Patents

Literature

49 results about "Viscoplasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Viscoplasticity is a theory in continuum mechanics that describes the rate-dependent inelastic behavior of solids. Rate-dependence in this context means that the deformation of the material depends on the rate at which loads are applied. The inelastic behavior that is the subject of viscoplasticity is plastic deformation which means that the material undergoes unrecoverable deformations when a load level is reached. Rate-dependent plasticity is important for transient plasticity calculations. The main difference between rate-independent plastic and viscoplastic material models is that the latter exhibit not only permanent deformations after the application of loads but continue to undergo a creep flow as a function of time under the influence of the applied load.

Long fiber reinforced thermoplastic composite material multi-scale simulation method

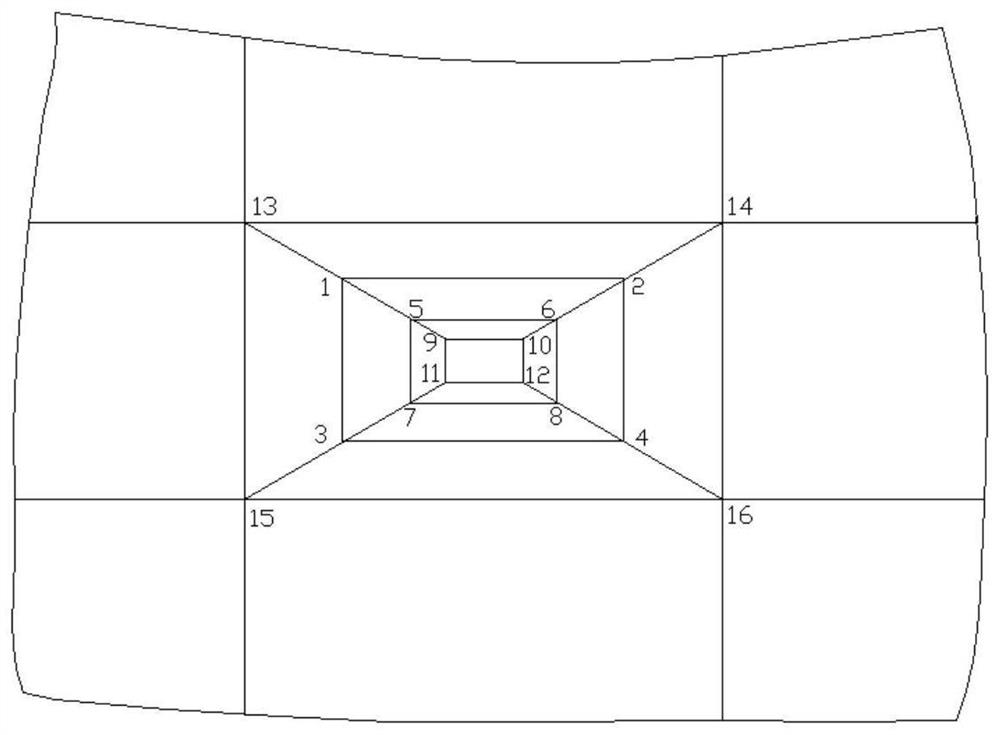

InactiveCN107356478ALow imaging resolutionRequires minimizationMaterial strength using tensile/compressive forcesMaterial analysis by transmitting radiationElement modelX-ray

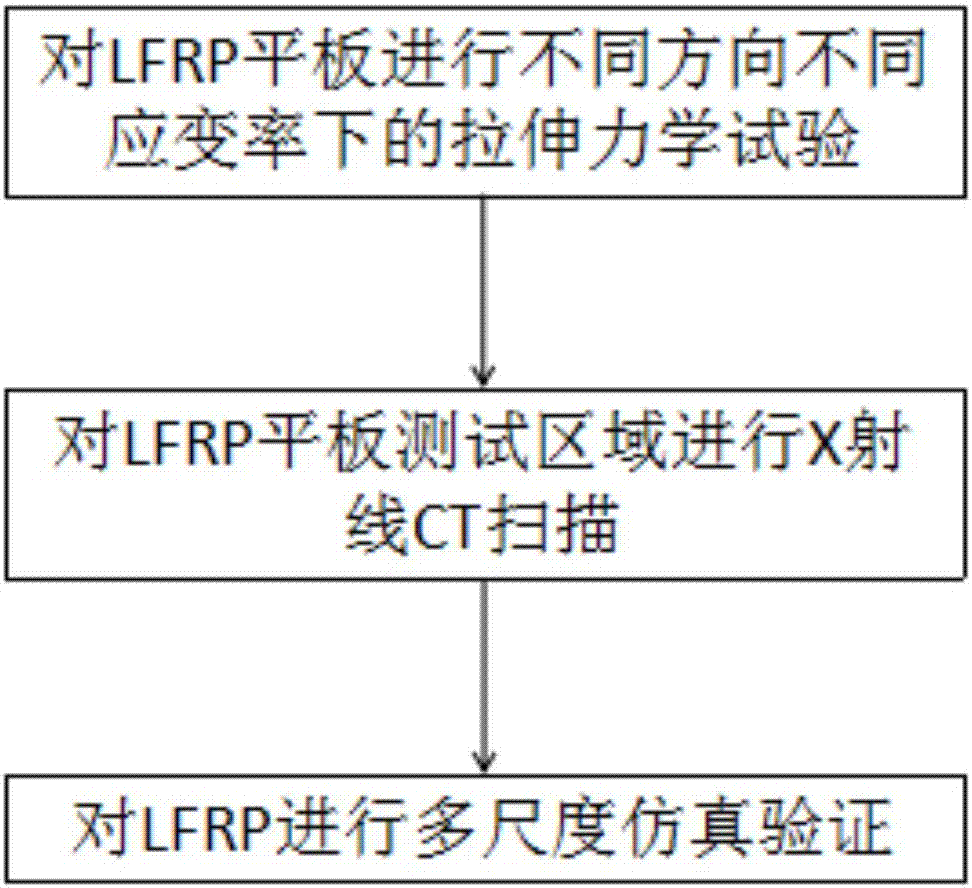

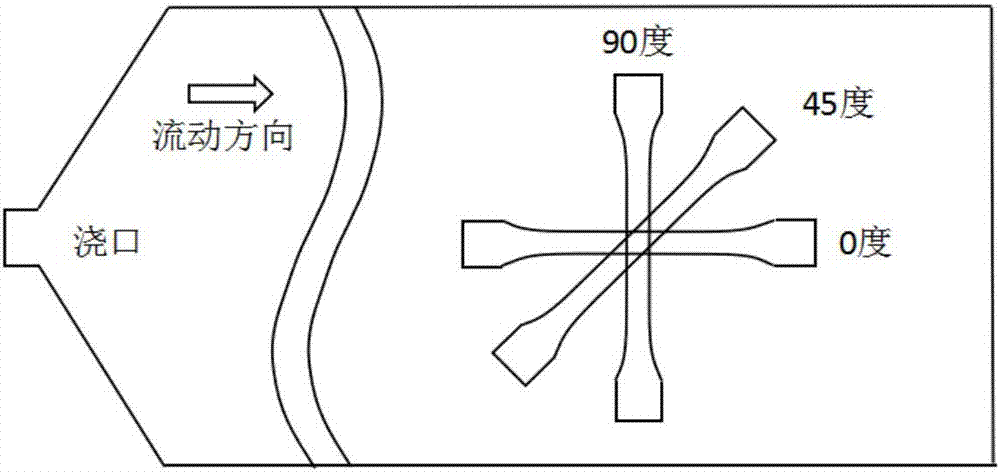

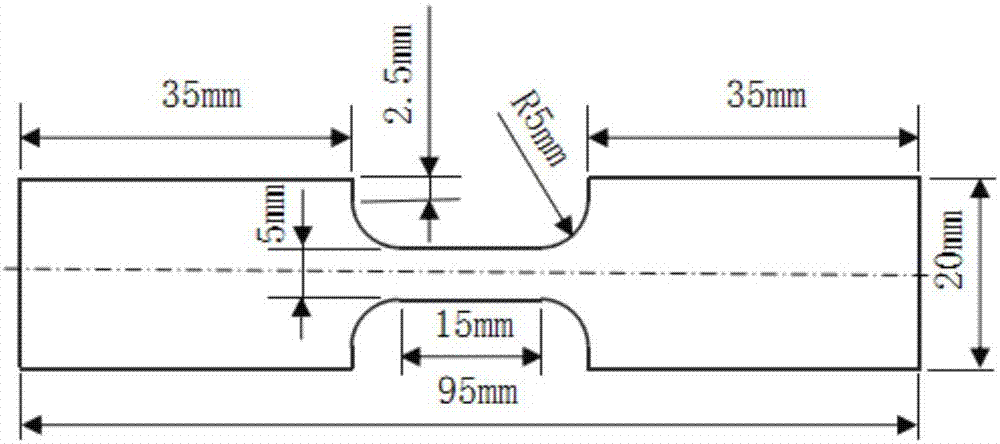

The invention discloses a long fiber reinforced thermoplastic composite material multi-scale simulation method to solve the problem of difficult accurate simulation of long fiber reinforced thermoplastic composite material in simulation because of strain rate effect and anisotropic mechanical properties. The method includes the steps of: 1. conducting tensile test on an LFRP plate under different directions and different strain rates; 2. performing x-ray CT scanning on an LFRP plate test area; and 3) carrying out multi-scale simulation verification on the LFRP plate: 1) viscoelastic-viscoplastic material model and failure; and 2) simulation verification: using ABAQUS software and Digimat software coupling to establish a simulation finite element model, conducting simulating calculation of tensile test under three strain rates, wherein 0.001s<-1> and 1s<-1> adopt implicit algorithm, and 100s<-1> adopts display algorithm; fixing one end of the finite element sample model, and applying load to the other end along the length direction, and comparing all the mechanical characteristic curves obtained by simulating calculation with test data.

Owner:JILIN UNIV

A Multiaxial Creep-Fatigue Prediction Method Based On ABAQUS

PendingUS20220026326A1Strong intuitivenessPracticalMaterial strength using tensile/compressive forcesDesign optimisation/simulationFatigue damageElement model

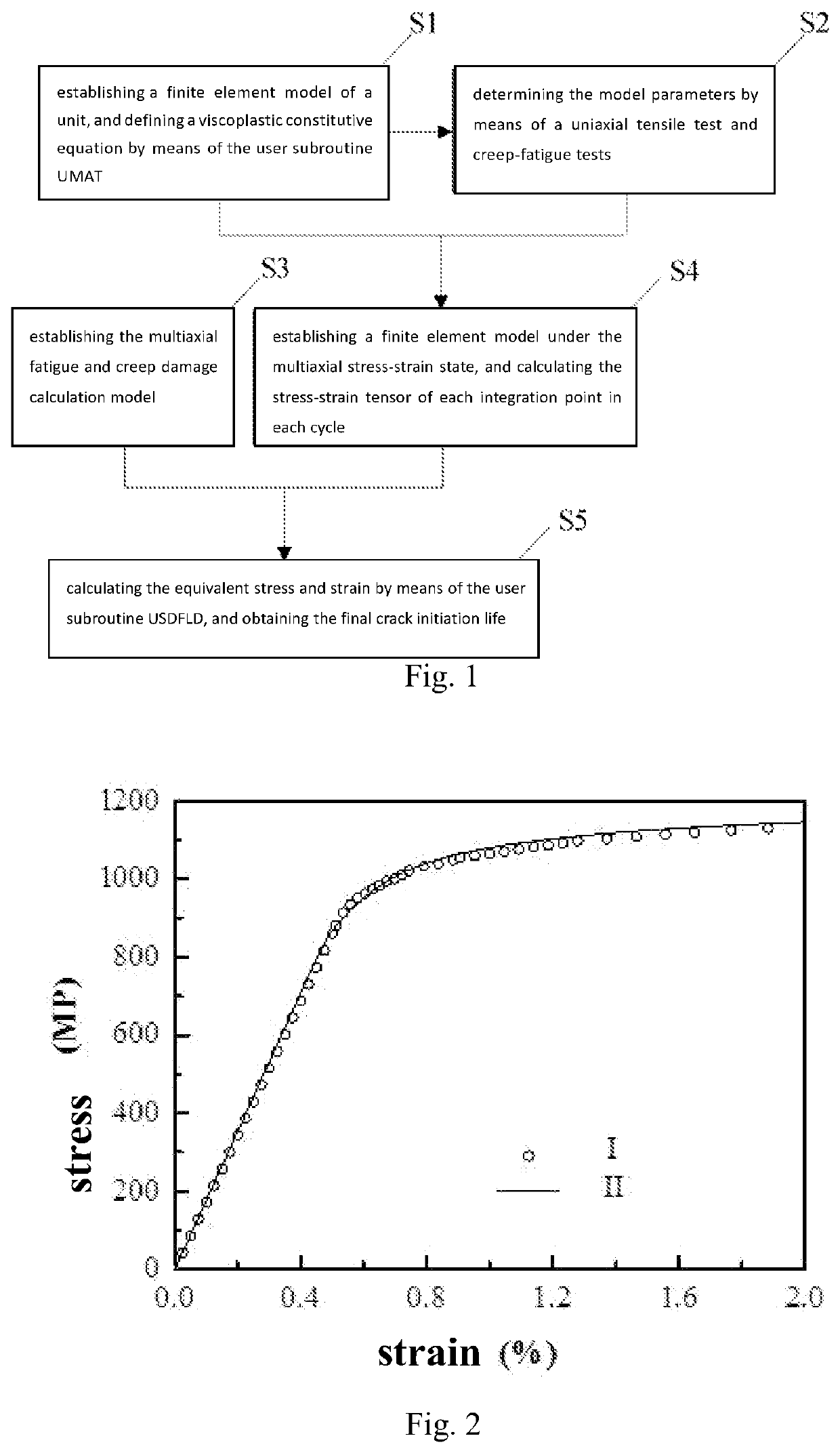

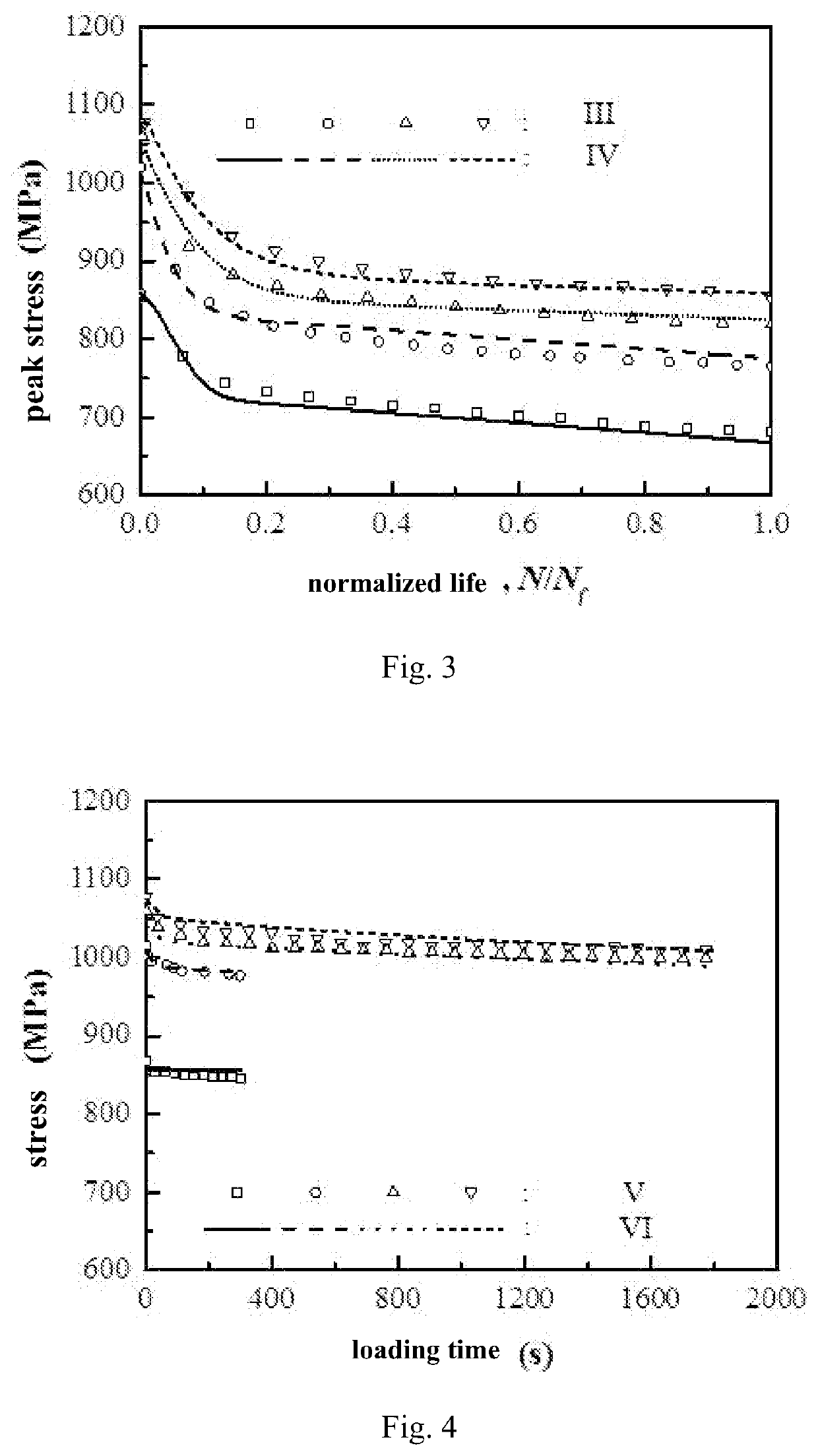

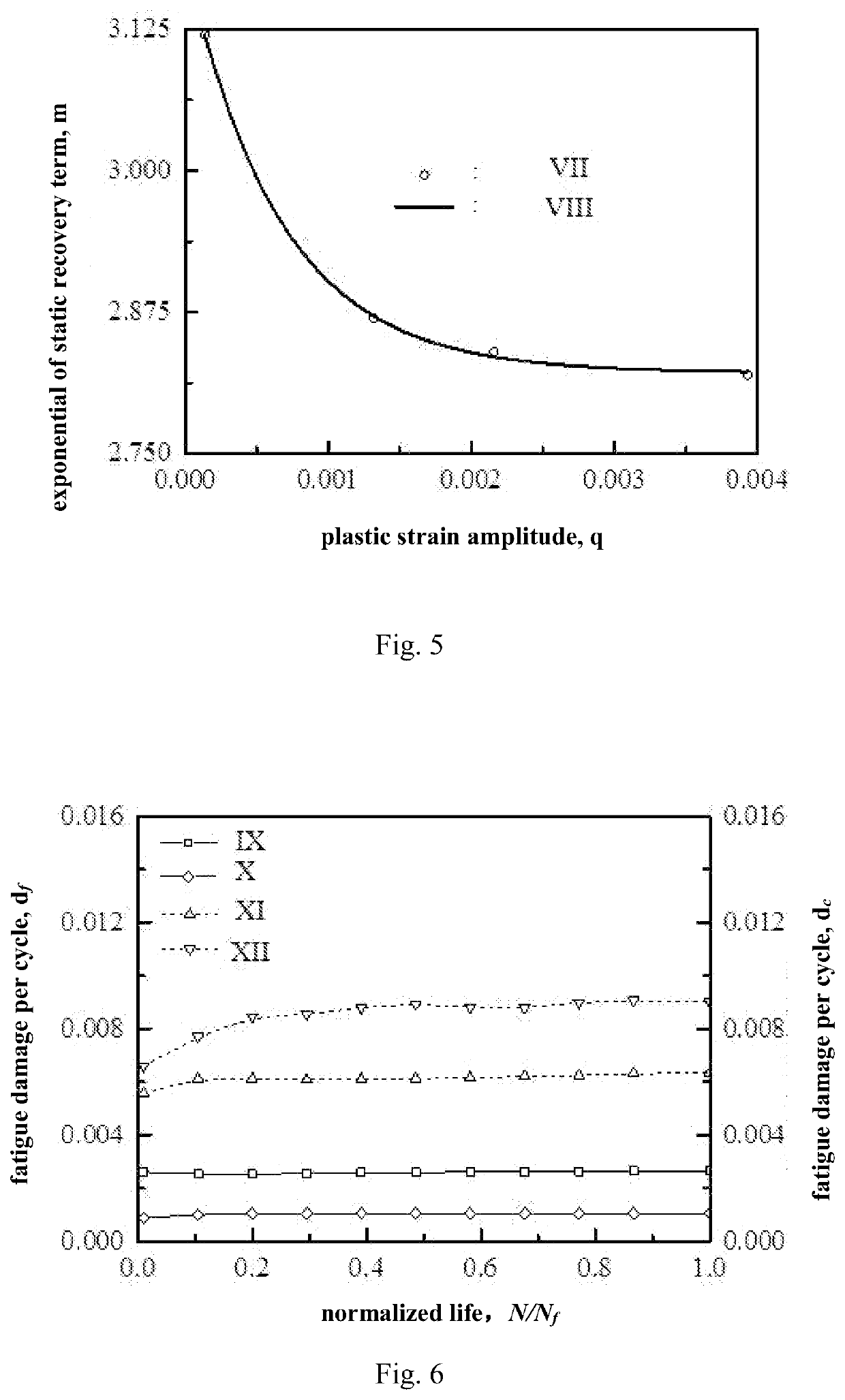

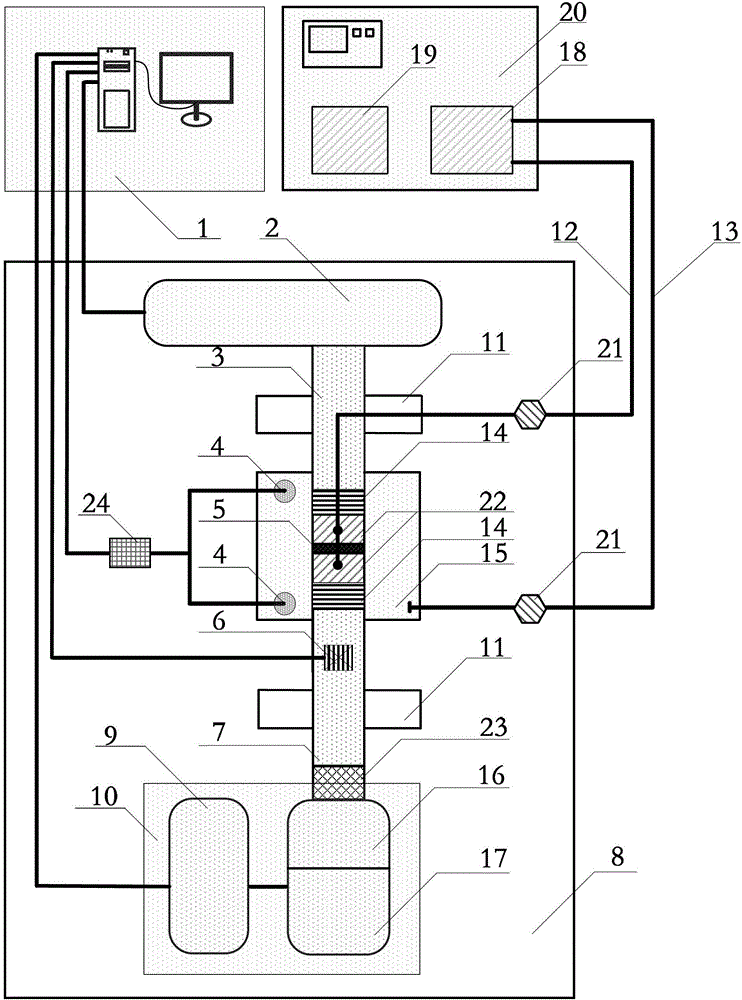

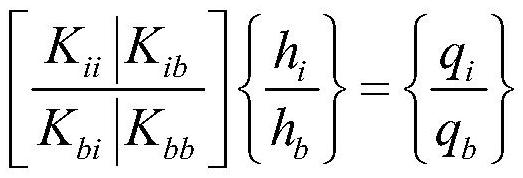

The present invention discloses a multiaxial creep-fatigue prediction method based on ABAQUS, which comprises: S1: establishing an ABAQUS finite element model, and defining the viscoplastic constitutive equation of the material to be tested by means of the user subroutine UMAT; S2: determining the model parameters required by the viscoplastic constitutive equation; S3: establishing the fatigue damage calculation model and creep damage calculation model of the multiaxial stress-strain state of the material to be tested; S4: establishing an ABAQUS finite element model under the multiaxial stress-strain state, and calculating the stress-strain tensor of each cycle based on the defined viscoplastic constitutive equation and the model parameters; S5: calculating the equivalent stress and equivalent plastic strain by means of the user subroutine USDFLD, and superimposing the fatigue damage and creep damage of each cycle according to the linear cumulative damage criterion to obtain the crack initiation life of the material to be tested based on the fatigue damage calculation model and creep damage calculation model in combination with the stress-strain tensor.

Owner:EAST CHINA UNIV OF SCI & TECH

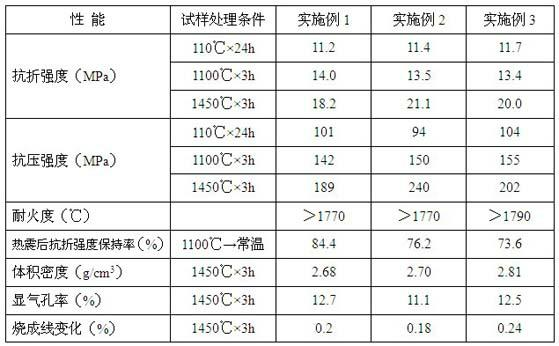

Pitch rotation shear failure experimental device

InactiveCN103149098AMaterial strength using steady shearing forcesComputer control systemTemperature control

The invention discloses a pitch rotation shear failure experimental device and belongs to the test field of material mechanics properties. The pitch rotation shear failure experimental device comprises an experimental platform, a temperature control system and a computer control system. The computer control system is capable of automatically controlling loading facilities to carrying out rotating shear loading to experimental test specimen and controlling an experimental process. The temperature control system is capable of controlling temperatures of the experiment. The pitch rotation shear failure experimental device can be suitable for determining low-temperature brittle failures and middle-high-temperature viscoplasticity failures of asphalt cements such as ordinary pitch, SBS modified asphalt, rubber asphalt and other polymer modified asphalt under different shear rates and tests of cementation interface mechanical property of materials such as bitumen mastic materials, stones, steels and plastic under the low-temperature conditions.

