Patents

Literature

119results about How to "Moisture stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal blending and coking method for metallurgical coke

The present invention relates to coal blending and coking method for metallurgical coke, and especially the coal blending and coking method with thermal coal and weakly caking coal. The present invention adopts conventional coking process and the coal consists of weakly caking coal 0-15 wt%, thermal coal 0-10 wt%, gas coal 13-45 wt%, fatty coal 9-20 wt% and coking coal 40-45 wt%. The produced coke has dropping strength M40 of 77-78.5 %, abrasion resistance strength M10 <8.6 %, reactivity of 35-37 %, thermal state strength of 45-55 %, and granularity of 25-40 mm and 40-80 mm, and meets the requirement for iron smelting in blast furnace of 1000 cubic meter or larger. The present invention has expanded coal variety range for coking, and lowered coking cost.

Owner:武钢集团有限公司

Stable simvastatin oral tablet and preparation method thereof

InactiveCN102091050AEffective isolationGood film formingOrganic active ingredientsMetabolism disorderMedicineAntioxidant

The invention provides a stable simvastatin oral tablet which is prepared from the following components in percentage by weight: 10-20% of simvastatin, 0.01-0.04% of antioxidant, 0.5-2.0% of acidifier, 70-80% of filler, 5-10% of disintegrant, 1-1.2% of lubricant and 0.5-2% of binder. The invention also provides a method for preparing the stable simvastatin oral tablet. By strictly controlling the moisture of a finished product, the doses of the antioxidant and acidifier in the components are obviously reduced, the product stability is better, and the safety is higher.

Owner:CHONGQING KERUI PHARMA GRP

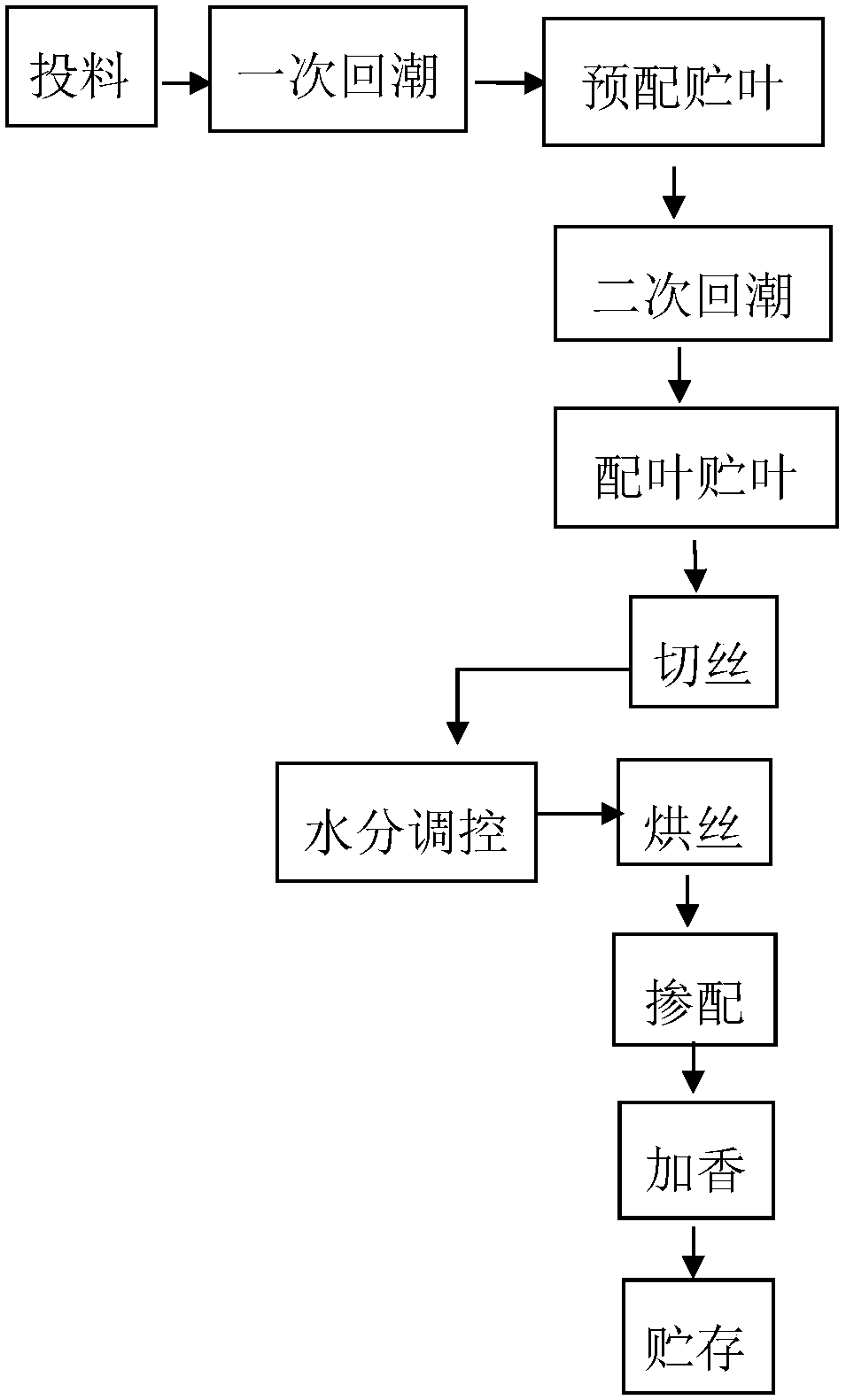

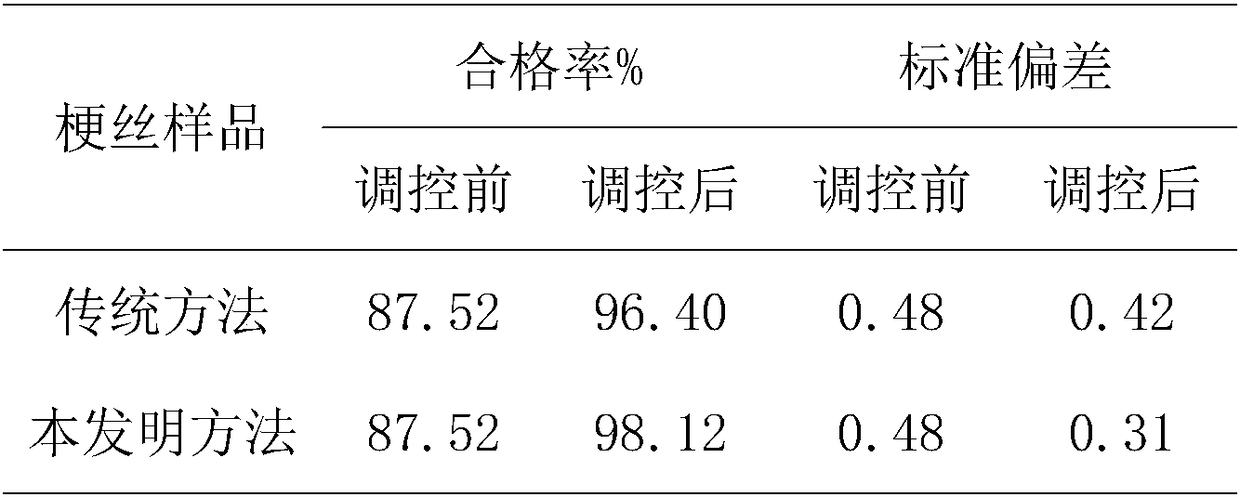

Method for improving tobacco shred preparing quality stability

InactiveCN108308691ASmall process changesRenovation investment is smallTobacco preparationEngineeringUltimate tensile strength

The invention provides a method for improving the tobacco shred preparing quality stability. The method specifically includes the steps of material putting, primary moisture regaining, stored leaf preparing, secondary moisture regaining, stored leaf distributing, shredding, moisture controlling, shred drying, mixing, flavoring and storing. The moisture controlling process is added after shredding,so the problems that due to the long process route, the material process water content is greatly influenced by the environment temperature and humidity and the shred drying inlet water content of different batches fluctuates obviously are solved, the incoming material water content of the shred drying process is stabilized, the stability of the water content of different batches of materials entering the shred drying process is ensured, the shred drying machine outlet material water content meets the processing requirement, and therefore the processing intensity and dewatering amount of theshred drying process of different batches are stabilized, and the stability of the sensory quality of shred drying outlet materials is ensured; compared with other methods, the method has the advantages of being small in technological change, small in refitting investment, capable of saving energy and reducing consumption and free of newly constructing or refitting of a factory.

Owner:HONGTA TOBACCO GRP

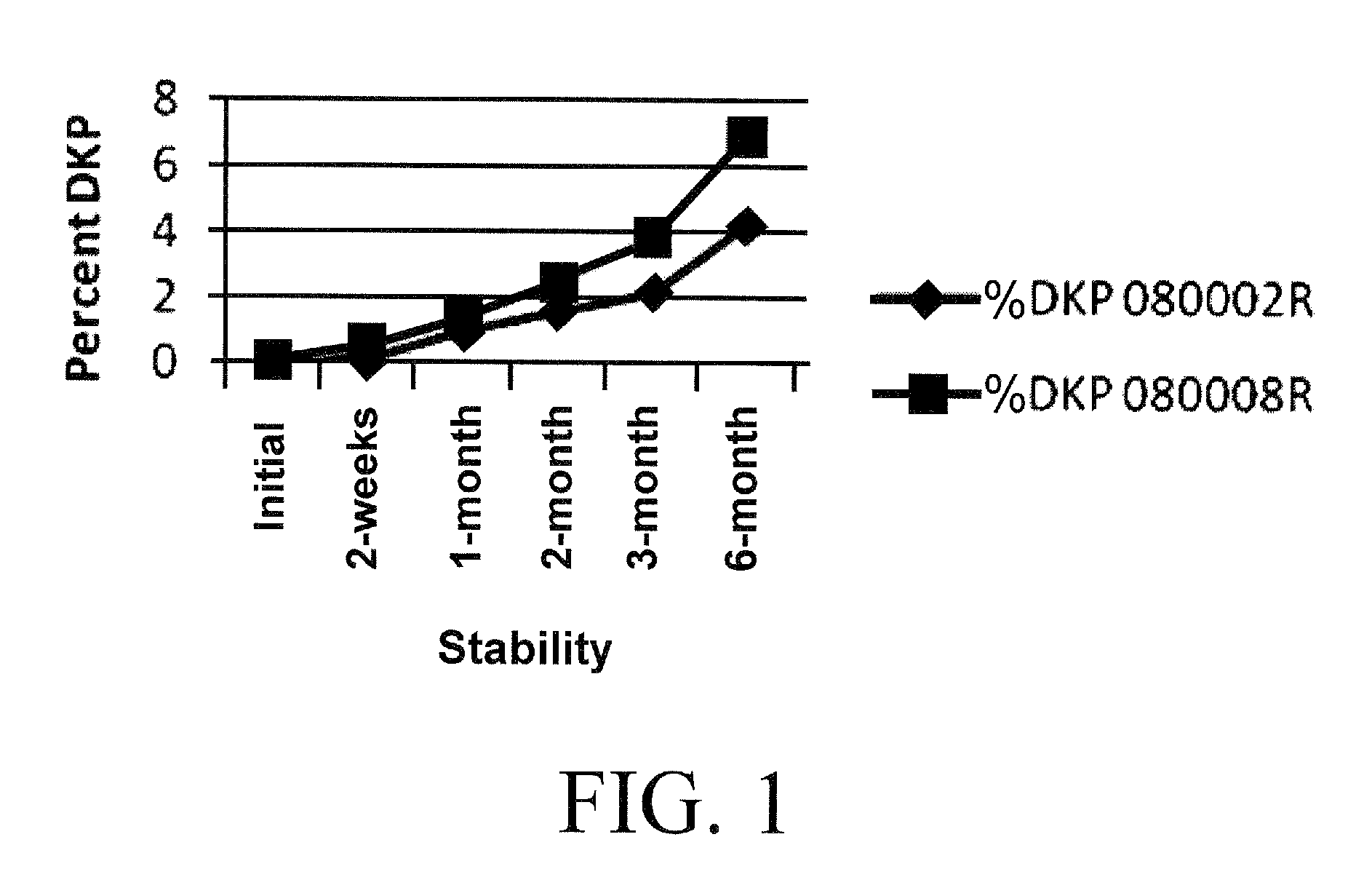

Stabilized Coating for Pharmaceutical Formulations

InactiveUS20100062062A1Improve stabilityEfficiently coat and stabilizeBiocidePharmaceutical non-active ingredientsPolyvinyl alcoholDiketopiperazines

A process is described for preparing stabilized tablet formulations for temperature and moisture sensitive active drugs. Water soluble polyvinyl alcohol is processed with drugs such as angiotensin converting enzyme (ACE) inhibitors and compressed into solid form once excess water is removed. Low dose polyvinyl alcohol ramipril tablets prepared by this process are stable under conditions of high humidity and heat for periods of at least up to six months with less than 8% hydrolysis of the prodrug to the active metabolite diketopiperazine (DKP).

