Construction method for steel bar work down electro-slag pressure welding

A technology of electroslag pressure welding and construction method, which is applied in the direction of arc welding equipment, manufacturing tools, welding equipment, etc., and can solve the problems of low carbon equivalent, low efficiency, and poor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

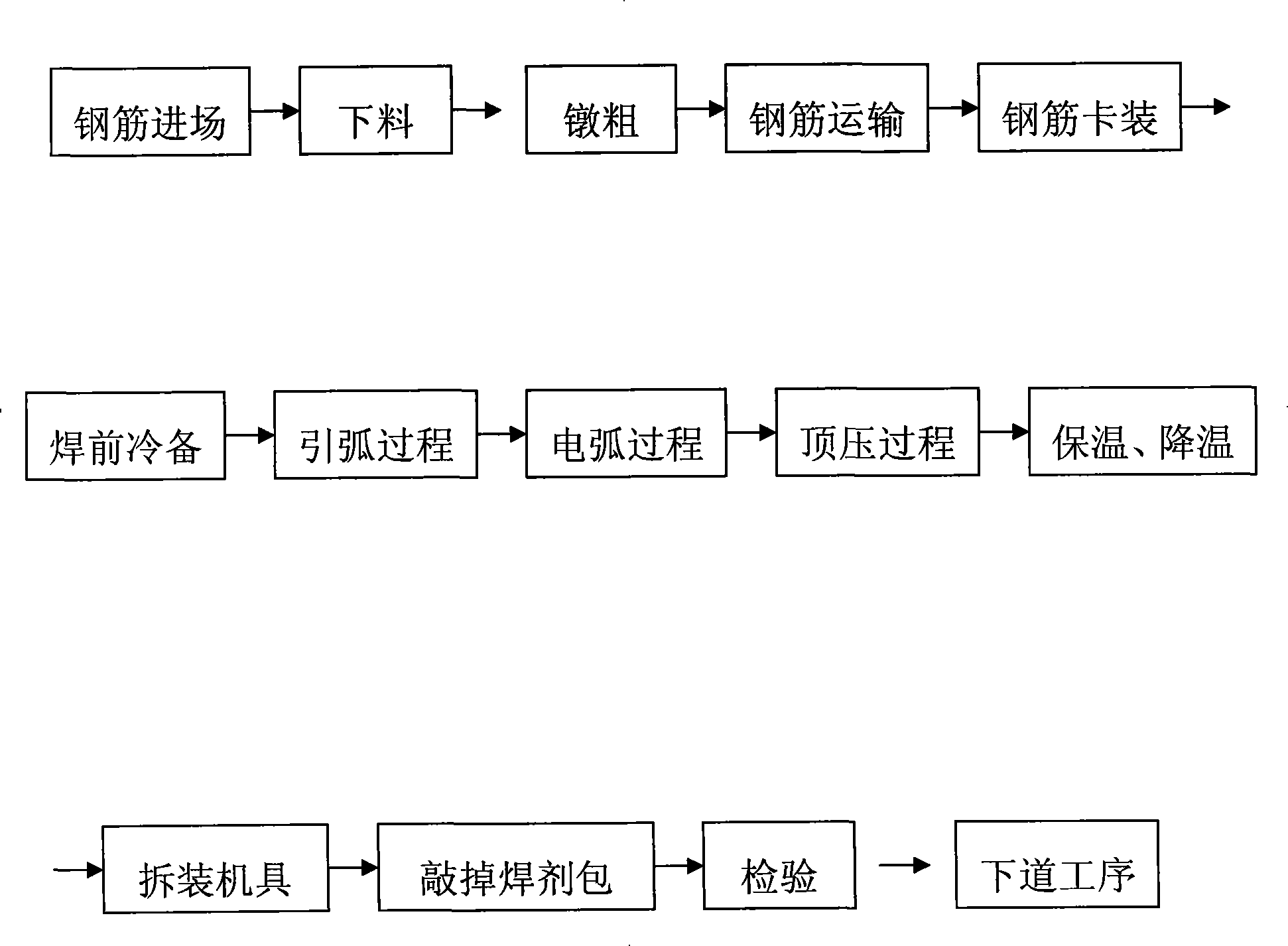

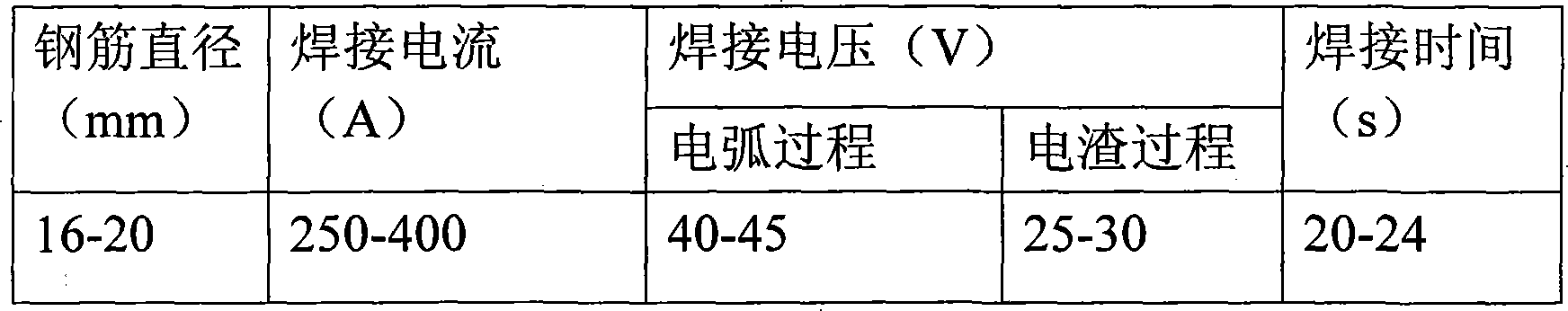

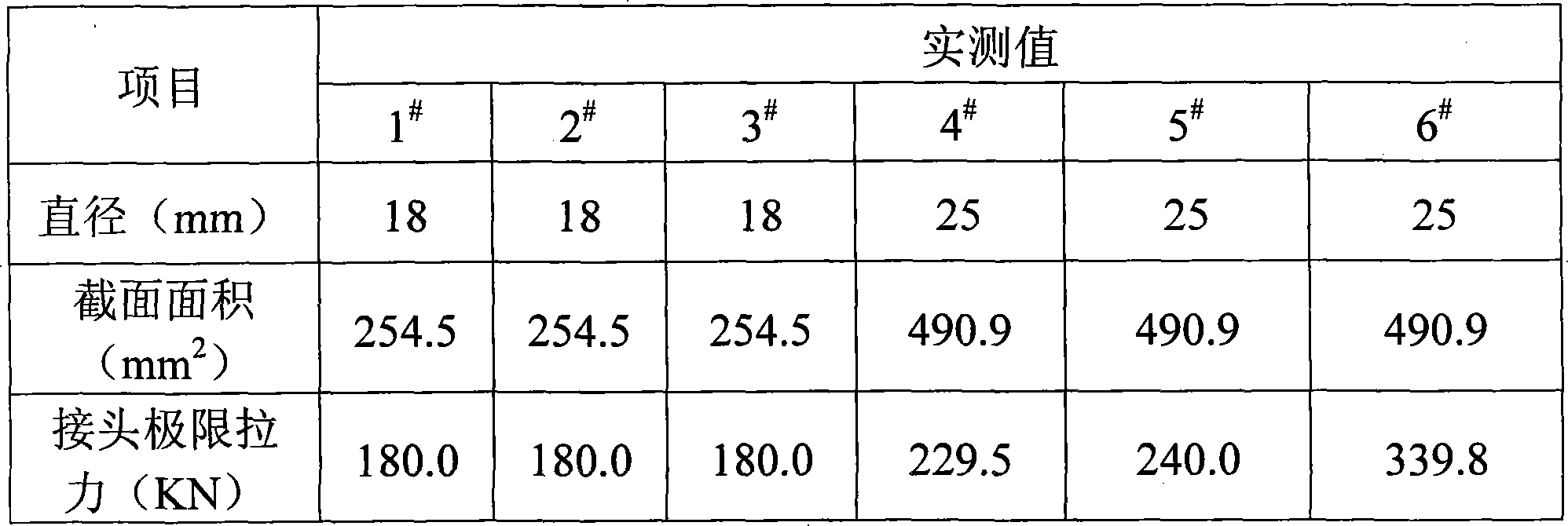

[0005] The present invention will be described in detail below in conjunction with the process flow diagram. Given by the process flow chart, the construction method of the present invention is as follows: after the steel bar enters the site and is unloaded, the end of the steel bar is upset by the upsetting machine into a welding plane, and then transported to the steel bar clamping machine, and the two welded steel bars are vertically clamped. Install it on the clamping machine so that the ends of the two steel bars are in the form of butt joint, the two ends are not connected, and they are in a disconnected state. Make preparations before welding, then turn on the power, use the AC arc welding machine to start the arc, and the arc welding machine will weld The pliers clamp the upper and lower steel bars respectively, turn on the power supply, and after applying the welding voltage to the upper and lower steel bars, quickly lift the upper steel bar so that the distance betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com