Patents

Literature

259results about How to "Suppress overflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

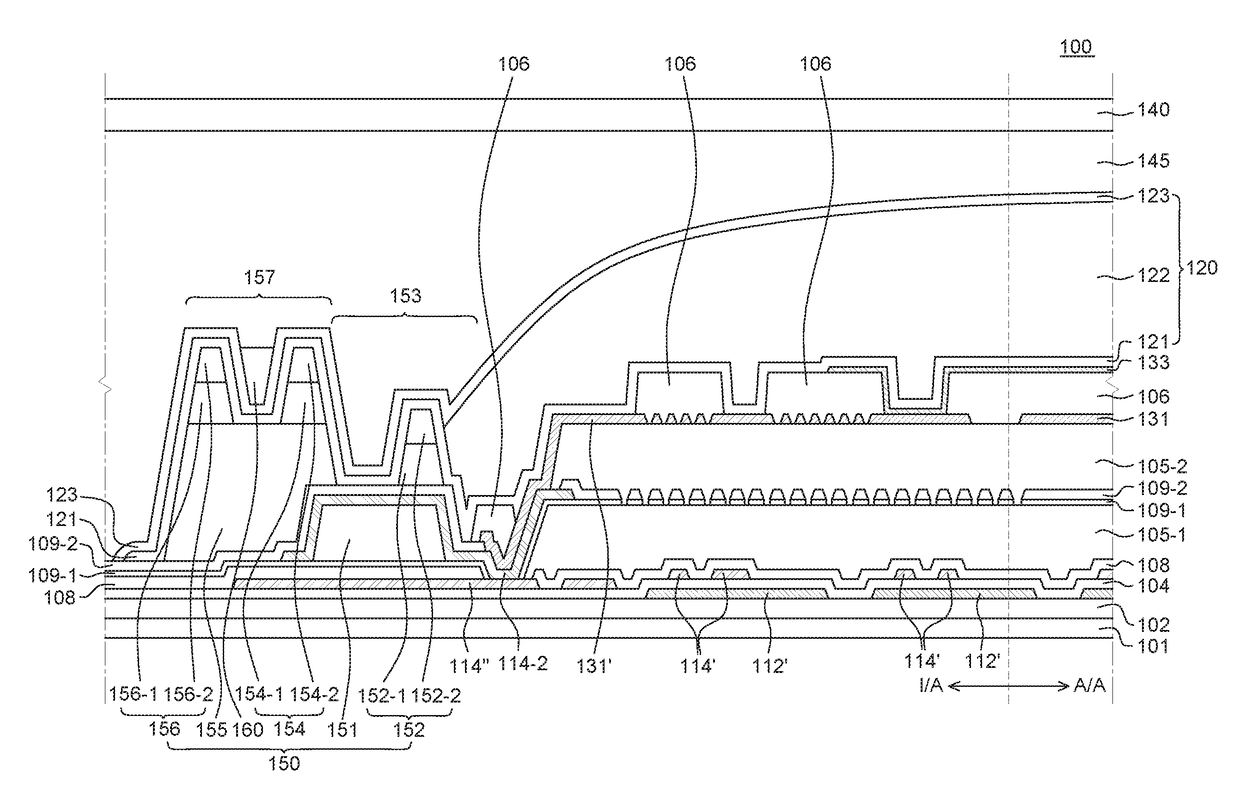

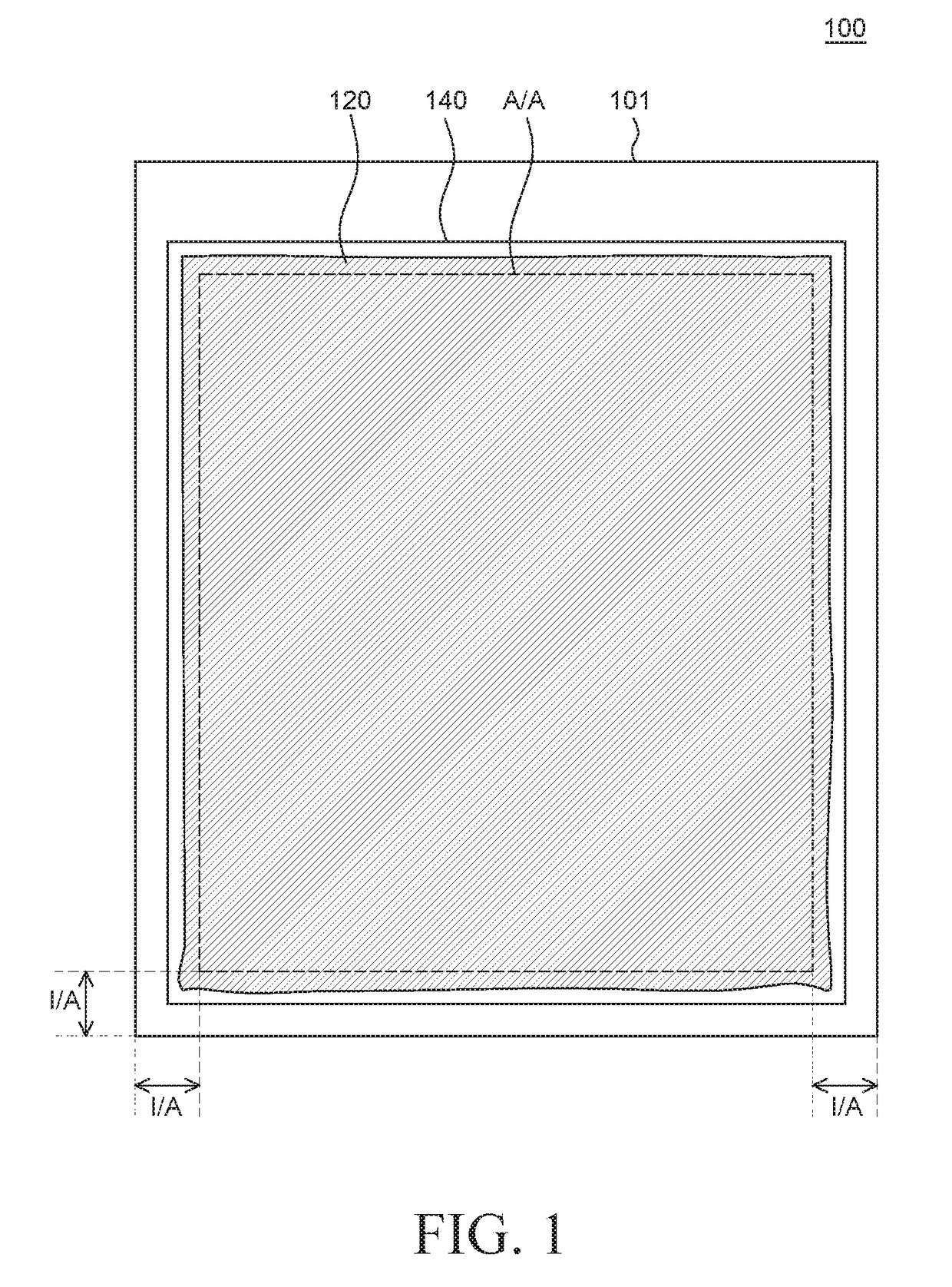

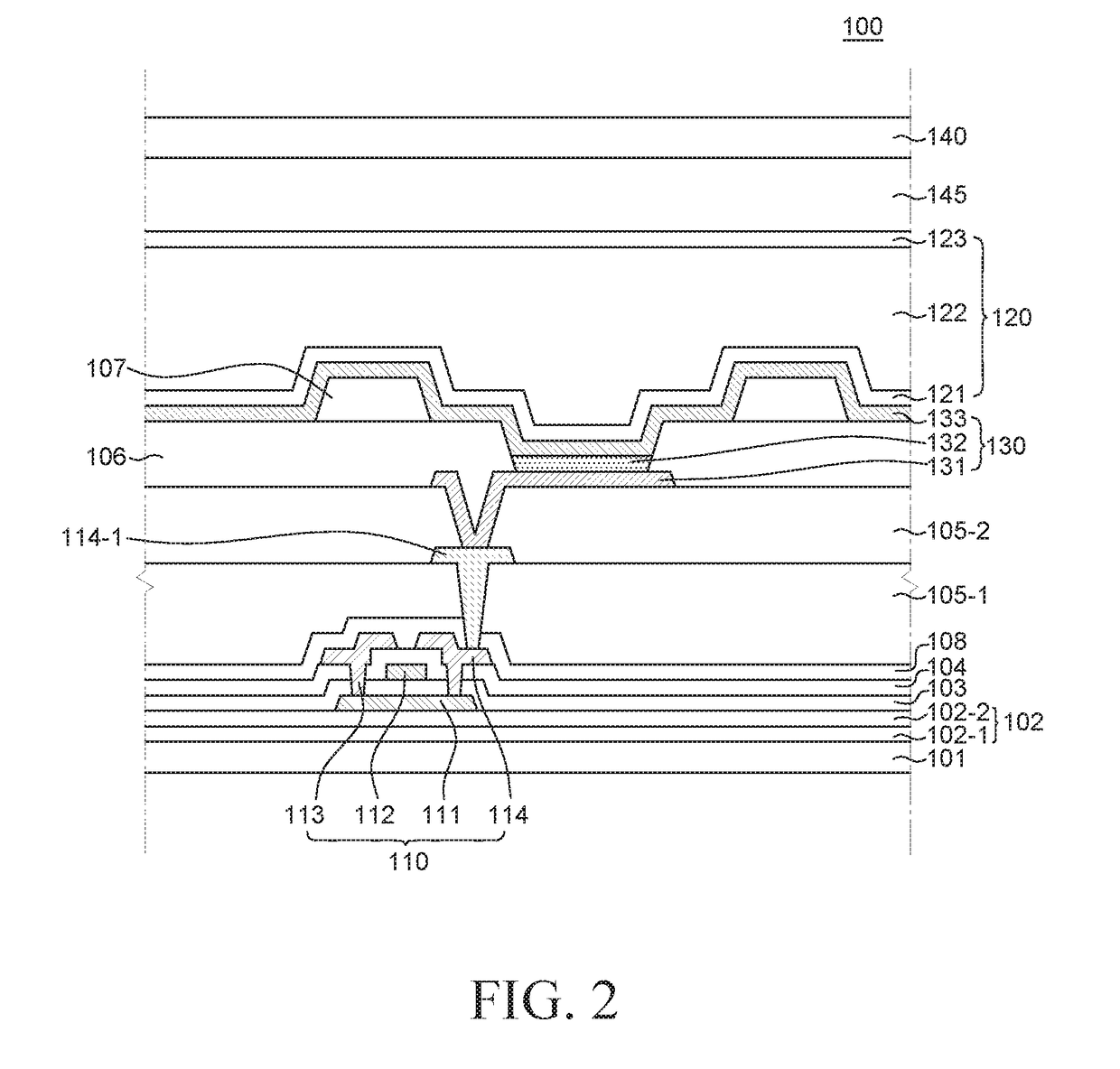

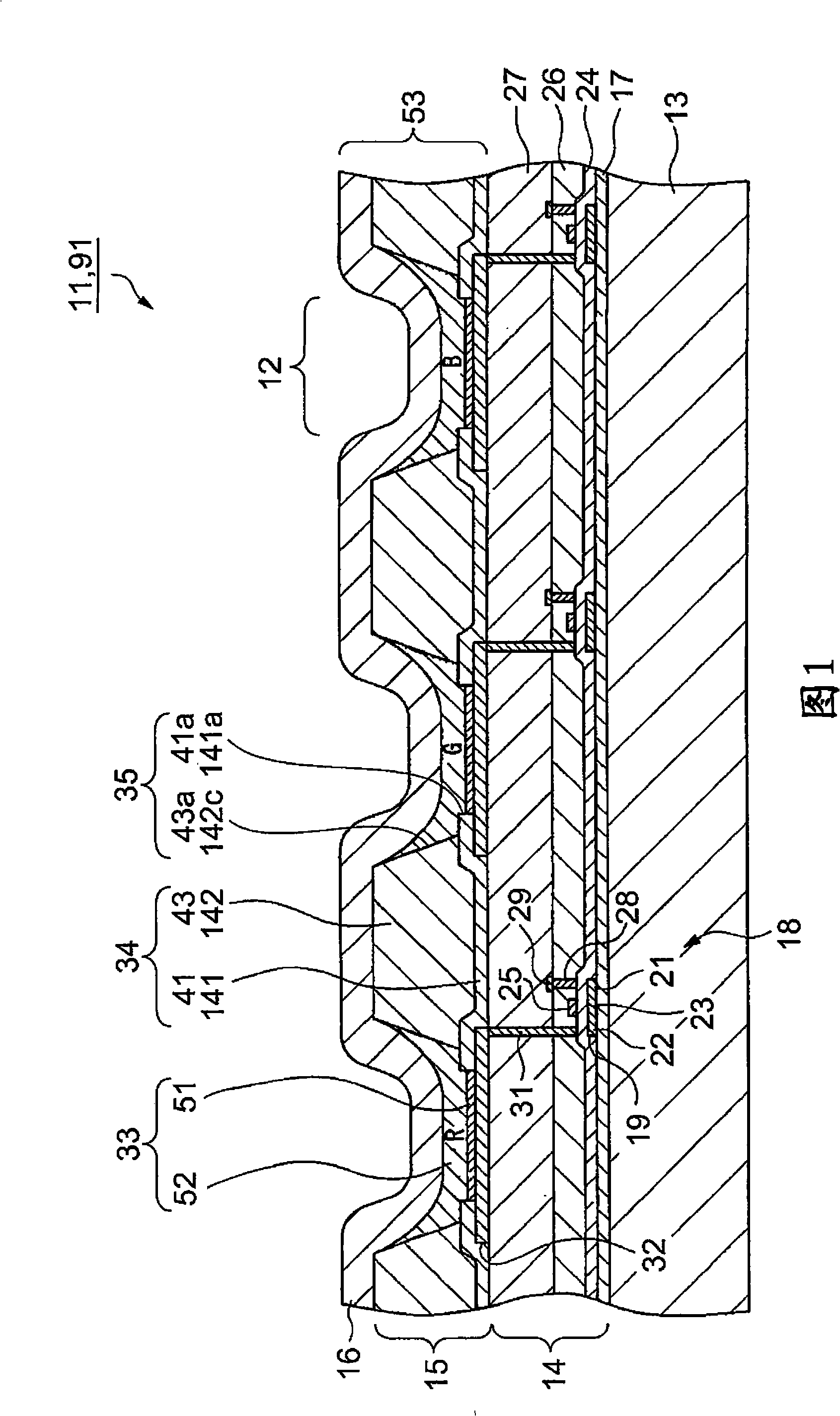

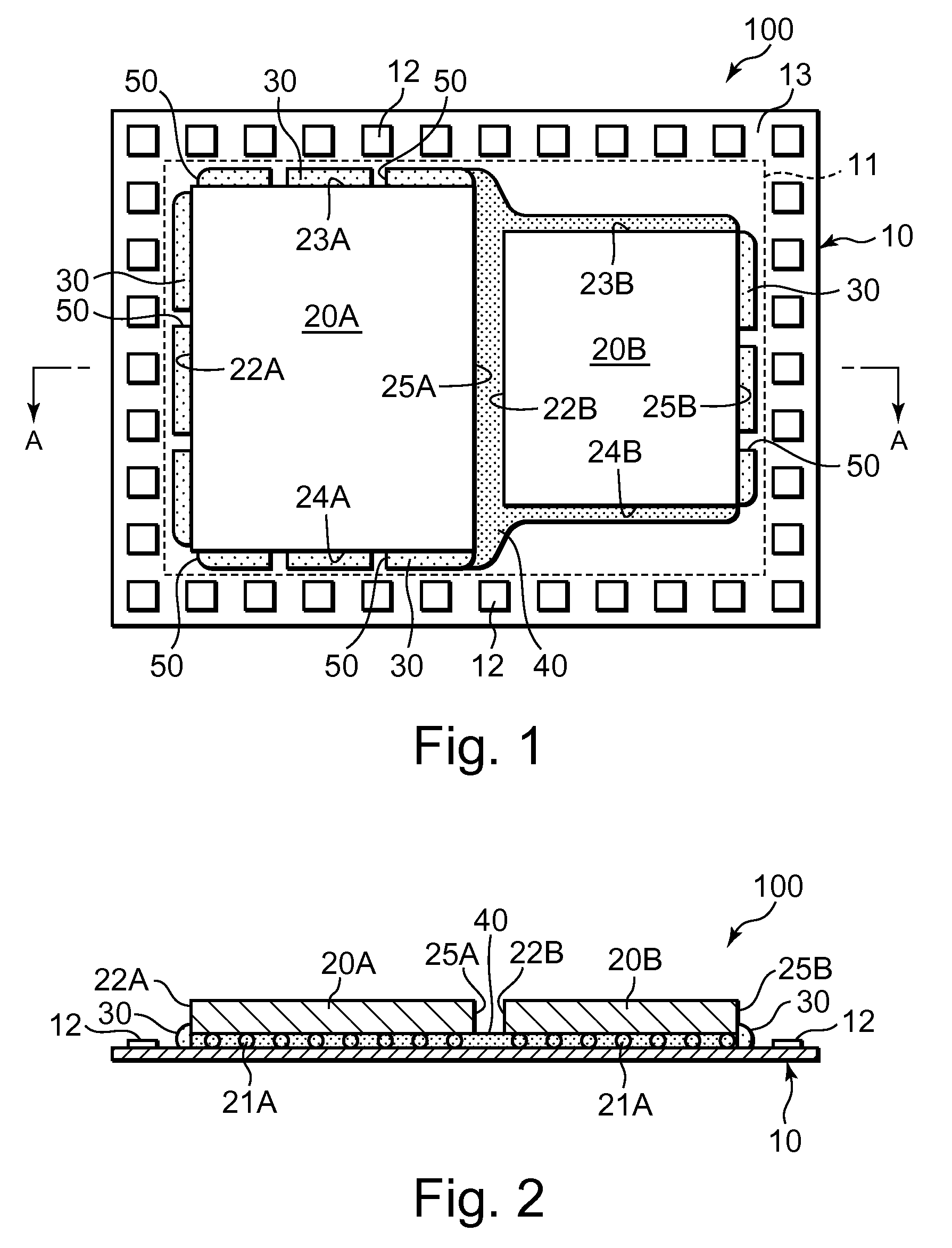

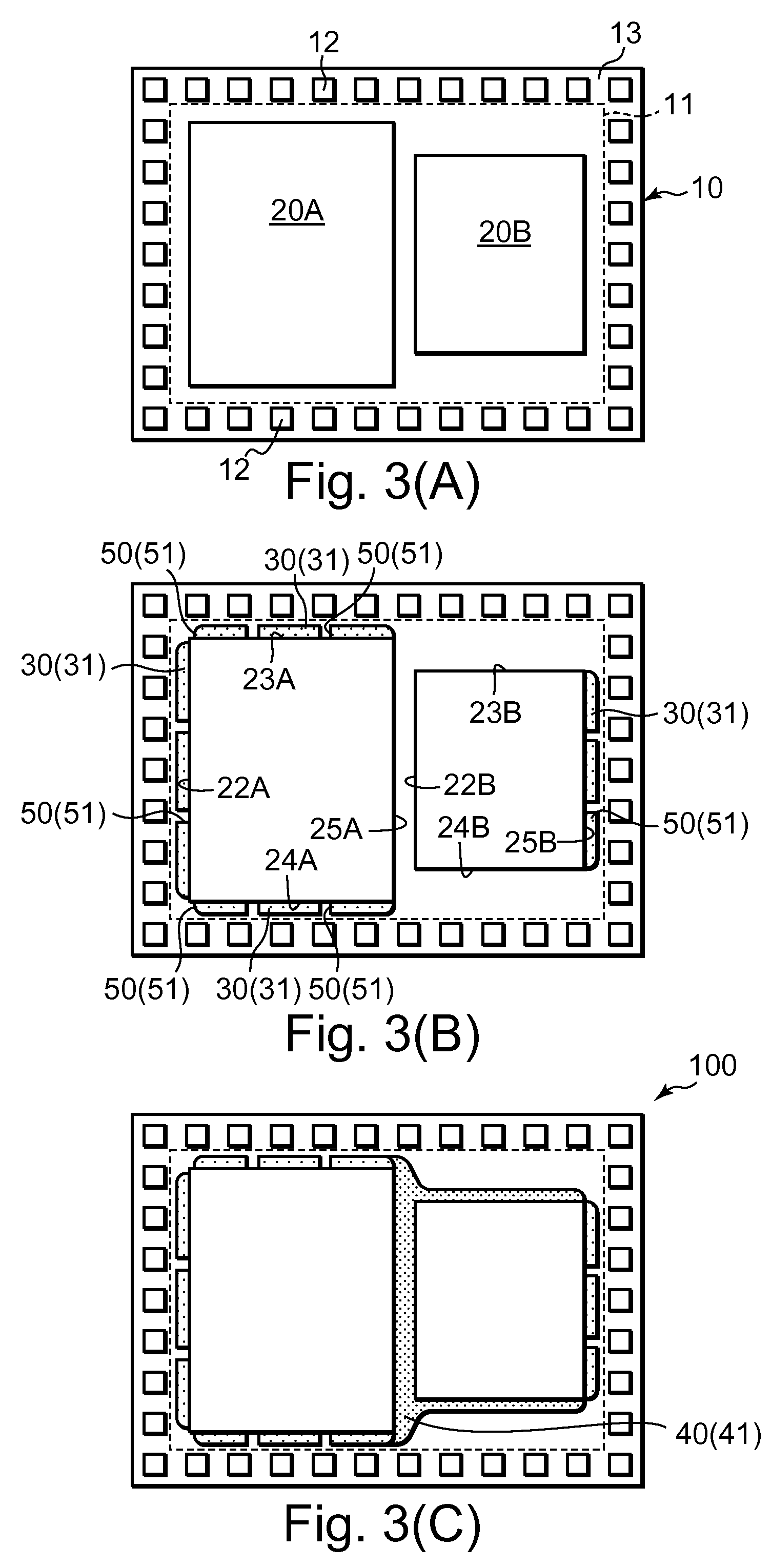

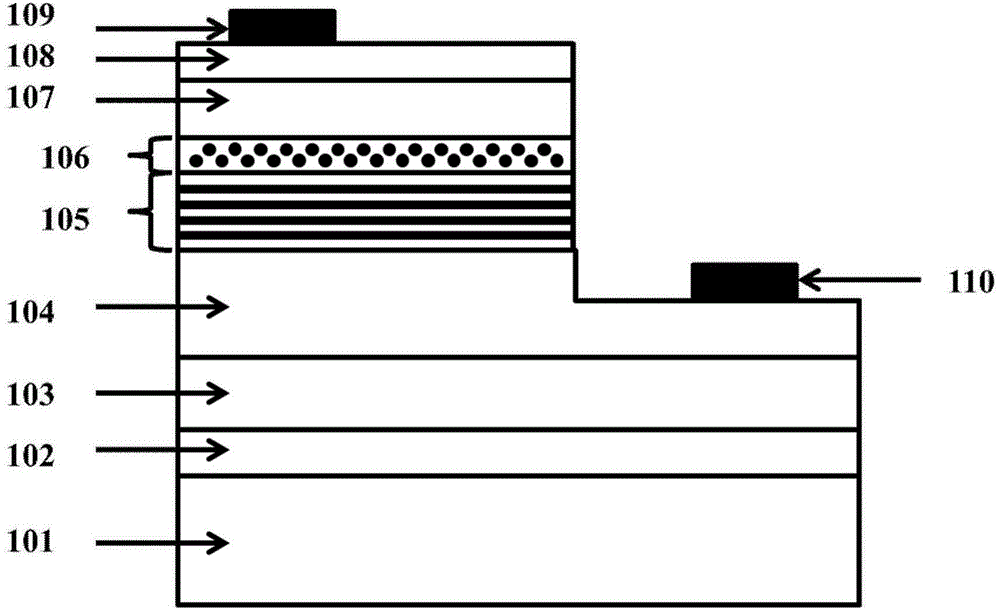

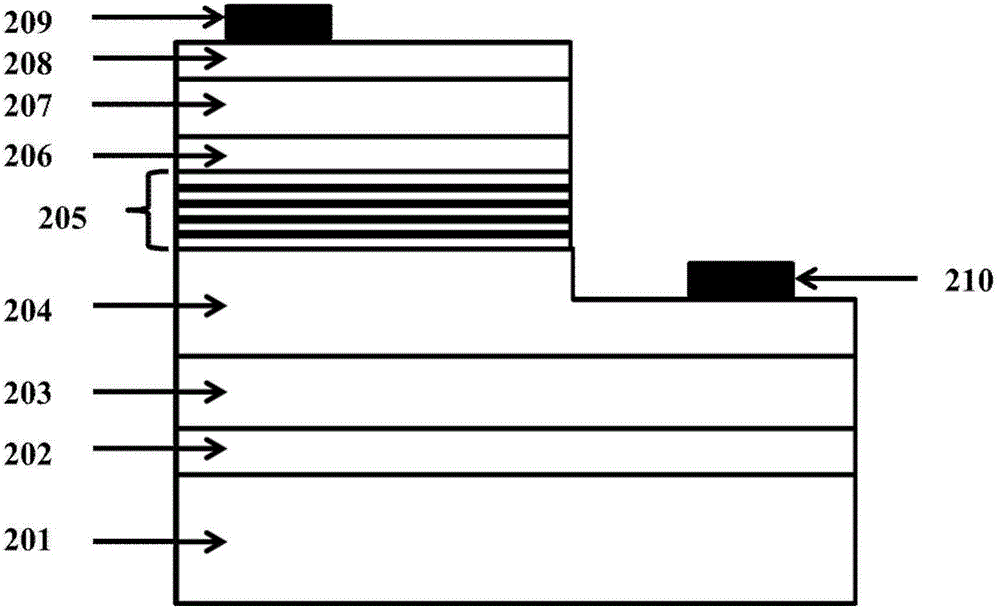

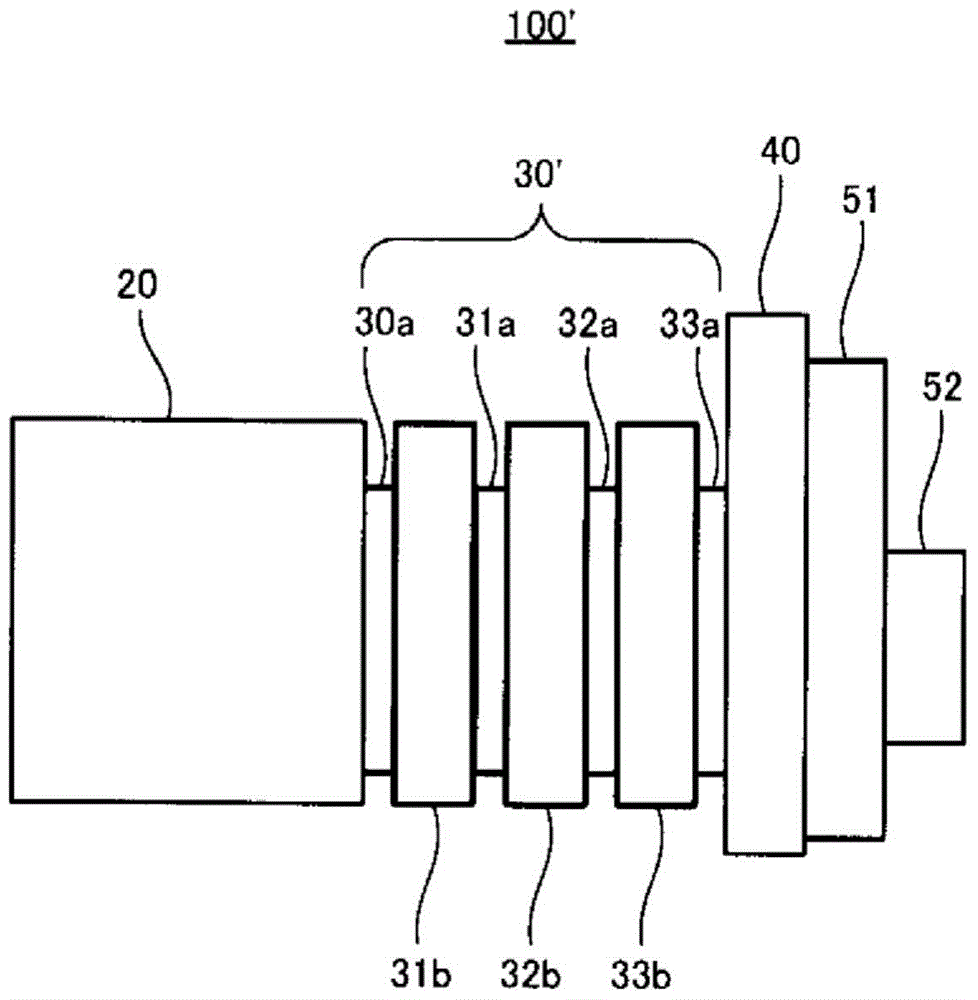

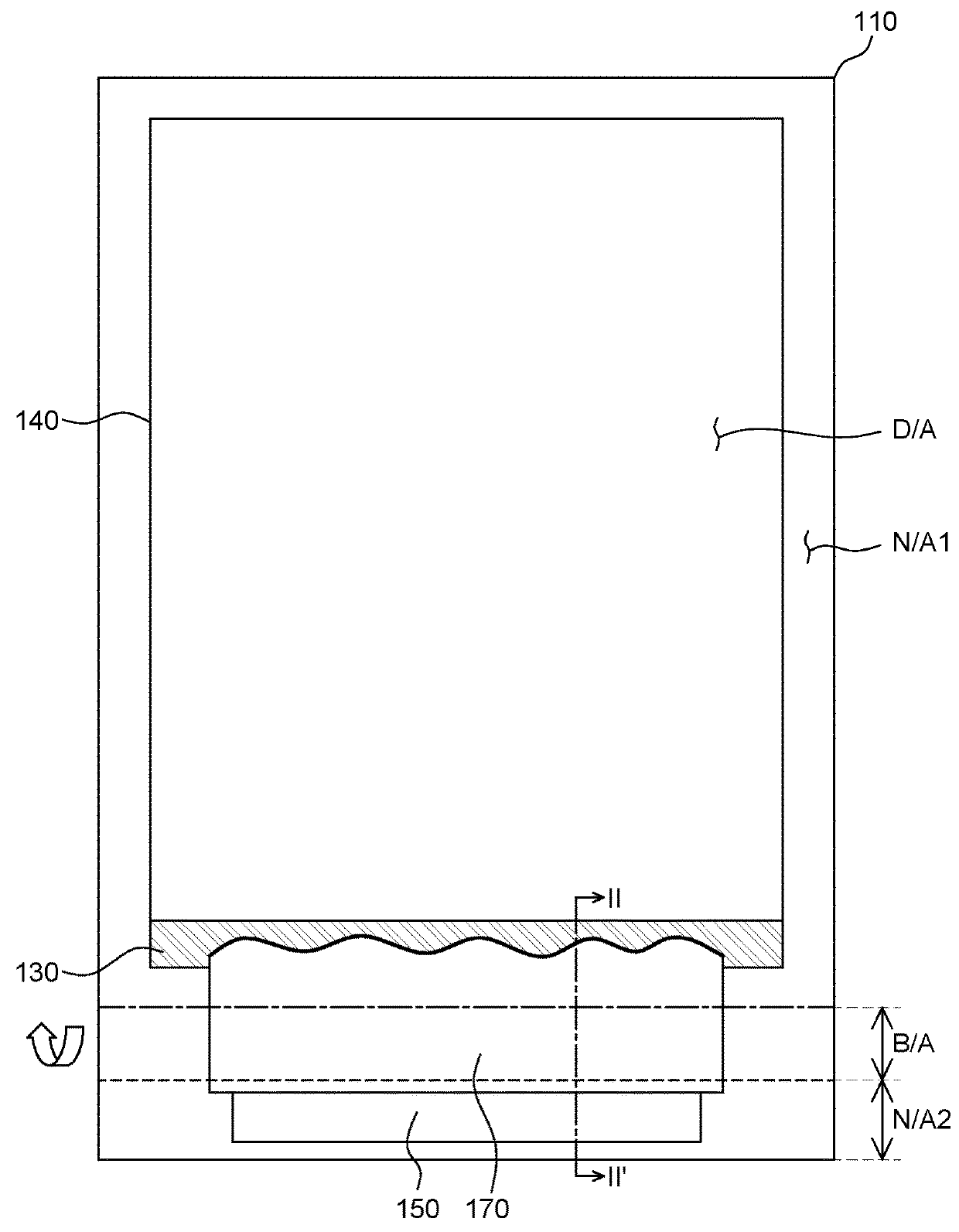

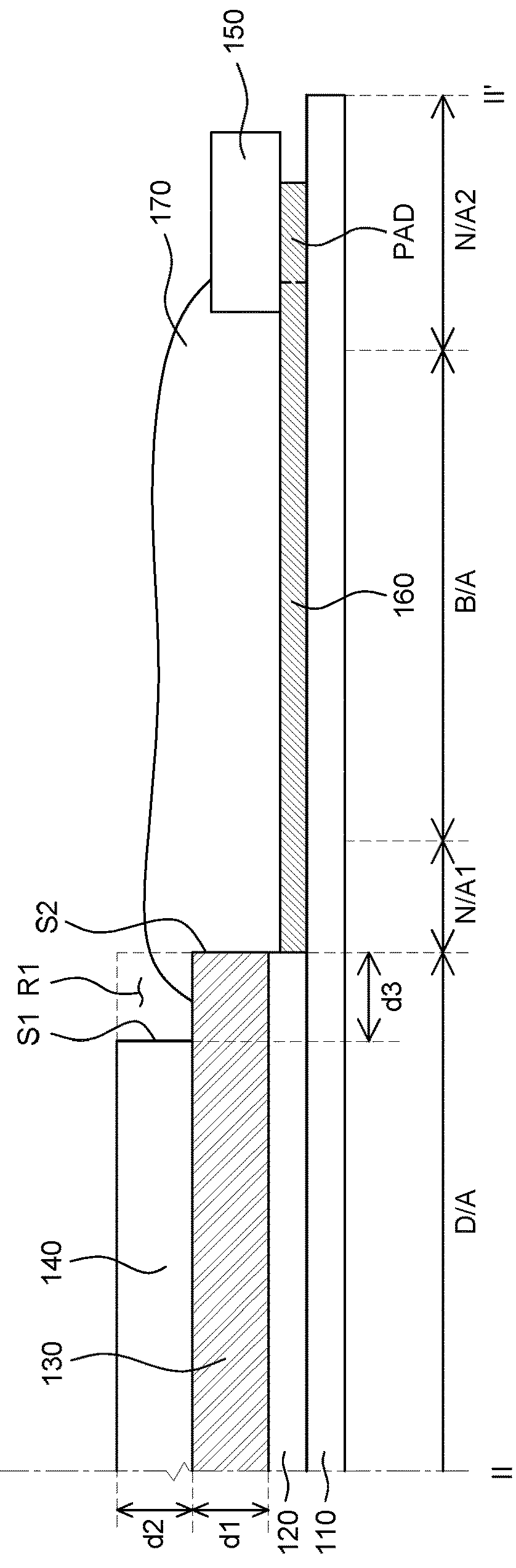

Organic light-emitting display device

ActiveUS20180151838A1Reduce level differenceSuppress overflowSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

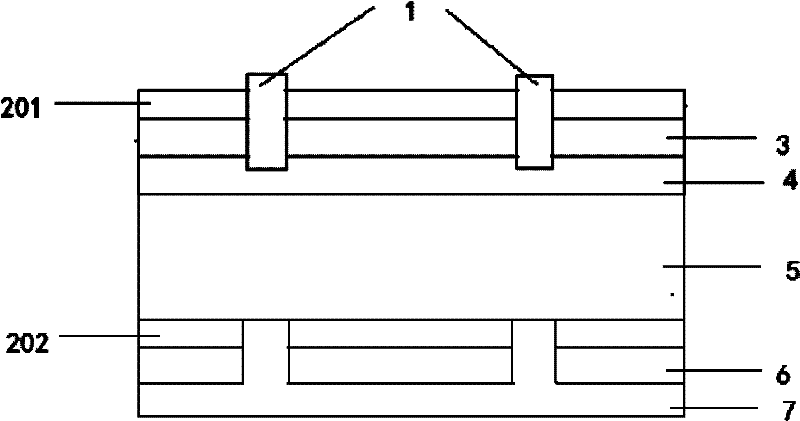

Disclosed herein is an organic light-emitting display (OLED) device including: a substrate comprising an active area and an inactive area surrounding the active area; a first planarization layer; a second planarization layer; an organic light-emitting element; an encapsulation layer comprising a first inorganic layer, a second inorganic layer and a first organic member; a first structure in the inactive area and comprising a first support layer made of the same material as the first planarization layer or the second planarization layer, a second structure in the inactive area and comprising a second support layer made of the same material as the first planarization layer or the second planarization layer.

Owner:LG DISPLAY CO LTD

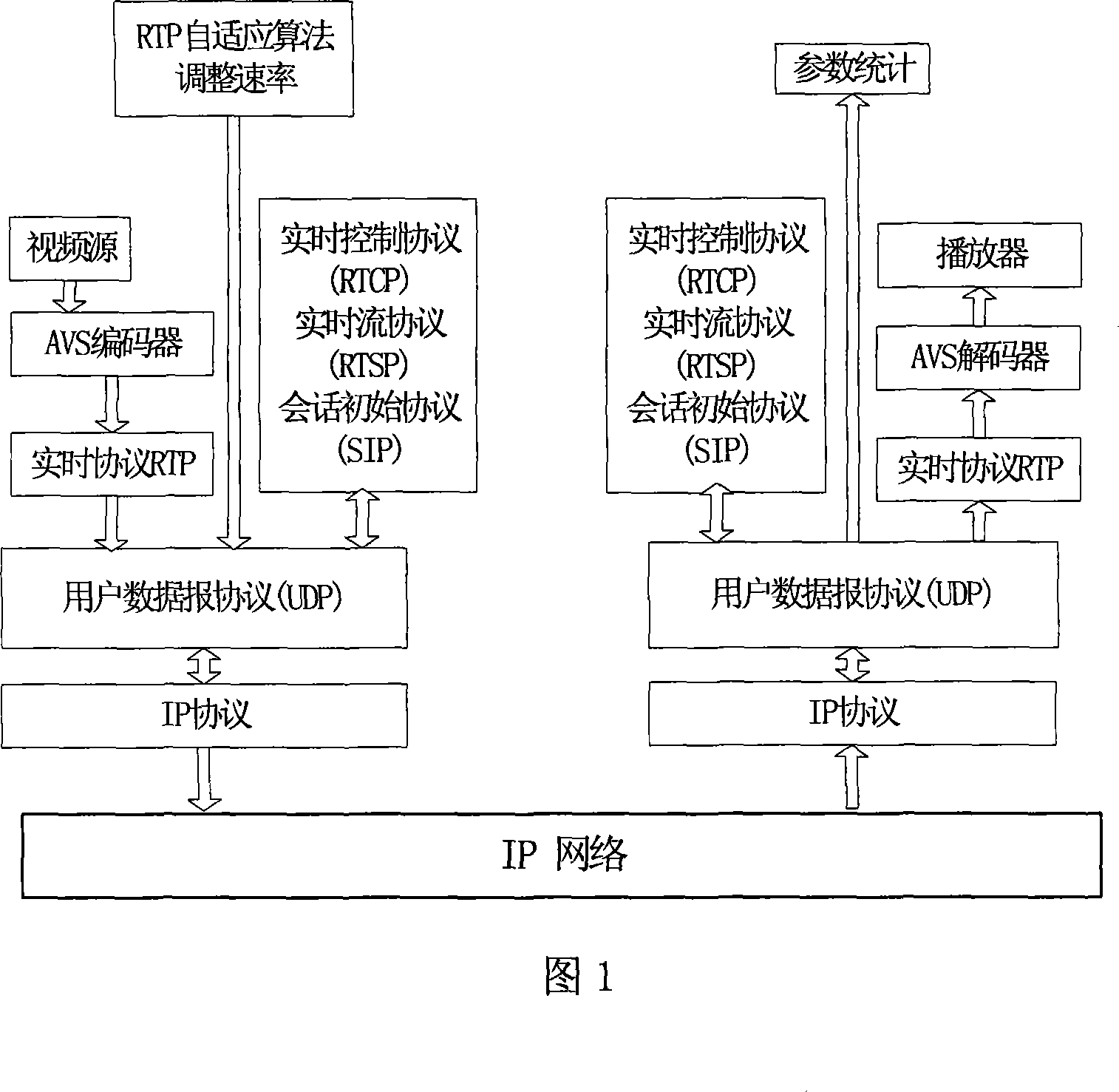

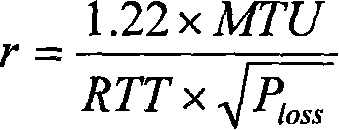

Method for controlling AVS fluid-medium transmission

InactiveCN101075957ASuppress overflowGuaranteed service qualityData switching networksQuality of serviceVideo transmission

