Patents

Literature

73results about How to "Increase destructive power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

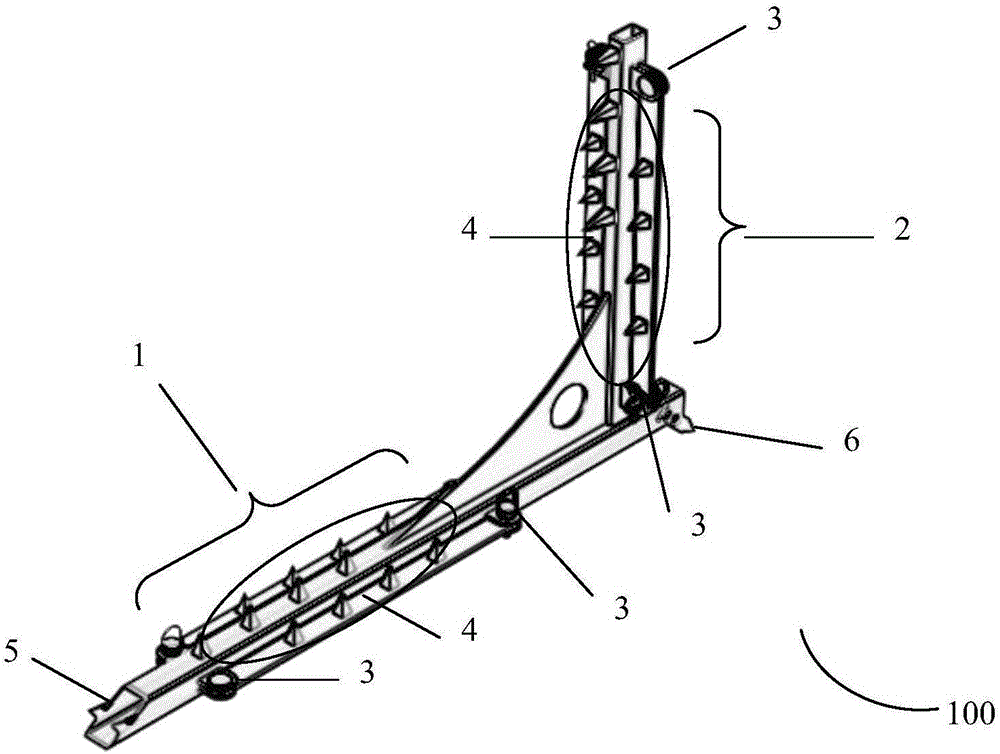

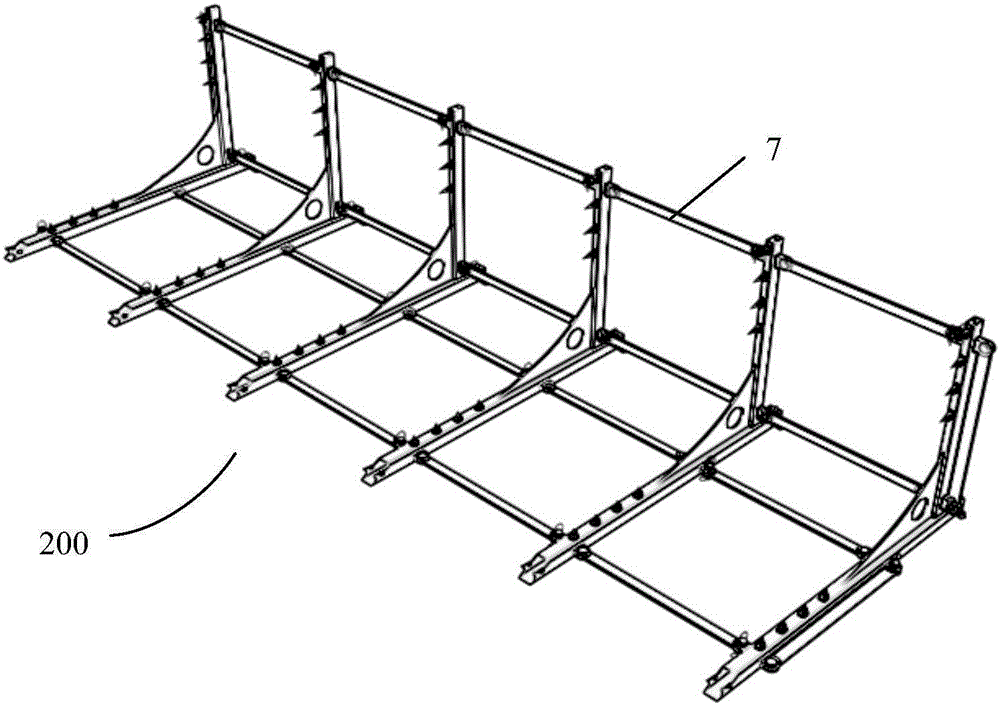

Car arrester module capable of achieving modularization assembling and matrix car arrester

InactiveCN106468049AImprove interception abilitySimple structureTraffic restrictionsModularityEngineering

The invention provides a car arrester module capable of achieving modularization assembling and a matrix car arrester composed of the same. The car arrester module comprises an L-shaped body support and at least one connecting device arranged on the L-shaped body support. The support is composed of a transverse beam and a vertical beam. The connecting devices are used for splicing the car arrester module with other car arrester modules to form the matrix car arrester. Tire breaking assemblies such as bore spines and racks can be arranged on the body support and / or a connector for breaking car tires. The car arrester module has the advantages of being low in weight, small in size and convenient to carry. In addition, due to the fact that the car arrester has the modularization structure, the flexible and maneuverable arresting purpose under various road conditions and clamping setting requirements can be achieved, and the application range is wide.