Owner:AETHOS PHARMA

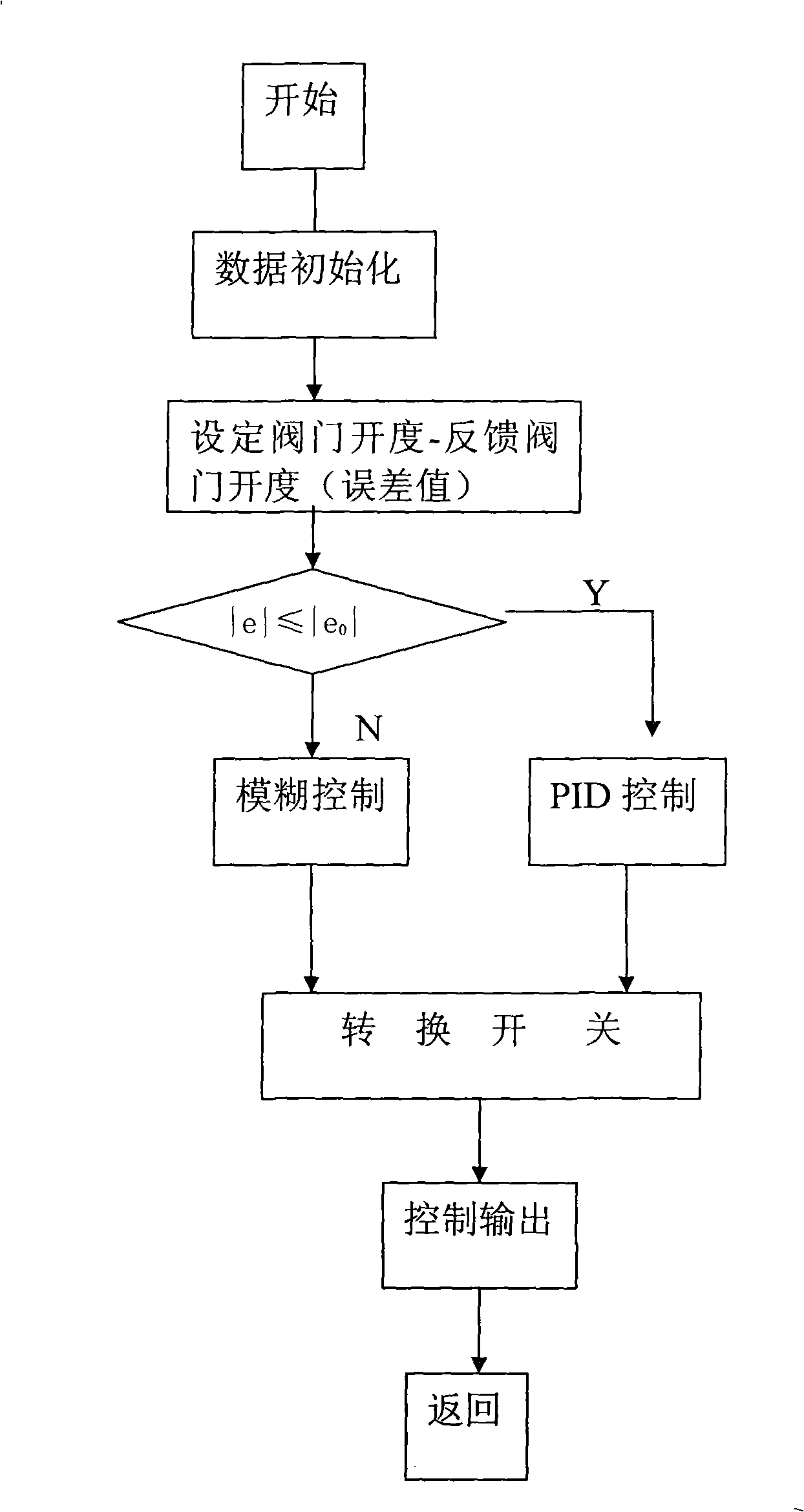

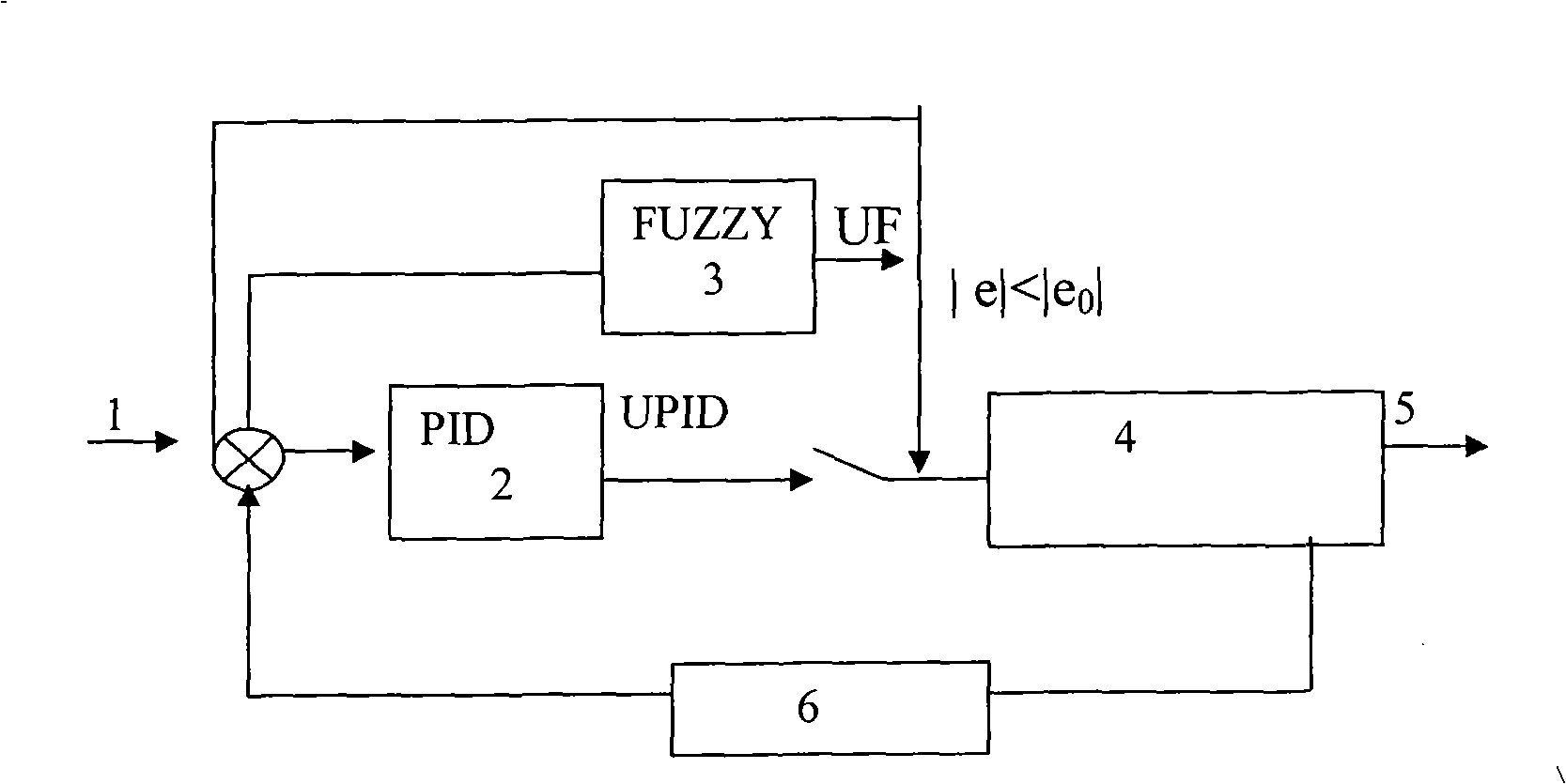

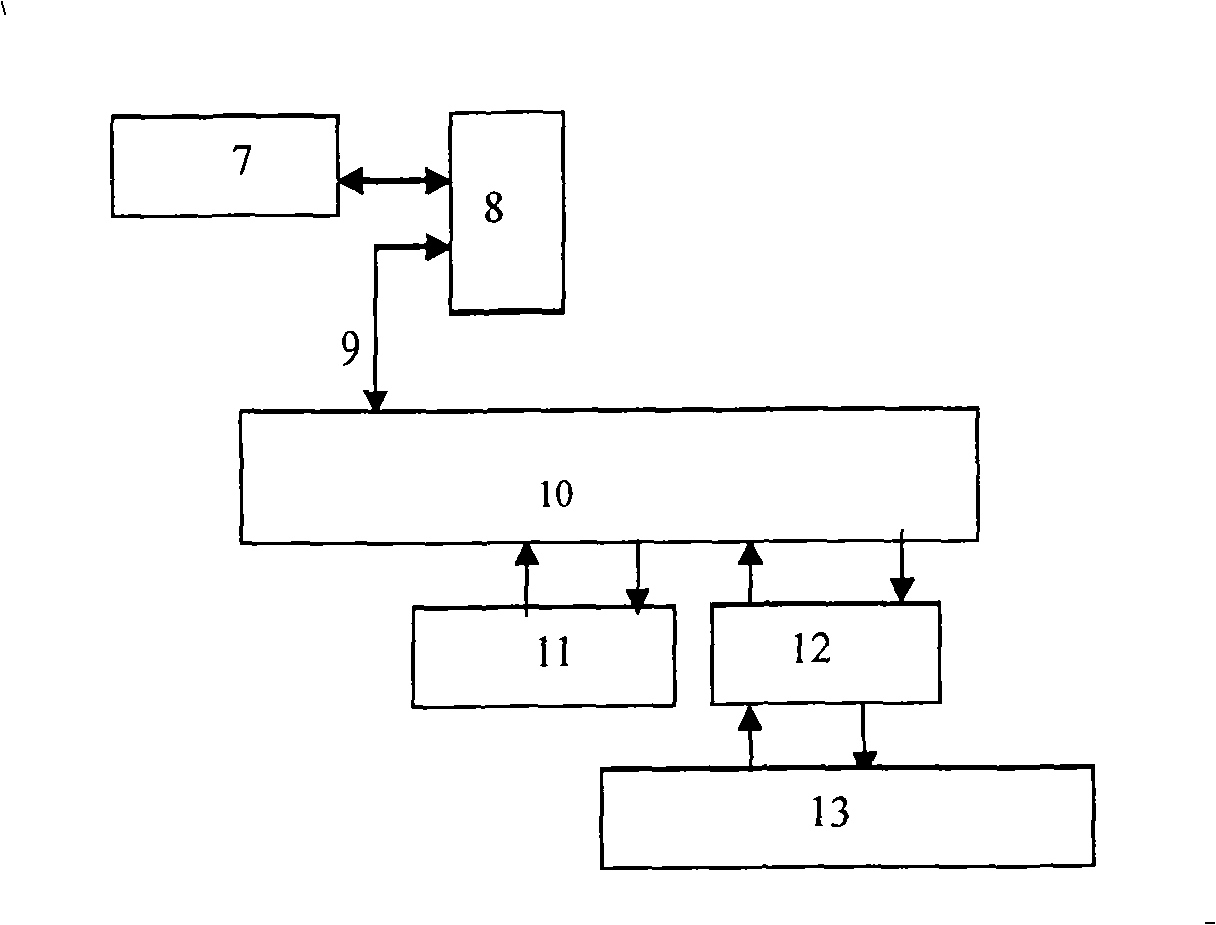

Fuzzy-PID compound control system in sintered mixing water supply

The invention relates to a sintering mixing water-feeding checking and controlling system, in particular to a Fuzzy-PID compound control system for sintering mixing water-feeding, which comprise a PID control strategy, a check instrument and a controller, wherein the control process of the Fuzzy-PID compound control system comprises: initializing the system data, setting a valve opening degree and a feedback valve opening degree error |e|, judging if |e|=|e0|, when |e|<=|e0|, using the PID control strategy, when |e|>=|e0|, using Fuzzy control strategy, when the PID control is switched to the Fuzzy control, the output of the adjuster holds the output value UPID under the PID control strategy until the Fuzzy controller output |UF|>=|UPID|, when the Fuzzy control is switched to the PID control, the output of the adjuster holds the output value UF under the Fuzzy control strategy until the PID controller output |UPID|<=|UF|. The invention improves the permeability of sintered mixture, improves the thickness of sintered layer, the speed of sintering machines and reduces sintering negative pressure.

Owner:NORTHERN ENG & TECH CORP MCC

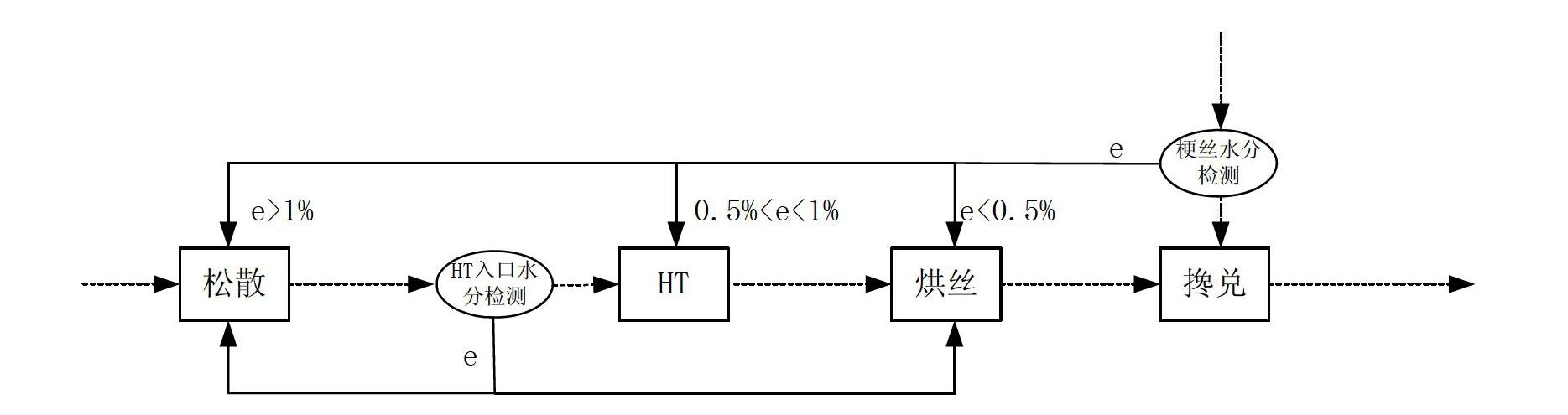

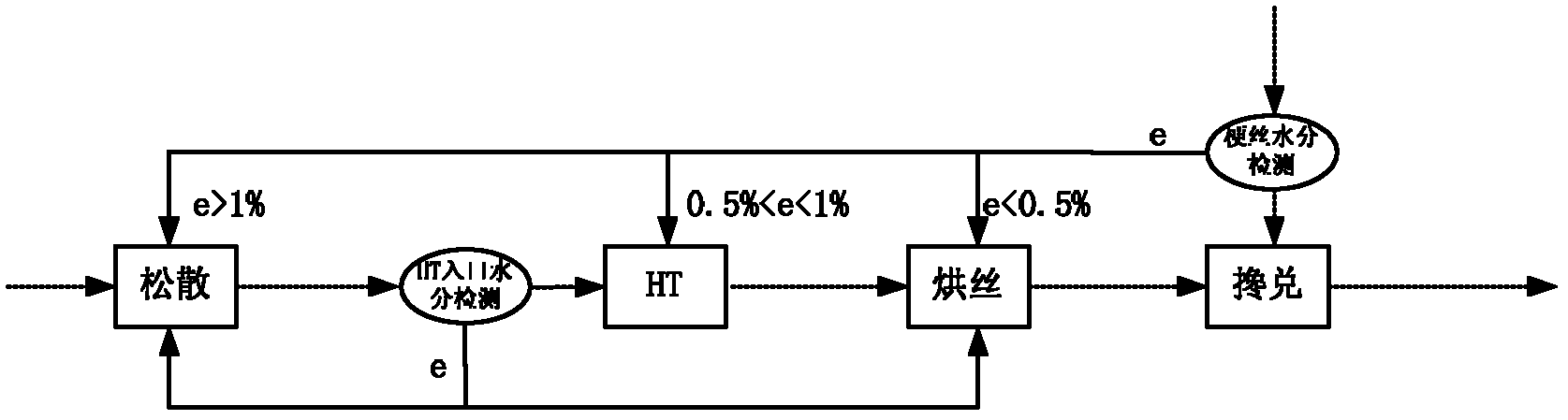

Moisture chain control method for tobacco shred manufacturing process

InactiveCN102613680AGuaranteed process parametersMoisture stableTobacco preparationTobacco treatmentProcess engineeringEngineering

A moisture chain control method for a tobacco shred manufacturing process includes two synchronous steps of adjustment based on moisture fluctuation of blended stems and shreds and adjustment based on moisture fluctuation of tobacco shreds at an HT (humidifying tunnel) inlet. Detection to moisture of stems and shreds before the stems and the shreds are blended is added, moisture of an HT joint and moisture of a stem and shred blending joint are detected, when the HT inlet tobacco shred moisture and stem and shred moisture in the two joints are abnormal, key parameters of other relevant work procedures at joints in front and rear of the two joints on a tobacco shred processing chain are quantitatively adjusted, effective front and rear feedback is realized, stability of shred blending moisture after the stems and the shreds are blended is guaranteed, and stability of technological parameters of a shred drying procedure is ensured.