The method comprises: counting the output rate of the buffer at receiving end; estimating the sending rate of the sending end; feeding back it to the send end via RTCP; at send end, the estimated transmission rate and the transmission rate returned from the receiving end are compared in order to adjust the transmission rate. The invention controls the buffer overflow and keeps the Quos of video transmission.

Owner:SHANGHAI UNIV

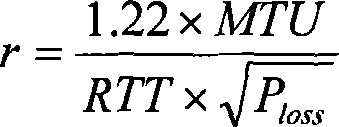

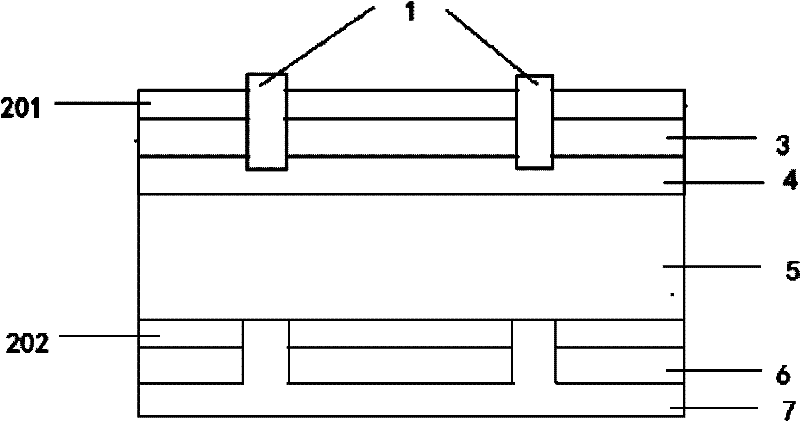

A kind of rear point contact crystalline silicon solar cell and its preparation method

ActiveCN102290473AImprove photoelectric conversion efficiencyIncrease internal reflectionFinal product manufacturePhotovoltaic energy generationPower flowRadiance

The invention discloses a back point contact crystalline silicon solar cell and a preparation method thereof. The front surface of the solar cell is passivated by a silicon nitride / alumina double-layer film, the back surface of the solar cell is passivated by an alumina / silicon nitride double-layer film, and the back surface conducts current by point contact. The preparation method comprises the following steps: preparing the silicon nitride and the alumina, opening pores on the alumina / silicon nitride on the back surface, and removing an affected layer. The solar cell has the advantages of good surface passivation effect, good ultraviolet (UV) radiance resistance performance, high photoelectric conversion efficiency and the like, the back surface enhances internal reflection on the infrared light, and the front surface double-layer anti-reflection coating reduces surface reflection.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

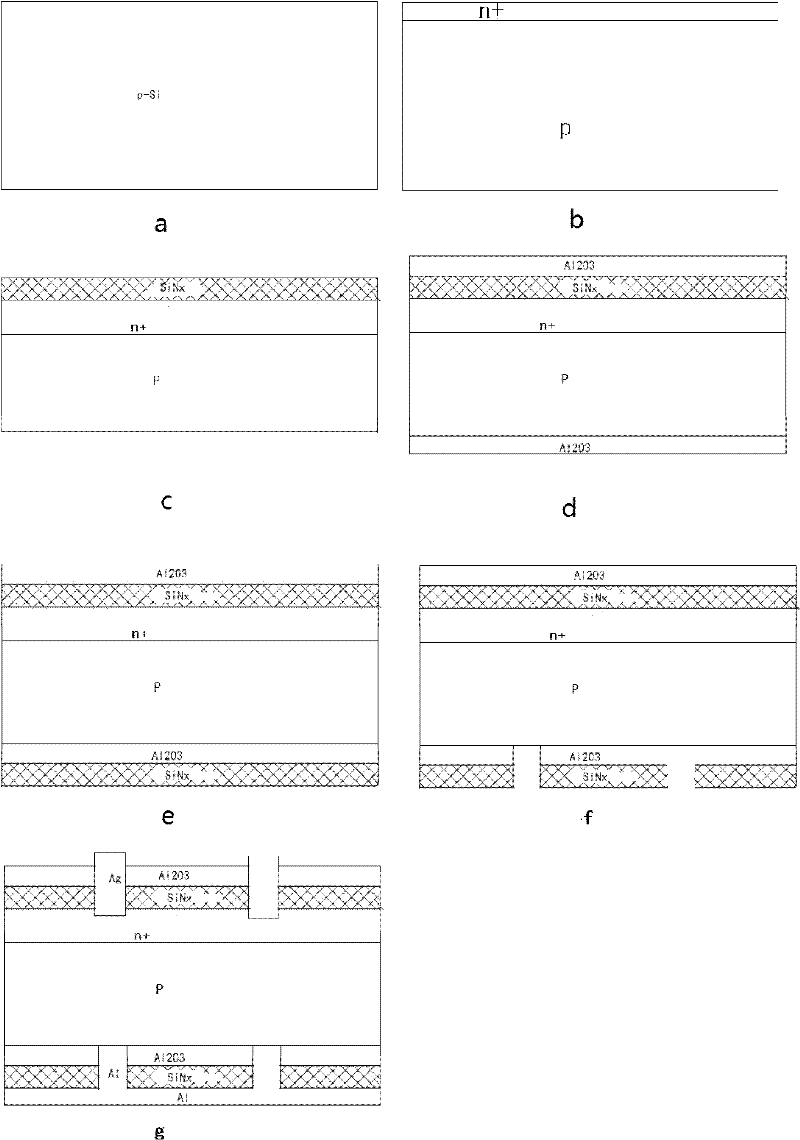

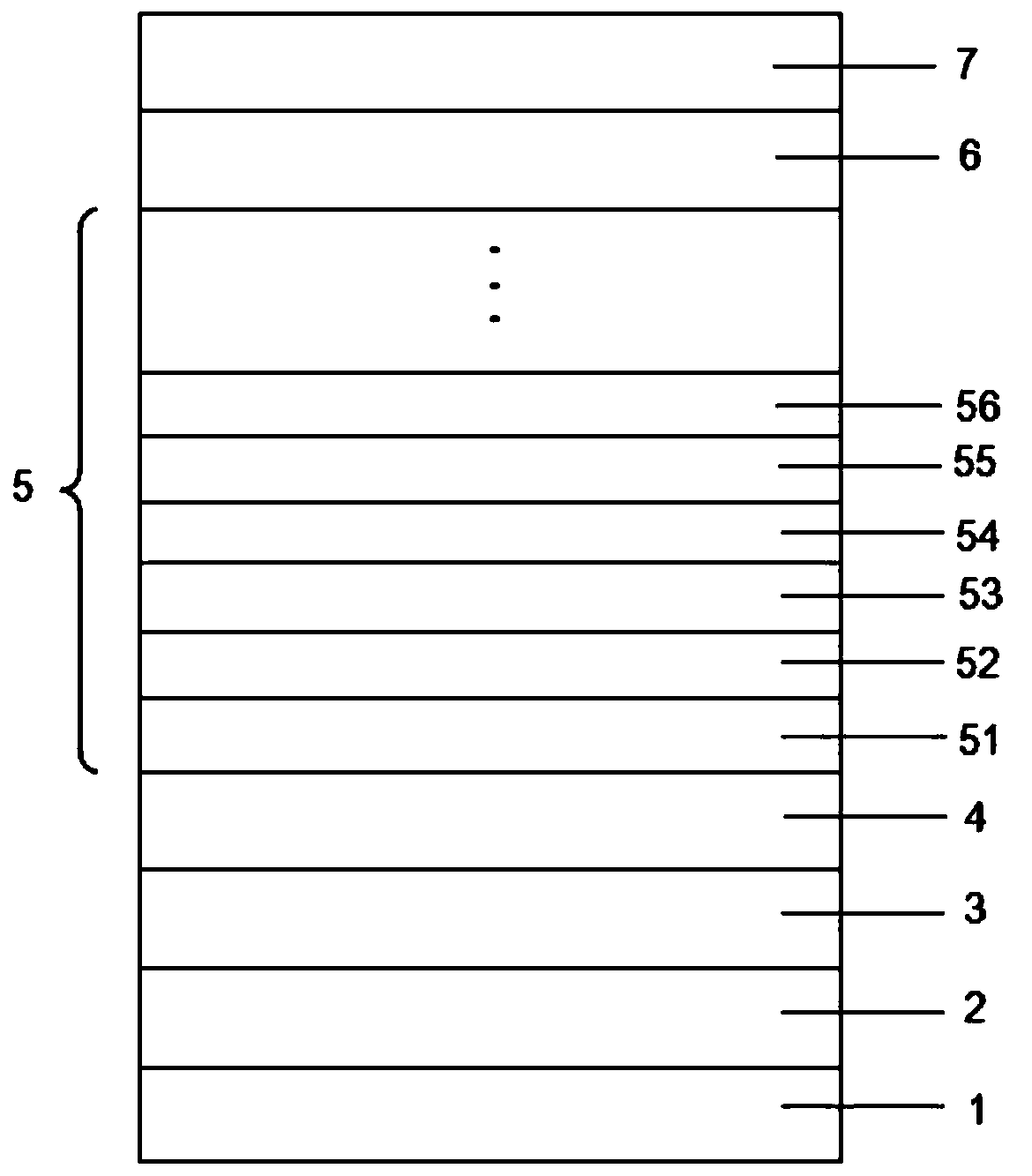

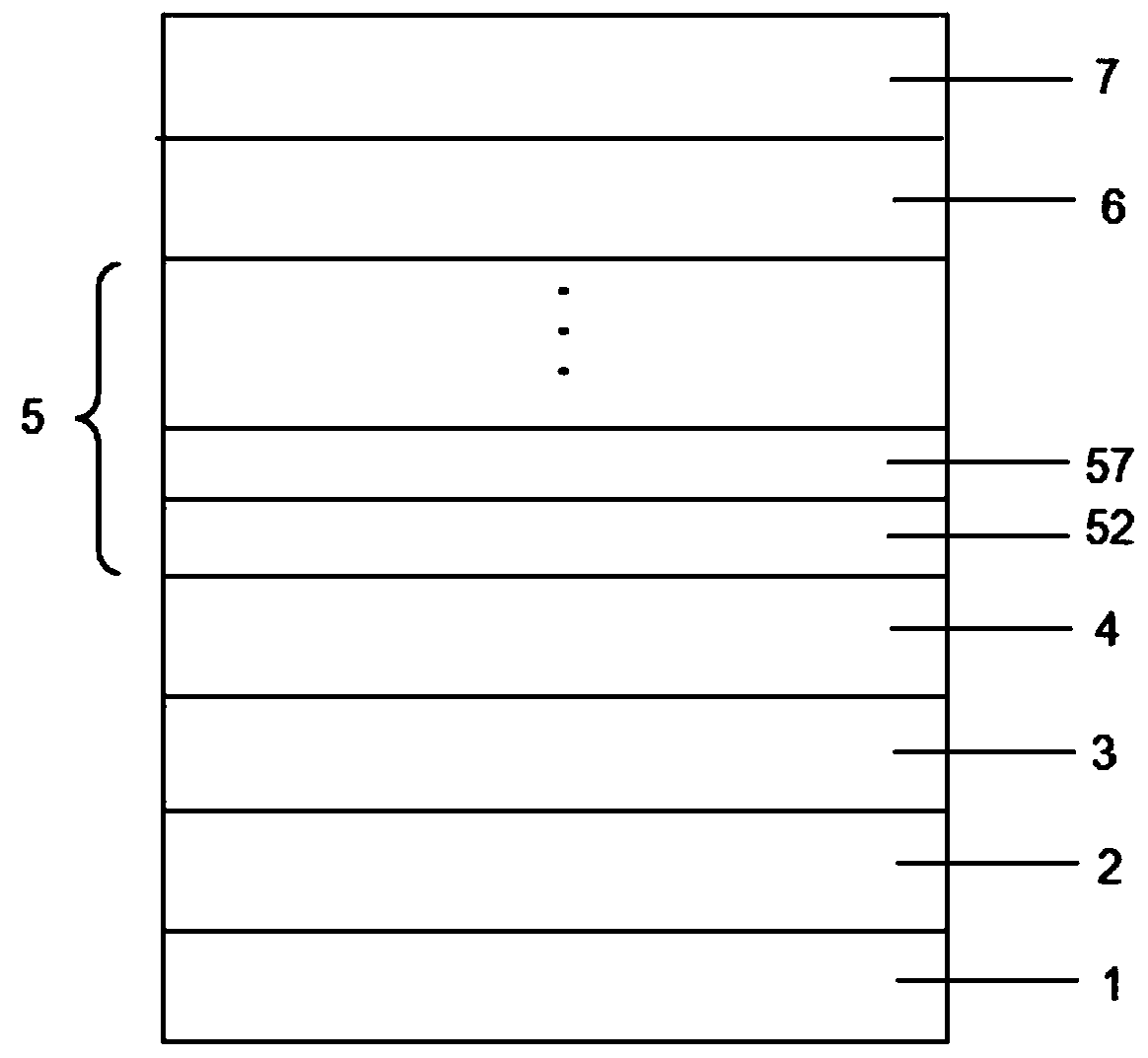

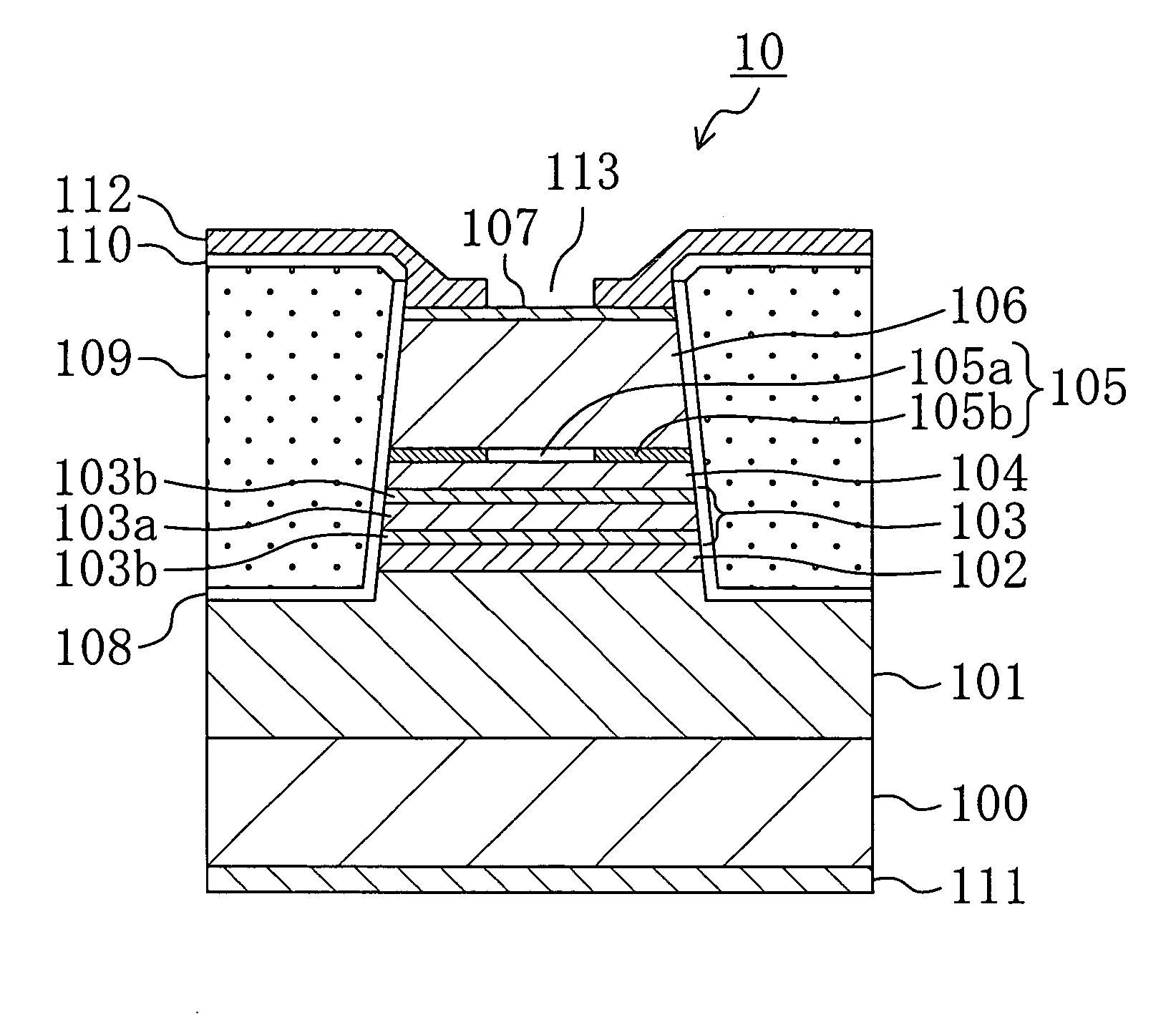

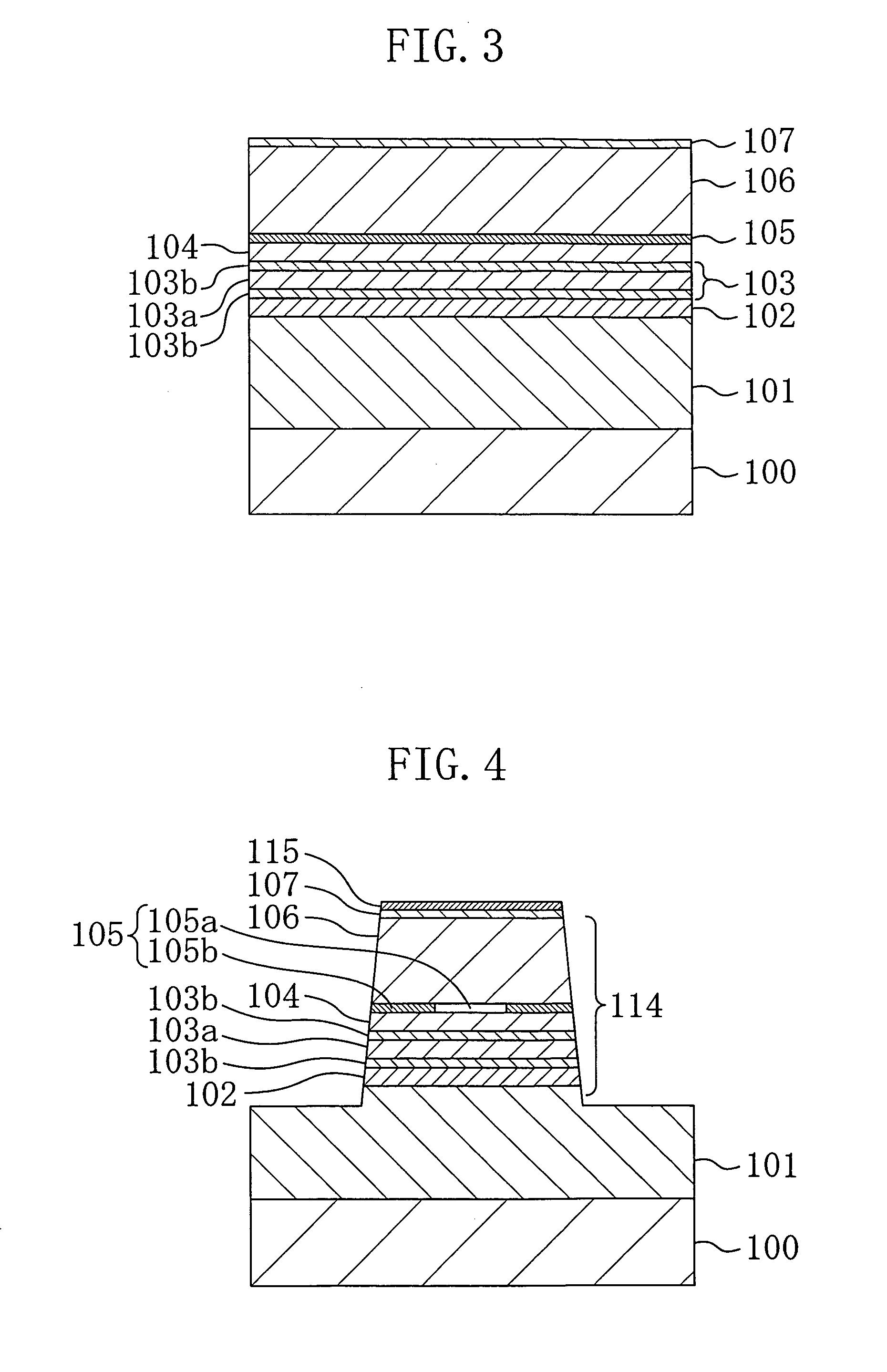

Nitride semiconductor light emitting element and method for manufacturing nitride semiconductor