Owner:DALIAN UNIV OF TECH

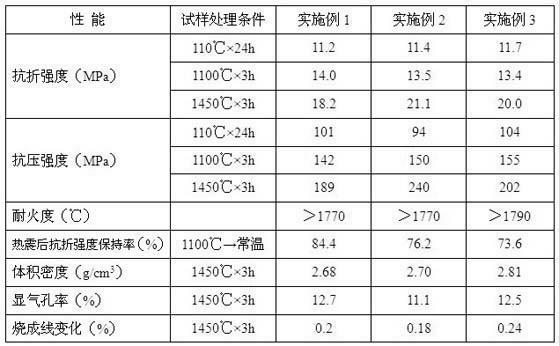

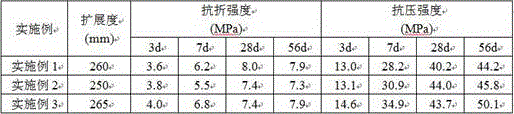

Refractory castable containing viscoplasticity phase and preparation method thereof

The invention discloses a refractory castable containing viscoplasticity phase, comprising refractory aggregate, refractory fine powder, oxide fine powder, a bonding agent and an additive, wherein the granularity of the refractory aggregate is 1-8mm, the granularity of the refractory fine powder is 0.044-1mm, the granularity of the oxide fine powder is less than 5mum, and the granularity of the bonding agent is less than 0.088 mm. According to the invention, single-substance aluminum powder and single-substance silicon powder are added into the refractory castable; the single-substance silicon powder is liquefied or softened during the material sintering, so that the material can produce liquid-phase sintering at low temperature to improve the bonding strength; the introduced aluminum powder reacts with water to form Al(OH)3 and then forms Al2O3 with big activity after being heated and decomposed; the SiO2 and Al2O3 react to form needle / column-shaped mullite crystals, therefore strength of the castable is improved; and meanwhile, part silicon powder becomes viscoplasticity phase at high temperature, and disperses in the material, thus, the toughness of the material is improved and the thermal shock resistance of the castable is improved.

Owner:LUOYANG INST OF SCI & TECH +1

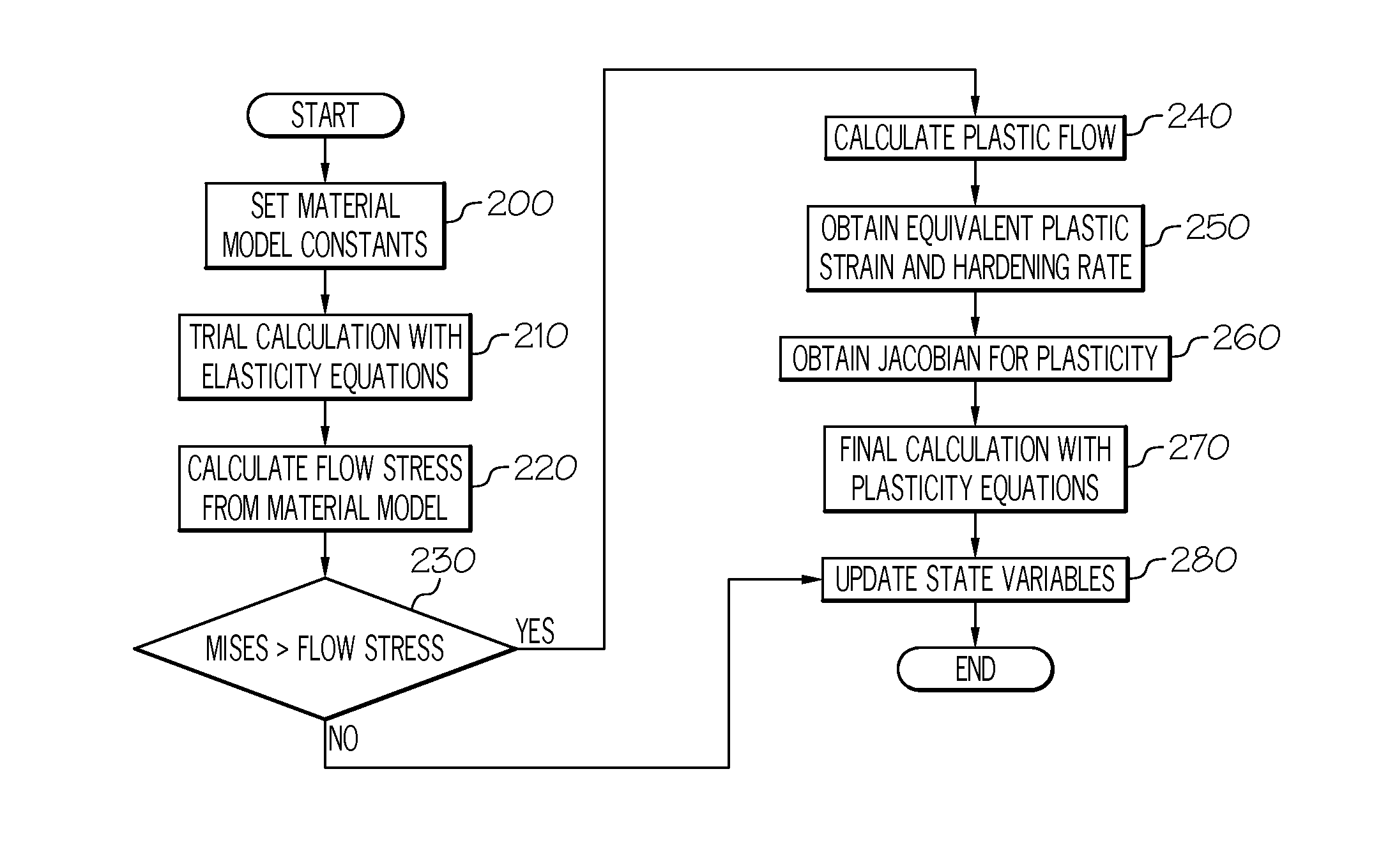

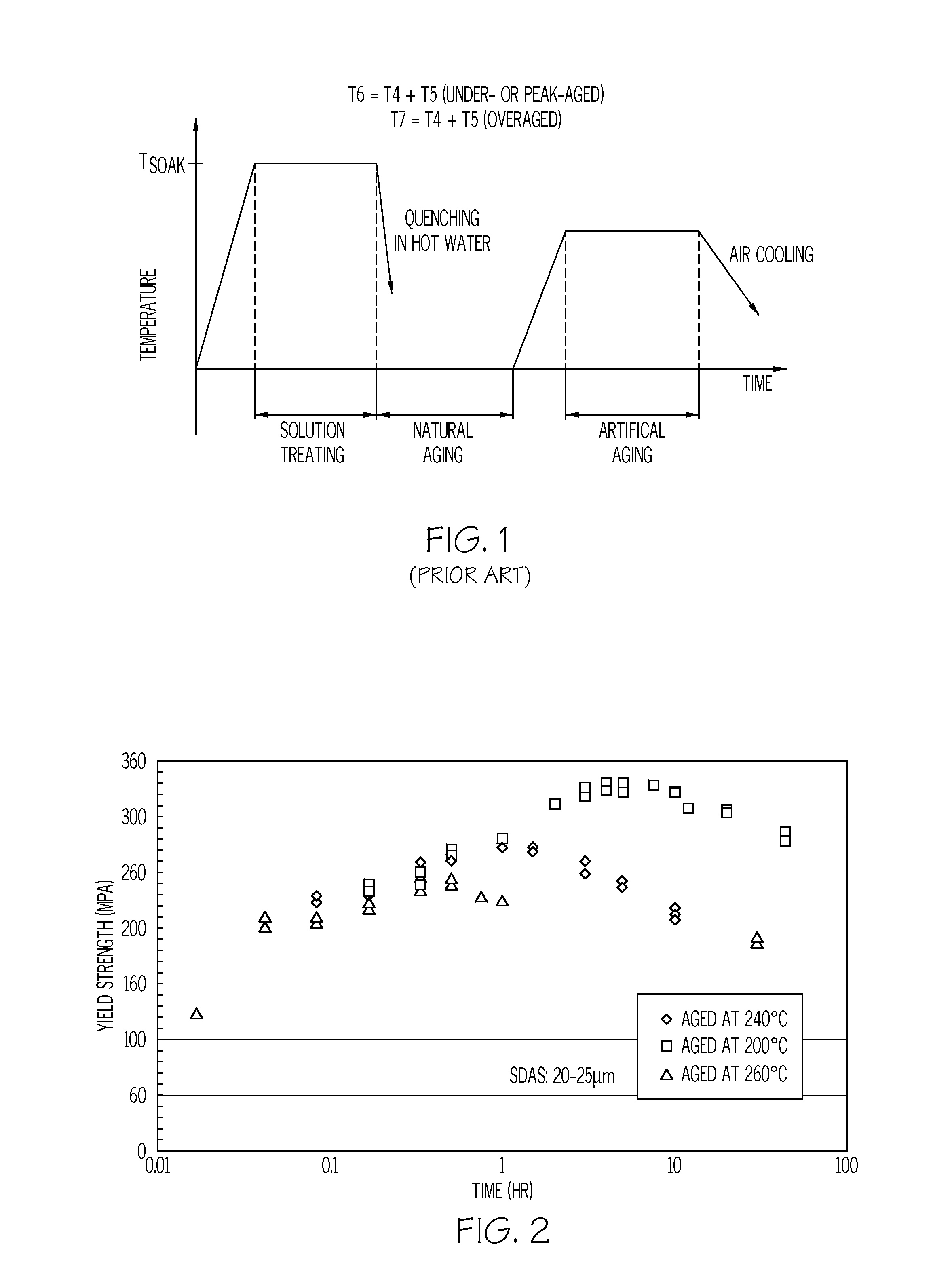

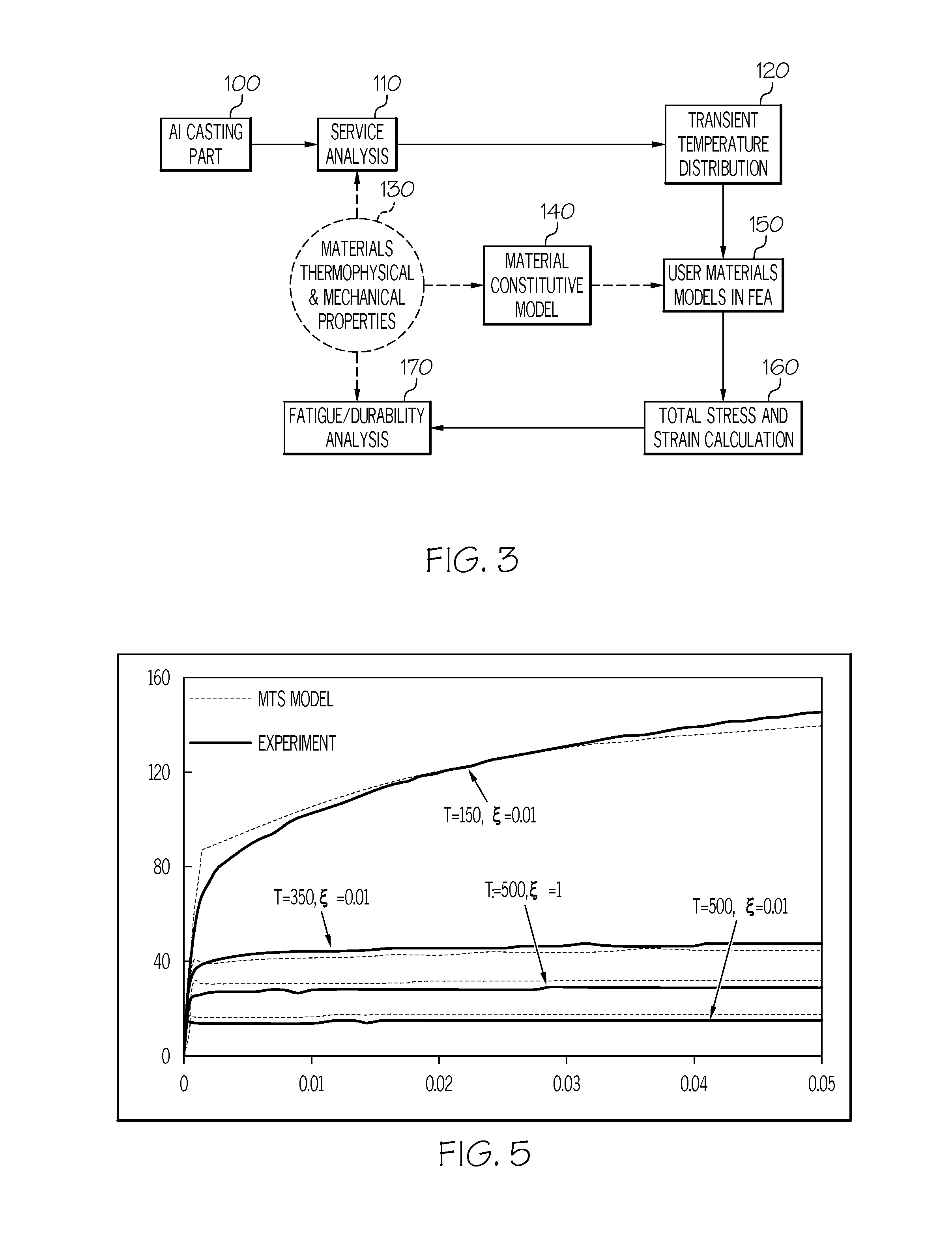

Product design reliability with consideration of material property changes during service

InactiveUS20150213164A1Accurate modelingImprove analysis accuracyComputation using non-denominational number representationDesign optimisation/simulationNODALDependability

A method of computationally determining material property changes for a cast aluminum alloy component. Accuracy of the determination is achieved by taking into consideration material property changes over the projected service life of the component. In one form, the method includes accepting time-dependent temperature data and using that data in conjunction with one or more constitutive relationships to quantify the impact of various temperature regimes or conditions on the properties of heat-treatable components and alloys. Finite element nodal analyses may be used as part of the method to map the calculated material properties on a nodal basis, while a viscoplastic model may be used to determine precipitation hardening and softening effects as a way to simulate the time and temperature dependencies of the material. The combined approach may be used to determine the material properties over the expected service life of a cast component made from such material.

Owner:GM GLOBAL TECH OPERATIONS LLC

Manufacture method for integrally extruding and forming graphite-based composite material radiator

The invention relates to the field of heat source radiator technology of an electronic device, in particular to a manufacture method for integrally extruding and forming a graphite-based composite material radiator. The method comprises the manufacture and process steps of: hot-kneading raw materials to prepare a paste with uniform mixing performance and excellent viscoplasticity, arranging the paste into an extrusion press to carry out pre-compression to form a billet, extruding and forming the billet, cooling and cutting the billet after extruding, baking and graphitizing the extruded raw product, and soaking and surface-treating the graphitized product, thus preparing the final radiator product. The manufacture method has the following advantages of (1) being capable of manufacturing graphite radiator with complex section; (2) large flexibility and being capable of producing the graphite radiators with different shapes, specifications and types on the same extrusion press by replacing an extrusion die; and (3) simple process flow and high production efficiency. The graphite radiator manufactured by the method has the advantages of good heat conduction, light weight, etc., and has no pollution during the process, is simple and feasible and has low consumption and high efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

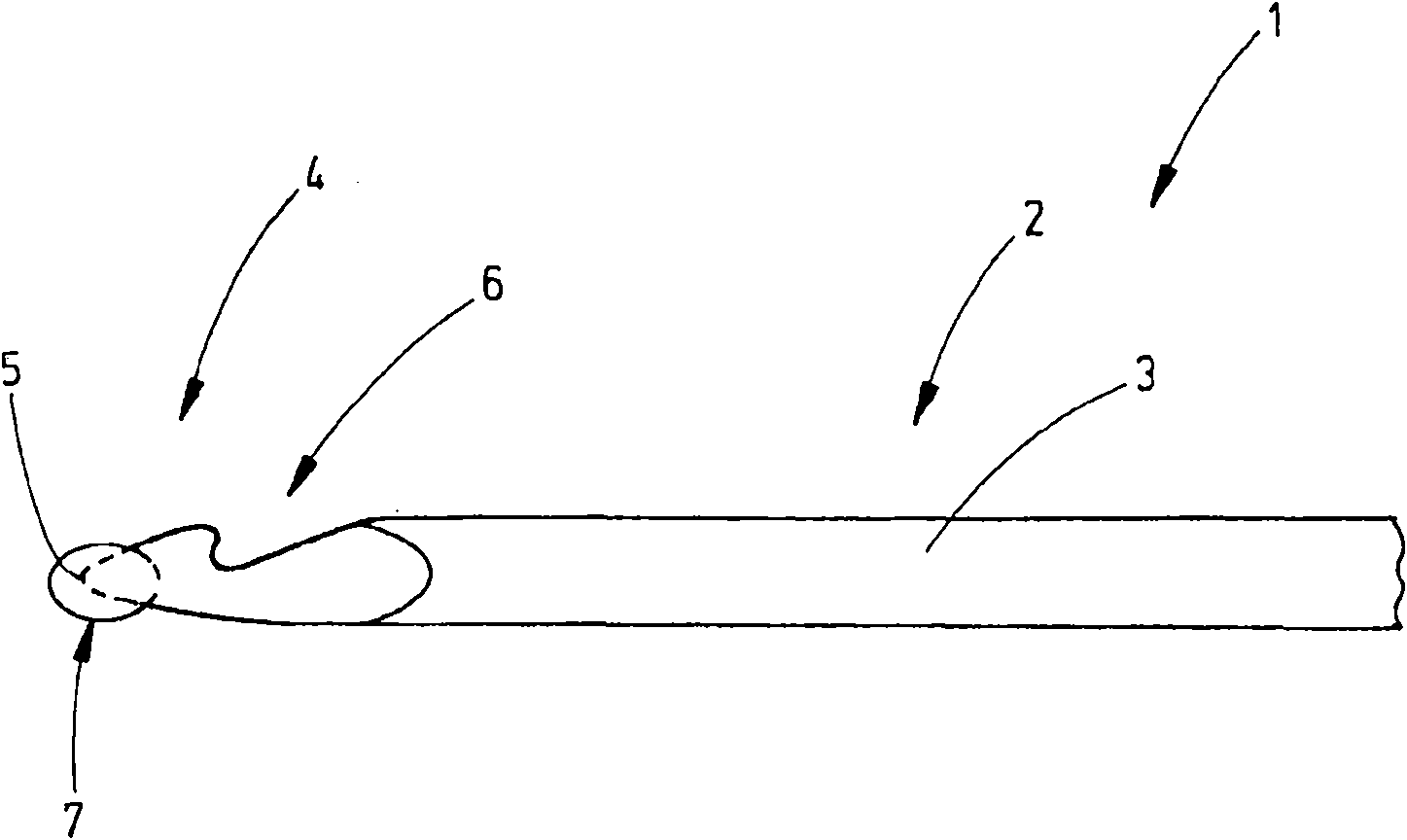

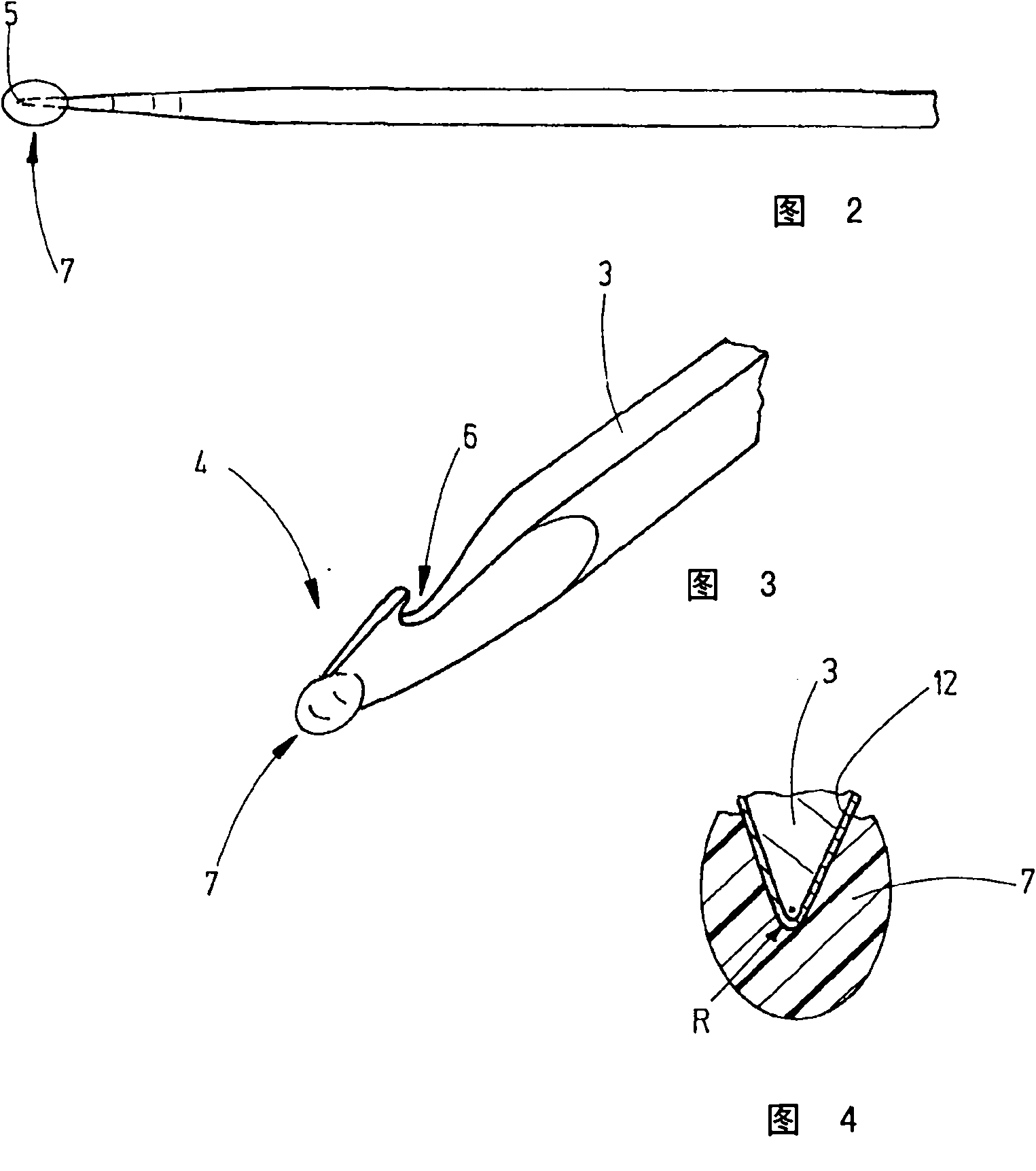

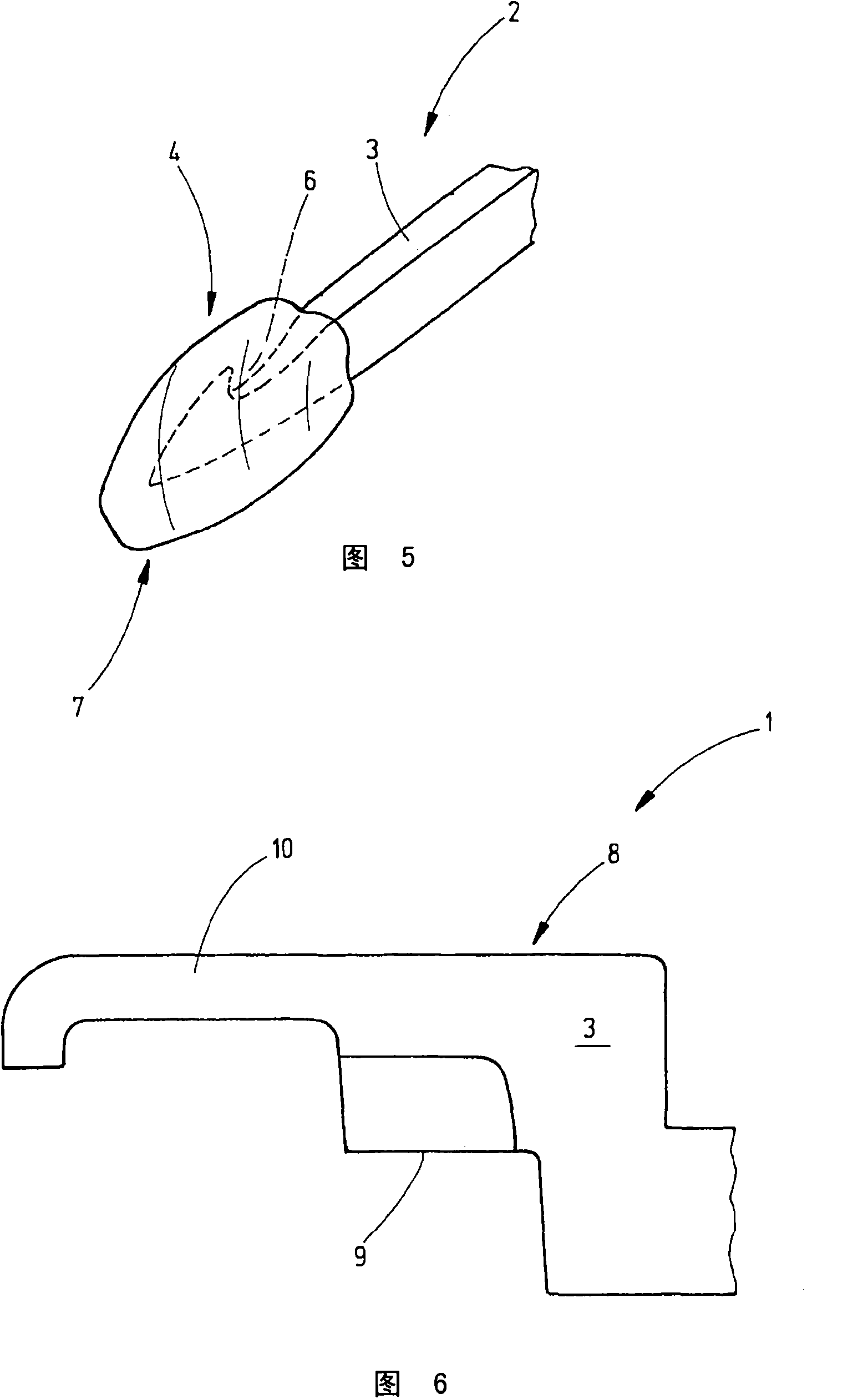

Textile tool with temporary protection

ActiveCN101988235APrevent wear attacksAvoid harmWeft knittingTufting apparatusEngineeringMechanical engineering

The present invention relates to a textile tool with temporary protection. An anti-abrasion layer (12) is provided on the textile tool (1). The anti-abrasion layer extends and covers a cutting edge (9) or a top end (5). A cap (7) or a cap (11) which is made of protection material is provided for the top end (5) or the cutting edge (9). The protection material is preferably constructed to have viscoplasticity or damping characteristic. Preferably, the cap (7,11) can be easily removed. For instance, in a first using process of the textile tool, the cap is integrally or partially separated from the textile tool (1). Preferably, the protection material is molten impregnated material, such as molten impregnated material based on thermoplasticity.

