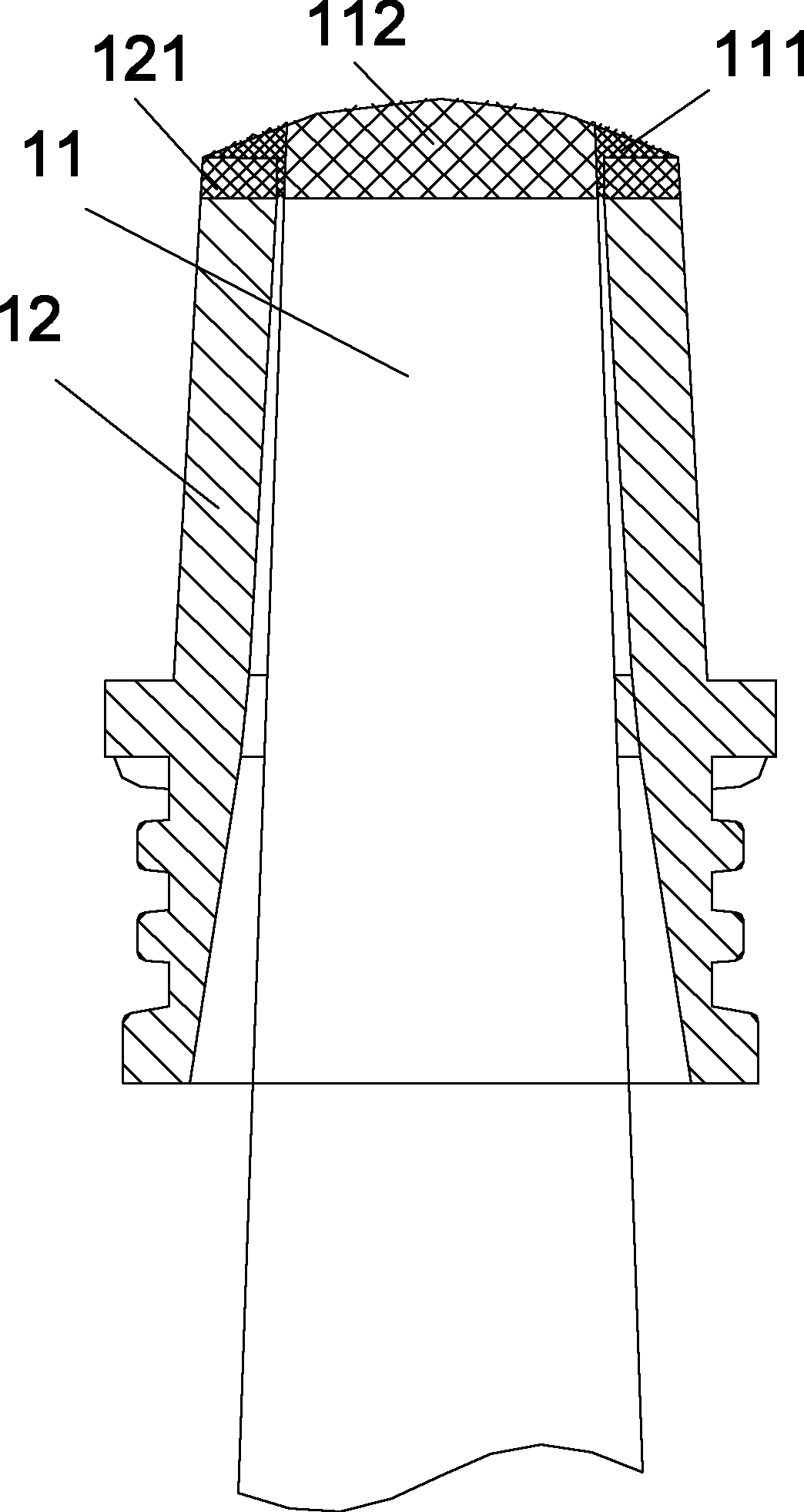

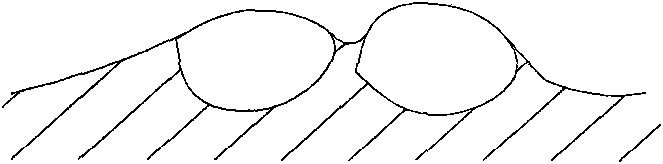

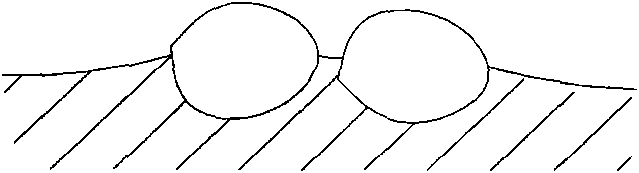