InactiveCN101689586AGood lattice matchingImprove crystal qualityNanoopticsSemiconductor devicesActive layerNitride semiconductors

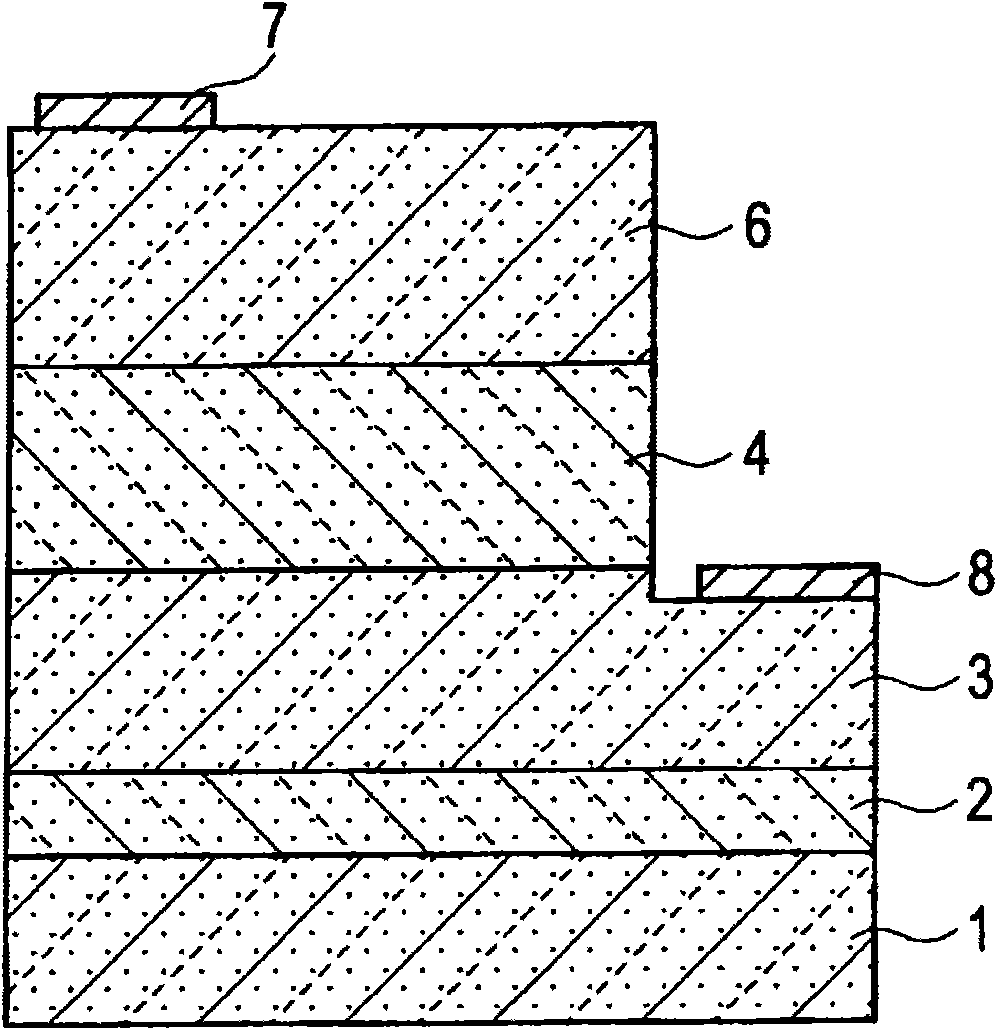

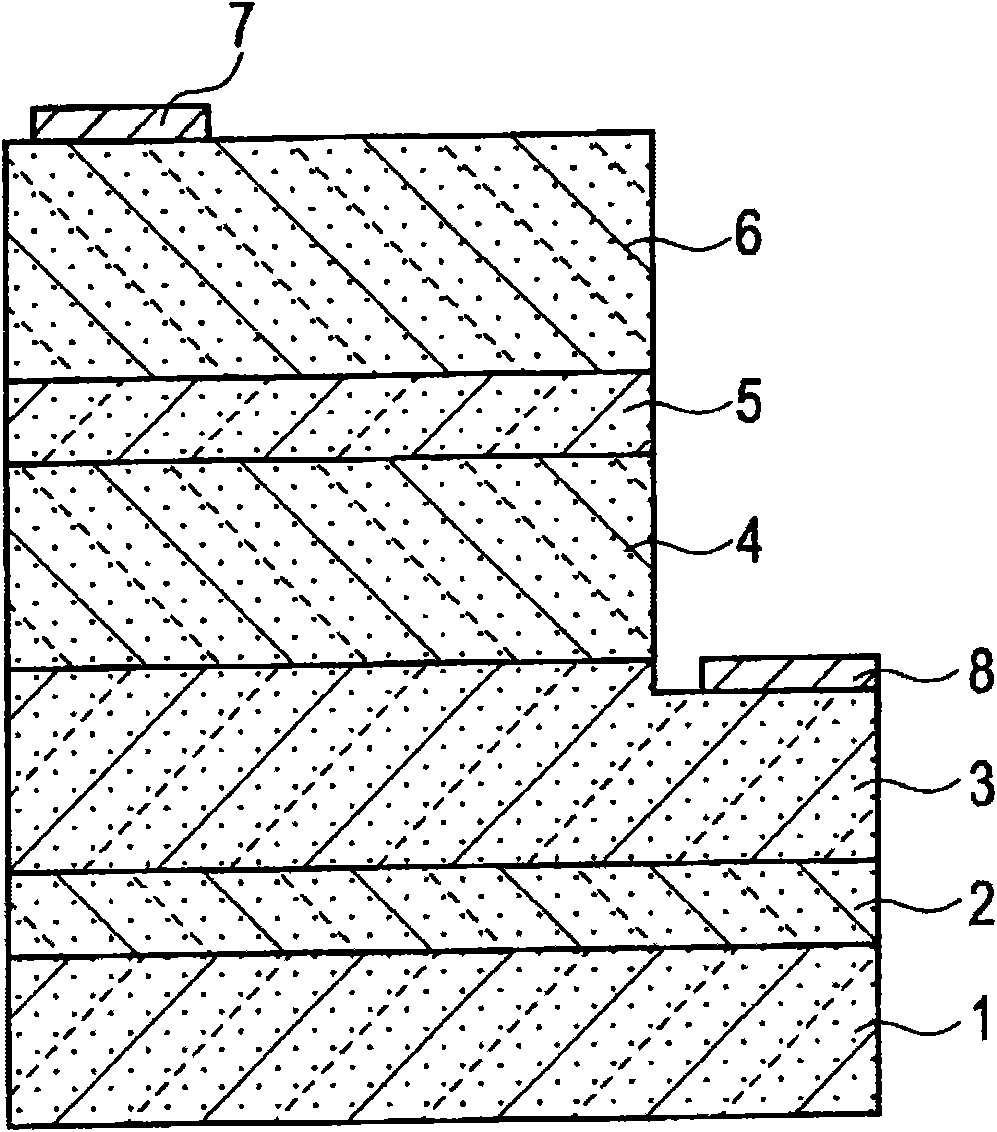

Provided is a nitride semiconductor light emitting element having improved optical output with improved qualities, such as crystal qualities, of a nitride semiconductor laminated on an AlN buffer layer. An AlN buffer layer (2) is formed on a sapphire substrate (1), and on the buffer layer, nitride semiconductors of an n-type AlGaN layer (3), an InGaN / GaN active layer (4) and a p-type GaN layer (5)are laminated in sequence. On the surface of the n-type AlGaN layer (3), an n-electrode (7) is formed, and on the p-type GaN layer (5), a p-electrode (6) is formed. The n-type AlGaN layer (3) operates as a clad layer for confining light and carriers. The AlN buffer layer (2) is manufactured by alternately supplying an Al material and an N material at a growing temperature of 900 DEG C or higher.

Owner:ROHM CO LTD

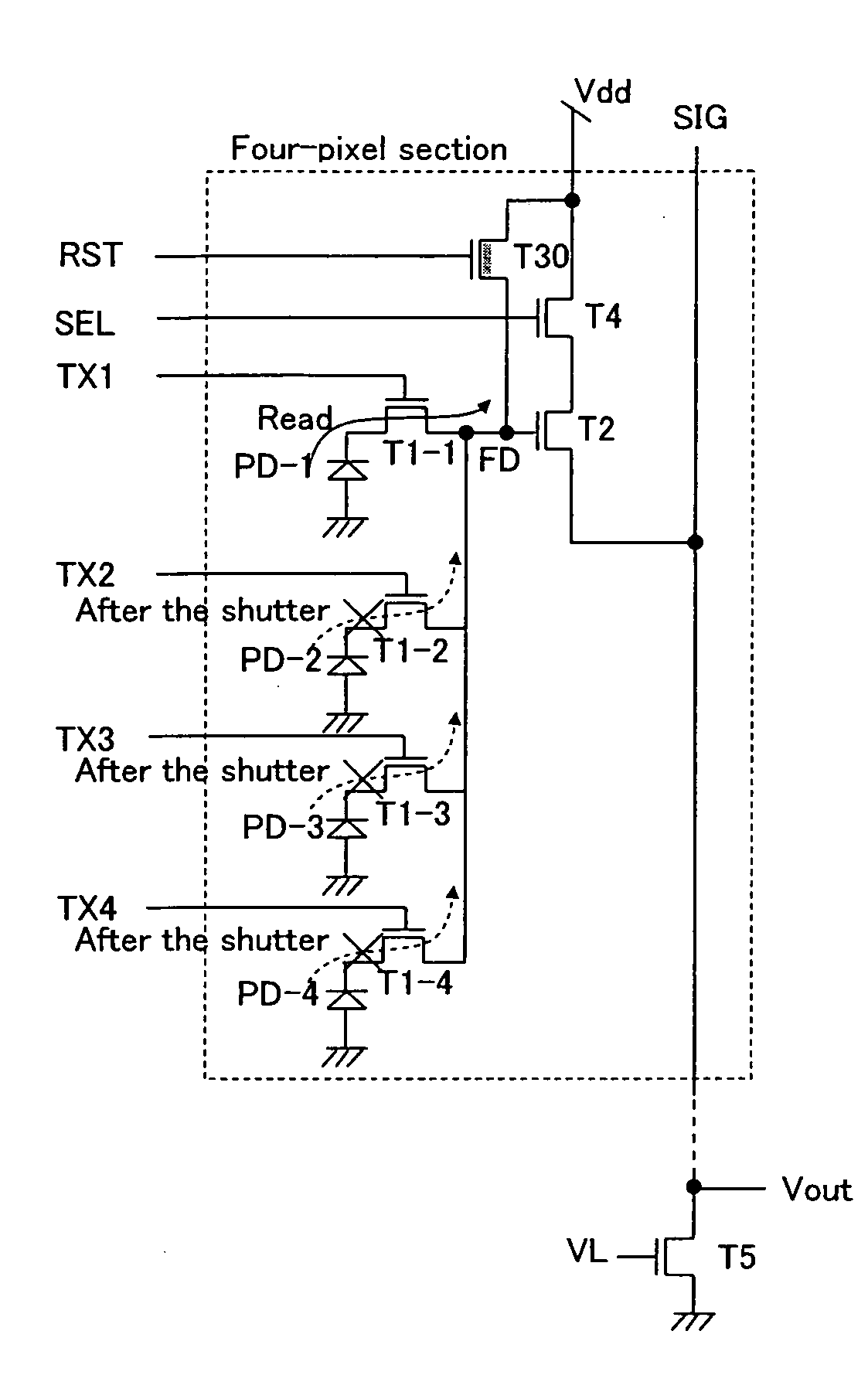

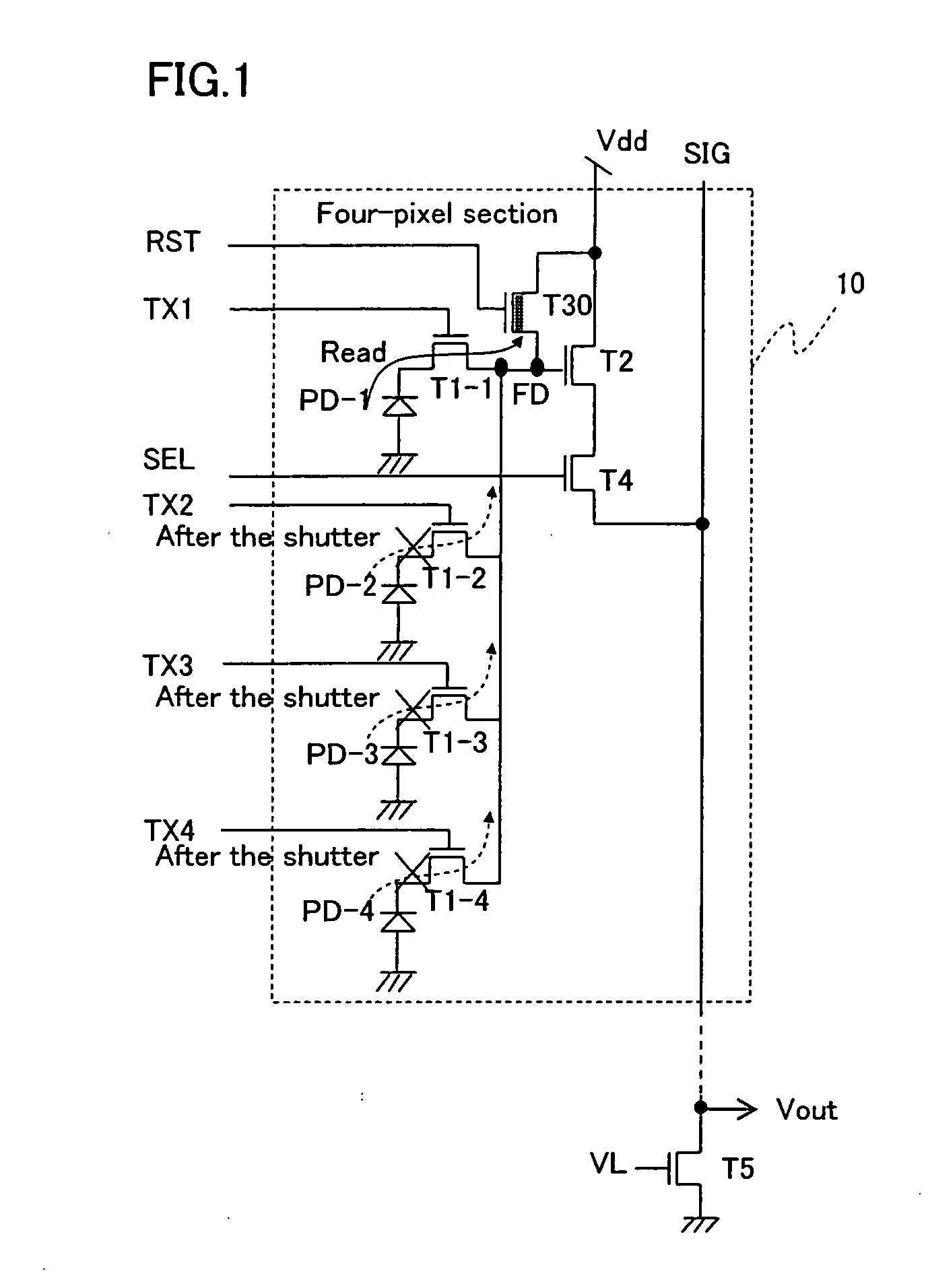

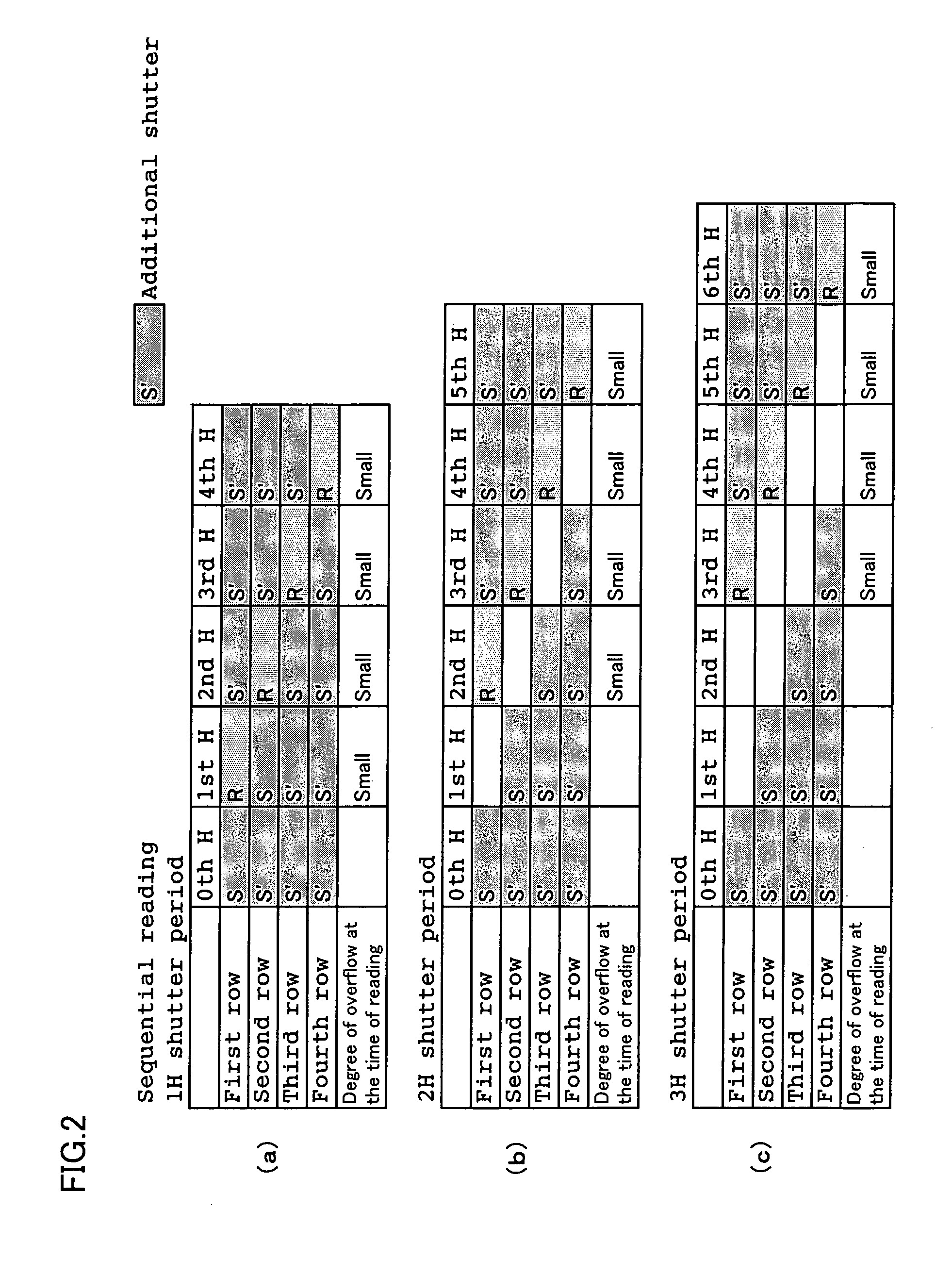

Amplification-type solid-state image capturing apparatus and electronic information device

ActiveUS20080180558A1Correctly readAccurate readingTelevision system detailsTelevision system scanning detailsCharge detectionElectronic information

An amplification-type solid-state image capturing apparatus according to the present invention, having a plurality of pixel sections each including a photoelectric conversion element for receiving light of a subject and performing a photoelectric conversion on the light of the subject and a transfer section capable of transferring signal charge from the photoelectric conversion element to a charge detection section, the plurality of pixel sections connected to each charge detection section, and the amplification-type solid-state image capturing apparatus amplifying and reading potential at the charge detection section as signal data for each of the pixel sections, includes: when one of the plurality of pixel sections which share the charge detection section performs an original shutter operation, a shutter control section for performing an additional shutter operation on the remaining pixel sections which share the charge detection section with the one pixel section and have not performed the original shutter operation yet.

Owner:SMARTSENS TECH (SHANGHAI) CO LTD

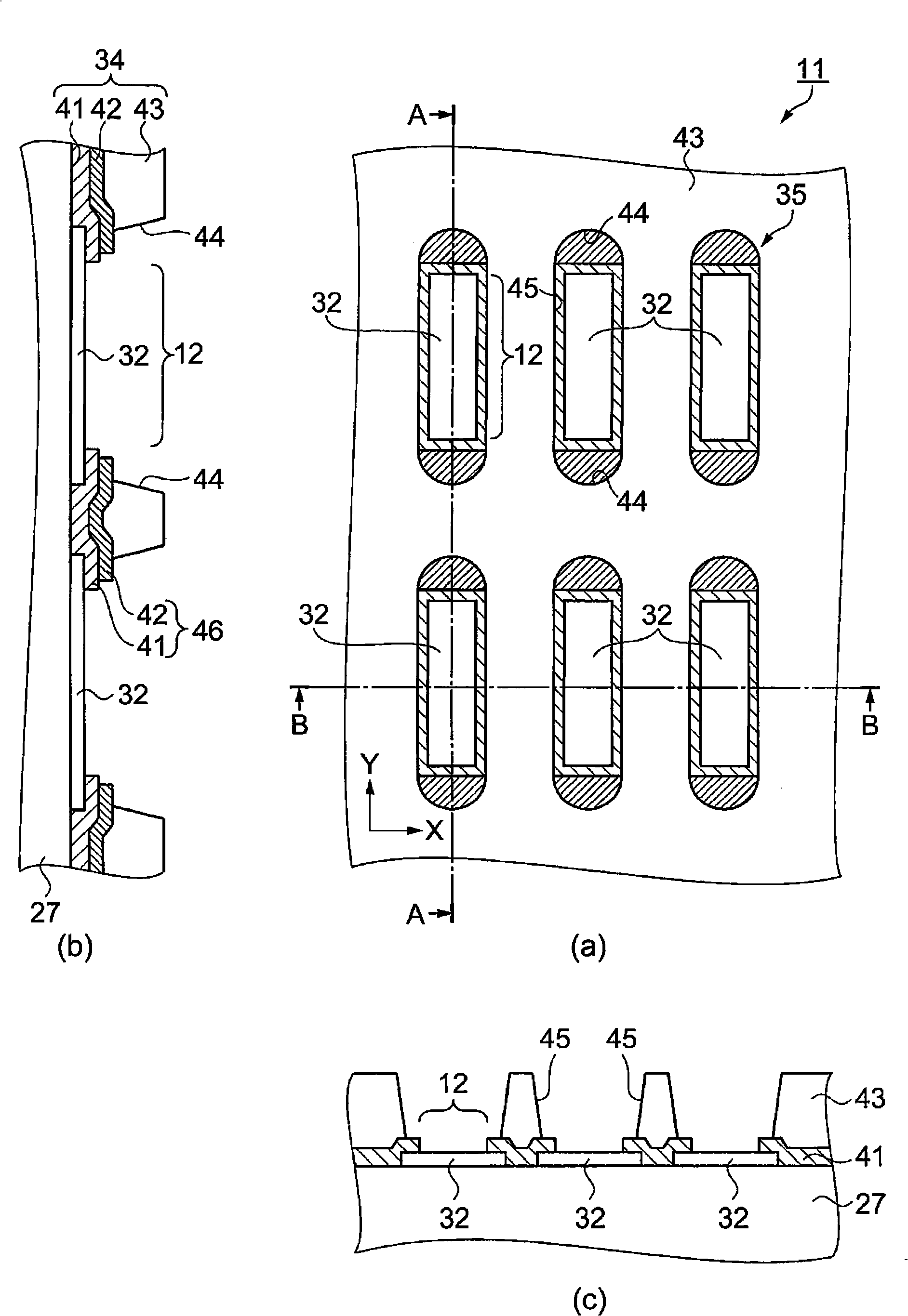

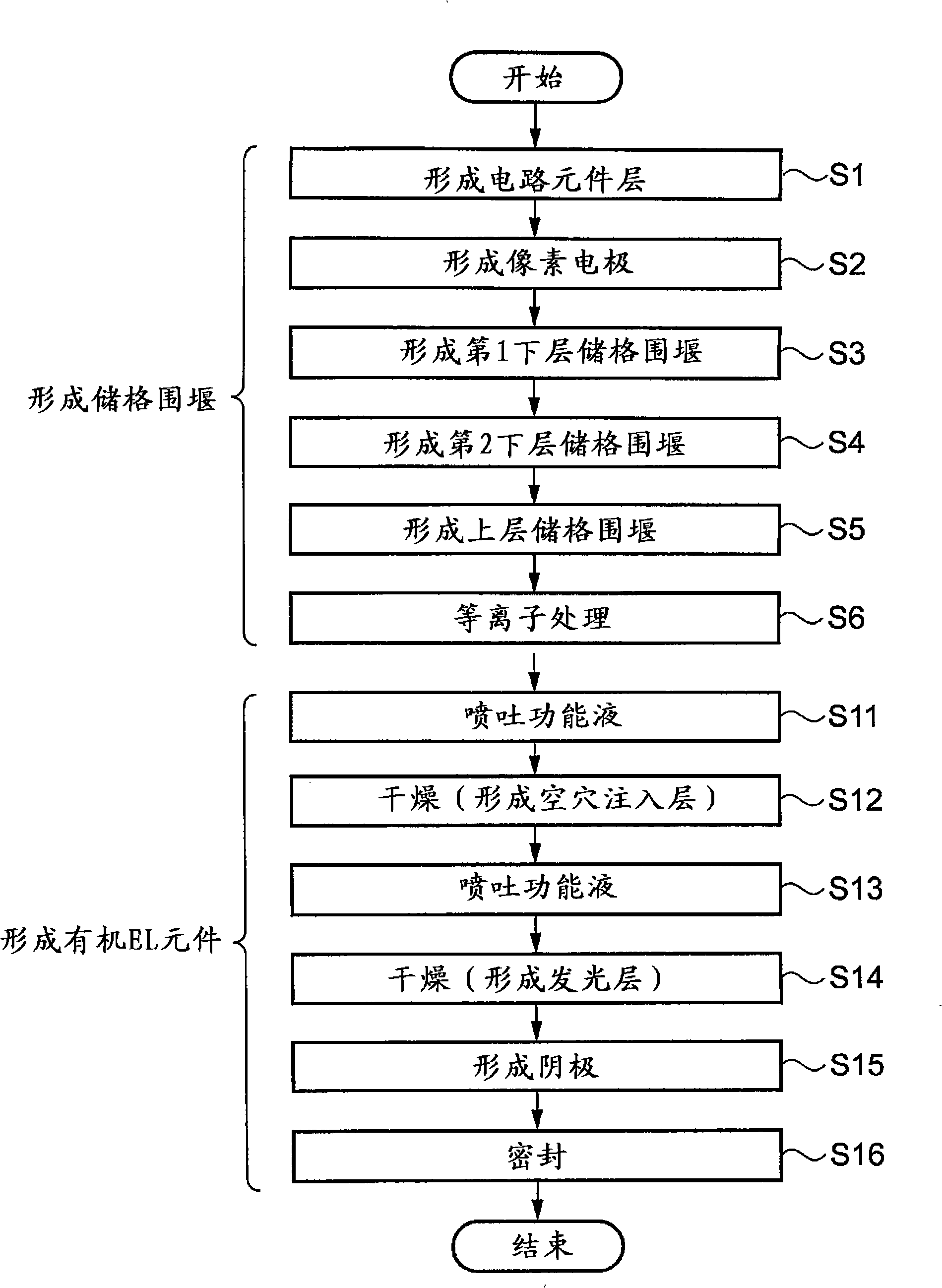

Electrooptical device, electronic apparatus, and method for producing electrooptical device

InactiveCN101355097AImprove liquid repellencySuppress overflowSolid-state devicesSemiconductor/solid-state device manufacturingCofferdamEngineering

The invention provides an electrooptical device capable of restraining irradiance characteristic difference, electronic appliance and a method for the electrooptical device. An organic EL device is provided with a glass substrate, a circuit element layer and a cathode. A light-emitting element layer is provided with a functional layer formed on a pixel electrode and a lattice storing cofferdam dividing the functional layer. The lattice storing cofferdam is provided with a first lower layer lattice storing cofferdam, a second lower layer lattice storing cofferdam and a upper layer lattice storing cofferdam. The lattice storing cofferdam is in a magnetic track shape, and has a irradiance area with different length to width ratio and a circular arc area at the short edge side of the irradiance area. In the irradiance area, the first lower layer lattice storing cofferdam, the second lower layer lattice storing cofferdam and the upper layer lattice storing cofferdam form in an echelonment. On the other hand, the first lower layer lattice storing cofferdam and the upper layer lattice storing cofferdam form form in an echelonment.

