Drill bit and sampling device

A sampler and drill technology, which is applied in sampling devices, buildings, etc., can solve the problems of hard coal, freezing coal, and inability to accurately obtain coal sample information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

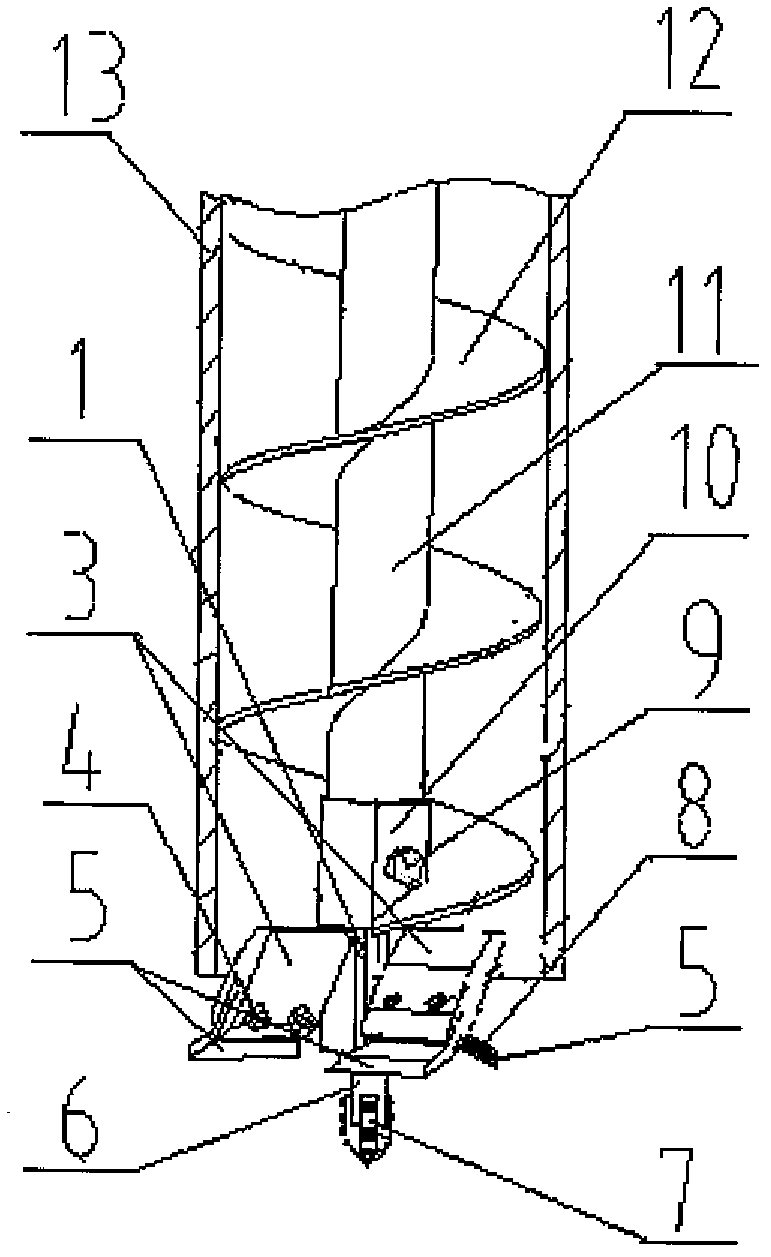

[0029] In order to effectively improve the comprehensiveness of the acquired coal samples and ensure the accuracy of the acquired coal sample quality information, the present invention provides a drill bit and a sampler including the drill bit.

