A method of using an additive manufacturing device based on electroslag remelting

A technology of additive manufacturing and electroslag remelting, applied in the direction of additive processing, etc., can solve the problems of low production efficiency, low purity, high quality and diversity of formed parts materials, and achieve reduced overall process flow, stable quality, and pure metal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

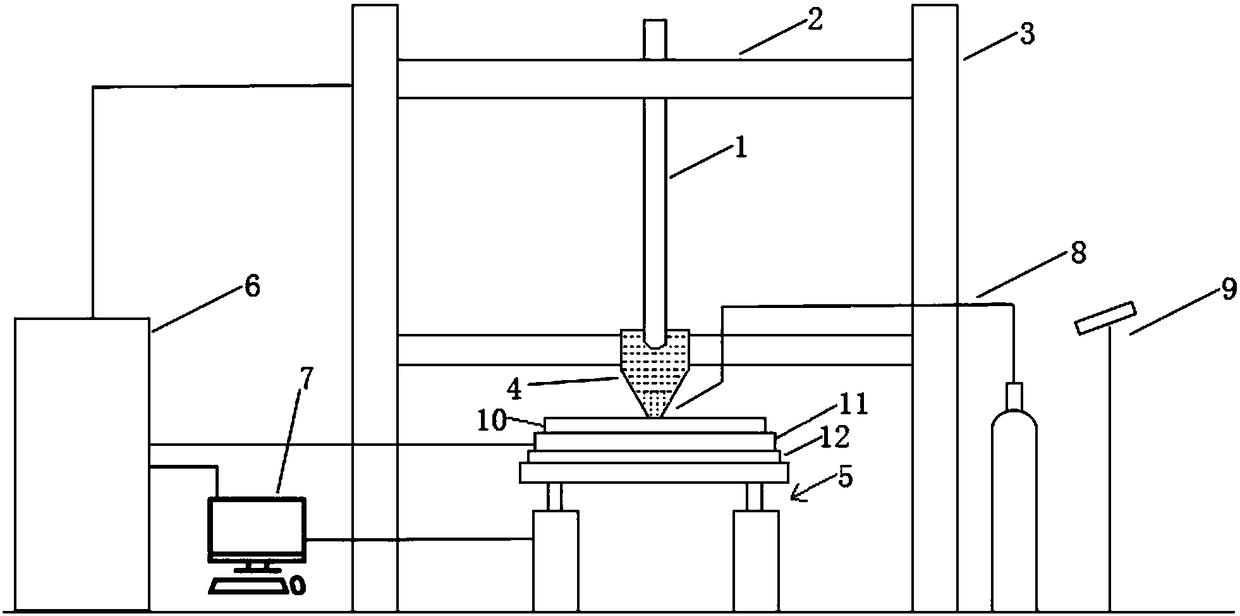

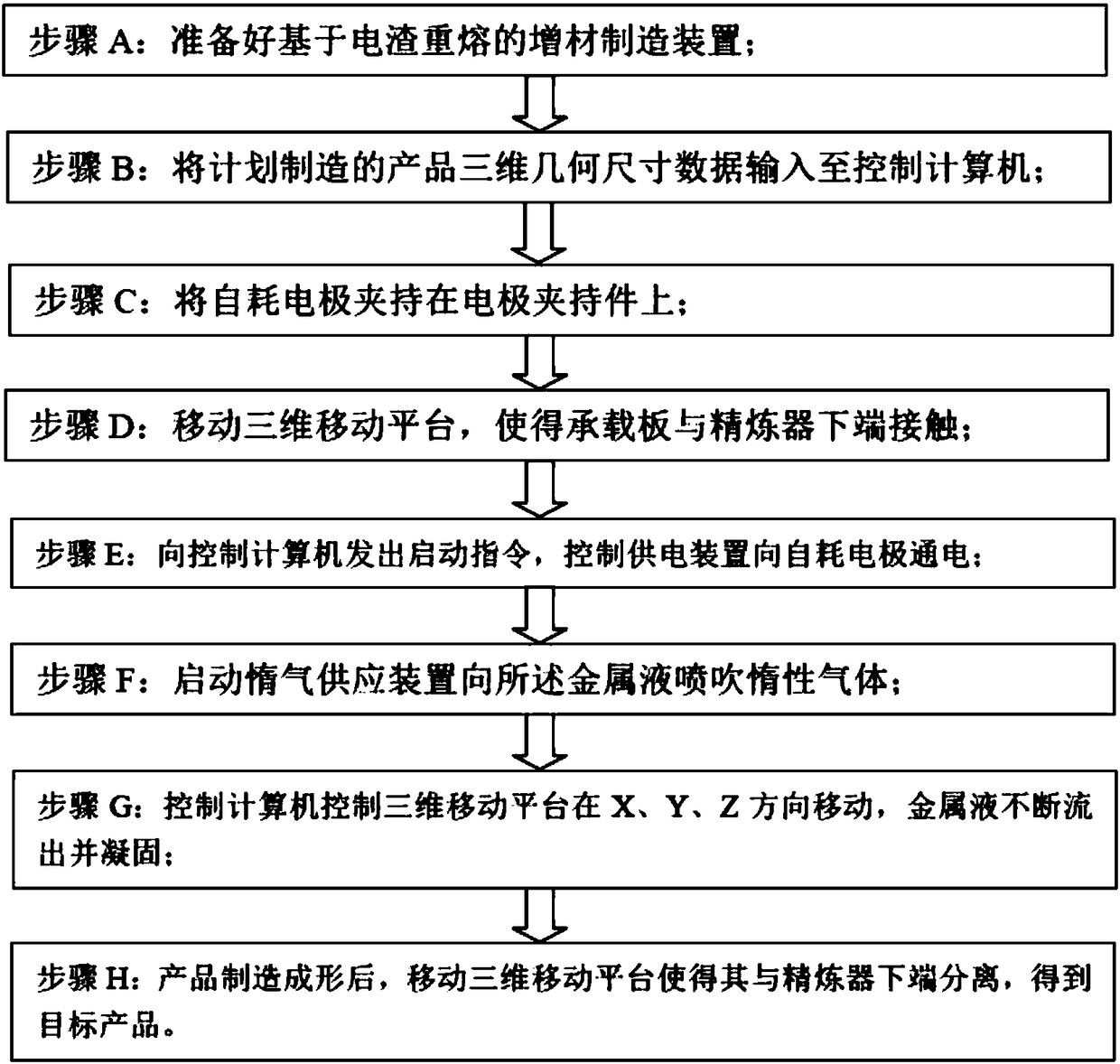

[0051] combine figure 1 , the electroslag remelting-based additive manufacturing device of this embodiment includes a consumable electrode 1, a refiner 4, a three-dimensional mobile platform 5, an inert gas supply device 8, a carrier plate 10, an electrode holder 2, and a mounting frame 3. The power supply device 6 and the non-contact temperature measuring device 9, the consumable electrode 1 is located above the refiner 4, the refiner 4 is filled with refining slag, the three-dimensional mobile platform 5 is located below the refiner 4, and the three-dimensional mobile platform 5 Can move freely in three-dimensional space. Among them, the refiner 4 is composed of upper and lower sections, the upper section is a hollow cylinder, and the lower section is an inverted hollow round platform. The upper section and the lower section are seamlessly welded together. The refiner 4 is filled with refining slag. After the lower end of 1 is melted, the liquid droplets pass through the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com