Prediction method for aluminum alloy thermal deformation behaviors and yield strength after forming

A yield strength and prediction method technology, applied in the field of aluminum alloy processing and forming, can solve problems such as unpredictable post-forming strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082]In order to understand the technical features, objects and effects of the present invention, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings.

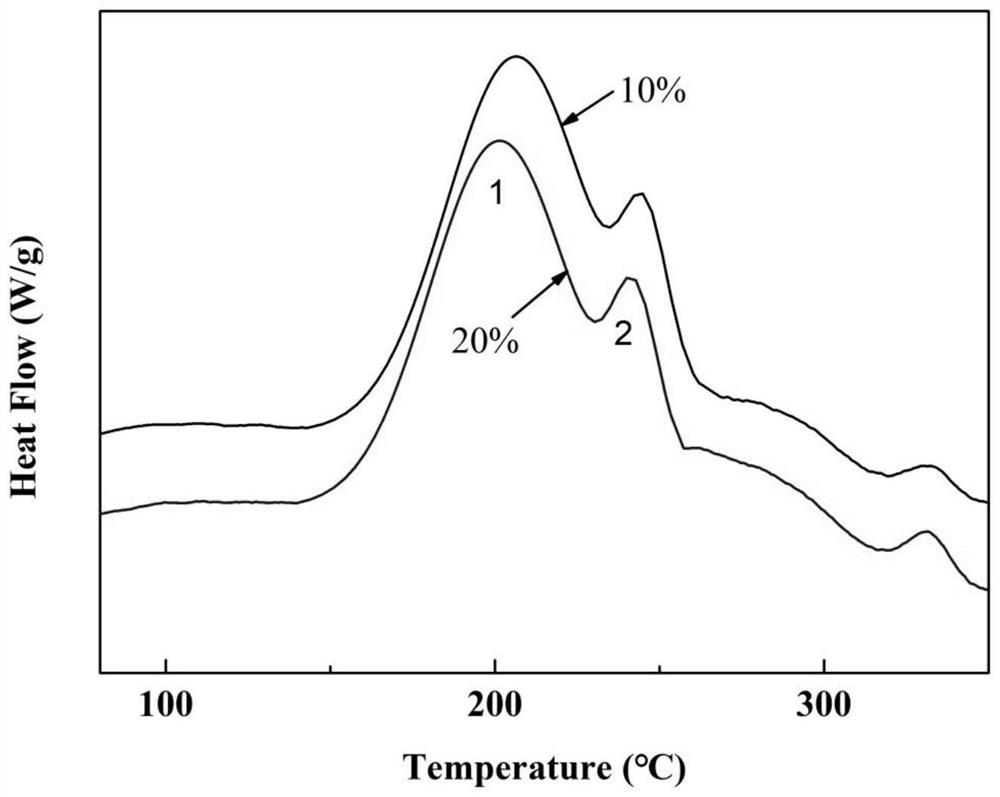

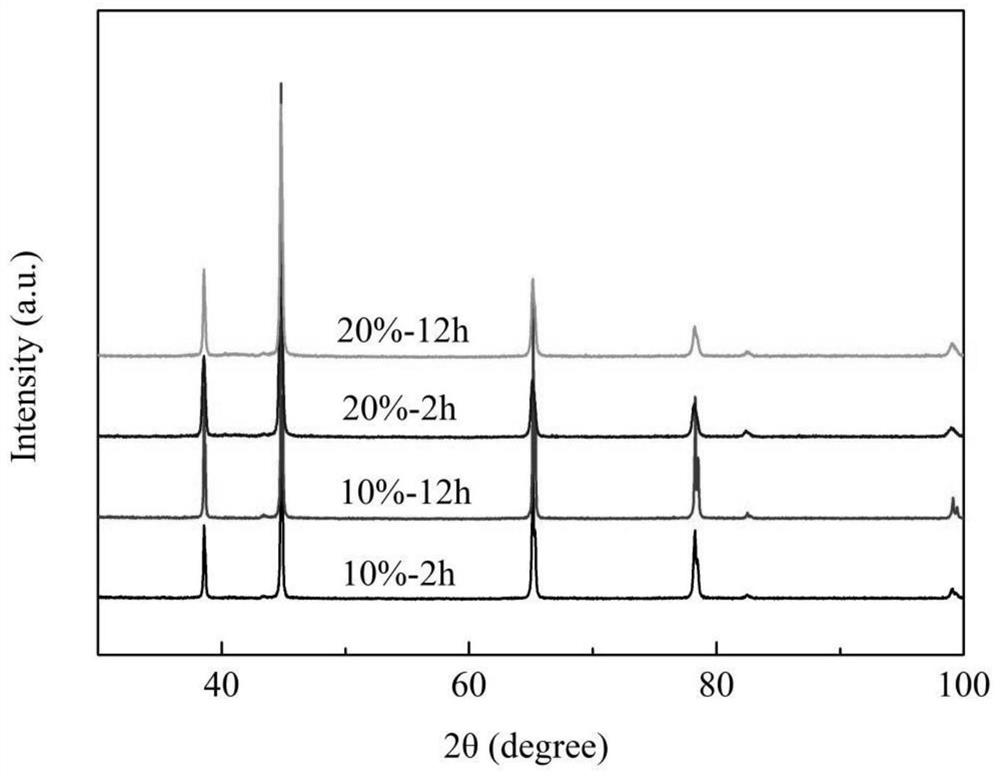

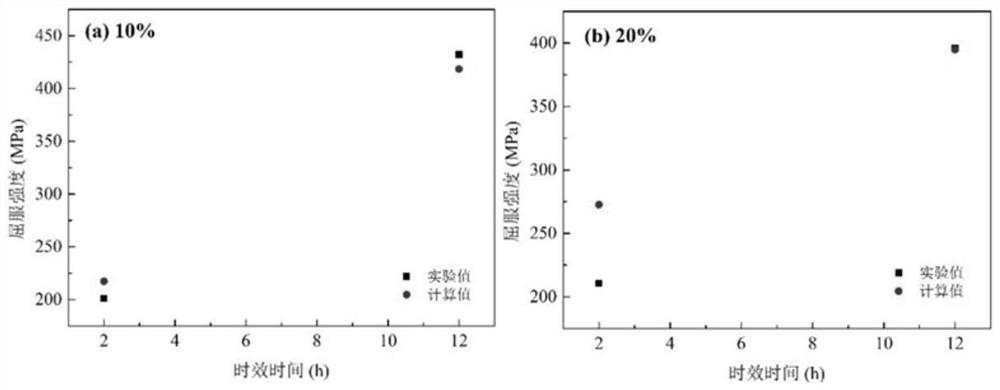

[0083]The prediction method of the aluminum alloy thermal deformation behavior and the formation of the aluminum alloy, and the modifications of aluminum alloy are described by single-axis thermal stretching experiments and aluminum alloys (including hardenability, yielding criteria and fluctuations) and intensity prediction models. Behavior and predict the yield strength of the aluminum alloy after forming, including the following steps:

[0084]S1, by tensile data to solve the local model of aluminum alloy, where aluminum alloy's yield criterion selects a widely used HILL48 anisotropic yield criterion, for planar stress, yield criteria expressions 2F (IJ ) = (G + h) σ112-2Hσ11σ22+ (H + f) σ222+ 2nσ122= Σ2

[0085]Where is σIJ The stress tensor; F, G, H, L, M and N are const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com