Owner:CHINA TOBACCO HUNAN INDAL CORP

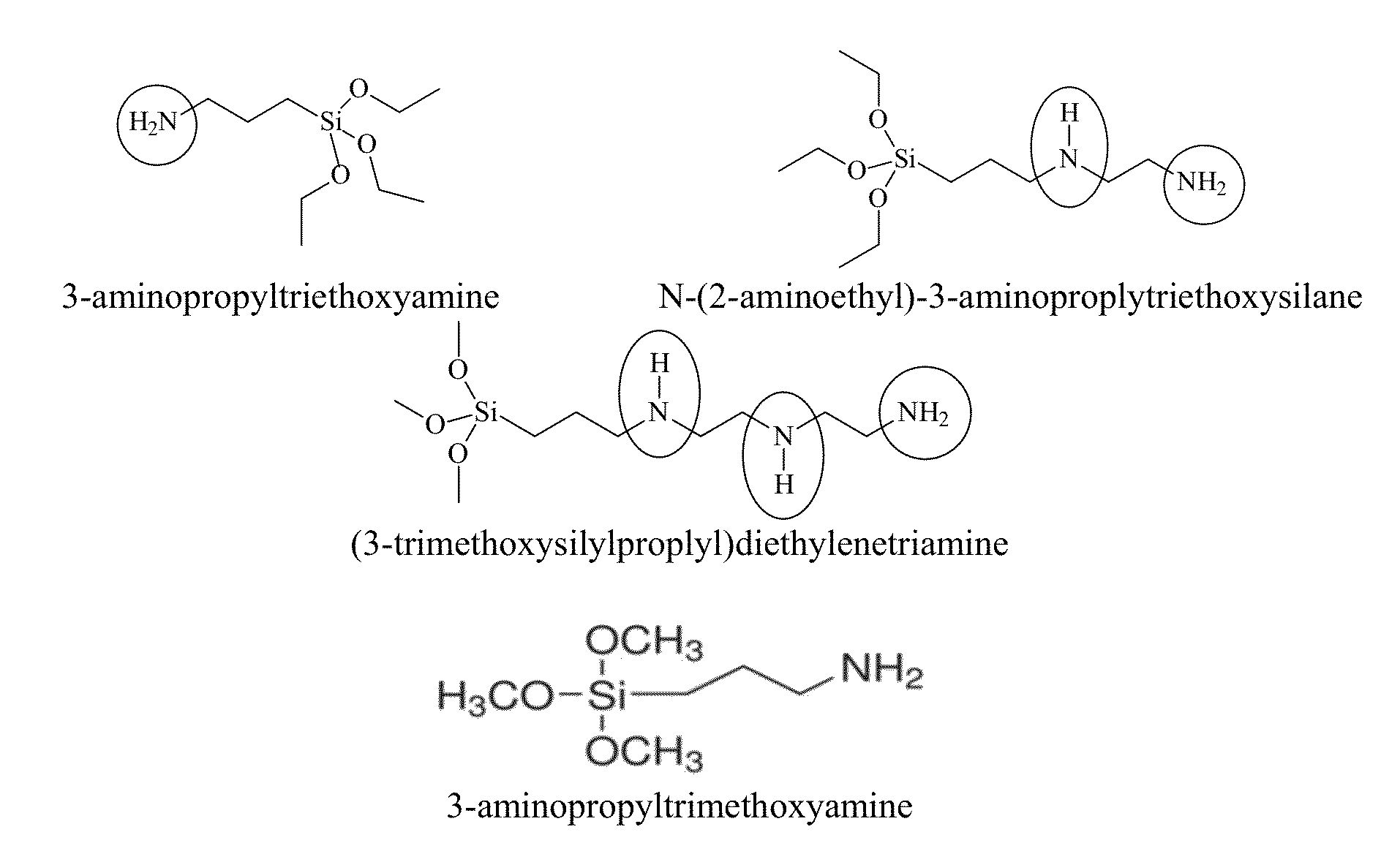

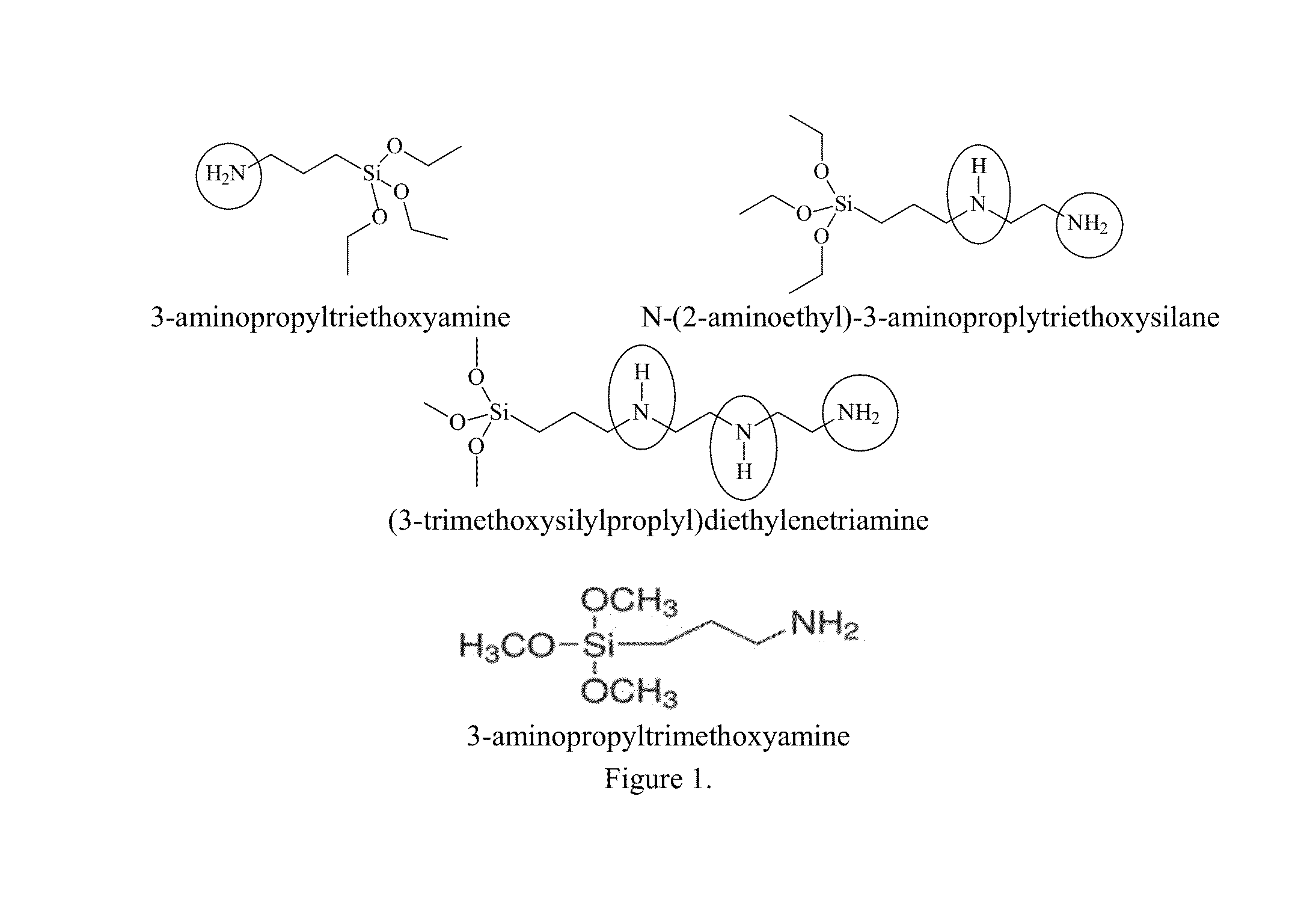

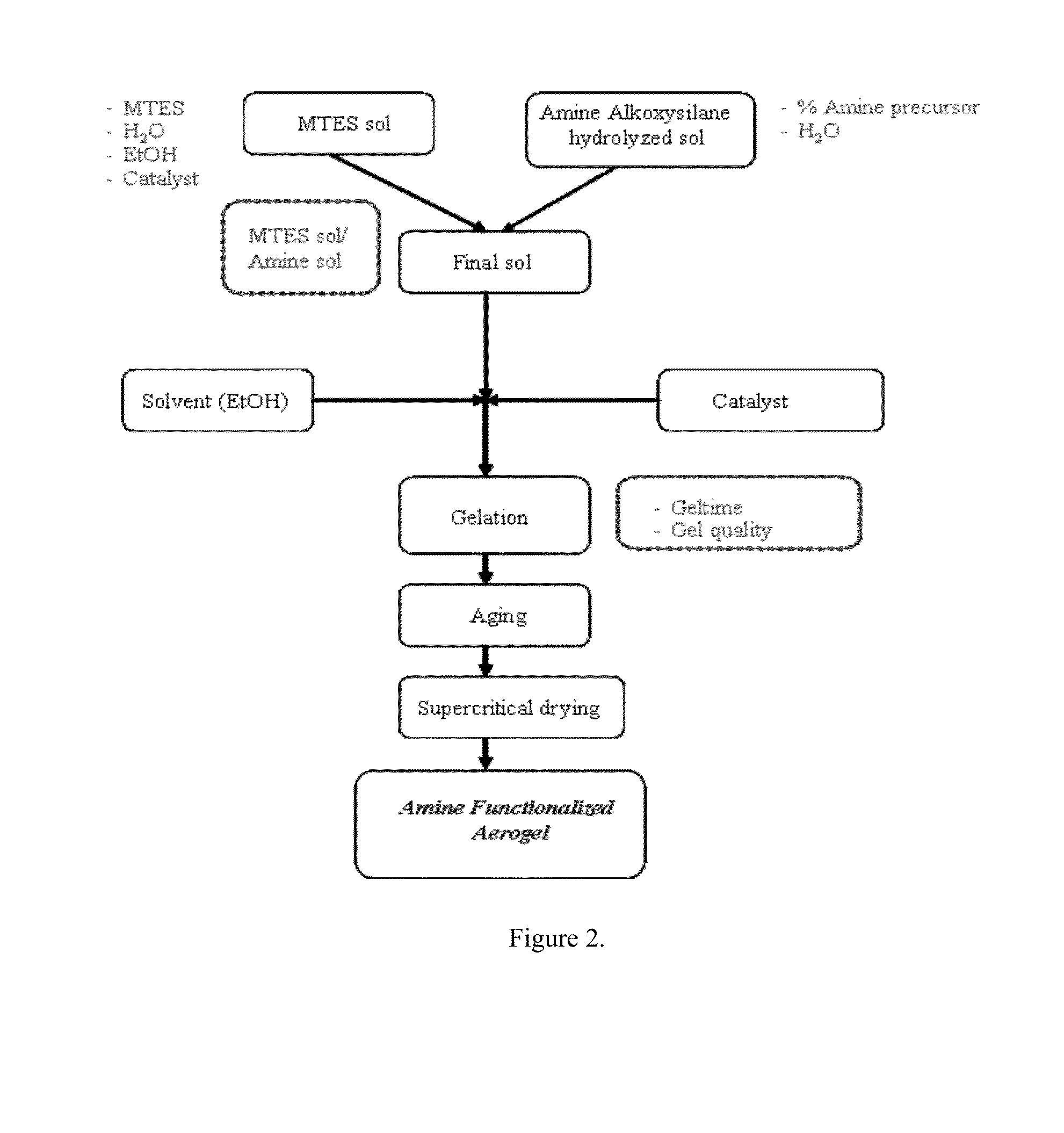

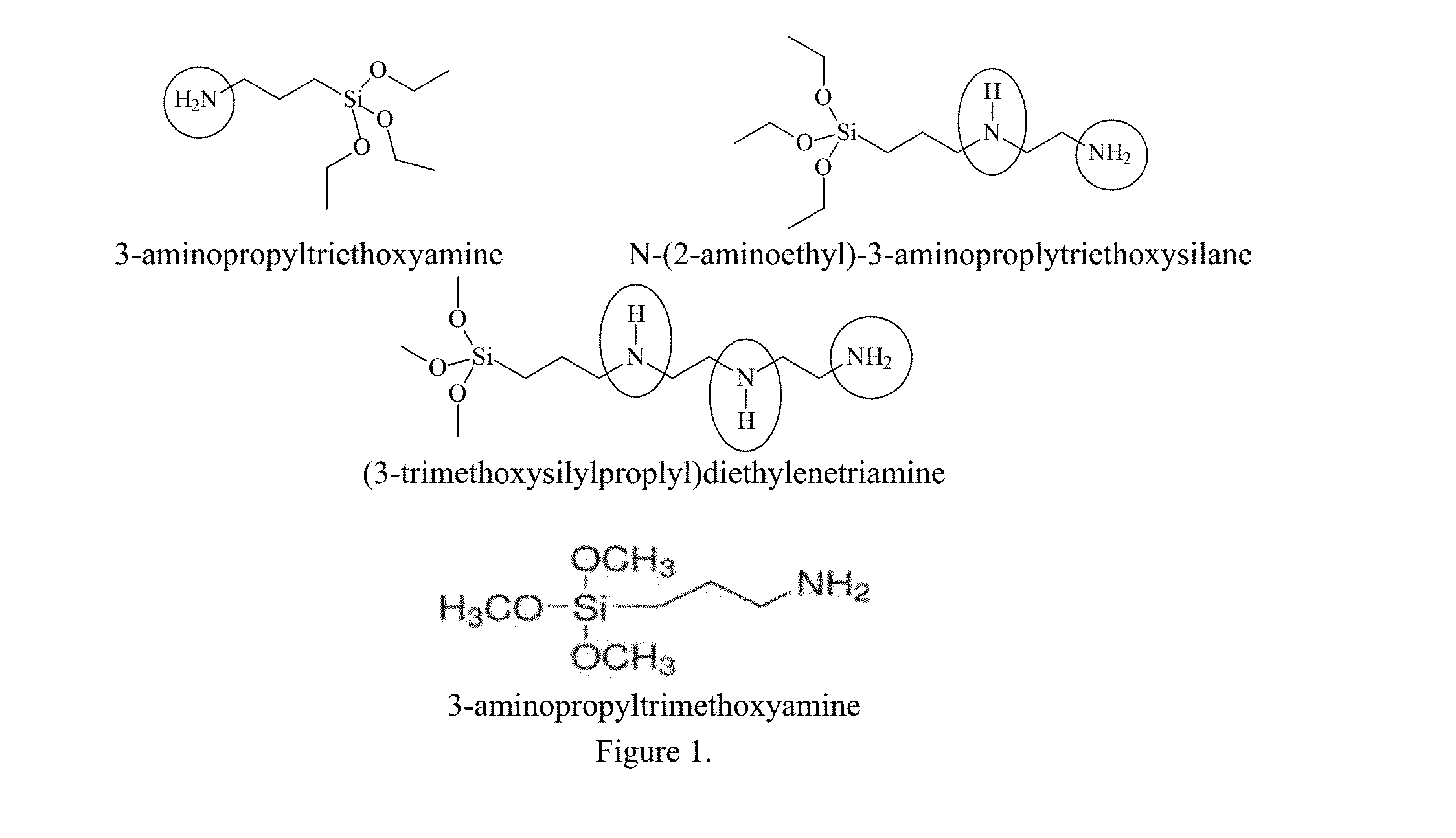

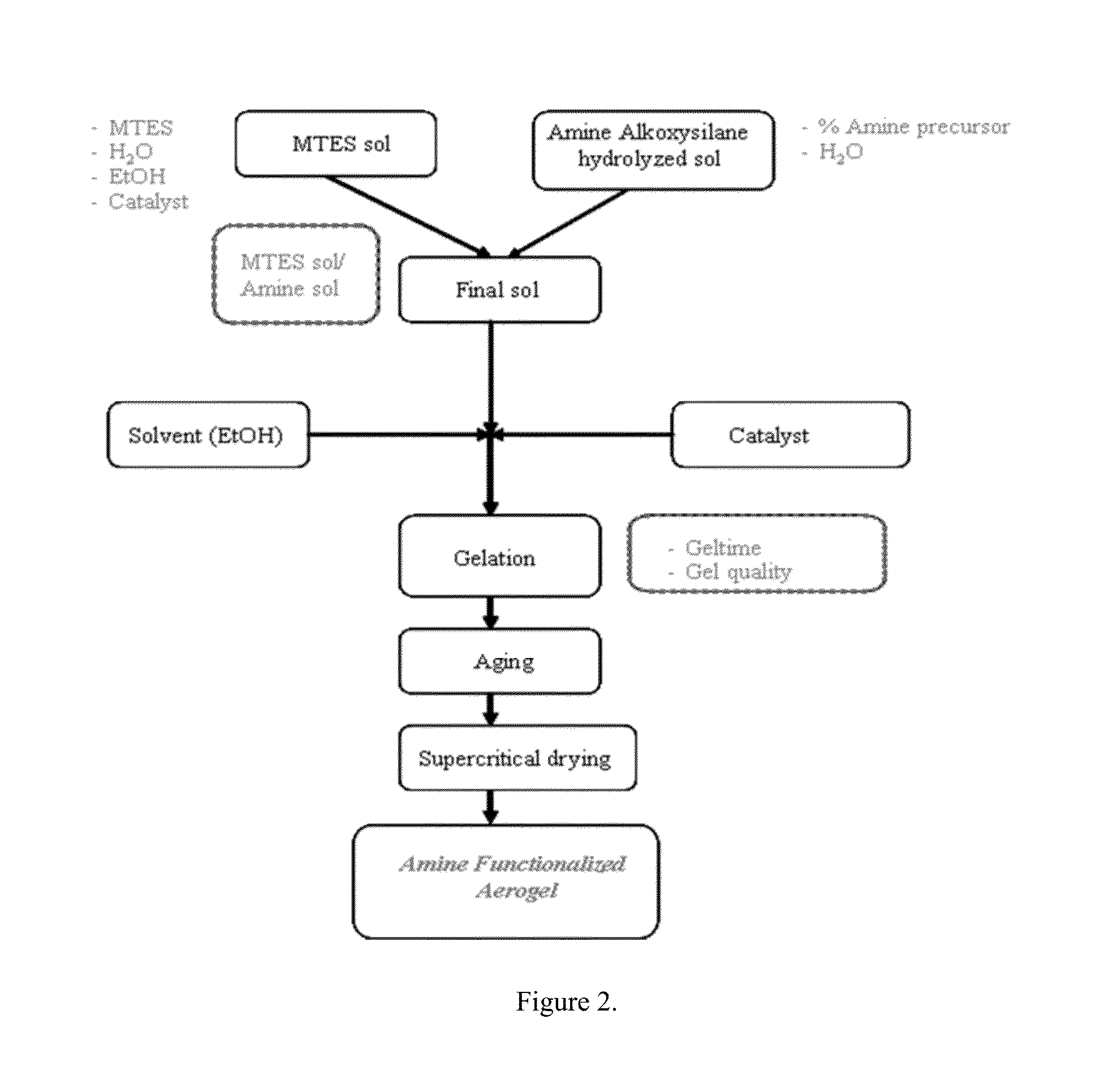

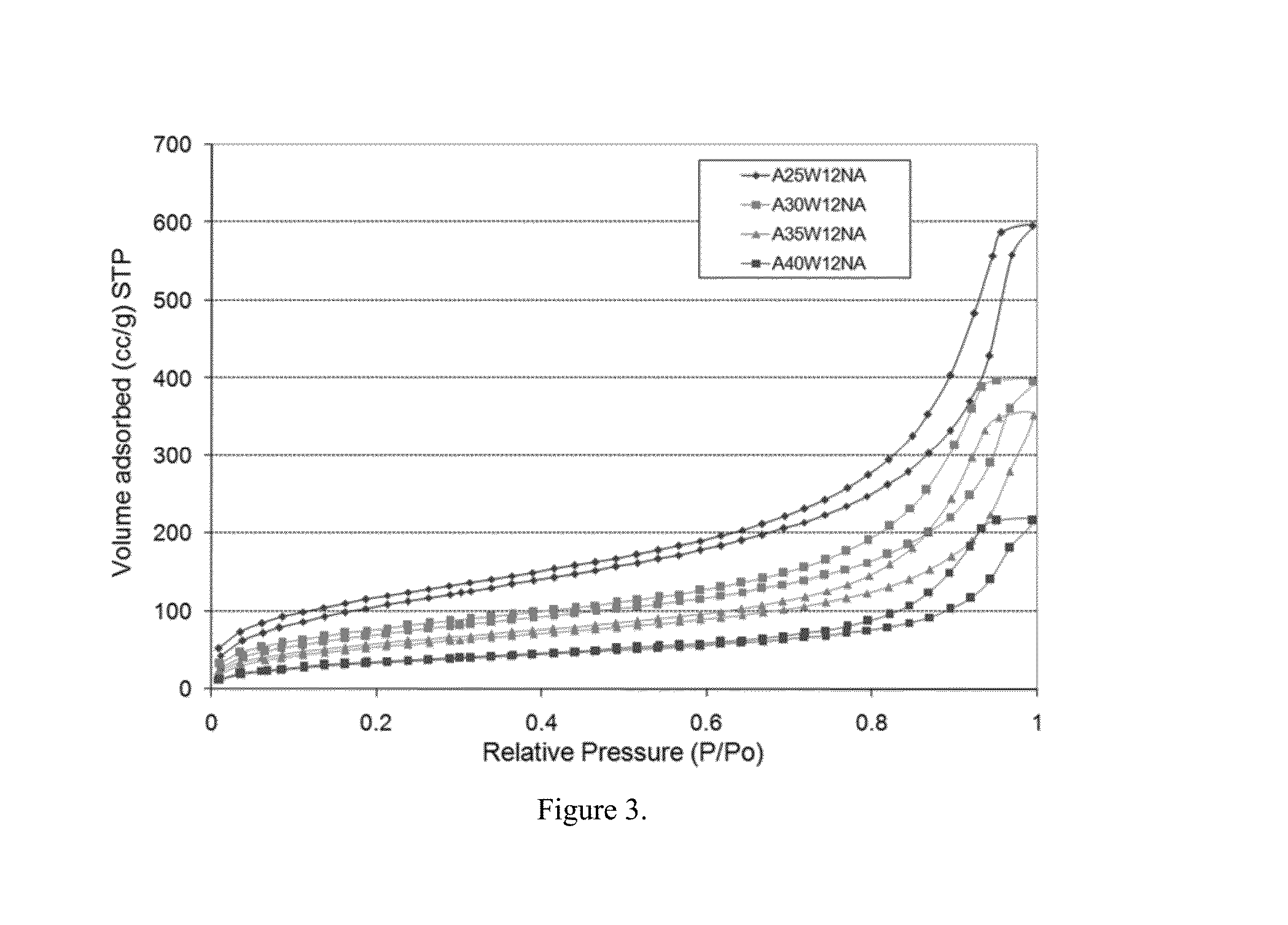

Aerogel sorbents

The current invention describes methods and compositions of various sorbents based on aerogels of various silanes and their use as sorbent for carbon dioxide. Methods further provide for optimizing the compositions to increase the stability of the sorbents for prolonged use as carbon dioxide capture matrices.

Owner:ASPEN AEROGELS INC

Aerogel sorbents

The current invention describes methods and compositions of various sorbents based on aerogels of various silanes and their use as sorbent for carbon dioxide. Methods further provide for optimizing the compositions to increase the stability of the sorbents for prolonged use as carbon dioxide capture matrices.

Owner:ASPEN AEROGELS INC

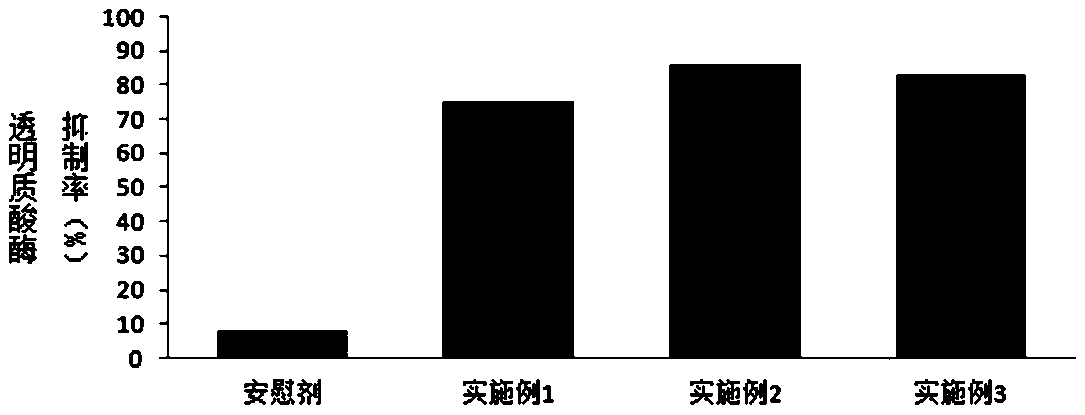

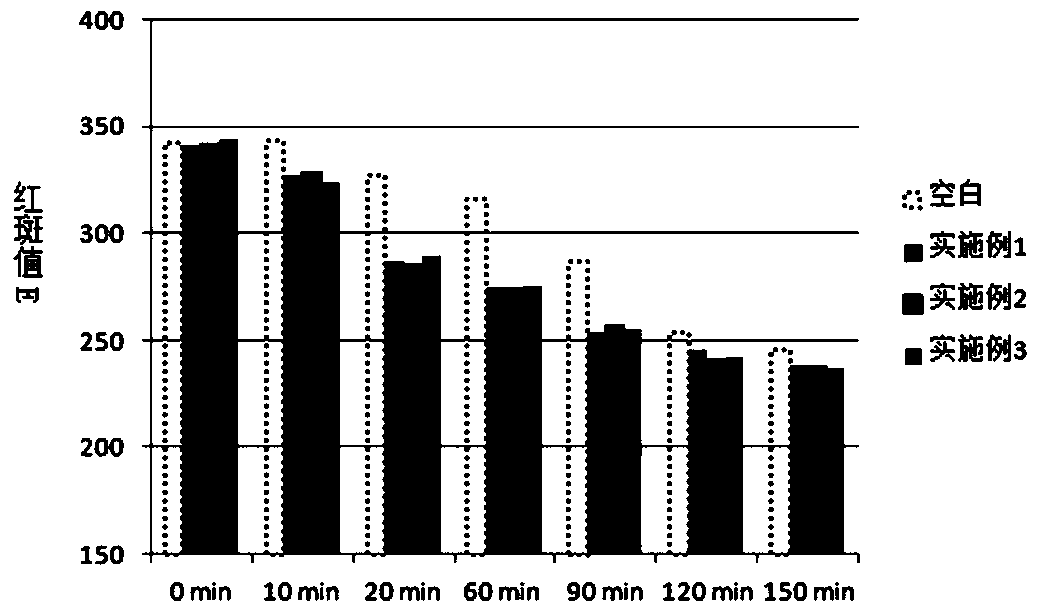

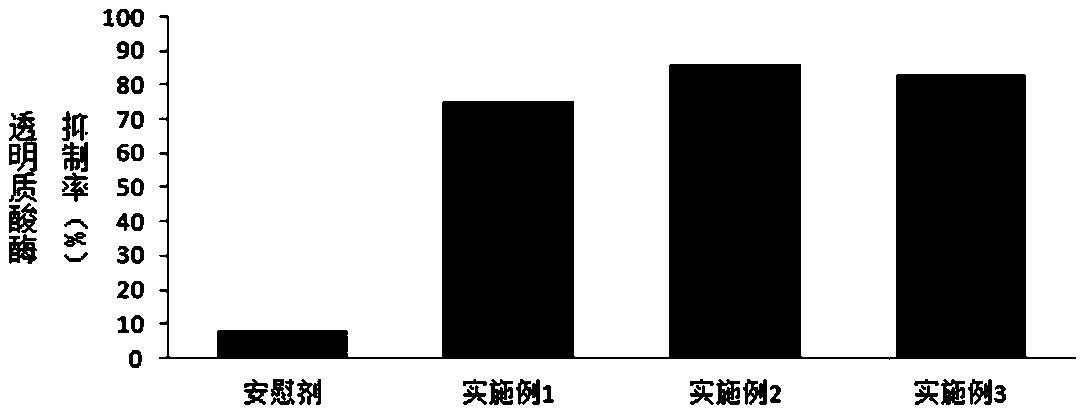

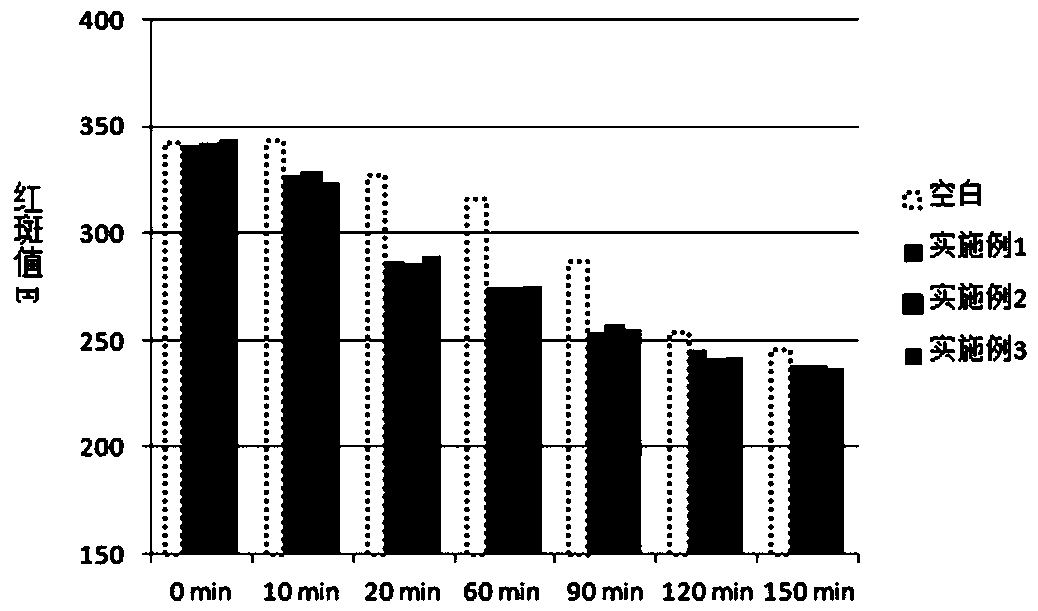

Polypeptide essence having efficacy of relieving allergy and repairing skin and preparation method of polypeptide essence

InactiveCN110448509AEnhance skin toleranceSuppresses skin sensitivity triggersCosmetic preparationsToilet preparationsLicorice root extractPanax notoginseng root extract

The invention specifically relates to polypeptide essence having efficacy of relieving allergy and repairing skin and a preparation method of the polypeptide essence. The essence is an aqueous system,a micromolecule peptide composition is used as a core and is compounded with a plant extract having the efficacy of relieving allergy and a plant extract having the efficacy of repairing skin, wherein the micromolecule peptide composition comprises oligopeptide, oat peptide and copper tripeptide-1, the plant extract having the efficacy of relieving allergy comprises trehalose, an opuntia streptacantha stem extract and a radix ophiopogonis root extract, and the plant extract having the efficacy of repairing skin comprises a harba dendrolii nobilis stem extract, a radix sophorae yellowish sophora root extract, a lycium barbarum fruit extract, a pseudo-ginseng root extract, an astragalus membranaceus root extract, a glossy privet fruit extract and a licorice root extract. The prepared essence has the double functions of relieving allergy and repairing skin, is safe and mild and can solve the sensitive skin problems that skin flushes, and turns red and swollen caused by weather, geographical environment, and improper use of skin care products.