Owner:GROZ BECKERT KG

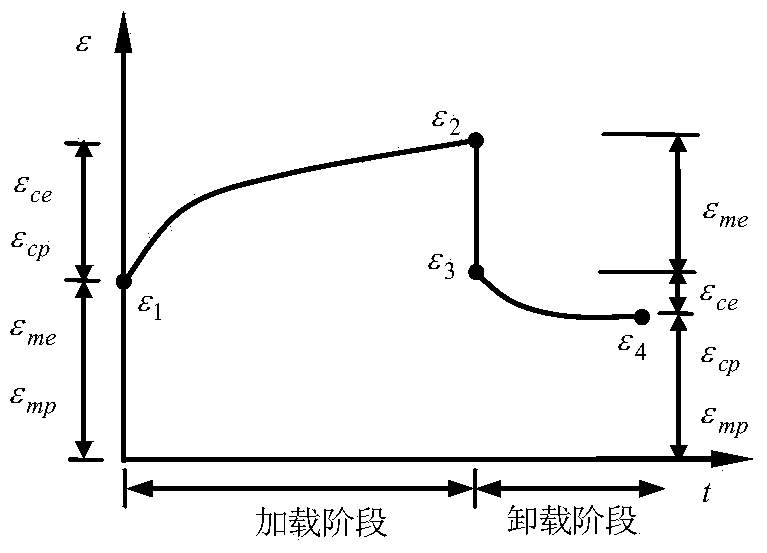

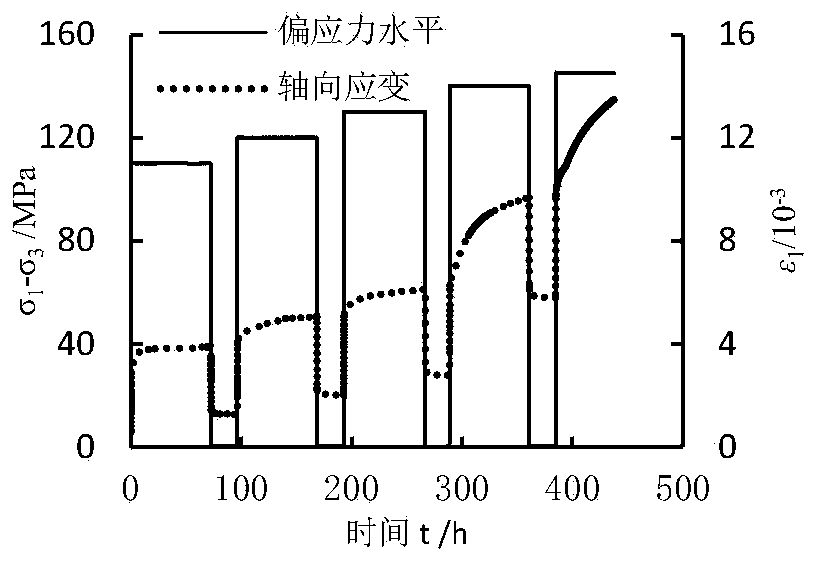

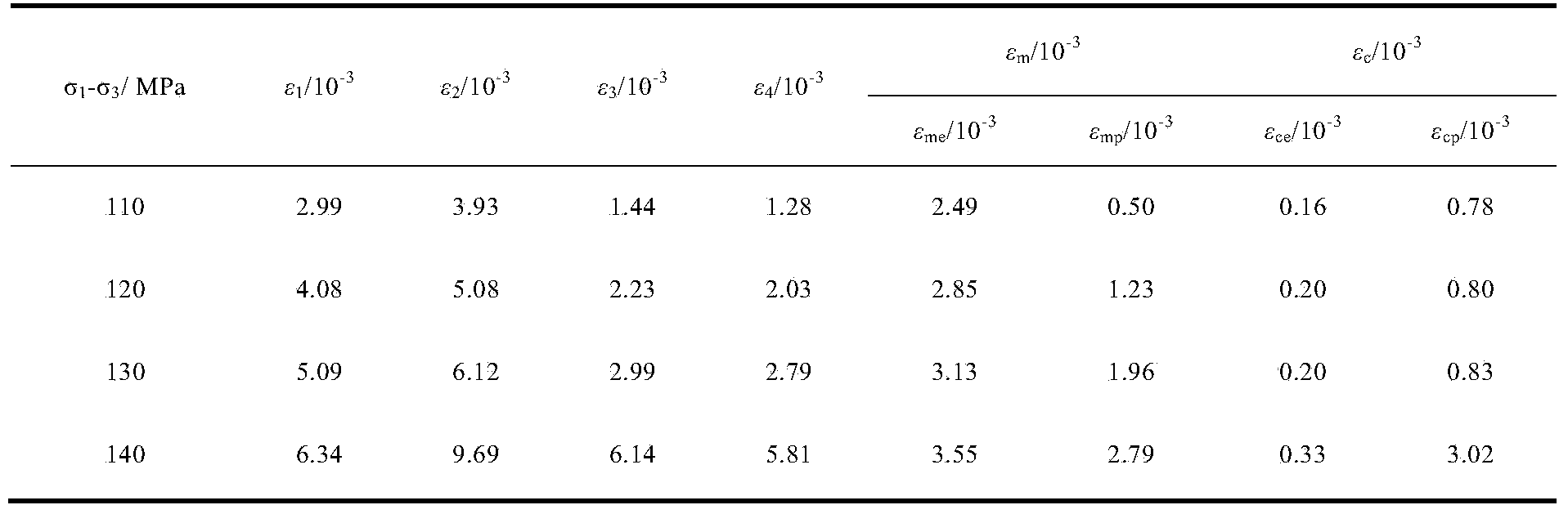

Method for separating viscosity-elasticity-plasticity characteristic parameters in triaxial rheological test on rocks

InactiveCN103822835ADeep understandingEasy to operateInvestigating material ductilityTest designElastic plastic

The invention discloses a method for separating viscosity-elasticity-plasticity characteristic parameters in a triaxial rheological test on a rock. The method comprises the following steps: making a sampled rock body into a standard cylindrical test sample, firstly applying a static water pressure state to the cylindrical test sample to load initial confining pressure of the test sample to reach a rheological test designed value sigma 3, keeping the confining pressure unchanged, performing the triaxial rheological test on the rock in a multistage increment circulated loading and unloading mode till the test sample is damaged, recording deformation characteristics, including an instant strain value epsilon 1, a loading stable strain value epsilon 2, an unloading instant strain value epsilon 3 and an unloading rheology stable value epsilon 4, of the test sample in each stage of axial deviatoric stress level, and identifying according to an elastic-plastic theory to obtain the instant elasticity strain valve epsilon me, the instant plasticity strain value epsilon mp, the viscoelasticity strain value epsilon ce and the viscoplasticity strain value epsilon cp of the test sample. By the viscosity-elasticity-plasticity parameter separation method, the viscosity-elasticity-plasticity rheological characteristics of the rock under different deviatoric stress levels can be identified, and corresponding technical measures are provided for reinforcement of surrounding rock bodies under high ground stress conditions in deep underground engineering.

Owner:CHINA UNIV OF MINING & TECH

Low-grade machine-made sand hectometer-height pumping concrete

ActiveCN101182169AReduce constructionLow workabilitySolid waste managementCeramicwareTerrainLower grade

The invention relates to the building material technical field, in particular to a low grade machine-made sand one hundred elevation pumping concrete, which solves problems that the first grade pumping height of an existing low grade pumping concrete is low and the cost of most adopted river sands with high quality is high. The concrete per cube is made from the raw materials with the following weight ratio of 300-310kg of cement, 90-100kg of fly ash, 750-780kg of machine-made sand, 1000-1100kg of gravels, 170-180kg of water and 3-4kg of compound admixture. The invention adopts the raw materials of the machine-made sand, low content cement, etc. to prepare low grade concrete through a series of optimization tests, which has the advantages of good fluidity, no segregation, small frictional resistance, good viscoplasticity, good pumpability and good construction workability. The first grade vertical pumping height can reach to 100m above. The invention is especially applied to the constructions in mountain areas with precipitous terrain. And the machine-made sand is adopted to replace river sand, which leads to the lower cost.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Glass fiber reinforced gypsum capable of being used for 3D printing

InactiveCN105731968ASolve the problem of resource utilizationProduction is widely applicableAdditive manufacturing apparatusGlass fiberSlag

The invention belongs to the technical field of building materials, and particularly relates to glass fiber reinforced gypsum capable of being used for 3D printing. The glass fiber reinforced gypsum is prepared from phosphorus gypsum, slag powder, cement, glass fibers, a water-reducing agent and an early strength agent. The glass fiber reinforced gypsum with high viscoplasticity, low shrinkage rate, small hydration heat and good working performance can be obtained and directly used for 3D printing to produce a gypsum building material product. By using the glass fiber reinforced gypsum provided by the invention, the problem of resource utilization of the phosphorus gypsum can be effectively solved, and the purposes of high consumption amount of the phosphorus gypsum, low energy consumption and efficient resource utilization of the phosphorus gypsum are realized.

Owner:TONGJI UNIV

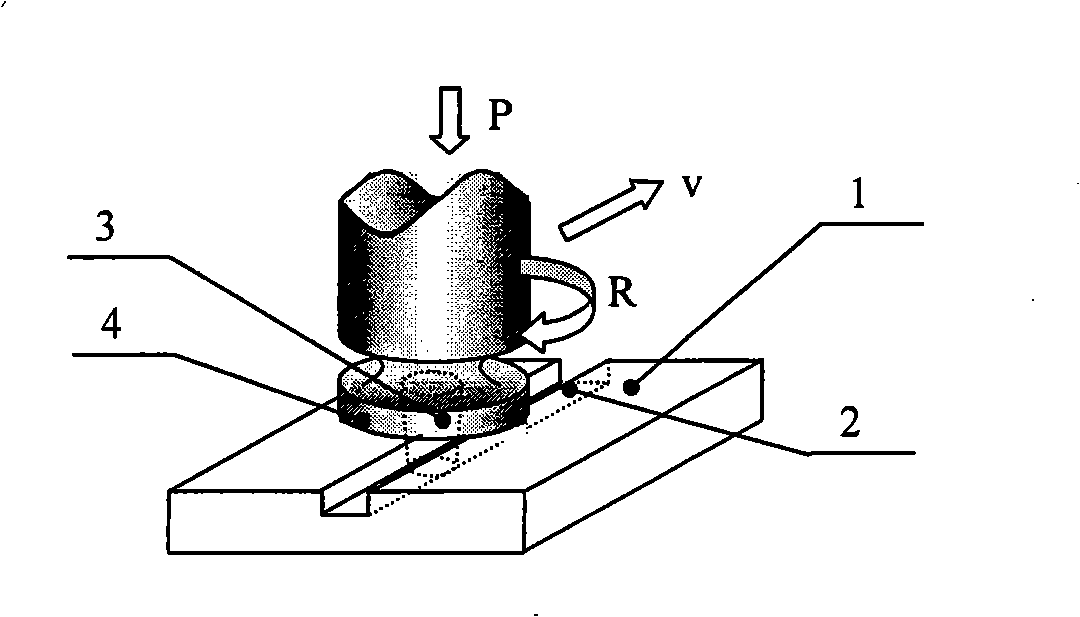

Method for preparing titanium alloy/hydroxylapatite gradient composite coating

InactiveCN101327337AFacilitates atomic diffusionHigh tensile bond strengthCoatingsProsthesisMachine partsHydroxylapatite

The invention discloses a gradient compound coating of a titanium alloy / hydroxyapatite and a preparation method thereof. The surface of the titanium alloy to be made is polished, cleaned and baked; 2 to 10 perforated flutes of 2mm multiplied by 2mm to 4 mm multiplied by 4mm are processed on the surface of the titanium alloy every 12mm; all the flutes are parallel to each other and are filled with powder; the titanium alloy filled with powder is placed on a tool with a heating device and is fixed and clamped; the titanium alloy is stirred by friction under the conditions that the room temperature rises to 350 DEG C to 500 DEG C, the rotation speed of a stirrer head ranges from 450 r / min to 850 r / min; the horizontal speed ranges from 28 mm / min to 90 mm / min, with an angle of inclination of 2.5 DEG. The rear area of a stirring area is provided with a cooling device, with the machining parts protected by argon gas. By a stirring method, the HA powder is stirred on the surface of the titanium alloy, thus forming viscoplasticity, speeding up the atom proliferation between the titanium alloy and the HA powder, and generating a chemical bond. The tensile-bonding strength is raised from 24.8MPa in the prior art to ranging from 65 MPa to 103MPa.

Owner:NANTONG MING YU NEW MATERIAL TECH CO LTD +1

Method for manufacturing iron-based alloy part

InactiveCN104972129AImprove performanceHigh dimensional accuracyTurbinesOther manufacturing equipments/toolsMachiningPowder injection

The invention relates to a method for manufacturing an iron-based alloy part and belongs to the technical field of iron-based alloy forming. According to the method for manufacturing the iron-based alloy part, a powder injection forming technology is adopted; firstly, metal and polymer binder powder are mixed into even injection forming feed with viscoplasticity; then, injection is conducted on an injection machine so that an injection blank can be formed; afterwards, the iron-based alloy part is manufactured through the steps of degreasing, sintering and the like. The finished iron-based alloy part product which is good in performance and high in size precision is obtained after heat treatment is conducted on the sintered product. The method for manufacturing the iron-based alloy part has the advantages that the product is formed with a net dimension, subsequent machining is not needed, the production cost is low, and iron-based alloy part products which are complex in shape and good in comprehensive performance can be produced in a batched mode; and the method is suitable for industrial production.

Owner:YUXI DAHONGSHAN MINING

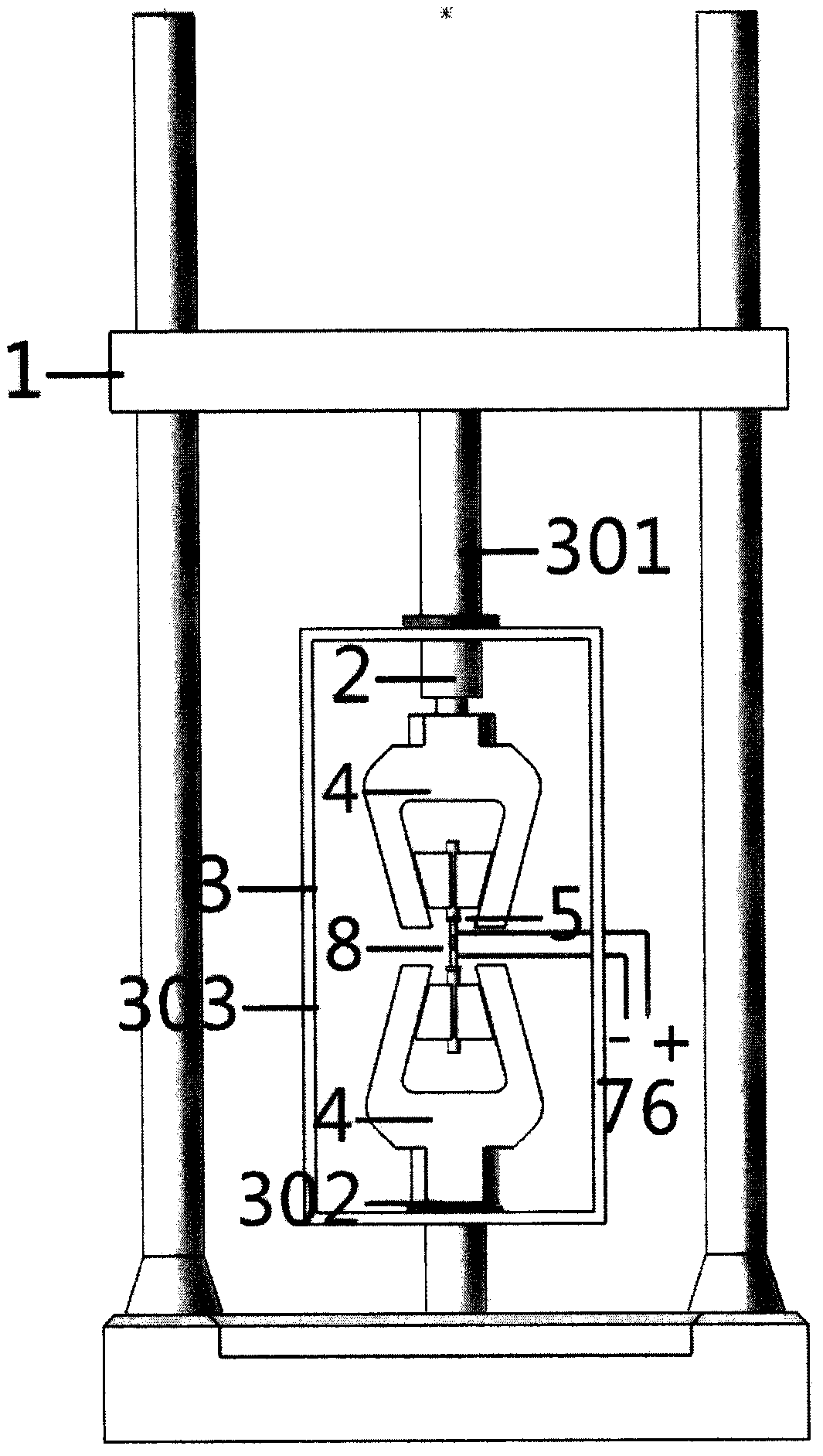

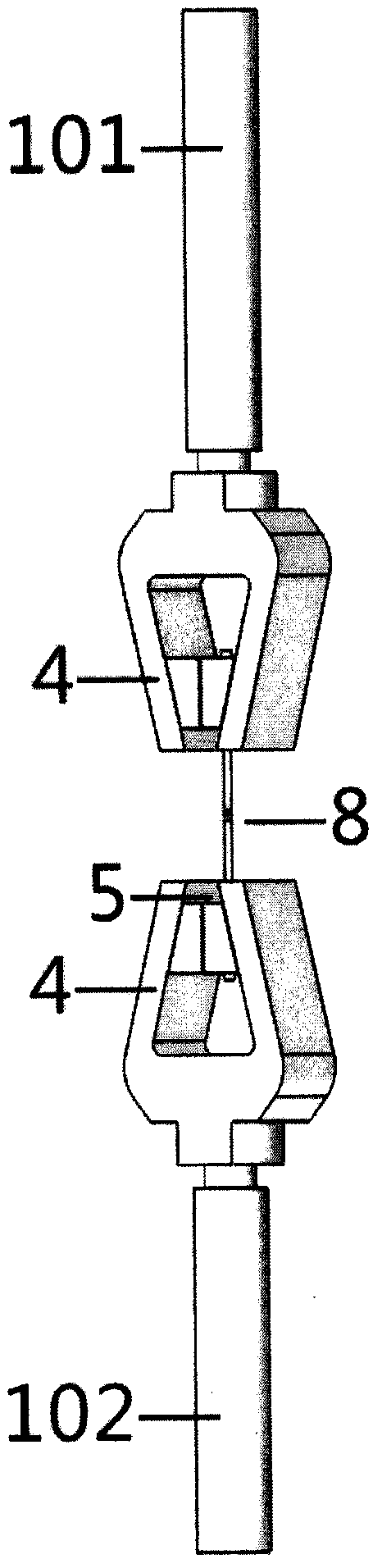

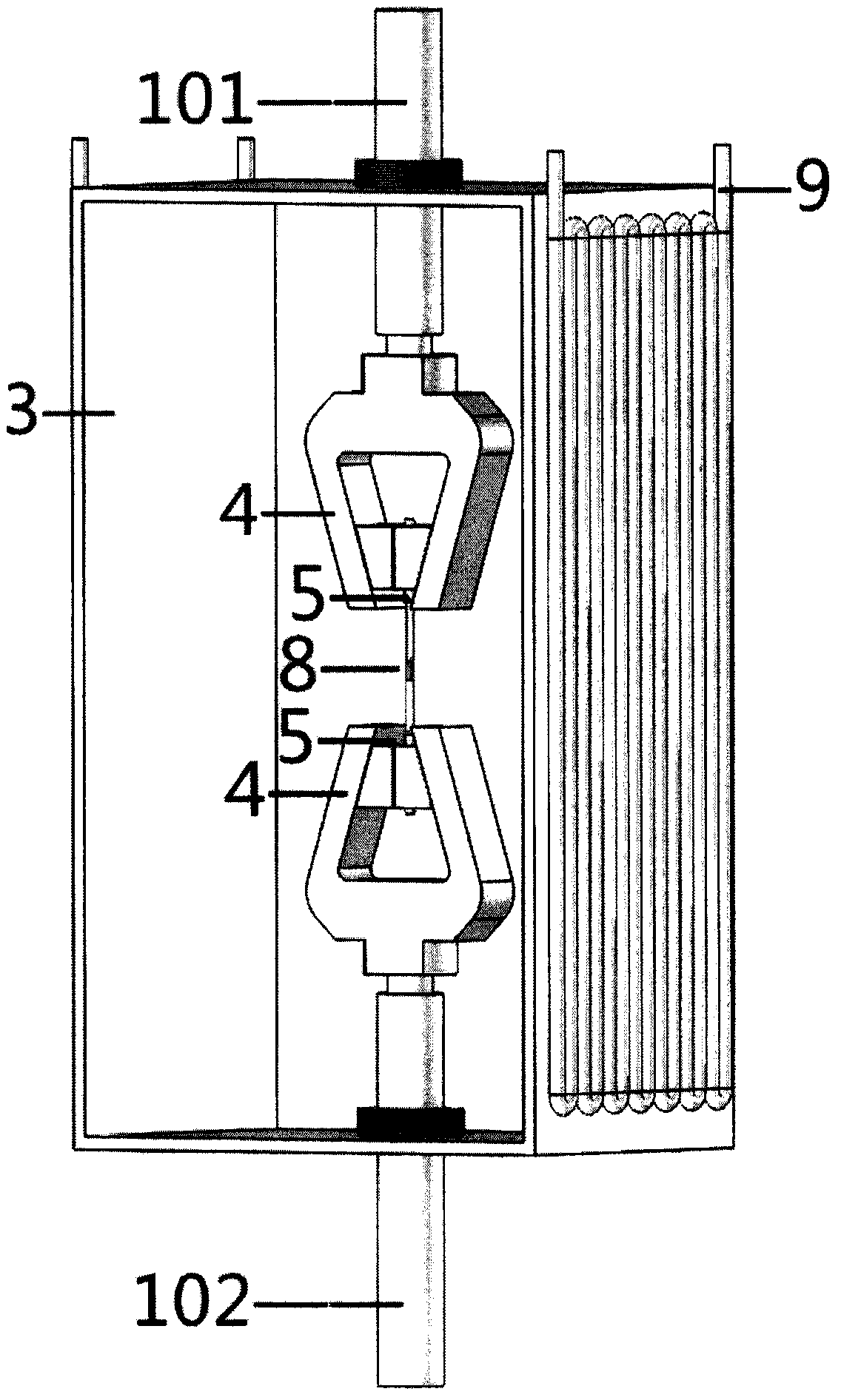

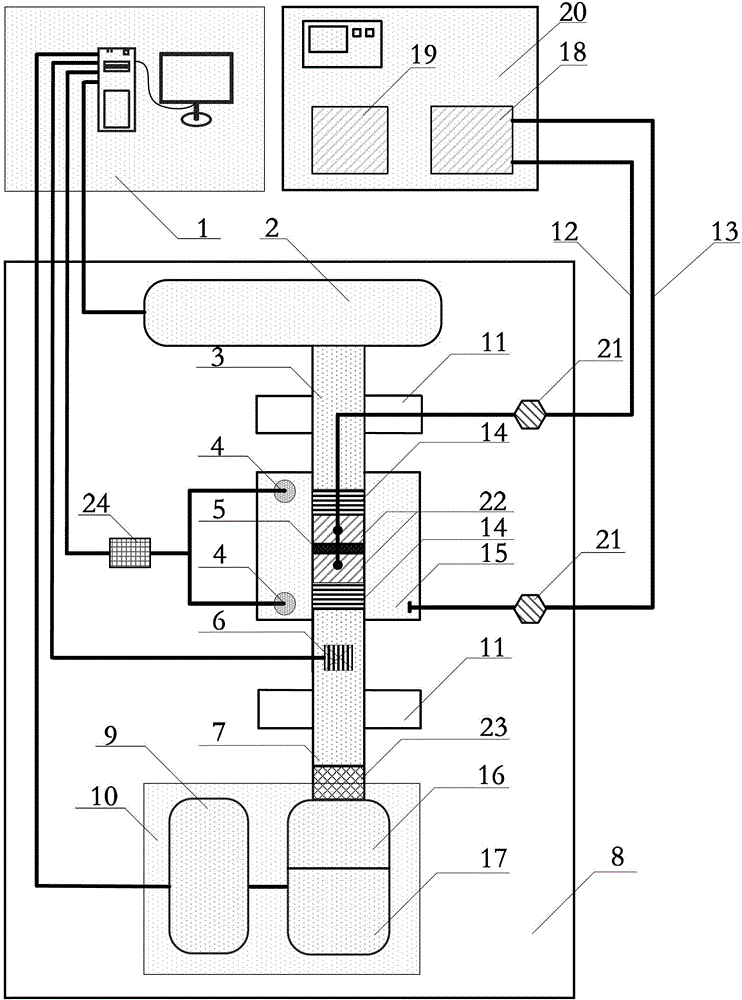

System for testing viscoplastic material creep by utilizing heat-electricity-force coupling field

PendingCN107655764ARealize creep performance observationEasy to explore the damage creep mechanismMaterial strength using tensile/compressive forcesPower couplingElectricity