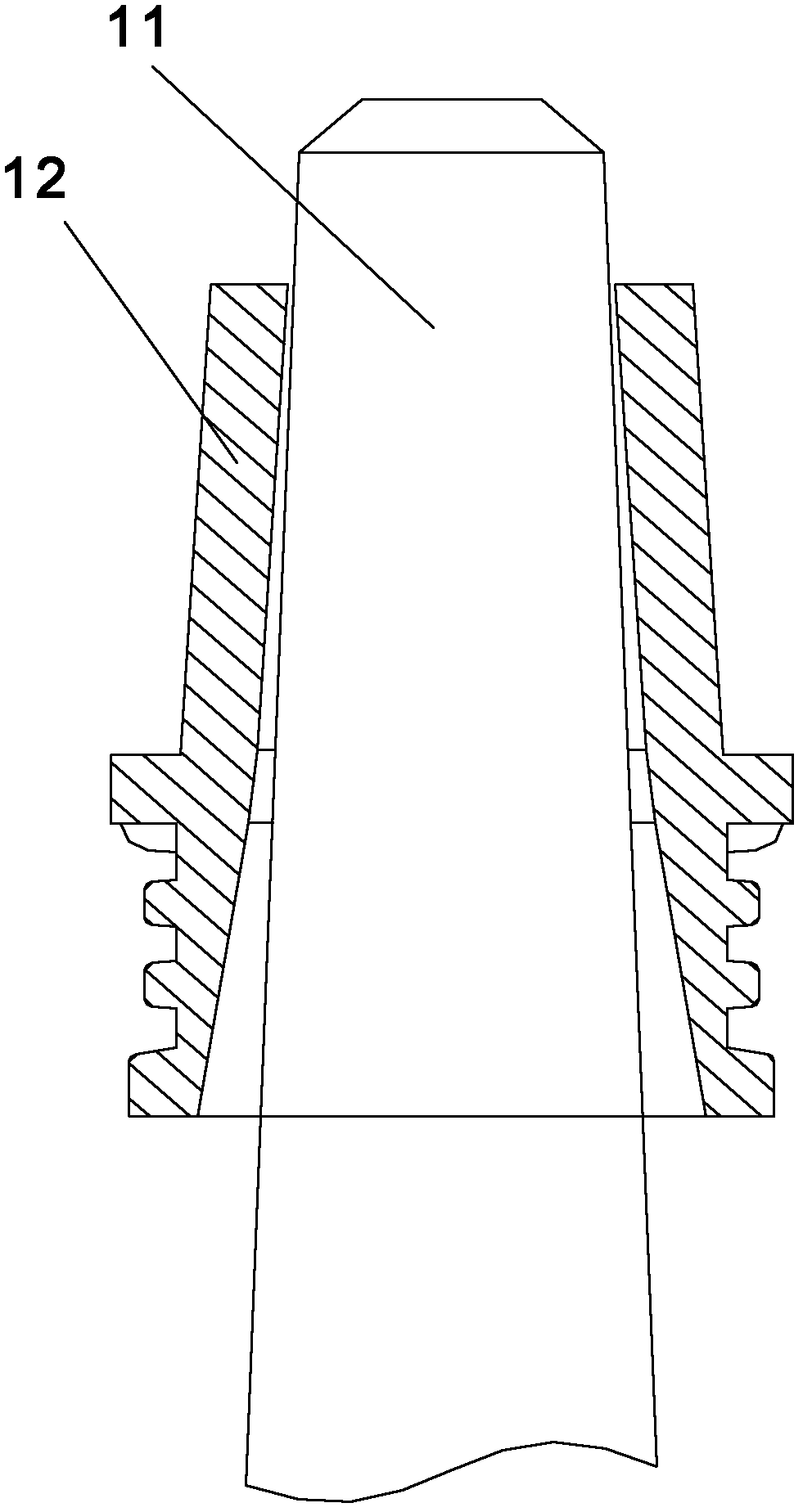

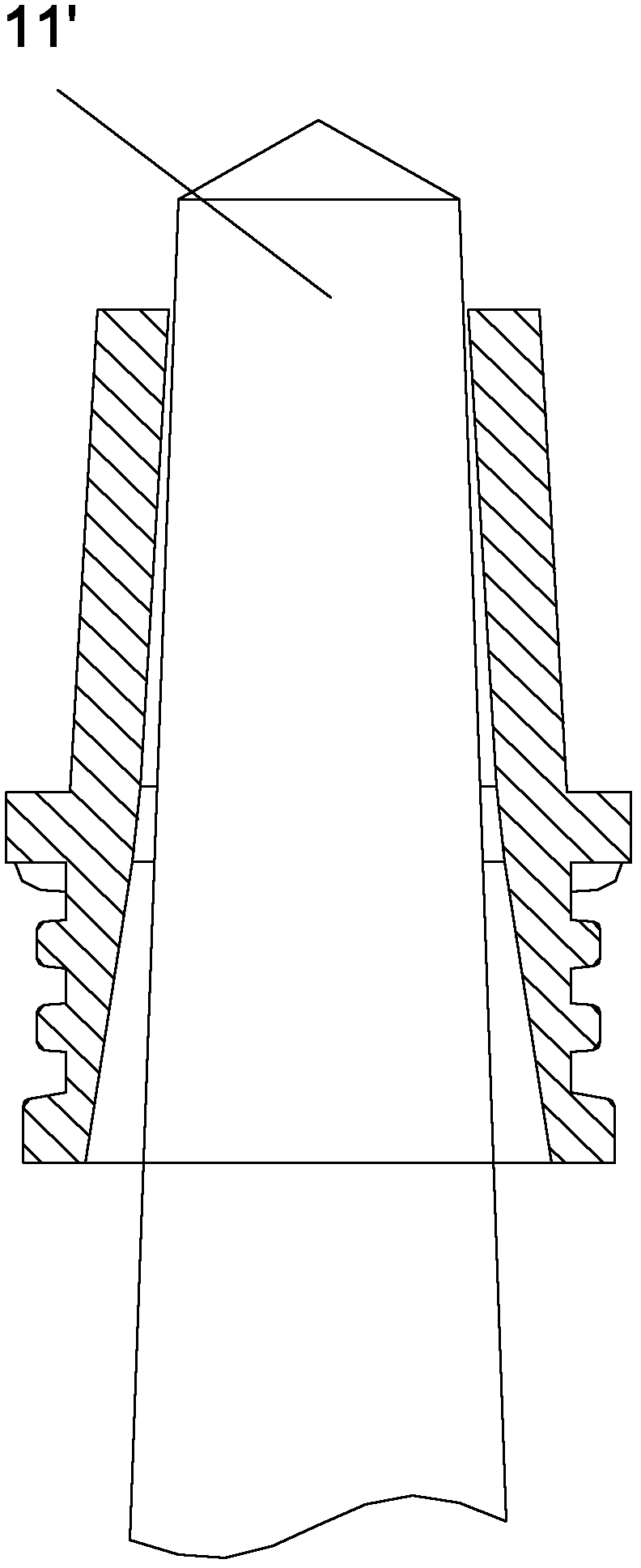

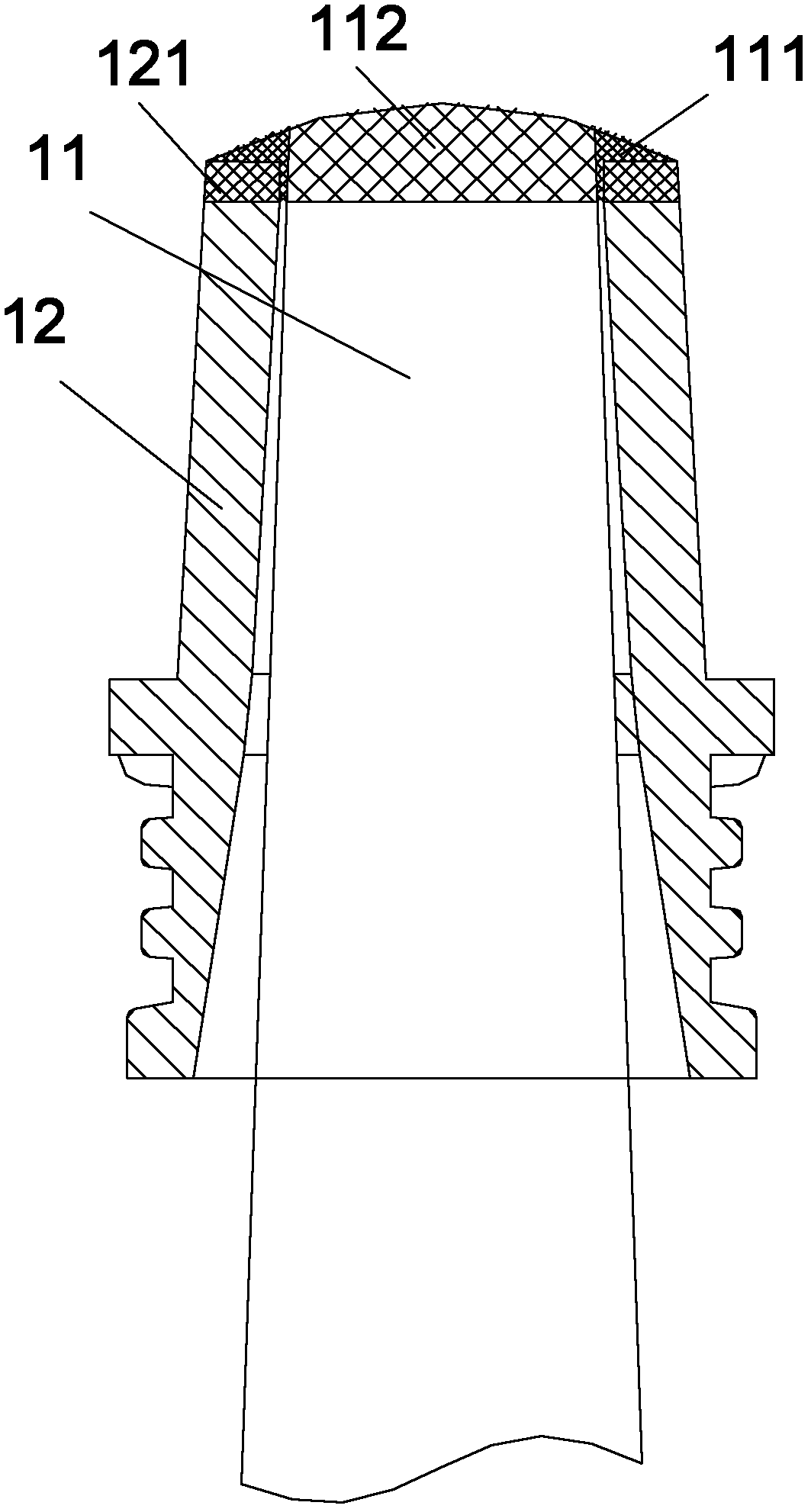

Polar post and lead bushing structure and fusion welding method as well as storage battery employing structure