Owner:奢脉国际化妆品(北京)有限公司

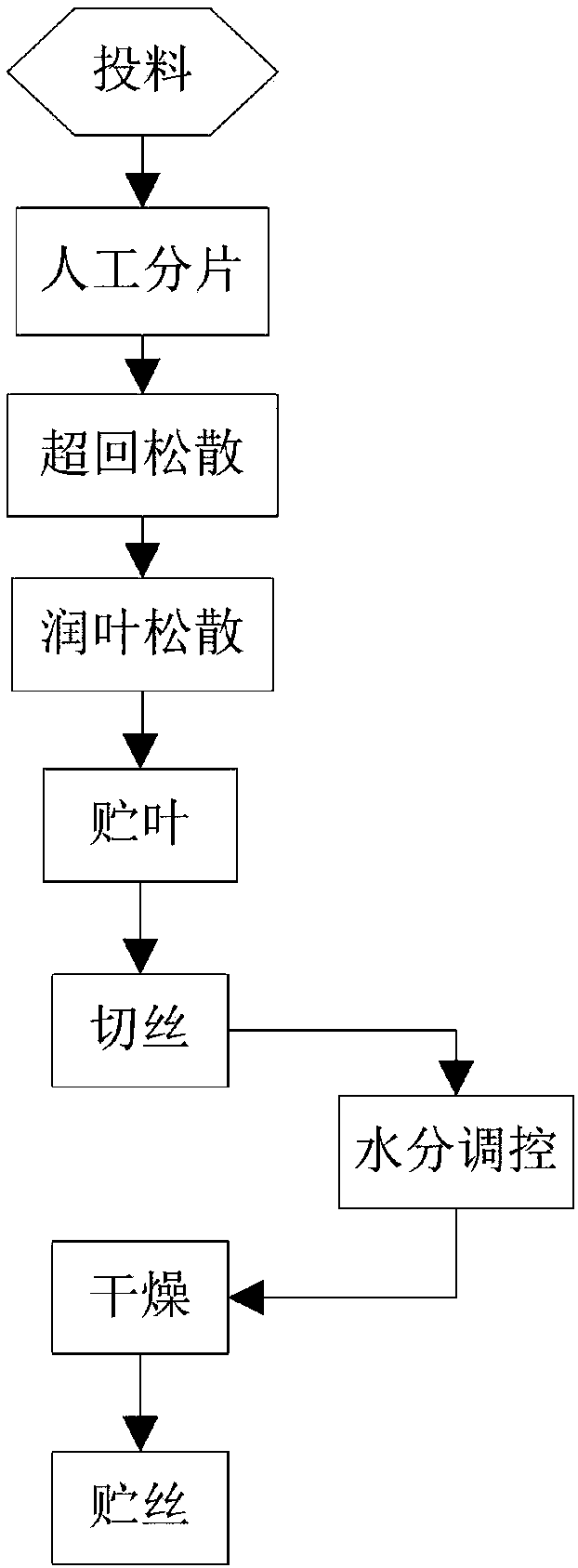

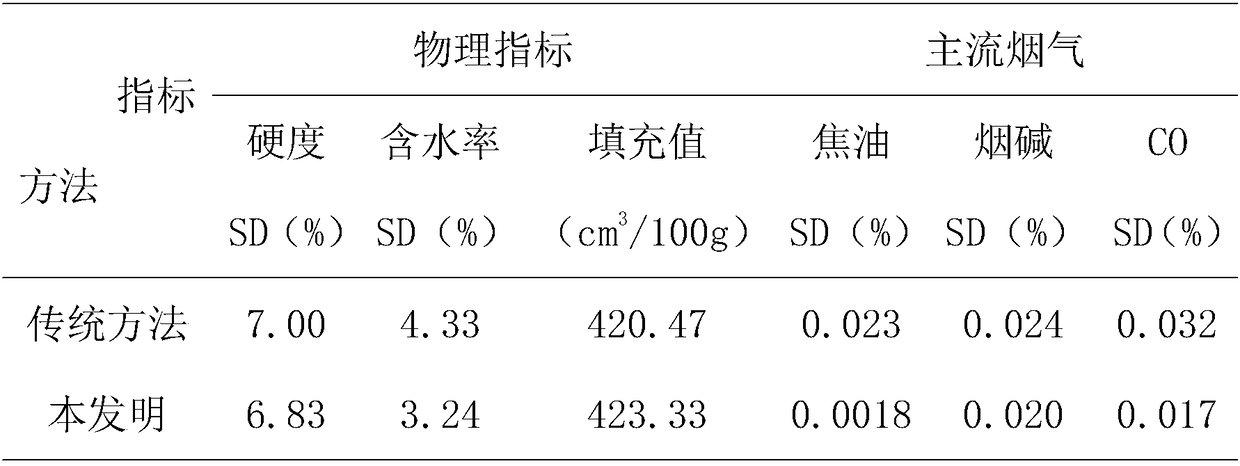

Method for improving tobacco shred making quality of reconstituted tobacco

InactiveCN108185504AImprove sensory qualityImprove processing strength and stabilityTobacco preparationMoisture absorptionEngineering

The invention provides a method for improving the tobacco shred making quality of reconstituted tobacco. The method comprises the specific steps of putting, manual fragmentation, super-return loosening, tobacco moistening and feeding, tobacco storage, shredding, moisture regulation and control, drying and tobacco shred storage. The process of moisture regulation and control is added, and the problems are solved that the technological path is long, the reconstituted tobacco has special moisture absorption performance, the water content in the material process is excessively influenced by the temperature and humanity of the environment, and accordingly the water content of batch-to-batch drying inlets is obviously fluctuated; the water content of shredded materials is stable, the stability of batch-to-batch moisture of the materials which enter the drying process is guaranteed, the water content of materials of drying outlets meets the processing requirement, the stability of the processing intensity and dewatering amount in the batch-to-batch tobacco shred drying process is achieved, and the stability of the smoking quality of the reconstituted tobacco shreds of tobacco shred dryingoutlets is guaranteed. Compared with other methods, the method has the advantages that the technological path is less changed, the reconstitution investment is low, the energy is saved, the consumption is lowered, and meanwhile workshops do not need to be newly built or rebuilt.

Owner:HONGTA TOBACCO GRP

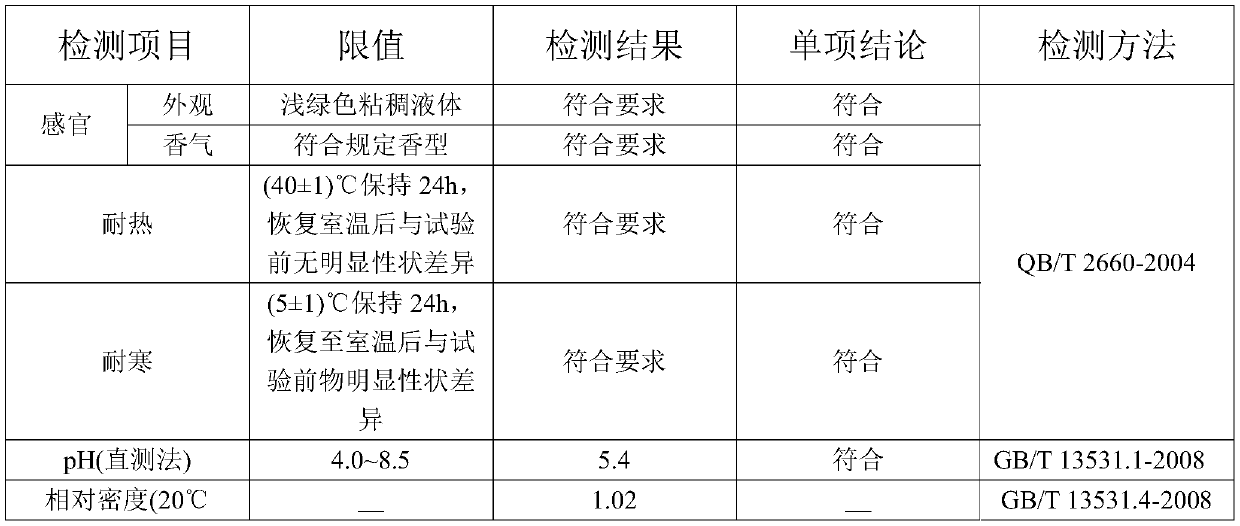

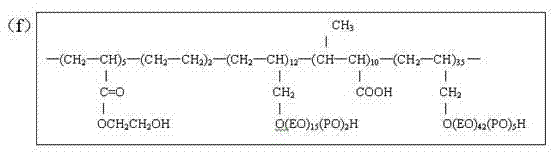

Water-based cutting fluid of hard brittle material and preparation method of water-based cutting fluid

ActiveCN102952620ALong-lasting dispersionMoisture stableLubricant compositionChemistryComposite material

The invention relates to a water-based cutting fluid of a hard brittle material and a preparation method of the water-based cutting fluid, in particular to a water-based cutting fluid applied to cutting of solar crystal crystalline silicon. The water-based cutting fluid comprises the following components in percentage by weight: 10-40 percent of deionized water, 55-85 percent of dihydric alcohol, 0.001-5 percent of water-retaining agent, 0.001-5 percent of thixotropic thickening agent and 0-5 percent of washing foam controlling agent. The cutting fluid has the advantages of no loss of water in a cutting process, high specific heat capacity, good cooling property and environmental friendliness, and is a novel water-based cutting fluid with stable property.

Owner:JIANGSU OXIRANCHEM CO LTD +1

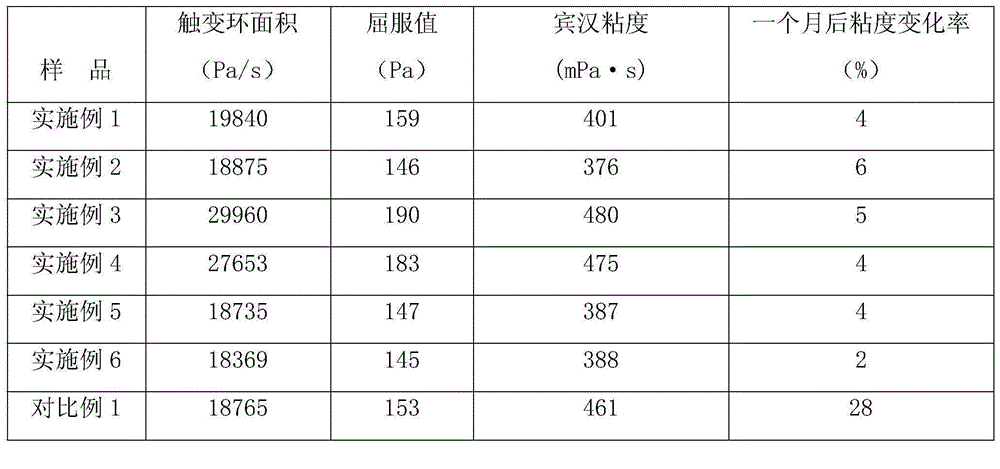

Preparation method for special precipitated calcium carbonate for PVC (polyvinyl chloride) stone chip resistant coating

ActiveCN104403433AGood dispersionThixotropicCalcium/strontium/barium carbonatesCoatingsFiltrationPolyvinyl chloride

The invention discloses a preparation method for special precipitated calcium carbonate for a PVC (polyvinyl chloride) stone chip resistant coating. The preparation method comprises the technical operation as follows: adjusting the ratio of lime milk to be 1.040-1.080, feeding kiln gas with the flow of 6-10m<3> / h, controlling the specific surface area of matured slurry to be 16-40m<2> / g when the pH value of reaction liquid is reduced to be below 7.0, and adding a composite surface treatment agent at the temperature of 50-90 DEG C for wrapping, wherein the total adding amount of the surface treatment agent is 1.5-5.0 percent of dry calcium carbonate base; performing pressure filtration dewatering, drying, smashing and packaging on the slurry to obtain a precipitated calcium carbonate product for the PVC stone chip resistant coating. The precipitated calcium carbonate prepared by the preparation method disclosed by the invention is lower in hygroscopicity, so that the thixotropy, yield value and viscosity of filling of PVC plastipaste are effectively controlled, and the rheology stability of the PVC plastipaste is improved. The method disclosed by the invention is simple, feasible and low in production cost, and has higher economical and social benefits.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Fresh-keeping technique for Chinese yam

InactiveCN101292678AMoisture stableQuality improvementFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by dehydrationChemical compositionMedicine

The invention discloses a fresh-keeping technique of rhizoma dioscoreae, which comprises the steps in sequence: (1) the rhizoma dioscoreae is washed and classified into different categories according to the degree of thickness and length; (2) the moisture on the surface of the rhizoma dioscoreae is removed by hypobaric drying at normal temperature; (3) rhizoma dioscoreae is weighed and put into packing bags; (4) the air in the packing bags are evacuated and inactive gas are injected into the packing bags; (5) the packing bags are sealed and inspected; (6) the gamma ray is adopted for the quantitive irradiation of the packing bags of rhizoma dioscoreae. The fresh-keeping technique of the invention can keep the quality of components contained, moisture, color and taste relatively stable for 12 months at the normal temperature without residues of any other chemical composition, maintains the eating effect of fresh rhizoma dioscoreae, thus ensuring convenient storage, transportation and sales of the rhizoma dioscoreae.

Owner:隋纪成

Microcapsule humectant for cigarettes, preparation method of microcapsule humectant and application of microcapsule humectant

ActiveCN103504465AIncrease the aroma of tobaccoIncrease sweetness and moisturizationTobacco treatmentChemistrySodium triphosphate

The invention relates to the technical field of tobacco processing, in particular to a microcapsule humectant for cigarettes, a preparation method of the microcapsule humectant and application of the microcapsule humectant. The microcapsule humectant for the cigarettes comprises, by weight, 100 parts of chitosan solution with the mass concentration of 1-5%, 0.05-2 parts of emulgator sucrose ester, 10-20 parts of oil materials and 100-400 parts of sodium tripolyphosphate aqueous solution with the mass concentration of 0.5-3%, and the microcapsule humectant is prepared through emulsification and microencapsulation methods. By means of the microcapsule humectant, compositions of the microcapsule humectant are optimized, the technical problem that an existing humectant cracks under the 120-degree cut tobacco drying condition in the tobacco production process is solved in a targeted mode, the microcapsule humectant has the humectant performance and the dampproof performance, water losses or moisture absorption of cut tobaccos can be slowed down in the drying or high humidity environment, when the cigarettes are smoked, the cigarette aroma and the fresh and sweet tastes can be increased, the drying sense and stimulation are reduced, miscellaneous gas and remaining taste are improved, and quality of the cigarettes is greatly improved.

Owner:CHINA TOBACCO GUANGDONG IND +1

Coated sustained release tablets of a hygroscopic compound for once-a-day therapy

InactiveUS20030215509A1Moderate weight and volumeEasy to swallowBiocideAnimal repellantsProlonged-release tabletExcipient

The present invention provides coated sustained release tablets of a hygroscopic compound for once-a-day therapy, said tablets having a moderate weight and volume and comprising-(a) a core comprising the hygroscopic compound and pharmaceutically acceptable excipients, (b) a first coating layer comprising a polymer selected from the group consisting of water-insoluble polymers, pH dependent polymers or a mixture thereof, and (c) a second coating layer comprising a water-insoluble polymer.