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

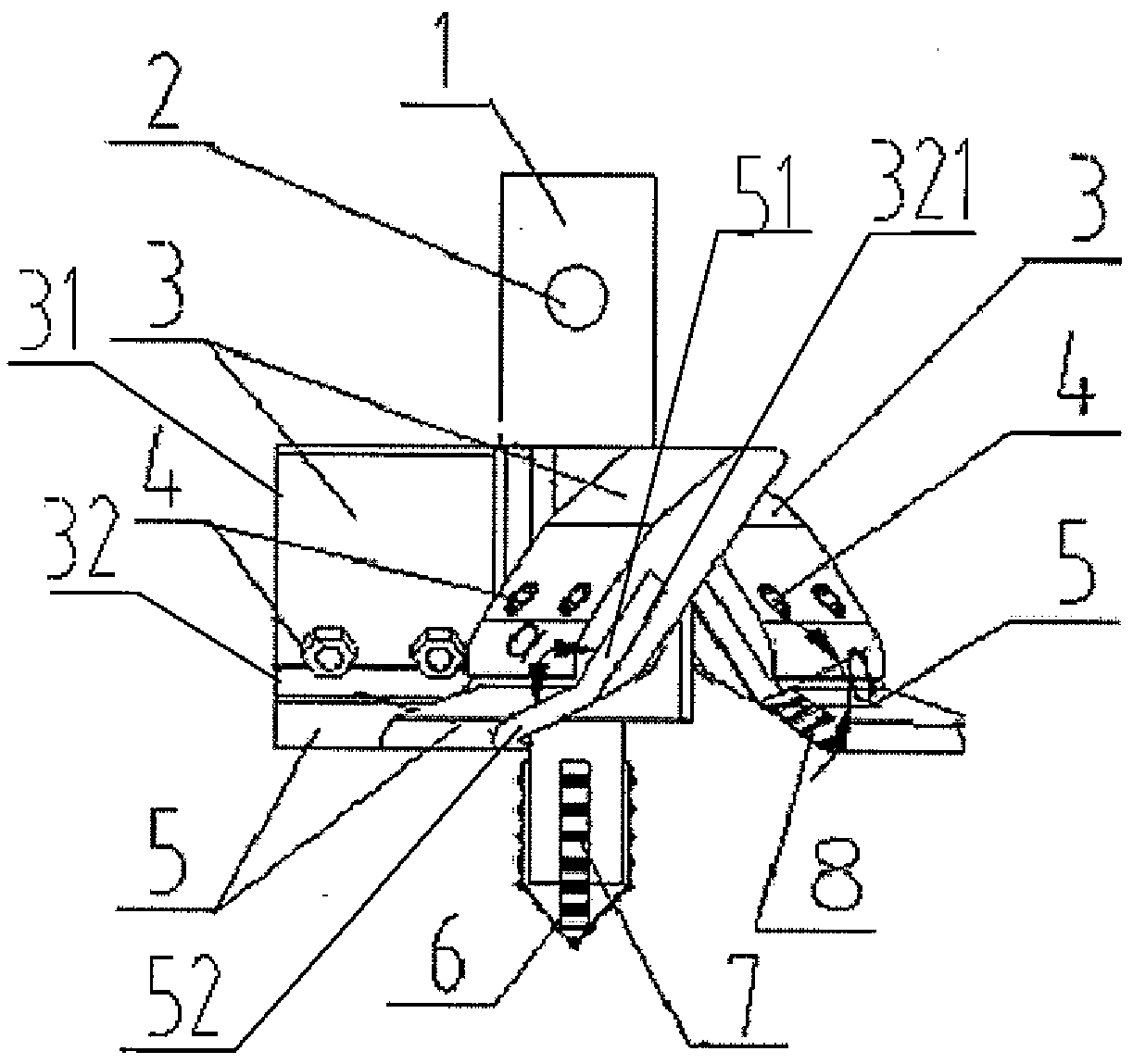

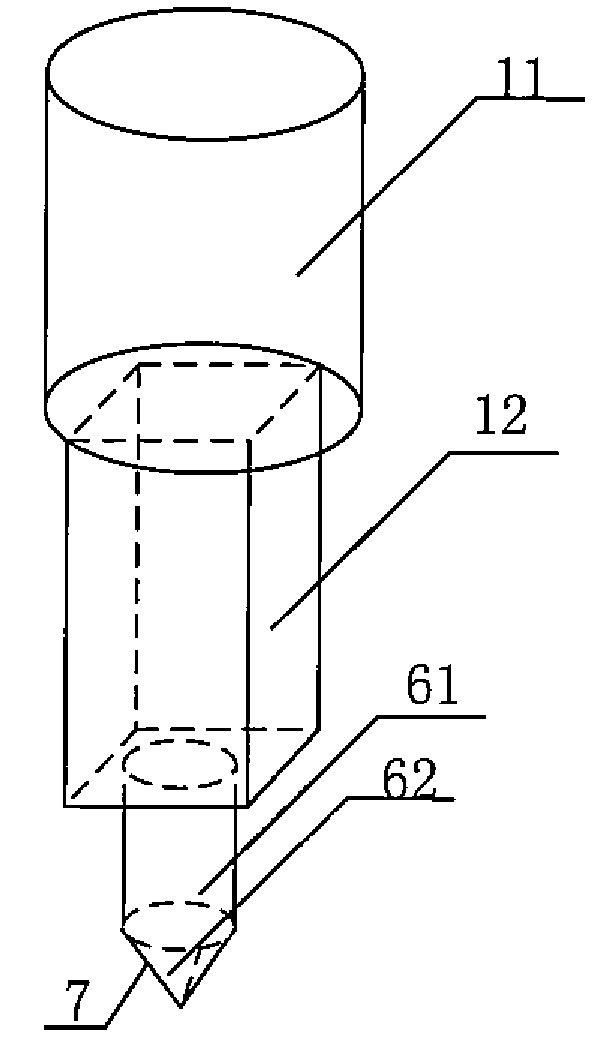

[0031] figure 1 The perspective view of the drill bit provided by the present invention, according to figure 1 As can be seen, the drill bit includes: a drill bit connecting rod 1, a side blade and a main drill bit; wherein,

[0032] The drill connecting rod 1 includes a first connecting rod 11 and a second connecting rod 12, wherein the first connecting rod 11 is a cylinder, and the bottom end of the first connecting rod 11 is connected to the bottom of the second connecting rod 12. At the top, the cross-section of the second connecting rod 12 is a regular polygon;

[0033] The main drill bit includes a main tooth column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com