ActiveCN102610784BIncrease the welding areaMeet different process requirementsCell component detailsEngineeringFusion welding

The invention relates to a polar post and lead bushing structure and a fusion welding method as well as a storage battery employing the structure. The polar post and lead bushing structure comprises a lead bushing, a polar post and fusion welding bodies formed by welding the polar post, wherein the polar post and a bushing hole of the lead bushing are in clearance fit, a fusion welding end of the polar post penetrates out from the bushing hole, an inner hole wall at the upper end of the bushing hole and an outer peripheral face of the polar post form a fusion welding groove with an upper opening in an enclosure manner, and the fusion welding bodies are distributed on the surface of the polar post, the surface of the lead bushing and the interior of the fusion welding groove so as to connecting the polar post and the lead bushing into a whole through fusion welding. According to the invention, the fusion welding groove is arranged between the outer peripheral face of the polar post and the inner hole wall at the upper end of the bushing hole of the lead bushing, and flowing fusant produced during fusion welding of the polar post flows into the fusion welding groove to increase the fusion welding area between the polar post and the lead bushing. Upon differences in the depth and size of the fusion welding grooves, the finally formed fusion welding areas are different, so that an operator can design the depth and size of the fusion welding groove according to the needs of a practical situation so as to meet different technological requirements.

