Polar post and lead bushing structure and fusion welding method as well as storage battery employing structure

A pole and welding technology, applied to structural parts, battery pack parts, circuits, etc., can solve the problems of poor welding quality, difficult inspection, small welding area, etc., to improve battery quality and life, prevent melting phenomenon, and ensure The effect of weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

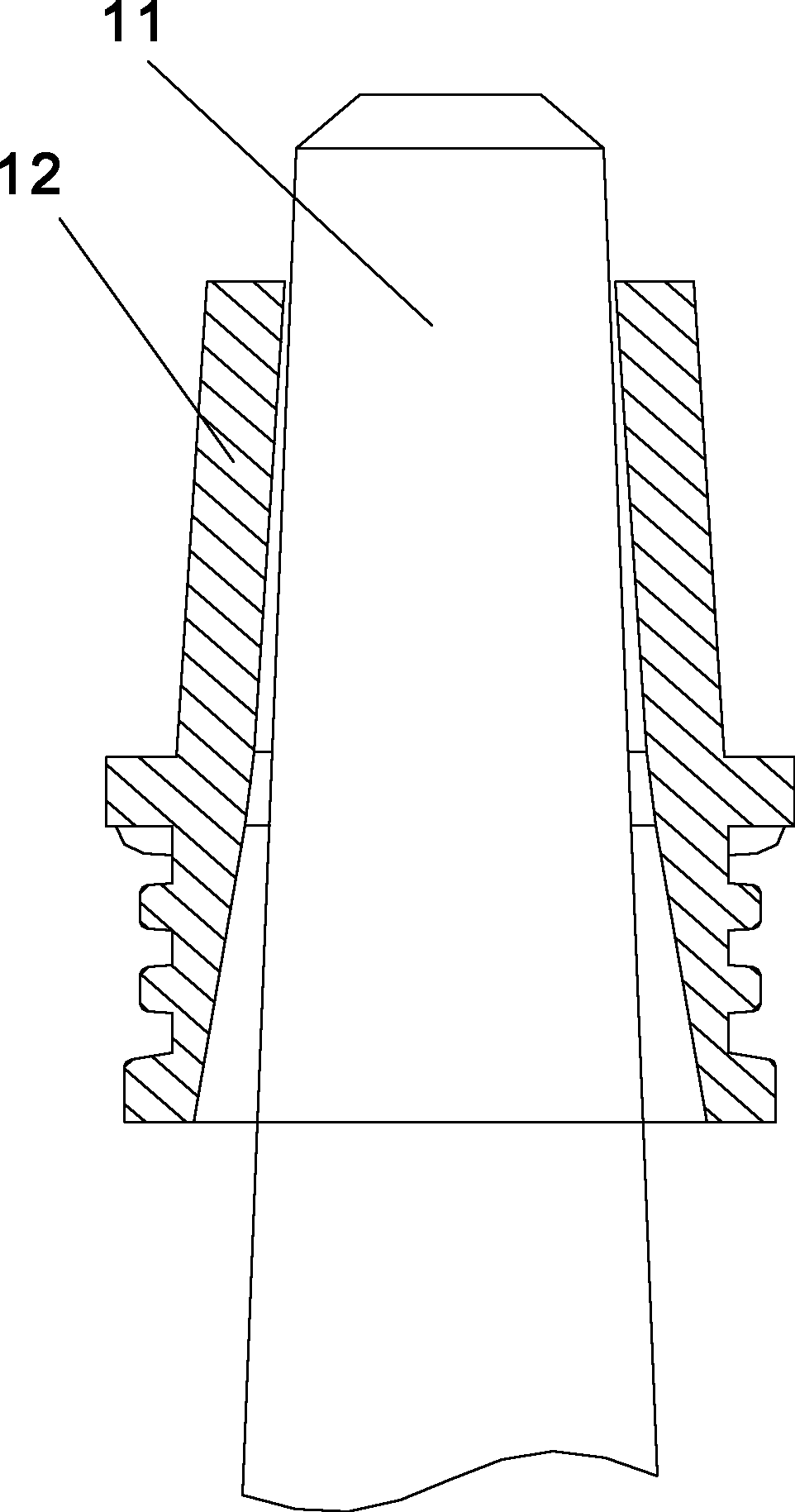

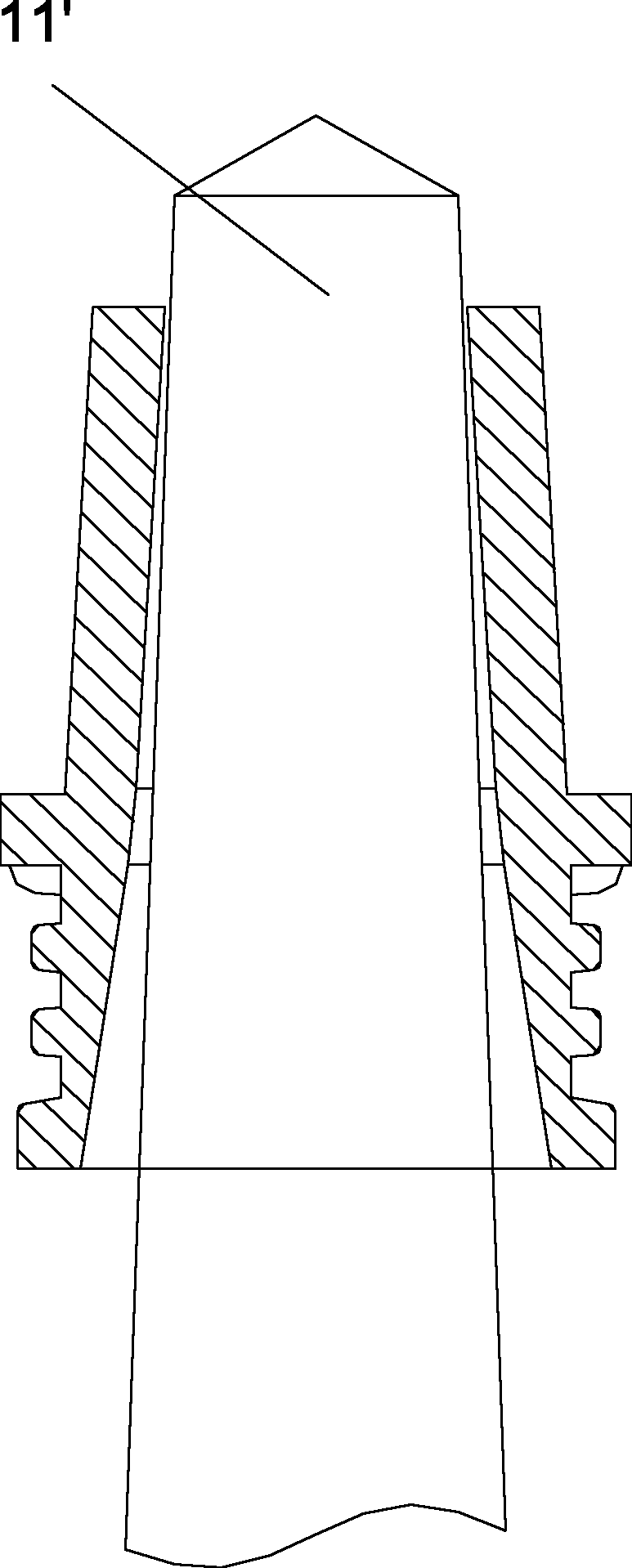

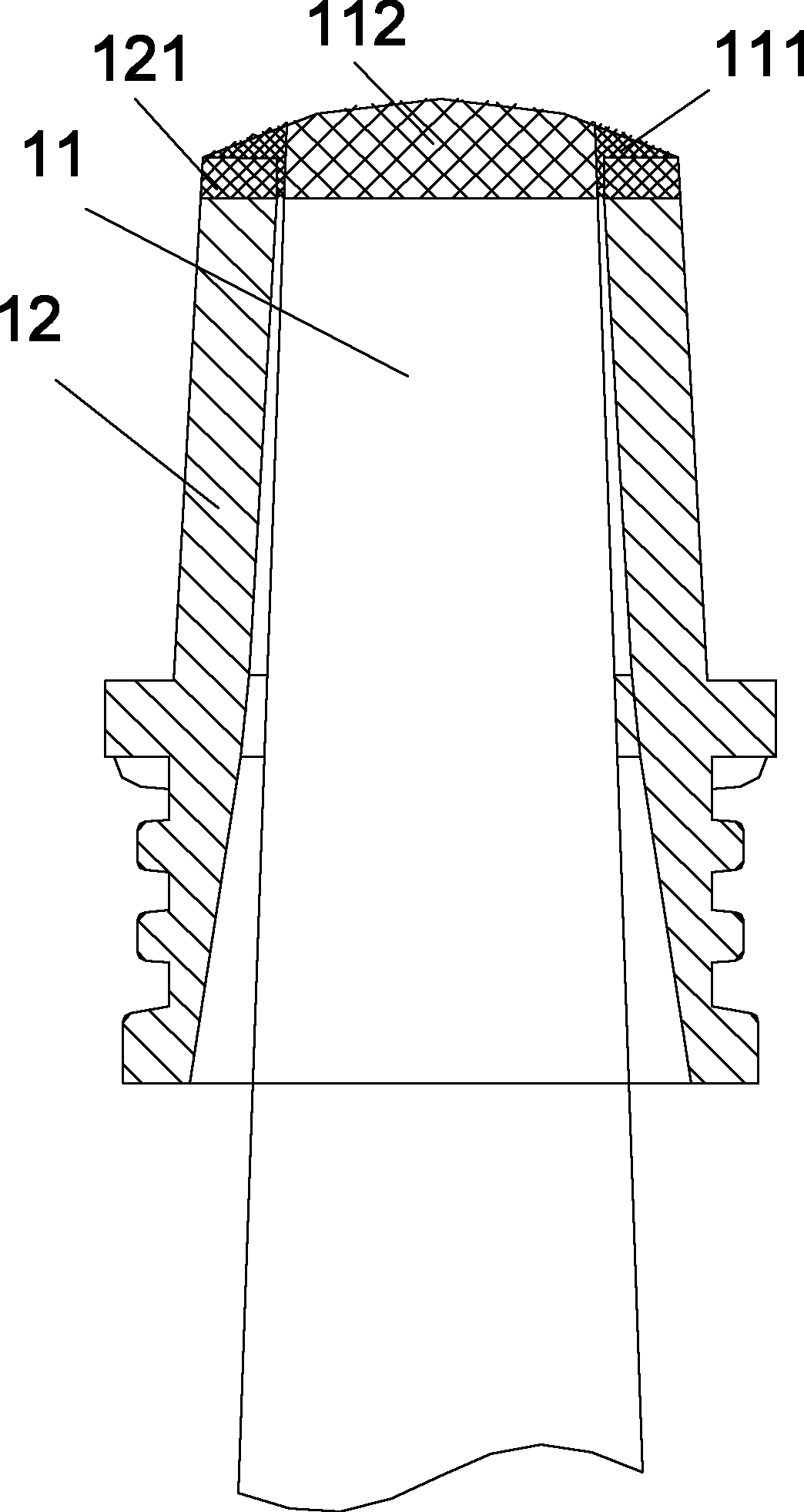

[0031] In an embodiment of the present application, a structure of a pole and a lead sleeve includes a lead sleeve, a pole, and a welded body formed by welding the pole. The gap between the pole and the hole of the lead sleeve is matched to facilitate the assembly of the pole and the lead sleeve, but the matching gap is small, usually about 0.2mm, to prevent