Patents

Literature

78 results about "Hard coal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anthracite, often referred to as hard coal, is a hard, compact variety of coal that has a submetallic luster. It has the highest carbon content, the fewest impurities, and the highest energy density of all types of coal and is the highest ranking of coals.

System and method for atmospheric carbon sequestration

ActiveUS20100257775A1Increase carbon emissionsLiquid surface applicatorsSolid waste disposalCarbon sequestrationCoal

This invention relates to systems and methods for converting biomass into highly inert carbon. Specifically, some embodiments densify the carbon into anthracite-style carbon aggregations and store it in geologically stable underground deposits. The use of certain embodiments yield a net effect of removing atmospheric carbon via the process of photosynthesis and converting it into hard coal, which can be stored in underground beds that mimic existing coal deposits which are known to be stable for thousands of years.

Owner:COOL PLANET ENERGY SYST

Method for progressive gas drainage in high gas medium-hard coal seam

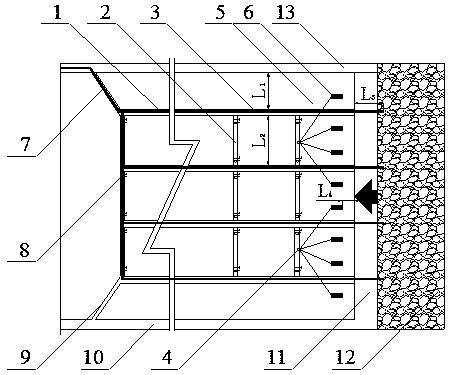

The invention relates to a coal seam gas drainage method, specifically to a method for progressive gas drainage in high gas medium-hard coal seam, which solves the problem of areal gas extraction efficiency. When stopes in multiple roadways are excavated, a long borehole, the length of which is required to be capable of at least running through the distance of reserved roadway strips at two sides of the next stope, is constructed in advance for a next adjacent stope area inside a column outside the stope, drainage in the mining area of the next stope area is performed in advance during excavation of this stope, in order to guarantee that the next adjacent stope area has sufficient drainage time, roadway excavation of the next stope area is performed at the drained strip position, the adjacent stope area is then mined, and simultaneously, the long borehole is constructed for the next adjacent stope area to continue gas drainage in such a progressive, circulative advancing manner. Thus normal alternation of drainage, excavation and mining is ensured.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