Owner:SUN PHARMA INDS

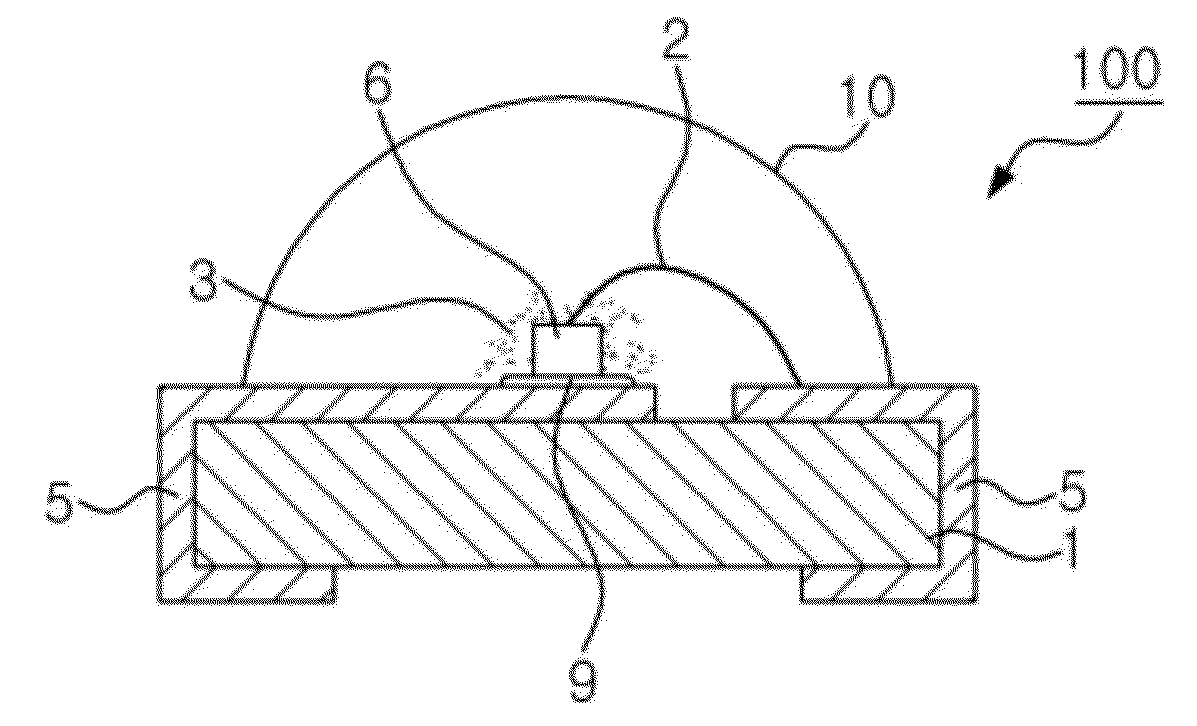

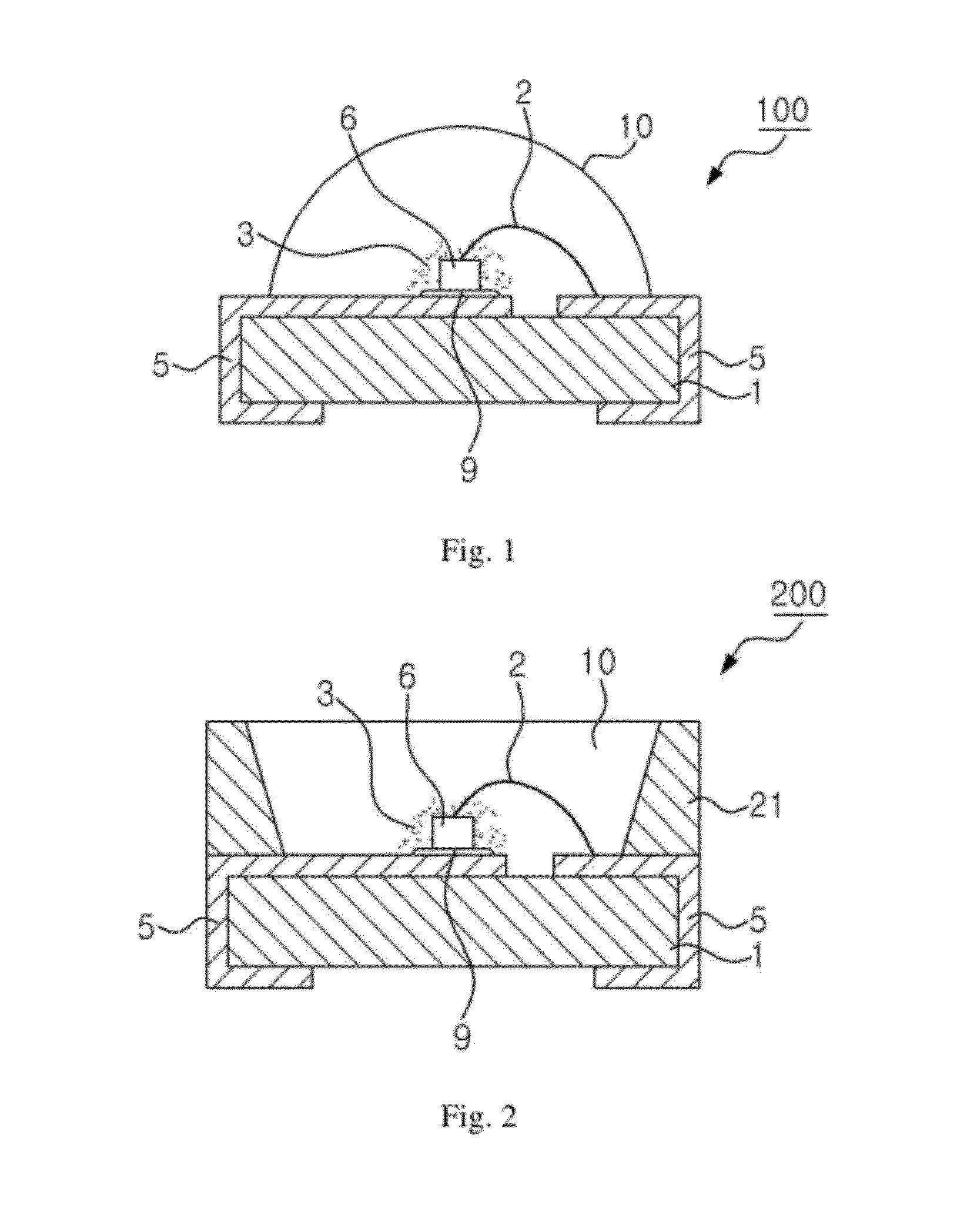

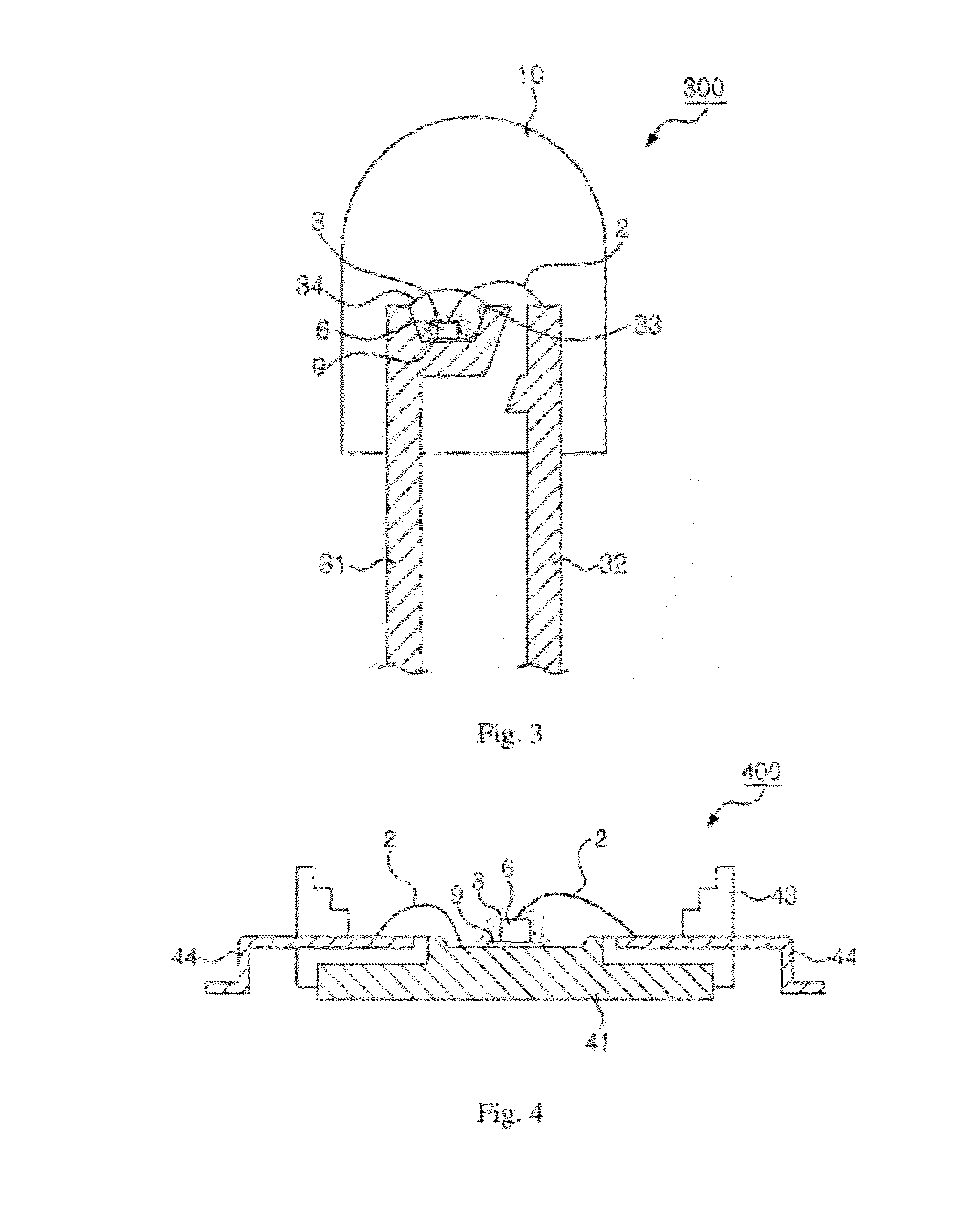

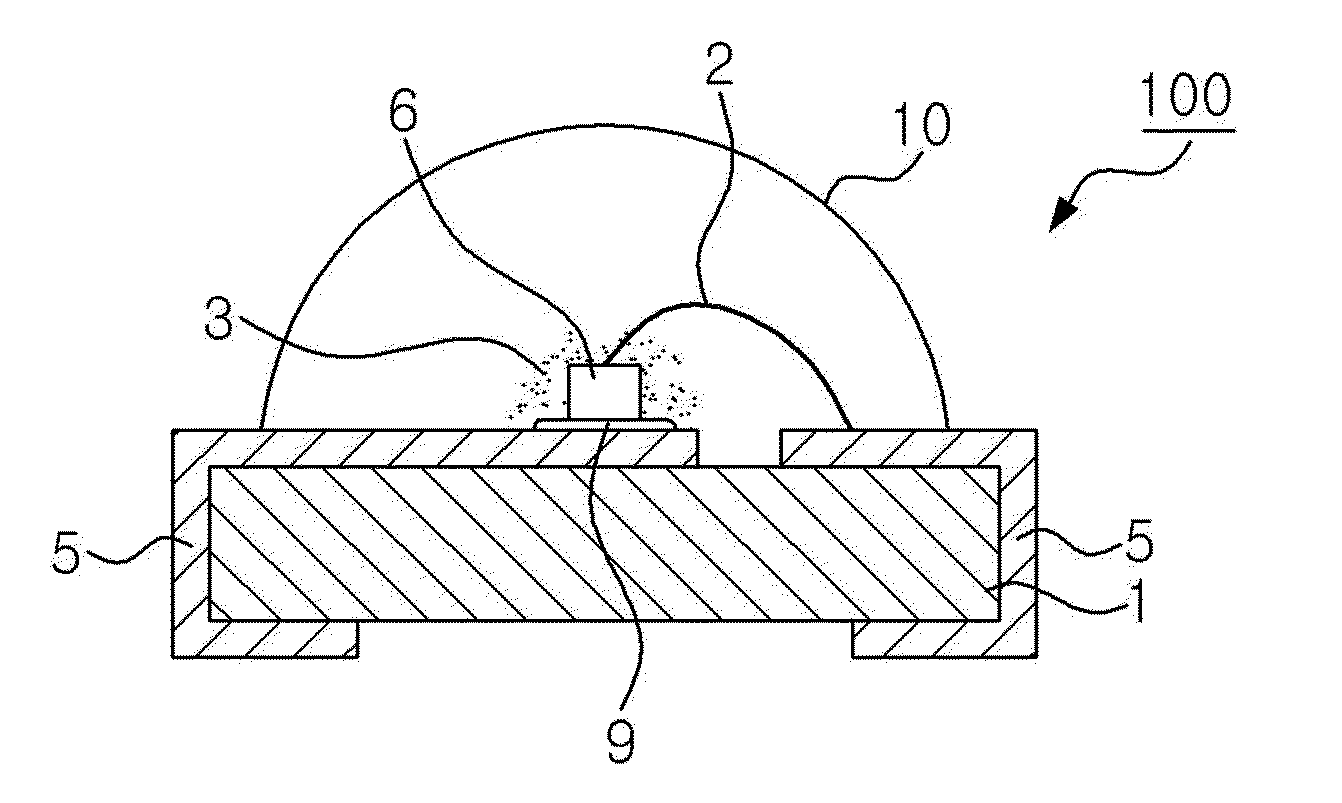

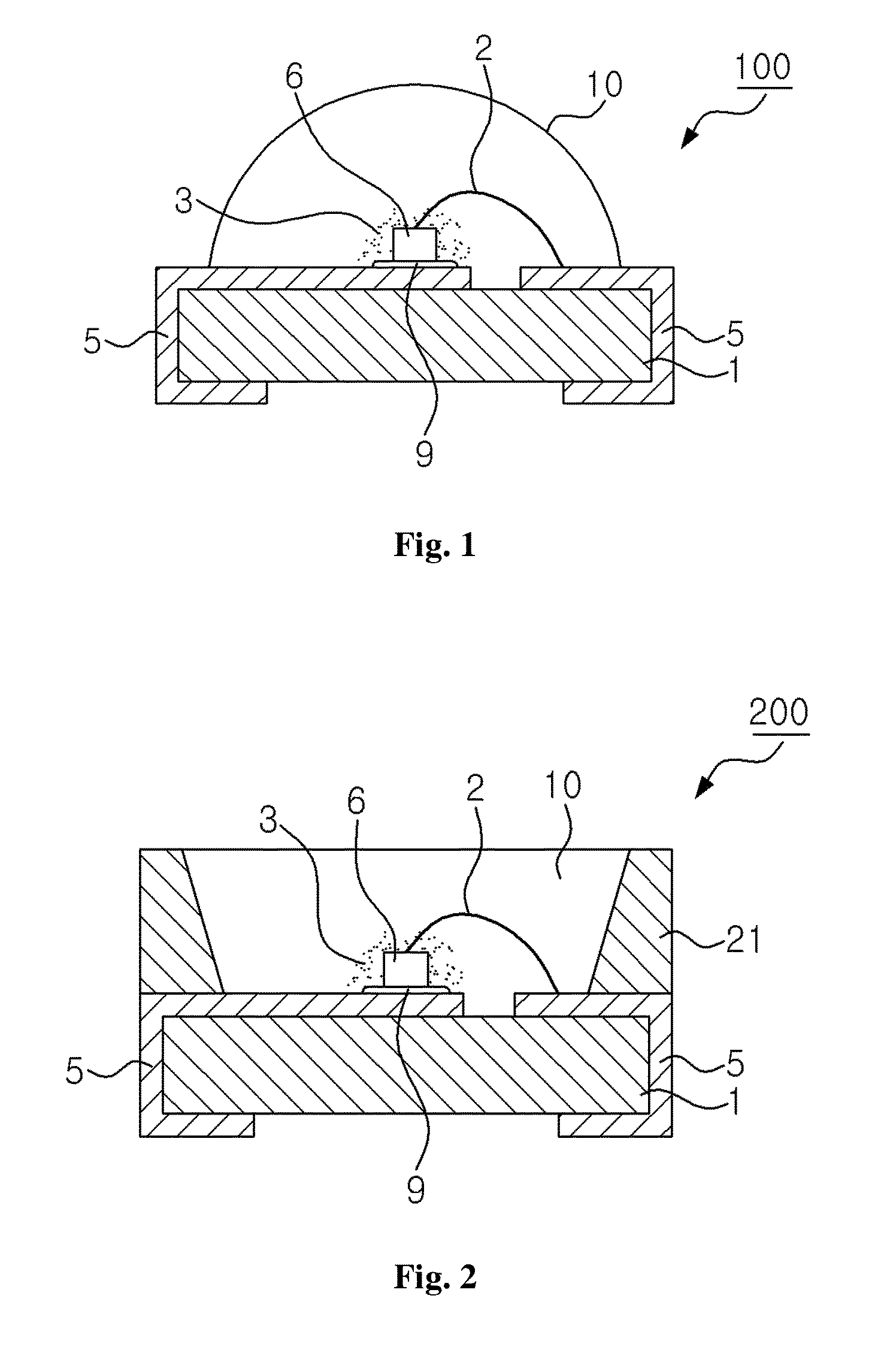

Light emitting device having surface-modified silicate luminophores

ActiveUS20120205674A1Moisture stableEasy to operateSolid-state devicesEnergy efficient lightingLuminophoreLight emitting device

Exemplary embodiments of the present invention relate to a light emitting device including a light emitting diode and a surface-modified luminophore. The surface-modified luminophore includes a silicate luminophore and a fluorinated coating arranged on the silicate luminophore.

Owner:LITEC GBR +1

Light emitting device having surface-modified quantum dot luminophores

ActiveUS9196785B2Moisture stableEasy to operateSolid-state devicesLuminescent compositionsLuminophoreQuantum dot

Exemplary embodiments of the present invention relate to a light emitting device including a light emitting diode and a surface-modified luminophore. The surface-modified luminophore includes a quantum dot luminophore and a fluorinated coating arranged on the quantum dot luminophore.

Owner:SEOUL SEMICONDUCTOR +1

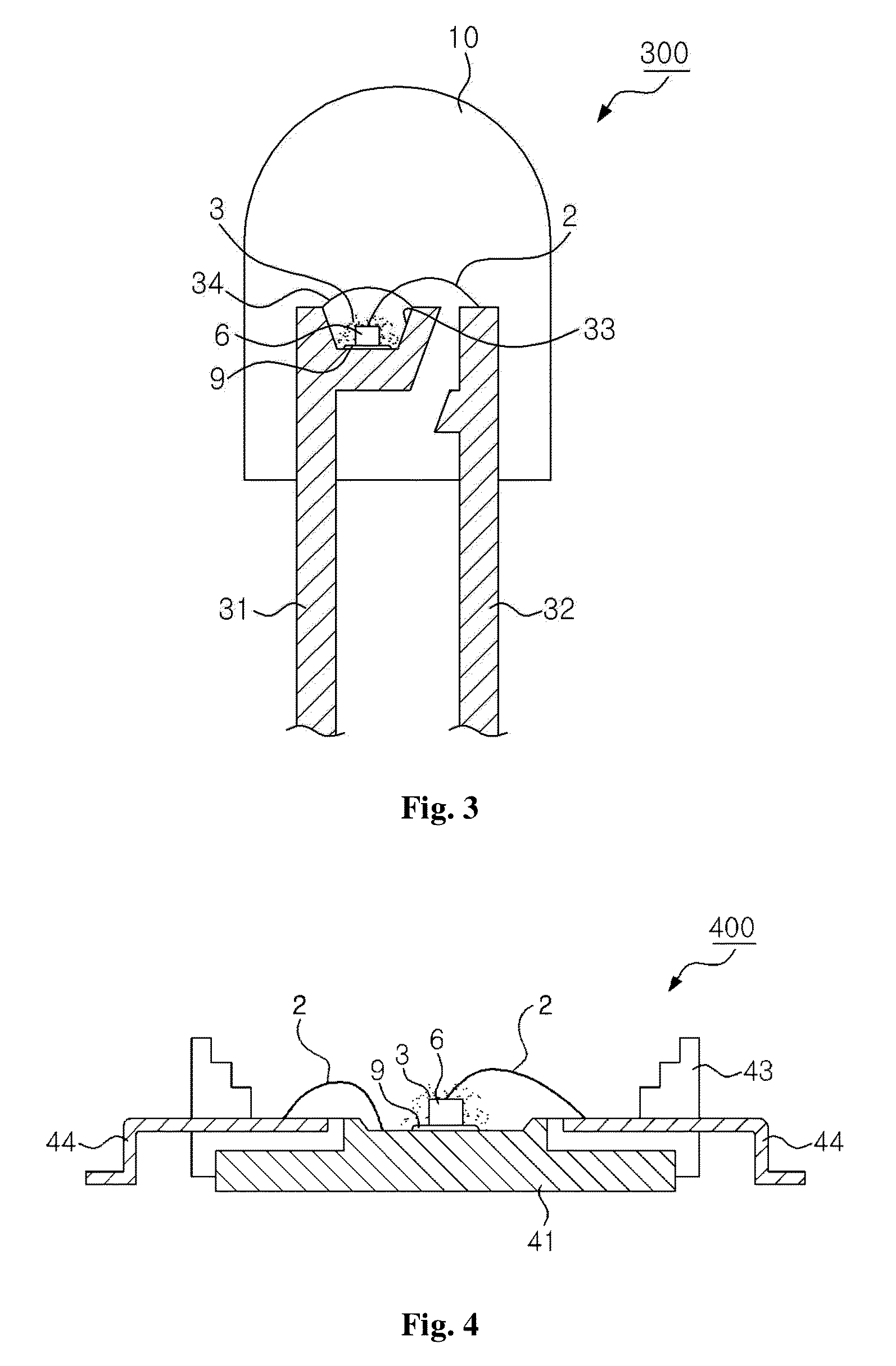

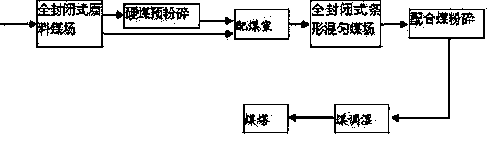

Technology for improving quality stability of coking charge coal

InactiveCN104140832AMoisture stableImproved stability of quality indicatorsCoke ovensCoal waterThermodynamics

The invention provides a technology for improving the quality stability of coking charge coal. The technology comprises the following steps: storing raw coal in a totally closed raw material coal yard, pre-crushing hard coal, uniformly mixing through a coal blending chamber in a totally closed bar-shaped mixing coal yard, crushing the obtained blended coal, damping the blended coal, and allowing the damped blended coal to go through a coal tower in order to realize final charge coking. The charge coal obtained through the technology has the characteristics of stable coal water, ash, volatile compounds and sulfur, stable coking performance and fines, and quality index stability increasing to above 4 sigma level.

Owner:SD STEEL RIZHAO CO LTD

Ecological restoring device and method for sand plants

InactiveCN102783374AMaterial universalSimple constructionSelf-acting watering devicesCultivating equipmentsBatch productionEngineering

The invention provides an ecological restoring device and method for sand plants. The ecological restoring device comprises a water-collecting moisture-preserving sand-proof device, a plant planting device and a continuous water supply device and is characterized in that the bottom of the water-collecting moisture-preserving sand-proof device is in a funnel shape, the water-collecting moisture-preserving sand-proof device is placed at the upper end of the plant planting device and crossed with the plant planting device, and the continuous water supply device is located beside the plant planting device and connected with the plant planting device through a pipeline. The ecological restoring method for the sand plants comprises the steps of hole digging, presetting, backfill, seedling planting, seeding, placing of the water-collecting moisture-preserving sand-proof device, water injection of the water supply device and surface soil covering and the like. The ecological restoring device and method for the sand plants have the advantages of universality in materials, easiness in manufacturing construction, convenience in transportation and batch production, degradation and little pollution to the environment and the like.