Owner:SEIKO EPSON CORP

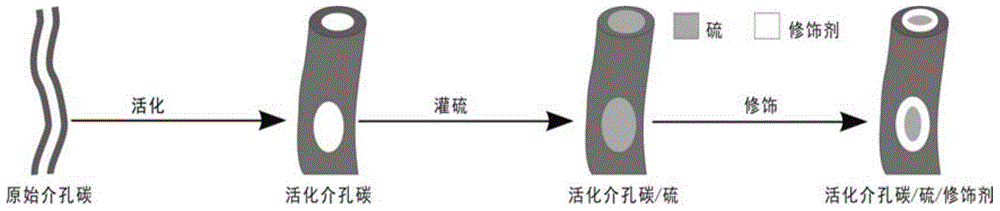

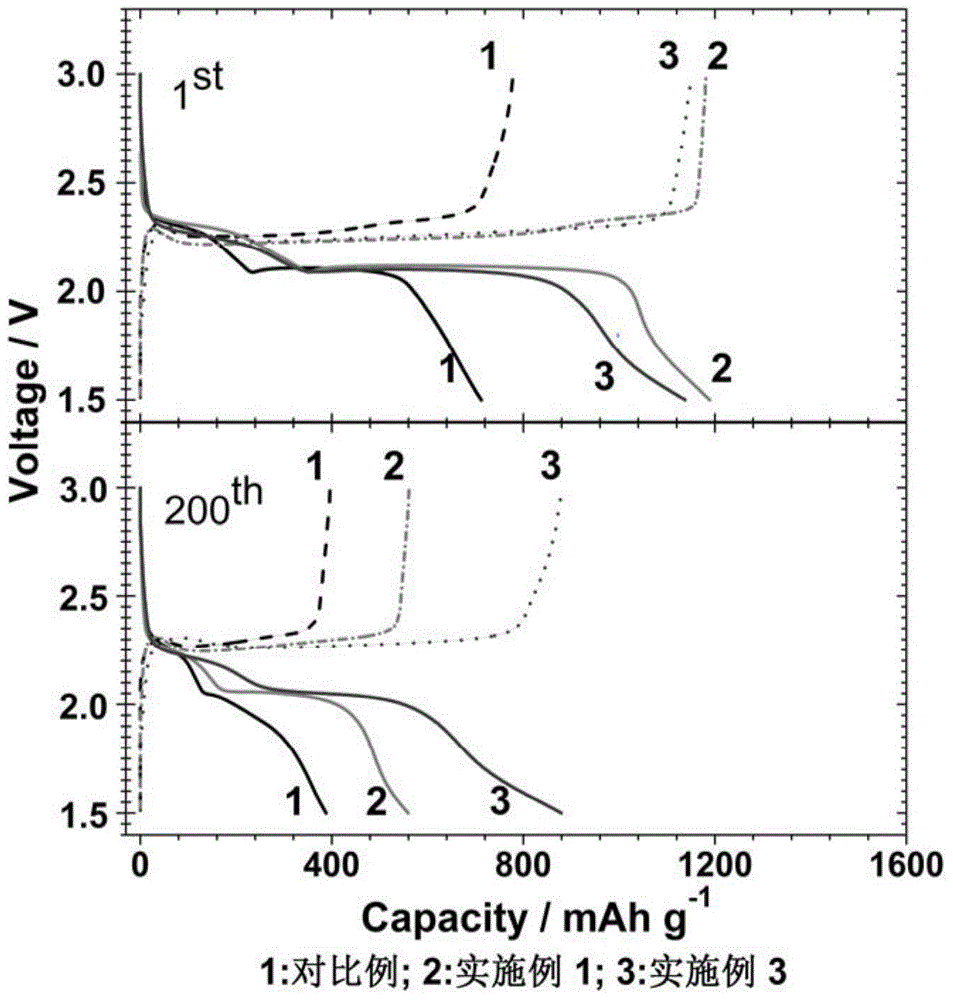

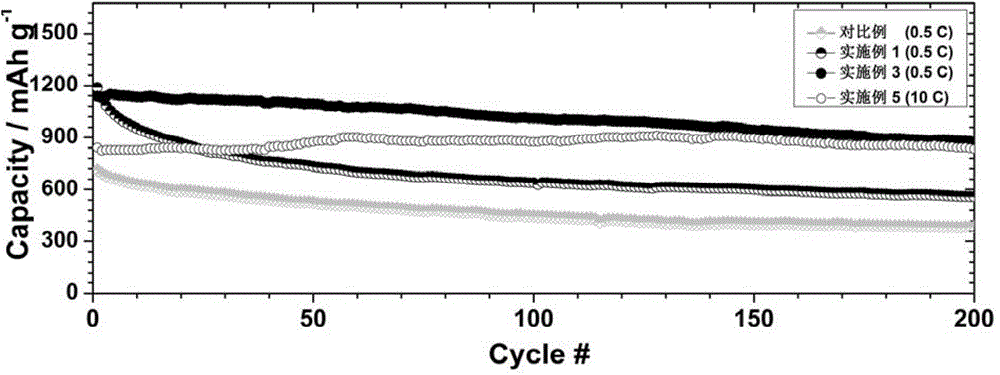

Composite cathode material used for lithium-sulfur battery and having high-rate performance and preparation method

InactiveCN104577080AExcellent magnification performanceImproved magnification performanceNon-aqueous electrolyte accumulator electrodesHigh rateCorrosion

A composite cathode material used for a lithium-sulfur battery and having high-rate performance comprises a conductive agent, electrochemical active substances and a modifier, wherein the conductive agent adopts a mesoporous carbon material, the electrochemical active substances are dispersed in holes of the mesoporous carbon material, and the modifier is introduced in a chemical bonding manner to adjust the property of the holes, so that lithium ions freely pass to inhibit passing of polysulfide ions. According to the composite cathode material, by means of the characteristic of selective passing of ions, efficient immigration and moving out of the lithium ions in the cathode material can be guaranteed, meanwhile, lithium polysulfide is effectively inhibited from overflowing from the holes of the mesoporous carbon material in a charge-discharge process, and dissolution of lithium polysulfide in an electrolyte is inhibited. Therefore, the composite cathode material can have excellent high-rate performance and can effectively reduce influence of active substance loss as well as lithium cathode corrosion, fast capacity fading and the like caused by a shuttling effect because of lithium polysulfide dissolution, and the cycle performance of the lithium-sulfur battery is remarkably improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

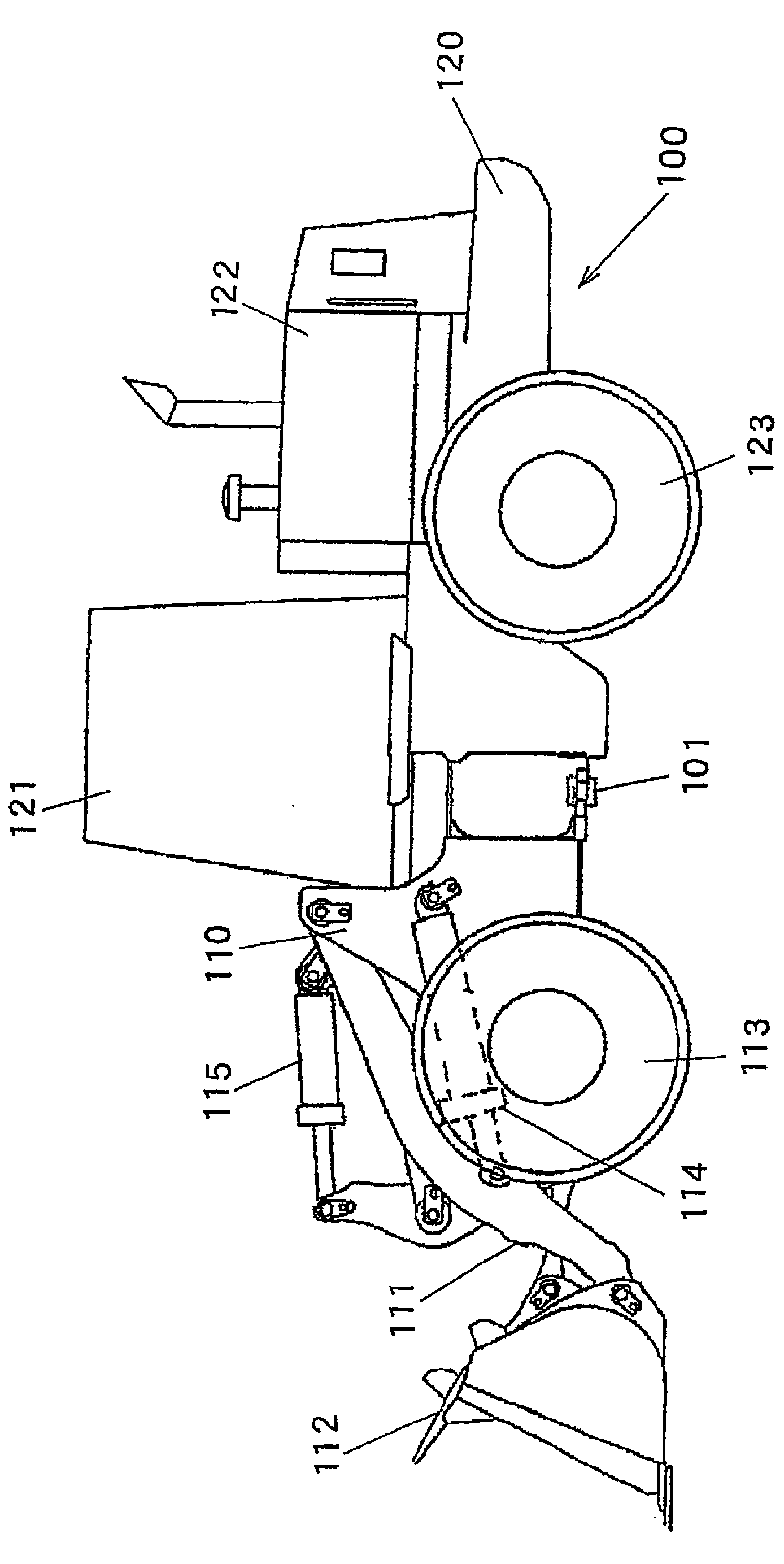

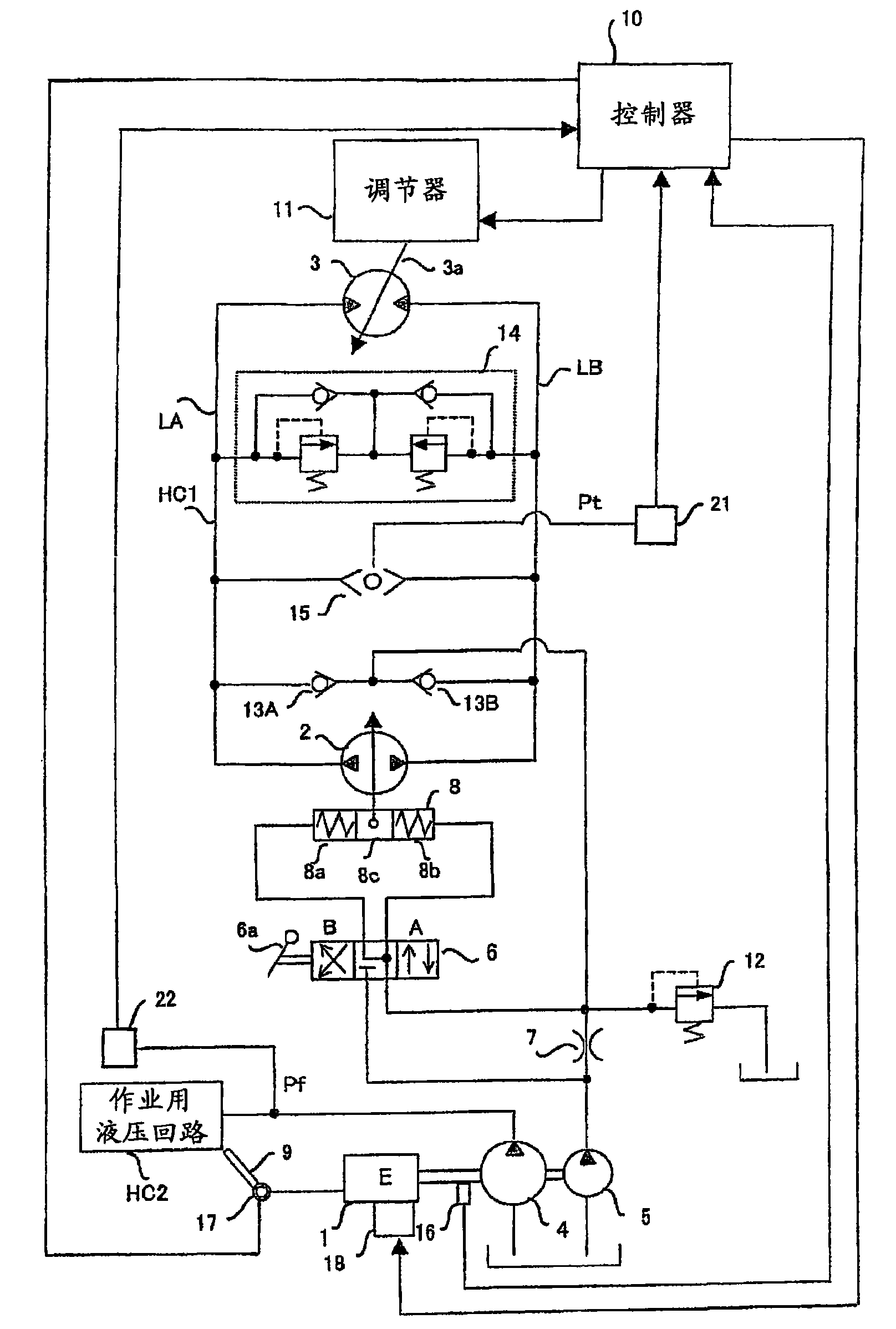

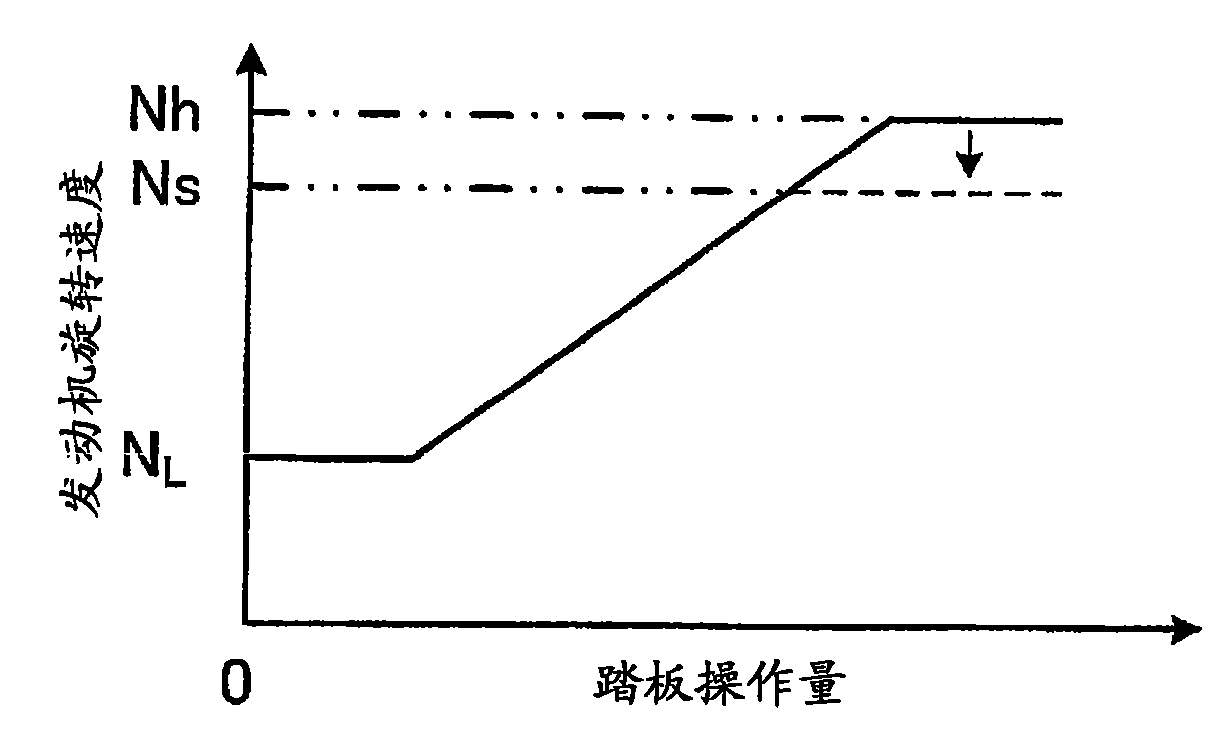

Control device for working vehicle

ActiveCN101631942AUpper limit loweredReduce lossesElectrical controlTelemotorsHydraulic motorHydraulic pump

A control device for a working vehicle, the device including a circuit (HC1) for traveling constructed as a closed circuit by interconnecting a variable displacement hydraulic pump (2) driven by an engine (1) and a variable displacement hydraulic motor (3), a circuit (HC2) for working having a hydraulic pump (4) for working driven by the engine (1) and also having hydraulic actuators (114, 115) for working driven by pressurized oil from the hydraulic pump (4), a relief valve (14) for relieving pressurized oil in the circuit (HC1) for traveling, rotational speed control sections (10, 18) for controlling the speed of the engine according to the amount of operation of an accelerator pedal (9), condition detection sections (21, 22) for detecting the vehicle being simultaneously in both a high load travel condition and a high load work condition, and a speed limit section (10) which, when the condition detection sections (21, 22) detect that the vehicle is simultaneously in both high load travel and high load work conditions, reduces an upper limit value (Nlim) of the engine speed.

Owner:NIHON KENKI CO LTD

Device capable of testing stress-electrochemical corrosion

InactiveCN104458559AConstant and accurate controlSuppress overflowWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceWater bathsEngineering

The invention relates to a device capable of testing stress-electrochemical corrosion in the presence of anaerobic bacteria. The device comprises an electrochemical workstation, a stress corrosion stretcher, a constant-temperature water bath and a self-control stretching box, wherein the self-control stretching box adopts a cylindrical double-chamber structure; a medium solution flows in the outer chamber of the self-control stretching box; a test solution is contained in the inner chamber of the self-control stretching box; the top end of the outer chamber is sealed; a bracket is arranged on the wall of the inner chamber; the inner chamber is lower than the outer chamber; a polarity of holes are drilled in a box cover; the gap between the box cover and a box body is sealed with a sealing film; the self-control stretching box is sleeved by a layer of cylindrical heat insulation cover; rubber bands are arranged at two ends of the heat insulation cover; two medium solutions can be adopted in the constant-temperature water bath to heat or cool the test solution. The device can prevent the solutions from spilling out of the self-control stretching box, provides a constant-temperature closed stress corrosion environment for a stretching sample and realizes synchronous testing of various testing methods.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Method for manufacturing wheat germ oil microcapsule

InactiveCN102228249AKeep functional ingredientsPlay a protective effectFood shapingFood preparationAdditive ingredientLiquid state

The invention relates to a method for manufacturing a wheat germ oil microcapsule. The method comprises the following steps of preparing wall material phases, blending an emulsifier and preparing a core material phase, mixing, pre-emulsifying, homogenizing, spray-drying and the like. The encapsulation efficiency of a wheat germ oil microcapsule product prepared by the method disclosed by the invention is as high as 80-86%, and a surface oil content of the wheat germ oil microcapsule product is 14.5-19.1%; functional active ingredients of wheat germ oil are greatly kept, oxidation stability is strengthened, odor smell of the wheat germ oil is covered, and quality of products is improved; simultaneously, According to the method disclosed by the invention, the wheat germ oil is changed from liquid to more stable solid, thus the solid wheat germ oil is convenient to store and transport, and is more probably produced in various product forms; in addition, the application range is extended and varying requirements of consumers are met.

Owner:HEFEI UNIV OF TECH

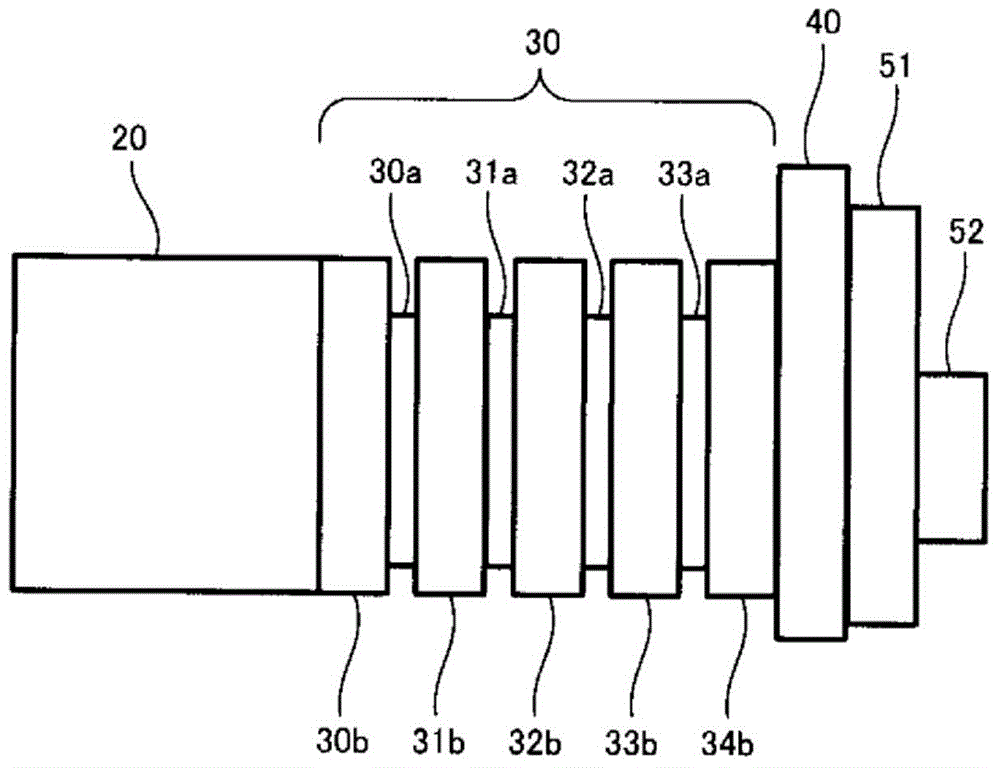

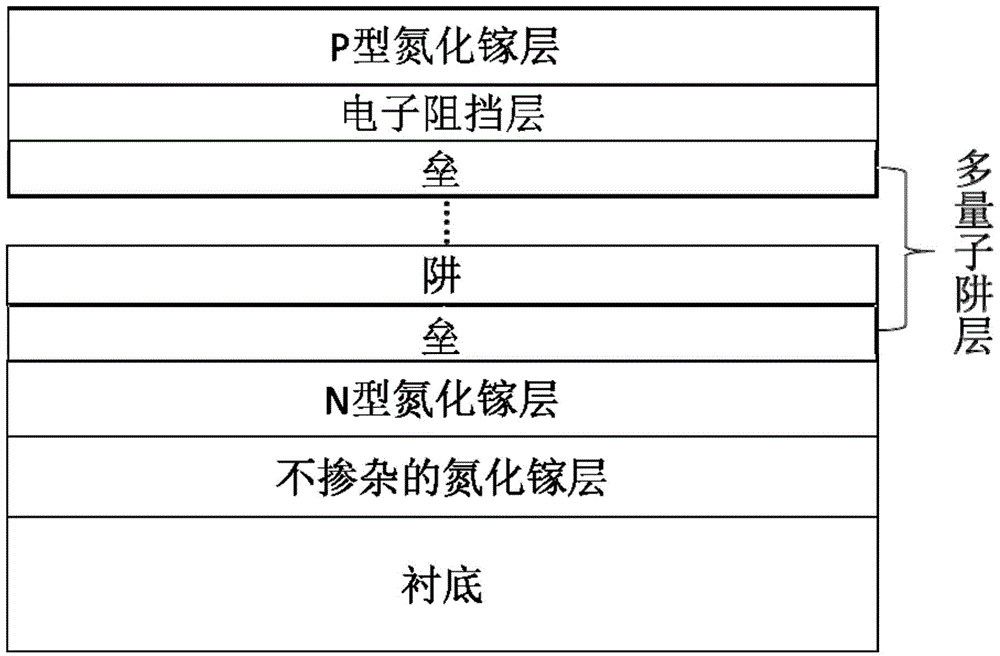

LED epitaxial growth method for improving radiation recombination efficiency

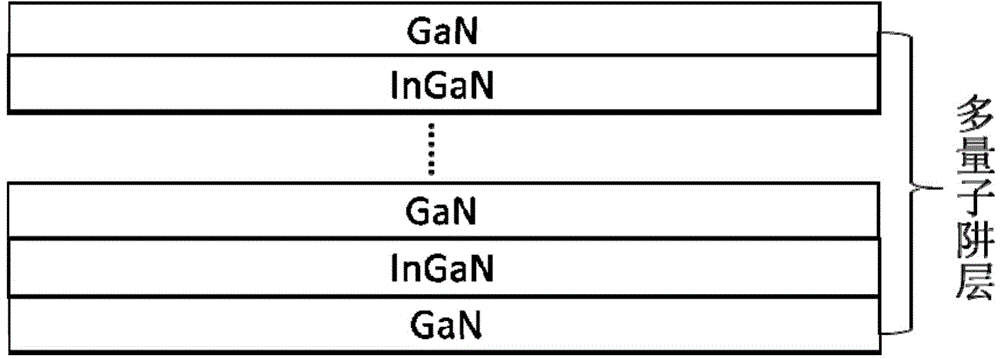

PendingCN111223764AImprove luminous efficiencyIncrease hole concentrationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingElectron blocking layerMultiple quantum

The invention discloses an LED epitaxial growth method for improving radiation recombination efficiency. The method sequentially comprises the steps of processing a substrate, growing a low-temperature buffer layer GaN, growing an undoped GaN layer, growing a Si-doped N-type GaN layer, growing a multi-quantum well layer, growing an AlGaN electron blocking layer, growing a Mg-doped P-type GaN layerand cooling, wherein the step of growing the multi-quantum well layer sequentially comprises the sub-steps of growing an InGaN transition layer, growing an InGaN well layer, growing a doped gradientSiN layer, growing a doped gradient MgN layer, growing a GaN barrier layer doped with Mg in a linear gradient mode and growing an InAlN layer. According to the method, the problems of low quantum wellgrowth quality and low quantum well radiation recombination efficiency in the existing LED epitaxial growth method are solved, so that the luminous efficiency of the LED is improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

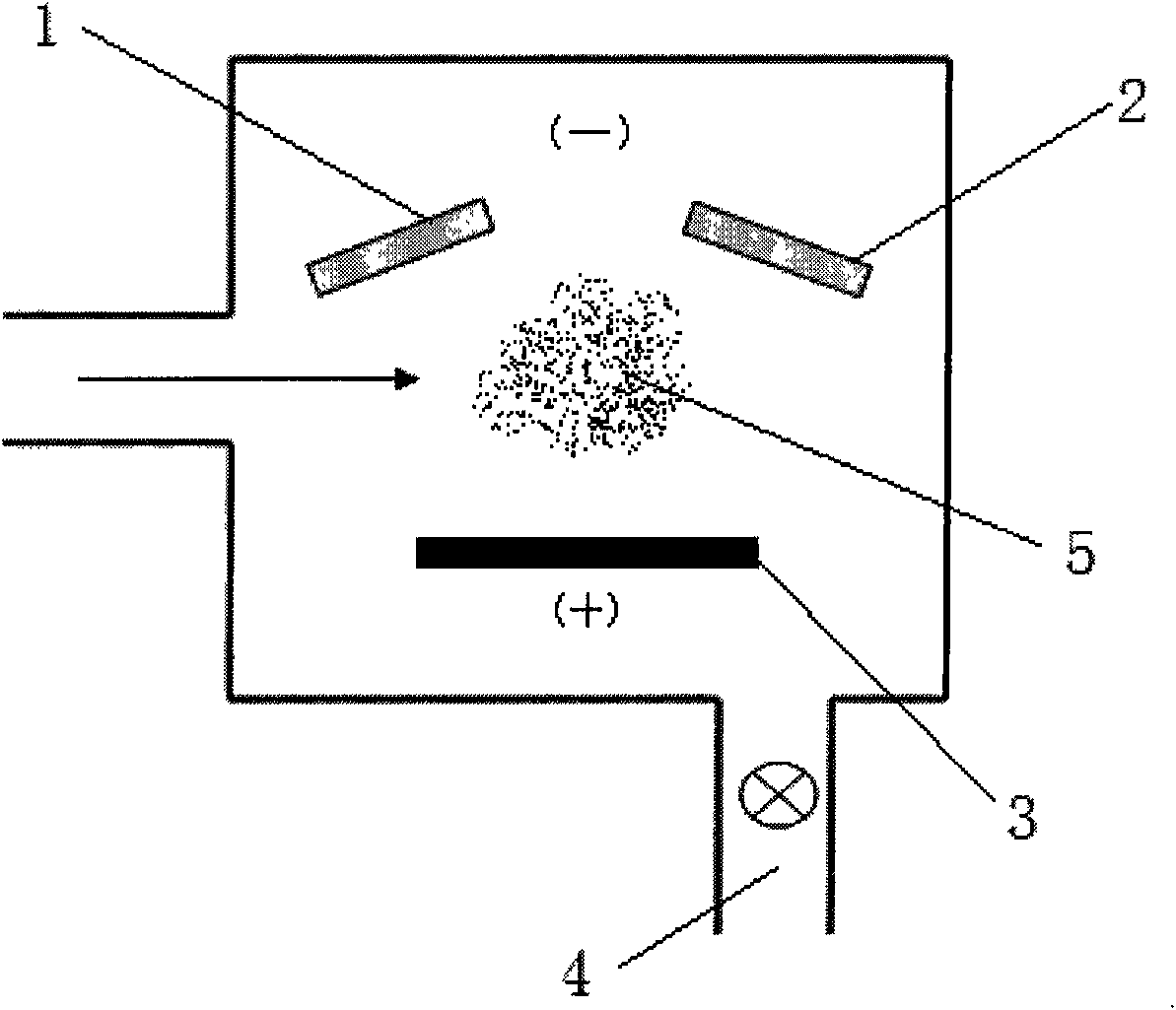

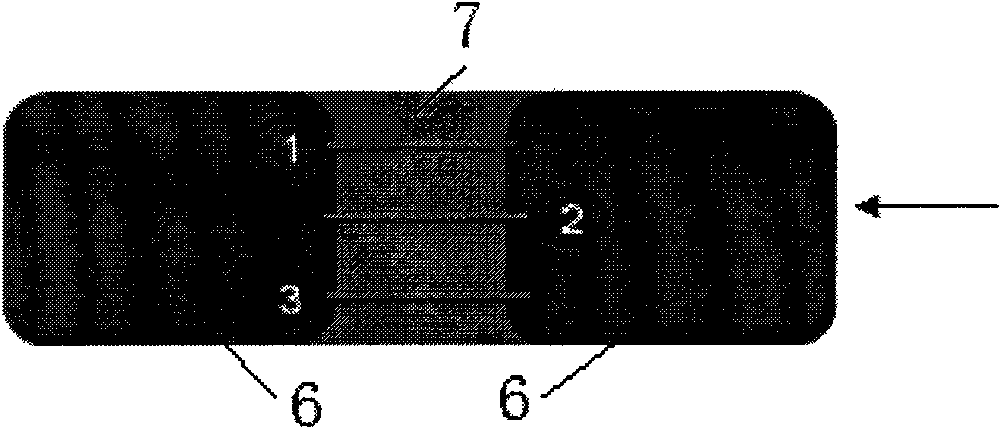

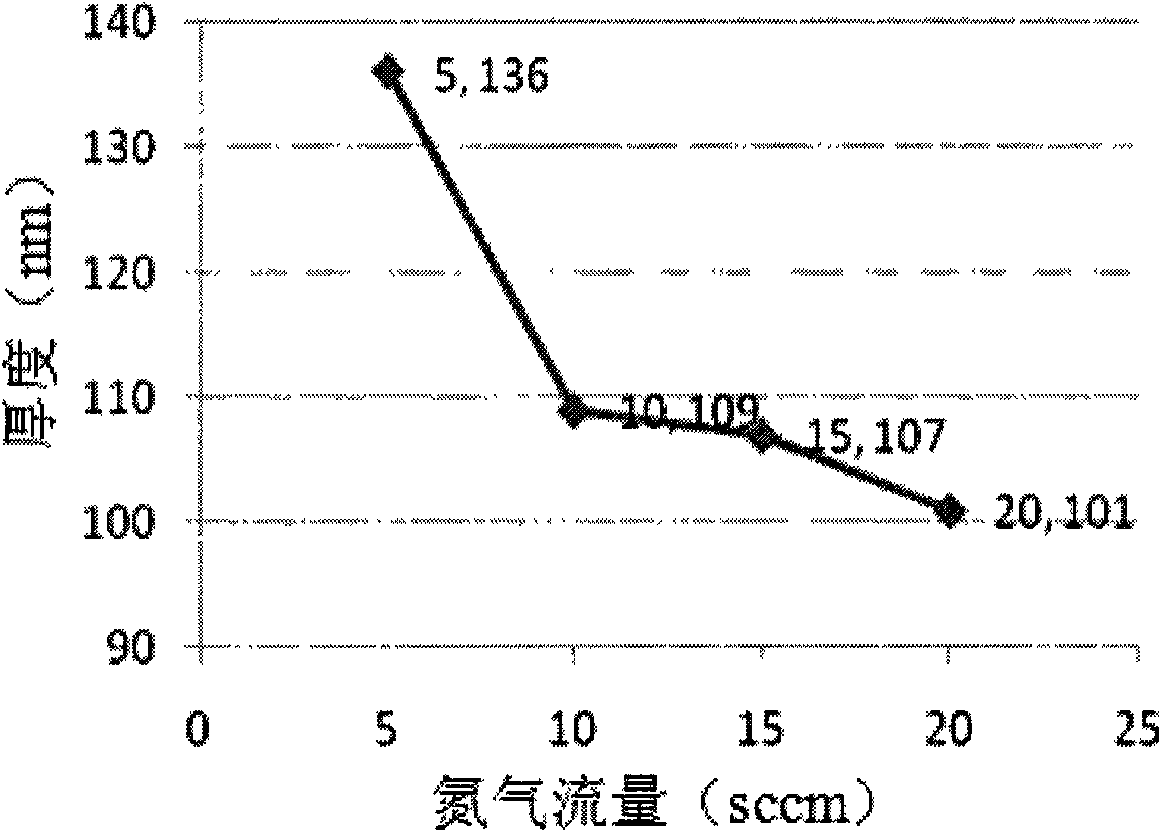

Preparation method of thin film of diffusion impervious layer

InactiveCN101673705AImprove performanceFlat surfaceVacuum evaporation coatingSputtering coatingCopper atomSputtering

A preparation method of a thin film of a diffusion impervious layer relates to a preparation method of a new diffusion impervious layer between copper and silicon in an integrated circuit. The preparation method solves the problem that an N element in the existing diffusion impervious layer Ru-N between copper and silicon easily overflows at high temperature, thus causing the Ru-N diffusion impervious layer to lose efficacy. The preparation method comprises the following steps: 1. cleaning a silicon substrate; 2. using a magnetic control sputtering method for depositing the thin film; and 3. obtaining the Ru-N diffusion impervious layer after annealing. The method has simple technology; and the obtained Ru-N diffusion impervious layer can effectively inhibit the diffusion between copper atoms and silicon atoms.