lead leakage during the welding process. The welding end of the pole passes through the sleeve hole, and the inner hole wall at the upper end of the sleeve hole and the outer peripheral surface of the pole surround to form a welding groove with an upper opening. The welding body is distributed on the surface of the pole, the surface of the lead sleeve and the welding groove, and welds the pole and the lead sleeve into one body.

[0032] In this example, the flowing melt produced by the welding process on the upper end of the pole is mainly distributed on the surface of the welding end of the pole, the upper surface of the ...

Embodiment 2

[0040] The application also discloses a welding method of a pole and a lead sleeve, the welding method comprising:

[0041] Step a, matching the gap between the pole and the sleeve hole of the lead sleeve, the upper end of the pole passes through the sleeve hole, and the inner hole wall at the upper end of the sleeve hole and the outer peripheral surface of the pole are enclosed to form a welding groove;

[0042] Step b, welding the pole so that the upper end of the pole forms a welded body (the welded body is defined the same as in Embodiment 1), and the welded body is distributed on the surface of the pole, the surface of the lead sleeve and the welding groove, and the pole and the lead The sleeve is welded into one and fixed.

[0043] In this example, the welding groove is arranged around the pole, and its number can be one or more. For example, the welding groove can be one or more arc-shaped grooves or square grooves arranged around the pole, or only one Set of ring groo...

Embodiment 3

[0048] The present application also discloses a pole and lead sleeve structure manufactured according to the welding method described in the third embodiment above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com