Owner:路域生态工程有限公司

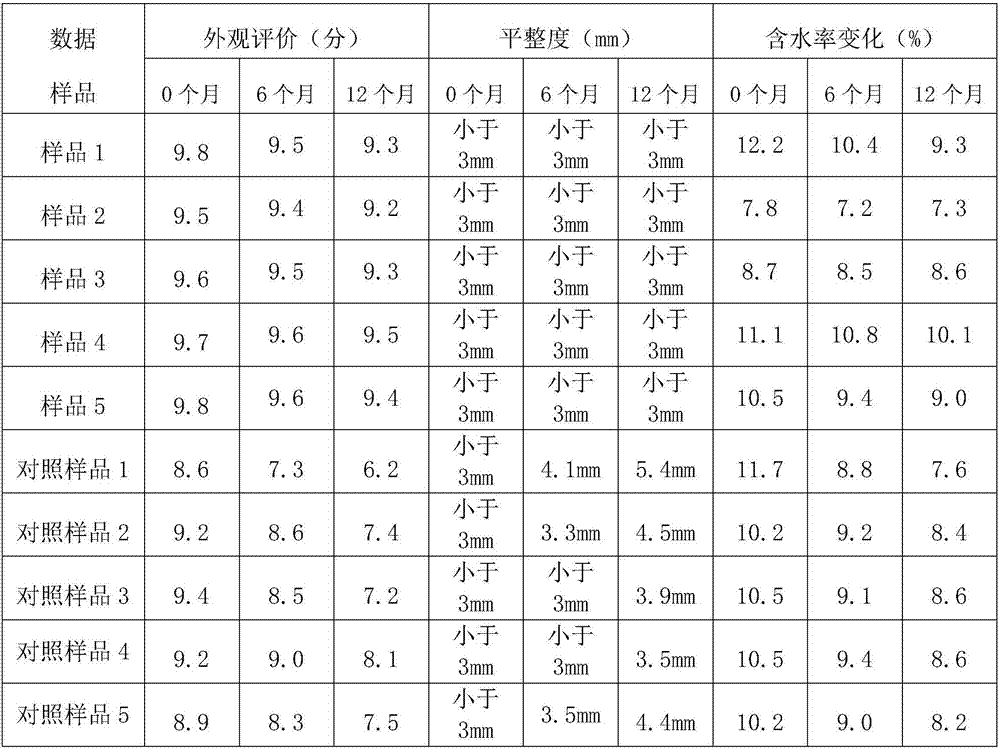

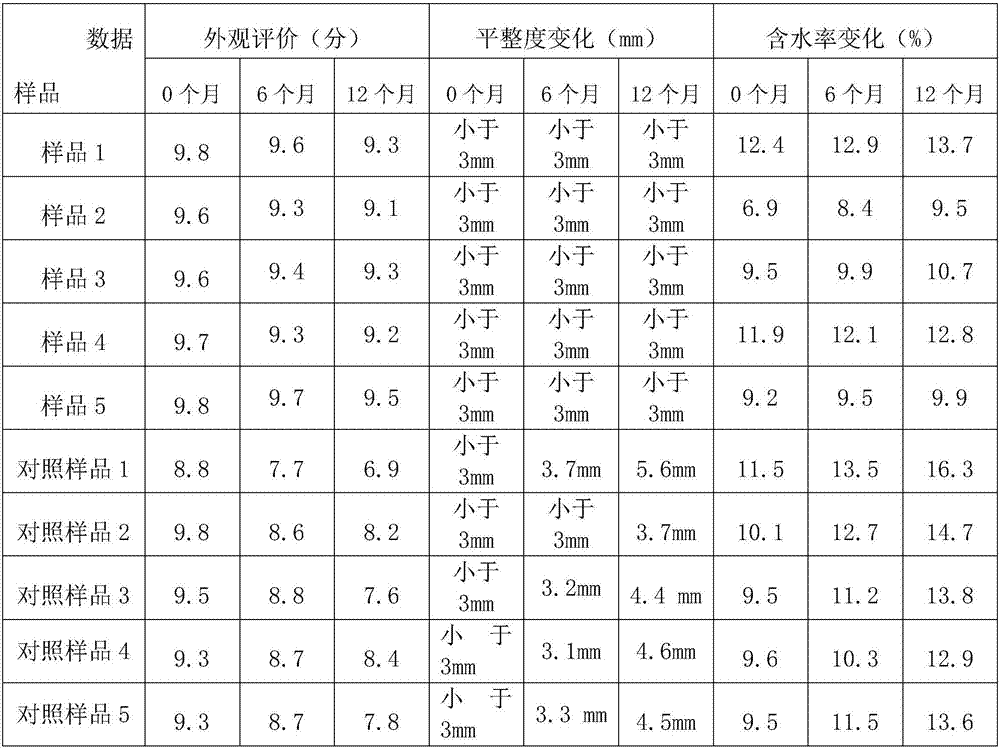

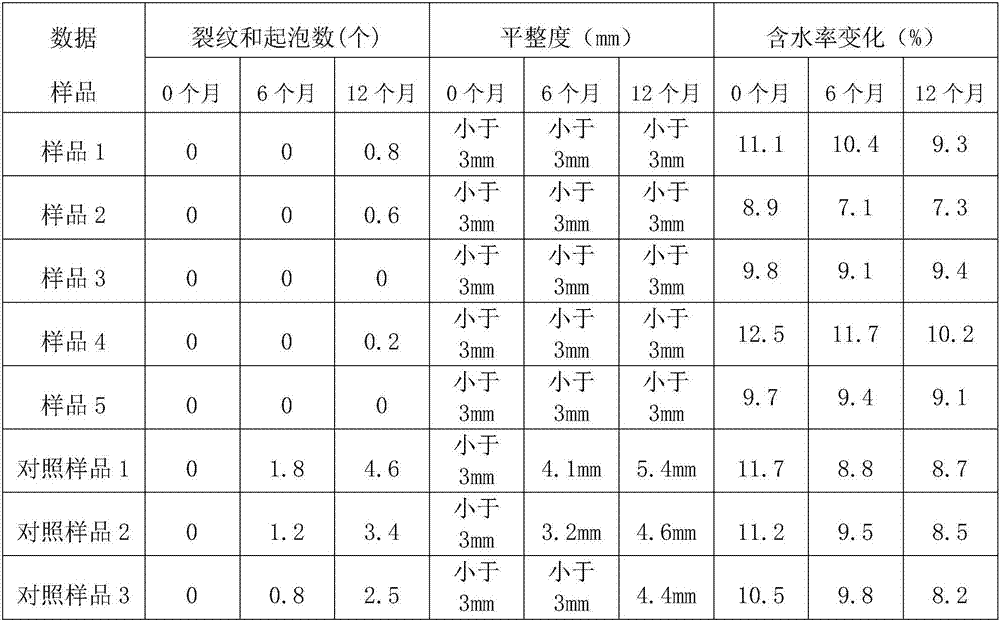

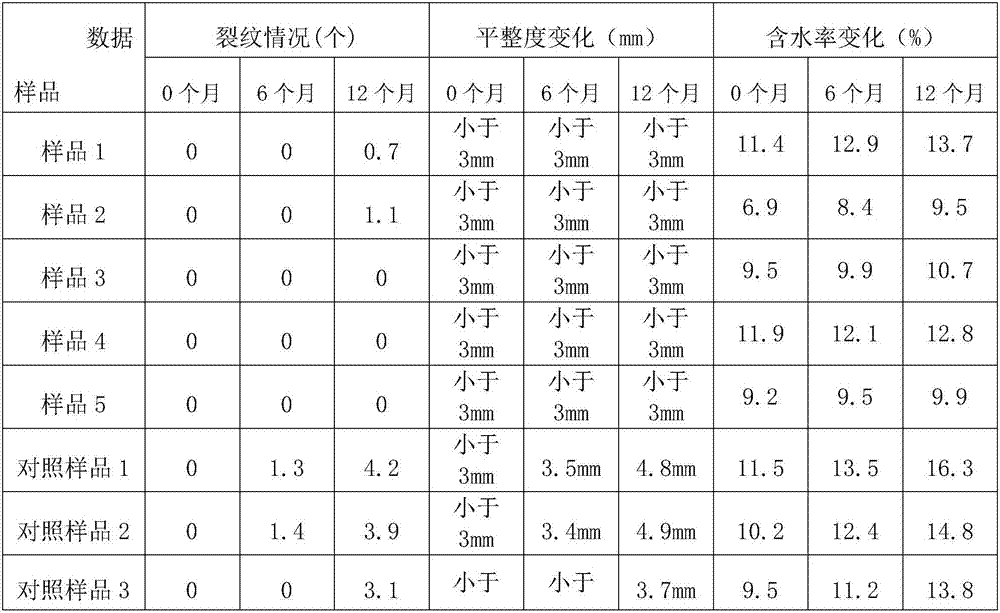

Production process of solid wood ecological board

InactiveCN107972137ASmall flatness changesMoisture stableLaminationLamination apparatusSolid woodEngineering

The invention relates to the technical field of solid wood board processing, in particular to a production process of a solid wood ecological board. The method comprises the steps that a, the saltingtreatment is carried out on a timber raw material; b, the raw material is cut into strips, and moisture control is carried out on the strips; c, the board strips are spliced into a board core, dust scraping is carried out on the board core, moisture control is carried out on the board core, and sanding is carried out on the board core; d, an eucalyptus wood chip is prepared; e, the board core andthe eucalyptus wood chip are attached and combined to undergo compression molding to obtain a blank board; f, standing and maintaining are carried out on the blank board; g, the blank board sequentially undergoes, first-time edge sawing, dust scraping, moisture control and sanding; h, the blank board and the poplar bark are attached and combined to obtain a base board; i, the base board sequentially undergoes sanding and second-time edge sawing; and j, a surface paper is pasted on the base board to obtain the solid wood ecological board. The formaldehyde releasing grade of the solid wood ecological board prepared by the production process is the E0 grade, and the ecological board can be directly used indoors; and in the using process, the solid wood board is stable in product quality, is not prone to deform and crack, can keep the original appearance for a long time, and meets the requirements of people on the high-quality furniture boards.

Owner:RONGAN HUAHAI WOOD

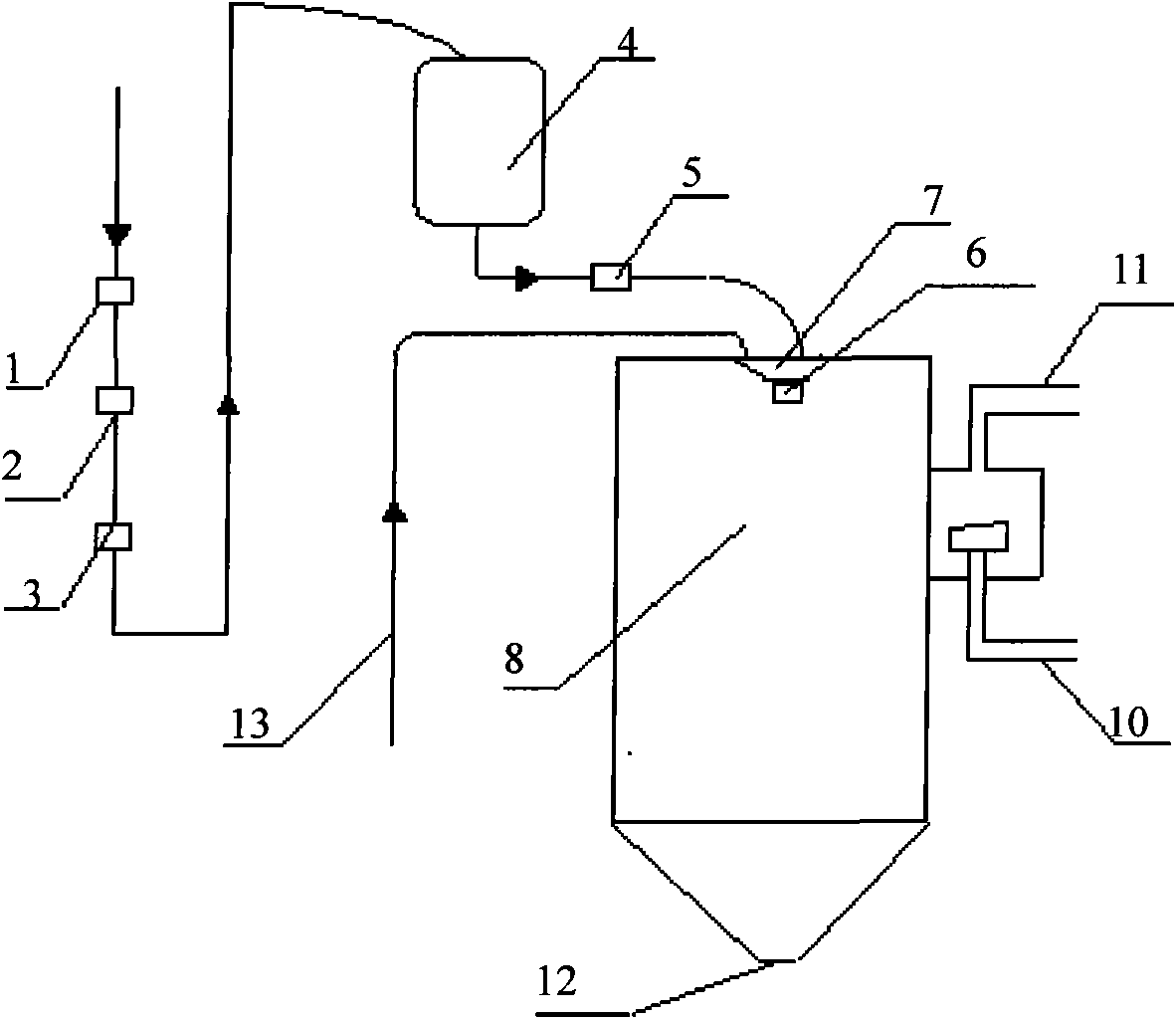

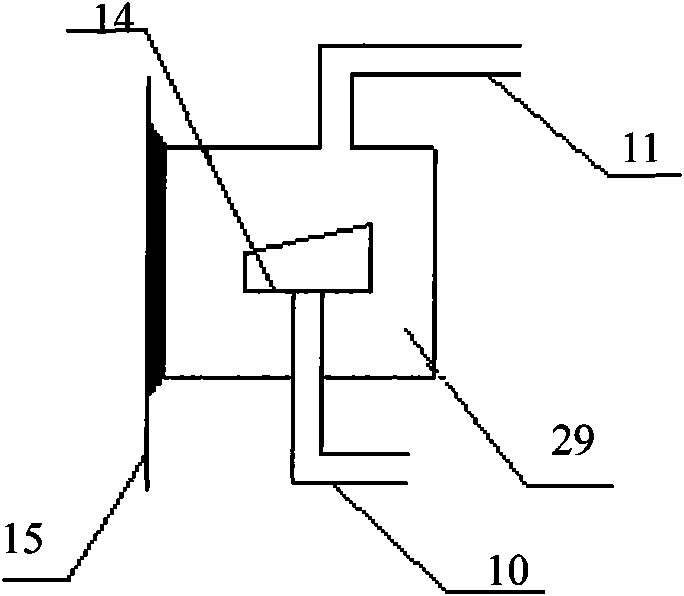

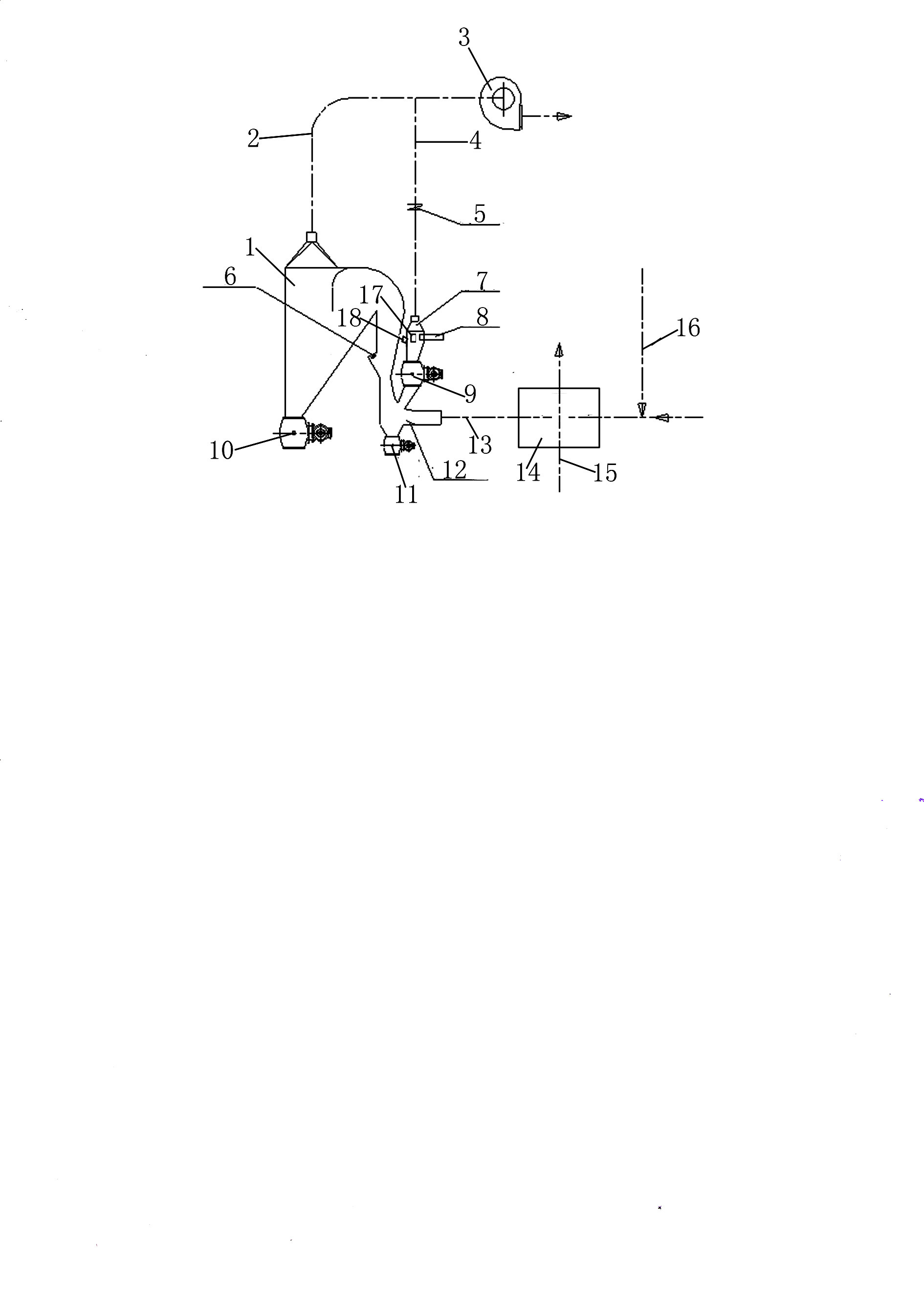

Method for drying hydrocortisone sodium succinate asepsis powder

ActiveCN101559287ASolve the problem of heat deteriorationSolve for uniform dryingSteroidsEvaporation by sprayingTemperature controlTower

The invention discloses a method for drying hydrocortisone sodium succinate asepsis powder, which comprises the following steps: delivering filtered hydrocortisone sodium succinate water solution into a temperature control tank, delivering the water solution after passing through a second precision filter into a spray drying tower, atomizing the water solution through an atomizer, and contacting the water solution with hot aseptic air to be dried. The top inside the spray drying tower is provided with a hot air distributor which comprises an inner pipe and an air deflector, the lower part of the air deflector is bent to one side, the outer surface of the tower wall of the spray drying tower is provided with a tower wall shaking device, one end of a dust discharge pipe is connected with an air hammer chamber, the other end of the dust discharge pipe is arranged outside a sterile room, the air hammer chamber is hermetically connected with the tower wall of the spray drying tower, and the dried hydrocortisone sodium succinate asepsis powder is discharged from a discharge hole at the bottom of the spray drying tower and collected by a cyclone separator. The method strictly ensures asepsis of liquid medicine, ensures even drying of materials, avoids dust pollution, and strictly ensures the cleanliness of the sterile room.