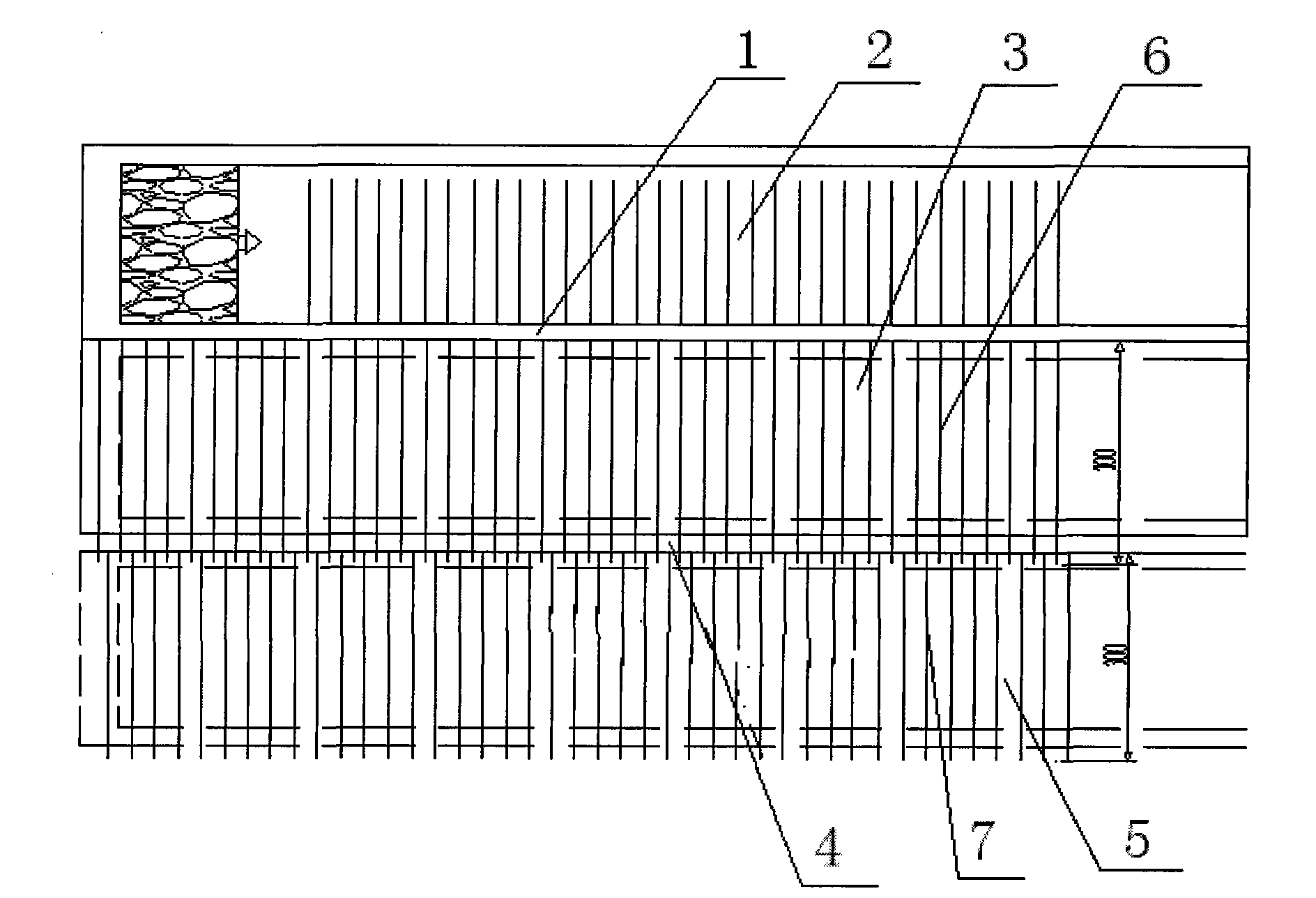

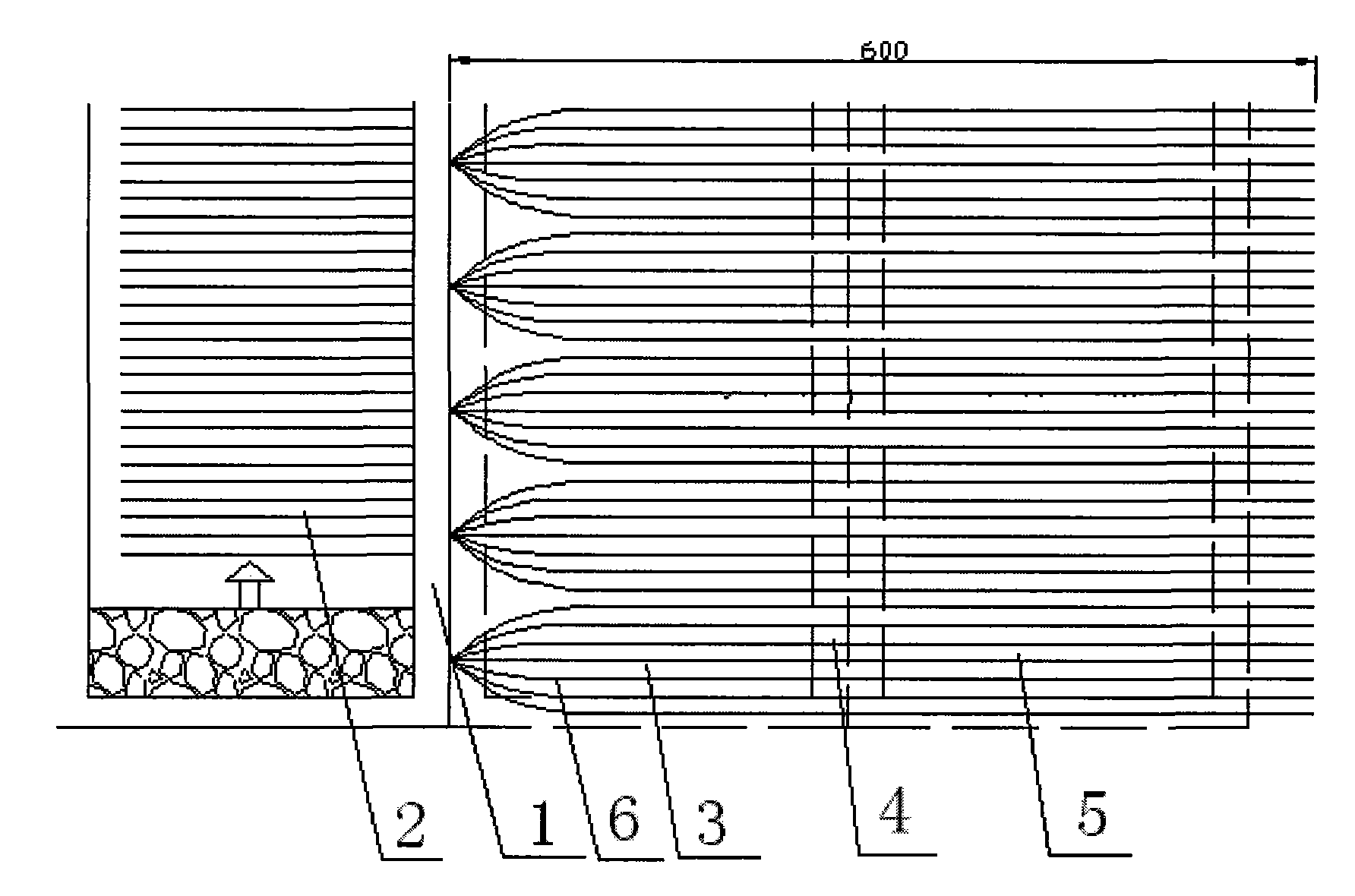

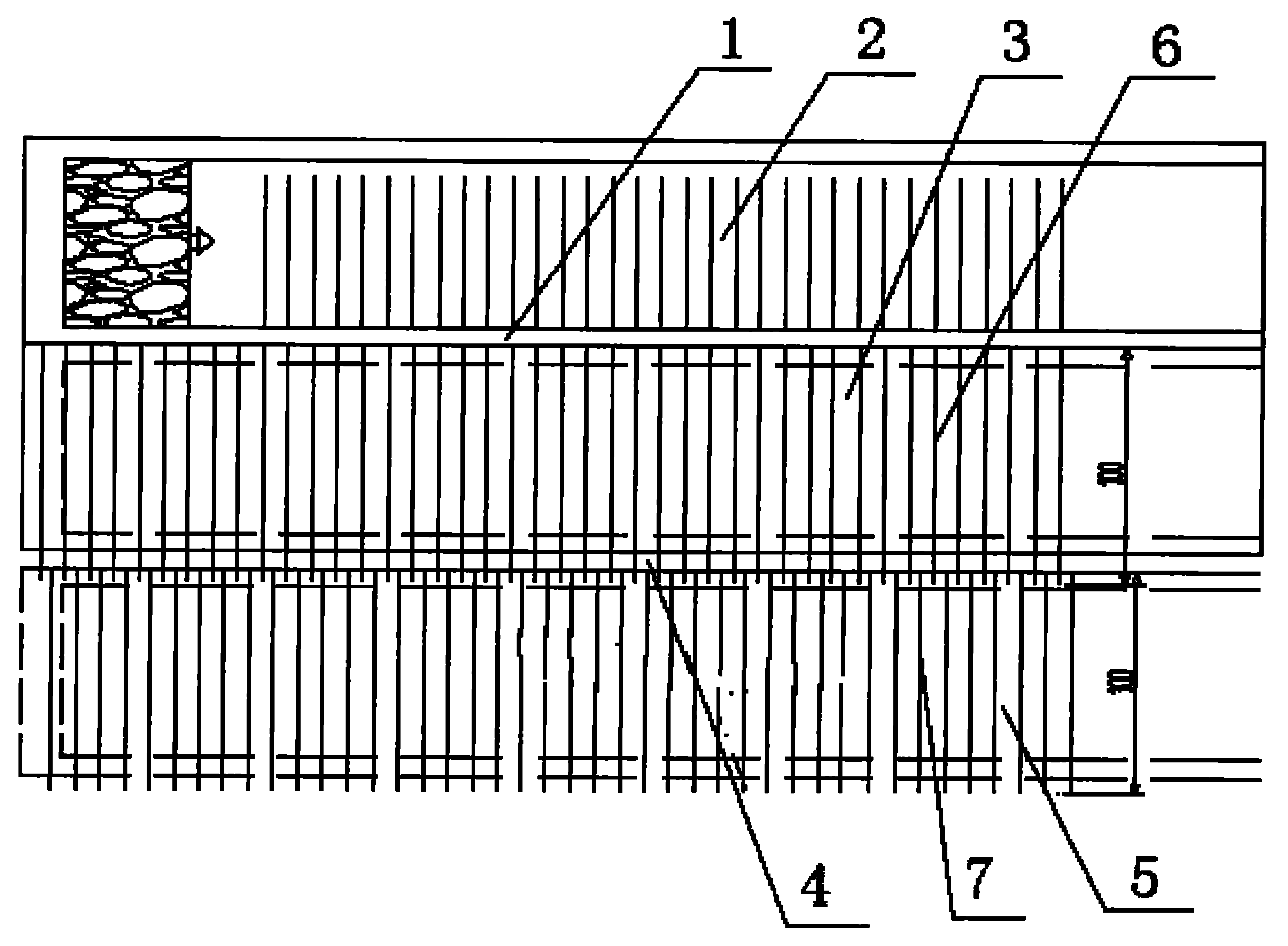

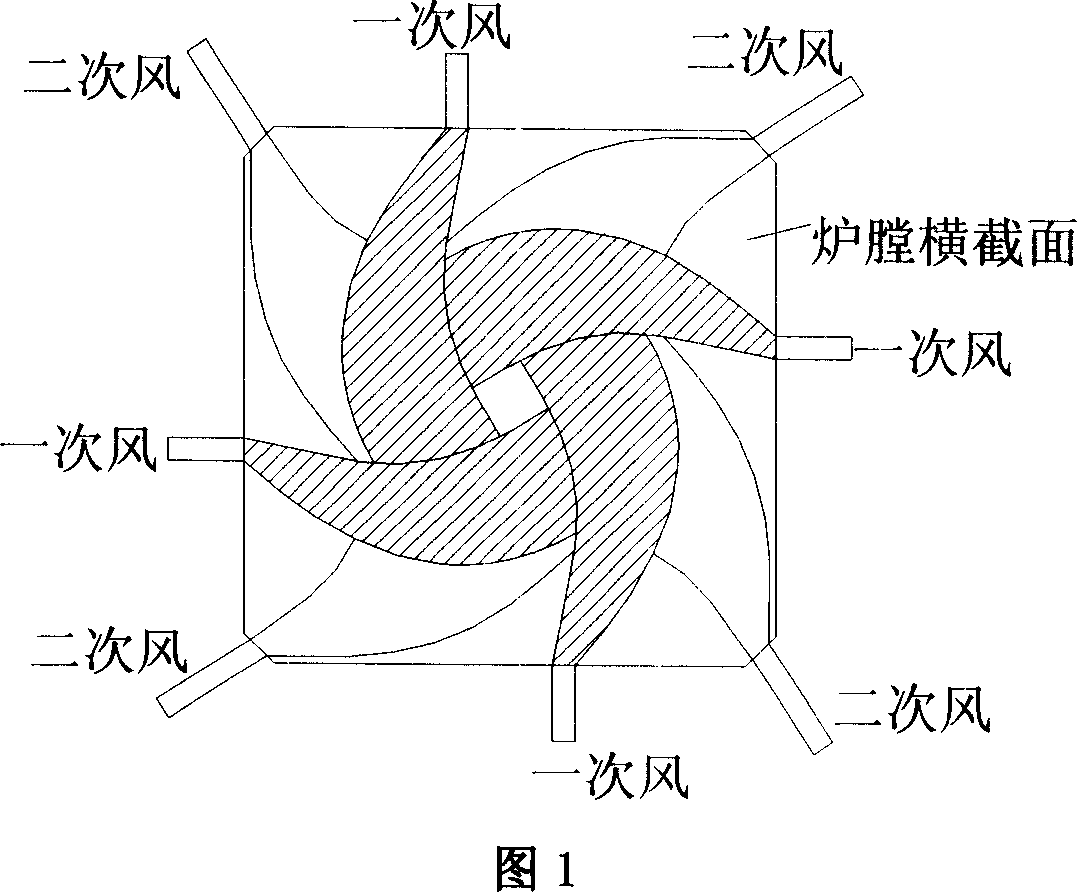

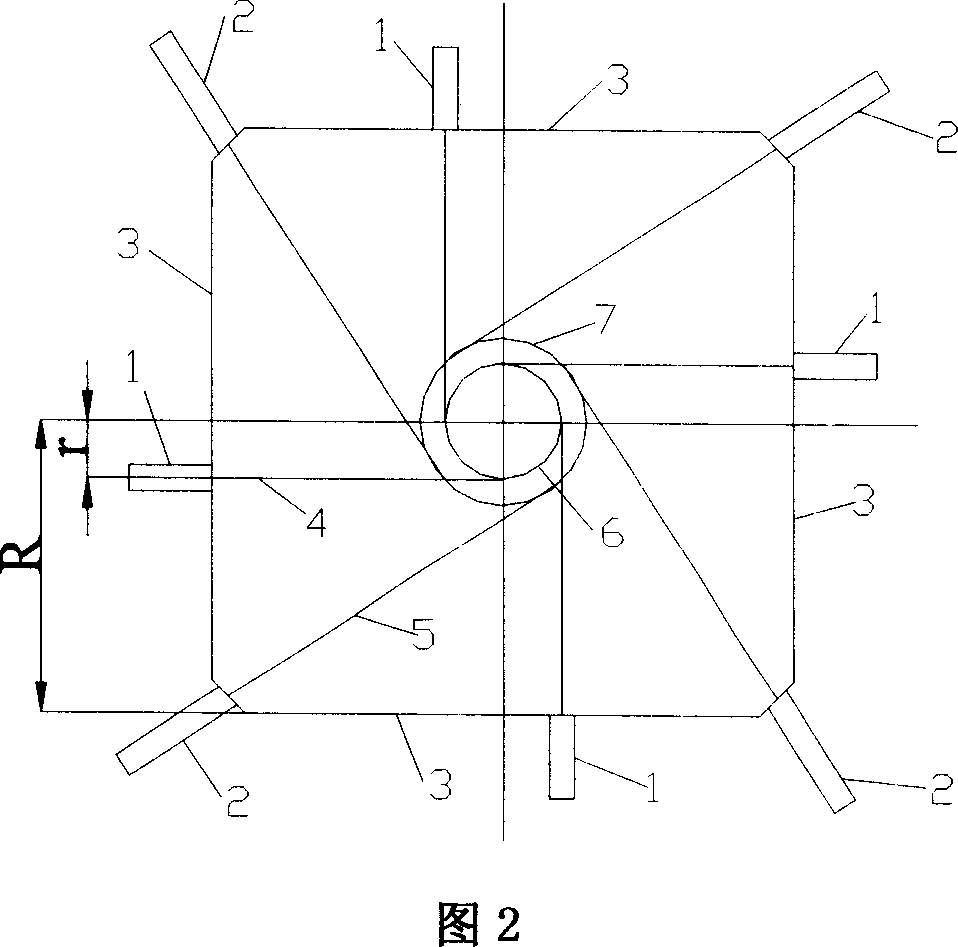

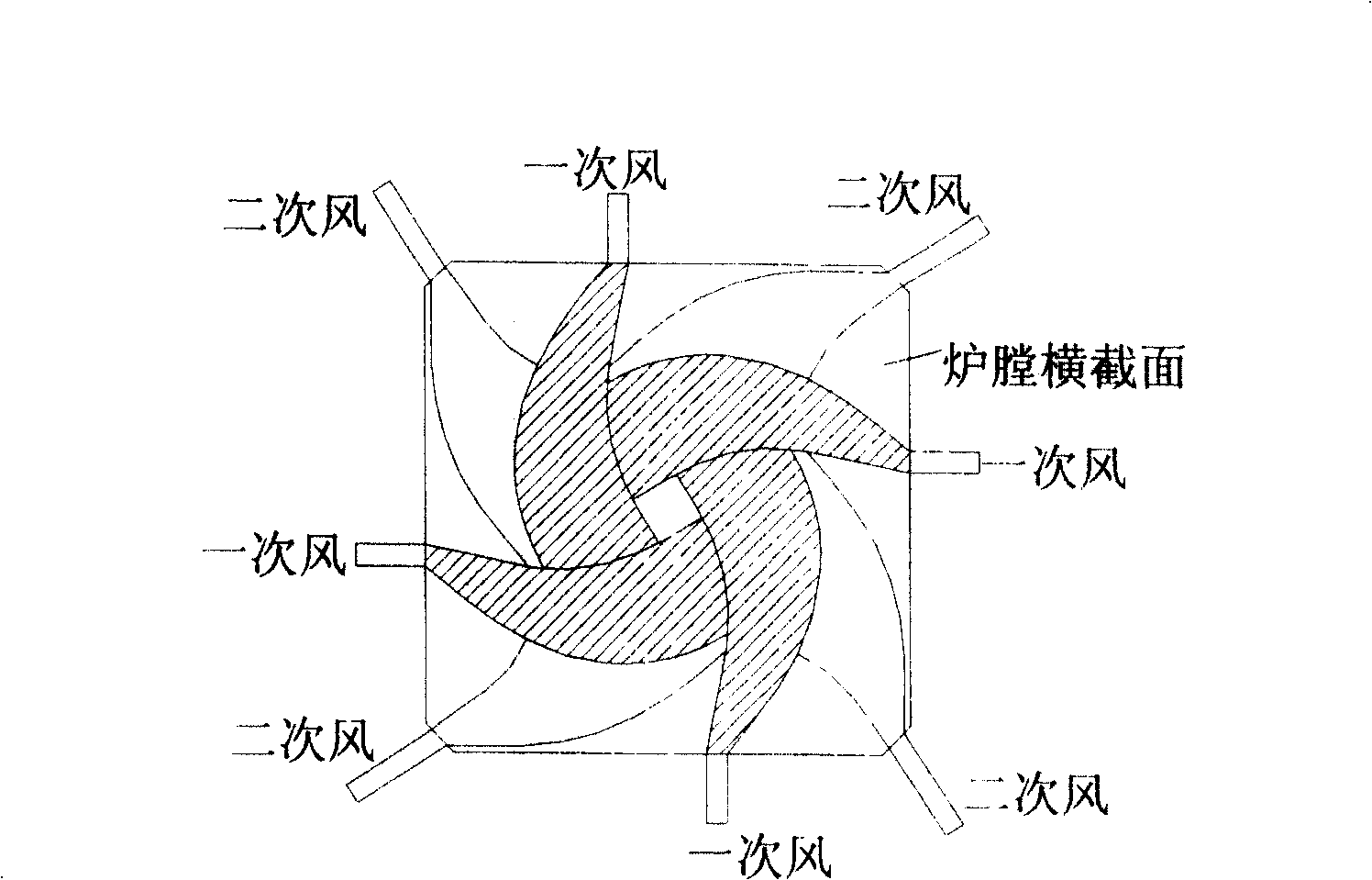

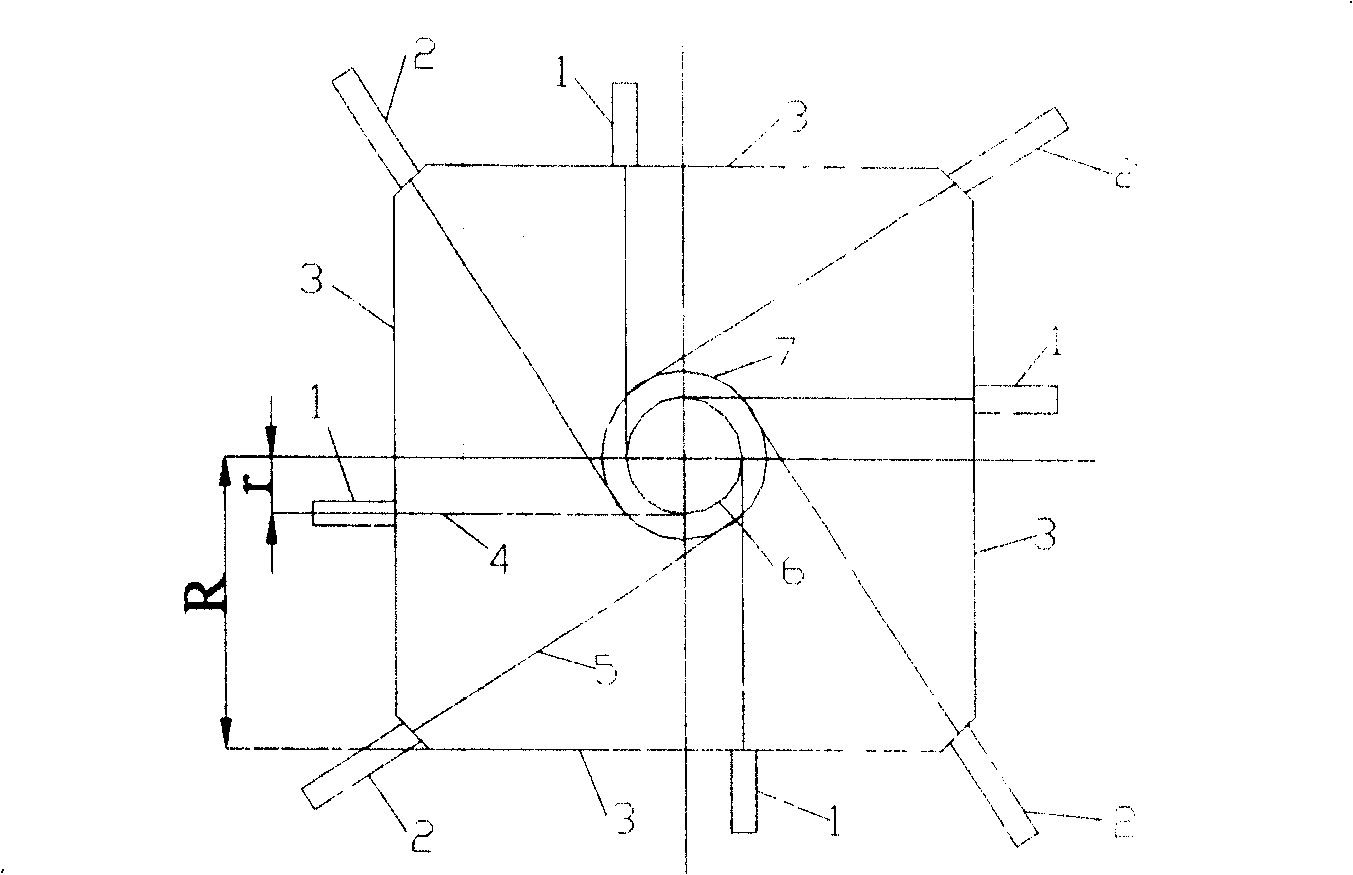

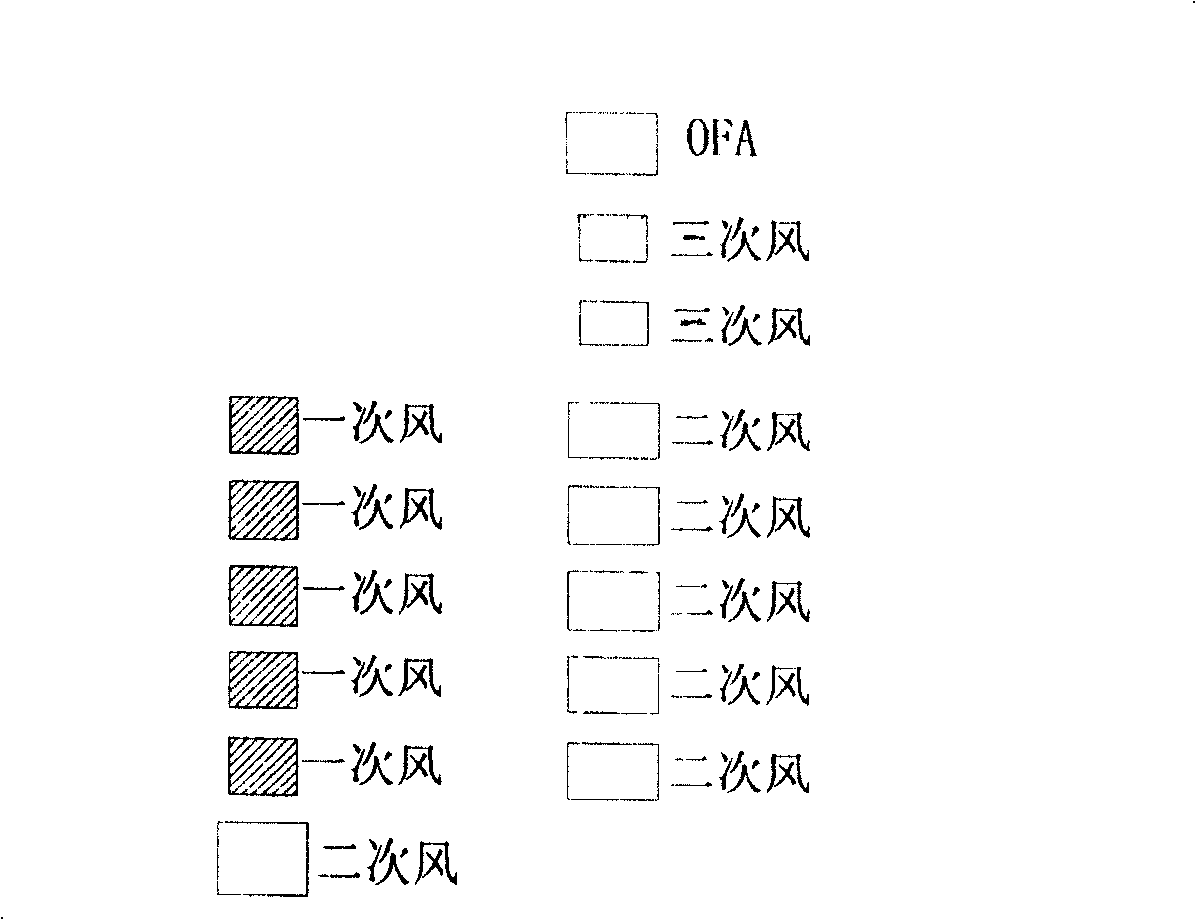

Combustion method of anthracite coal

InactiveCN1959205ASolve the problem of ignition stabilityGuaranteed uptimeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelJet flowCombustor

A method for burning hard coal includes setting four lines of burners formed by primary air ejector on wall of bottom firepot at boiler and setting another four lines of burners formed by secondary air ejector at four corners of firepot, setting two said air ejectors on the same level to form two concentric tangent circular rotary movements of internal and external in boiler by jet flows formed by primary and secondary airs, wrapping primary air by secondary air, setting tertiary air and burn-out air ejector at corners on top of master combustion region to form four-corner tangent-direction jet flow.

Owner:SHANGHAI JIAO TONG UNIV

Composite coal binder for lime vertical kiln

InactiveCN101037632AImprove hydrophilic abilityImprove adhesionSolid fuelsLime productionFiberBriquette

The invention discloses a composite coal bonder for lime vertical kiln, which is used for producing coal of lime vertical kiln cold molded by hard coal powder or breeze. Components of the bonder and weight percent thereof is: 25-35% of curing agent, 5-10% of activator, 6-12% of biomass fibre, 0.5-1.5% of surfactant, 50-60% of thermal bonder. The bonder used for producing coal has advantage of simple technology, low cost, coal indexes of compressing strength in state of thermal and cold, dropping strength, thermal stability, caloricity, volatile constituent, ash fusion point, cokability are satisfied producing requires of the lime vertical kiln and with good waterproofness.

Owner:CENT SOUTH UNIV

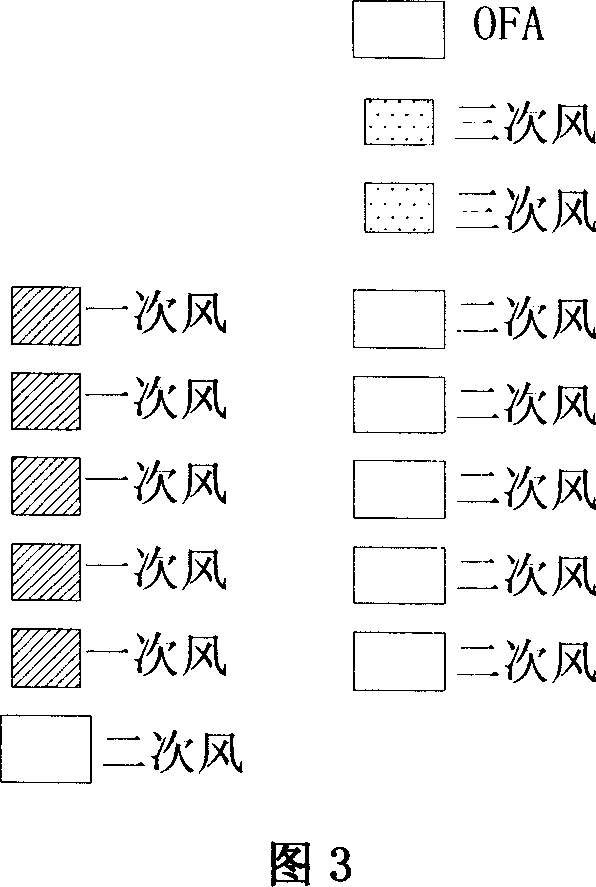

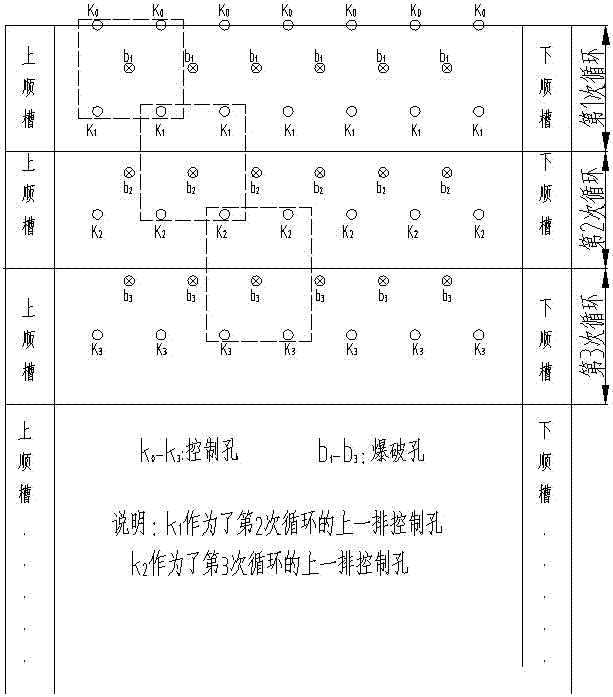

Porous control method for blasting softening of hard top plate and coal seam

InactiveCN107387085ASoften evenlySpread evenlyUnderground miningBlastingMiddle groupMechanical engineering

Disclosed is a porous control method for blasting softening of a hard top plate and a coal seam. The method comprises the following steps that a drilling arrangement scheme is determined according to the hard top plate and the coal seam at an underhole place to be blasted, that is to say, three groups of blast-holes are formed along the overall length of a working surface in an up-down parallel mode at equal intervals, wherein the uppermost group of blast-holes and the lowermost group of blast-holes are both rows of control hole groups, the middle group of blast-holes is a row of blasting hole groups, and each control hole group comprises several control holes which are formed along the overall length of the working surface in a parallel mode at equal intervals. Thus, according to the method, the overall blasting softening effects on the hard top plate and a coal body are good; by conducting blasting softening treatment on the hard coal rock mass covering at the front of the working surface in advance, the limit caving step of the top plate at the rear portion of the working surface is reduced, and puking, nicking and other accidents are prevented from occurring on a mined surface; the method has the advantages of being high in drilling hole utilization rate, low in engineering workload, high in blasting safety factor and the like and can be applied to softening and caving control of various hard top plates and coal bodies under coal mines.

Owner:HENAN POLYTECHNIC UNIV

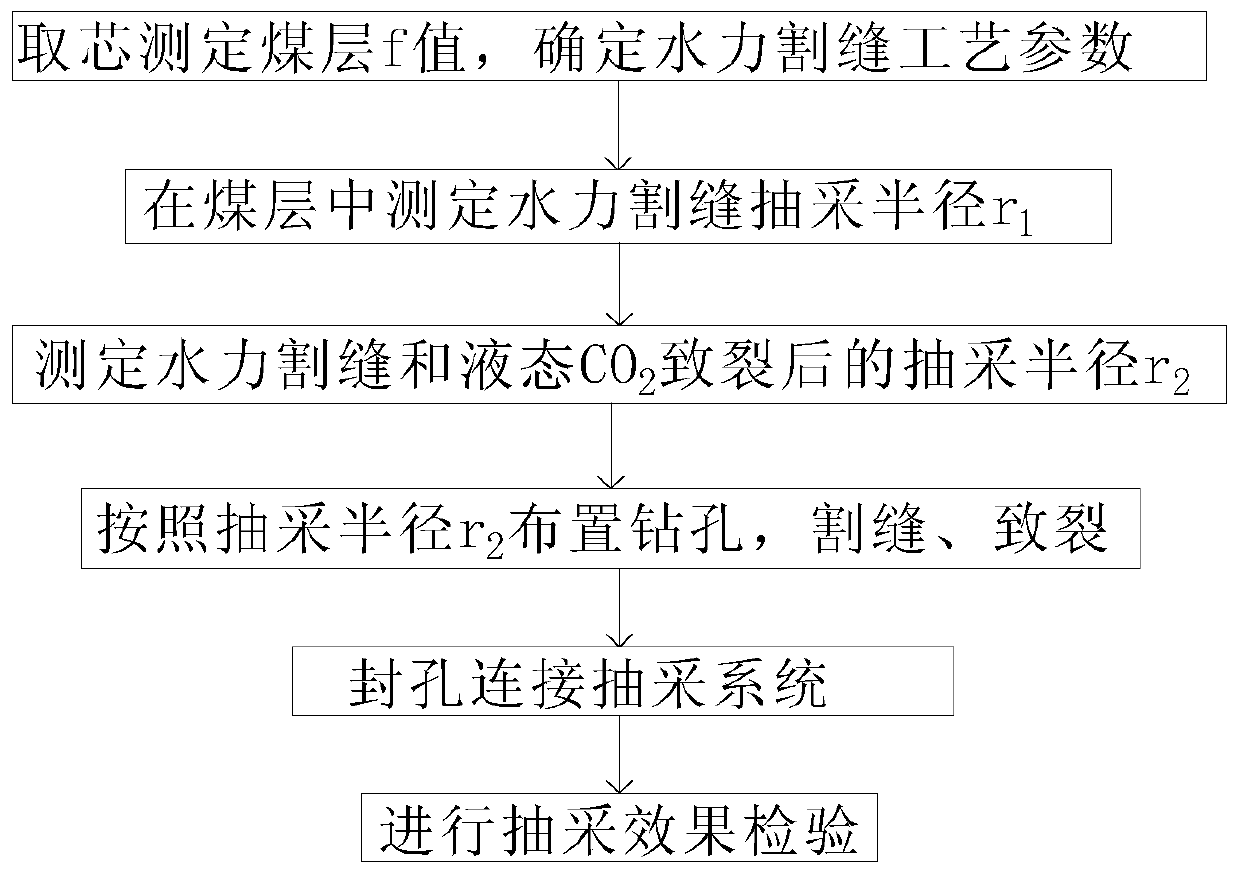

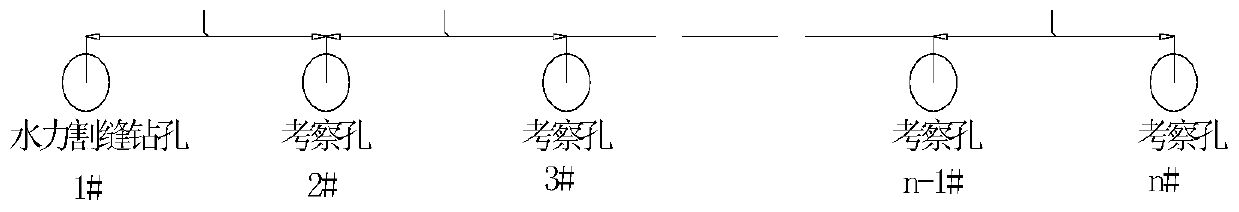

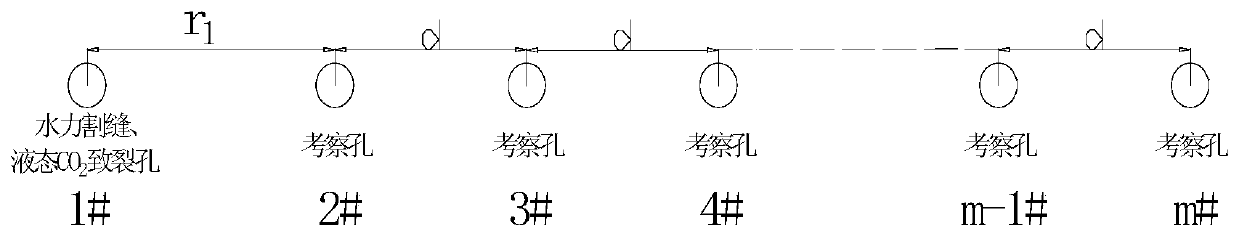

Medium-hard coal seam bedding drill hole gas treatment method

ActiveCN109751075AIncrease disturbanceShorten the timeFluid removalGas removalProduct gasHigh pressure

The invention discloses a medium-hard coal seam bedding drill hole gas treatment method. The method comprises the following steps: measuring an average f value of a coal seam by coring, determining hydraulic slotting process parameters, determining an extraction radius r1 after hydraulic slotting in the coal seam, determining an extraction radius r2 after hydraulic slotting and liquid CO2 phase change fracturing, rearranging drill holes according to the numerical value of r2, performing hydraulic slotting and liquid CO2 phase change fracturing, sealing the holes, conducting connection with anunderground extraction system, and performing extraction effect inspection. According to the method, firstly, a seam along the direction of a coal seam is directionally cut by utilizing a hydraulic slotting technology, pressure relief disturbance is conducted on the coal seam, then high-pressure gas generated after liquid CO2 phase change is used for directional cracking along the seam, and therefore the cracking effect can be effectively improved, coal seam gas extraction is accelerated, the gas treatment time is shortened, and safe production of a working face is guaranteed.

Owner:HUNAN UNIV OF SCI & TECH +1

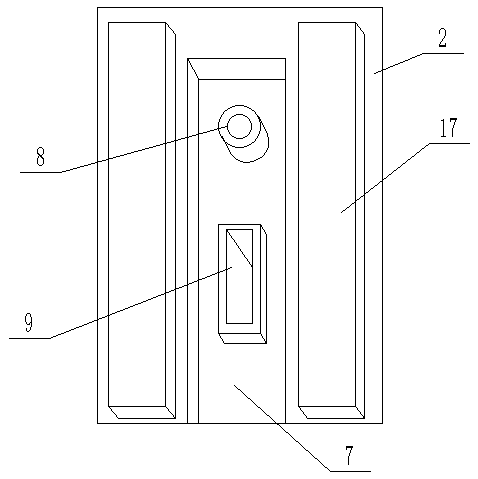

Drill bit and sampling device

ActiveCN102251746AEasy to sampleEnsure comprehensivenessConstructionsWithdrawing sample devicesCutting forceCoal

The invention provides a drill bit and a sampling device which can be used for solving the problems that the existing sampling device can not accurately get information of coal samples due to large coal blocks, hard coal blocks and icing of the coal blocks. The drill bit comprises a drill bit connecting rod, a lateral tooth piece and a main drill bit, wherein the lateral tooth piece is connected to the side surface of the drill bit connecting rod and comprises lateral teeth for cutting the coal blocks from the side surface, the main drill bit is connected at the bottom of the drill bit connecting rod and comprises downward main teeth, and a main tooth blade is arranged on the main teeth. The drill bit comprises a lateral blade and the main drill bit, when coal samples are collected, not only can the main teeth of the main drill bit exert static pressure on the contact surfaces of the coal samples to be collected, but also the lateral teeth of the lateral blade can exert lateral rotary cutting force on the coal samples to be collected, thereby increasing the destructive power on the coal samples to be collected, facilitating the collection of the coal samples in the large coal blocks, the hard coal blocks and the iced coal blocks, ensuring the comprehensive collection of the coal samples and the accuracy of the obtained coal samples and further accurately knowing the quality of coal as received.