Owner:BAOTOU NORTH JERRY DEFENSE TECH CO LTD

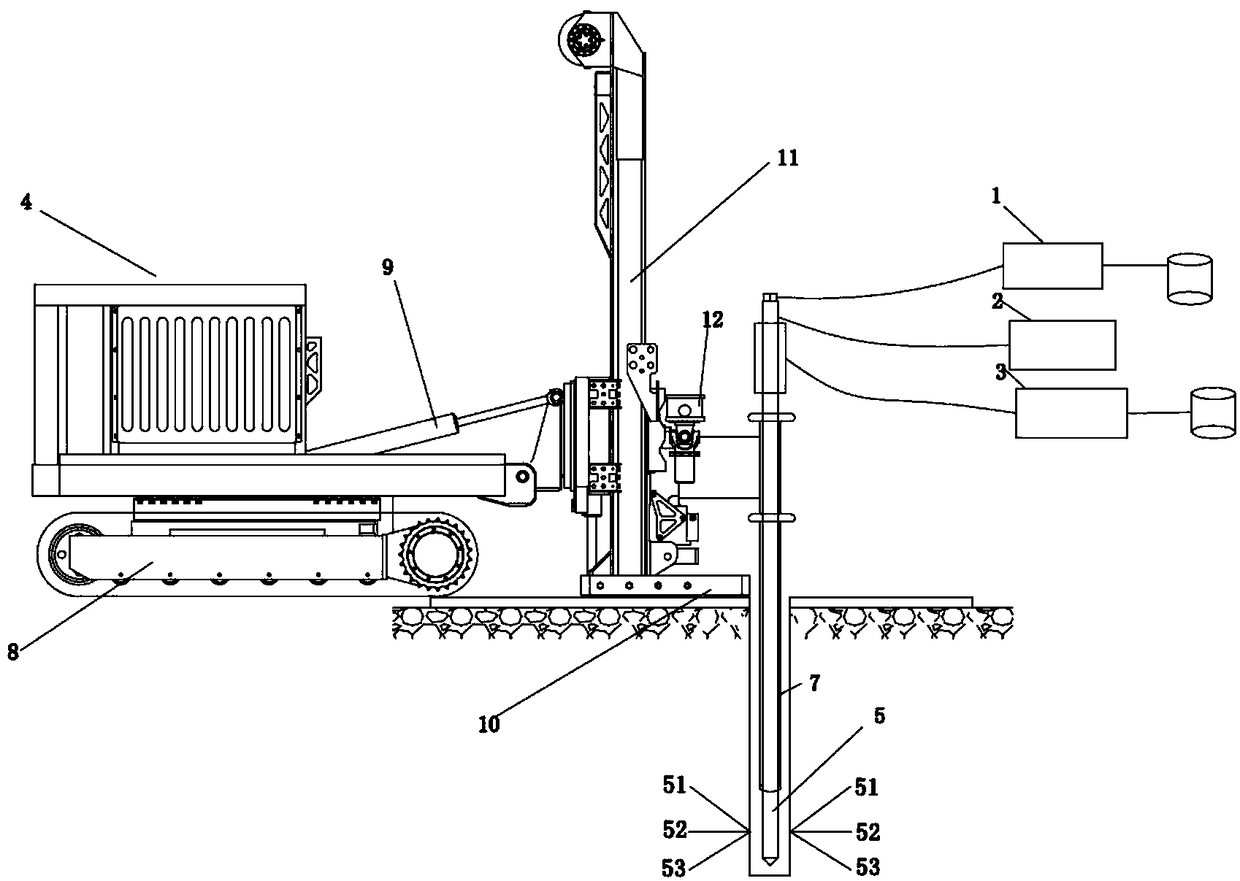

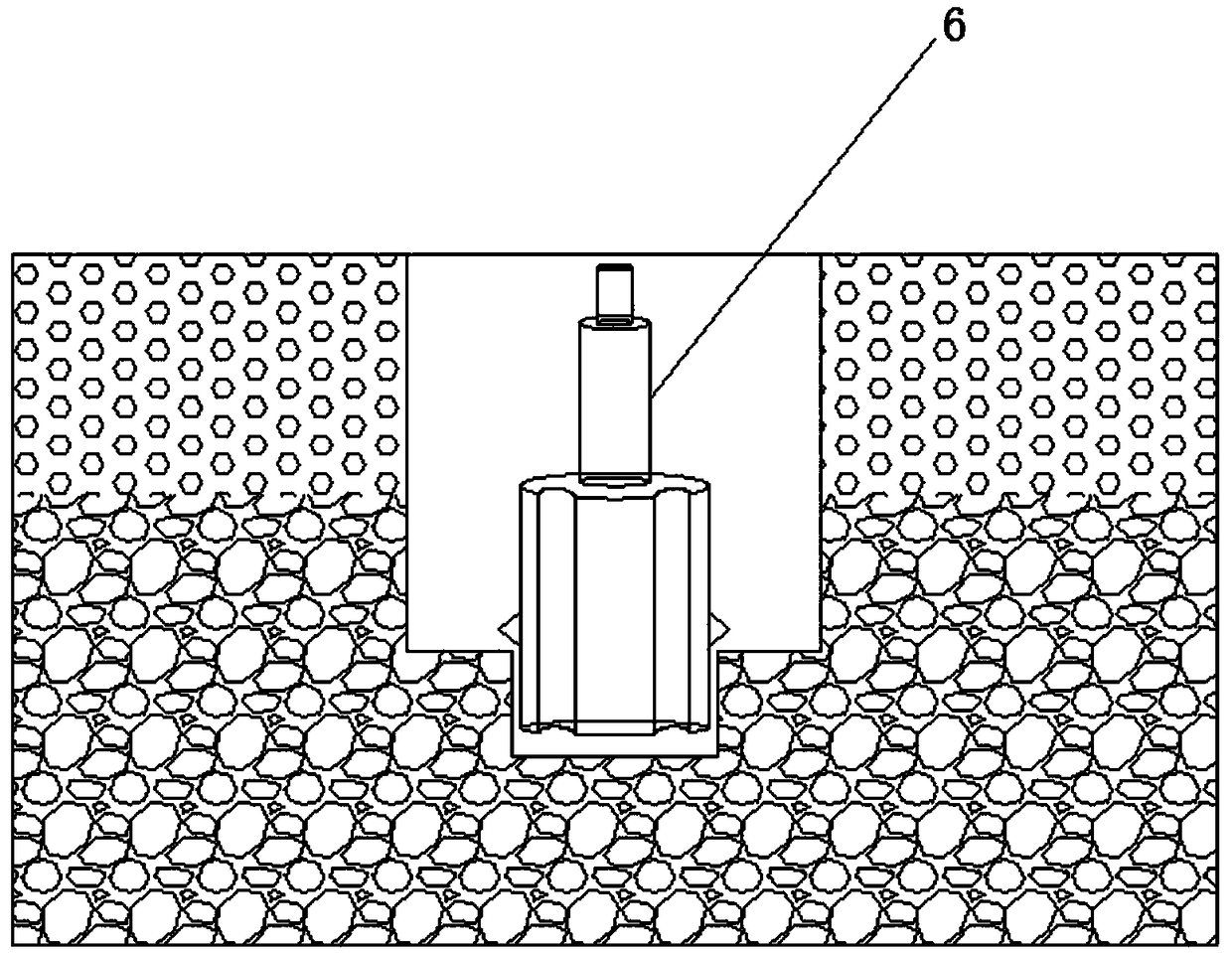

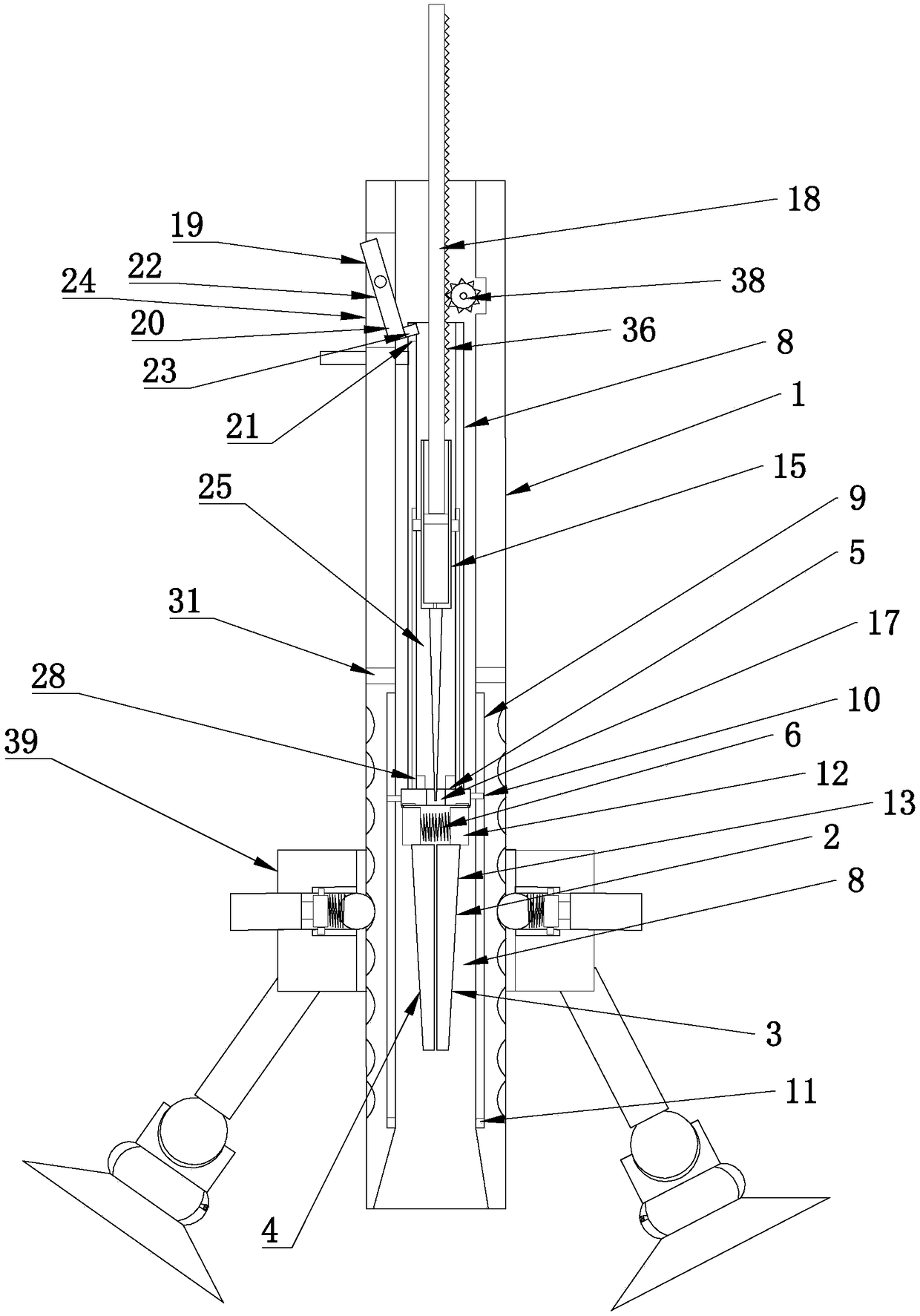

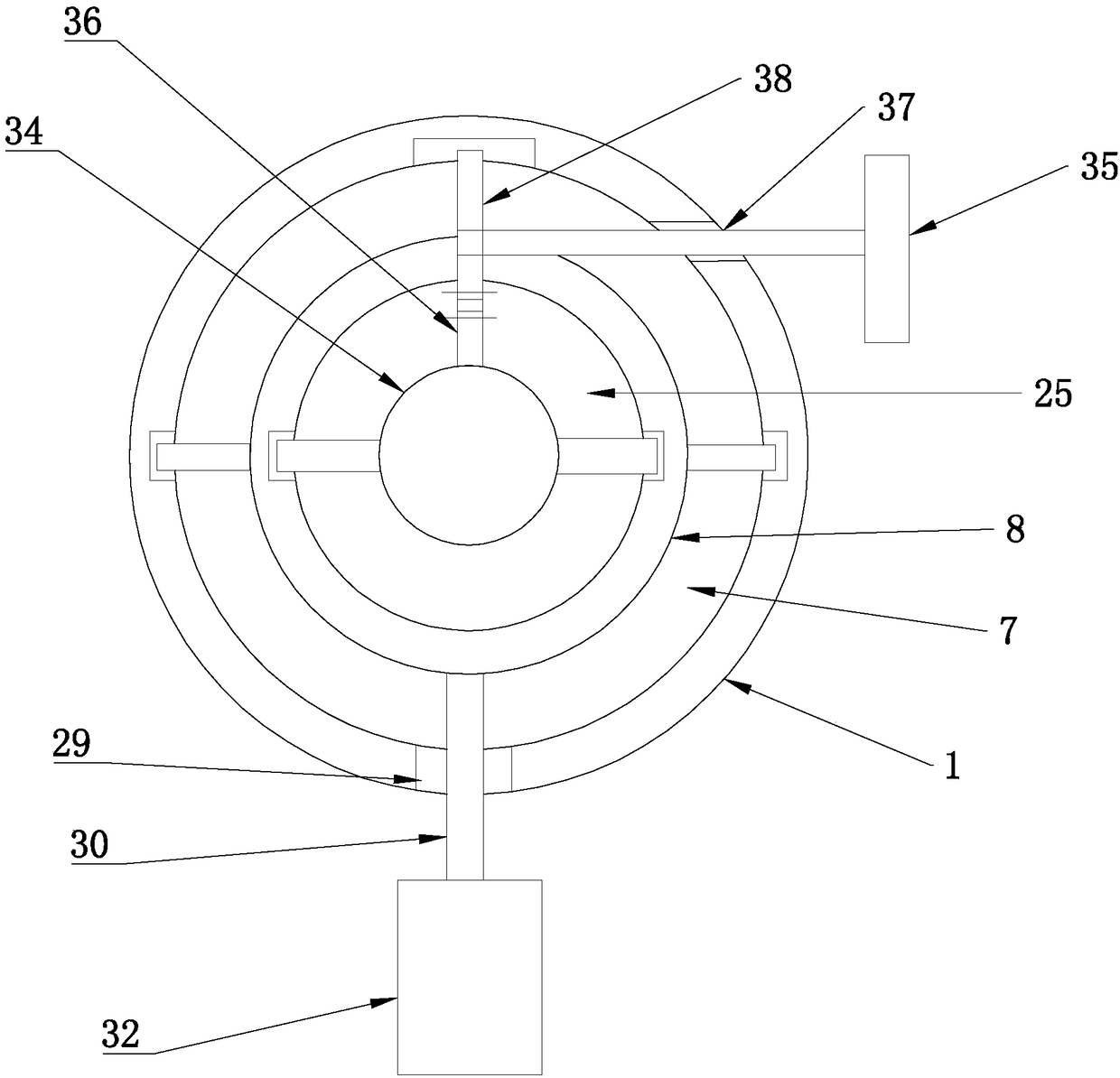

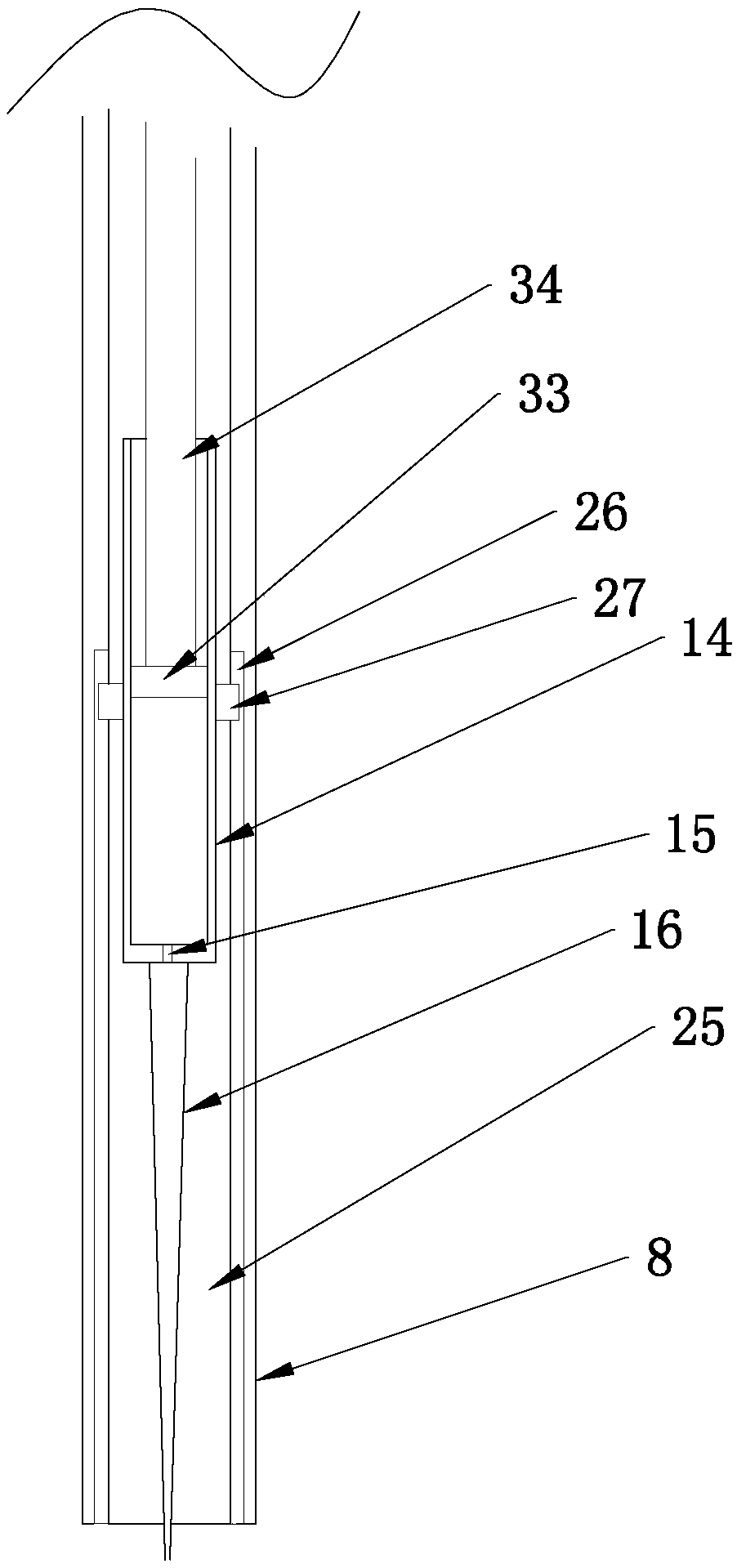

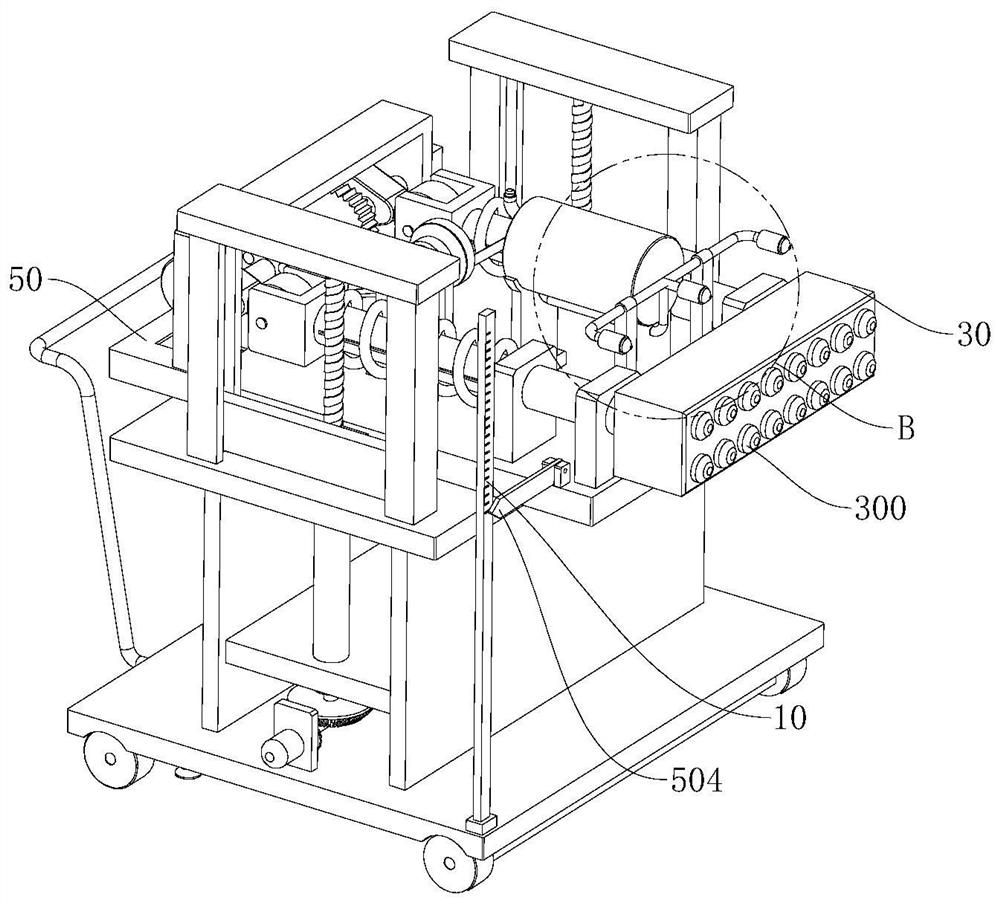

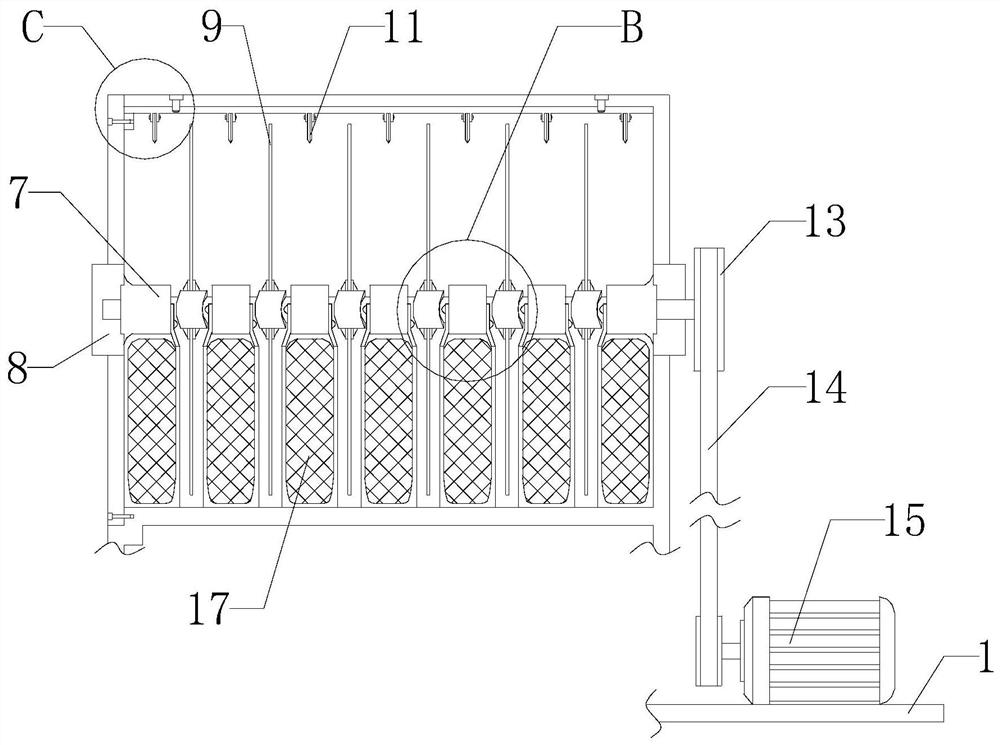

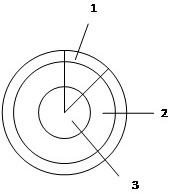

Triple rotary spraying device for soil remediation and method thereof

PendingCN108080409AIncrease destructive powerAdd depthContaminated soil reclamationSupporting systemSoil remediation

The invention discloses a triple rotary spraying device for soil remediation and a method thereof. The triple rotary spraying device for soil remediation comprises a remediation drilling machine, a crawler walking system, a hydraulic support system, a derrick, a power head, a horizontal plate support and a triple rotary spraying system. The triple rotary spraying system comprises a high pressure drug injecting pump, an air compressor, a high pressure water injecting pump and a rotary spraying pipe. According to the device provided by the invention, the triple high pressure rotary spraying pipeis adopted for injecting high pressure water, high pressure air and a high pressure drug, high pressure spray has higher destructive power on soil, and a spraying range of high pressure spray can befurther enlarged. Meanwhile, the spraying depth of the rotary spraying pipe can be adjusted according to the drilling depth of the remediation drilling machine, and the remediation depth and a remediation range of the soil are increased. Meanwhile, a guiding hole driller is adopted for drilling a sandy cobble stratum, so that the triple rotary spraying device for soil remediation provided by the invention is not limited in a soil environment with different hardness, and has a favorable effect on complex hard geological conditions such as clay, silty soil, sandy soil and muddy soil.

Owner:JIANGSU GAIYA ENVIRONMENTAL SCI & TECH CO LTD

Carbon fiber sizing agent and preparation method as well as reinforced carbon fibers and carbon fiber composite material

The invention discloses a carbon fiber sizing agent and a preparation method as well as reinforced carbon fibers and a carbon fiber composite material. The carbon fiber sizing agent is prepared from modified epoxide resin, an organic solvent, a surfactant and water; the modified epoxide resin is obtained by modifying the epoxy resin by using polyurethane and acrylic monomers; the polyurethane is obtained by enabling isocyanate to react with a hydroxyl polymer. The carbon fiber sizing agent prepared by the method is used for sizing the carbon fibers so as to obtain the reinforced carbon fibers,and the reinforced carbon fibers are then compounded with resin matrix, so that the carbon fiber composite material is obtained; a sizing agent transition layer between the carbon fibers and the resin matrix of the carbon fiber composite material can withstand higher impact force and the destructive force, so that the bonding force between the carbon fibers and the resin matrix in the carbon fiber composite material can be increased.

Owner:BYD CO LTD

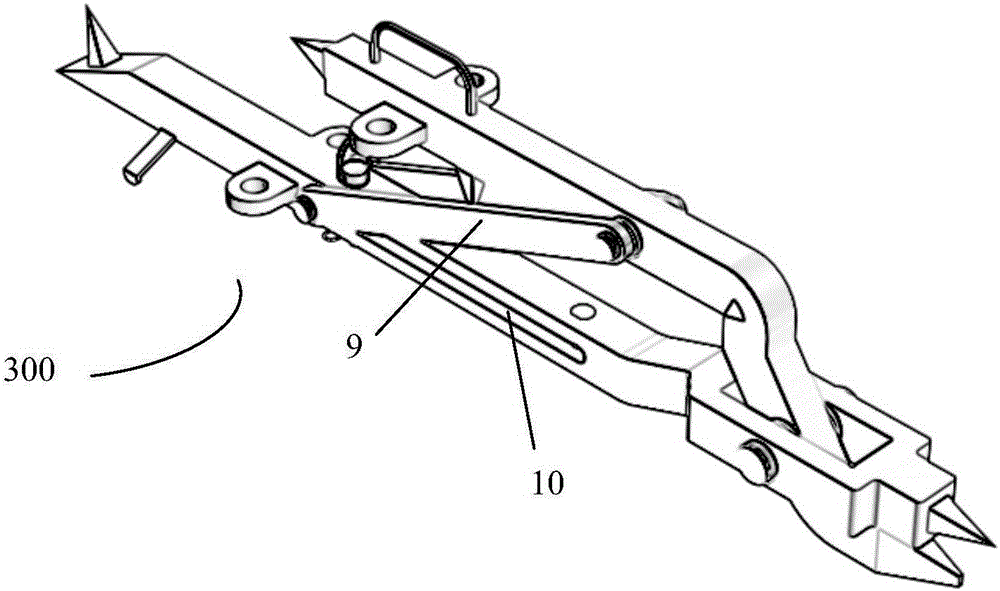

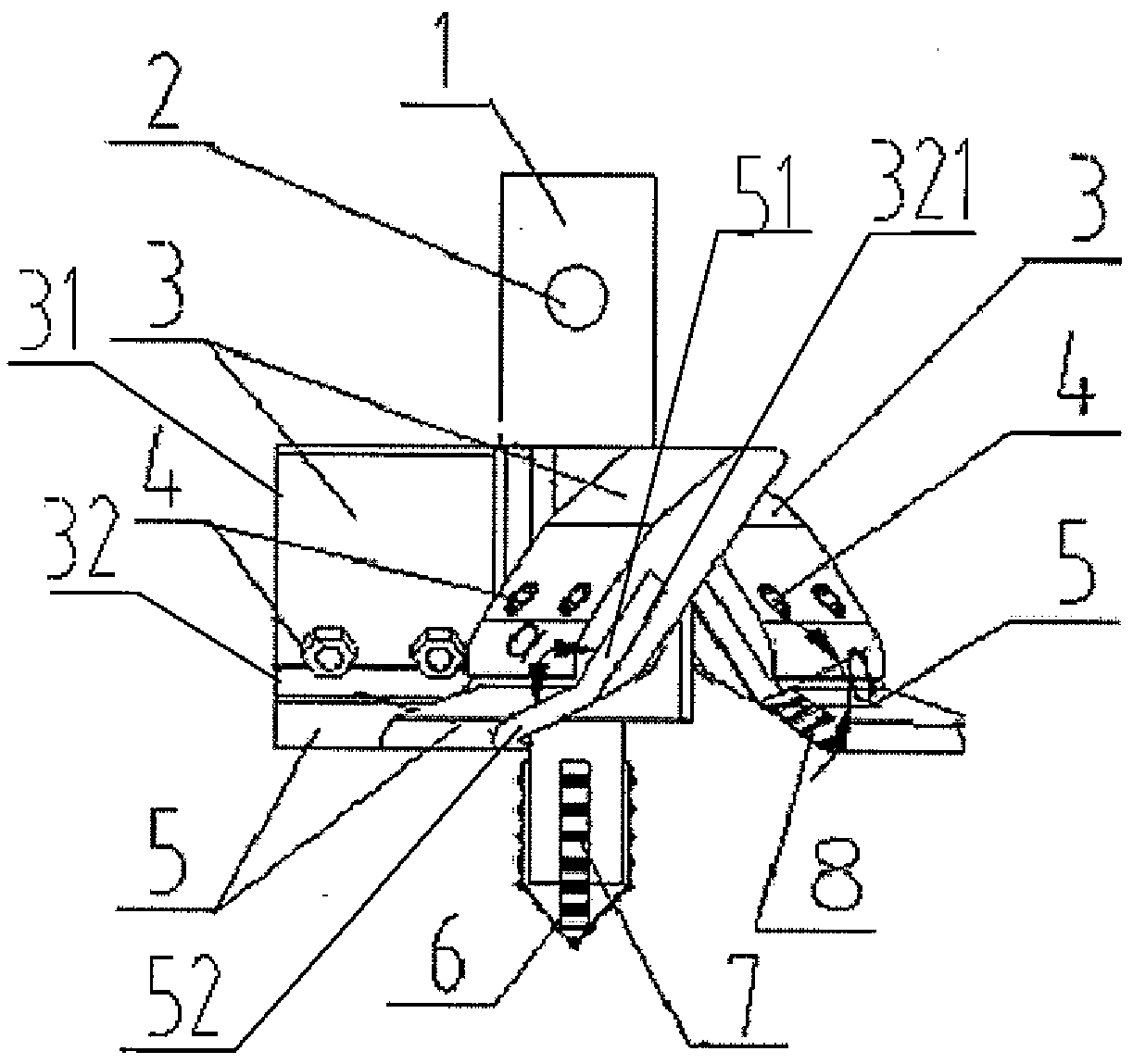

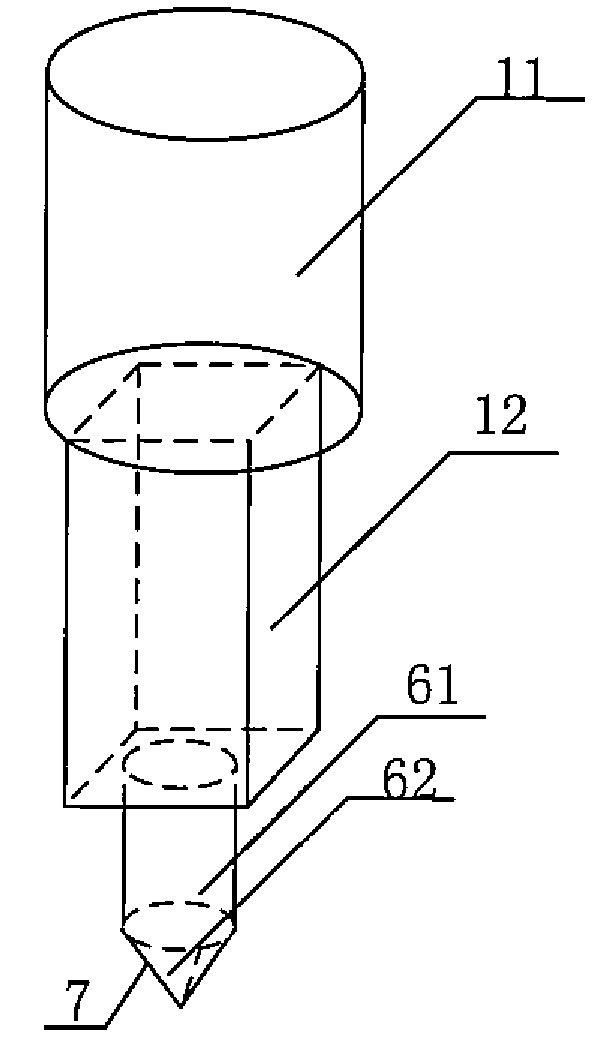

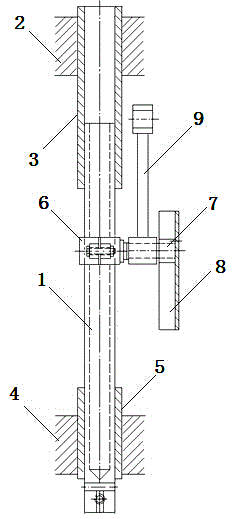

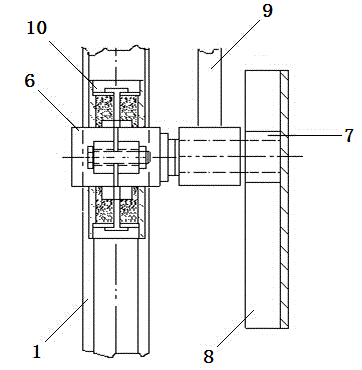

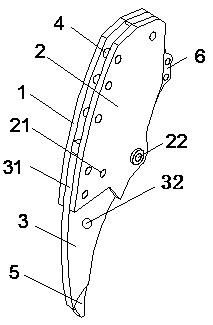

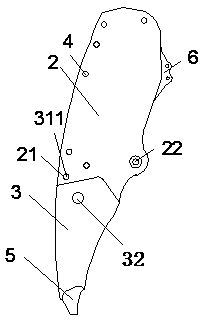

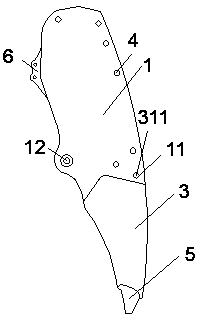

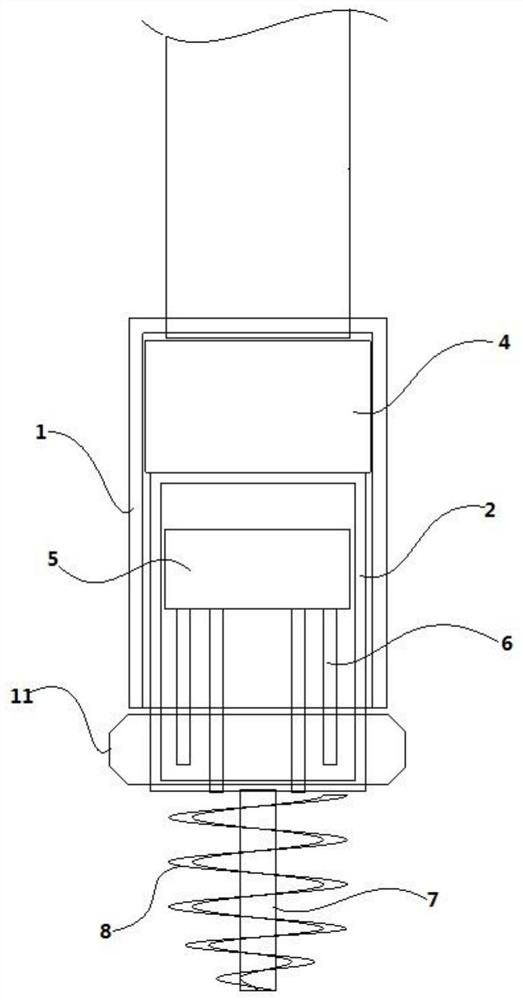

Drill bit and sampling device

ActiveCN102251746AEasy to sampleEnsure comprehensivenessConstructionsWithdrawing sample devicesCutting forceCoal

The invention provides a drill bit and a sampling device which can be used for solving the problems that the existing sampling device can not accurately get information of coal samples due to large coal blocks, hard coal blocks and icing of the coal blocks. The drill bit comprises a drill bit connecting rod, a lateral tooth piece and a main drill bit, wherein the lateral tooth piece is connected to the side surface of the drill bit connecting rod and comprises lateral teeth for cutting the coal blocks from the side surface, the main drill bit is connected at the bottom of the drill bit connecting rod and comprises downward main teeth, and a main tooth blade is arranged on the main teeth. The drill bit comprises a lateral blade and the main drill bit, when coal samples are collected, not only can the main teeth of the main drill bit exert static pressure on the contact surfaces of the coal samples to be collected, but also the lateral teeth of the lateral blade can exert lateral rotary cutting force on the coal samples to be collected, thereby increasing the destructive power on the coal samples to be collected, facilitating the collection of the coal samples in the large coal blocks, the hard coal blocks and the iced coal blocks, ensuring the comprehensive collection of the coal samples and the accuracy of the obtained coal samples and further accurately knowing the quality of coal as received.