The invention provides a system for testing viscoplastic material creep by utilizing a heat-electricity-force coupling field. The system comprises a drawing machine, an upper dowel bar piece and a lower dowel bar piece, wherein a high-low temperature environment test chamber is arranged between the upper dowel bar piece and the lower dowel bar piece; an insulated clamping end is arranged at each of the tail ends of the upper dowel bar piece and the lower dowel bar piece in a chamber body, and the insulated clamping ends are arranged oppositely and used for clamping a test piece; a conducting ring is connected with a current source by a current lead; a force sensor is arranged near the insulated clamping end on the upper dowel bar piece. Compared with relative technologies, a heat field, anelectric field and a force field are simultaneously exerted on the test piece by the creep test system of the viscoplastic material by utilizing the heat-electricity-force coupling field, so that thecreep property of an electronic packaging material in a real extreme working condition can be observed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

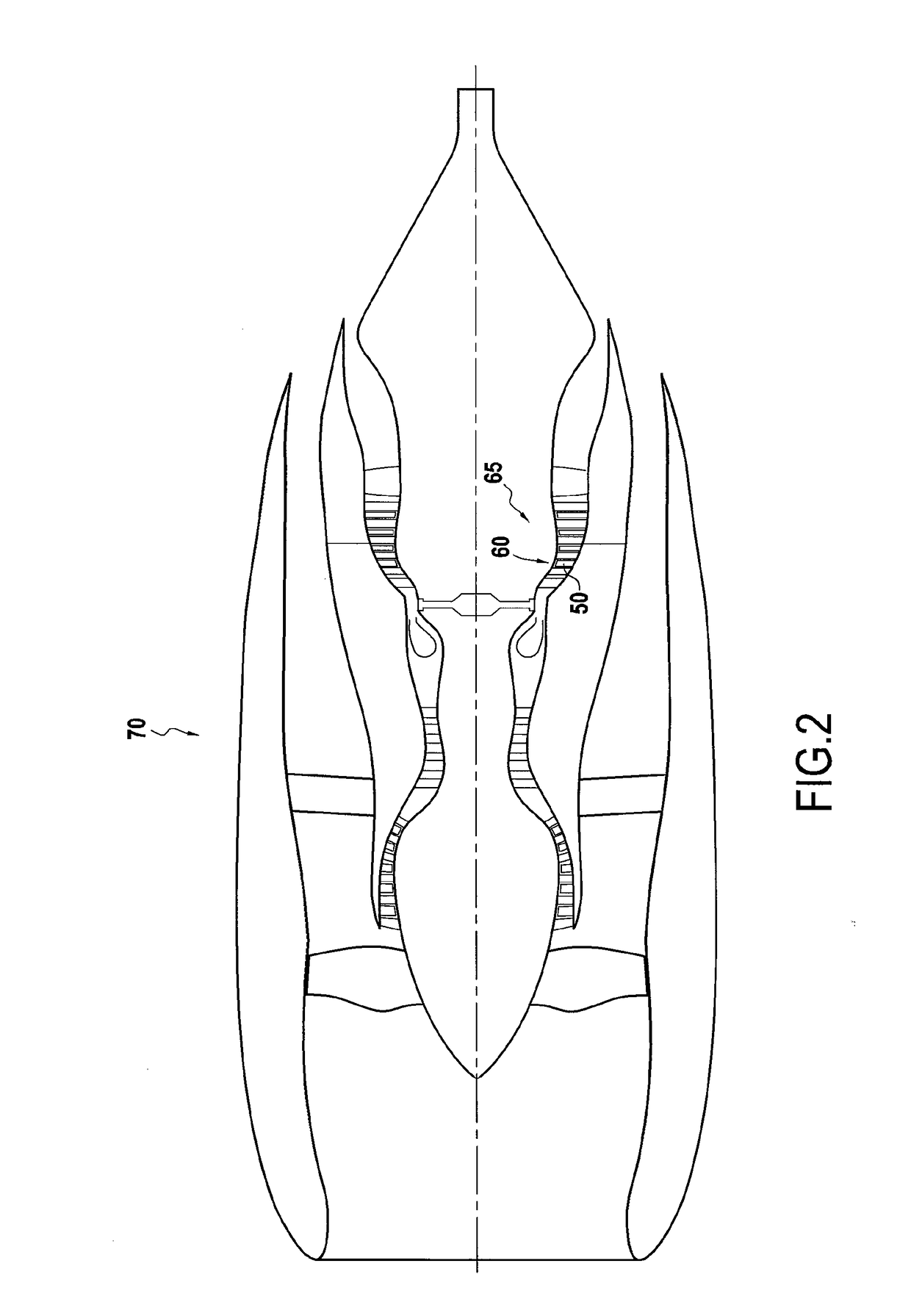

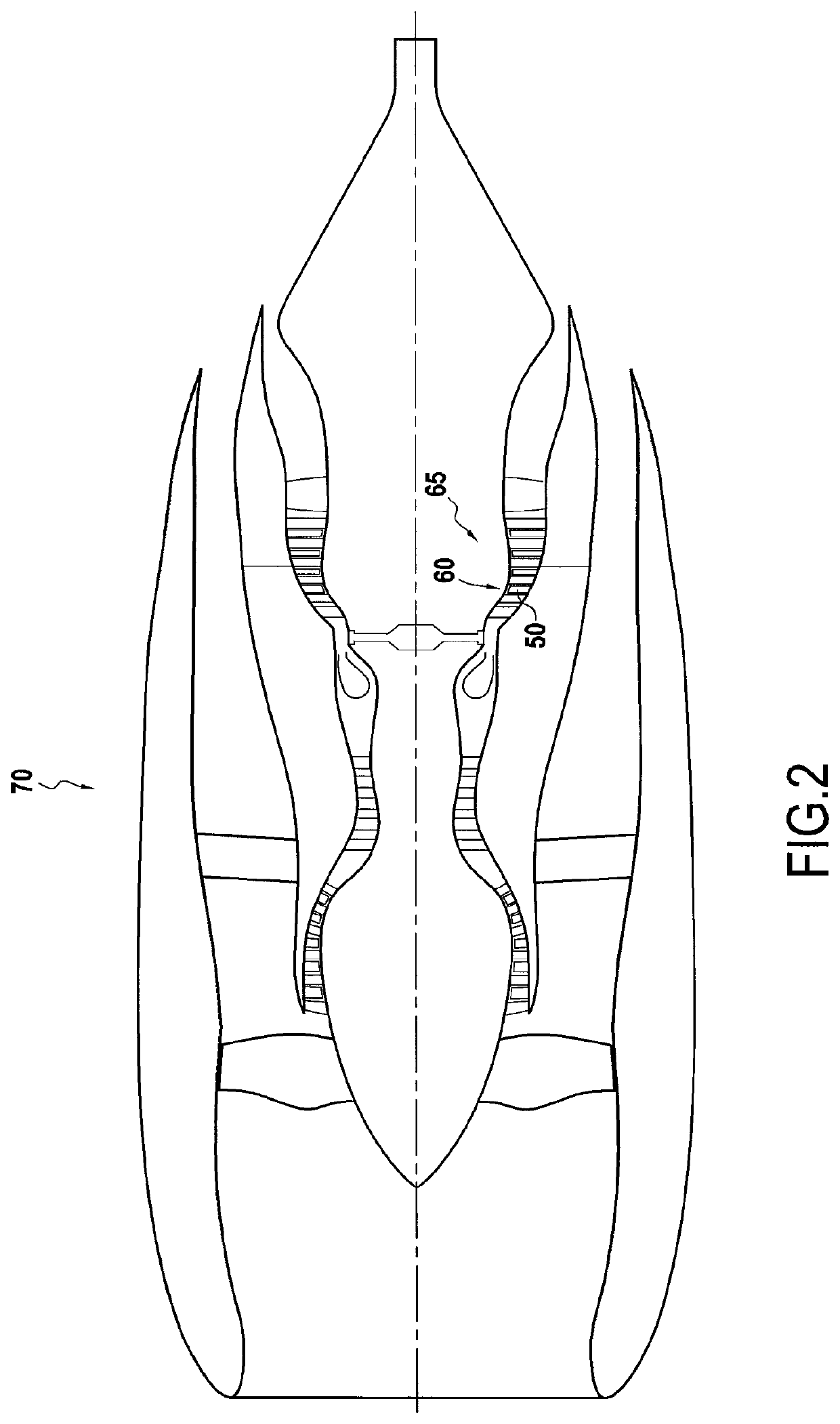

Friction welding

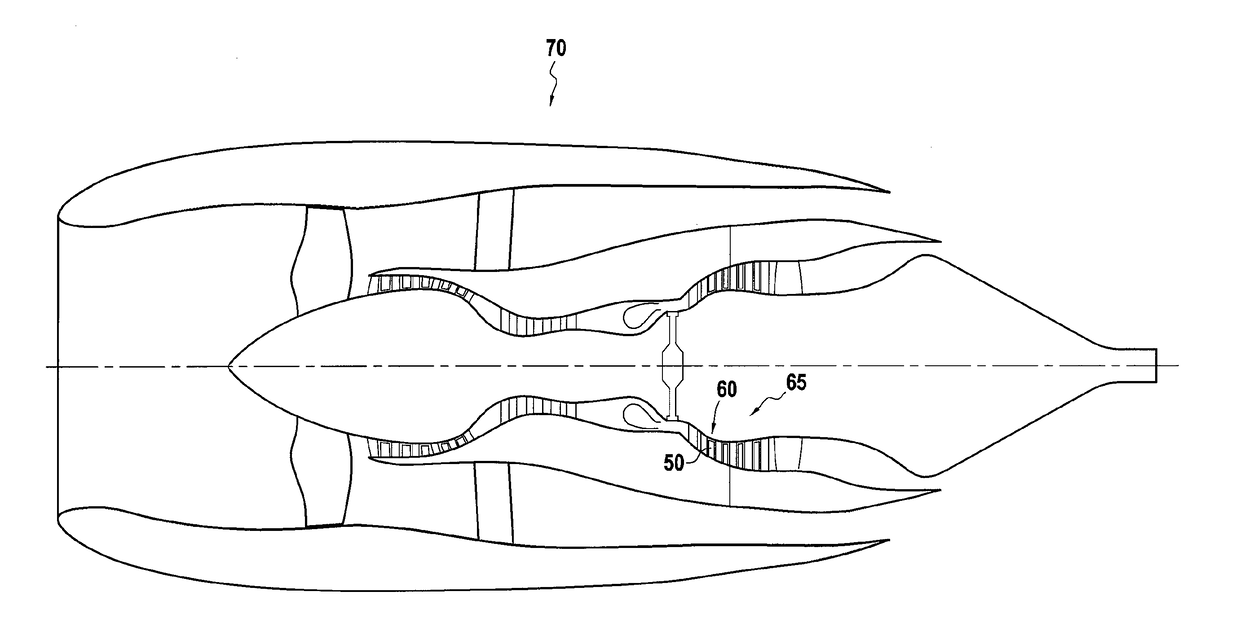

InactiveUS20170246707A1High temperature capabilityImprove performanceTurbinesBlade accessoriesEngineeringSuperalloy

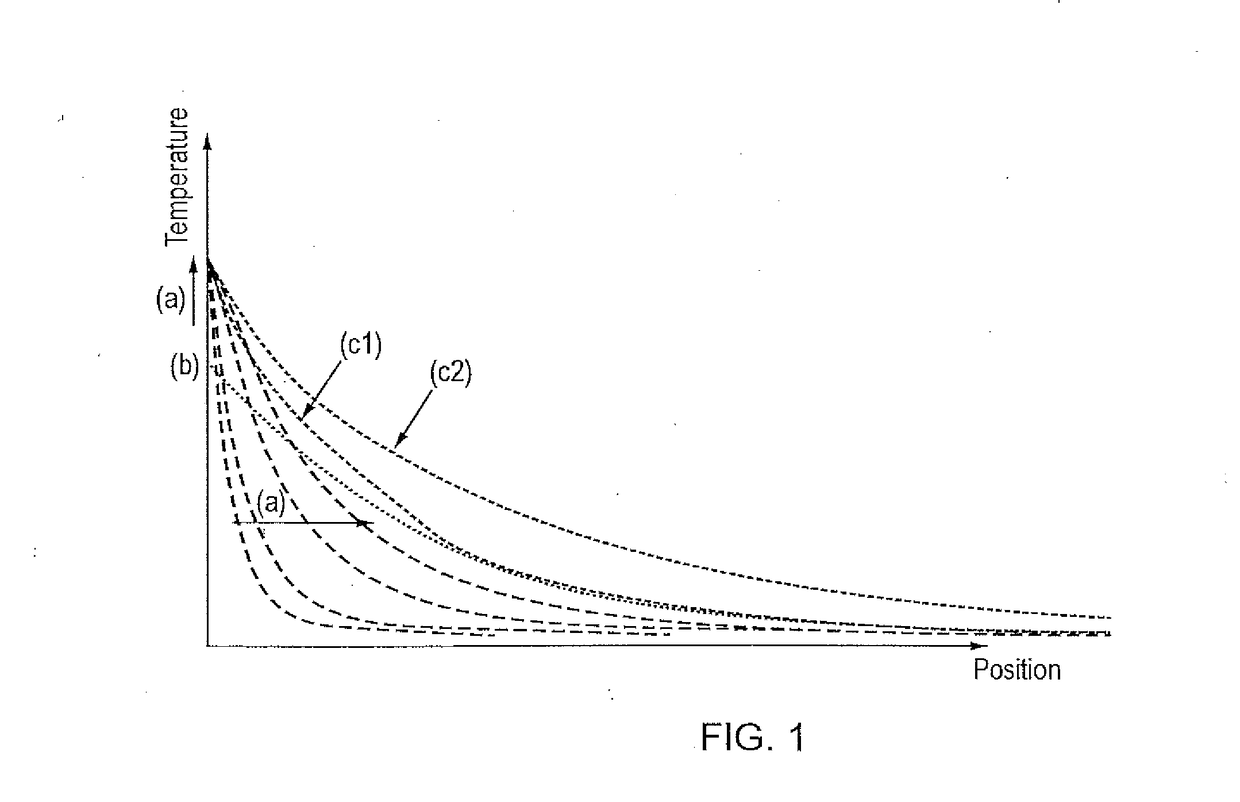

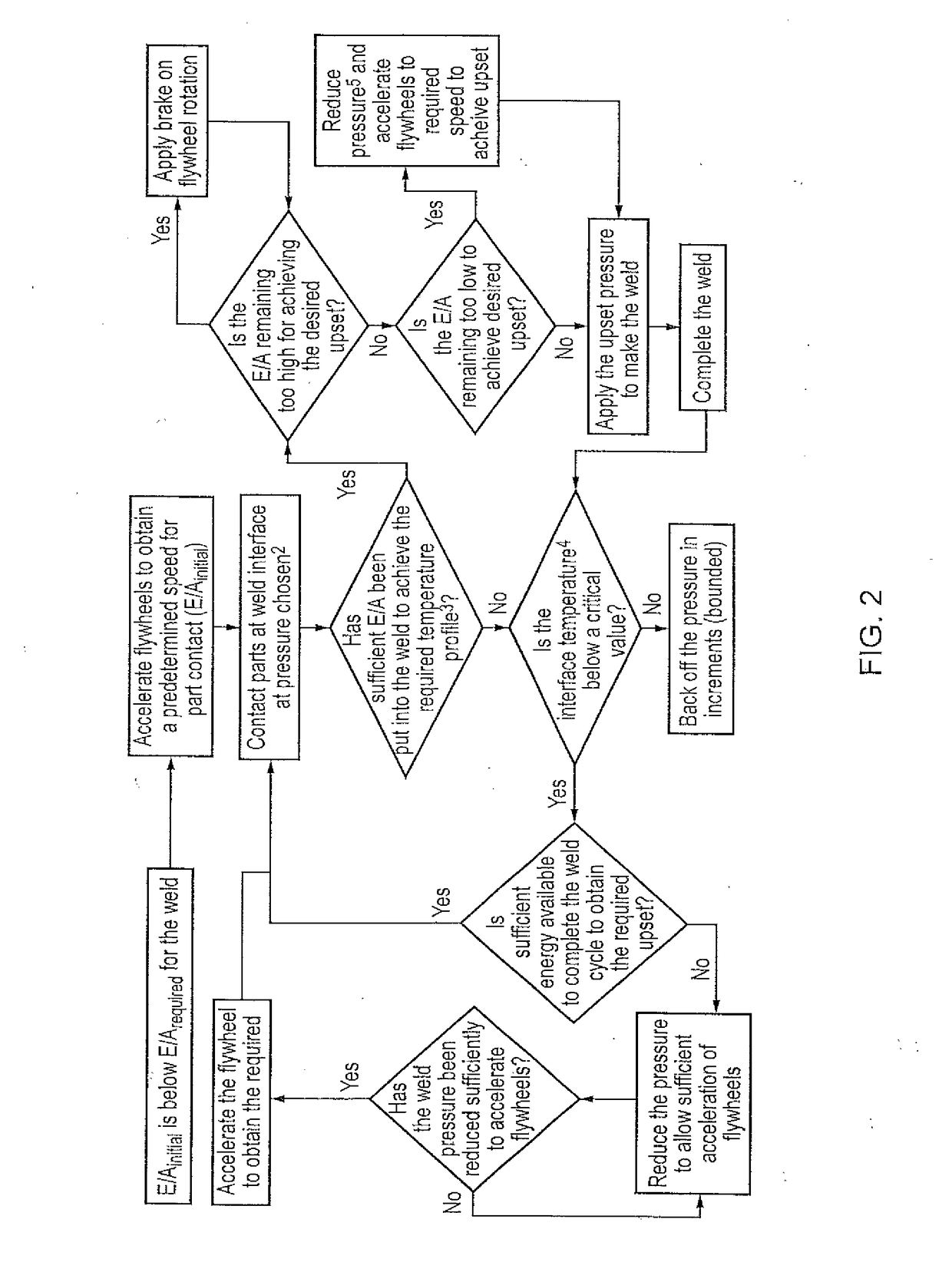

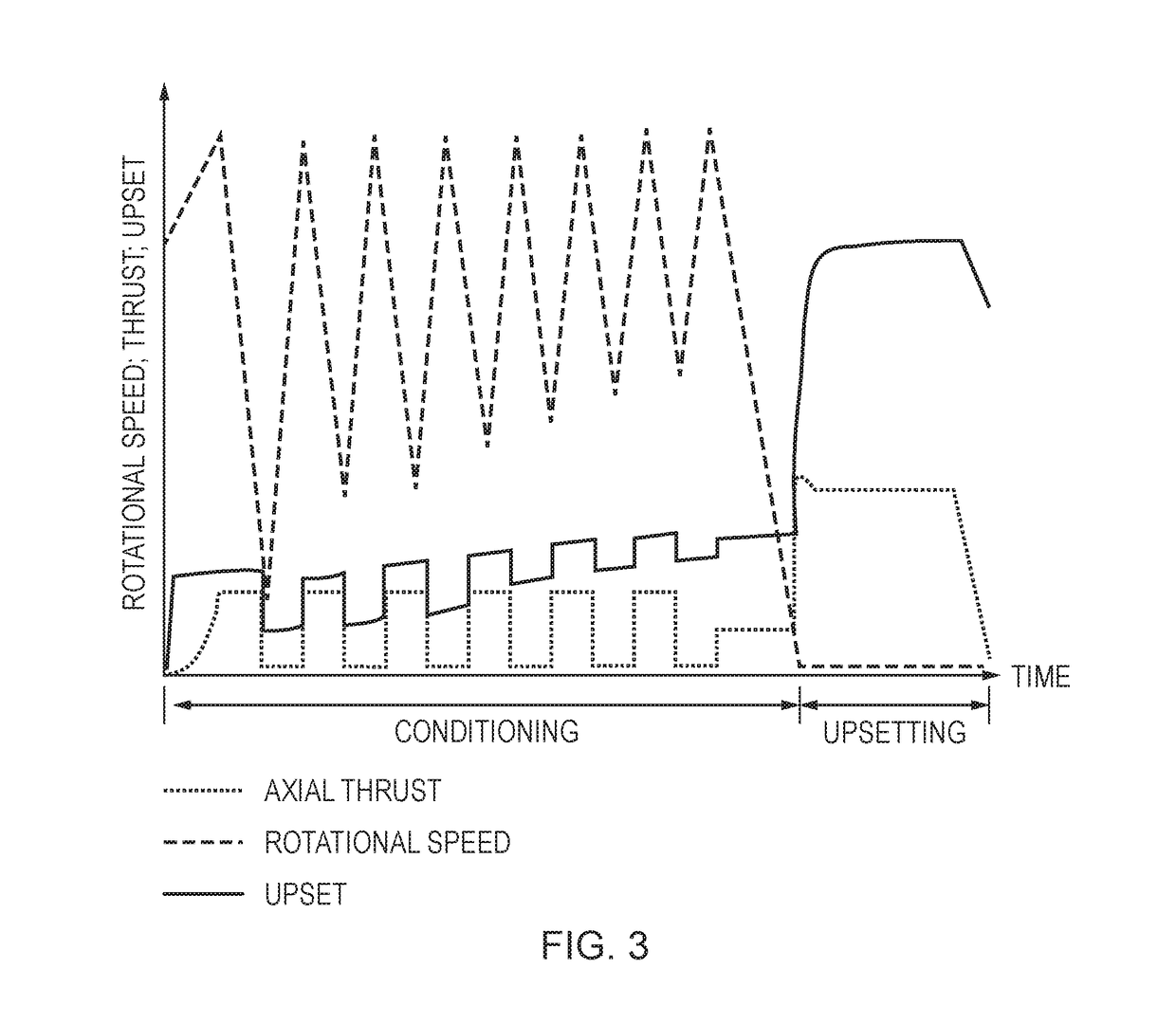

A method for friction welding of inter alia coarse grain superalloy components, involving conditioning a shear zone of components to be welded by; a) pre-determining temperature profile for which the material of the shear zone of the components approaches viscoplasticity but does not undergo undesirable phase transformations, b) introducing friction at one or both surfaces of the components to be welded to provide a pre-defined quantum of energy sufficient to generate a peak temperature of the temperature profile at that surface whilst simultaneously applying pressure to the surfaces which is below a pressure which will cause upset at the surface, c) withdrawing the friction and / or pressure allowing the heat to disperse by conduction through the shear zone; d) after the temperature at the surface falls below peak temperature, repeating steps b) and c); and repeating step d) as necessary until the pre-determined temperature gradient is achieved throughout the shear zone.

Owner:ROLLS ROYCE PLC

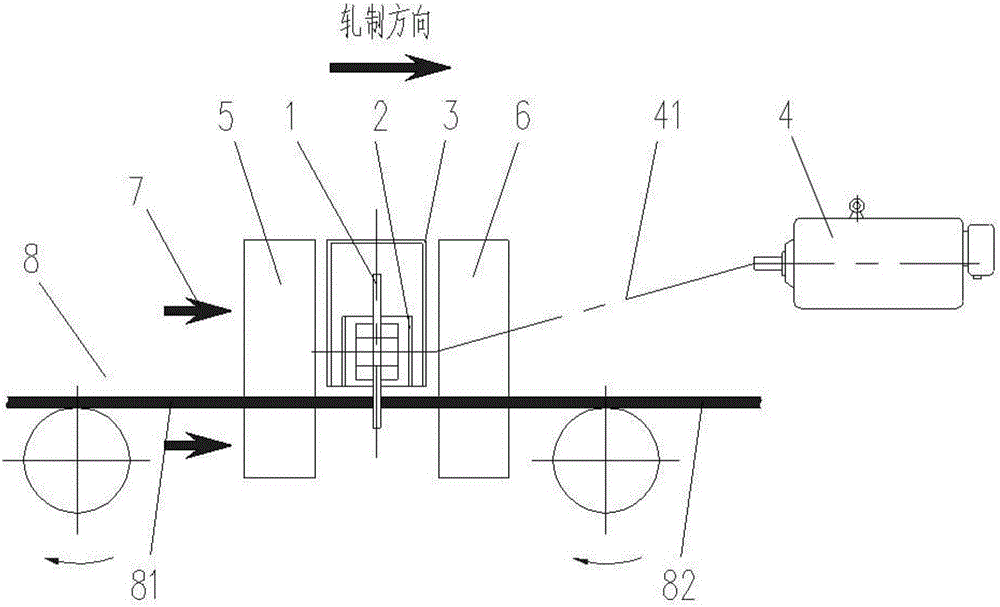

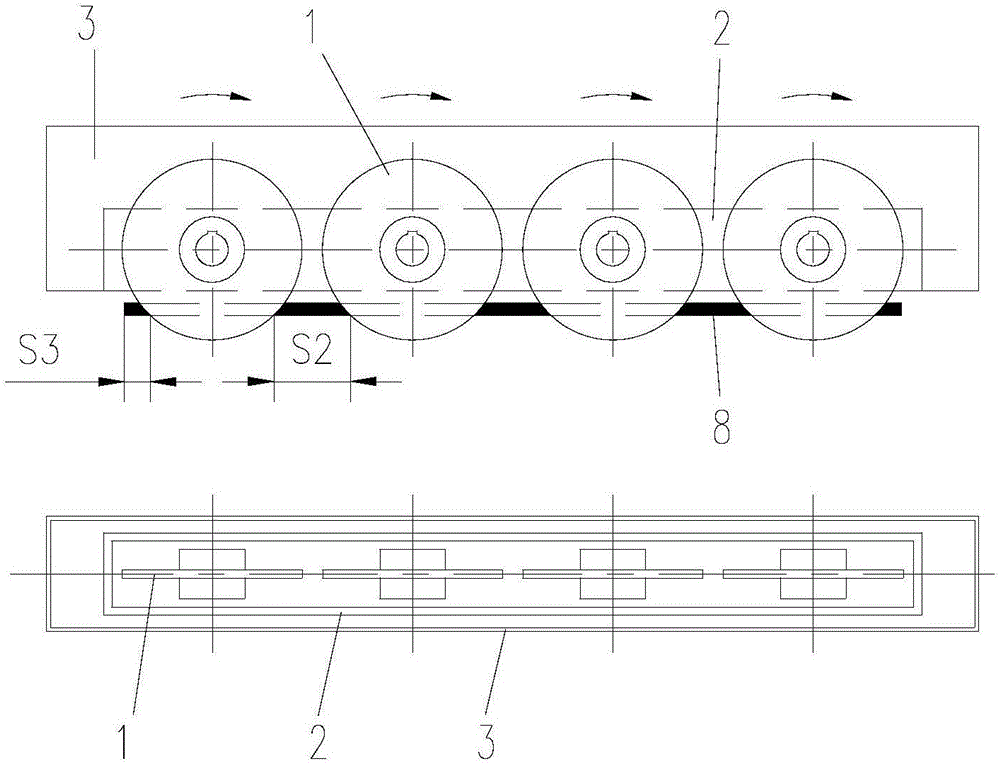

Intermediate slab connecting equipment and system

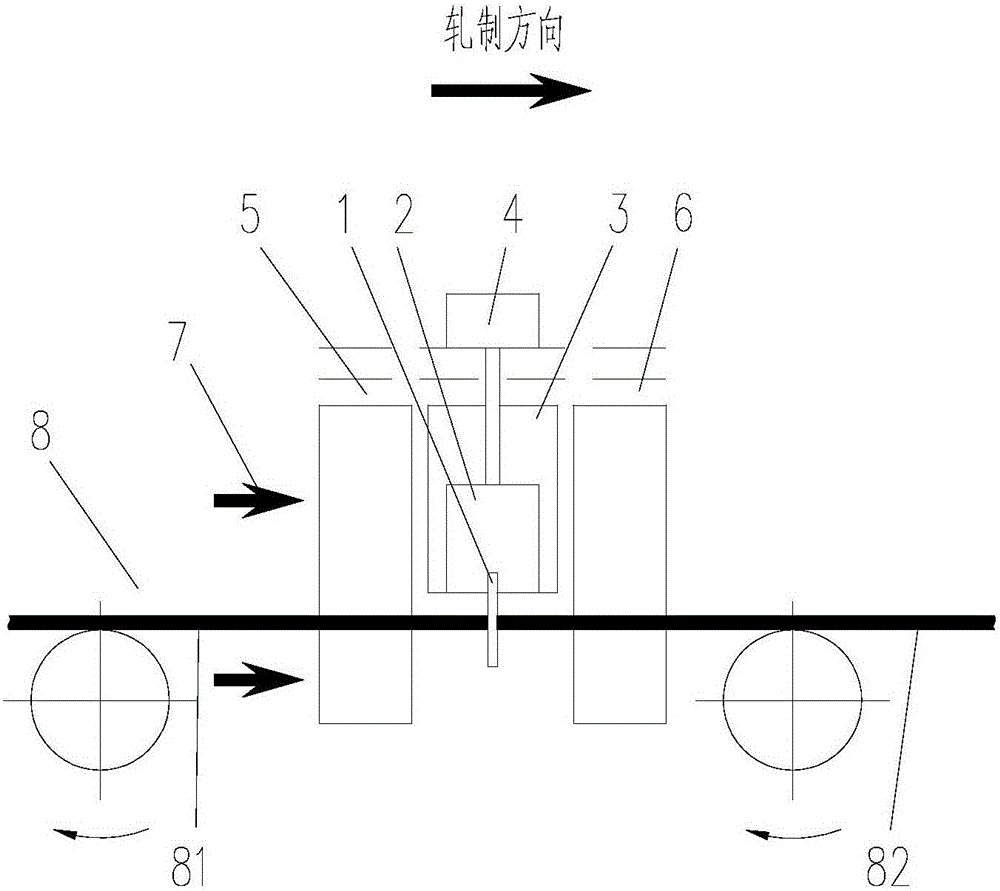

ActiveCN106694553AFast connectionImprove connection strengthMetal rolling arrangementsNon-electric welding apparatusUltimate tensile strengthMechanical engineering

