Method for preparing titanium alloy/hydroxylapatite gradient composite coating

A hydroxyapatite and composite coating technology, used in coatings, medical science, prostheses, etc., can solve the problems of low tensile bonding strength, accelerated diffusion of titanium alloys and HA atoms, etc., to improve tensile bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

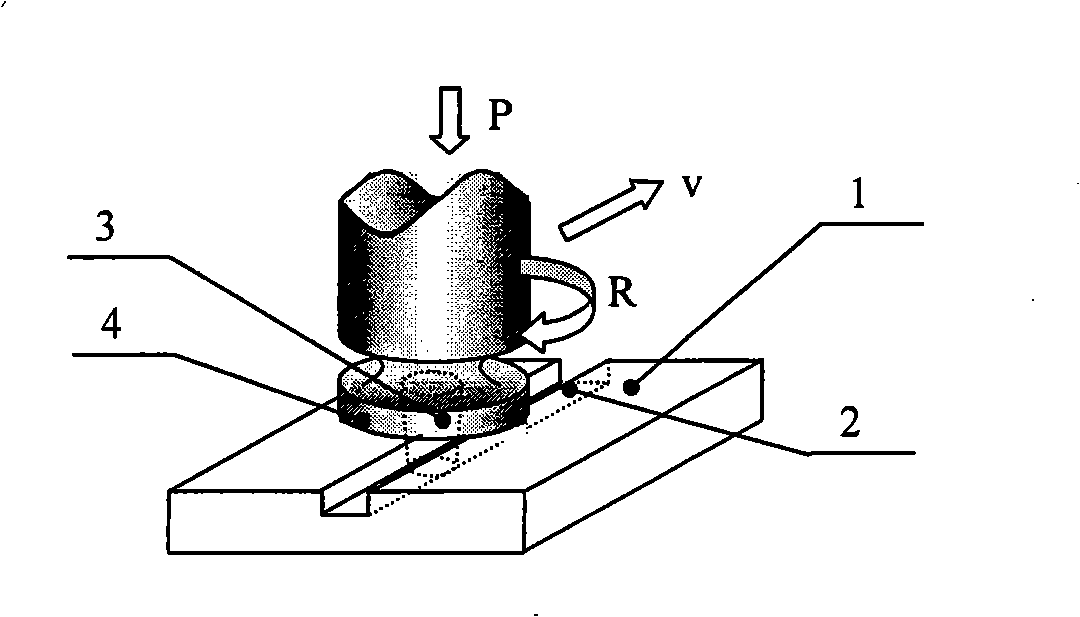

[0018] Example 1: Preparation of HA gradient composite coating on Ti-6Al-4V surface by friction stir.

[0019] Select Ti-6Al-4V titanium alloy 1, grind it with sandpaper, polish it with a polishing machine, clean it ultrasonically with acetone and alcohol for 20 minutes, rinse it with double distilled water, and dry it. Two grooves 2 with a depth of 2 mm and a width of 3 mm are opened on the titanium alloy 1 at an interval of 12 mm, and the grooves 2 are filled with HA micron powder, and the particle size of the micron powder is 3 μm. The stirring head 3 is made of tungsten-rhenium alloy, the diameter of the stirring needle end is Φ3.5mm, the height is 4mm, and the diameter of the stirring head shoulder 4 is Φ12mm. The rotation speed of the stirring head 3 is 850r / min, the lateral movement speed is 36mm / min, and the inclination angle is 2.5°, and the Ti-6Al-4V groove 2 filled with HA micron powder is stirred and rubbed. During the friction stir process, titanium alloy 1 was h...

Embodiment 2

[0021] Example 2: Multi-pass stir friction on the surface of Ti-6Al-4V to prepare a gradient composite coating of HA nanopowder and titanium alloy powder mixed in different proportions.

[0022] Select Ti-6Al-4V titanium alloy 1, grind it with sandpaper, polish it with a polishing machine, clean it ultrasonically with acetone and alcohol for 20 minutes, rinse it with double distilled water, and dry it. Ten grooves 2 with a depth of 4 mm and a width of 4 mm are opened on the titanium alloy 1 at an interval of 12 mm, and the grooves are first filled with 20% by mass of HA nanopowder and 80% of titanium alloy mixed powder. The stirring head 3 is made of tungsten-rhenium alloy, the diameter of the stirring needle end is Φ3.5mm, the height is 4mm, and the diameter of the stirring head shoulder 4 is Φ12mm. The rotation speed of the stirring head 3 is 700r / min, the lateral movement speed is 90mm / min, and the inclination angle is 2.5°, and the Ti-6Al-4V groove 2 containing the mixed p...

Embodiment 3

[0024] Example 3: Gradient composite coating of Ti-6Al-4V nano powder + HA nano powder mixed on the surface of Ti-6Al-4V with a friction stir volume ratio of 1:1.

[0025] Select Ti-6Al-4V titanium alloy 1, grind it with sandpaper, polish it with a polishing machine, clean it ultrasonically with acetone and alcohol for 20 minutes, rinse it with double distilled water, and dry it. A plurality of grooves 2 with a depth of 2 mm and a width of 4 mm are opened on the titanium alloy 1 at an interval of 12 mm, and the grooves are filled with Ti-6Al-4V nano-powder+HA nano-powder mixed at a volume ratio of 1:1. The stirring head 3 is made of tungsten-rhenium alloy, the diameter of the stirring needle end is Φ3.5mm, the height is 4mm, and the diameter of the stirring head shoulder 4 is Φ12mm. The rotation speed of the stirring head 3 is 450r / min, the lateral movement speed is 28mm / min, and the inclination angle is 2.5°, and the Ti-6Al-4V groove 2 containing the mixed nano powder is subj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com