Owner:CHINA SHENHUA ENERGY CO LTD +1

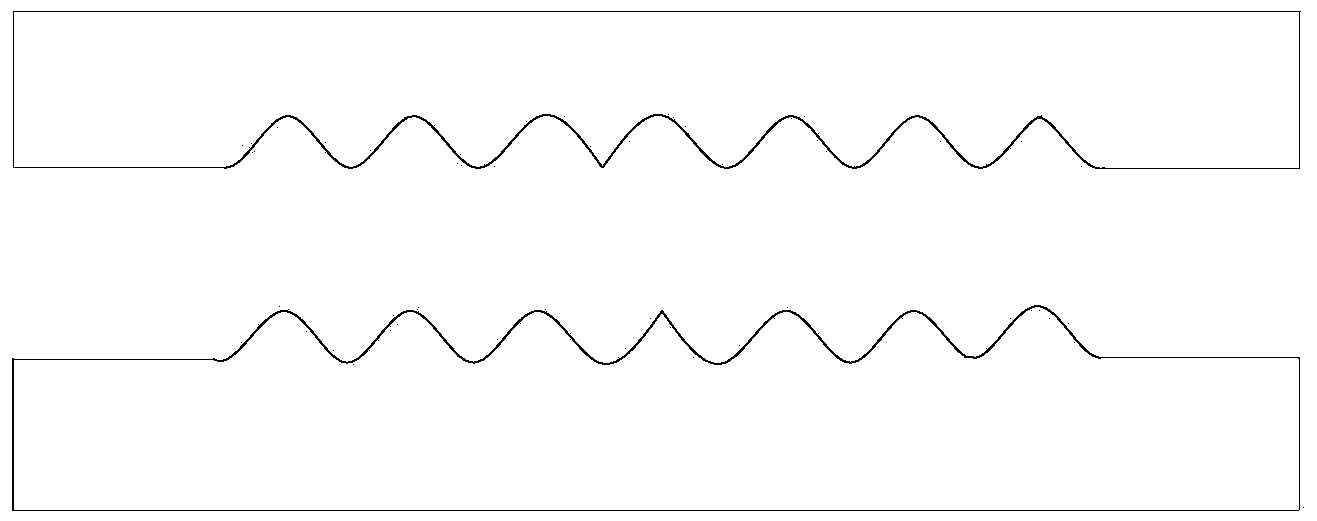

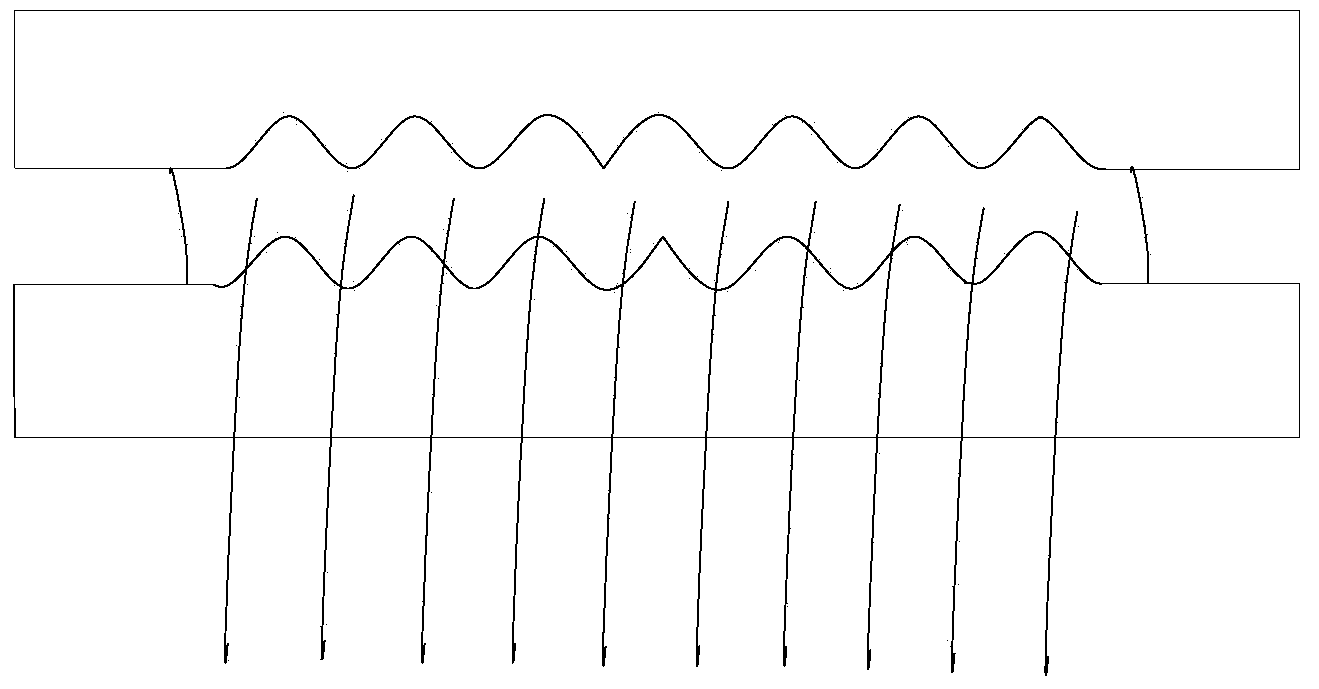

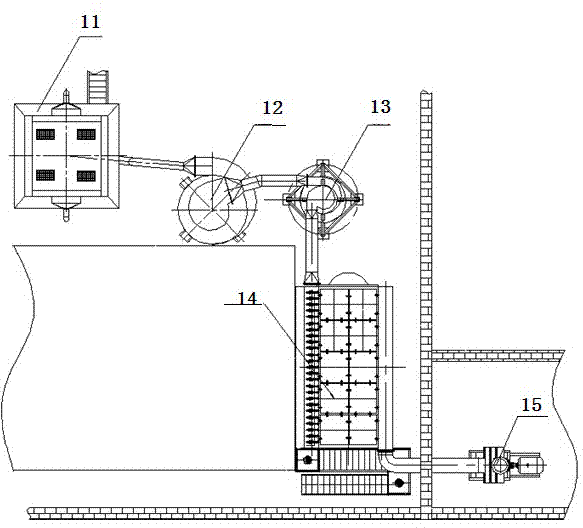

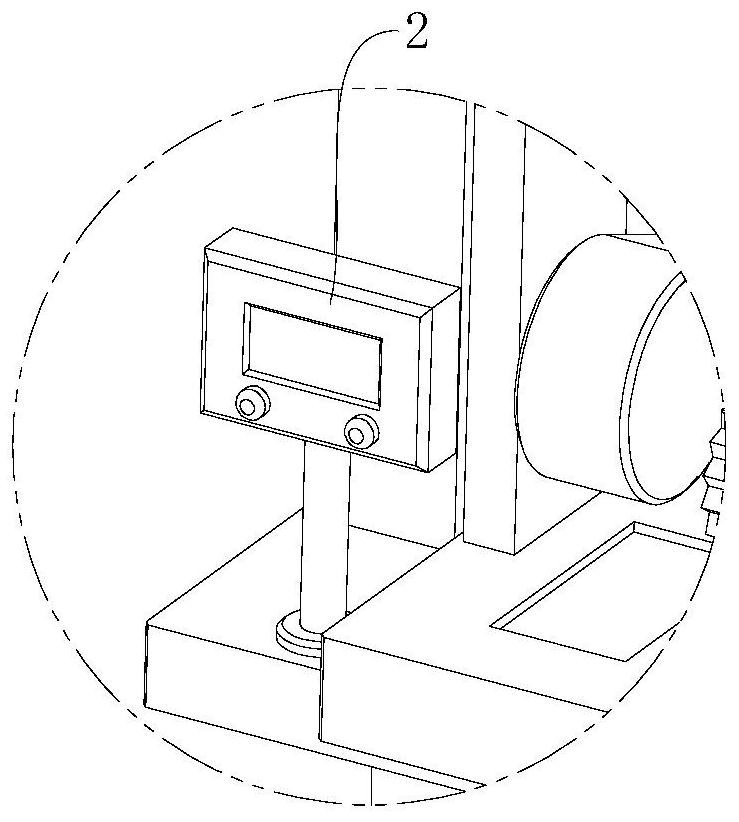

Method and tester for testing dynamic adhesive retention force of rubber and steel wire

ActiveCN104297150AImprove key performanceIncrease added valueUsing mechanical meansMaterial analysisAdhesiveControl system

The invention relates to a method and a tester for testing a dynamic adhesive retention force of rubber and a steel wire. The testing method comprises the following steps: applying a dynamic force to a vulcanized sample of the rubber and the steel wire by virtue of a wave-type mould, and then measuring a residual adhesive drawing force of the rubber and the steel wire so as to represent the magnitude of the adhesive retention force of the rubber and the steel wire under a dynamic condition. The tester comprises a mainframe, a drive system, a measurement control system and a safety protection device. The wave-type mould is used for applying the dynamic force to the vulcanized preparation sample of the rubber and the steel wire.

Owner:EVE RUBBER RES INST

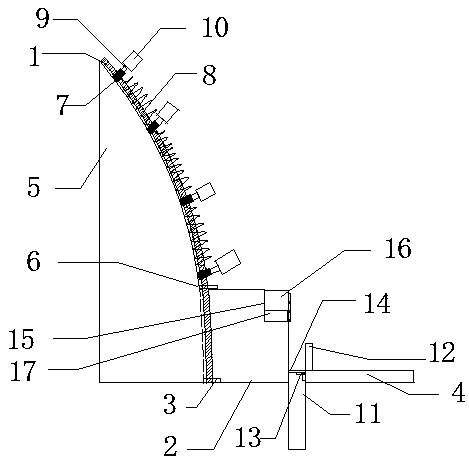

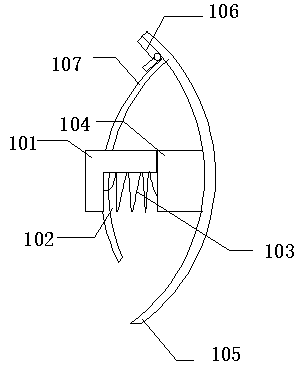

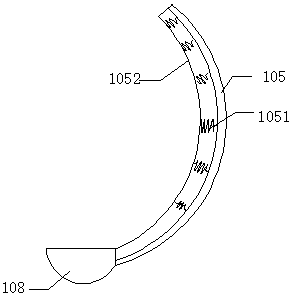

Protecting device for debris flow frequently-occurring slope

ActiveCN110130366AReduce speedReduce destructive powerFatty/oily/floating substances removal devicesSewerage structuresControl measureNatural disaster

The invention discloses a protecting device for a debris flow frequently-occurring slope, and relates to the technical field of geological natural disaster equipment. The protecting device comprises abuffering slide rail; the bottom of the buffering slide rail is fixedly connected with fixed piers, and the bottom end of the buffering slide rail penetrates through the fixed piers, extends to the interiors of the fixed piers, and is connected with the ground through fixing piles; roads are arranged on the bottoms, away from one side of the buffering slide rail, of the outer surfaces of the fixed piers; the slope is connected to the surface, away from one sides of the roads, of the buffering slide rail; a fixing limiting block is arranged on the position, connected with the fixed piers, of the surface of the buffering slide rail, and decelerating sliding blocks are evenly arranged on the positions, above the fixing limiting block, of the surface of the buffering slide rail; and the surfaces of the decelerating sliding blocks are fixedly connected with buffering springs, and the decelerating sliding blocks are connected together in pairs through the buffering springs. According to theprotecting device for the debris flow frequently-occurring slope, the problems that existing debris flow prevention and control equipment has great difficulty in accurately predicting a disaster andtaking prevention and control measures in time in the face of the disaster, disaster prevention and control effects are poor, destructive power of a debris flow cannot be effectively reduced, and thelarge economic loss is caused are solved.

Owner:陕西地矿第三工程勘察院有限公司

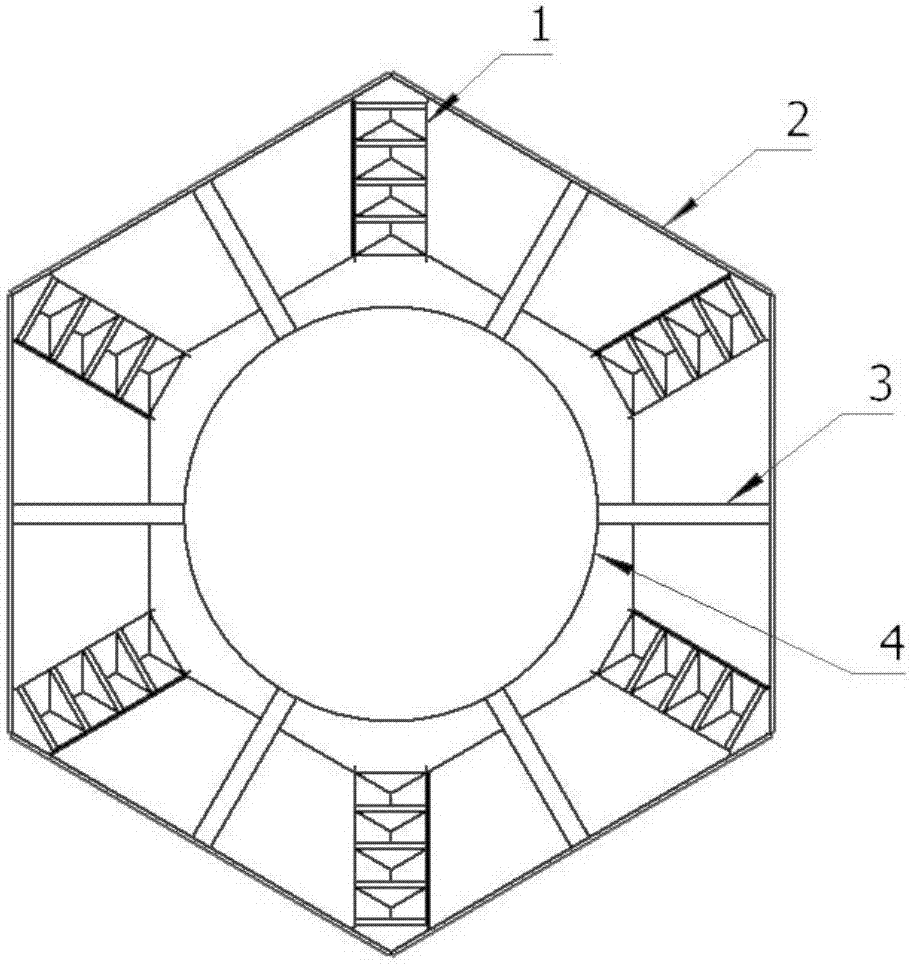

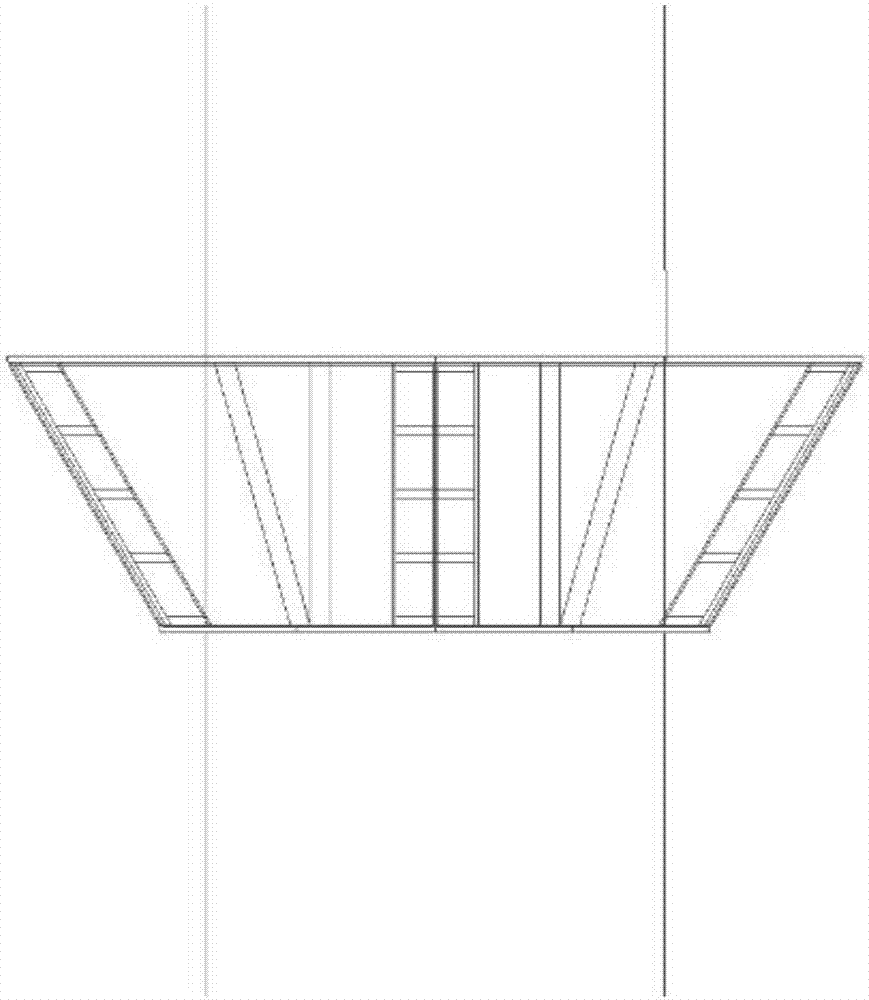

Polyhedral ice-resistant unit suitable for single-column three-pile type offshore wind power foundation

ActiveCN107022990AGuaranteed safe operationReduce ice force extremesArtificial islandsUnderwater structuresElectricitySea ice

The invention belongs to the technical field of ice-resistant units for offshore wind power foundations, and discloses a polyhedral ice-resistant unit suitable for a single-column three-pile type offshore wind power foundation. The wind power foundation is provided with a set of ice-resistant unit with a polyhedron structure, and the ice-resistant unit comprises a polyhedral inverted ice-resistant cone, connecting parts arranged between the foundation and the ice-resistant cone, an upper plane and a lower plane of the cone and conical surface steel plate reinforcing devices. After the ice-resistant cone is adopted, extrusion damage is converted into bending damage in the interaction of sea ice and the structure, so that the extreme static ice force and the structural ice-induced vibration borne by the offshore wind power foundation are effectively reduced, and the safe operation of the wind power structure is guaranteed; meanwhile, the polygonal cone adopts a plane steel plate splicing structure, so that the production-manufacturing and installing are convenient, the manufacturing cost is lower compared with a traditional circular-cone-shaped cone, and the economic performance of the offshore wind power structure is considered while the ice-resistant function is achieved; and the connecting reinforcing devices are arranged between every two adjacent contact planes of the polyhedral ice-resisting cone, so that the stability of the ice-resistant cone structure is enhanced.