The invention provides intermediate slab connecting equipment. The intermediate slab connecting equipment comprises an outlet clamping device for clamping a front intermediate slab, an inlet clamping device for clamping a back intermediate slab, a friction blade for rubbing the connecting end surfaces of the front intermediate slab and the back intermediate slab, and an upsetting device for applying upsetting force; the friction blade is positioned between the inlet clamping device and the outlet clamping device; and the friction blade is connected with a friction blade vibration device. The friction blade extends between the front intermediate slab and the back intermediate slab for rubbing the end surfaces of the two, so that the end surfaces of the intermediate slabs and near areas are quickly heated to reach a viscoplasticity state; the upsetting device applies the upsetting force to the back intermediate slab; after the friction blade is shifted away, the front intermediate slab is connected with the back intermediate slab. The intermediate slab connecting equipment is simple in structure, high in connecting strength, fast in connecting speed, low in energy consumption and suitable for connecting slabs with different materials.

Owner:CISDI ENG CO LTD

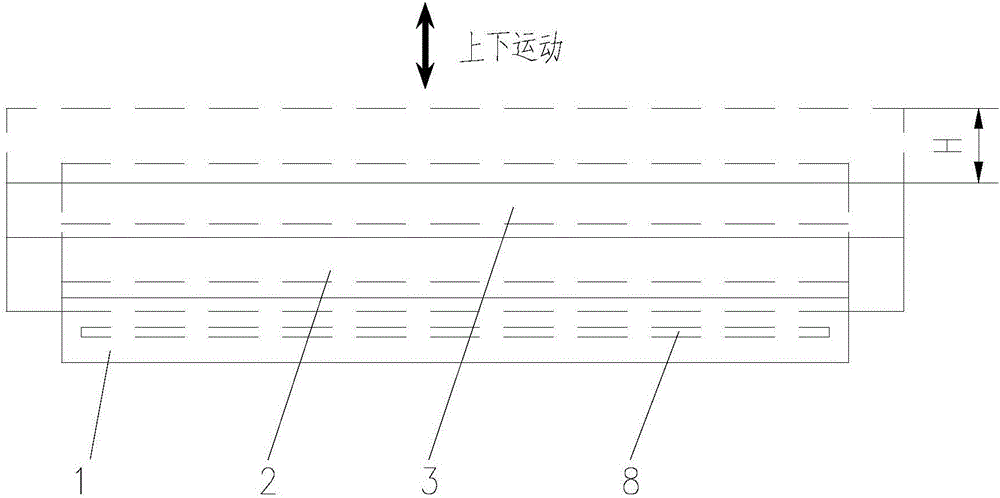

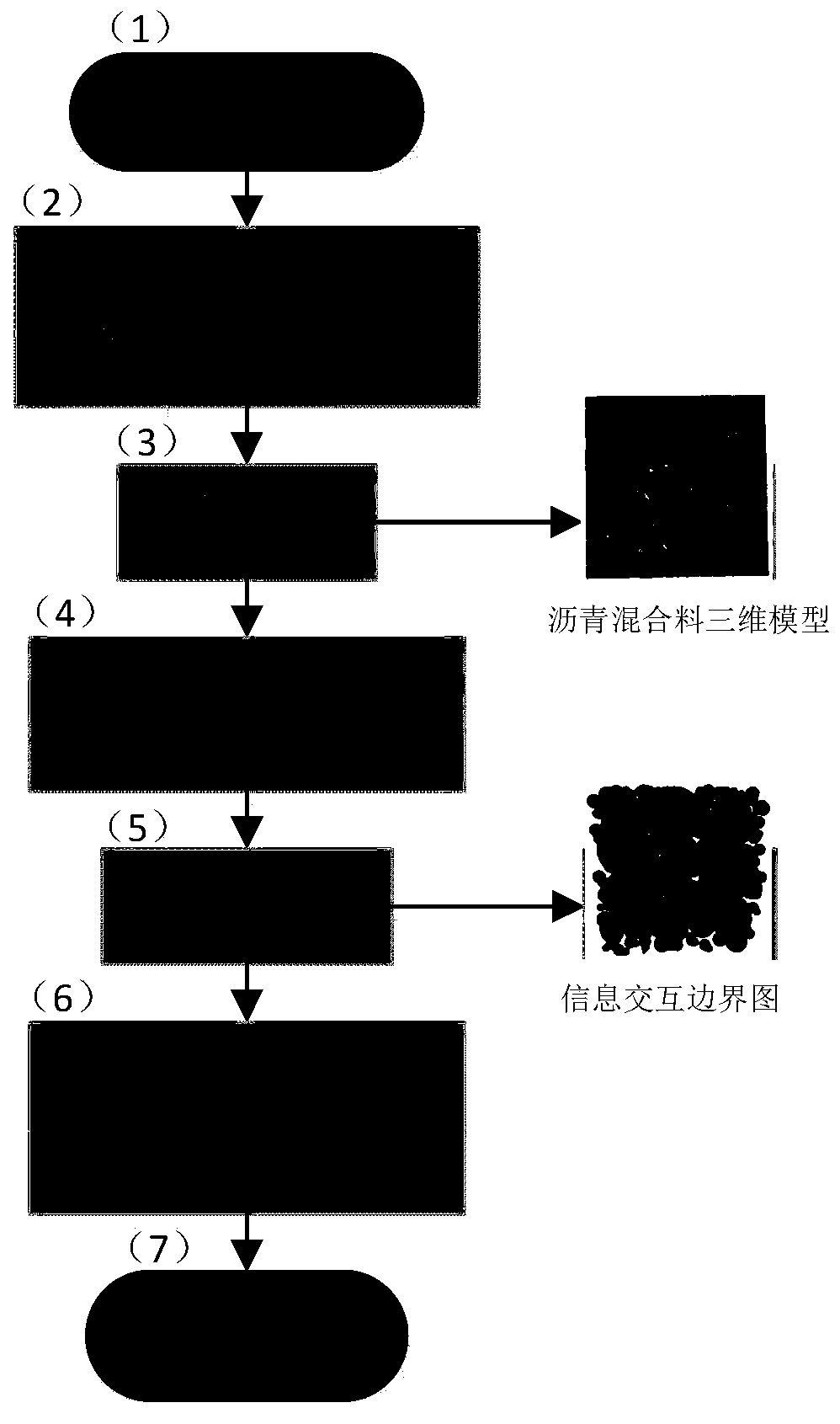

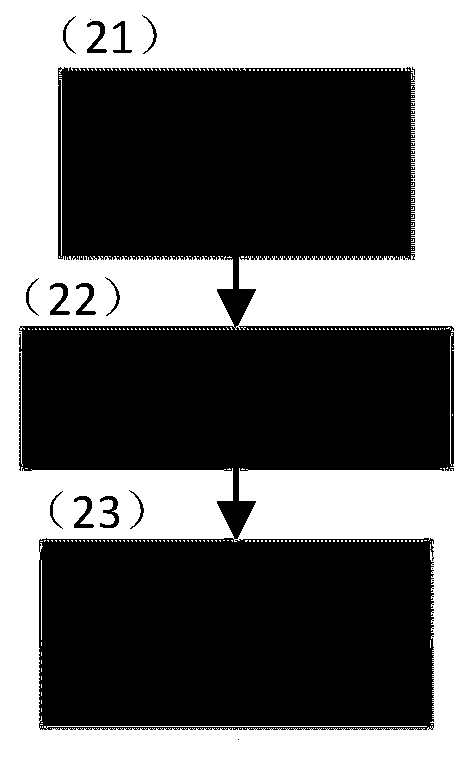

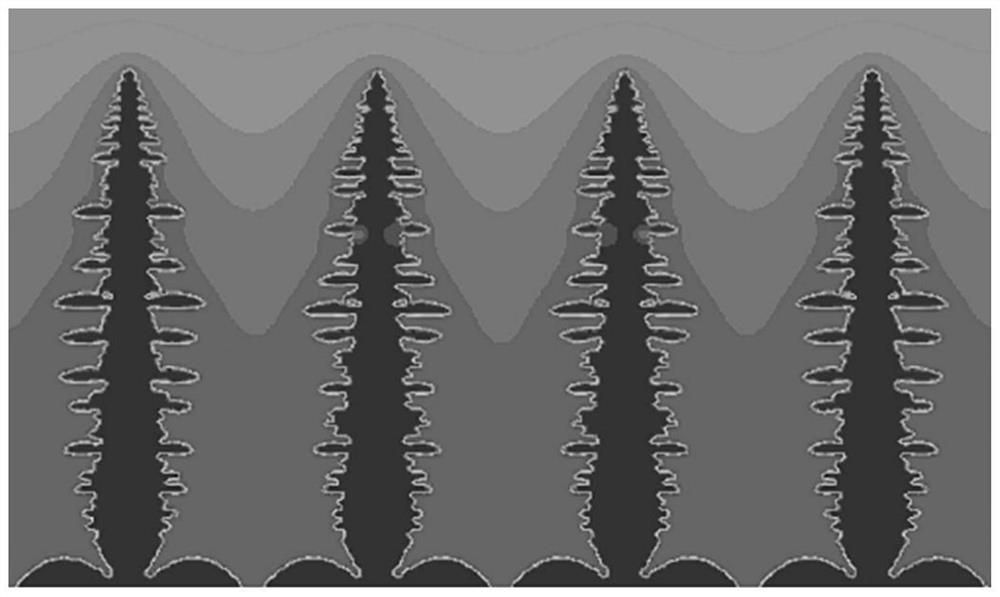

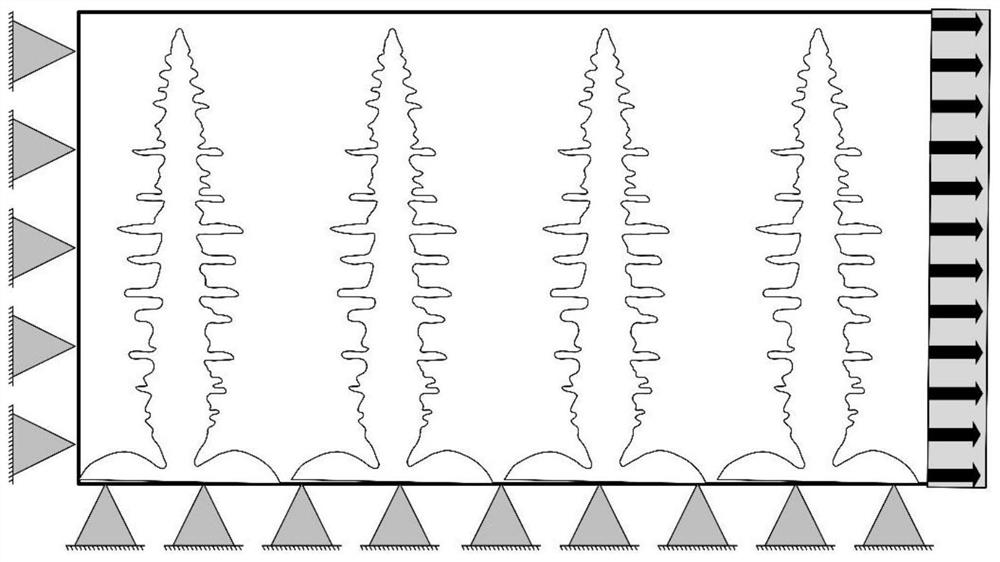

Discrete element and finite difference method coupled bituminous mixture simulation modeling method

PendingCN110750819AOvercome limitationsGood precisionGeometric CADDetails involving 3D image dataUltimate tensile strengthMechanical engineering

The invention discloses a discrete element and finite difference method coupled bituminous mixture simulation modeling method, which comprises the following steps of: realizing bituminous cement continuous medium simulation in a bituminous mixture by adopting a finite difference method through bituminous mixture aggregate discrete element treatment; by considering the influence of the coupling effect of discrete elements and a finite difference method on the mechanical properties such as the strength and modulus of the bituminousasphalt mixture, realizing the simulation of the processes such as deformation, shrinkage and cracking of the multi-phase material of the asphalt mixture under the action of different loads is realized. According to the invention, the real shapes and sizes of the aggregate and the cementing material in the asphalt mixture can be accurately restored; according to the method, the distribution characteristics of the porous structure and the void structure are represented, the limitations of discrete elements and finite difference methods on respective analysis methods of bituminous mixture numerical simulation are overcome, and the method is suitable for analyzing the problem of large viscoplasticity deformation of the bituminous mixture multiphase material under different conditions.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

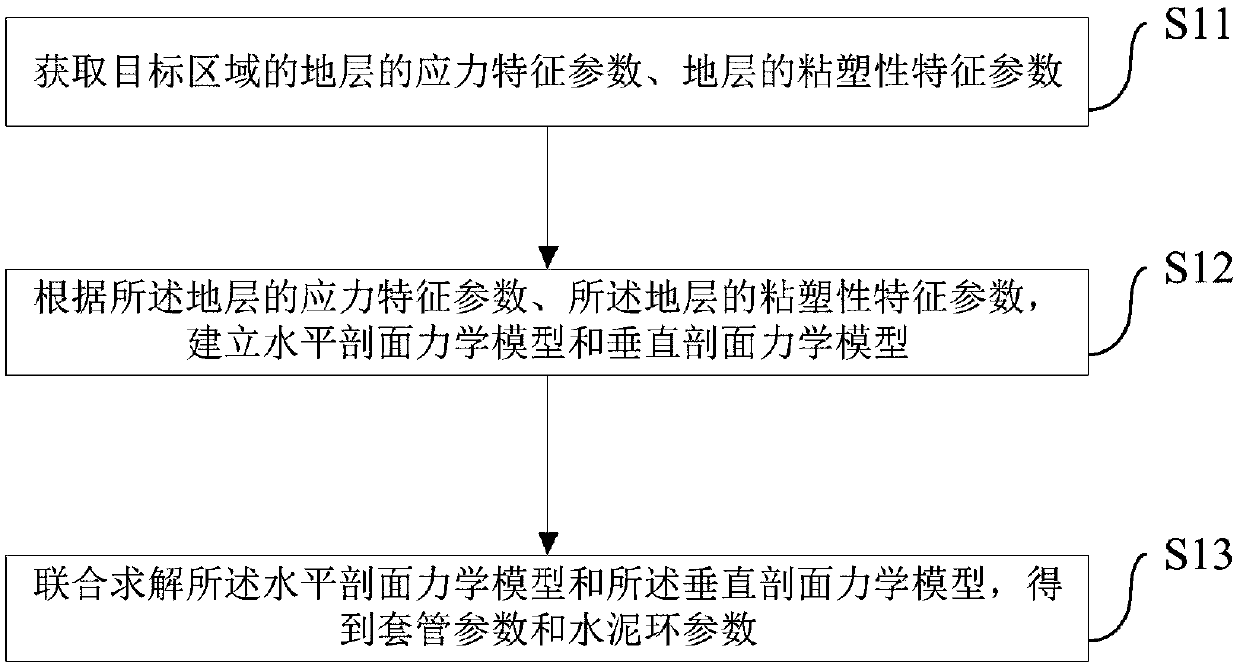

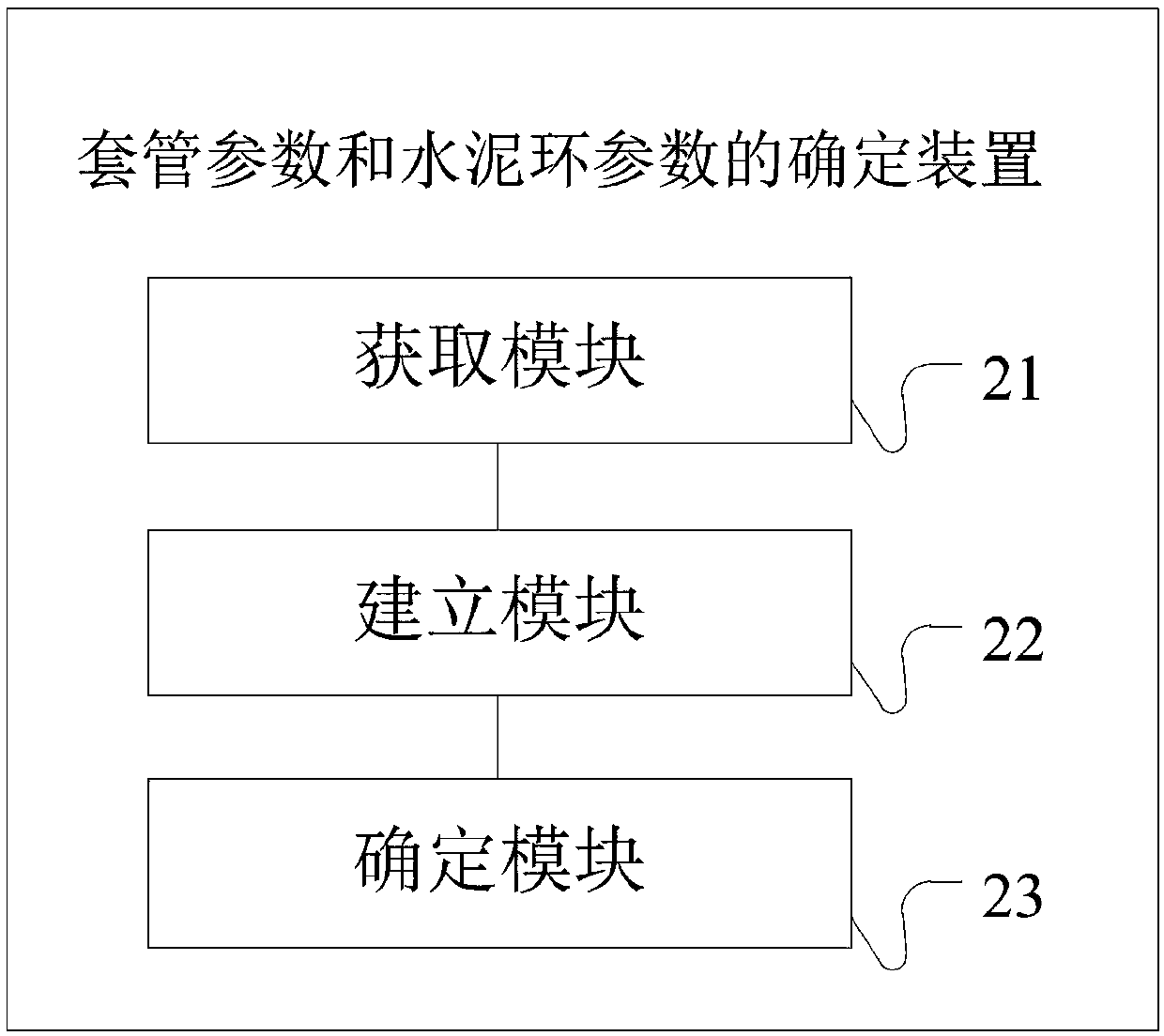

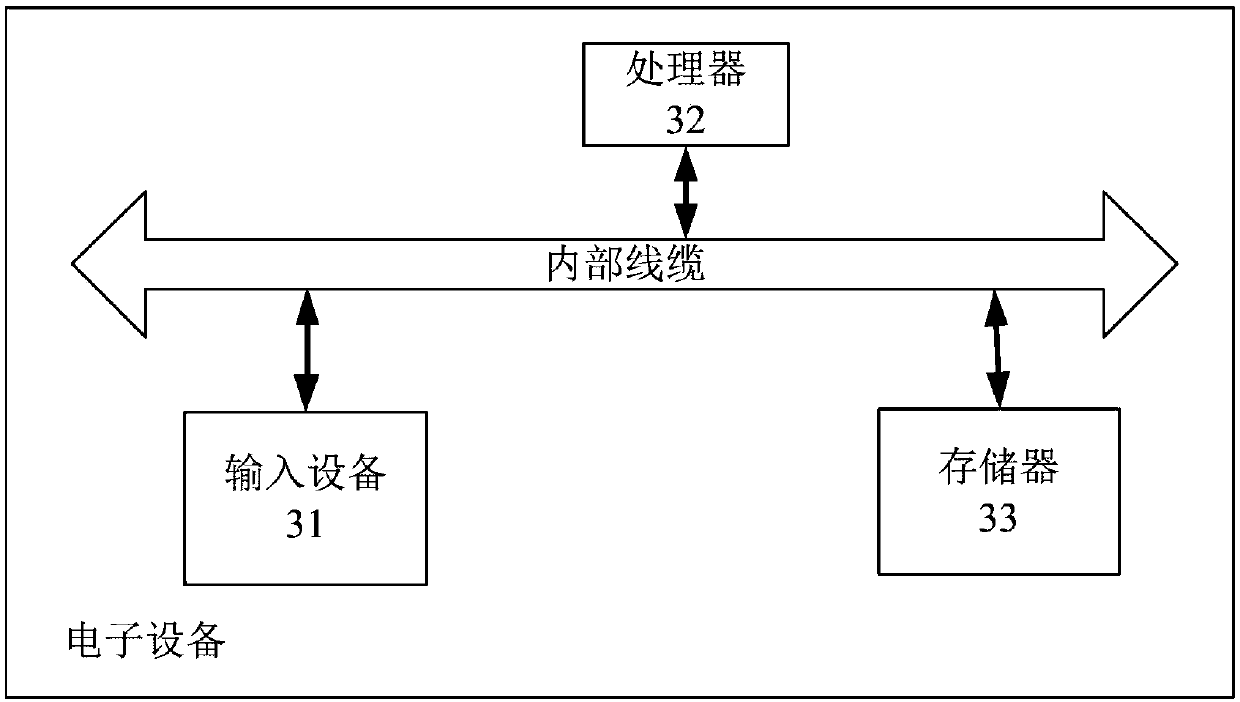

Casing pipe parameter and cement sheath parameter determination method and casing parameter and cement sheath parameter determination device

ActiveCN108733895AAccurately determineEfficient determinationGeometric CADDesign optimisation/simulationMechanical modelsFeature parameter

The embodiment of the invention provides a casing pipe parameter and cement sheath parameter determination method and a casing parameter and cement sheath parameter determination device, wherein the method comprises the following steps: acquiring a stress feature parameter of stratum and a viscoplasticity feature parameter of the stratum of a target region; according to the parameters, building ahorizontal section mechanical model and a vertical section mechanical model; jointly solving the horizontal section mechanical model and the vertical section mechanical model, thereby determining thecasing pipe parameter and the cement sheath parameter which confirm to a plurality of preset targets. Since geological environment of a casing pipe and a cement sheath under real work conditions is considered in the scheme, the stress feature parameter and the viscoplasticity feature parameter of the stratum are obtained and used for accurately simulating the viscoplasticity feature of the stratumwhere the casing pipe is; two mechanical models in a horizontal direction and a vertical direction are built simultaneously for performing multi-target optimization solving, and thus, a technical problem of relatively poor accuracy of the casing pipe parameter and the cement sheath parameter determined in the existing method is solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