Owner:TIANJIN BIOCHEM PHARMA

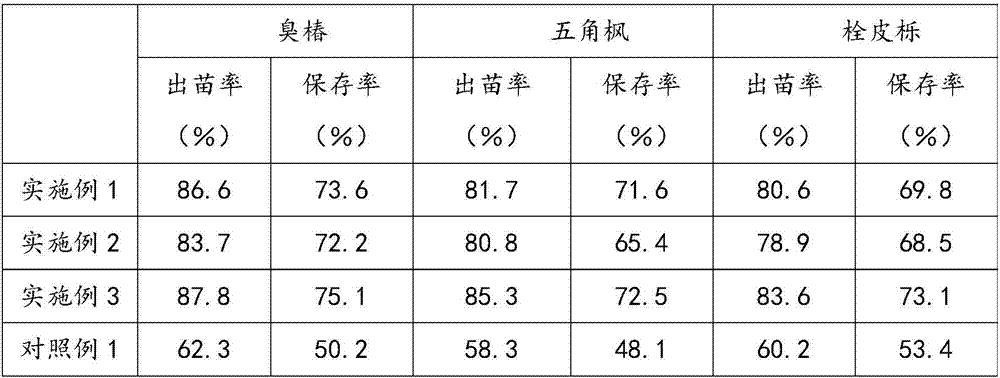

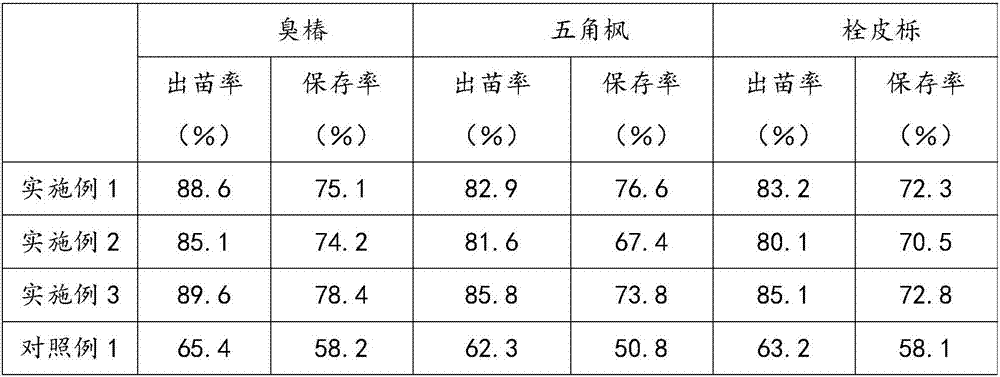

Seed vegetation block matrix suitable for arid stony mountainous area and preparation method thereof

The invention discloses a seed vegetation block matrix suitable for an arid stony mountainous area and a preparation method thereof and relates to the technical field of seed seedling raising. The technical problems of low afforestation seeding emergence rate, low qualified seedling percentage and low survival rate of the arid stony mountainous area are solved. The seed vegetation block matrix suitable for the arid stony mountainous area is prepared from, by weight, 5-8 parts of clay, 2-5 parts of organic matter, 0.005-0.05 part of water-retaining agent and 0.005-0.05 part of slow release fertilizer. The preparation method comprises the steps that organic matter is collected, smashed and screened to obtain organic matter with the particle size of 40-60 mesh, then composting is performed, the composted organic matter, the clay, the water-retaining agent and the slow release fertilizer are fully mixed and stirred evenly, the prepared mixture is compressed by using a three-hole former or two-hole former with the diameter of 10 cm and the length of 15 cm to obtain the seed vegetation block matrix. The seed vegetation block matrix has the advantages of ensuring sufficient moisture and nutrient supply for seeds during germination and seedling growth and improving the emergence rate and preserving rate.

Owner:河南省林业科学研究院

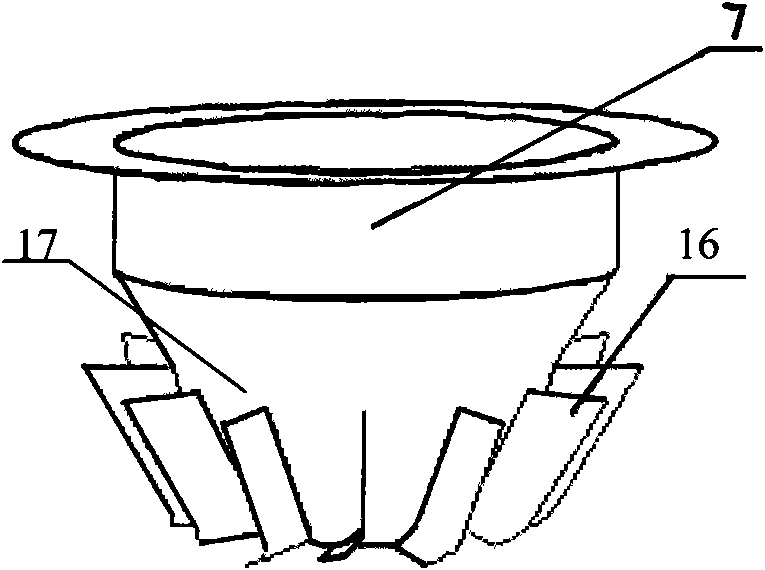

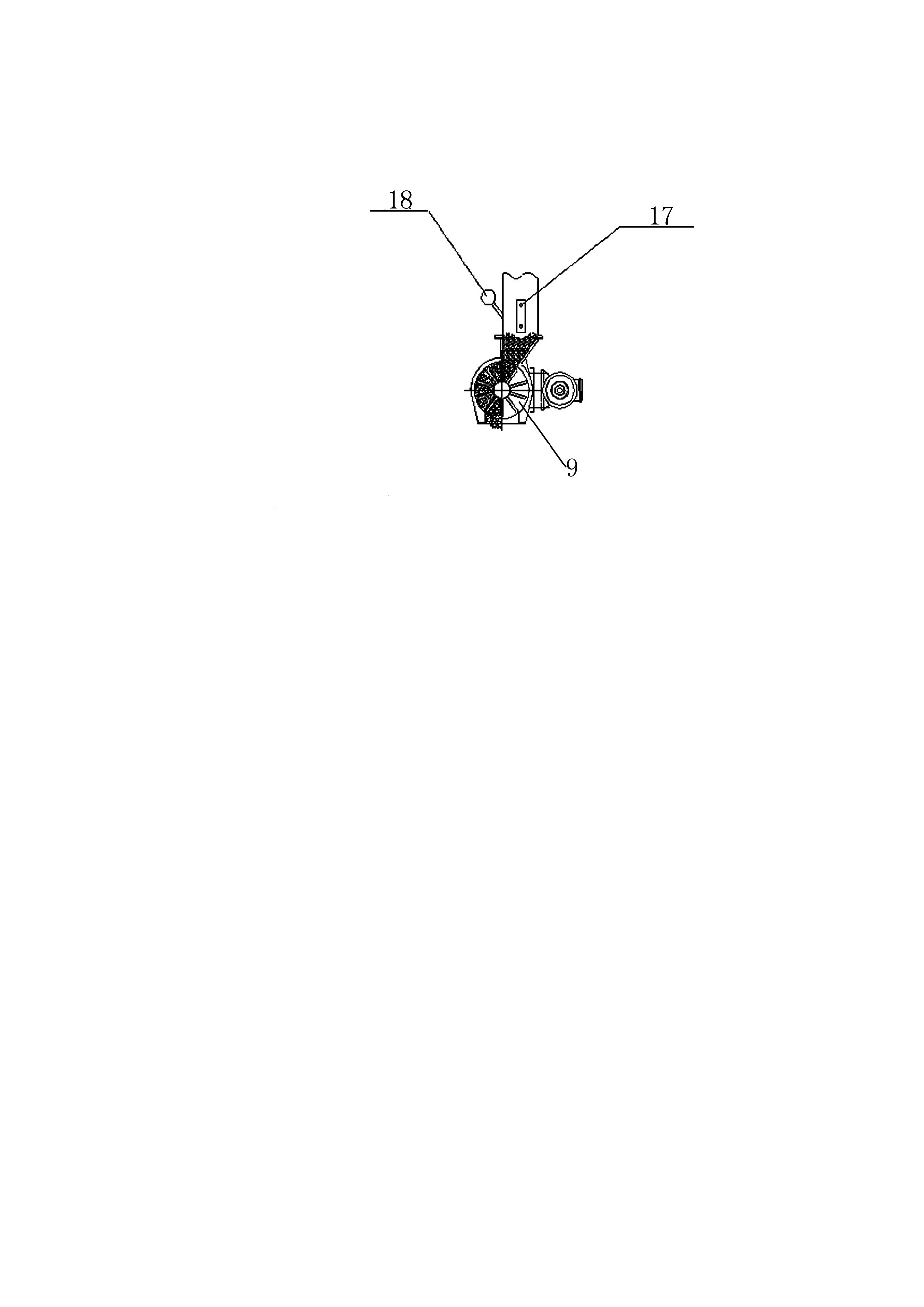

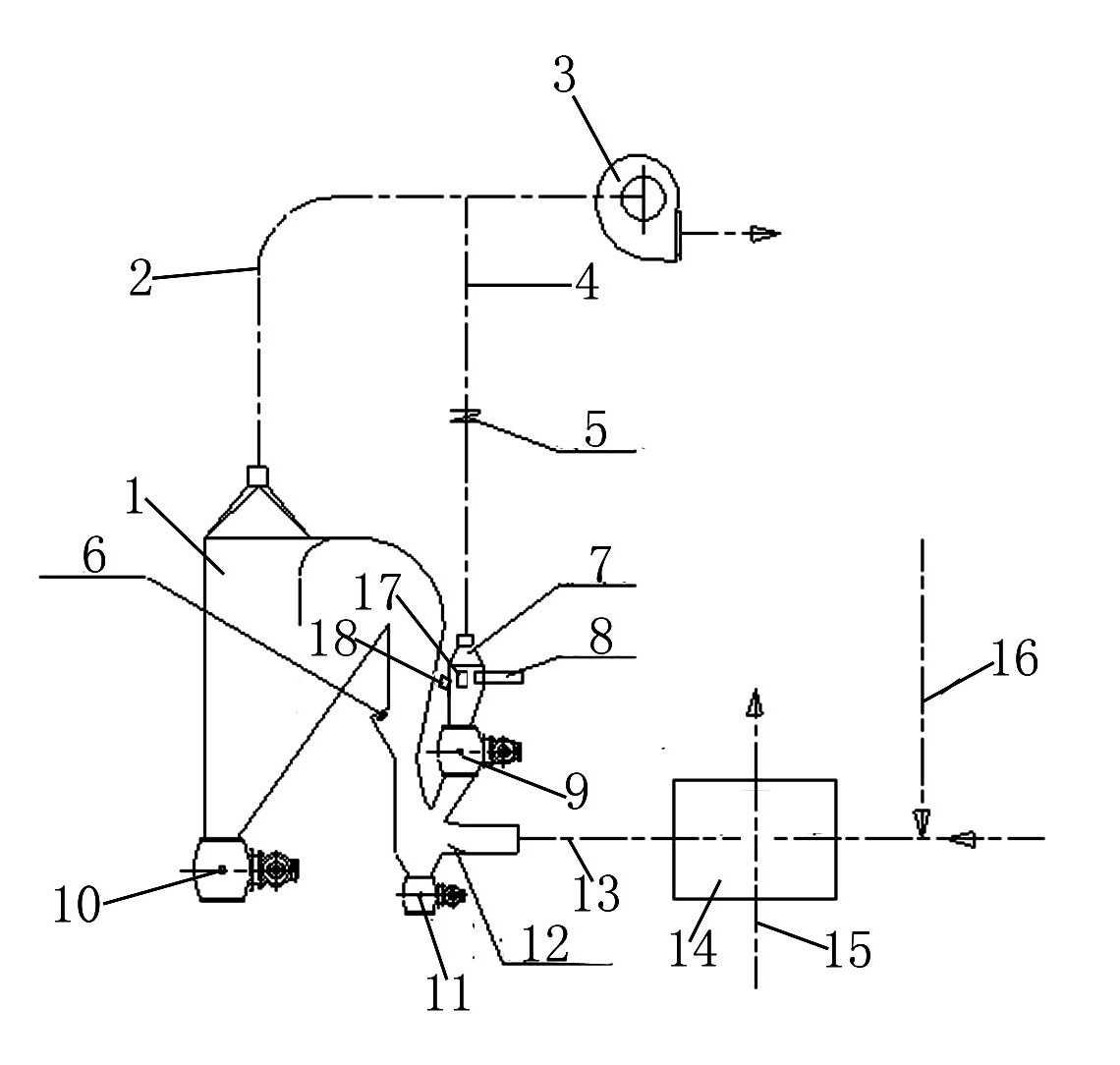

Feeding device for gas flow equipment

InactiveCN101982387AMoisture stableReduce purityTobacco preparationFinal product manufactureCross connectionEngineering

The invention discloses a feeding device for gas flow equipment. The feeding device comprises blanking units of branched cylinders, wherein the lower part of the blanking unit of one branched cylinder is provided with a discharge gas lock, and the upper part of the blanking unit is connected with a dehumidifying fan; the lower part of the blanking unit of the other branched cylinder is provided with a three-way port; the lower port of the three-way port is provided with an impurity removal gas lock, the horizontal port of the three-way port is connected with a dehumidifying process gas pipeline and a supplementary steam pipeline after being in cross connection with burner flue gas pipelines, and the upward inclination port of the three-way port is provided with a feed gas lock and a dehumidifying pipeline; the lateral cylinder of the blanking unit on the upper part of the impurity removal gas lock is provided with a charging nozzle; a cache straight pipe section with a dehumidifying hood is installed between the feed gas lock and the pipeline; and the intersection of a burner flue gas pipeline outlet and the dehumidifying process gas pipeline is provided with a heat-pipe heat exchanger. The feeding device disclosed by the invention has the functions of energy recovery, air-separation impurity removal, quantitative feeding, outlet moisture stabilization and uniform charging, and satisfies the process requirements of a gas flow drying technology in tobacco processing.

Owner:QINHUANGDAO TOBACCO MACHINERY

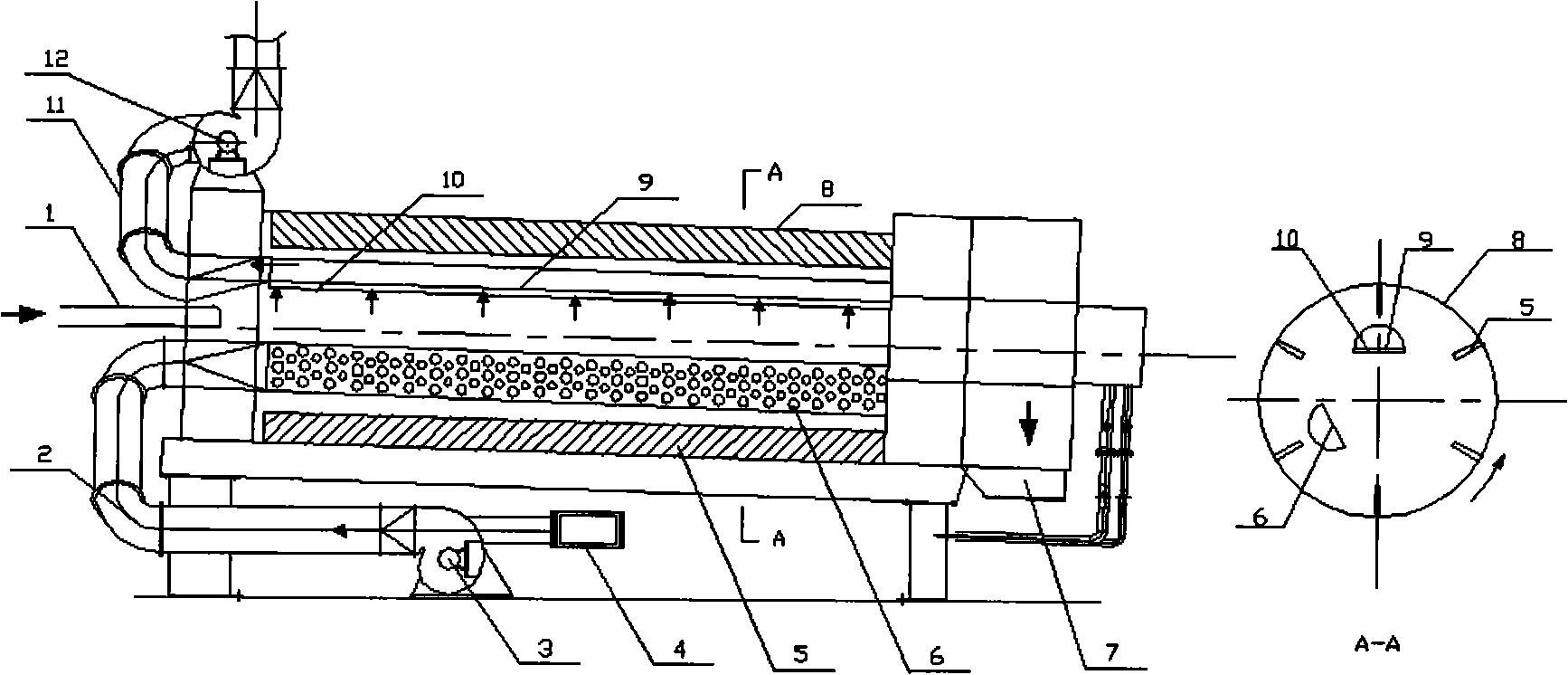

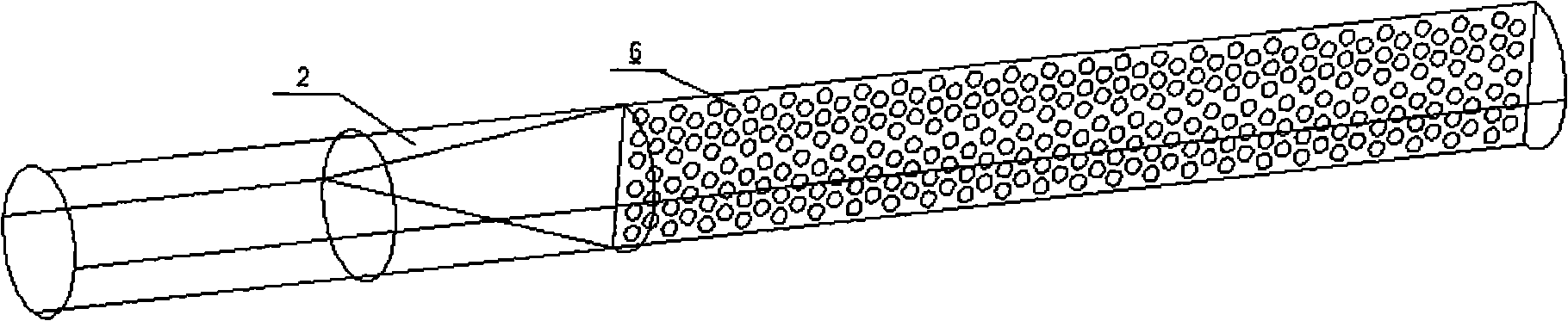

Cross-flow type cylinder tobacco dryer

ActiveCN101491367ADwell time has no effectStable residence timeTobacco preparationPulp and paper industryUltimate tensile strength

The invention provides a cross flow type roller tobacco dryer, which comprises a roller, a hot air inlet pipeline system, a moisture discharging pipeline system, a feed opening and a discharge opening. The tobacco dryer is characterized in that a hot air pipe is inserted from the lower part of the feed opening of the roller; an air inlet of the hot air pipe is arranged on the eight-o'clock position(on the side opposite to the lifted cut tobacco) in the roller, and the width of the air inlet is the same as the length of the roller; the radial air inlet is realized along the direction of the opening face of the air inlet facing to the shaft line of the roller, and air inlet grid plates are arranged along the whole air inlet; a moisture discharging port is arranged on the twelve-o'clock position, the opening of the moisture discharging port is downward, and the width of the moisture discharging port is the same as the length of the roller; and a filter net and air outlet grid plates are arranged along the whole moisture discharging port, and a moisture discharging pipe extends out of the upper part of the feed opening. The tobacco dryer is characterized in that due to the reasonable arrangement of the hot air inlet and the moisture discharging port, the problem of uneven treatment strength along the axial direction and the influence of air speed on the staying time are eliminated. According to style characteristics of products, a control method can be freely chosen, thereby reducing the risk of structural fluctuation of the cut tobacco and stabilizing the physical indexes of the products.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