Owner:DALIAN UNIV OF TECH

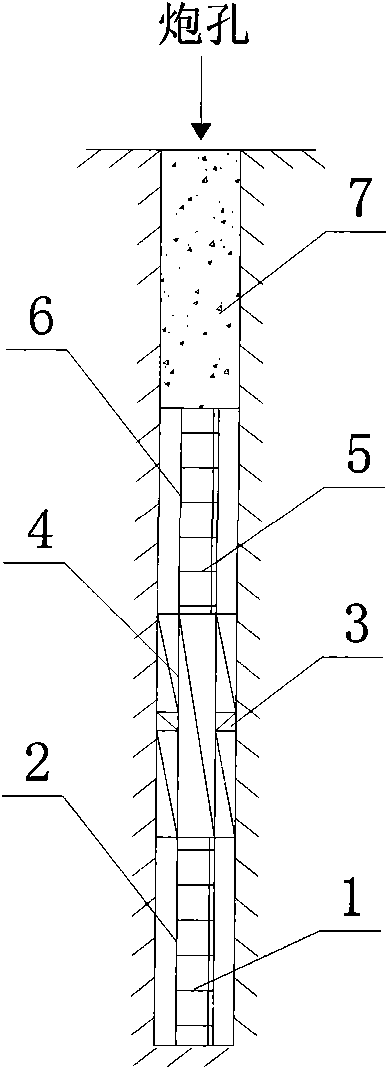

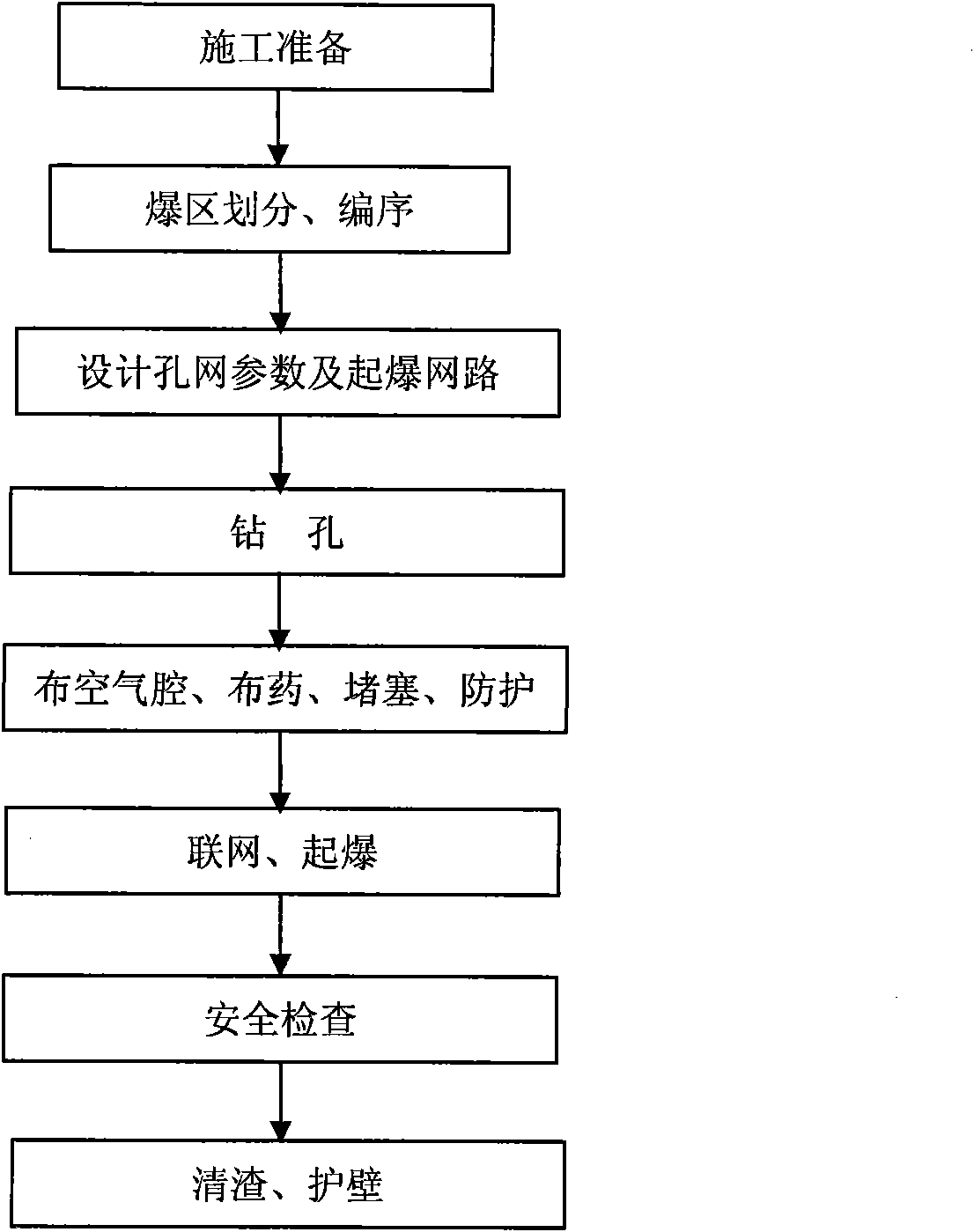

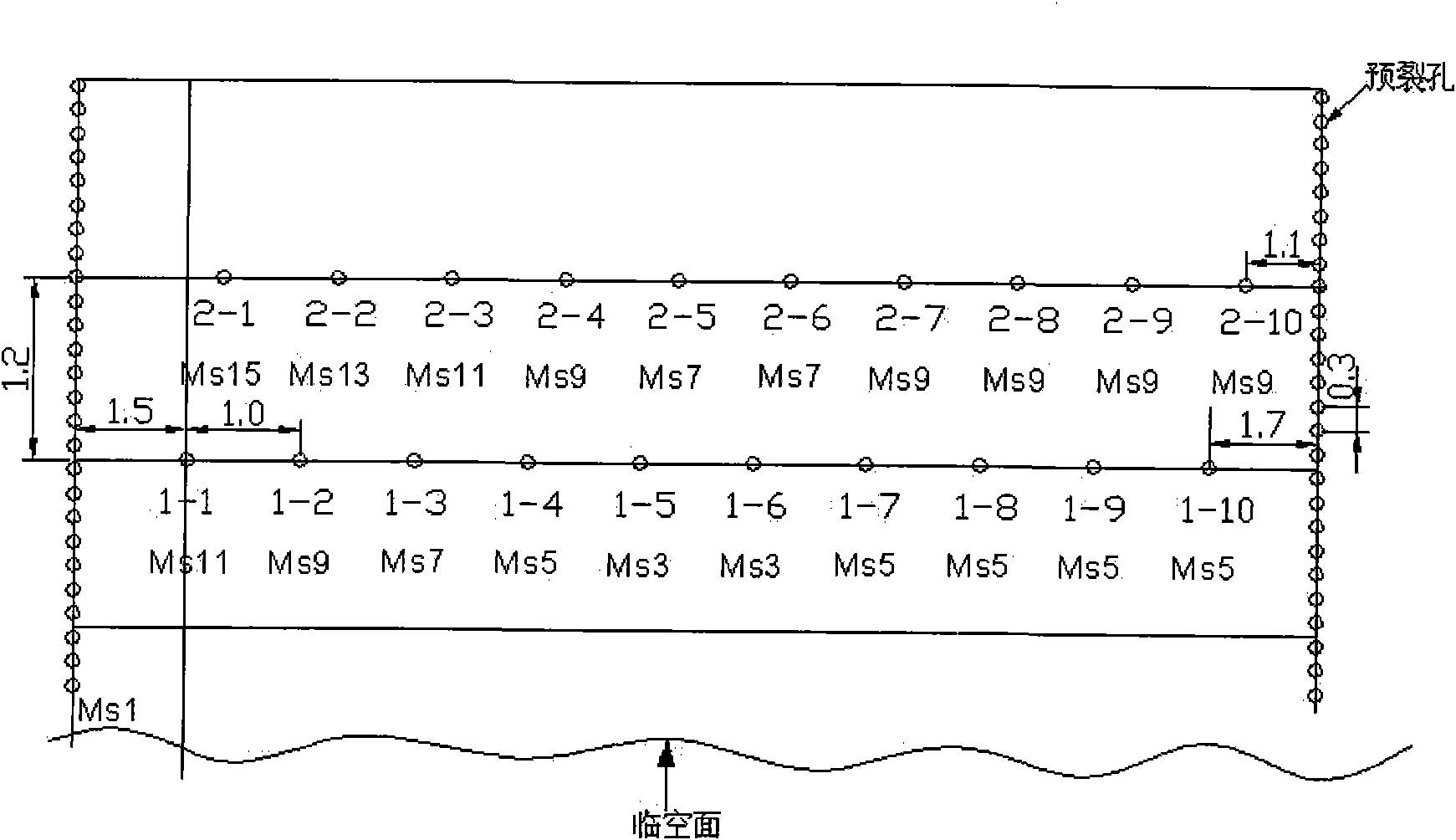

Vibration-reducing blasting construction method of air spring

InactiveCN101672613AReduce vibration peaksResolve stress buildupBlastingExcavationsSmall peakAir spring

The invention relates to a vibration-reducing blasting construction method of an air spring, the parameters of a perforated mesh and a blasting initializing network are designed in a divided blastingregion, a hole is drilled in a determined blasting hole point and explosives are filled in the hole; and when the explosives are filled in a blasting hole, the operation is carried out according to the following steps: 1) reserving an air cavity at the bottom of the hole, wherein, the air cavity is formed by a cavity in a support body arranged at the bottom of the hole, and the support body is a hollow tubular structure with openings at two ends; 2) sequentially mounting a blasting initializing body and the explosives at the opening arranged at the upper end of the air cavity at the bottom ofthe hole, wherein, the blasting initializing body is connected with an external blasting initializing device through a lead wire; 3) further setting the air cavity at the upper end of the explosives,wherein, the air cavity is formed through the cavity in the support body; and 4) filling a blocking material in the blasting hole, wherein, the blocking material is used for filing gap in the periphery of the support body and the explosives and filling the blasting hole. The construction method has the advantages of small peak vibration during blasting, high safety, strong damage, high utilizationrate of energy and abilities of effectively controlling the blasting range and reducing the environmental pollution.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD +1

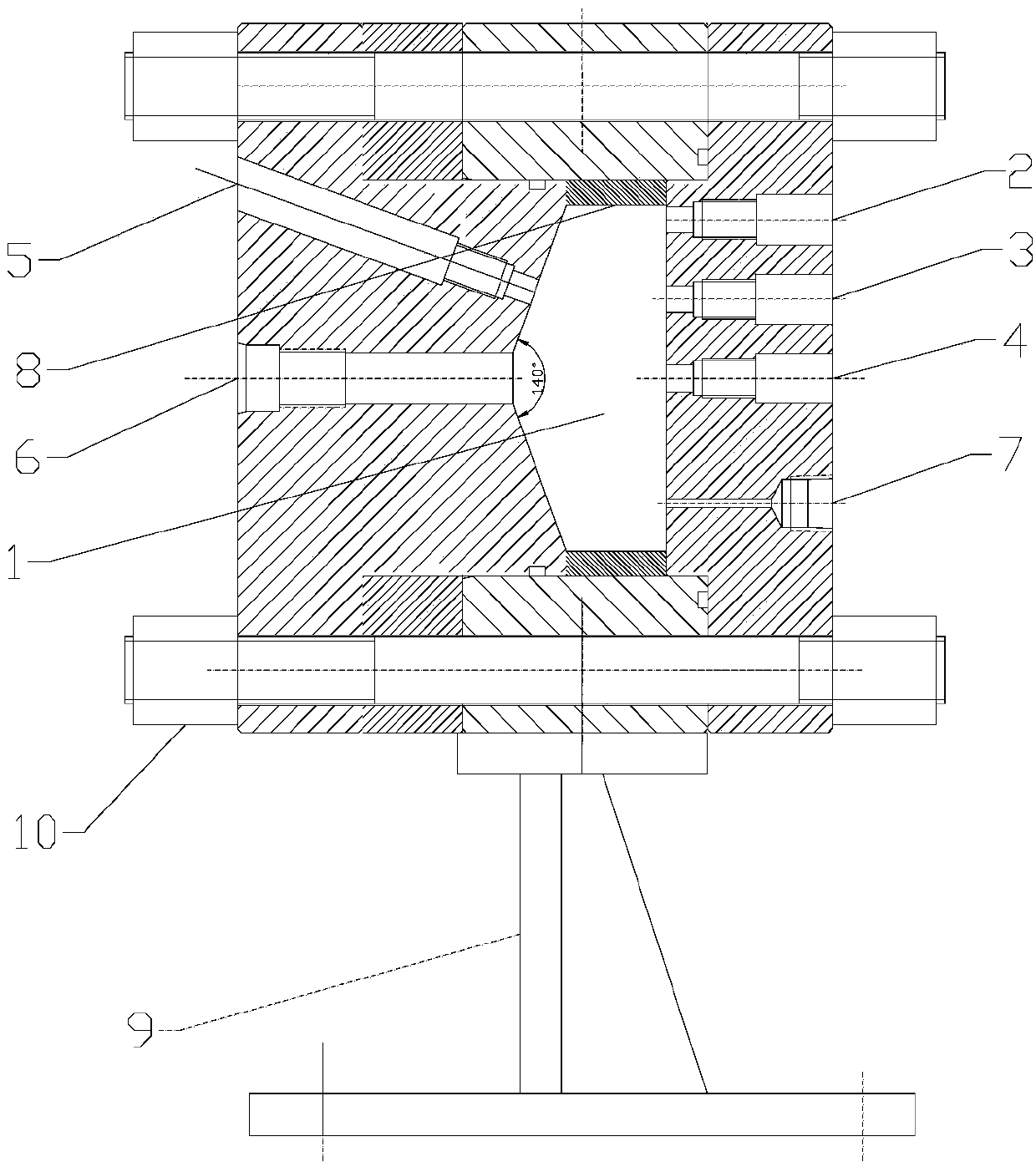

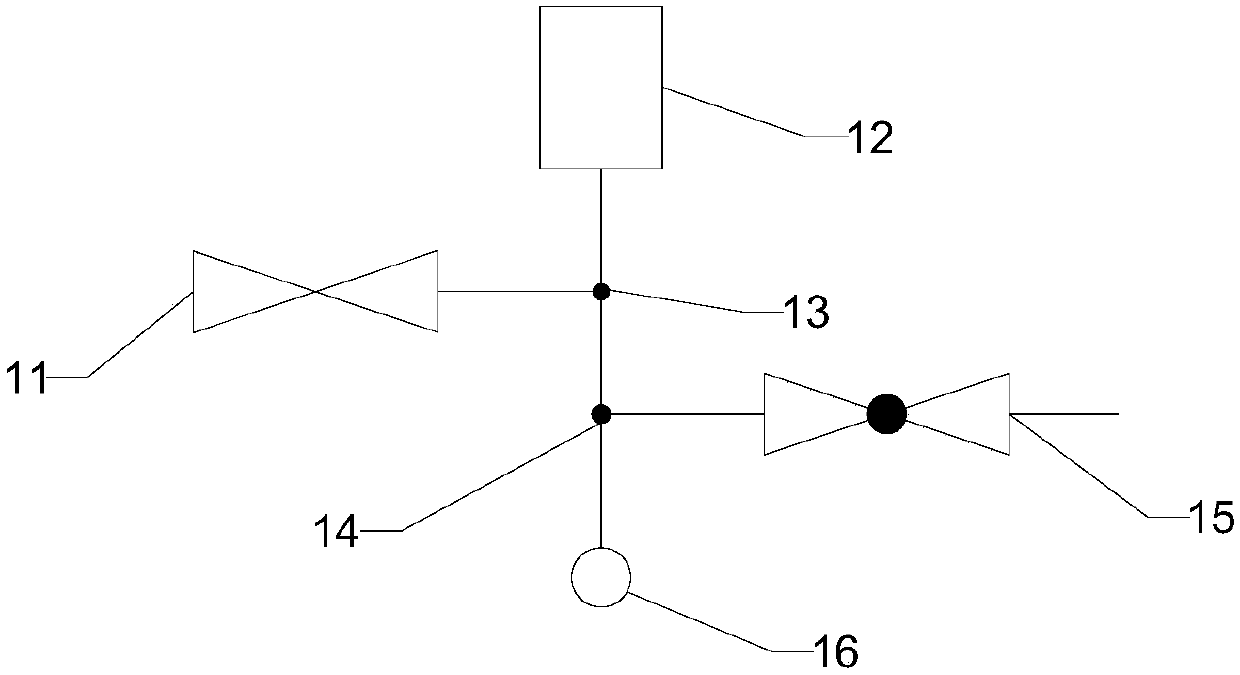

Constant-volume detonation combustion test device and method with function of monitoring detonation wave fluctuation behavior

PendingCN107796628ASimple structureLow costInternal-combustion engine testingCombustion chamberData acquisition

The invention relates to a constant-volume combustion bomb, in particular to a constant-volume detonation combustion test device and method with the function of monitoring a detonation wave fluctuation behavior. The device comprises a constant-volume detonation combustion bomb body, an air intake system, a high-energy ignition system, and a data acquisition and analysis system. The device and themethod have the following beneficial effect: when the constant-volume detonation combustion bomb system is applied to the study on the behavior characteristic of the detonation wave in the combustionroom for the research of super detonation of the engine, the high-energy ignition device and acetylene / oxygen mixed gas are used for generate a stable detonation wave.

Owner:TIANJIN UNIV

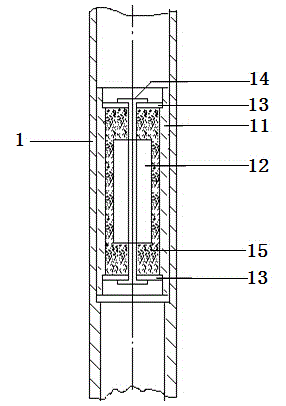

Needle bar equipped with vibration absorber

InactiveCN104805604AImprove dynamic working conditionsReduce wall thicknessNeedle barsReciprocating motionEngineering

The invention discloses a needle bar equipped with a vibration absorber. The needle bar comprises a needle bar, wherein the upper part of the needle bar is nested in an upper sleeve of the top of a lathe head, the lower part of the needle bar is nested in a lower sleeve of the bottom of the lathe head, the needle bar is in movable fit with the upper and lower sleeves and can slide up and down in the upper and lower sleeves, a slider pin is arranged at the middle part of the needle bar and is connected with a slider, the slider is arranged in a sliding groove, a connecting rod is arranged at the joint of the slider pin and the slider and is connected with an upper shaft of a sewing machine through a crank, the upper shaft of the sewing machine drives the crank to rotate, the crank drives the connecting rod to do planar motion, the connecting rod drives the slider and the needle bar to do up-and-down reciprocating motion, and the vibration absorber is arranged on the needle bar. According to the needle bar disclosed by the invention, the vibration absorber is mounted at a maximum-bending position of the needle bar and contains an additional mass, the additional mass moves along with the needle bar and generates motion damping, bending energy of the needle bar is absorbed by a damping material in the vibration absorber, and steepness of bending vibration peaks is reduced by the motion damping, so that the dynamic working conditions of the needle bar are improved.

Owner:WUJIANG WANGONG ELECTROMECHANICAL EQUIP

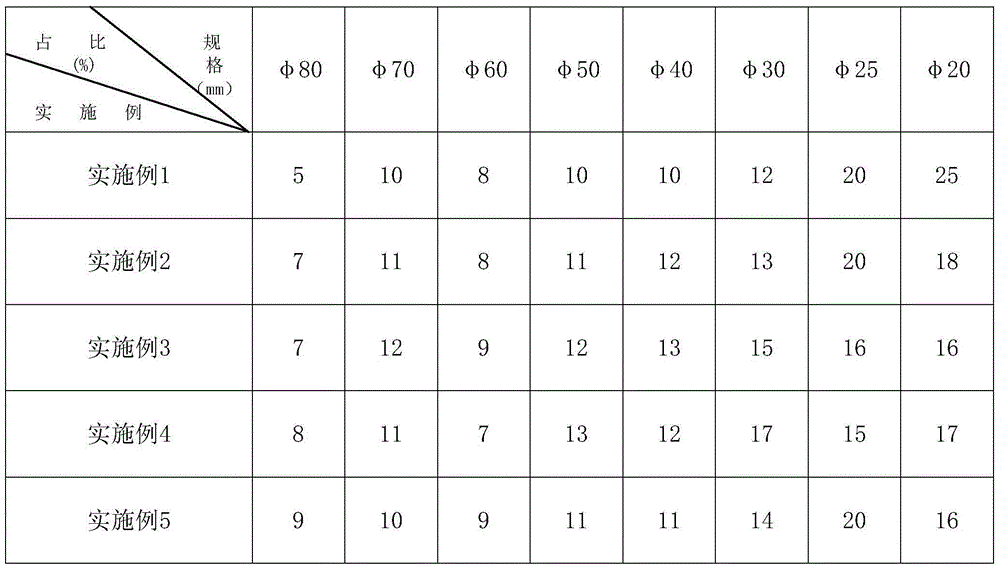

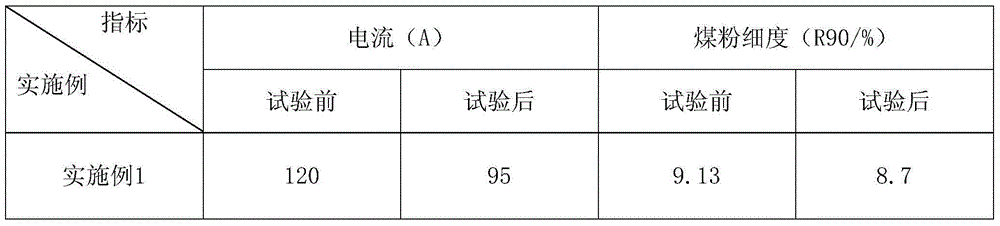

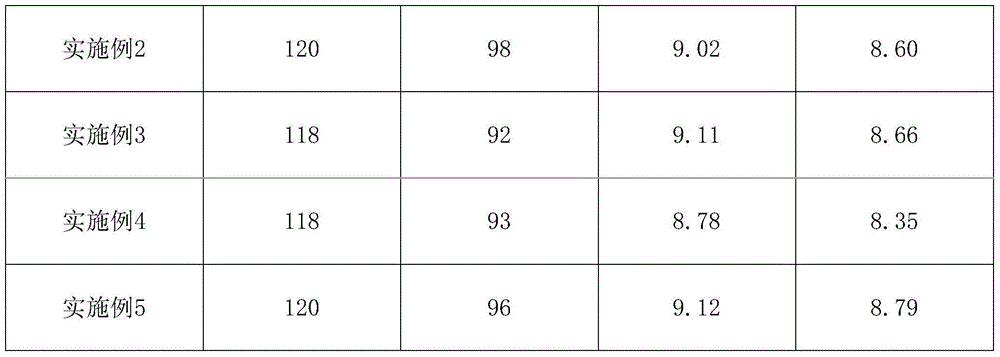

Grading method of coal mill steel balls and application thereof

The invention discloses a grading method of coal mill steel balls. The method comprises the step of filling steel balls with different sphere diameters in a ball mill according to the following weight ratios: 5-10% of steel balls with sphere diameters of 80mm, 10-15% of steel balls with sphere diameters of 70mm, 8-10% of steel balls with sphere diameters of 60mm; 10-15% of steel balls with sphere diameters of 50mm, 10-18% of steel balls with sphere diameters of 40mm, 12-18% of steel balls with sphere diameters of 30mm, 15-30% of steel balls with sphere diameters of 25mm, and 15-30% of steel balls with sphere diameters of 20mm. The grading method disclosed by the invention is used for reasonably grading the steel balls to reduce the energy consumption of a coal mill while ensuring the output of the coal mill, and meanwhile since the attrition of the steel balls is small, the production cost of the coal mill is reduced.

Owner:QINGDAO CHUTIAN ENERGY SAVING TECH

Fetal reduction device

ActiveCN108814692AIncrease destructive powerGuaranteed to stopObstetrical instrumentsPropellerCervix

The invention discloses a fetal reduction device. The device comprises a handle and a strangling assembly disposed at one end of the handle. The strangling assembly is retractably disposed in a firstcontaining cavity in the handle and comprises a first strangling blade and a second strangling blade, and the first strangling blade and the second strangling blade can be retracted and expanded. Thestrangling assembly is retracted in the first containing cavity of the handle before the fetal reducing device is positioned to prevent the strangling assembly from damaging the cervix when the fetalreducing device passes through the cervix, and the first strangling blade and the second strangling blade are expanded when the strangling blades puncture a fetal heart, so that the destructive capability of the strangling assembly is enhanced to ensure that the fetal heart of a fetus subjected to fetal reduction is stopped; moreover, a syringe is arranged in the handle, an injection needle is poked into the fetal heart, and a propeller is pushed for injecting potassium chloride to make the fetal heart stop immediately, so that the two operating means are conveniently switched.

