Grading method of coal mill steel balls and application thereof

A coal mill and steel ball technology, applied in grain processing and other directions, can solve the problems of single installed gradation of grinding balls, affecting the normal development of enterprises, and increasing the labor intensity of workers, so as to improve grinding efficiency, increase specifications, and reduce operating power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The coal mill steel ball grading method of the present invention will be further described below through five specific examples. The same coal mill is selected for testing, and the output of the ball mill remains unchanged before and after the test. Changes in indicators, as shown in the table below:

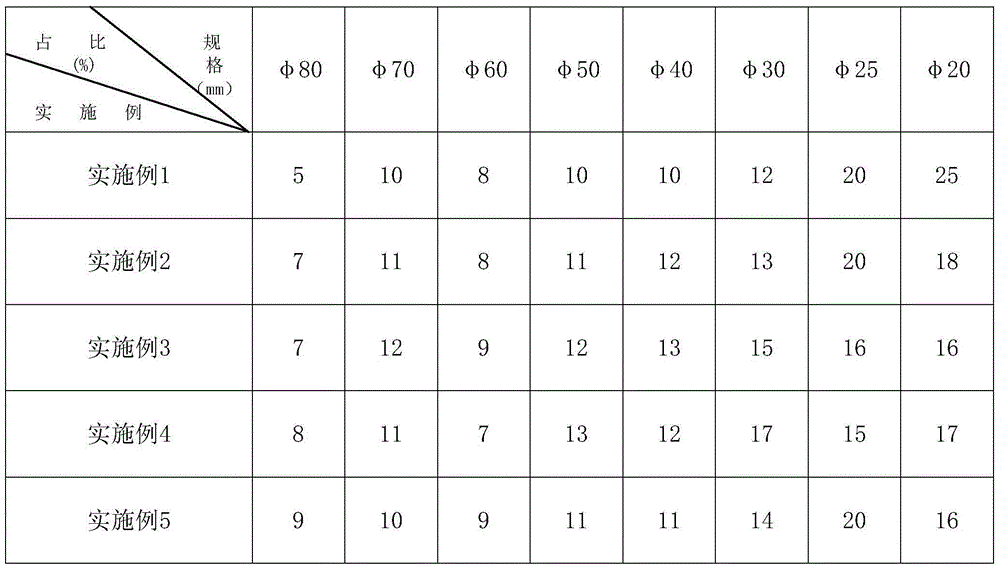

[0076] Table 1 Ball weight ratio of steel balls in each embodiment

[0077]

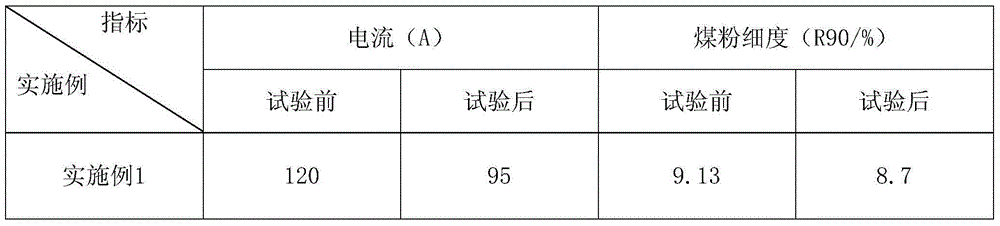

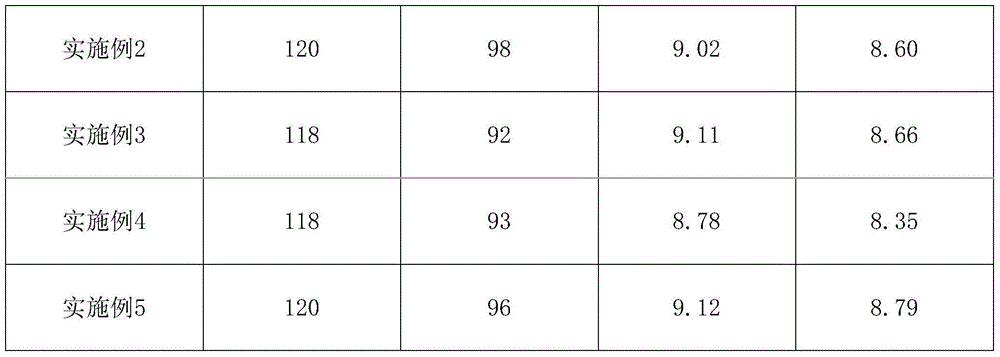

[0078] Table II

[0079]

[0080]

[0081]It can be seen from the comparison results before and after the test of the five embodiments in Table 2 that after using the grading method of the present invention, the current of the coal mill is significantly reduced, and the pulverized coal is finer.

[0082] The production practice proves that after the steel ball grading method of the coal mill is used in the present invention, the ball mill runs stably and reliably, and the natural grading tends to be more reasonable due to the increase of grading specifications, effectively improving th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com