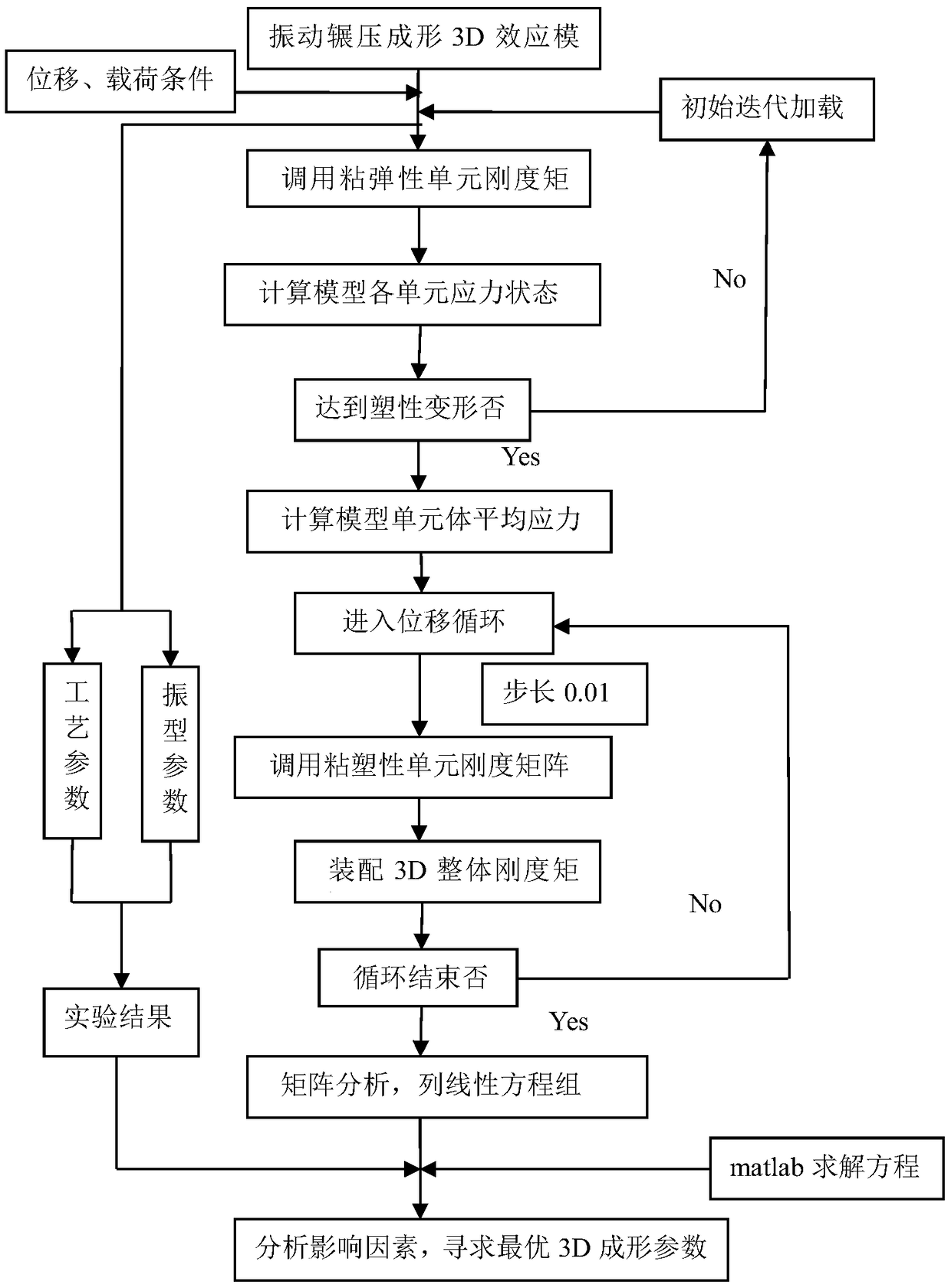

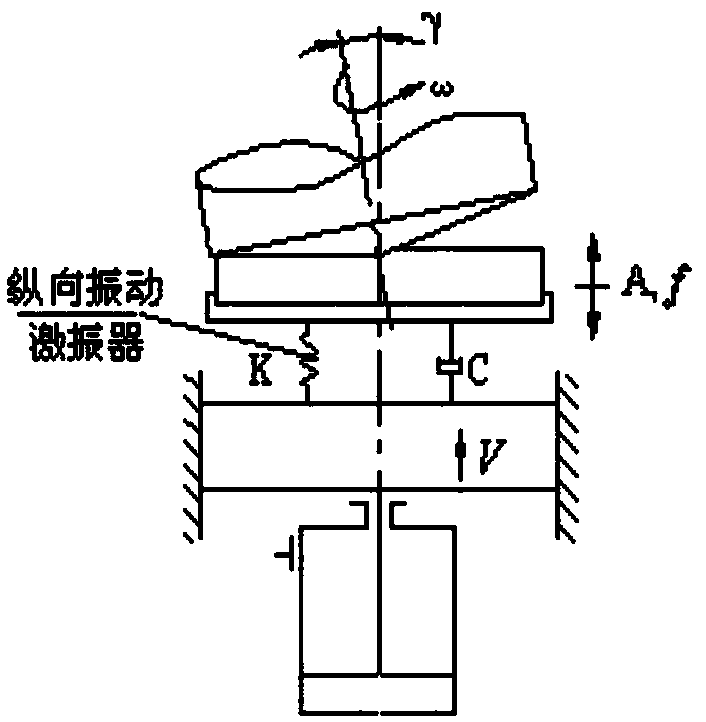

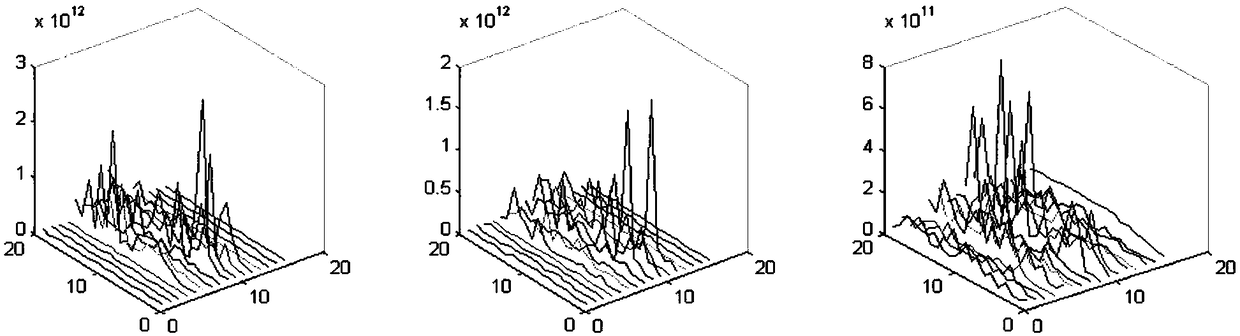

Method for analyzing rotary forging effect based on 3D constitutive model under alternating load

InactiveCN108664709AReduce deformation resistanceReduce energy consumptionGeometric CADDesign optimisation/simulationMATLABViscoelasticity

The invention belongs to the technical field of mechanical manufacturing, and discloses a method for analyzing rotary forging effect based on 3D constitutive model under alternating load comprising the following steps of: performing 3D volume effect and surface effect analyzing on vibration rotary forging visco-elasticity plasticity constitutive model by using MATLAB software, then performing describing on three dimensional contact problem by simulating contact boundary in vibration rotary forging process through multi-parameter coupling; deriving viscoelasticity space matrix and viscoplasticity space matrix respectively by using generalized Hooke law in elastic mechanics and incremental theory in plastic mechanics, then establishing a surface effect analysis model in vibration rotary forging forming; performing finite element simulation analyzing and surface effect analyzing on the vibration rotary forging model under different vibration mode parameters through providing reasonable assumptions. According to the method for analyzing rotary forging effect based on 3D constitutive model under alternating load, vibration forging forming mechanism is disclosed, material vibration forging forming process analysis under the three dimensional constitutive model is perfected, and important theoretical significance and practical value are achieved for building vibration forging formingequipment.

Owner:NANCHANG CAMPUS OF JIANGXI UNIV OF SCI & TECH

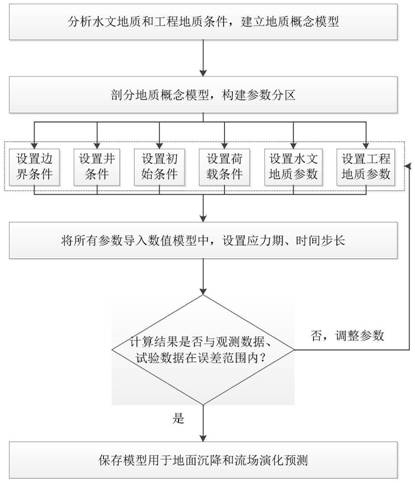

Three-dimensional variable-parameter full-coupling simulation calculation method for ground subsidence caused by load and underground water exploitation

ActiveCN113591338AAchieve couplingGuaranteed Conservation of QualityClimate change adaptationDesign optimisation/simulationGround subsidenceSoil science

The invention provides a three-dimensional variable parameter full-coupling simulation calculation method for ground subsidence and ground fissures caused by load and underground water exploitation. The problem of calculation of the ground subsidence and the ground fissures under the dual action of overlying load on a soil body and underground water exploitation is solved. The geological conceptual model is established according to the actual background of underground water exploitation. Based on a Biot consolidation theory, full coupling of a seepage field and a stress field is realized, and a three-dimensional full-coupling numerical model for predicting ground settlement and ground fracture development is constructed. According to the calculation method, a mechanism in a rock-soil body compression process is considered, constitutive models of elasticity, viscoelasticity and viscoplasticity are coupled, and a seepage field and a stress field are closely linked by combining changes of rock-soil body parameters, so that the ground settlement amount and the ground fracture extension amount under the conditions of ground load and groundwater dynamic decline can be simultaneously simulated, and a basis is provided for researching seepage field evolution and ground subsidence evolution laws and a fluid-solid coupling action mechanism in the underground water exploitation process.

Owner:HOHAI UNIV

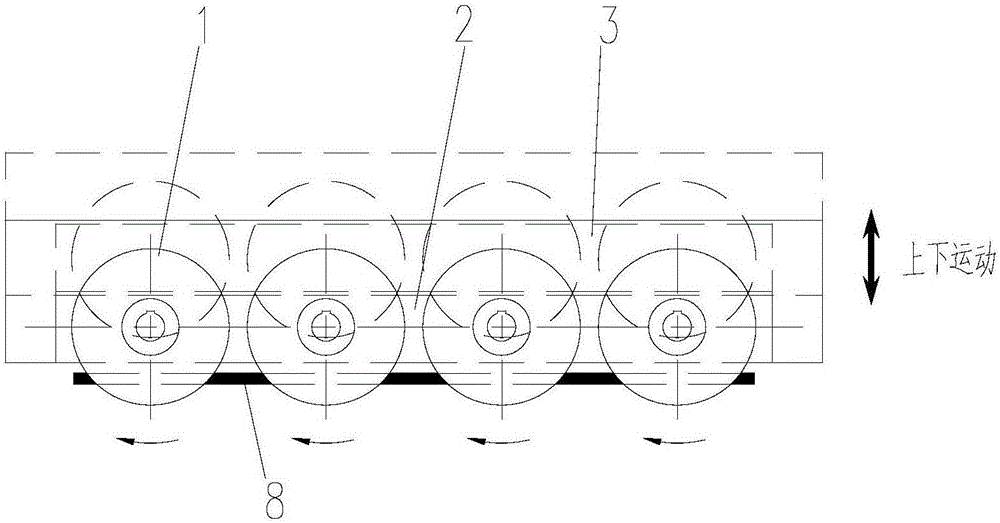

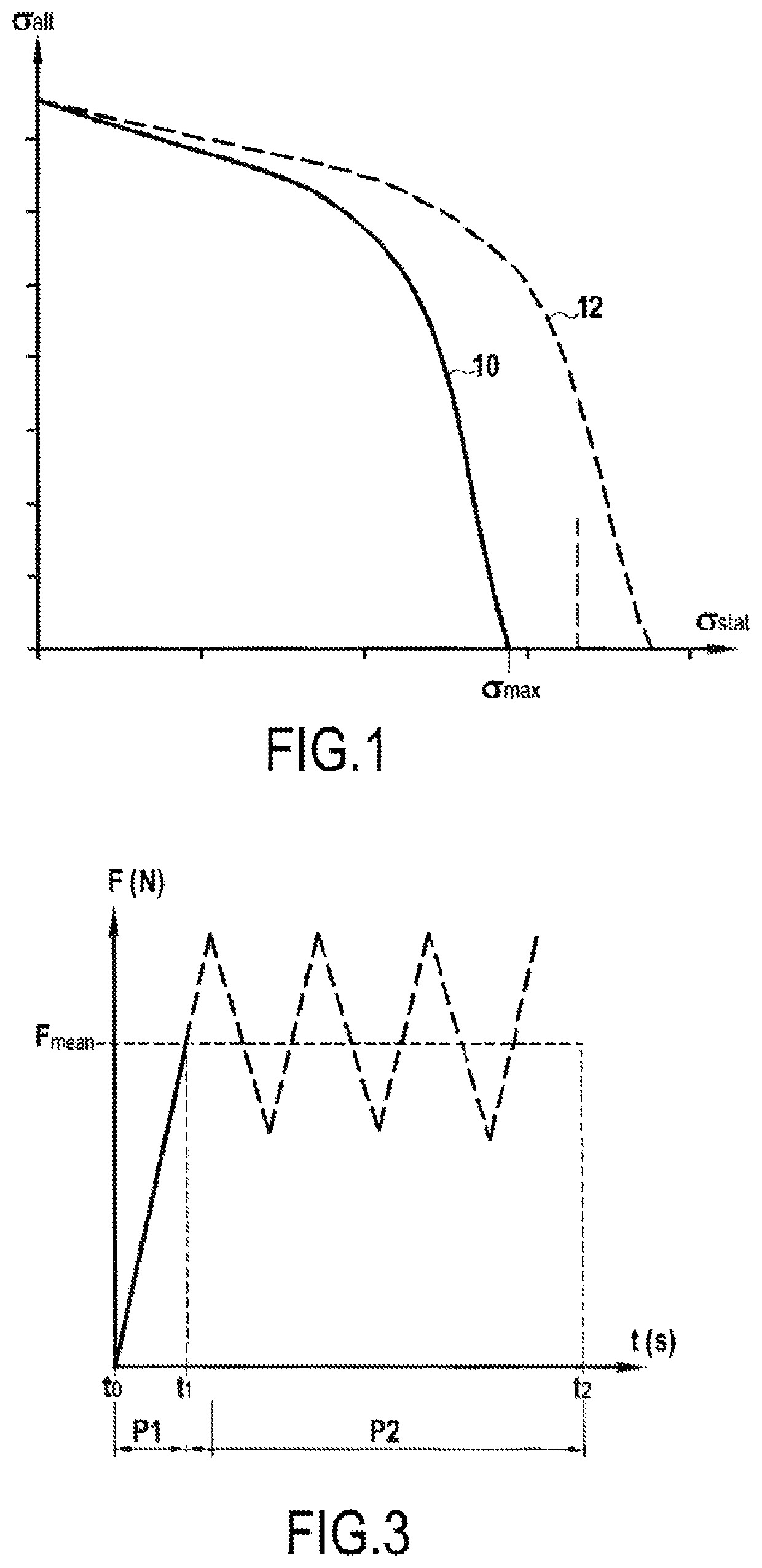

A method of determining a maximum acceptable alternating stress for a part that is subjected to cyclic loading; a unit for determining such a stress

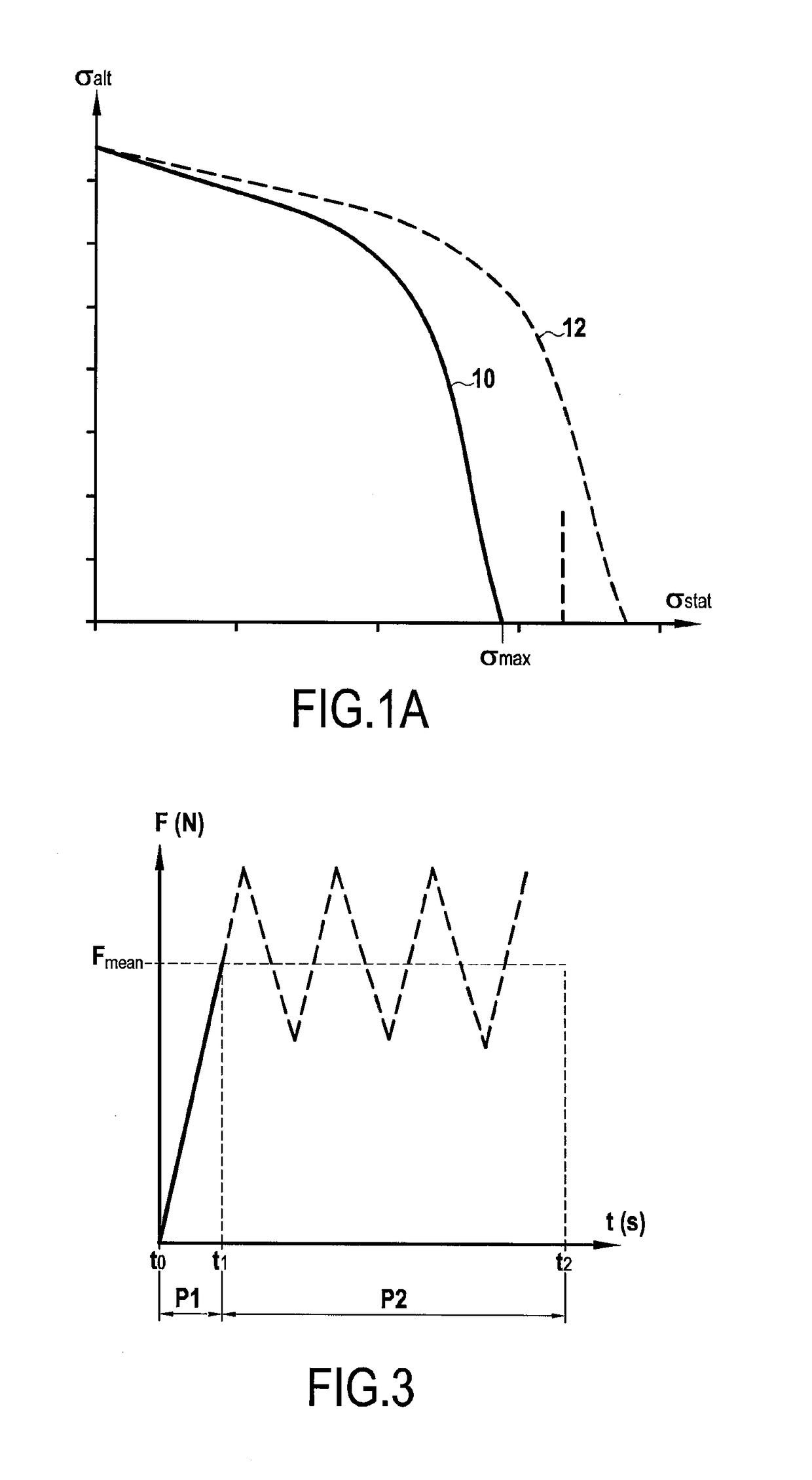

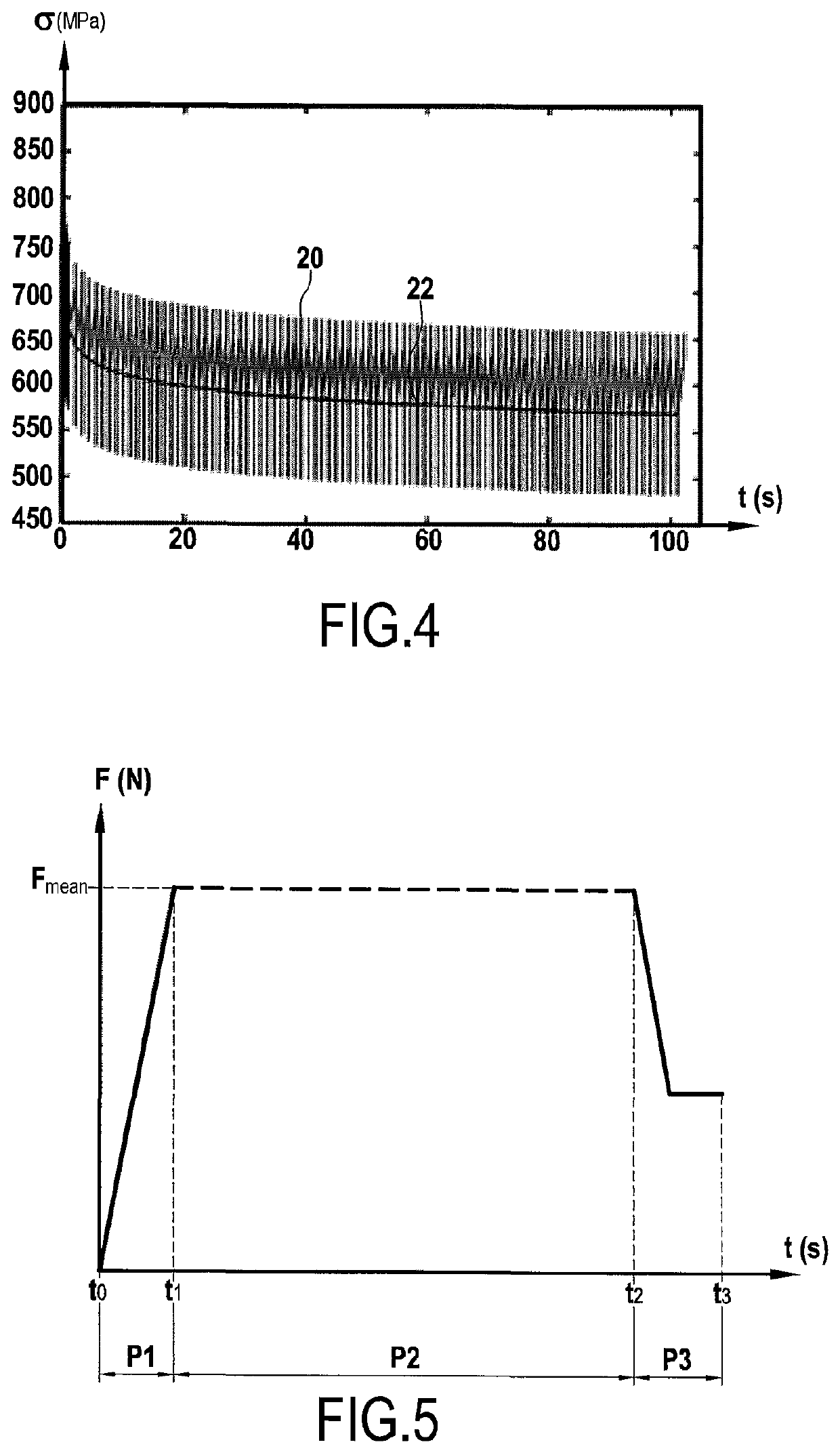

ActiveUS20180232472A1Simple loading processShort calculation timeGeometric CADDesign optimisation/simulationViscoplasticityCyclic loading

A method of determining a maximum acceptable alternating stress at a point of a part subjected to cyclic loading: simulating that the part is subjected to constant loading equal to a threshold value during a level period, and assuming that the part has elasto-viscoplastic behavior; from the results of the simulation, determining a final static stress at the point at the end or after the end of the level period; and for the point under consideration, using a Goodman diagram to determine the maximum acceptable alternating stress, which is determined for a static stress equal to the final static stress; the duration of the level period being equal to the duration of the loading of the testpieces that were used to draw up the Goodman diagram.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