Owner:THE SECOND HOSPITAL AFFILIATED TO WENZHOU MEDICAL COLLEGE

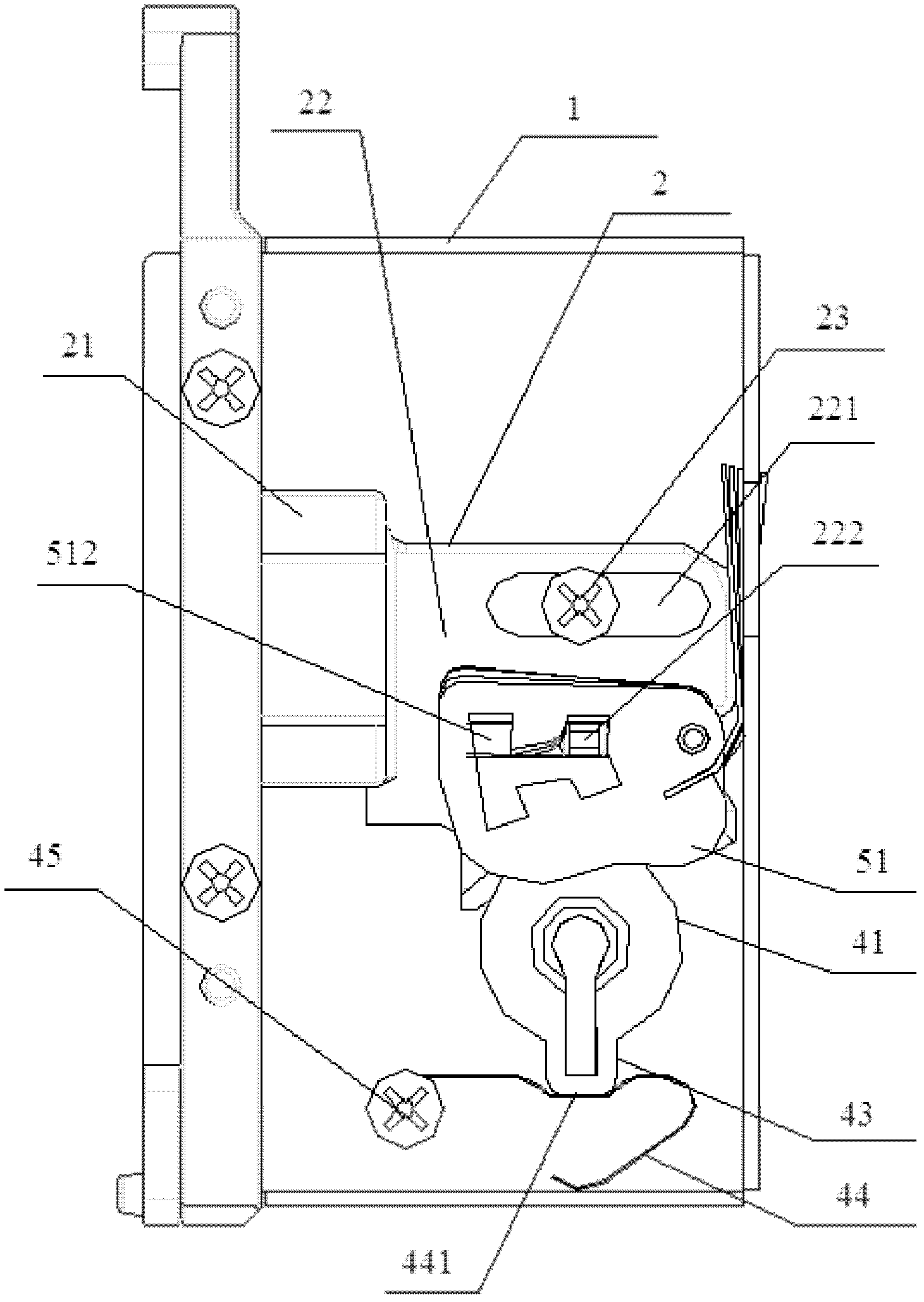

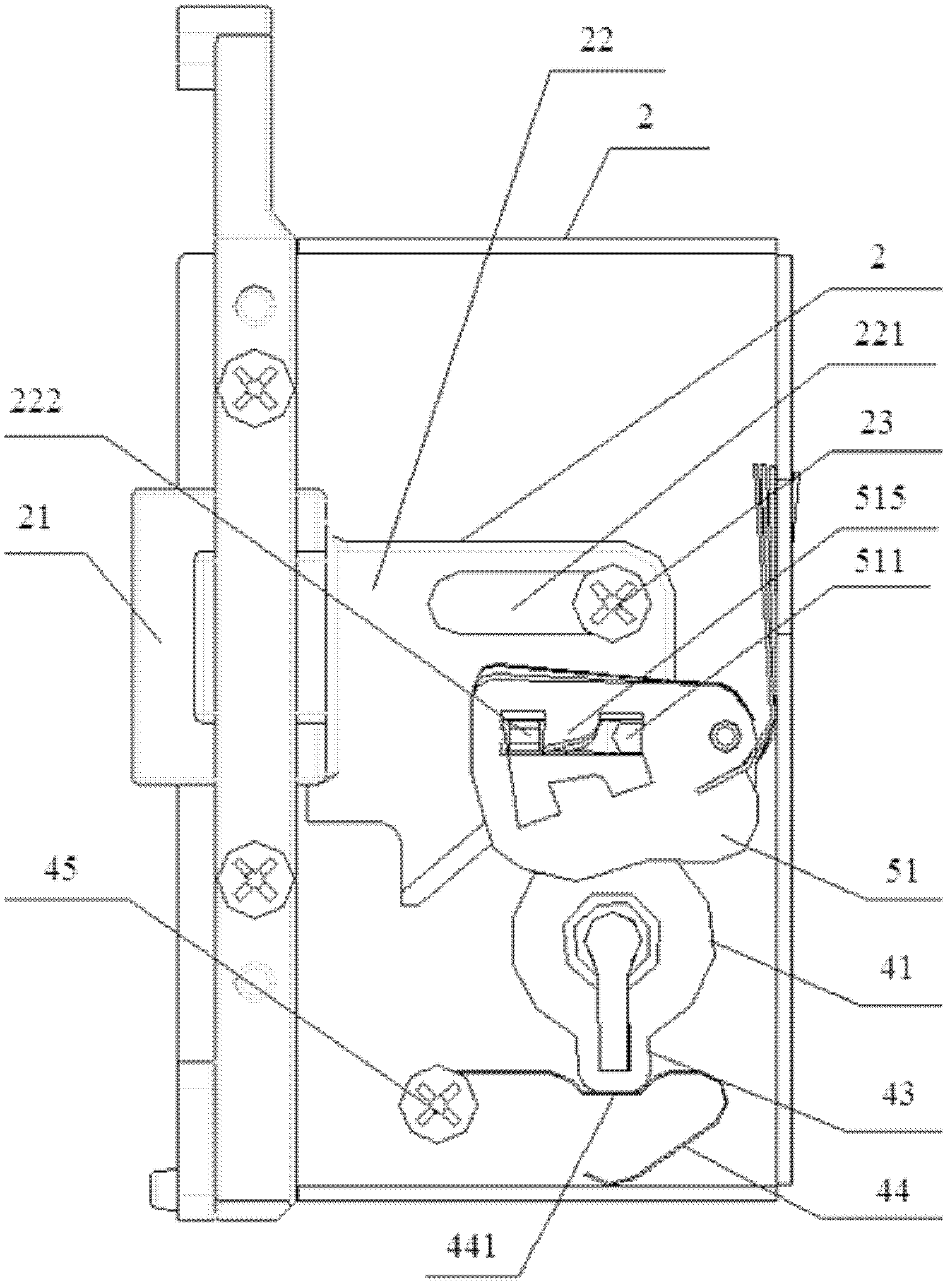

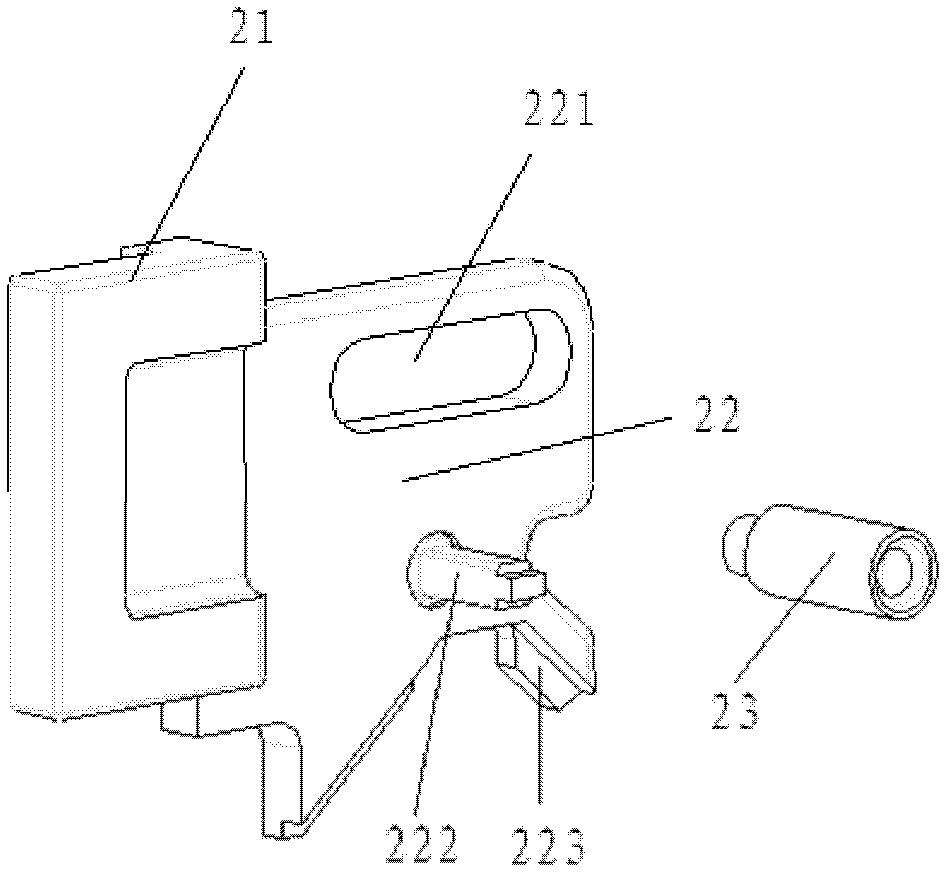

Mechanical row sheet lock

InactiveCN102561815AImprove securityReduce the stress areaLock casingsCylinder locksElectrical and Electronics engineering

Owner:联程机械(宁波)有限公司

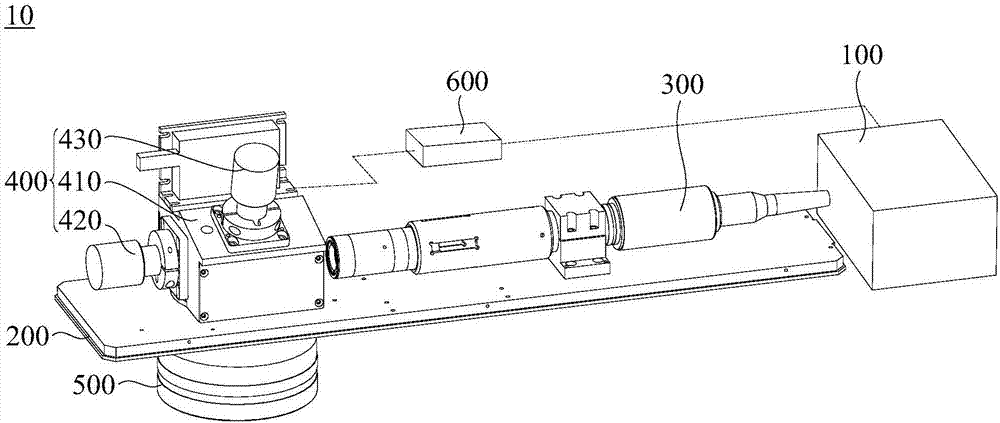

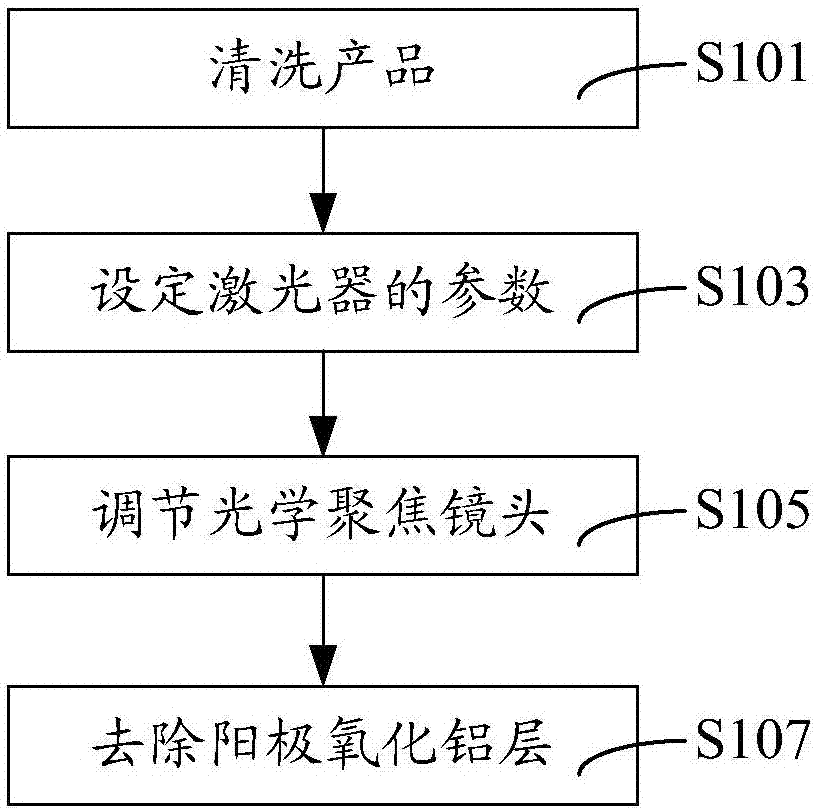

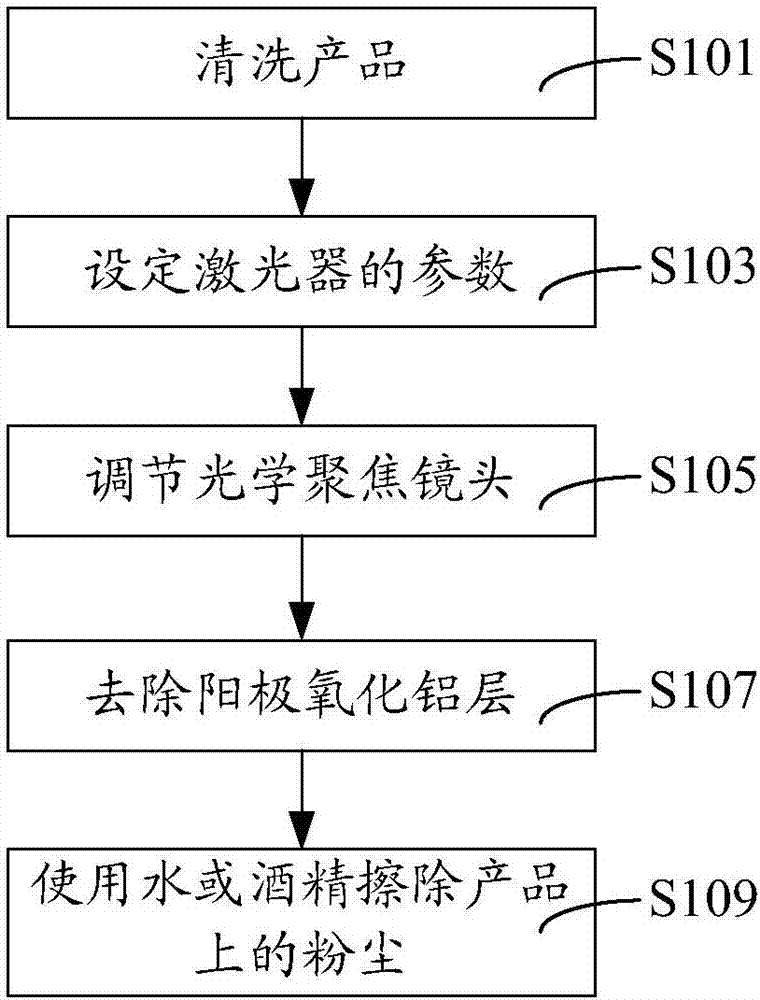

Marking method and marking device

InactiveCN107262934AImprove power densityIncrease destructive powerLaser beam welding apparatusGalvanometerEngineering

The invention relates to a marking method and a marking device. The marking device is used for removing anodic aluminum oxide on a product. The marking device comprises a laser, a fixed seat, a beam expander, a galvanometer and a focusing lens; the laser is used for generating a laser beam; the fixed seat is provided with a through hole; the beam expander is arranged on the fixed seat, is opposite to the laser, and is used for enlarging the diameter of the laser beam; the galvanometer is arranged on the fixed seat, and is close to the beam expander; the galvanometer is used for deflecting the laser beam output by the beam expander, so as to allow the laser beam to pass the through hole; and the focusing lens is arranged on the fixed seat, is located on one side, departing from the galvanometer, of the fixed seat, and corresponds to the through hole. According to the marking method and the marking device, the laser beam generated by the laser is subjected to combined action of the beam expander and the focusing lens, and then the power density of the laser beam acting on the surface of the product is increased substantially, so that a situation that no product after being marked generates stress deformation is ensured, and the product has good conductivity.

Owner:HANS LASER TECH IND GRP CO LTD +1

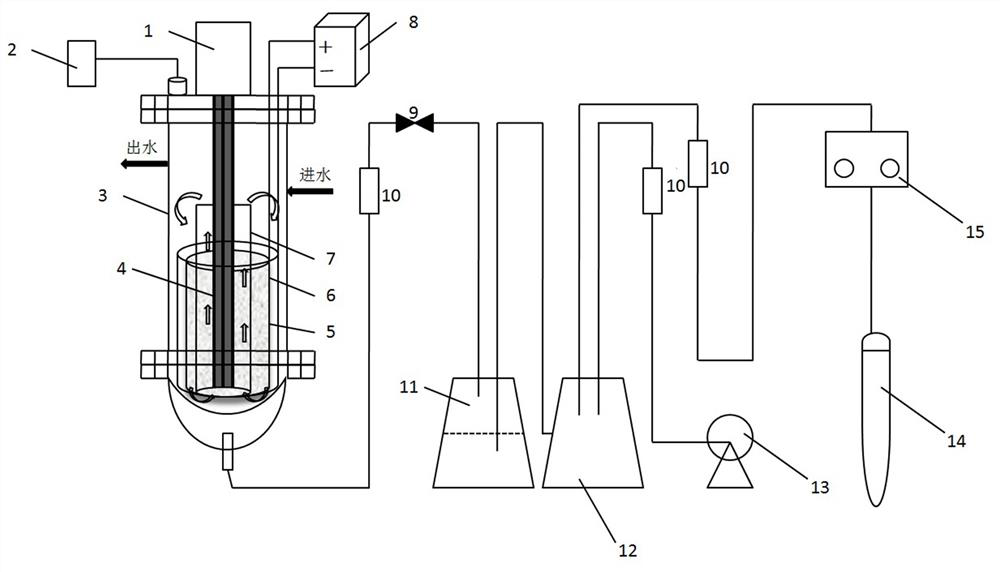

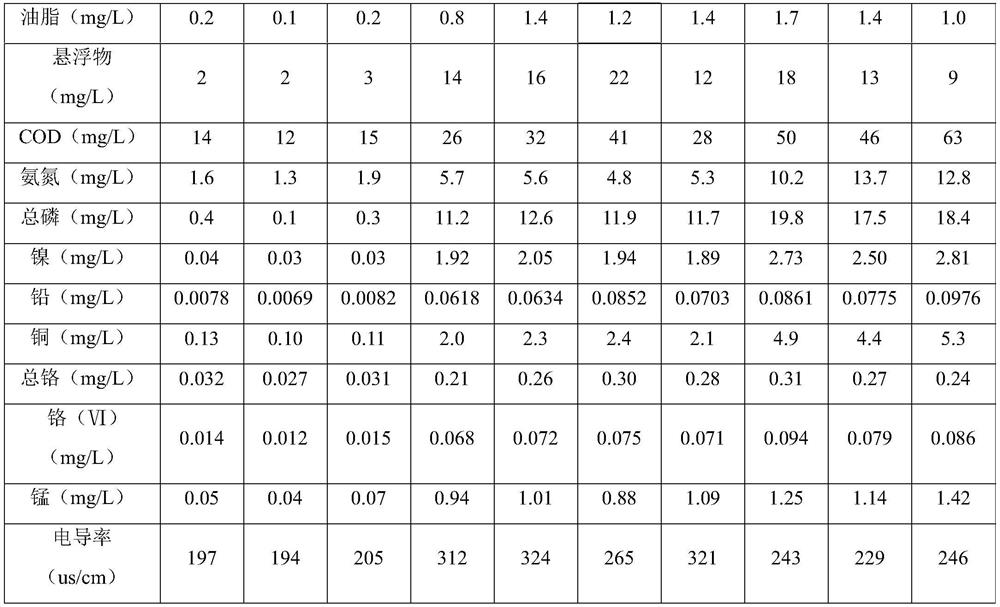

Advanced treatment method for electroplating wastewater

InactiveCN111606519AEasy to separateNot affectedFatty/oily/floating substances removal devicesTreatment using aerobic processesCyanide compoundReverse osmosis

The invention discloses an advanced treatment method for electroplating wastewater. The advanced treatment method comprises the following steps: step 1, pretreatment; step 2, coagulating sedimentation; step 3, electrochemical-photocatalysis-ozone synergistic treatment; step 4, treatment by a cation exchange resin column; step 5, treatment in a biological aerated filter; and step 6, nanofiltrationand reverse osmosis treatment. The process steps are matched with one another, the layout is compact, the floor area is small, and the energy consumption is low. Oil is removed through pretreatment, suspended matters, cyanides and colloids are removed through coagulating sedimentation, nitrogen and phosphorus can be removed through electrochemical-photocatalysis-ozone synergy, organic contaminantsare thoroughly removed, most heavy metal ions are removed through treatment by the cation exchange resin column, the biological aerated filter is capable of remarkably improving water quality, reducing the workload of a subsequent membrane system and removing residual trace organic pollutants and heavy metal ions, and finally desalination is carried out by virtue of nanofiltration and a two-stagereverse osmosis system, so that the effluent quality meets the electroplating wastewater discharge standard GB21900-2008.