Owner:HARBIN INST OF TECH

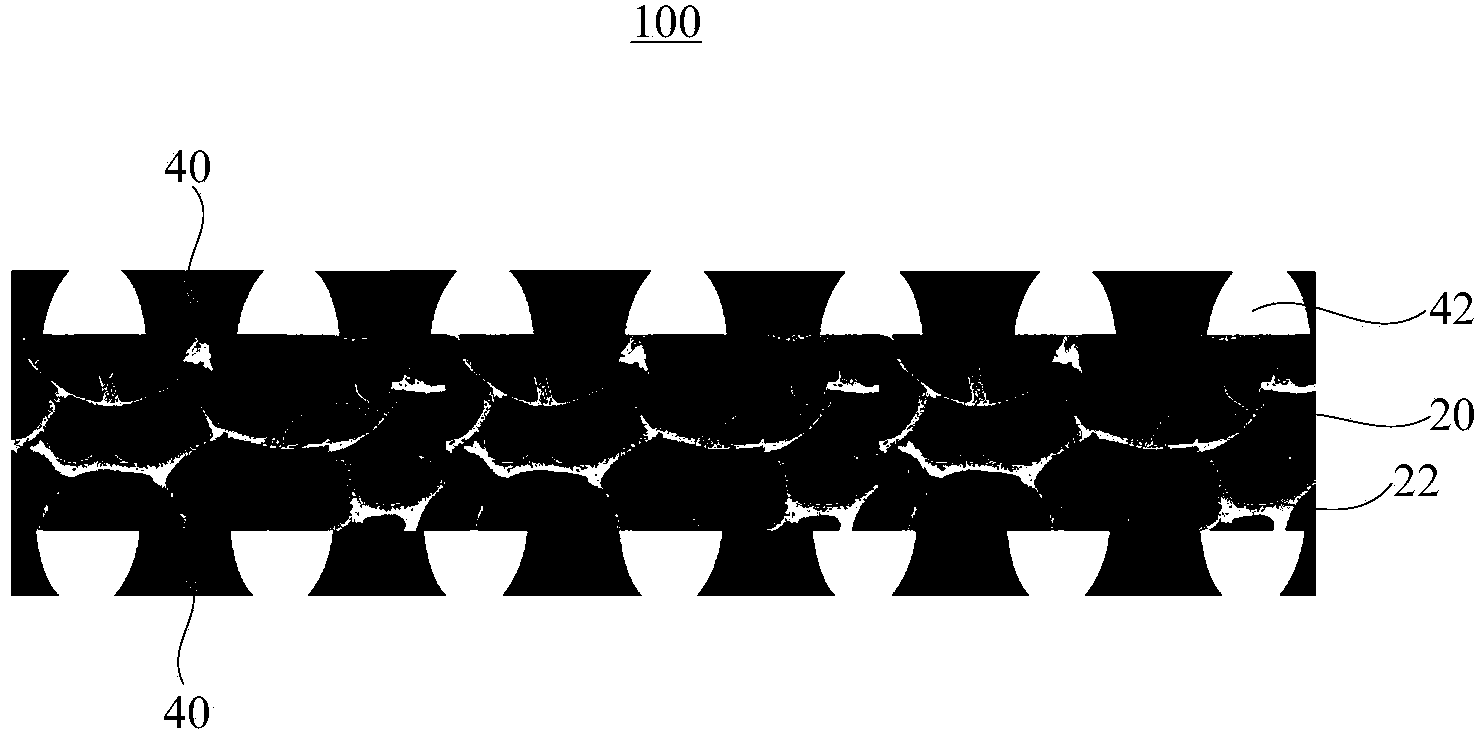

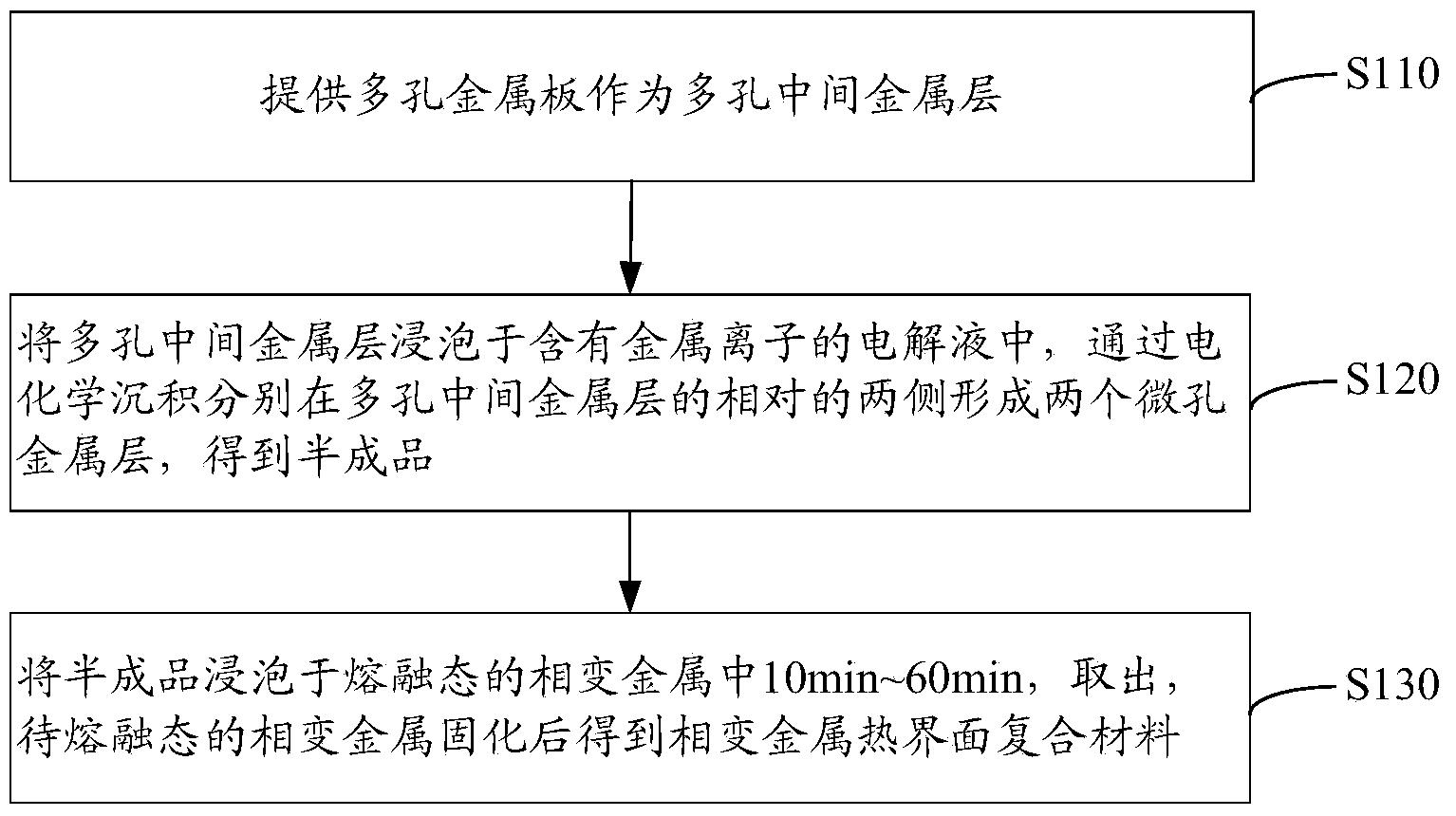

Phase-change metal thermal interface composite material and preparation method thereof

ActiveCN103862742AWon't overflowSuppress overflowSemiconductor/solid-state device detailsSolid-state devicesMolten statePhase change

The invention relates to a phase-change metal thermal interface composite material and a preparation method thereof. The phase-change metal thermal interface composite material comprises a porous middle metal layer, two microporous metal layers respectively arranged at two opposite sides of the porous metal layer, and phase-change metal, wherein the the porous middle metal layer and the two microporous metal layers are filled with the phase-change metal. The composite material has the advantages that the porous middle metal layer serving as a structure supporting layer can bear certain pressure to ensure that the phase-change metal in a molten state cannot be extruded and overflown and the phase-change metal can run through up and down to ensure that the phase-change metal thermal interface composite material has the low thermal resistance and the high heat-conducting property; the phase-change metal can be effectively prevented from being overflown by adopting the two microporous metal layers, after being molten and expanded, the phase-change metal can be oozed from micropores of the microporous metal layers to effectively fill up gaps in the composite material and no hole occurs in the using process.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Semiconductor device and manufacturing method thereof

InactiveUS20080081401A1Suppress overflowImprove seal qualitySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipViscosity

The present invention provides a method for manufacturing a semiconductor device, which is capable of suppressing an overflow of a sealing resin and obtaining good sealing quality, simply and at low cost. Further, the present invention provides a semiconductor device that suppresses an overflow of a sealing resin and has good sealing quality, simply and at low cost. Liquid first underfill higher in viscosity than liquid second underfill is charged into space defined between a corresponding edge side of four edge sides of each of semiconductor chips, at which the distance between at least one edge side and each of pads opposite thereto, of an interposer is of the shortest, and the interposer. The liquid first underfill is cured and sealed with first underfill. Thereafter, the liquid second underfill is charged into space defined between the semiconductor chip and the interposer excluding the space sealed with the first underfill. The liquid second underfill is cured and sealed with second underfill.

Owner:LAPIS SEMICON CO LTD

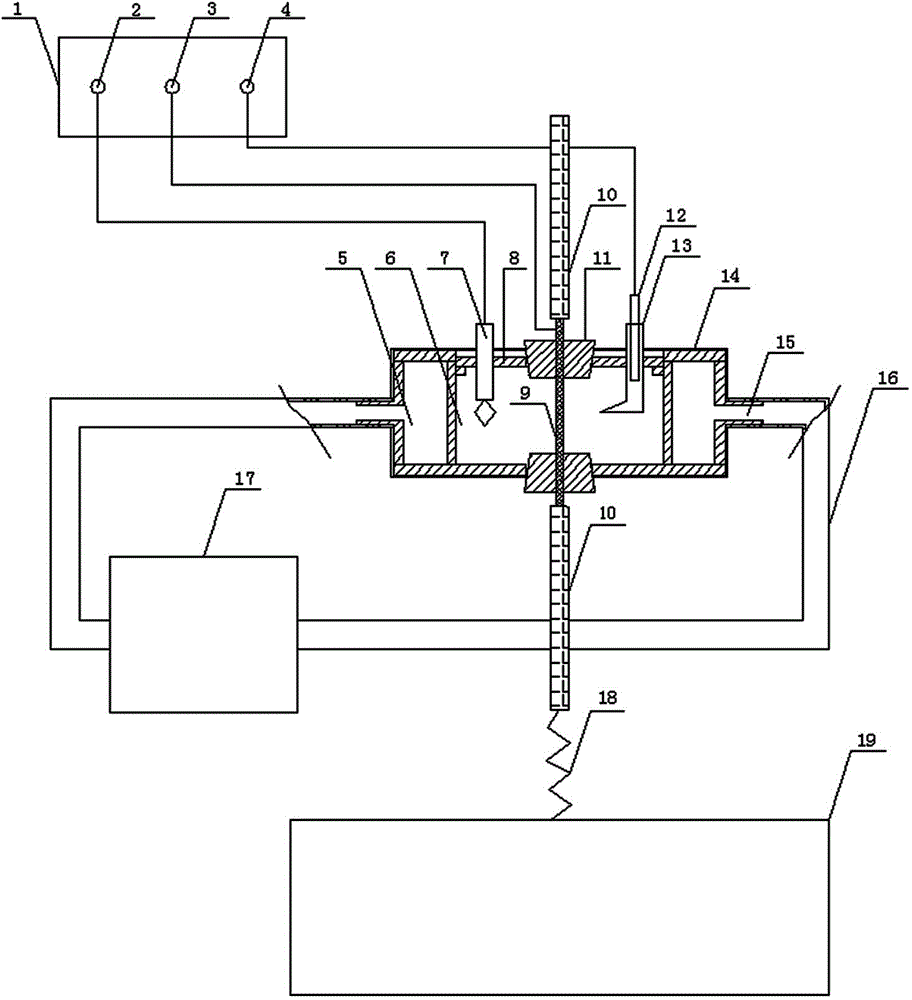

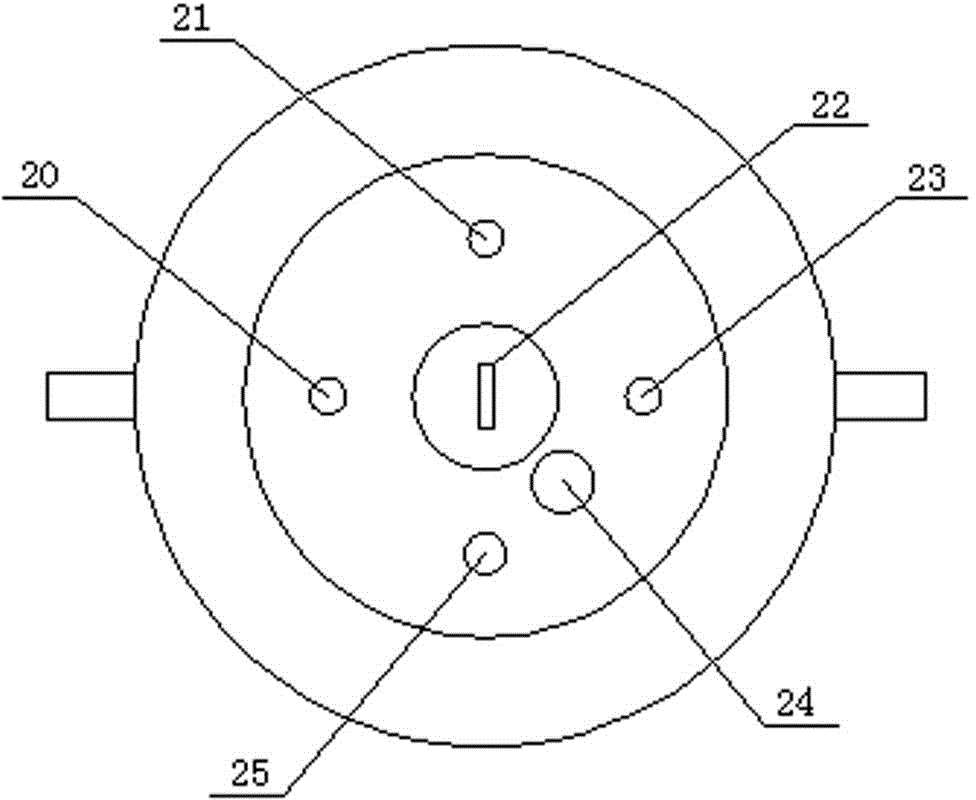

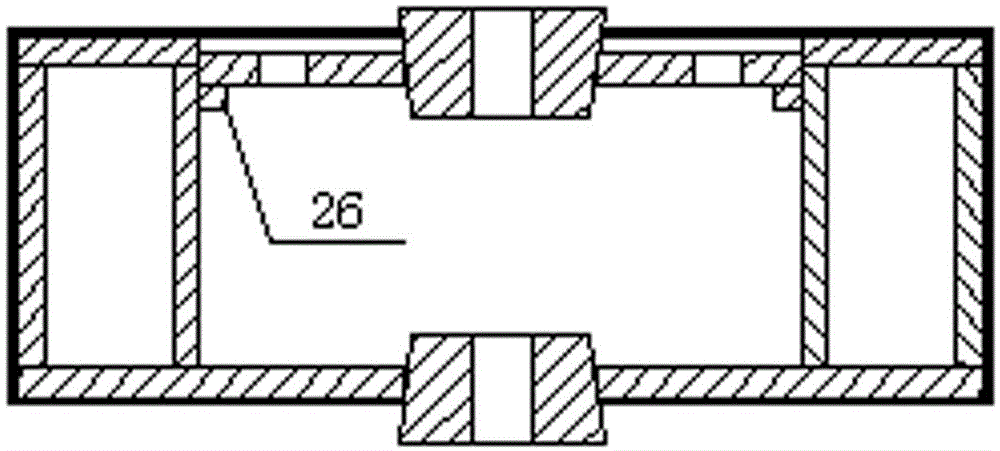

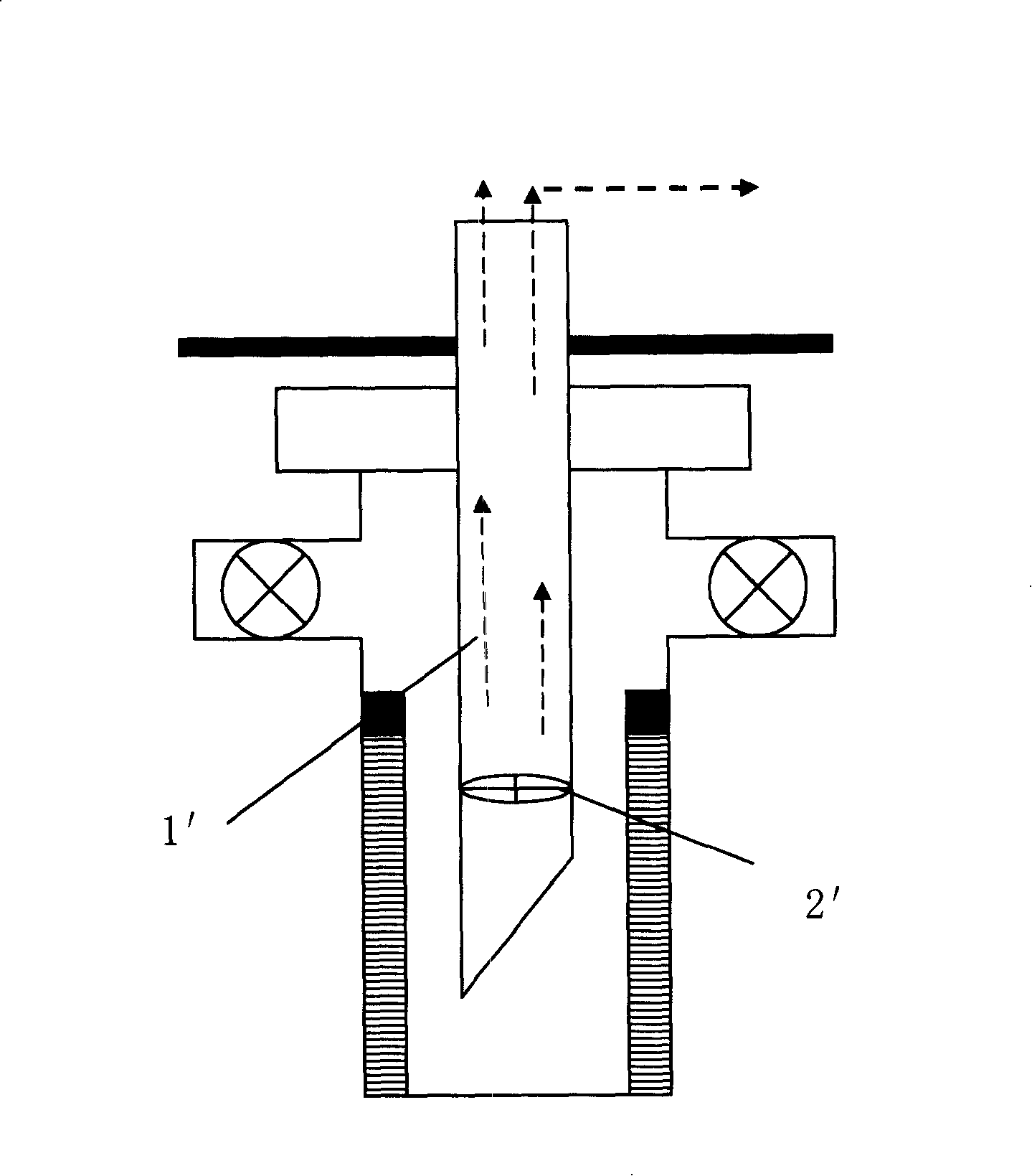

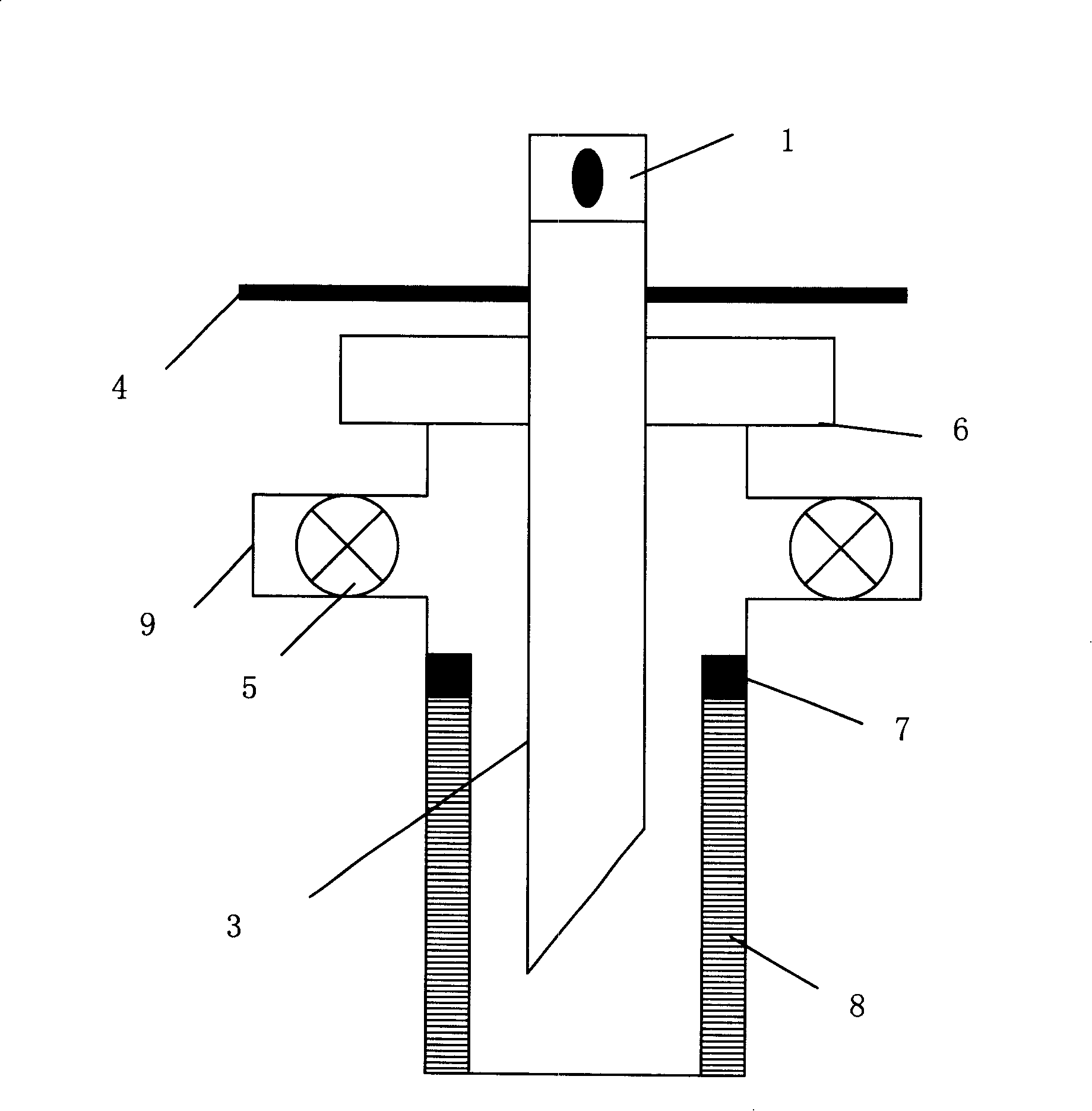

Continuous sand flushing technique and continuous sand flushing device thereof

The invention discloses a continuous sand-washing process and a continuous sand-washing device formed by, firstly, mounting control valves one by one on the upper port of a sand-washing pipe column and on the upper port of a single sand-washing pipe column. When the control valve is open, a regular sand-washing pipe column reaches down. When the sand-washing pipe column approaches or reaches the sand sediment or oil send at the bottom of a well, if extension is needed, single sand-washing pipe columns provided with control valves are connected one by one to establish sand-washing circulation channel, start a mud pump and carry out sand-washing operation; the control valve in open state allows double-way passage and offers such options as regular positive circulation operation and reverse circulation operation. Meanwhile, the control valve is started or closed manually to decouple from or couple with the single sand-washing pipe column. The invention is not subject to the restriction of sand medium and is particularly suitable for sand-washing operation by nitrogen foam under low-pressure well. The process saves the pressure-releasing time for connecting single sand-washing pipe column every time, realizes continuous sand washing, improves efficiency, prolongs the time of oil well production, and thus reduces cost and increases benefits.