Owner:CHINA SHENHUA ENERGY CO LTD +1

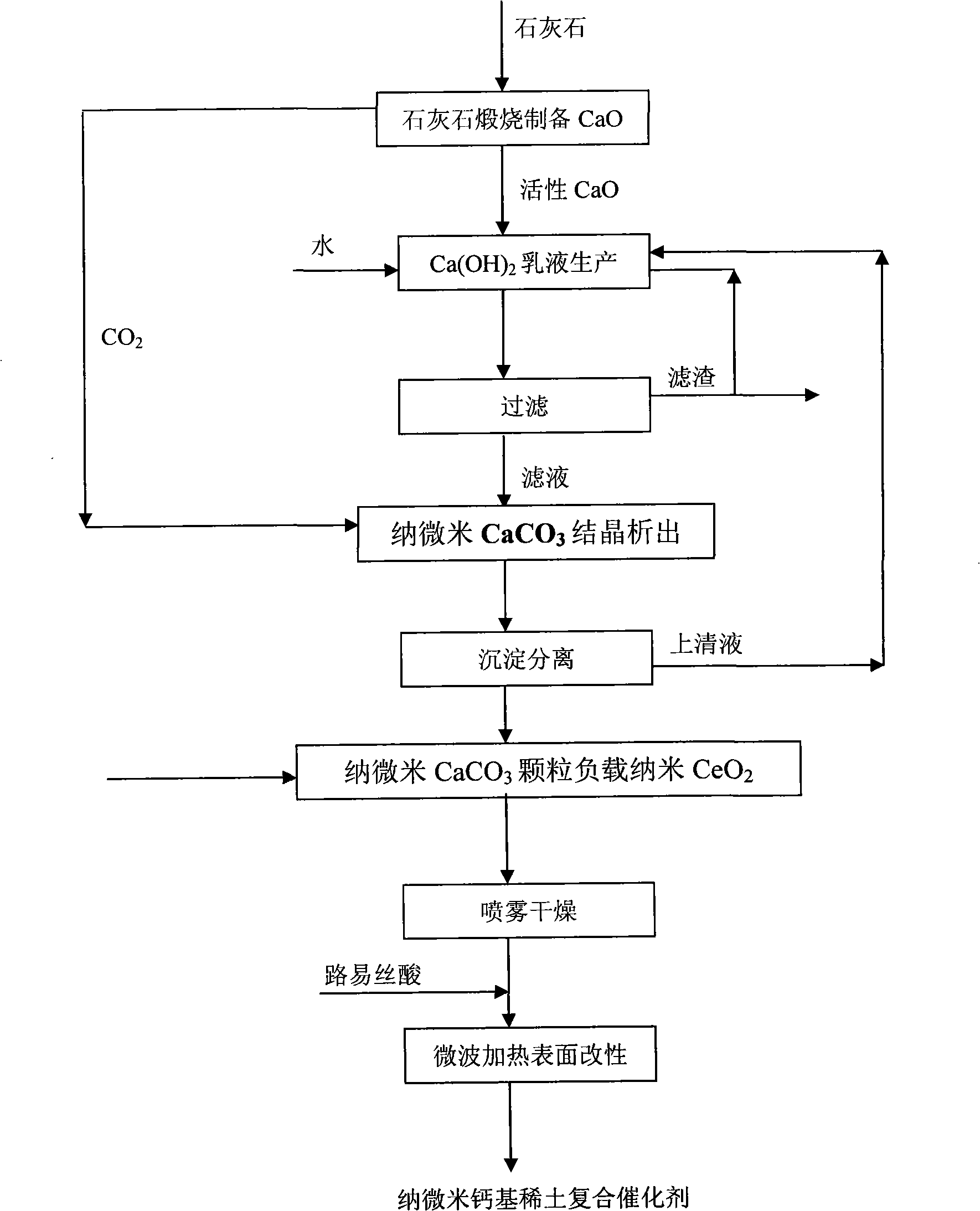

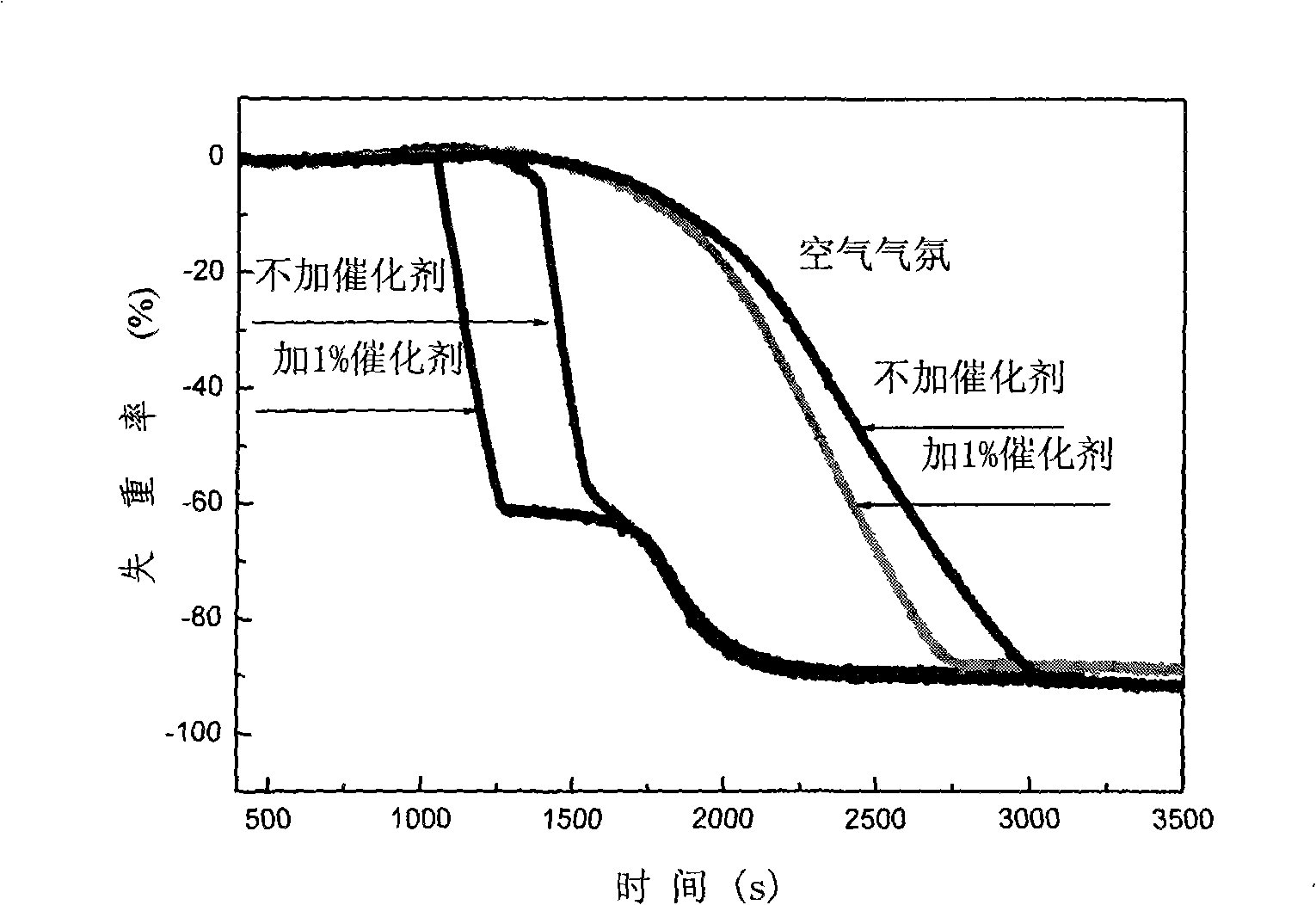

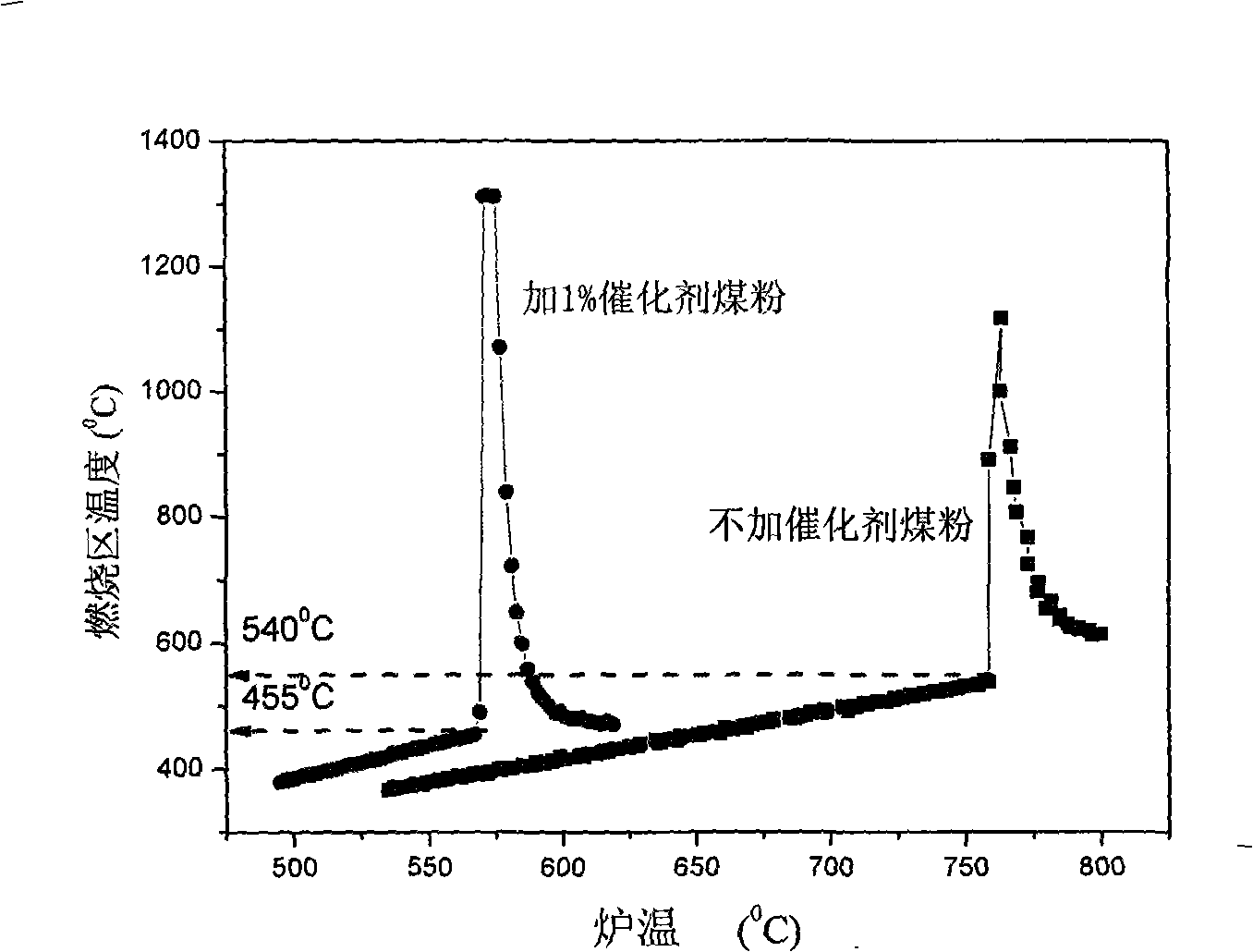

Method for producing and using calcium based rare earth composite catalyst for accelerating pulverized coal burning

InactiveCN101492626ASimple production processLow costSolid fuelsBlast furnace detailsRare earthCarbonization

The invention belongs to the field of energy utilization, and relates to a production and application method for a calcium-based rare earth composite catalyst which promotes the combustion of pulverized coal. The invention is suitable for the pulverized coal blowing and burning process of soft coal and hard coal. The invention is characterized in that CaO and nano CeO2 are used as the materials; the CaO is dissolved in water and is carbonized by CO2 to generate nano-micron CaCO3 serosity; then the nano CeO2 is added and is loaded on the nano-micron CaCO3 crystal grains generated by carbonization; the serosity containing CaCO3 loaded with CeO2 is condensed, sprayed and dried to obtain the CaCO3 loaded with CeO2 with a granularity smaller than 10 microns; then Lewis acid is added, and microwave treatment and heating drying treatment are carried out to lead the surface of catalyst grains to be electropositive; the weight ratio of CaCO3 to CeO2 is 1: 0.05 to 1 : 0.3; the adding amount of Lewis acid is 0.5 to 1.0wt percent of the grain powder of nano-micron CaCO3 loaded with nano CeO2. The catalyst has the characteristics of simple production technique, low cost, high activity, little dosage, and no corrosion; moreover, the catalysis combustion-supporting effect is excellent.

Owner:UNIV OF SCI & TECH BEIJING

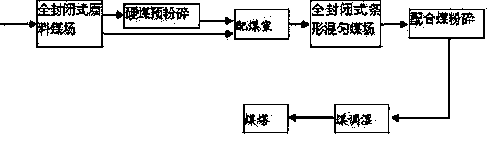

Technology for improving quality stability of coking charge coal

InactiveCN104140832AMoisture stableImproved stability of quality indicatorsCoke ovensCoal waterThermodynamics

The invention provides a technology for improving the quality stability of coking charge coal. The technology comprises the following steps: storing raw coal in a totally closed raw material coal yard, pre-crushing hard coal, uniformly mixing through a coal blending chamber in a totally closed bar-shaped mixing coal yard, crushing the obtained blended coal, damping the blended coal, and allowing the damped blended coal to go through a coal tower in order to realize final charge coking. The charge coal obtained through the technology has the characteristics of stable coal water, ash, volatile compounds and sulfur, stable coking performance and fines, and quality index stability increasing to above 4 sigma level.

Owner:SD STEEL RIZHAO CO LTD

Longhole pressure-bearing blasting method of hard coal rock

InactiveCN106323109AImprove the utilization rate of explosion energyExpand the range of loosening and weakening controlBlastingUtilization rateHard coal

The invention particularly provides a longhole pressure-bearing blasting method of hard coal rock and solves the problem that a conventional blasting roof control measure has a poor effect for a hard roof. The longhole pressure-bearing blasting method of the hard coal rock comprises following steps: roof caving hole construction is performed; then construction of charging holes is performed, the charging holes are 35 m long, angles of elevation are 9 degrees and 13 degrees, level angles are set as 15 degrees and 20 degrees, and large-diameter guiding holes are formed between the adjacent charging holes; the charging holes and the guiding holes are subjected to alternate spaced charging, a special hole sealing device provided with a liquid injection pipe and a drain pipe is adopted to seal orifices, and blasting is executed after liquid injection. With the adoption of the method, the utilization rate of explosive energy is high, only 70% of traditional explosive dosage is needed, the degree of damage to the coal surface is more severe, and the blasting is more efficient.

Owner:DATONG COAL MINE GRP

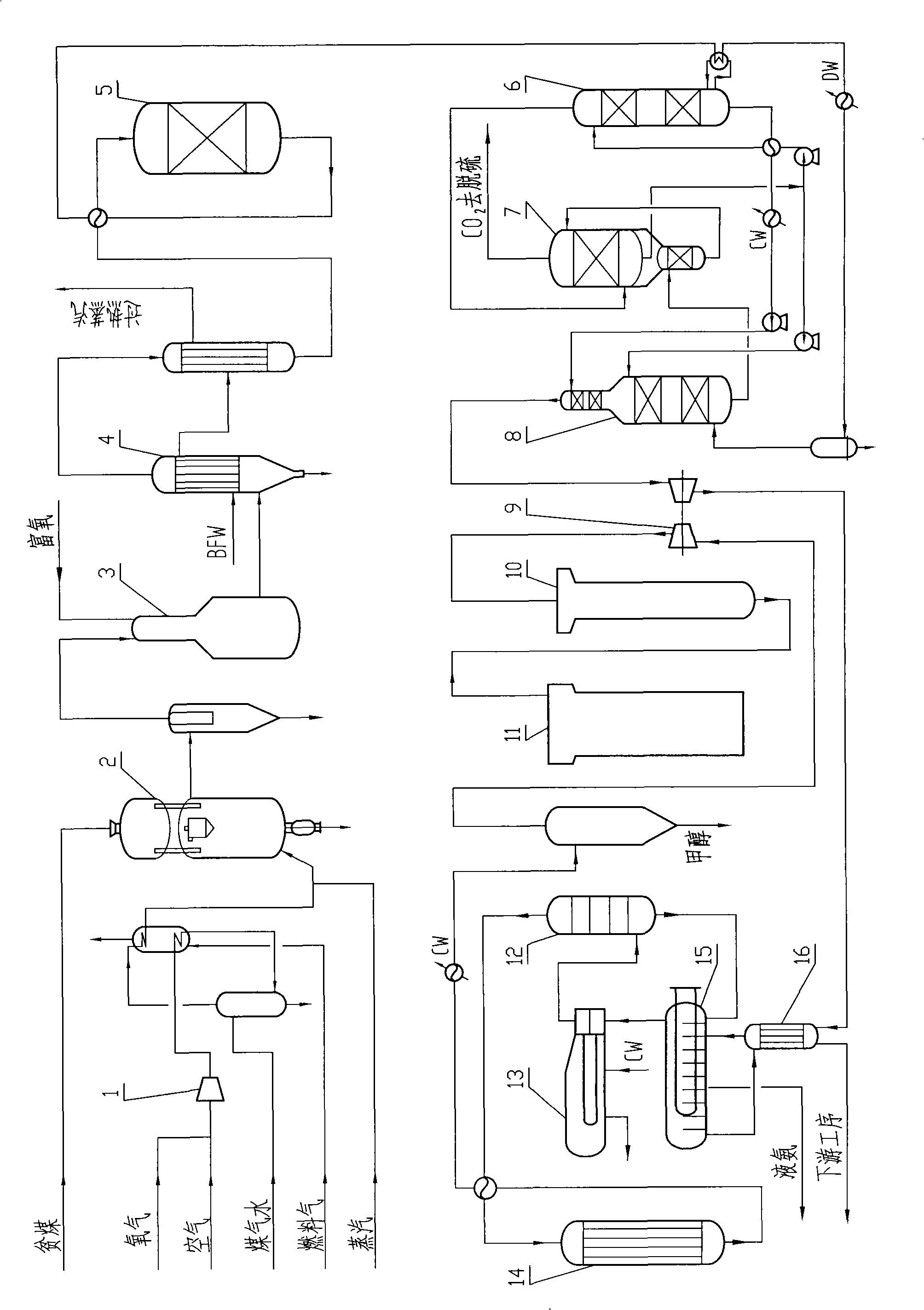

Clean low energy consumption synthesis ammonia production method

InactiveCN101348264AReduce the amount of coal dustWide variety of sourcesUrea derivatives preparationOrganic compound preparationPartial oxidationDouble tube

The invention relates to a method for preparing clean low energy consumption synthetic ammonia, in particular to a method for preparing synthetic ammonia by oxygen rich pressurized gasification meager coal joint production urea and methanol. The widely available raw materials of the invention include all types of bituminous coal, meager coal, lean coal, hard coal and brown coal even with high ash content and sulfur content. A gasification furnace takes rich oxygen and vapor as gasification agents, the steps of gasification and solidification are performed on a fixed layer for discharging slag, and a double-pipe coal feeder is used to make coal with small grain size uniformly distributed on the surface of a coal bed; rotary separators are arranged inside and outside the furnace so as to reduce the coal dust content in discharging gases; a high-temperature partial oxidation furnace is additionally arranged to completely oxidize tar in the coarse gases by rich oxygen, simultaneously, the methane content of the gases is partially oxidized about 0.5 percent, thereby not only preventing environmental pollution of tar, but also avoiding air pollution due to the discharge of the air gases containing CO and SO2 into the air and river pollution due to the discharge of gas liquors containing phenol and cyanogen in rivers.

Owner:黄鸿宁

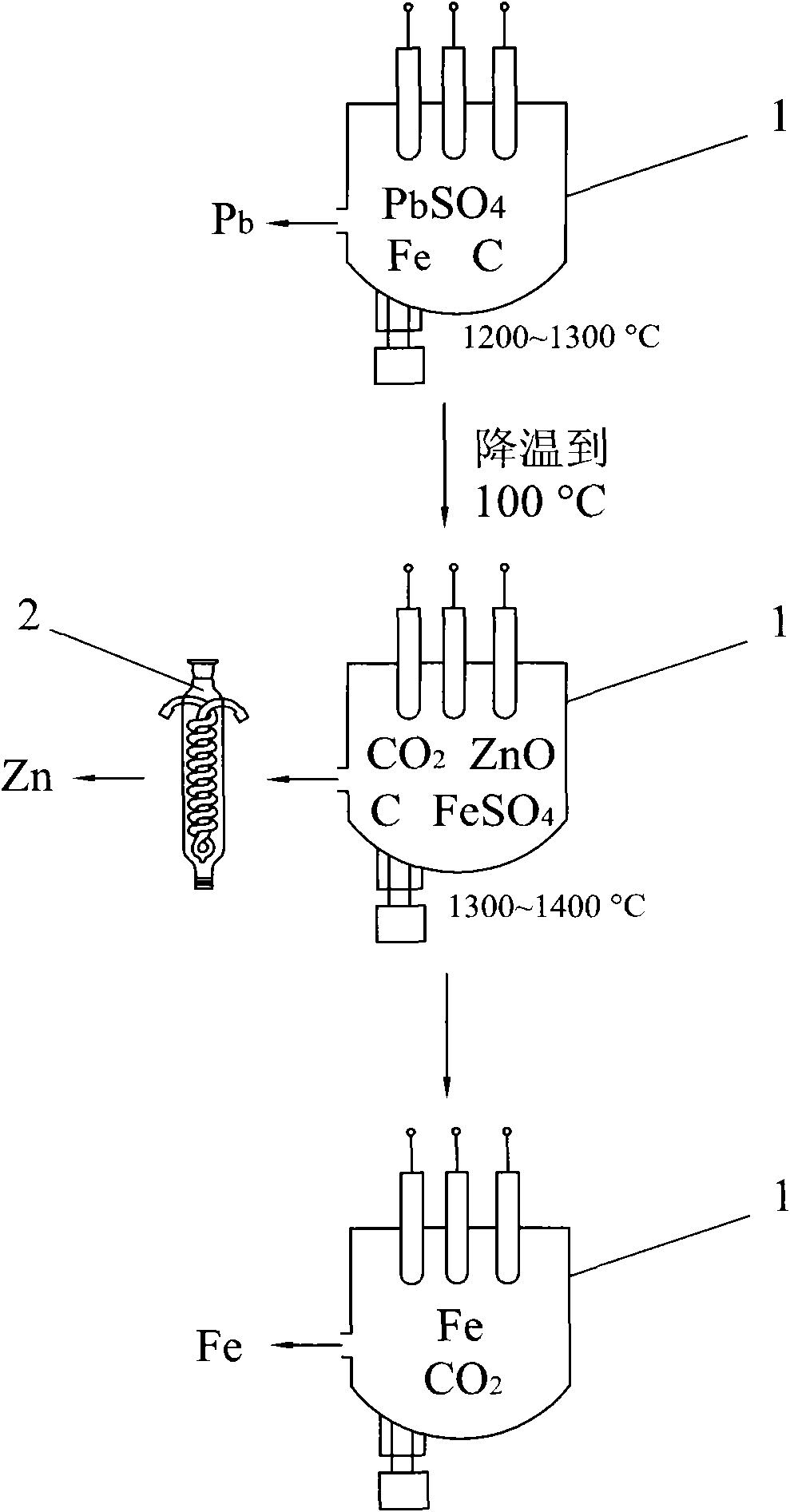

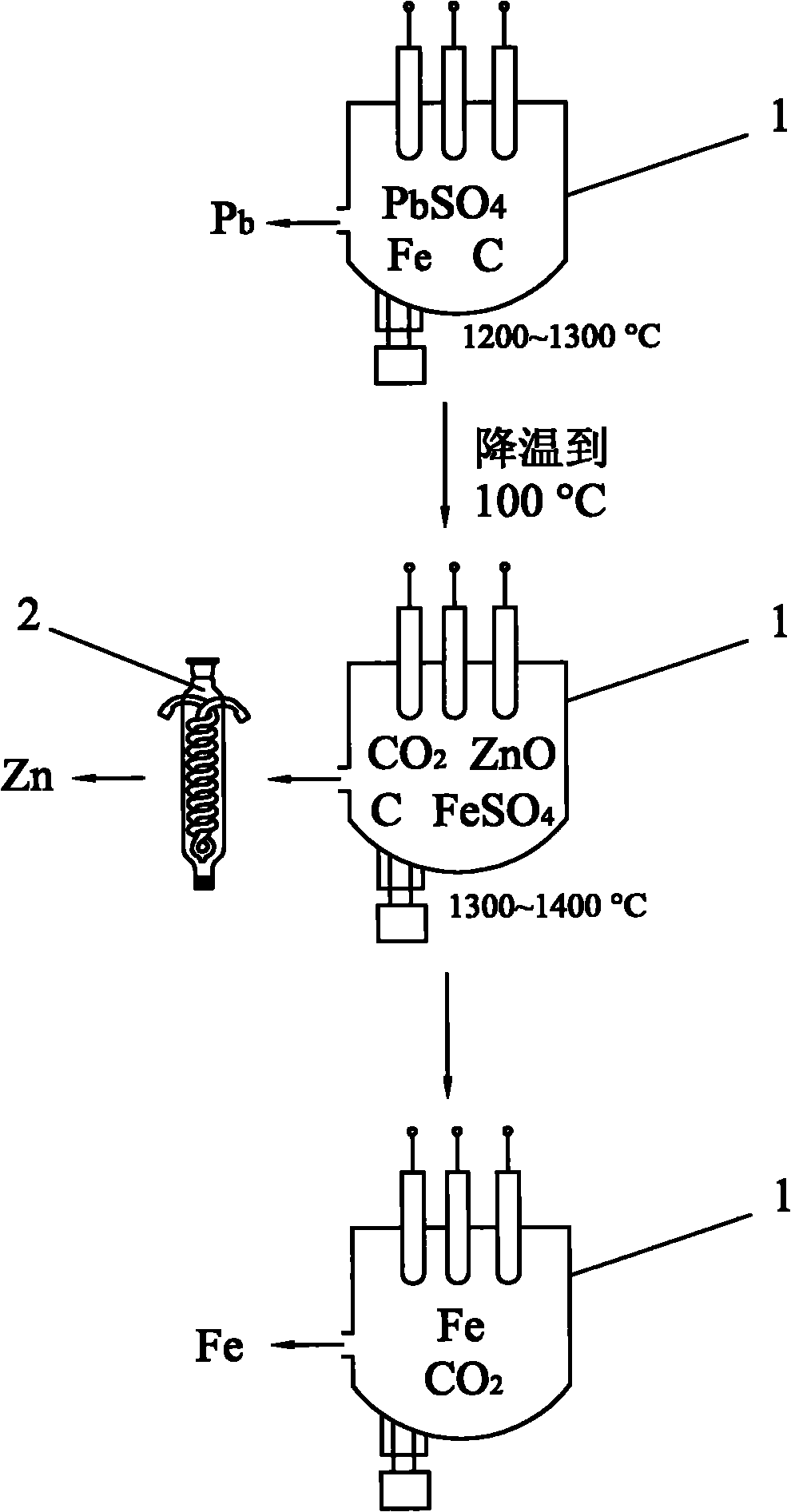

Method for preparing lead ingots, zinc powder and mixed iron slag from waste residues in lithopone production