Owner:闫娟

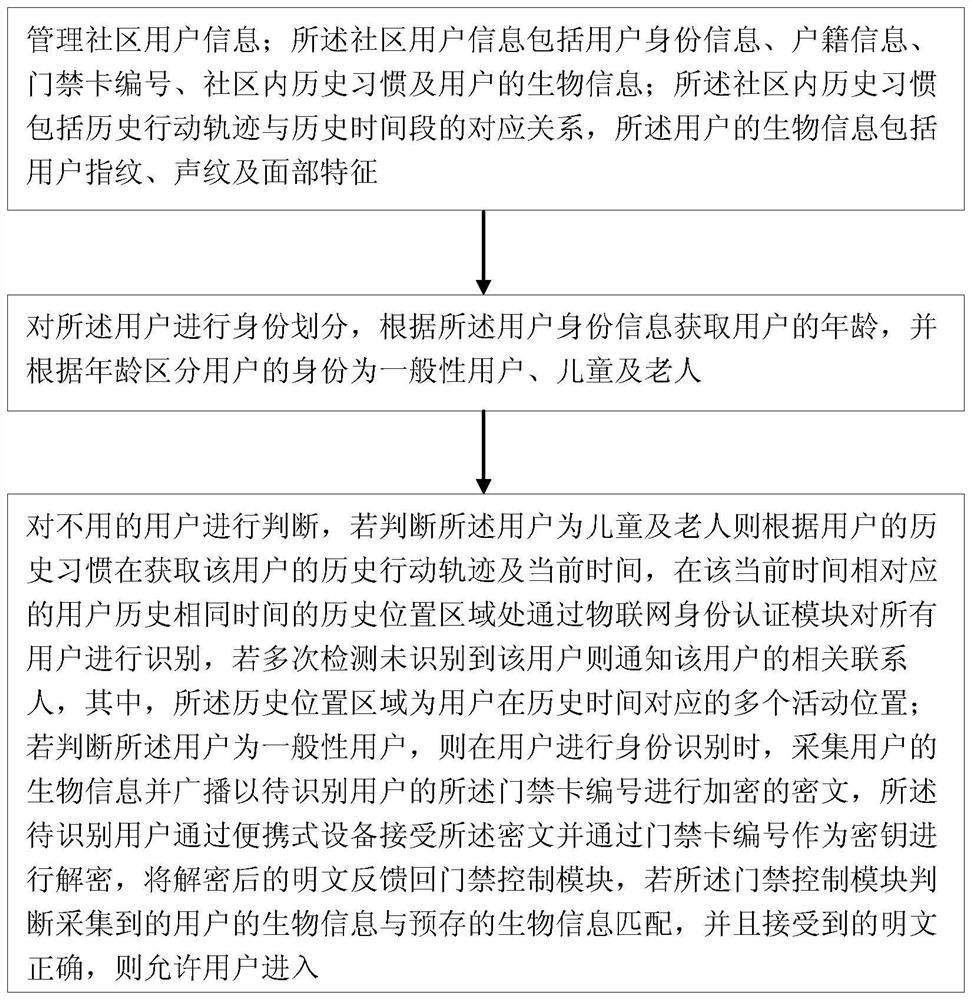

Community security management system and method based on Internet of things

ActiveCN111932749AAccelerate matching authentication speedProtection securityData processing applicationsSpeech analysisIdentity recognitionInternet privacy

The invention discloses a community security management method based on the Internet of things. The method is characterized by comprising the steps that community user information is managed, whereinthe community user information comprises user identity information, household registration information, access control card numbers, historical habits in a community and biological information of users, the historical habits in the community comprise a corresponding relationship between a historical action track and a historical time period, and the biological information of users comprises user fingerprints, voiceprints and facial features; identity division is carried out on a user, the age of the user is acquired according to the user identity information, and the identity of the user is classified into a general user, a child or an old person according to the age; and the user is judged, and different identity authentication modes are carried out. Through the method, relatively weak users can be tracked and protected, and multiple identity recognition can be carried out on adult users who may have dangers.

Owner:湖南大汉无忧智慧科技有限公司

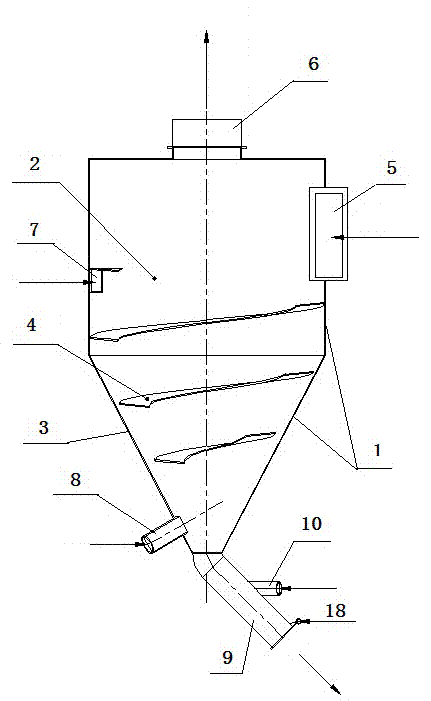

Dust-containing scorched particle winnowing and separating device and method thereof

InactiveCN104741254ASimple structureReduce manufacturing costReversed direction vortexEngineeringSeparation method

The invention discloses a dust-containing scorched particle winnowing and separating device which comprises a barrel, and is characterized in that the barrel is formed by fixedly connecting a cylinder and a cone tube, wherein a spiral guide plate is arranged on the inner wall of the barrel; a powder outlet is formed in the top of the cylinder; a winnowing material inlet is formed in the peripheral wall of the cylinder; an upper air pipe is formed at the initial part of the spiral guide plate of the cylinder; a main air pipe is formed at the side wall on the lower part of the cone tube; a coarse material discharge pipe is arranged at the bottom of the cone tube; and an auxiliary air pipe is formed on the coarse material discharge pipe. The invention also provides a separation method. The device is reasonable in structure, high in winnowing and separating speed, high in efficiency and low in cost.

Owner:JILIN CARBON

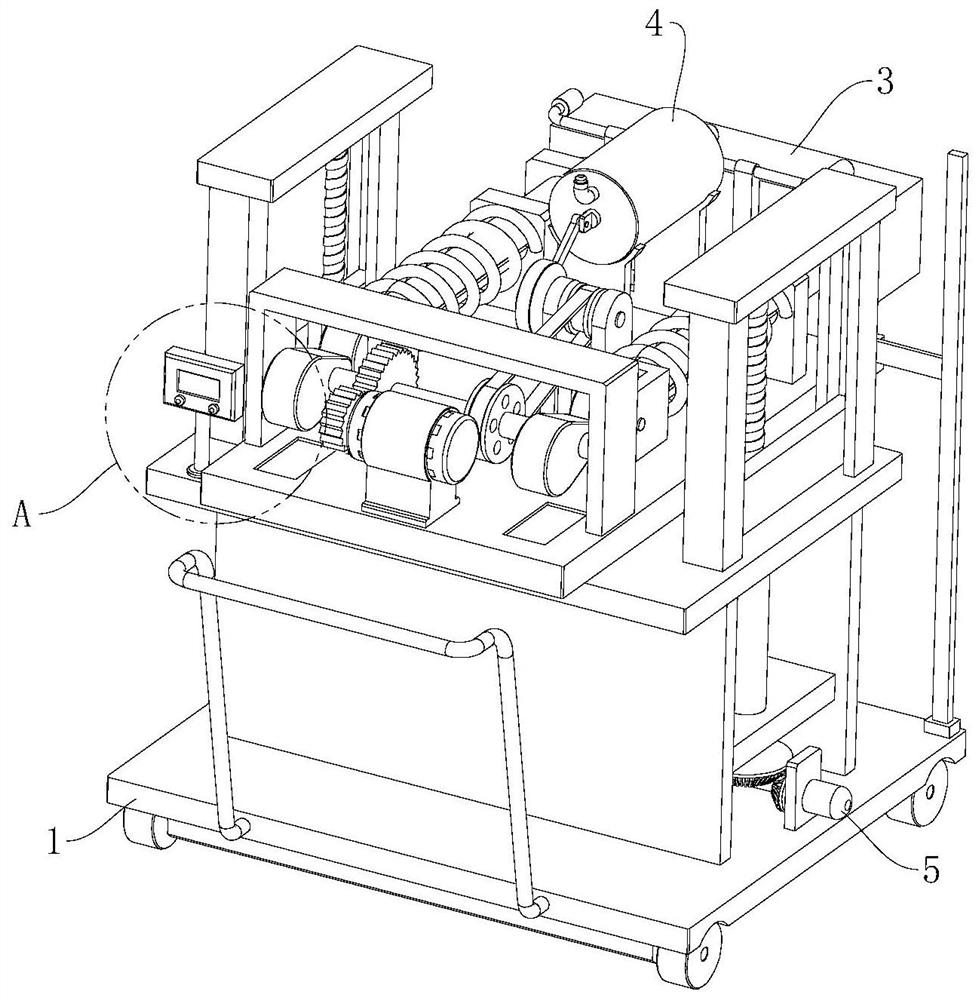

Safe construction device

ActiveCN112196308AImprove demolition efficiencyIncrease destructive powerUsing liquid separation agentBuilding repairsArchitectural engineeringDust control

The invention relates to the technical field of wall dismantling, and particularly relates to a safe construction device. The safe construction device comprises a flat plate cart, and further comprises a controller, a hammering mechanism, a dust removing mechanism and a lifting mechanism, wherein the lifting mechanism comprises a lifting plate and a driving assembly; the hammering mechanism is arranged at the top of the lifting plate and used for hammering a wall; the hammering mechanism comprises a hammer head, a transmission assembly and two pushing assemblies; the dust removing mechanism isarranged at the top of the lifting plate and used for removing dust generated when the wall is hammered; the dust removing mechanism comprises a water supply barrel, an extrusion assembly and a plurality of atomizing spray heads; and the driving assembly and the transmission assembly are electrically connected with the controller. According to the safe construction device, water can be sprayed synchronously when the wall is dismantled, dust removing is achieved, workers are prevented from inhaling a large amount of dust, and the health of the workers is guaranteed; and meanwhile, lifting is more stable, the wall dismantling height can be accurately controlled, and various wall dismantling requirements are met.

Owner:山东城邦建设有限公司

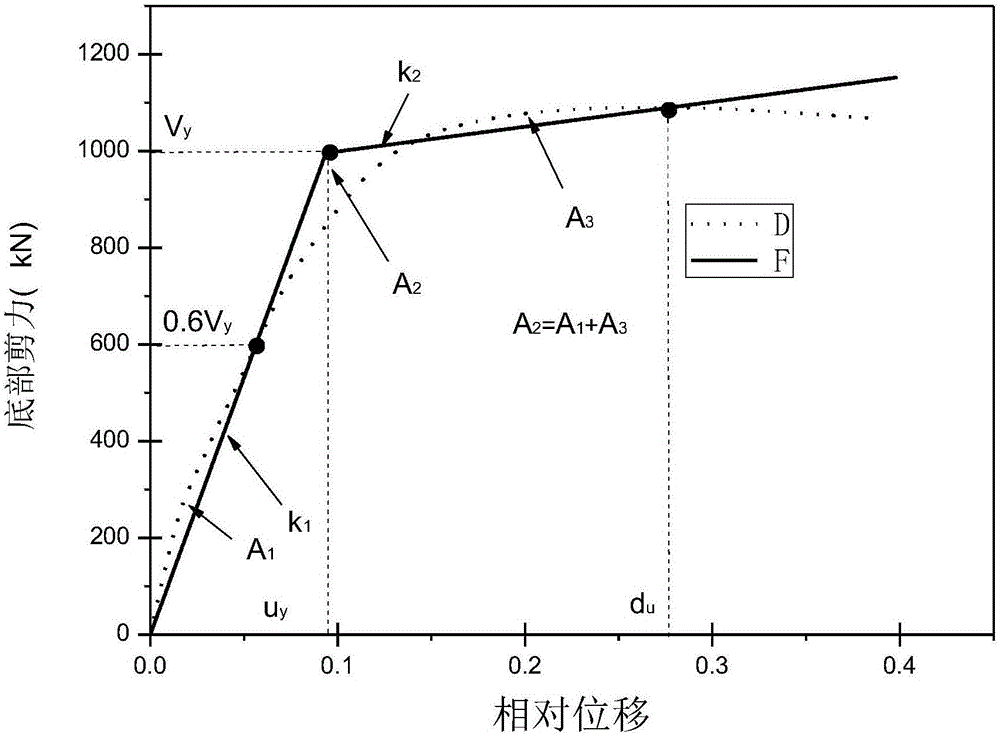

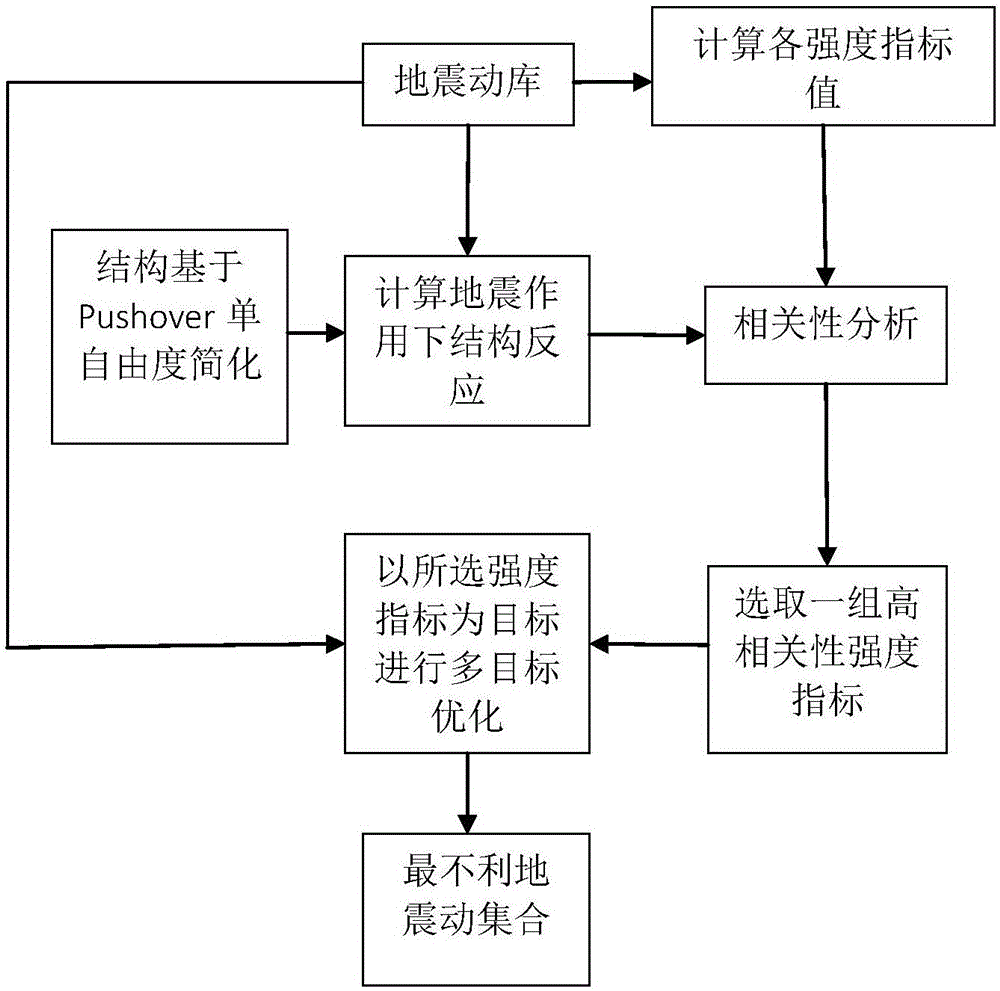

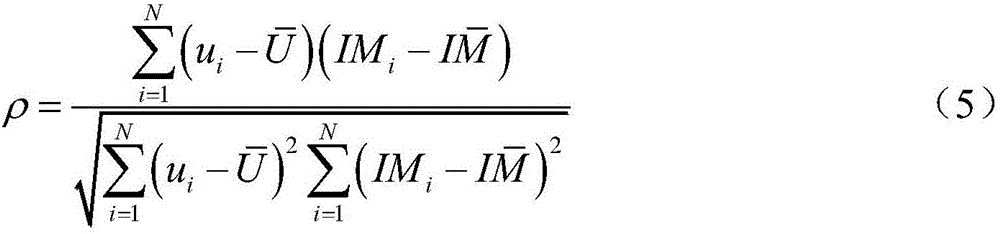

Severest ground motion selection method based on Pareto multi-objective optimization

ActiveCN106803006AIncrease destructive powerReduce analysis costsGeometric CADSpecial data processing applicationsScientific theorySmall sample

The invention discloses a severest ground motion selection method based on Pareto multi-objective optimization. Severest ground motions are selected based on Pareto multi-objective optimization, a plurality of ground motion intensity indexes serve as targets, large sample data in a ground motion base are optimized and selected, small sample severest ground motions with larger collapsing force are selected, elastic-plastic time-history analysis cost is effectively reduced, a equivalent single-degree-of-freedom system based on anti-seismic structures is provided in a ground motion intensity index step, correlation analysis of response between IMs and the anti-seismic structures under the single-degree-of-freedom system is performed, high efficiency of selection of the ground motion intensity indexes is effectively solved, sensitive degrees of different anti-seismic structures for different ground motion indexes are considered, high-correlation IMs are comprehensively selected for the different ground motion indexes, selected high-correlation IMs vector groups serve as targets, dominance relation among different ground motions is determined by the aid of a Pareto multi-objective optimization method, and a scientific theory basis is provided for selection of the severest ground motion.

Owner:HUAZHONG UNIV OF SCI & TECH

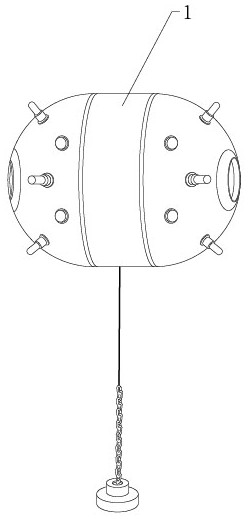

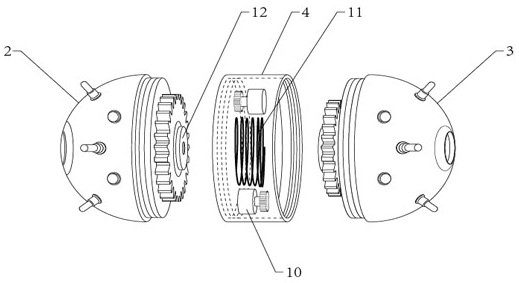

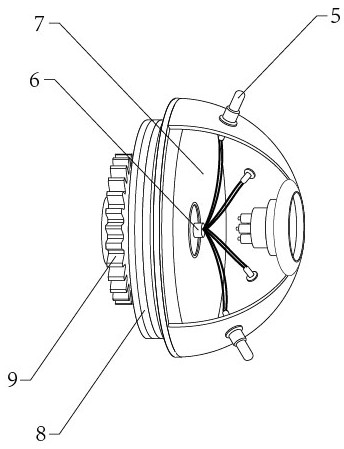

Small mine

PendingCN112729025ACombining autonomous attack featuresBreak the single-point attack methodMarine minesDetonatorSonar

The invention discloses a small mine which comprises a small mine body, a left shell, a right shell, a middle shell, fuses, an electric detonator, an explosive chamber, a threaded connector, a gear, a motor, a spring, a propeller device, a nozzle opening, a combustion channel, an explosive column, a heat insulation layer, an ignition device and a sealing heat protection ring. The small mine body is provided with the left shell and the right shell in left-right symmetry, the left shell and the right shell are connected and installed through the middle shell, the left shell and the right shell are the same in structure, and the fuses are installed on the left shell and the right shell respectively. The mine has the advantages that a target can be locked or nearby mine explosion can be sensed through sonar of the mine, the left shell and the right shell are separated from each other and become independent small mine individuals respectively, automatic navigation attacking is achieved, the single-point attacking mode of a traditional mine is broken through, and the hit rate and destructive power of undersea attacking are improved; and propeller devices are installed in the left shell and the right shell respectively and can be aligned with a target to implement attacks, and destructive power is increased in combination with the autonomous attack characteristic of a torpedo.

Owner:浙江铭品海工智能科技有限公司

High-pressure gas water-bomb firing apparatus

ActiveCN103007469AIncrease destructive powerIncrease kinetic energyFire rescueEngineeringHigh pressure

The invention provides a high-pressure gas water-bomb firing apparatus which comprises an acceleration cylinder and a cushion cylinder. In the acceleration cylinder, the upper end of an acceleration cylinder body is connected with an upper end cover of the acceleration cylinder, the lower end of the acceleration cylinder body is connected with a lower end cover of the acceleration cylinder, a piston capable of moving up and down is installed in the acceleration cylinder body, a buffering ring capable of moving up and down is installed in the acceleration cylinder body, and the upper end cover of the acceleration cylinder is connected with a lower end cover of the cushion cylinder; in the cushion cylinder, an inner cylinder body is located in an outer cylinder body, an upper end cover of the cushion cylinder is respectively connected with upper ends of the inner cylinder body and the outer cylinder body, and the lower end cover of the cushion cylinder is respectively connected with lower ends of the inner cylinder body and the outer cylinder body; an annular piston is arranged in an annular cylinder, at least 3 piston rods are mounted on the annular piston, extend out from the lower end cover of the cushion cylinder and are inserted into the acceleration cylinder, and the piston rods are connected with the buffering ring in the acceleration cylinder; and the lower part of a water retaining drum is connected with the inner side of the buffering ring, and the upper part of the water retaining drum is inserted into a central hole in the cushion cylinder. The high-pressure gas water-bomb firing apparatus provided by the invention has a long firing range.