Owner:CHINA NAT OFFSHORE OIL CORP +1

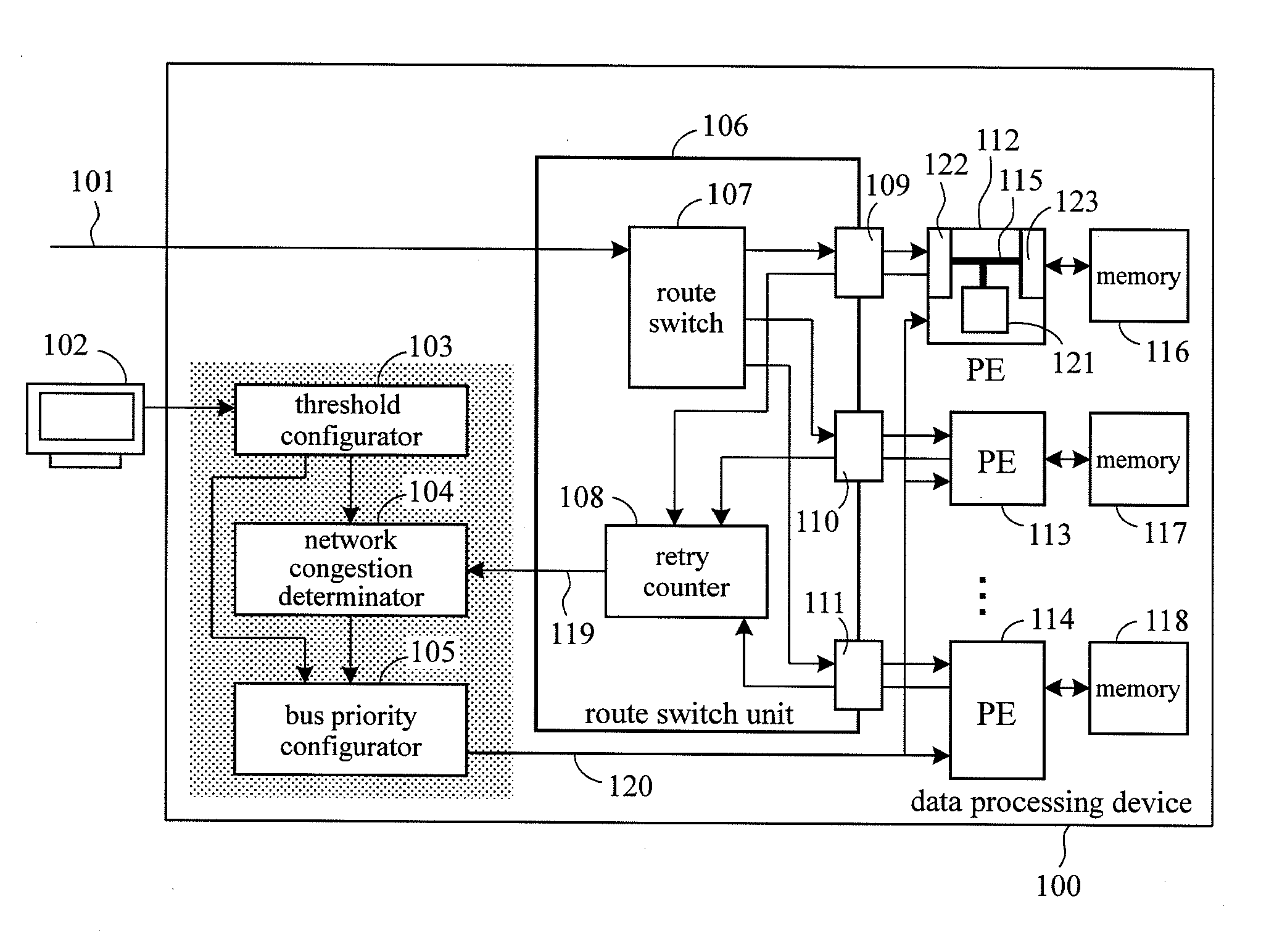

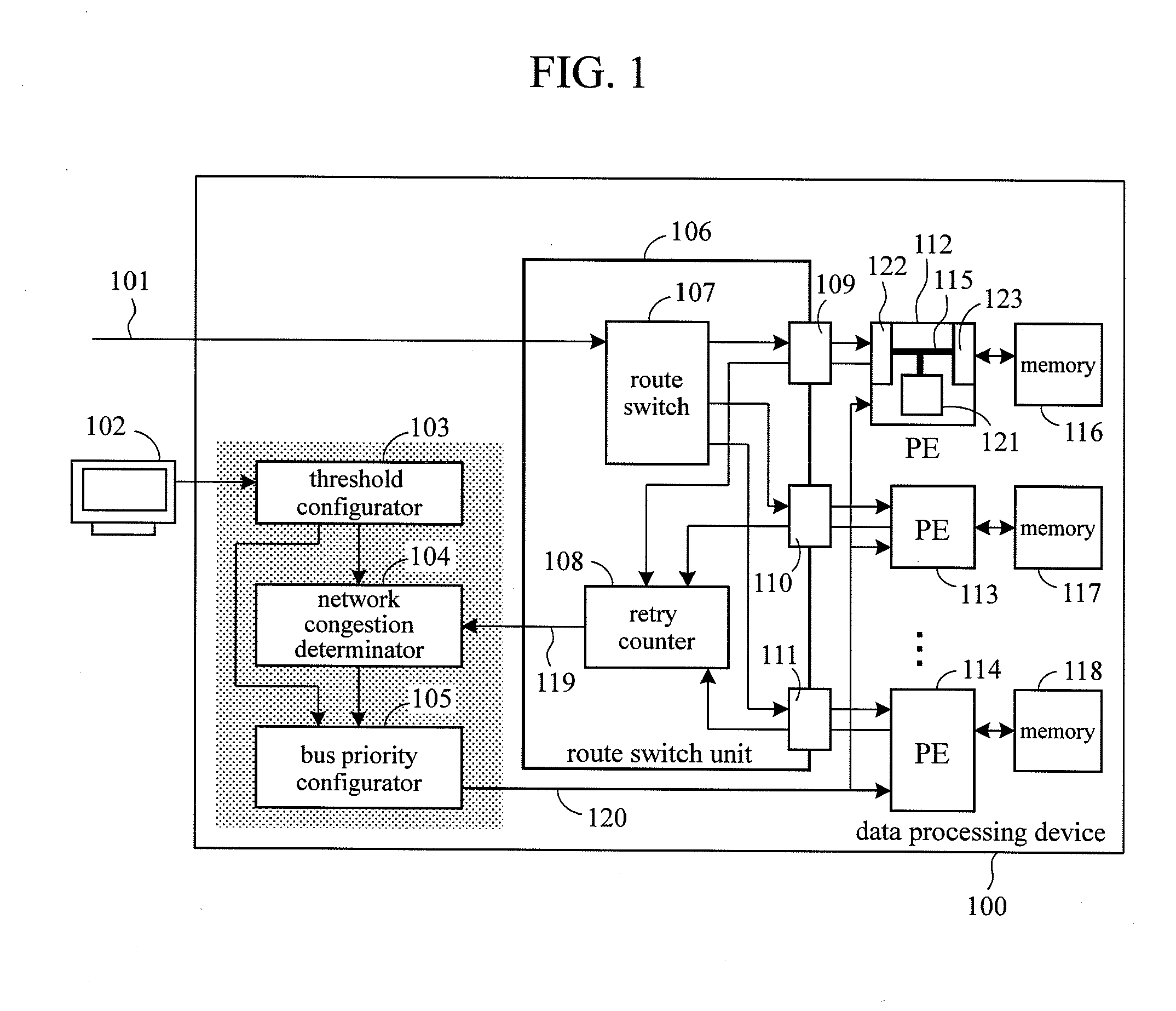

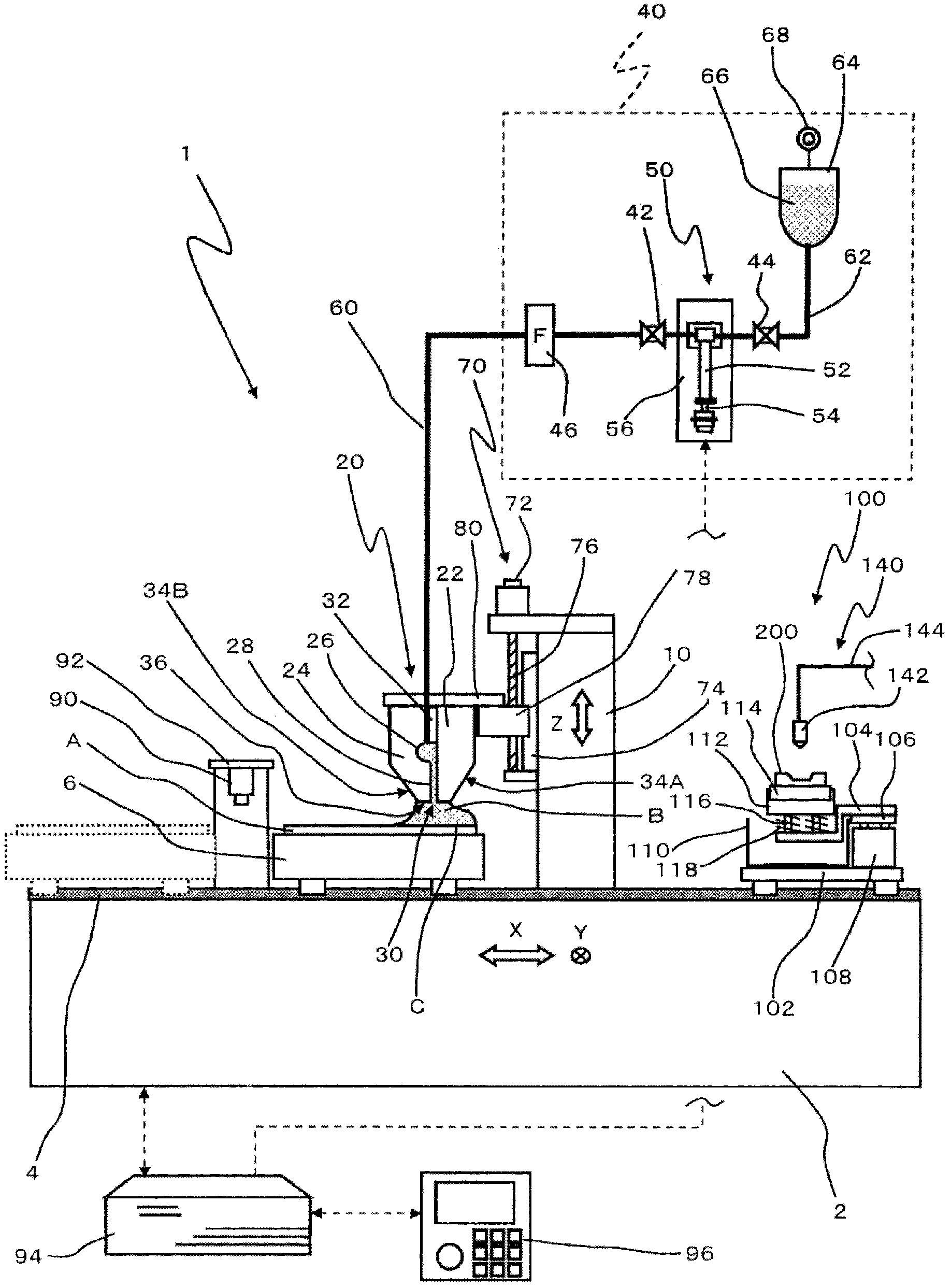

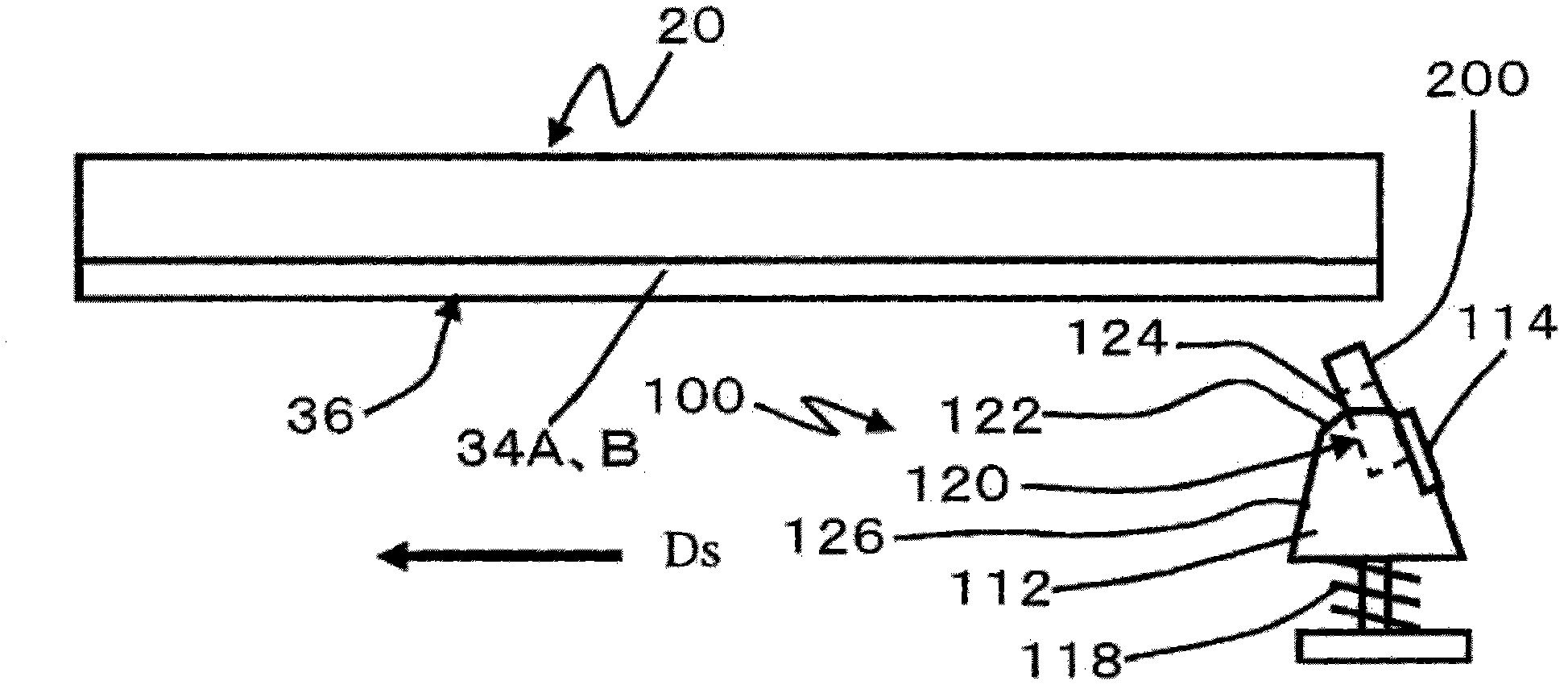

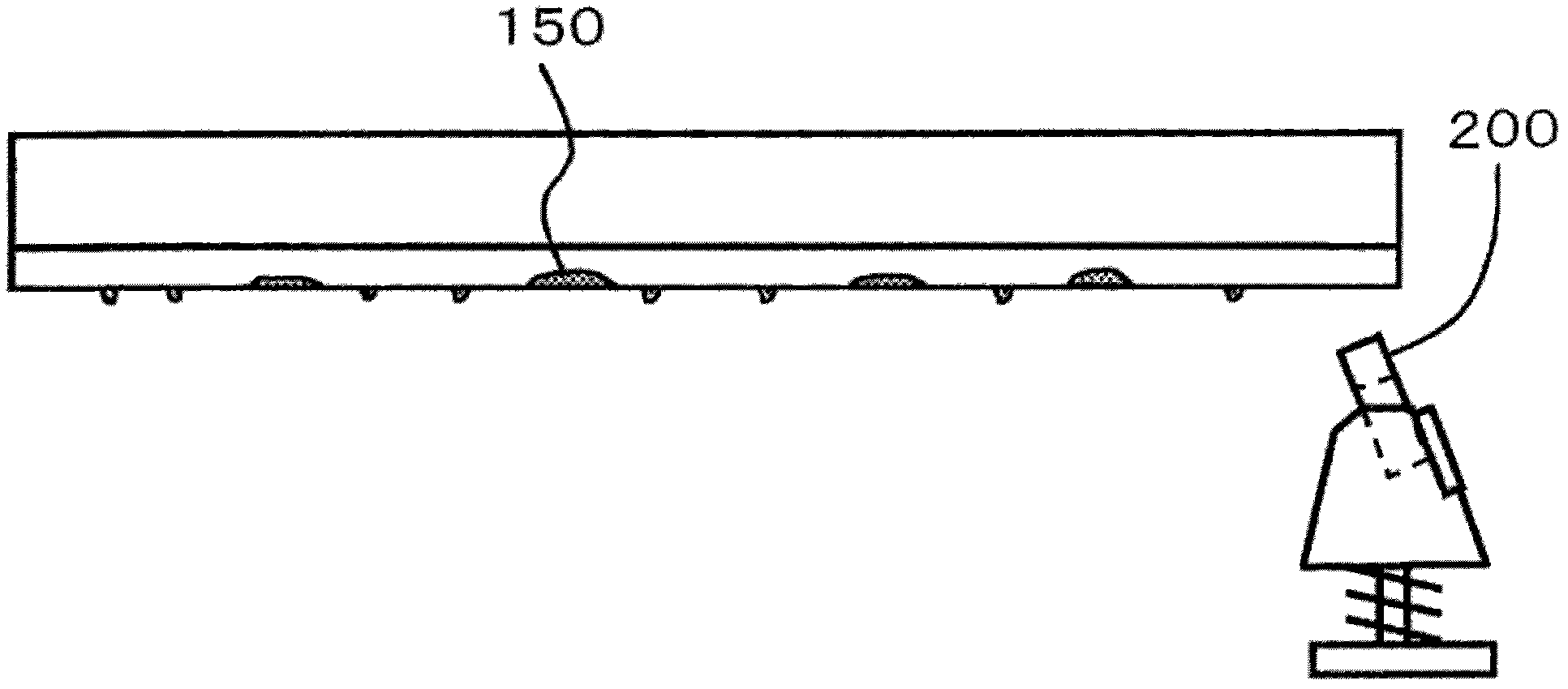

Data processing device, semiconductor external view inspection device, and data volume increase alleviation method

ActiveUS20140372656A1Suppressing buffer over flowSuppress overflowProcessor architectures/configurationElectric digital data processingStack buffer overflowProcessor element

Provided is a data processing device with which, when a temporary network congestion occurs, it is possible to avoid a buffer overflow and sustain a process. When a request for retransmission of the same data with respect to a processor element from a buffer occurs continuously a prescribed number of iterations, a data processing device according to the present invention determines that it is possible that a buffer overflow occurs, and suppresses an increase in the volume of data which is accumulated in the buffer (see FIG. 1).