InactiveCN102011012AEasy to operateLow investment costProcess efficiency improvementElectric arc furnaceSlag

The invention provides a method for preparing lead ingots, zinc powder and mixed iron slag from waste residues in lithopone production. The method comprises the following steps of: uniformly mixing the waste residues and filings in lithopone production, hard coal and sodium carbonate, and delivering to a hermetic air-isolated arc furnace; raising the temperature to between 1,200 and 1,300 DEG C for reaction; casting lead to form a lead ingot crude product after the lead flows out from the furnace in a molten state, and remelting and refining to prepare quality metal lead; adding coke into the arc furnace when the temperature of the arc furnace is reduced to about 100 DEG C, raising the temperature to between 1,300 and 1,400 DEG C, reducing zinc oxide into zinc steam, condensing the zinc steam by using a serially connected condenser, collecting, and screening by using an 80-mesh screen to obtain qualified zinc powder which has no screen tailings; and mixing the rest of furnace slags in the arc furnace, which is a large quantity of iron slags, and a small amount of rare metal salt, further processing through smelting to obtain iron ingots.

Owner:王嘉兴

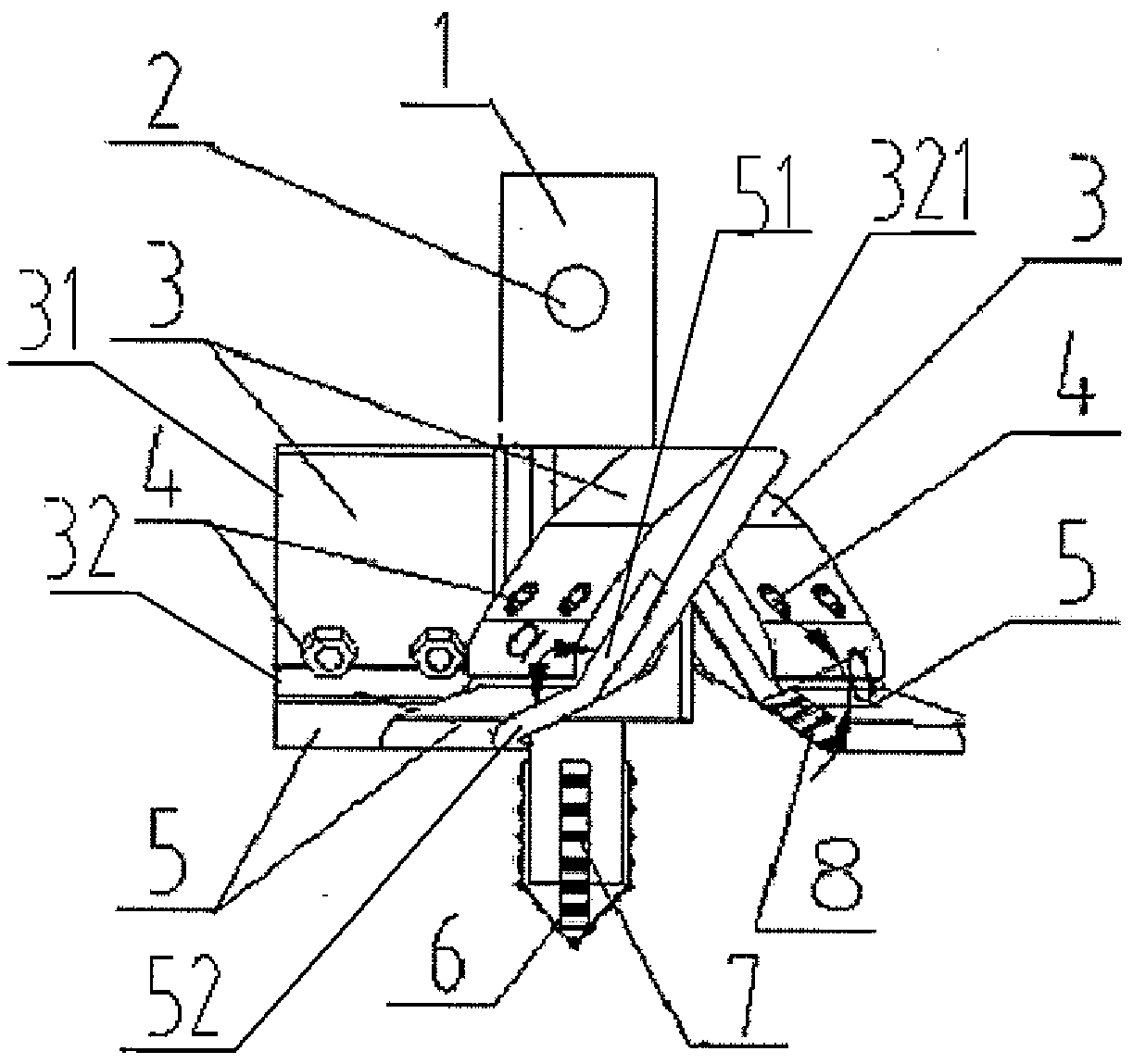

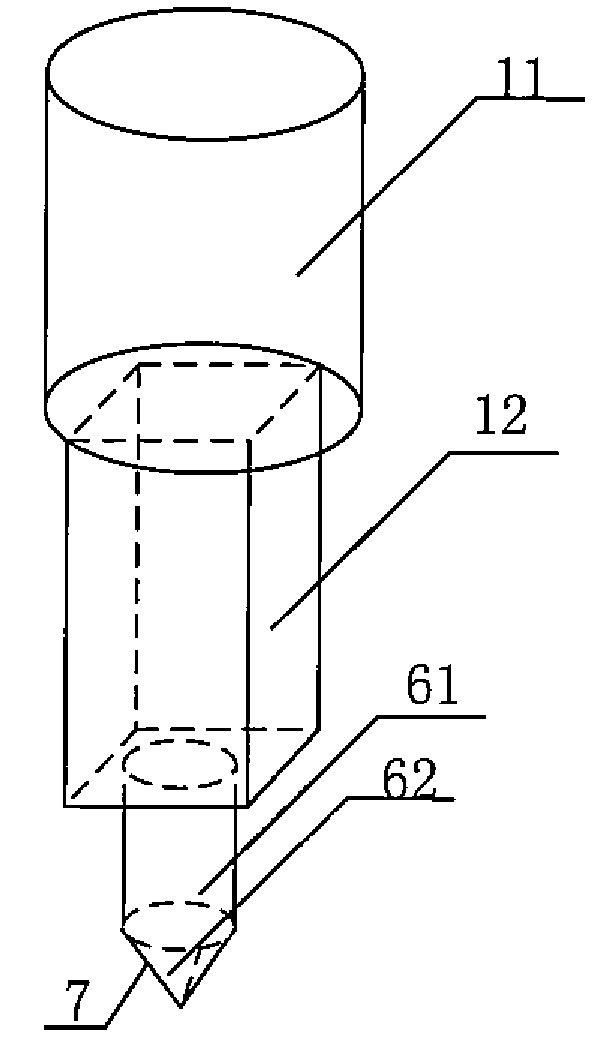

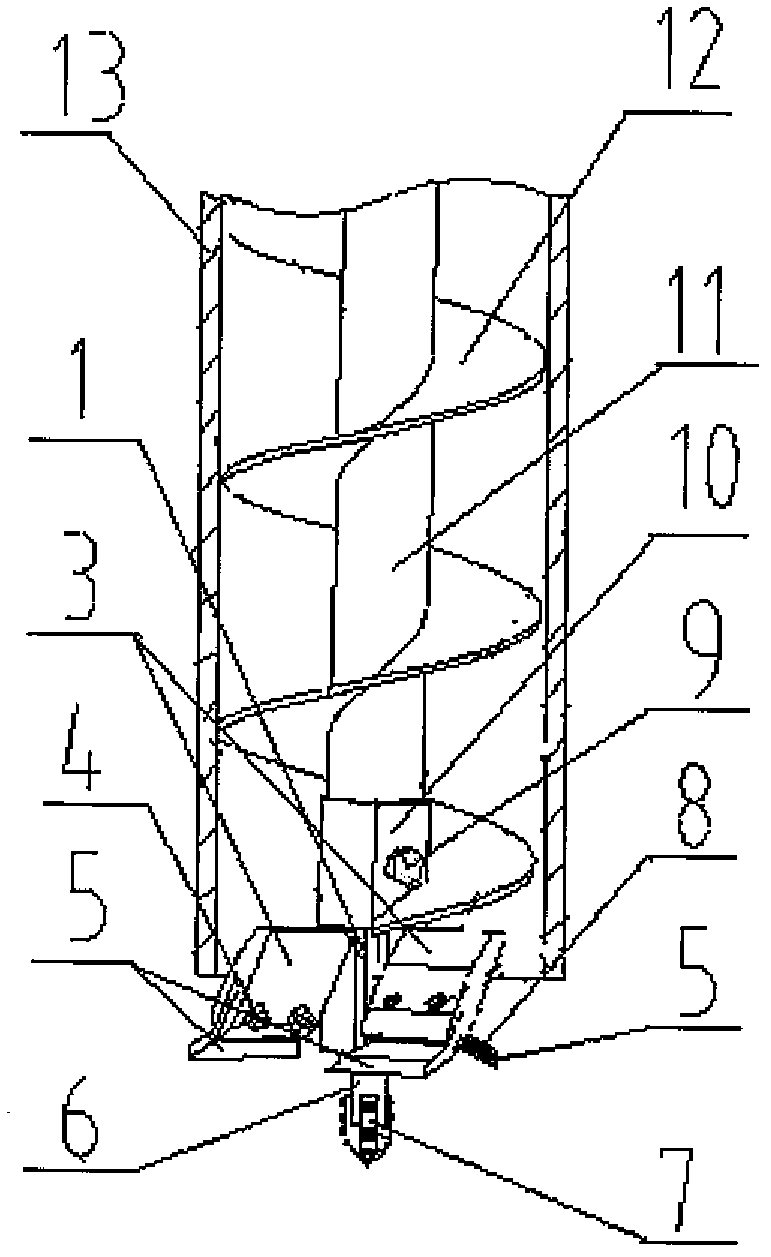

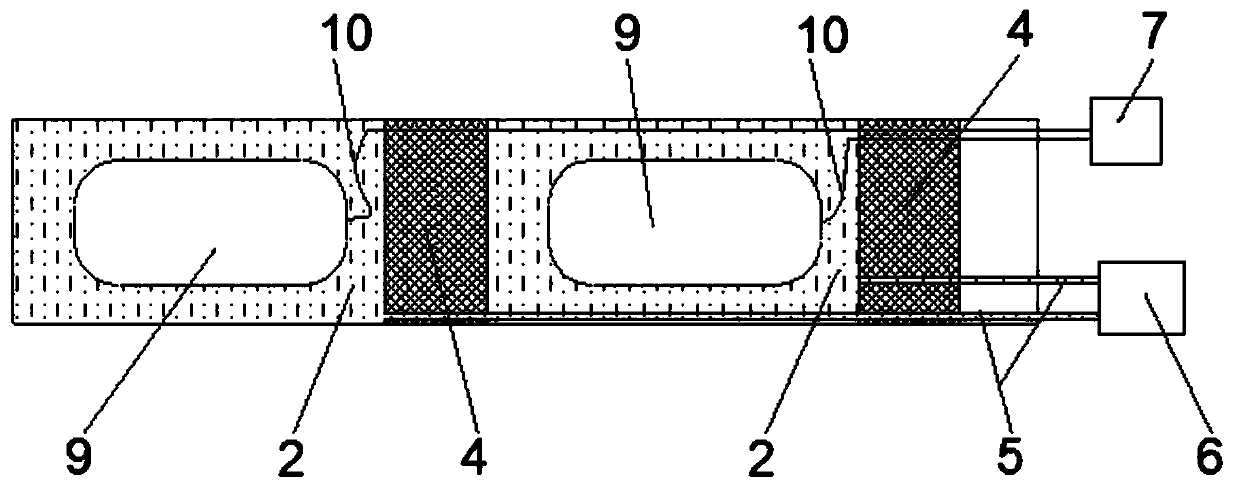

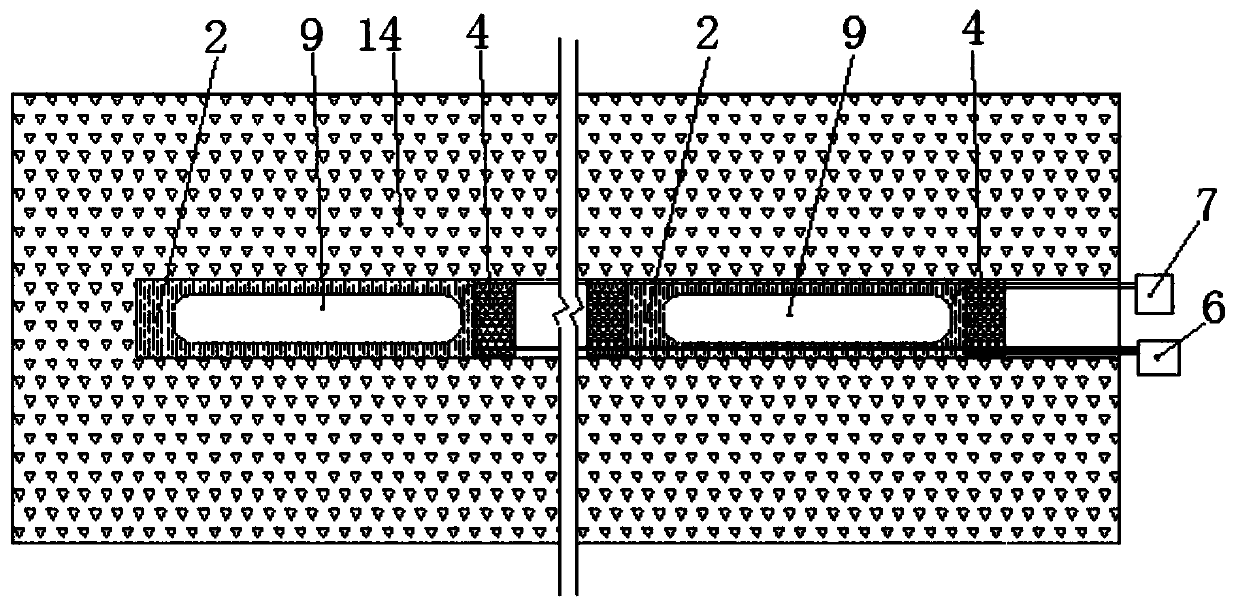

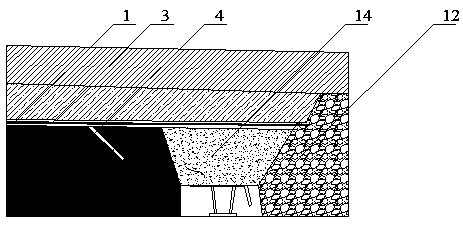

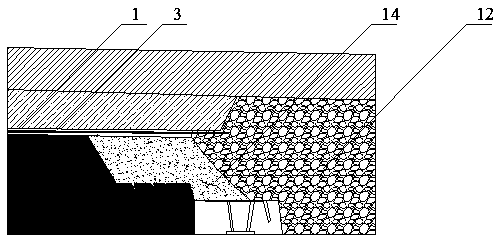

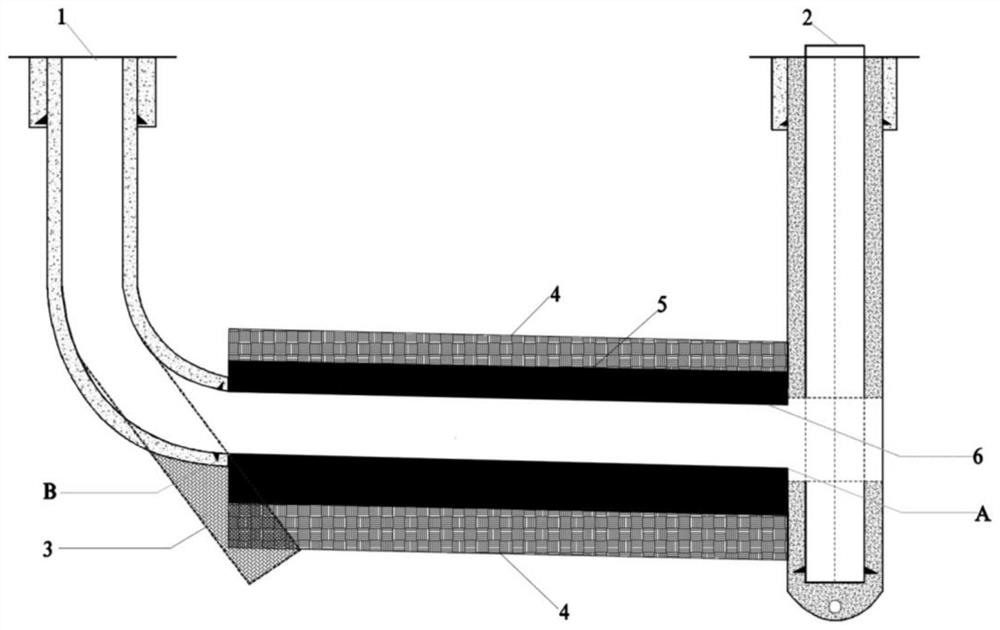

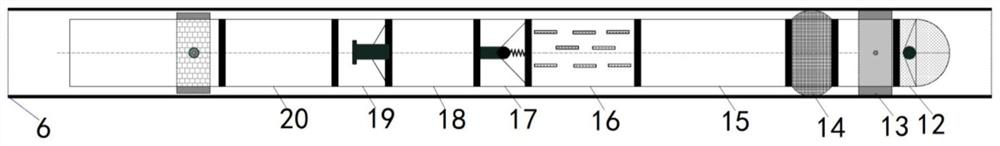

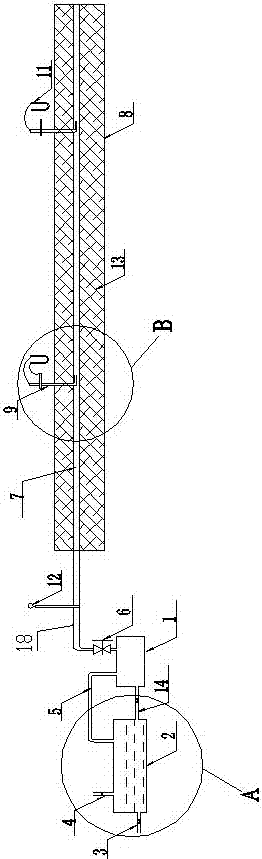

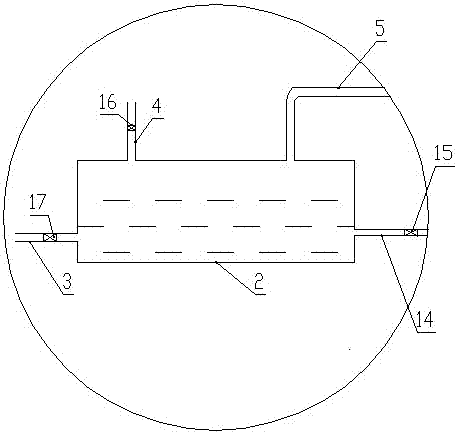

Hydraulic fracturing combined hydraulic blasting roadway large-size tunneling method and fracturing device

PendingCN110725685AAvoid randomnessEffective isolationFluid removalBlastingMining engineeringHydraulic fracturing

The invention belongs to the technical field of roadway tunneling, and particularly relates to a hydraulic fracturing combined hydraulic blasting roadway large-size tunneling method and a fracturing device. Firstly, contour blasting holes are arranged on a working contour surface, a combined fracturing method combining hydraulic fracturing-burst fracturing-hydraulic fracturing is adopted, a largecrack is formed on the working contour surface of a tunnel firstly, a mining area and a non-mining area are separated, the expansion of cracks in other directions is effectively prevented, the depth and the width of the crack extension are greatly improved, the hard coal rock becomes more loose, mining is facilitated, and the air permeability of coal seams can be improved. In addition, multiple sections of the fracturing device can be arranged on the length of the whole blast hole, sealing is carried out in a sectional mode, millisecond delay blasting is achieved in the blasting holes, then multiple disturbances on the coal rock mass are achieved, the method is suitable for super-long drilling and large-size blasting construction, and rapid tunneling of the roadway can be achieved.