Owner:ZHEJIANG UNIV OF TECH

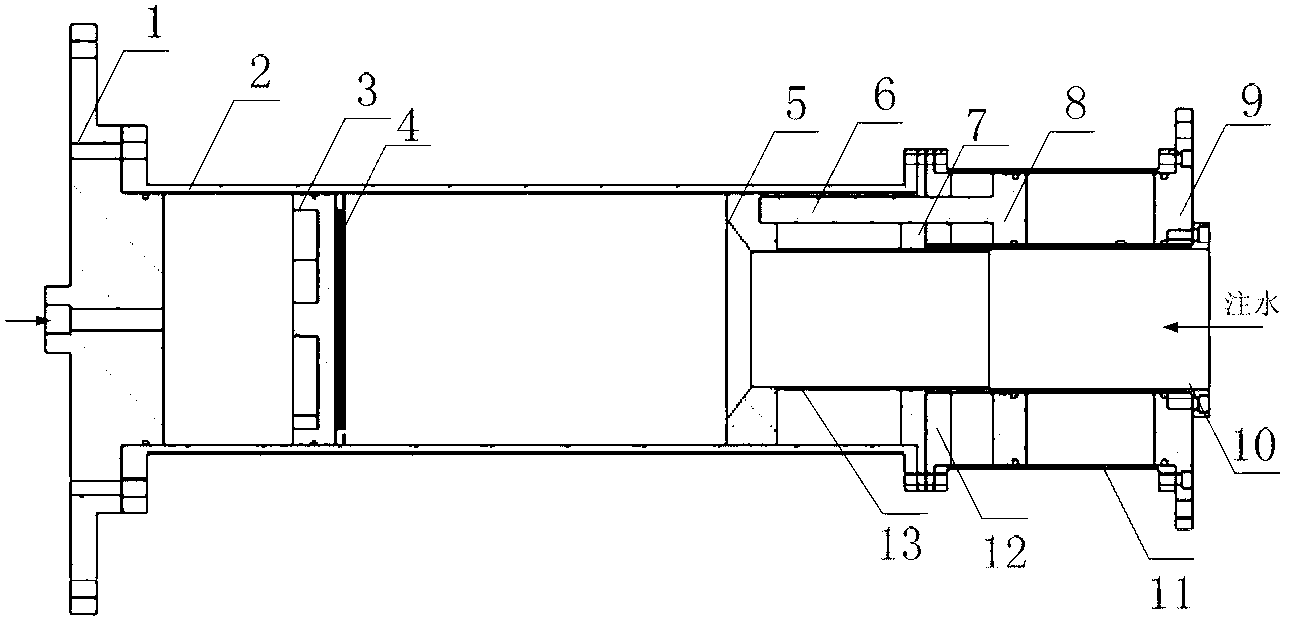

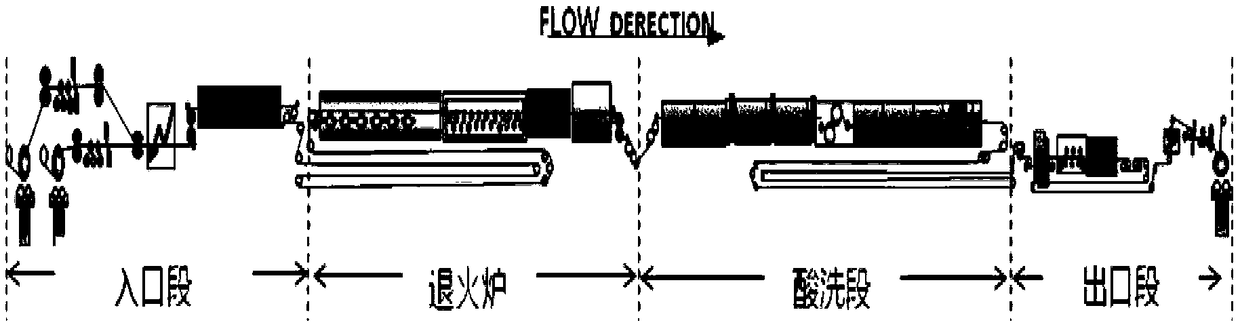

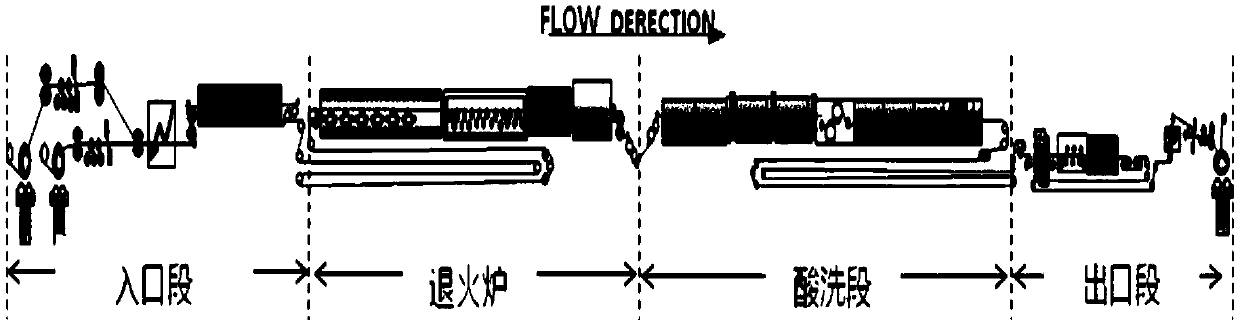

Cold annealing and pickling technique for 204 Cu stainless steel with thickness of 1.5-2.0 mm

InactiveCN109371208AReduce thicknessImprove uniformityElectrolysis componentsFurnace typesCombustion chamberUltimate tensile strength

The invention discloses a cold annealing and pickling technique for a 204 Cu stainless steel with thickness of 1.5-2.0 mm, which comprises a cold roll annealing step and a mixed-acid pickling step. The cold roll annealing step is used for setting different temperatures of heating zones from Z1 to Z10 in combustion chambers of an annealing furnace. Working intensity of the brush rolls is adjusted through the mixed-acid pickling step, wherein current of 1 # brush roll and 2 # brush roll is 15.4A to 26.8A, the rotating speed is 600rmp to 800rpm, and load is 2mm to 3mm; and current of 6 # brush roll and 4 # brush roll is 10.7A to 16.4A, the rotating speed is 600rmp to 800rpm, and load is 2mm to 3mm. The cold annealing and pickling technique for the 204 Cu stainless steel with thickness of 1.5-2.0 mm has the advantage of being suitable for preparing the 204 Cu stainless steel with thickness of 1.5-2.0 mm, and beneficial effects that annealing temperature benchmarks are refined according tothickness of the stainless steel, thickness of the oxide skin is reduced, uniformity of the oxide skin is improved, destructive power of the brush rolls to the oxide skin on surface is enhanced, upperand low surfaces of an obtain stainless steel plate has no white spots over full width, and the product surface quality is improved.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

Anti-winding straw crushing device

InactiveCN111955184AImprove crushing efficiencyAccelerated destructionCuttersAgricultural engineeringElectric machinery

The invention provides an anti-winding straw crushing device. The anti-winding straw crushing device comprises a bottom plate; an enclosure is welded on the upper surface of the bottom plate; a crushing cavity is arranged in the enclosure; a feeding hole is welded at one side over the enclosure; the feeding hole is communicated with the crushing cavity; a crushing shaft is arranged in the crushingcavity; one end of the crushing shaft extends out of the enclosure, and is in transmission connection with a driving motor arranged on the bottom plate through a transmission wheel and a transmissionbelt; several crushing blades are fixed on the crushing shaft; several auxiliary cutters are fixed on the inner wall of the enclosure through a cutter frame; a base plate connected with the enclosureis at the bottom of the feeding hole through a screw assembly; several baffles are installed on the base plate; a discharging hole is arranged at the bottom of the crushing cavity; and a dischargingplate extending out of the enclosure is arranged below the discharging hole. According to the anti-winding straw crushing device in the invention, a movable cutter base is arranged; the movable cutterbase can horizontally move while rotating so as to drive the crushing blades to horizontally move; therefore, the crushing force of the crushing blades on straw structures can be increased; the ratethat the straw structures are wound on the crushing shaft is reduced; and thus, the anti-winding straw crushing device in the invention has good development prospect.

Owner:杨秋华

Chaenomeles speciosa extract as well as preparation method and application thereof

InactiveCN109221382AFacilitate extractionHigh extraction rateFruit and vegetables preservationChemistryAqueous solution

The invention relates to a chaenomeles speciosa extract as well as a preparation method and application thereof. The chaenomeles speciosa extract comprises the following components: 10-30wt% of polysaccharide, 7-40wt% of triterpene, and 1-4wt% of antioxidative active substances. The preparation method comprises the following steps: treating a proper amount of chaenomeles speciosa by a pressure cooker; mixing the chaenomeles speciosa powder after high-pressure treatment with different proportions of ethanol aqueous solution according to a certain proportion; carrying out reflux extraction; anddrying the extract to obtain the chaenomeles speciosa extract. According to the preparation method provided by the invention, the high-pressure treatment is utilized to destroy the tissue structure ofthe chaenomeles speciosa, so that the extraction rate of active ingredients in the chaenomeles speciosa and the contents of polysaccharide, triterpene and antioxidative active substances in the chaenomeles speciosa extract are improved.

Owner:HEFEI UNIV OF TECH

Hook digging rock arm small arm with material filling mechanism

ActiveCN107630482AWeight increaseReduce maintenance costsMechanical machines/dredgersEngineeringRock breaking

The invention discloses a hook digging rock arm small arm with a material filling mechanism. The hook digging rock arm small arm comprises a left clamping plate, a right clamping plate and a hook digging plate, wherein the left clamping plate and the right clamping plate are arranged side by side; the upper part of the hook digging plate is clamped between the left clamping plate and the right clamping plate; the hook digging plate is detachably connected with the left clamping plate and the right clamping plate; the hook digging plate is of a hollow structure; a filler port is formed in the middle part of one side of the hook digging plate. The problems that the connected structure of an existing hook digging rock arm small arm and a digging hook is complicated and the maintenance cost after the integration of the hook digging rock arm small arm and the digging hook is high are solved, and further, the problem that the weight of the hook digging rock arm small arm is inconvenient to adjust according to the harness condition of rock stratum since the weight of the existing hook digging rock arm small arm is constant is solved, so that the hook digging rock arm small arm has a preferable rock breaking effect.

Owner:CHENGDU KAILONG MACHINERY MAINTENANCE

Method for reducing natural disaster loss through manual intervention of earthquakes

InactiveCN113009555AReduce lossesIncrease destructive powerEarthquake measurementSeismologyEarth crustNatural disaster

The embodiment of the invention relates to geosciences, and discloses a method for reducing natural disaster loss through manual intervention of earthquakes. According to the invention, through drilling and deep burying, explosives are placed near the position of the earth crust with potential earthquake risk, the explosives are detonated, and the stress and energy accumulated in the earth crust are released, so that the purposes of early prediction and planned occurrence of an earthquake are achieved. And casualties and property loss caused by the uncertainty of the earthquake are avoided. The earthquake, which is an originally uncertain and high-loss natural disaster, can be intervened and is low in loss.

Owner:沈阳讯网网络科技有限公司

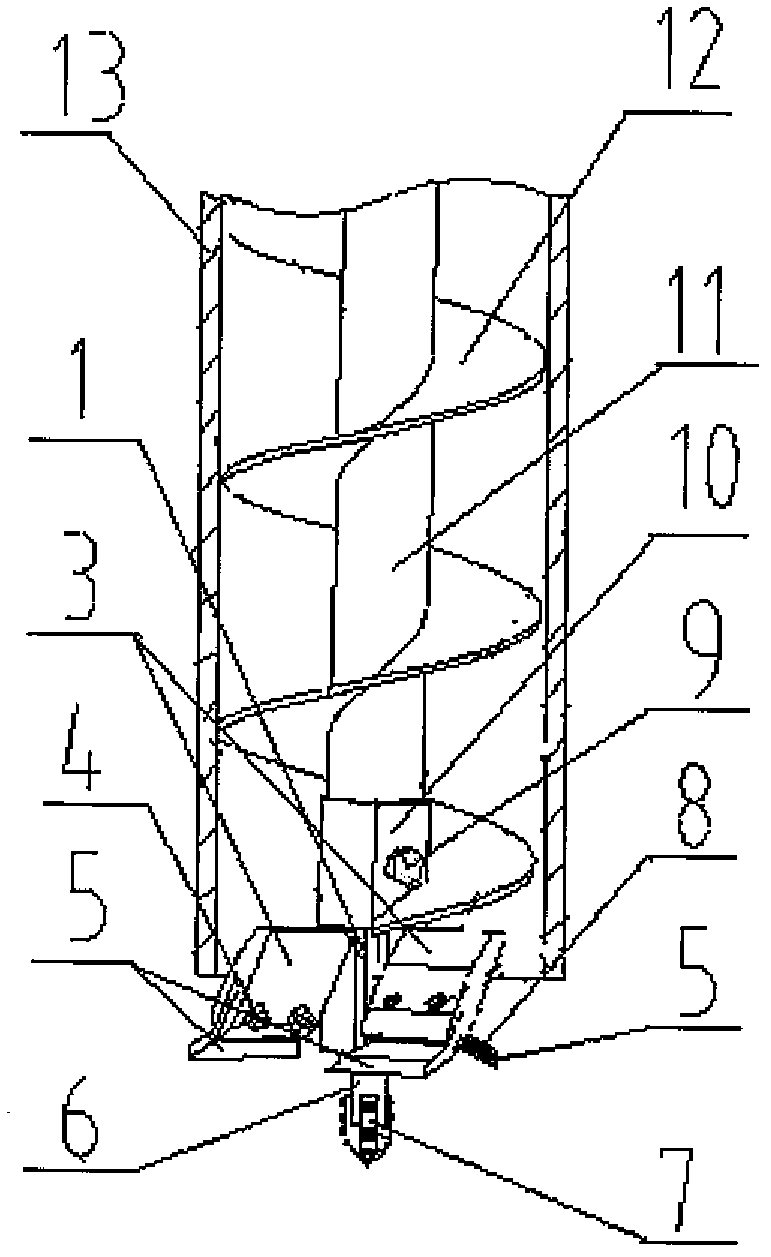

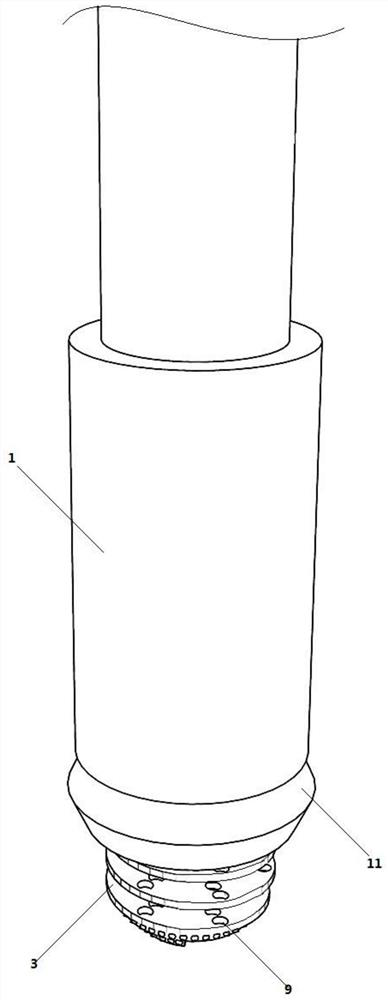

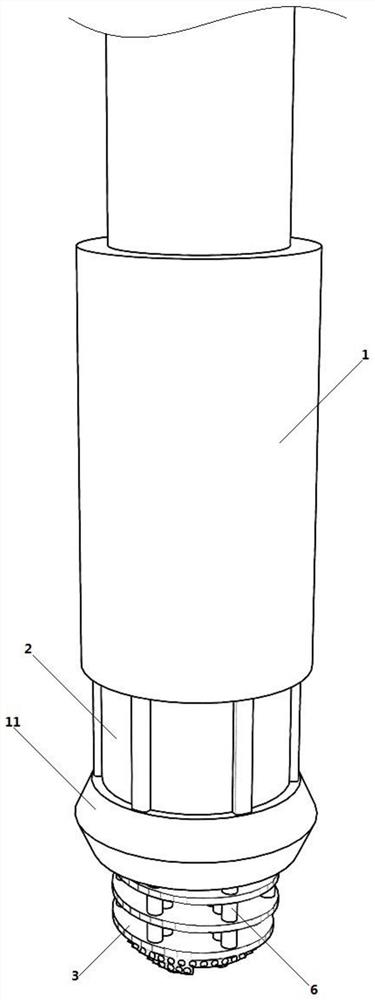

Piston hammer machine drill-in type hammer and drill combined drilling machine

InactiveCN113006679AImprove protectionEasy to useDrill bitsBorehole drivesStructural engineeringAir compressor

The invention discloses a piston hammer machine drill-in type hammer and drill combined drilling machine, and relates to the technical field of drilling machine instruments. The drilling machine comprises a connecting cylinder, a hammer body and a spiral drill bit; the hammer body is in sliding connection with the inner wall of the connecting cylinder; the hammer body is of a cavity structure; a connecting piston is slidably mounted in the hammer body; the connecting piston is fixedly connected with a supporting drill rod; the connecting cylinder and the hammer body are respectively communicated with an air compressor; the spiral drill bit comprises a connecting shaft and a guide blade; the connecting shaft is fixedly connected with the hammer body; and the supporting drill rod is in sliding insertion fit with a connecting opening. The piston hammer machine drill-in type hammer and drill combined drilling machine has the beneficial effects that a torque sensor is used for monitoring a stratum environment to protect the spiral drill bit, so that the spiral drill bit rotates to drill holes when the stratum environment is soft, and the supporting drill rod supports and reinforces the spiral drill bit after the stratum environment is hardened to hammer rocks and the like to perform hammering and drilling operation. Therefore, the drill bit is prevented from being replaced during drilling operation in different stratum environments, the drilling efficiency is improved, and the use is more flexible and convenient.

Owner:WENZHOU POLYTECHNIC

Cold annealing and acid pickling technology of 204 Cu stainless steelwith thickness smaller than or equal to 1.5 mm

InactiveCN109554528AReduce thicknessImprove uniformityFurnace typesHeat treatment furnacesHearthFull width

The invention discloses a cold annealing and acid pickling technology of 204 Cu stainless steel with the thickness smaller than or equal to 1.5 mm. The cold annealing and acid pickling technology of the 204 Cu stainless steel with the thickness smaller than or equal to 1.5 mm comprises the steps of cold rollingannealing and mixed acid pickling, in the cold rolling annealing step, different temperatures are set in heating areas Z1 to Z10 in a furnace hearth of an annealing furnace, the mixed acid pickling step comprises the steps of neutral saltelectrolysis, mixed acid pickling andbrushing through brush rollers, and working modes of the brush rollers comprise that the current of the first brush roller and the second brush roller is 15.4-26.8 A, the rotating speed of the first brush roller and the second brush roller is600-800 rmp, and the load of thefirst brush roller and the second brush roller is 2-3 mm; and the current of the thirdbrush roller and the fourth brush roller is10.7-16.4A, the rotating speed of the third brush roller and the fourth brush roller is600-800 rmp,and the load ofthe third brush roller and the fourth brush roller is2-3 mm. Compared with the prior art, the cold annealing and acid pickling technology of the 204 Cu stainless steel with the thickness smaller than or equal to 1.5 mm has the advantages that annealing temperature standard is detailed accordingto the thickness interval, the cold annealing and acid pickling technology is applied to preparing the 204 Cu stainless steel with the thickness smaller than or equal to 1.5 mm, the thickness of oxide skin is decreased, uniformity of the oxide skin is improved, white spots do not exist on the upper surface and the lower surface of a stainless steel plate in full width, and the surface quality ofa product is improved.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

