Discrete element and finite difference method coupled bituminous mixture simulation modeling method

A technology of asphalt mixture and finite difference method, which is applied in 3D modeling, CAD numerical modeling, details involving 3D image data, etc. Lock and other problems, to achieve good accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

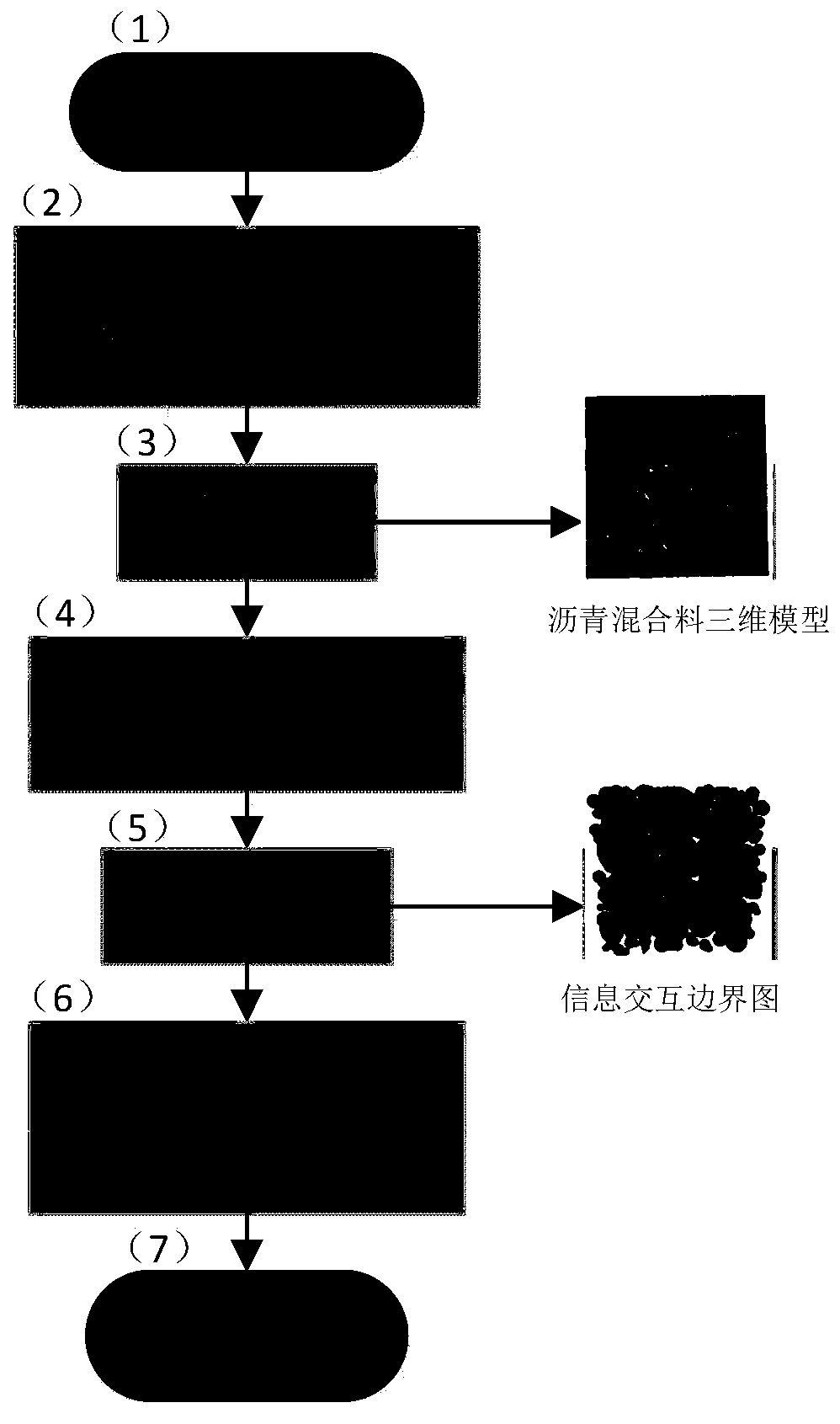

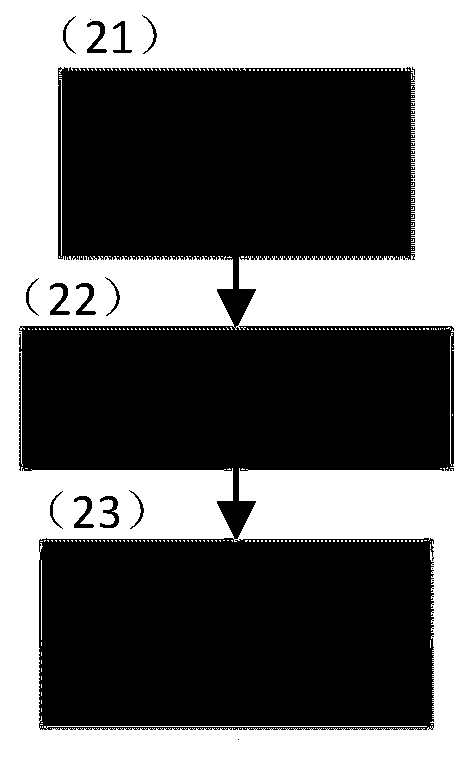

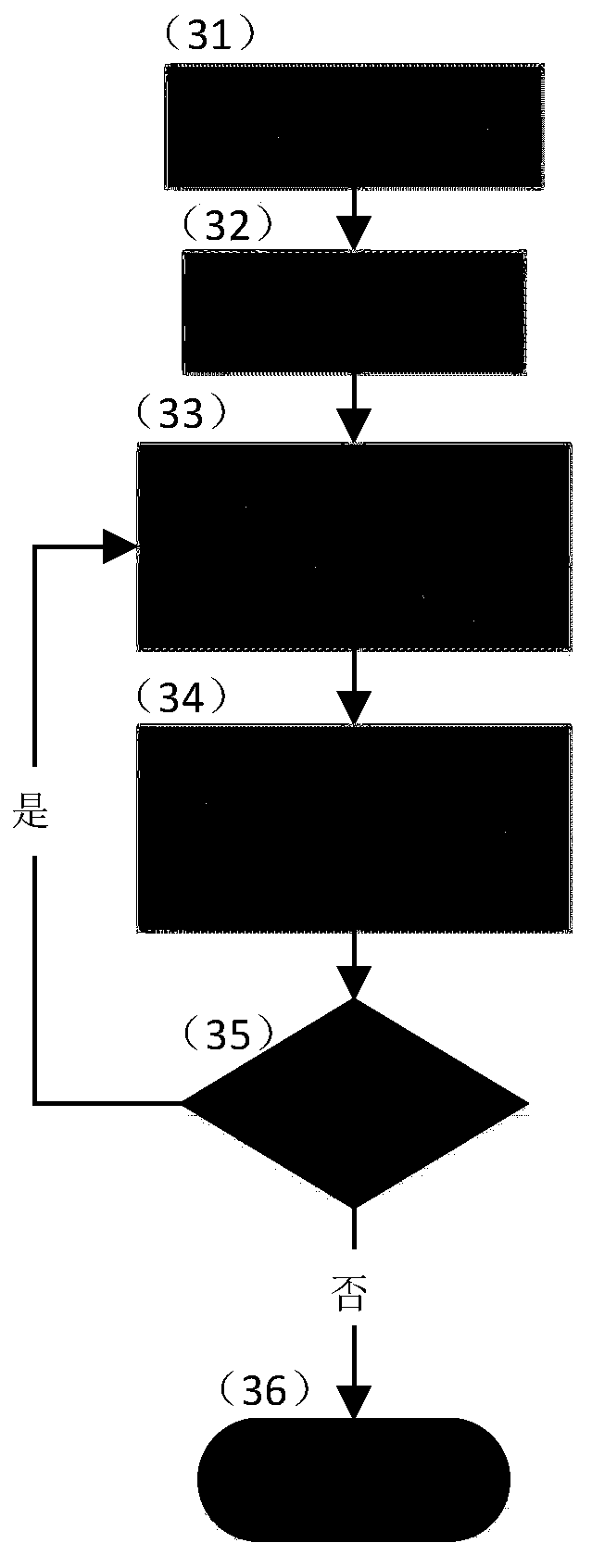

[0009] The working process of the inventive method is as Figure 1-Figure 3 shown.

[0010] figure 1 A flow chart is implemented for a 3D discrete element and finite difference coupled simulation modeling method for asphalt mixtures.

[0011] (1) Scan the asphalt mixture specimen by industrial CT scanning to obtain the CT tomographic picture of the asphalt mixture;

[0012] (2) Process and three-dimensionally reconstruct the CT tomographic image of asphalt mixture to obtain the three-dimensional coordinate values of the pixels in the aggregate, cement and void structure of the asphalt mixture;

[0013] (3) Construct the three-dimensional model of asphalt mixture; establish the discontinuous model of aggregate in the three-dimensional discrete element, and establish the continuous model of asphalt binder in the finite difference method;

[0014] (4) Input the aggregate parameters, asphalt binder parameters, displacement boundaries, model constraint conditions, and load con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com