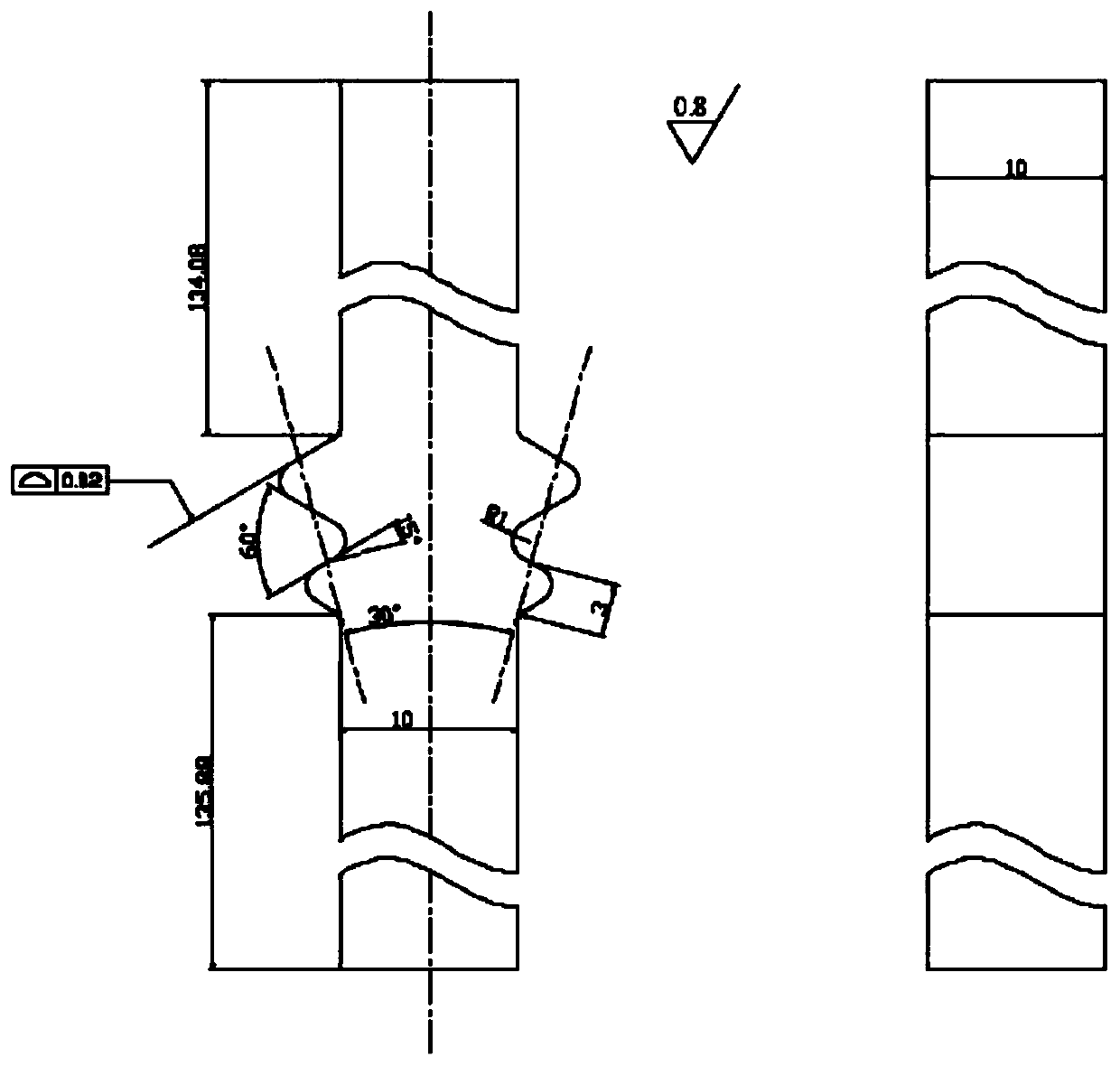

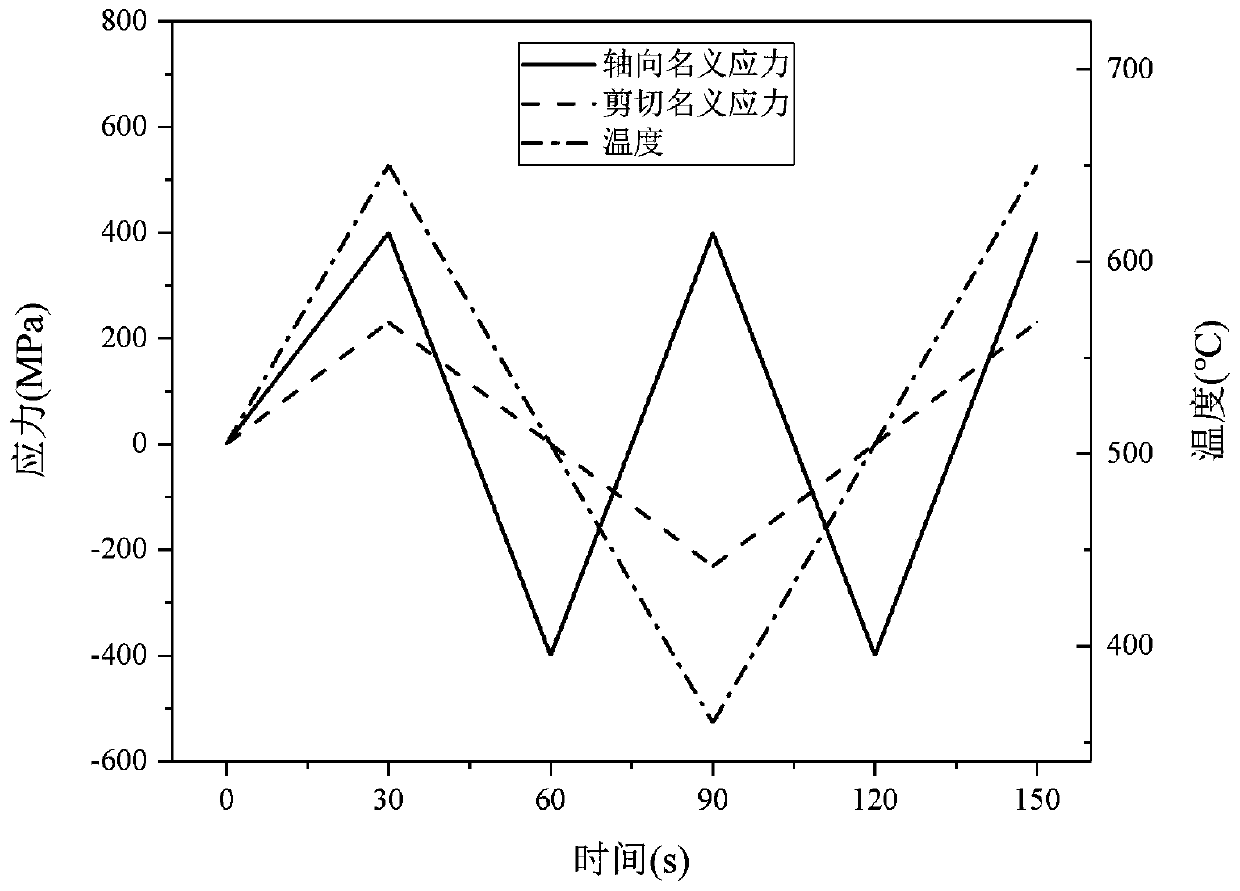

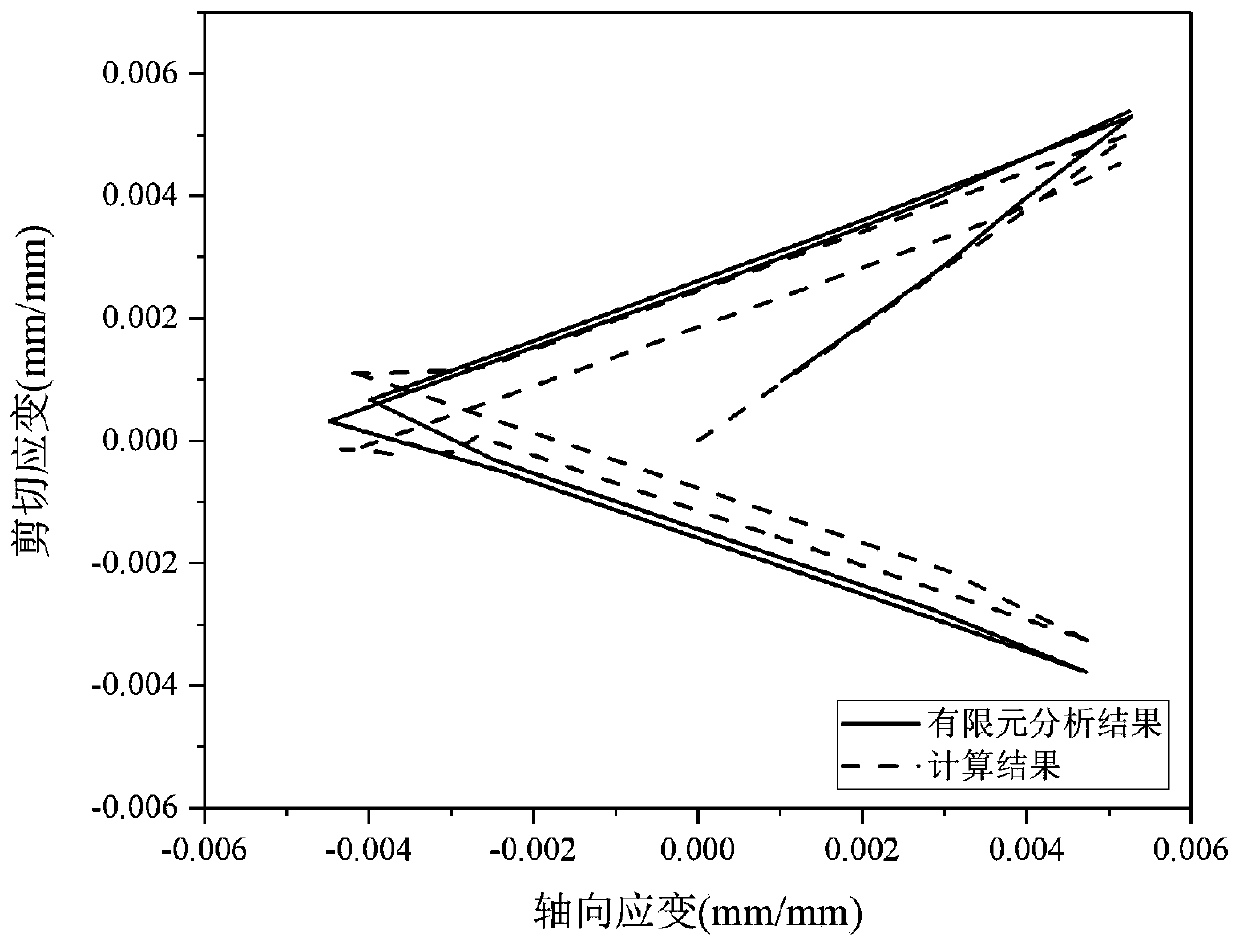

High-temperature structure dangerous point stress-strain calculation method

PendingCN111090957AGuaranteed life prediction accuracySimple methodGeometric CADDesign optimisation/simulationStructural engineeringNonlinear finite element analysis

The invention discloses a high-temperature structure dangerous point stress-strain calculation method, aims to solve the problem of notch stress-strain overestimation in the Neuber criterion, adopts an effective stress concentration coefficient to calculate pseudo stress, and improves the calculation method of the effective stress concentration coefficient. In addition, the proposed notch correction method is combined with a Caboch unified viscoplasticity constitutive model, and the stress-strain state of the dangerous point under the heat engine load is estimated. In order to evaluate the reliability of the method, an estimated result is compared with a nonlinear finite element analysis result, and the result shows that the method can accurately estimate the notch stress and strain underthe multi-axis thermal-mechanical cyclic load. The method is of great significance in guaranteeing the life prediction accuracy of structural parts in actual engineering, safety service of various important devices and accurate life extension.

Owner:BEIJING UNIV OF TECH

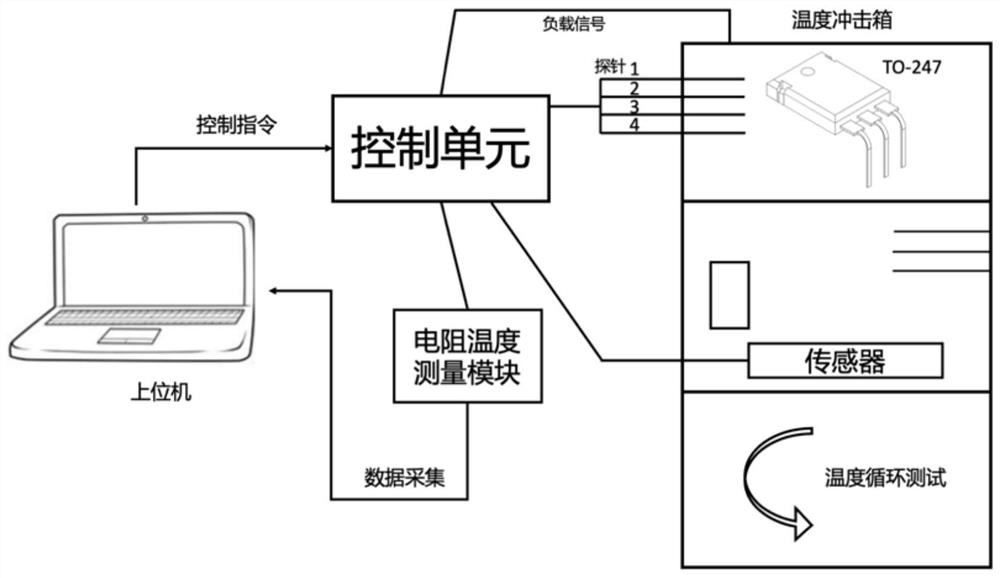

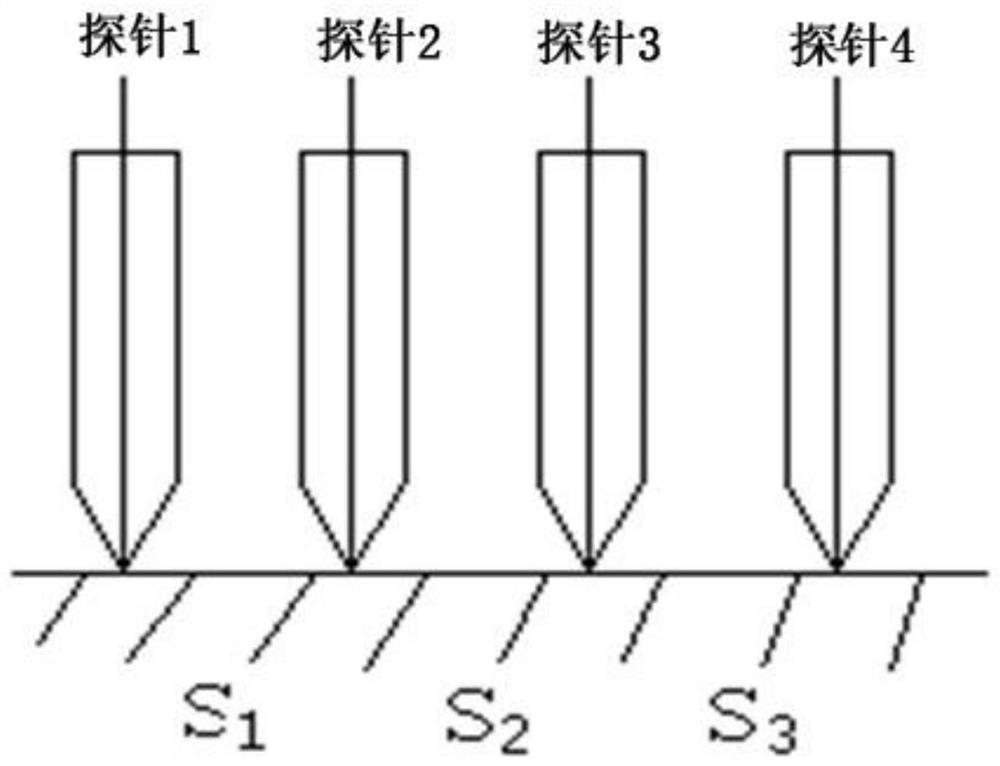

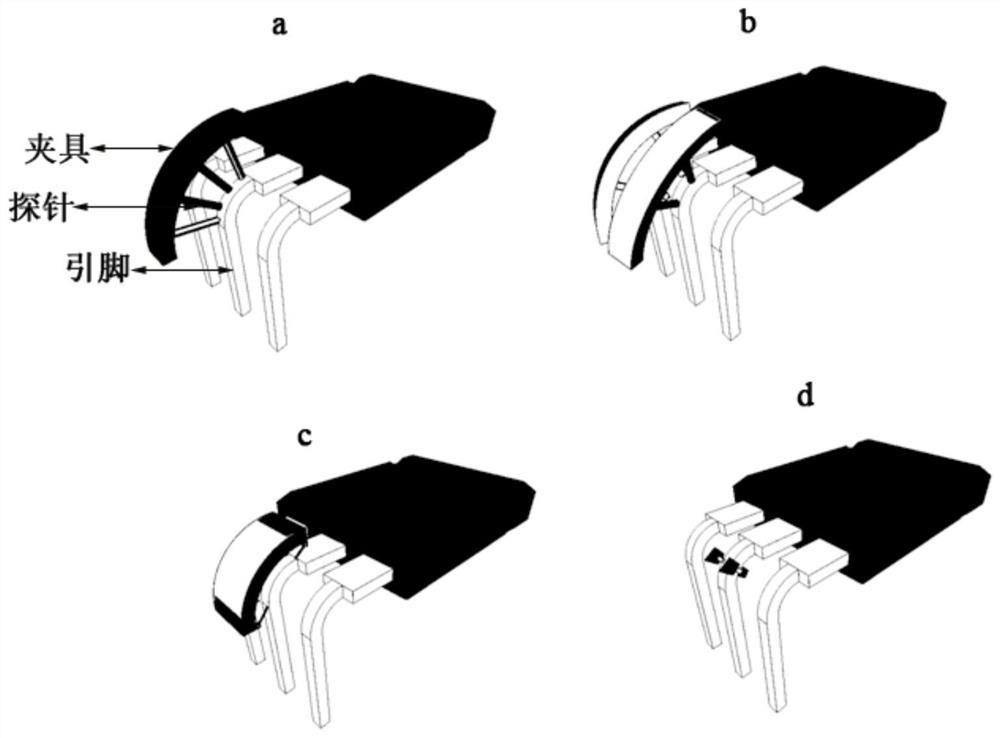

Method for monitoring pin reliability of pin packaging in situ in real time by using four-probe method

PendingCN113690154AShorten the timeAvoid measurement errorsSemiconductor/solid-state device testing/measurementEngineeringMechanical engineering

The invention discloses a method for monitoring pin reliability of pin packaging in situ in real time by using a four-probe method. According to the method, the resistance of the pins in the packaging structure is monitored and measured by using a four-probe method, viscoplastic deformation before cracks are generated and expansion of the cracks in the pins are detected based on resistance change, and accurate in-situ crack identification is realized. According to the invention, based on the characteristic of micro-resistance change caused by crack generation in the pin, the problems of crack generation and failure of the pin are rapidly and accurately judged by accurately measuring the resistance change of the pin, in-situ monitoring is carried out on the pin reliability, and compared with other measurement methods in the prior art, the method is simpler and more efficient; crack judgment can be performed in a reliability test of a device, and an experiment is terminated in advance, so that time and cost are saved; according to the invention, a plurality of probe pin contact schemes are adopted, good contact between the probe and a tested point is realized, and the test accuracy can be further improved.

Owner:FUDAN UNIV

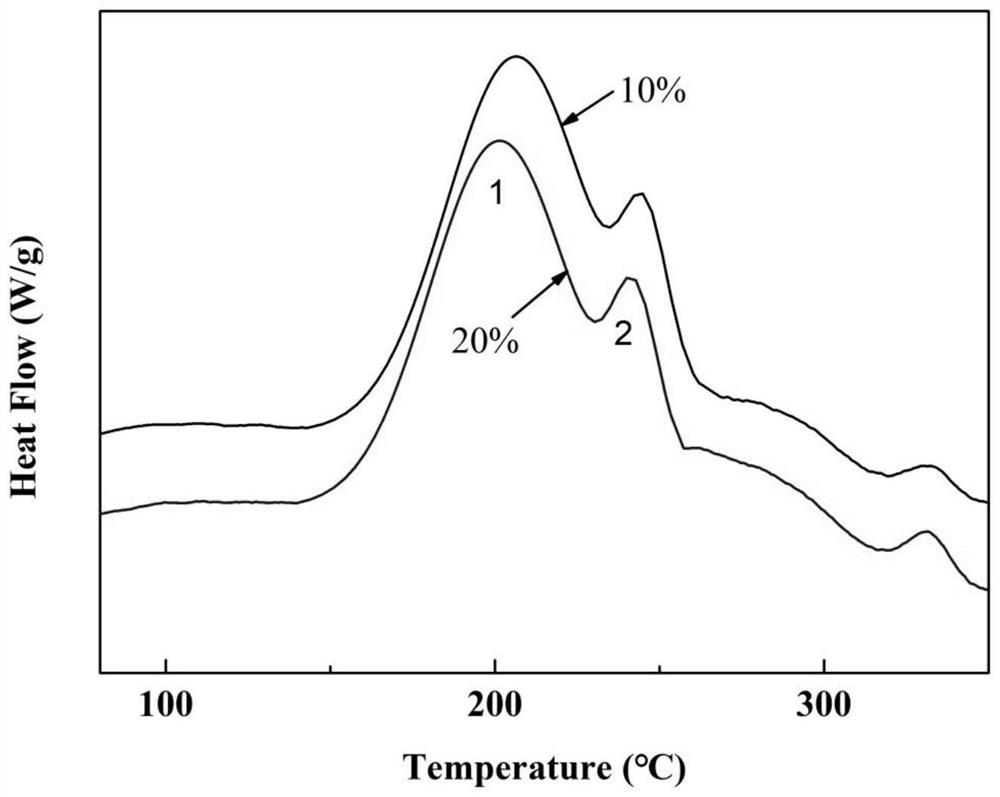

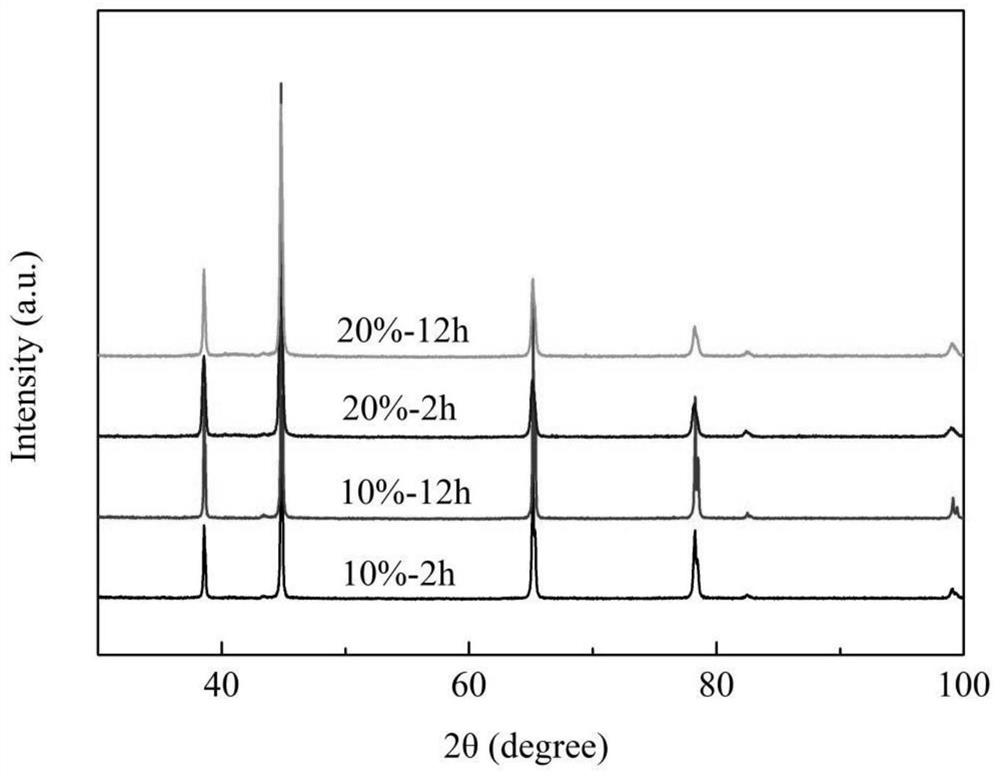

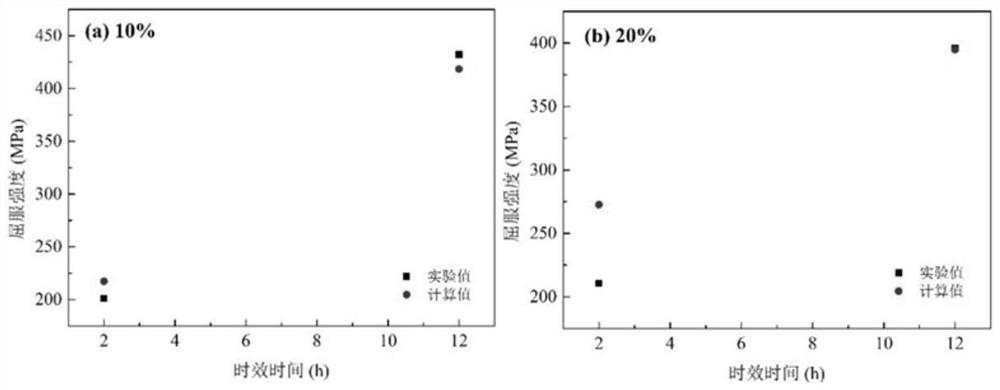

Prediction method for aluminum alloy thermal deformation behaviors and yield strength after forming

ActiveCN112733330ASimple calculation and analysisFew parametersDesign optimisation/simulationSpecial data processing applicationsThermal deformationModel parameters

The invention relates to a prediction method for aluminum alloy thermal deformation behaviors and yield strength after forming. The prediction method comprises the following steps that S1, solving a constitutive model of the aluminum alloy through tensile data; S2, converting the engineering stress-strain curve into a real stress-strain curve; S3, establishing a unified viscoplasticity constitutive model of the aluminum alloy to obtain the dislocation density and hardening of the aluminum alloy in the deformation process and the relationship between the grain size and the viscoplasticity flow behavior; S4, making DSC analysis on the deformed aluminum alloy; S5, making XRD analysis of deformed aluminum alloy; S6, obtaining the element concentration, the precipitated phase volume fraction and the precipitated phase size according to the calculation result; S7, establishing a yield strength prediction model; and S8, solving model parameters. The calculation and analysis process involved in the method is simple, parameters are few, application and popularization are convenient, the model precision is high, and verification can be conducted through an aluminum alloy hot stamping experiment.