Owner:HITACHI HIGH-TECH CORP

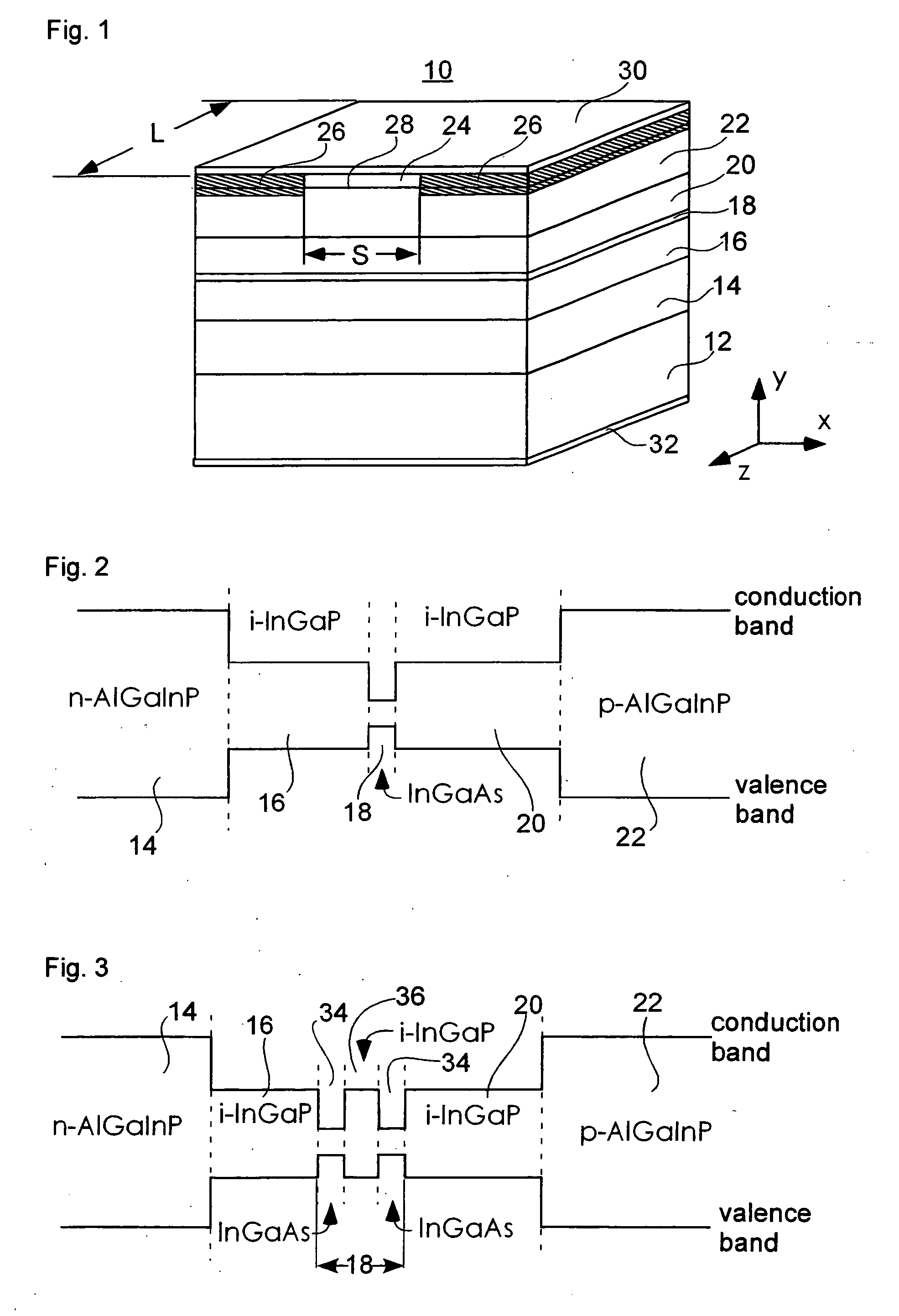

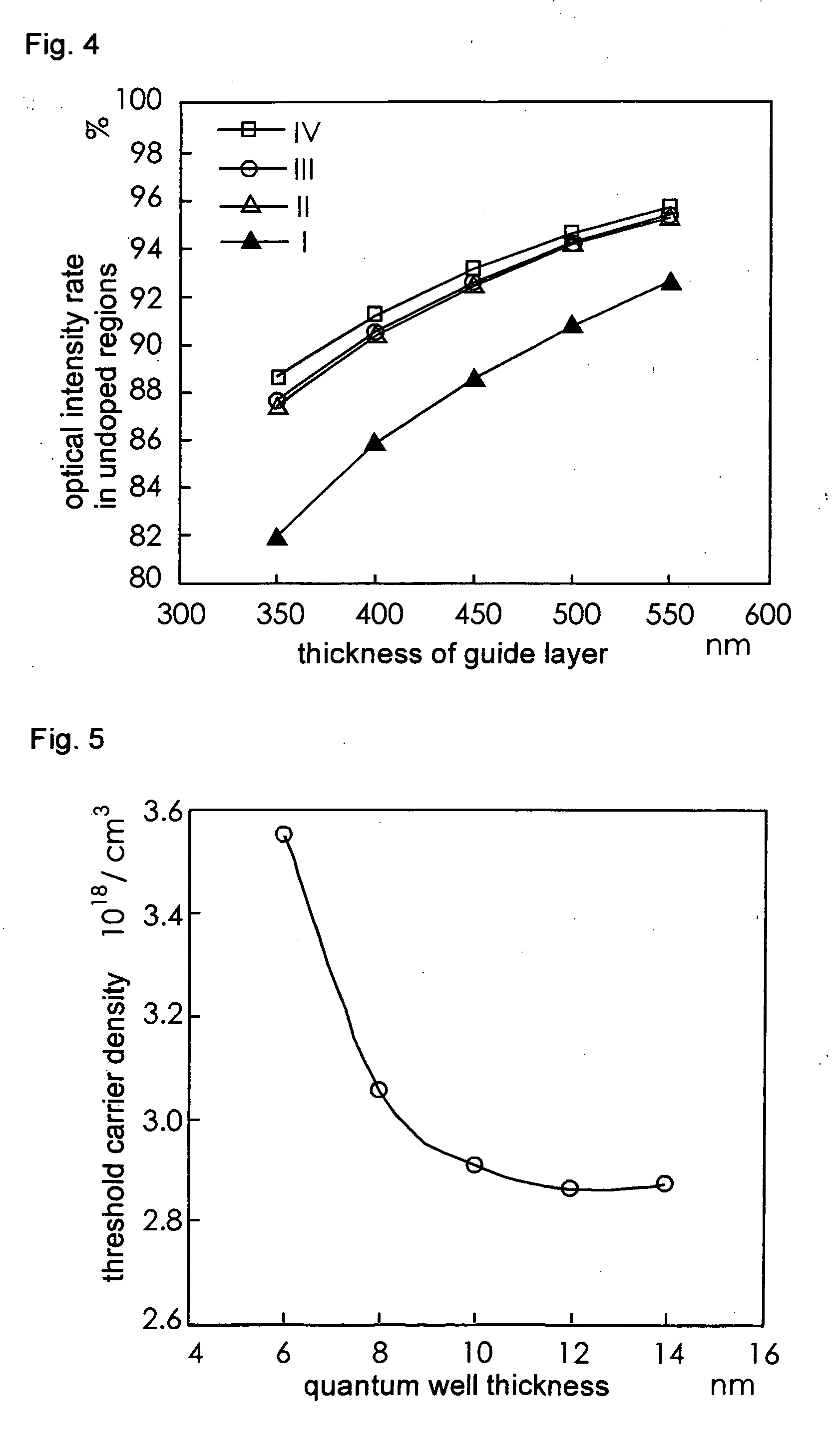

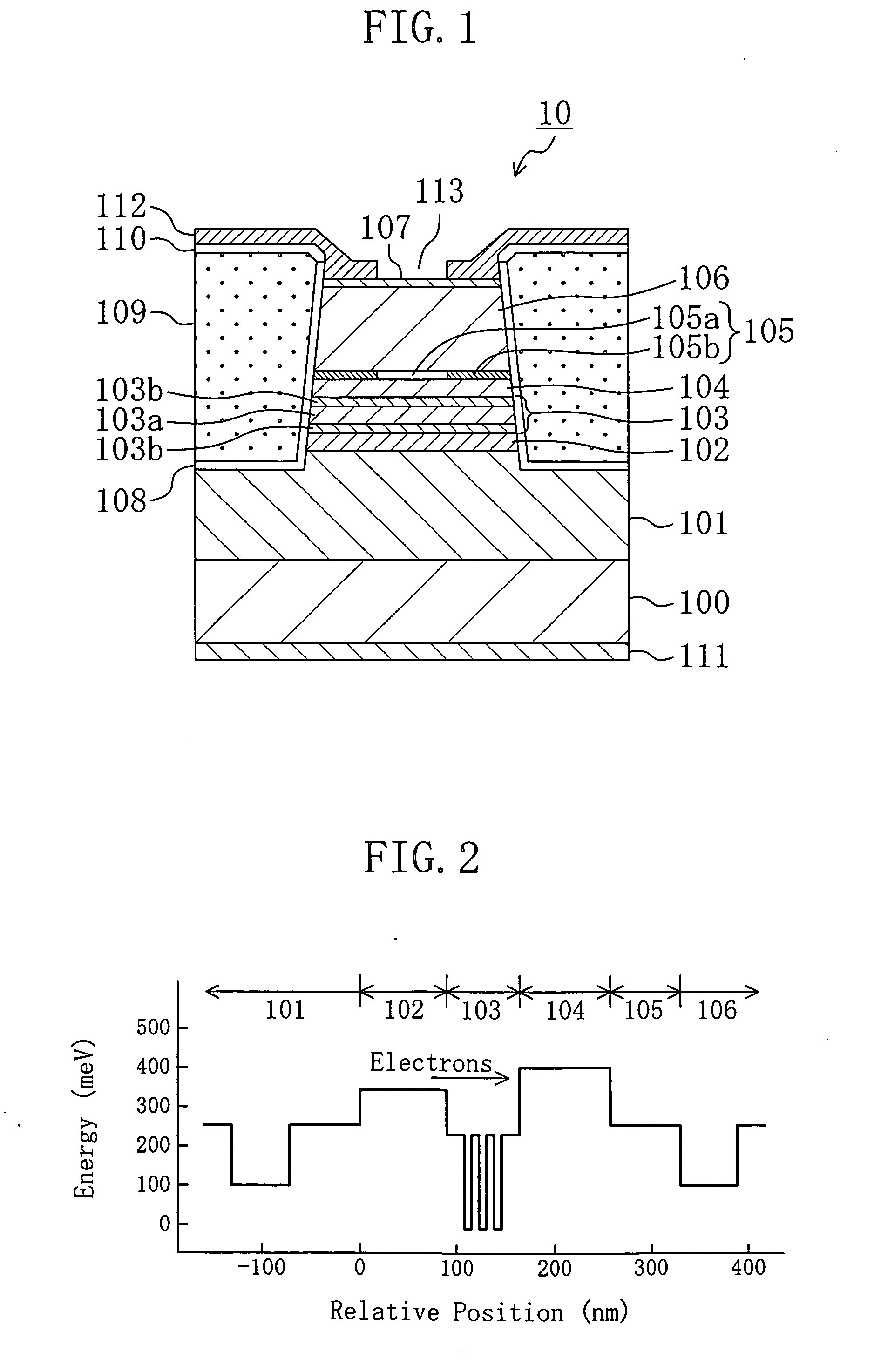

Semiconductor laser device

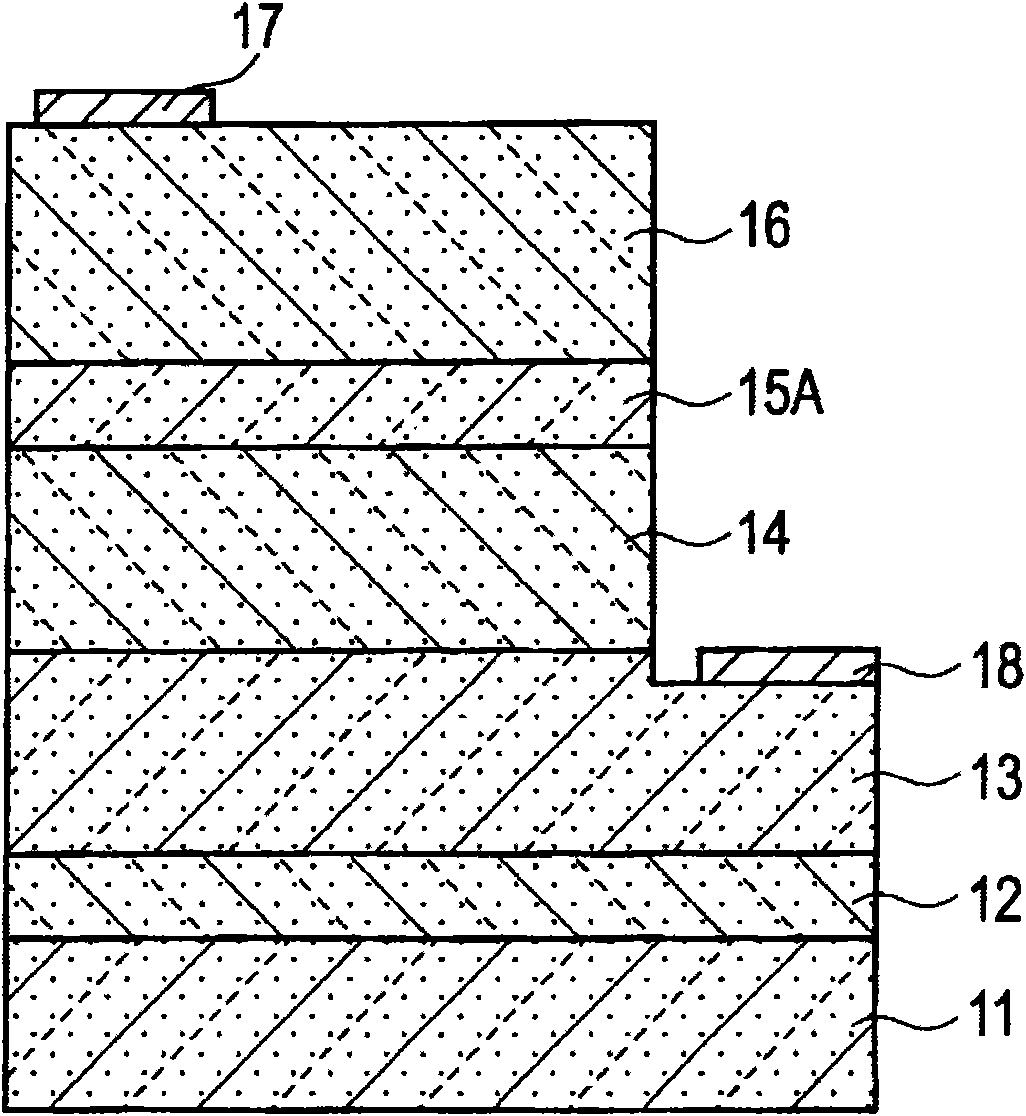

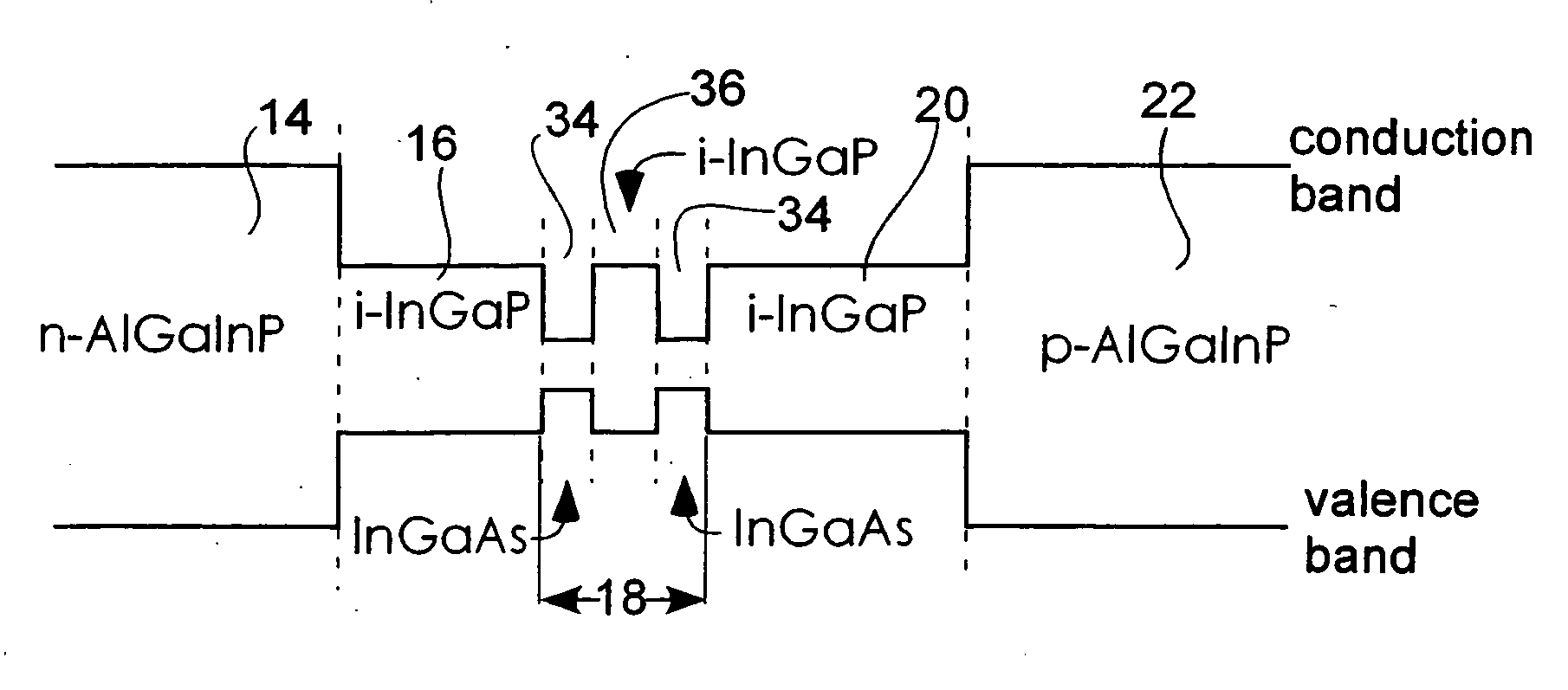

InactiveUS20070009001A1Improve efficiencyEnhancing anti-COD levelOptical wave guidanceLaser detailsQuantum wellRefractive index

A semiconductor laser device includes: on an n-GaAs substrate, an n-type cladding layer of n-(Al0.3Ga0.7)0.5In1.5P, an n-side guide layer of i-In0.49Ga0.51P lattice-matched to GaAs, an active layer having a larger refractive index than the n-side guide layer, and including an In0.07Ga0.93As quantum well layer, a p-side guide layer of i-In0.49Ga0.51P, and a p-type cladding layer of p-(Al0.3Ga0.7)0.5In0.5P. Therefore, the anti-COD level increased, and internal loss minimized.

Owner:MITSUBISHI ELECTRIC CORP

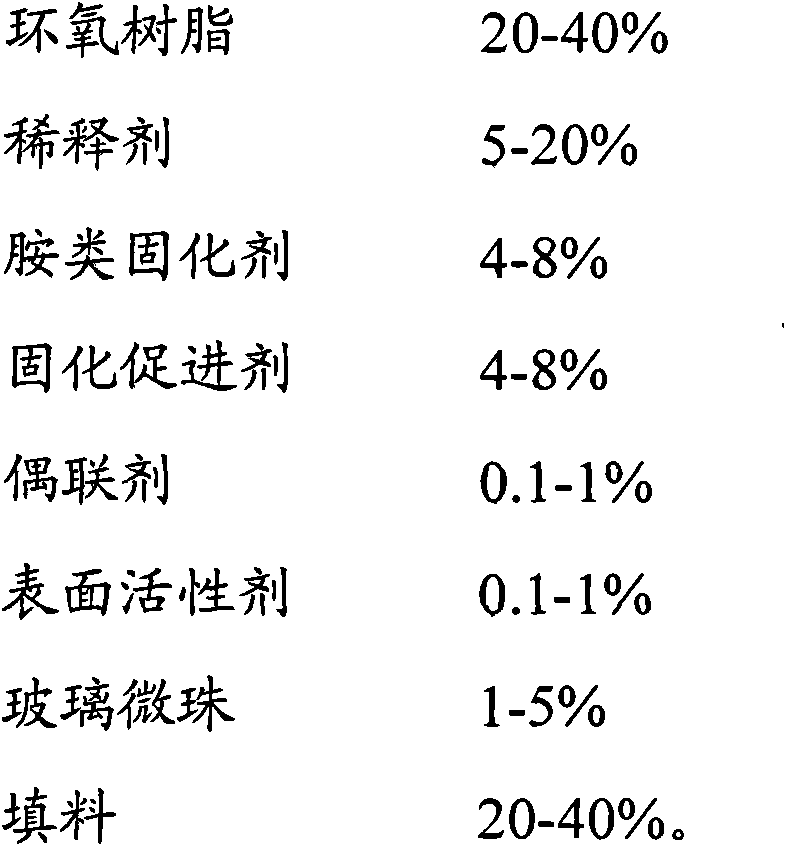

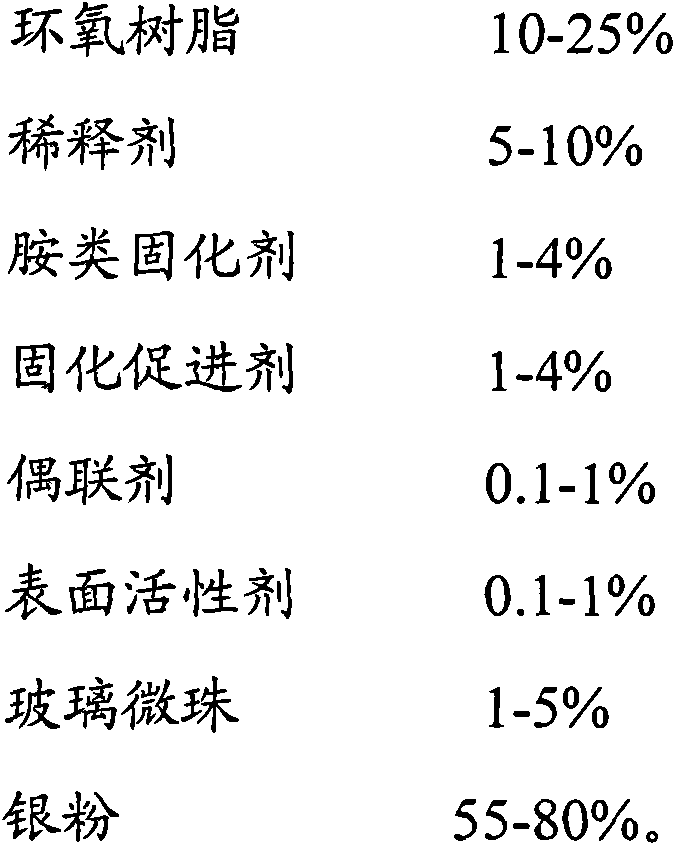

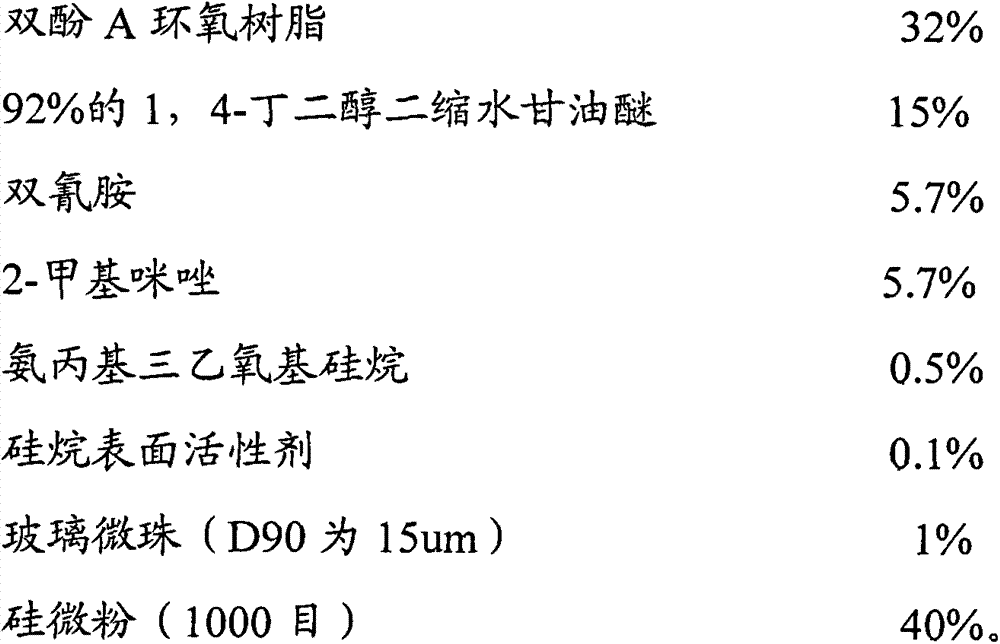

Epoxy resin adhesive used for encapsulating smart cards

ActiveCN103540285ASuppress overflowEffective thickness controlNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxySmart card

The invention discloses an epoxy resin adhesive used for encapsulating smart cards. The epoxy resin adhesive is non-conductive adhesive and conductive adhesive and comprises the following components in percentage by weight: 20-40% of epoxy resin, 5-20% of diluent, 4-8% of amine curing agent, 4-8% of curing accelerator, 0.1-1% of coupling agent, 0.1-1% of surfactant, 1-5% of glass microspheres and 20-40% of fillers. The epoxy resin adhesive is prepared in a special preparation sequence. The surfactant is added to effectively inhibit the resin overflow, improve the routing yield and ensure the reliability of the product at the same time, the glass microspheres are added to effectively control the thickness of the adhesive layer, prevent the adhesive layer from becoming excessive thin or thick after being pasted, ensure the reliability of the encapsulated product, and meanwhile, reduce the height difference of four corners and improve the routing yield and efficiency.

Owner:CHANGCHUN YONGGU TECH

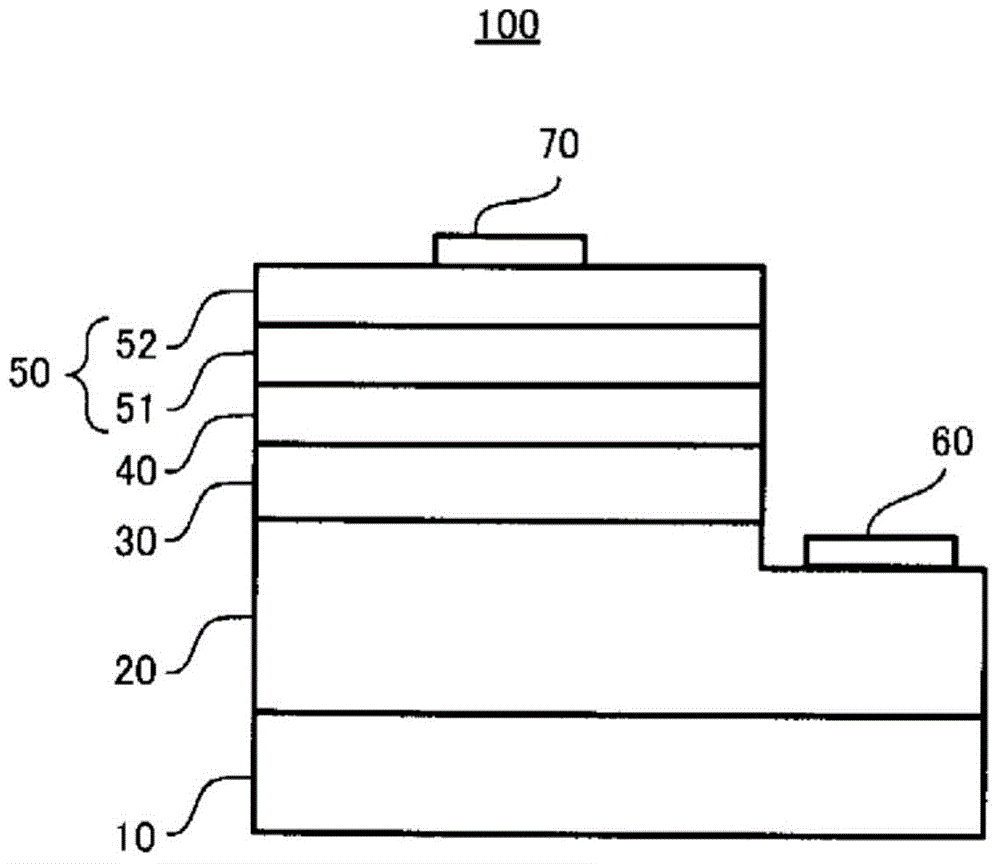

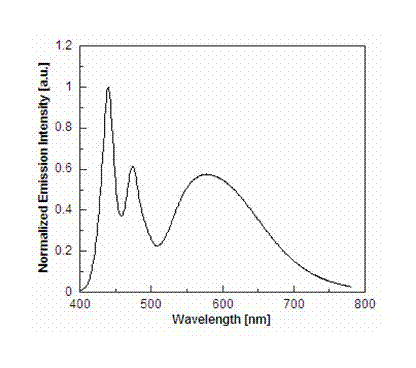

UV-LED with quantum dot structure

ActiveCN104966768ASuppress overflowStrong quantum confinement effectSemiconductor devicesHole injection layerQuantum well

The invention discloses an UV-LED with a quantum dot EBL, comprising a sapphire substrate, an A1N nucleating layer, a non-doped u type A1GaN buffer layer, an n type A1GaN layer, an A1xGa1-xN / A1yGa1-yN quantum well active region, a p type A1N / A1GaN quantum dot EBL, a p type A1GaN layer and an ITO conductive layer. An n type ohmic electrode is lead out on the n type A1GaN layer, and a p type ohmic electrode is lead out on the ITO conductive layer. The UV-LED with a quantum dot EBL employs the p type doping layer of self-assembly A1N / A1GaN quantum dots as the EBL and a hole injection layer, which can effectively inhibit electrons from overflowing out of an active region, enhance the efficiency of hole injection to the active region, and thereby increase the carrier composite efficiency in the active region; in addition, A1N is used as the EBL to replace the A1GaN commonly used in blue LED, which can more effectively reduce UV absorption by the EBL, and increase UV-LED luminous efficiency.

Owner:江西力特康光学有限公司

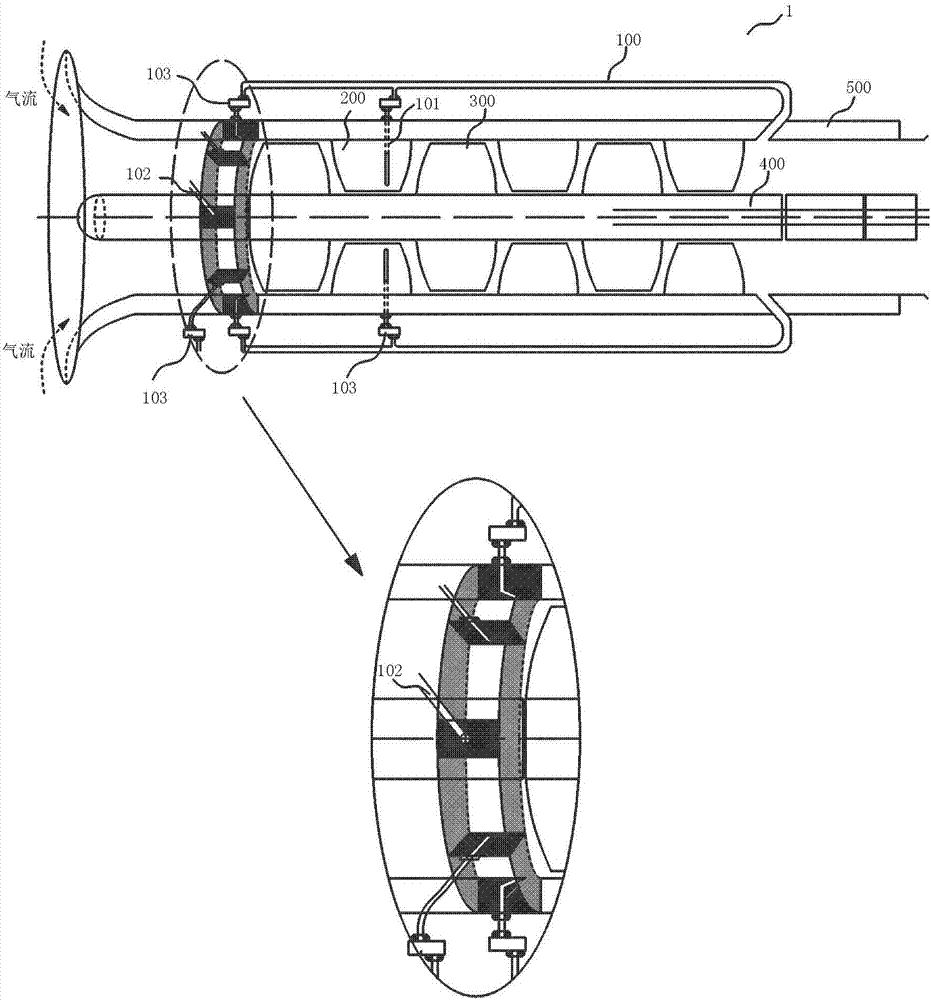

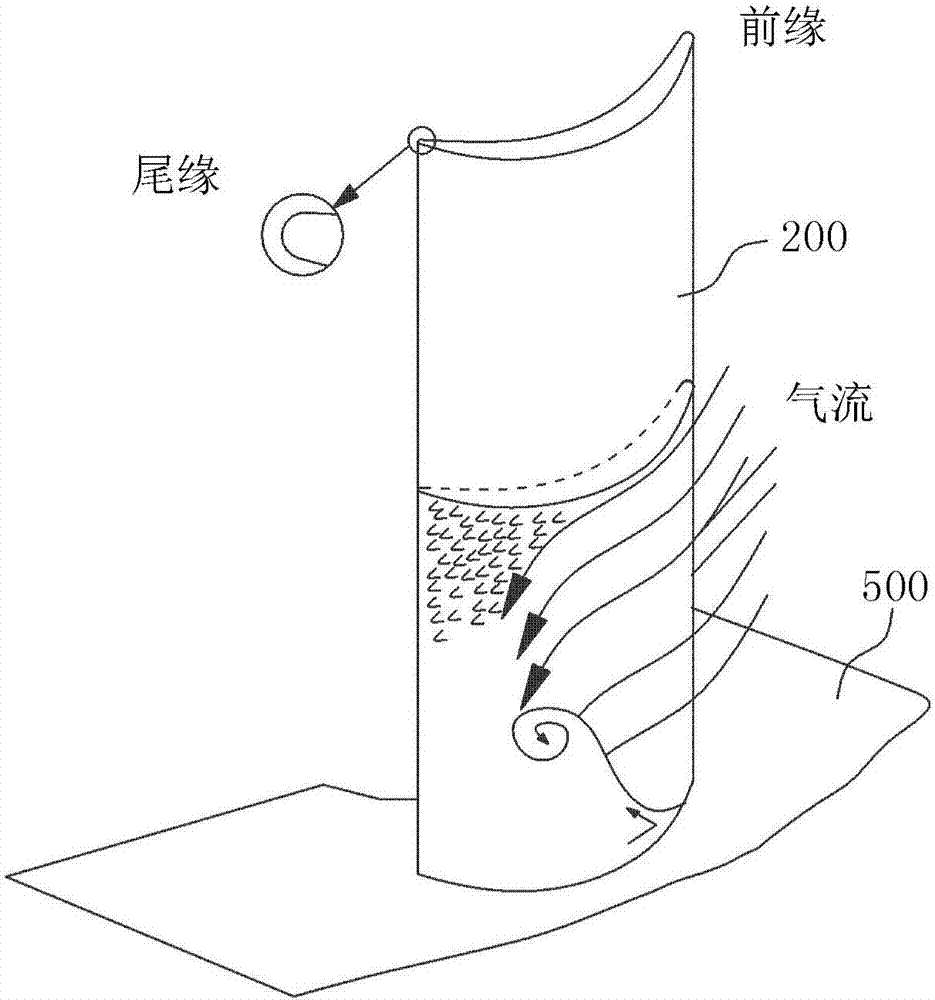

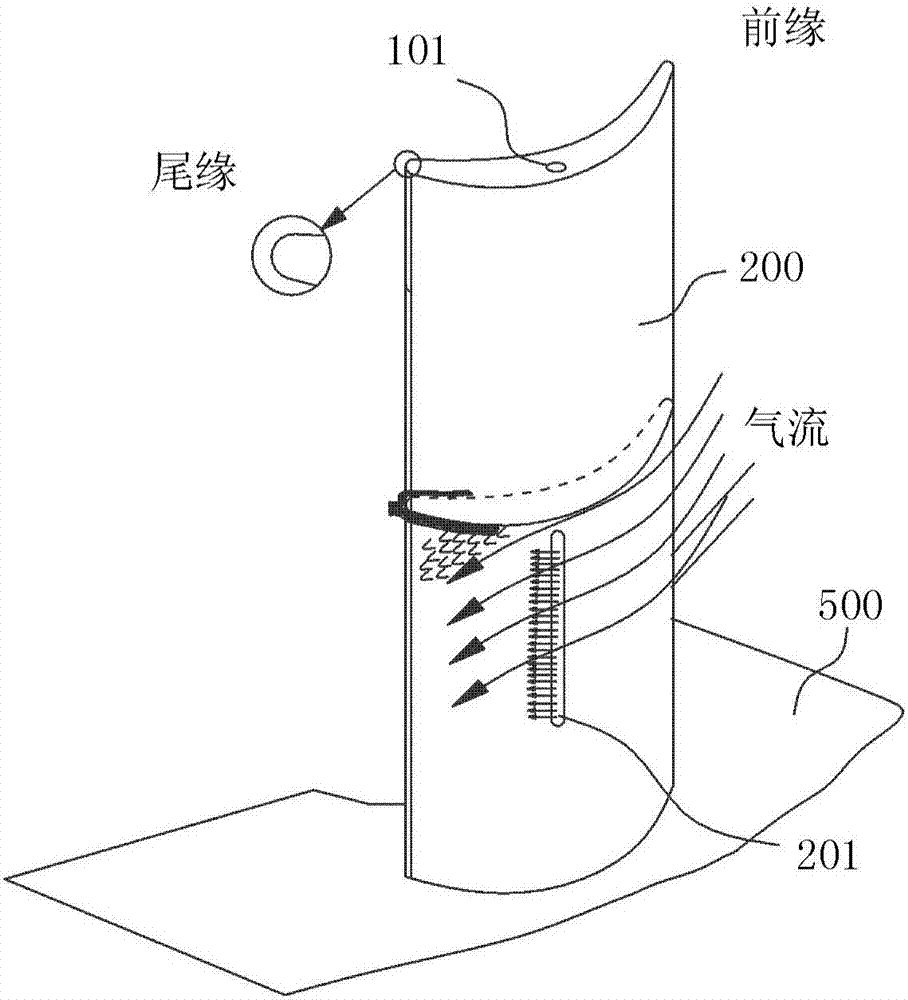

Gas compressor, gas turbine and gas compressor stability enhancement and efficiency improvement method

ActiveCN106870465AInhibition of separation vortex developmentImprove wall effectPump componentsPumpsLeading edgeGas compressor

The invention provides a gas compressor, a gas turbine with the gas compressor and a gas compressor stability enhancement and efficiency improvement method. According to the gas compressor, through holes are formed in the wall surface, located on the high-pressure stage, of a casing, through holes are formed in the wall surfaces, located on the blade tops of low-pressure stage movable blades, of the casing, through holes are formed from the root portions of low-pressure stage stationary blades to suction surfaces of blade surfaces, and the through holes formed in the wall surface, located on the high-pressure stage, of the casing, the through holes formed in the wall surfaces, located on the blade tops of the low-pressure stage movable blades, of the casing and the through holes formed from the root portions of the low-pressure stage stationary blades to the suction surfaces of the blade surfaces are connected in sequence, so that a self-circulation mechanism with a suction-ejection function is formed. Part of gas sucked from the high-pressure stage of the gas compressor is guided back to the leading edges of the blade tops of the low-pressure stage movable blades and the suction surfaces of the blade surfaces of the low-pressure stage stationary blades through the self-circulation mechanism, and is ejected, and therefore the stall margin of the gas compressor is broadened, flow separation is restrained, and the efficiency of the gas compressor is effectively improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Semiconductor laser device

InactiveUS20060245459A1Suppress overflowGood surface smoothnessLaser detailsNanoopticsActive layerElectron

Owner:PANASONIC CORP

Nitride semiconductor light-emitting element

ActiveCN105009310ASuppress overflowImprove luminous efficiencyLaser detailsSemiconductor lasersUltraviolet lightsLength wave

Provided is a nitride semiconductor deep ultraviolet light-emitting element having exceptional light-emitting efficiency. A nitride semiconductor light-emitting element having a light-emission wavelength of 200-300 nm, wherein said element has an n-type layer comprising a single layer or a plurality of layers with differing bandgaps, a p-type layer comprising a single layer or a plurality of layers with differing bandgaps, and an active layer arranged between the n-type layer and the p-type layer. The p-type layer has a p-type first layer having a bandgap that is larger than the bandgap of the n-type first layer having the smallest bandgap within the n-type layer. An electron block layer is provided between the active layer and the p-type first layer, the electron block layer having a bandgap that is larger than the bandgaps of any of the layers forming the active layer and the p-type layer.

Owner:STANLEY ELECTRIC CO LTD

Steel for high-carbon low-aluminum low-oxygen cutting steel wires and vacuum induction smelting method thereof

The invention discloses steel for high-carbon low-aluminum low-oxygen cutting steel wires and a vacuum induction smelting method thereof. The steel comprises the following chemical components in percentage by mass: 0.9-0.94% of C, 0.12-0.3% of Si, 0.3-0.65% of Mn, 0.1-0.3% of Cr, Al not more than 0.004%, O not more than 0.003%, N not more than 0.0025%, S not more than 0.01%, P not more than 0.01%,and the balance of Fe and inevitable impurity elements. Through control of the carbon feeding sequence and timing, the vacuum air cavity in different smelting phase and the low-temperature refining of 1540+-5 DEG C, the purpose of smelting the steel for the high-carbon low-aluminum low-oxygen cutting steel wires by an aluminum oxide crucible of a vacuum induction furnace is achieved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

Cleaning component, cleaning method of coater, cleaning device and manufacture method of component for display

ActiveCN102674702APrevents reattachment problems on applicatorsQuality improvementOptical filtersPretreated surfacesAbnormal thicknessDisplay device

The present invention relates to a cleaning component, a cleaning method of a coater, a cleaning device and a manufacture method of a component for a display. During the cleaning process, the flowing speed of a coating fluid removed from the coater along the cleaning component is improved, thus the coating fluid is not adhered on the coater and because of no residue of the coating fluid or a solvent for cleaning, abnormal thickness of a coating film or defect on the surface of the coating film is not generated. The cleaning component comprises a first surface and a second surface opposite to the first surface. The cleaning component contacts with a discharge port surface of a discharge port extending along one direction of the coater and two adjacent surfaces of the discharge port surface and simultaneously slides along the direction, thus the discharge port surface and the two adjacent surfaces are cleaned. The cleaning component comprises a cleaning portion arranged on the first surface side and simultaneously contacted with the discharge port surface and the two adjacent surfaces; a plurality of flowing path surfaces started from the cleaning portion and always extending to the second surface side, wherein a cutting groove is arranged on the second surface side on the flowing path surface.

