Technology for improving quality stability of coking charge coal

A technology of quality stability and furnace loading, applied in the field of coking coal, can solve the problems of large fluctuation of coal fineness, poor hysteresis and controllability, fluctuation of coal fineness, etc., and achieve small fluctuation of coke strength index, The effect of high product qualification rate and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

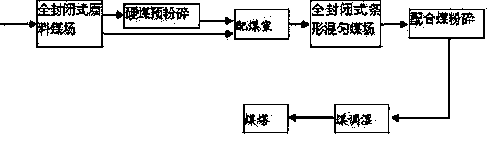

[0041] Each coking single coal is transported to the fully enclosed rectangular coal yard through the belt conveyor, and is stored separately by the coal type by the stacking equipment, and the coal quality is initially homogenized, for example, even for two types of coal that are the same gas coal , and their properties will also be different. Mixing them together can make the gas coal homogeneous, and naturally control a certain amount of moisture during the storage period.

[0042] According to production needs, the coking coal stored in the closed coal yard is sent to the next process by the reclaiming equipment and conveyor, and the hard gas coal, lean coal, 1 / 3 coking coal, etc. are pre-crushed to make them fine The temperature is increased by 10%, and then sent to the coal blending section. Coking coal, coking coal and fat coal with small hard coal equipment do not need to be pre-crushed, but are directly sent to the coal blending section to be blended with pre-crushed ...

Embodiment 2

[0048] Each coking single coal is transported to the fully enclosed circular coal yard through the belt conveyor, and is stored by the stacking equipment according to the coal type, and the coal quality is initially homogenized and a certain amount of moisture is naturally controlled during the storage period.

[0049] According to production needs, the coking coal stored in the closed coal yard is sent to the next process by the reclaiming equipment and conveyor, and the hard gas coal, lean coal, 1 / 3 coking coal, etc. are pre-crushed to make them fine The degree is increased by 15%, and then sent to the coal blending section. Coking coal, coking coal and fat coal with small hard coal equipment do not need to be pre-crushed, but are directly sent to the coal blending section to be blended with pre-crushed hard coal according to coking needs to prepare blended coal.

[0050] The blended coal obtained is sent to the fully enclosed strip-shaped mixed coal yard through the belt co...

Embodiment 3

[0055] Each coking single coal is transported to the fully enclosed circular coal yard through the belt conveyor, and is stored by the stacking equipment according to the coal type, and the coal quality is initially homogenized and a certain amount of moisture is naturally controlled during the storage period.

[0056] According to production needs, the coking coal stored in the closed coal yard is sent to the next process by the reclaiming equipment and conveyor, and the hard gas coal, lean coal, 1 / 3 coking coal, etc. are pre-crushed to make them fine The degree is increased by 20%, and then sent to the coal blending section. Coking coal, coking coal and fat coal with small hard coal equipment do not need to be pre-crushed, but are directly sent to the coal blending section to be blended with pre-crushed hard coal according to coking needs to prepare blended coal.

[0057] The blended coal obtained is sent to the fully enclosed strip-shaped mixed coal yard through the belt co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com