Owner:HENAN POLYTECHNIC UNIV

System and method for atmospheric carbon sequestration

Owner:COOL PLANET ENERGY SYST

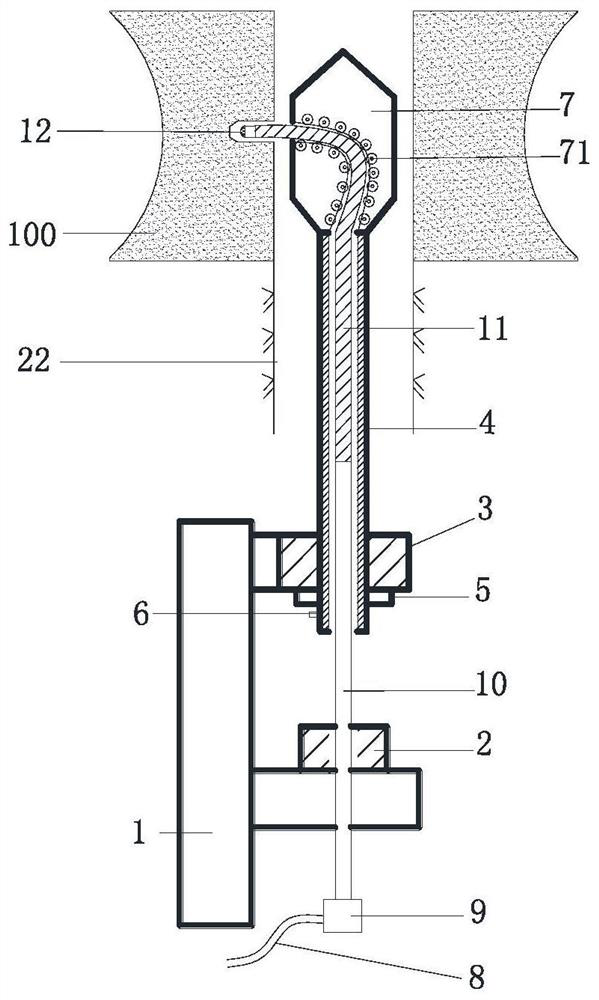

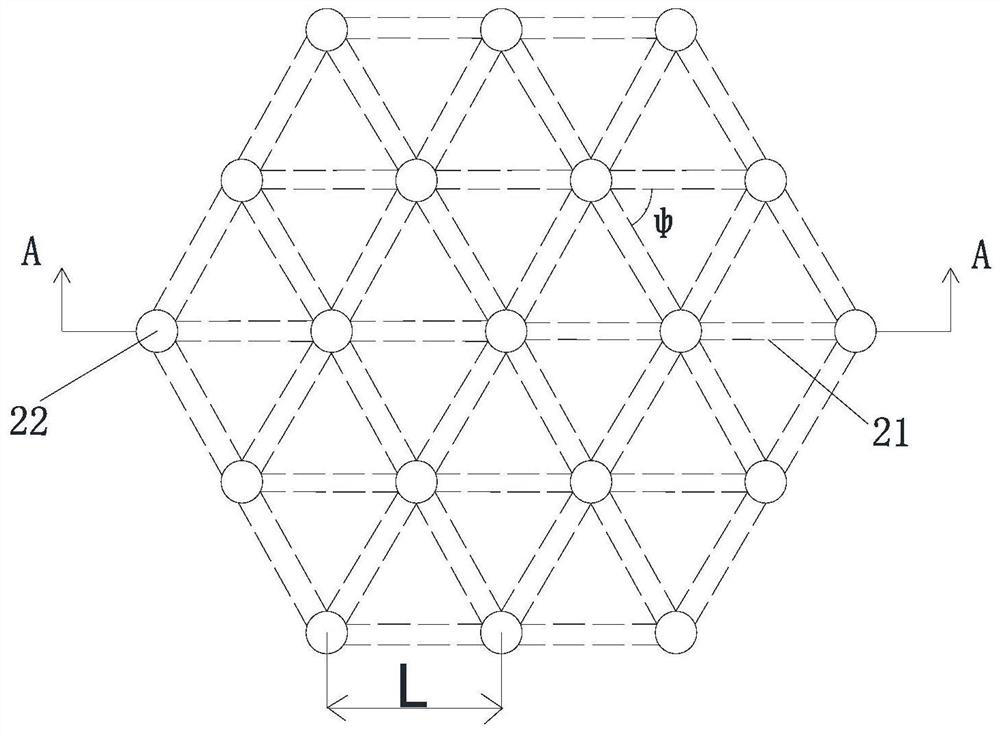

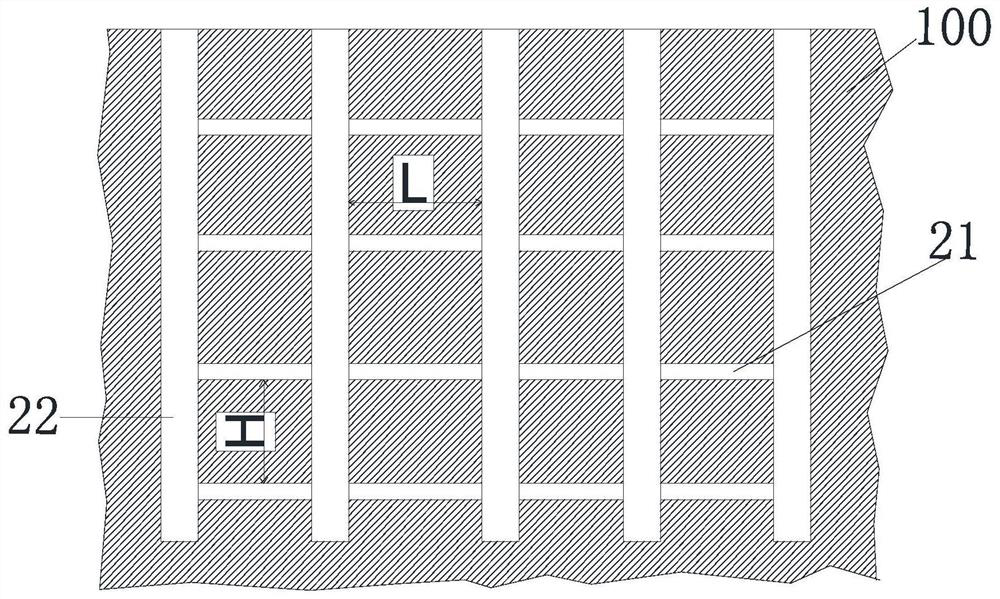

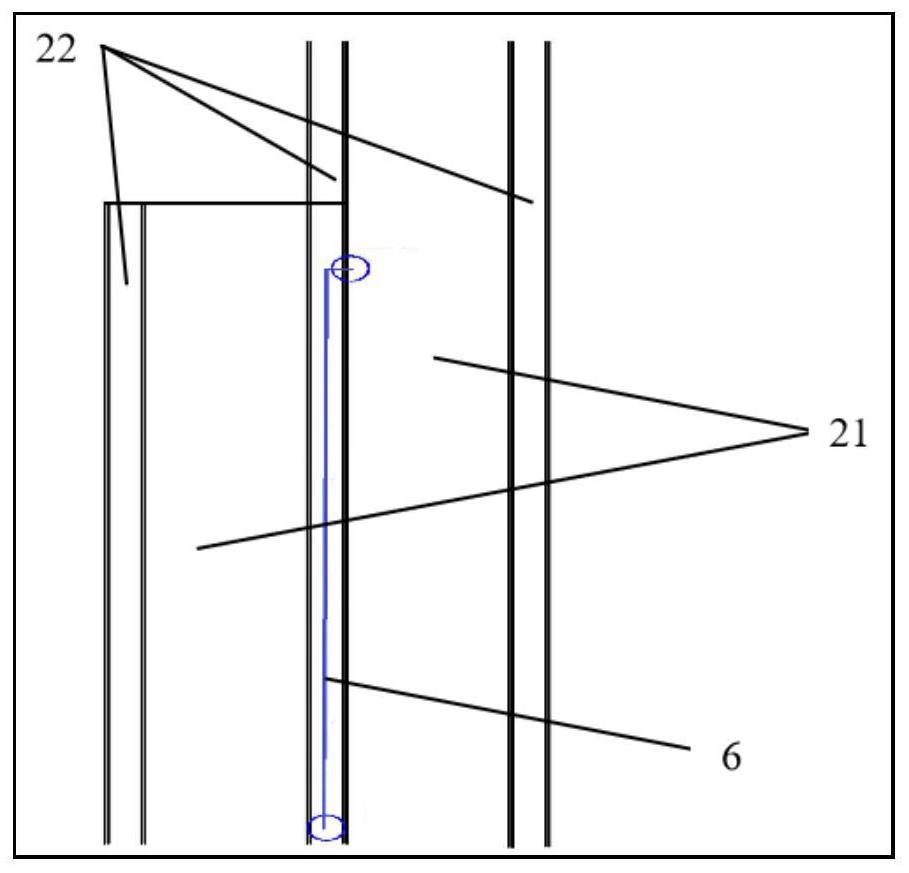

Coal seam reticulated gas extraction drilling construction method of water jet drilling machine

PendingCN111810084AImprove the pumping effectExpand the sampling rangeLiquid/gas jet drillingFluid removalThermodynamicsAnthracite

The invention relates to a coal seam reticulated gas extraction drilling construction method of a water jet drilling machine. The coal seam reticulated gas extraction drilling construction method comprises the step of drilling a plurality of water jet construction drilling holes in a coal seam, and is characterized in that the water jet drilling machine with a 360-degree direction identification plate is utilized, an outer drill rod is mainly rotated, so that the direction identification position of a water jet nozzle is aligned with the position of another adjacent water jet construction drilling hole of the water jet construction drilling hole to which the angle of a dial corresponds; the water jet drilling machine is started, so that an inner drill rod drills by L<drill> meters to formanother water jet drilling hole in the direction from the water jet construction drilling hole to the adjacent water jet construction drilling hole; and all water jet drilling holes in the direction from all the water jet construction drilling holes to all the adjacent water jet construction drilling holes are repeatedly completed. The reticulated through gas extraction drilling holes can be constructed directionally according to the needs; the gas extraction range of the extraction drilling holes is expanded; the pressure relief area is enlarged; and the coal seam reticulated gas extraction drilling construction method is particularly suitable for gas extraction in hard coal seams with low permeability such as anthracite coal seam gas extraction, and effectively improves the gas drainageeffect of the coal seam.

Owner:CCTEG SHENYANG RES INST

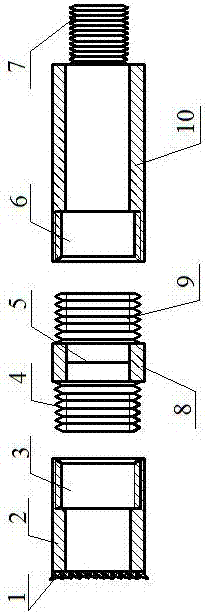

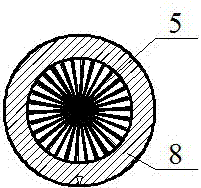

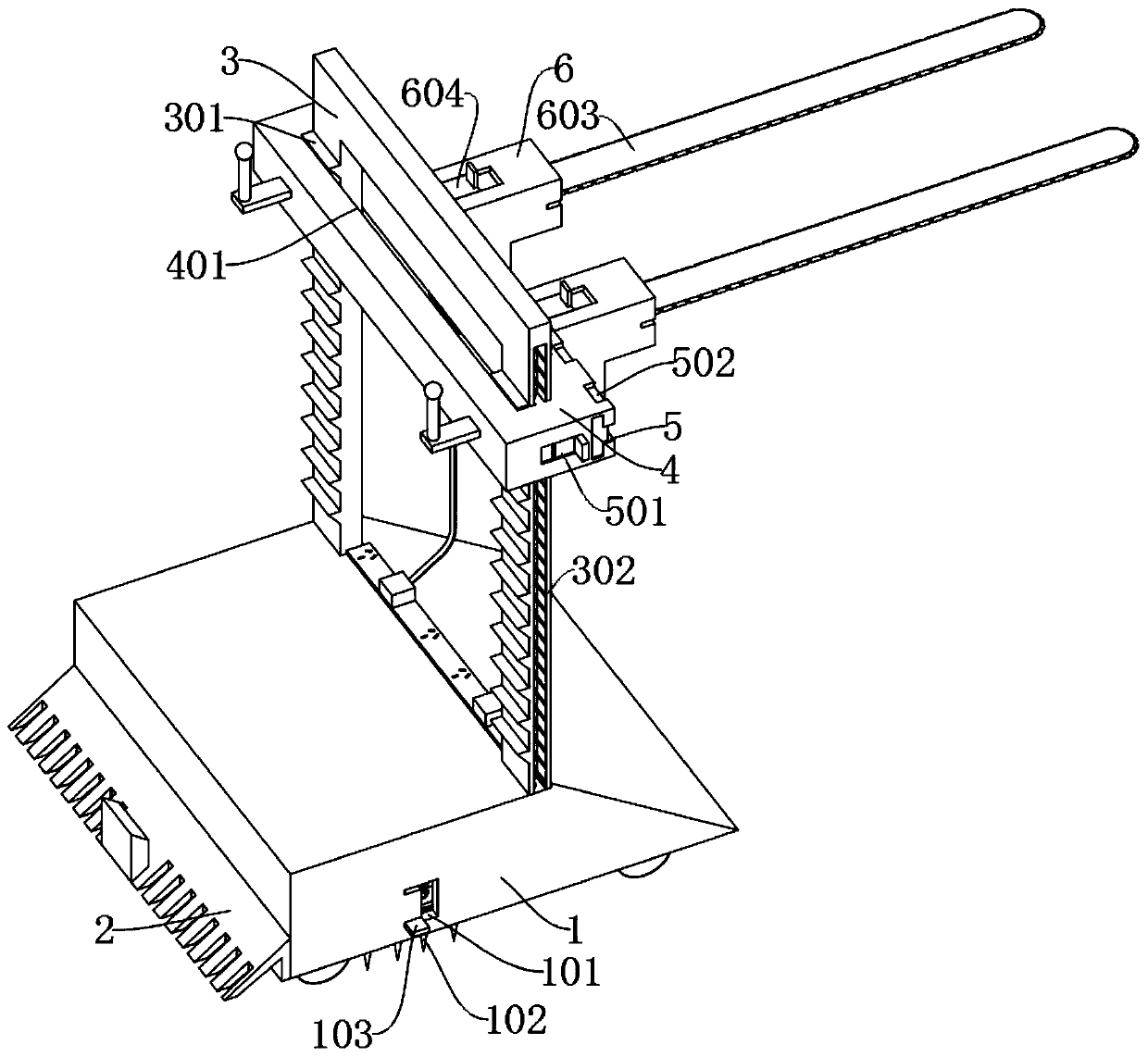

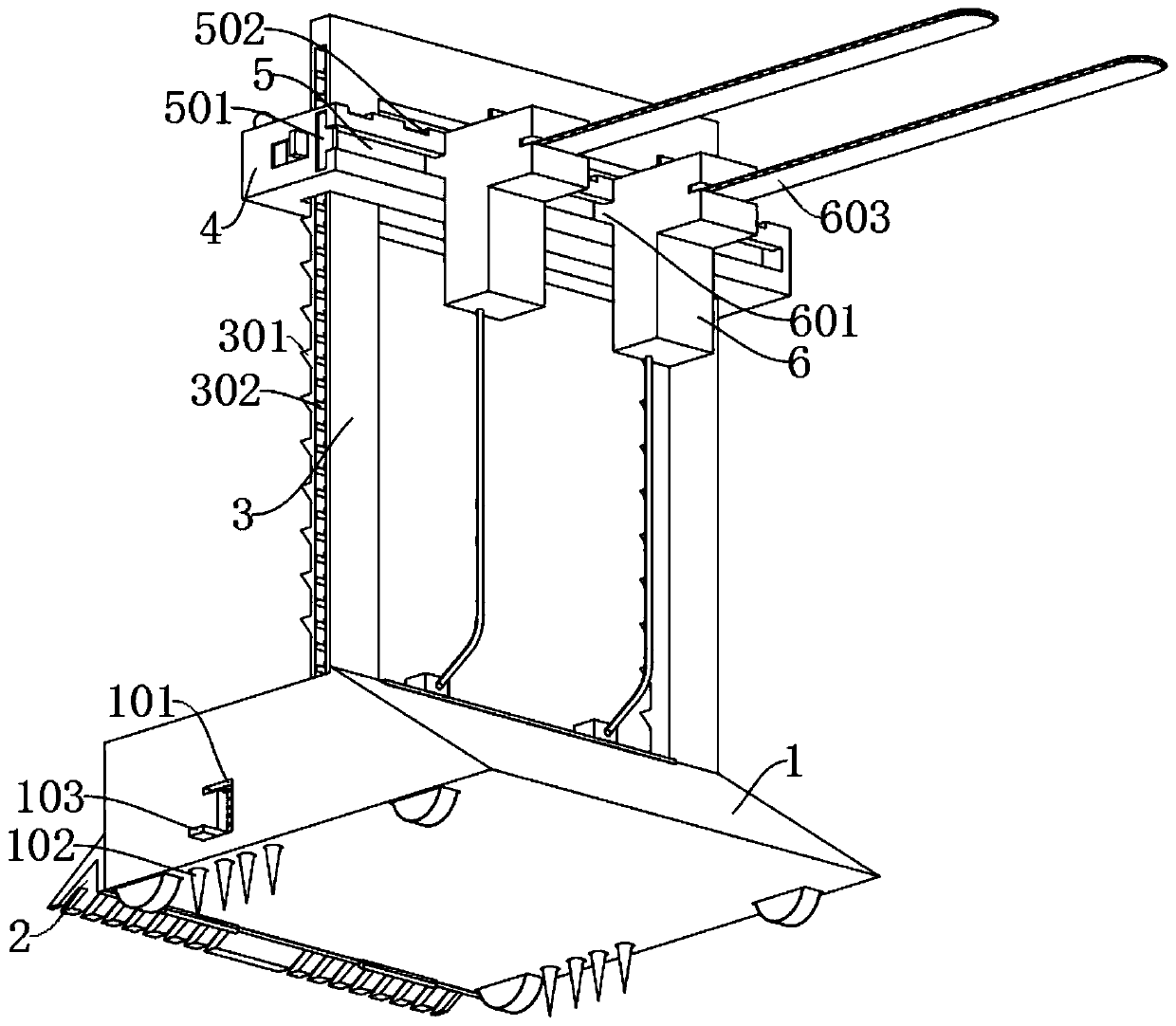

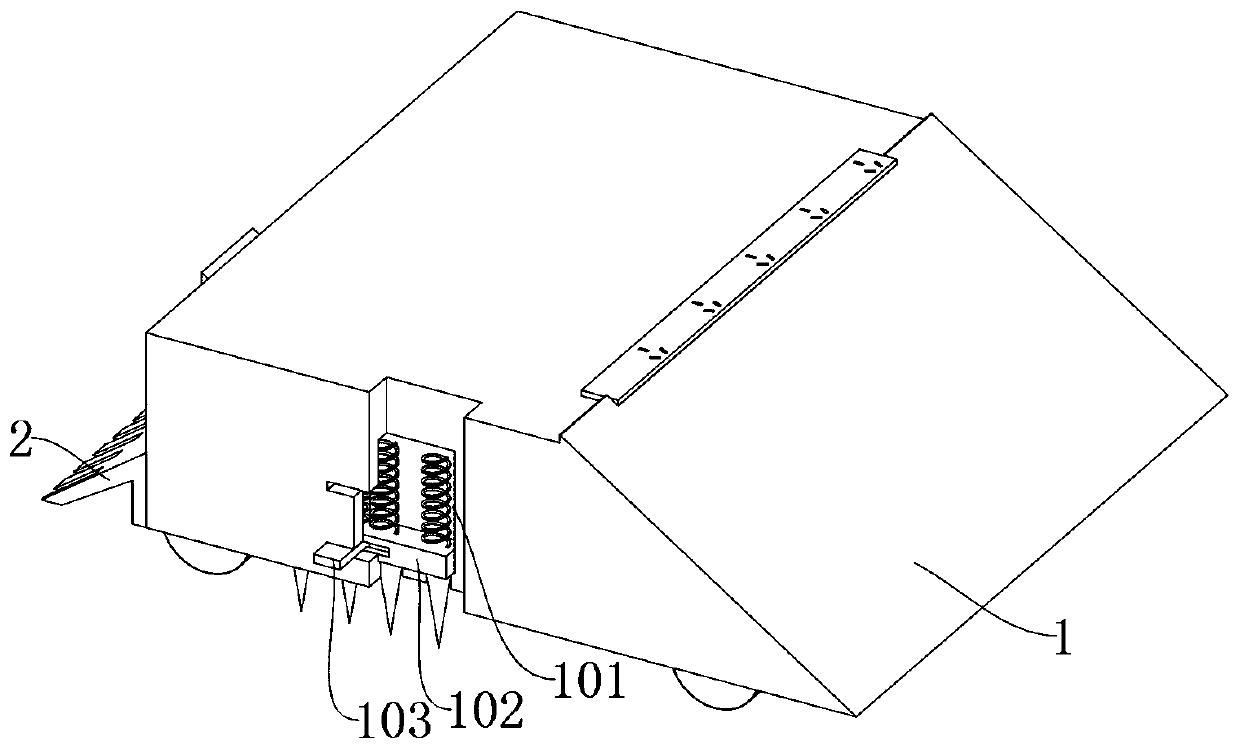

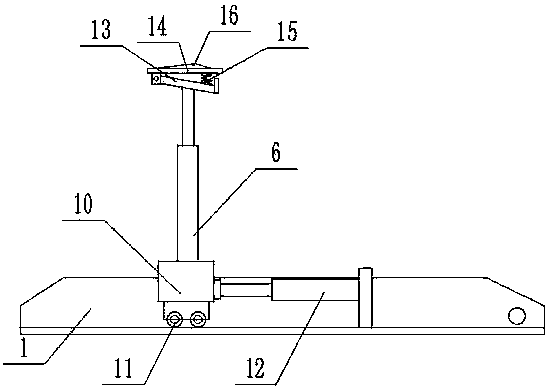

Coal sample extracting device for underground drilled hole of coal mine

PendingCN107269271AEasy to disassemble and take outEasy to removeBorehole/well accessoriesMining engineeringHard coal

The invention relates to a coal sample extracting device for an underground drilled hole of a coal mine. The coal sample extracting device for the underground drilled hole of the coal mine comprises a coal feeding barrel, a coal feeding clamping groove and a coal storing barrel. The coal feeding clamping groove, the coal feeding barrel and the coal storing barrel are sequentially connected in a threaded mode and communicate with one another; rotary vane cutter teeth are arranged on the section of the coal inlet end of the coal feeding barrel in the circumferential direction; an elastic blocking device capable of enabling an inner cavity of the coal feeding clamping groove to be switched between opening and closing is installed in the coal feeding clamping groove; and the coal storing barrel is connected with a drill rod in a threaded mode. The overall coal sample extracting device for the underground drilled hole of the coal mine is simple in structure and is divided into three parts, and disassembling and assembling are convenient so that a coal sample can be taken out; cost is low, requirements of extracting of the coal samples from various drilled holes in underground soft coal bodies or hard coal bodies are met, and meanwhile, most of the extracted coal samples are in a blocky shape for convenient rejecting of gangue parts, and the purity of the coal samples is guaranteed; and especially, a mine party can conduct processing according to the sizes of the drilled holes and the required amount of the coal samples.