Owner:TORAY ENG CO LTD

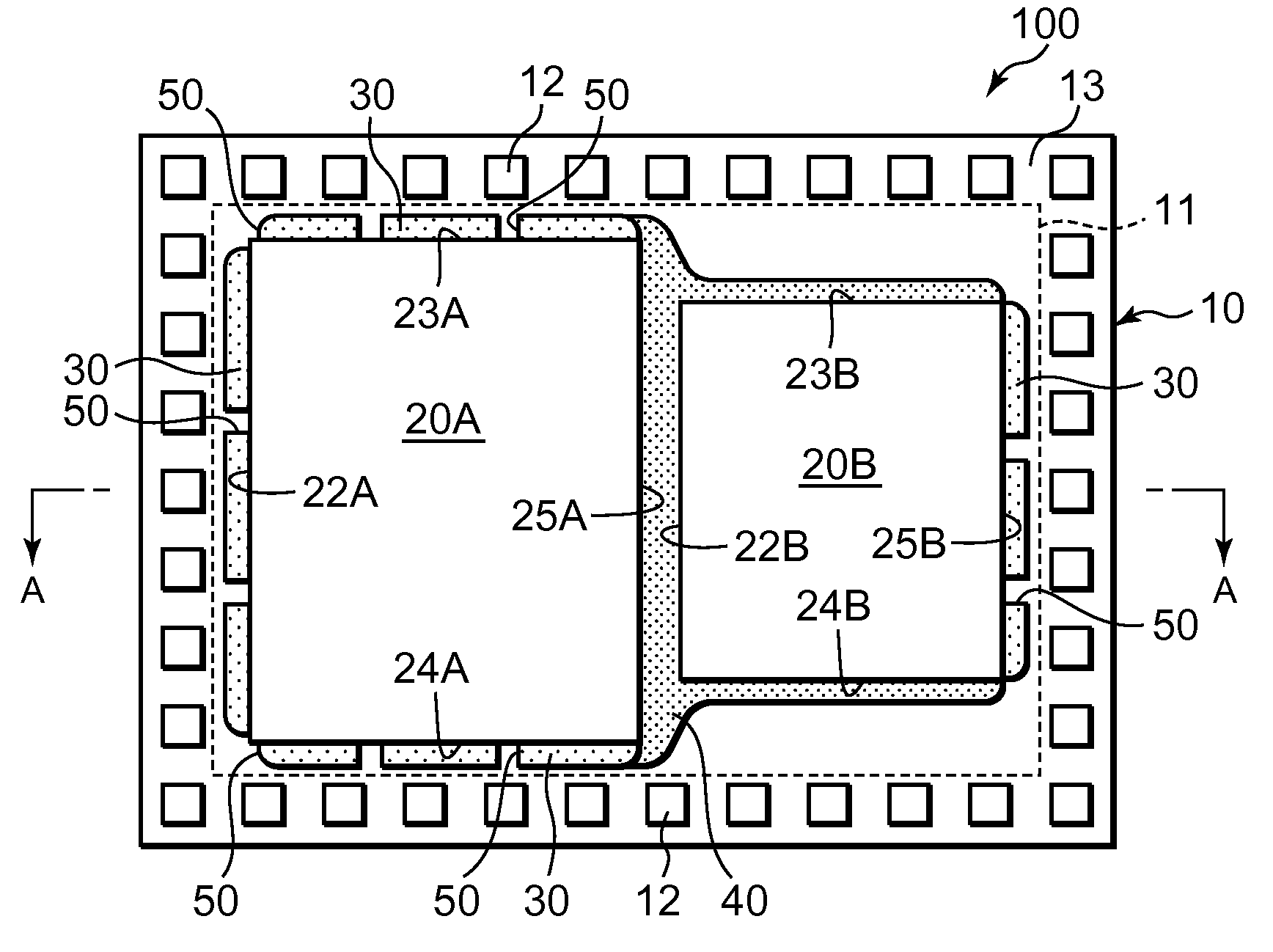

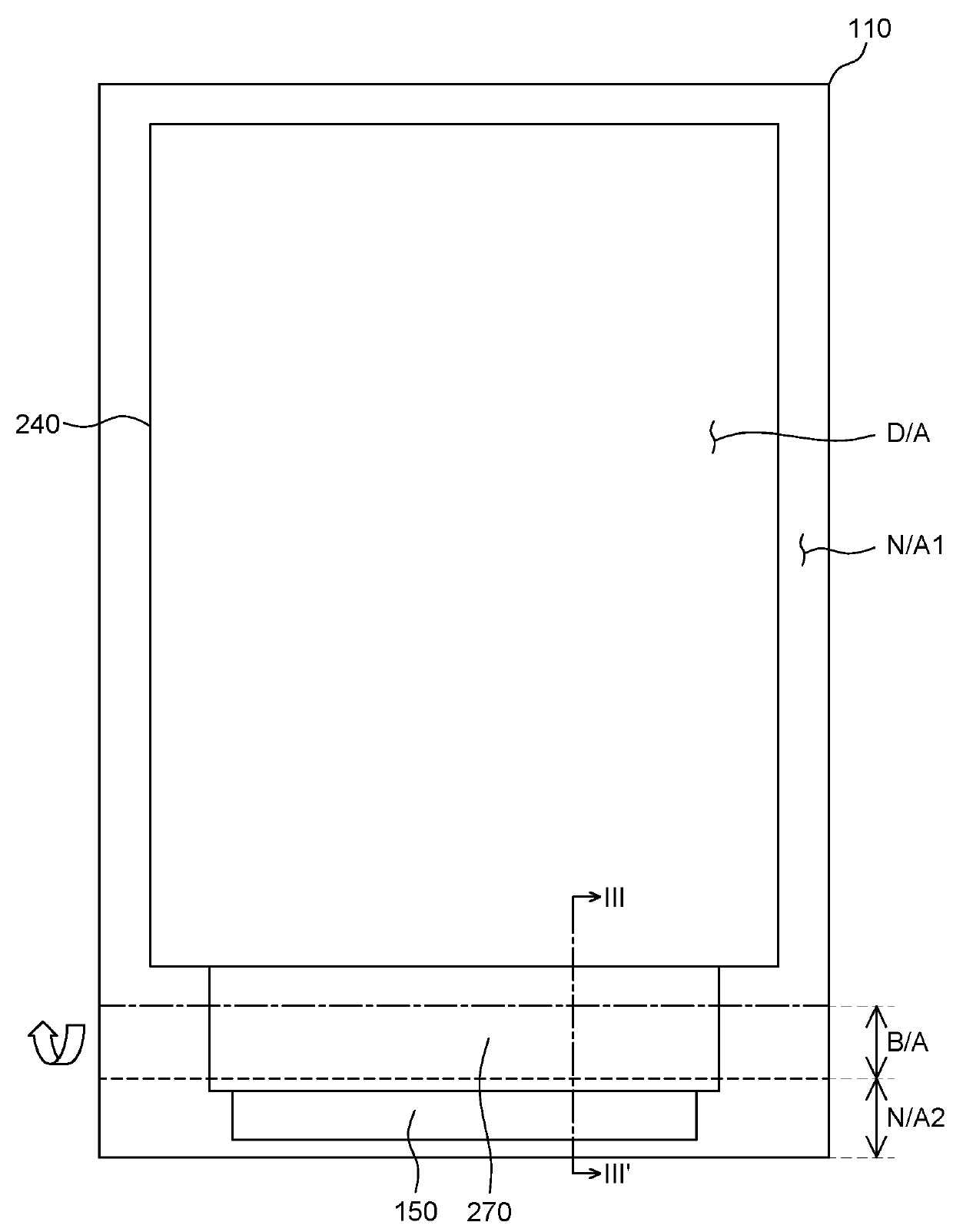

Organic Light Emitting Display Device

ActiveUS20180183001A1Stress minimizationMinimize failureSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

An organic light emitting display device according to an exemplary embodiment of the present disclosure includes a flexible substrate, a polarization layer, an adhesive layer, and a micro coating layer. The flexible substrate includes a display area in which a display unit is disposed, a first non-display area which encloses the display area, a bending area extending from the first non-display area, and a second non-display area extending from one side of the bending area. The polarization layer is disposed on the display unit. The adhesive layer is disposed on at least one of a lower surface and an upper surface of the polarization layer. The micro coating layer is disposed to cover a plurality of wiring lines on the bending area. In this case, at least a part of the side of the adhesive layer adjacent to the bending area is located inside more than a side of the polarization layer adjacent to the bending area. In the organic light emitting display device according to an exemplary embodiment of the present disclosure, the side of the adhesive layer adjacent to the bending area is located more than the side of the polarization layer adjacent to the bending area or a side of the adhesive layer forms a concavely recessed concave portion to form a receiving portion which receives the micro coating layer.

Owner:LG DISPLAY CO LTD

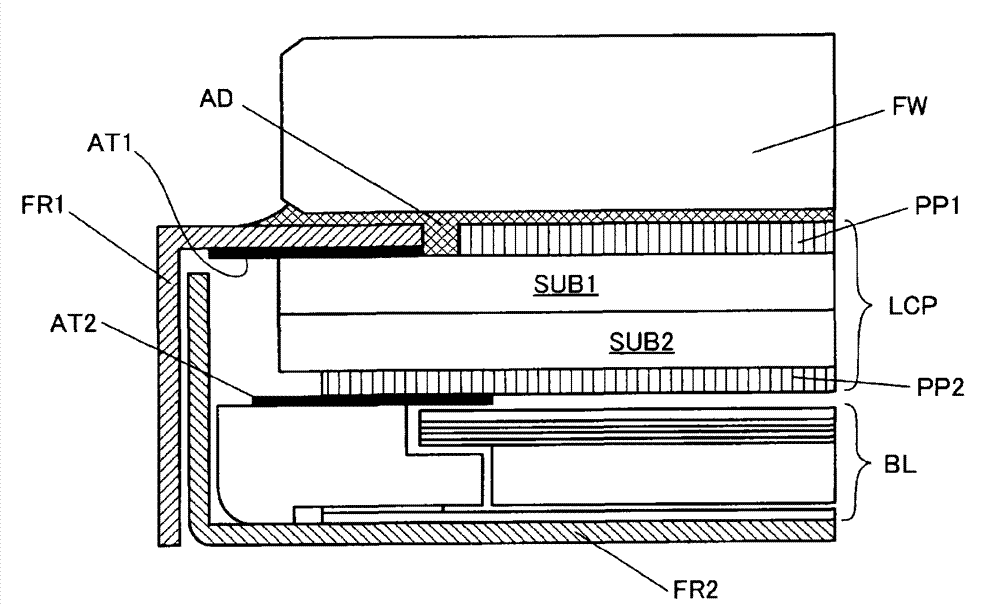

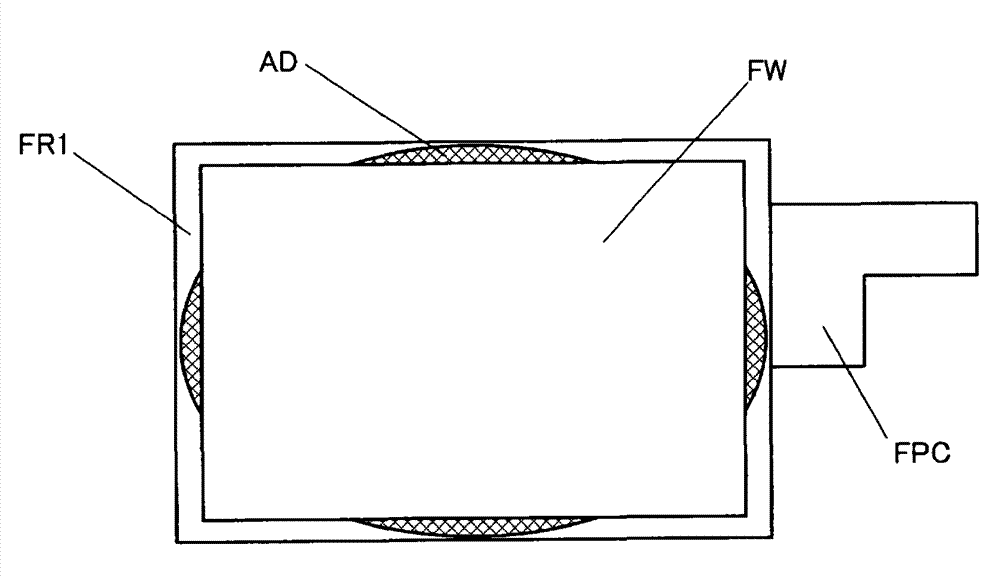

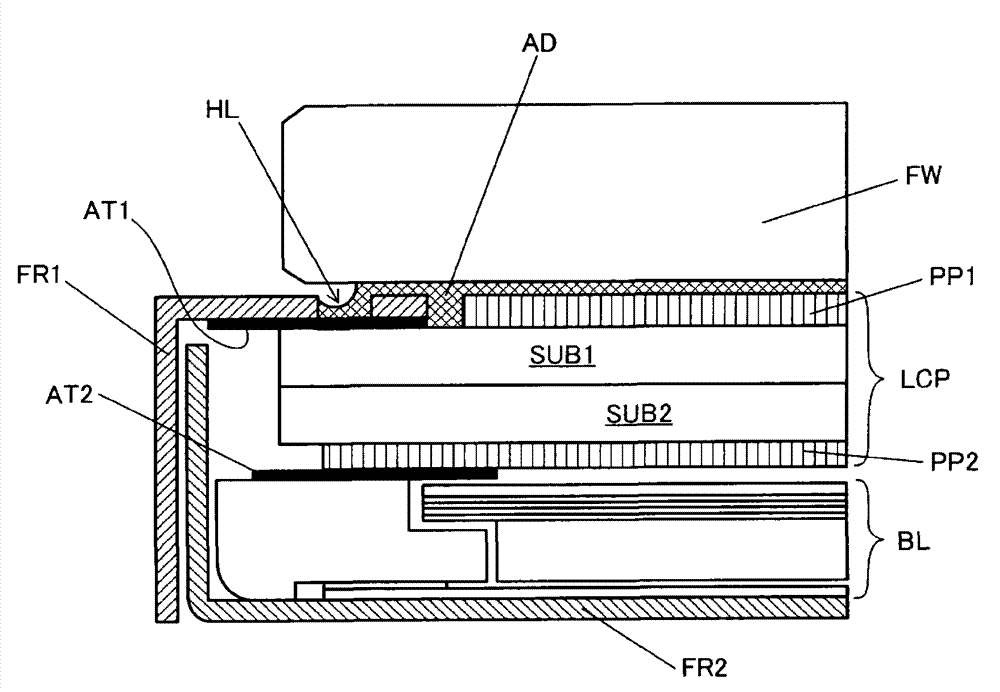

Display device

ActiveCN103048820APrevent overflowPrevents the disadvantages of attaching to the metal frameNon-linear opticsIdentification meansAdhesiveDisplay device

The present invention is a display device where it is possible to prevent, at a high level, an adhesive from protruding to the metal frame for supporting the display panel in the case where the front window is pasted to the display panel via the adhesive. Specifically, the present invention provides a display device having; a display panel LCP; a metal frame FR1 for supporting the display panel; and a front window FW pasted to a front of the display panel using an adhesive AD, characterized in that the front window is provided so as to cover part of a front of the metal frame, and a containing portion HL for containing the adhesive that overflows from a space between the display panel and the front window is created in an area, which is part of the metal frame and is covered by the front window.

Owner:JAPAN DISPLAY INC

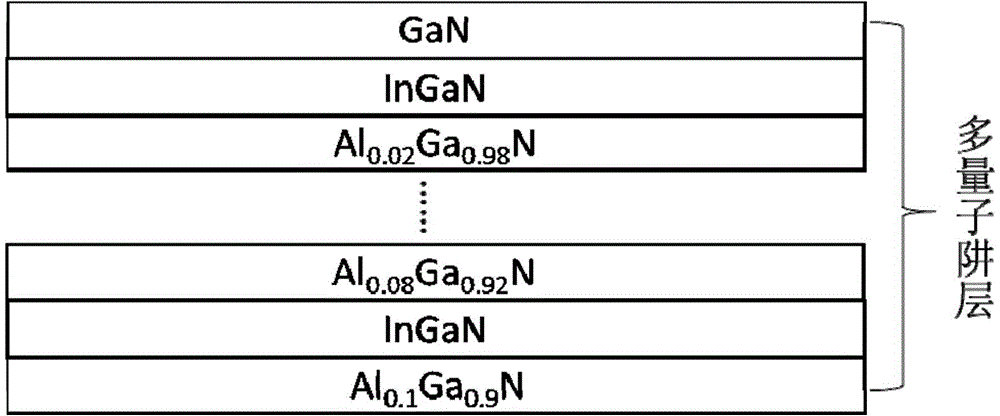

Epitaxial structure capable of effectively reducing Droop effect of LED

InactiveCN104821355APull down the price bandPull down the barrier drop of the barrier layer close to the electron blocking layerSemiconductor devicesValence bandQuantum well

The invention discloses an epitaxial structure capable of effectively reducing the Droop effect of an LED. The epitaxial structure comprises a substrate, an undoped gallium nitride layer, an N-type gallium nitride layer, a multi-quantum well layer, an electron barrier layer and a P-type gallium nitride layer which are successively stacked from bottom to top, wherein the multi-quantum well layer is formed by alternatively superposing multiple barrier layers AlxGa(1-x)N and trap layers InyGa(1-y)N. According to the invention, gradual change AlGaN of Al components are taken as the barrier layers, the barrier height difference between the valence band of the electron barrier layer and the barrier layer close to the electronic barrier layer is effectively reduced, the injection efficiency of cavities is improved, at the same time, through increasing the barrier height differences between the traps and the barriers in a multi-quantum well, the binding effect on electrons is further enhanced, the electrons are effectively prevented from overflowing, the composite probability of the electrons and the cavities in the multi-quantum well is enhanced, and the luminescence efficiency of the LED is accordingly improved. Compared to the prior art, the epitaxial structure provided by the invention is relatively simple in structure and facilitates MOCVD growth. According to the invention, the epitaxial structure capable of effectively reducing the Droop effect of the LED can be widely applied to the field of LEDs.

Owner:SOUTH CHINA NORMAL UNIVERSITY

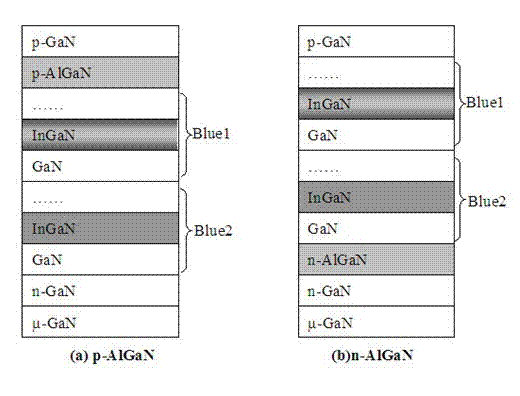

GaN-base double-blue-light wavelength luminescent device and preparation method thereof

InactiveCN102347408AImprove injection efficiencySuppress overflowSemiconductor devicesQuantum wellLength wave

The invention discloses a GaN-base double-blue-light wavelength luminescent device and a preparation method thereof, aiming to solve the problem that the color rendering properties of a white-light LED (Light-emitting Diode) which is packaged by stimulating yellow-light fluorescent powder through a single-blue-light chip are not good. The structure of a GaN-base double-blue-light wavelength LED epitaxial wafer is sequentially composed of following members from a substrate: a GaN buffer layer, a GaN intrinsic layer, an n-GaN layer, an asymmetrical n-AlGaN layer, a high In component quantum well, a low In component quantum well and a p-GaN layer. The structure is characterized by leading the asymmetrical n-AlGaN layer between a mixed multi- quantum-well active layer and the n-GaN layer, removing a p-AlGaN electron barrier layer at the side of the p-GaN layer at the same time, and then packaging the double-blue-light wavelength chip and the yellow-light fluorescent powder to form the white-light LED.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Medicine for treating angiocardiopathy and cerebrovascular disease and its preparing method

InactiveCN1557403AReduce manufacturing costActive ingredients are clearPowder deliveryUnknown materialsDiseaseSide effect

The medicine for treating cardiac and cerebral vascular diseases is prepared with astragalus root and notoginseng as material, and is Chinese medicine injection, including injection liquid, transfusion liquid and freeze dried powder for injection, prepared through extraction, purification and addition of proper amount of medicinal supplementary material. The medicine has high stability and long effective period, and may be used in intramuscular injection, intravenous injection and intravenous instillation. Pharmacodynamic test shows that the medicine can protect brain against oxygen lack and cardiac muscle damage, raise anaerobic resistance, lower serum LDH and CK activity and reduce myocardial infarction range. The medicine is used in treating cardiac and cerebral vascular diseases and has fast acting, determined curative effect and no toxic side effect.

Owner:陈玲玲

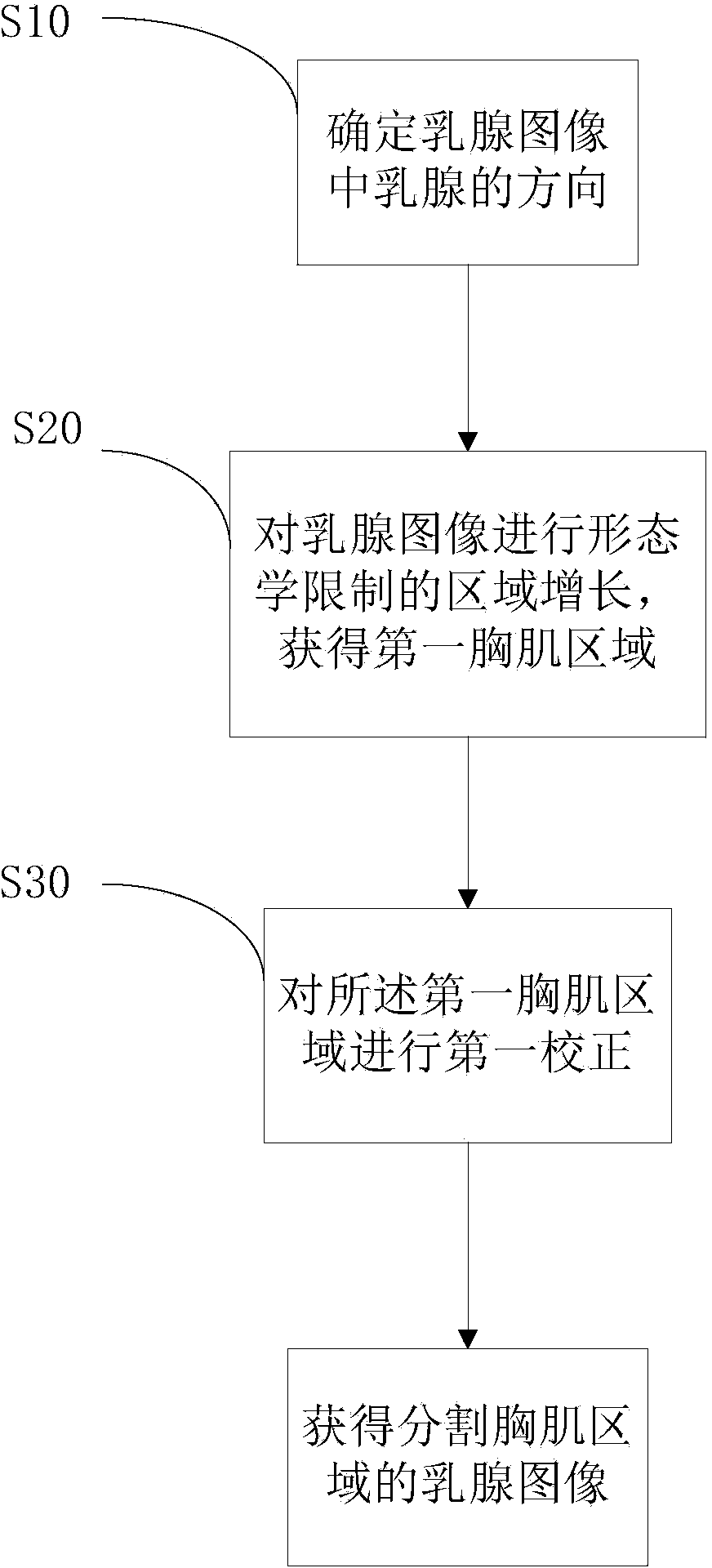

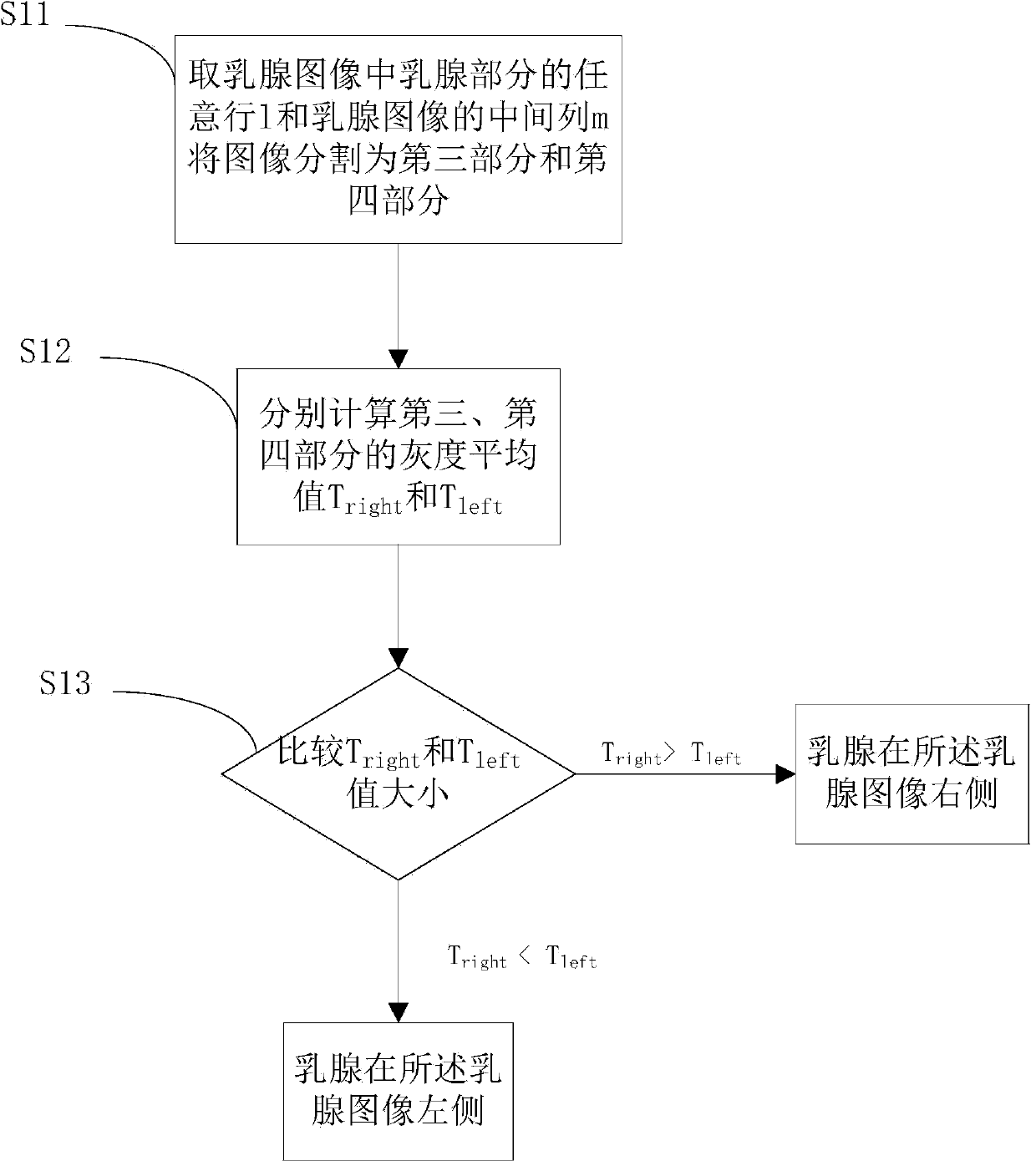

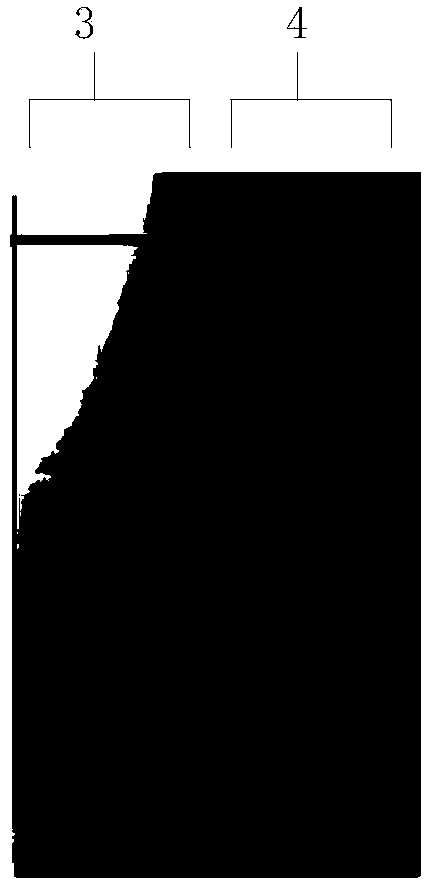

Pectoralis segmentation method in breast image

ActiveCN104182965AImprove robustnessGuaranteed smoothnessImage analysisComputer visionComputer science

The invention provides a pectoralis segmentation method in a breast image. The pectoralis segmentation method in the breast image comprises the following steps: carrying out morphological restriction region growing to a breast image to obtain a first pectoralis area; and carrying out first correction to the first pectoralis area to obtain the breast image of a pectoralis segmentation area. The pectoralis segmentation method provided by the invention has an automatic correction function, pectoralis parts can be quickly and effectively segmented and removed in a mediolateral oblique position mammogram, and the pectoralis segmentation method exhibits high accuracy and robustness. For multi-level greyscales, the pectoralis with fuzzy edges and irregular edges can be effectively segmented.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com