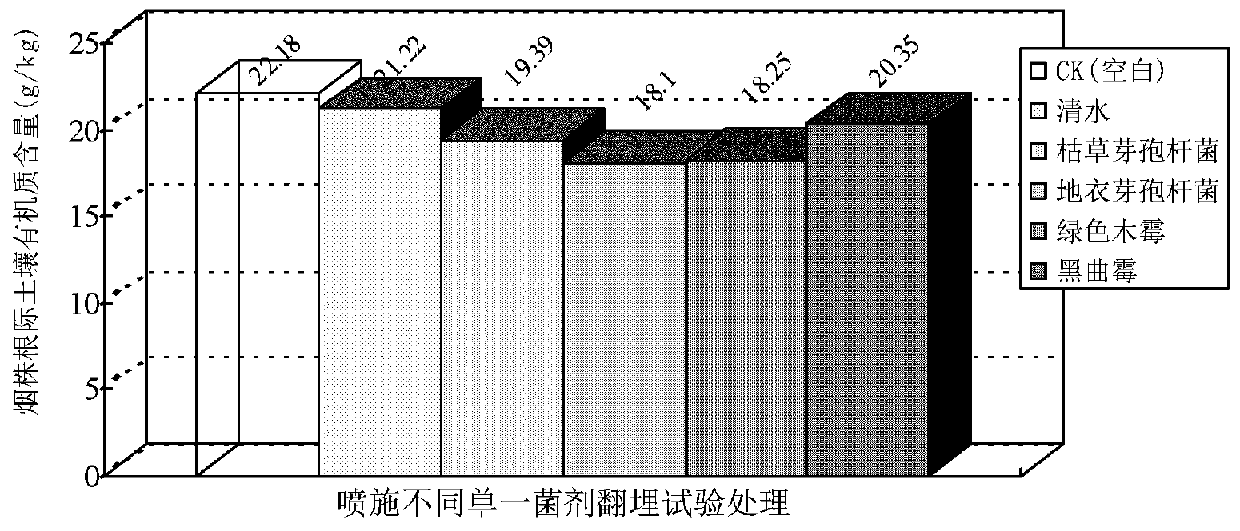

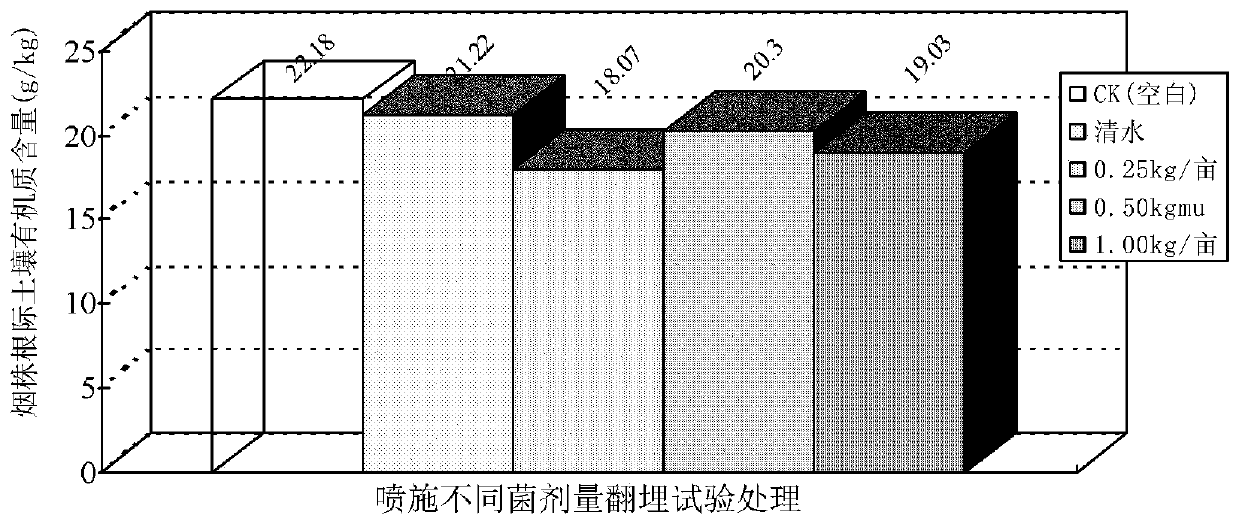

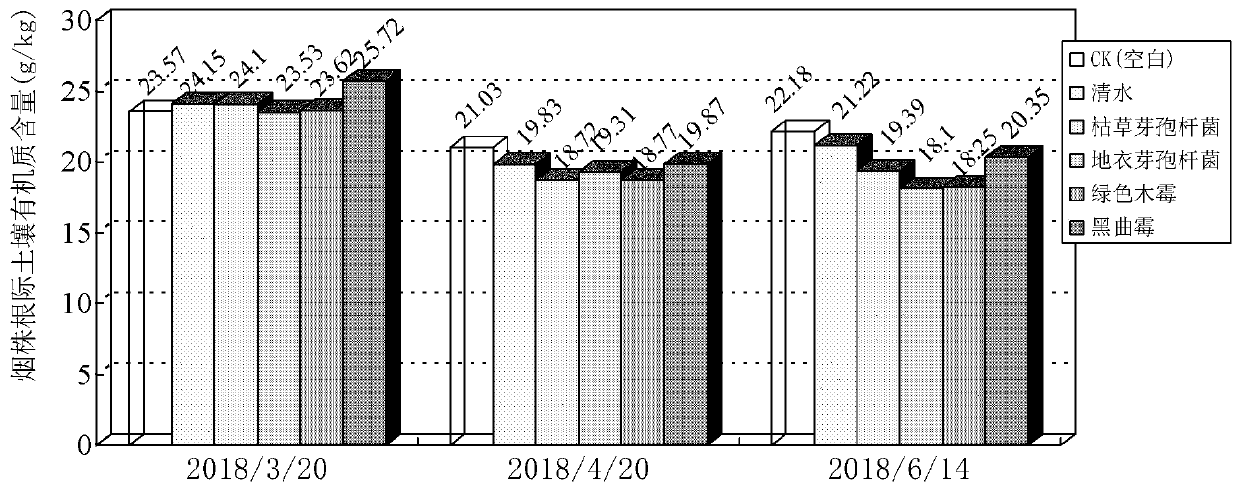

Method of quickly decomposing green straws of plant and preventing and controlling root knot nematode disease of flue-cured tobacco

InactiveCN109748735AImprove soil textureIncrease temperatureFungiBio-organic fraction processingFungicideNutrient

The invention relates to a method of quickly decomposing green straws of a plant and preventing and controlling root knot nematode disease of flue-cured tobacco. The method comprises the following steps: selecting oil radish with a root knot nematode disease resistant gene as a green straw of green manure; screening four microorganisms which have preventing and controlling effects and decompose the green straw efficiently to the root knot nematode disease; spraying a decomposing fungicide in a full-bloom stage by proportioning the four fungicides at proper concentrations; and turning over anddecomposing the green straw sprayed by the fungicide locally for over 60 days, wherein by accelerating quick and efficient decomposition of the green straw, in the condition of reducing 30% of a chemical fertilizer, organic matters of rhizosphere soil of flue-cured tobacco cultivation are degraded quickly, and primary nutrients: nitrogen phosphorus and potassium are full. The method is obvious inpreventing and controlling effects to the root knot nematode disease in the flue-cured tobacco cultivation process, and the tobacco leaf output value is improved obviously. The invention relates to the simple method which decomposes the green straw quickly, increases organic matters and nutrients of soil effectively, prevents and controls root knot nematode disease of cultivated crops in the nextstubble and improves the crop output and quality.

Owner:HONGHEZHOU BRANCH OF YUNNAN TOBACCO +1

Method for controlling moisture content of solid wood ecological board

ActiveCN107984575APrecise control of moisture contentLittle changeWood compressionWood treatment detailsSolid woodEngineering

The invention relates to the technical field of solid board processing, in particular to a method for controlling the moisture content of a solid wood ecological board. The method for controlling themoisture content of the solid wood ecological board comprises the following steps of a, processing wood raw materials; b, cutting the raw materials into platens; c, controlling the moisture of the platens; d, splicing the platens to form a board core; e, controlling the moisture of the board core; f, controlling the moisture of eucalyptus chips; g, forming a laminating board through the eucalyptuschips and the board core; and h, controlling the moisture of the laminating board. According to the method for controlling the moisture content of the solid wood ecological board, a multi-step moisture control method is adopted for key materials from the raw materials to the finished product, the product moisture is controlled to be in a reasonable and stable environment, the product is not proneto deforming or cracking in the using process, and the using quantity of chemical waterproof reagents is reduced.

Owner:RONGAN HUAHAI WOOD

Polypeptide essence having efficacy of relieving allergy and repairing and preparation method of polypeptide essence

InactiveCN110652489ARepair barrierOvercome barriersCosmetic preparationsToilet preparationsAllergyTrehalose

Owner:奢脉国际化妆品(北京)有限公司

Preparation method of precipitated calcium carbonate special for pvc anti stone impact coating

ActiveCN104403433BLow hygroscopicityMoisture stableCalcium/strontium/barium carbonatesCoatingsFiltrationPolyvinyl chloride

The invention discloses a preparation method for special precipitated calcium carbonate for a PVC (polyvinyl chloride) stone chip resistant coating. The preparation method comprises the technical operation as follows: adjusting the ratio of lime milk to be 1.040-1.080, feeding kiln gas with the flow of 6-10m<3> / h, controlling the specific surface area of matured slurry to be 16-40m<2> / g when the pH value of reaction liquid is reduced to be below 7.0, and adding a composite surface treatment agent at the temperature of 50-90 DEG C for wrapping, wherein the total adding amount of the surface treatment agent is 1.5-5.0 percent of dry calcium carbonate base; performing pressure filtration dewatering, drying, smashing and packaging on the slurry to obtain a precipitated calcium carbonate product for the PVC stone chip resistant coating. The precipitated calcium carbonate prepared by the preparation method disclosed by the invention is lower in hygroscopicity, so that the thixotropy, yield value and viscosity of filling of PVC plastipaste are effectively controlled, and the rheology stability of the PVC plastipaste is improved. The method disclosed by the invention is simple, feasible and low in production cost, and has higher economical and social benefits.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

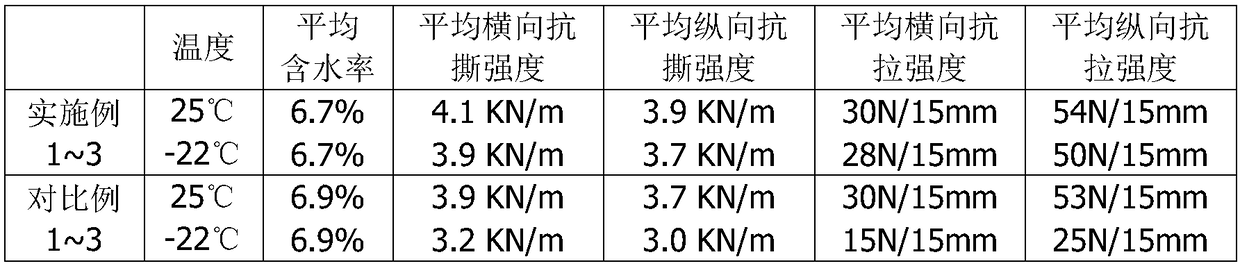

Freeze-resistant twisted paper and production method thereof

ActiveCN108691248AGood flexibilityHigh tear strengthNon-fibrous pulp additionFlexible coversWaxD-mannitol

The invention discloses a freeze-resistant twisted paper and a production method thereof and belongs to the field of packaging. The freeze-resistant twisted paper comprises a paper base layer, a printing layer disposed on the upper surface of the paper base layer, and a wax layer disposed on the lower surface of the paper base layer. The paper base layer is subjected to osmotic treatment. A penetrant comprises 30% of glycerin, 20% of D-mannitol, 3% of sorbitol and 47% of water. The freeze-resistant twisted paper solves the problem that the common wrapping paper is easy to crack and hardens after absorbing water.

Owner:SHANTOU FANGDA INNOVATIVE TECH

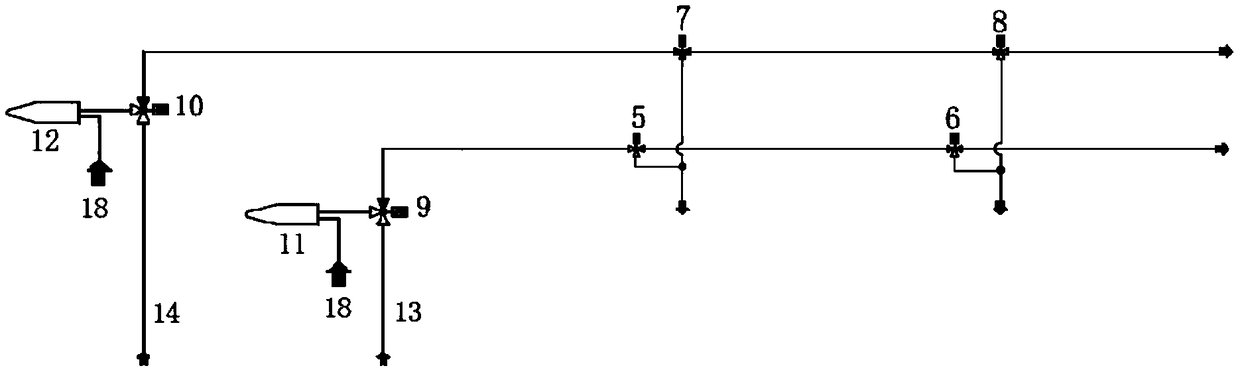

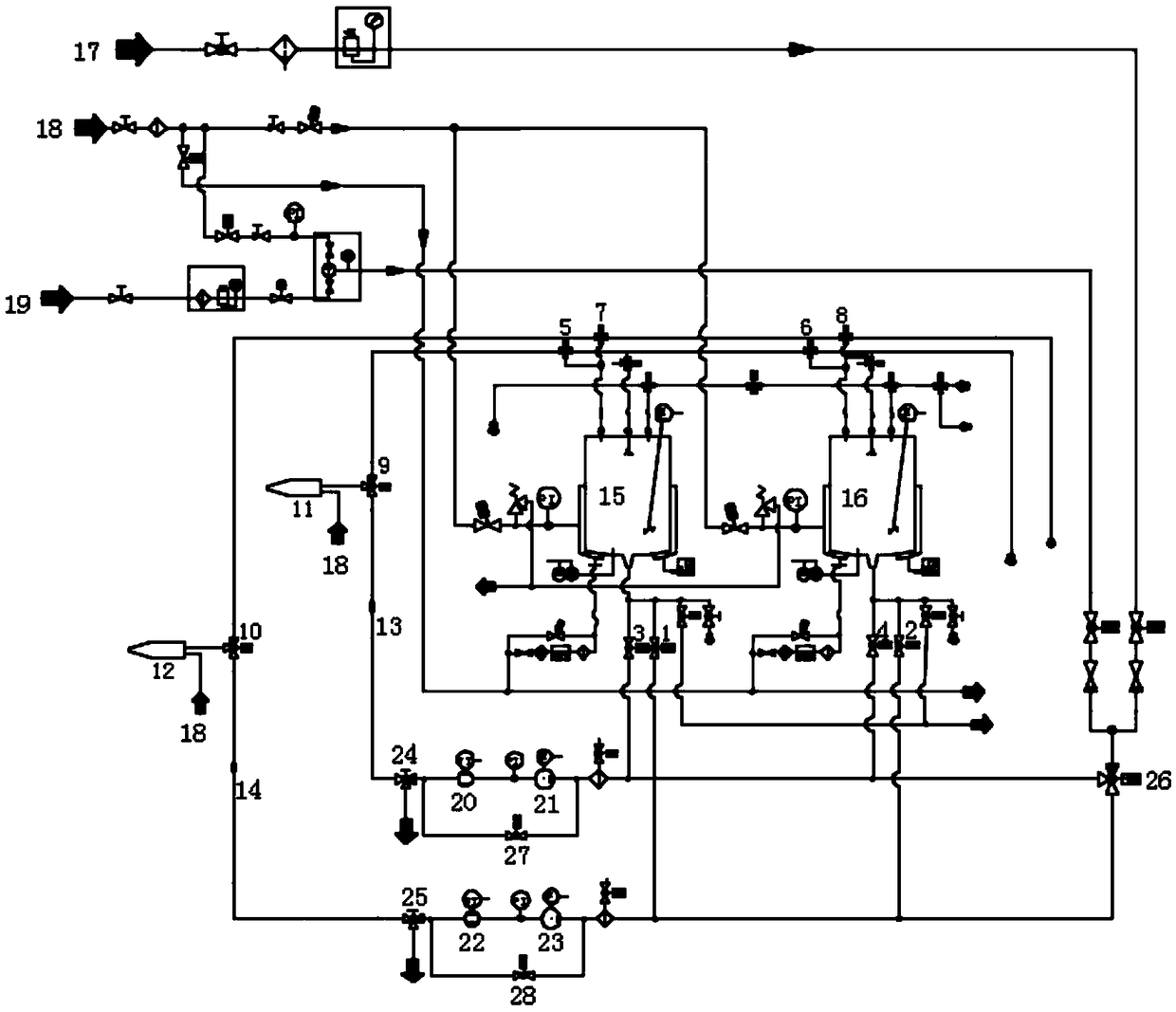

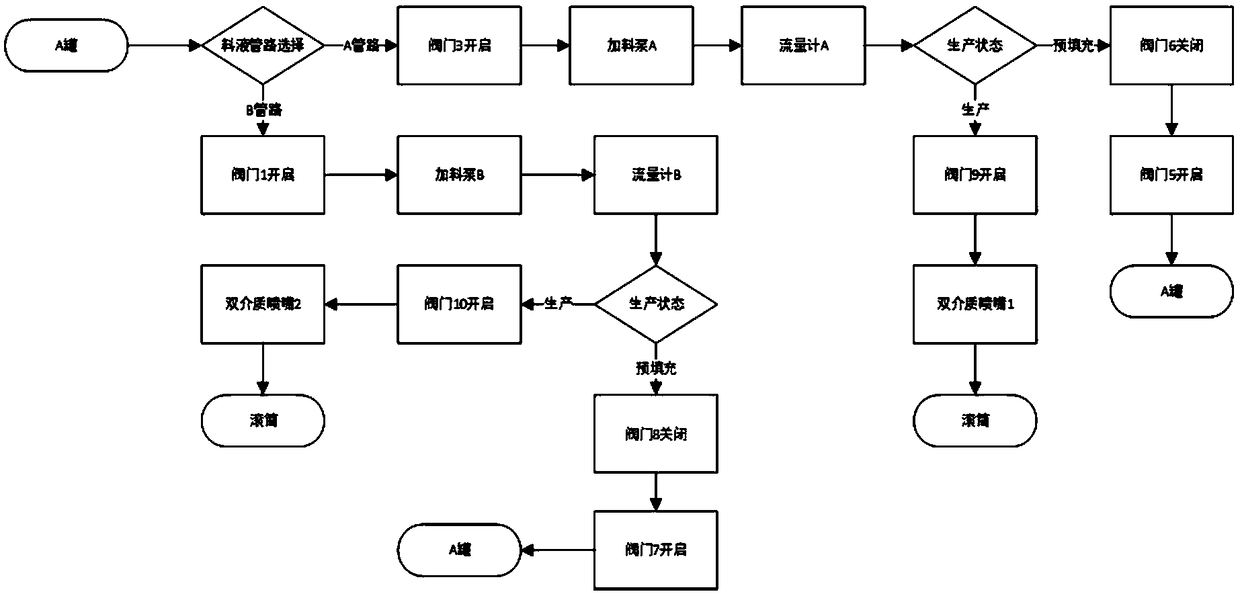

Tobacco primary processing secondary charging and water replenishing control system and method

PendingCN108887730AEnsure continuous production of equipmentMeeting Diversity RequirementsTobacco preparationTobacco treatmentSteel tubeContinuous production

A tobacco primary processing secondary charging and water replenishing control system is characterized in that two independent charging and water replenishing pipelines are designed after an originalpipeline exits from a flowmeter, a first pneumatic three-way valve, a second pneumatic three-way valve, a fifth pneumatic three-way valve and double-medium nozzles A and B are newly added, and are connected together by a stainless steel tube, and by the pipeline, two independent charging and water replenishing pipelines can be formed; the first pneumatic three-way valve and the second pneumatic three-way valve are switched over for a feeding tank of a feed liquid pipeline loop; and the fifth pneumatic three-way valve is switched over for production and pre-filling pipelines. Quantified water replenishing and proportional water replenishing are designed and meet different process requirements; double charging pipelines are selected in production, and can be used flexibly, the pipelines canbe switched over if equipment fails in production, and continuous material feeding in production is realized; and continuous production of the equipment and completeness of a blade assembly formula can be ensured.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com