Owner:WUHAN UNIV OF TECH

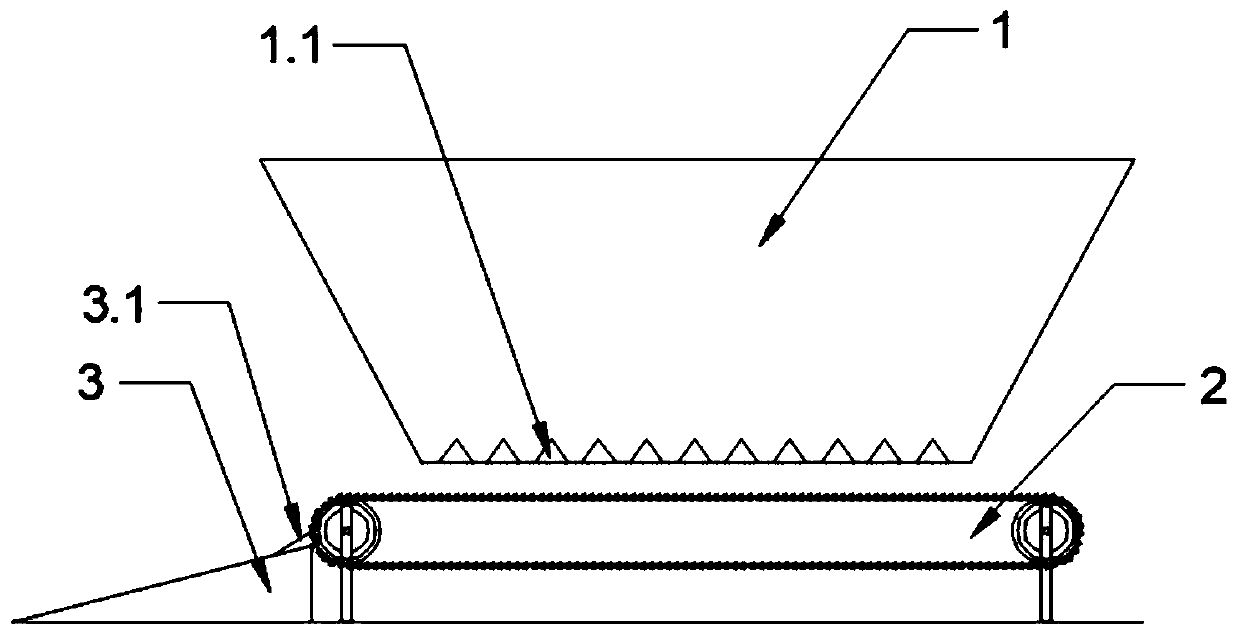

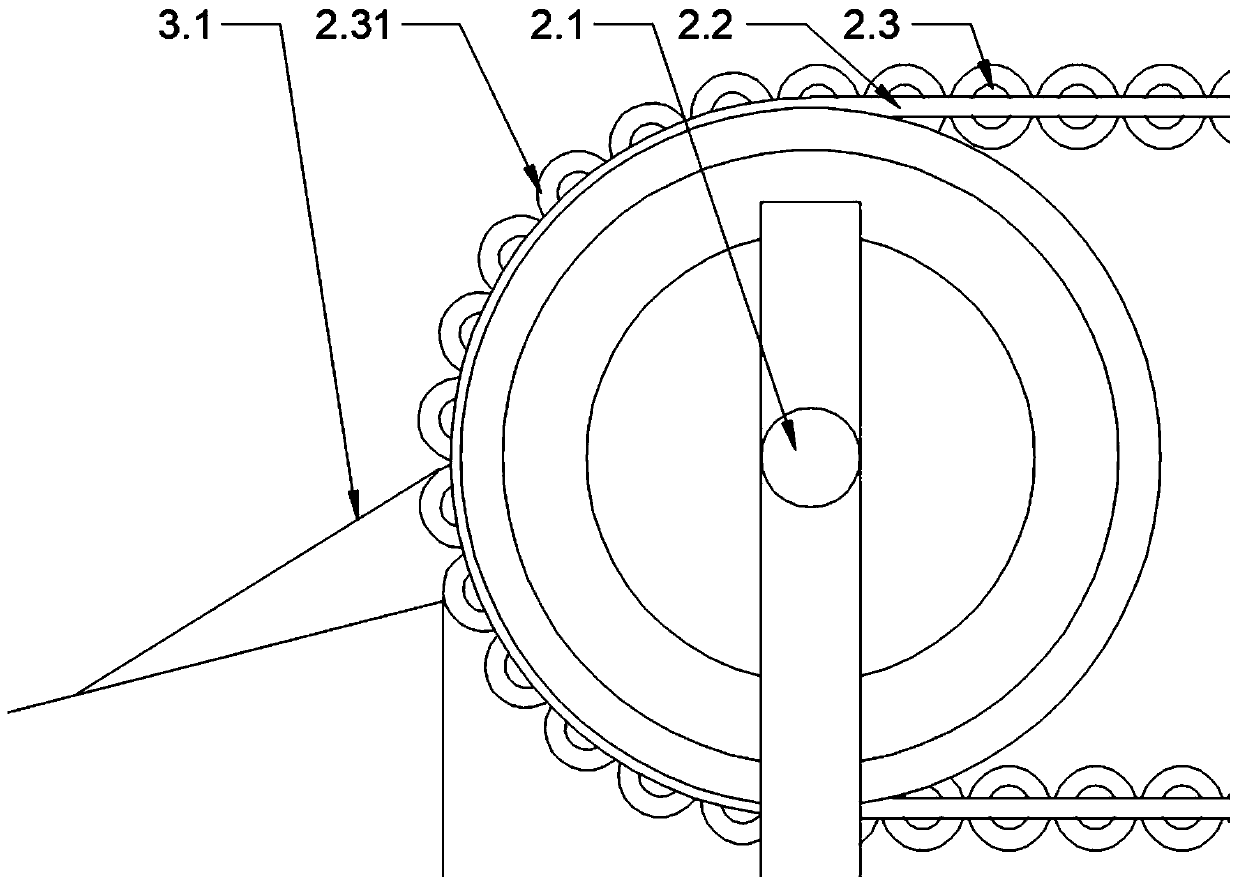

Device for conveying discharged mud cakes of plate-and-frame filter press

The invention relates to a device for conveying discharged mud cakes of a plate-and-frame filter press. The device comprises a mud hopper and a conveyor under the mud hopper, and the lower portion ofthe mud hopper is provided with gratings. By additional arrangement of the gratings, with large mud cake breaking power, on the lower portion of the mud hopper, the mud cakes are cut into small-size blocks by the gratings under the action of gravity so as to achieve convenience in transporting. The conveyor conveys cylindrical rollers through a chain-sprocket structure and is less prone to slipping or deflecting and low in operating noise. The multiple cylindrical rollers are arrayed to form an uneven transporting surface which is capable of withstanding direct impact of mud blocks with certain weights, and the concave-convex surface enables increasing of a contact area, so that convenience in mud block conveying is achieved. By arrangement of a roller brush and a cleaning procedure, the whole device for conveying is low in requirement on intrinsic weights of the mud cakes, the conveyor is slightly affected by the moisture content or viscoplasticity of the mud cakes, and the device forconveying is less prone to failure caused by mud accumulation.

Owner:ROAD ENVIRONMENT TECH

Upright magnetorheological polishing device and method

The invention relates to an upright magnetorheological polishing device. The device comprises a polishing mechanism and a clamping mechanism; the polishing mechanism comprises a magnetic frame, a coiland a vertically arranged liquid storage pipe; the inner hole of the liquid storage pipe fits a workpiece and contains magnetorheological liquid; the workpiece is clamped by the clamping mechanism tofit the position of the liquid storage pipe; a magnetic field is formed in the inner hole of the liquid storage pipe by the coil, and a flexible polishing film is formed by the magnetorheological liquid; the workpiece and the polishing film move relatively in the vertical direction and rotate relatively along the axis of the workpiece. According to the upright magnetorheological polishing deviceand an upright magnetorheological polishing method, a rheologic effect is generated by the magnetorheological liquid to shear the polishing film with higher yield stress and apparent viscosity and viscoplasticity, the relative movement of the magnetorheological liquid and a to-be-processed surface is utilized to perform material removing on the surface, the polishing process is not limited by theshape of the surface of the workpiece, the polishing efficiency is high, and damage is not generated. The device has a simple structure and is easy to control, and workpieces with different characteristics and demands can be polished.

Owner:NORTHEASTERN UNIV

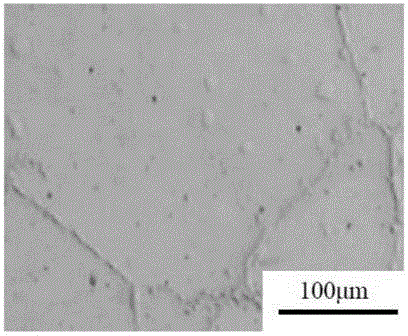

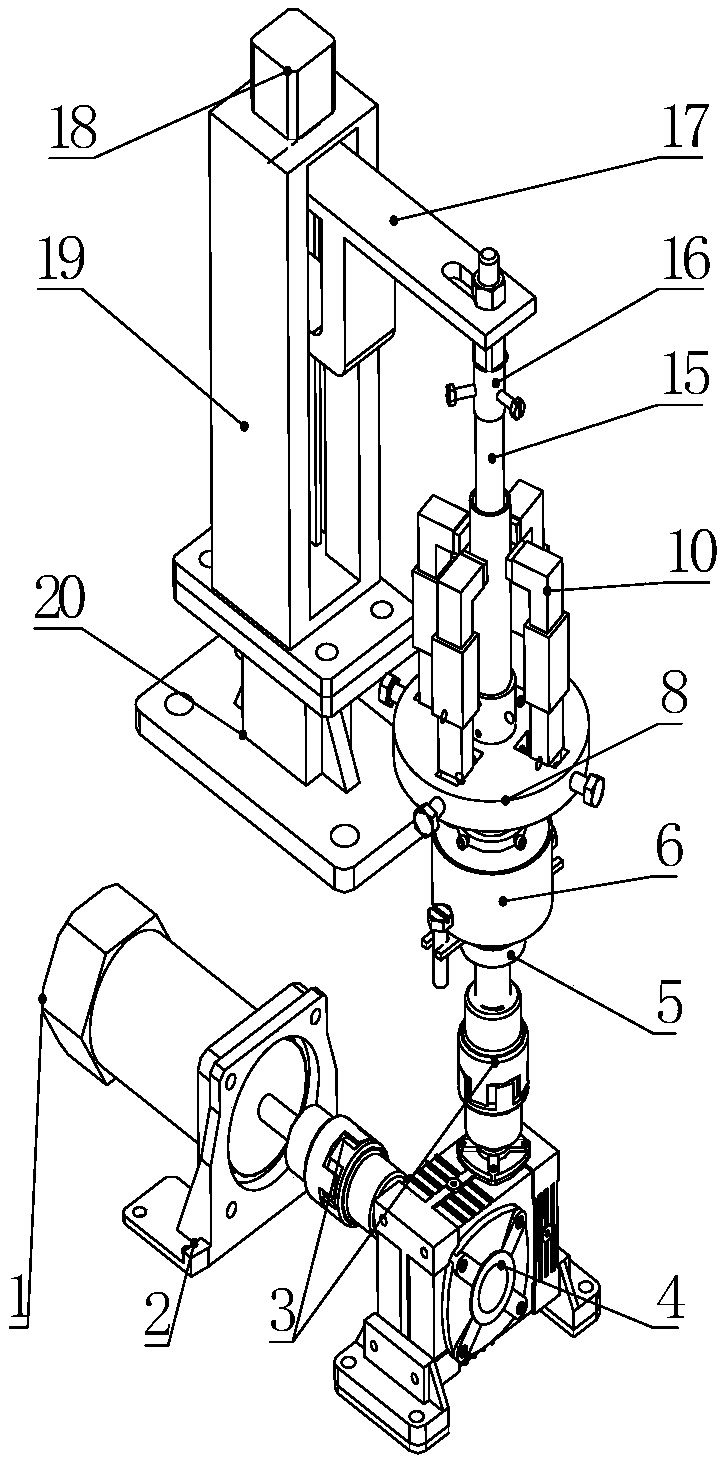

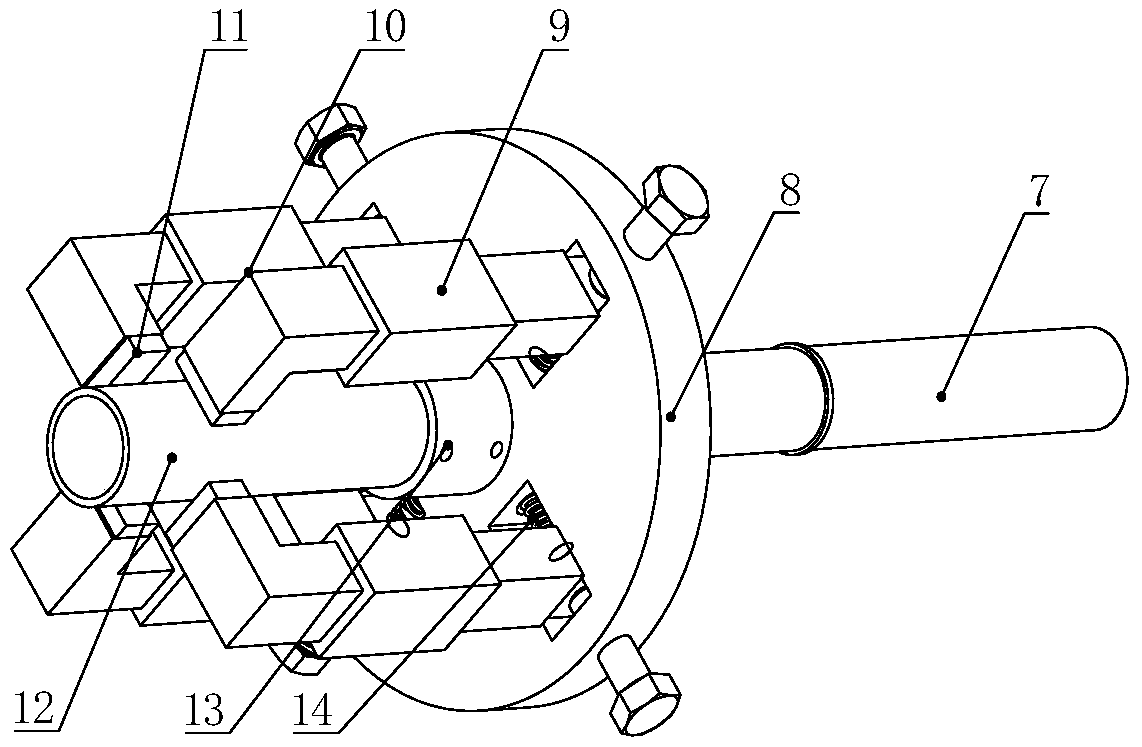

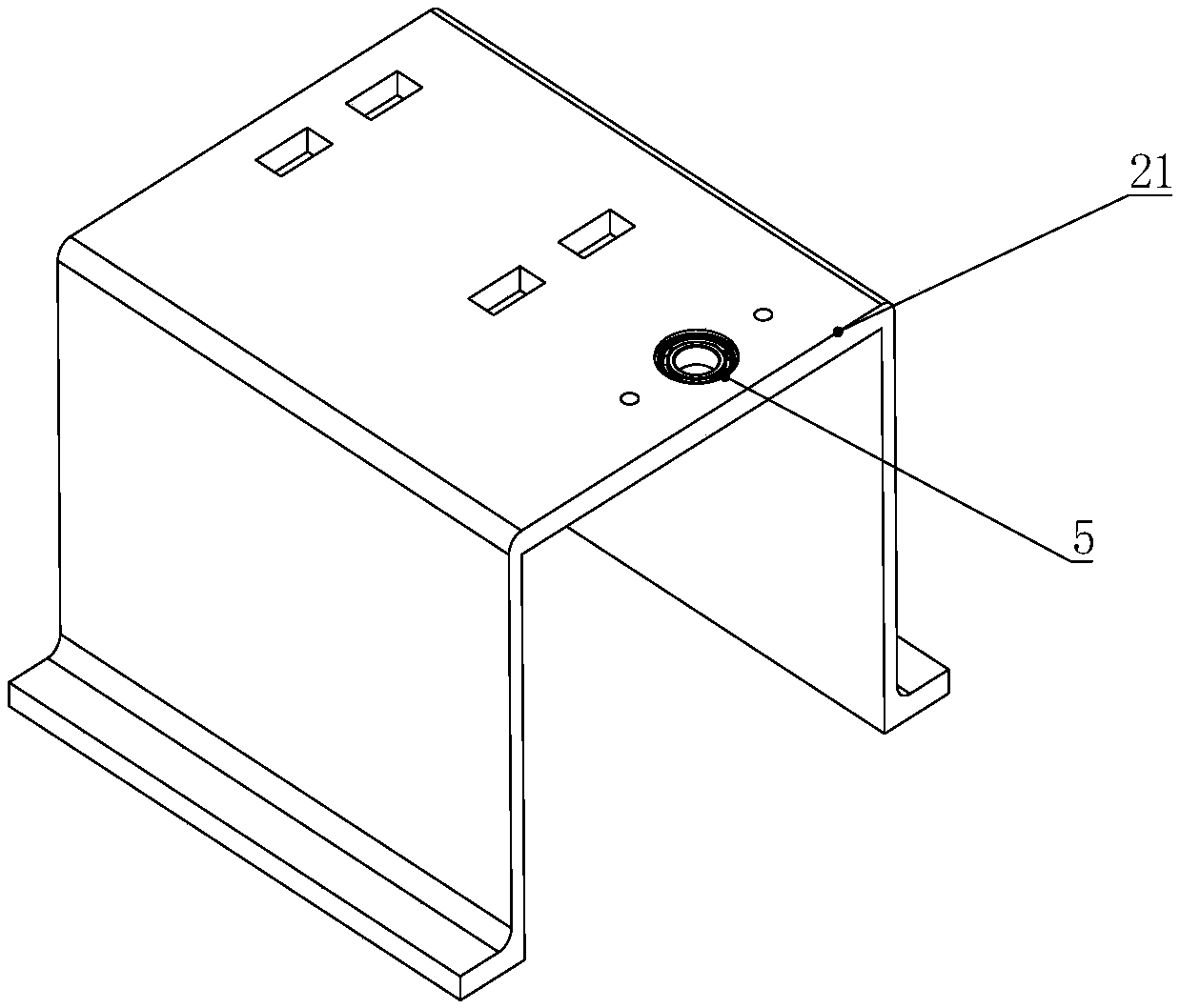

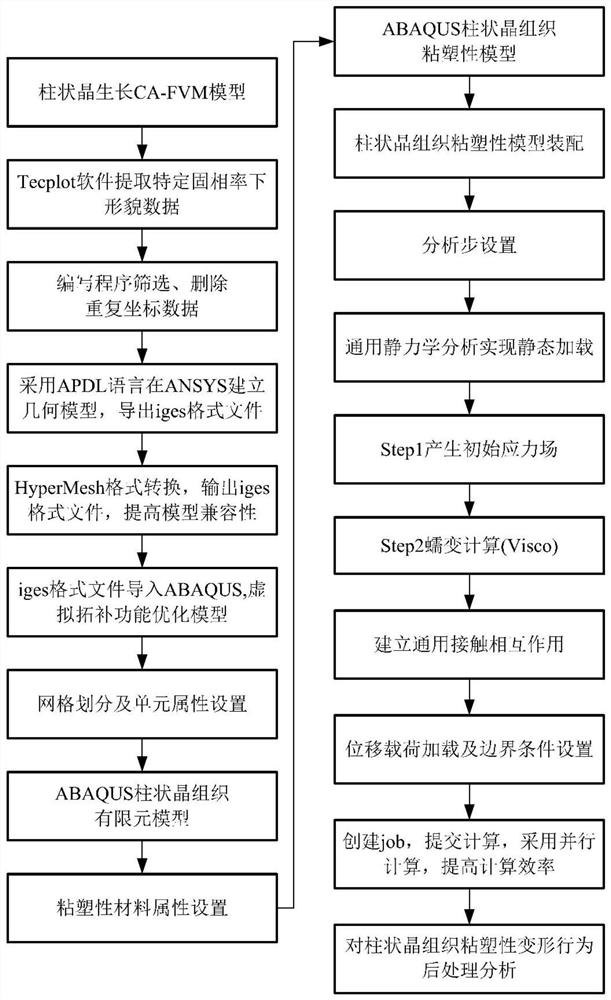

Calculation method for viscoplastic tensile deformation of columnar crystal structure in steel solidification process

PendingCN113486518AAvoid crack defectsQualitatively well characterizedDesign optimisation/simulationSpecial data processing applicationsElement modelCrystal structure

The invention provides a method for calculating viscoplastic tensile deformation of a columnar crystal structure in a steel solidification process, and relates to the technical field of metallurgical continuous casting. The method comprises the following steps: based on a two-dimensional columnar crystal growth CA-FVM model, calculating a columnar crystal structure growth morphology; extracting growth morphology data of the columnar crystal structure under a specific solid fraction, and establishing a geometric model and a finite element model of the columnar crystal structure; based on the finite element model of the columnar crystal structure, setting viscoplasticity attributes of the columnar crystal structure, and establishing a constitutive model, namely a columnar crystal structure viscoplasticity model, representing the viscoplasticity mechanical behavior of the columnar crystal structure; setting conditions for calculating viscoplastic deformation of the columnar crystal structure; calculating viscoplastic deformation of the columnar crystal structure in finite element software, and carrying out visualization and data post-processing. The method can qualitatively characterize the deformation evolution condition of the columnar crystal structure under the tensile effect in the steel solidification process and the overlarge stress and strain concentrated distribution part, and can also qualitatively characterize the viscoplastic deformation mechanical behavior of the secondary dendritic crystal arm well.

Owner:NORTHEASTERN UNIV

Experimental device for asphalt rotational shear failure

The invention discloses a pitch rotation shear failure experimental device and belongs to the test field of material mechanics properties. The pitch rotation shear failure experimental device comprises an experimental platform, a temperature control system and a computer control system. The computer control system is capable of automatically controlling loading facilities to carrying out rotating shear loading to experimental test specimen and controlling an experimental process. The temperature control system is capable of controlling temperatures of the experiment. The pitch rotation shear failure experimental device can be suitable for determining low-temperature brittle failures and middle-high-temperature viscoplasticity failures of asphalt cements such as ordinary pitch, SBS modified asphalt, rubber asphalt and other polymer modified asphalt under different shear rates and tests of cementation interface mechanical property of materials such as bitumen mastic materials, stones, steels and plastic under the low-temperature conditions.

Owner:DALIAN UNIV OF TECH

Intermediate blank connecting device and system

InactiveCN106826244AFast connectionSuitable for viscoplastic stateOther manufacturing equipments/toolsNon-electric welding apparatusEngineeringUltimate tensile strength

The invention provides an intermediate blank connecting device, which includes an outlet clamping device for clamping the front intermediate blank, an inlet clamping device for clamping the rear intermediate blank, and a connecting device for aligning the front intermediate blank and the rear blank. The friction disc connecting the end surface of the intermediate billet for friction and the upsetting device for applying upsetting force, the friction disc is located between the inlet clamping device and the outlet clamping device, and the friction disc is connected to drive the friction disc to rotate and Mobile drive mechanism. The friction disc extends between the front middle billet and the rear middle billet, and rubs the end faces of the two, so that the end face of the middle billet and the surrounding area rapidly heat up to a viscoplastic state, and the rear middle billet is subjected to a topping by an upsetting device. Forging force, after the friction disc is removed, the front block middle blank and the rear block middle blank are connected together. The invention has the advantages of simple structure, high connection strength, fast connection speed and low energy consumption, and is suitable for connection between slabs of different materials.

Owner:CISDI ENG CO LTD

Method of determining a maximum acceptable alternating stress for a part that is subjected to cyclic loading; a unit for determining such a stress

ActiveUS10984153B2Load is appliedSimple loading processGeometric CADDesign optimisation/simulationMechanicsViscoplasticity

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Surface film drag reduction effect tester for viscoplastic material pipeline transportation

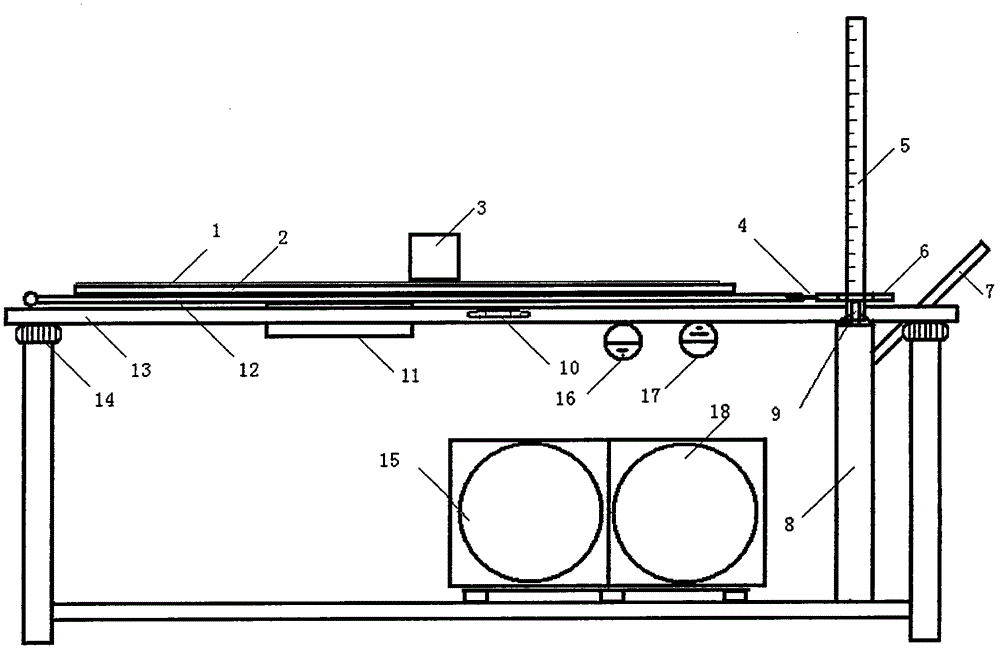

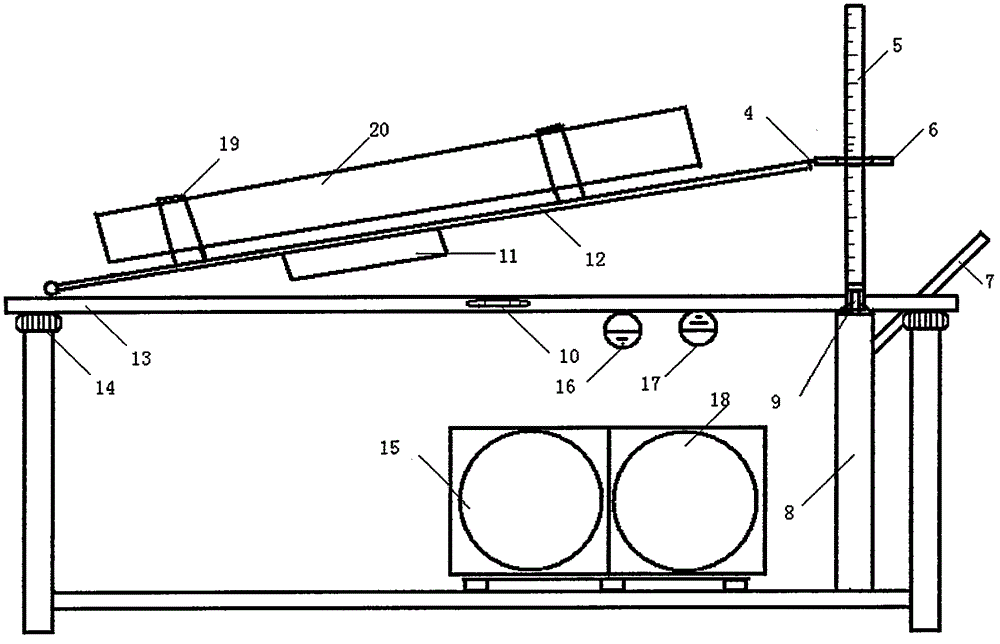

InactiveCN102628853BOvercome viscosityComplex problems simplifiedMaterial analysisTester deviceEngineering

The invention which relates to a resistance reduction effect tester for a s viscoplastic material pipeline convey surface film belongs to experiment equipment. The tester comprises an experiment table, a mobile plate, a lifting device, a horizontal adjustment system, an air compressor and a vacuum machine. The tester is characterized in that a test plate is fixed on the mobile plate, the surface film to be tested is sprayed, and a test piece is arranged on the surface film; one end of the mobile plate is connected with the lifting device and is provided with a vertical height scale; and a frequency and amplitude adjustable vibrator is arranged on the lower surface of the mobile plate. The tester has the characteristics of simple principle, convenient calculation, real condition approach, and strong comparability. The application of the selected surface film in engineering makes the convey amount be large, the convey distance be long and consumed energy be saved. The tester is suitable for selecting and testing various resistance reduction surface films in the convey of the viscoplastic material pipeline.

Owner:昆仑检验认证有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com