A method of repairing long-volume defects in metal components by friction stir welding

A technology for friction stir welding and metal components, which is applied in metal processing equipment, welding equipment, non-electric welding equipment, etc., and can solve the problems of thinning of the repaired area of metal components, reduced fatigue life of joints, and easy occurrence of interface defects. The effect of increasing metallurgical bonding effect, increasing performance, and not reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

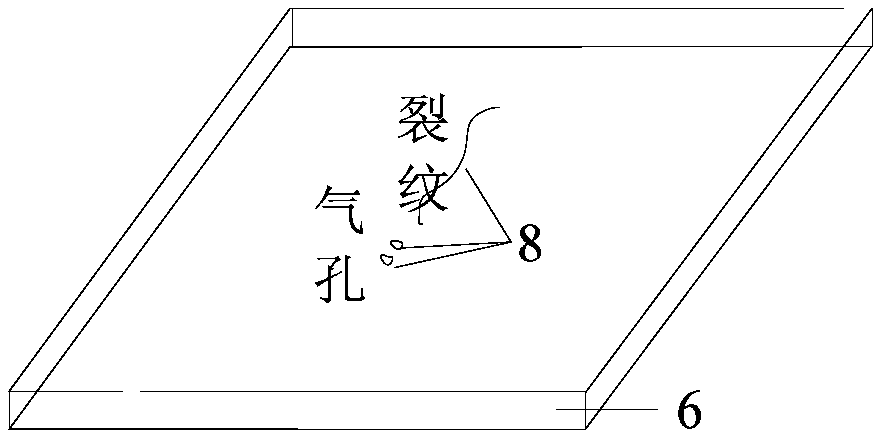

[0029] In this embodiment, friction stir welding is used to repair the internal defect 8 of the casting made of air holes and cracks in the aluminum alloy metal member 6 shown in Fig. 3(a). The operation steps are as follows:

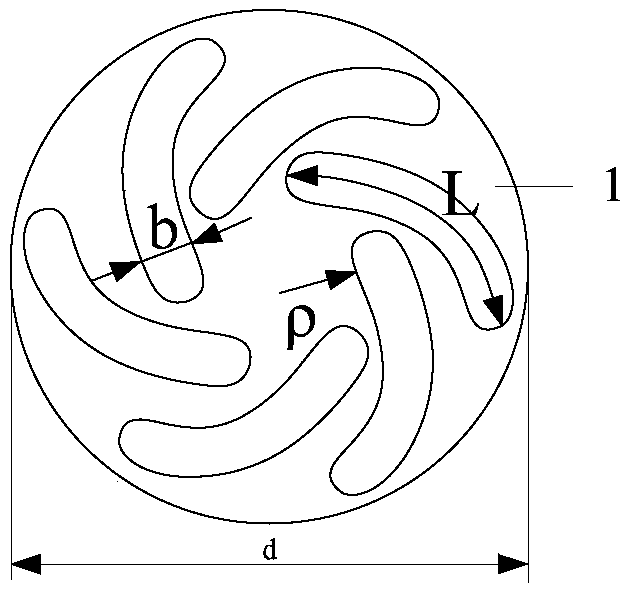

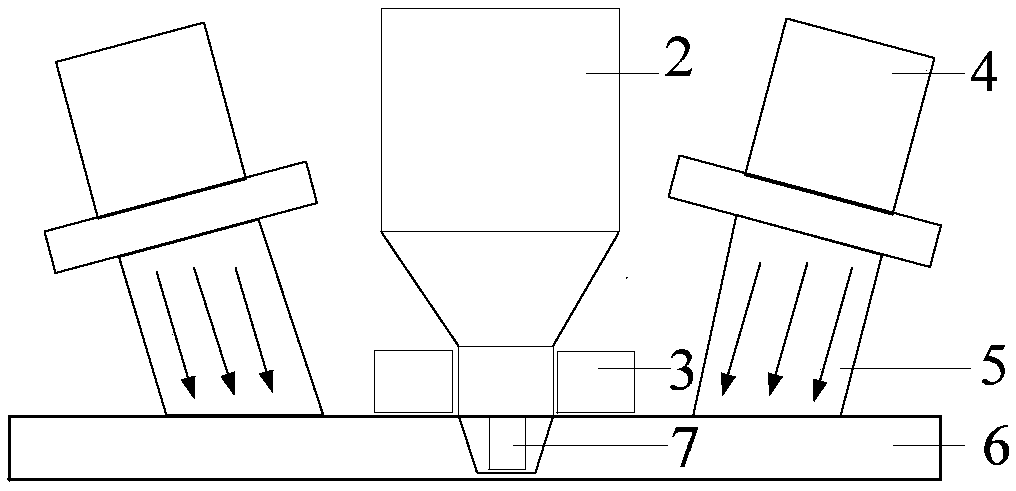

[0030] Step 1, excavate the pores and cracks in the metal member 6 to form a long strip groove 9 (section is П-shaped) as shown in Figure 3 (b), the width and depth of the long strip groove are respectively 3mm and 2mm; then fill the elongated groove with filler metal 7 that is homogeneous to the metal component and of the same size as the groove (such as figure 2 shown);

[0031] Step 2. Place the metal component in step 1 on the backing plate, use multiple spacers (not shown) to level the repaired area of the metal component, and then fix it;

[0032] Step 3, fixing the filler metal in the elongated hook groove of the metal member by fric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com