Tobacco primary processing secondary charging and water replenishing control system and method

A technology of secondary feeding and control system, applied in the field of tobacco, can solve the problem of inability to realize precise control of feeding and feeding pipeline logic switching, and achieve the effect of ensuring continuous production of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

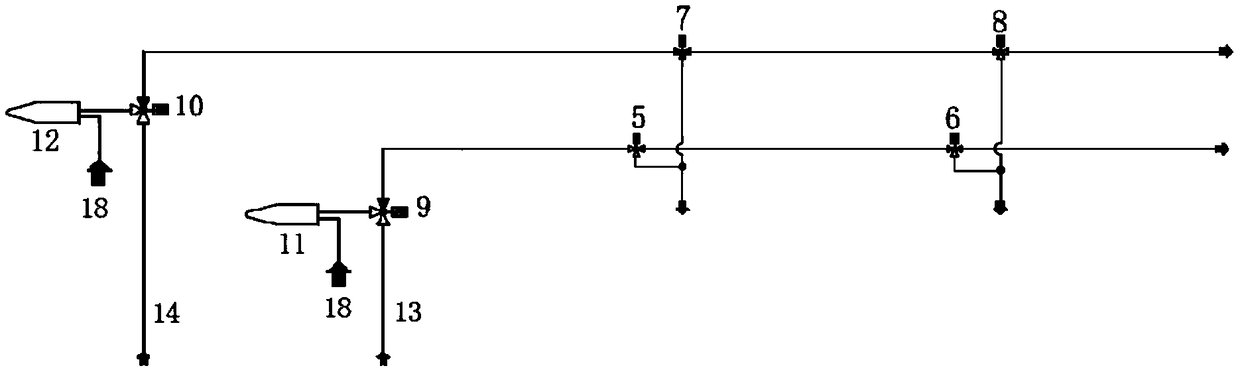

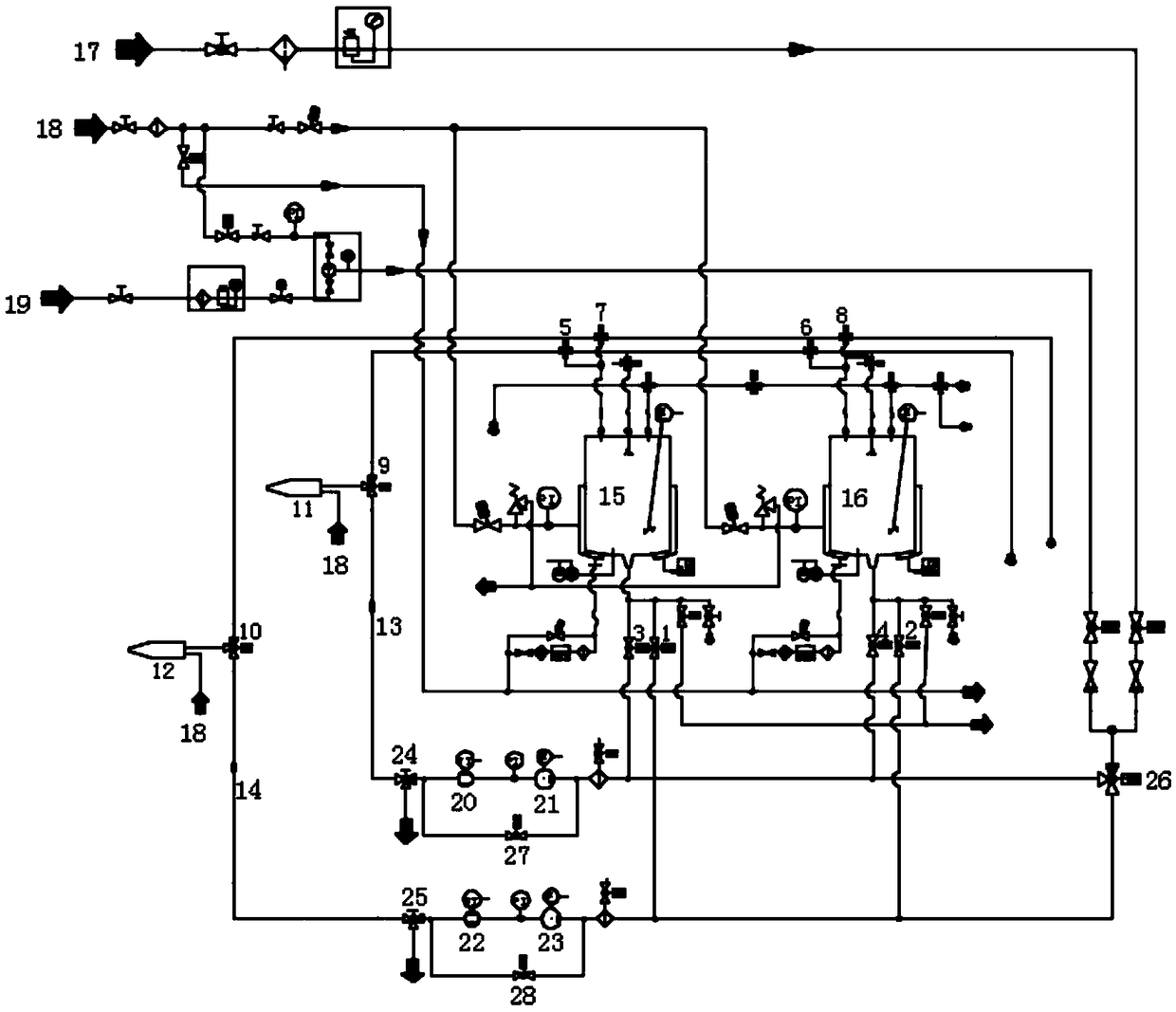

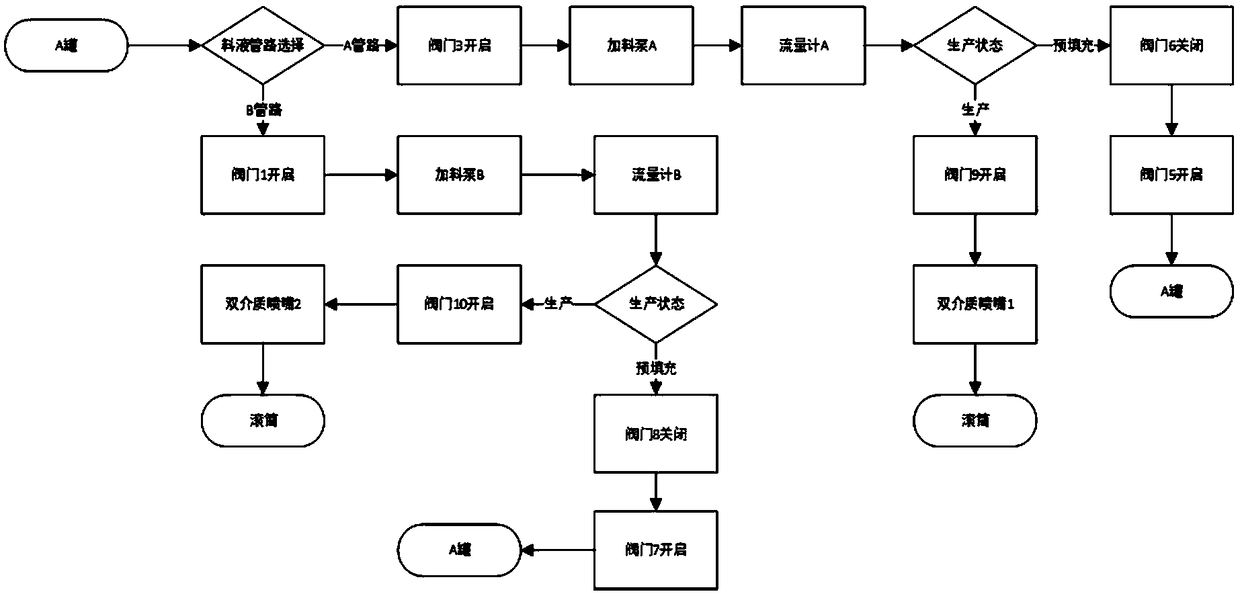

[0049] Such as Figure 1-2 Shown: a new type of feeding pipeline design pipeline connection diagram. The feeding and water supply pipeline includes material tank A15, material tank B16, A pump 21, B pump 23, A flow meter 20, B flow meter 22, dual-medium nozzle A11, dual-medium nozzle B12, pneumatic three-way valve, pneumatic two-way Valves, three-way joints and other components. 1: Change the pipeline: after the original pipeline comes out of the flowmeter, two independent feeding and water supply pipelines are designed. Newly added pneumatic three-way valve one 5, pneumatic three-way valve two 6, pneumatic three-way valve five 9, double-medium nozzle A11 and double-medium nozzle B12, connected together with stainless steel pipes, the pipeline can form two independent feeding Water supply line. Pneumatic three-way valve one 5 and pneumatic three-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com