Owner:刘荣亮

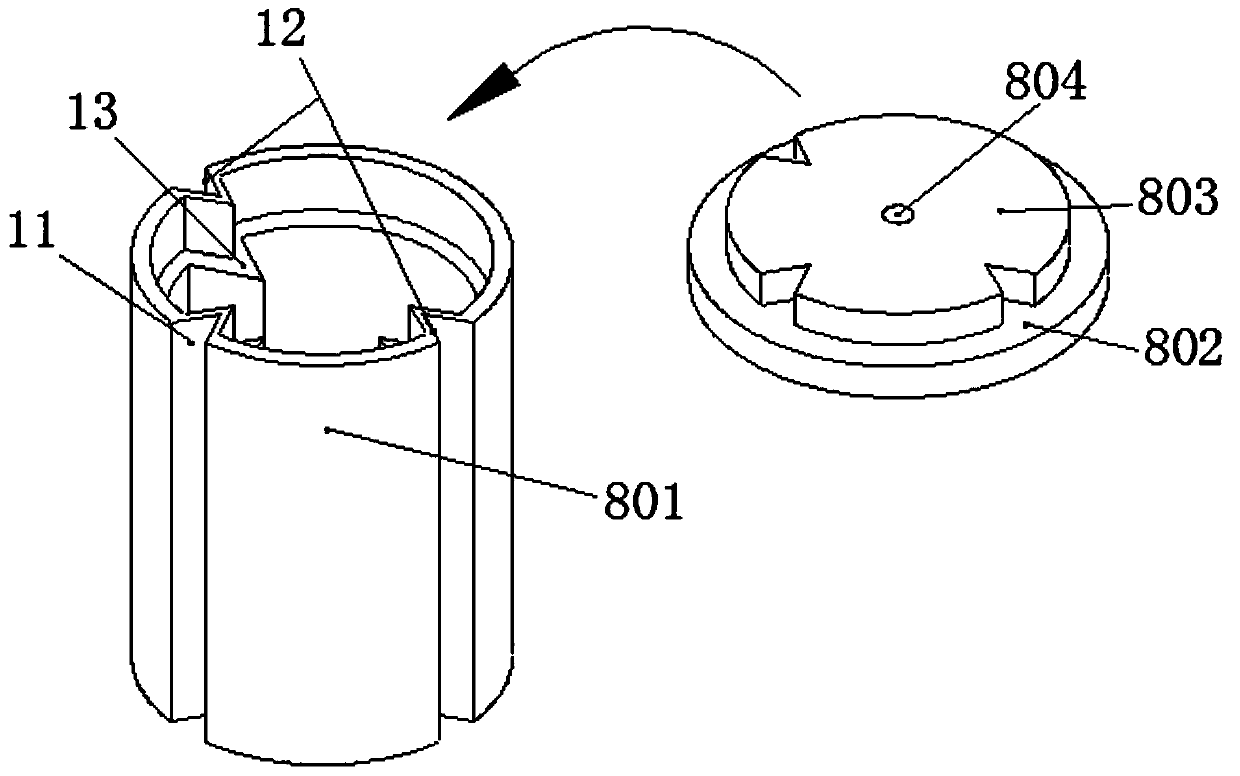

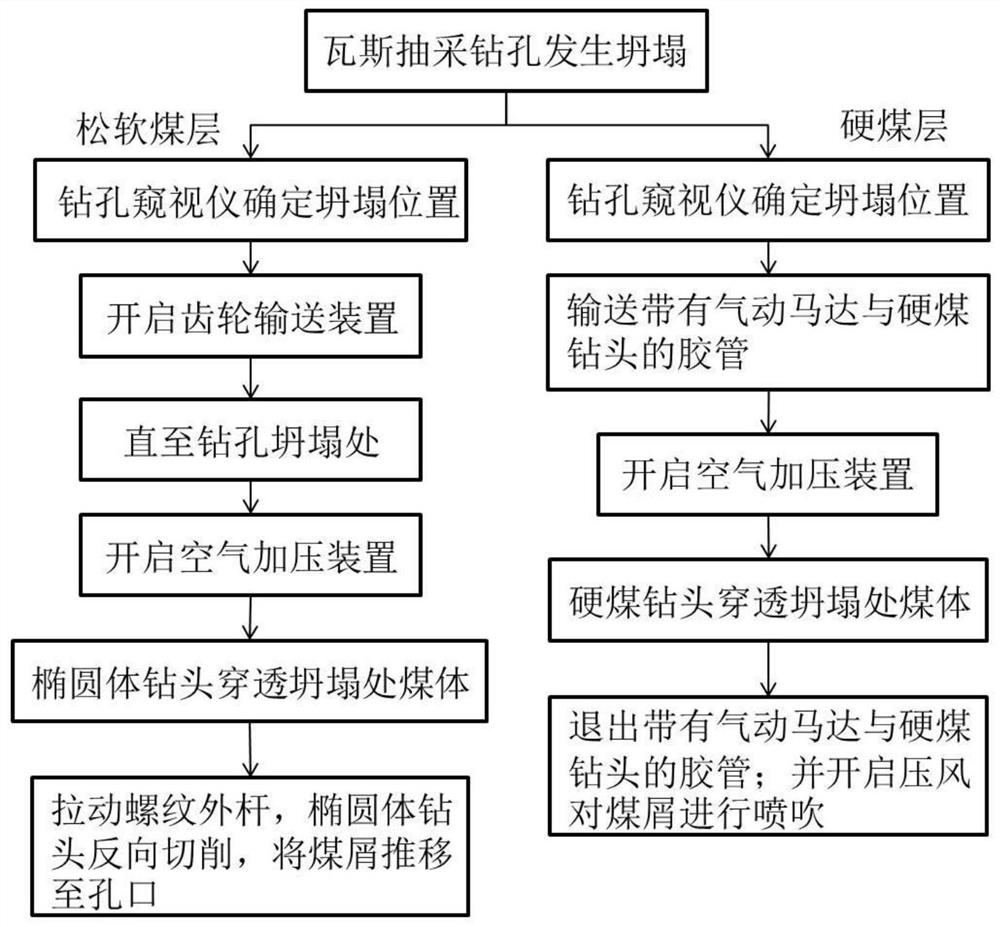

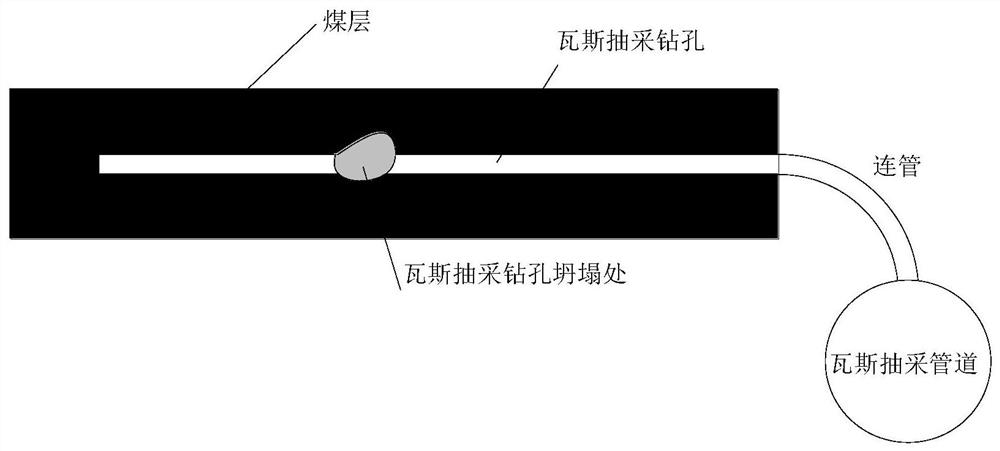

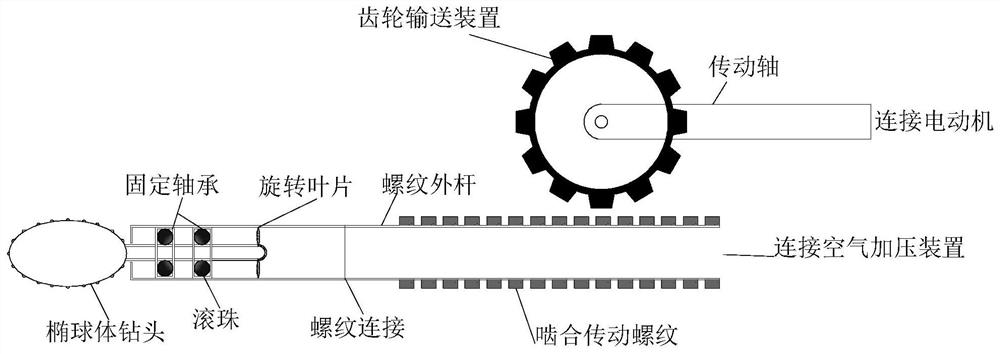

Dredging and re-extraction method for coal seam gas extraction borehole collapse

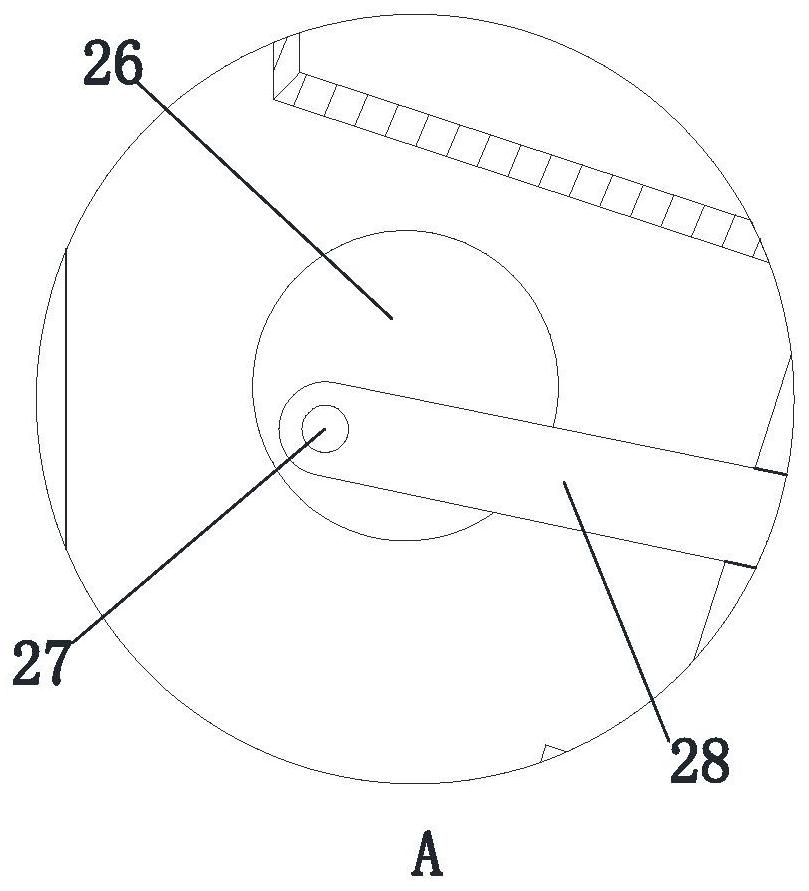

ActiveCN112554781AGrooming to achieveStable deliveryDrill bitsDrilling rodsRotational axisThermodynamics

The invention belongs to the field of coal mine safety, and relates to a dredging and re-extraction method for coal seam gas extraction borehole collapse. The dredging and re-extraction method comprises the steps that if the coal seam is a soft coal seam, a gear conveying device is started to convey a threaded outer rod with a soft coal seam cutting part to the collapse position, and high-pressureair in the threaded outer rod drives rotating blades to rotate, so that an ellipsoid drill bit is driven to rotate to penetrate through a collapsed coal body; if the coal seam is a hard coal seam, arubber pipe with a pneumatic motor and of a hard coal drill bit is conveyed to the collapse position, enters the air inlet end of the pneumatic motor through a high-pressure air conveying pipe, and then the rotating blades are driven to rotate, so that a rotating shaft rotates and drives the hard coal drill bit to rotate to cut a coal body at the collapse position; after the coal body at the collapse position of the gas extraction drill hole penetrates through, the corresponding device can be withdrawn immediately; and the coal body at the collapse position is penetrated through through a special drilling process, the extraction attribute of the drill hole is recovered, the gas extraction efficiency of a mine is powerfully guaranteed, and gas accidents are practically prevented.

Owner:SHANDONG UNIV OF SCI & TECH +1

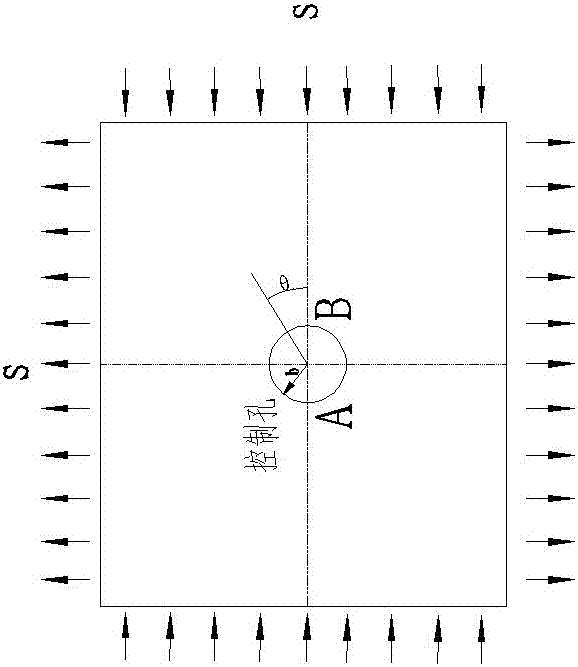

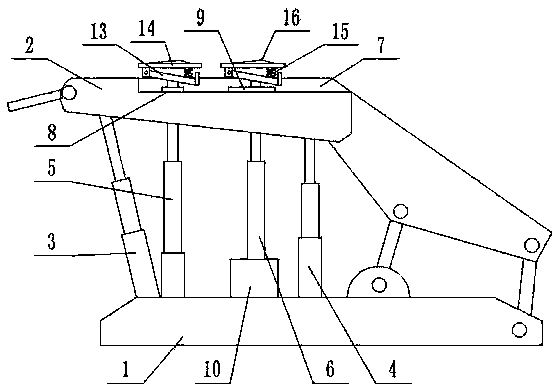

Hard coal seam mining method for balancing energy induced plastic damage and preventing and controlling dynamic damage and experimental device

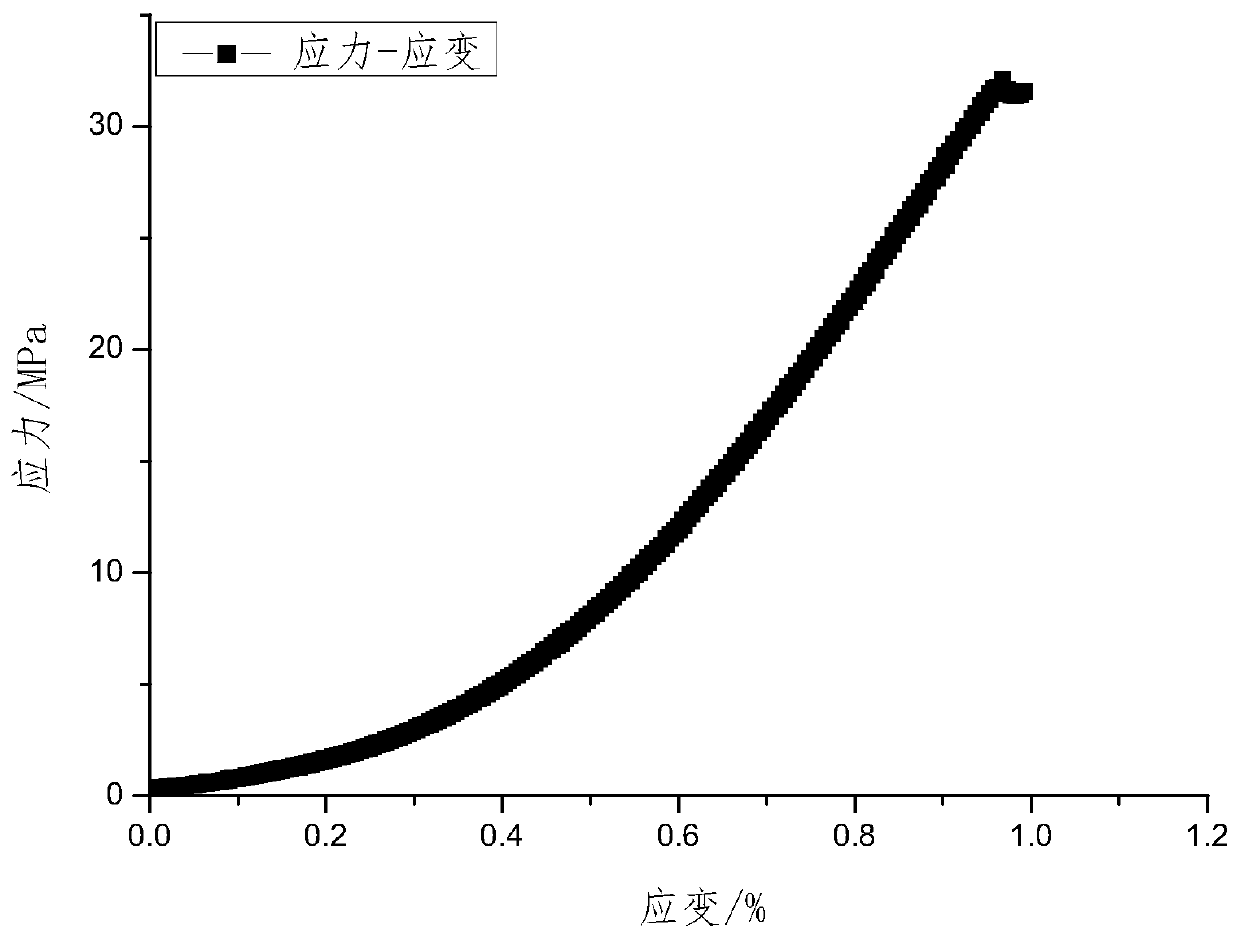

ActiveCN109915139ARelieve stressAvoid the problem of excessive energy differenceUnderground miningMaterial strength using tensile/compressive forcesMonitoring systemEngineering

The invention discloses a hard coal seam mining method for balancing energy induced plastic damage and preventing and controlling dynamic damage and an experimental device, belongs to the technical field of coal mining, particularly relates to a hard coal seam mining method and an experimental device, and aims to solve the problems that cutting teeth are seriously abraded and power damage is easily caused in the existing hard coal seam mining method. An energy compensation hole array is arranged on a mining surface of a hard coal seam, an energy compensation device is arranged in each energy compensation hole; a rock burst monitoring system is arranged to monitor the energy distribution of the coal wall, before coal seam mining, the energy conditions of a plurality of coal wall units of the coal wall are detected in real time through the arranged rock burst monitoring system, an energy distribution array is correspondingly generated, the average energy value of the energy distributionarray is calculated, energy distribution adjustment is carried out, and therefore mining of the hard coal seam is achieved. The method is suitable for hard coal seam mining.

Owner:ANHUI UNIV OF SCI & TECH

Distance adjustable cutting type coal mining device for coal mining

ActiveCN111411950ANo mobile impactEasy to fixSlitting machinesCutting machinesMining engineeringMechanical engineering

The invention provides a distance adjustable cutting type coal mining device for coal mining. The distance adjustable cutting type coal mining device comprises a main body, a rear piece, a support piece, a movable piece, a guiding groove and an adjusting piece; the main body is of rectangular structure; movable wheels are arranged at the bottom corners of the main body; the rear piece is arrangedat the rear end of the main body; the inner bottom of the rear piece is connected with the bottom of the rear end of the main body through a connecting shaft; the support piece is mounted at the top end of the main body; and the bottom of the support piece is connected above a front end plane of the main body through welding. The rear piece is arranged at the rear end of the main body, so that when the distance adjustable cutting type coal mining device is used, a foot of a person can control the rear piece to overturn, the bottom of the external end of the rear piece can be inserted in soil to firmly fix the distance adjustable cutting type coal mining device, the distance adjustable cutting type coal mining device does not move backward even if meeting harder coal, and a cutting piece can steadily mine coal.