Owner:ANHUI LEOCH BATTERY TECH

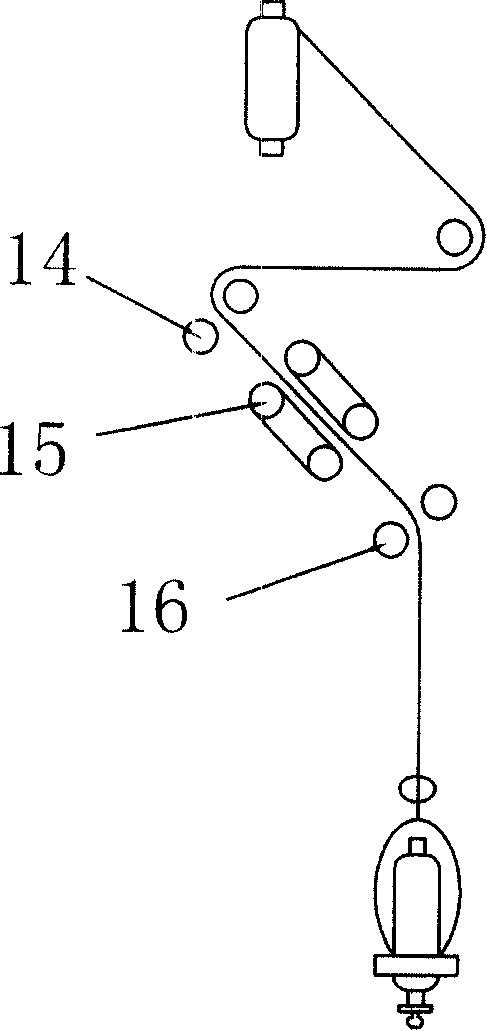

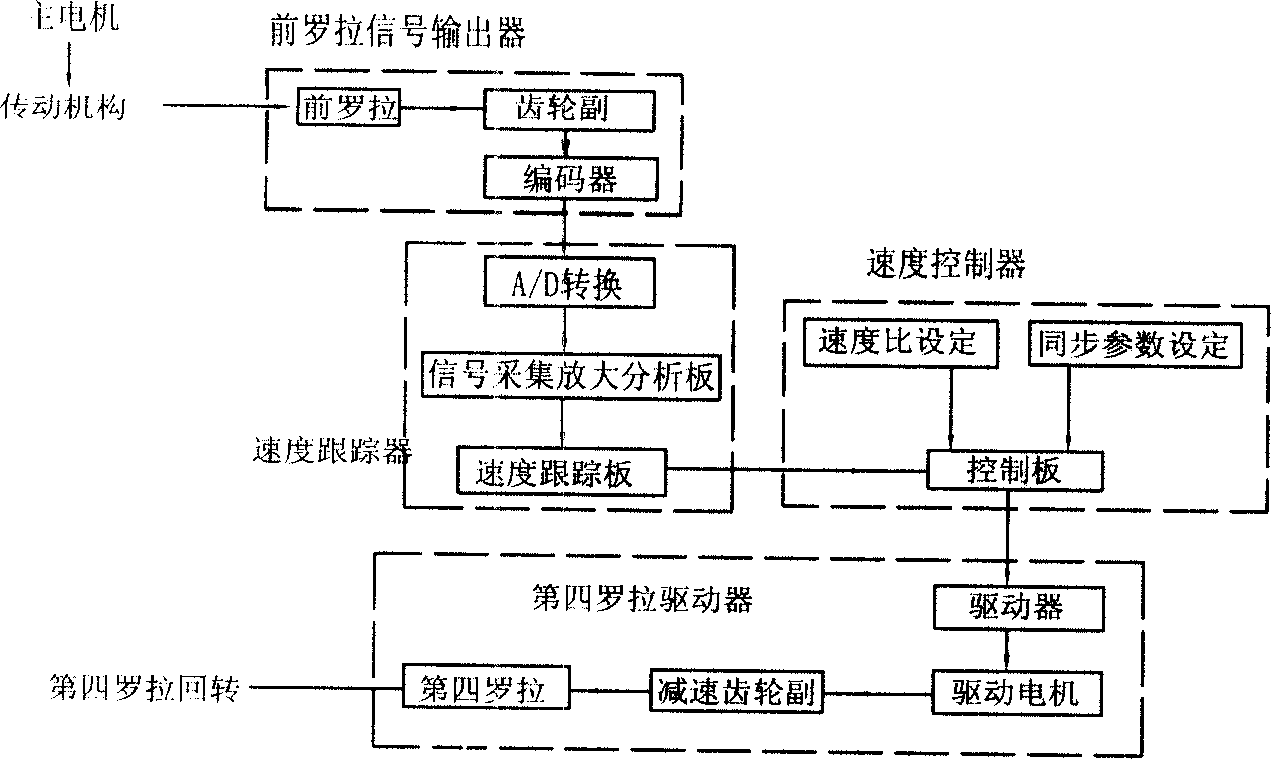

Fourth roller speed automatic regulating device

InactiveCN101161882AAutomatically adjust operating speedAuto track running speedContinuous wound-up machinesFiber bundleEngineering

The present invention discloses an automatic fourth-roller speed regulating device, mainly comprising a front roller signal follower, a fourth-roller driver and an automatic fourth-roller speed regulator, wherein, the front roller signal follower converts the rotation signals of a front roller into angle analog signals; the automatic fourth-roller speed regulator receives the angle analog signals, sends out instructions and controls the fourth-roller driver to move. A fourth roller is provided between the front roller and a jaw, increasing a new space, and a fully elongated fiber bundle can be sorted out and processed in the new space, for instance, changing the width of the fiber bundle, adding filaments in and having the speed of the fourth roller automatically track the running speed of the front roller through the automatic regulator. The present invention can be used for the agglomeration process of fiber strand and so on. The moving speed of the fourth roller is regulated according to technological requirements, contrasted with the front roller to reach different speed ratio, so as to meet various technological requirements.

