Heat exchange plate for plate heat exchanger and plate heat exchanger with same

A technology of plate heat exchanger and heat exchange plate, which is applied in the direction of heat exchange equipment, lighting and heating equipment, laminated components, etc., can solve the problems of low strength and stress concentration of heat exchangers, increase the welding area, increase Strength, effect of promoting lateral fluid distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

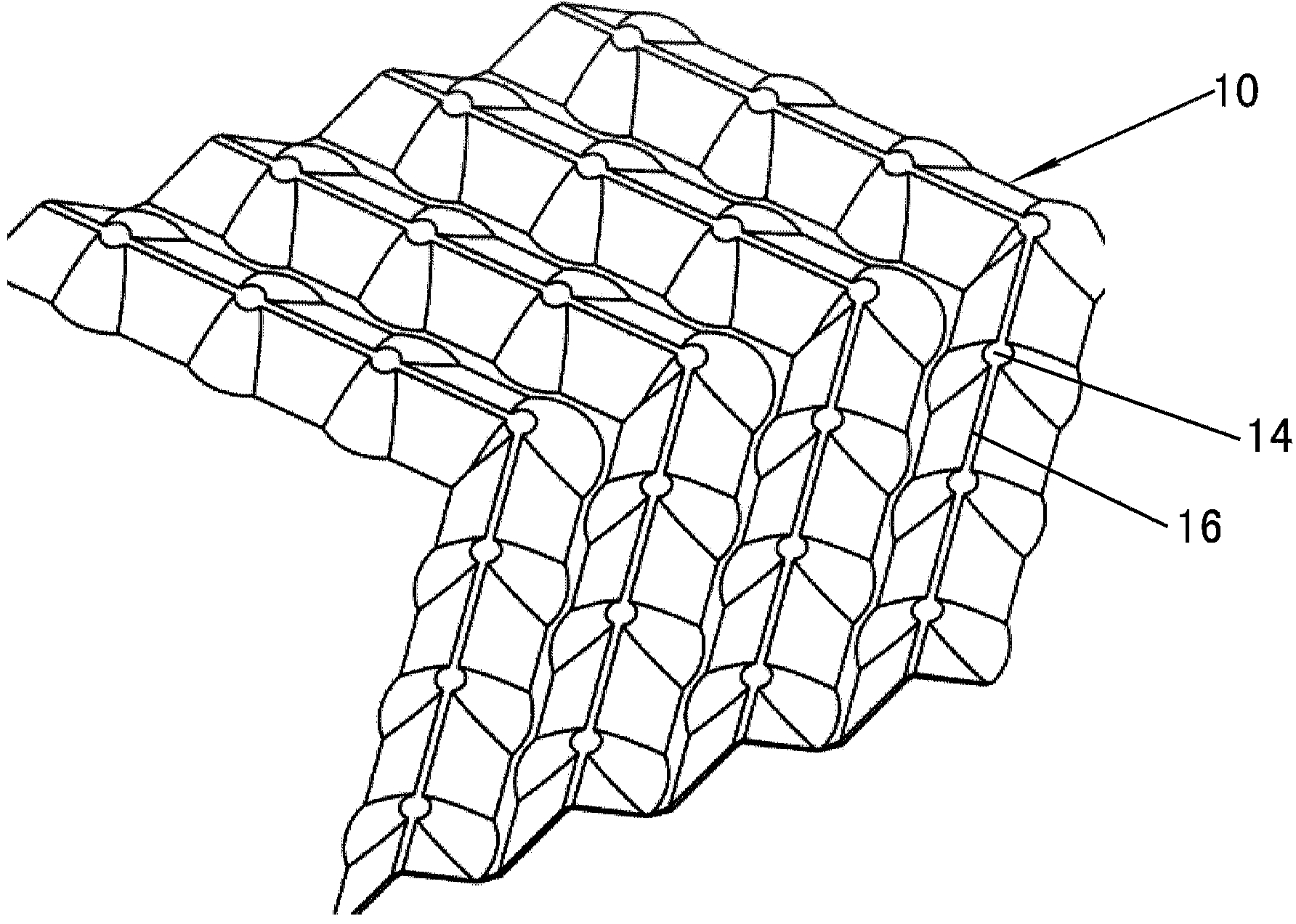

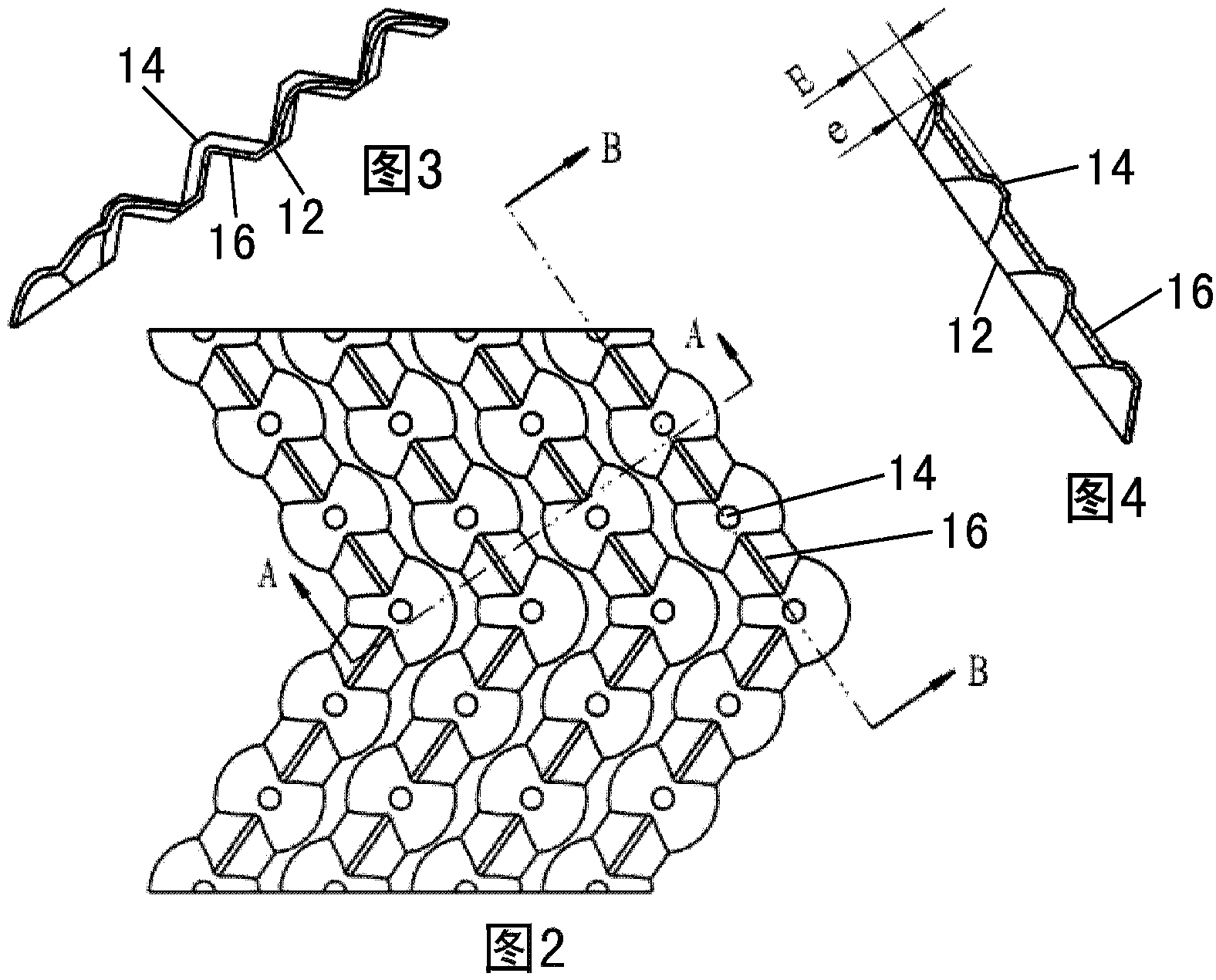

[0036] Such as Figures 1 to 4 As shown, the heat exchange plate for a plate heat exchanger according to an embodiment of the present invention includes a heat exchange portion 10 constituting a heat exchange portion of a fluid of the plate heat exchanger. The heat exchange plate also includes a plurality of protrusions 14 protruding from the plate plane 12 to one side of the plate plane 12 in the heat exchange part 10, the plurality of protrusions 14 are arranged along a plurality of lines, and a part of the plurality of protrusions 14 It can be used as a welding part or a receiving part where the heat exchange plate is welded or received with an adjacent heat exchange plate. The plurality of lines are generally arranged in a V-shape, W-shape or wave pattern or in other suitable pattern when viewed towards the plane of the panel. The plate plane 12 is the plane in which the heat exchange plate lies before it has been stamped.

[0037] Such as Figures 1 to 4 As shown, the ...

Embodiment 2

[0041] Embodiment 2 according to the present invention differs from the above embodiments in that the transition portion 16 is provided with a stepped portion.