Owner:湖南煤业牛马司矿业有限公司

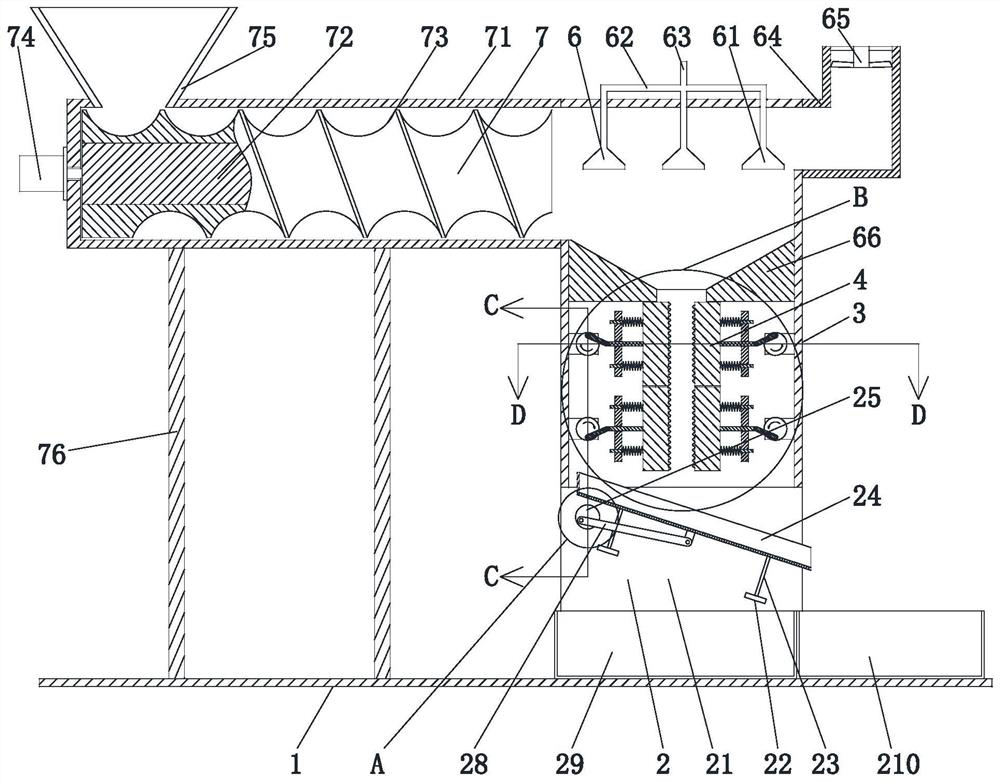

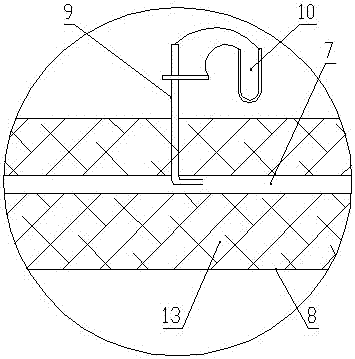

Crushing device of top coal caving hydraulic support

ActiveCN110748364APromote fragmentationAvoid smashingSlitting machinesProps/chocksBriquetageHard coal

The invention provides a crushing device of a top coal caving hydraulic support. The crushing device of the top coal caving hydraulic support comprises a base, an ejecting beam, a front telescopic stand column and a rear telescopic stand column, and further comprises an ejecting block device; the ejecting block device comprises a front telescoping ejecting column, a rear telescopic ejecting column, crushing plates at the upper end of the front telescopic ejecting column and the upper end of the rear telescopic ejecting column, wherein a crushing groove located in the middle is arranged at theupper end of the ejecting beam, a front ejecting column sleeve ring and a rear ejecting column moving groove are arranged in the crushing groove, the bottom end of the front telescoping ejecting column is fixed on the base, the telescoping end of the upper end of the front telescoping ejecting column is installed at the front ejecting column sleeve ring, the bottom end of the rear telescopic ejecting column is fixed on a sliding frame, the telescopic end of the upper end of the rear telescopic ejecting column is installed at the rear ejecting column moving groove, the lower end of the slidingframe is provided with sliding wheels, and the right end of the sliding frame is connected with a telescopic end of a movable hydraulic rod fixed on the base. According to the crushing device, a hardcoal seam is conveniently crushed, the crushing device of the top coal caving hydraulic support tightly presses against the coal seam in the moving process of the crushing device of the top coal caving hydraulic support, and the large hard coal briquette is prevented from smashing the ejecting beam.

Owner:HENAN POLYTECHNIC UNIV

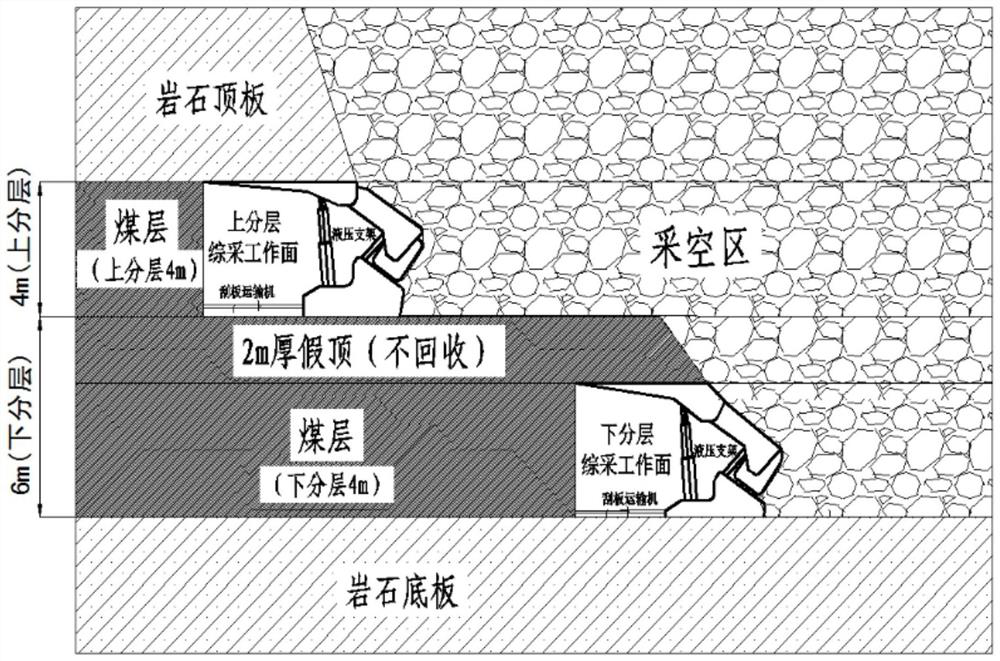

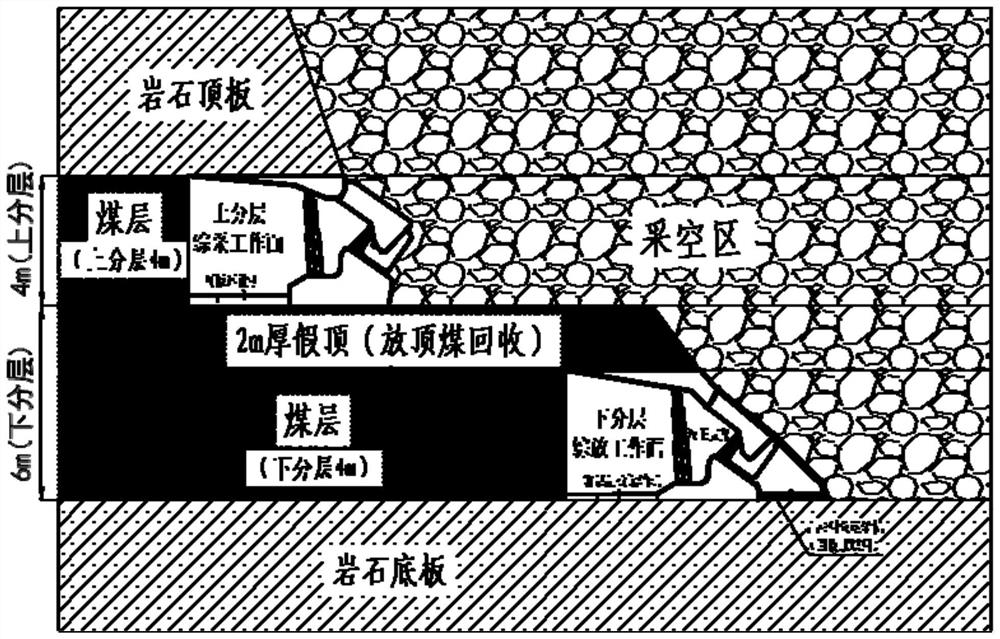

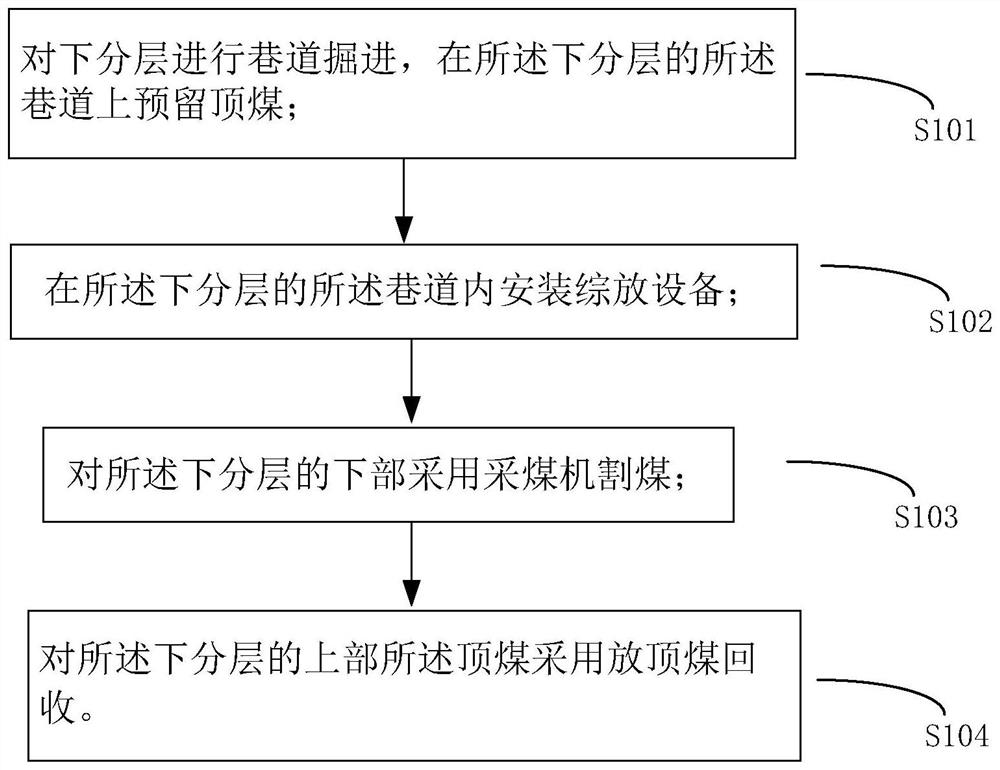

Fully mechanized caving mining method for extra-thick hard coal lower layer

InactiveCN111946345AEnsure safetyHigh recovery rateUnderground miningSurface miningSpontaneous combustionMining engineering

The invention discloses a fully mechanized caving mining method for an extra-thick hard coal lower layer. The method includes the steps that an extra-thick hard coal layer is divided into an upper layer and the lower layer; the lower layer is tunneled after the fully mechanized mining of the upper layer is finished; top coal on the roadway of the lower layer is reserved and the top coal is taken as a fully mechanized mining roof which does not need to be paved with a net; coal is recycled as caving coal after the coal arrives at the back of a frame; fully mechanized caving equipment is mountedin the roadway of the lower layer; a coal mining machine is adopted to cut the coal at the lower part of the lower layer; and the top coal is recycled at the upper part of the lower layer by top coalcaving. According to the fully mechanized caving mining method for the extra-thick hard coal lower layer, the top coal is used as the fully mechanized mining roof, lapping is not needed, and the topcoal is recycled the as caving top coal after arriving at the back of the frame, so that the safety of the roof is ensured, and coal resources are recycled. The method improves the recovery rate of the coal resources, reduces the hidden danger of the spontaneous combustion of goaf, which is better in safety, is high in efficiency, is good in benefit, and provides a new technology, a new method andnew experience for the safe and efficient recovery of the lower layer after the upper layer fully mechanized mining of the extra-thick hard coal.

Owner:CHINA SHENHUA ENERGY CO LTD +1

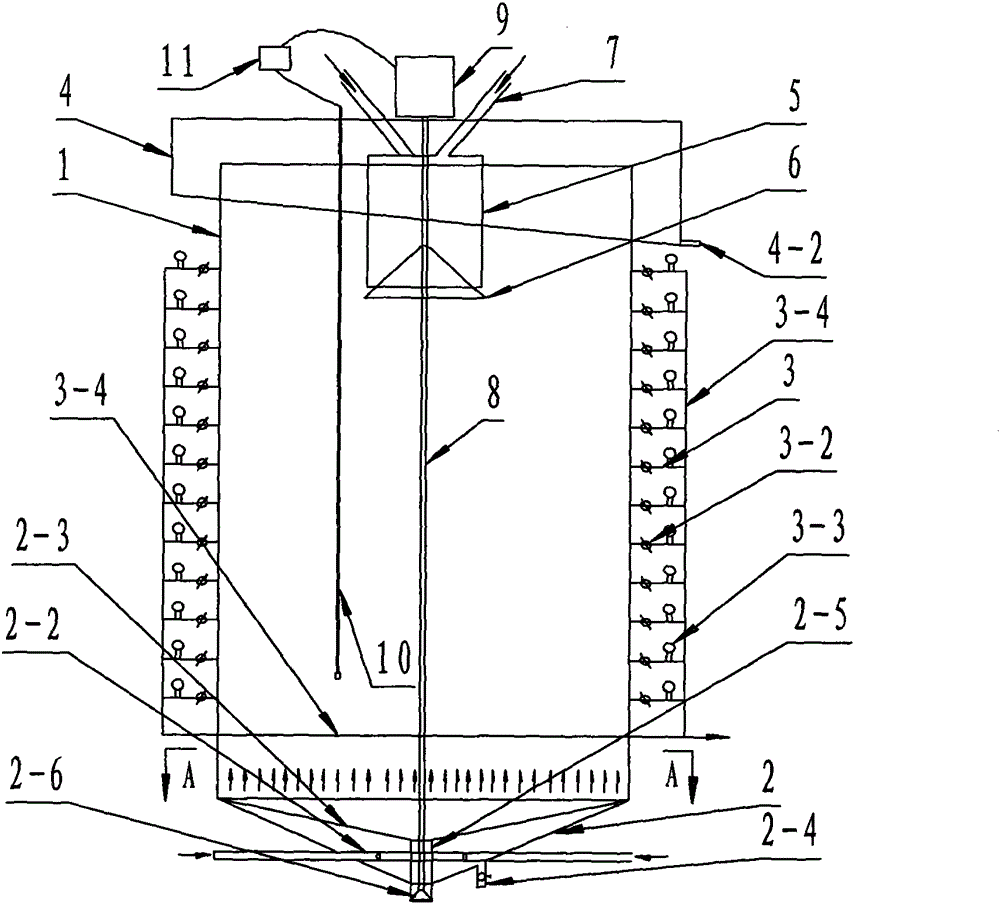

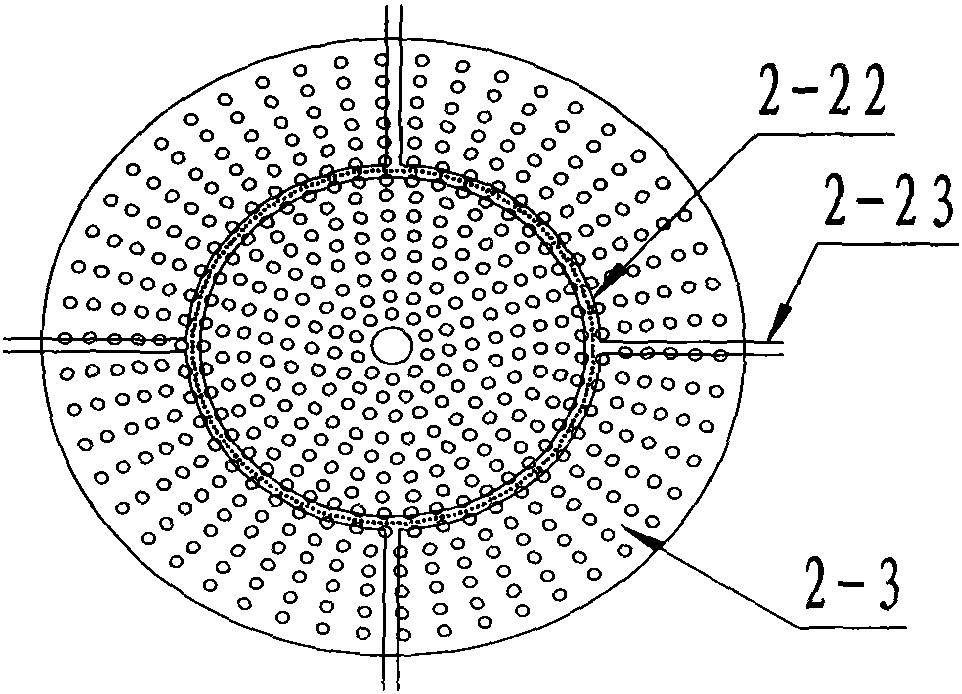

Operation method for liquid-solid fluidization bed coarse slime sorting device capable of adjusting water speed in height direction

Disclosed is an operation method for a liquid-solid fluidization bed coarse slime sorting device capable of adjusting the water speed in the height direction. Coarse slime evenly enters a cylinder body of a fluidization bed through a scattering plate. Coarse slime particles are gradually layered according to the final sedimentation velocity. Low-density coarse slime particles move upwards to enter an overflowing concentrate collection mechanism to be discharged from a concentrate discharging pipe and used as concentrate. High-density coarse slime particles move downwards to enter the bottom of the cylinder body of the fluidization bed. Meanwhile, the concentration of the coarse slime particles inside the cylinder body of the fluidization bed is adjusted through a drainage pipeline, and the equal settling ratio among the coarse slime particles is increased. A controller controls an ore discharge execution mechanism to discharge ore automatically. A frequency converter control pump controls the speed of water entering a water inlet pipe, and the sorting density of the liquid-solid fluidization bed for coarse slime is adjusted. The sorting time of the coarse slime in the fluidization bed is prolonged, sorting of the coarse slime on the whole bed layer height according to the density is enhanced, and the liquid-solid fluidization bed coarse slime sorting device has the obvious advantages for hard sorting and extreme hard coal slime sorting compared with a traditional fluidization bed coarse slime sorting machine.

Owner:LUOYANG MINING MACHINERY ENG DESIGN & RES INST

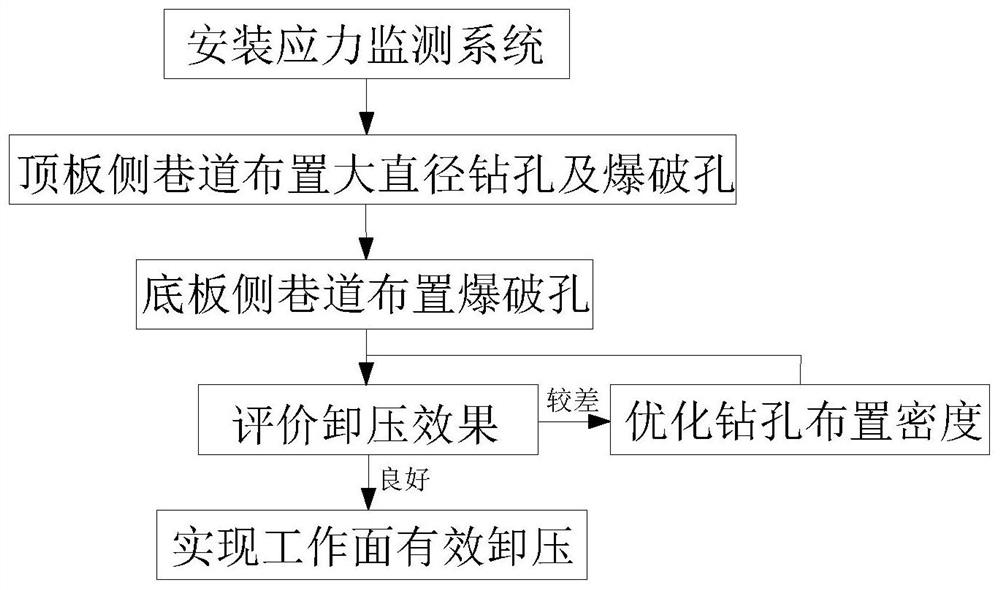

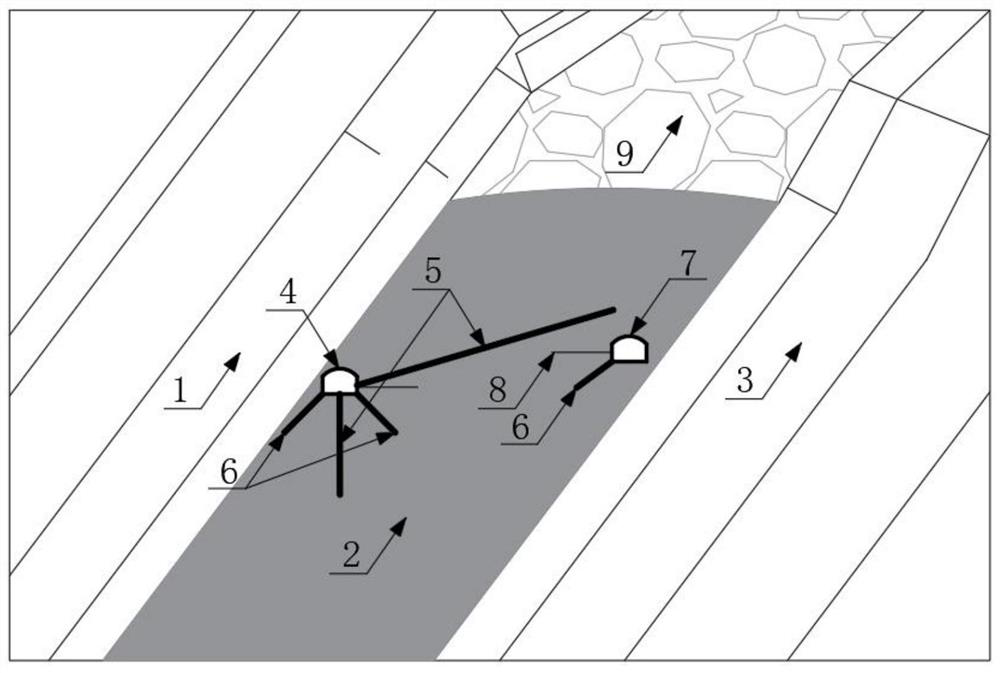

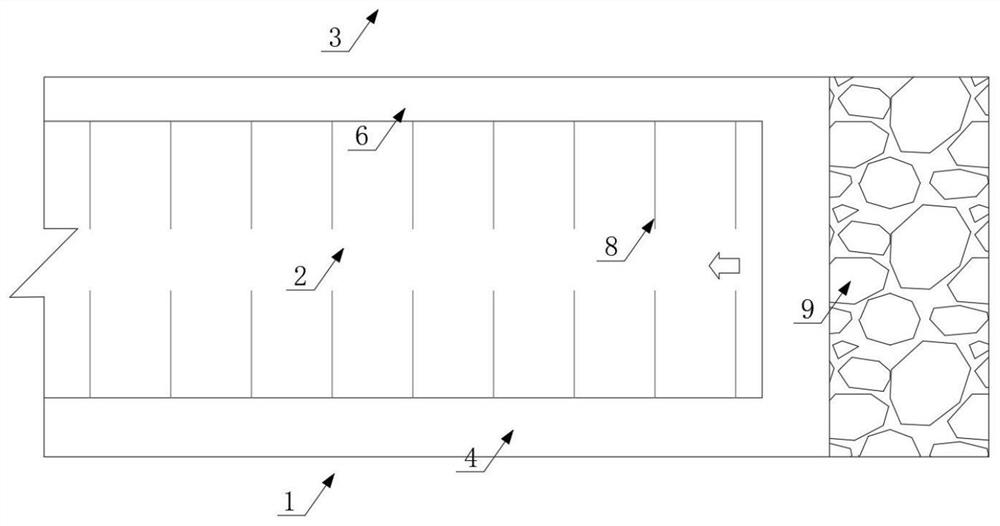

Steeply-inclined extra-thick hard coal seam blasting and large-diameter drilling combined pressure relief method

PendingCN113756808AImprove recovery rateReduce concentrated stressUnderground miningSurface miningStress concentrationMining engineering

The invention discloses a steeply-inclined extra-thick hard coal seam blasting and large-diameter drilling combined pressure relief method. The steeply-inclined extra-thick hard coal seam blasting and large-diameter drilling combined pressure relief method specifically comprises the following steps that firstly, in the mining process of a steeply-inclined extra-thick hard coal seam, a top plate side roadway and a bottom plate side roadway are arranged in a staggered mode, and a plurality of drilling stress meters are mounted on the two roadways and covering the whole roadway and used for monitoring roadway surrounding rock stress changes; according to the mechanical properties of a coal body and a coal seam top plate and a coal seam bottom plate, the mounting parameters of blast holes and large-diameter drill holes are determined, the large-diameter drill holes and the blast holes are formed in the top plate side roadway, and the blast holes are formed in the bottom plate side roadway; and finally, after the blasting large-diameter combined pressure relief drilling construction is completed, the pressure relief effect is evaluated according to a stress value monitored by the drilling stress meter. According to the steeply-inclined extra-thick hard coal seam blasting and large-diameter drilling combined pressure relief method, the stress concentration and the impact danger degree of the steeply-inclined coal seam can be reduced, the pressure relief effect is better, the recovery rate is effectively increased, and the steeply-inclined extra-thick hard coal seam blasting and large-diameter drilling combined pressure relief method is more suitable for the particularity of the steeply-inclined extra-thick hard coal seam.