Owner:JEEONE PRINTING & DYEING MACHINERY

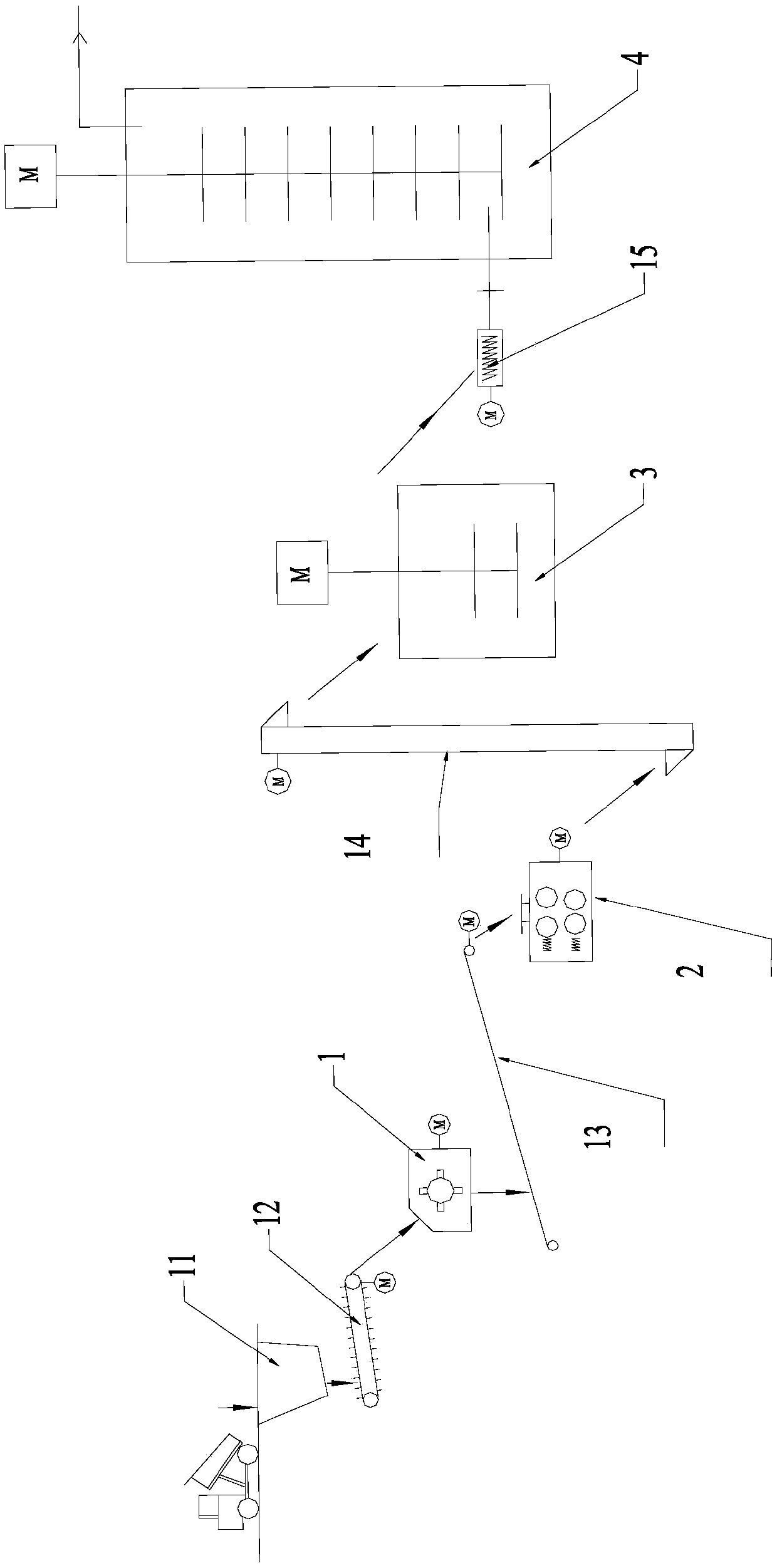

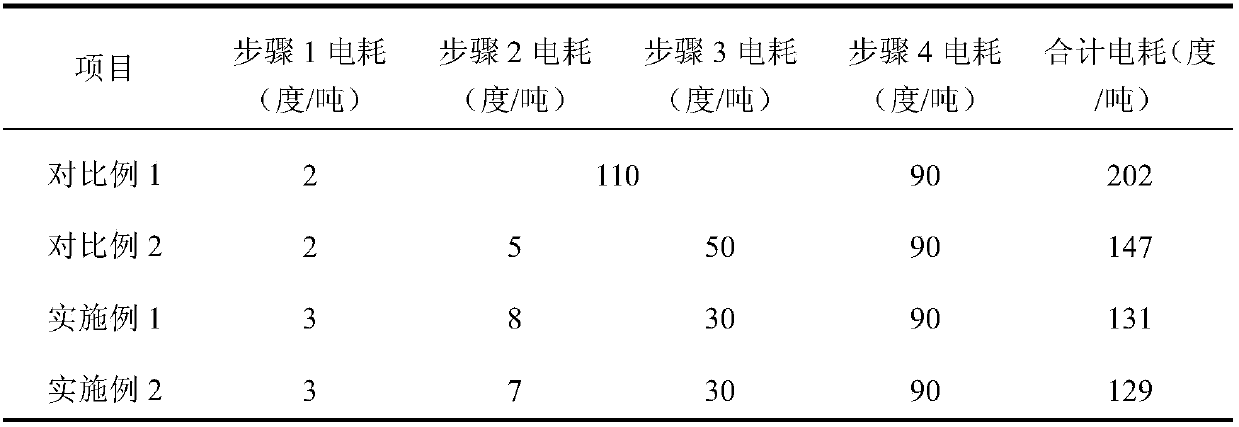

Ultra-fine kaolin four-stage powder making equipment and ultra-fine kaolin and four-stage powder making production process of ultra-fine kaolin

ActiveCN109569845AReduce energy consumptionReduce manufacturing costSilicon compoundsGrain treatmentsSolid particleUltra fine

The invention discloses ultra-fine kaolin four-stage powder making equipment and ultra-fine kaolin and a four-stage powder making production process of the ultra-fine kaolin. The ultra-fine kaolin four-stage powder making equipment comprises a first crushing device, a second crushing device, a first wet grinding device and a second wet grinding device, wherein the first crushing device is used forenabling the crude ore to be subjected to coarse crushing through a dry method to form at least 90% coarse materials with the particle diameter less than 30mm;; the second crushing device is arrangedat the output end of the coarse material of the first crushing device and used for enabling the coarse materials to be subjected to fine crushing through the dry method to form at least 90% of solidparticles with particle diameter of less than 1 mm; the first wet grinding device is arranged at the output end of the solid particles of the second crushing device and used for enabling the solid particles to be subjected to coarse grinding through a wet method to form at least 90% of slurry with particle diameter less than 325 meshes; and the second wet grinding device is arranged at the outputend of the slurry of the first wet grinding device and used for enabling the slurry to be subjected to fine grinding through the wet method to form at least 90% of ultra-fine slurry with particle diameter less than 2[mu]m. The ultra-fine kaolin four-stage powder making equipment follows the principle of 'crushing is in preference to grinding, wet grinding is in preference to dry grinding', and thus production efficiency is improved and energy consumption is reduced.