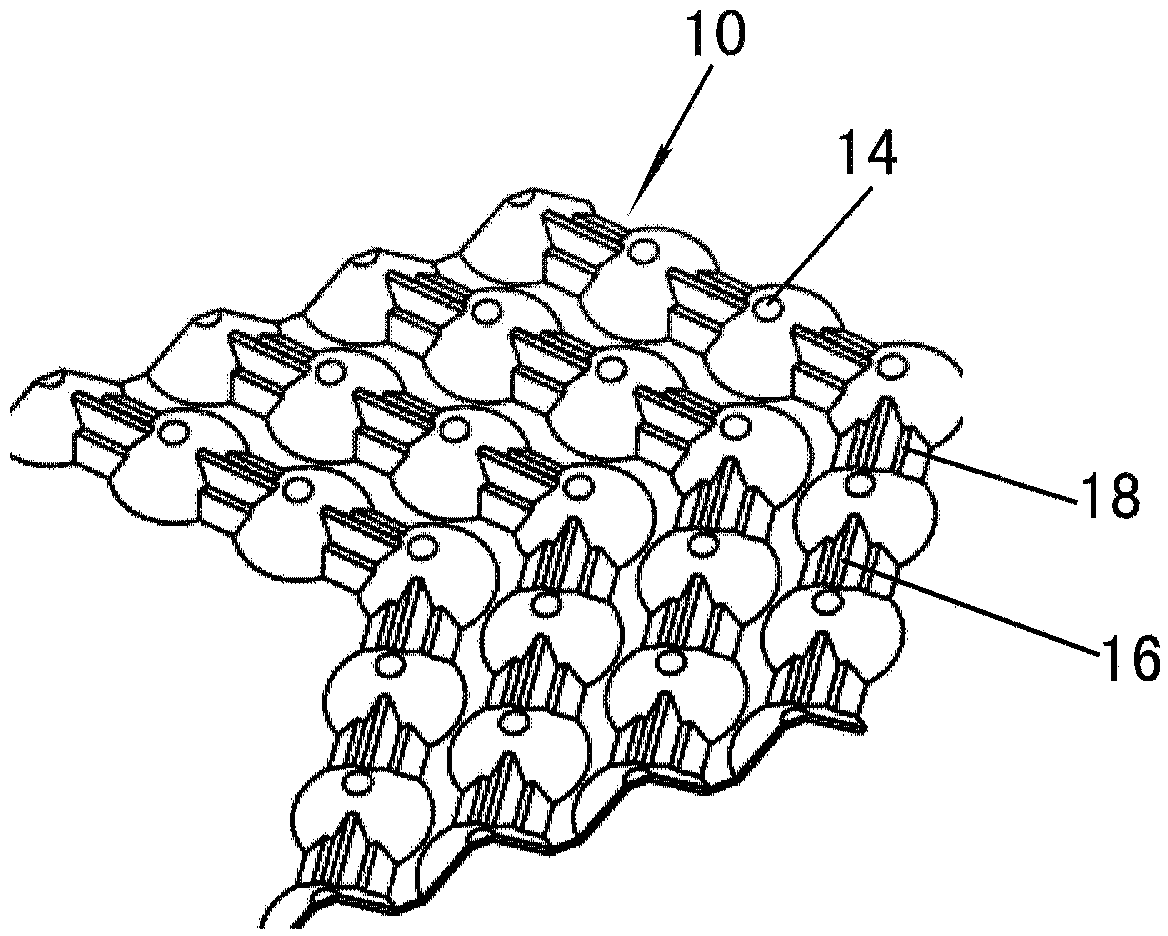

[0042] Such as Figures 5 to 8 As shown, the transition 16 has a step 18 between the top of the transition 16 and the plate plane 12 when viewed in a direction perpendicular to the line. The steps 18 are arranged on both sides of the symmetry plane of the transition part 16, so that the cross-sectional shape of the transition part 16 is roughly "convex".

[0043] Such as Figure 7 As shown, the distance E of the top of the protrusion 14 from the plate plane 12 is greater than or equal to the distance e2 of the top of the transition portion 16 from the plate plane 12 . The distance e1 of the top of the step 18 from the plate plane 12 is smaller than the distance e2 of the top of the transition portion 16 from the plate plane 12 and the distance E of the top of the protrusion 14 from the plate plane 12 .

[0044] By ...

Embodiment 3

[0046] Embodiment 3 according to the present invention differs from Embodiment 2 above in that the top of the transition portion and the top of the protrusion 14 are substantially in the same plane.

[0047] Such as Figures 9 to 12As shown, the distance E of the top of the protrusion 14 from the plate plane 12 is equal to the distance e2 of the top of the transition portion 16 from the plate plane 12 . The distance e1 of the top of the step 18 from the plate plane 12 is smaller than the distance e2 of the top of the transition portion 16 from the plate plane 12 and the distance E of the top of the protrusion 14 from the plate plane 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com