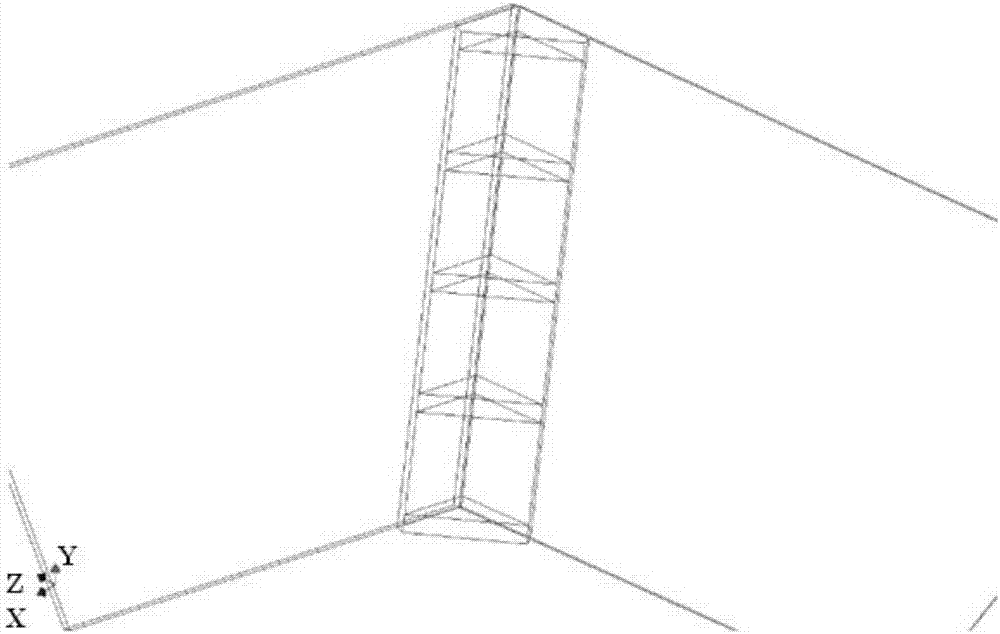

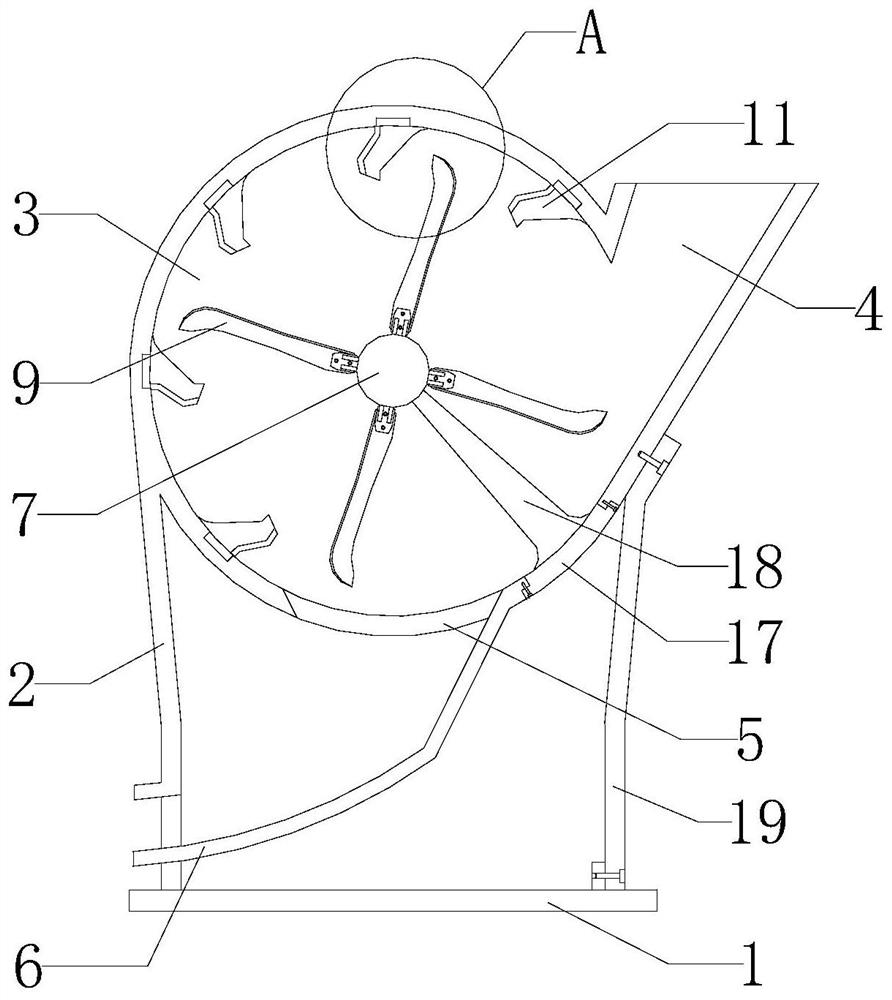

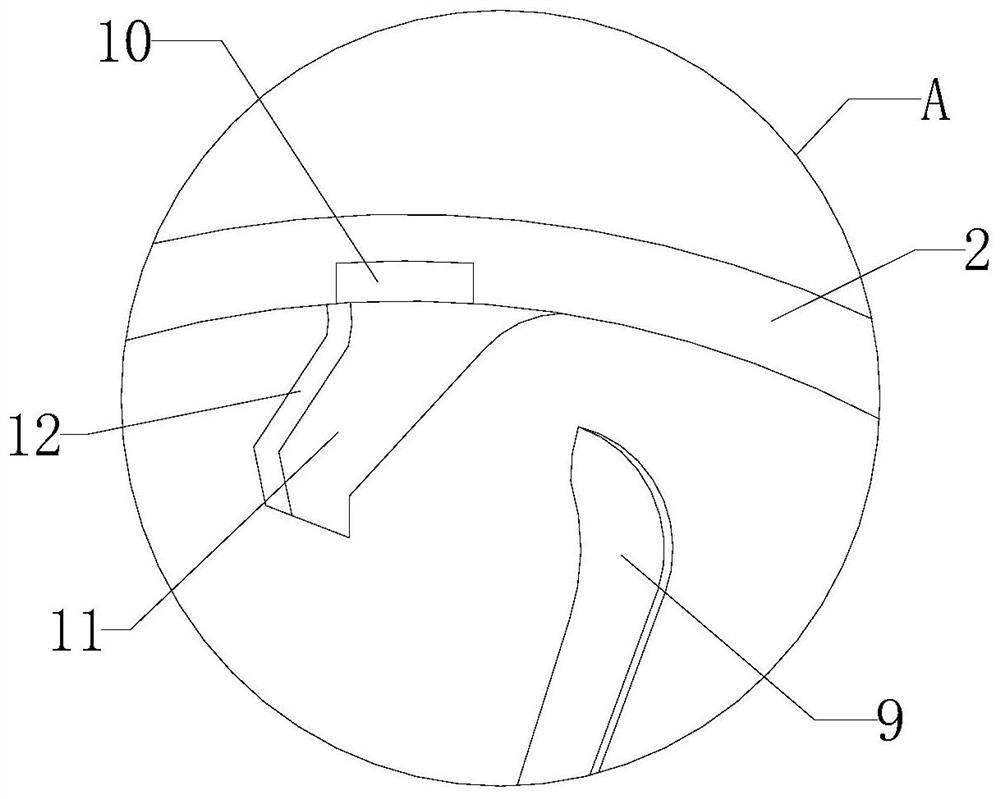

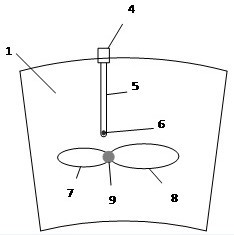

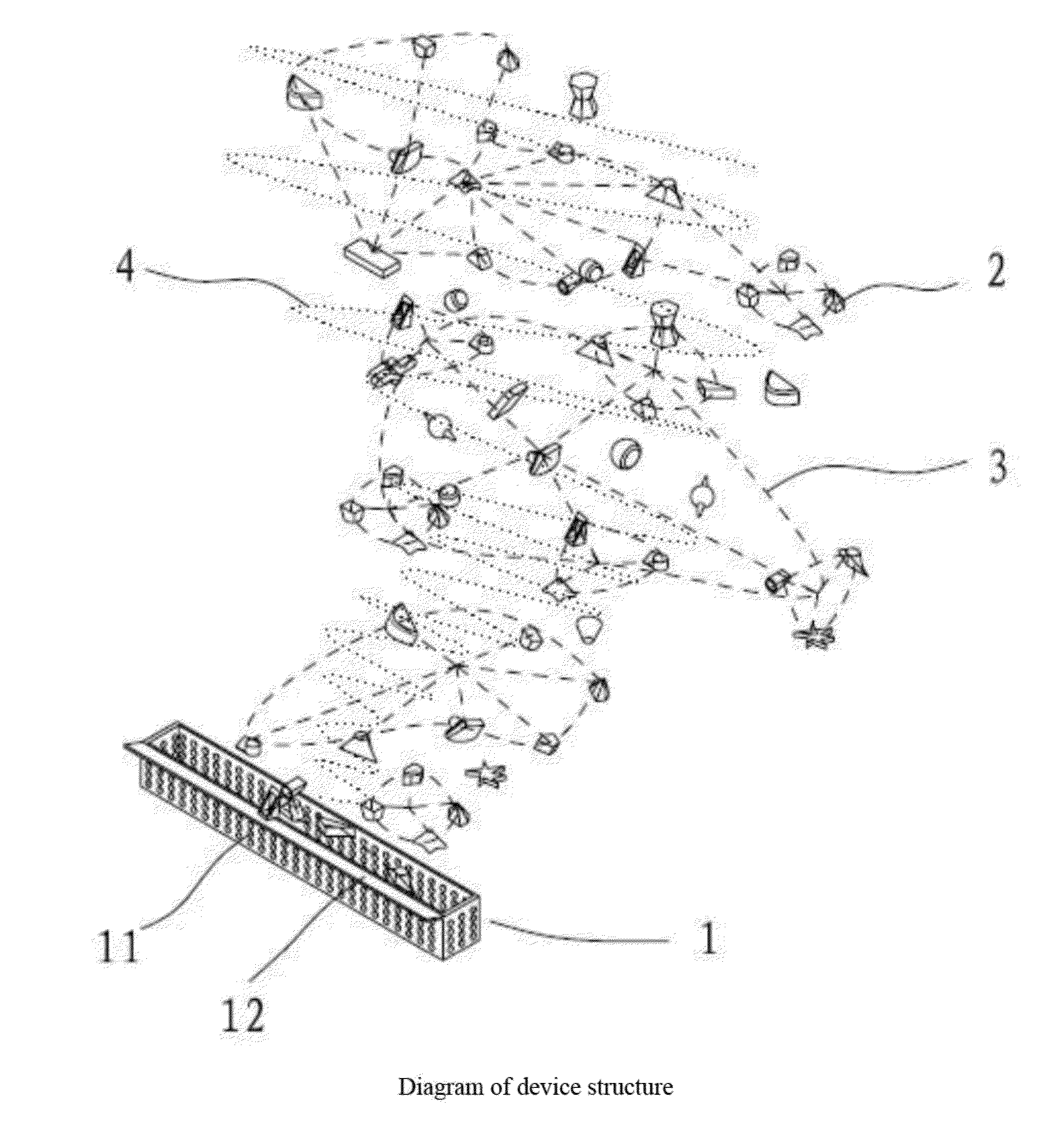

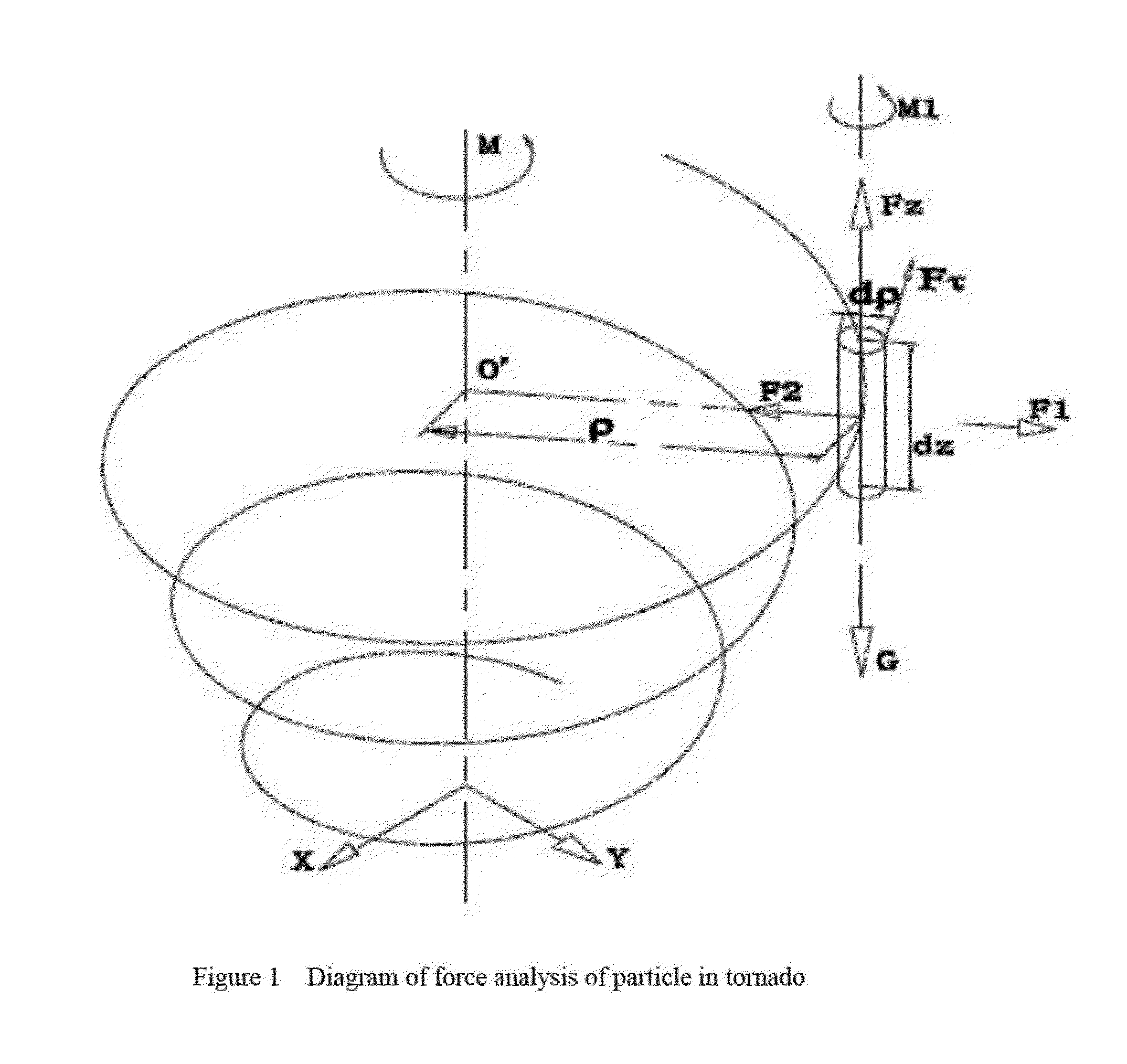

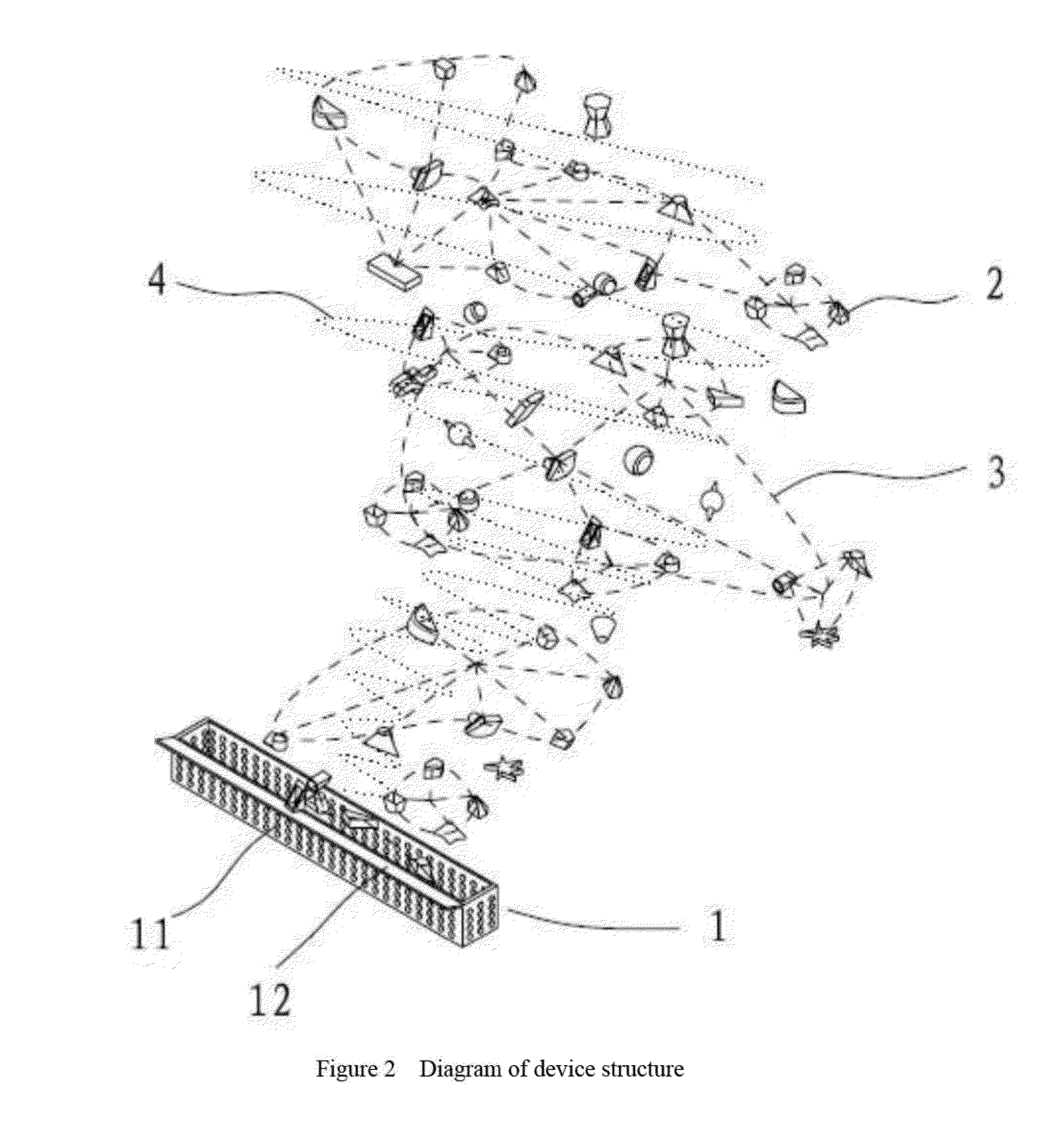

Method and Device of Weakening Tornado

ActiveUS20150327448A1Reduce partDisaster reductionFog dispersionWeather influencing devicesCycloneEngineering

The field of this invention is tornado disaster. This invention proposes a method of weakening tornado, the contents are as follows: A. provide Provide plenty of non-fixed turbolators called free turbolators; B. Provide plenty of turbolators fixed on free ropes, called free turbolator strings; C. Provide plenty of turbolators fixed on ropes installed on storage boxes at lease in one spot, called swinging turbolator strings; D. Install free turbolators, free turbolator strings and swinging turbolator strings, in order to reduce energy of tornado cyclone. On the other hand, this invention also proposes a device for weakening tornado based on the above method, the contents are as follows: there are free turbolators, free turbolator strings and swinging turbolator strings which are installed in proper areas. This invention is for reducing tornado energy, and even interrupting tornado.

Owner:JIANG LIPING

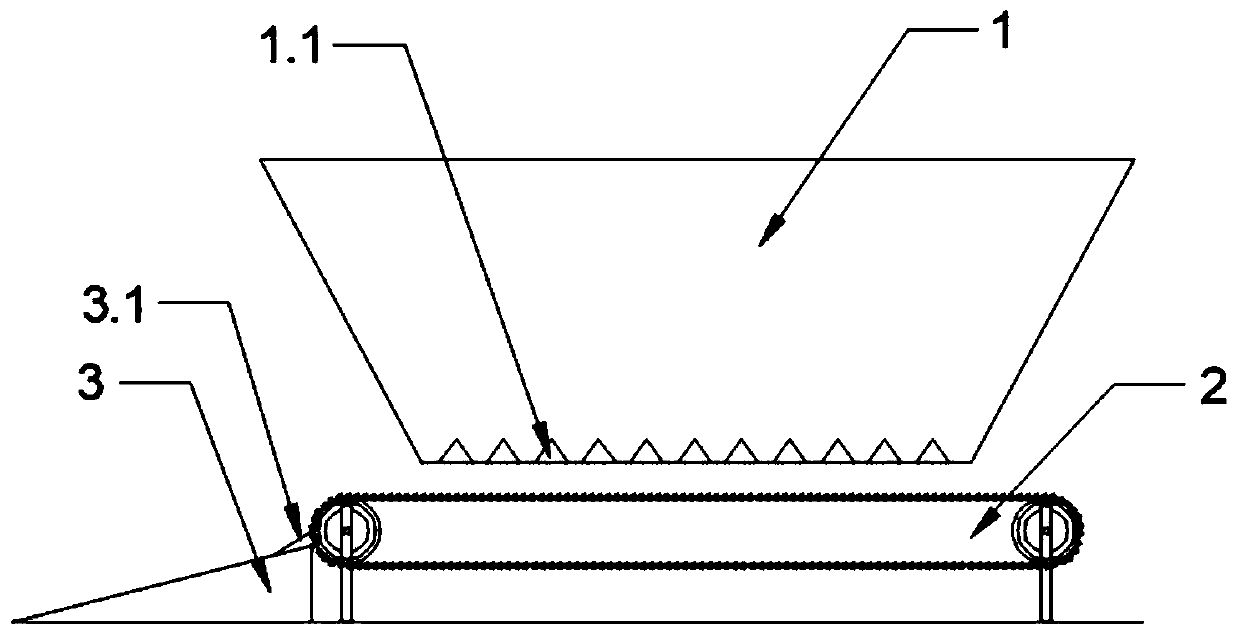

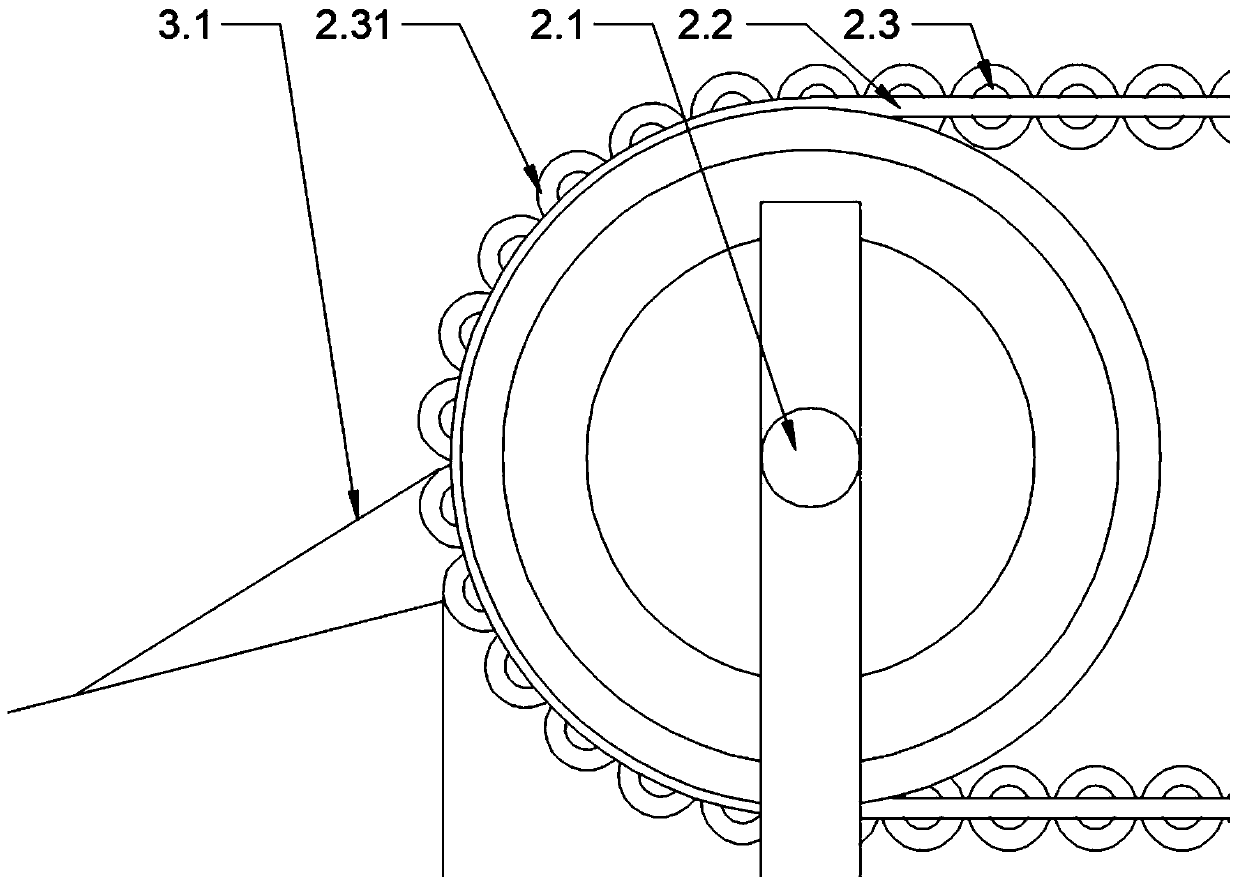

Device for conveying discharged mud cakes of plate-and-frame filter press

The invention relates to a device for conveying discharged mud cakes of a plate-and-frame filter press. The device comprises a mud hopper and a conveyor under the mud hopper, and the lower portion ofthe mud hopper is provided with gratings. By additional arrangement of the gratings, with large mud cake breaking power, on the lower portion of the mud hopper, the mud cakes are cut into small-size blocks by the gratings under the action of gravity so as to achieve convenience in transporting. The conveyor conveys cylindrical rollers through a chain-sprocket structure and is less prone to slipping or deflecting and low in operating noise. The multiple cylindrical rollers are arrayed to form an uneven transporting surface which is capable of withstanding direct impact of mud blocks with certain weights, and the concave-convex surface enables increasing of a contact area, so that convenience in mud block conveying is achieved. By arrangement of a roller brush and a cleaning procedure, the whole device for conveying is low in requirement on intrinsic weights of the mud cakes, the conveyor is slightly affected by the moisture content or viscoplasticity of the mud cakes, and the device forconveying is less prone to failure caused by mud accumulation.

Owner:ROAD ENVIRONMENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com