Owner:CHINA UNIV OF MINING & TECH +2

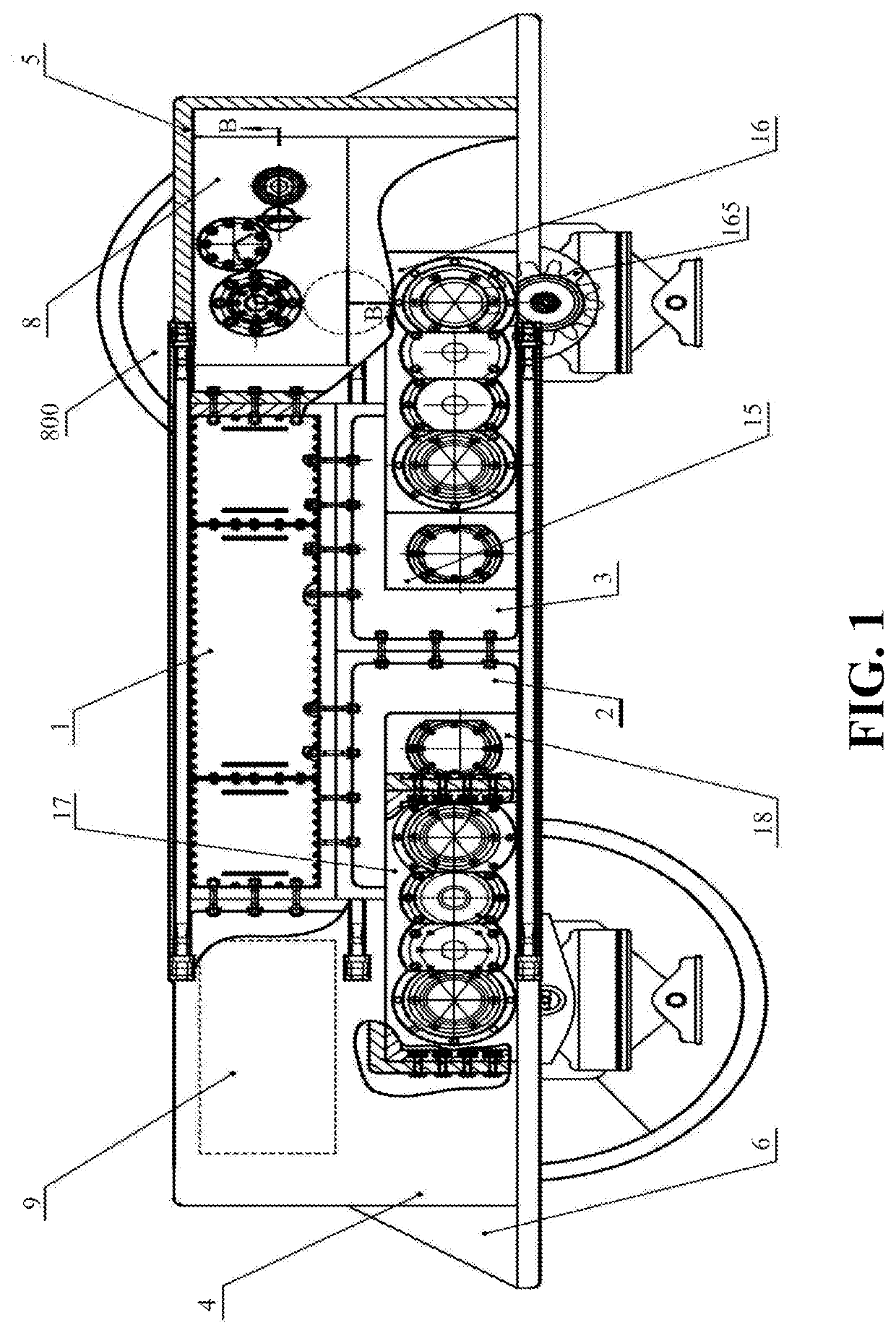

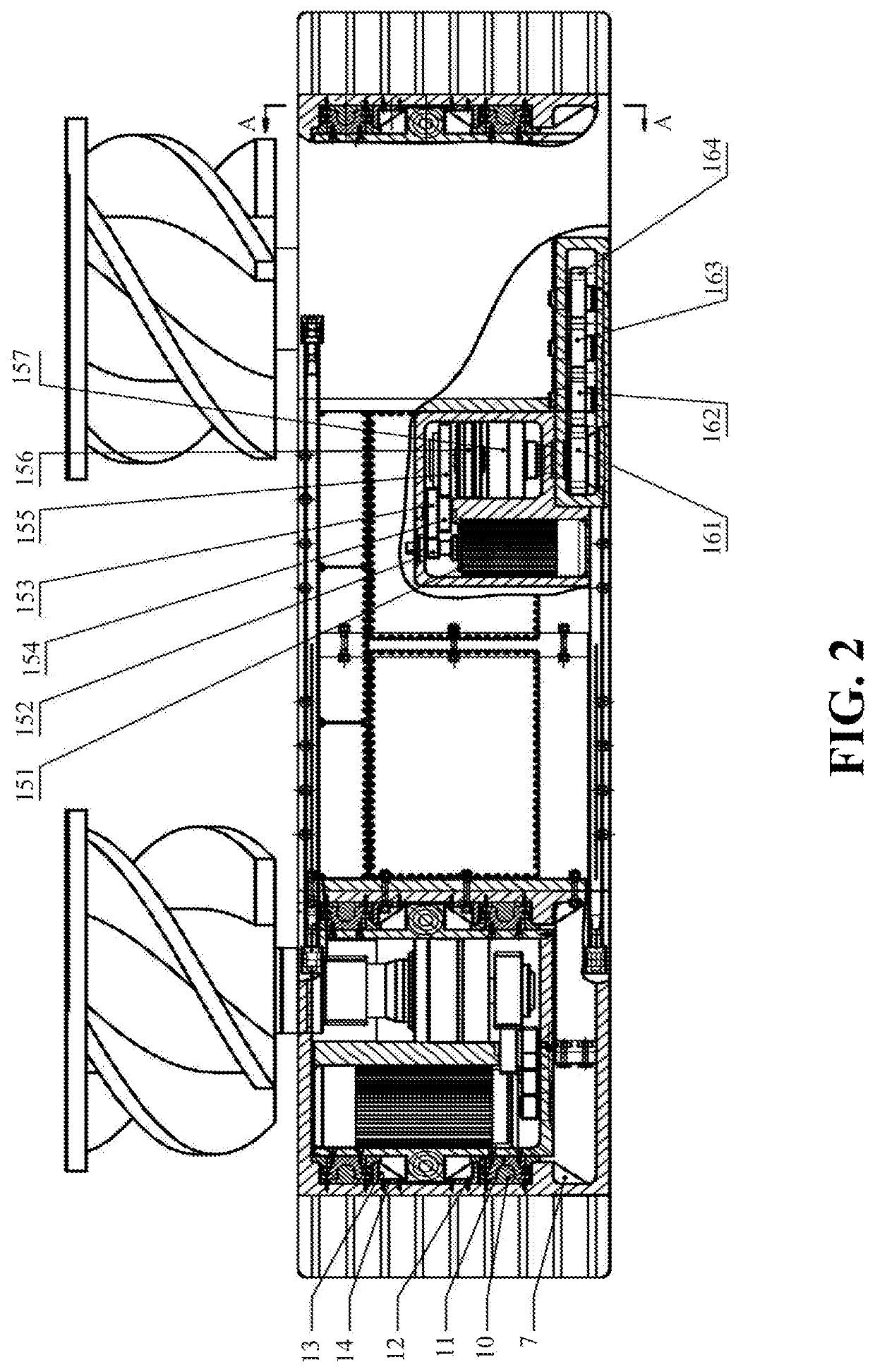

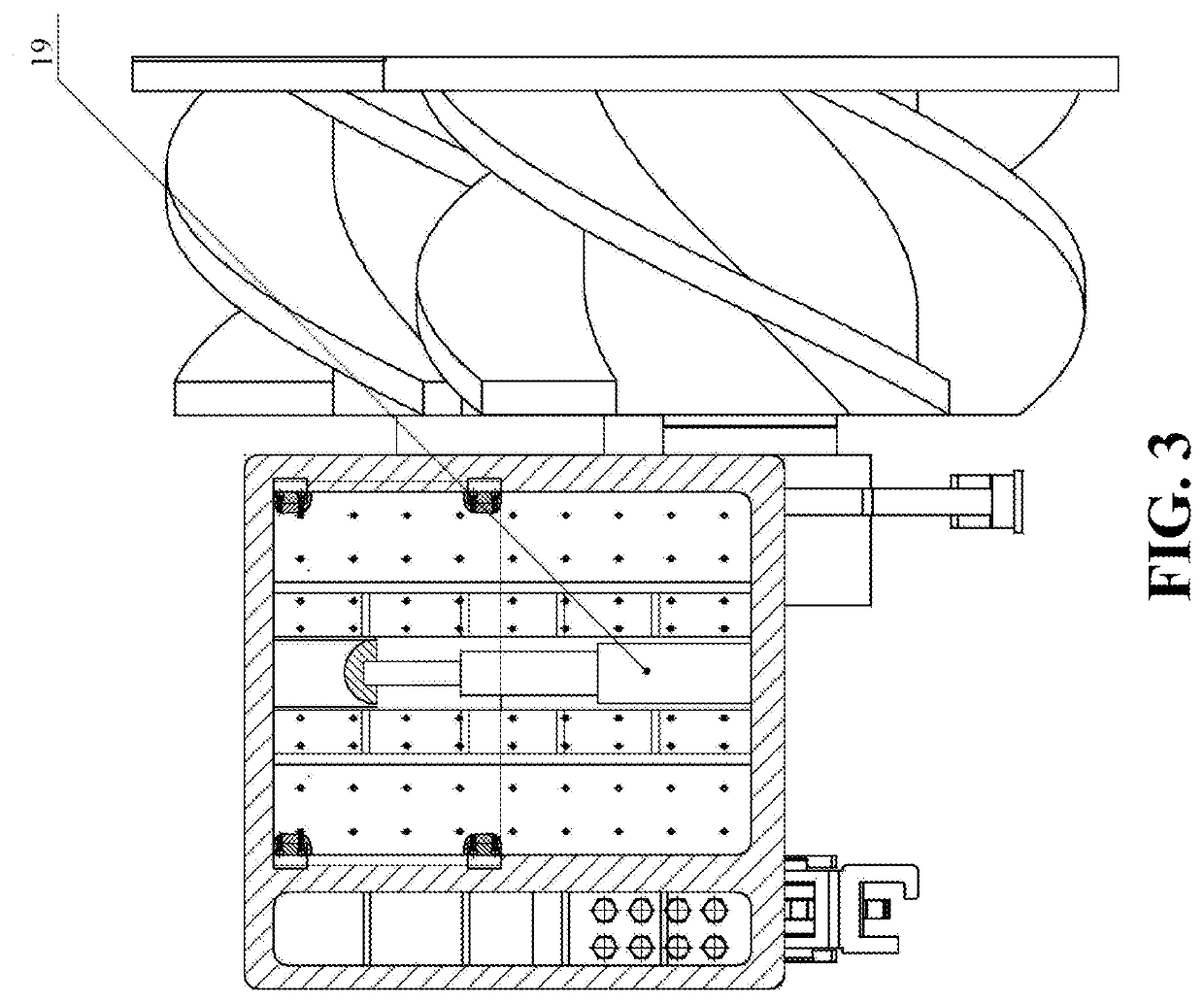

Vertical lifting type comprehensive drum coal-mining machine without rocker arm

ActiveUS20200011174A1Reduce mechanical vibrationWork moreDriving meansPropulsionGear driveGear wheel

Disclosed is a comprehensive vertical-lifting drum shearer without a rocker arm suitable for mining a medium-thick long wall coal seam having a coal seam dip angle of less than 30 degrees and a medium-hard or hard coal quality. The comprehensive vertical-lifting no-rocker drum shearer comprises a central control box (1), left and right cutting lifting reduction boxes (9, 8), left and in right side guiding rail fixing casings (4, 5), left and right traction reduction boxes (18, 15), and left and right walking gearboxes (17, 16); the left and right cutting lifting reduction boxes (9, 8) are provided with slideways which are matched with lifting guiding rails (10) of the left and right side guiding rail fixing casings (4, 5) in a sliding manner; the left and right cutting lifting reduction boxes (9, 8) are driven to perform a lifting motion by lifting oil cylinders (19), and meanwhile, cutting motors of the left and right cutting lifting reduction boxes (9, 8) drive a spiral drum to rotate by means of a cutting gear reduction mechanism; the left and right traction reduction boxes (18, 15) drive the left and right walking gearboxes (17, 16), and then drive the whole machine to perform left and right traction movement. The cutting gear reduction mechanism of said shearer uses two-level gear transmission and two-level planetary gear transmission, without a plurality of idle wheel sets, and the transmission chain is simple; and the cooperation of the lifting guiding rails and the slideways makes the whole machine compact in structure, improving the operation reliability and stability.

Owner:ZHANG YIMIN

Preparation technology of dolomite sand

The invention provides a preparation technology of dolomite sand, which comprises the following steps: (1) dolomite with the particle size of 10-80 mm is selected, wherein the dolomite comprises the following chemical components in parts by weight: larger than or equal to 0.29 part of SiO2, larger than or equal to 0.1 part of Fe2O3, larger than or equal to 0.15 part of Al2O3, larger than or equal to 30.06 parts of CaO, and larger than or equal to 22.7 parts of MgO, in addition, the dolomite is cut down for 40-50 according to the circumference, (2) low-ash hard coal is adopted as fuels to be calcinated in a high temperature shaft kiln, wherein the calcinating temperature is 1,750-1,850 DEG C; an intermittent oxygen-enriched calcination way is adopted, wherein one-time drawing out of the kiln is carried out in calcinating for 4-6 hours, and the times of entering in and drawing out of the kiln is 4-6; (3) the calcinated dolomite sand comprises the chemical components in parts by weight: 1.11-1.18 parts of SiO2, 0.56-0.6 part of Fe2O3, 0.45-0.64 part of Al2O3, 56.94-57.67 parts of CaO, and 39.93-40.21 parts of MgO, in addition, the calcinated dolomite sand is cut down for 0.28-0.43 according to the circumference, and has volume density of higher than or equal to 3.2. The dolomite sand is manufactured by one-step calcinating, and on one hand, the consumption of raw materials and fuels are enabled to be remarkably reduced, on the other hand, the preparation technology is greatly simplified, therefore, the production cost is lowered greatly.

Owner:大石桥市大岭天成耐火材料有限公司 +1

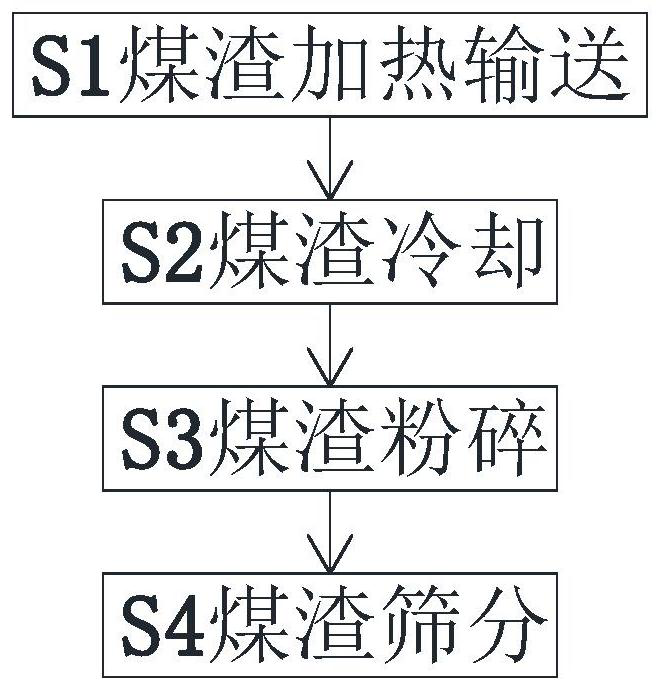

Industrial solid waste environmental protection treatment method

ActiveCN112742845AEfficient crushingReduced crushing effectSolid waste managementSolid waste disposalEnvironmental engineeringCinder

The invention discloses an industrial solid waste environmental protection treatment method which uses industrial solid waste environmental protection treatment equipment. The industrial solid waste environmental protection treatment method can solve the following problems in coal cinder treatment by existing industrial solid waste environmental protection treatment equipment that 1, when the existing industrial solid waste environmental protection treatment equipment treats coal cinder, the coal cinder generally contains relatively hard coal cinder blocks to be difficult to effectively crush, the hard coal cinder is left in the smashed coal cinder, subsequent further treatment of the coal cinder is affected, and the efficiency is caused to be low; and 2, when the existing industrial solid waste environmental protection treatment equipment treats the coal cinder, the coal cinder is not screened, so that fine coal cinder and coarse coal cinder in the crushed coal cinder are mixed together, and the crushing effect of the coal cinder is reduced. By means of the industrial solid waste environmental protection treatment method, the hard coal cinder is effectively smashed, and the coal cinder smashing effect is improved through screening.

Owner:ANHUI XINLU CONSTR ENG GRP

Combustion method of anthracite coal

InactiveCN100451447CSolve the problem of ignition stabilityGuaranteed uptimeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelJet flowCombustor

A method for burning hard coal includes setting four lines of burners formed by primary air ejector on wall of bottom firepot at boiler and setting another four lines of burners formed by secondary air ejector at four corners of firepot, setting two said air ejectors on the same level to form two concentric tangent circular rotary movements of internal and external in boiler by jet flows formed by primary and secondary airs, wrapping primary air by secondary air, setting tertiary air and burn-out air ejector at corners on top of master combustion region to form four-corner tangent-direction jet flow.

Owner:SHANGHAI JIAOTONG UNIV

Method for top coal caving mining of pressure unloading by blasting and gas drainage of huge thick and hard coal bed

InactiveCN108104815AFacilitate transportation and drainageHigh densityDisloding machinesUnderground miningDrill siteLiquid carbon

The invention discloses a method for top coal caving mining of pressure unloading by blasting and gas drainage of a huge thick and hard coal bed, and belongs to the technology field of top coal cavingmining. The method comprises the steps that a top coal caving working face is arranged at the bottom of the huge thick and hard coal bed, a lower connecting roadway and an upper connecting roadway are obliquely arranged on a conveying roadway and a wind return roadway of the top coal caving working face correspondingly and communicate with the top of the huge thick and hard coal bed, a set of parallelly-arranged high-level process roadways is tunneled at intervals along the top of the huge thick and hard coal bed, the high-level process roadways communicate with one another through a set of connection roadways arranged at intervals, the connection roadways are internally provided with adjusting air windows for controlling ventilation, high-level gas drainage pipes are arranged in the high-level process roadways, drill sites are arranged in the connection roadways, construction is conducted downwards for drilling by utilizing the drill sites, liquid carbon dioxide blasting generators are arranged in drilled holes, and the carbon dioxide blasting generators are arranged in advance compared with the top coal caving working face. According to the method for top coal caving mining of pressure unloading by blasting and gas drainage of the huge thick and hard coal bed, safe mining of the working face is achieved, the production efficiency is high, safety is intrinsically achieved byadopting liquid carbon dioxide for blasting, and gas is transported and drained to the high-level process roadways advantageously.

Owner:孟思思

Soft and hard interaction coal seam horizontal well staged fracturing gas advanced extraction method

PendingCN113107450ATo achieve the purpose of coordinated developmentAvoid stabilityFluid removalGas removalThermodynamicsHorizontal wells

The invention relates to a soft and hard interaction coal seam horizontal well staged fracturing gas advanced extraction method. The method comprises the steps that a vertical well is constructed in the deep structure of a protection coal pillar, and the cave position of the vertical well is located in a hard coal layer of a soft and hard interaction coal seam; a horizontal well set in butt joint with the vertical well is constructed in the direction of a protection coal pillar between planned coal faces, and the horizontal section of the horizontal well set is located in a hard coal layer of the soft and hard interaction coal seam; the horizontal well is subjected to staged perforation fracturing construction in a retreating mode, and high-speed jet flow of the staged perforation fracturing construction induces water flow to break through a hard coal layer and then enter a soft coal layer; and after the staged perforation fracturing construction, gas extraction is conducted on the horizontal well, and drainage operation is conducted on the vertical well. According to horizontal well planning and deployment, the influence of later-stage coal mining activities is considered, coal mining and gas mining integrated design is achieved, and the purpose of coordinated development of coal and coal bed gas is achieved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Experiment device and experiment method for measuring negative pressure and flow distribution characteristic in drilling hole

The invention discloses an experiment device for measuring negative pressure and a flow distribution characteristic in a drilling hole. The experiment device comprises a gas-water separation box, a water ring vacuum pump and an anthracite sand filling box. The top of gas-water separation box is upwards connected with a water inlet / gas outlet pipe and a first connection flexible pipe, and the first connection flexible pipe is connected with the gas outlet of the water ring vacuum pump. The gas-water separation box is connected with a water outlet pipe and a water supply pipe. The anthracite sand filling box is compactly filled with anthracite sand, and an extracting pipe is arranged in the middle of the anthracite sand filling box. A plurality of pitot pipes are evenly connected with the extracting pipe at intervals. A plurality of air vents are evenly formed in the front and rear side walls and the bottom wall as well as a box cover of the anthracite sand filling box. The invention further discloses an experiment method using the experiment device. The experiment device and the experiment method can simulate the gas extraction processes of a hard coal drilled hole and a soft coal drilled hole, can measure the negative pressure and the flow distribution characteristic of the drilled hole when the hole is complete, collapsed, and blocked. A measuring device makes low influences on the negative pressure in the drilled hole, and the measuring result is close to a theoretical calculation.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com