Owner:内蒙古超牌新材料股份有限公司

Electroplating additive for diamond grinding tool

The invention relates to the field of electroplating additives, and discloses an electroplating additive for a diamond grinding tool. The additive comprises three groups of mixtures, namely a mixtureA comprising pyridine internal salt, diol substituted ether, pentyne carbonyl ether and unsaturated alkyl pyridine internal salt, a mixture B comprising unsaturated carbonyl pyridine internal salt, quaternized carboxylic acid internal salt, alkynyl sodium sulfonate, phosphorus sulfur phenone formyl-imine and aromatic diethyl amine sulfoacid condensed polymer, and a mixture C which is polyoxythyl phenol sodium sulfate solution. The grinding force of the diamond grinding tool made of the electroplating additive provided by the invention through electrofacing is greatly strengthened; compared with the conventional additive, the service life is improved by 20-30%; and the electroplating additive has great economic benefit for various machining industries widely applying diamond electroplatingproducts.

Owner:SHENZHEN CHANGXING TECH

Polar post and lead bushing structure and fusion welding method as well as storage battery employing structure

ActiveCN102610784AIncrease the welding areaMeet different process requirementsCell component detailsEngineeringFusion welding

The invention relates to a polar post and lead bushing structure and a fusion welding method as well as a storage battery employing the structure. The polar post and lead bushing structure comprises a lead bushing, a polar post and fusion welding bodies formed by welding the polar post, wherein the polar post and a bushing hole of the lead bushing are in clearance fit, a fusion welding end of the polar post penetrates out from the bushing hole, an inner hole wall at the upper end of the bushing hole and an outer peripheral face of the polar post form a fusion welding groove with an upper opening in an enclosure manner, and the fusion welding bodies are distributed on the surface of the polar post, the surface of the lead bushing and the interior of the fusion welding groove so as to connecting the polar post and the lead bushing into a whole through fusion welding. According to the invention, the fusion welding groove is arranged between the outer peripheral face of the polar post and the inner hole wall at the upper end of the bushing hole of the lead bushing, and flowing fusant produced during fusion welding of the polar post flows into the fusion welding groove to increase the fusion welding area between the polar post and the lead bushing. Upon differences in the depth and size of the fusion welding grooves, the finally formed fusion welding areas are different, so that an operator can design the depth and size of the fusion welding groove according to the needs of a practical situation so as to meet different technological requirements.

Owner:ANHUI LEOCH BATTERY TECH

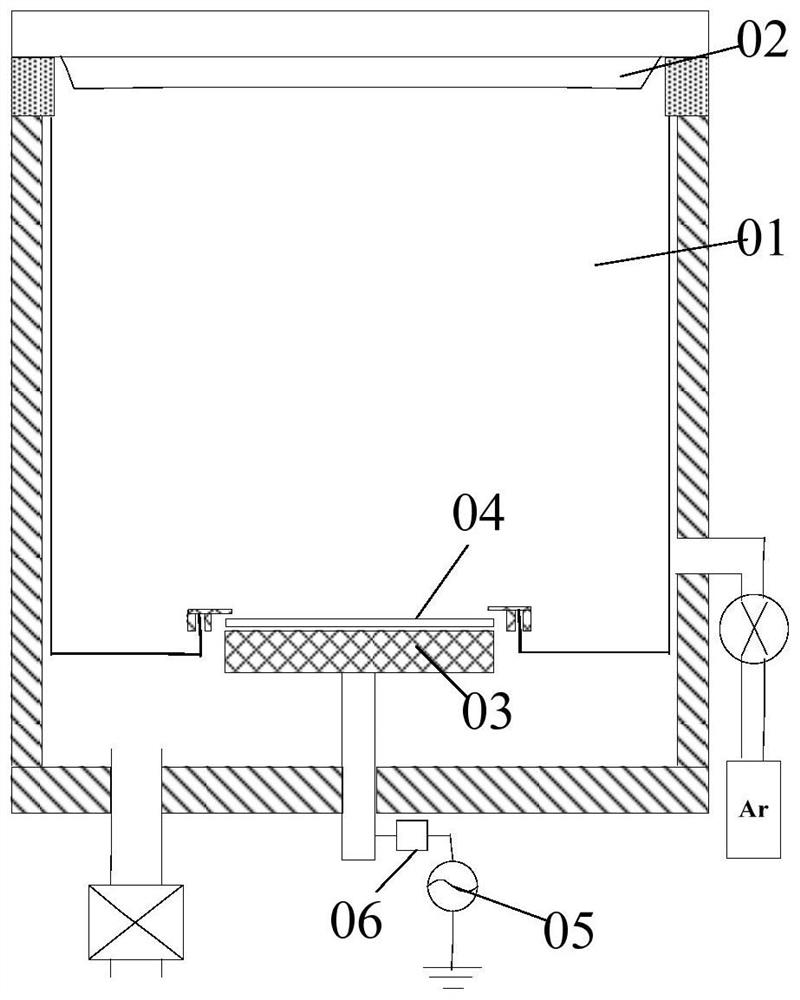

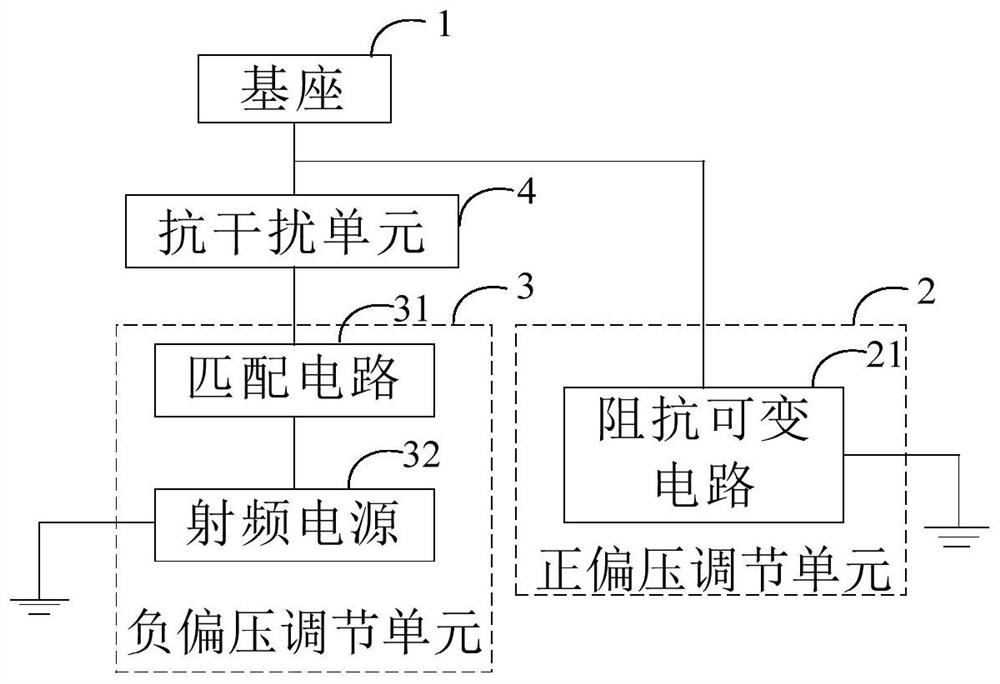

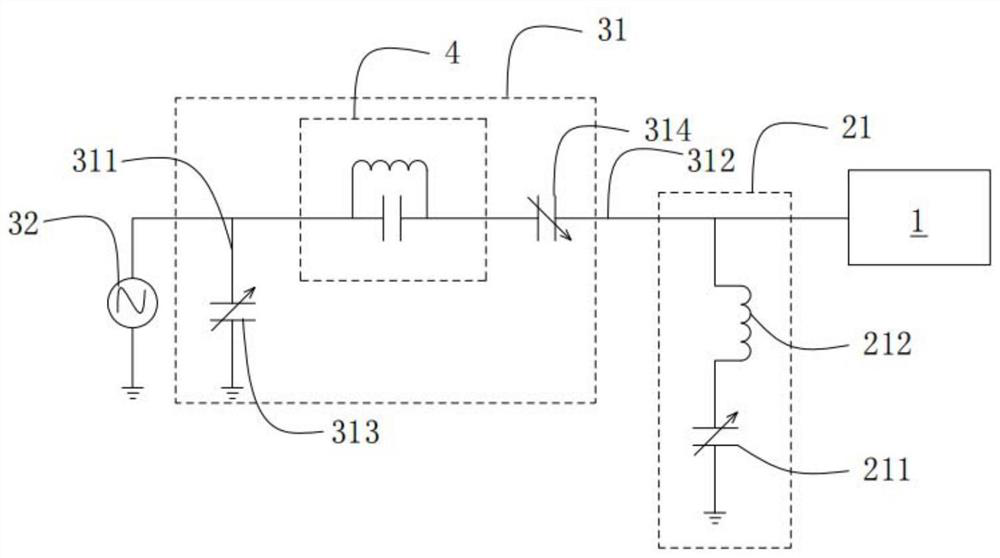

Base bias voltage adjusting device and method and semiconductor process equipment

ActiveCN113604788ALarge adjustment rangeTo achieve simultaneous useVacuum evaporation coatingSemiconductor/solid-state device manufacturingProcess equipmentElectrical connection

The invention provides a base bias voltage adjusting device and method and semiconductor process equipment. The device comprises a positive bias voltage adjusting unit, a negative bias voltage adjusting unit and an anti-interference unit, wherein the first end of the positive bias voltage adjusting unit is grounded, the second end of the positive bias voltage adjusting unit is electrically connected with a base, the positive bias voltage adjusting unit is used for adjusting the bias voltage of the base, and the base can generate positive bias voltage; the first end of the negative bias voltage adjusting unit is grounded, the second end of the negative bias voltage adjusting unit is electrically connected with the base, and the negative bias voltage adjusting unit is used for adjusting bias voltage of the base, and the base can generate negative bias voltage; and the anti-interference unit is connected to a circuit between the negative bias voltage adjusting unit and the base and used for inhibiting current in a circuit between the positive bias voltage adjusting unit and the base from flowing into the circuit between the negative bias voltage adjusting unit and the base. According to the technical scheme of the base bias voltage adjusting device and method and the semiconductor process equipment provided by the invention, different process requirements can be met, so that a process window is expanded.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com